Patents

Literature

57 results about "Experimental mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

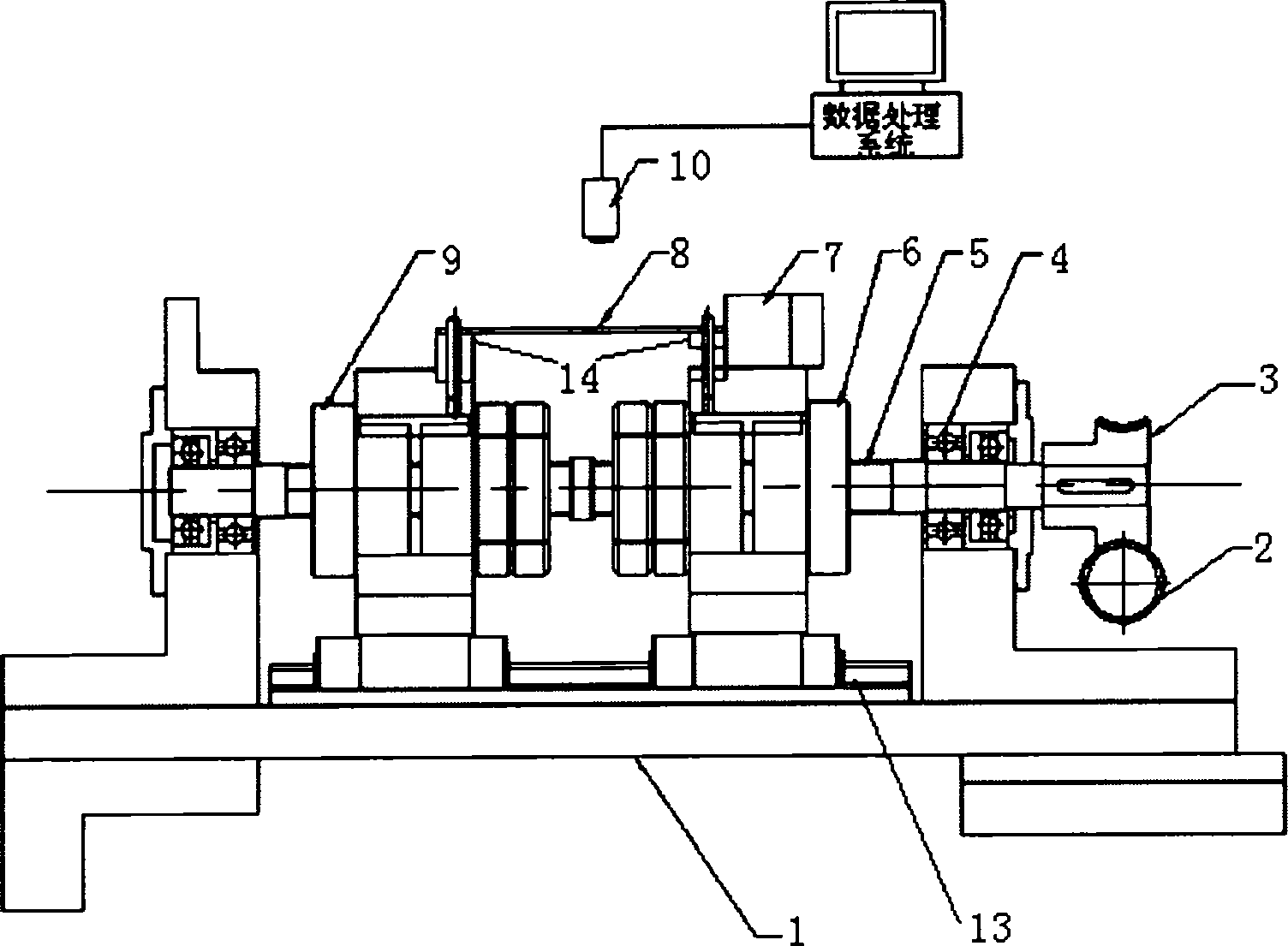

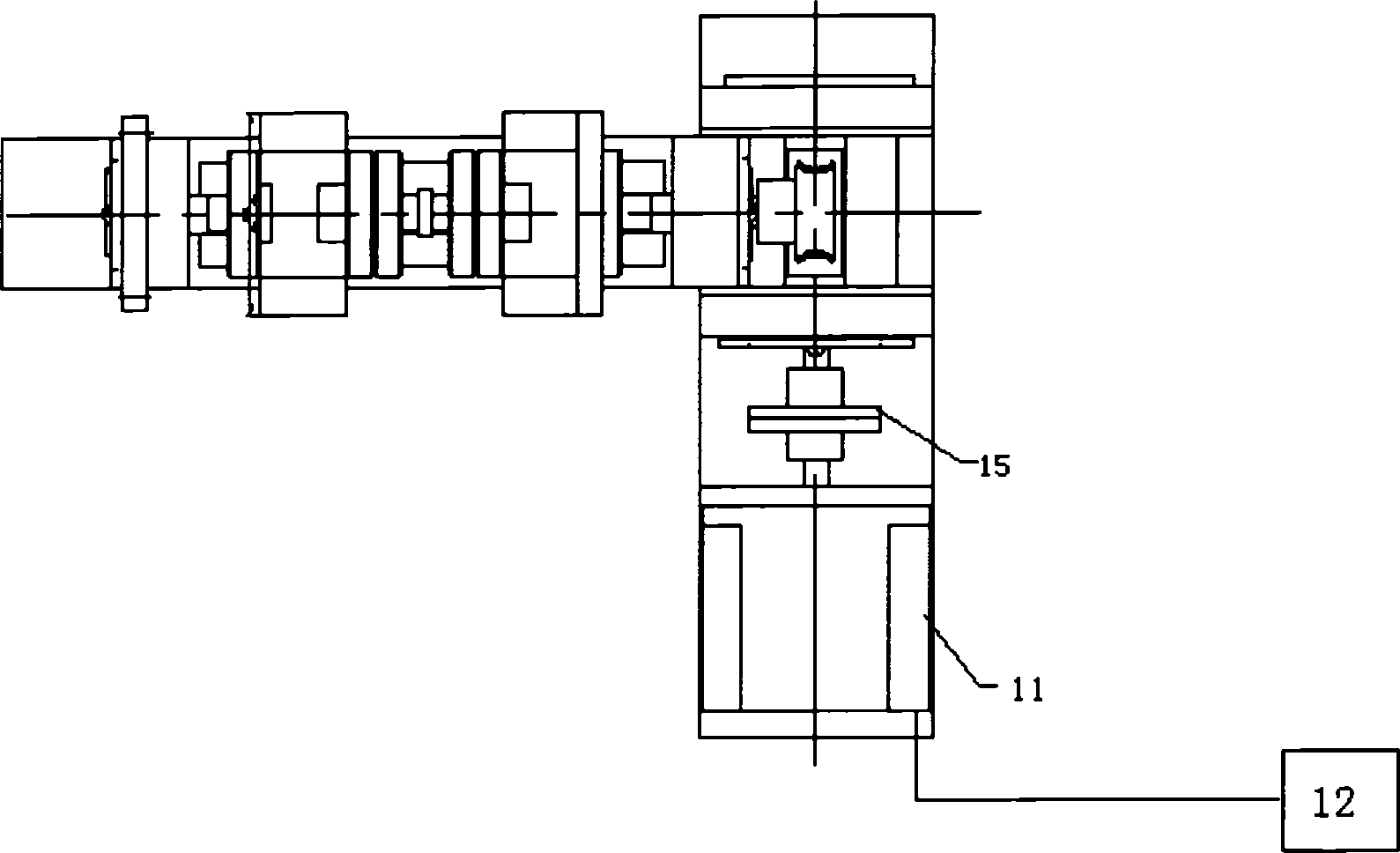

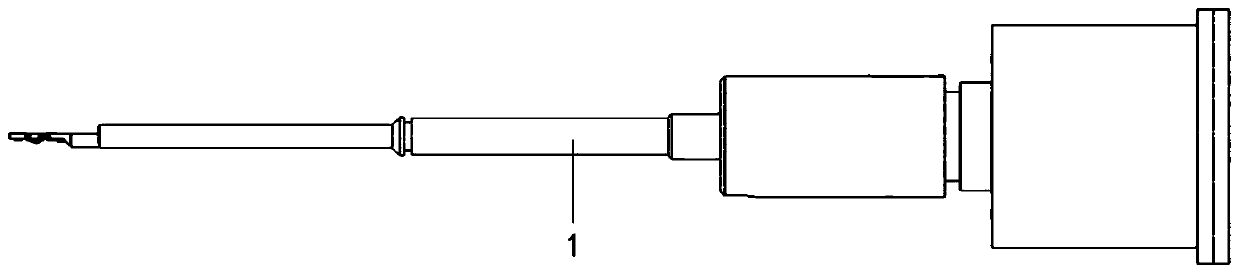

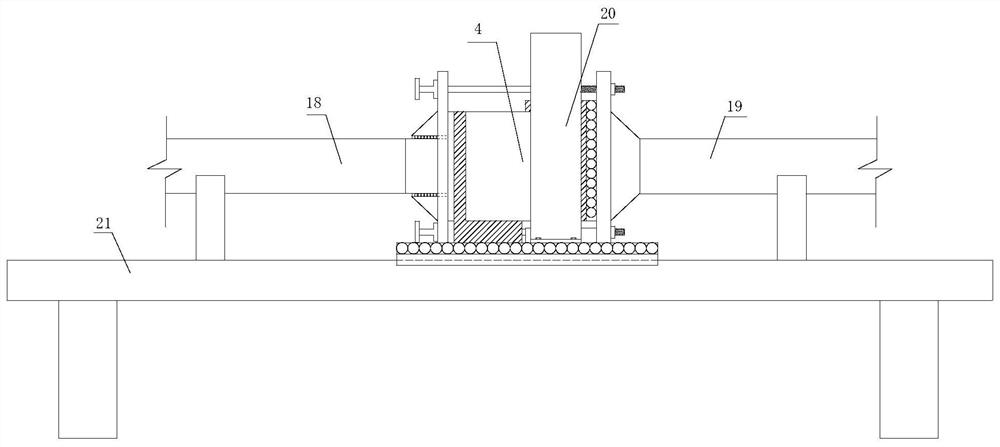

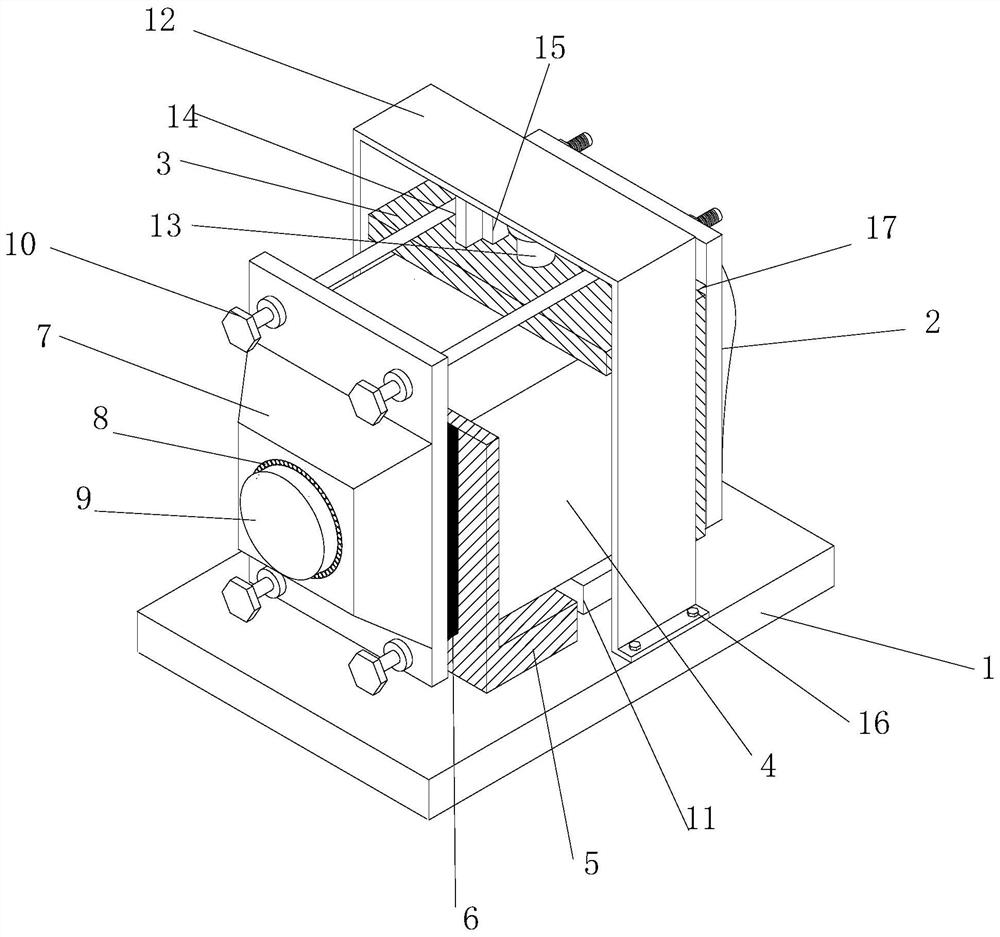

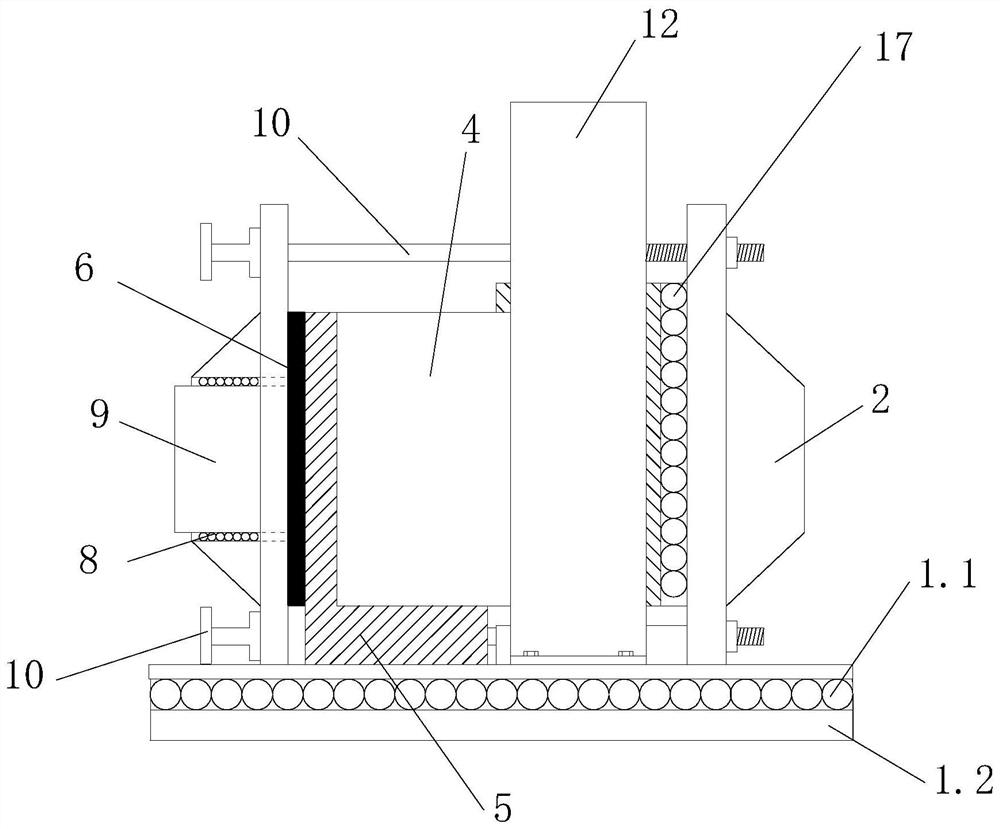

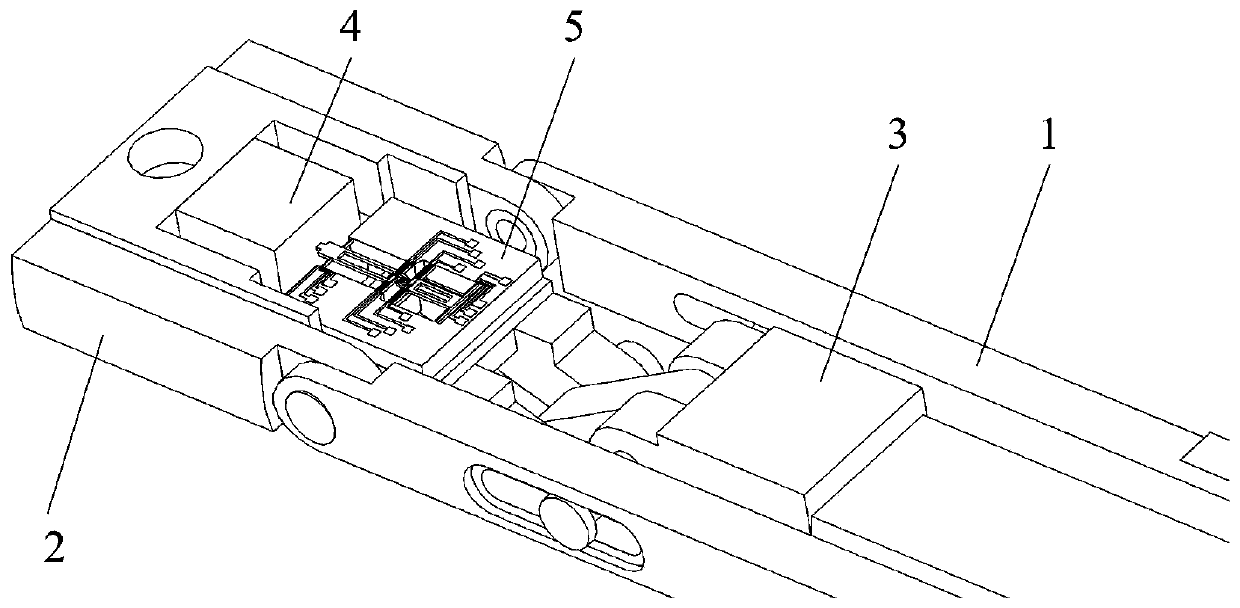

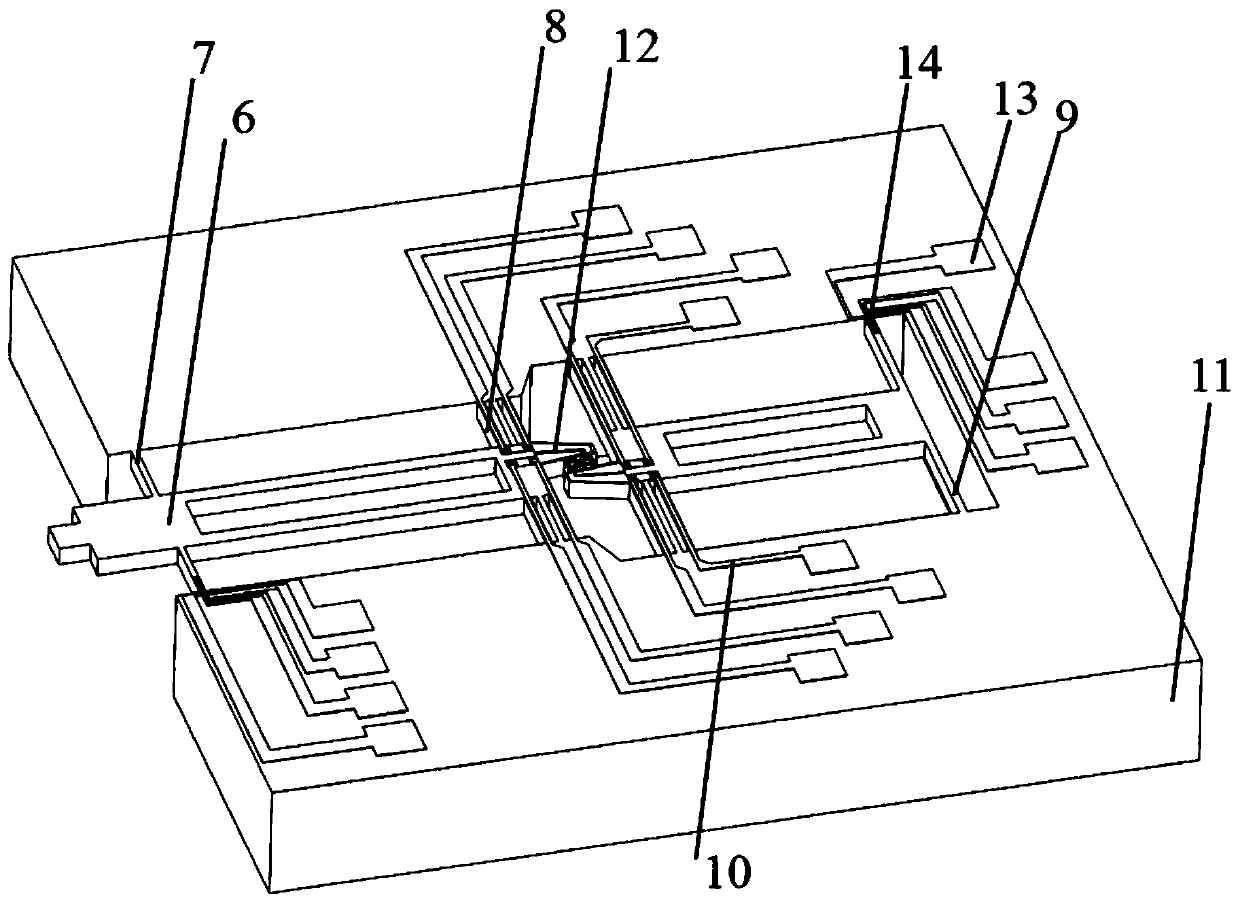

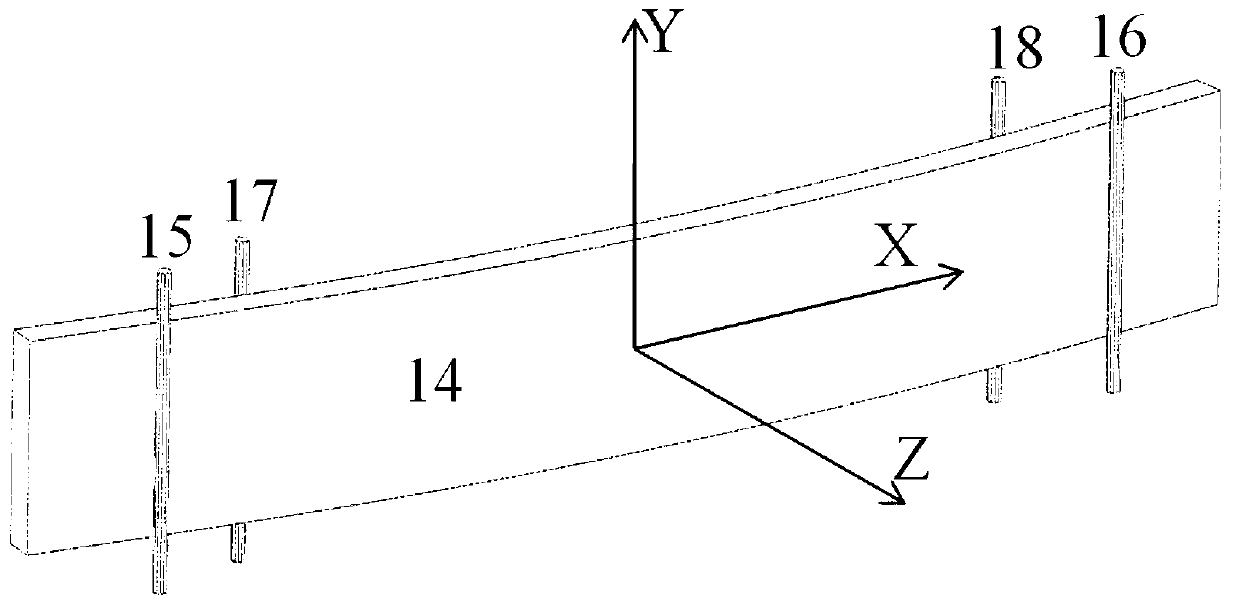

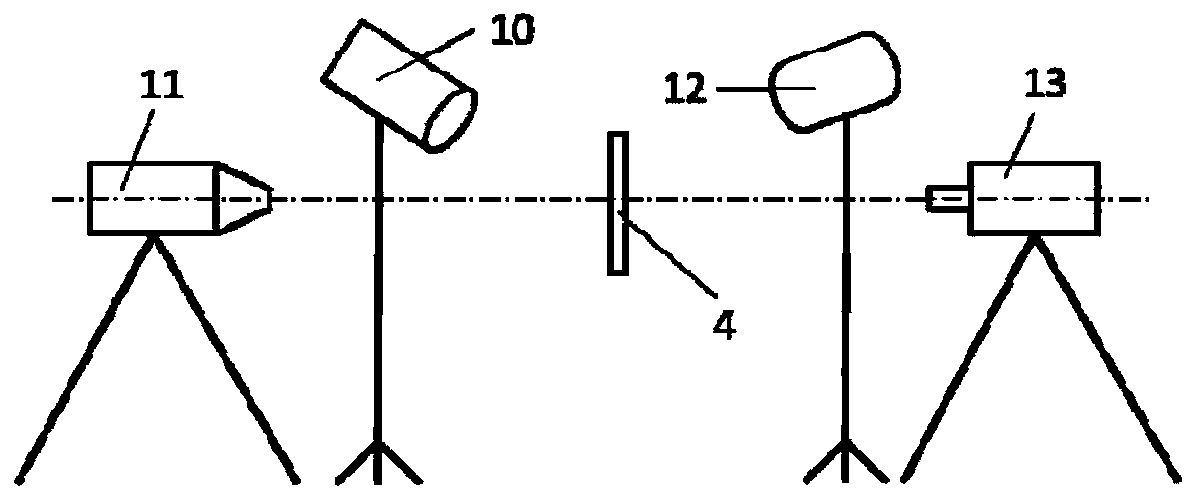

Single-axle double-direction symmetric stretching experimental machine

InactiveCN1888855ARealize displacement loadingIncrease diversityMaterial strength using tensile/compressive forcesBall bearingCoupling

