Patents

Literature

112 results about "Particle collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear aperture pseudospark switch

InactiveUS6104022AApply evenlyImprove current carrying capacityMaterial analysis by optical meansPhotoelectric discharge tubesPseudospark switchParticle collision

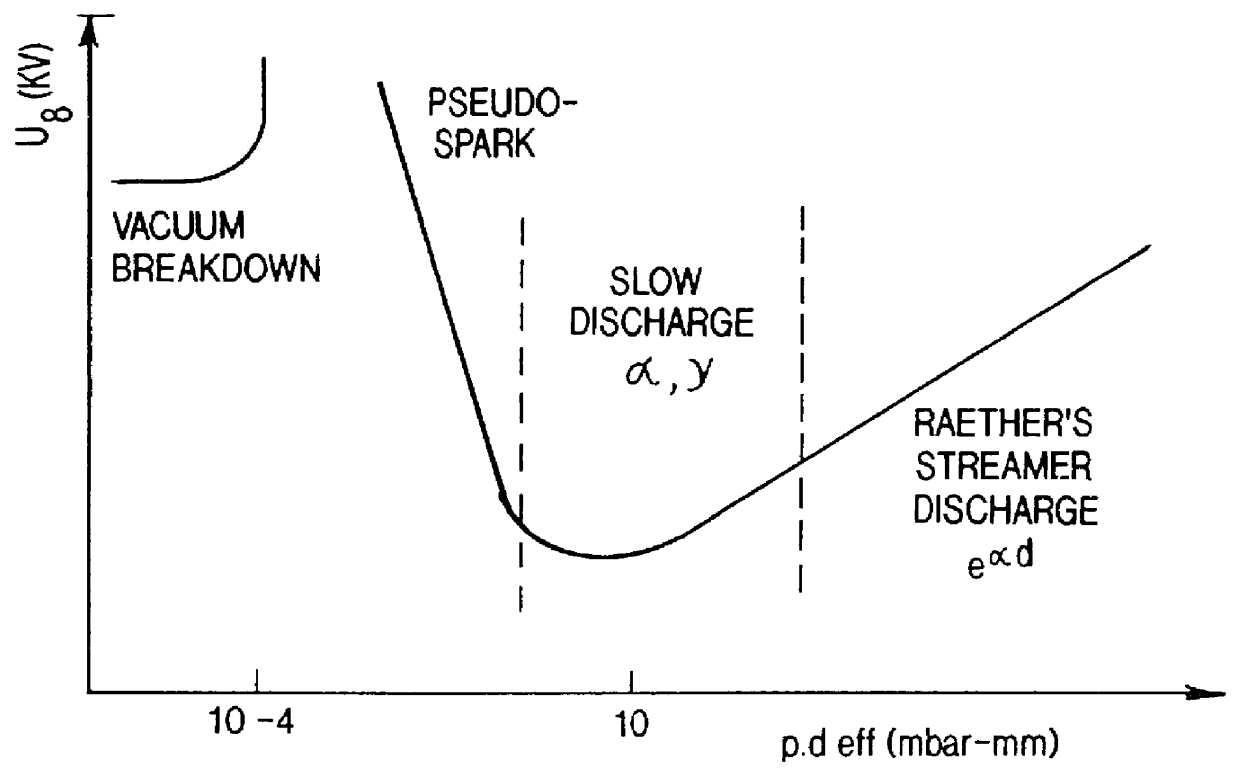

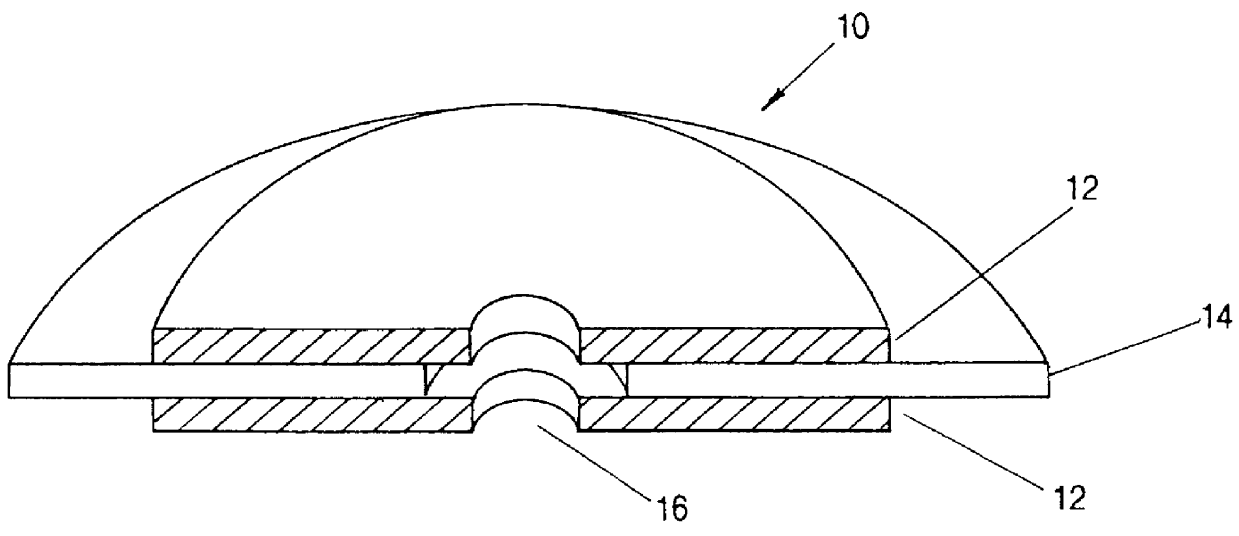

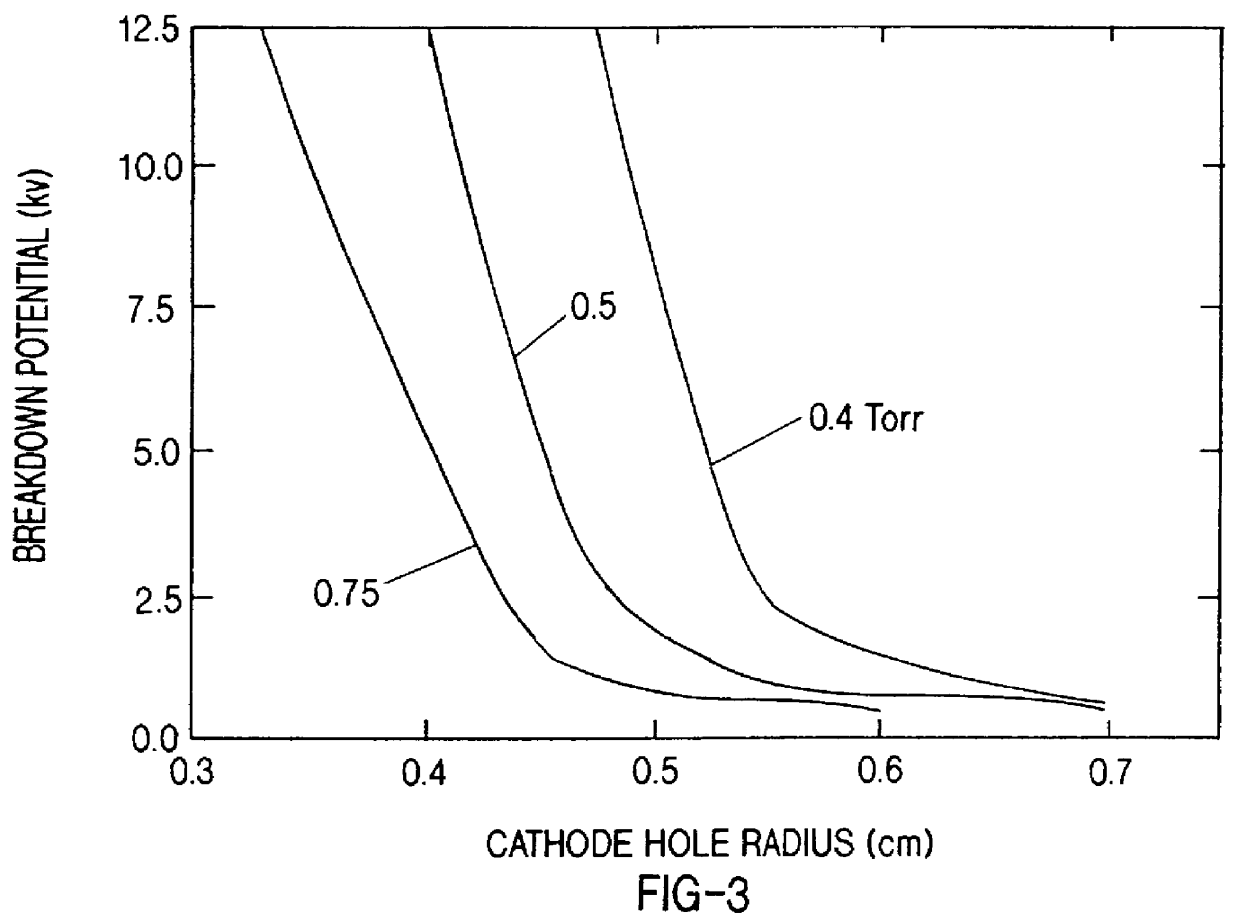

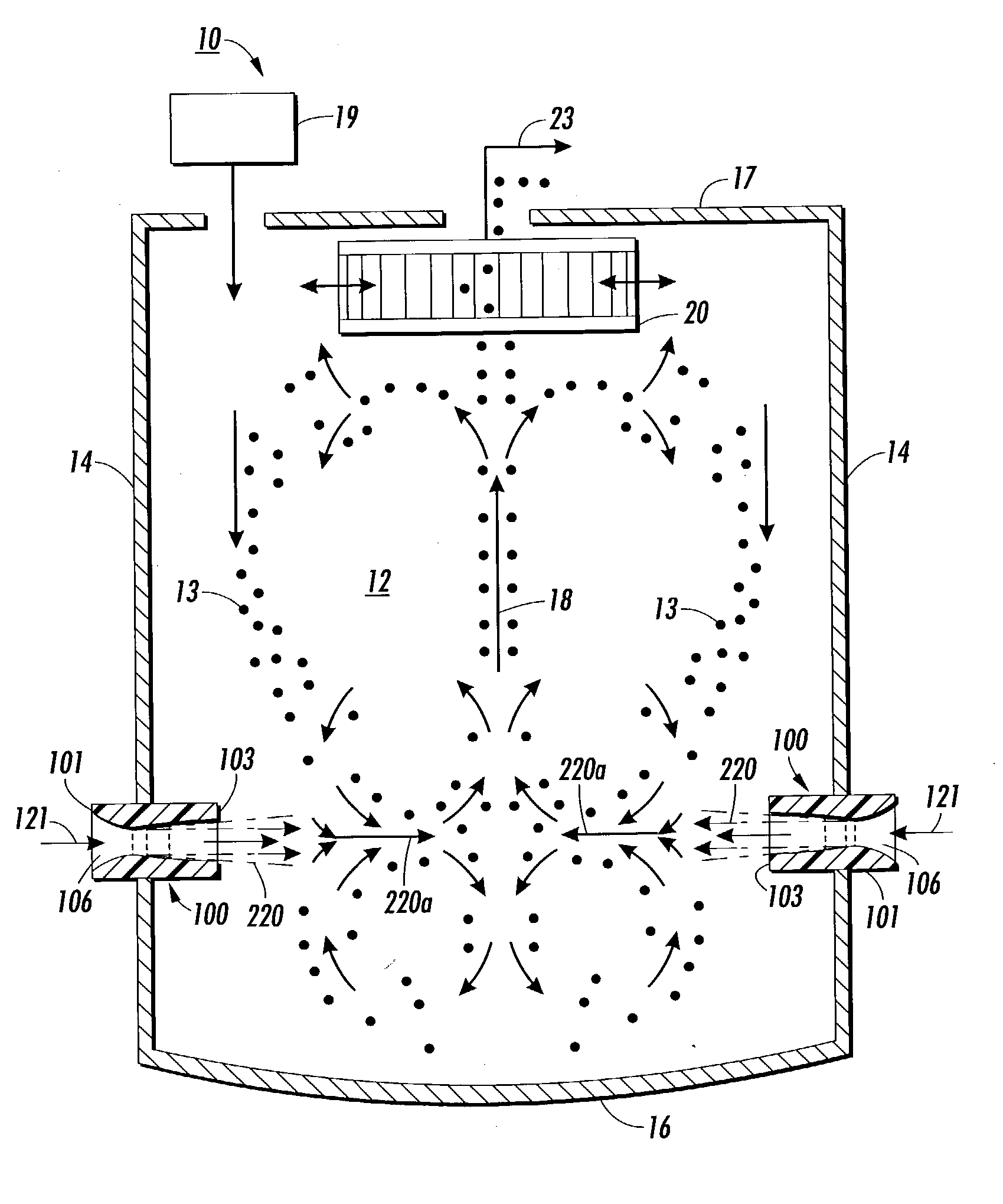

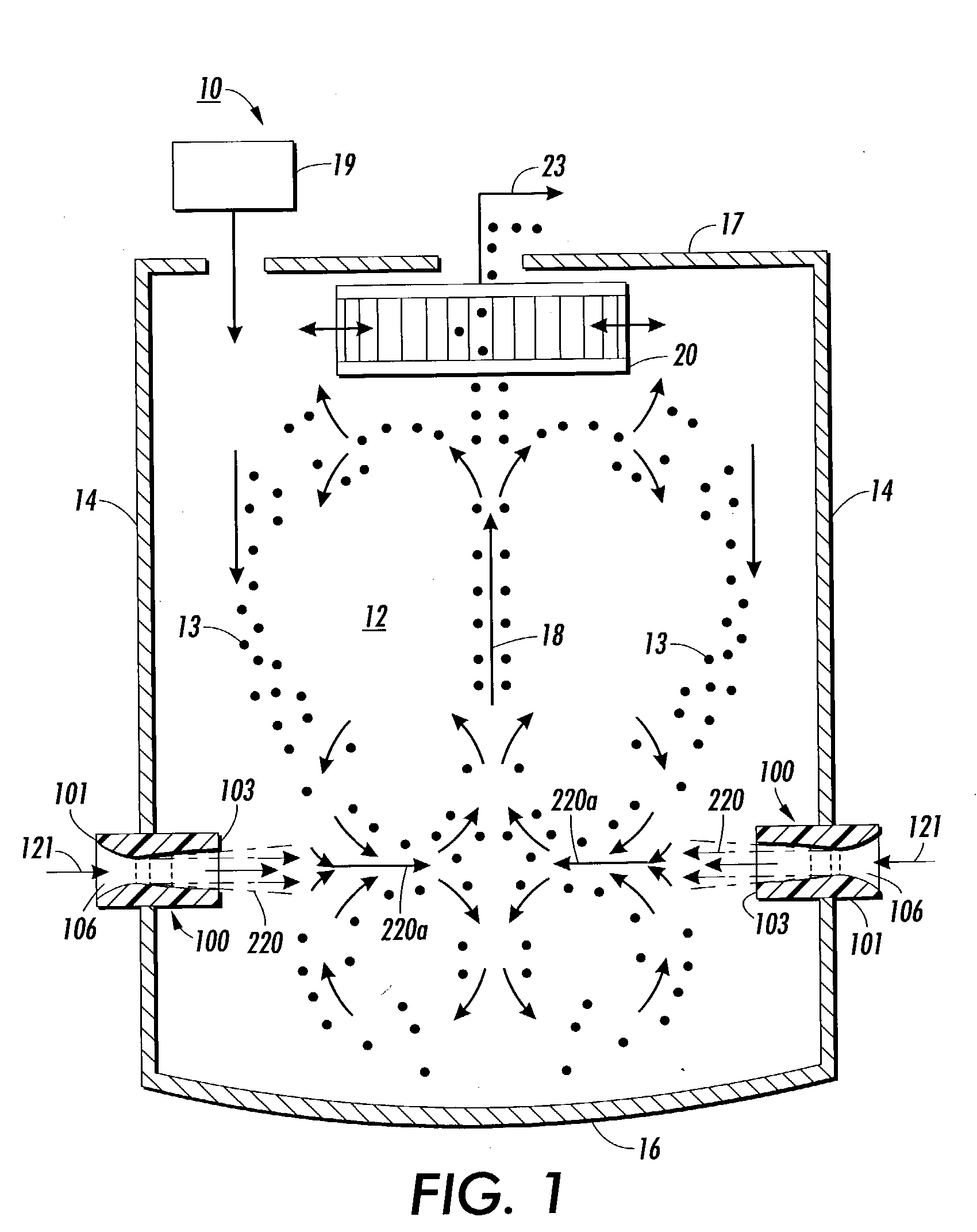

The present invention is of a glow discharge switch operating in the low pressure regime where gas breakdown is limited by the distance between electron-gas particle collisions (pseudospark discharge). The invention utilizes linear discharge apertures (length greater than width) in the electrodes. The linear apertures provide significantly higher current conduction without discharge constriction than conventional round-hole pseudospark switches. A radial version of the linear pseudospark switch also is disclosed that provides for self-canceling of the magnetic fields induced by the discharge, and thus prevents discharge constriction and provides for very high current conduction.

