Flexure testing method and flexure testing device for quantitatively characterizing interface binding property of thin-film material

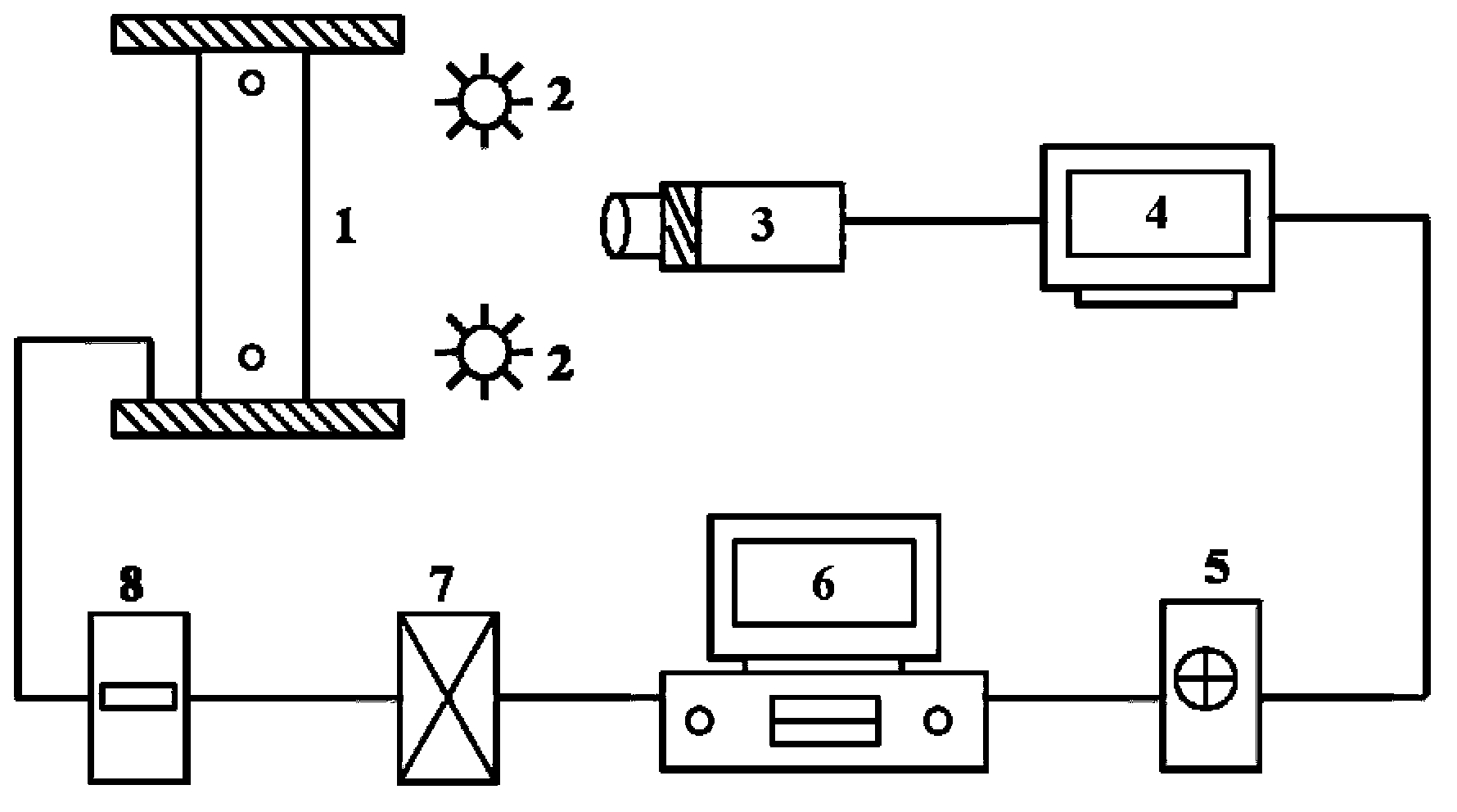

A technology of interfacial bonding and thin-film materials, which is applied in measurement devices, analysis materials, and mechanical devices, etc., can solve the problems of application limitation of indentation method, increase the difficulty of experiments, and difficulty in sample preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