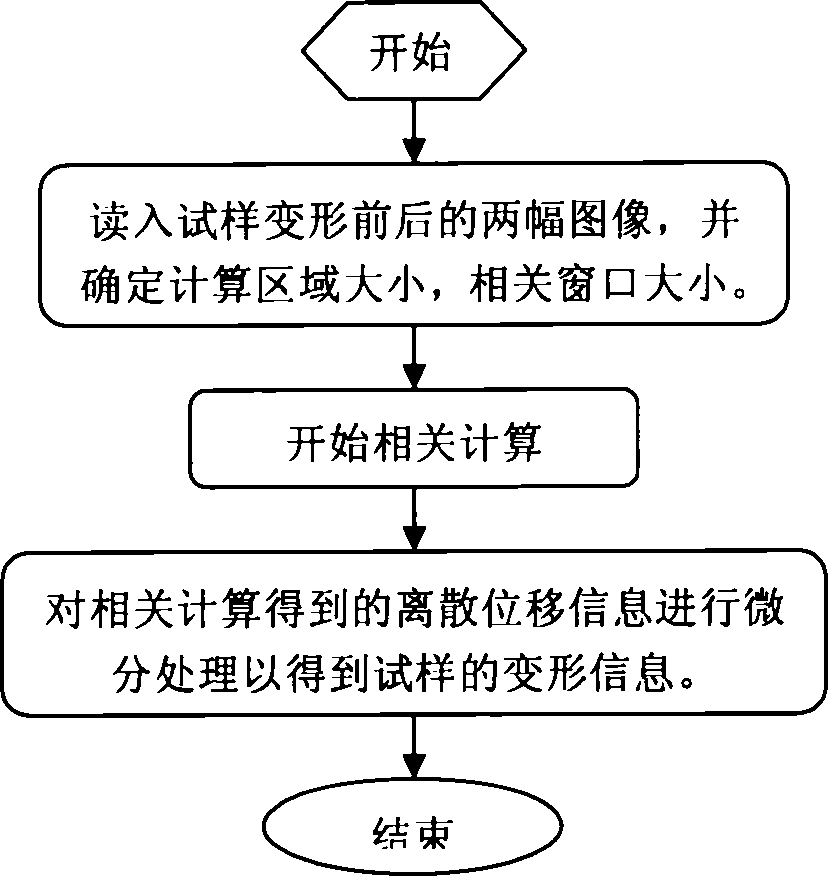

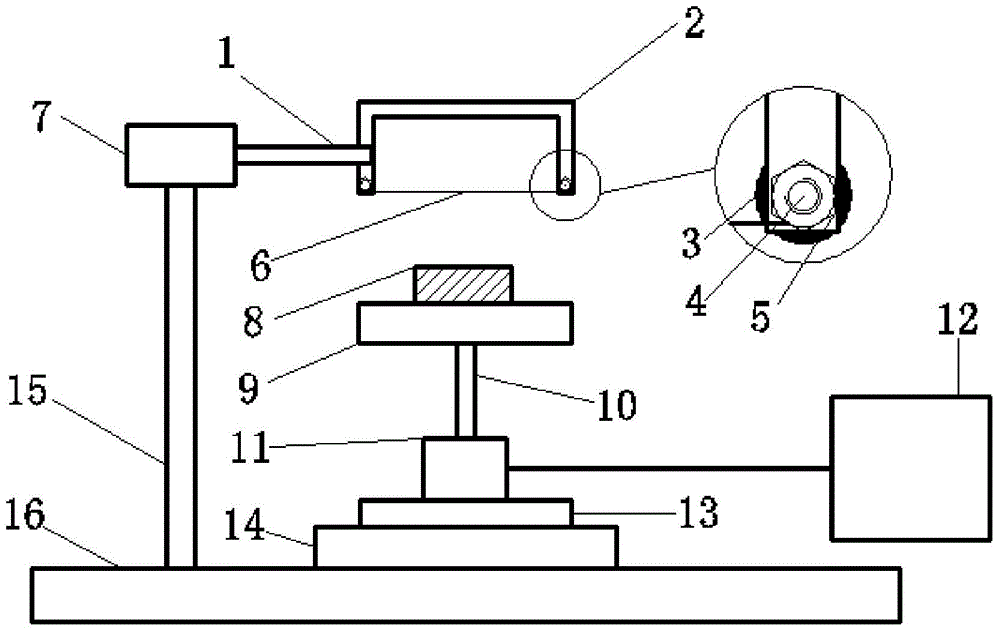

A single axle bidirectional symmetry stretch testing machine belongs to the experimental mechanics equipment technology field, including: the step-by-steps motor 11, the step-by-steps motor controller, the strength sensor, the wormwheel, the worm, the ball bearing screw mandre, the left nut, the right nut, the linear slideway, the axletree, the base 1, the shaft coupling, the testing sample holding device; the step-by-steps motor connects with the worms by the shaft coupling; the wormwheel cooperates with the worm, the linear slideway and the axletree locates on the base; the strength sensor fixes on the right nut of the ball bearing screw mandrel, spreads the one side of the testing sample holding device, the other side of the testing sample holding device fixes on the left nut. The invention is: uses the machine transmission to improve the transmitting precision; uses the step-by-steps motor to load; the distortion measure can use the step-by-steps motor to compute or uses the non-touch photics displacement measure system.

Owner:TSINGHUA UNIV

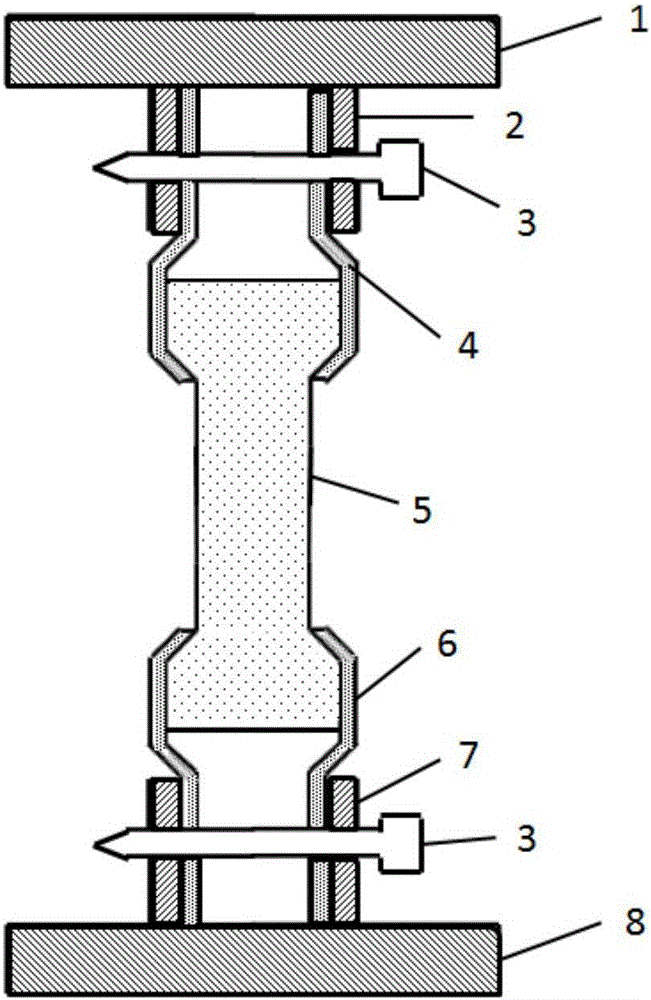

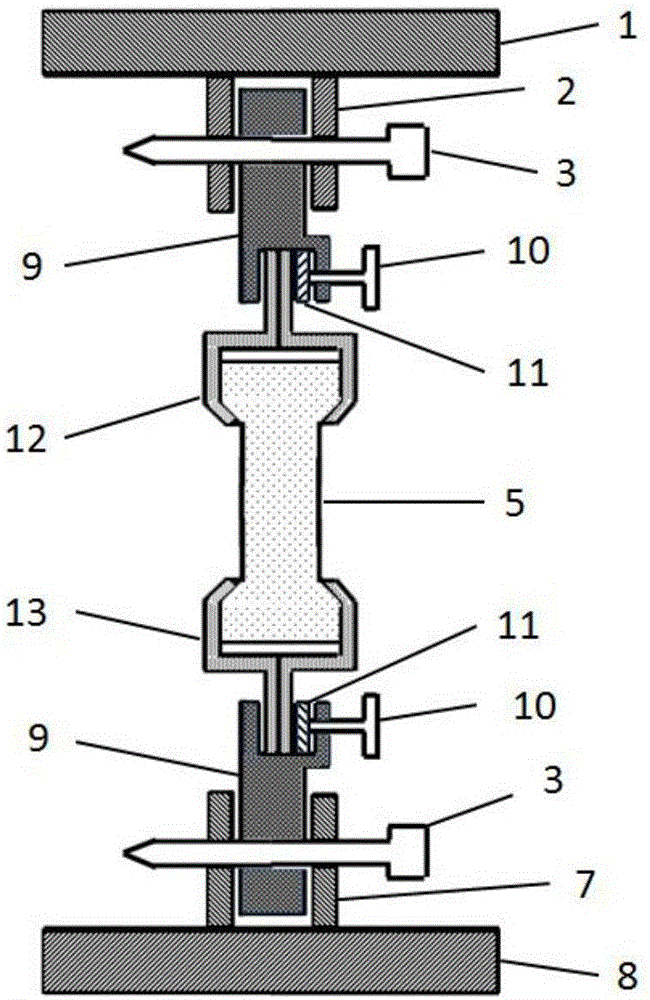

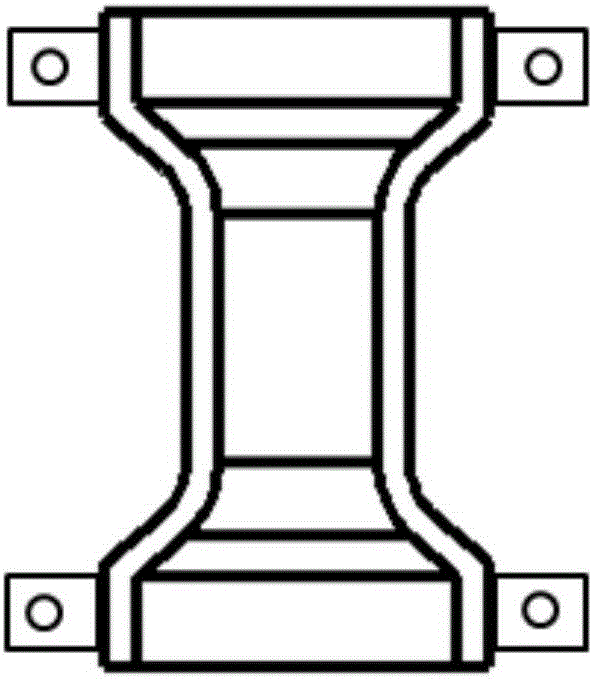

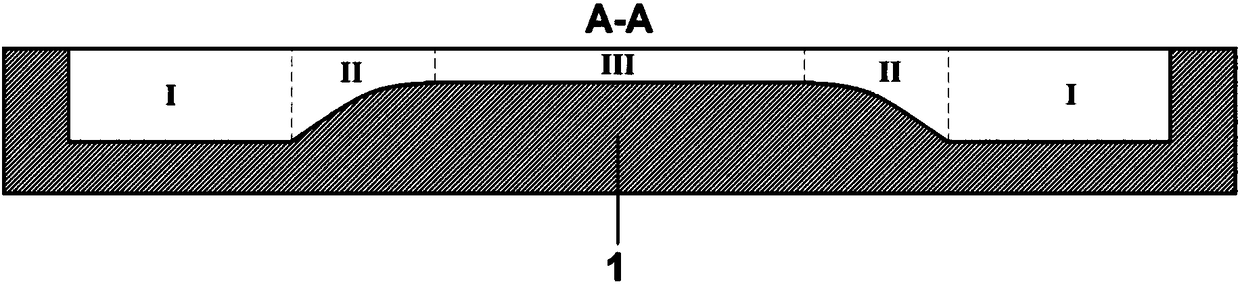

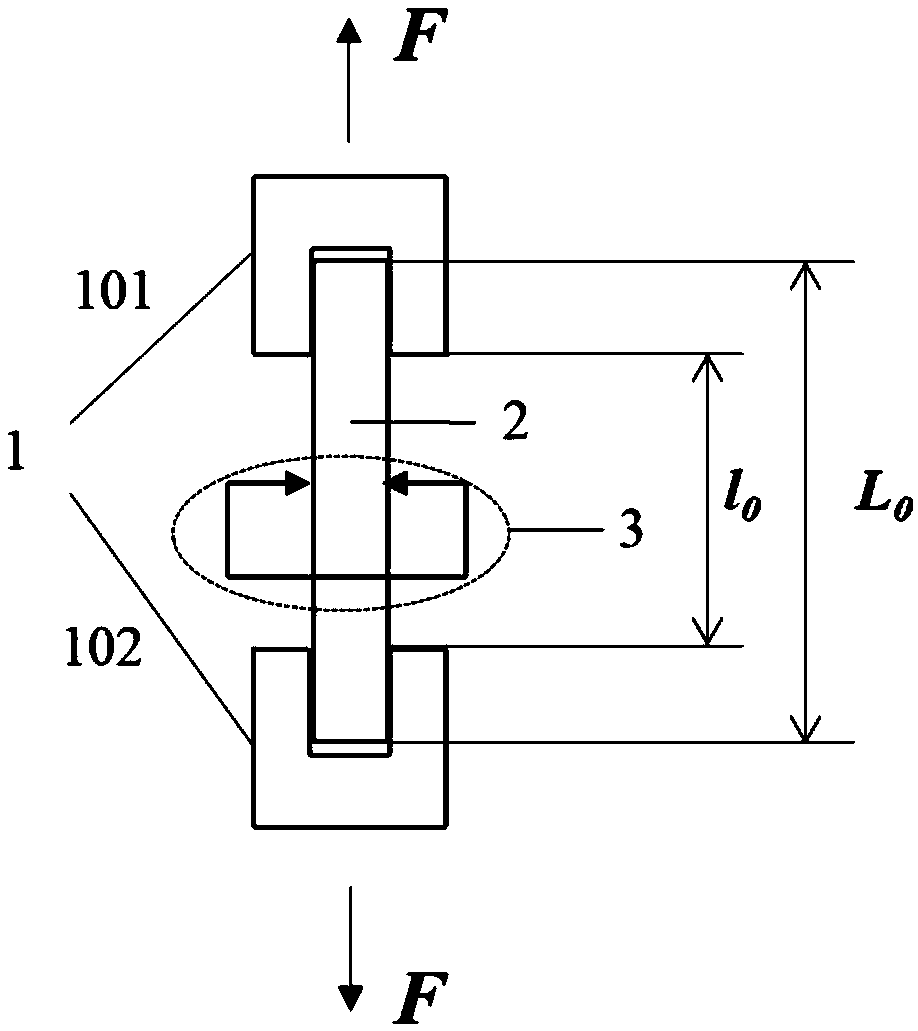

Gripping device for testing pull-power property of low intensity hydrogel

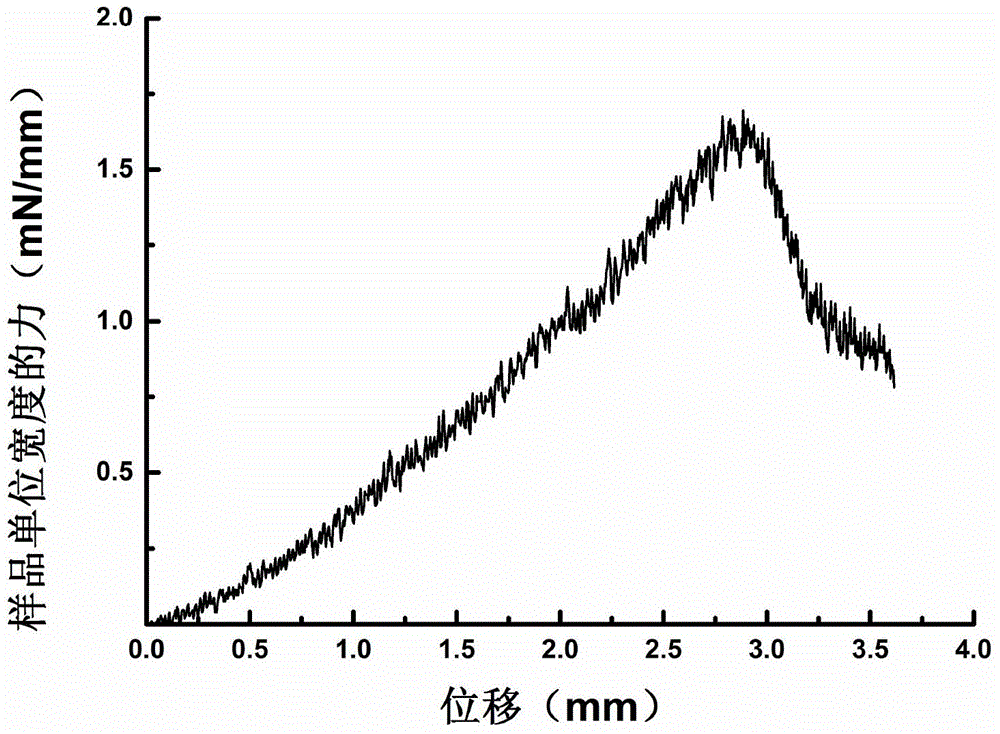

InactiveCN106323772AImprove accuracyLow costMaterial strength using repeated/pulsating forcesCyanoacrylatePull force

The invention belongs to the technical field of functional macromolecule and experimental mechanics, and provides a gripping device for testing pull-power property of low intensity hydrogel. The device includes a dumbbell shaped mould, a gripping device A applied to a reciprocally moving testing machine and accessories thereof, or includes a dumbbell shaped mould, a gripping device B applied to a reciprocally moving testing machine and accessories thereof; different gripping devices correspond to different accessories. The reciprocally moving testing machine applies static, dynamic load to hydrogel samples, and finishes curve measurement for power and displacement. The present invention has the effects and benefits that the pull provided by the gripping device when pulling to the gripping head of hydrogel samples, replaces in the original method the adhesive force of using glue, whose main component is cyanoacrylate, to stick the hydrogel sample on the gripping device. The present invention enhances the measurement accuracy for the pull-power property of low intensity hydrogel. The device has strong controllability, operates conveniently and fast, and is simple for production and promotion.

Owner:DALIAN UNIV OF TECH

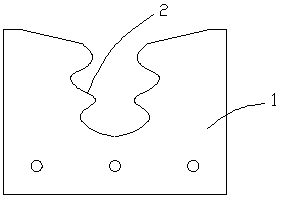

Test device and test method for measuring residual stress of bent pipe

InactiveCN102052981AReduce cumbersome proceduresThe result is accurateForce measurement by measuring optical property variationPrincipal stressSpeckle correlation

The invention relates to a test device and test method for measuring residual stress of a bent pipe and belongs to the technical field of experimental mechanics and residual stress measurement. In the method provided by the invention, the digital speckle correlation technique is combined with the drilling technique, and the method comprises the following steps: using a CCD (charge coupled device) camera to take photos of the bent pipe before and after the bent pipe is drilled; utilizing the digital speckle technique to measure the stretched displacement of two ends of the front and back drilled round holes; and measuring the residual stress of the bent test piece with a confirmed principal stress direction, so as to acquire the residual stress. The digital speckle correlation technique used in the method refers to non-contact measurement. Compared with the traditional electrical testing method, the method has the advantage that the complex process of sticking a foil gauge each time is omitted, thereby being more convenient and simpler. For the measurement of the residual stress of the bent pipe, a column correcting process is added in the method provided by the invention as compared with the traditional method, thus the acquired result is more accurate.