Owner:SDG LLC

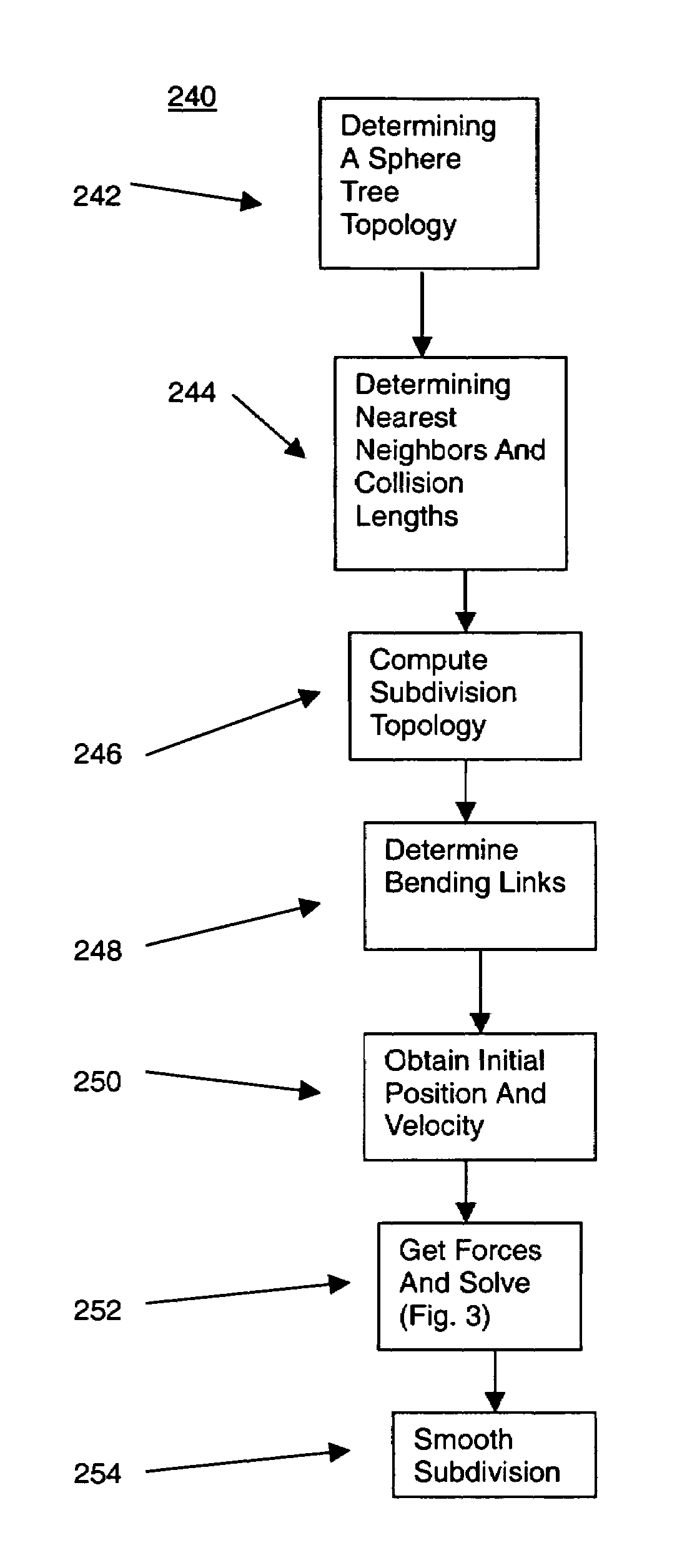

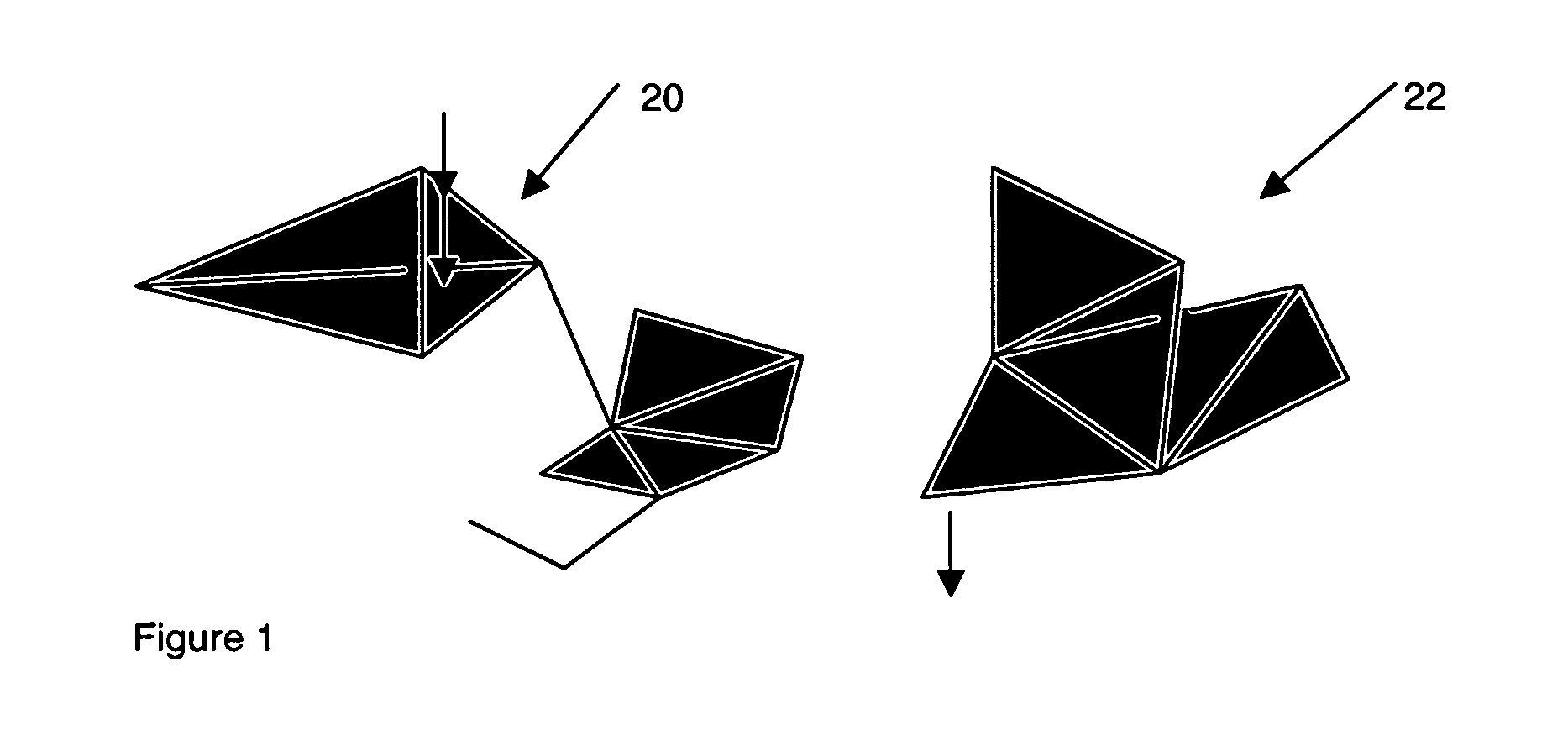

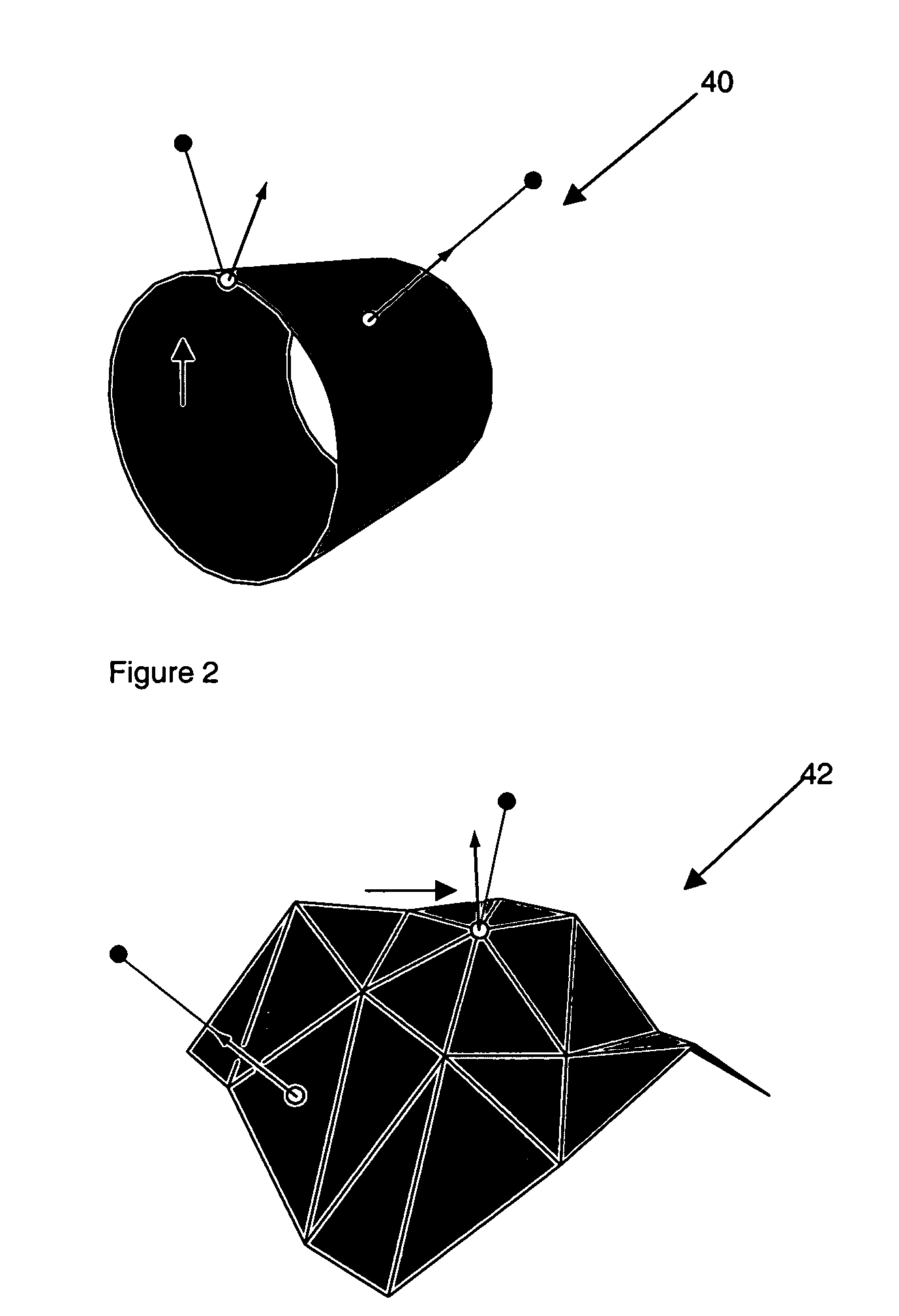

Fixed time step dynamical solver for interacting particle systems

ActiveUS20060235659A1Simple calculationMore cost-effectivelyComputation using non-denominational number representationDesign optimisation/simulationParticle collisionParticle position

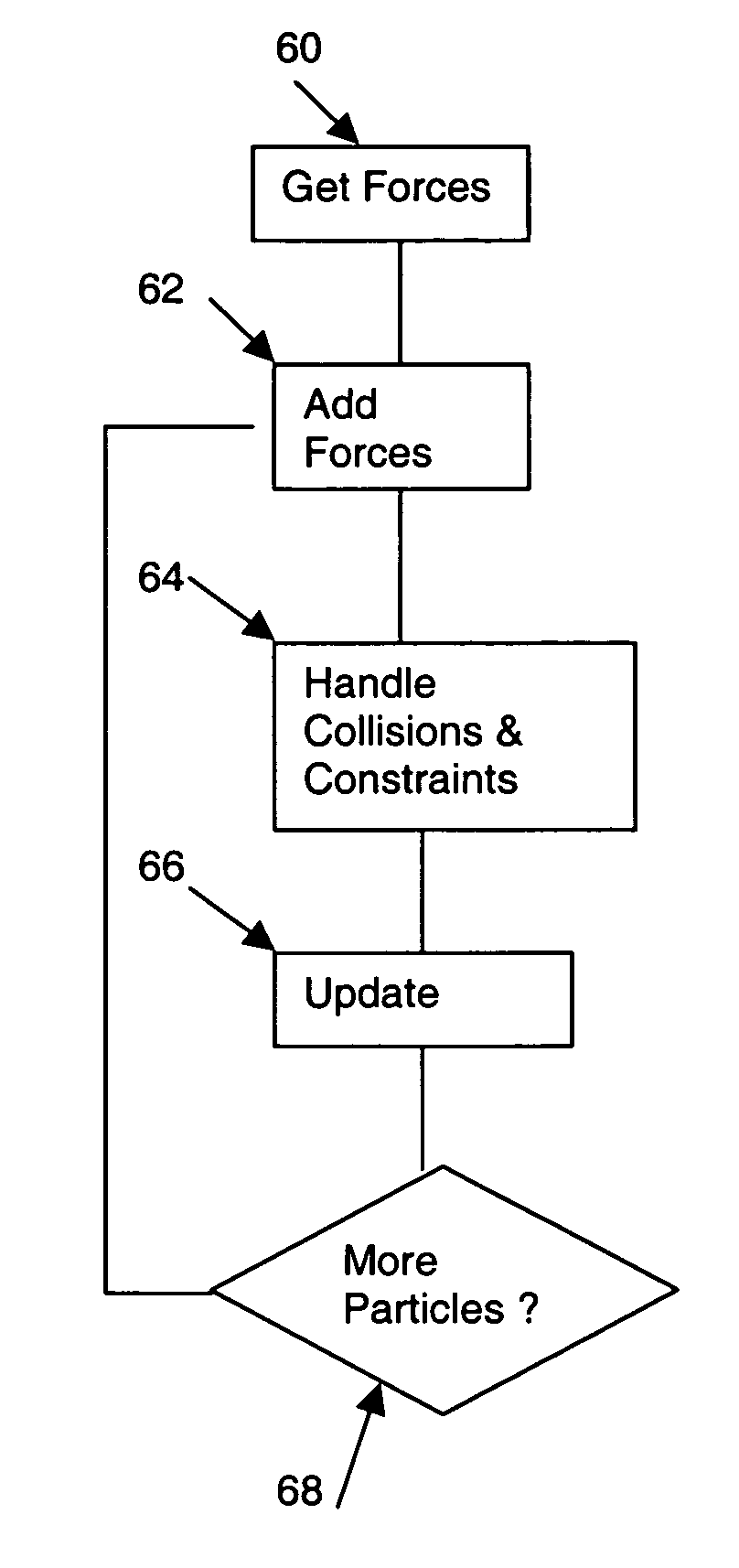

The present invention is a particle position solver that allows particles to reach an end of a fixed time, time step in an invalid state and which are then pushed toward a valid state. This allows the solver to continue the simulation while the simulation results move toward a valid behavior. Particle collision calculations are simplified by adopting a non-sequential model ignoring some collisions or combining them. The speed of the simulation is also improved by performing some operations outside the solver calculation loop and by using specialized data structures.

