Patents

Literature

476results about How to "Realize non-contact measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for measuring diameter and straightness accuracy parameters of seamless round steel pipe

InactiveCN101571379ARealize onlineRealize non-contact measurementUsing optical meansEllipseEngineering

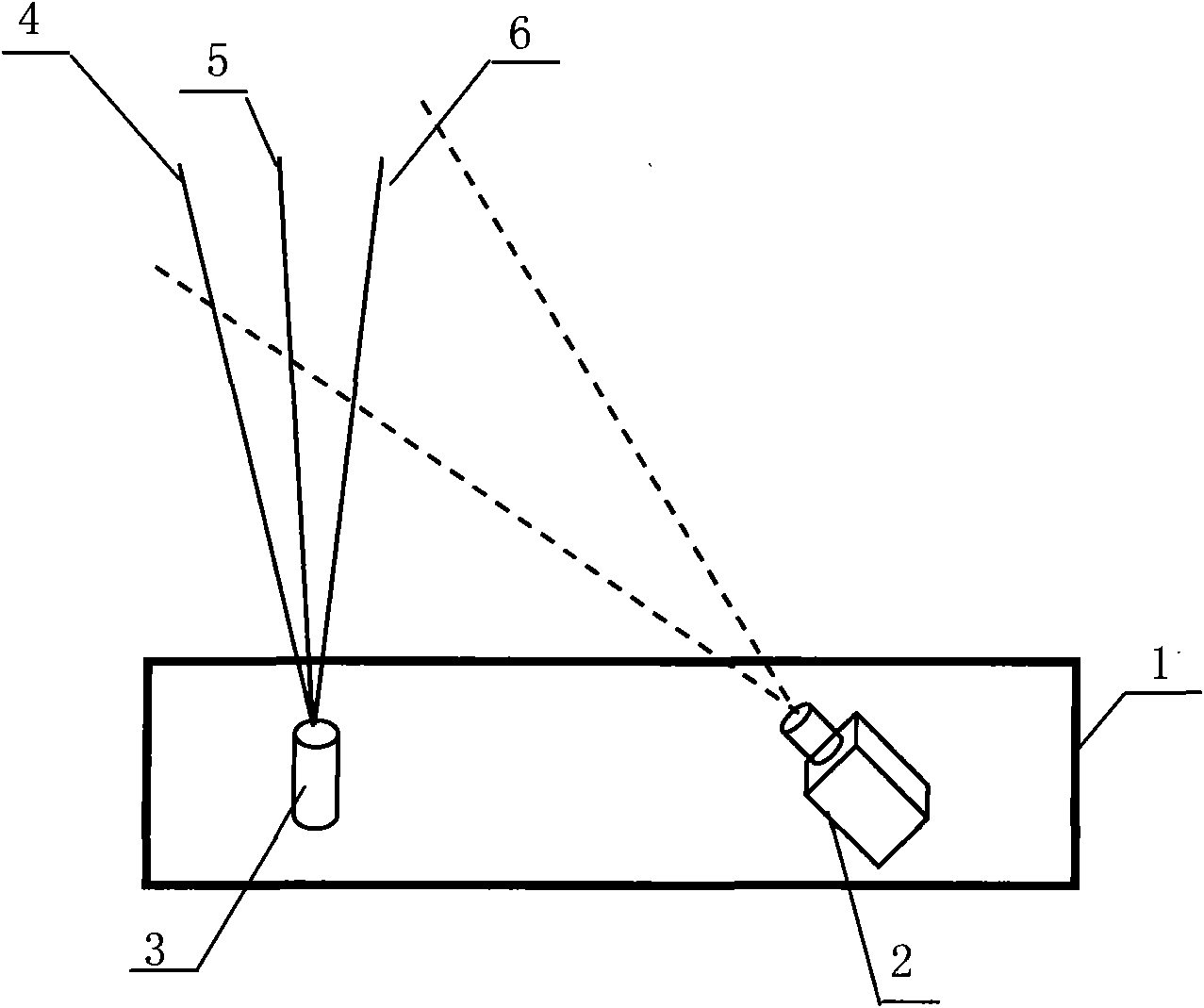

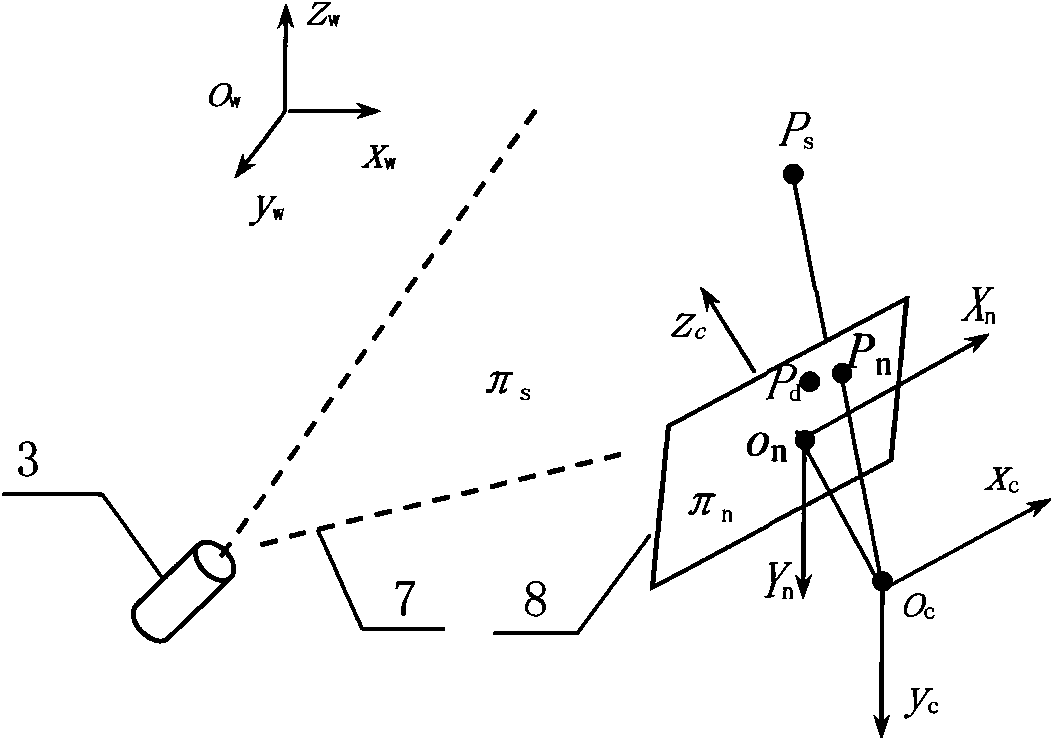

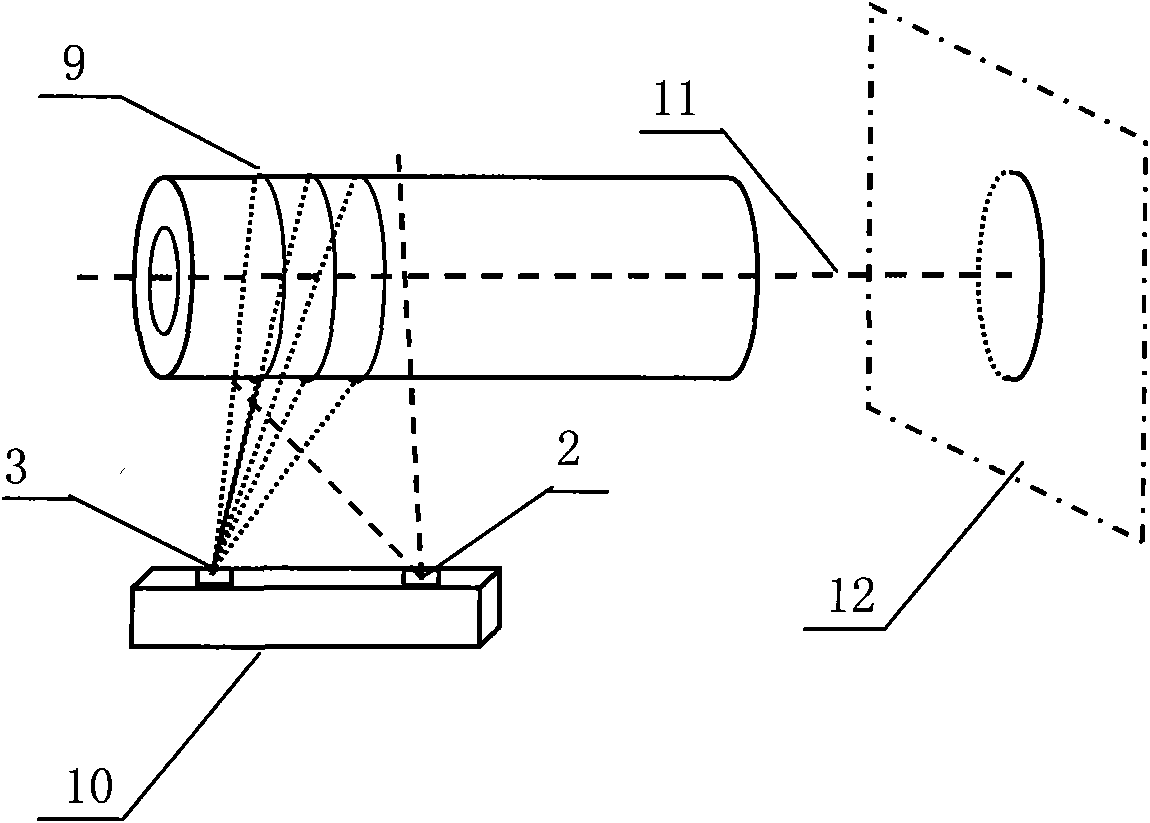

The invention relates to a method for measuring the diameter and the straightness accuracy parameters of a seamless round steel pipe. The method includes the steps as follows: accomplishing the calibration of parameters of a multi-linear structured light vision sensor formed by one video camera and multi-line laser projectors; distributing the multi-linear structured light vision sensors on the periphery of the seamless round steel pipe to be tested; respectively controlling the laser projectors to project structured light plane onto the measured section of the seamless round steel pipe by a computer, collecting the images of laser stripes on the surface of the seamless round steel pipe and processing the images of the laser strip by a video camera, and calculating the three-dimensional coordinates of different sections according to a measurement model; determining the elliptical center of each section of the space, realizing the measurement of the straightness accuracy of the seamless round steel pipe and establishing the dynamic and virtual central axis of the seamless round steel pipe; establishing the reference plane of the dynamic and virtual projection of ellipse of the section of the space; and front projecting the ellipse of the section of the space onto the reference plane of the dynamic and virtual projection, and carrying out the operation of circle fitting on the reference plane, thereby obtaining the section circle of the steel pipe. The method can realize the on-line, real-time, automatic and noncontact measurement of the diameter and the straightness accuracy parameters of the seamless round steel pipe.

Owner:TIANJIN UNIV

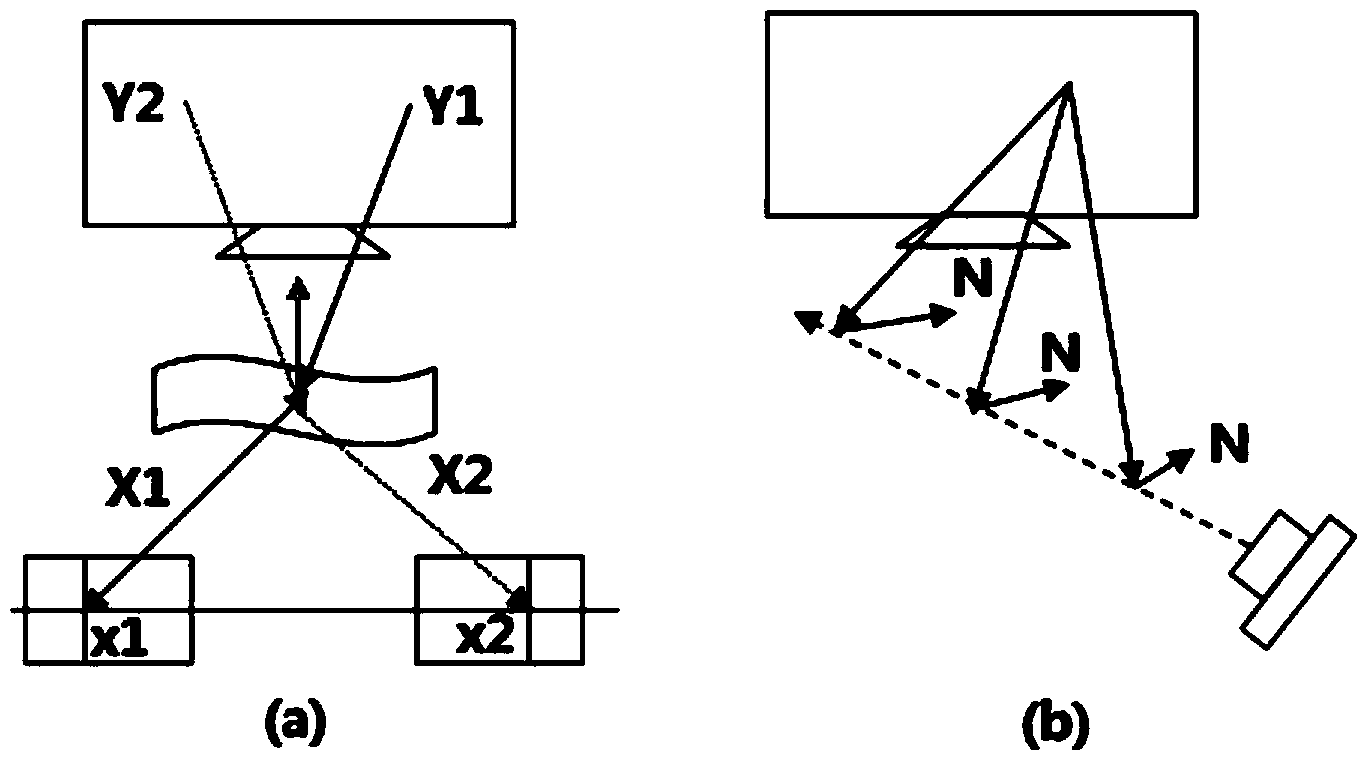

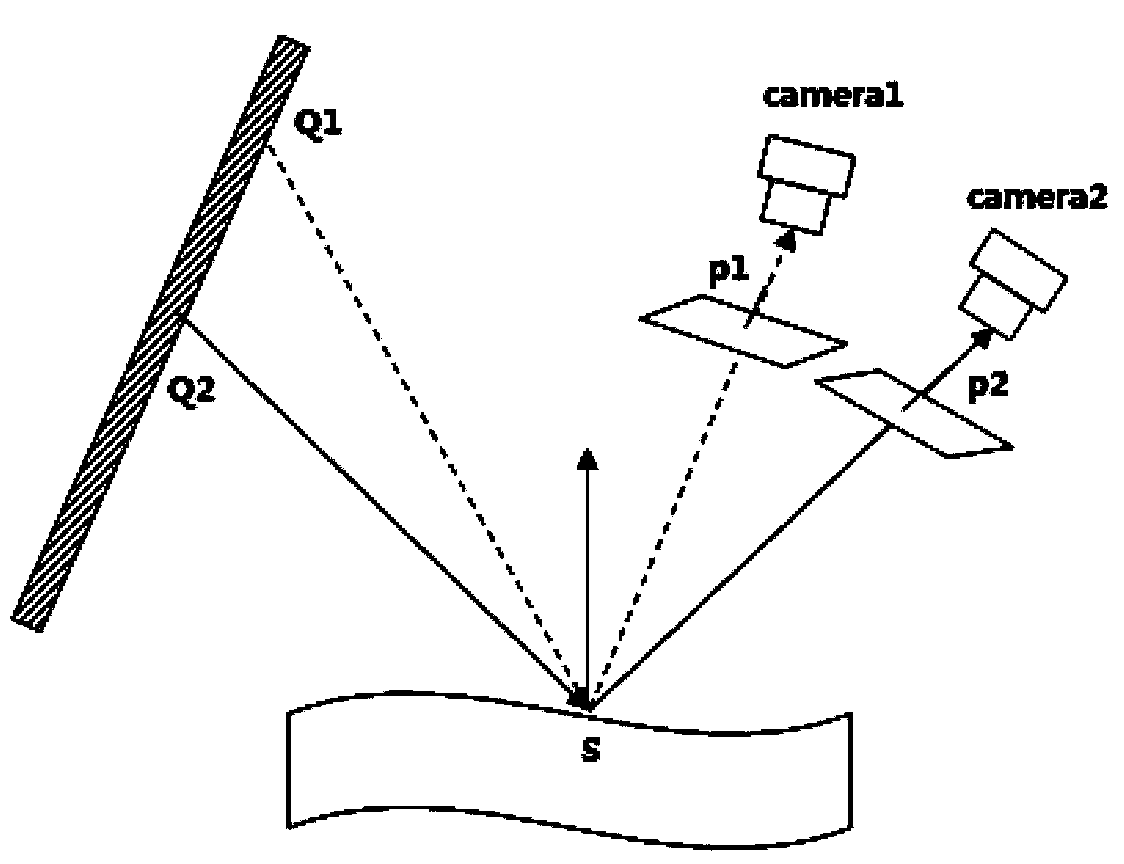

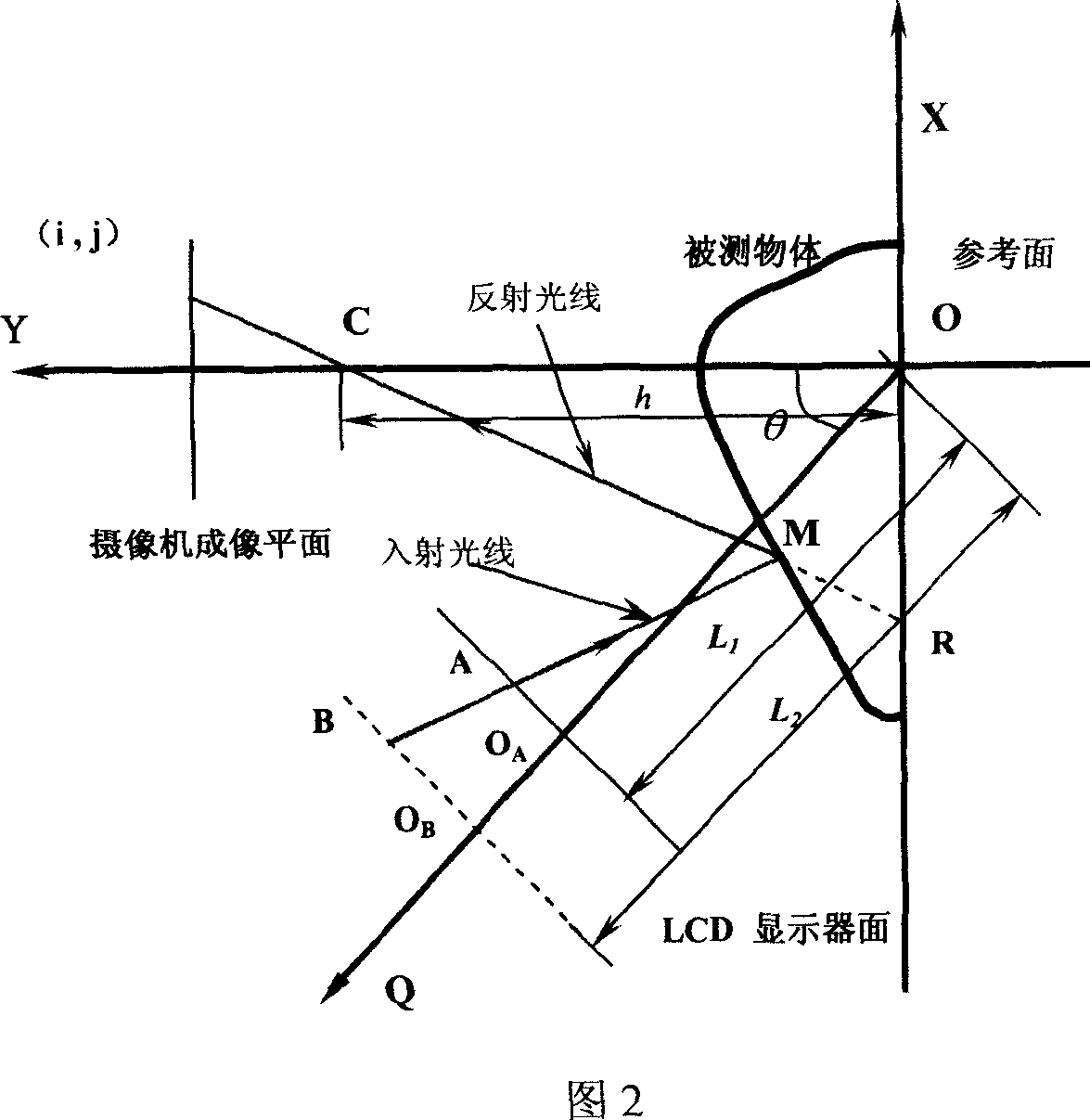

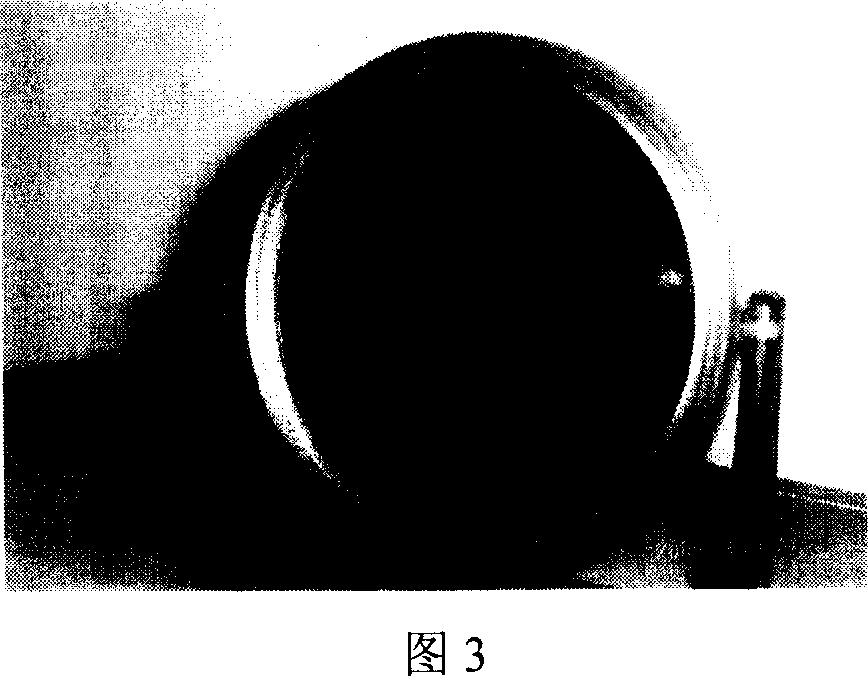

Mirror object measuring device and method based on binocular vision

InactiveCN104111036ASimple structureRealize non-contact measurementUsing optical meansMeasurement deviceMeasurement cost

The invention relates to a mirror object measuring device and a method based on binocular vision. According to the device, a computer is connected with a liquid crystal display device and a camera, and the liquid crystal display device is arranged above a measured mirror object. The measuring method comprises steps that: a binocular camera is calibrated, an internal matrix of the binocular camera and a rotating translation matrix between the cameras are acquired, and relative position relations between the liquid crystal display device and the binocular camera are acquired; a sine fringe is generated by the computer, the liquid crystal display device is controlled to project an image of the sine fringe to the measured mirror object, and a virtual image which is formed on a surface of the measured mirror object and is generated by the sine fringe shot by the camera is inputted to the computer; information of the virtual image acquired by the camera is processed by the camera according to the calibrated relative position relations and the internal matrix of the camera to acquire a three-dimensional profile of the surface of the measured mirror object. The mirror object measuring device has a simple structure, can realize non-contact measurement, needs no contact probes in the traditional technology, reduces measurement cost and improves measurement efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

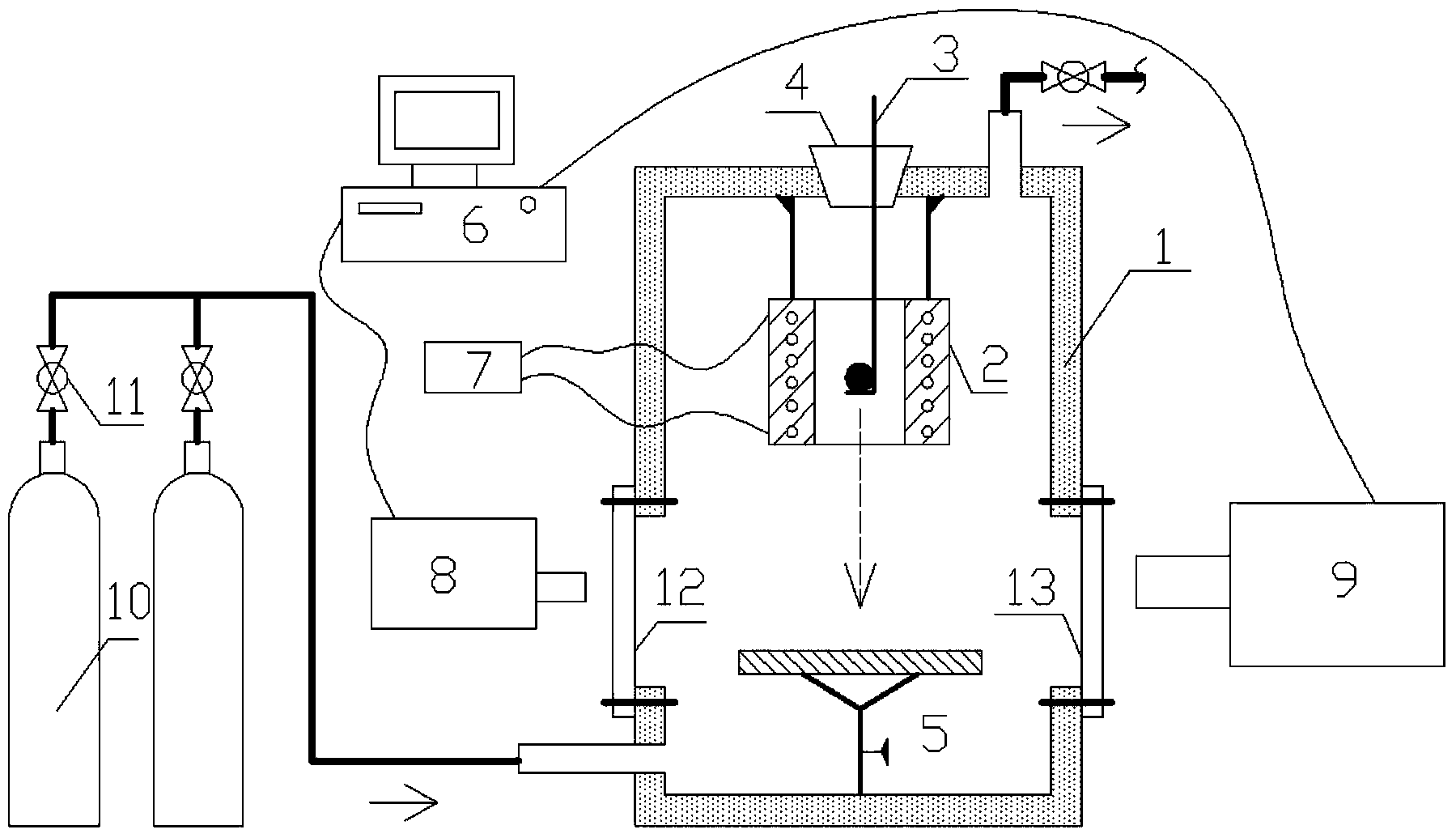

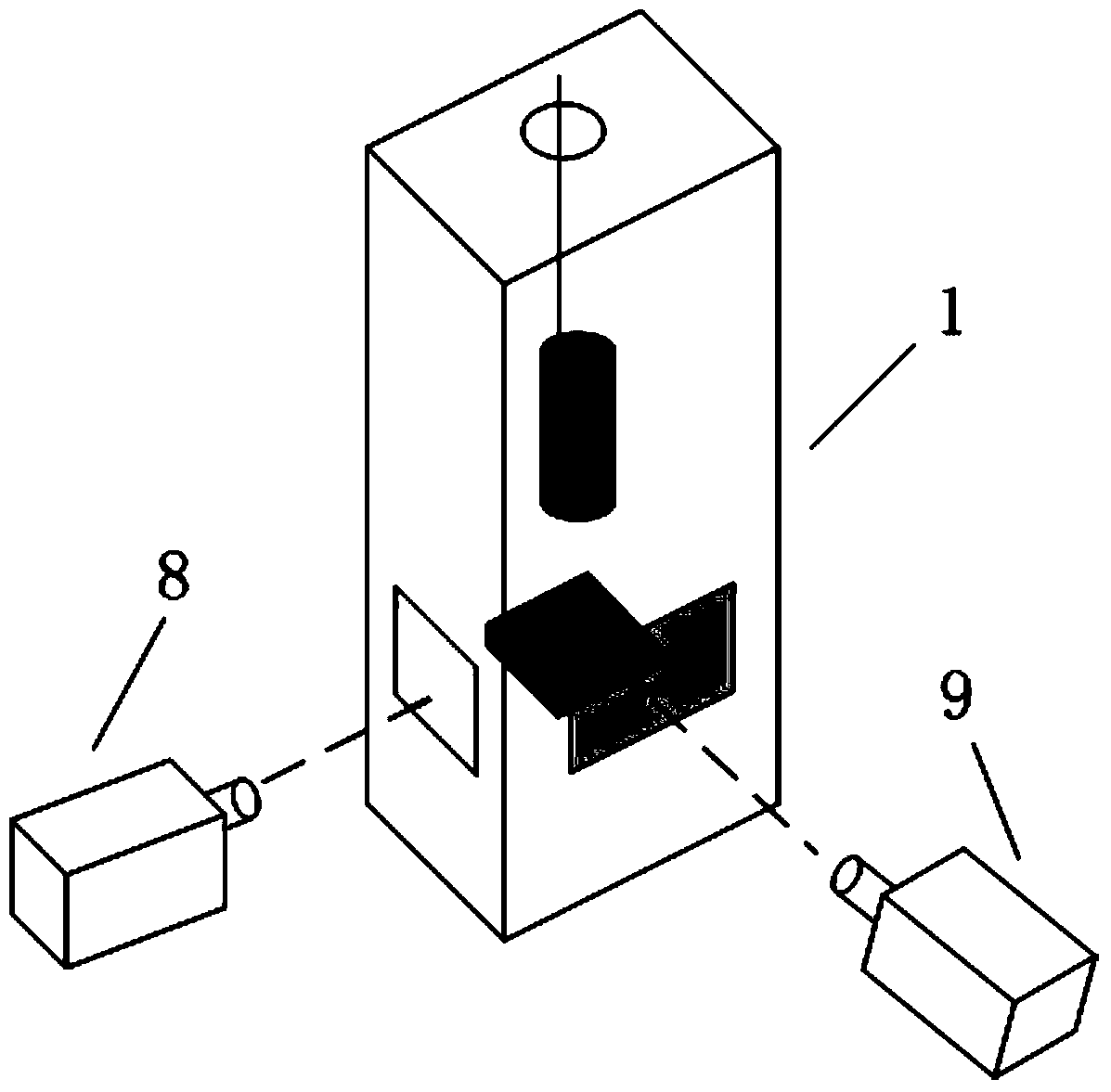

Fuel particle hot collision recovery coefficient measurement device and measurement method

ActiveCN104297252AControllable reaction atmosphereRealize non-contact measurementChemical analysis using combustionInvestigating moving fluids/granular solidsImage analysisMeasurement device

The invention discloses a fuel particle hot collision recovery coefficient measurement device and a measurement method. A combustion system and a collision system are arranged in a sealed cavity which is connected with a gas source, and the combustion atmosphere can be adjusted by a flow valve; a combustion reaction device is a tubular electrical heating furnace with a temperature control function and can realize heating of the fuel particle; the temperature of the fuel particle is tracked by an infrared thermal imaging instrument, so that the temperature of particle collision in a non-contact manner can be measured; a high-speed camera is adopted to capture the movement images of the fuel particle before and after collision, the speed of the fuel particle before and after collision can be acquired through image analysis and the collision recovery coefficient can be computed. The device can measure the particle collision recovery coefficient in a high-temperature hot state, and has important practical value on the mathematical modeling of a hot fluidized bed; different from the cold state experiment, the hot working status is more close to the real fuel combustion environment in the fluidized bed, therefore, the obtained experimental data can be used for analyzing and judging the agglomeration and caking tendency during fuel combustion.