Owner:TSINGHUA UNIV

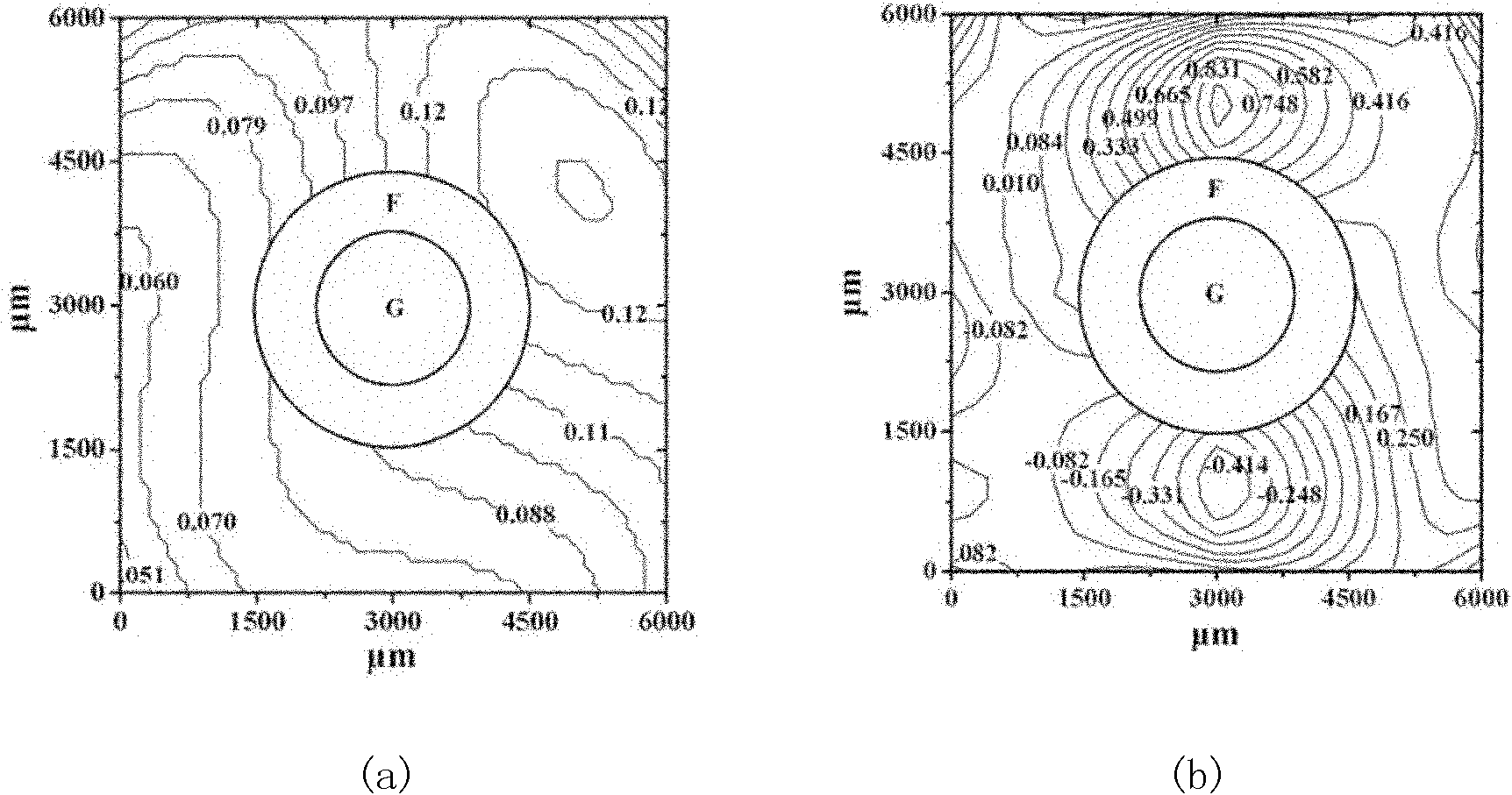

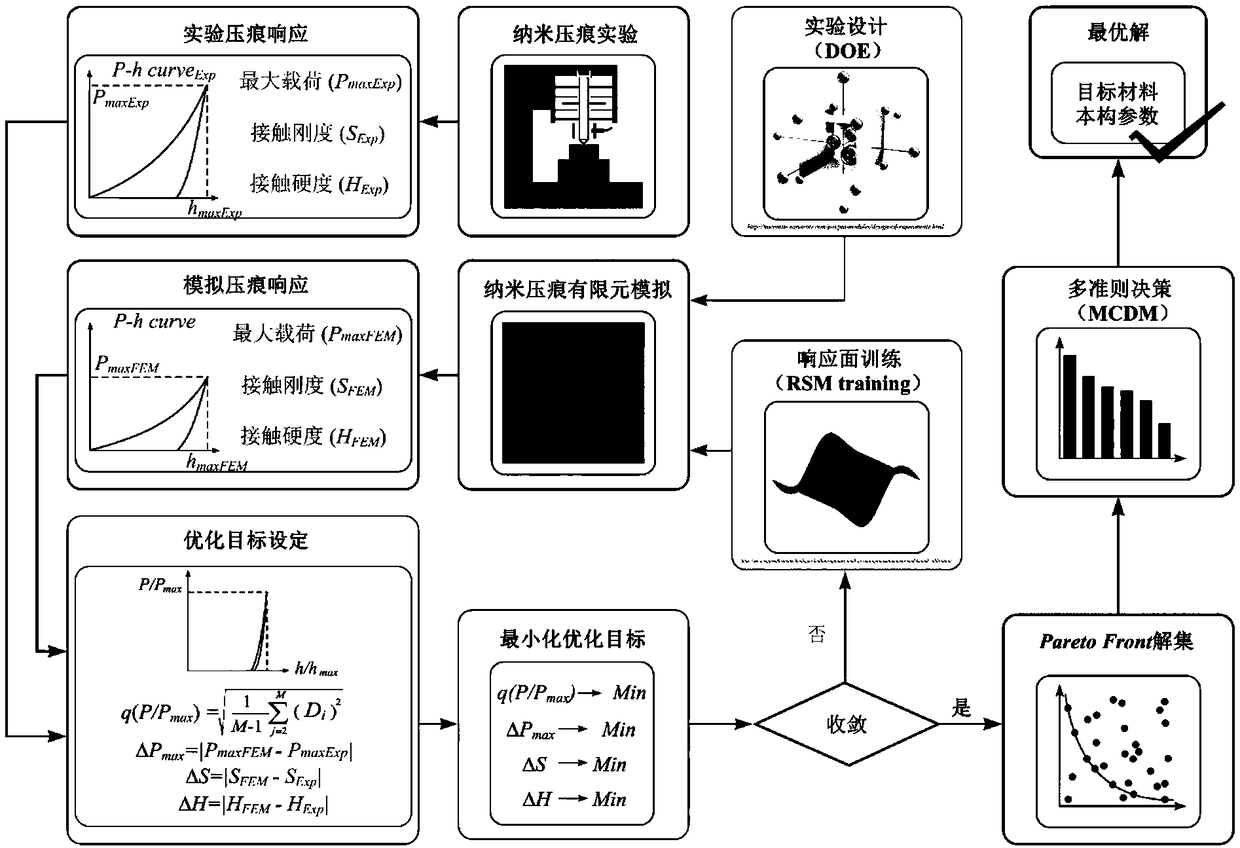

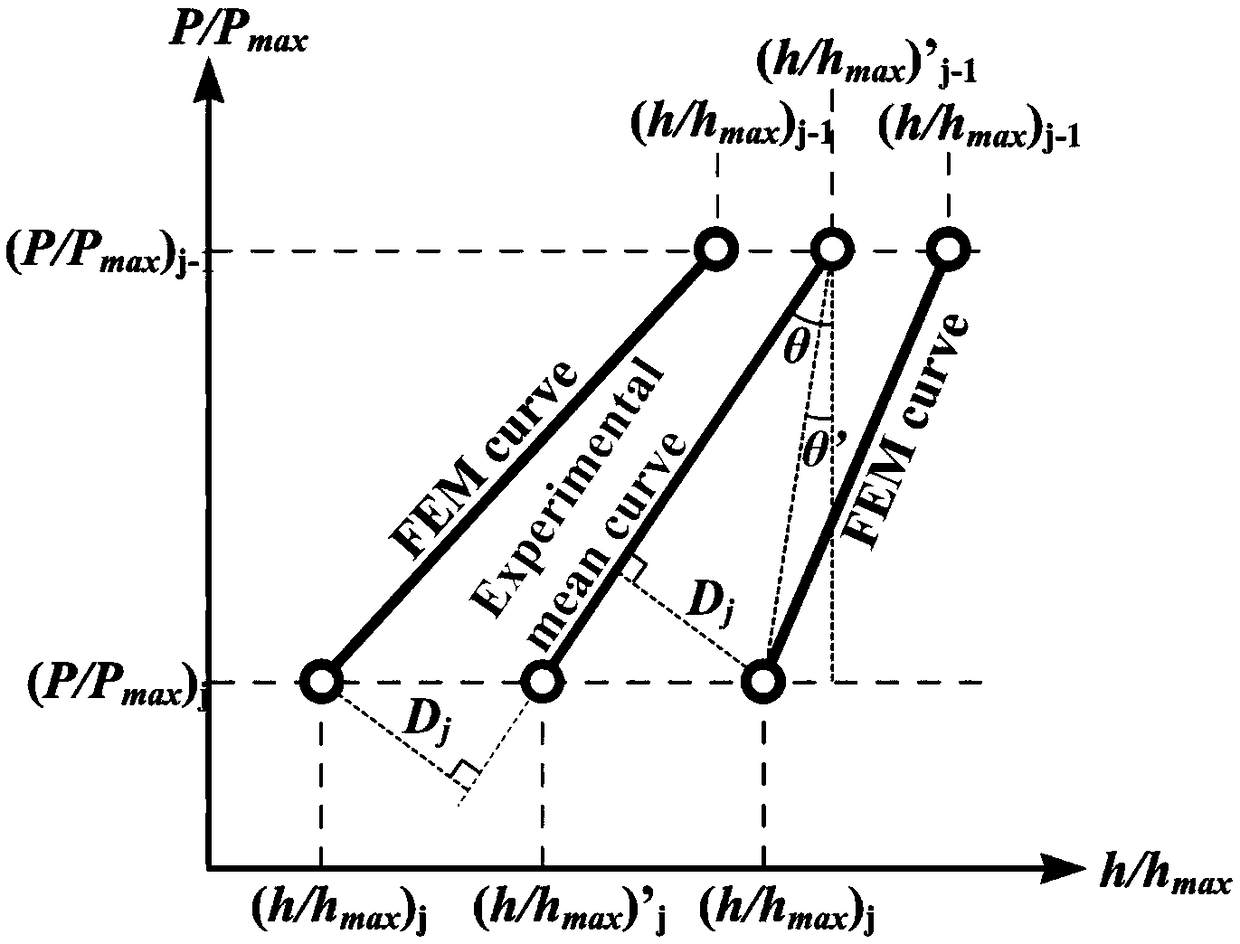

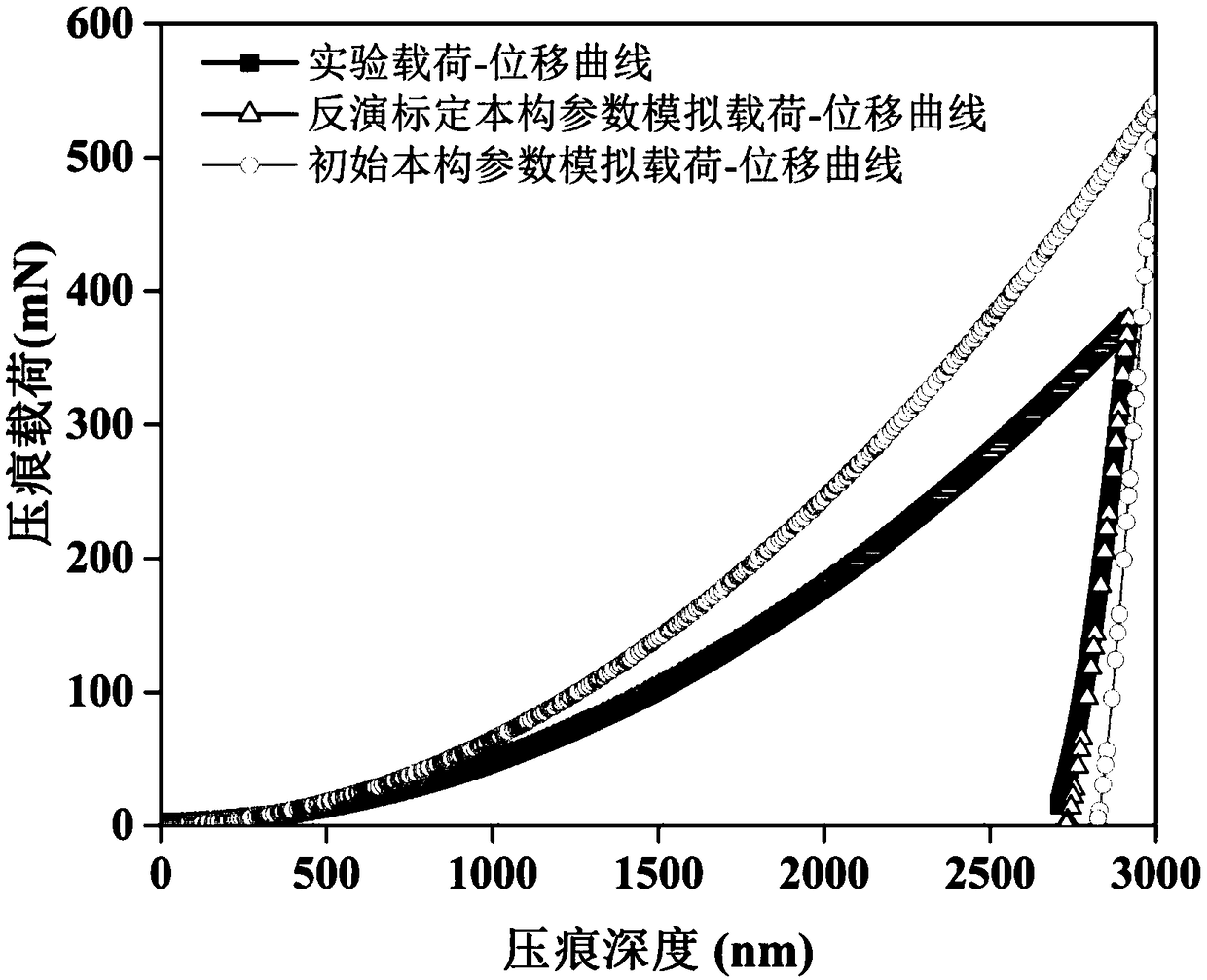

Method for inversion calibration of microscopic constitutive parameters of metal material on the basis of nanoindentation and finite element simulation

ActiveCN108645704AAchieving precise quantitative descriptionAvoid the problem of too large set of non-inferior solutionsMaterial strength using tensile/compressive forcesMetallic materialsDisplacement control

The invention discloses a method for inversion calibration of microscopic constitutive parameters of a metal material on the basis of nanoindentation and finite element simulation. The method comprises the following steps: S1, carrying out a nanoindentation test on the surface of the metal material through displacement control so as to obtain an experimental indentation response; S2, establishinga nanoindentation and finiteelement model under an ABAQUS or standard module, and carrying out finiteelement simulation to the process of the nanoindentation test on the metal material mentioned in the step S1 so as to obtain a simulated indentation response; and S3, constructing a multi-objective optimization platform, setting optimization objectives and constraint conditions, acquiring a non-inferior optimal solution set Pareto Front through a multi-objective optimization method based on FMOGA-II algorithm, and determining a unique optimal solution. The method provided by the invention has low cost, is rapid and accurate to calculate, is simple and practicable, is extensively applicable to inversion calibration of microscopic constitutive parameters of multi-metal materials, and has highpractical value in computational mechanics, experimental mechanics and engineering practical application.

Owner:SHANGHAI JIAO TONG UNIV

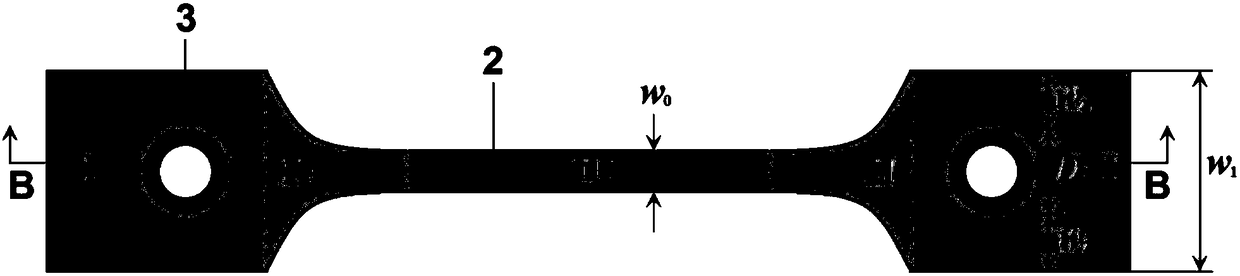

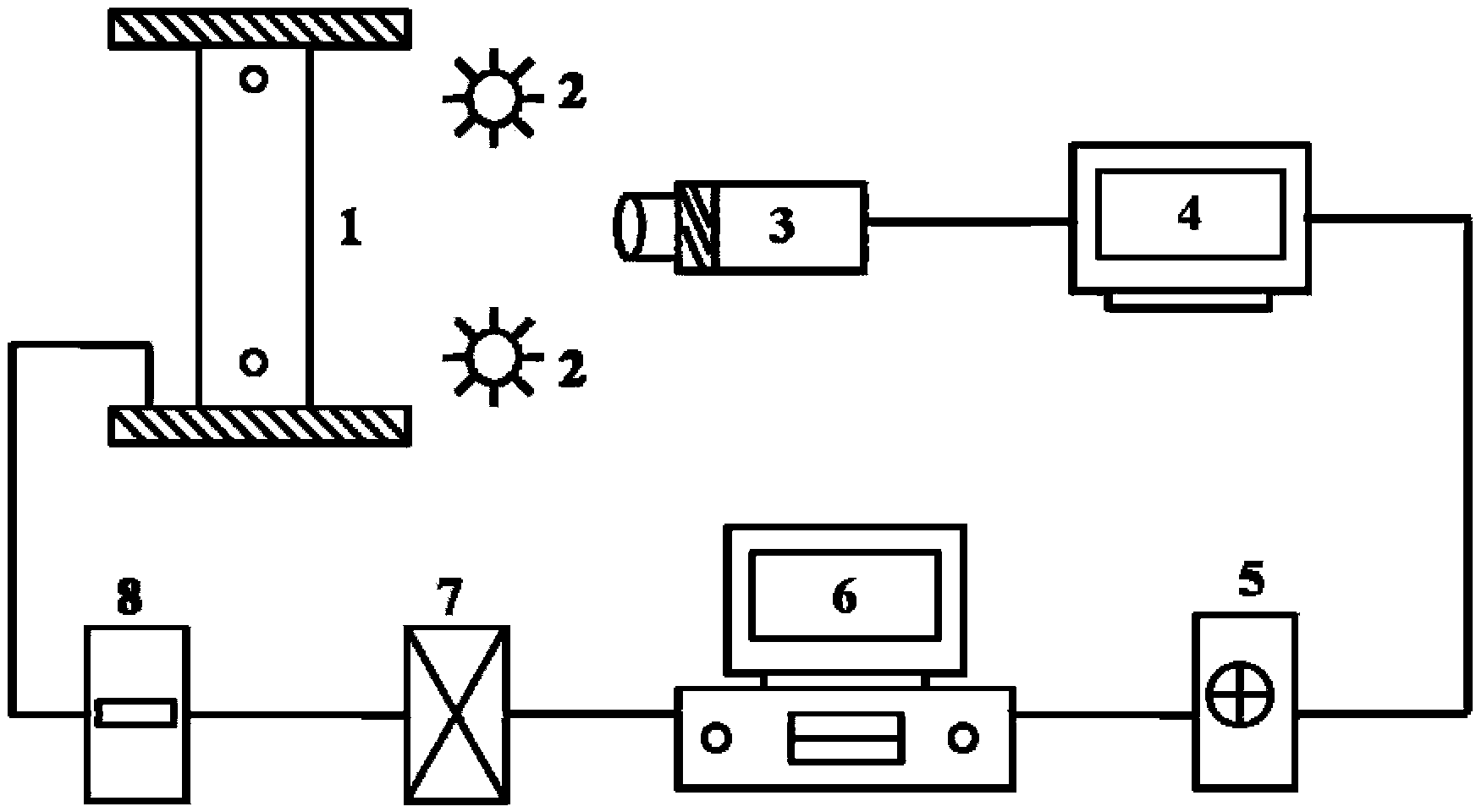

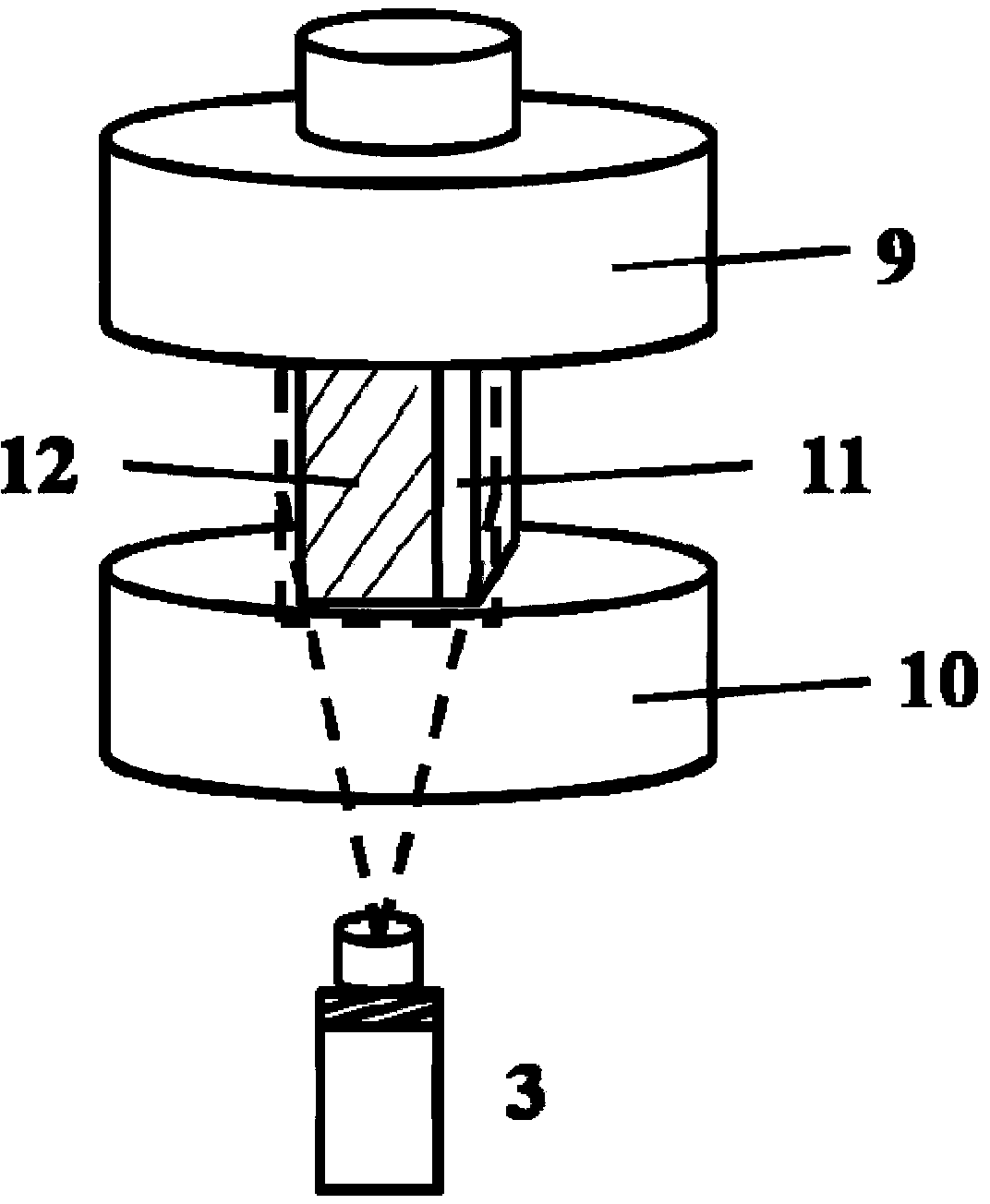

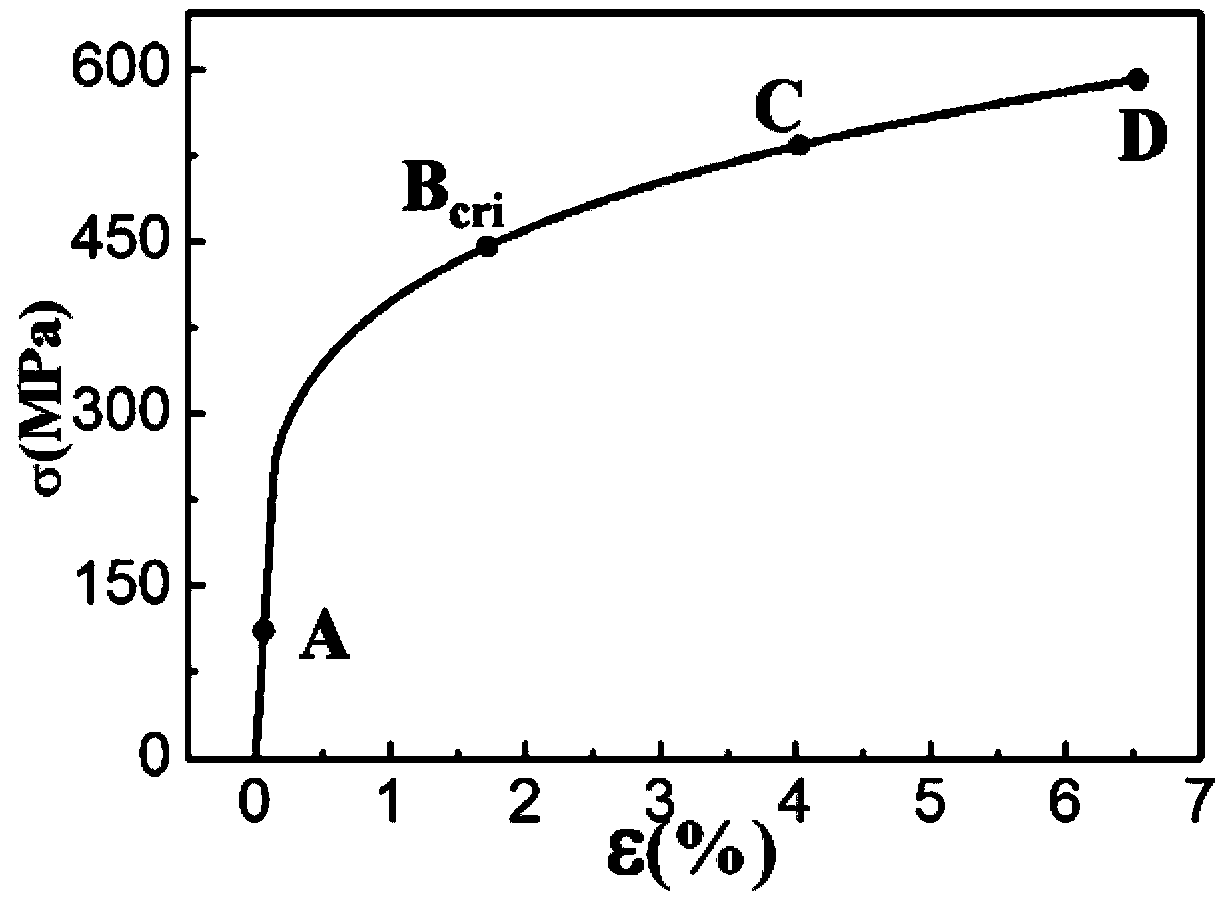

Flexure testing method and flexure testing device for quantitatively characterizing interface binding property of thin-film material

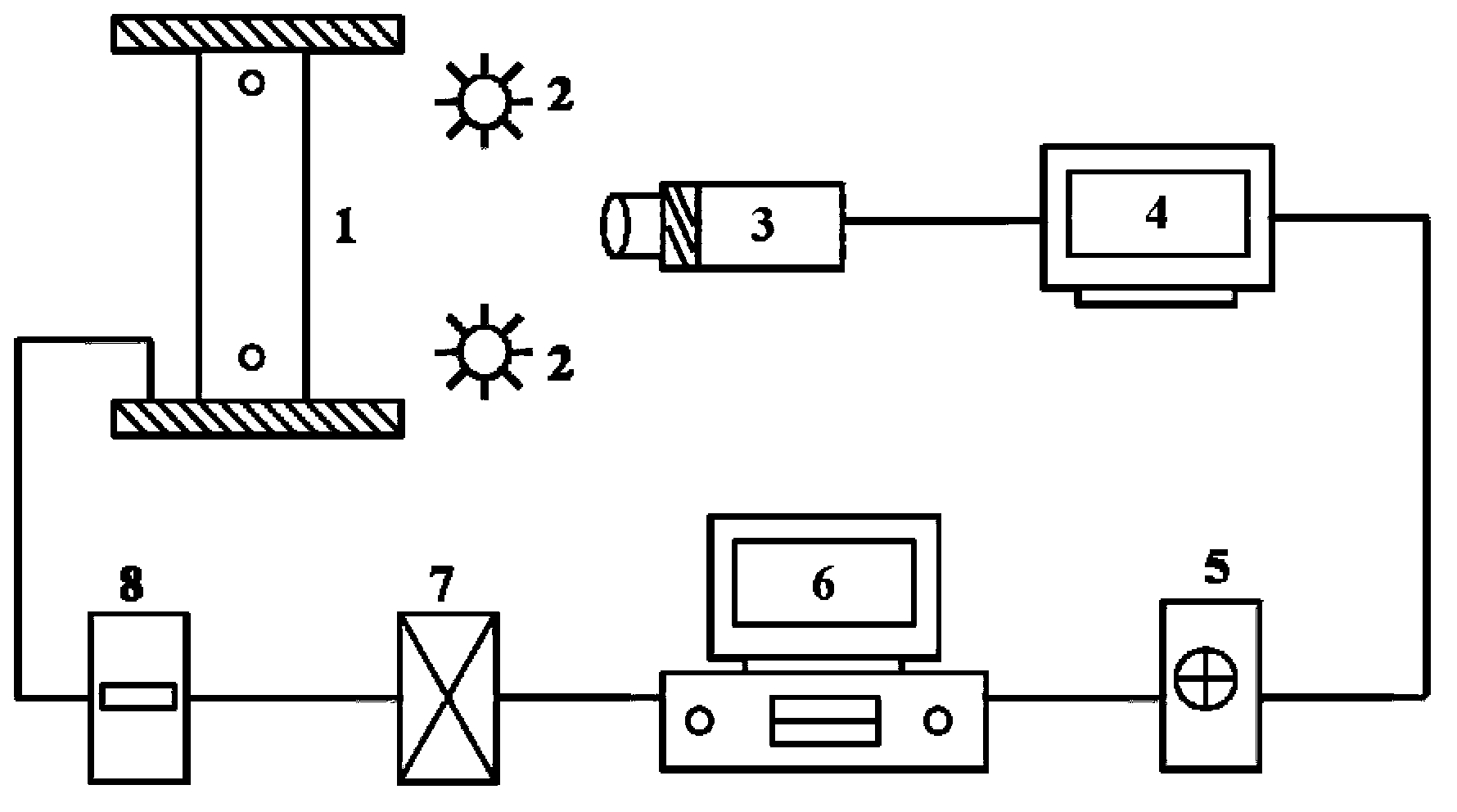

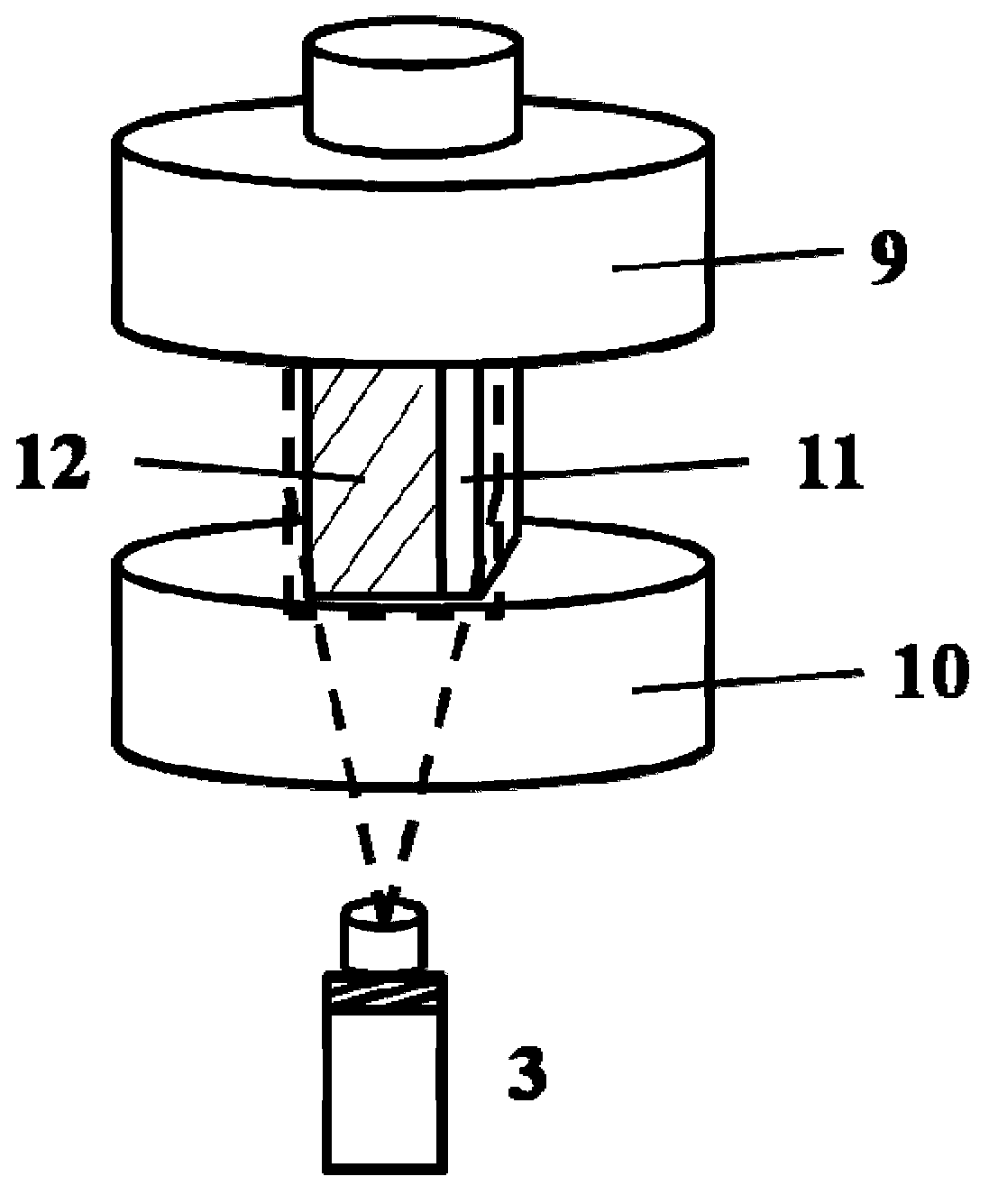

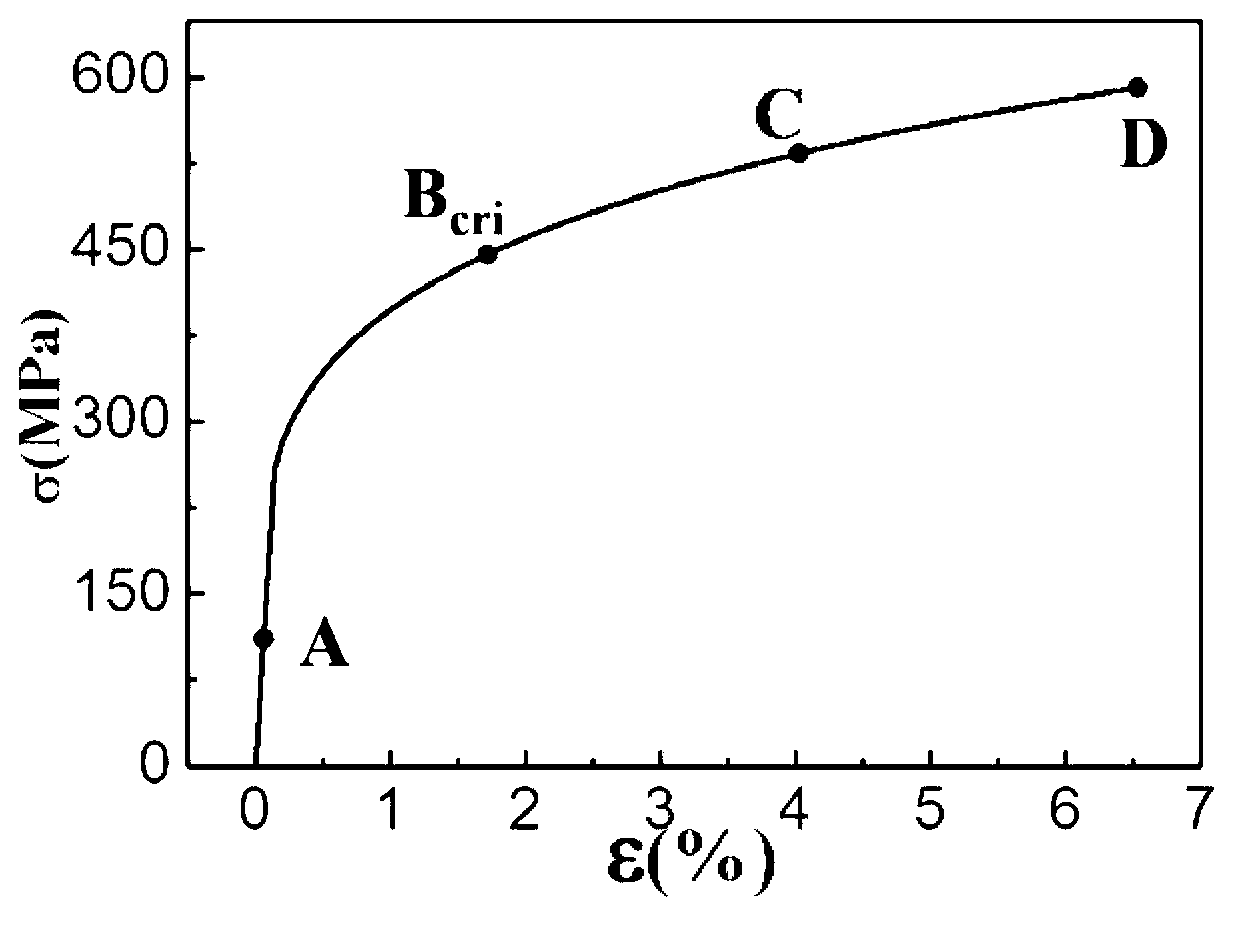

ActiveCN103018160AEasy to makeThe principle is simpleUsing mechanical meansMaterial analysisUniaxial compressionImaging processing