Owner:AUTODESK INC

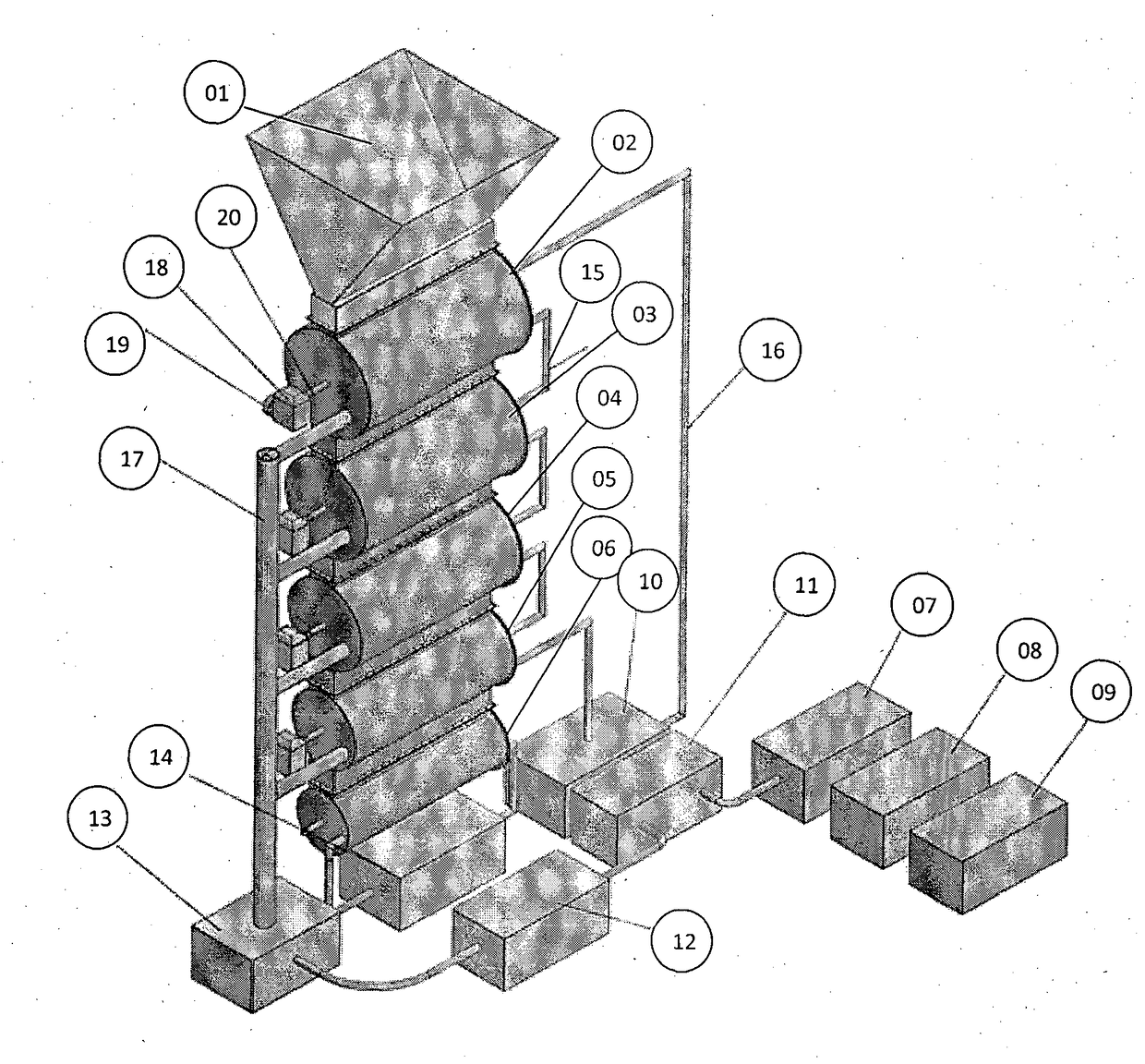

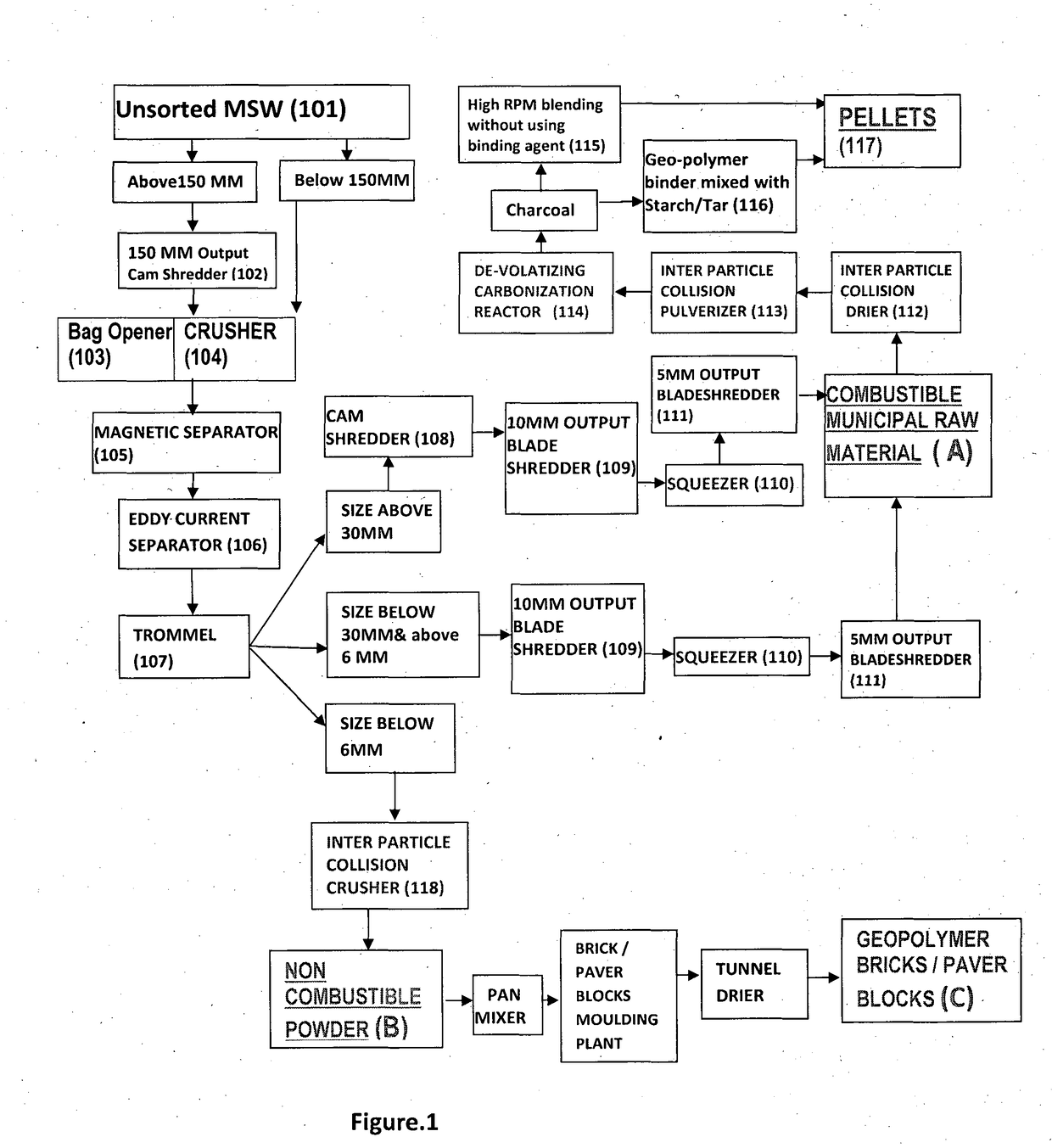

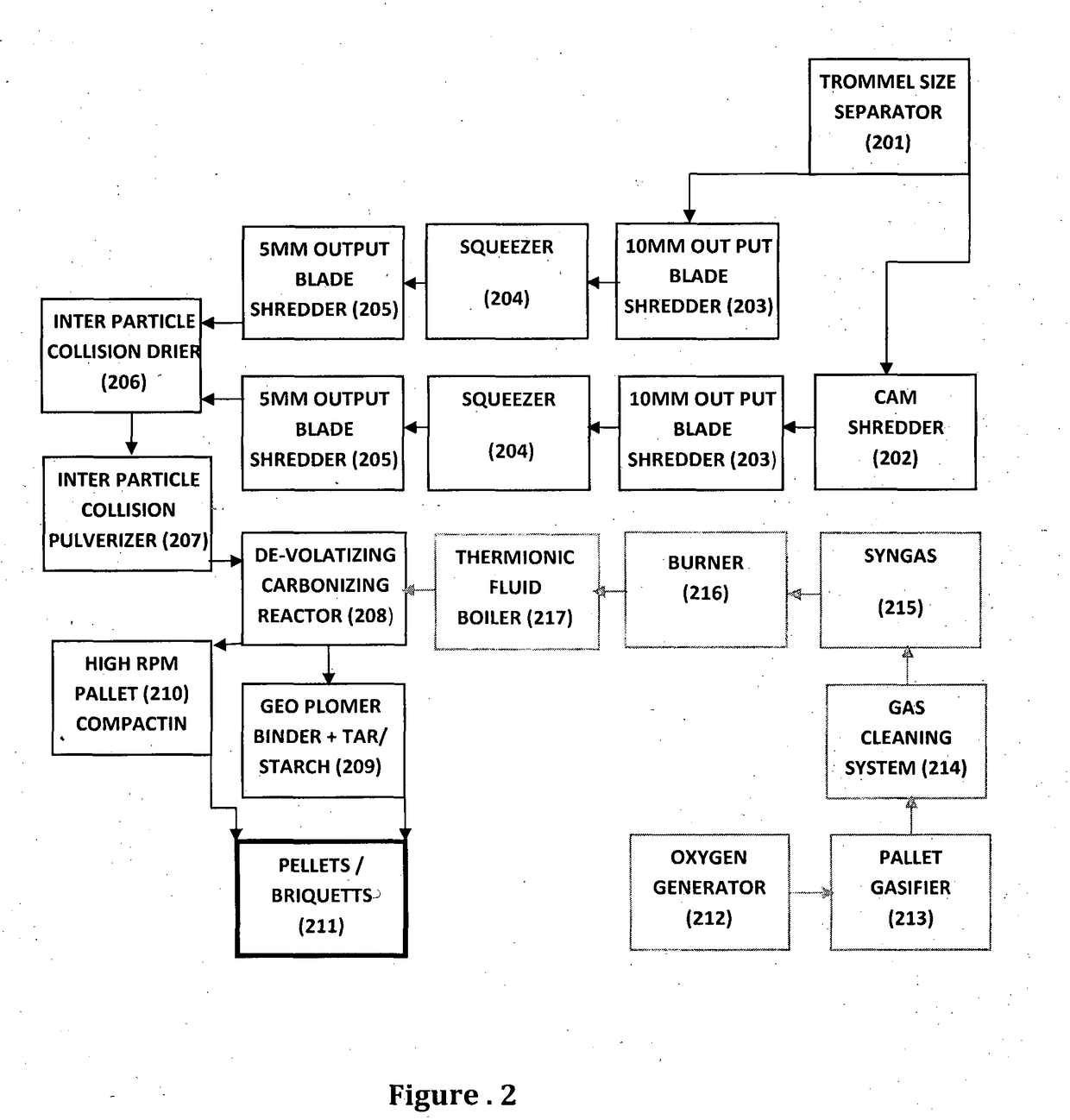

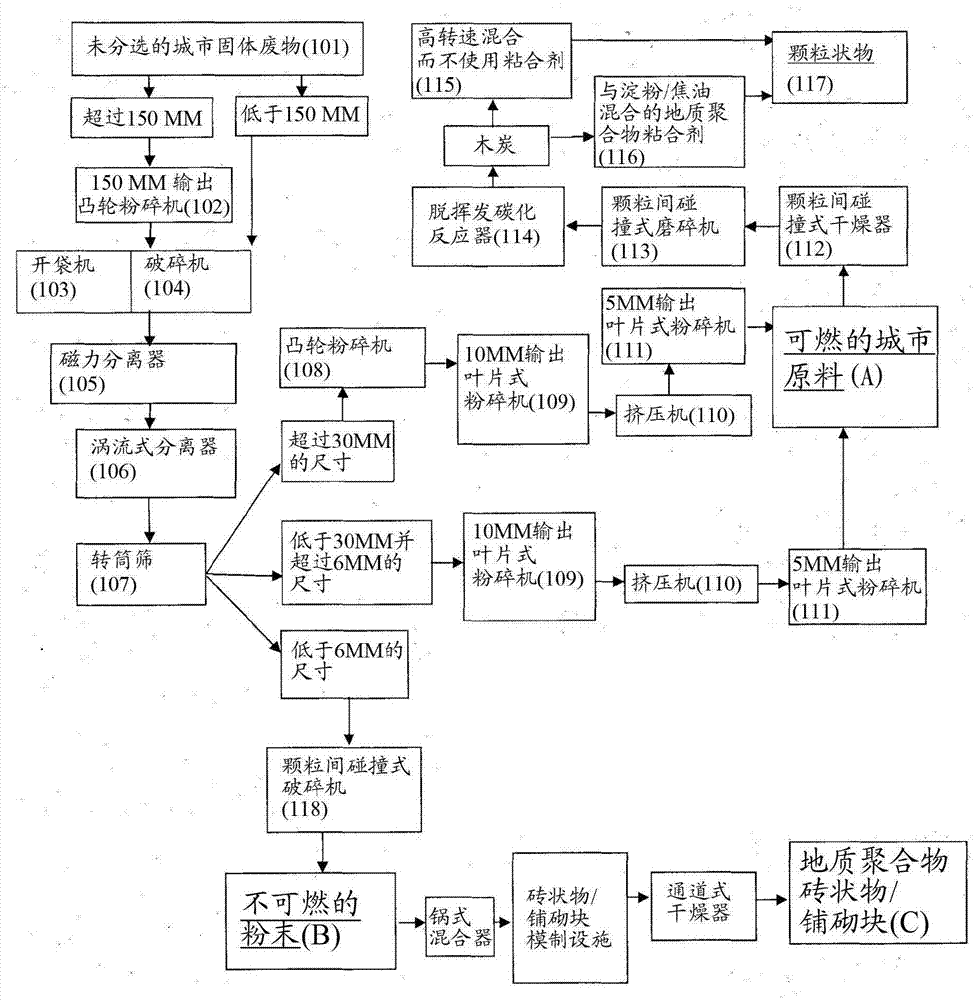

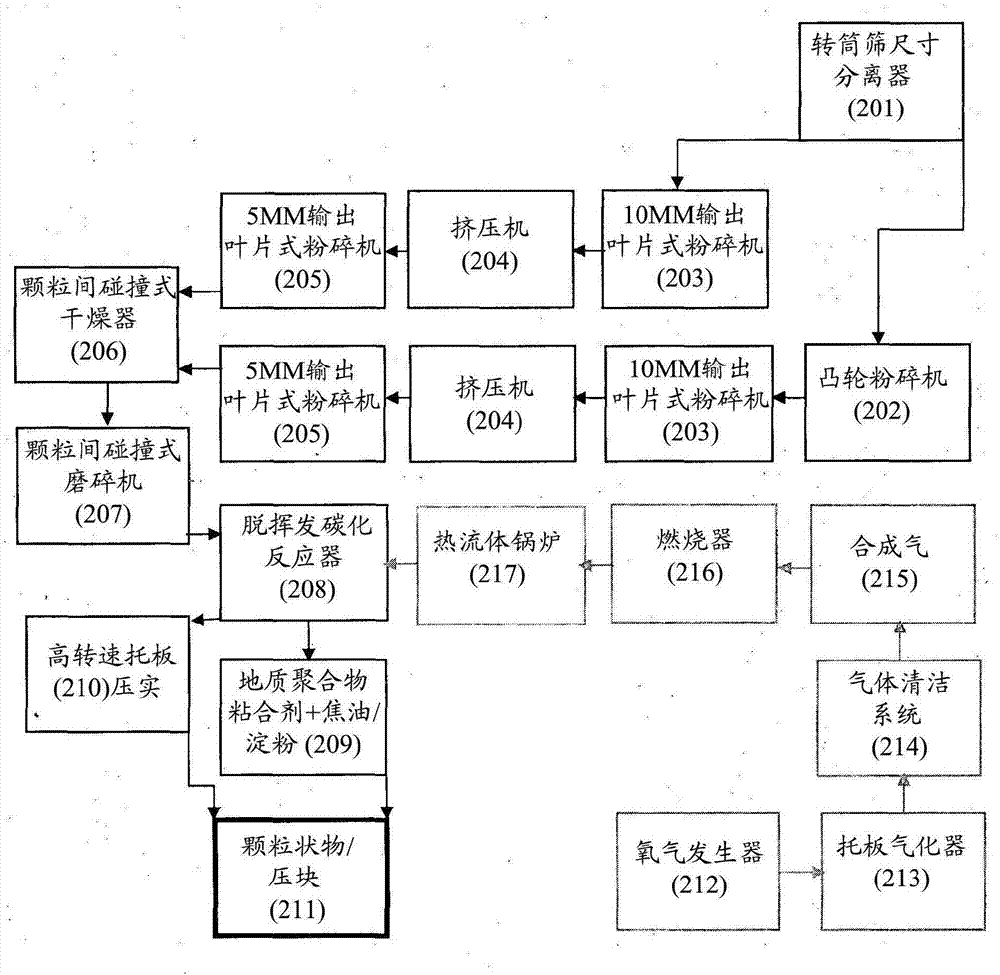

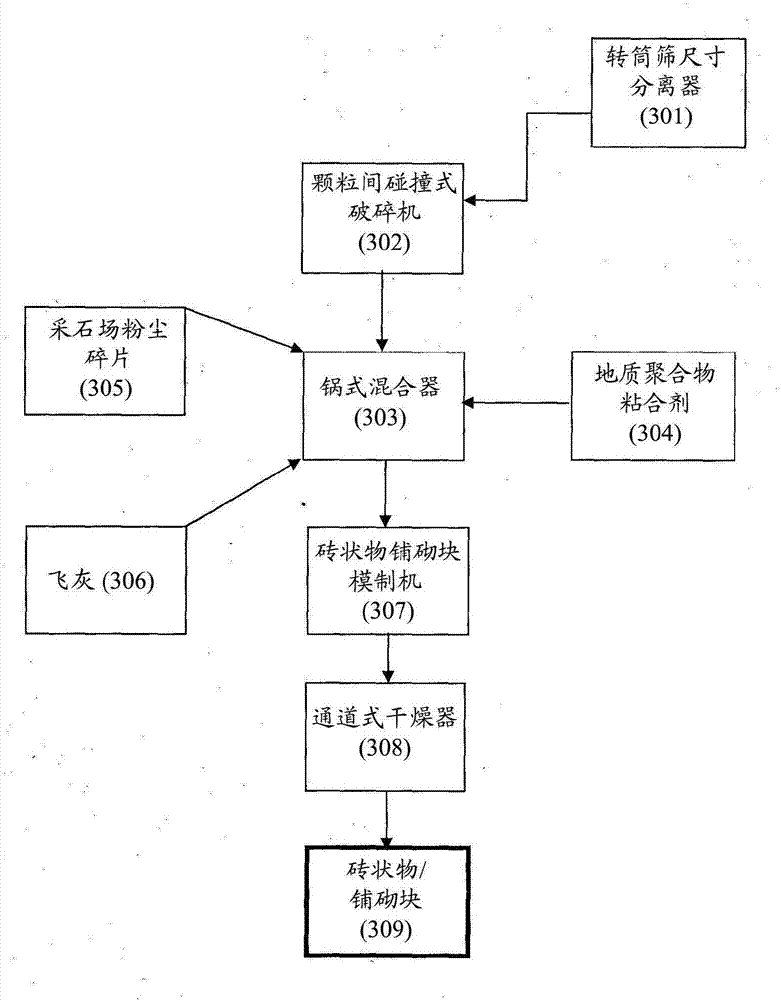

A novel method and an apparatus in converting unsorted municipal solid waste into geo-polymer pellets/briquettes and geo-polymer bricks/paver blocks

InactiveUS20180015515A1High calorific valueLow ashSolid waste disposalTransportation and packagingBrickCarbonization

Apparatus and method in converting municipal solid waste into geo-polymer briquettes and geo-polymer bricks comprising bag opener cum crushers, magnetic separators for ferrous and-eddy current separators for non-ferrous things; squeezer for removing liquid content; inter particle collision driers for drying; pulverizer for pulverizing, and devolatizing carbonization reactor for carbonisation of combustible MSW to produce solid char with low water content. Solid char is mixed with geo-polymer binding agent / starch / tar / to form combustible pellet / briquette. These highly combustible briquette / pellets have high calorific value. The pellet / briquette is formed by rotating combustible char at high rpm and compaction. Pellet has a water content of less than 5% by weight and fuel value of 5500 to 6500 KCAL. This process produces non-combustible geo-polymer brick. The non-combustible MSW separated by a trommel is crushed by inter particle collision crusher and pan mixers mixing with geo-polymer binding agent / fly ash / quarry dust / chips or china clay and moulded.