Owner:SOUTHEAST UNIV

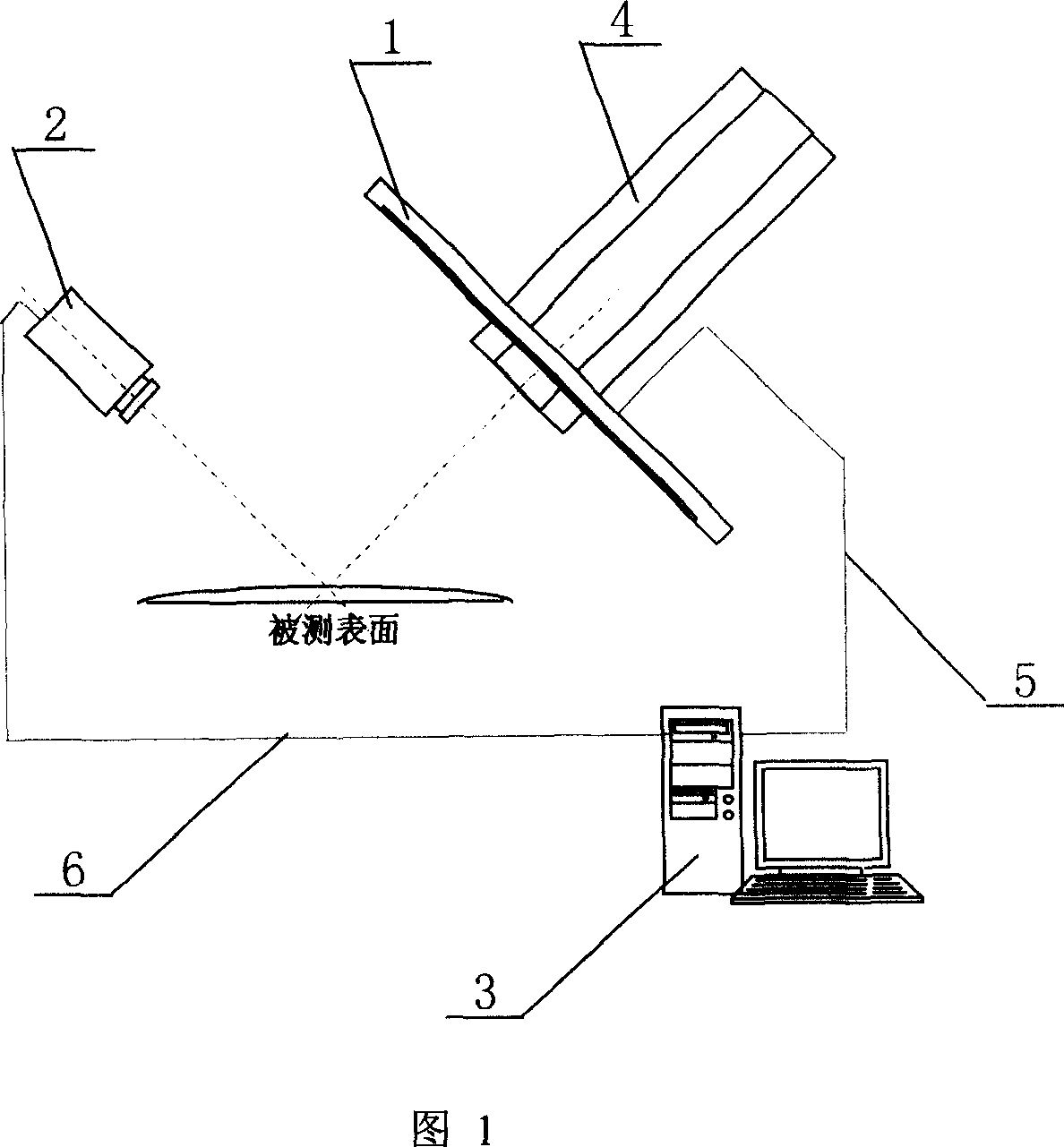

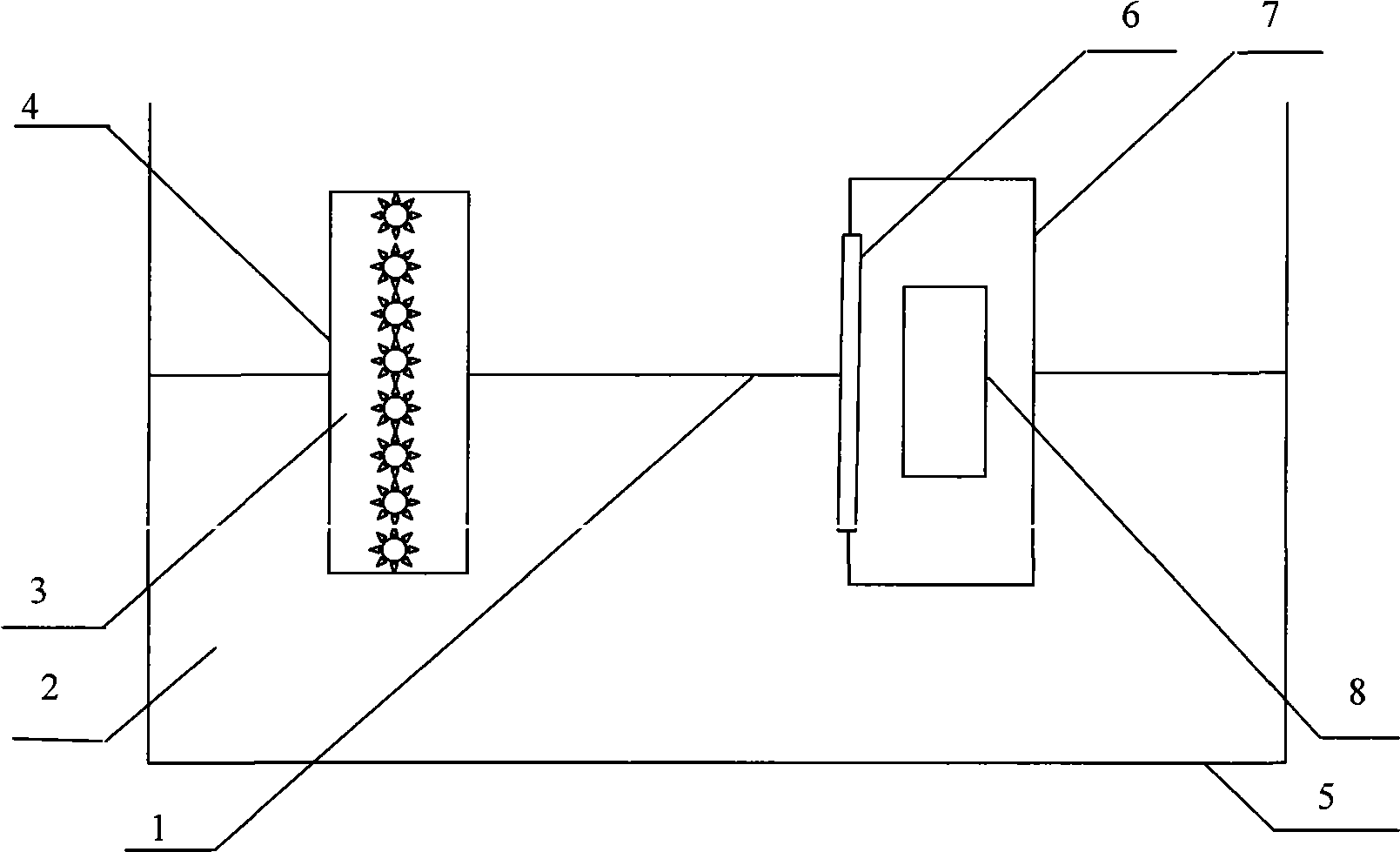

Three dimension outline measuring device and method for mirror article surface

InactiveCN1945204ASimple structureRealize non-contact measurementUsing optical meansMeasurement deviceData acquisition

The present invention provides 3D mirror object surface outline measuring device and method. The measuring device consists of LCD panel display, industrial video camera, computer and guide track. The LCD panel display is fixed on the guide track and connected via electric cable to the computer, and the industrial video camera is connected via video line to the computer. The measuring method includes device regulation, data acquisition, data processing and other steps. The device of the present invention is simple in composition, and the measuring method is simple and has data processing with less complexity.

Owner:SHANGHAI UNIV

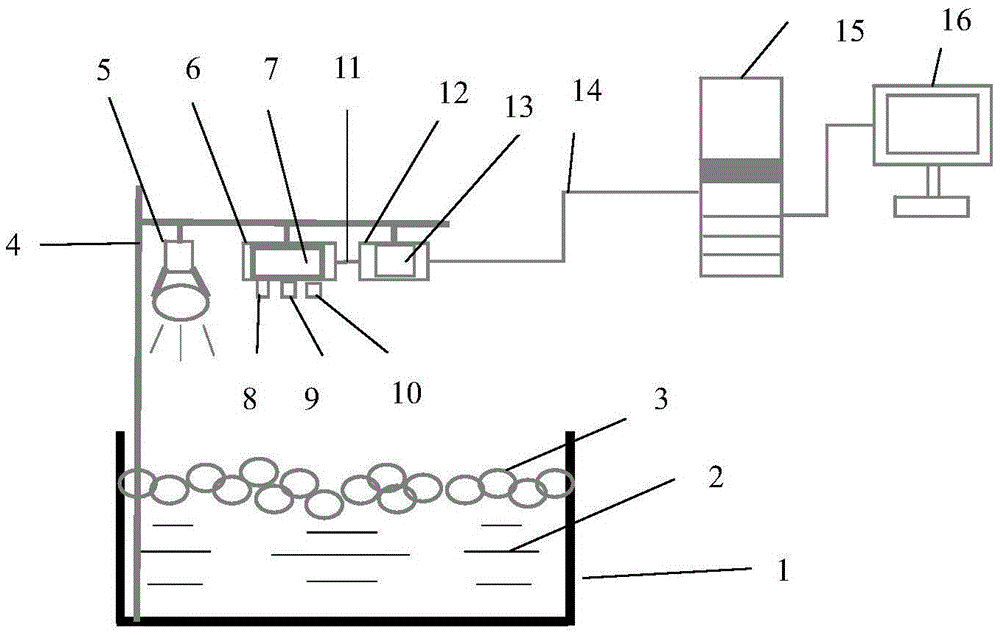

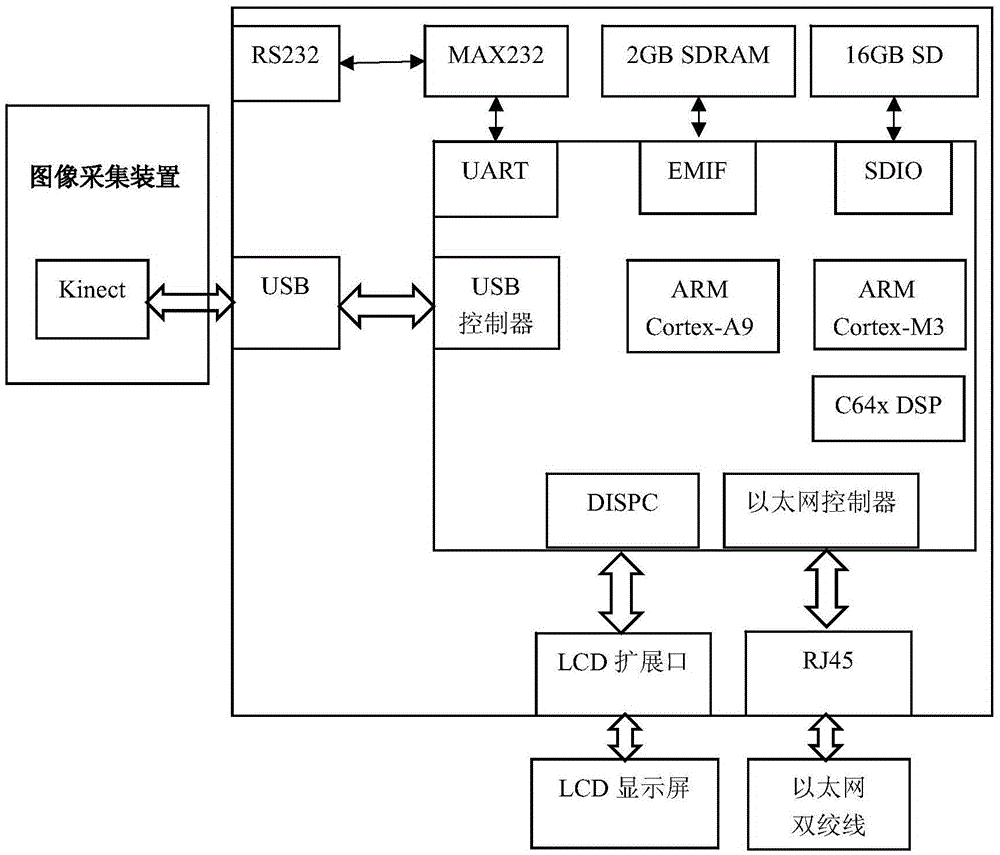

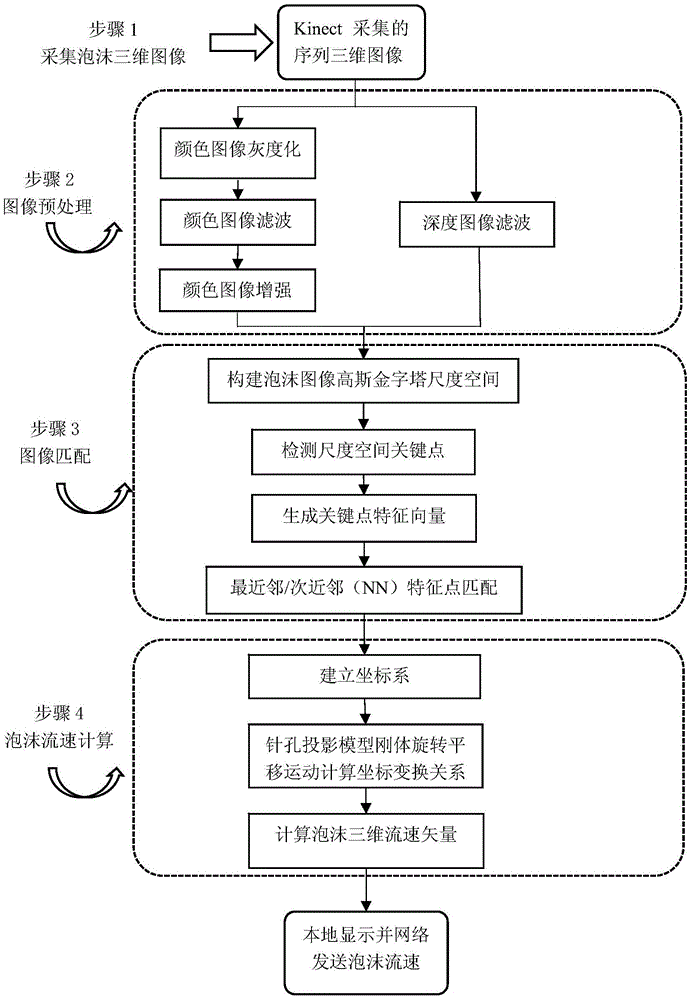

On-line detection device and method of mineral flotation froth flow velocity on the basis of three-dimensional visual information

ActiveCN105488816ARealize non-contact measurementImprove operational efficiencyImage enhancementImage analysisColor imageThree-dimensional space

The invention discloses an on-line detection device and method of mineral flotation froth flow velocity on the basis of three-dimensional visual information. Kinect is adopted to obtain the color image and the depth information of forth to form the three-dimensional visual information of the forth. A current frame of image and a previous frame of image are subjected to characteristic point extraction and matching in an embedded heterogeneous multi-core processor, and a three-dimensional space coordinate of the image characteristic point is calculated by the pixel coordinate information and the depth information of the characteristic point and a pinhole projection imaging model. The three-dimensional space coordinate and the image acquisition rates of the matched characteristic points of two frames of images are used for calculating a movement rate, i.e., the froth flow velocity of the froth on three dimensionalities. The real-time on-line non-contact detection of the flotation cell froth flow velocity is realized, and the on-line detection device has the characteristics of being small in volume, high in mobility, low in power consumption, low in cost, high in detection speed and high in reliability, is especially suitable for the real-time on-line measurement of the field froth flow velocity index of mineral flotation, and is favorable for realizing the automatic monitoring of a flotation process so as to improve mineral separation efficiency.

Owner:CENT SOUTH UNIV

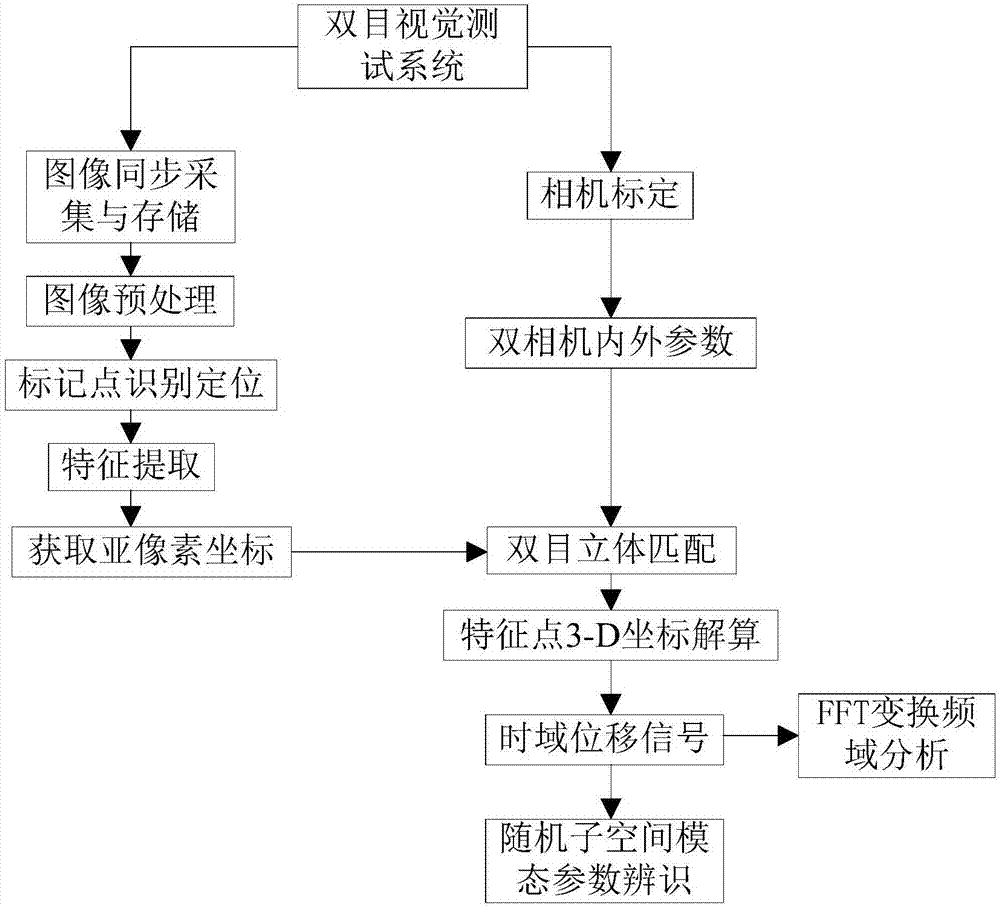

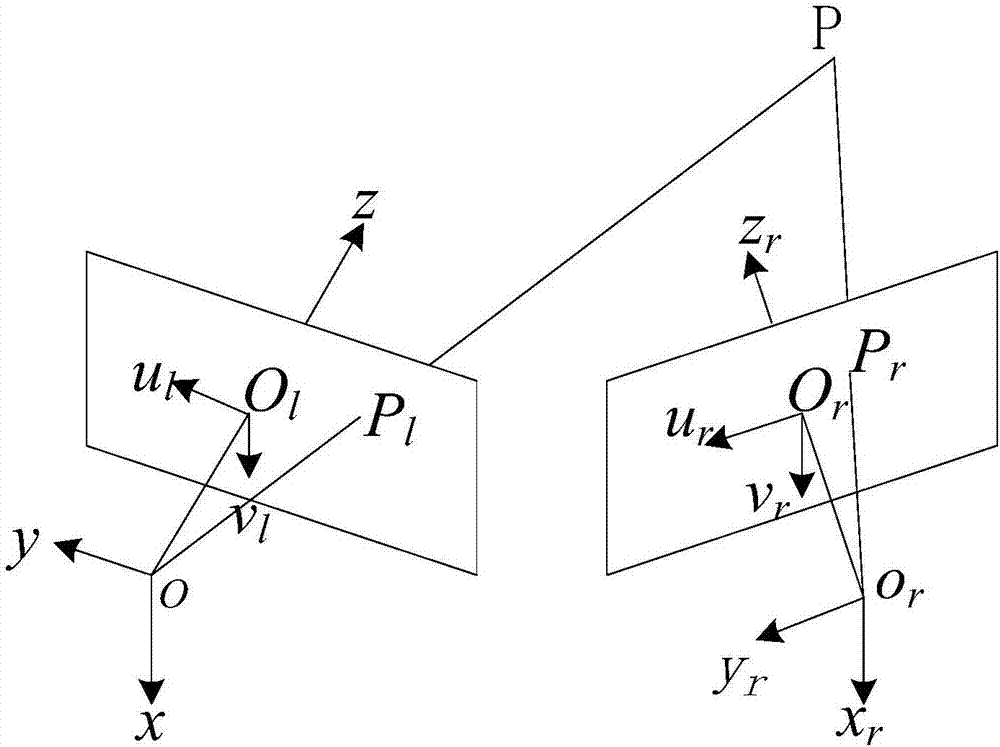

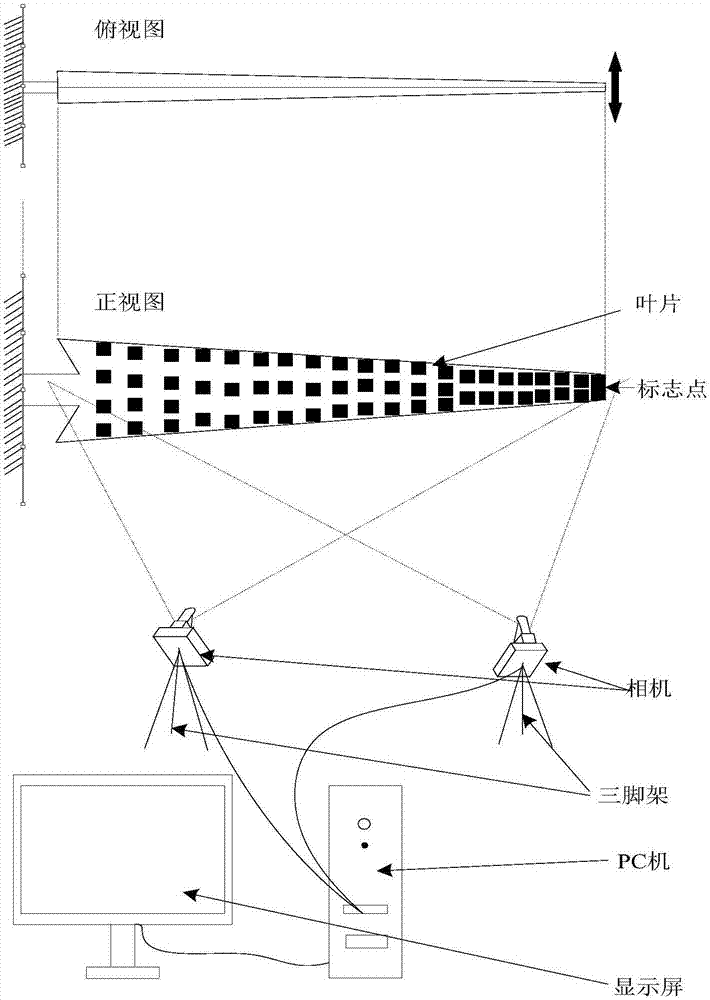

Modal test method of large draught fan blade based on photography measurement technology

ActiveCN106989812AThe influence of dynamic characteristicsRealize non-contact measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement pointFourier transform on finite groups

The invention discloses a modal test method of a large draught fan blade based on the photography measurement technology. The method comprises steps of using a pair of CMOS / CCD industrial cameras to carry out synchronous shooting on surface images of the draught fan blade under random excitation vibration; identifying and positioning multiple marking points in the images; extracting central sub-pixel level coordinates of the marking points and carrying out stereo matching of the double cameras; calculating three-dimensional coordinates of each measurement point through the three-dimensional reconstruction technology; carrying out micro-division processing on displacement data to obtain required vibration response (speed and accelerated speed) signals; through the Fourier transform, converting time domain signals into observation peak values in frequency domains to find corresponding modal frequencies; by combining analyzed frequency values, further using the stochastic subspace identification method (SSI) to precise calculate modal parameters of the blade; and acquiring the fixed frequency, the vibration mode and the damping ratio of the blade. According to the invention, by use of non-contact type multi-point synchronous vibration measurement, rapid high-precision model test on the draught fan blade can be achieved.