The invention relates to a flexure testing method and a flexure testing device for quantitatively characterizing the interface binding property of thin-film material and belongs to the technical field of property characterization of experimental mechanics and material mechanics. The method is characterized in that uniaxial compression is performed to a sample in the axial direction through a universal material testing machine, and the stress strain values of the sample are recorded; meanwhile, the cross section of the sample is observed synchronously in real time through a CCD camera during the loading process, and stripping characteristics such as critical stress, deflexion and crack length can be recorded in real time during the flexure process; and a relation between the coating and plating-substrate stress strain history and the stripping characteristics is established to characterizing the interface binding property of the coating and plating-substrate. According to the device, the CCD camera, a monitor, an image processing card, a computer, a data processing card, a load sensor and the universal material testing machine are connected in sequence. The invention has the advantages of simple principle, simplicity in sample preparation, clear model, easiness in operation, and the like.

Owner:XIANGTAN UNIV

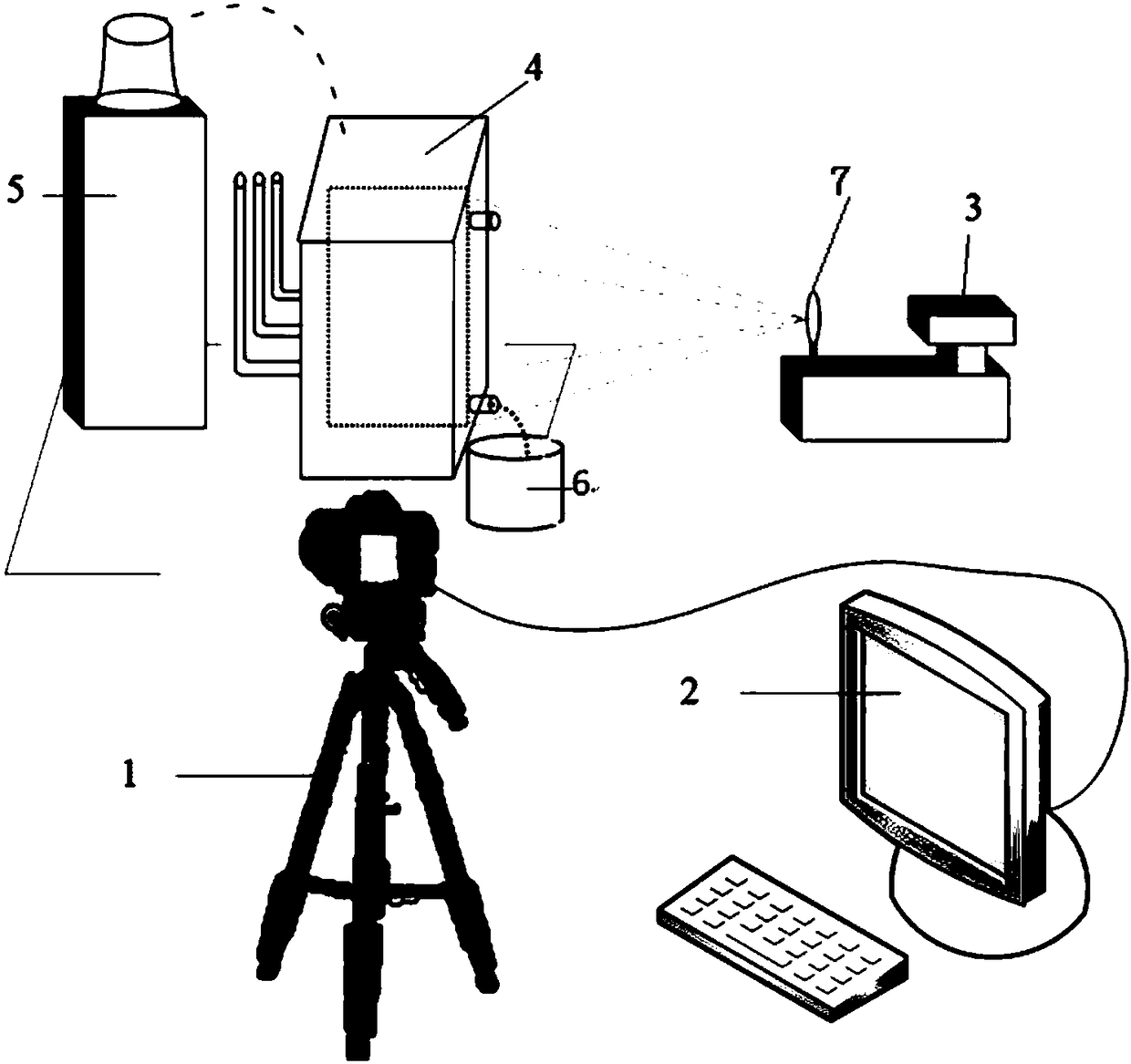

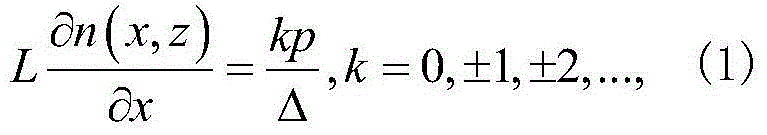

Method for measuring liquid flow in saturated porous medium

InactiveCN108106981ALaw understandingReduce research costsPermeability/surface area analysisPore fluidCorrelation analysis

The invention provides a method for measuring a liquid flow in a saturated porous medium. The method belongs to the technical field of experimental mechanics testing, and comprises the steps of continuously downwards flowing fluorescence pore fluid in a porous transparent medium, producing a sector laser light by a laser through the transparent medium, entering a saturated transparent porous medium, and acting with fluorescent particles in the flowed pore fluid to produce a laser speckle effect; shooting laser speckle plane images in the transparent saturated porous medium at different times through a digital camera, carrying out correlation analysis, acquiring movement displacement, a speed value and a vector of the fluorescent particles, and obtaining the flowing speed magnitude and a vector diagram of the pore fluid; finally combining with a calibration parameter of the digital camera to obtain actual displacement and speed value, and obtaining flowing speed magnitude distribution and direction of the fluid in the saturated transparent porous medium. The method provided by the invention is used for researching a speed field change rule of seepage in the saturated porous medium in a natural world, and has significance on researching oil gas flowing and mining.

Owner:DALIAN UNIV OF TECH

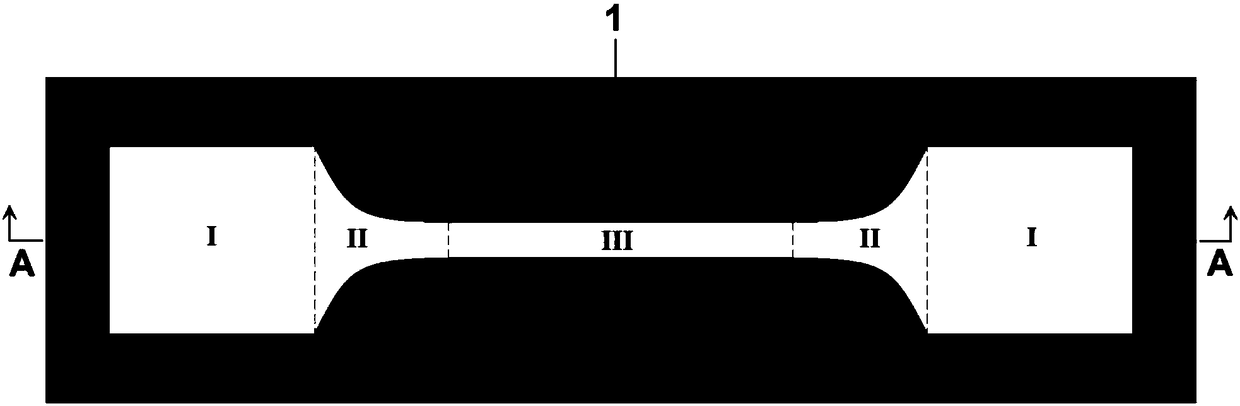

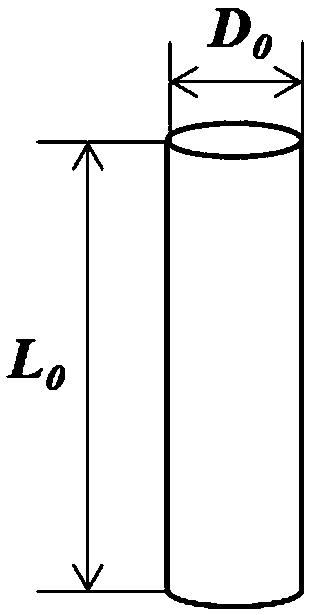

Preparation and clamping testing device of variable-thickness hydrogel tensile sample with preset clamping rings

ActiveCN108195675AAvoid breakingPrevent slidingPreparing sample for investigationMaterial strength using tensile/compressive forcesStress concentrationVariable thickness

The invention discloses a preparation and clamping testing device of a variable-thickness hydrogel tensile sample with preset clamping rings, and belongs to the technical fields of functional polymermaterials and experimental mechanics. The sample is molded through mold casting, wherein a mold is rectangular, the inner cavity is in the shape of a dumbbell and is divided into a clamping section, atransition section and a scale distance section in the length direction, each part meets certain dimension requirements, the three sections are symmetrically distributed by taking the scale distancesection as a center, and the cross section of each section is rectangular; the clamping section and the scale distance section are connected by adopting arc-shaped transition, and are used for avoiding stress concentration. The clamping rings in a pair are prepared, and are placed at the corresponding positions of the clamping sections in advance. Blended hydrogel is poured into a mold cavity, thevariable-thickness hydrogel tensile sample with the clamping rings is obtained after solidification and demolding, and a clamp prepared by a testing machine is used for clamping, so that the operation of a tensile test is carried out. The hydrogel can be effectively prevented from sliding or breaking in the clamping part, and simultaneously, strain measurement is further convenient to perform byadopting an optical stress measurement technology, so that the testing result is more accurate.

Owner:DALIAN UNIV OF TECH

Non-contact experimental method for measuring heat constant of high-temperature material

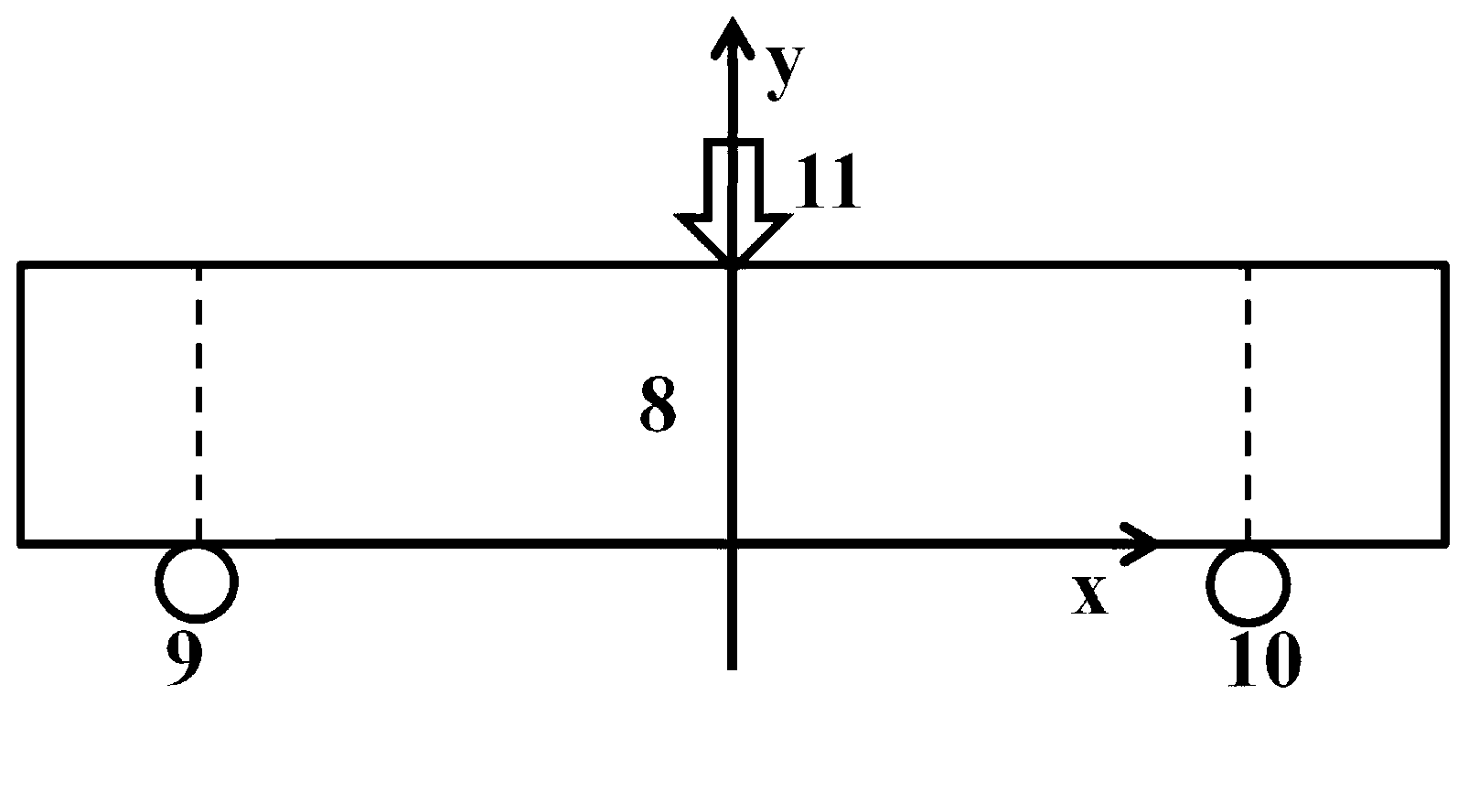

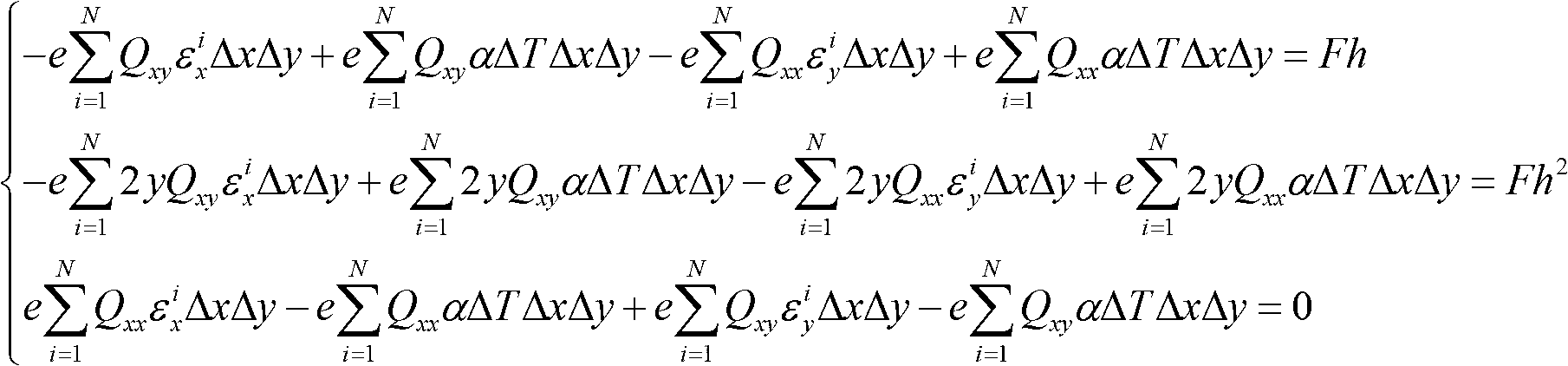

InactiveCN103018111ALabor savingEasy to operateMaterial thermal coefficient of expansionMaterial strength using steady bending forcesVirtual fieldFull field

The invention discloses a non-contact experimental method for measuring a heat constant of a high-temperature material, and belongs to the technical field of experimental mechanics and high-temperature test. An elastic modulus, a poisson ratio and a thermal expansion coefficient of the material under a high temperature are measured by combining a high-temperature digital speckle technology, a three-point bending technology and a virtual field technology. By the method, a charge coupled device (CCD) is used for recording speckle maps of a three-point bent test sample before and after thermal load; a full-field strain before and after the thermal load is calculated by a digital speckle method; the elastic modulus, the poisson ratio and the thermal expansion coefficient of the material under high temperature are calculated; and the elastic modulus, the poisson ratio and the thermal expansion coefficient of the material under high temperature can be measured at the same time.

Owner:TSINGHUA UNIV

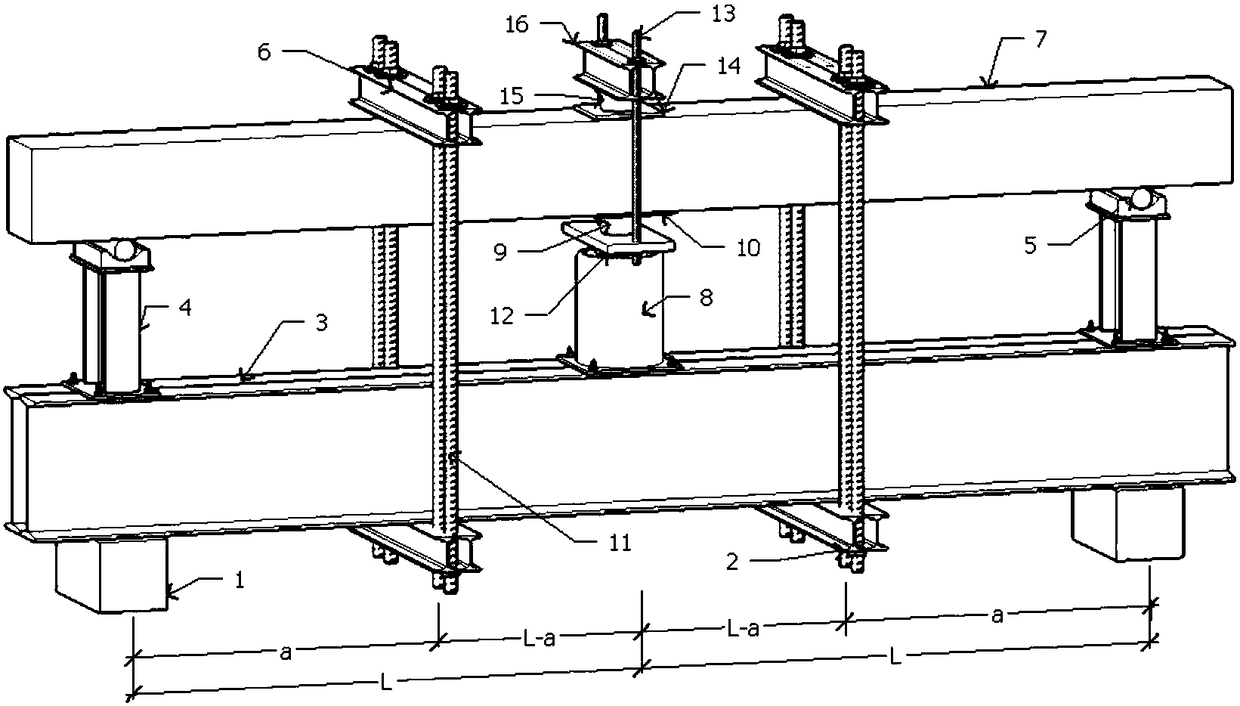

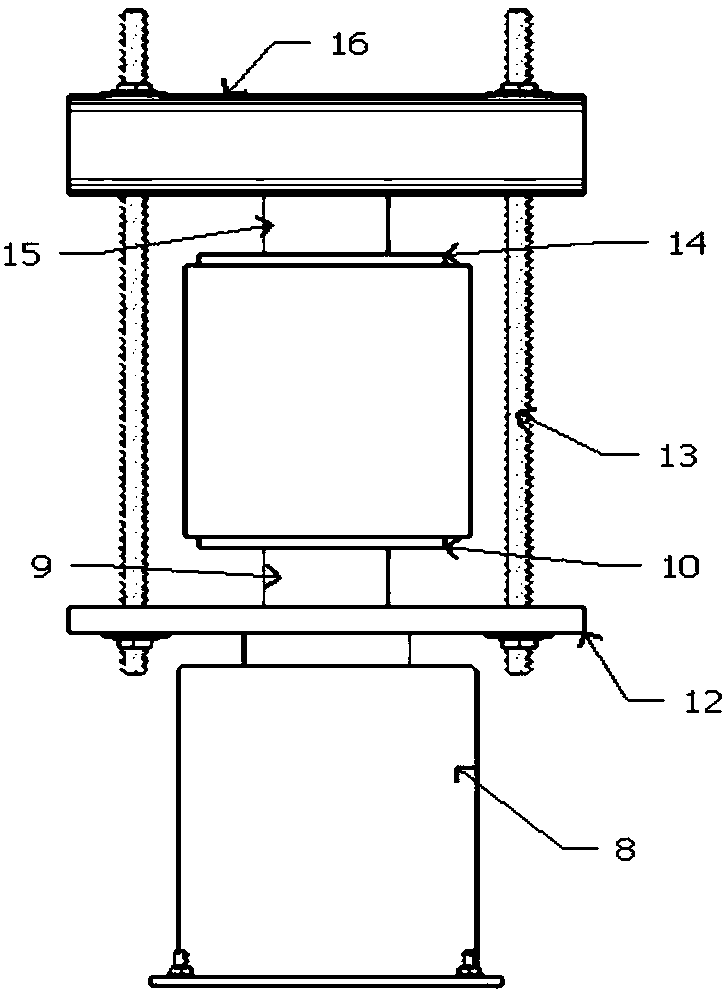

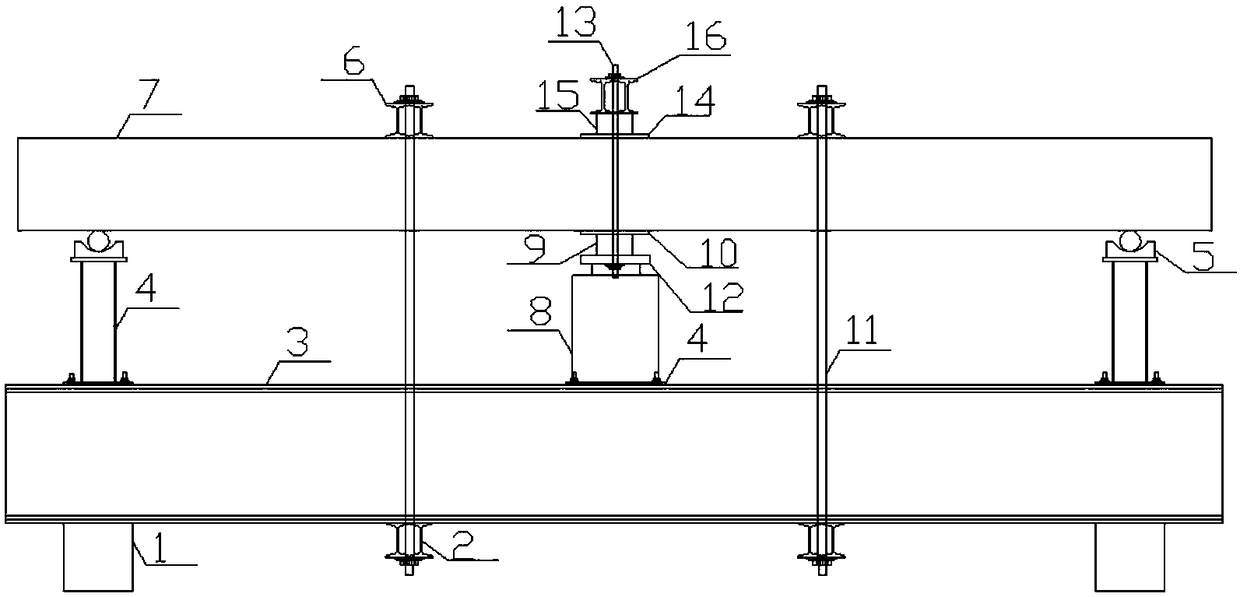

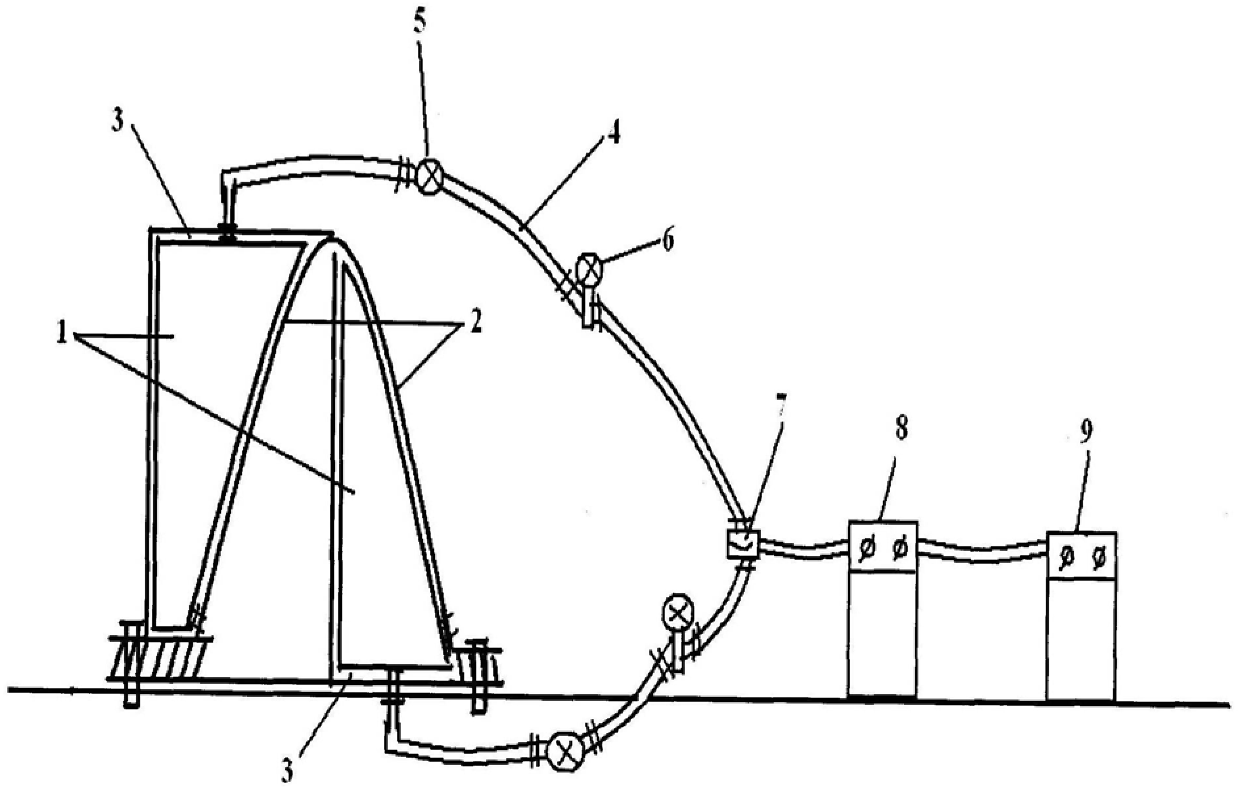

Test device and test method for long-term alternating load of continuous beam bridge