Owner:NEWAY MSW IP HLDG LLP

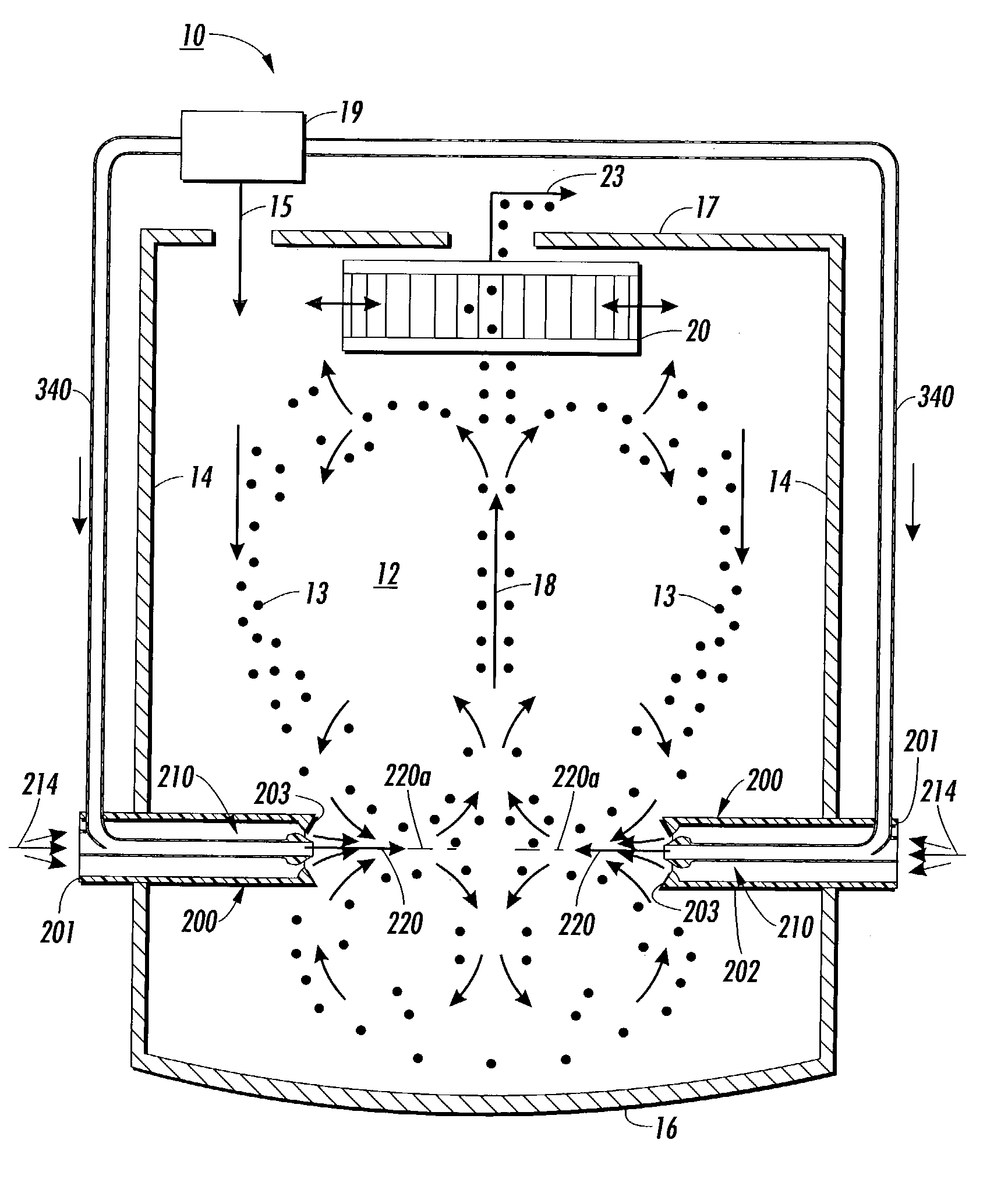

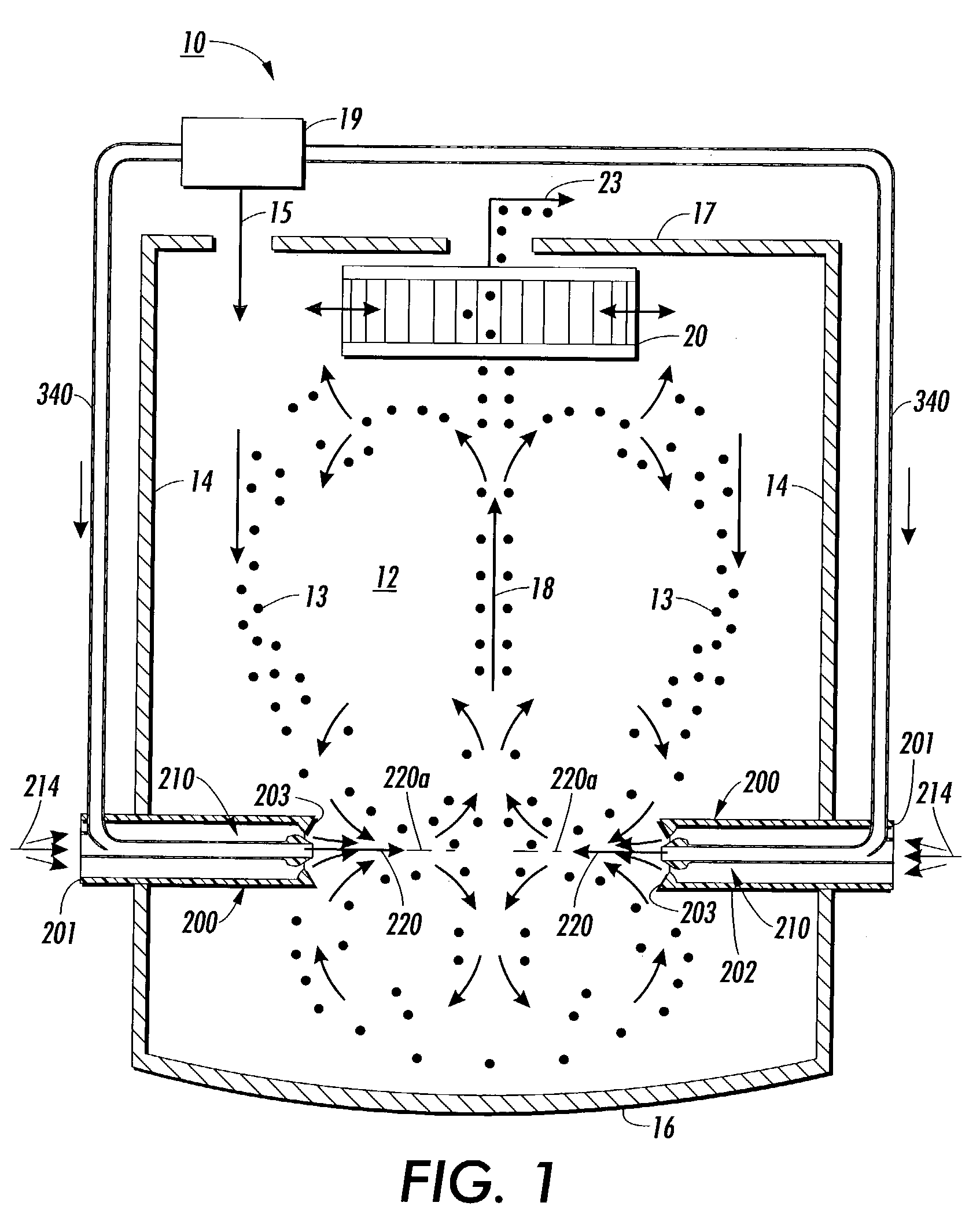

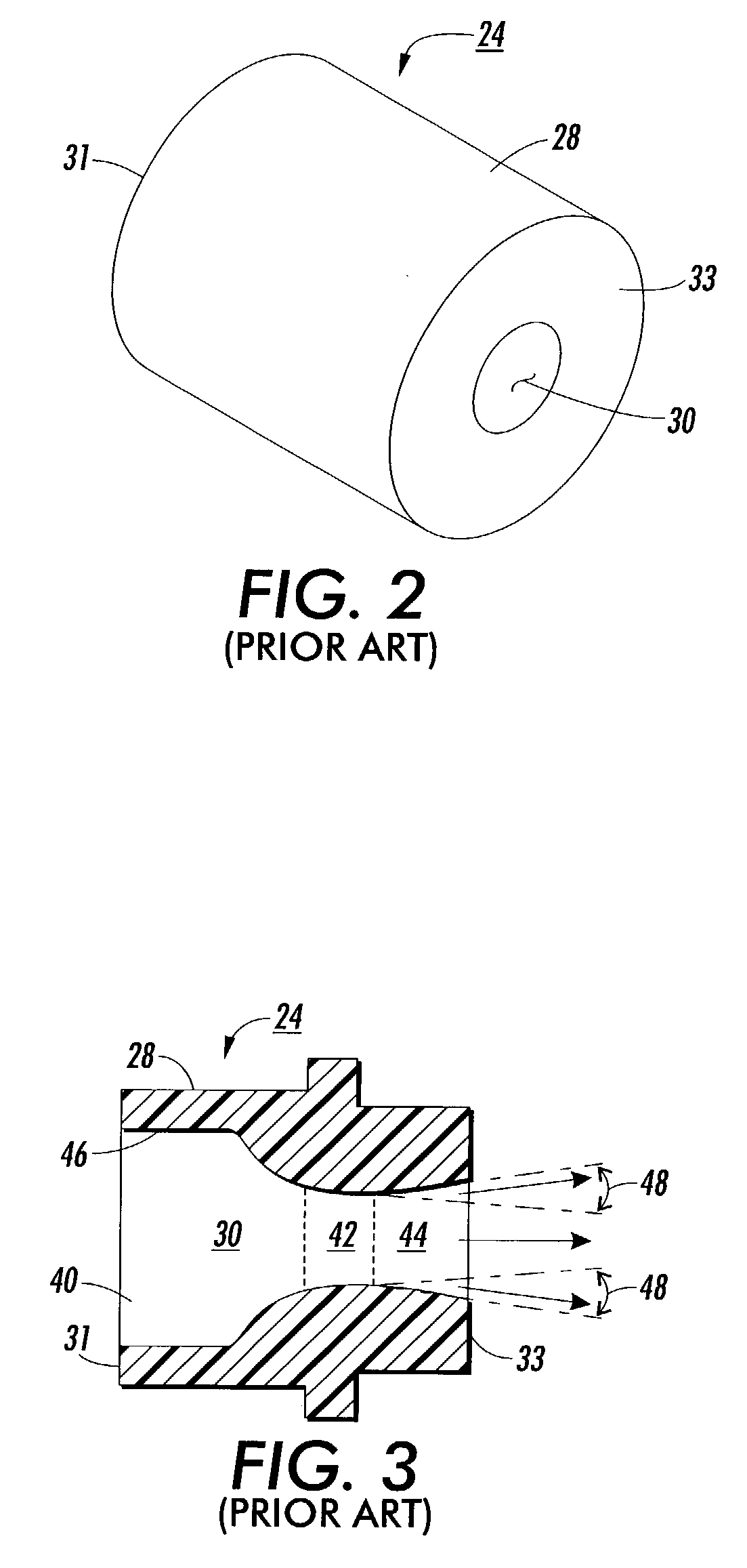

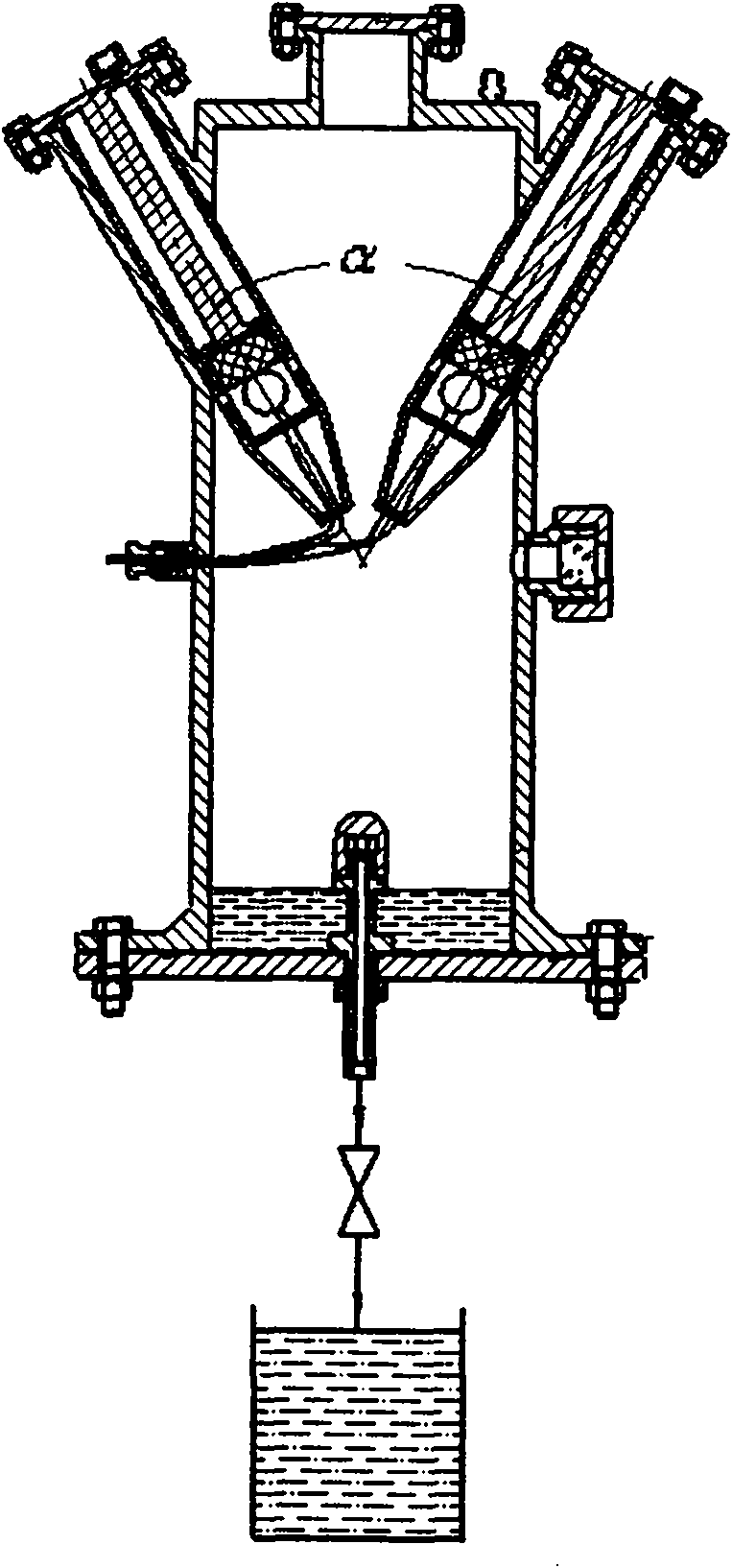

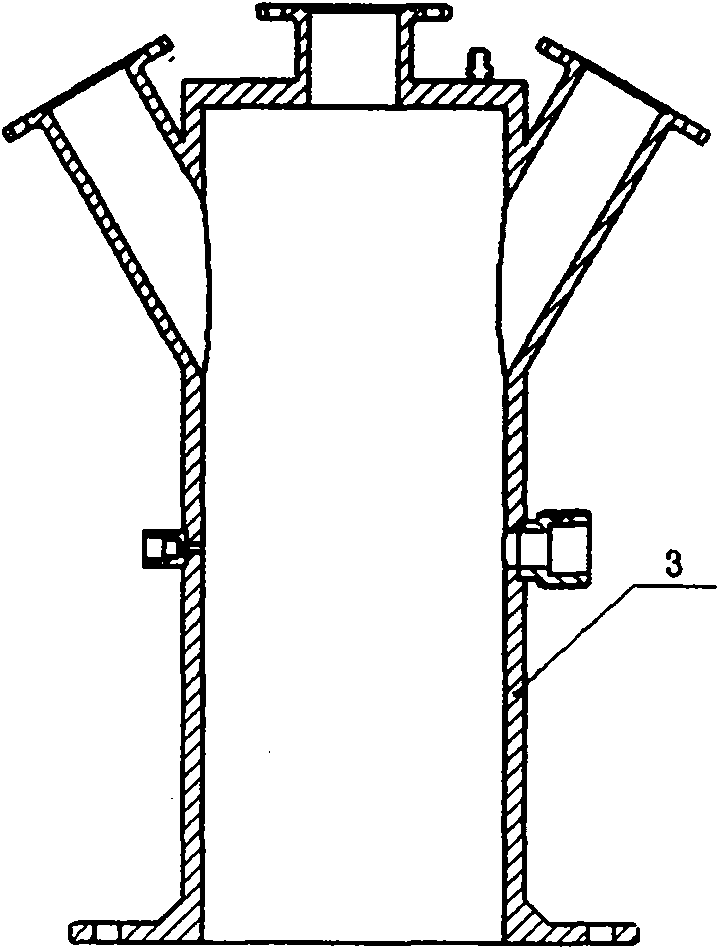

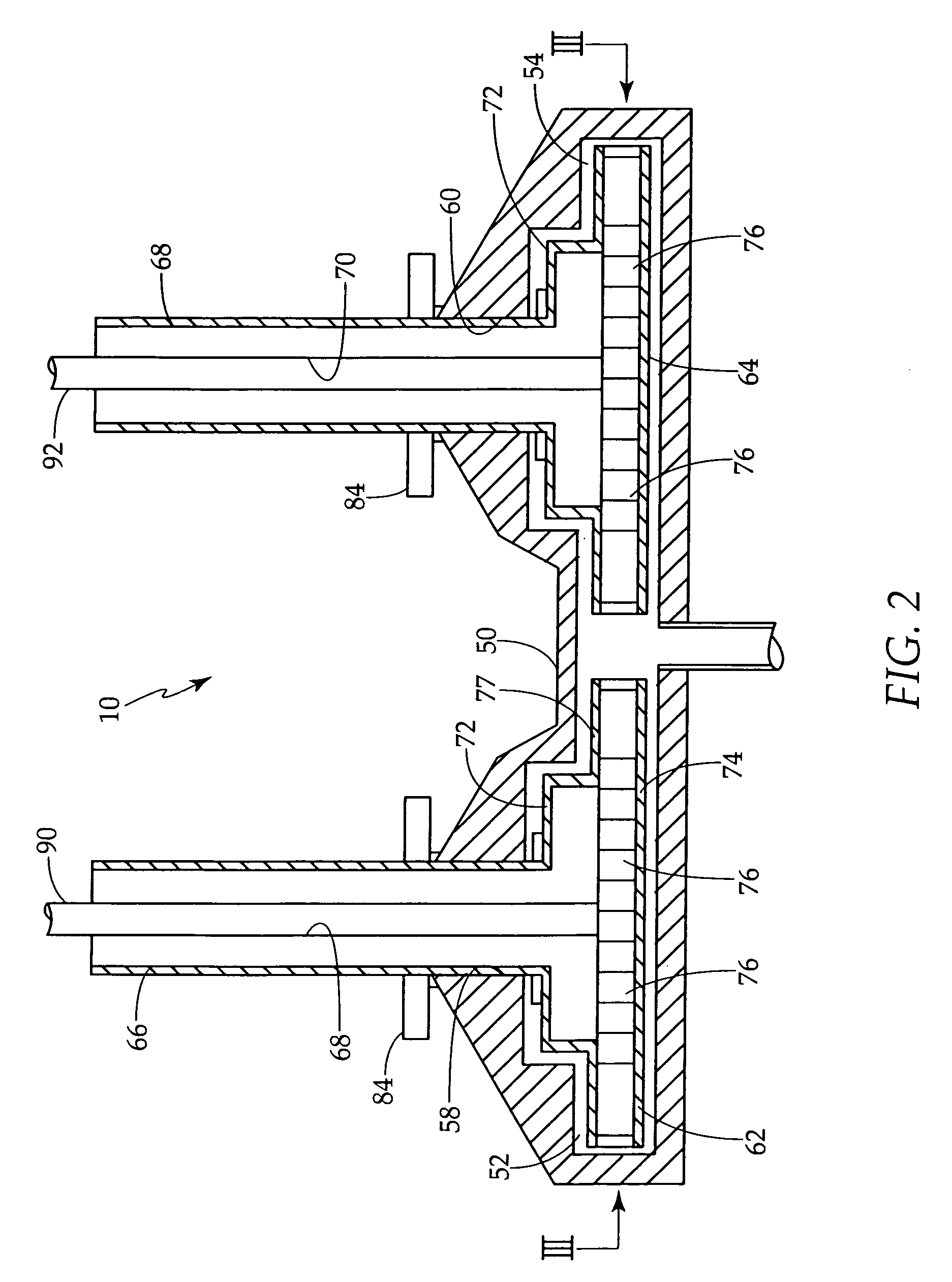

Particle entraining eductor-spike nozzle device for a fluidized bed jet mill

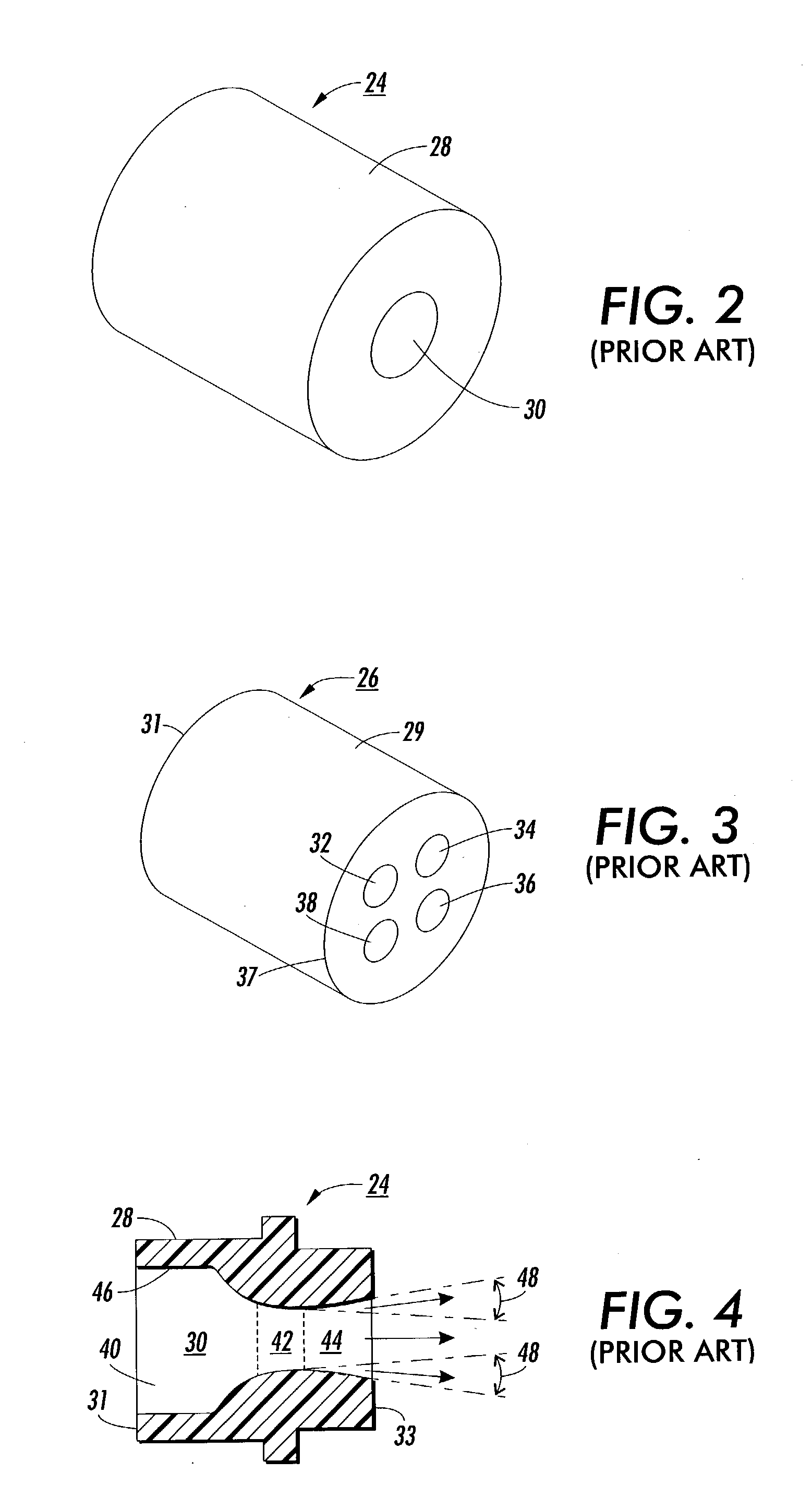

An eductor-spike nozzle device is provided for mounting through side walls of a fluidized bed jet mill to discharge a composite stream of high velocity fluid for receiving, entraining and delivering particles of material into a grinding chamber of a fluidized bed jet mill for particle to particle collisions. The eductor-spike nozzle device includes (a) a first cylindrical member having a first wall including a cowl lip and defining a first hollow interior, and (b) a second cylindrical member mounted within the first hollow interior and having a second wall (i) externally defining an annular flow path with the first wall for flow of a first stream of fluid, and fluid compressing throat region with the cowl lip for creating a high velocity stream, and (ii) internally defining a second hollow interior for flow of a second stream of fluid so as to form the composite stream of high velocity fluid with the first stream of fluid, thereby increasing a probability of the composite stream receiving and entraining particles introduced into the composite stream.

Owner:XEROX CORP

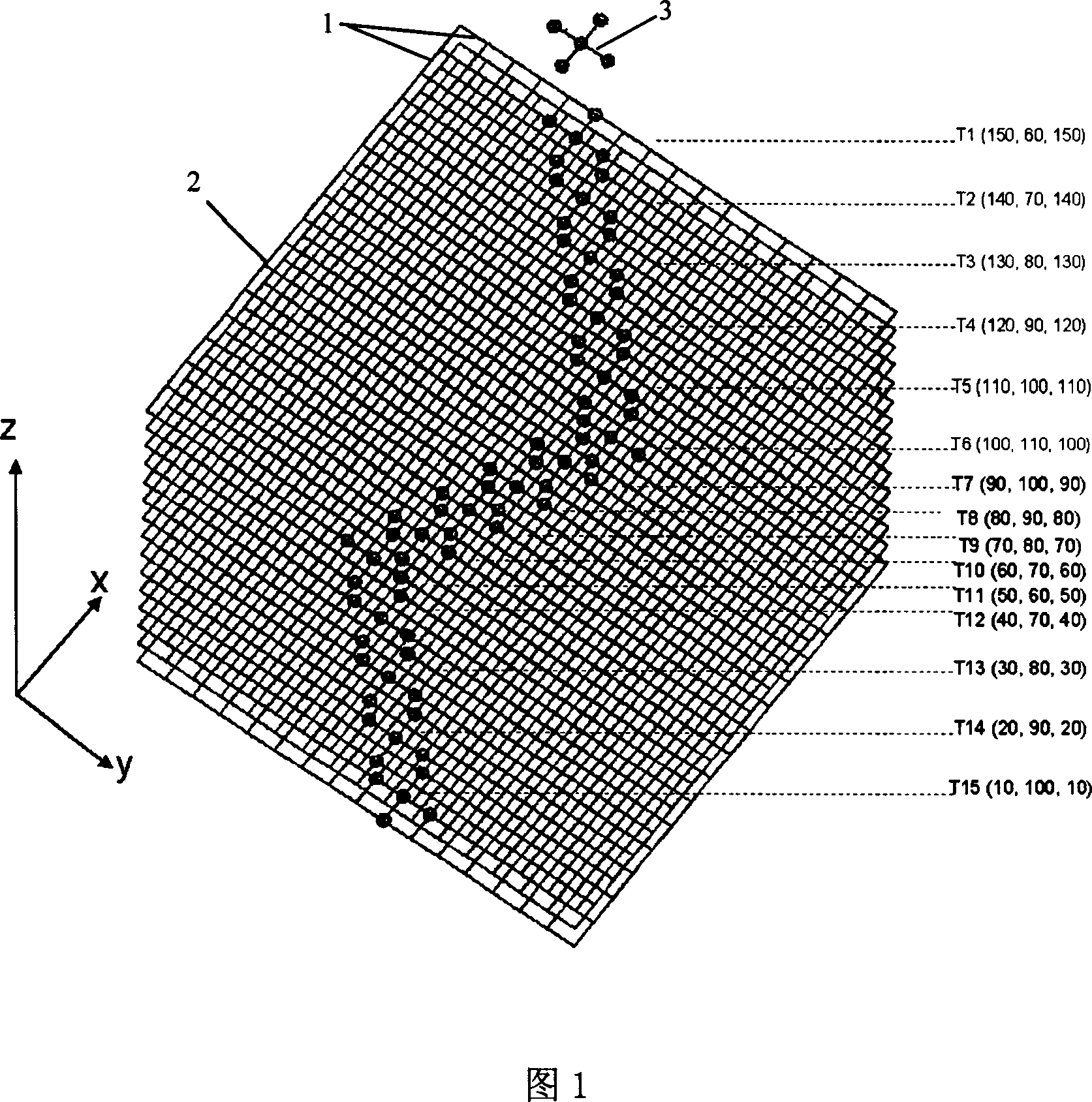

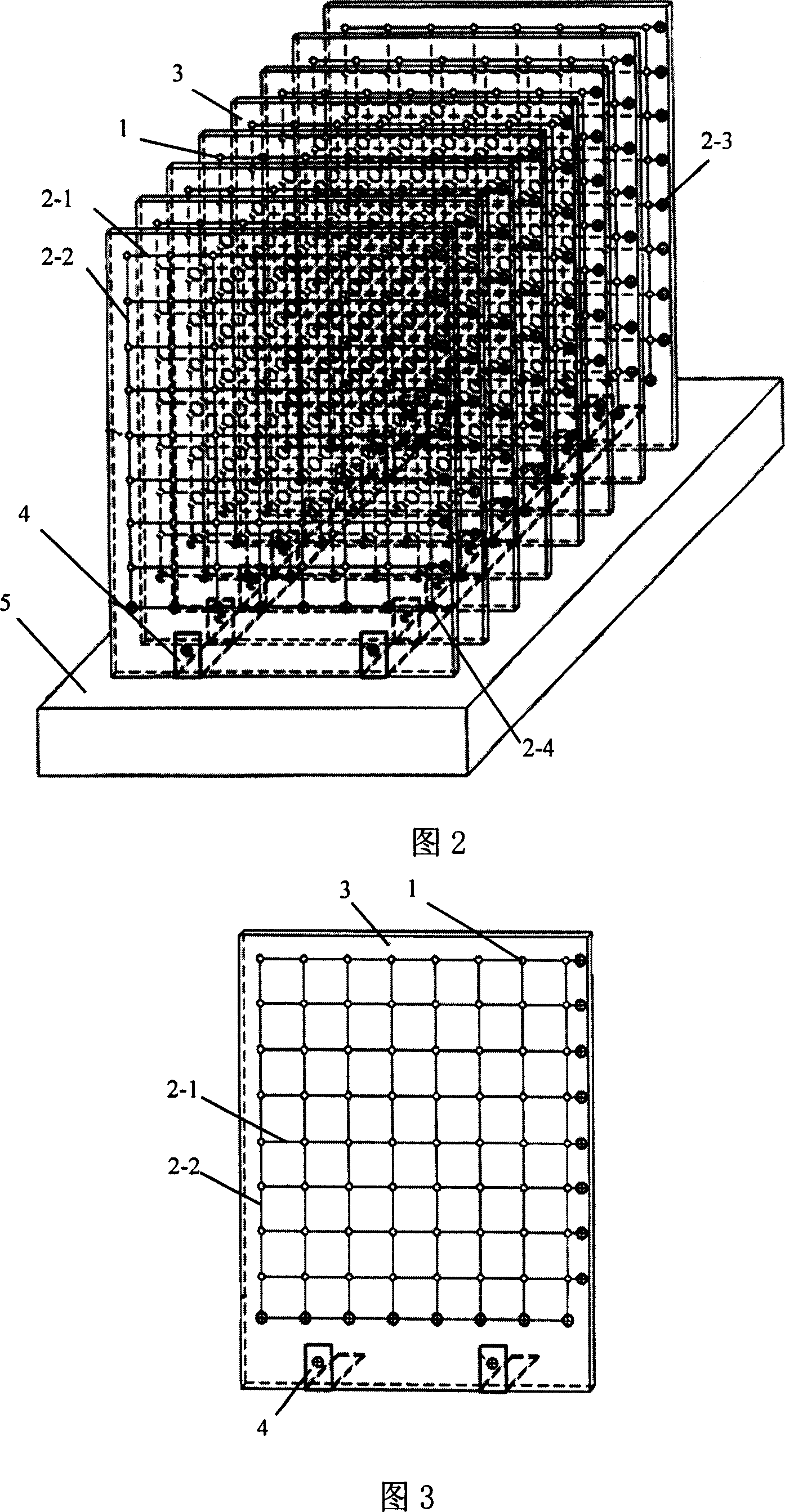

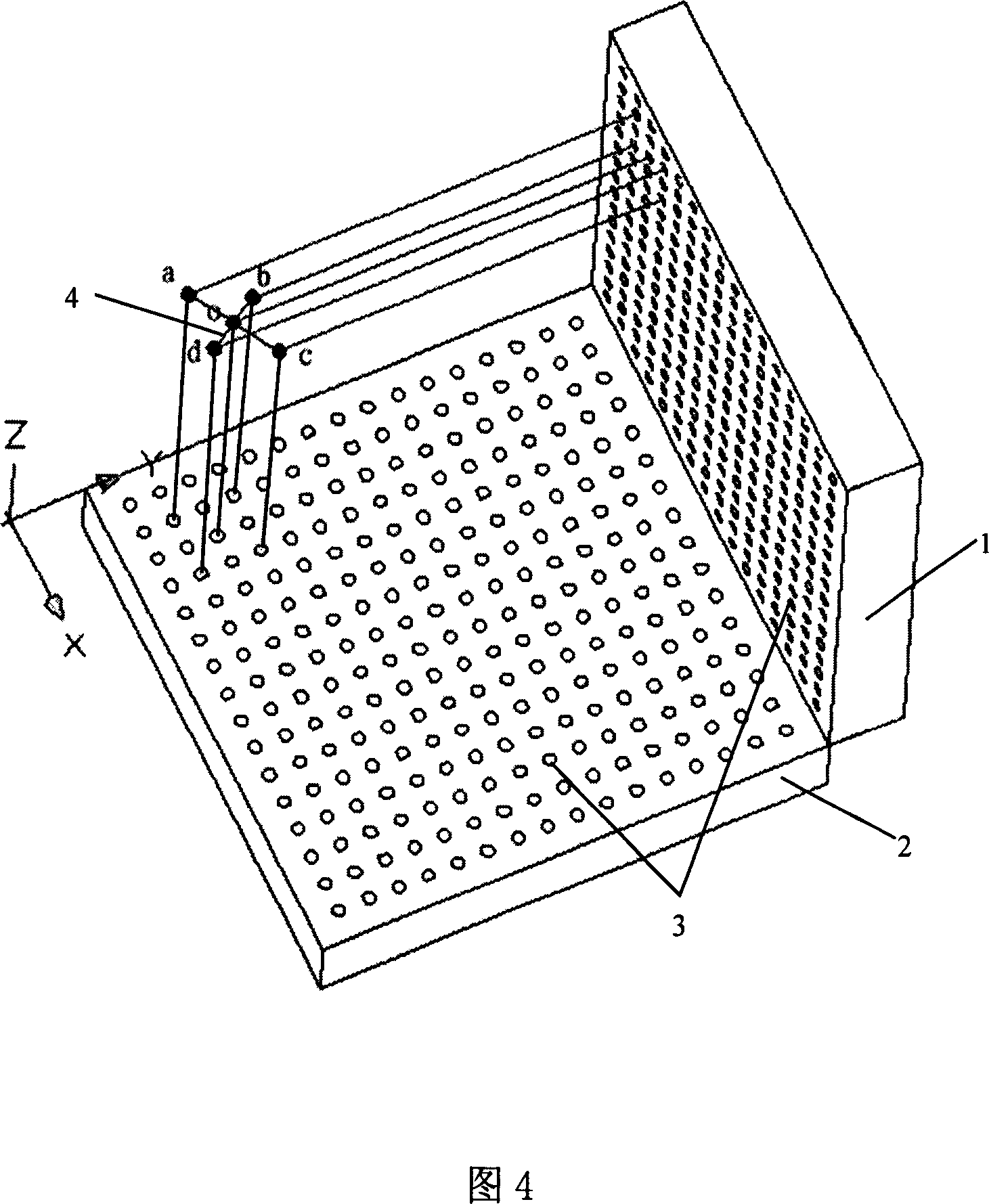

Three-dimensional visual display method and device

InactiveCN101013202AThe display effect is intuitiveThe display is accurate3D modellingOptical elementsData processing systemAnimation

The invention provides a 3D visual display method, with the steps: data processing system uses the 3D object scanning equipment or artificial design, to obtain 3D data; through the calculation, the data processing system produces the node 3D coordinates value of 3D data corresponding to the space lattice (X, Y, Z) of 3D visual display device, in which X>=8, Y>=8, Z>=8; according to the 3D coordinates value, the data processing system outputs signal to 3D visual display device, making the node corresponding to the space lattice (X, Y, Z) to be luminous in the 3D visual display device, so to achieve the 3D visual display. The node luminous method includes LED conductive luminescence, sports particle collisions luminescence. The invention can display 3D composition and animation under no picture or video circumstances, making people viewing 3D results within 360-degree, with good display effect, and accurate, and it can easily control and adjust through data processing system (such as computers, etc.), and have wide application.