Owner:HUNAN UNIV OF SCI & TECH

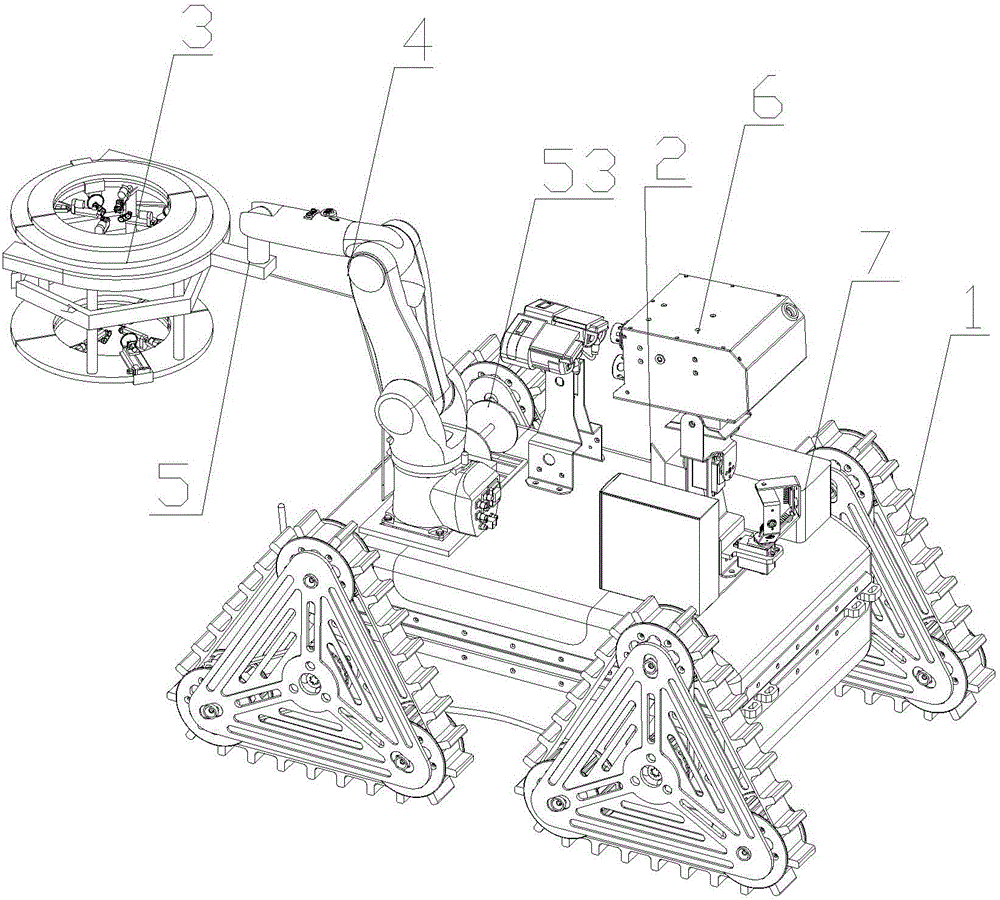

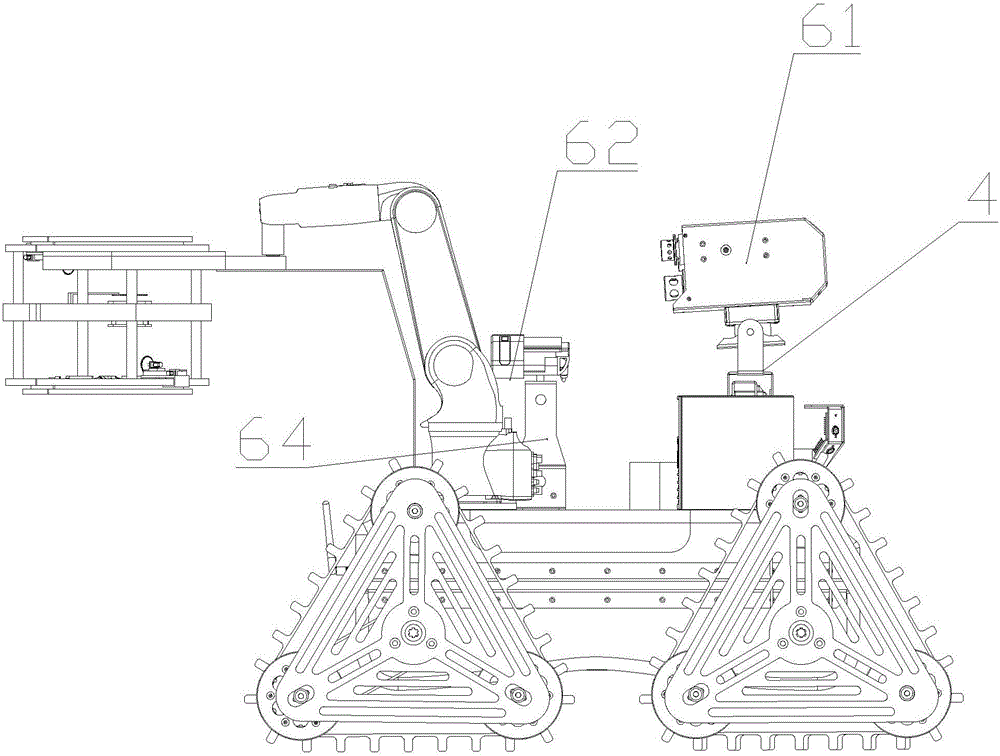

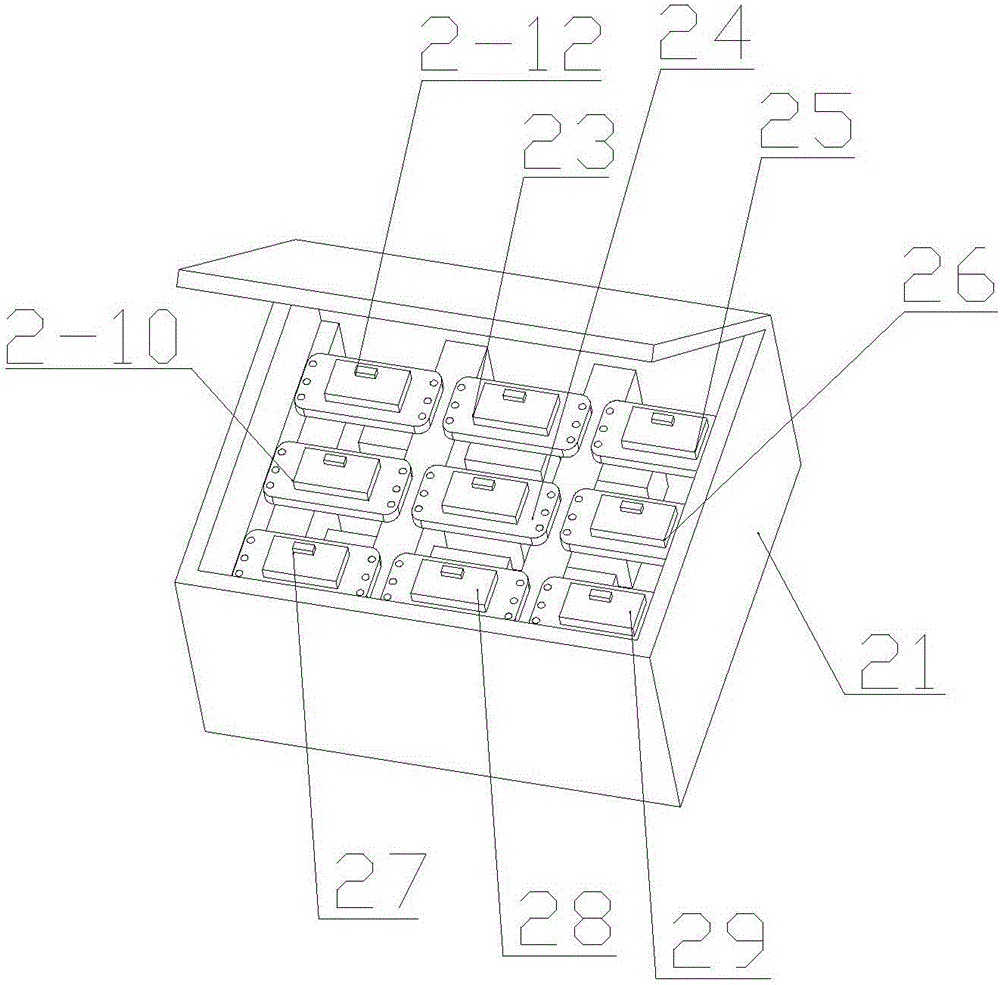

Full-automatic branch trimming robot and method

ActiveCN105794502ARealize automatic identificationRealize computingCuttersCutting implementsTerrainOperational costs

The invention relates to a full-automatic branch trimming robot.The full-automatic branch trimming robot is composed of an all-terrain chassis movable platform, an electronic control unit, a separable tail-end execution unit, a mechanical arm, an execution unit releasing and withdrawing mechanism, a visual navigation mechanism and a high-capacity lithium battery.The brand-new branch trimming robot for high trunks is designed, automatic identification, calculation, measurement and trimming of tree trunks are achieved, and the invention further provides a corresponding mechanical structure and trimming steps and method related to electrical connection; the voids of a full-automatic trimming robot and a high-altitude tree trimming robot on the present market are filled, the efficiency of branch trimming is improved, the labor intensity of workers is reduced, and the operating cost of social public services is reduced.

Owner:SHANDONG GUOXING SMARTECH CO LTD

Device for measuring spacecraft structure deformation based on speckle interference and fringe projection and measurement method

InactiveCN104132624ARealize non-contact measurementRealize micro-deformation measurementUsing optical meansMeasurement deviceData acquisition

The invention discloses a device for measuring spacecraft structure deformation based on speckle interference and fringe projection. The device mainly comprises a laser speckle projection device, a CCD camera, a fringe projection device, a data acquiring and control unit and the like, wherein local deformation of a measured structural slab is measured by the laser speckle projection device through a laser speckle interference measurement method, and the fringe projection measurement device is used for measuring large-scale deformation through fringe projection measurement and multiple times of measurement data combination. The spacecraft structure deformation is measured based on combination of speckle interference and fringe projection, large-scale and non-contact measurement on the spacecraft structure micro deformation can be achieved, the overall precision can reach 10 microns within the range of 2 m*2 m, and the measurement precision can reach 1 micron within the range of 0.2 m*0.2 m needing local high-precision measurement.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

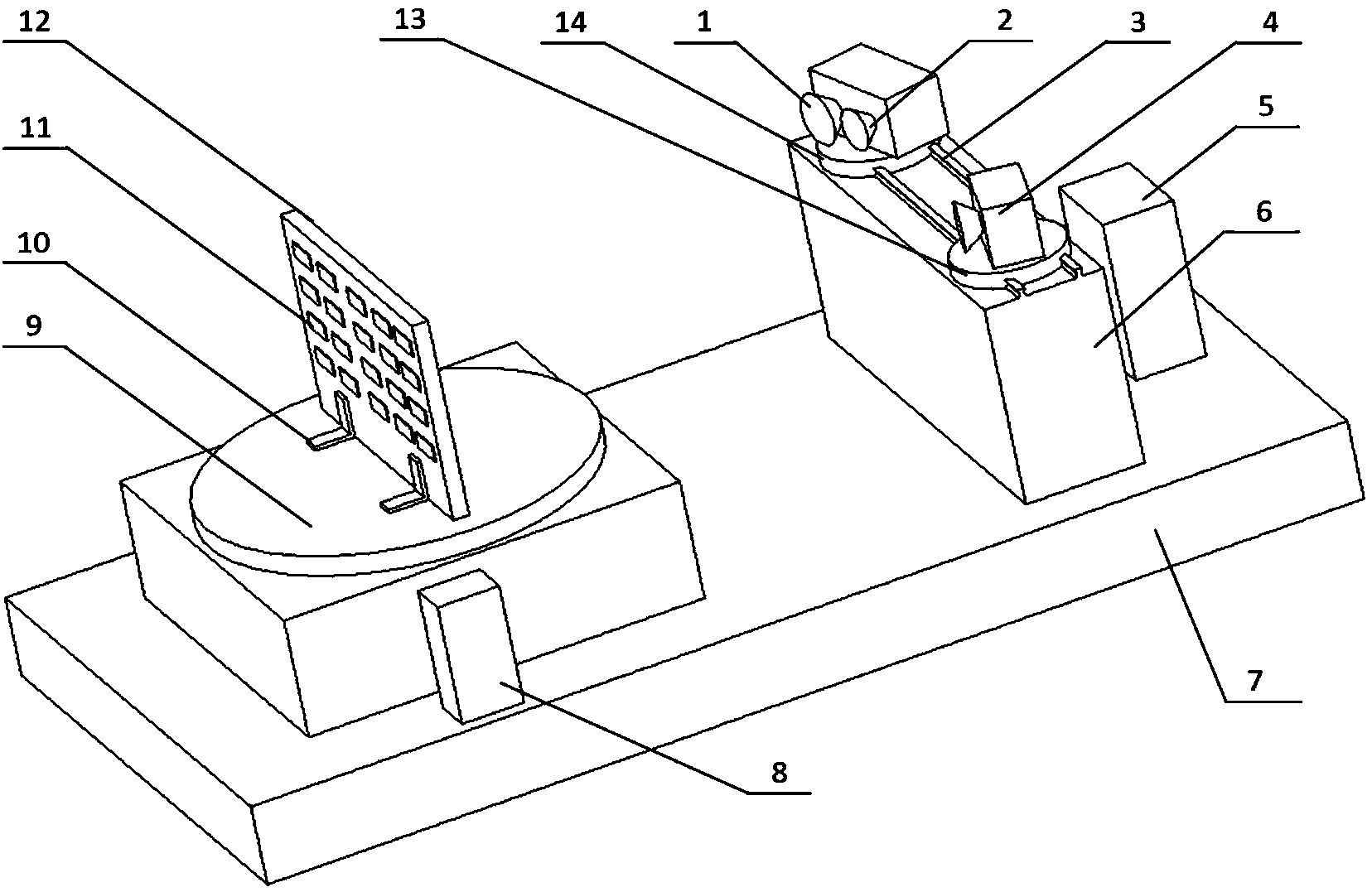

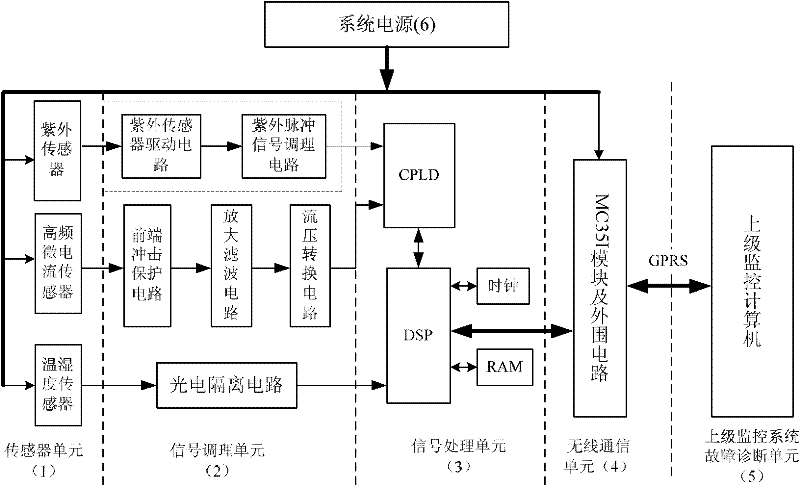

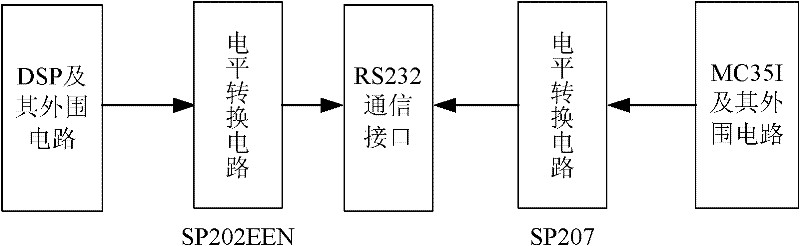

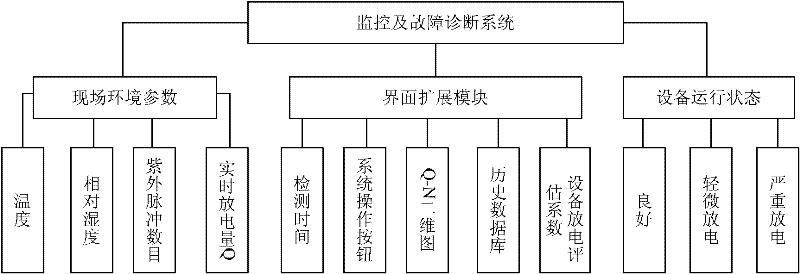

On-line monitoring device and method for corona discharge of ultra-high voltage power transmission line

InactiveCN102331540AImprove accuracyReliable insulation propertiesTransmission systemsElectrical testingUltra high voltageComputer monitoring

The invention discloses an on-line monitoring device and method for the corona discharge of an ultra-high voltage power transmission line. The on-line monitoring device comprises a sensor unit, a signal conditioning unit, a signal processing unit, a wireless communication unit, an upper computer monitoring unit, a system failure diagnosing unit and a system power supply unit. The on-line monitoring method comprises the following steps of: carrying out signal acquisition for the field working state of power transmission equipment by the sensor unit; transforming data types through the signal conditioning unit to obtain a useful signal which can be identified by a CPU (Central Processing Unit) of the signal processing unit; sending the processed data to the wireless communication unit through a serial port by the signal processing unit; and receiving the data and carrying out failure diagnosis by an upper computer server so as to give the current operation state of the equipment, equipment parameters and a failure diagnosis result.

Owner:JIANGSU UNIV OF SCI & TECH

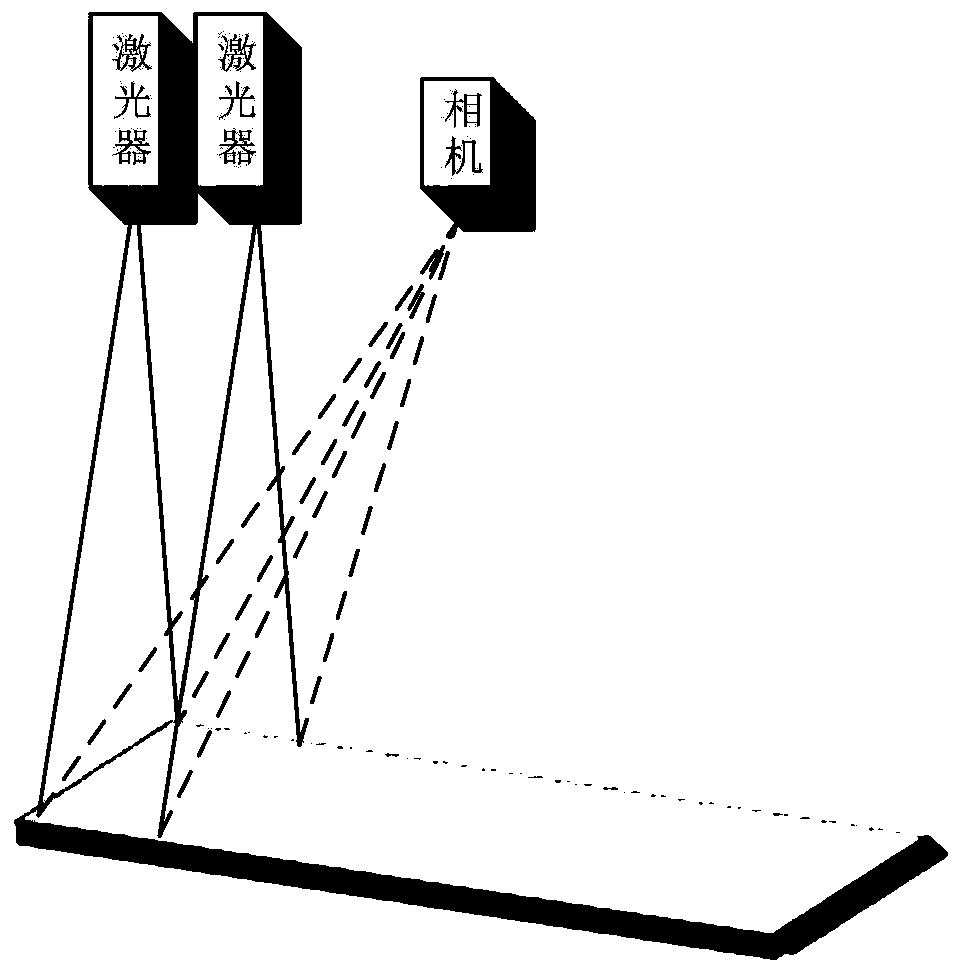

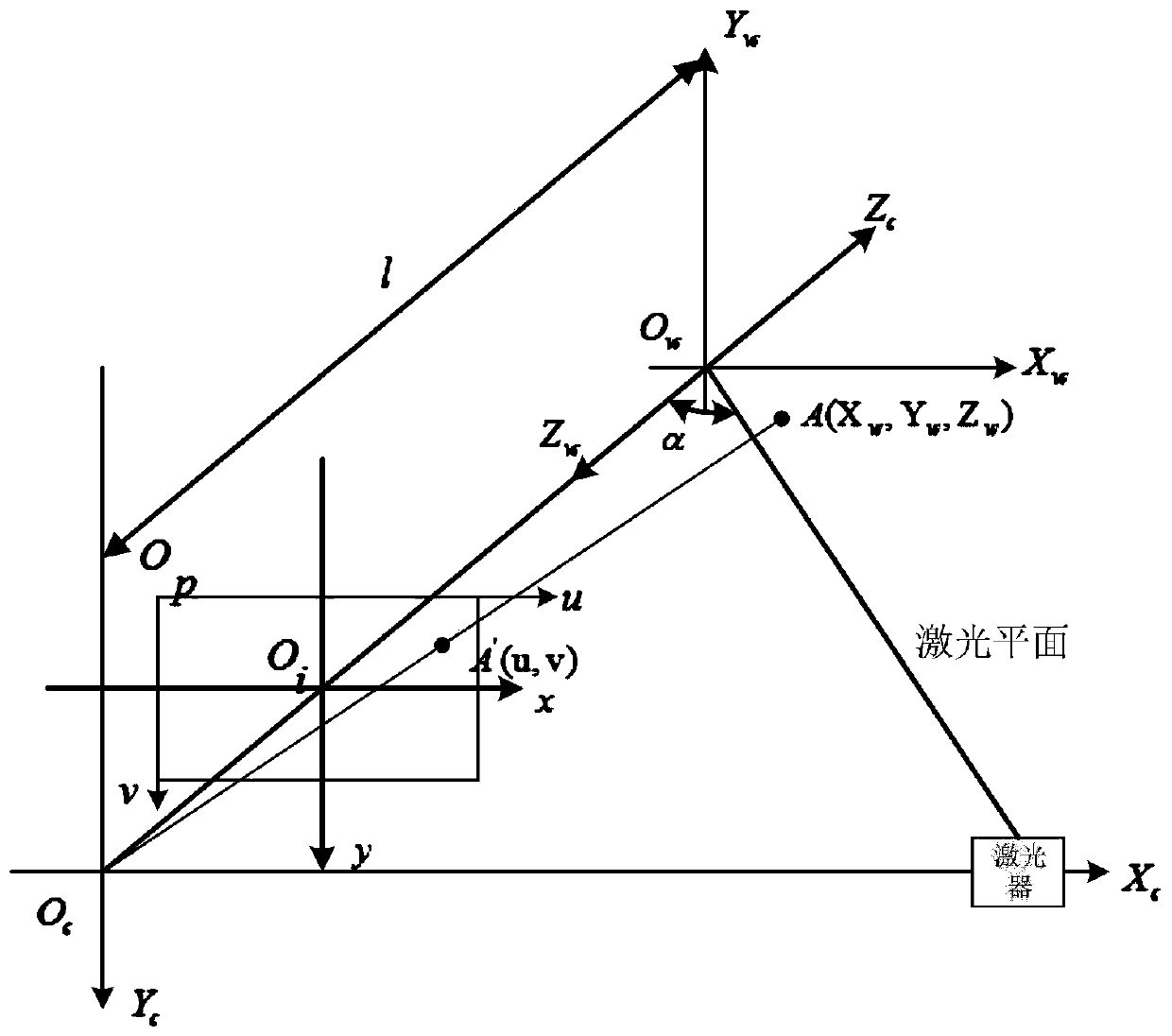

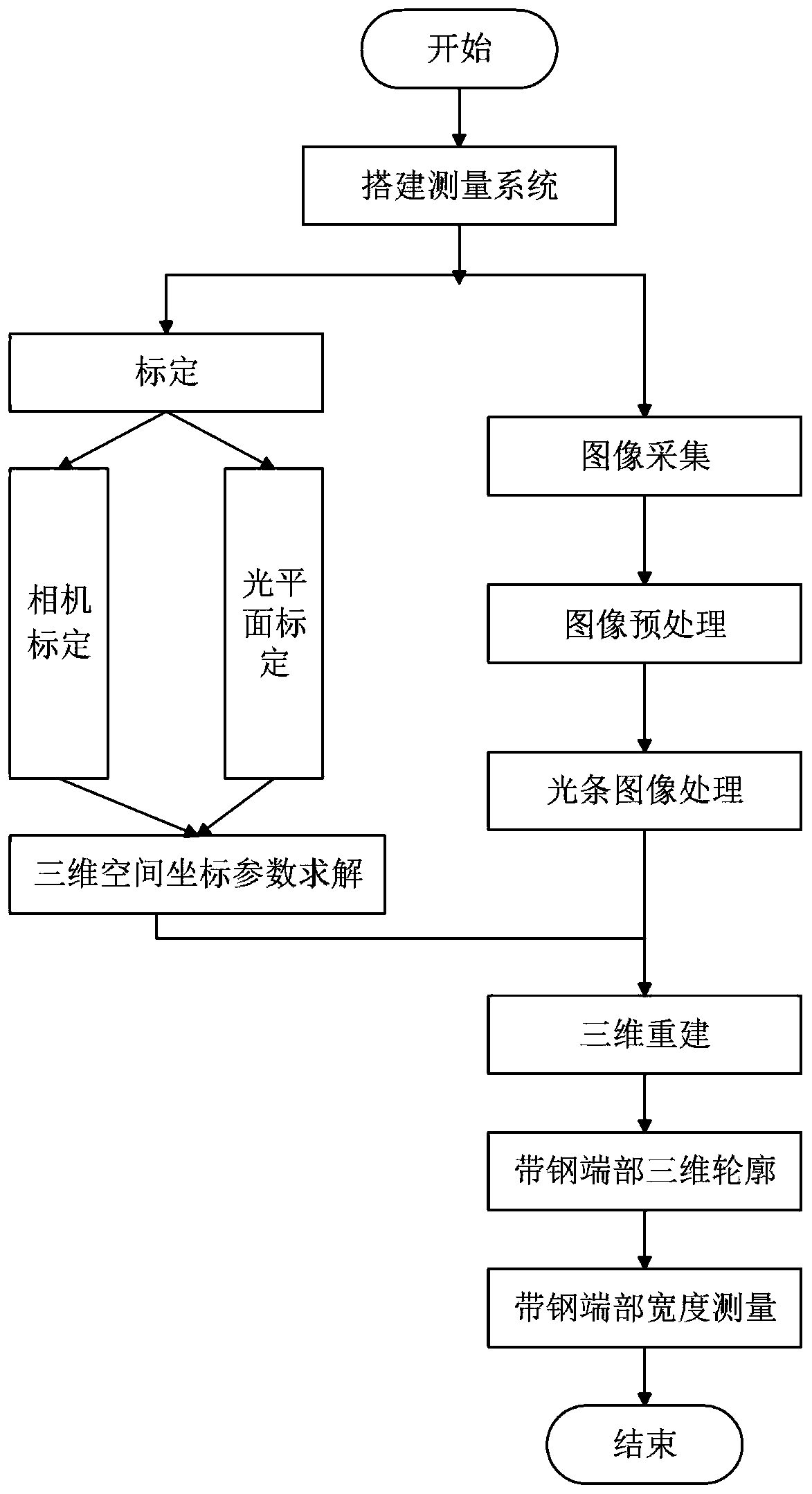

Hot-rolled strip steel end part three-dimensional contour measurement method based on double-line structured light

InactiveCN111207695AReduce complexityGuaranteed validityUsing optical meansProduction lineImaging processing

The invention belongs to the field of machine vision and particularly relates to a hot-rolled strip steel end three-dimensional contour measurement method based on double-line structured light. The method mainly adopts a double-line structured light method to carry out three-dimensional contour measurement of the shape of an end part of a strip steel which runs at a high speed of 120m / min on a hotrolling production line, and comprises operation steps of 1) establishing a system; 2) camera calibration; 3) light plane calibration; 4) solving three-dimensional space coordinates; 5) image acquisition and preprocessing; 6) processing a light bar image; 7) establishing the triangular relationship; and 8) performing three-dimensional reconstruction to obtain a three-dimensional point cloud chartof the strip steel. The method is advantaged in that the double-line structured light is projected to a plane of the end part of the strip steel, an intersection point of a line structured light andan edge of the strip steel is detected through image processing, a point is converted from a two-dimensional coordinate system to a three-dimensional coordinate system according to the structured light triangulation theory, the shape of the end part of the strip steel is obtained, and width of the strip steel is calculated.