InactiveCN108489748AEvenly loadedImprove economyStructural/machines measurementSupporting systemBridge engineering

The invention provides a test device and test method for the long-term alternating load of a continuous beam bridge and belongs to the field of bridge engineering experimental mechanics measurement methods. The test device comprises a base system, an intermediate support system, a measurement system and an intermediate force transmission system. A test is carried out according to the steps of calculating a control cross section bending moment affecting line shape in advance, determining a most unfavorable loading position, assembling a test self-balancing frame and adjusting a hydraulic jack.The test device and the test method have the advantages of simple structure installation, synchronous alternating balanced loading and the adaption to actual field conditions, and the adaption of actual field conditions, the long-period alternating continuous loading test can be carried out on a two-span continuous beam bridge.

Owner:西安华清科教产业(集团)有限公司

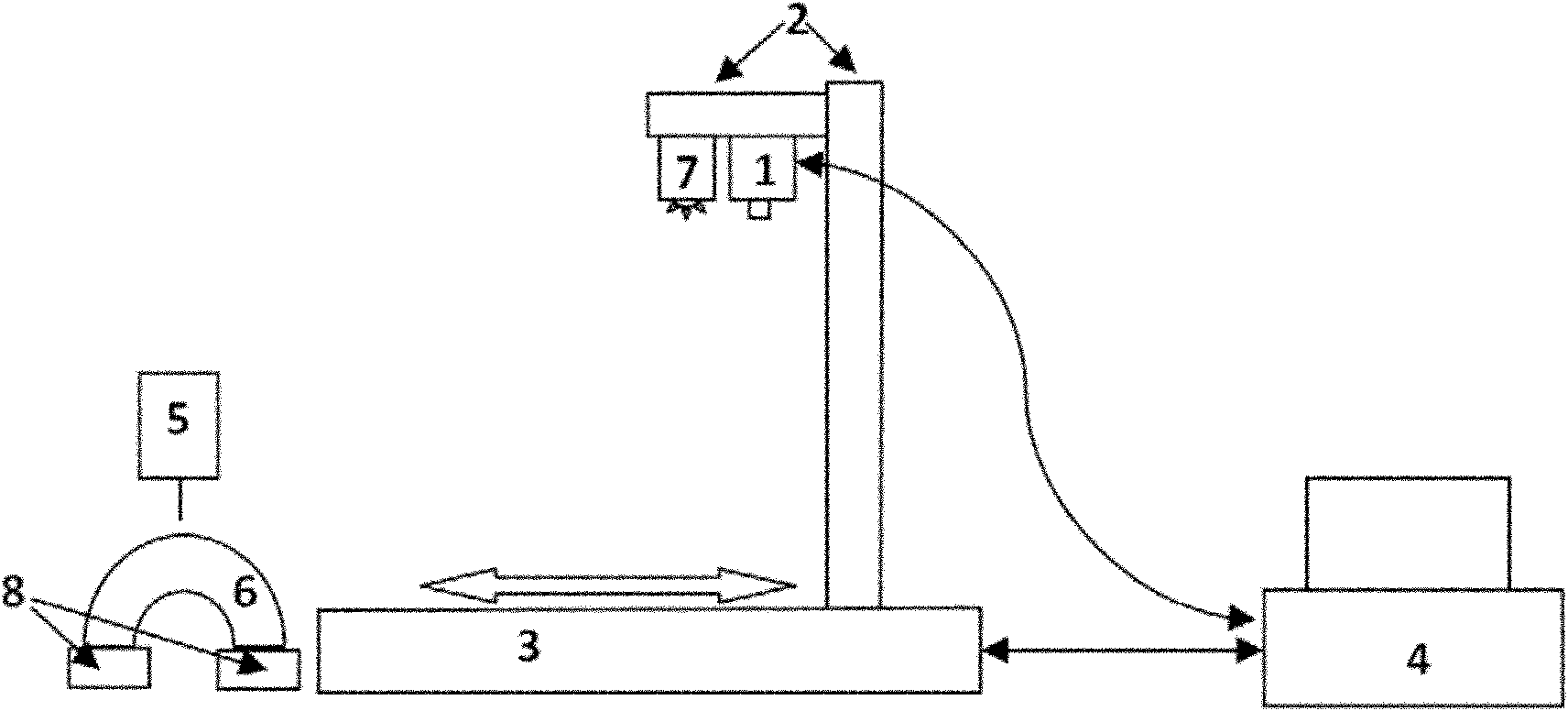

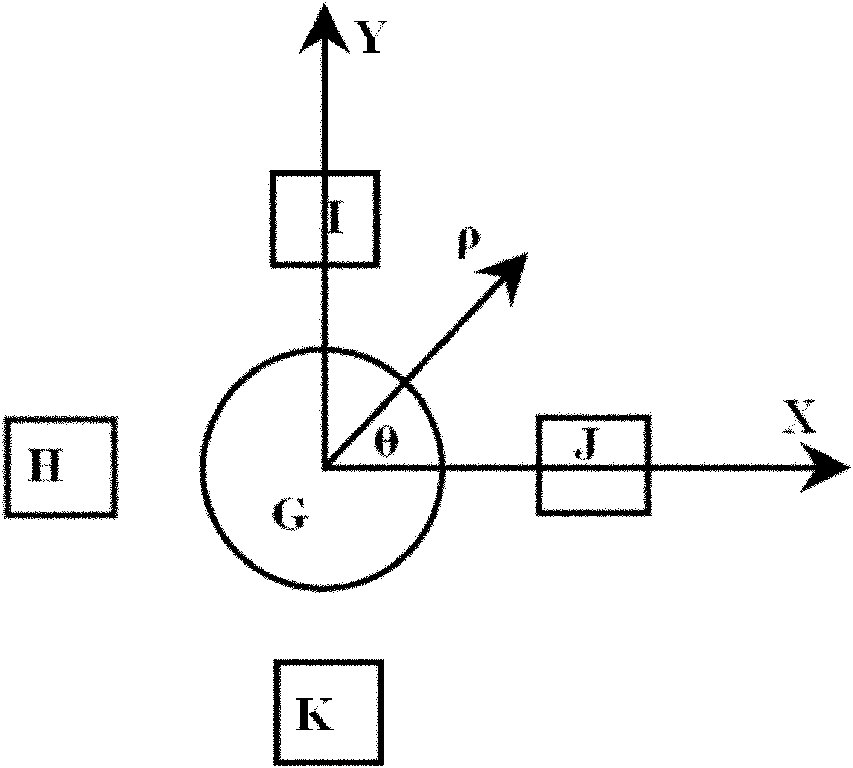

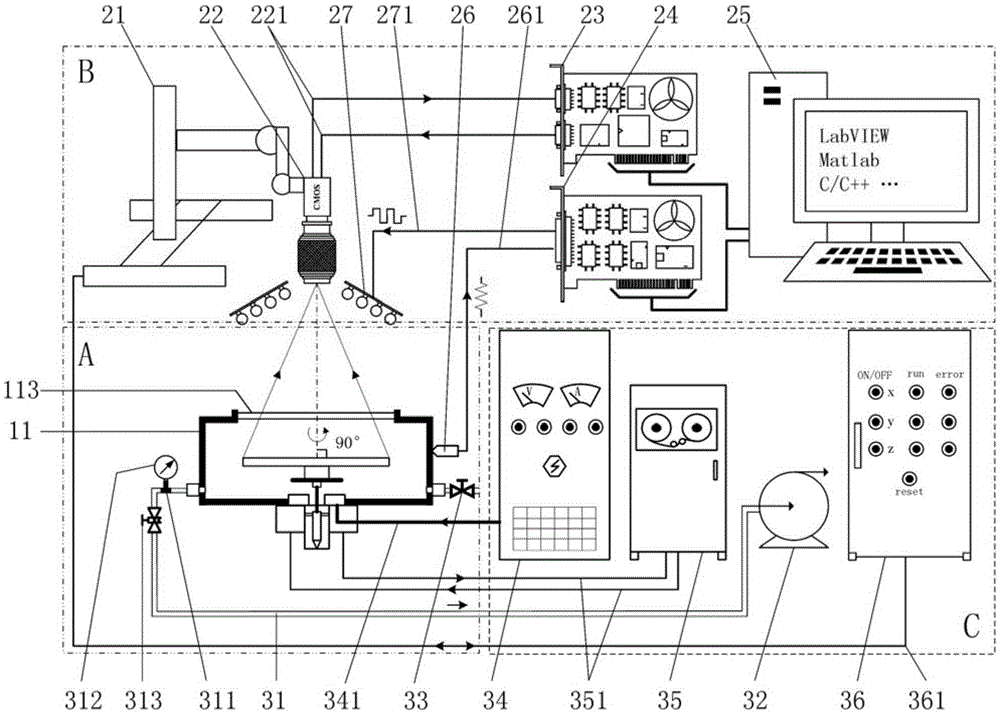

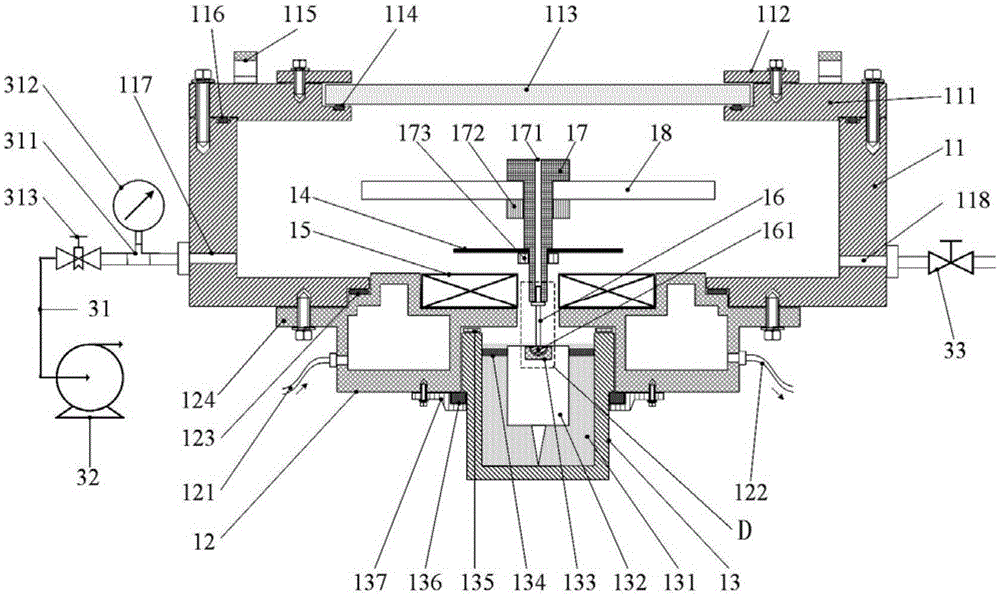

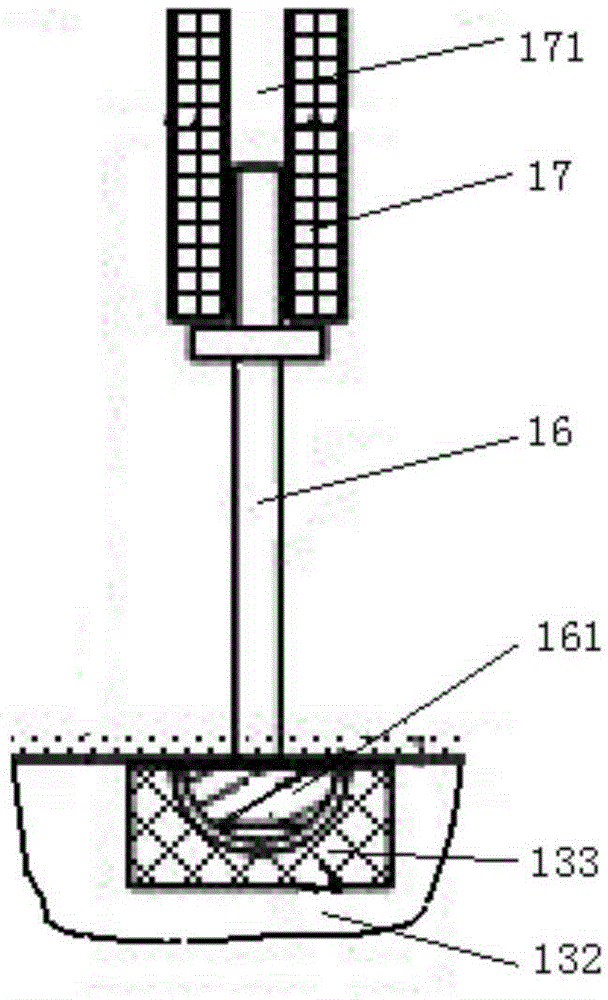

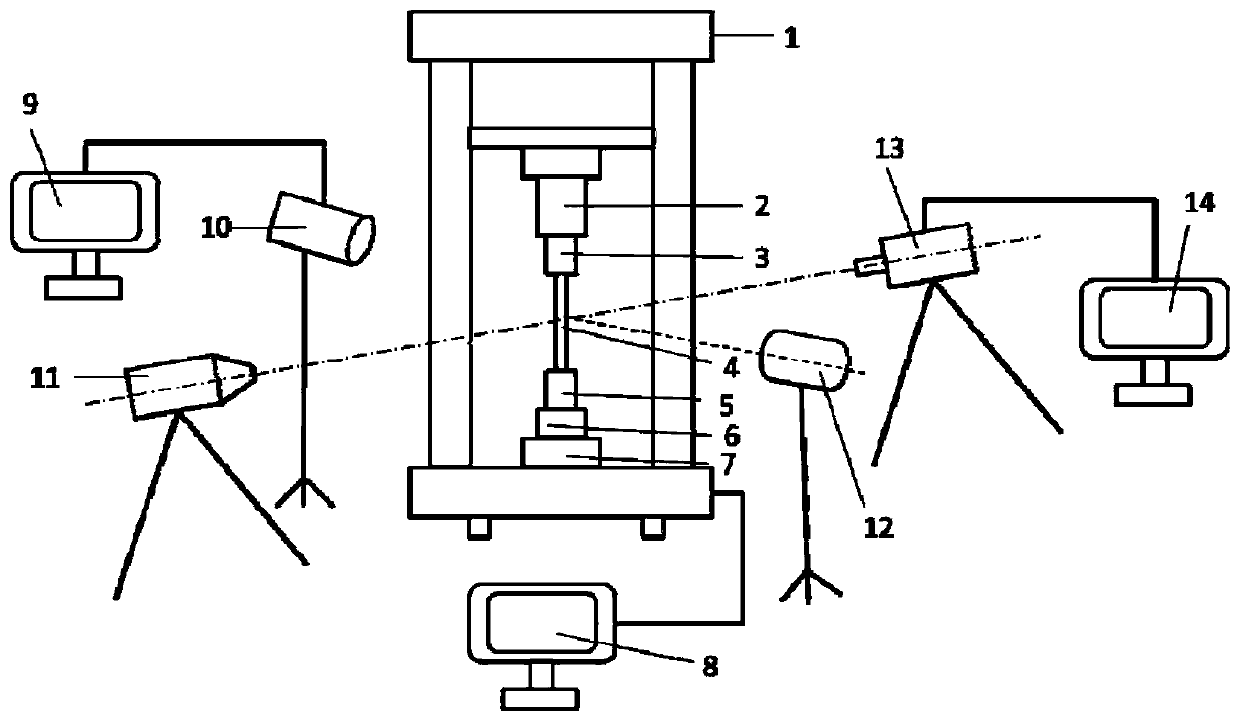

Optical measuring method and apparatus for deformation and strain of high speed rotating structural member

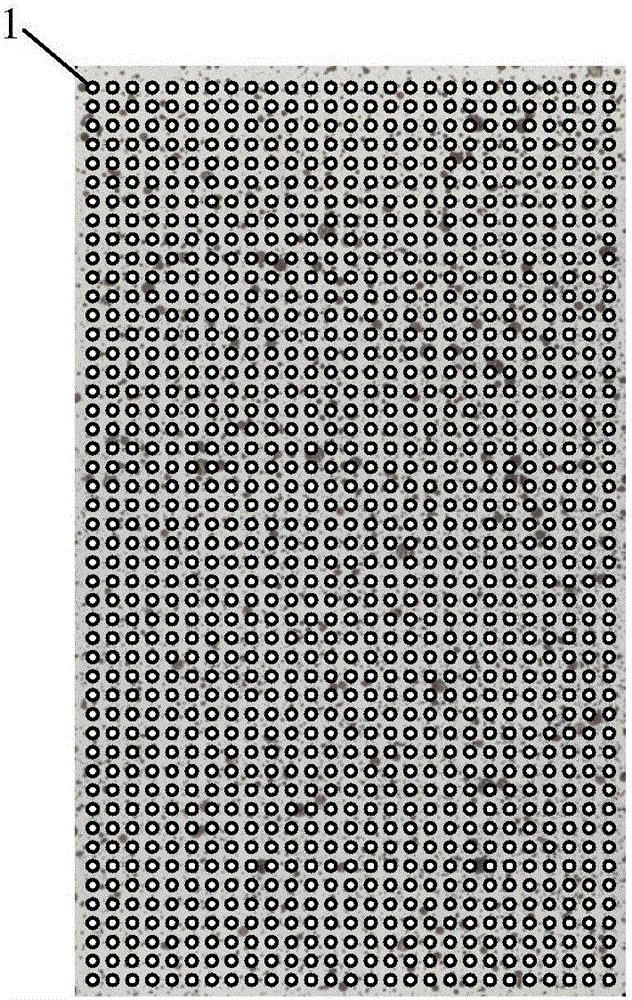

ActiveCN105333832ARealize variable frequency driveQuality improvementUsing optical meansSurface patternLow speed

The invention belongs to the field of rotating machinery experimental mechanics, and specifically relates to an optical measuring method and apparatus for deformation and strain of a high speed rotating structural member. The optical measuring apparatus comprises a high speed rotating system for a thin disk-shaped axisymmetric structural member, an image acquisition and signal processing system and an auxiliary test system, wherein the surface of a test member of the thin disk-shaped axisymmetric structure is coated with a pattern of concentric circles and a vertical ultra high-speed rotating axis is formed; a disk type variable frequency motor is used to drive the single-point supported vertical ultra high-speed rotating axis in a vacuum chamber; a common low-speed digital camera is used to acquire the surface pattern of concentric circles of the high-speed rotating thin disc-shaped axisymmetric structure test member under the irradiation of a stroboscopic light source; and the image identification technology is used to acquire the pattern change information and obtain deformation and strain of the high speed rotating test member after processing the pattern change information. The optical measuring method and apparatus for deformation and strain of a high speed rotating structural member can acquire the stress information by measuring changes of the radius of the concentric circles, and are suitable for the mechanical robustness testing field of high speed and ultra high-speed rotating structural member, wherein the rotating speed is greater than 10000rpm.