Owner:李溢雯

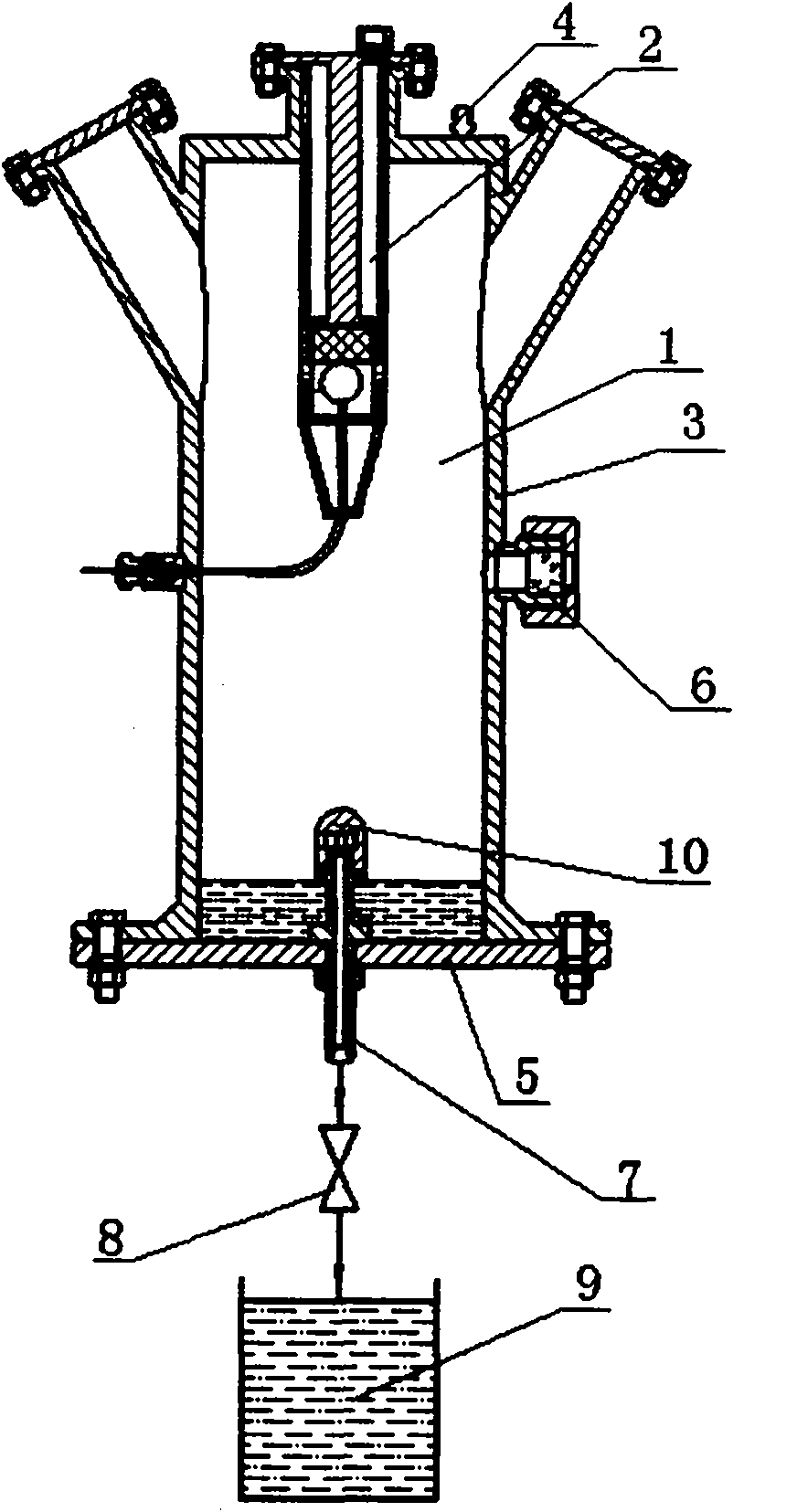

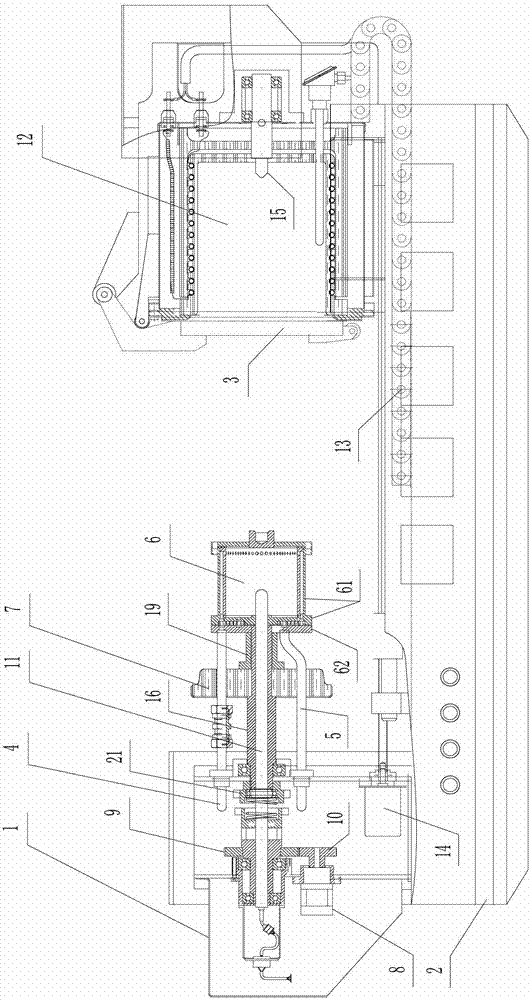

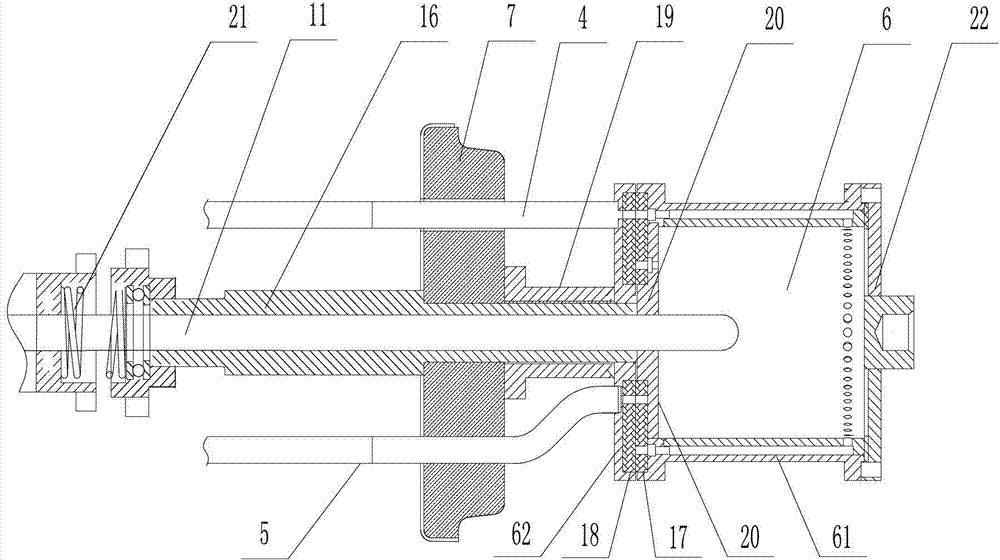

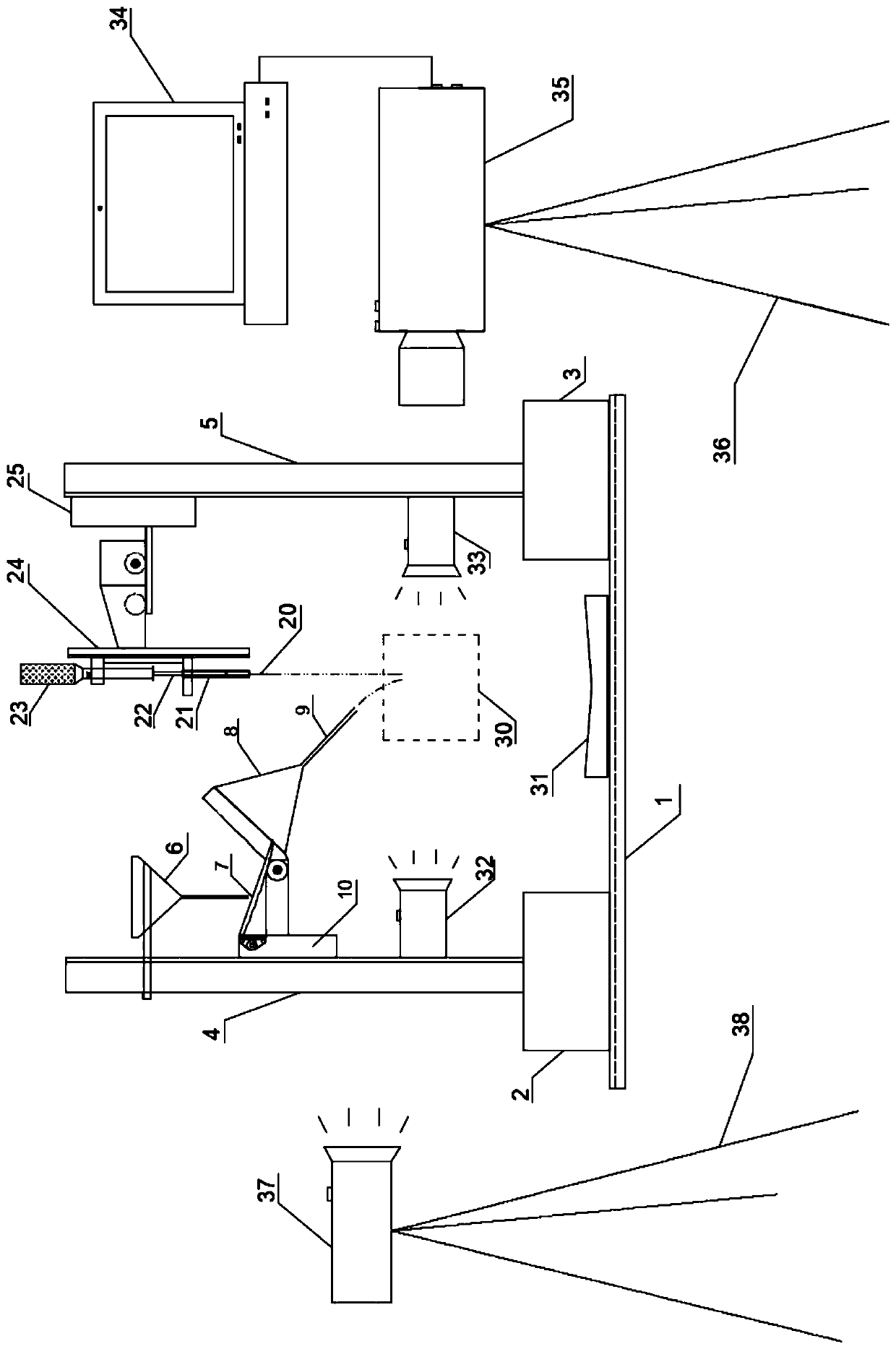

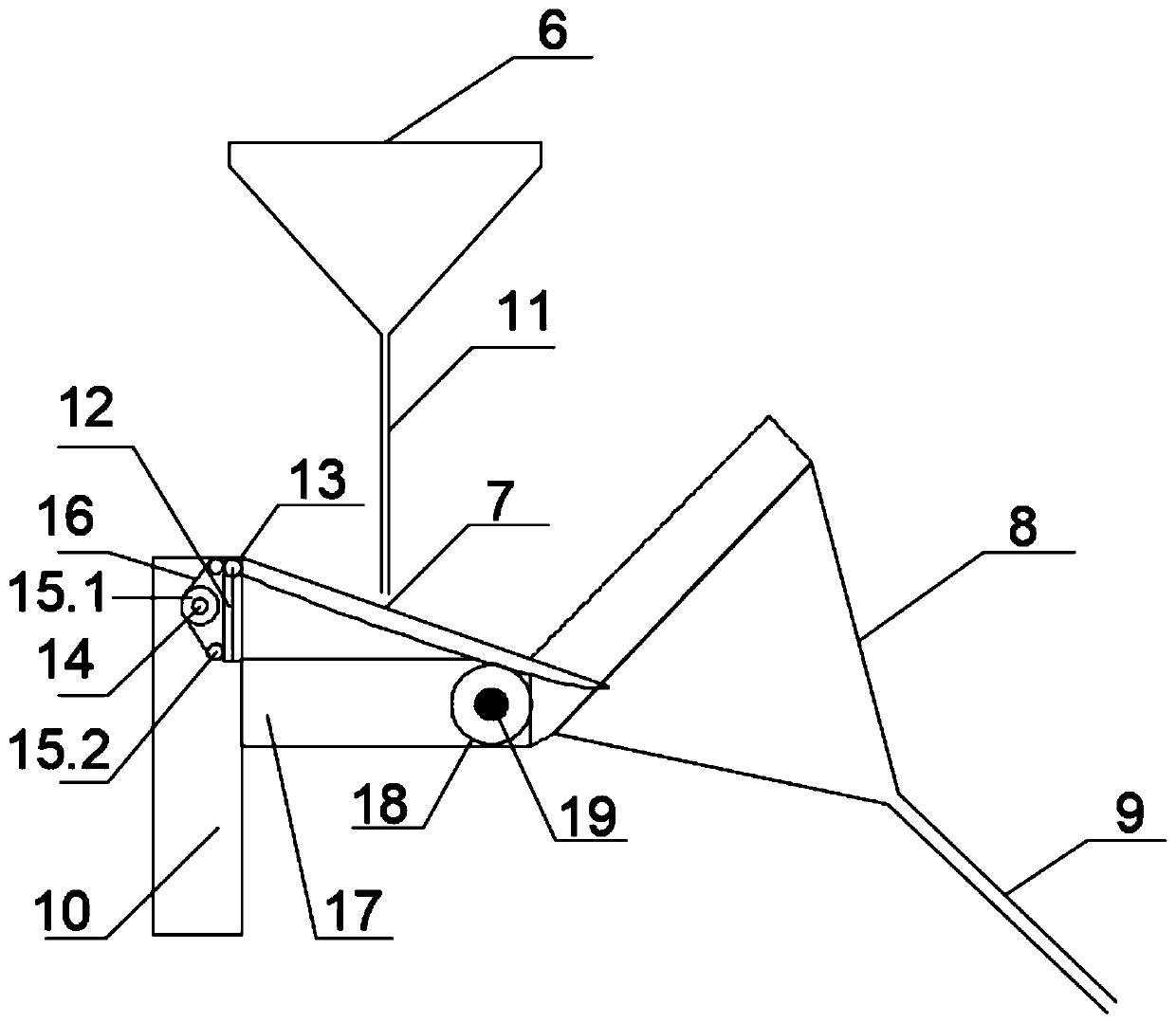

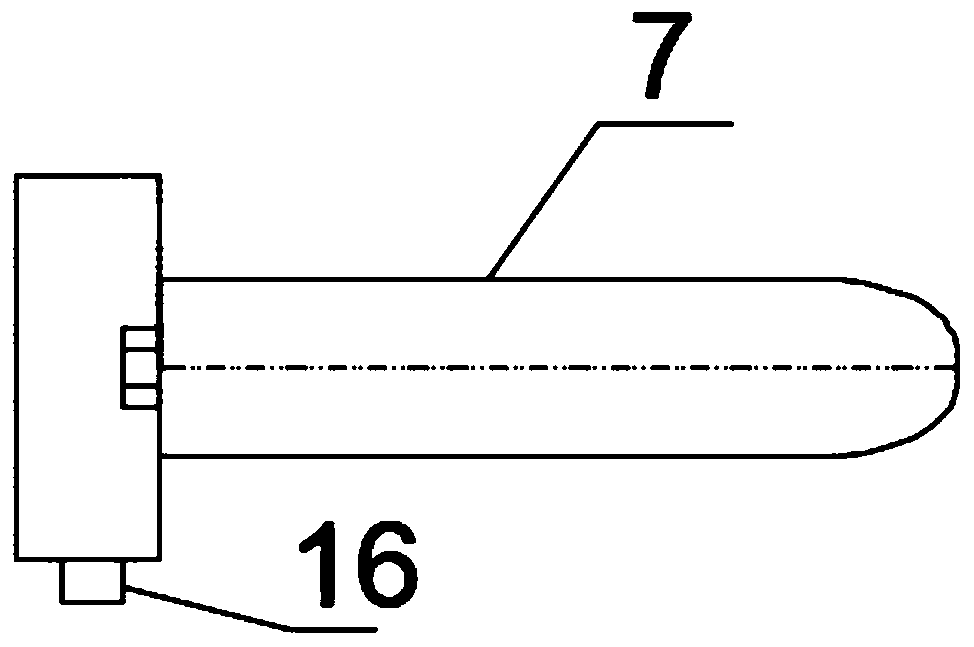

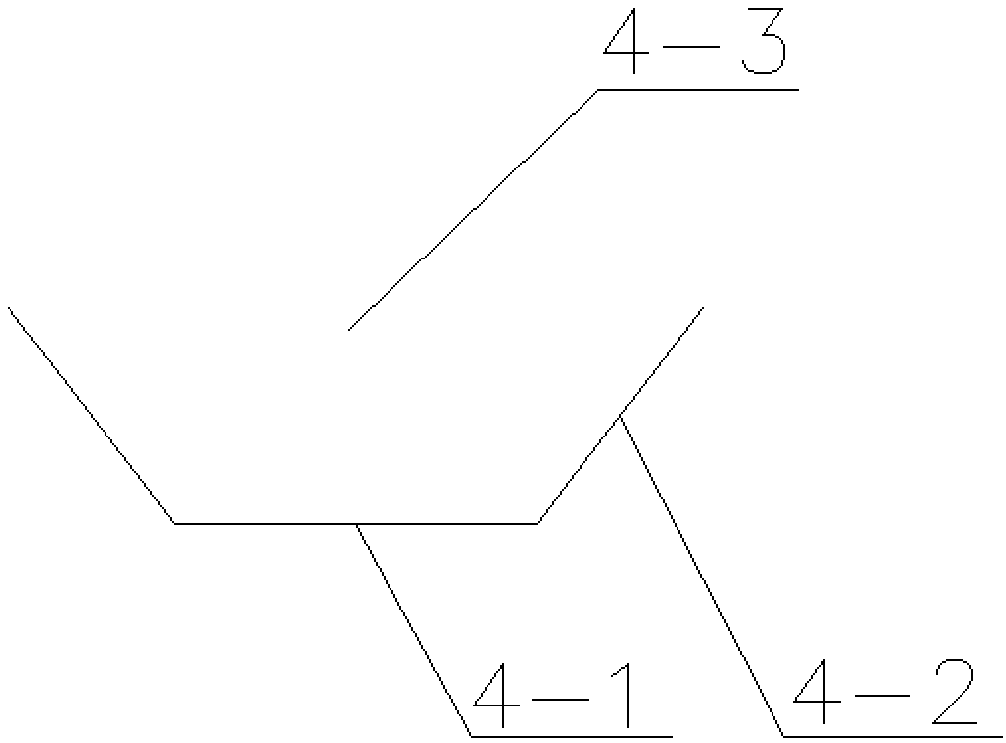

Test device for researching condensed phase particle collision discipline

InactiveCN102052199AAdjustable particle speedAdjustable angleRocket engine plantsEngineeringParticle collision