Owner:UNIV OF SCI & TECH BEIJING

Wireless passive capacitive accelerometer

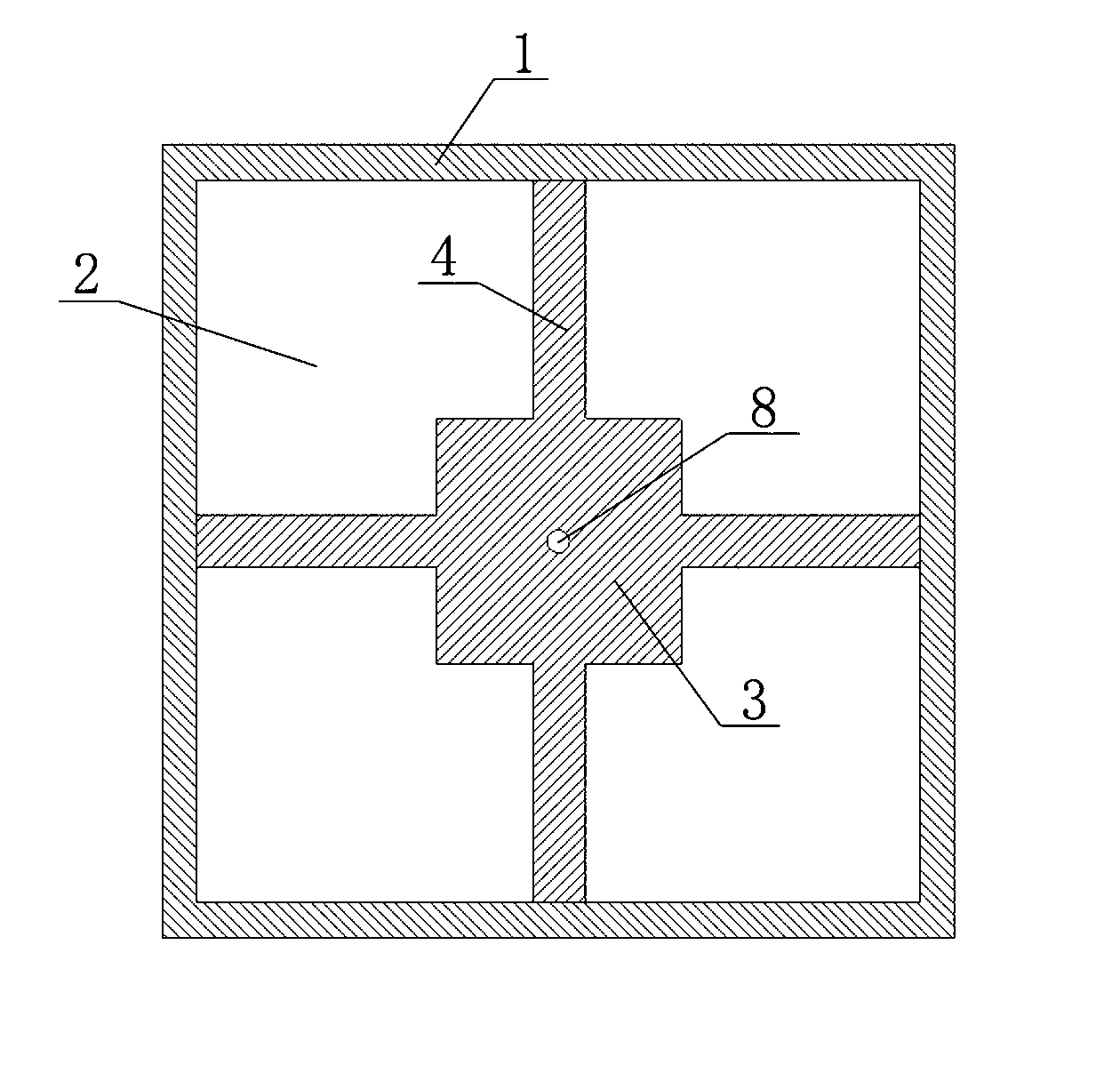

InactiveCN103293337ARealize measurementSimple structureTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricityPunching

The invention discloses a wireless passive capacitive accelerometer comprising a substrate with a closed cavity inside. A mass is fixed in the closed cavity through a cantilever; a first capacitor is arranged above the mass in the closed cavity, and a second capacitor is arranged below the mass in the closed cavity; a plane spiral inductor is arranged on the bottom surface of the substrate, electric connecting lines are sputtered on the substrate and the mass through TSV (through silicon via) technique punching, and the first capacitor, the second capacitor and the plane spiral inductor are in series connection to form a closed loop circuit through the electric connecting lines. The wireless passive capacitive accelerometer is skillful in design, simple in structure, high in sensitivity and accurate in test results, is wireless and passive, and can be used in severe environment; non-contact measurement is adopted during measuring, so that the range of application of the sensor is greatly broadened.

Owner:ZHONGBEI UNIV

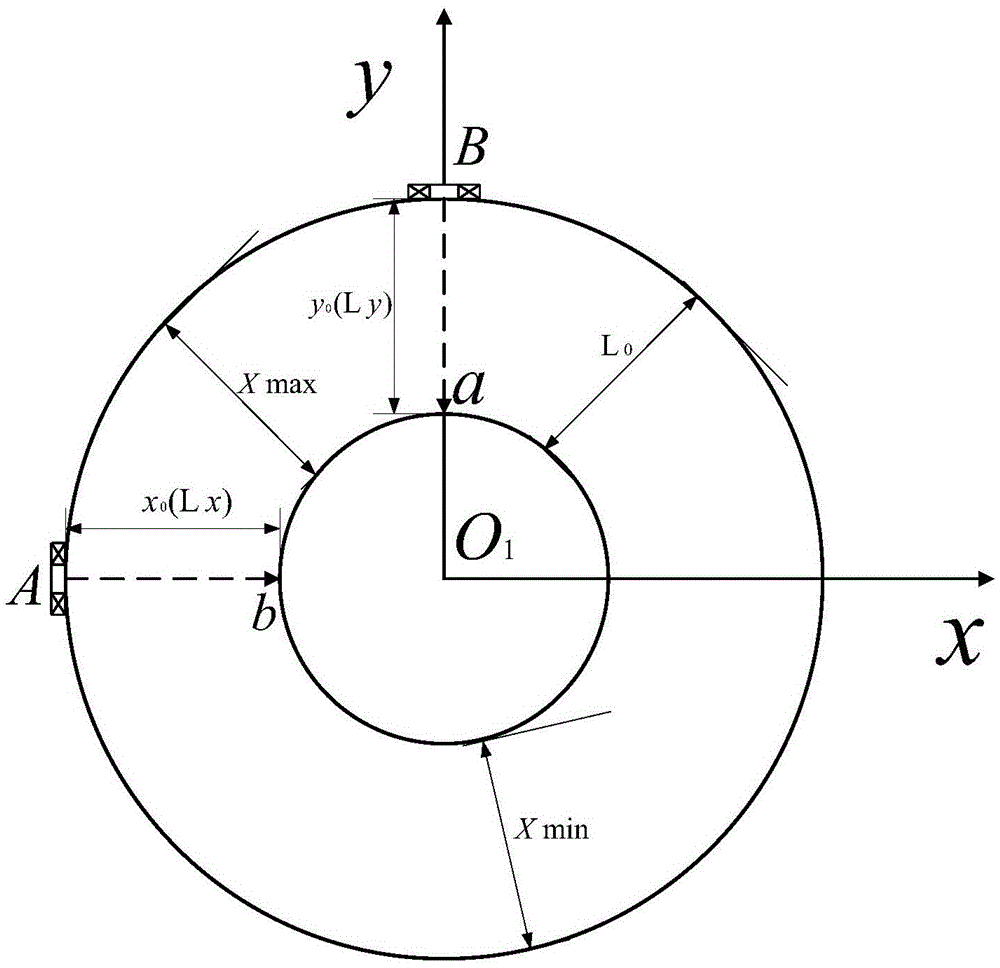

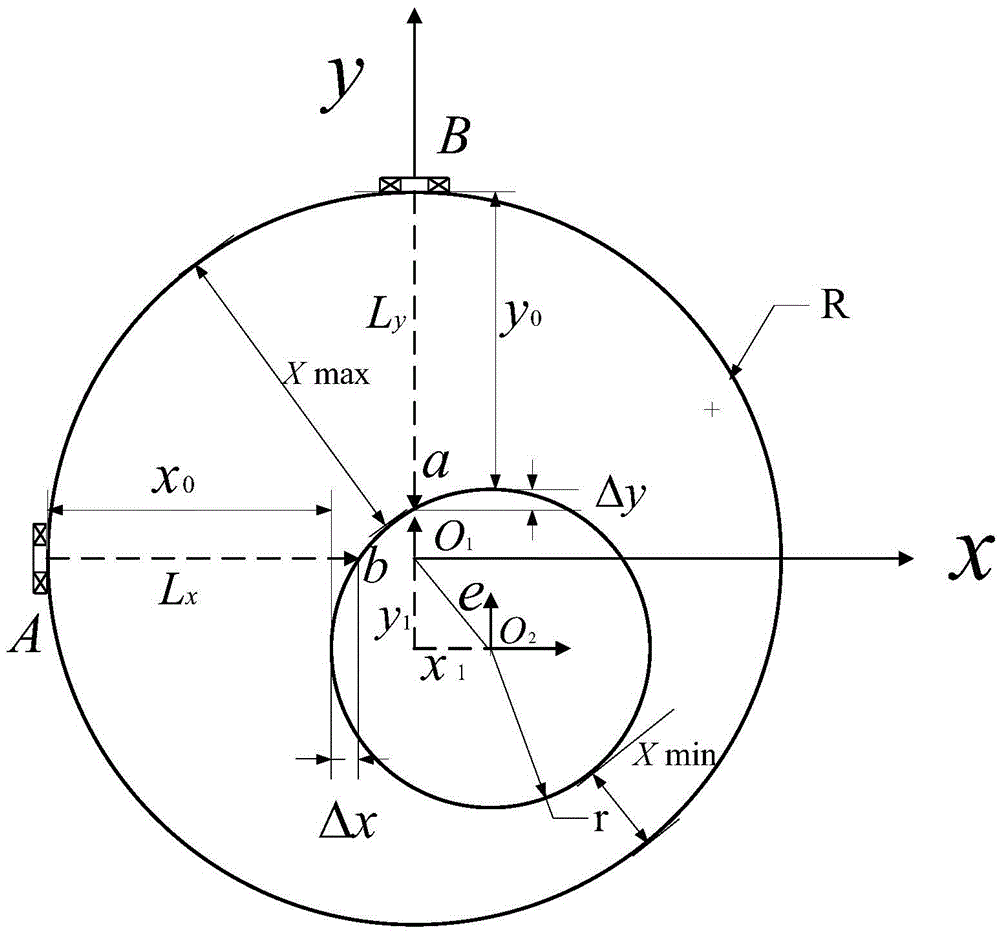

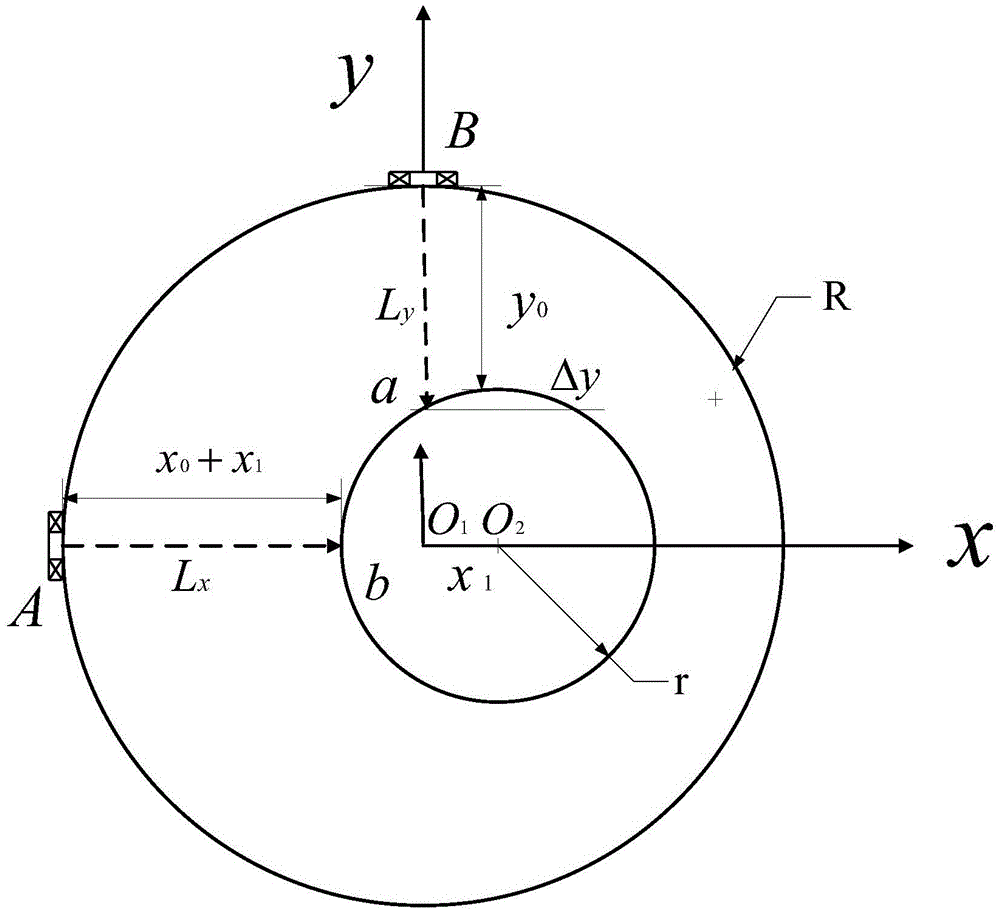

Real-time dynamic measurement method for measuring radial clearance between steam turbine rotor and stator

ActiveCN105526878ARealize non-contact measurementFast and accurate real-time dynamic online monitoringUsing optical meansObservational errorEngineering

The invention provides a real-time dynamic measurement method for measuring radial clearance between a steam turbine rotor and a stator. The method is characterized in that the method comprises the steps of determining distance measurement devices for radial clearance, determining radial clearance between the rotor and the stator, determining the radial clearance between the rotor and the stator, determining the distance from an emitter to the surface of the rotor, calculating vertical offset amount of the rotor when the center of the rotor shifts, calculating horizontal offset amount of the rotor when the center of the rotor shifts, calculating the rotor offset amount at any position and calculating the radial clearance between the steam turbine rotor and the stator. The method can carry out dynamic measurement on the rotor labyrinth clearance and blade top labyrinth clearance of a running steam turbine accurately and quickly, thereby solving the problem that the measuring error of the radial clearance between the steam turbine rotor and the stator is large and the radial clearance cannot be measured online dynamically and accurately, ensuring safe and economical operation of the machine set and saving halt overhaul time.