Owner:TSINGHUA UNIV

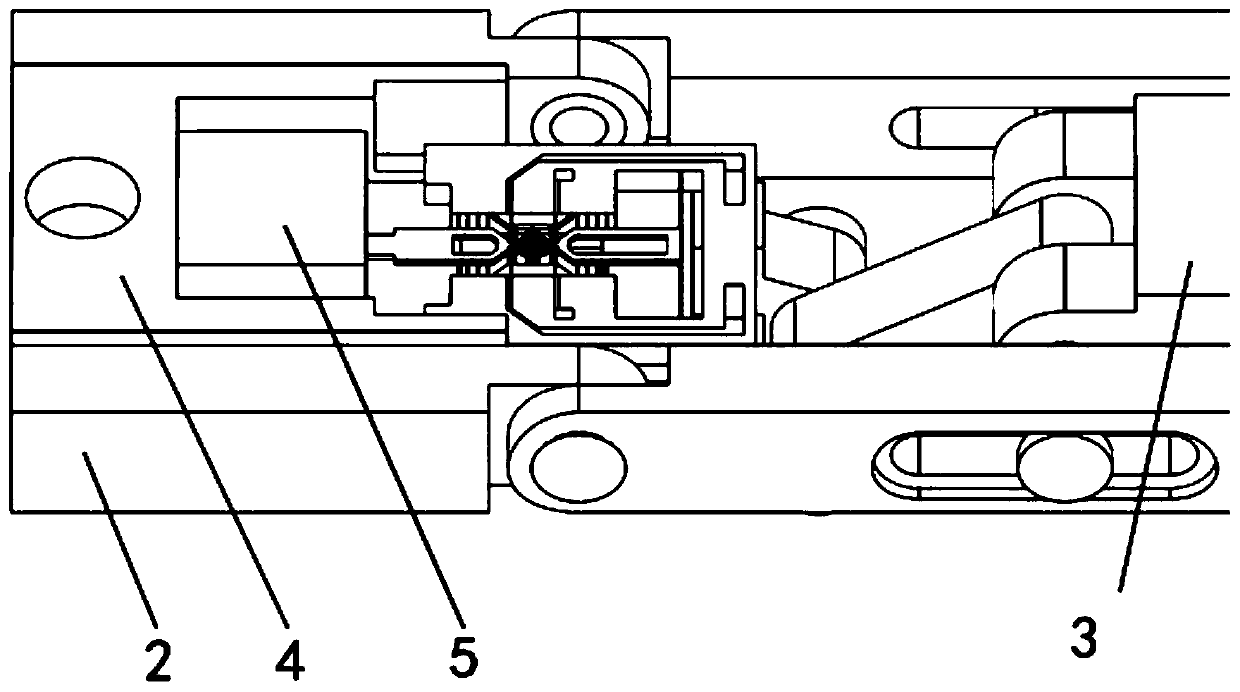

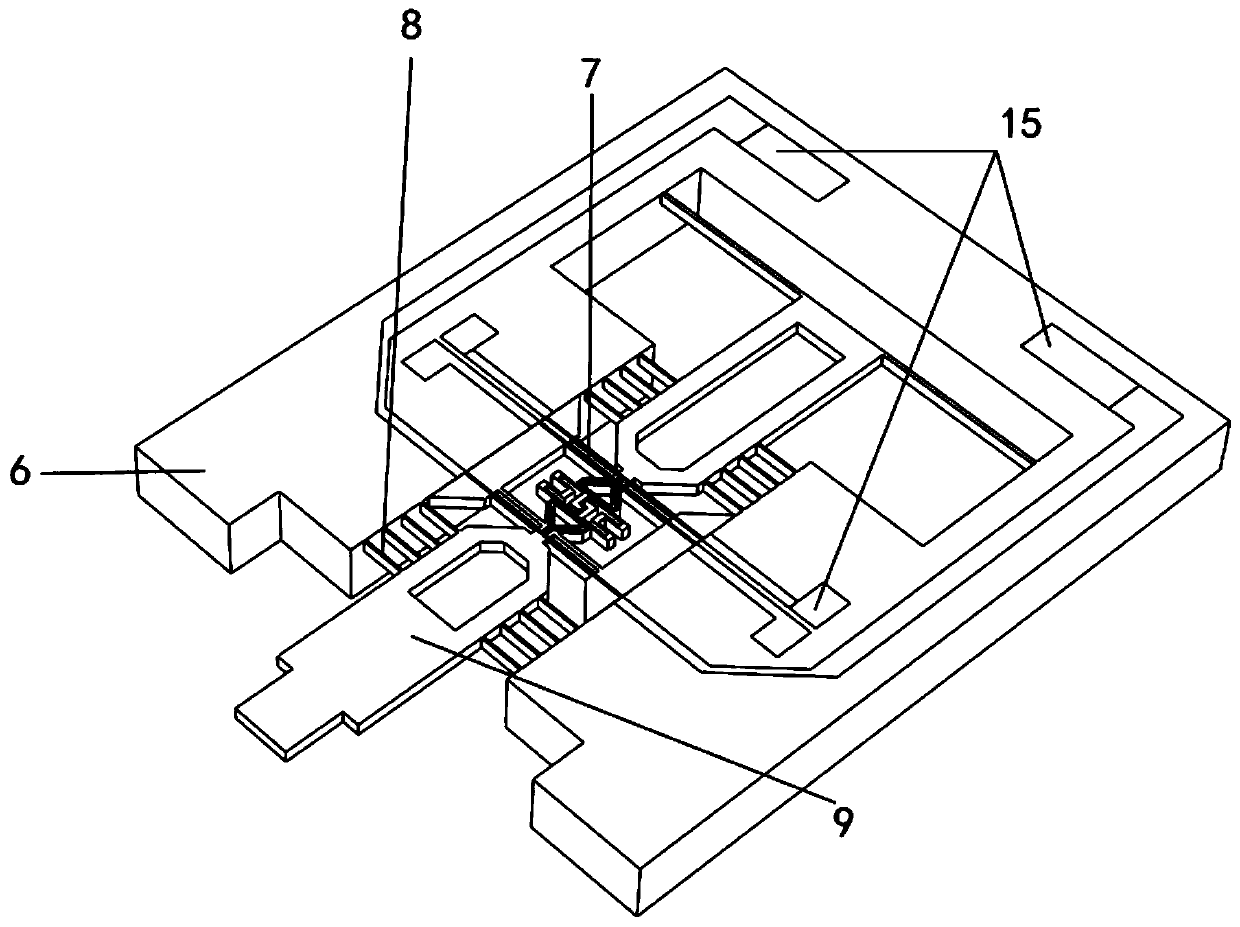

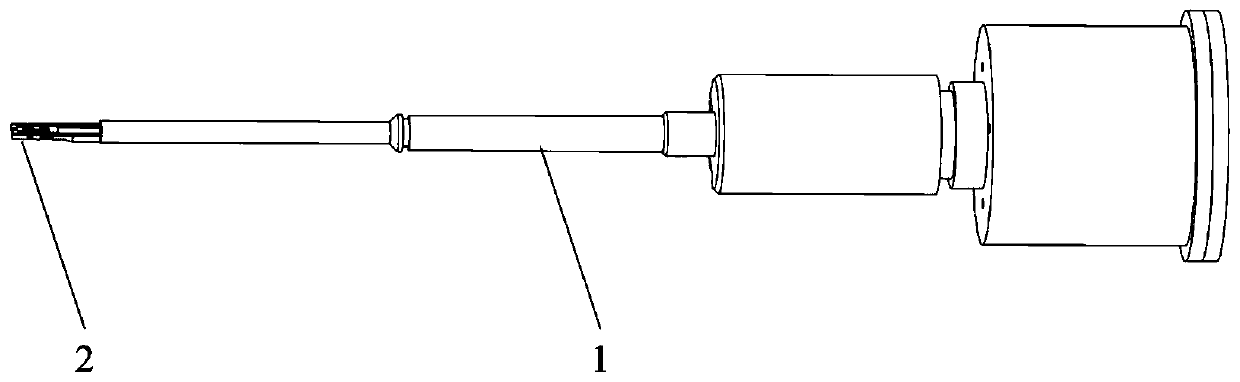

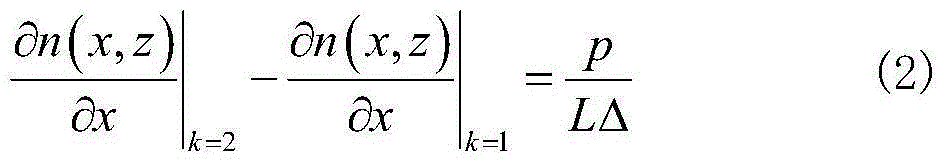

In-situ heating mechanical sample rod

PendingCN110006740AAchieve stretchAchieve compressionMaterial strength using tensile/compressive forcesMicro nanoMicroelectromechanical systems

An embodiment of the invention relates to the technical field of high-temperature micro-nano experimental mechanics, and provides an in-situ heating mechanical sample rod, which comprises a sample rodbody, a tilting table, a driving module and an in-situ mechanical-thermal coupling microelectromechanical system used for realizing stretch, compression and heating functions of a sample, wherein a linear stepping motor and a driving rod are arranged in the sample rod body, and a connecting part of the tilting table is rotationally connected to the sample rod body; the linear stepping motor is connected to the driving rod for enabling the driving rod to carry out reciprocating rectilinear motion along the length direction of the sample rod body in order to realize the rotation of a mounting part of the tilting table; the driving module comprises a driver stage and a driver; the driver stage is arranged on the mounting part of the tilting table; and the driver is arranged on the driver stage, and the action end of the driver is connected to the in-situ mechanical-thermal coupling microelectromechanical system. According to the in-situ heating mechanical sample rod, the stress is applied in situ while the temperature of the sample is adjusted in order to study the mechanical states and properties of the sample at different temperature.

Owner:BEIJING UNIV OF TECH

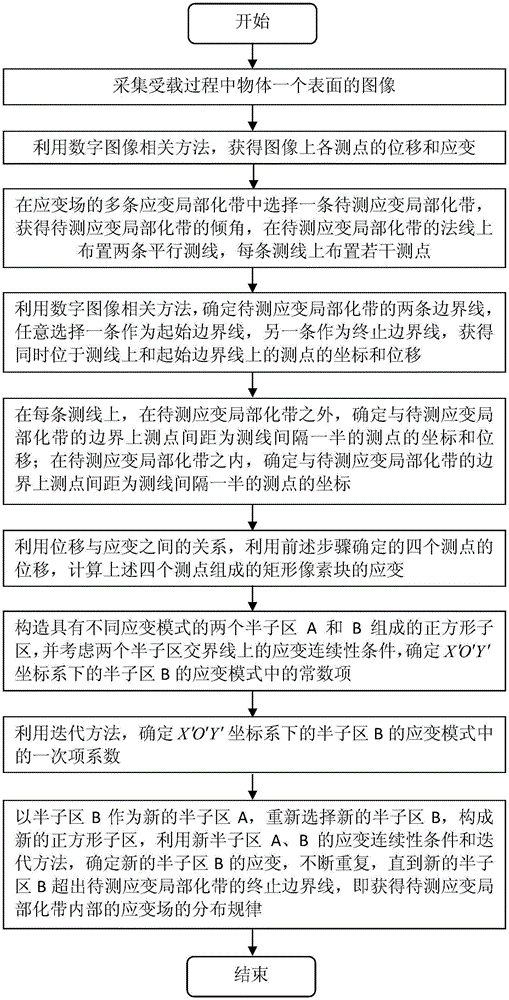

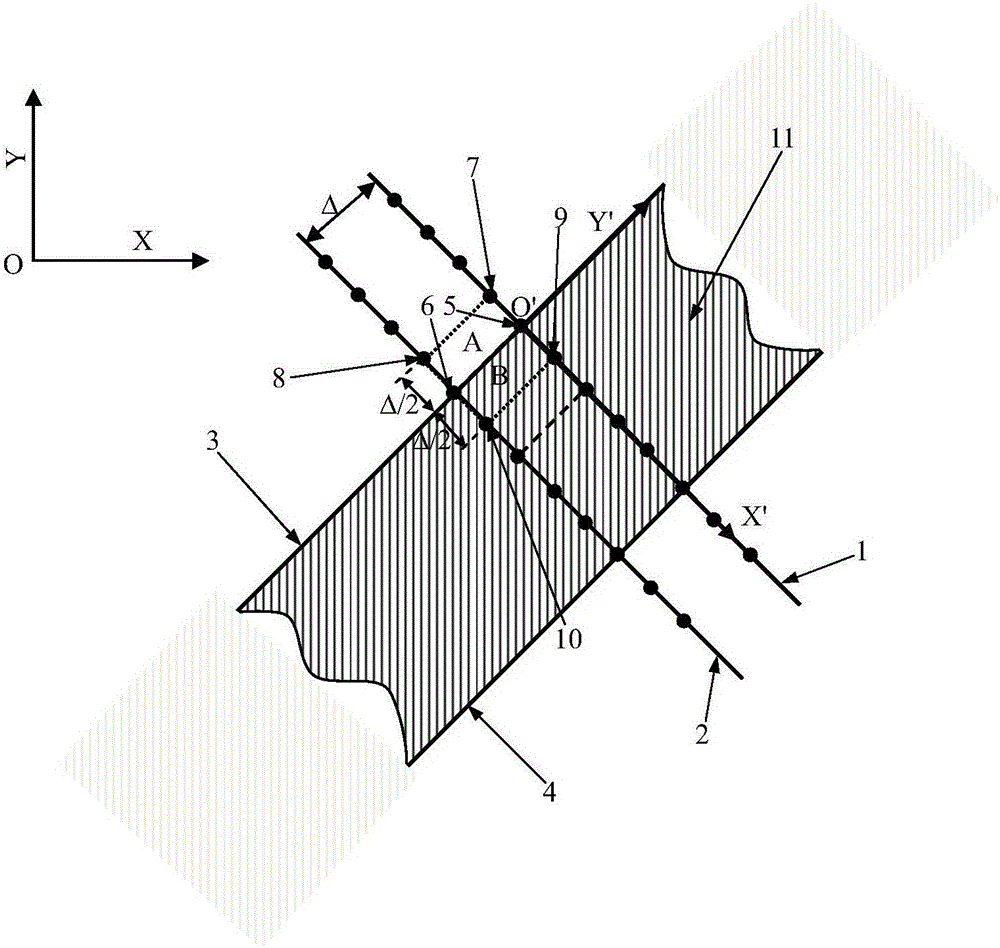

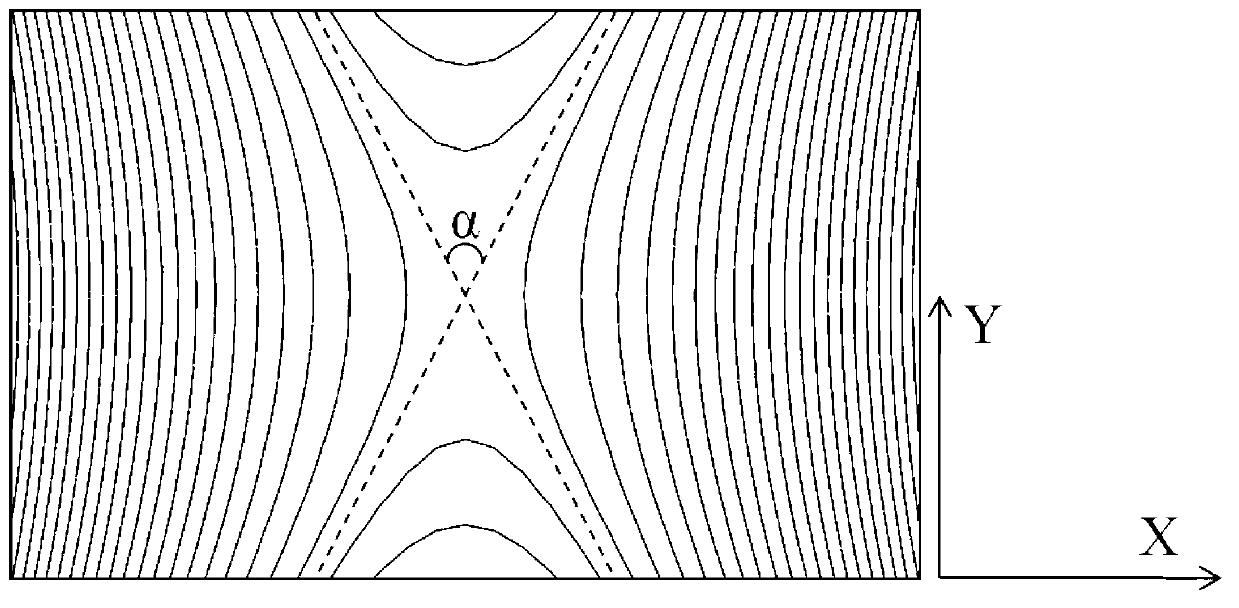

Half sub region relevant optical measurement method of strain field in strain localization zone

InactiveCN106767481AHigh measurement accuracyEasy to measureUsing optical meansClassical mechanicsOptical measurements

The invention provides a half sub region relevant optical measurement method of a strain field in a strain localization zone. An image of one surface of an object in a loaded process is collected; the displacement and the strain of each measuring point on the image and the inclination angle of the strain localization zone to be measured are obtained; two parallel measuring lines are arranged in the normal direction of the strain localization zone to be measured; a plurality of measuring points are arranged; the coordinates and the displacement of the measuring points simultaneously positioned on the measuring line and the starting boundary line of the strain localization zone to be measured are obtained; the coordinates and the displacement of the measuring points with the distance being a half of the distance of the measuring lines are determined inside and outside the strain localization zone to be measured; the strain of a rectangular pixel block is calculated; the distribution rule of the strain field inside the strain localization zone to be measured is obtained. The time-space distribution rule of the strain field in the strain localization zone can be better measured; the strain distribution in the strain localization zone obtained through measurement is smooth, continuous and accurate; the measurement precision of the inside strain field in the strain localization zone is improved; the wide application is realized in the field of solid experimental mechanics.

Owner:LIAONING TECHNICAL UNIVERSITY

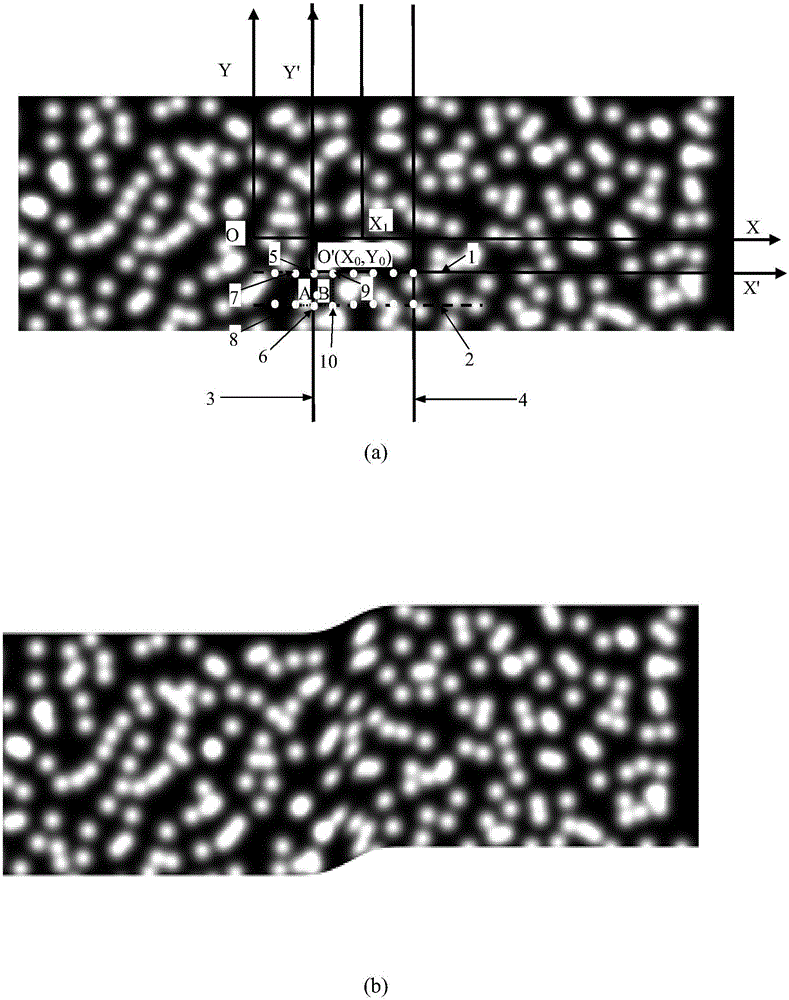

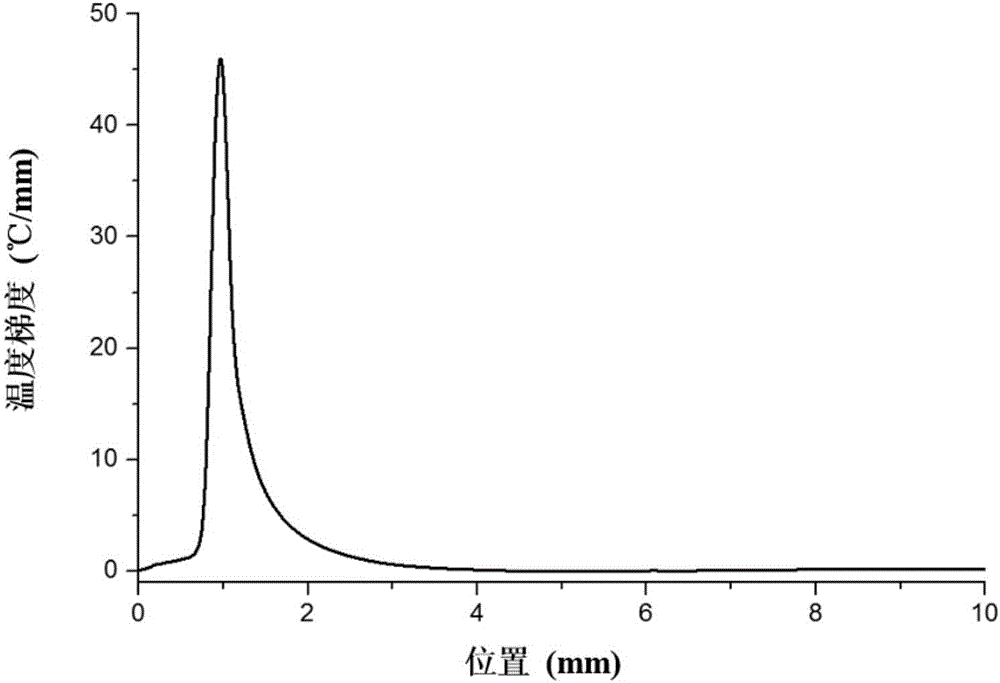

Non-contact detection method for leakage of gas with temperature higher than environment temperature

ActiveCN106706216ARealize non-contact measurementOvercoming the cumbersome process of measurementDetection of fluid at leakage pointPipeline systemsAnti jammingExperimental mechanics

The invention relates to a non-contact detection method for the leakage of gas with a temperature higher than an environment temperature, belonging to the technical fields of experimental mechanics and gas seal measurement. The non-contact detection method comprises the following steps: photographing a whole-field image of a to-be-detected region in real time by virtue of an infrared thermal imager to obtain a group of infrared images, so as to obtain corresponding temperature fields; carrying out temperature gradient operation on the obtained temperature fields, so as to obtain a temperature gradient; and processing the images by combining a heat conduction theory with an infrared image processing algorithm, so as to obtain a gas leakage position and a leakage rate. The position and the leakage rate during the leakage of gas with the temperature higher than the environment temperature are measured based on an infrared thermal imaging technique, an image processing theory and the heat conduction theory, so that the precise location of the leakage position and the quantitative measurement of the leakage amount can be simultaneously realized; and the non-contact detection method is wide in applicability, is not limited in certain specific gas and has the characteristics of high detection sensitivity, anti-jamming capability and the like.

Owner:TSINGHUA UNIV

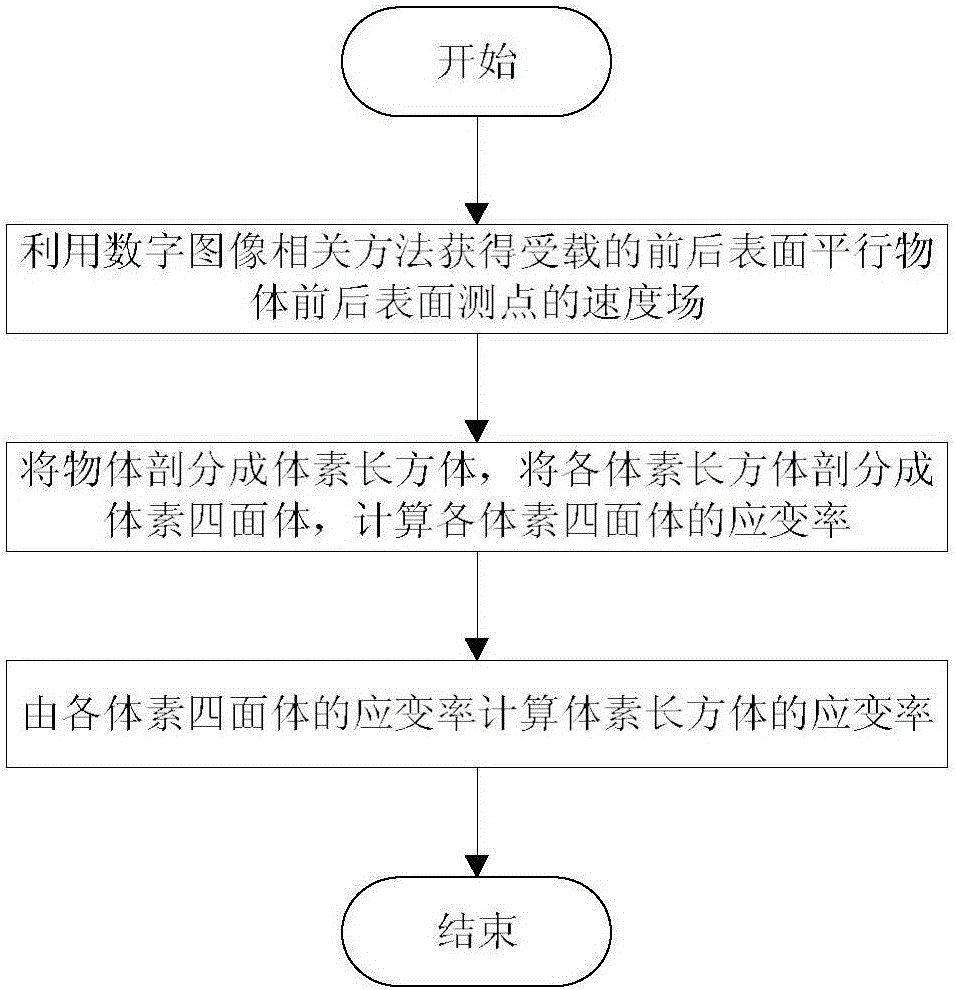

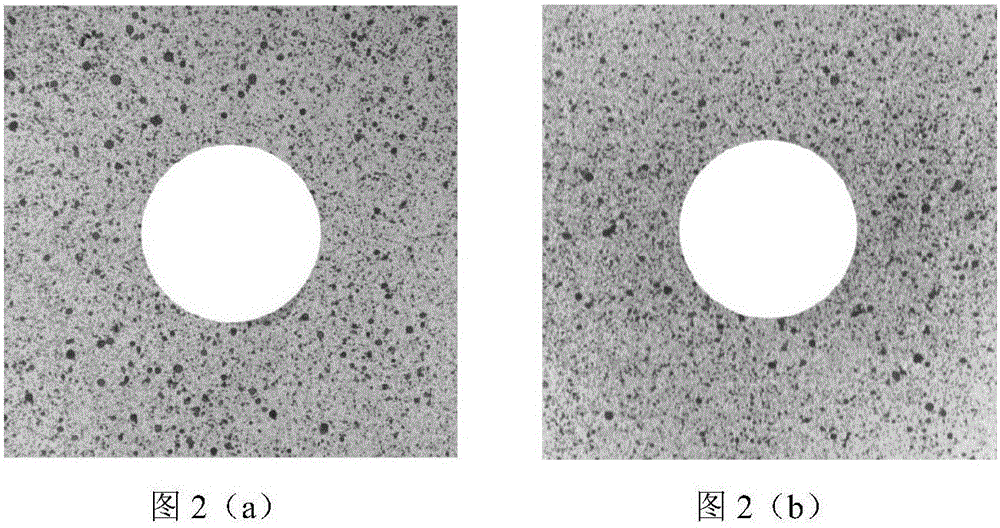

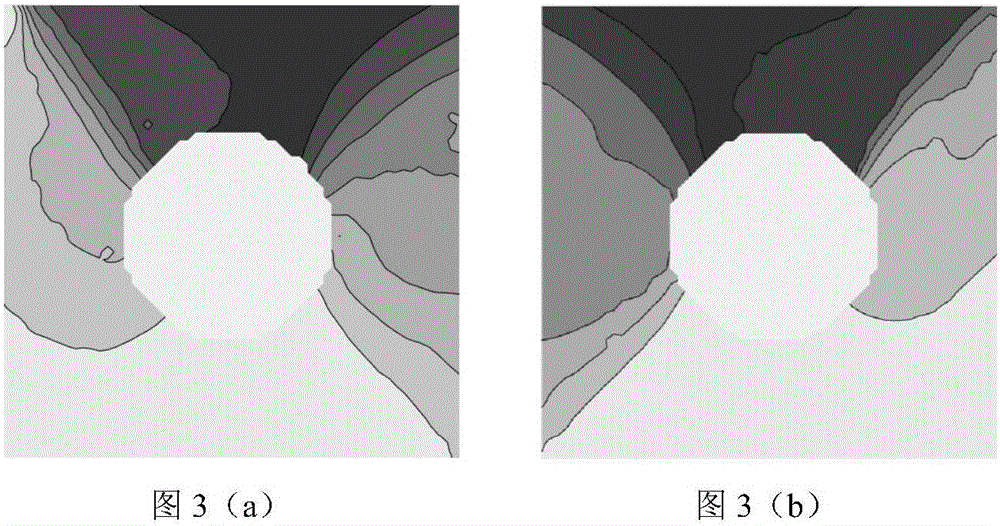

Optical measurement method for strain rate field inside object with parallel front and back surfaces

InactiveCN105806243ACalculation method is simpleHigh measurement accuracyUsing optical meansVoxelClassical mechanics

The invention discloses an optical measurement method for a stain rate field inside an objected with parallel front and back surfaces.The method comprises the steps that velocity fields of measuring points on the front and back surfaces of the loaded object with the parallel front and back surfaces are obtained through a digital image relative method at first; the object with the parallel front and back surfaces is divided into gap-free voxel cuboids which are arranged in rows and columns without being stacked and with measuring points are top points, each voxel cuboid is simplified into a hollow voxel cuboid formed by four voxel tetrahedrons, the measuring points on the front and back surfaces are the top points of the voxel tetrahedrons, and the stain rate of each voxel tetrahedron is calculated based on the velocity field of the top point of the voxel tetrahedron; the stain rates of the voxel cuboids are calculated based on the stain rates of the voxel tetrahedrons, and then the stain rate field inside the object with the parallel front and back surfaces is obtained.The optical measurement method is simple in calculation, has the advantages of being high in measurement precision and low in measurement condition, has the wide application prospect in the field of solid experimental mechanics, and is of great benefit to preventing landslide, rockburst and other disasters.