The invention provides a test device for researching condensed phase particle collision discipline. The device comprises a test section assembly and a particle generator. Through selecting the outlet area of a speed control piece of the particle generator, the content of metal in a propellant and an included angle of a plurality of particle generators, high temperature and high pressure environment of the condensed phase particle collision in an actual engine can be simulated, simultaneously the parameters such as particle speed, collision angle, particle concentration and the like can be adjustable under the condition that other parameters are unchanged, and the influence of the single parameter such as particle speed, collision angle and particle concentration on the changes of particlediameter before and after the collision can be researched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

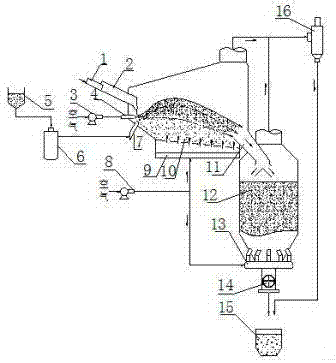

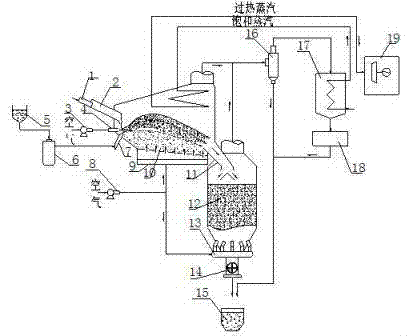

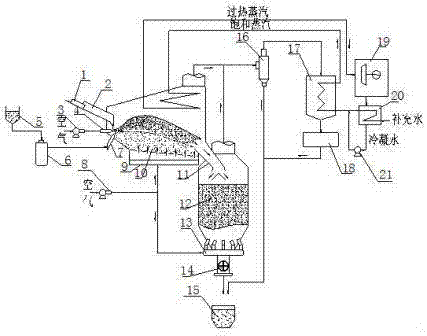

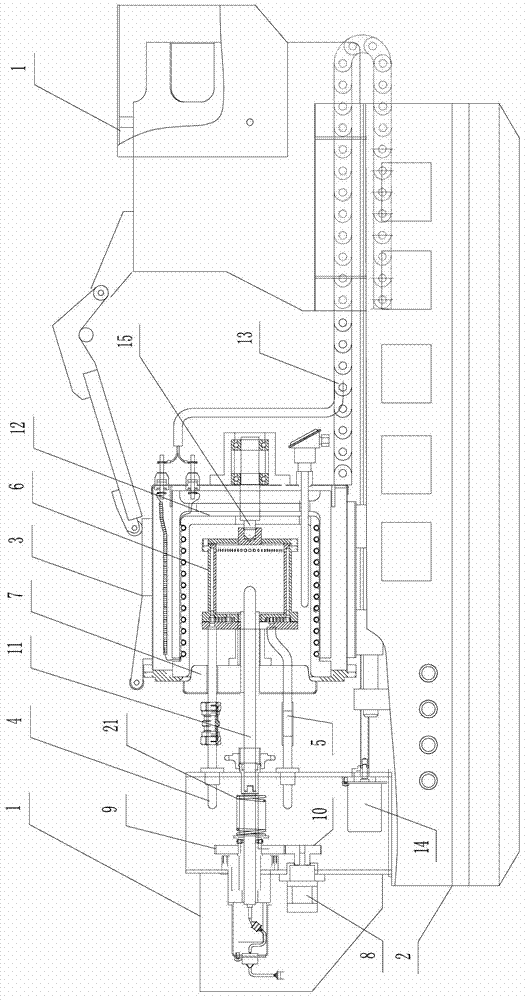

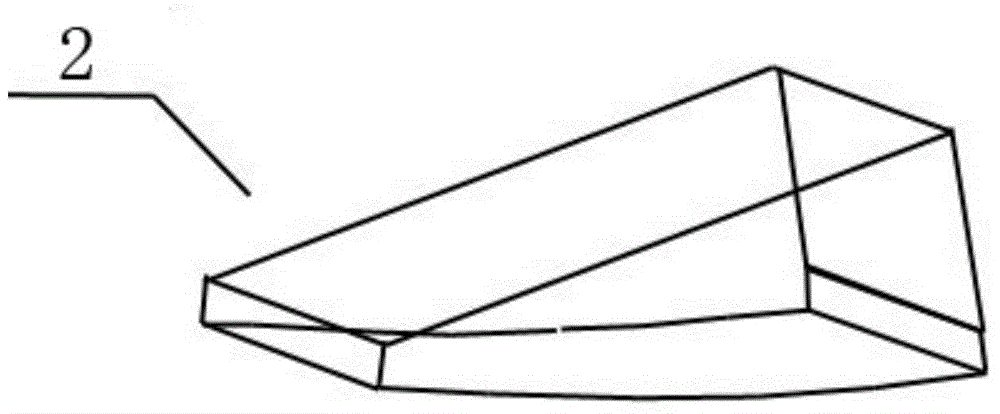

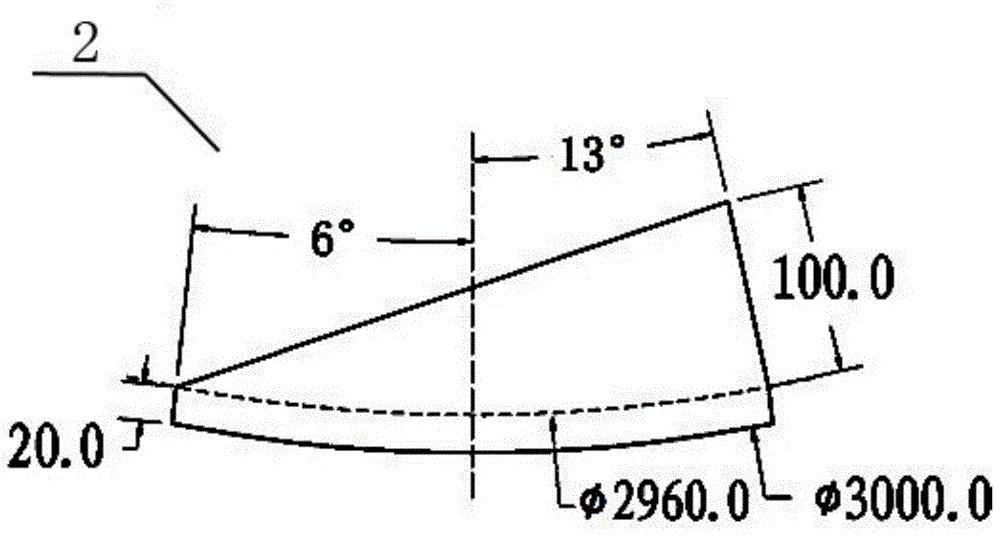

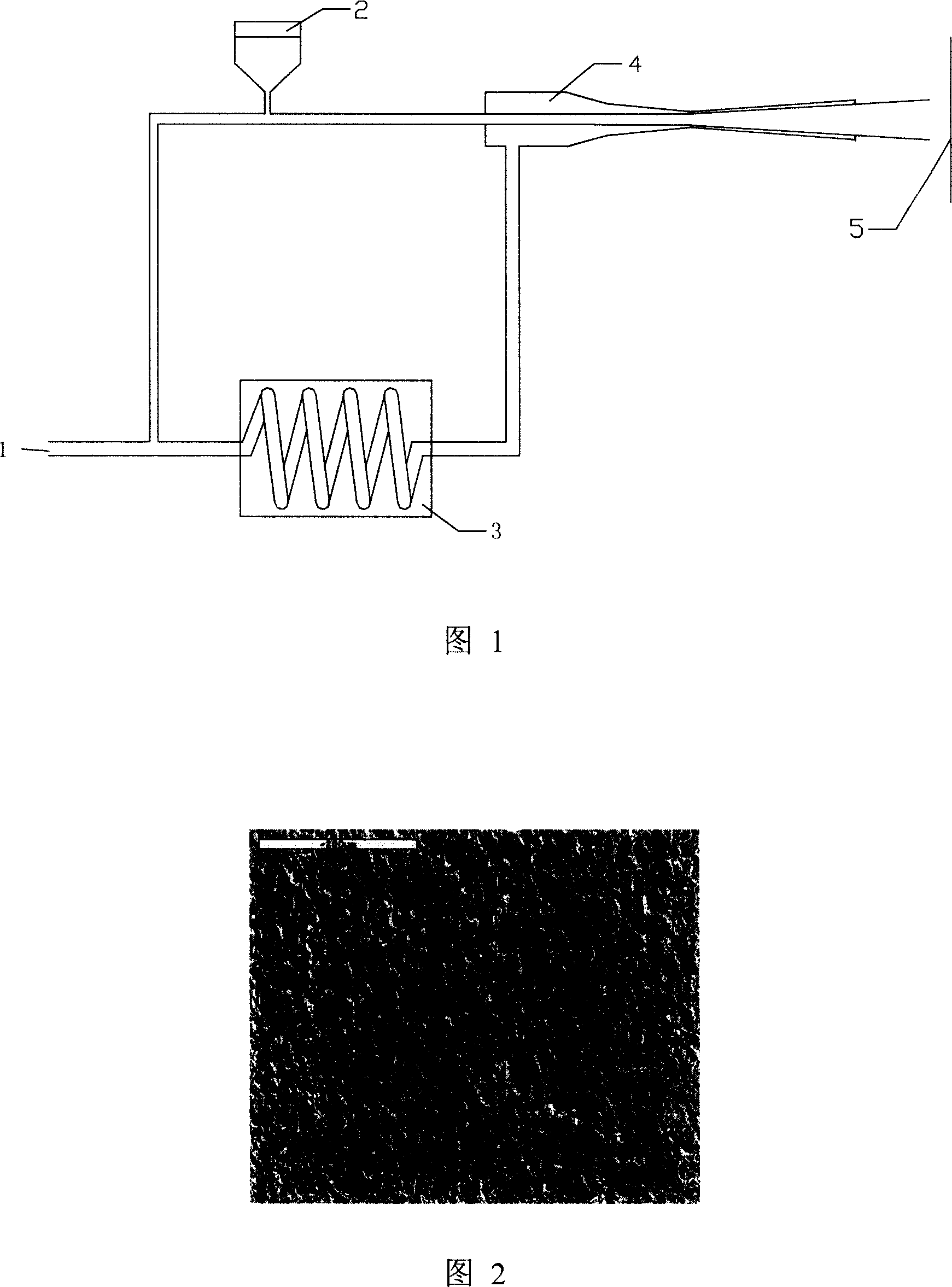

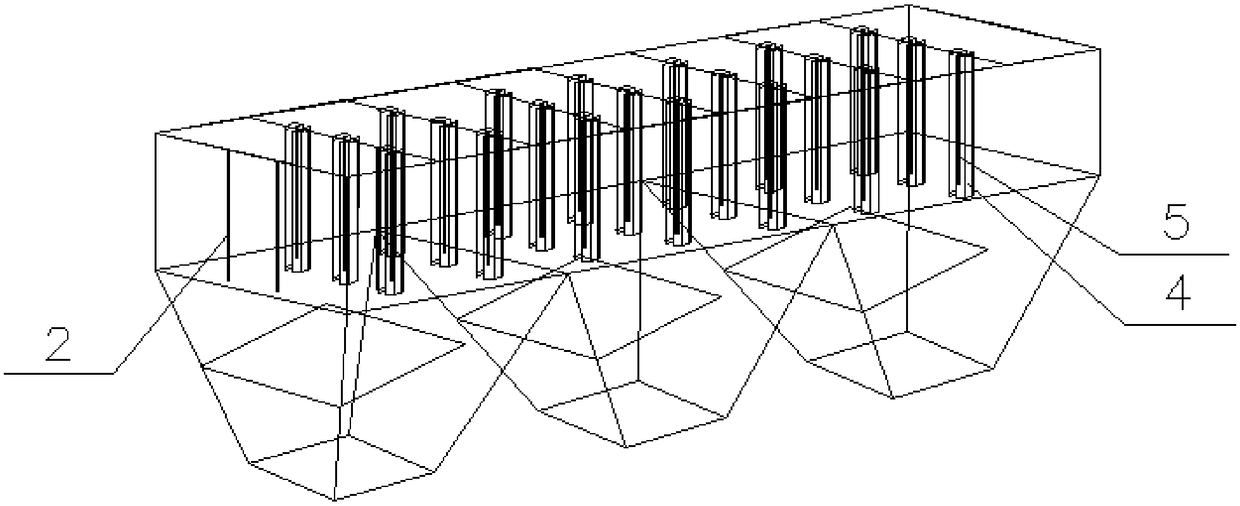

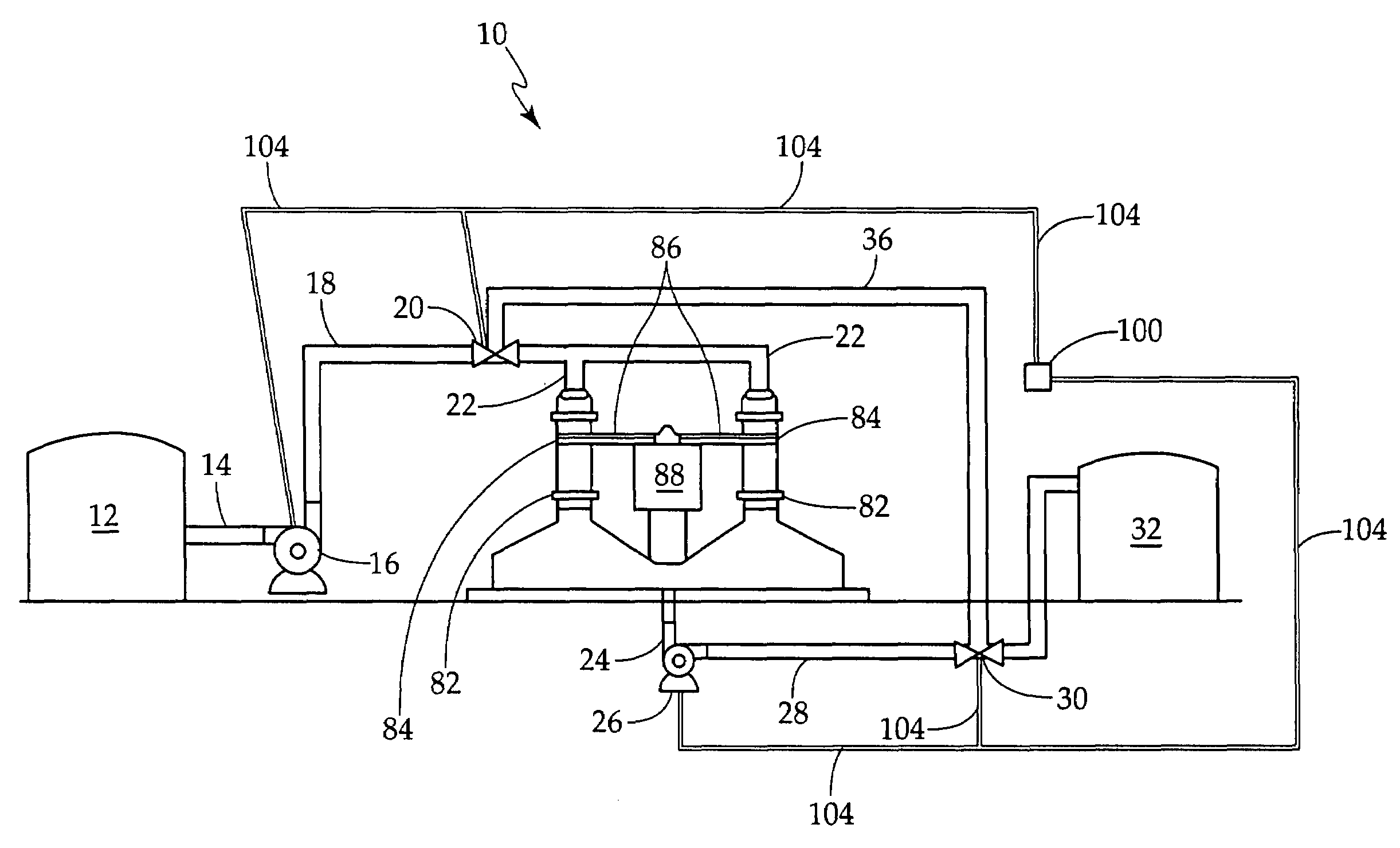

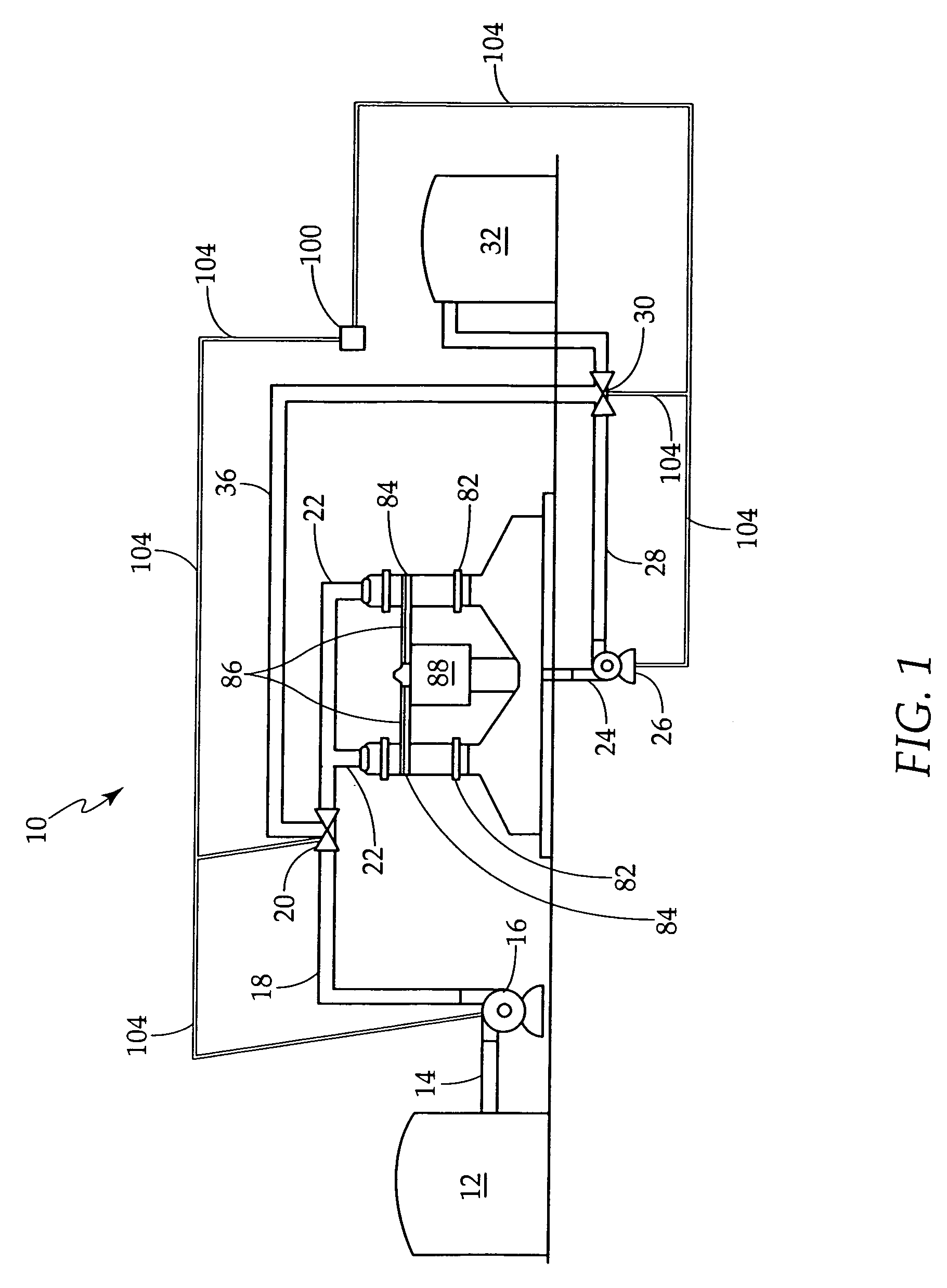

Recycling system of blast furnace slag heat

ActiveCN102851415AUniform particle sizeHigh granulation efficiencyIncreasing energy efficiencyRecycling and recovery technologiesThermal energySlag

The invention belongs to the field of energy recycling, and particularly relates to a recycling system of blast furnace slag heat in the metallurgical and steel industries. The recycling system of blast furnace slag heat comprises a pelletizing unit, a fluidized-bed slag particle collision unit, an air heat exchange unit, a superheated steam recovery unit, a deslagging unit. The pelletizing unit comprises a slag trough, a guide trough, an air-quenching fan, and an air-quenching nozzle. The slag trough is disposed above the guide trough at certain inclination. High-pressure air generated by the air-quenching fan on the lower portion of the guide trough is sprayed from the air-quenching nozzle, and an outlet of the guide trough is inserted into a fluidized bed. The recycling system of blast furnace slag heat has the advantages that the pelletizing efficiency is high, mutual adhesion of slag particles is reduced and the like.