Owner:NORTHEAST DIANLI UNIVERSITY

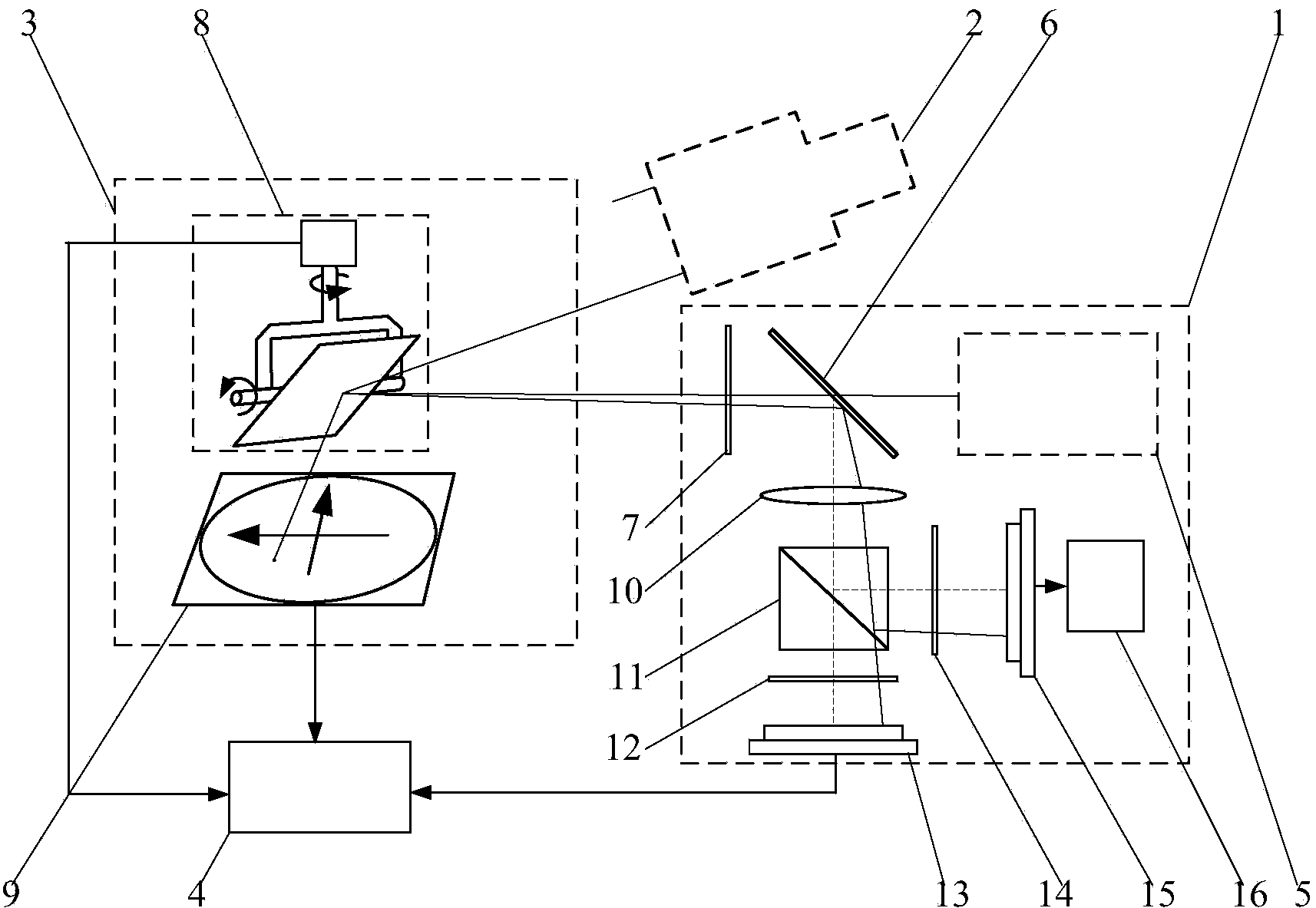

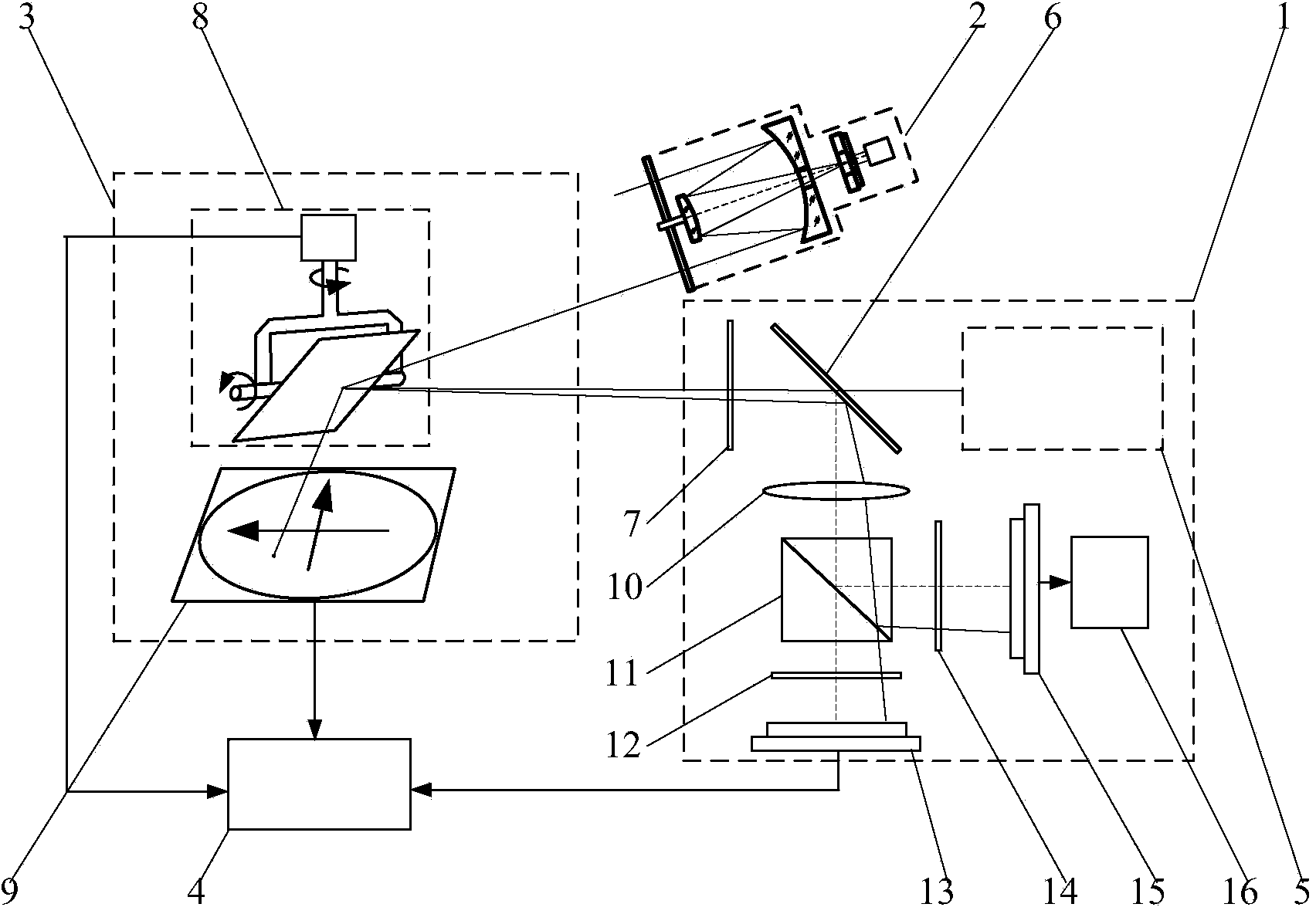

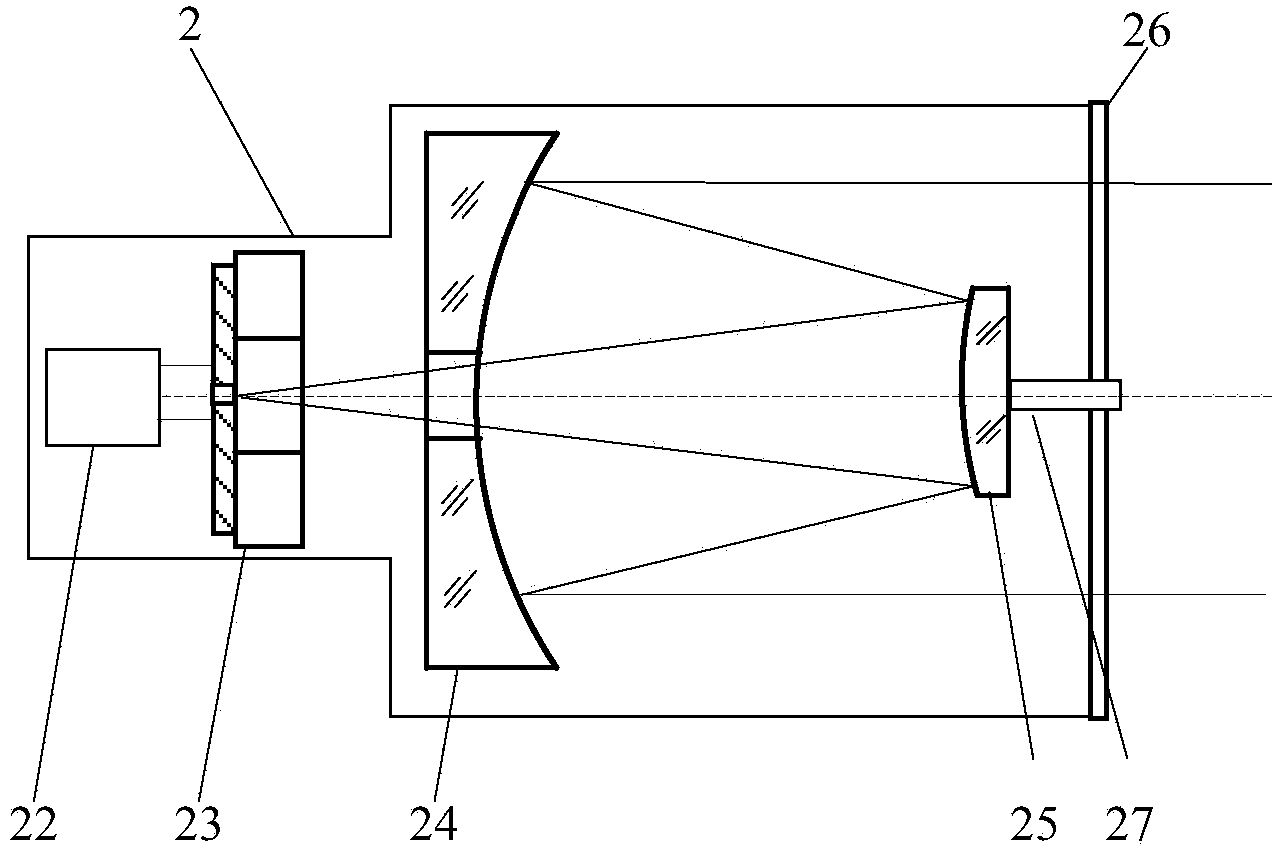

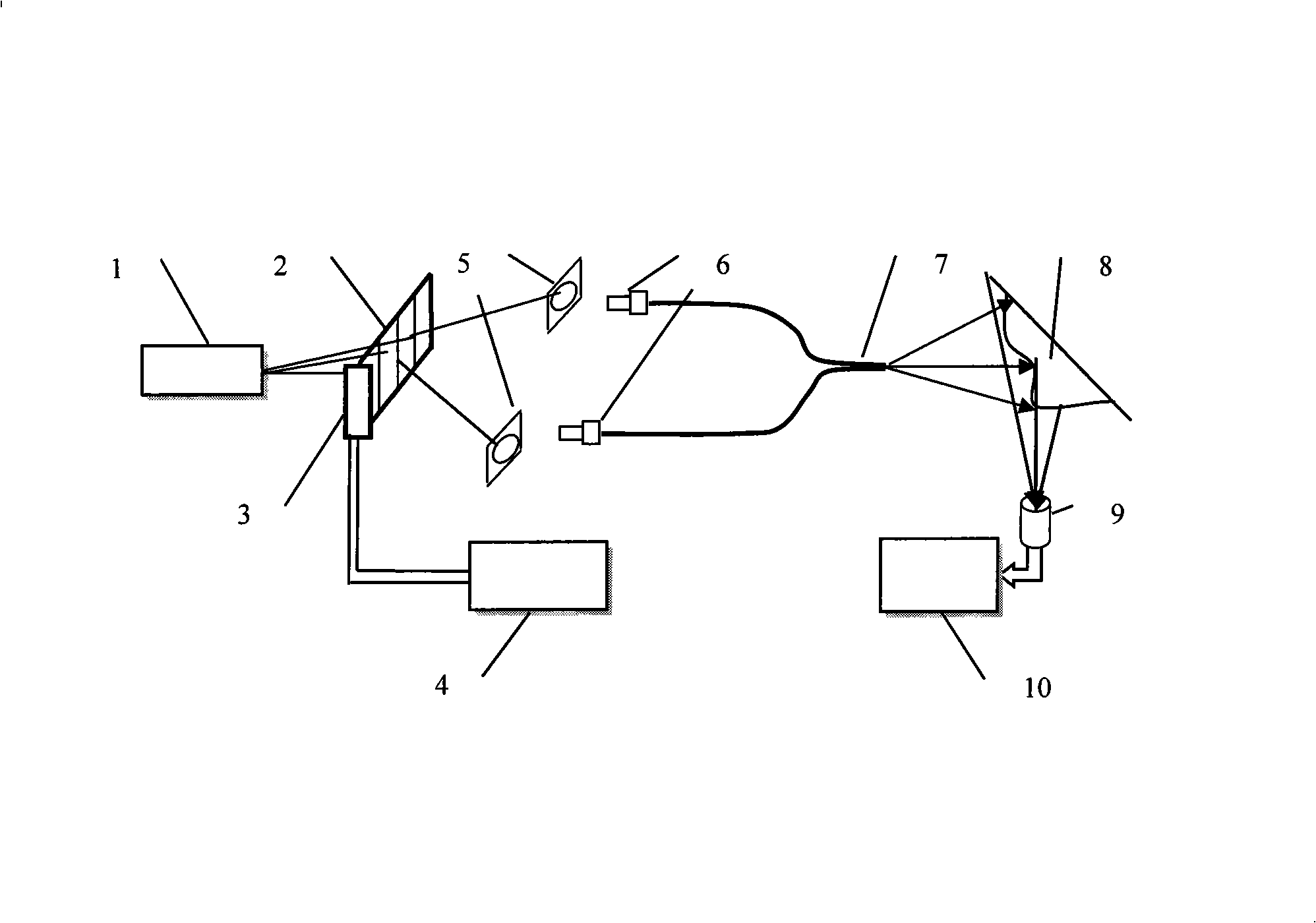

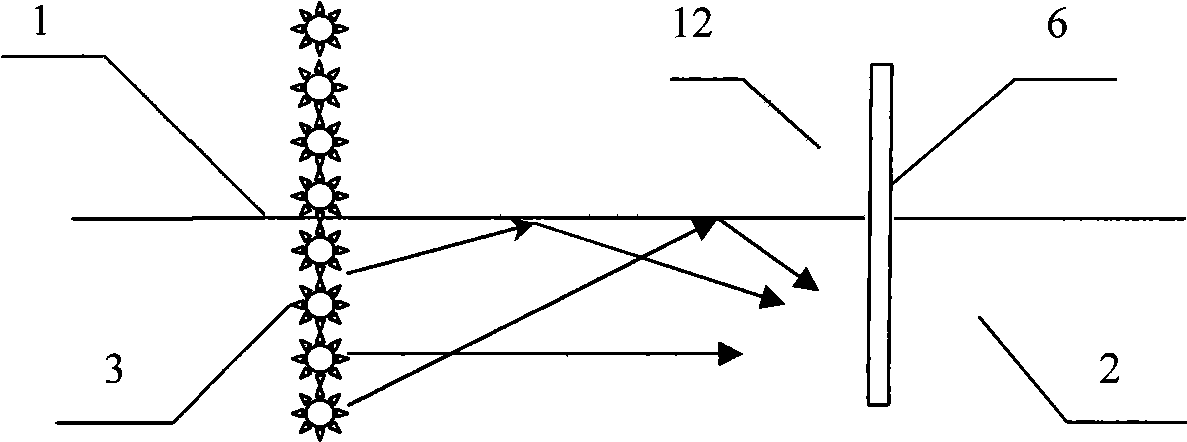

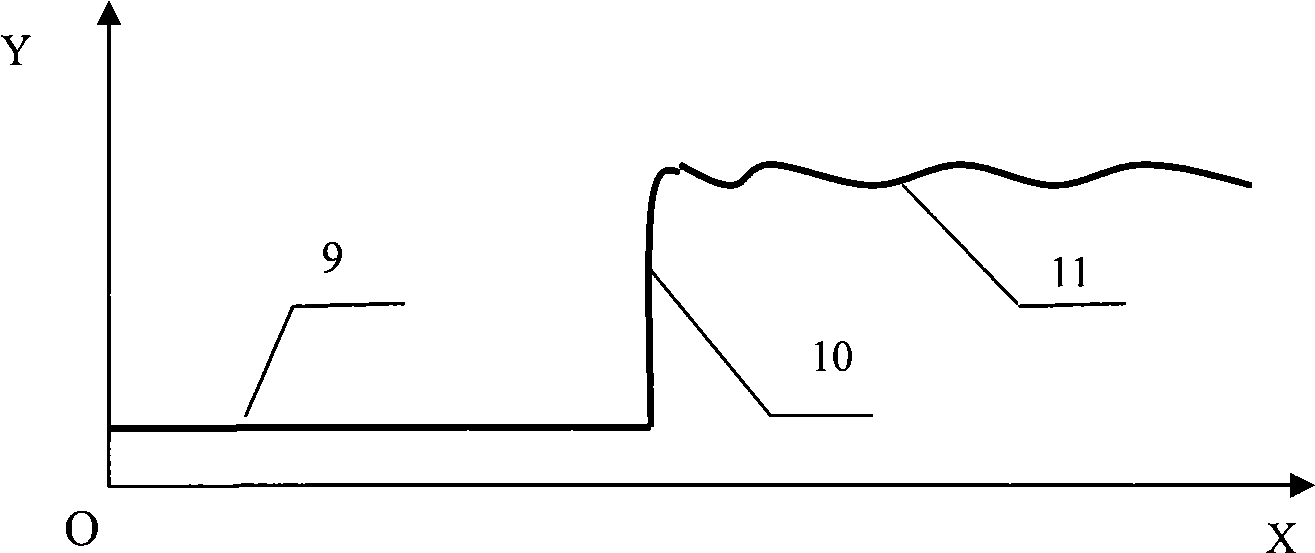

Two-dimensional dynamic angle measuring and calibrating method and device of scanning camera mirror

InactiveCN103884491ADoes not affect parallelismGuaranteed validityUsing optical meansTesting optical propertiesEffective solutionPhysics

The invention belongs to the technical field of optical precision measurement, and relates to a two-dimensional dynamic angle measuring and calibrating method and device of a scanning camera mirror. The two-dimensional dynamic angle measuring and calibrating method and device can be used for measuring and calibrating parameters of the scanning camera mirror in real time. According to the two-dimensional dynamic angle measuring and calibrating method and device, an infinite target generation system is used for generating an infinite target, the infinite target provides a target source for a scanning camera to be detected through the scanning camera mirror for detection, a two-dimensional dynamic angle measuring system is used for performing two-dimensional real-time measurement on the oscillation angle of the scanning camera mirror, a synchronous acquisition system is used for synchronously acquiring data of the scanning camera to be detected and data of the two-dimensional dynamic angle measuring system in real time, and the data of the two-dimensional dynamic angle measuring system are used for calibrating the scanning camera mirror. The two-dimensional dynamic angle measuring and calibrating method and device of the scanning camera mirror have the advantages of being high in speed, wide in range, free of contact and the like and provide an effective solution for measurement and calibration of the parameters of the scanning camera mirror.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

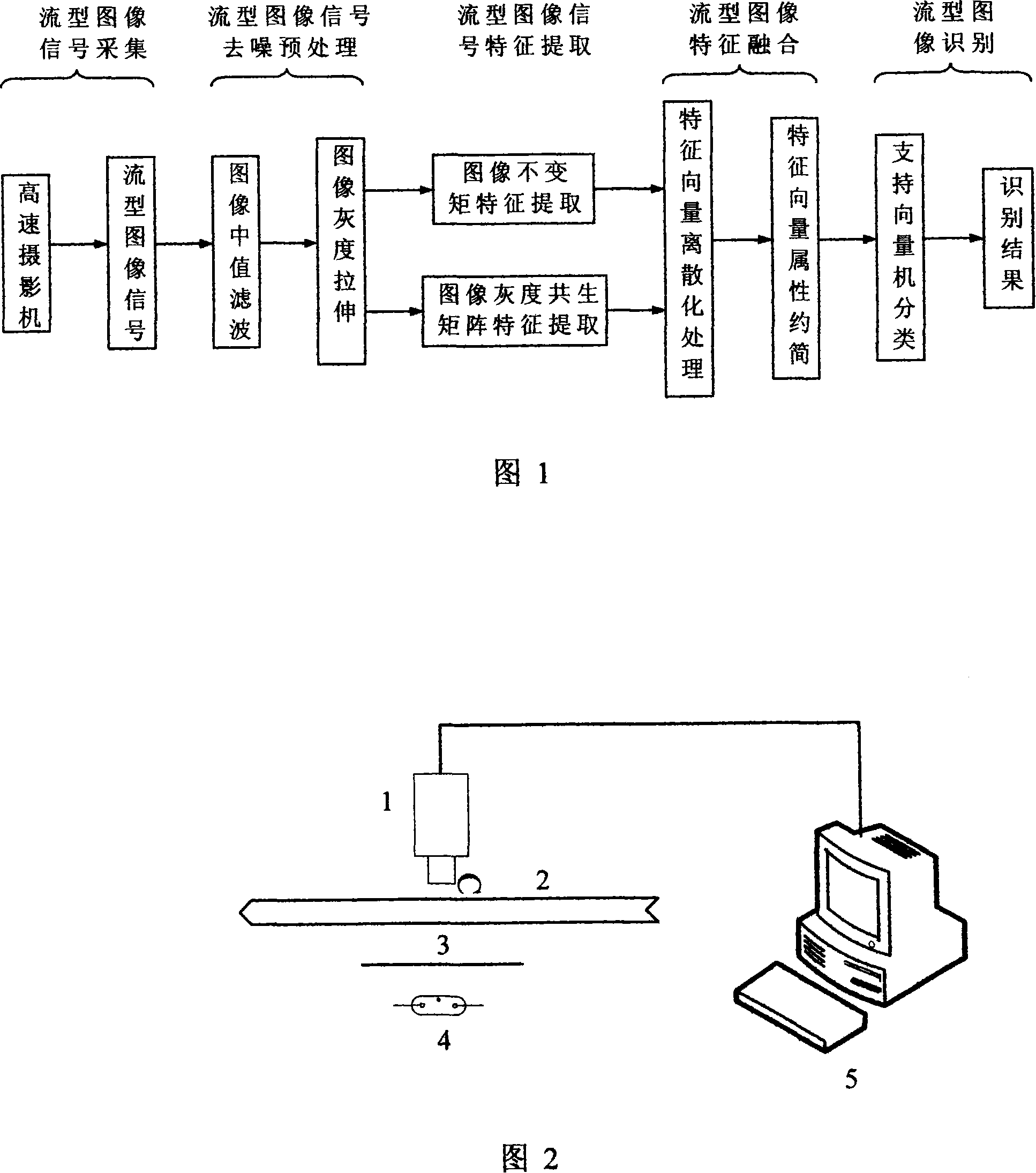

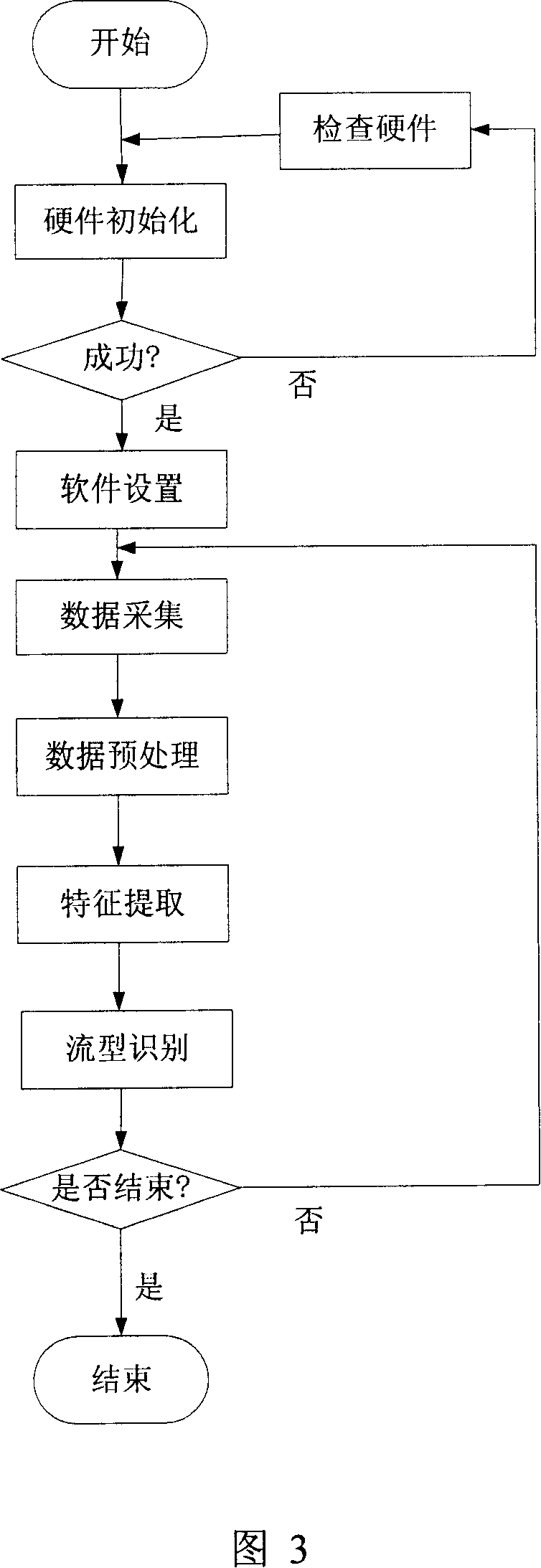

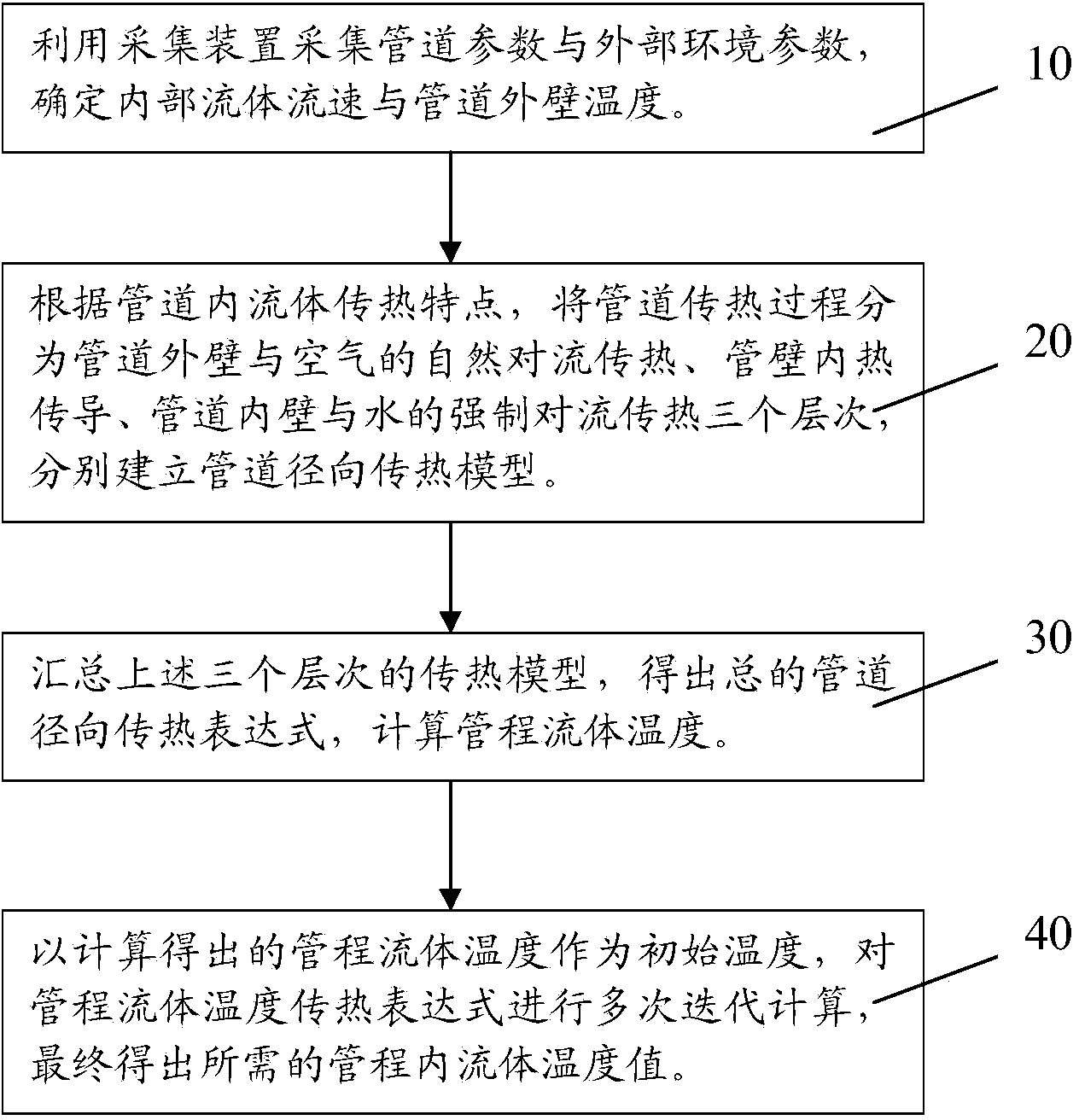

Gas-liquid two-phase flow type recognition method based on digital graphic processing technique

InactiveCN101140216ARealize non-contact measurementClear stream imageFlow propertiesCharacter and pattern recognitionCharacteristic spaceRough set

The invention relates to a gas-liquid two-phase flow pattern recognition method based on digital image processing technology, which is characterized in that the method uses a high-speed camera to gain the gas-liquid two-phase flow image in a horizontal pipeline under the different working conditions; the characteristics of invariant moment and gray level co-occurrence matrix of the image are extracted by the image processing technology; the characteristic fusion is implemented by using a rough set theory to reduce the characteristic dimensions, and the characteristic vector forms a flow pattern sample to implement the training for a support vector machine in order to complete the mapping from the characteristic space to the flow pattern space and finally realize the flow pattern recognition. The adopted rough set theory fuses image texture information and shape information, improves the recognition precision of a classifier, simultaneously reduces the training time, and can roundly reflect the characteristics of flow pattern image; the dependent degree and the generalization capacity of the flow pattern recognition method of the support vector machine for the sample data are better than the BP neural network; the invention has the shorter training time, and is applied to the flow pattern online recognition.

Owner:NORTHEAST DIANLI UNIVERSITY

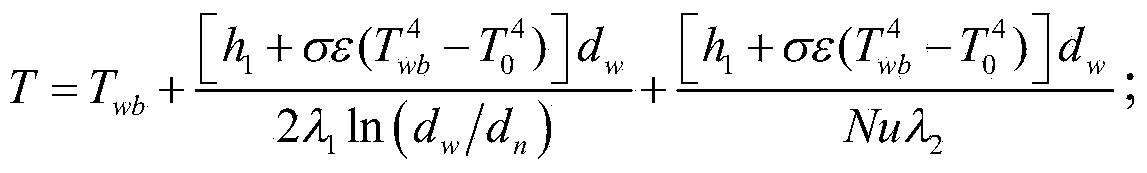

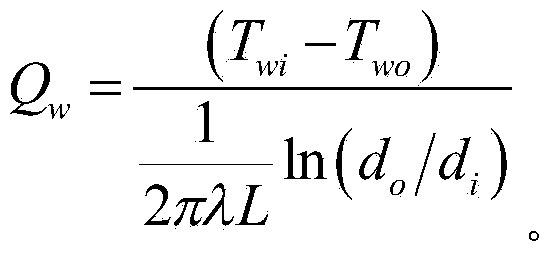

Non-contact tube pass fluid temperature measuring method based on temperature measurement of pipeline outer wall

ActiveCN104062034ARealize non-contact measurementEnables non-destructive measurementsTemperature measurement of flowing materialsThree levelNatural convection

Owner:SHENZHEN TAIKE TEST

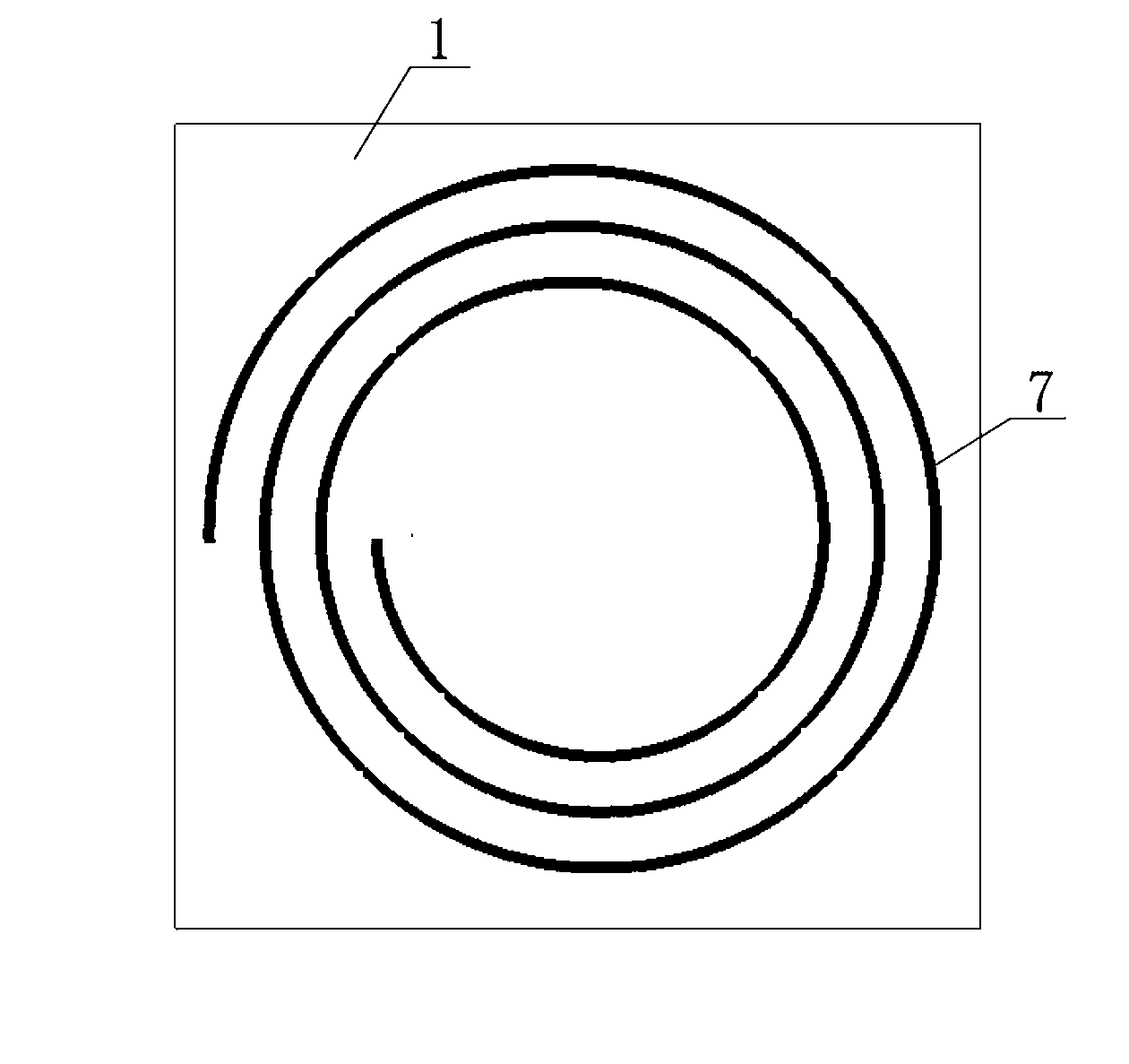

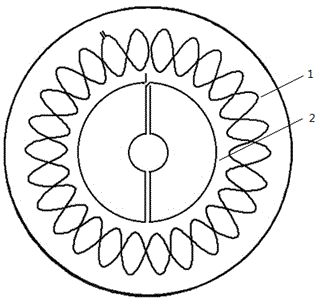

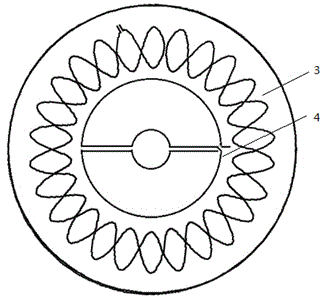

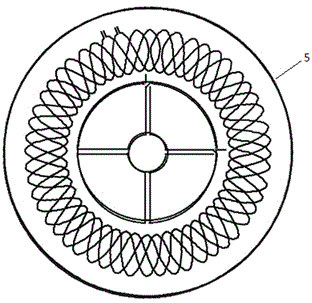

PCB coil and angle measuring method for electromagnetic induction type angle sensor apparatus

ActiveCN104061854ANo friction lossHigh precisionUsing electrical meansConverting sensor outputReceiver coilElectromagnetic induction

The invention discloses a PCB coil and an angle measuring method for an electromagnetic induction type angle sensor apparatus. The PCB coil and the angle measuring method for the electromagnetic induction type angle sensor apparatus comprise a receiving coil for receiving a signal sent by a rotor reflection coil, an excitation magnetic field rotor reflection coil for receiving stator transmitting coil, and the stator reflection coil for sending an excitation signal to the rotor reflection coil; the receiving coil and the stator transmitting coil are connected and fixed to a stationary rotation shaft, the rotor reflection coil is arranged on a sensor rotor, the three coils are coaxially and fixedly arranged in parallel, the rotor reflection coil comprises an annular coil portion and a copper portion, and the annular coil portion and the copper portion are fan-shaped. The PCB coil and the angle measuring method for the electromagnetic induction type angle sensor apparatus can implement non-contact angle measurement, has the advantages of high accuracy, low cost, installation convenience, maintenance and management easiness and low environmental requirements, can accurately, stably and quickly complete tasks and solves many problems such as reliability, accuracy and cost of angle measurement methods.