Owner:LIAONING TECHNICAL UNIVERSITY

Experimental device for normal disturbance induced rock mass shear fracture

PendingCN112146996AMaterial strength using steady shearing forcesMaterial strength using single impulsive forceShear stressClassical mechanics

The invention relates to the technical field of experimental mechanics research, and particularly relates to an experimental device for normal disturbance induced rock mass shear fracture. The experimental device comprises an SHPB device and a shearing device, wherein the SHPB device is used for providing impact load for a test piece; the shearing device is used for providing normal stress and tangential shearing stress for the test piece; and the shearing device is located between an incident rod and a transmission rod of the SHPB device and mounted on the outer surface of the test piece. Theexperimental device can reproduce rock mass shear fracture of rock mass in a complex stress state induced by external disturbance.

Owner:WUHAN UNIV OF TECH

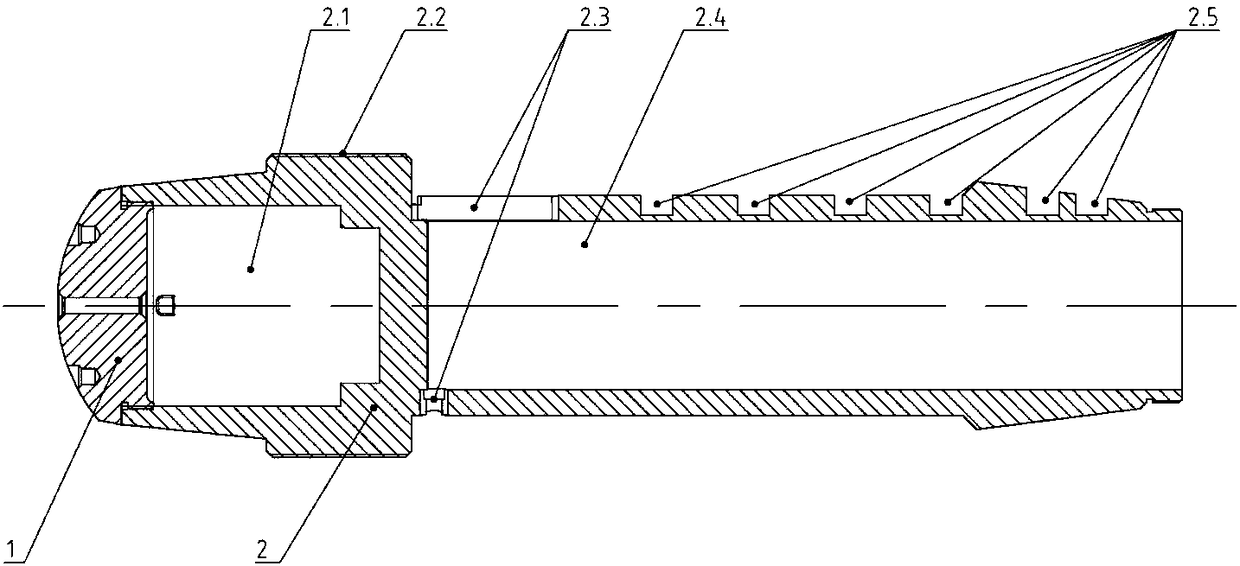

In-situ high-temperature quantitative mechanical experiment table for transmission electron microscope

PendingCN109883828ASolve incompatible technical problemsImprove spatial resolutionMaterial strength using tensile/compressive forcesTemperature stressLinear motion

The embodiment of the invention relates to the technical field of material in-situ micro-nano experimental mechanics, and provides an in-situ high-temperature quantitative mechanical experiment tablefor a transmission electron microscope. The in-situ high-temperature quantitative mechanical experiment table comprises a sample rod body, a tilting table, a driving module and a micro-electromechanical system integrated testing device for acquiring the stress-strain information of a sample under temperature-stress coupling conditions; a linear stepping motor and a driving rod are arranged in thesample rod body, and the connecting part of the tilting table is rotatably connected with the sample rod body; the linear stepping motor is connected with the driving rod and is used for enabling thedriving rod to do reciprocating linear motion along the length direction of the sample rod body, so that the mounting part of the tilting table can rotate; and the driving module is arranged on the mounting part of the tilting table and is used for carrying out mechanical loading on a sample on the micro-electromechanical system integrated testing device. The in-situ high-temperature quantitativemechanical experiment table for the transmission electron microscope can realize quantitative high-temperature mechanical test on micro-nano scale samples, and obtains an optimal observation angle inreal time through double-shaft tilting.

Owner:BEIJING UNIV OF TECH

Photoelastic model and manufacturing method thereof

The invention relates to the field of experimental mechanics researching, and discloses a photoelastic model and a manufacturing method thereof. 128# epoxy resin and maleic anhydride are mixed under the vacuum condition according to the mass ratio being 100:(30-35) and are then injected into a photoelastic model blank die on a vacuum pouring molding machine for molding, a blank is subject to isothermal curing, the blank is taken out from the die when the exterior is cured and the interior is not cured completely, and secondary curing is carried out to obtain a workblank; the edge of the workblank obtained in the step one is cut to be removed, the cutting temperature does not exceed 80 DEG C, and corresponding machine finishing is carried out according to the model structural design to obtain a model, wherein the machine finishing temperature does not exceed 80 DEG C; and the model obtained in the step two is polished to obtain the photoelastic model. The manufacturing method of the photoelastic model is simple in process, the obtained model is high in quality, the internal stress is close to zero, the external size error is smaller than 0.01 mm, and the photoelastic test accuracy is better improved.

Owner:CHINA AVIATION POWER MACHINE INST

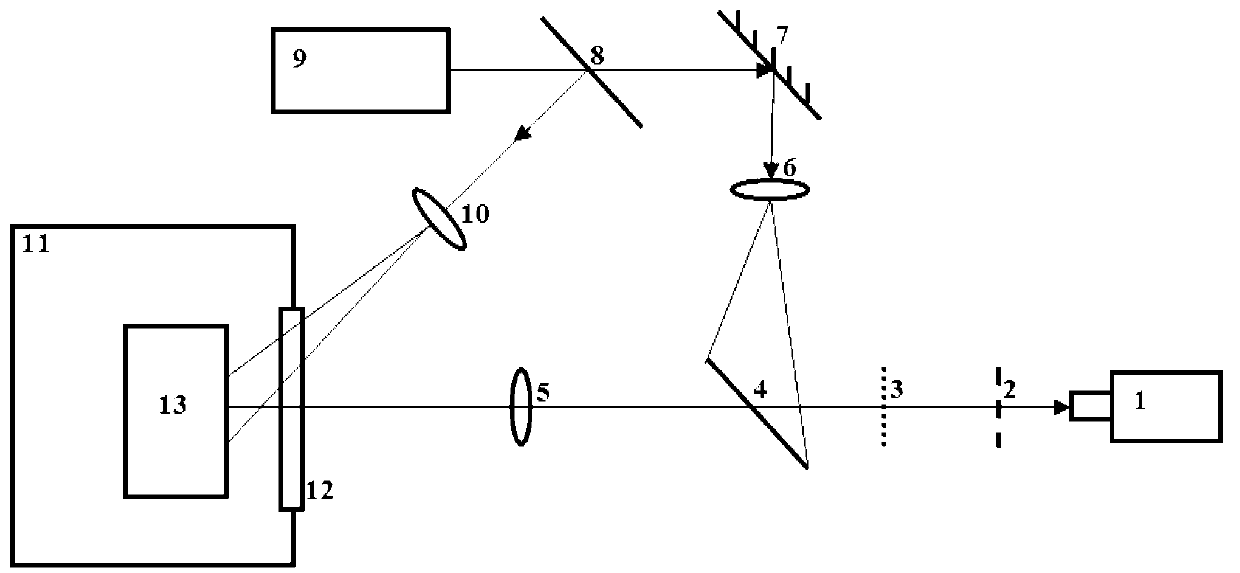

Experimental apparatus and method for measuring poisson ratio of material under high temperature

InactiveCN102980813AHigh measurement temperatureOvercome the disadvantages of more cumbersome proceduresMaterial strength using tensile/compressive forcesExperimental methodsHigh temperature electronics

The invention discloses an experimental apparatus and method for measuring a poisson ratio of a material under high temperature, belonging to the technical field of experimental mechanics and high-temperature tests. The experimental apparatus and method adopts a method combining high-temperature electronic speckling and four-point phase bending to measure the poisson ratio of the material under the high temperature, and is in particular applicable to measuring the poisson ratio of the material under the ultra-temperature (more than 1600 DEG C). The experimental method comprises the steps of: recording interference speckle fields generated by object light and reference light by adopting non-contact measurement and a CCD (Charge Coupled Device) after a four-point bent sample is irradiated by laser, and measuring the off-plane displacement before and after the four-point bending of the sample by adopting an electronic speckling technology, thus directly obtaining the poisson ratio of the material under the high temperature according to a bar chart of the off-plane displacement, so that a problem that the poisson ratio of the material under the high temperature is difficultly measured can be solved.

Owner:TSINGHUA UNIV

A static test method and device for a small-sized large-load radome

InactiveCN106507920BEvenly loadedEnsure safetyForce measurementRadiating element housingsMeasuring instrumentSoftware engineering

The invention belongs to the field of test mechanics, and relates to a static test method and a device for a small-size and large-load radome. The static test method of the present invention comprises the following steps: Step 1, processing the airbag loading chamber; Step 2, processing the airbag loading chamber to ensure that the surface of the loading chamber is smooth and flat, and placing felt on the inner cavity surface for protection; Step 2, installing the airbag In the airbag loading chamber; Step 3, connect the airbag and the loading pipeline, and use the pressure control machine, air compressor, pressure regulating valve and pressure gauge to control the pressurization; Step 4, connect the test loading instrument and the test measuring instrument to realize the static test. By using the static test method and device of the present invention, the radome can be loaded evenly and conservatively, ensuring the safety of the static test, and the environmental conditions can be applied according to GJB150, so that the static test with the radome under the environmental conditions can be realized.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

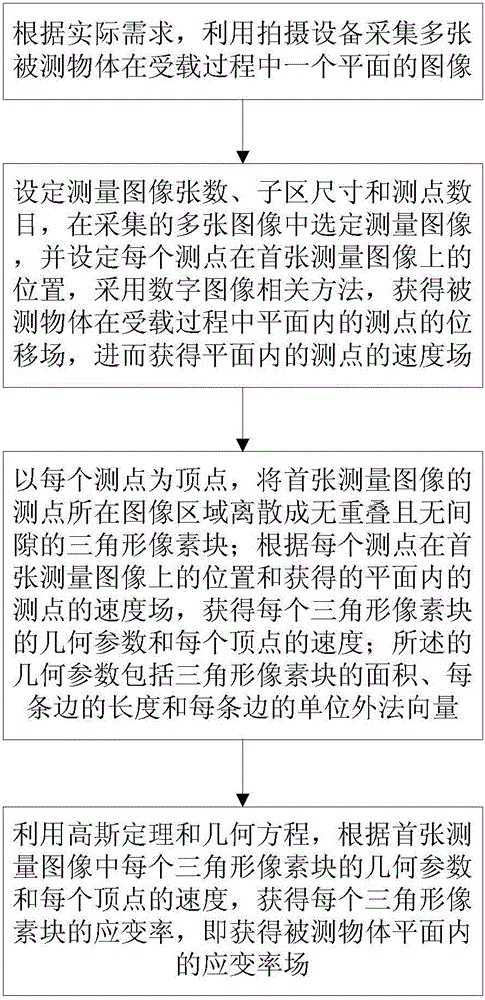

Optical measuring method of strain rate field in plane of object

InactiveCN105928466ACalculation is simple and fastEasy programmingUsing optical meansComputation processClassical mechanics

The invention relates to an optical measuring method of a strain rate field in the plane of an object and belongs to the object strain rate field measurement technical field. The method includes the following steps that: a photographing device is utilized to photograph a plurality of images of one plane of a measured object in a loaded process; measurement images are selected, and the number of the measurement images, sub area size and the number of measuring points are set; the measuring points are dispersed in an image area so as to form non-overlapping and gapless triangular pixel blocks; and a strain rate field in the plane of the measured object is obtained by using Gauss theorem and a geometric equation. The method of the invention is superior to a central difference method-based digital image correlation method. The calculation process of the method of the invention is simple and convenient, only summation calculation is required, so that a result can be obtained; the implementation of programming is easy; and accuracy and reliability can be improved. The optical measuring method has a broad application prospect in the solid experimental mechanics field.

Owner:LIAONING TECHNICAL UNIVERSITY

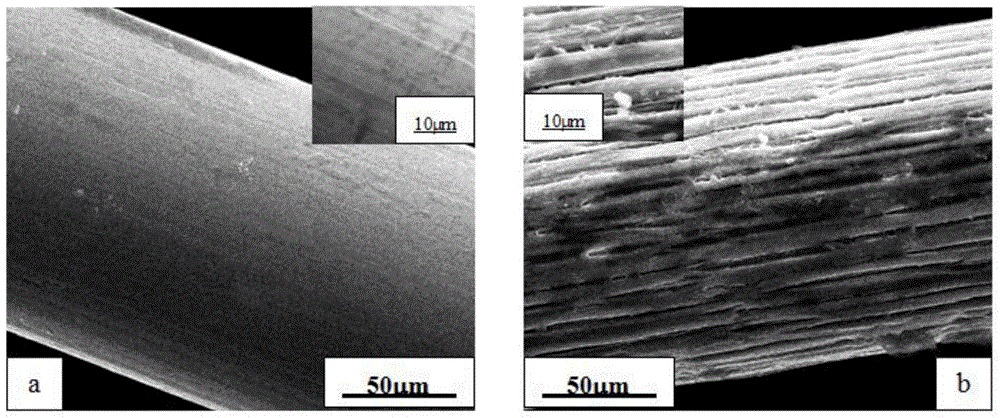

Metal wire tool for minimally invasive cutting of biological soft tissues

InactiveCN104634609AAvoid damageTruly reflect the mechanical propertiesWithdrawing sample devicesMicro nanoLinear motion

The invention belongs to the technical fields of soft materials and experimental mechanics, and discloses a metal wire tool for minimally invasive cutting of biological soft tissues. The tool comprises a metal wire cutter and a vibration device, wherein a metal wire is subjected to surface etching through a chemical method and has a proper micro-nano texture; by combination with a reciprocating linear motion cutting mode provided by the vibration device, the adhesive power between the biological soft tissues and the tool can be effectively reduced when the biological soft tissues are cut; the to-be-exerted cutting force is reduced; the destructive effects on soft tissues in the cutting process are reduced; minimally invasive cutting is achieved; a sample with a precise physical dimension can be obtained by cutting; and the cut sample can relatively really reflect the mechanical property of the biological soft tissues. The tool is simple in manufacturing method, convenient and fast to operate, low in cost and convenient to produce and popularize.

Owner:DALIAN UNIV OF TECH

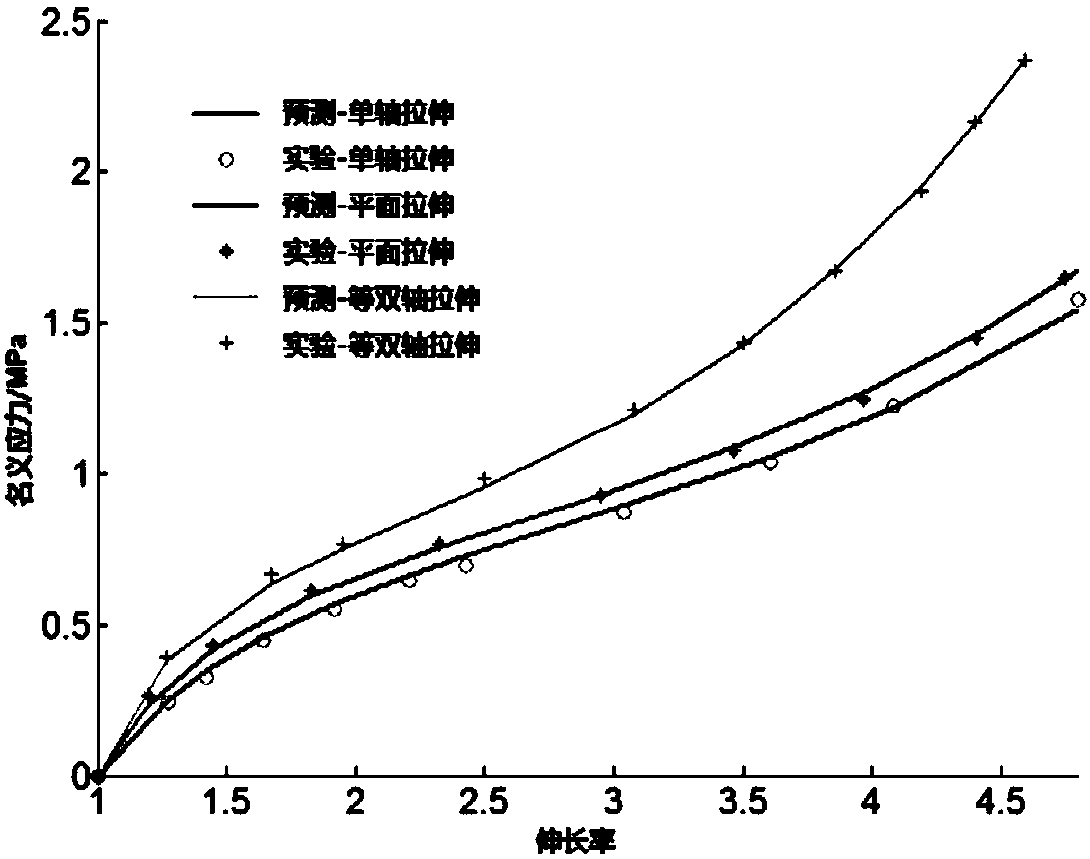

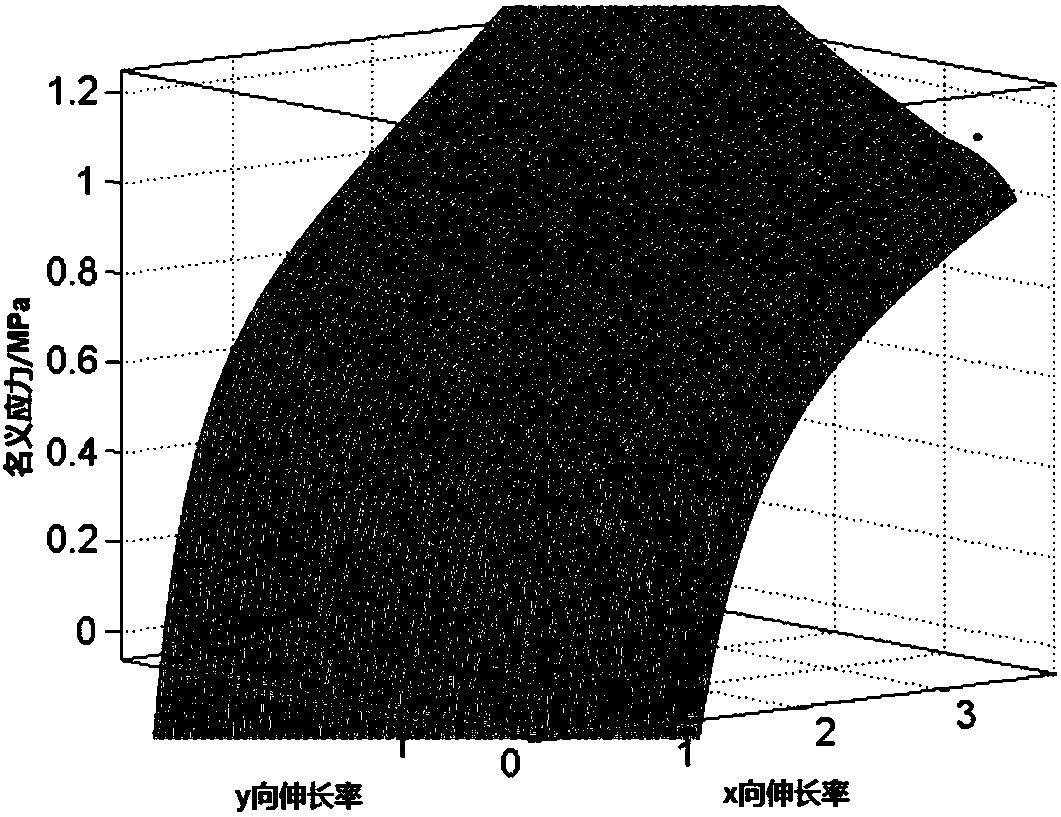

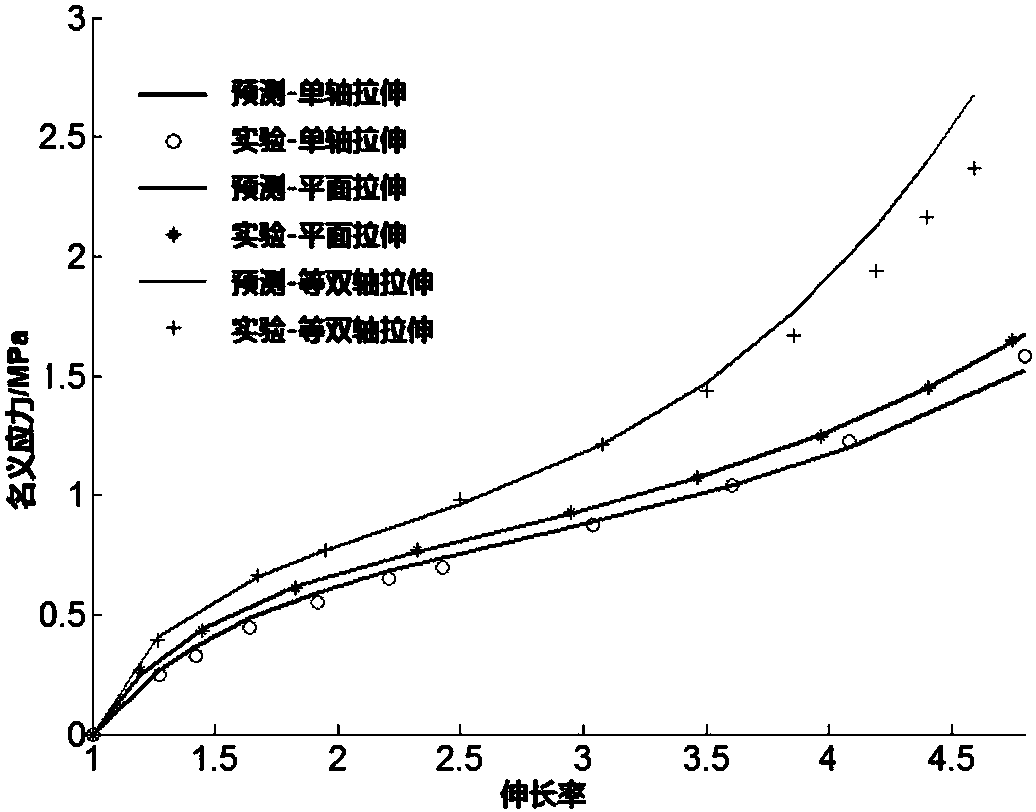

Elastic constitutive model suitable for rubber materials, and application thereof

InactiveCN107766659AFew parametersPromote engineering applicationDesign optimisation/simulationMaterial testing goodsExperimental mechanicsComputational mechanics

The invention discloses an elastic constitutive model suitable for rubber materials, and application thereof, and belongs to the technical field of solid mechanics, computational mechanics and experimental mechanics. The constitutive model which is put forward can adopt a single type of experiment data to obtain an accurate model of rubber incompressible hyperelastic materials. Compared with an existing model, the elastic constitutive model is high in accuracy and reliability and can obtain the accurate and comprehensive rubber material characteristic model only by a simple uniaxial elongationexperiment test, an equal biaxial drawing and plane drawing test which is difficult to be carried out in China at present does not need to be adopted, and the model has an extremely high engineeringapplication value and a computational mechanics use scene.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Buckling test method and device for quantitatively characterizing interfacial bonding properties of thin film materials

ActiveCN103018160BEasy to makeThe principle is simpleUsing mechanical meansMaterial analysisBound propertyCcd camera

The invention relates to a flexure testing method and a flexure testing device for quantitatively characterizing the interface binding property of thin-film material and belongs to the technical field of property characterization of experimental mechanics and material mechanics. The method is characterized in that uniaxial compression is performed to a sample in the axial direction through a universal material testing machine, and the stress strain values of the sample are recorded; meanwhile, the cross section of the sample is observed synchronously in real time through a CCD camera during the loading process, and stripping characteristics such as critical stress, deflexion and crack length can be recorded in real time during the flexure process; and a relation between the coating and plating-substrate stress strain history and the stripping characteristics is established to characterizing the interface binding property of the coating and plating-substrate. According to the device, the CCD camera, a monitor, an image processing card, a computer, a data processing card, a load sensor and the universal material testing machine are connected in sequence. The invention has the advantages of simple principle, simplicity in sample preparation, clear model, easiness in operation, and the like.