Owner:SCIMEE TECH & SCI CO LTD

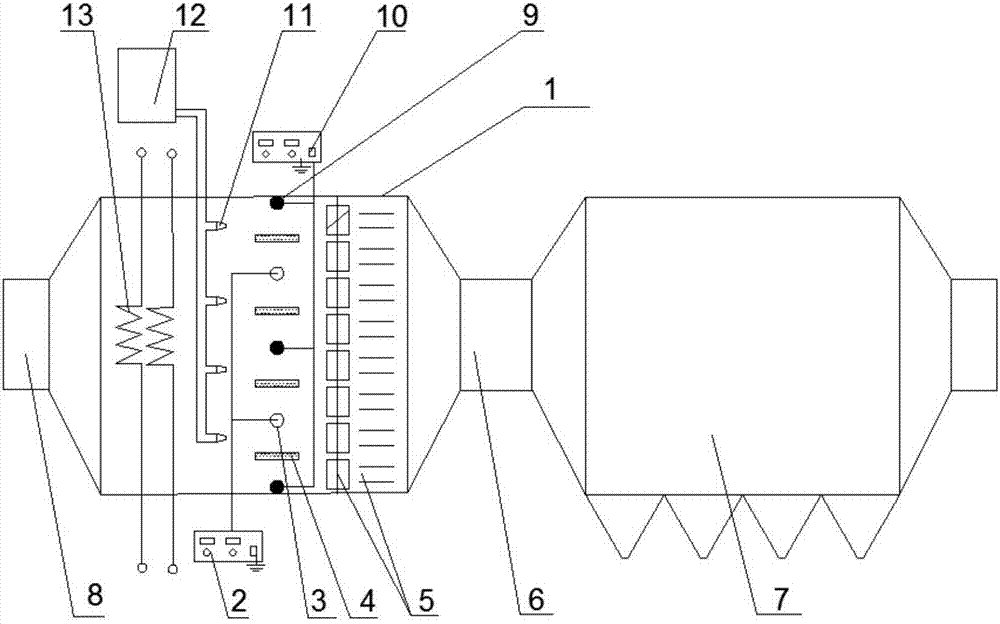

Multifield promotion-based coagulation and aggregation strengthening device and method for particulate matters

InactiveCN107138016AIncrease the probability of collisional condensationImprove removal effectAuxillary pretreatmentParticulatesEngineering

The invention relates to a multifield promotion-based coagulation and aggregation strengthening device and method for particulate matters. According to the coagulation and aggregation strengthening device, a heat-exchange cooling condenser, an ion wind-assisted orifice plate type electric coagulation system and a coagulation mixer are arranged in sequence in a coagulator, the ion wind-assisted orifice plate type electric coagulation system comprises an anode, orifice plate type polar plates and an cathode, the anode and the cathode are respectively arranged between two adjacent orifice plate type polar plates, a spray humidifier is also arranged in front of or behind the orifice plate type electric coagulation system, and the spray humidifier comprises a plurality of nozzles communicated with a liquid drop generating device. The coagulation and aggregation strengthening device combines phase change condensation with spray humidification and growth, simultaneously improves the particle collision and coagulation probability by using the ion wind convection field effect in an electric dust collector, and integrates multifield effects of electric field force, liquid bridge force, van der waals force, viscous force and the like in the same equipment for strengthening the coagulation and aggregation effects of the particles, so the average particle diameters of the particles are increased obviously, and the method is an efficient way for further increasing the removal effect of dedusting equipment and reducing the discharge concentration of particulate matters in flue gas.

Owner:ZHEJIANG UNIV

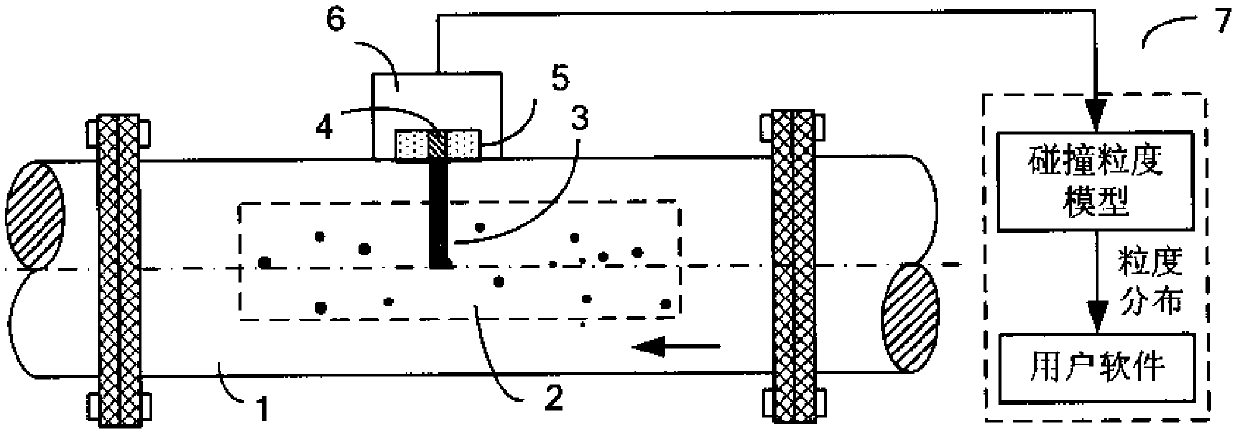

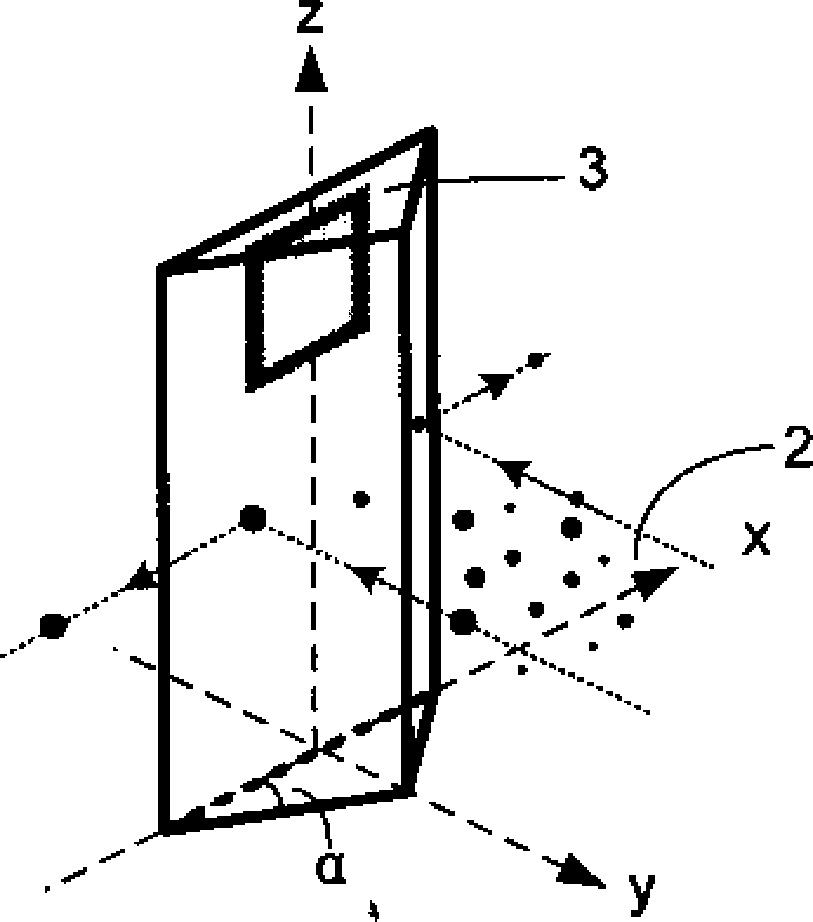

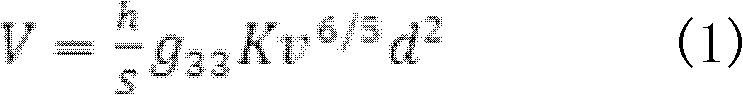

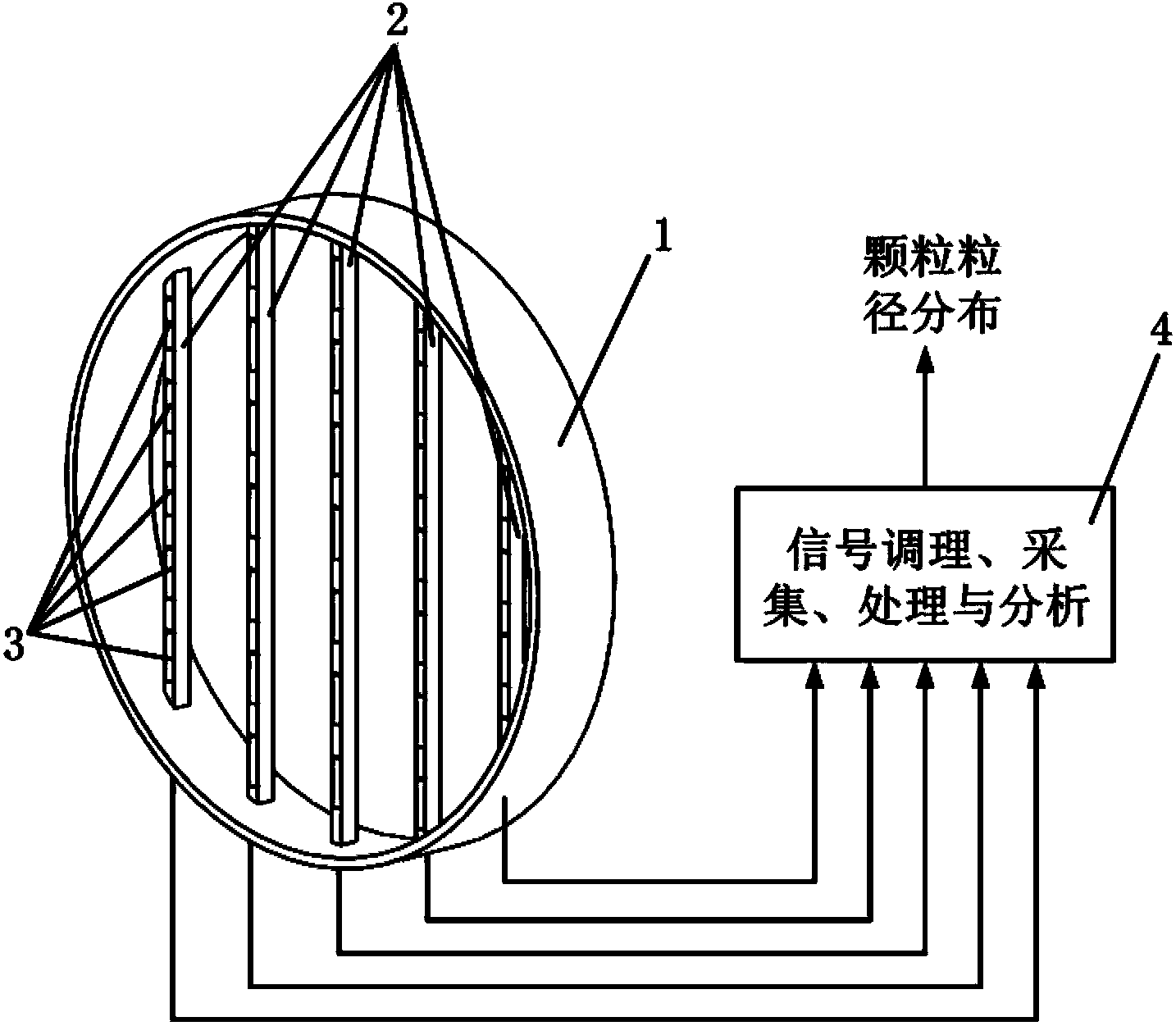

Piezoelectric sensor-based on-line measurement device and method for particle size distribution

InactiveCN102608005ASimple structureReduce volumeParticle size analysisCollision dynamicsMeasurement device

The invention discloses a piezoelectric sensor-based on-line measurement device and method for particle size distribution, which belong to the field of gas-solid two-phase flow on-line measurement technique. The on-line measurement device is characterized in that: a collision induction probe is inserted in the middle of a gas-solid two-phase flow pipeline; a piezoelectric sensor is arranged on the collision induction probe; a signal conditioning plate and a data acquisition module are connected with the piezoelectric sensor and a signal processing system; when solid particles are collided with the collision induction probe, the piezoelectric sensor senses a particle collision signal and sends the particle collision signal to the signal conditioning plate and the data acquisition module; and the particle size distribution is obtained through signal processing software and a collision particle model. The device has the characteristic that the piezoelectric sensor is utilized to obtain the collision signal of small particle collision directly so as to realize real-time monitoring on the particle size distribution; the influence of background noise on the collision signal is reduced; and a collision dynamics principle is utilized to build a mathematical model of the collision signal and the particle size, so that the size distribution of measured particles in the pipeline is obtained.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

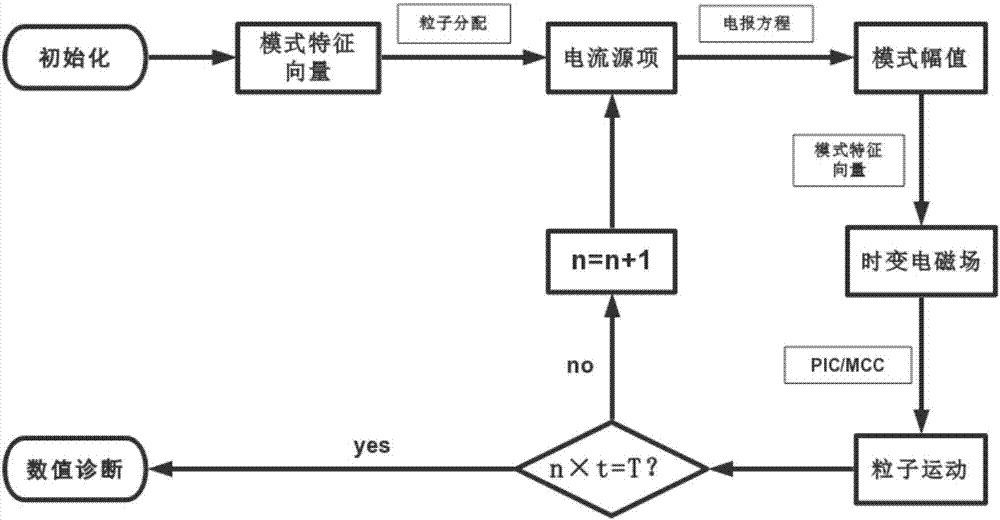

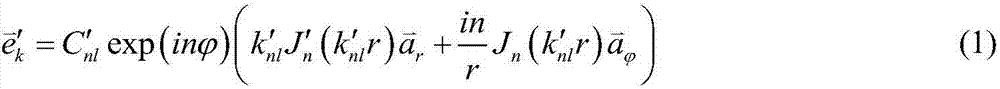

MPM hybrid algorithm applied to numerical simulation of ECR ion source

ActiveCN107577639AAccurate descriptionReduce computational complexityComplex mathematical operationsComputation complexityMaxwell's equations

The invention belongs to the field of numerical simulation technology of ECR ion sources, and particularly relates to an MPM hybrid algorithm applied to numerical simulation of an ECR ion source. Thealgorithm is suitable for use in an ECR ion source structure. The MPM hybrid algorithm of simulation of the ECR ion source is established through combining an MAGY theory and PIC / MCC simulation algorithms, a time-varying electromagnetic field is described by the MAGY theory, self-consistent interaction of charged particles and the electromagnetic field is described by the PIC algorithm, and inter-particle collision processes are described by the MCC algorithm. A complex and complete solving process which originally needs to be carried out on Maxwell's equations is enabled to be simplified to solving on a set of coupled one-dimensional partial differential equations about mode amplitudes, relatively larger time step length can also be taken due to that compared with high-frequency cycles, changes of the mode amplitudes are slower, and computational complexity and a computational amount are greatly reduced. In addition, an electromagnetic model is adopted, and thus compared with adoptingan electrostatic model, the algorithm can more accurately describe an actual physical process.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