Owner:杭州兆鼎科技实业有限公司

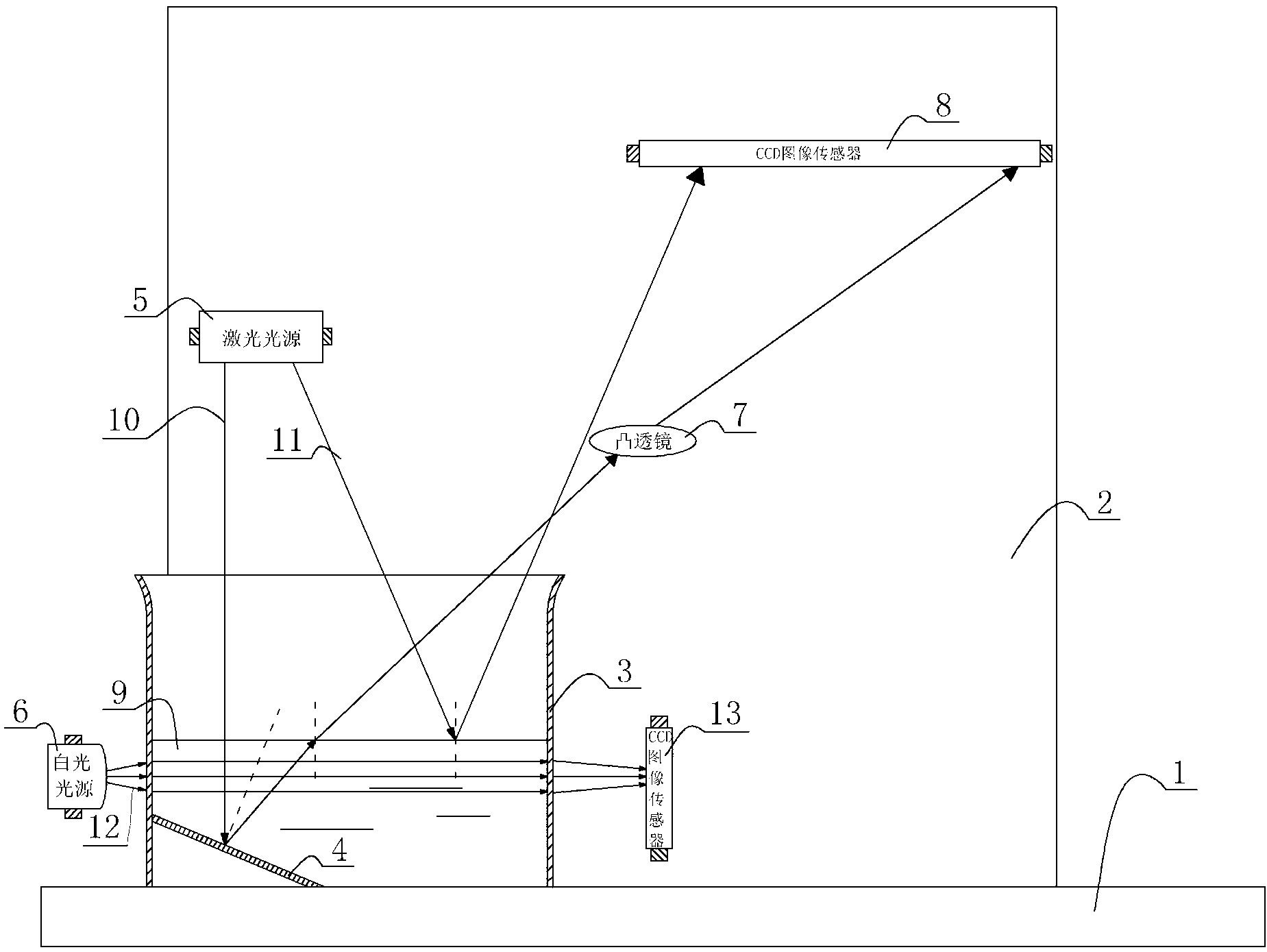

Solution information acquisition device

InactiveCN103278212AEfficient analysisRealize non-contact measurementVolume measurement apparatus/methodsPhase-affecting property measurementsLight irradiationLight beam

The invention relates to a solution information acquisition device which comprises a base and a circuit part. A vertical plate is fixed on the base. The solution information acquisition device is characterized in that a vessel is disposed on the base, a laser source, a white light source, a first CCD (charge coupled device) image sensor and a second CCD image sensor are disposed on the vertical plate and above the vessel, the laser source is used for generating vertical light beams and oblique light beams, the white light source is used for generating white light beams, an oblique reflector is fixed at the bottom of the vessel, the vertical light beams focused by a convex lens and the oblique light beams reflected by to-be-measured solution irradiate on the first CCD image sensor, and the white light beams penetrate the to-be-measured solution and irradiate on the second CCD image sensor. By light irradiation position measuring through the first CCD image sensor, concentration of known solution can be measured accurately, and pollution caused by solution sampling is avoided. In addition, non-contact measuring has evident advantages in measuring of toxic and corrosive solution.

Owner:燕宸

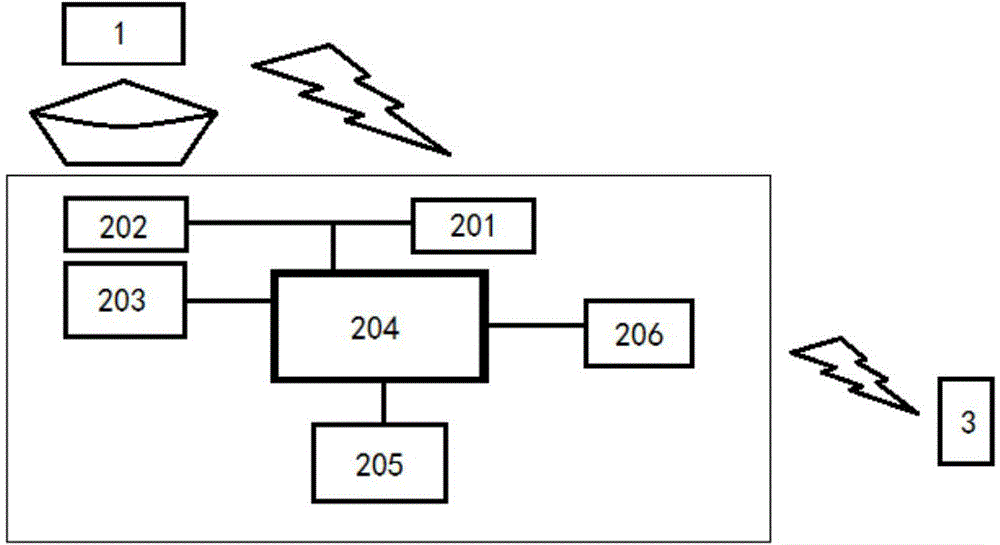

Networked parameter variable controlled intelligent electromagnetic oven and intelligent cooking method

InactiveCN104913351ARealize non-contact measurementSimple structureDomestic stoves or rangesLighting and heating apparatusWireless controlThe Internet

The invention discloses a networked parameter variable controlled intelligent electromagnetic oven and an intelligent cooking method. The intelligent electromagnetic oven comprises an electromagnetic oven body, and an intelligent module integrated on the electromagnetic oven body. The intelligent module comprises a wireless temperature and pressure measurement data receiving module, a pan bottom temperature measuring module, an electromagnetic oven power control module, an MUC processor module, a storage module and a wireless control module, wherein the pan bottom temperature measuring module and the wireless temperature and pressure measurement data receiving module respectively collect and receive pan bottom temperature data and temperature / pressure data inside the pan, and send the data to the MUC processor module; the MUC processor module stores the data into the storage module and synchronously sends the data to a mobile terminal or a back end. The intelligent electromagnetic oven consists of the wireless temperature and pressure measurements, the parameter variable controlled electromagnetic oven, a smart phone, and a cloud menu server, thereby being capable of finishing the intelligent cooking, and sharing the cooking menu online through the Internet, so as to achieve different interactions.

Owner:NANJING LEIZHI ELECTRONICS TECH CO LTD

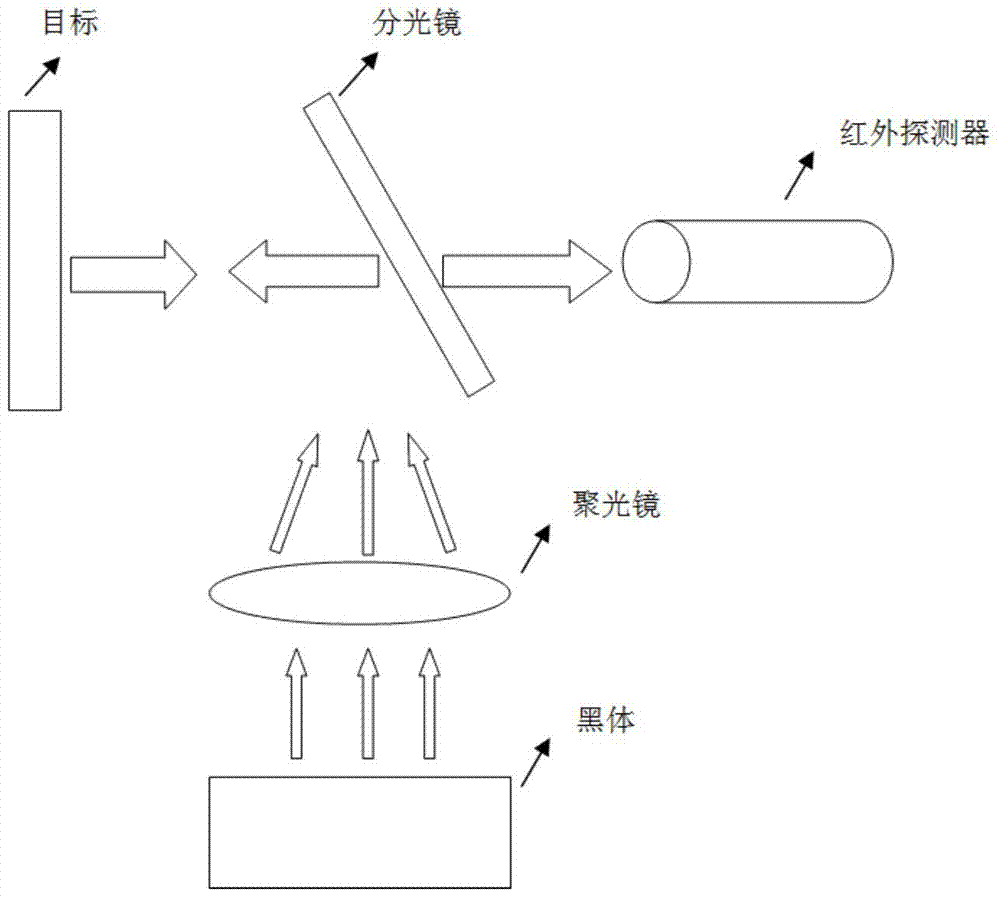

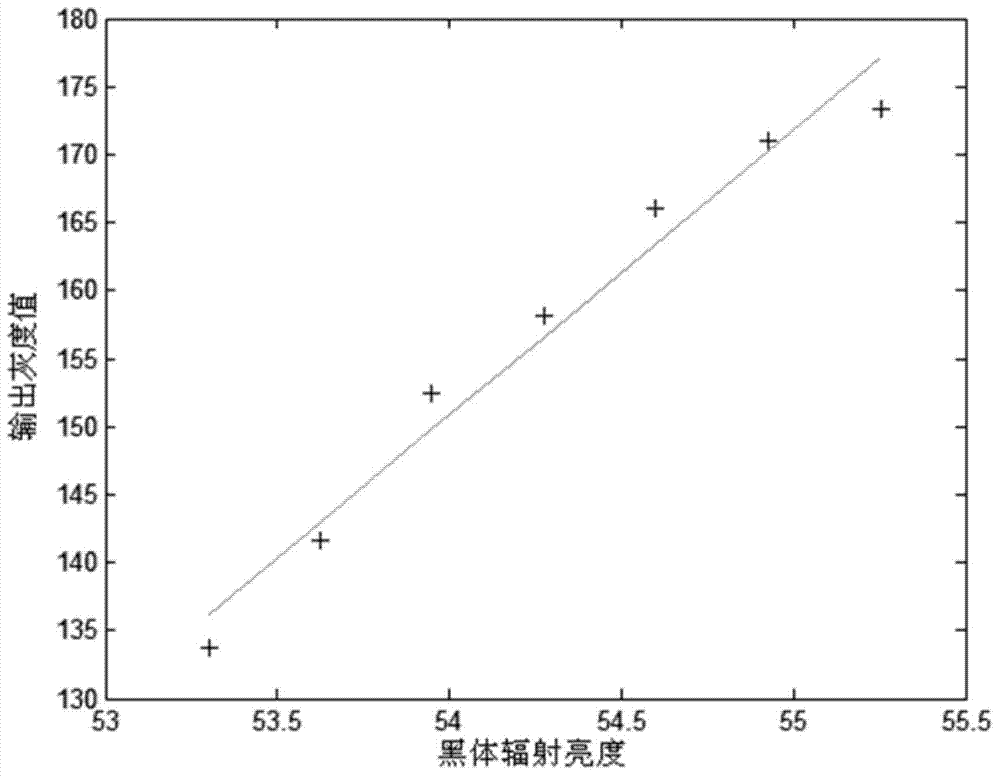

Site target emissivity measuring system and method based on environmental radiation change

InactiveCN104266762ARadiation characteristics do not changeDoes not change the temperature fieldPyrometry using electric radation detectorsEmissivityOptical axis

The invention discloses a site target emissivity measuring system and method based on the environmental radiation change. The system comprises a target, a spectroscope and an infrared detector, wherein the target, the spectroscope and the infrared detector are sequentially arranged in the optical path direction and located on the same optical axis. The system further comprises a black body and a collecting lens. Radiation light of the black body converges on the spectroscope through the collecting lens, is reflected to the target through the spectroscope, acts on the target, then is reflected to the spectroscope and reaches the detector. The method includes the steps that firstly, radiometric calibration is conducted on the infrared detector; a system response function is established with the radiation of the black body serving as the standard; an output response value V1 of the infrared detector is measured under the condition of the environmental radiation intensity Vs1; an output response value V2 of the infrared detector is measured when the condition is changed into the environmental radiation intensity Vs2; according to the output response values measured under the two different radiation intensity conditions of the infrared detector, the reflectivity and the emissivity of the target are calculated. According to the system and method, necessary parameters are provided for infrared radiation non-contact accurate temperature measurement.

Owner:NANJING UNIV OF SCI & TECH

Accurate measurement apparatus and method for workpiece surface appearance

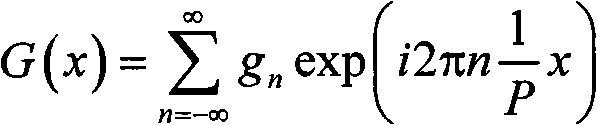

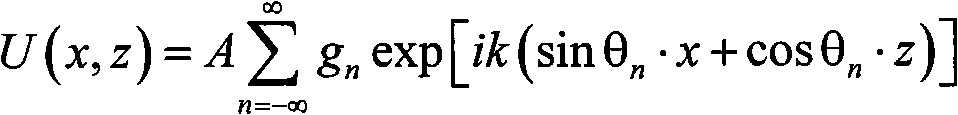

InactiveCN101403608AHigh measurement accuracyIncrease contrastUsing optical meansHigh contrastMeasurement device

The invention provides a precision measurement device and a measuring method based on workpiece surface appearance. Emergent light of a laser generates multi-level diffraction light after passing through a grating, the plus or minus 1 level diffraction facula is coupled into two fibers through a focus lens, two coherent point light sources are formed at the exit end of the fiber; the light beams emitted by two fiber point light sources have the same light intensity, therefore, a high contrast interference stripe is obtained and projected on the workpiece; when a piezoelectric ceramic drives the grating to carry out sinusoidal vibration, the position of the plus or minus 1 level diffraction facula coupled into two fibers is not changed, but the phase of the interference stripe generated by two fiber point light sources changes periodically; and the interference stripe image on the workpiece surface is acquired by a high-speed CCD image sensor, and the phase change of the interference stripe image is accurately measured by a sinusoidal phase algorithm. The invention overcomes influence to the object surface profile precision measurement by the light intensity and the wave motion of wavelength, and achieves the characteristics of the large measuring range, high precision and non-contact measurement.

Owner:HARBIN ENG UNIV

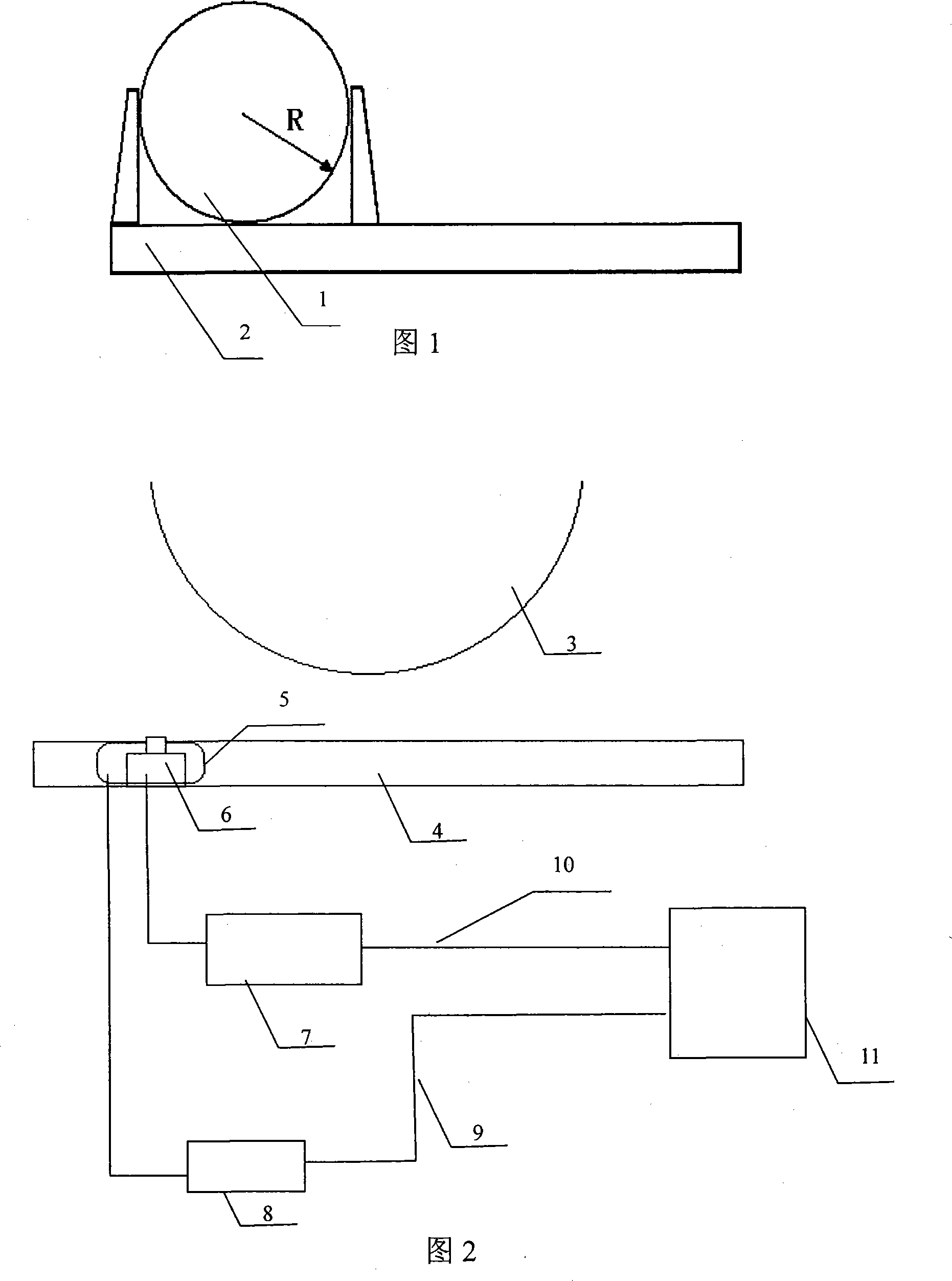

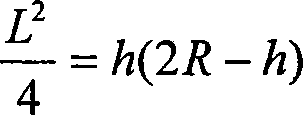

Device for non-contact measuring curvature radius with laser displacement sensor

InactiveCN101113895ARealize non-contact measurementSimple structureUsing optical meansMeasurement deviceGrating

A device that adopts a laser displacement sensor for achieving non-contact measurement of curvature radius is a curvature radius measurement device in the field of optoelectronic measuring technology. The technical problem of the invention to be solved is that the device adopting laser displacement sensor for achieving non-contact measurement of curvature radius is provided. The technic proposal of the invention includes a grating stator, a grating dynamic device, a laser displacement sensor, a processor, a grating data acquisition card and computer. The grating dynamic device can move along the direction of the length, the grating dynamic device is connected with the grating data acquisition card by wire, the output of the grating data acquisition card is connected with the input of the computer; the laser displacement sensor is arranged on the movable grating dynamic device and moves along with the grating dynamic device, the measurement head of the laser displacement sensor is towards to the measured workpiece, the output of the laser displacement sensor is connected with the input of the processor, the output of the processor is connected with the input of the computer. The device can measure large curvature radius.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

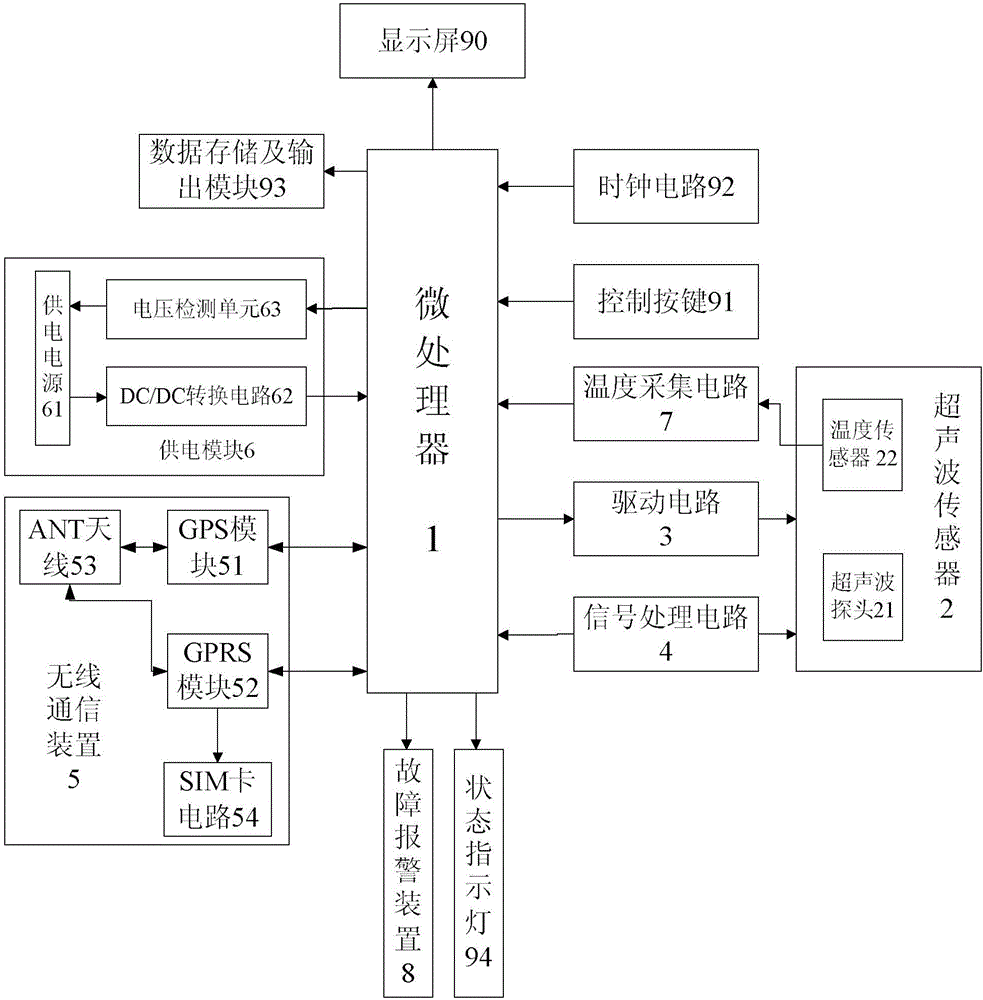

Ultrasonic oil conservator oil level detector for power transformer

InactiveCN105043506ARealize non-contact measurementNot affectedTransmission systemsMachines/enginesSignal processing circuitsUltrasonic sensor

The invention relates to the technical field of a transformer detecting device, and particularly to an ultrasonic oil conservator oil level detector for a power transformer. The ultrasonic oil conservator oil level detector comprises a microprocessor, an ultrasonic sensor, a driving circuit, a signal processing circuit, a wireless communication device and a power supply module. The driving circuit and the signal processing circuit are respectively connected between the ultrasonic sensor and the microprocessor. The wireless communication device is connected with the microprocessor in a TTL serial-port manner. The ultrasonic oil conservator oil level detector for the power transformer has beneficial effects of 1, realizing noncontact measurement for the oil level of a transformer oil conservator; 2, realizing fixed-point detection and continuous detection at different points; 3, realizing fixed-position fixed mounting, remote control and movable temporary detection; and 4, realizing no protection and no effect by light and an ambient medium and relatively low cost compared with other infrared, laser or radioactive detecting mode.

Owner:林 聪

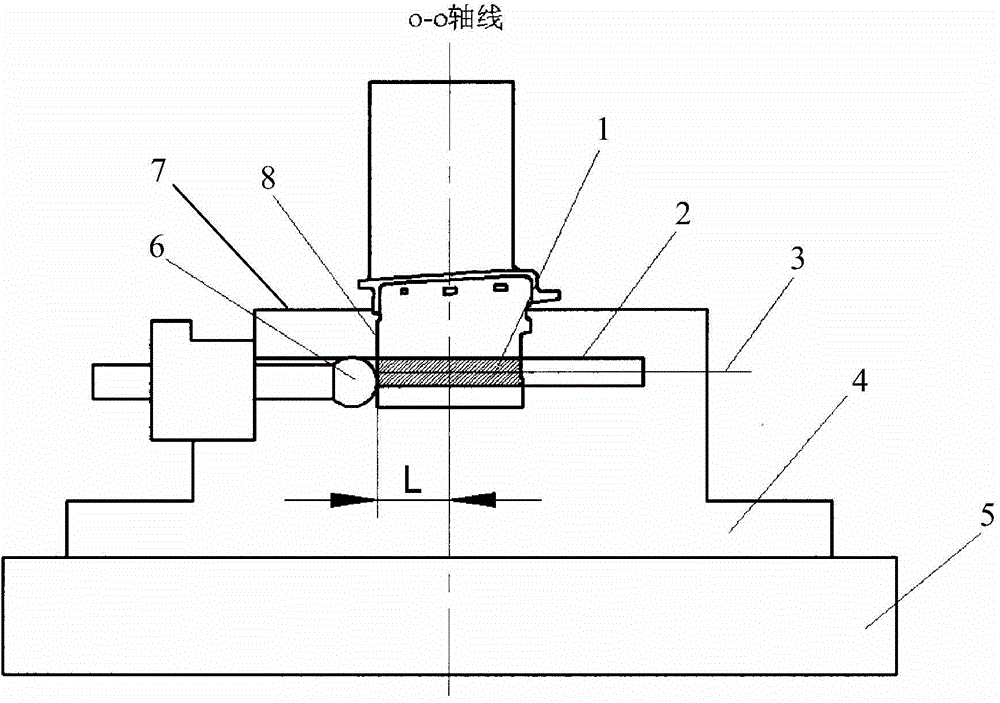

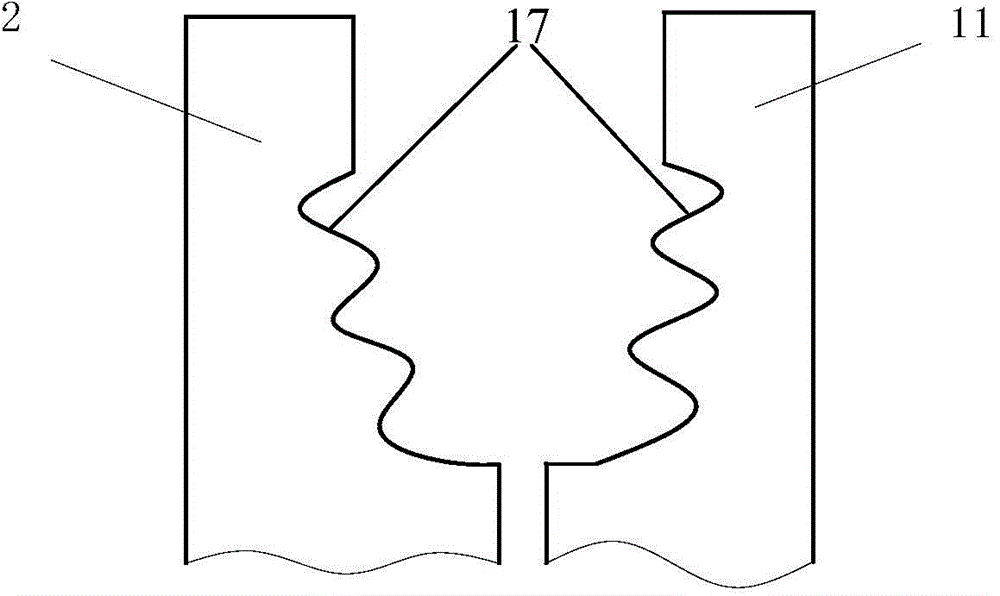

Method for measuring diameter and coordinate position of spatial curved surface micro-hole in non-contact mode

ActiveCN103557802AFix extraction issuesSolve the rotation positioning problemUsing optical meansAviationComputational physics