Owner:XIANGTAN UNIV

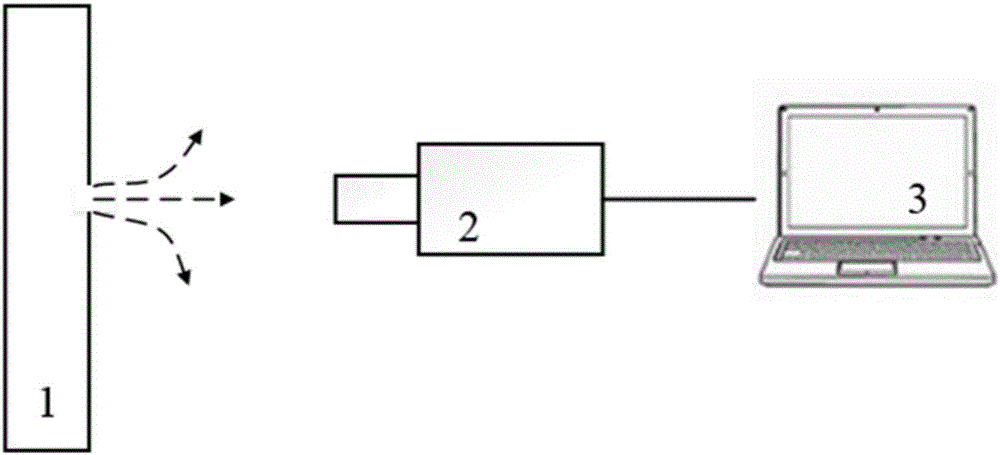

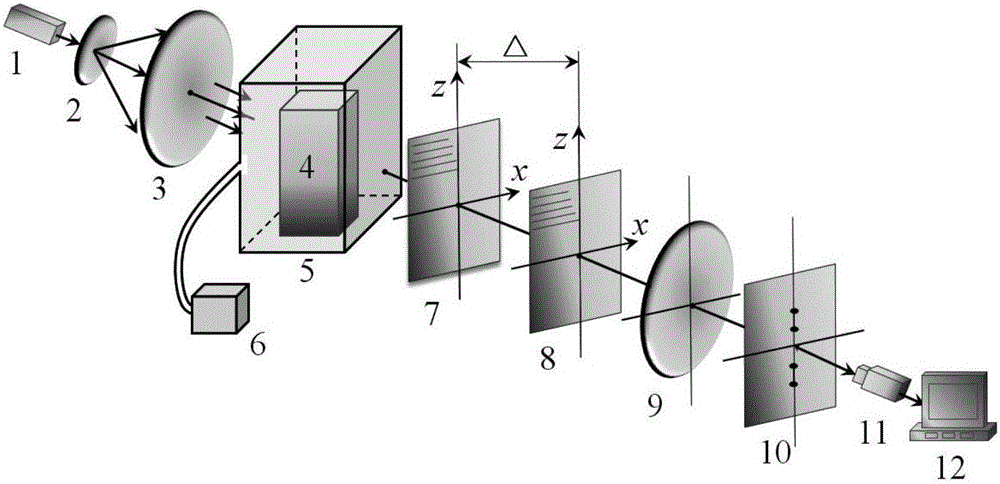

Experiment method for measuring asynchronous curing degree distribution of transparent resin material

ActiveCN104990923AReduce distractionsGlobal monitoring of asynchronous curingMaterial analysis by optical meansRelevant informationOptical measurements

The invention belongs to the technical field of experimental mechanics and non-contact optical measurement, and relates to an experiment method for measuring asynchronous curing degree distribution of a transparent resin material. By the adoption of the coherent gradient sensing method, curing degree distribution of the transparent resin material is measured in real time. According to the method, firstly, the transparent material is contained in a transparent container before curing; then, the container is placed in a heating furnace, wherein the front and the back of the heating furnace are provided with windows; then, the heating furnace is placed in a coherent gradient sensing measurement optical path, interference fringes caused by change of the curing degree of the material are shot in real time through a CCD camera, and accordingly relevant information of curing degree distribution of the material is obtained. The adopted coherent gradient sensing technology is optical non-contact measurement. Compared with a traditional DSC method, the measured material does not need to be contacted, interference on curing of the measured material is reduced, and asynchronous curing can be monitored globally.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Testing device for high-axial-overload test of energetic materials

InactiveCN108534616AEasy to installSave test costAmmunition testingEngineeringExperimental mechanics

The invention belongs to the field of experimental mechanics of energetic materials and relates a testing device for high-axial-overload test of the energetic materials. The testing device comprises afront shell cover and a powder shell, and the powder shell mainly comprises a data storage system mounting space, a connection thread, a displacement sensor mounting groove, a full-size powder loading and mounting space, strain foil mounting grooves and a wiring groove. The testing device realizes mechanical response data measurement of energetic material full-size powder loading in a gun-launched high-overload environment and has the advantage of saving of testing cost and time, high axial overload refers to 6000g-12000g, and further adaptability to a wider overload range can be realized byadoption of a high-overload-resistant sensor, adjustment of a sensor measuring range and increase of data storage system caching.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

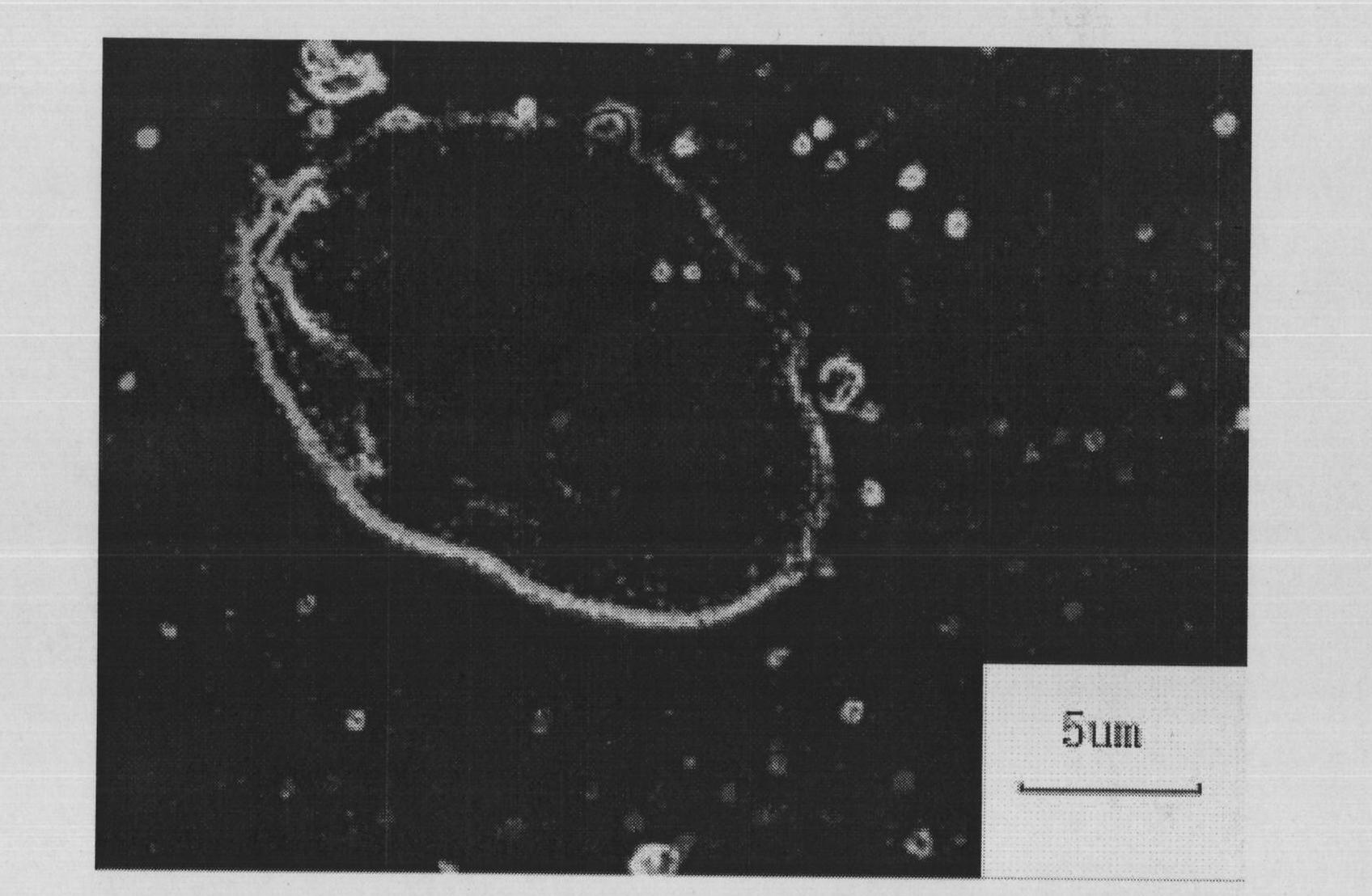

Optical detection method for microcosmic defect expansion of film surfaces and implementing device

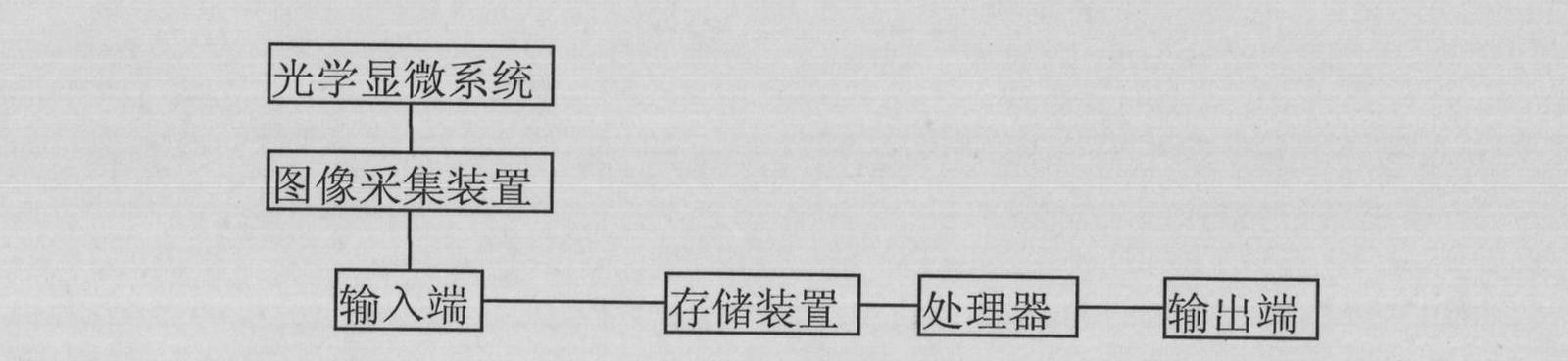

InactiveCN101782530ADetermining the Boundary of Debonding BucklingCalculate Relative DisplacementImage analysisOptically investigating flaws/contaminationImaging processingData set

The invention relates to image processing, the mechanics detection of microcosmic structures and experimental mechanics, in particular to an optical detection method for the microcosmic defect expansion of film surfaces. The invention aims to provide a technical scheme for detecting the expansion processes of buckling boundaries. The invention has the technical scheme that the implementing device of the optical detection method for the microcosmic defect expansion of the film surfaces comprises an optical microscope system, an image collecting device, an input end, a storing device and a processor, wherein the processor is used for processing datasets representing images under the control of a program so as to determine the boundaries destroyed by buckling in the film / base structures of the images and the expansions of the boundaries through operation, and the output end is used for displaying the detection results of the expansion of the buckling-destroyed boundaries. The invention is mainly applied to the mechanics detection of the microcosmic structures.

Owner:TIANJIN UNIV

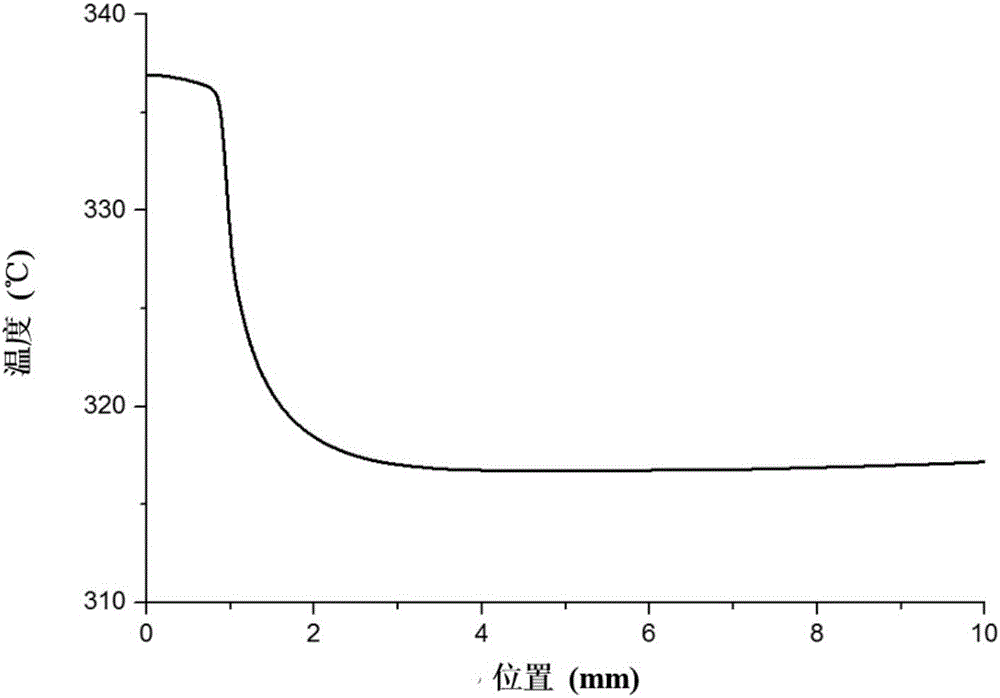

Material controllable high-temperature test device and method based on laser irradiation

InactiveCN110940570ALower requirementEasy to observeStrength propertiesEngineeringExperimental mechanics

The invention belongs to the fields of material science, high-temperature experimental mechanics, solid mechanics and the like, and relates to a material controllable high-temperature test device andmethod based on laser irradiation. The device comprises a material testing machine system, a test piece clamping device, a test piece heating device, a test piece temperature measuring device and a test piece strain measuring device. The mechanical property test and calibration of various materials at high temperature are met, and the technical problems of low temperature control precision, low efficiency, high requirements on a clamping device and the like of a material high-temperature experiment at the present stage are solved.

Owner:CHINA AIRPLANT STRENGTH RES INST

A photoelastic model and its manufacturing method

Owner:CHINA AVIATION POWER MACHINE INST

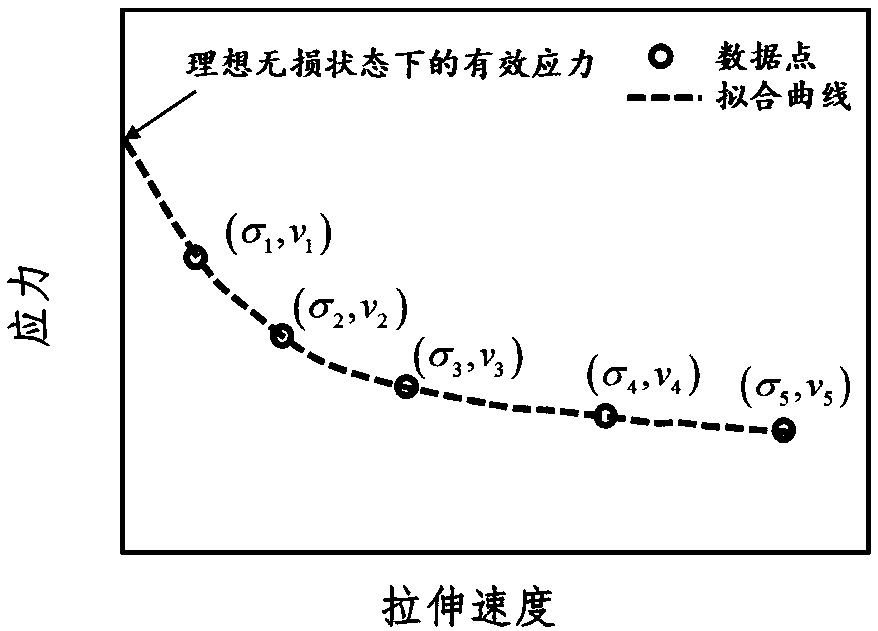

Testing method and testing system of effective stress of polyethylene under ideal non-damage state

ActiveCN109187186AEasy to implementOvercoming the limitations of the sample size rangeMaterial strength using tensile/compressive forcesEngineeringExperimental mechanics

The invention discloses a testing method and a testing system of effective stress of polyethylene under an ideal non-damage state. The method comprises the following steps: quantificationally introducing polyethylene material damage through a tensile testing machine; testing a damage parameter of the polyethylene material according to the damage, and consequently determining effective stress underthe ideal non-damage state. The method and the system provided by the invention has the advantages of being simple to realize, introducing the polyethylene material damage through the tensile testingmachine, testing the damage parameter of the polyethylene material according to the damage and consequently determining the effective stress under the non-damage state. Limit to a range of sampling size in the conventional microscopic damage test method is overcome, and dependence on a microscopic technology with high precision, complex operations and high cost is avoided. A defect of being not suitable for the polyethylene of the conventional method is remedied, a polyethylene material damage and failure mechanism and evolution law research especially suitable for the polyethylene material is used, and reliable method support can be provided for polyethylene damage and fracture representation and calculation simulation in the fields, such as experimental mechanics and numerical simulation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

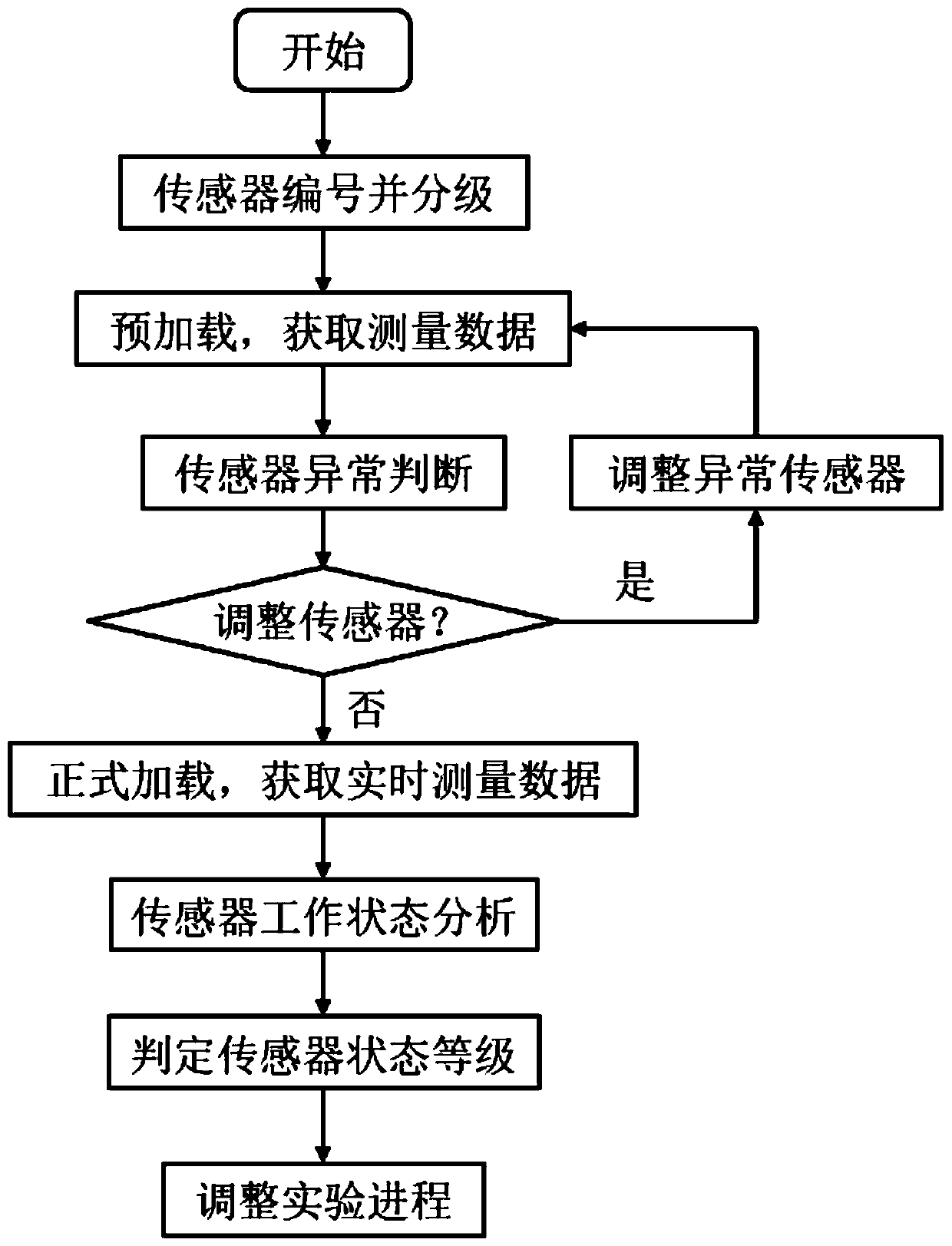

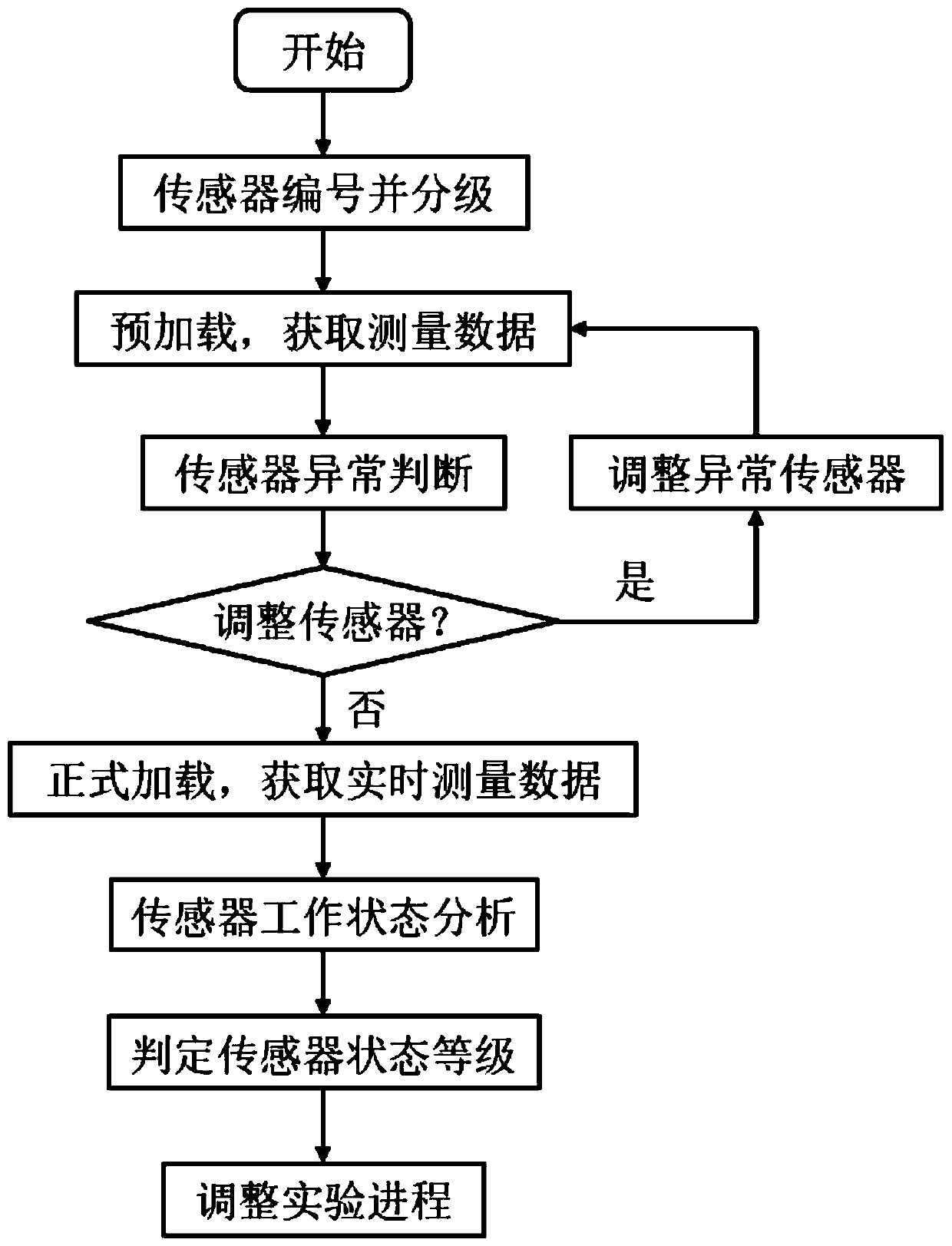

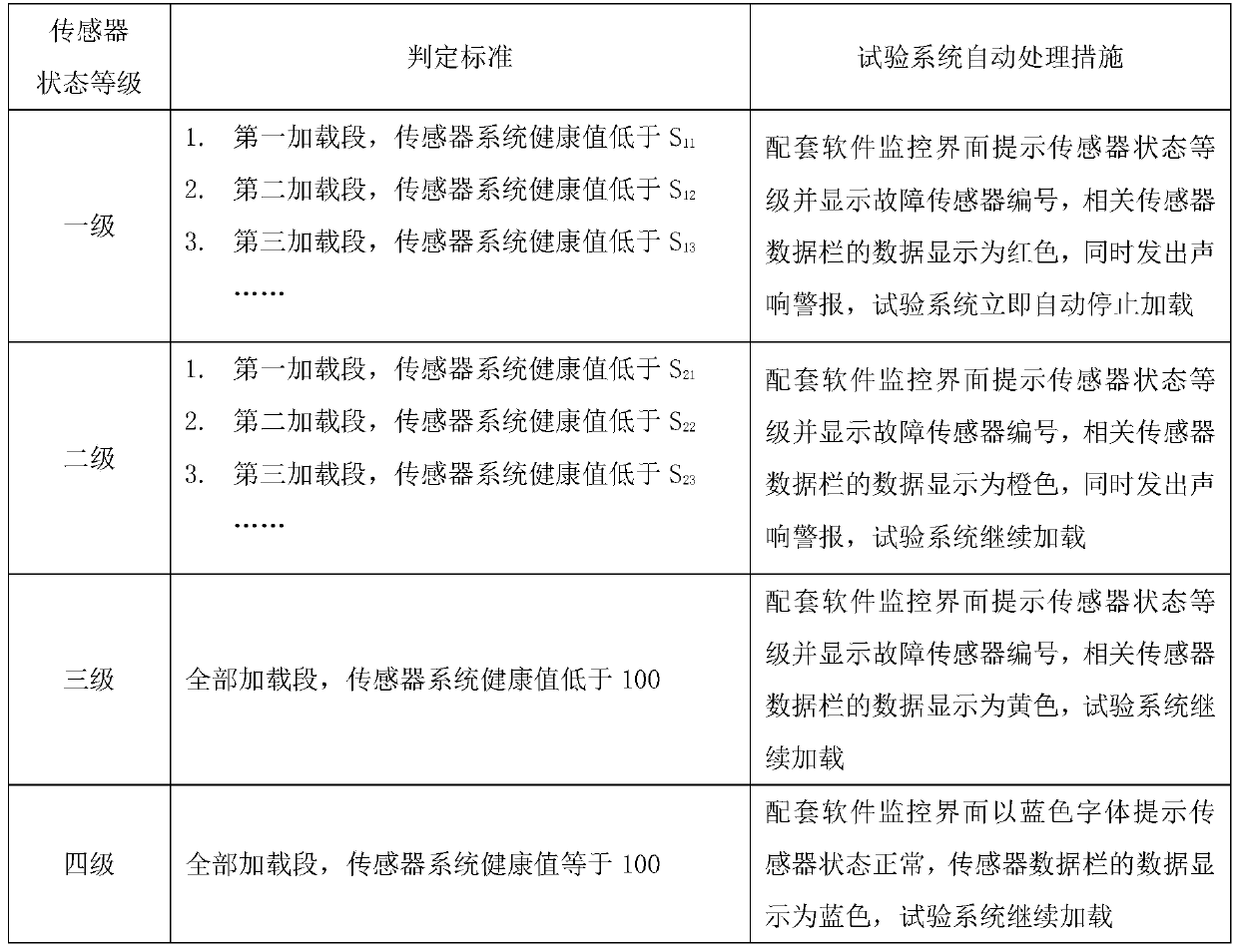

Real-time sensor state monitoring method for structure loading electric logging tests

ActiveCN110044693ASave computing resourcesShort timeStrength propertiesElectricityLinear correlation

The invention provides a real-time sensor state monitoring method for structure loading electric logging tests, belongs to the field of experimental mechanics. The monitoring method comprises the steps of: firstly, numbering and grading sensors before structure loading, carrying out pre-loading, automatically judging sensor abnormities according to measured data and adjusting the sensors by a tester; secondly, carrying out official loading after confirming that the sensor does not need adjustment, calculating linearly dependent coefficients between the measured data of each sensor and load data in real time in the loading process, and analyzing the working state of each sensor; and finally, judging the state grades of the sensors according to real-time working states and importance gradesof the sensors, and adjusting the test progress according to corresponding processing measures. According to the method, the automatic real-time monitoring and alarm for sensor states in structure loading electric logging tests are realized and the test risks can be effectively controlled to improve the test success rate.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com