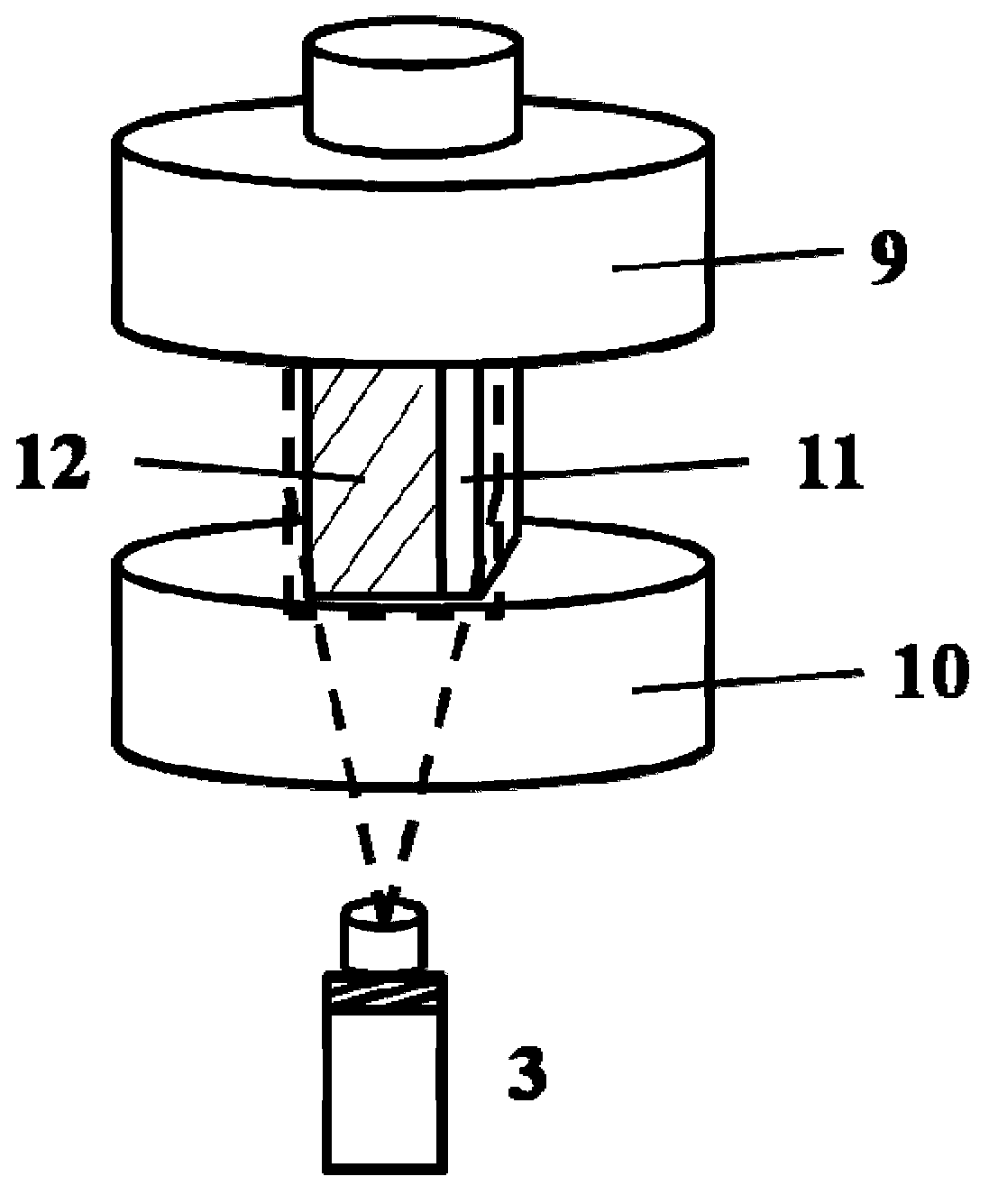

Method used

Image

Examples

Embodiment 1

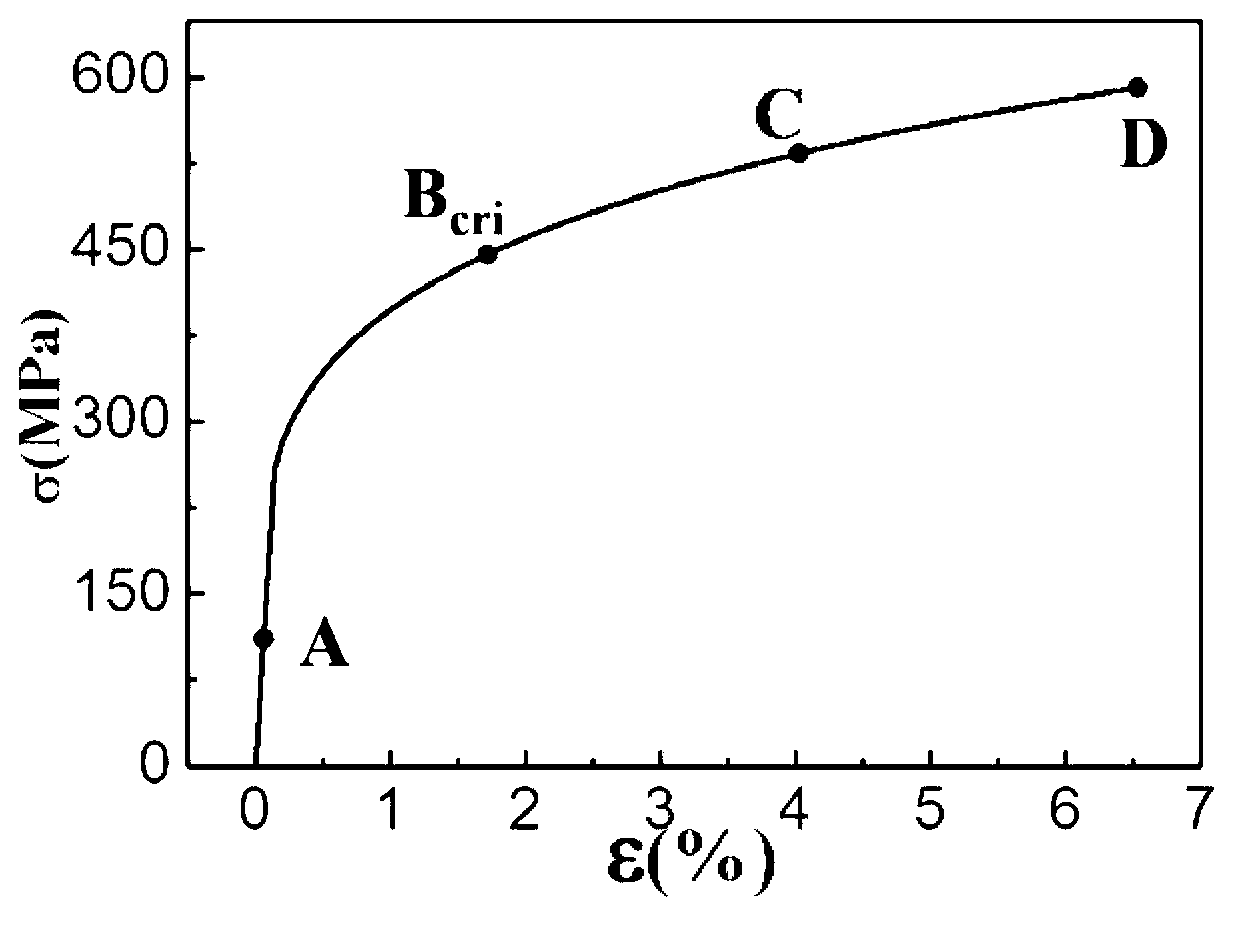

[0063] Consider a specific situation: the nickel film-low carbon steel system is selected as the coating-substrate, and the thickness of the nickel film is h=6×10 -5 m, the modulus of elasticity is E f =2.2×10 11 Pa, elastic modulus E of low carbon steel substrate s =2×10 11 Pa, Poisson's ratio υ f = υ s =0.3. critical buckling stress σ cr =4.46×10 8 Pa, the stress σ in the membrane when loaded 0 =6×10 8 Pa, for the nickel film-low carbon steel substrate system, α≈0, β≈0, from the data in the table, ω=52.1°, the deflection ω of the buckling center point of the sample coating max =6.7×10 -5 Substituting m into the above formula, the interface binding energy of the nickel film-low carbon steel substrate system is obtained G=37.1J / m 2 , the phase angle Ψ=-637°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com