The invention belongs to the field of measurement of the diameter and the space coordinate geometric dimensioning of a spatial curved surface thin-wall micro-hole, and relates to a method for measuring the diameter and the coordinate position of the spatial curved surface micro-hole in a non-contact mode, in particular to the method for measuring the diameter and the coordinate position of the spatial curved surface micro-hole in a blade body of a blade by compositely designing and applying a telecentric optical lens and a five-axis coordinate measurement machine. A contact-type probe of the five-axis optical composite coordinate measurement machine is used for setting up a measuring basis of the diameter and the coordinate position of the spatial curved surface micro-hole of a workpiece, a two-dimensional rotating table is used for determining a spatial posture according to the direction of the axis of the spatial curved surface micro-hole, and the telecentric optical lens is used for extracting an image of the spatial curved surface micro-hole. The method can solve the difficult technical problem that data extraction and evaluation can not be conduced due to the fact that the image of the micro-hole is blurred, digitalized precise measurement of the diameter and the coordinate position of the spatial curved surface micro-hole is achieved, and the feasible measurement method is provided for effectively controlling machining quality of a gas film hole of the blade of an aviation engine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

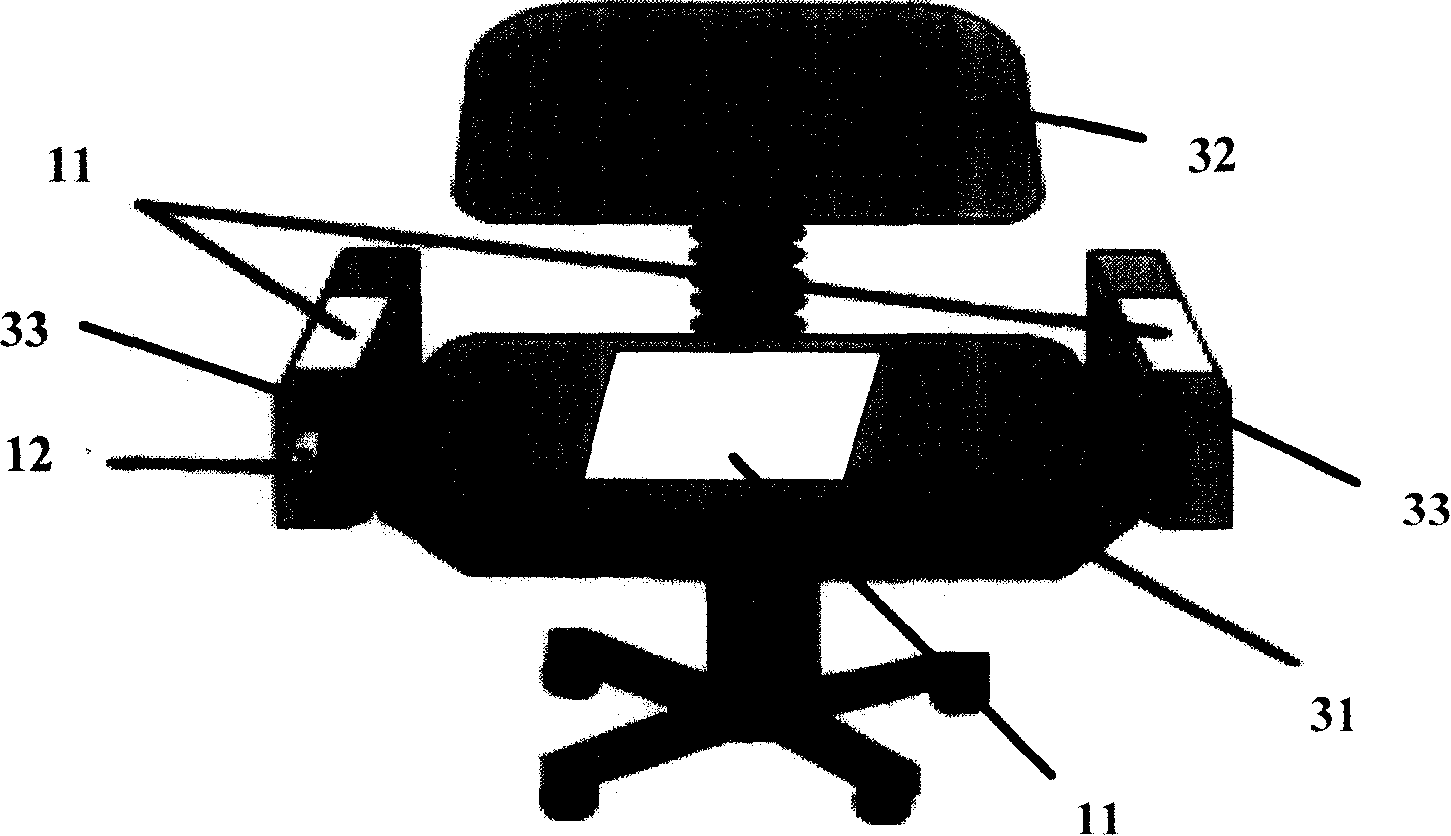

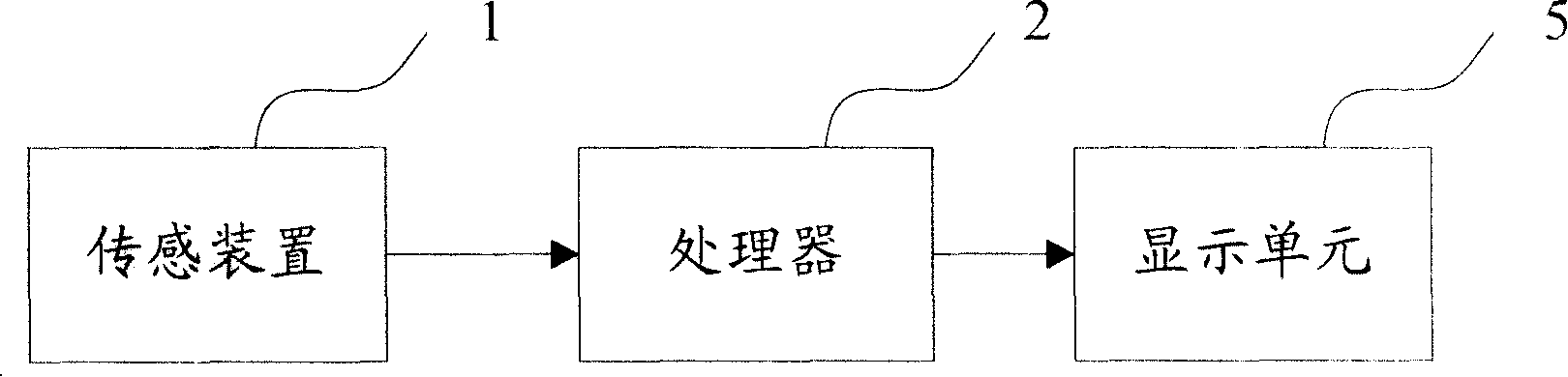

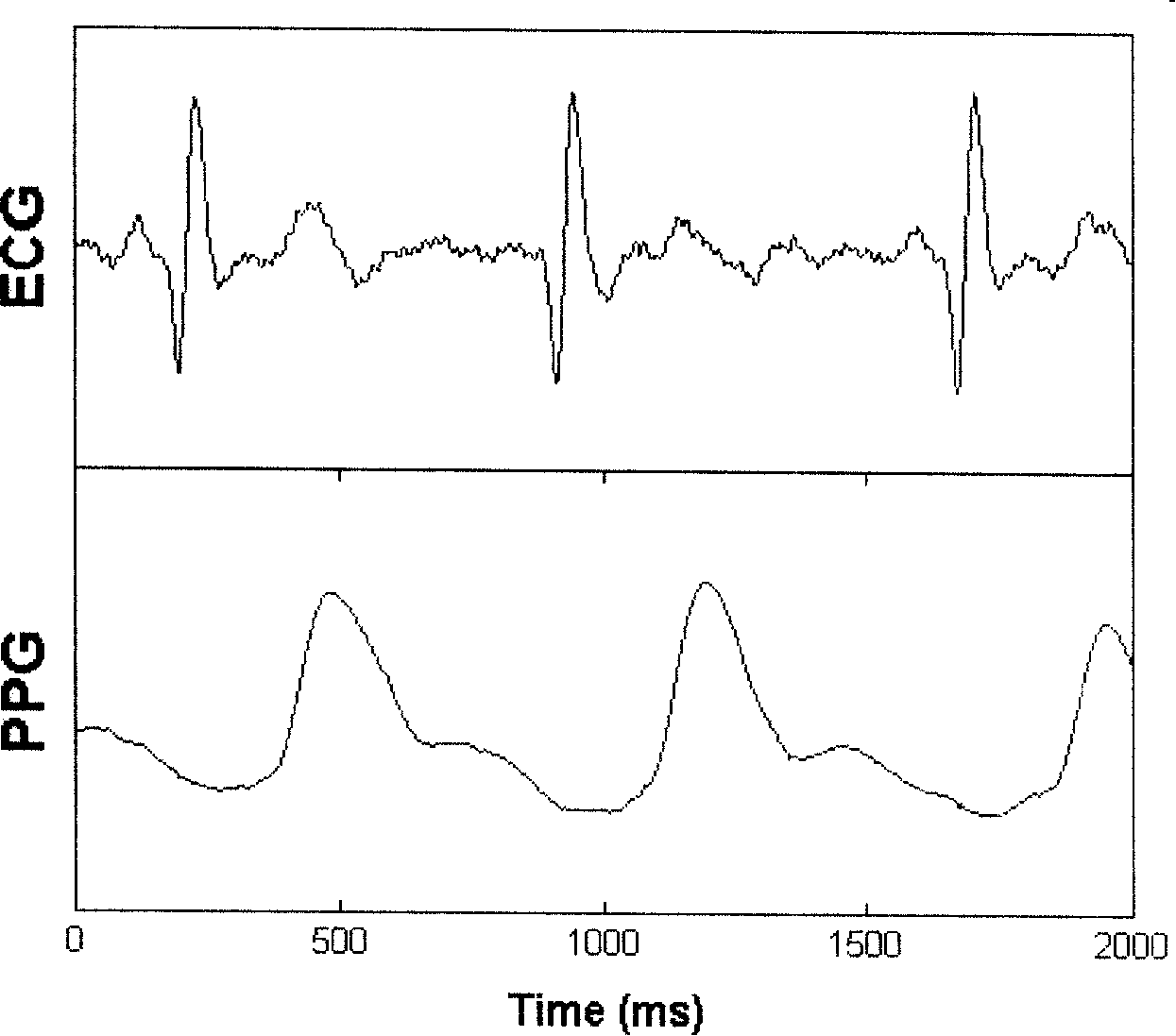

Physiological parameter measuring apparatus

InactiveCN101234016AEasy to operateVersatileDiagnostic recording/measuringSensorsMeasurement deviceEngineering

The invention relates to and discloses a measurement device for physiological parameters, which comprises a sensing device, a processor and a seat. The sensing device is fixed on the seat to collect physiological signals of users; the processor is connected with the sensing device to receive the physiological signals collected by the sensing device and to deal with the corresponding physiological parameters obtained by the physiological signals. The invention provides the measurement device for physiological parameters, which can simplify operating procedures, facilitate the convenient for the users operation and possess good generality.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

Intelligent light source linear array CCD liquid level measuring method and device

InactiveCN101509801AHigh strengthReduce intensityMachines/enginesLevel indicatorsLiquid temperatureLiquid level measurement

The invention discloses an intellectualized light source linear array CCD liquid level measurement method and a measurement device. By using a feedback measurement structure, the method can obtain a result of comparably high precision through measurement of twice or a plurality of times and the intellectualized regulation of the light source. The device mainly consists of a point-to-point switch controllable linear array light source, a linear array CCD, a control circuit, etc. During the measurement of liquid level, all the luminous points on the linear array light source intelligently complete primary measurement scanning and determine the basic position of liquid level; the partial luminous points on the linear array light source are closed so as to complete the accurate measurement of liquid level. The intellectualized light source linear array CCD liquid level measurement method is a liquid level measurement method with higher precision and also an optical liquid level measurement method needing no optical imaging lenses, and has the advantages of little effect on the precision by the temperature change and concentration change of liquid, relatively simple structure, easiness for arrangement and the capability of working under corrosiveness and other vile industrial environments, etc. If a receiving device is arranged outside a transparent container, non-contact measurement can be realized.

Owner:如皋市生产力促进中心

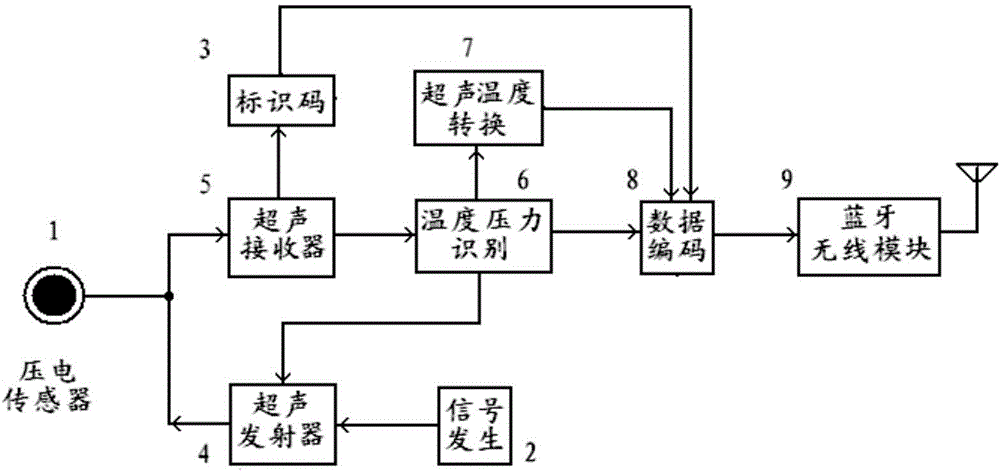

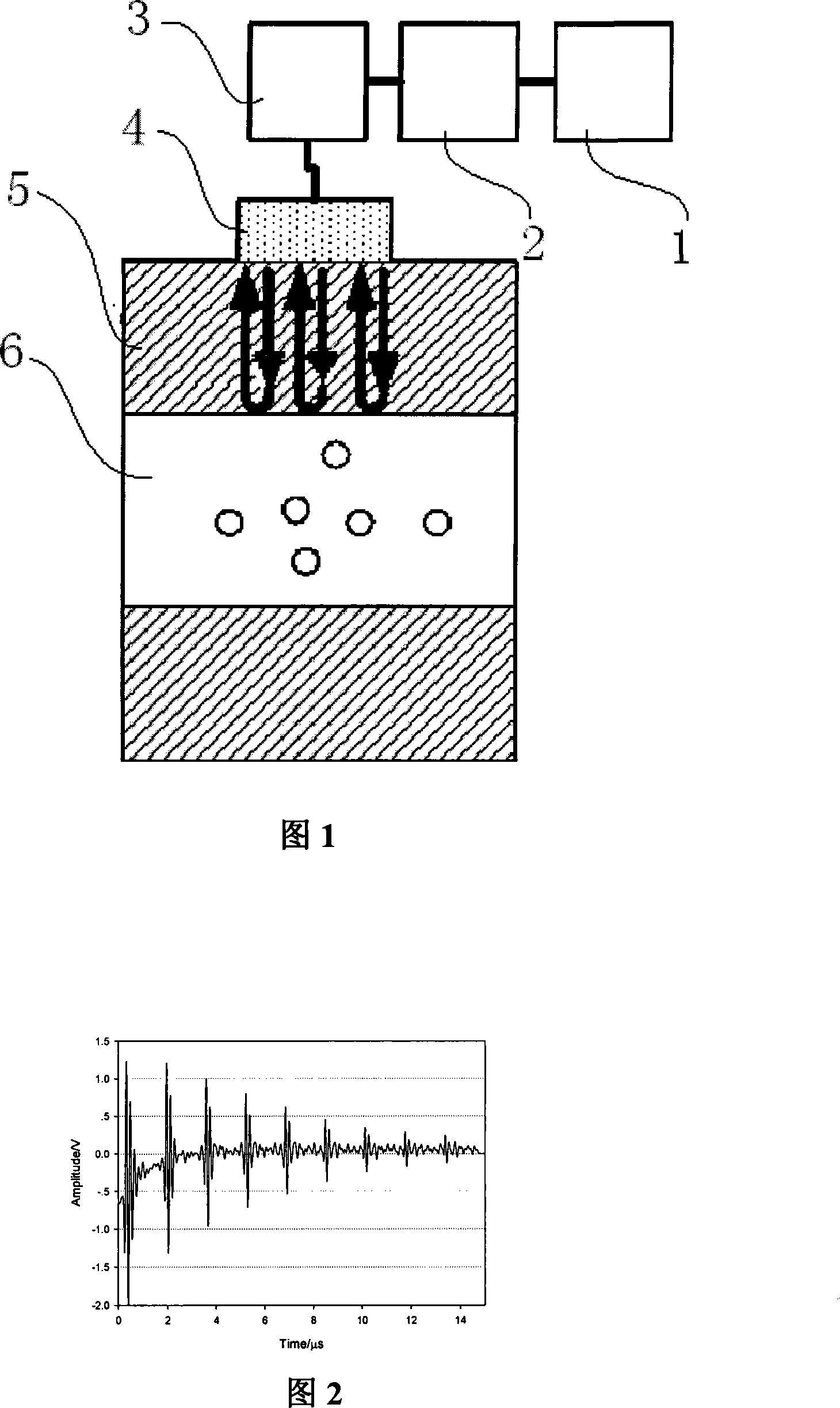

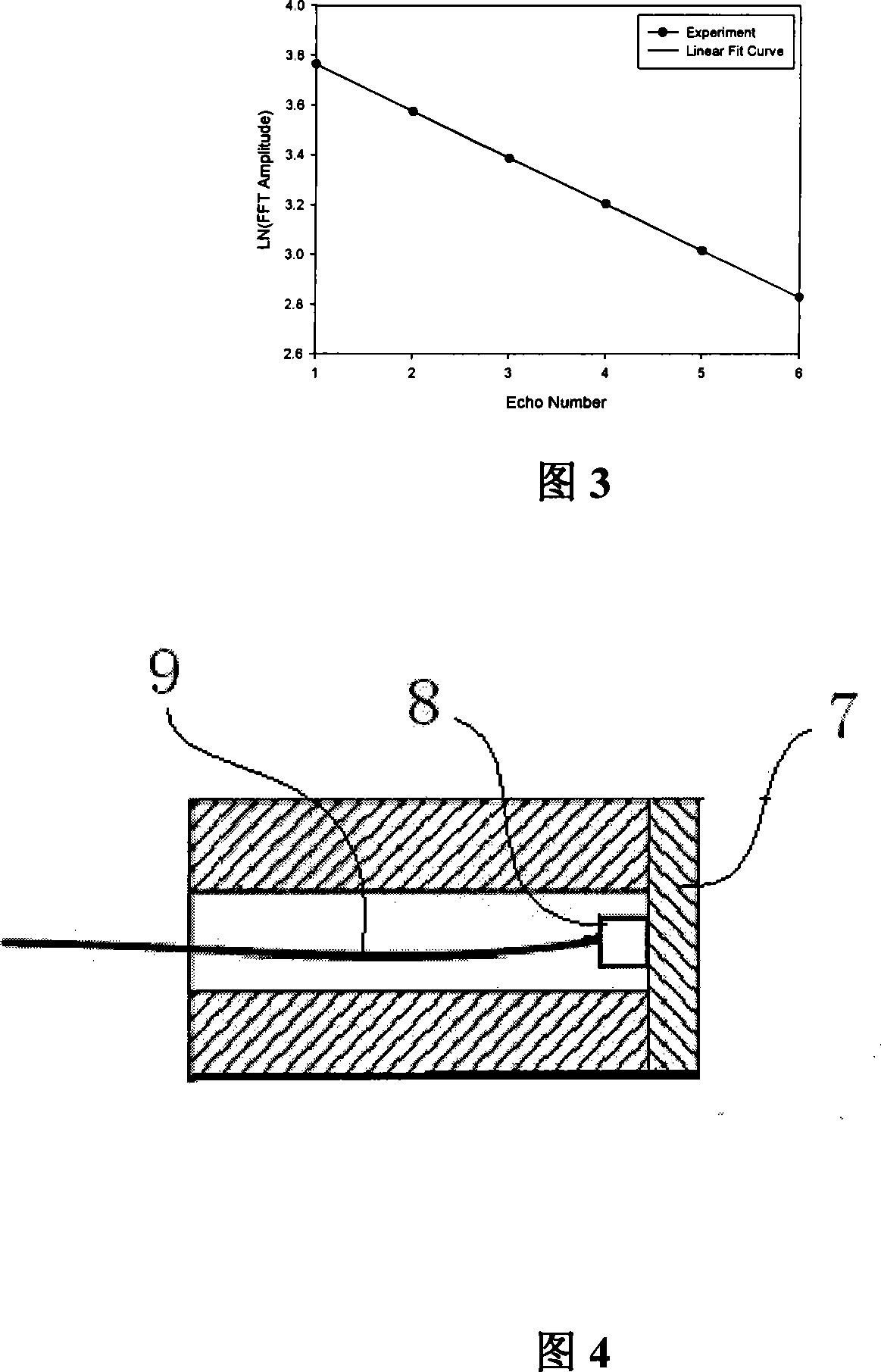

Method and device for measuring discrete state granule graininess distribution

InactiveCN101169364ARealize non-contact measurementDetection fitAnalysing fluids using sonic/ultrasonic/infrasonic wavesParticle size analysisSignal processing circuitsMeasurement device

The invention discloses a method and a measuring device thereof for measuring the granularity distribution of the particle in the discrete state, and the method and the measuring device thereof to the technical field of ultrasonic measurement. The invention aims at solving the technical problem of non contact measurement of the distribution of the particle granularity in the discrete state. The measuring device includes a computer which applies a complex wave number, a objective function, a distillation function and other calculation formulas to optimize the calculate the distribution of the particle granularity, a signal process circuit which is connected with the computer, a pulse wave launch / receive circuit which is connected with the signal process circuit, a broadband transducer which is connected with the pulse wave launch / receive circuit, and broadband transducer is arranged at the external side of a test plate. The measuring device is controlled by the computer, and the launch circuit sends out a pulse signal; a trigger transducer sends out the sound wave which is reflected by the wall of the test plate for a plurality of times and then is received by the transducer, and then the signal process circuit amplifies the signal, the high speed module coverts the signal and sends to the computer for processing. The invention is characterized in that the invention can completely realize the non contact measurement, and measure the high consistency and the two-phase flow of the high attenuation particle on line.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

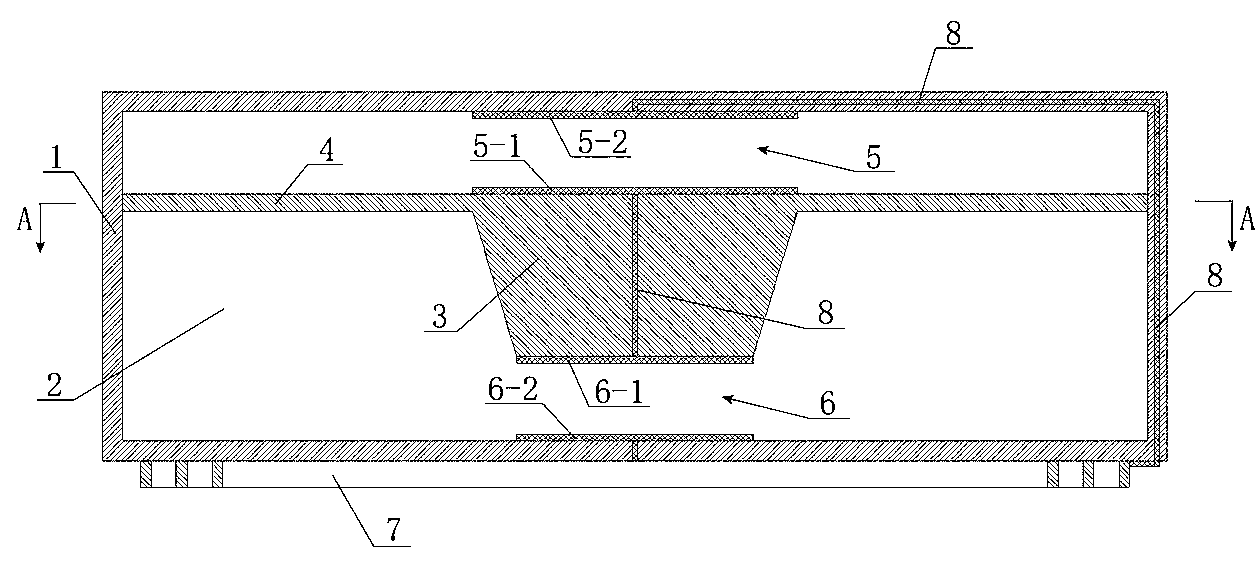

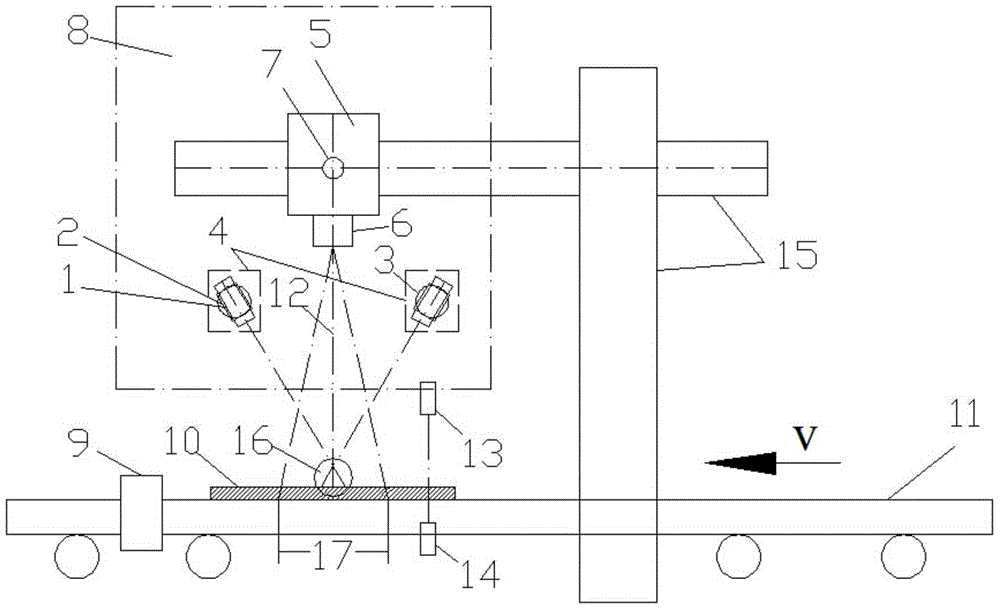

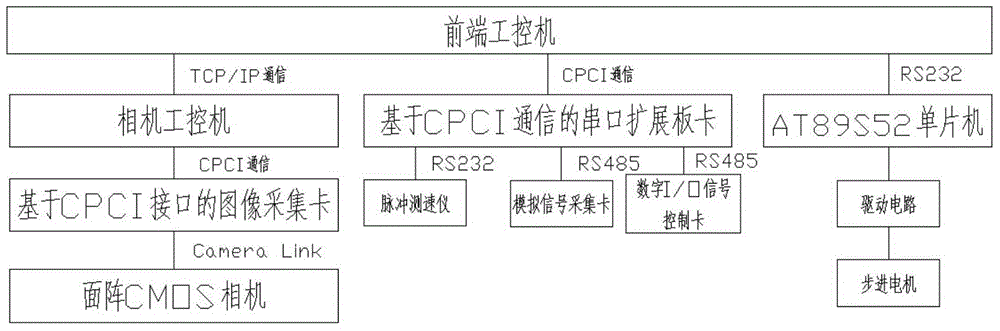

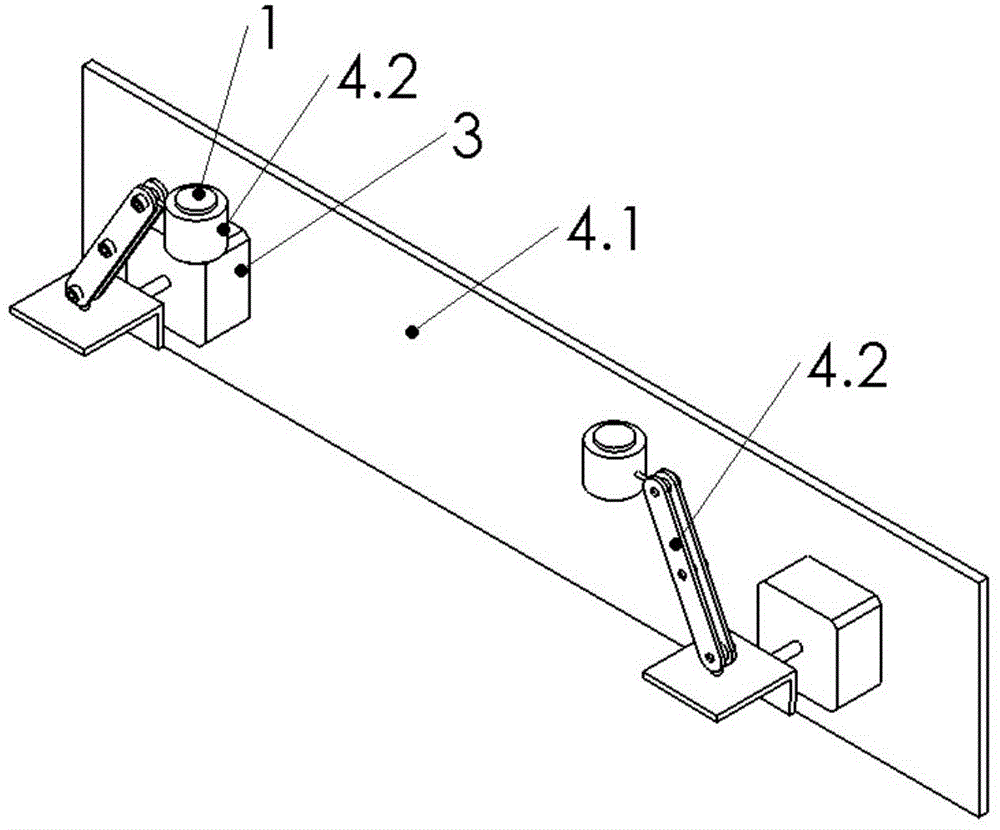

Medium or heavy steel plate morphology detection system based on controllable symmetrical double-line laser angle and method thereof

InactiveCN104833317ACalibration method is simpleImprove detection resolutionUsing optical meansCamera lensCMOS

The invention discloses a medium or heavy steel plate morphology detection system based on a controllable symmetrical double-line laser angle, and a method thereof. A sensor cabinet is internally provided with two planar array CMOS cameras in an equal-height plane. Each planar array CMOS camera is provided with a camera lens and furthermore is fixed on a bracket through a mounting device. Two sides of the planar array CMOS camera are respectively provided with a linear laser source. A pulse speed testing velocimeter is fixed at the side of a conveyor belt. The to-be-measured medium or heavy steel plate is placed on the conveyor belt. The to-be-measured medium or heavy steel plate is provided with the laser ray overlapping area of the symmetrical linear laser sources. Correlation is formed between a photoelectric switch transmitter and a photoelectric switch receiver. The sensor cabinet is placed on a bracket. A detecting device is controlled by a control device. According to the medium or heavy steel plate morphology detection system, simple calibration method is realized in detecting by two symmetrical linear laser sources, and furthermore high detection resolution and high precision are realized. The detecting system with two symmetrical linear laser sources is adopted, thereby realizing large incident angle of the linear laser, preventing detection inflection point failure, reducing drift and ensuring accurate and reliable result.

