Non-contact detection method for leakage of gas with temperature higher than environment temperature

A technology of ambient temperature and gas leakage, applied in the direction of detecting the appearance of fluid at the leakage point, testing the fluid tightness, testing of machine/structural components, etc., can solve the problems of leakage temperature image, cumbersome process, and long measurement cycle , to achieve the effect of simplifying the process, overcoming the cumbersome process, and requiring low environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific structure, working principle and working process of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited by this.

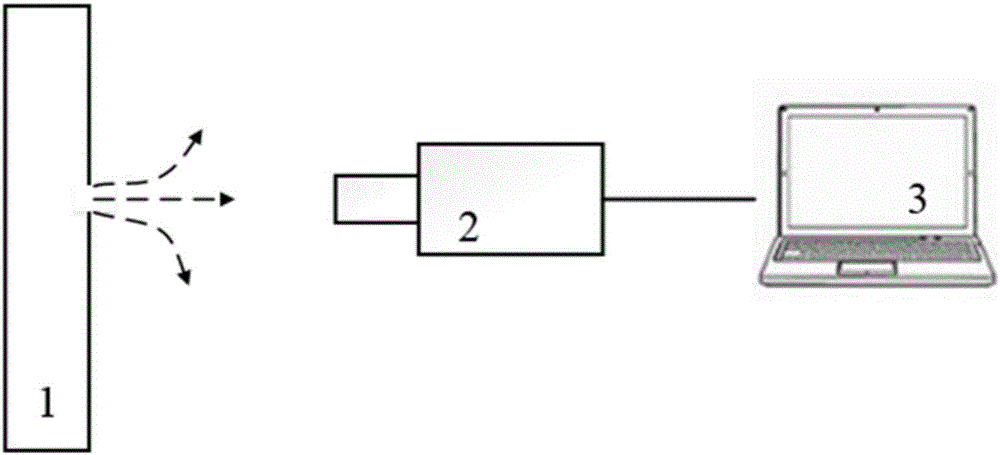

[0021] figure 1 It is a schematic diagram of the principle of a non-contact detection method for gas leakage at a temperature higher than the ambient temperature. The figure includes a pipeline with leaks, a container 1, an infrared thermal imager 2, a computer and related acquisition and processing software 3. The infrared thermal imager 2 shoots the area to be tested to obtain a temperature image, which is stored and processed by the computer and related acquisition and processing software 3 . The acquisition and processing software is written in MATLAB language, which can realize temperature extraction, gradient calculation and calculation of leakage position and leakage amount of infrared images.

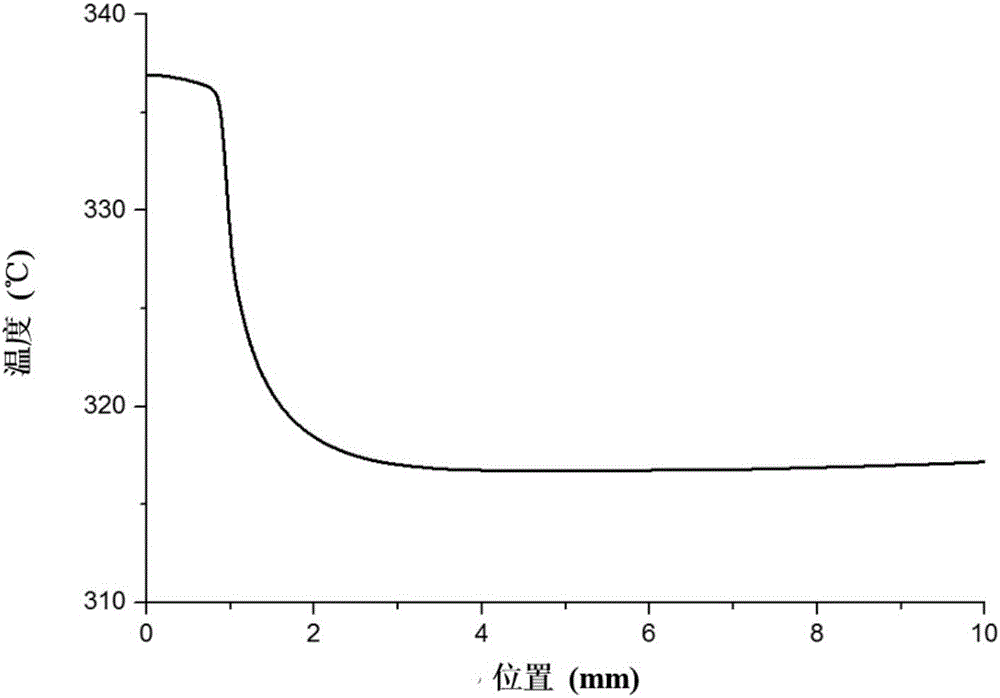

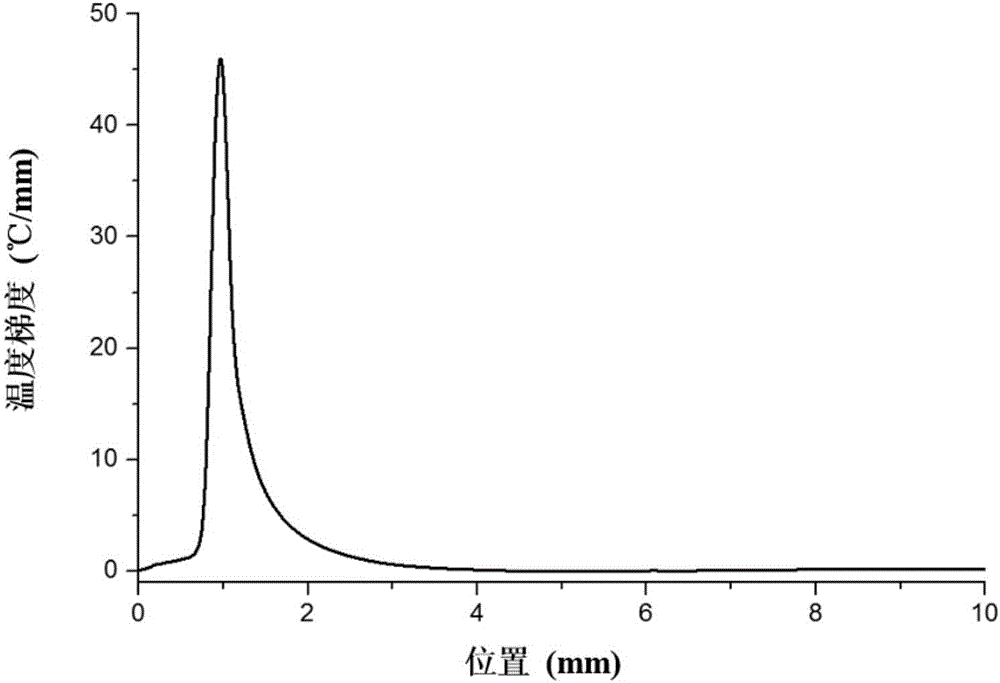

[0022] figure 2 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com