Owner:ZHEJIANG SCI-TECH UNIV

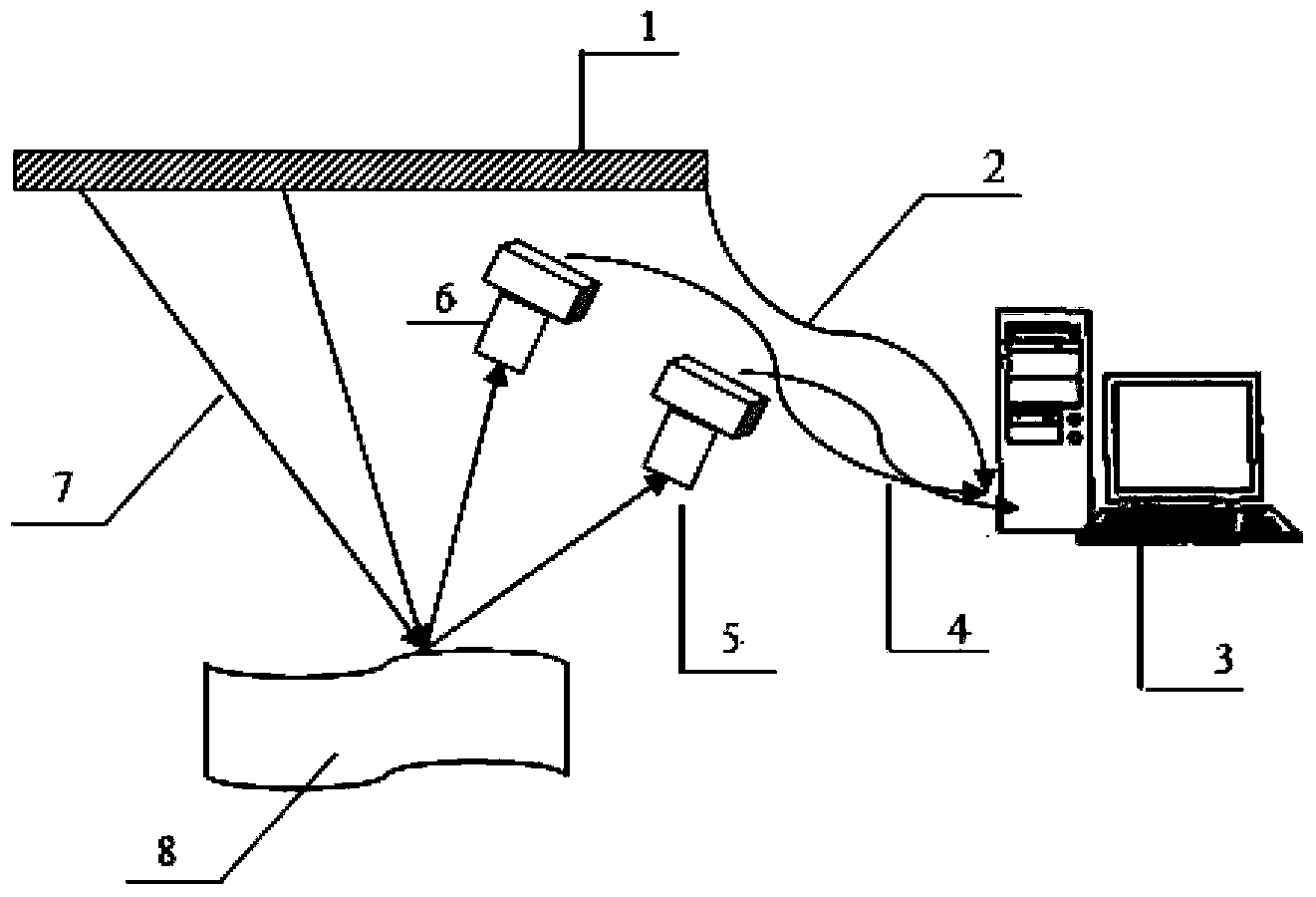

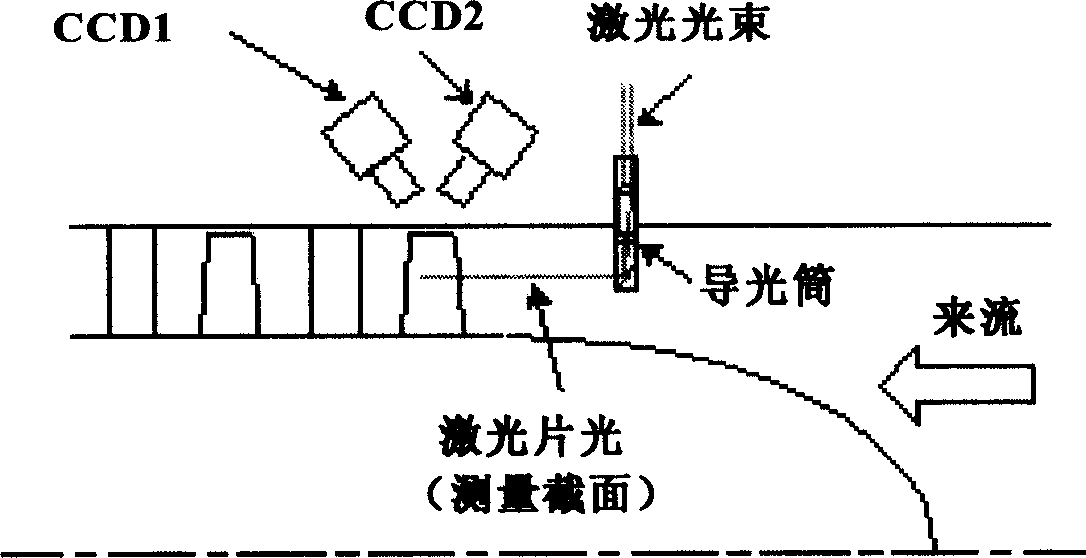

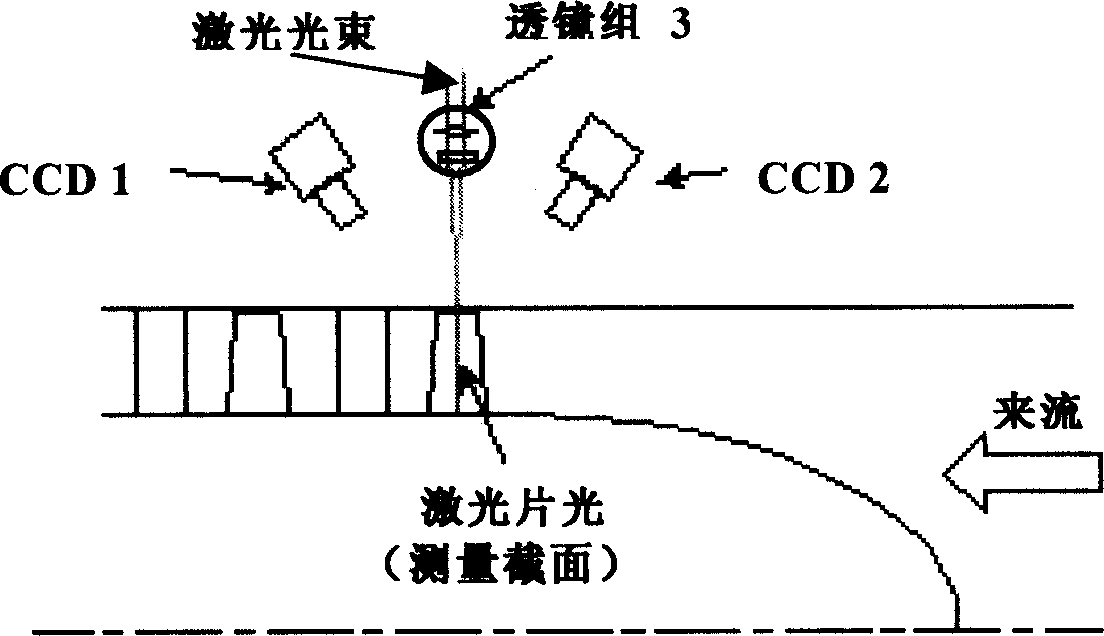

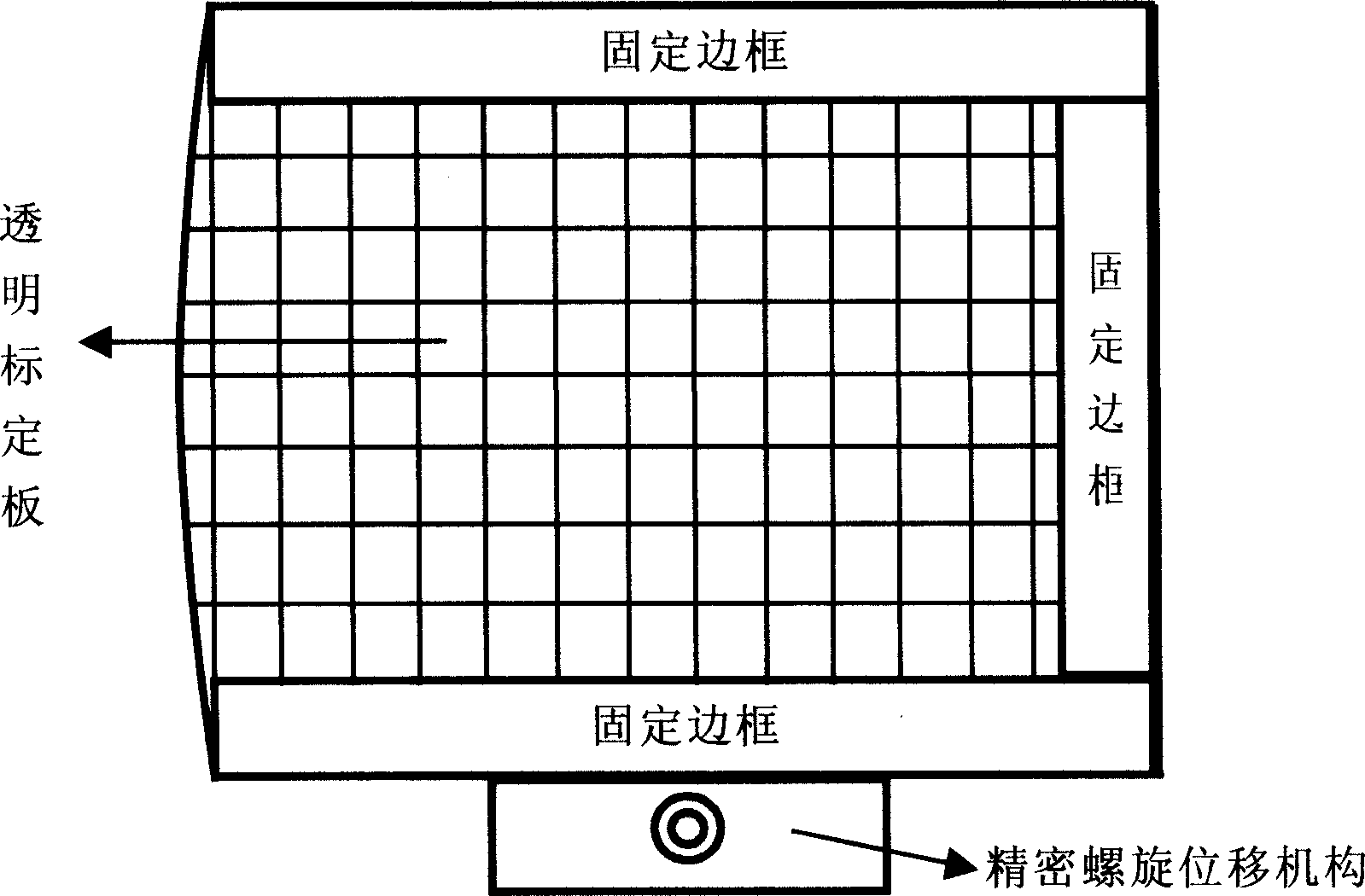

An interior flow field measurement method for turbomachine

The invention relates to a turbo-machine internal flow field measuring method, which does not need to change the current SPIV system and only need to displace the laser sheet light and the CCD camera according to the accompany diagram mold, then it dose special calibration and 3-D velocity field composition by the character of the turbine; it is characterized in that it does not need the complex leaded light column and all of the measuring devices are outside the box viewer; the laser sheet light through the box viewer and directly lightens the detected section; two suits CCD camera are separately positioned on the two sides of the laser sheet light so as to measure the box near-wall area. Using the 3-D velocity field composition can obtain high special resolution and large compositing area.

Owner:BEIHANG UNIV

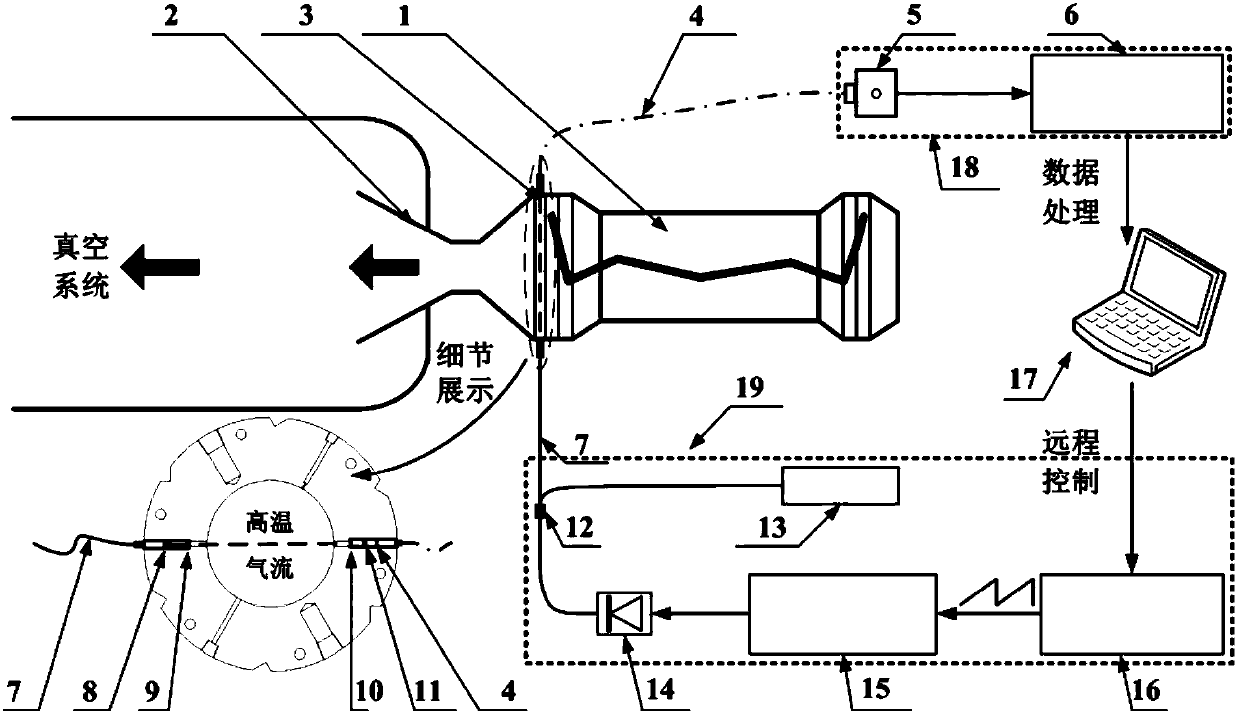

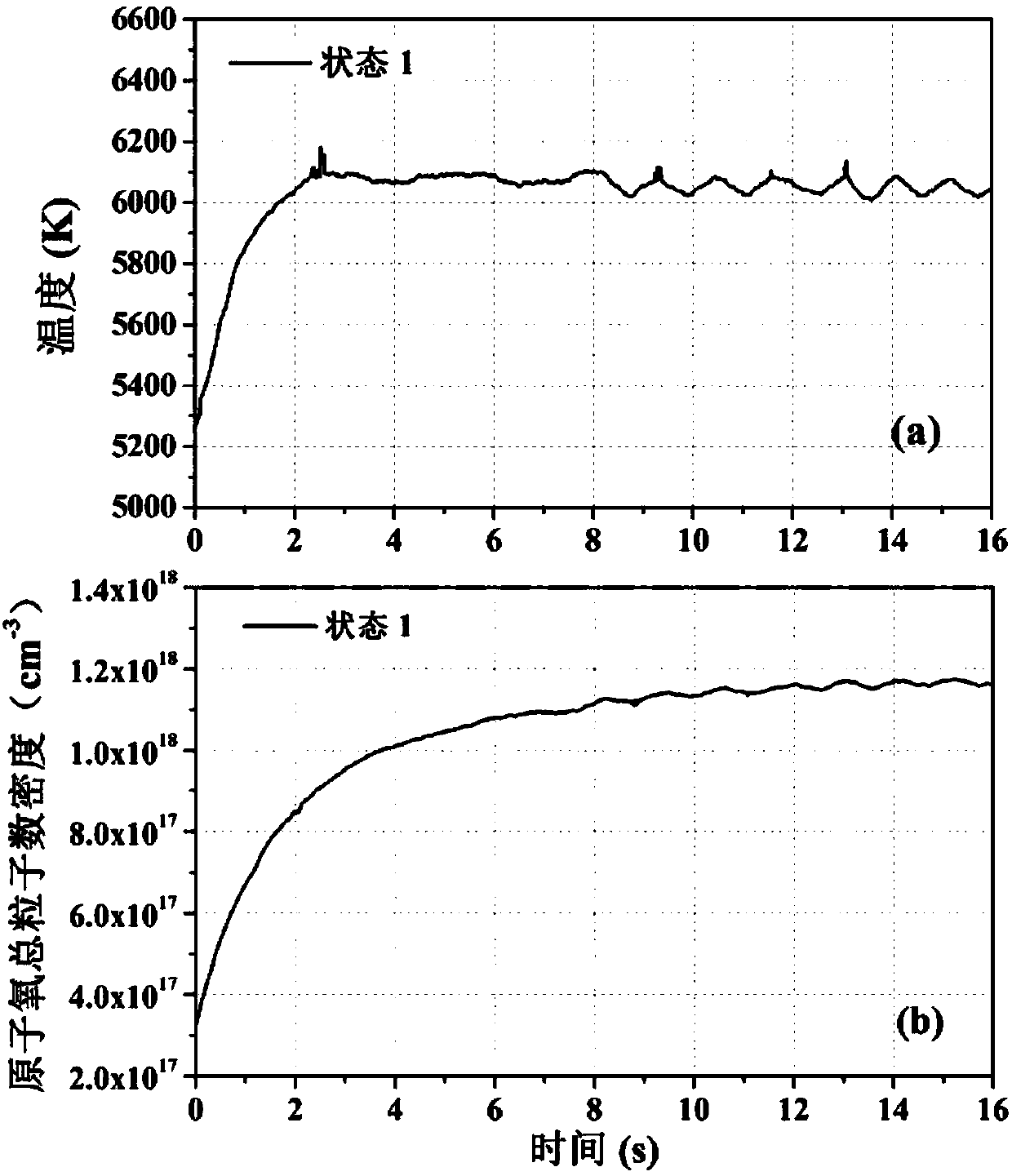

Laminated arc heater high-enthalpy airflow parameter diagnosis system

ActiveCN107907502ASolve difficult to applySolve the problem of plasma high temperature flow field diagnosisColor/spectral properties measurementsEngineeringOxygen

A laminated arc heater high-enthalpy airflow parameter diagnosis system is used for obtaining the airflow parameters (particle number density and static temperature) of a high temperature flow field in the ground heat protection test of an arc heater, and online diagnosing high temperature disassociated air test airflow in the arc heater by using an atom O (777.19 nm) spectral line to obtain the plasma airflow temperature and the atom oxygen particle number density in the arc heater. The system can be used as a routine way for the arc heater high-enthalpy airflow parameter diagnosis.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

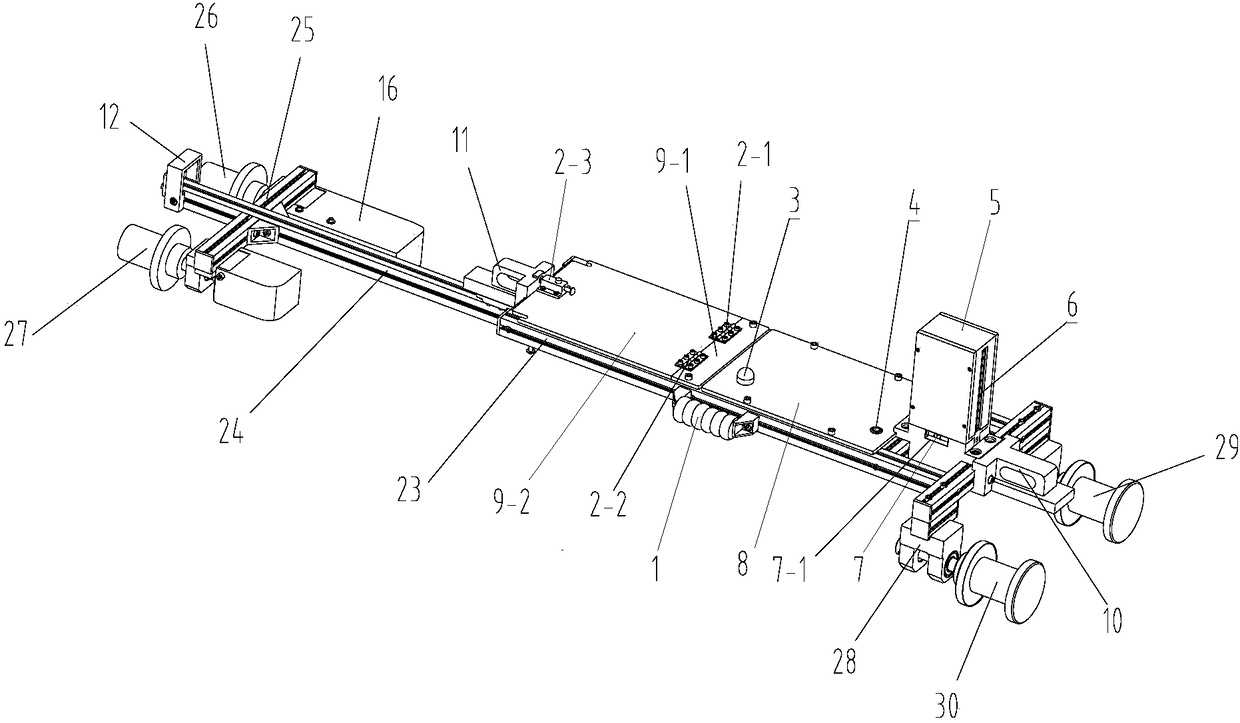

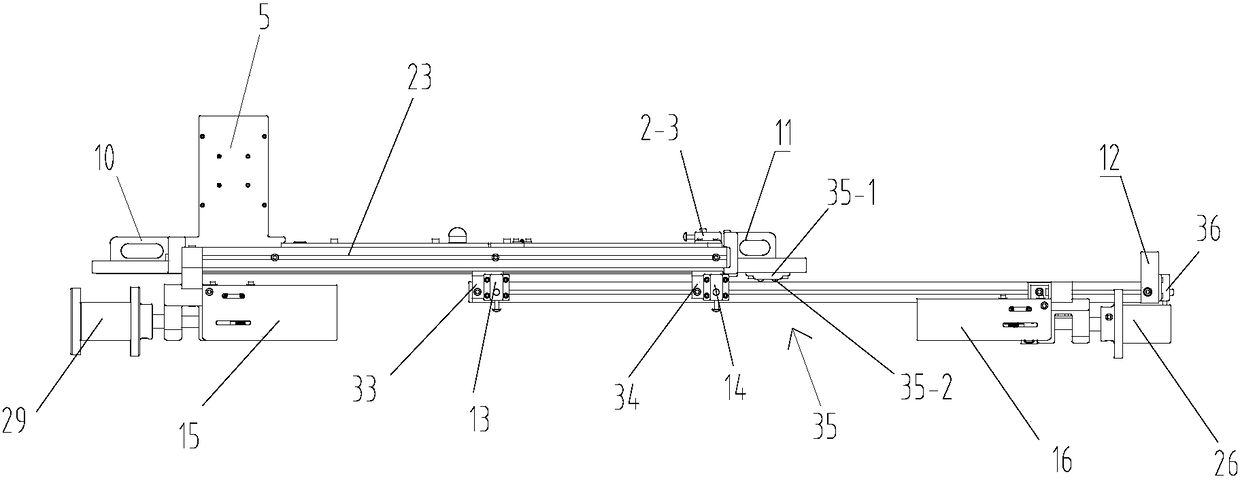

Measuring apparatus and measuring method of station platform gauge

PendingCN108413885ASimple structureReasonable designUsing optical meansLaser rangingMeasurement device

The invention discloses a measuring apparatus and a measuring method of a station platform gauge. The apparatus comprises a vehicle body, a measuring mechanism and a control module, the vehicle body comprises a vehicle frame, a fixed wheel group adjusting wheel mechanism and a walking driving mechanism, the measuring mechanism comprises a box body, a laser range finding sensor and a laser drivingmodule, and the control module comprises a walking control module, a laser control module and a handheld control terminal. The measuring method includes: step 1, extension of an adjusting wheel assembly; step 2, walking of the measuring apparatus of the station platform gauge; step 3, measurement of the station platform gauge; step 4, repetition of step 2 and step 3 until completion of the measurement of the whole platform gauge; and step 5, contraction of the adjusting wheel assembly. According to the measuring apparatus and the measuring method, the design is reasonable, the operation is simple, the usage effect is good, the station platform gauge is automatically measured, non-contact measurement is realized, the measuring efficiency is high, the manpower and material resources are reduced, the size is small, the cost is low, and the practicality is high.

Owner:吴立滨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com