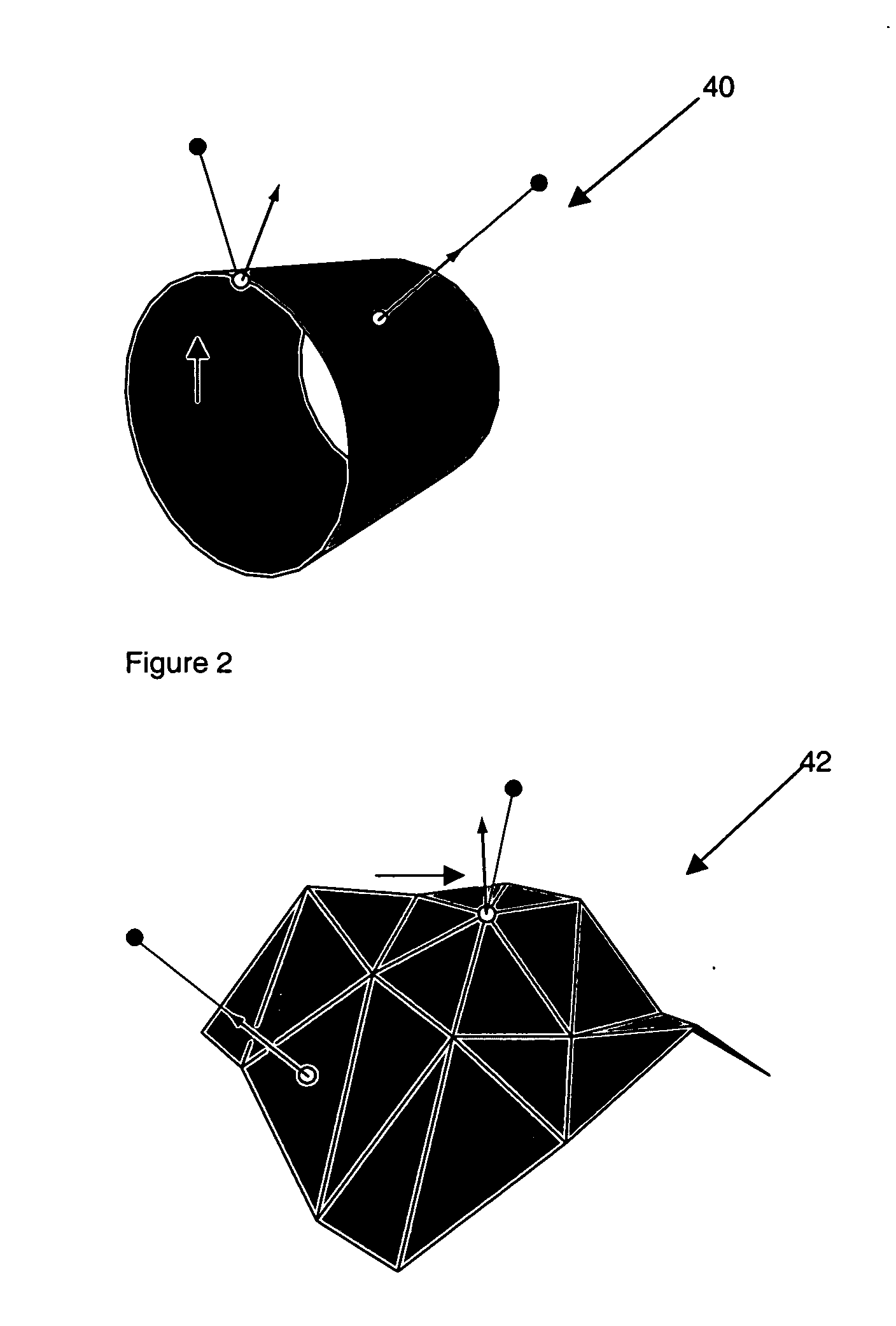

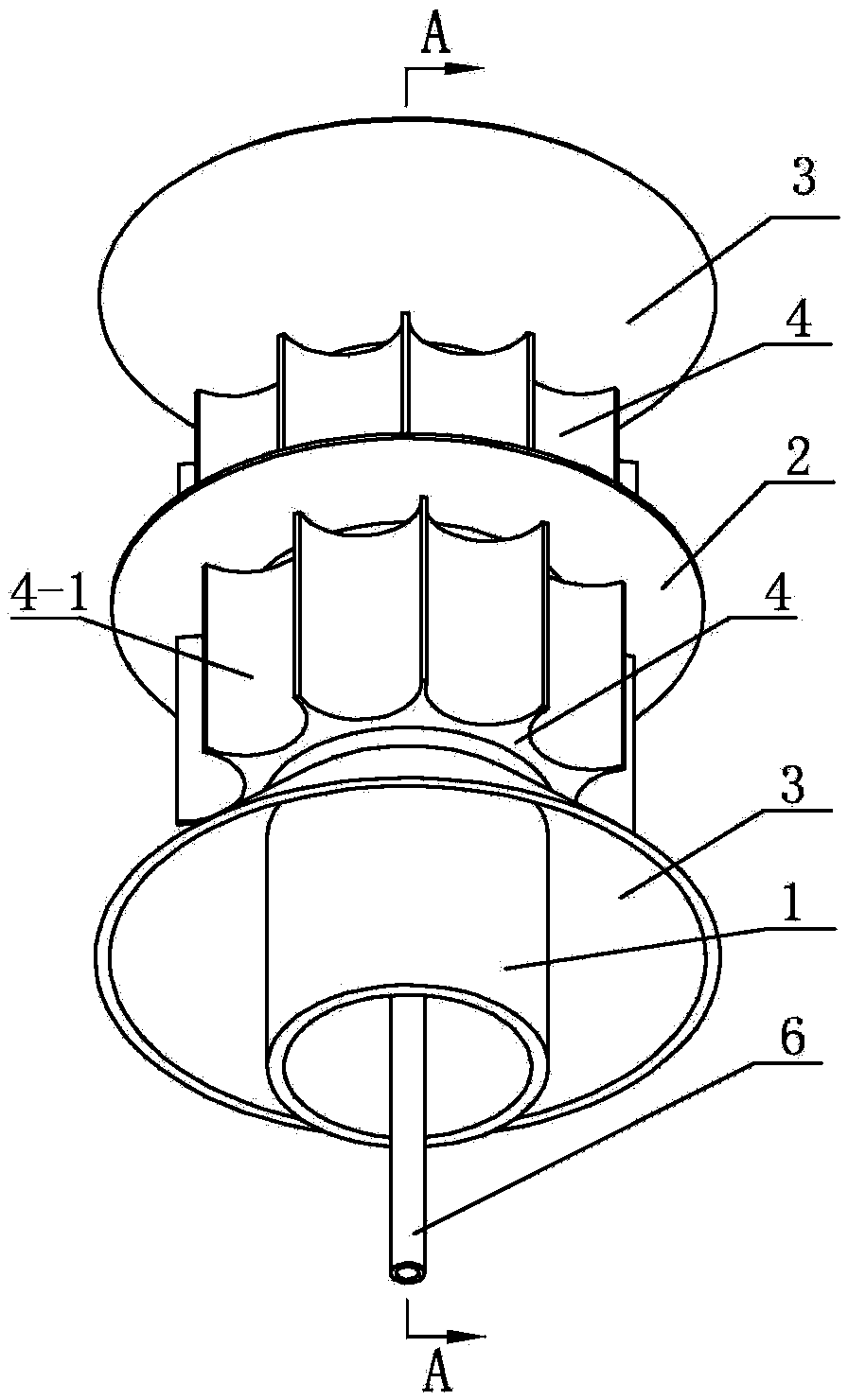

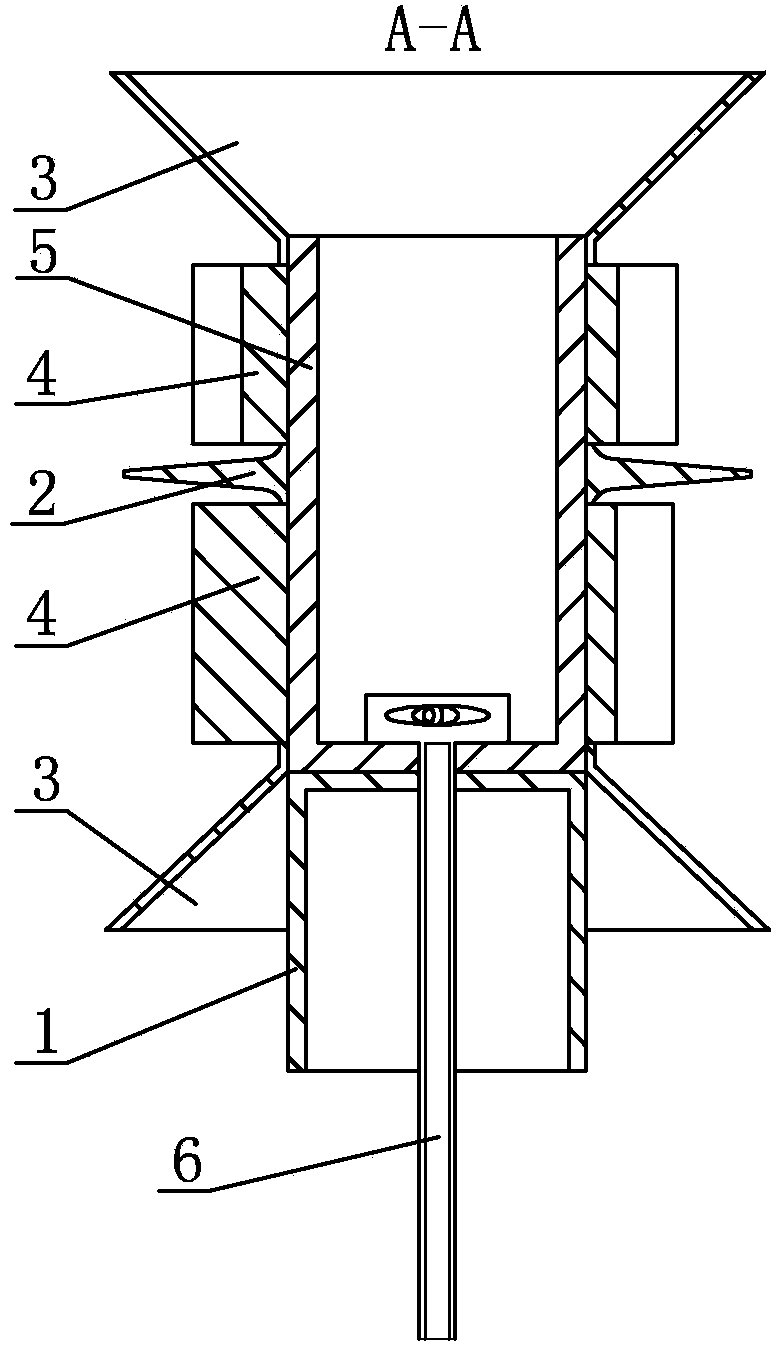

Radiation heat dissipation device for multistage cusped magnetic field plasma thruster

ActiveCN103790794AIncrease the areaReduce areaMachines/enginesUsing plasmaThermodynamicsParticle collision

The invention relates to a radiation heat dissipation device, in particular to a radiation heat dissipation device for a multistage cusped magnetic field plasma thruster. The radiation heat dissipation device for the multistage cusped magnetic field plasma thruster aims to solve the problems that due to the high anode temperature of the multistage cusped magnetic field plasma thruster, the high temperature of an outlet and the high temperature of the magnetic separatrix caused by particle collisions on the ceramic inner wall, heating carried out on the channel inner wall and the anode of the thruster is sharply enhanced within a short period, magnetism of a permanent magnet is seriously affected by heat conduction, and the thruster is poor in operation stability and reliability and short in service life. The radiation heat dissipation device for the multistage cusped magnetic field plasma thruster comprises a heat dissipation cylinder, a heat dissipation plate, two heat dissipation conical cylinders and two heat dissipaters, wherein a thruster shell is arranged between the two heat dissipation conical cylinders, the upper portion and the lower portion of the thruster shell are sleeved with the two heat dissipaters respectively, the heat dissipation plate is installed on the thruster shell in a sleeved mode and located between the two hear dissipaters, and the closed end of the heat dissipation cylinder is fixedly connected with the thruster shell. The radiation heat dissipation device is used for the multistage cusped magnetic field plasma thruster.

Owner:HARBIN INST OF TECH

Plural odd number bell-like openings nozzle device for a fluidized bed jet mill

A fluidized bed jet mill has been provided for grinding particles of material. The fluidized bed jet mill includes plural nozzle devices mounted through side walls into a grinding chamber for discharging a composite stream of high velocity fluid that receives and delivers, for particle to particle collision, entrained particles of material to be ground within the grinding chamber. Each of the nozzle device includes a plural odd number of bell-like nozzle openings for each discharging an individual stream of high velocity fluid that together form the composite stream of high velocity fluid. Each bell-like nozzle opening comprises (i) a converging region for converging and accelerating a volume of high pressure fluid being moved from a first end to a second end thereof; (ii) a throat region defining a narrowest diameter region of the bell-like nozzle opening; (iii) a first expansion region for producing a linear expansion of the volume of high pressure fluid passing through the throat region, and (iv) a second expansion region for producing a turning expansion as well as a parallel flow of the volume of high pressure fluid coming from the first expansion region. The first expansion region has a radius "r1" and a length "s1" running from the throat region towards the second end, and the radius r1 and length s1 are determined such that (dr1 / ds1) is a constant. The second expansion region has a radius "r2" and a length "s2" running from the first expansion region towards the second end, and the radius r2 and length s2 are determined such that (dr2 / ds2) is non-linear and is equal to a function of s2.

Owner:XEROX CORP

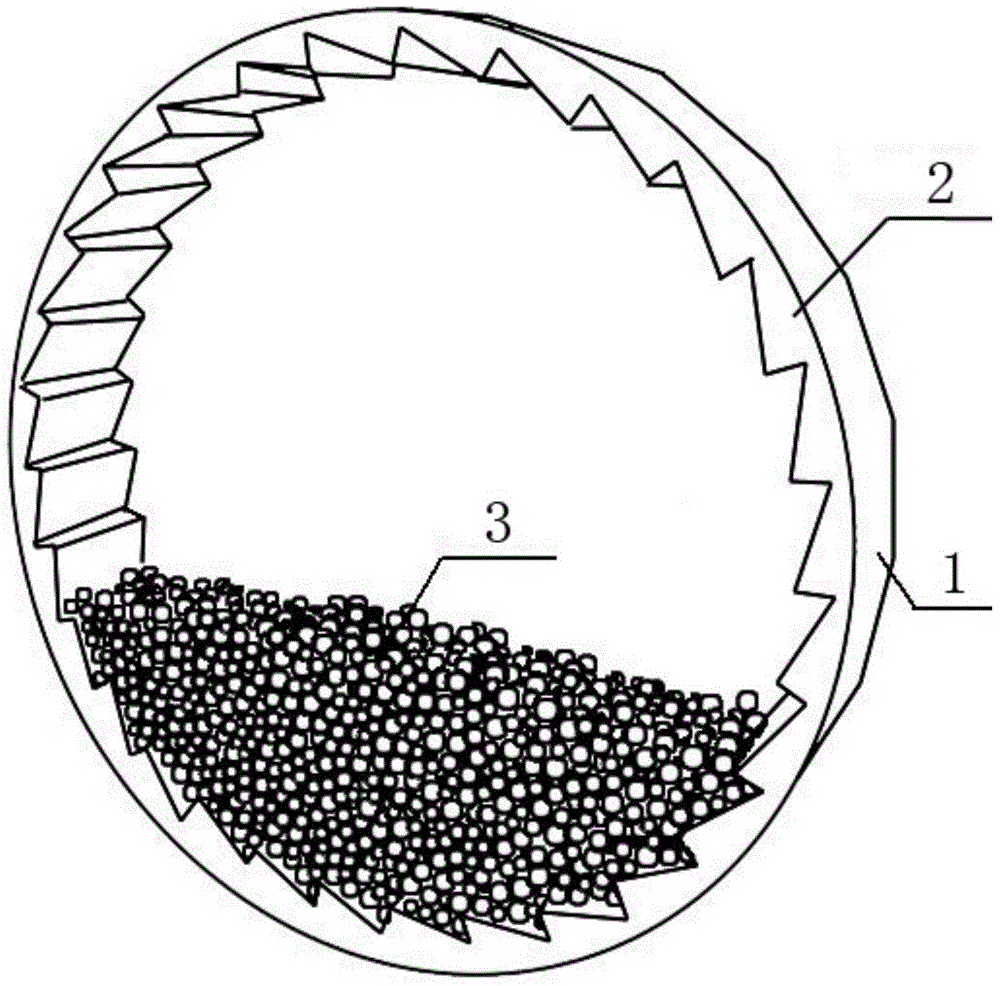

Method and apparatus for measuring dynamic thermal stability of solid particles

ActiveCN103196801AAchieve mutual frictionAchieve collisionMaterial analysisActivated carbonSolid mass

The invention discloses a method and an apparatus for measuring dynamic thermal stability of solid particles. The method, while heating the solid particles, enables the solid particles to move so as to realize mutual friction and collision among the solid particles. The apparatus comprises an actuating mechanism, a motion mechanism and a heating mechanism for heating the solid particles, wherein the solid particles are put into a rotating cylinder used as the motion mechanism, and the rotating cylinder is driven by the actuating mechanism to rotate. According to the invention, dynamic thermal stability of coal, semi-coke, activated carbon, coke, briquette and other solid particle samples can be stimulated under conditions of different temperature, heating ways, heating rates, environment atmospheres and rotating speeds of the rotating cylinder, that is, crushing and pulverization of the solid particle samples subjected to thermal stress, mechanical wear and particle collision in the rotating cylinder can be obtained through tests, thereby truly reflecting a crushing and pulverization degree of the solid particles during a practical industrial utilization process, and thus building a determination standard which is about dynamic thermal stability of the solid particles and is relatively close to the reality.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

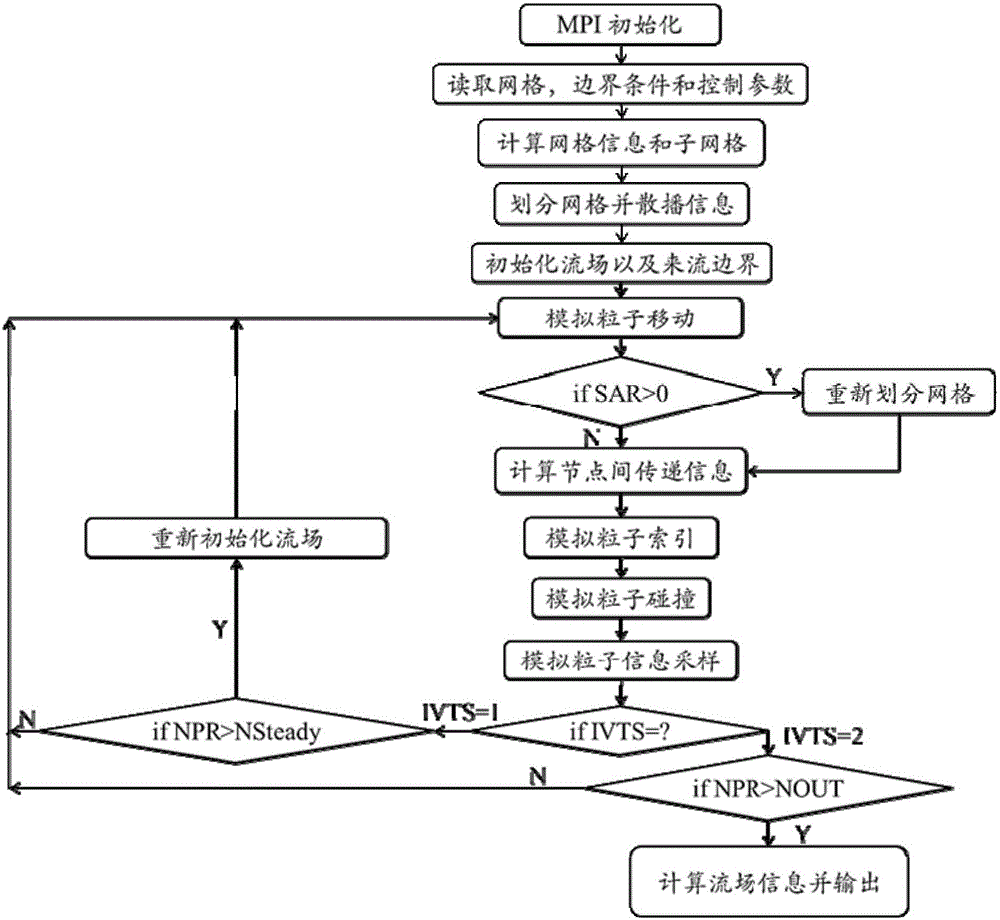

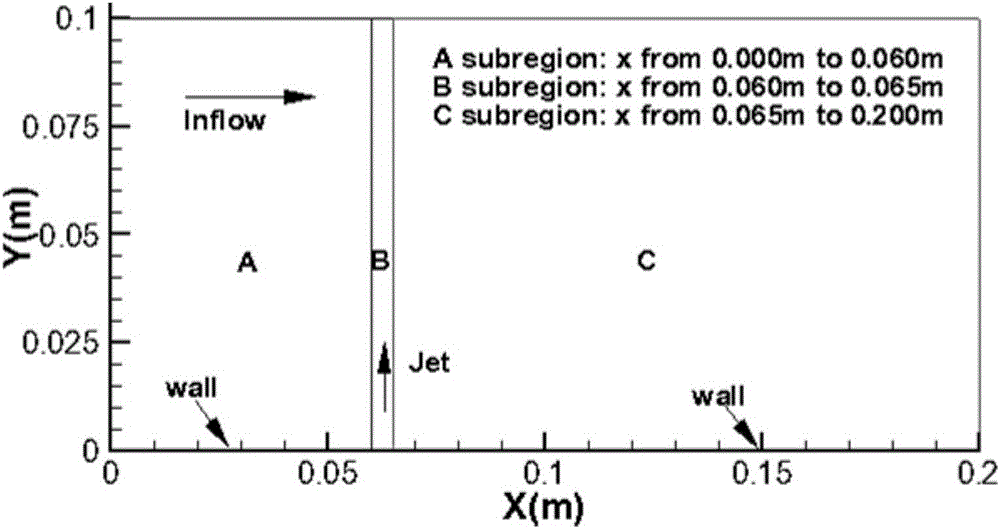

APDSMC flow field detection method specific to scale-span flow

InactiveCN106092496AShorten the timeCalculation accuracy unchangedAerodynamic testingTopology informationCollision kernel

Provided is an APDSMC (Asymptotic Preserving Direct Simulation Monte Carlo) flow field detection method specific to scale-span flow, comprising: initializing a flow field, employing an uniform motion particle movement model and a vector cross product to determine the particle change logic in a grid after movement, and obtaining position information and grid topology information after simulation particle updating; mapping particle numbers based on the grid and particle numbers based on particles; and finally, stimulating particle collisions to update speed distribution of particles in the grid, and realizing flow field detection after sampling flow filed information. The APDSMC flow field detection method processes computation requirements of different areas based on an AP scheme, and can select collision kernels of different computational domains in a more intelligent mode so as to accelerate an original DSMC method, and to allow a new algorithm to compute computational example conditions of larger spanning scales and greater density.

Owner:SHANGHAI JIAO TONG UNIV

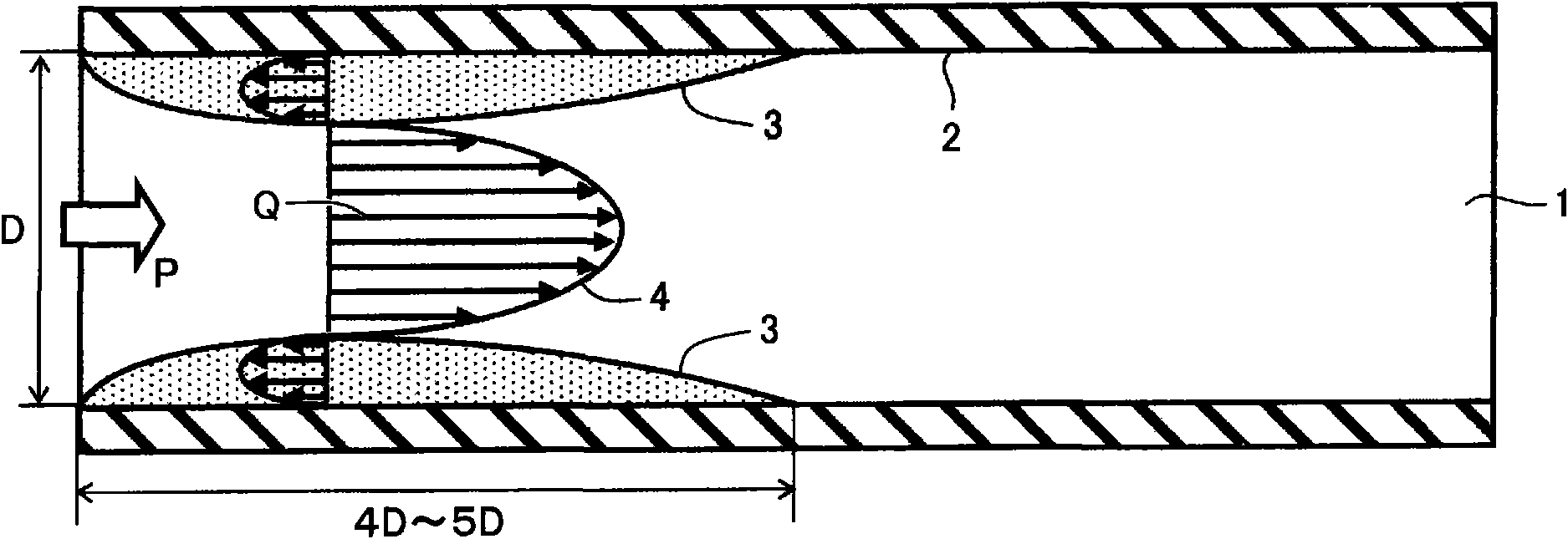

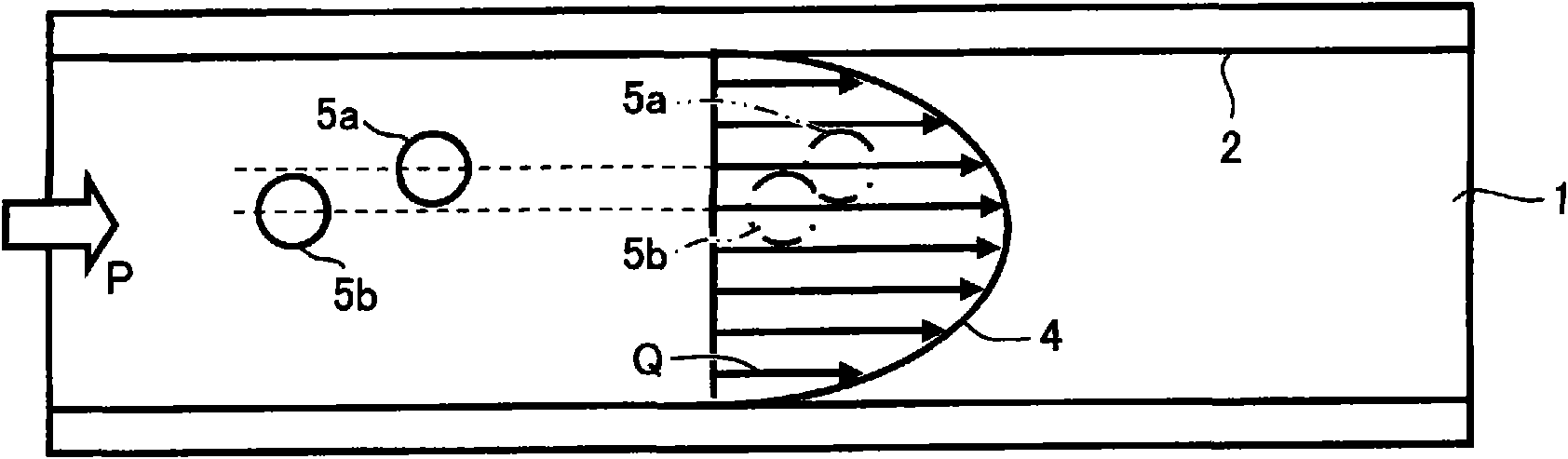

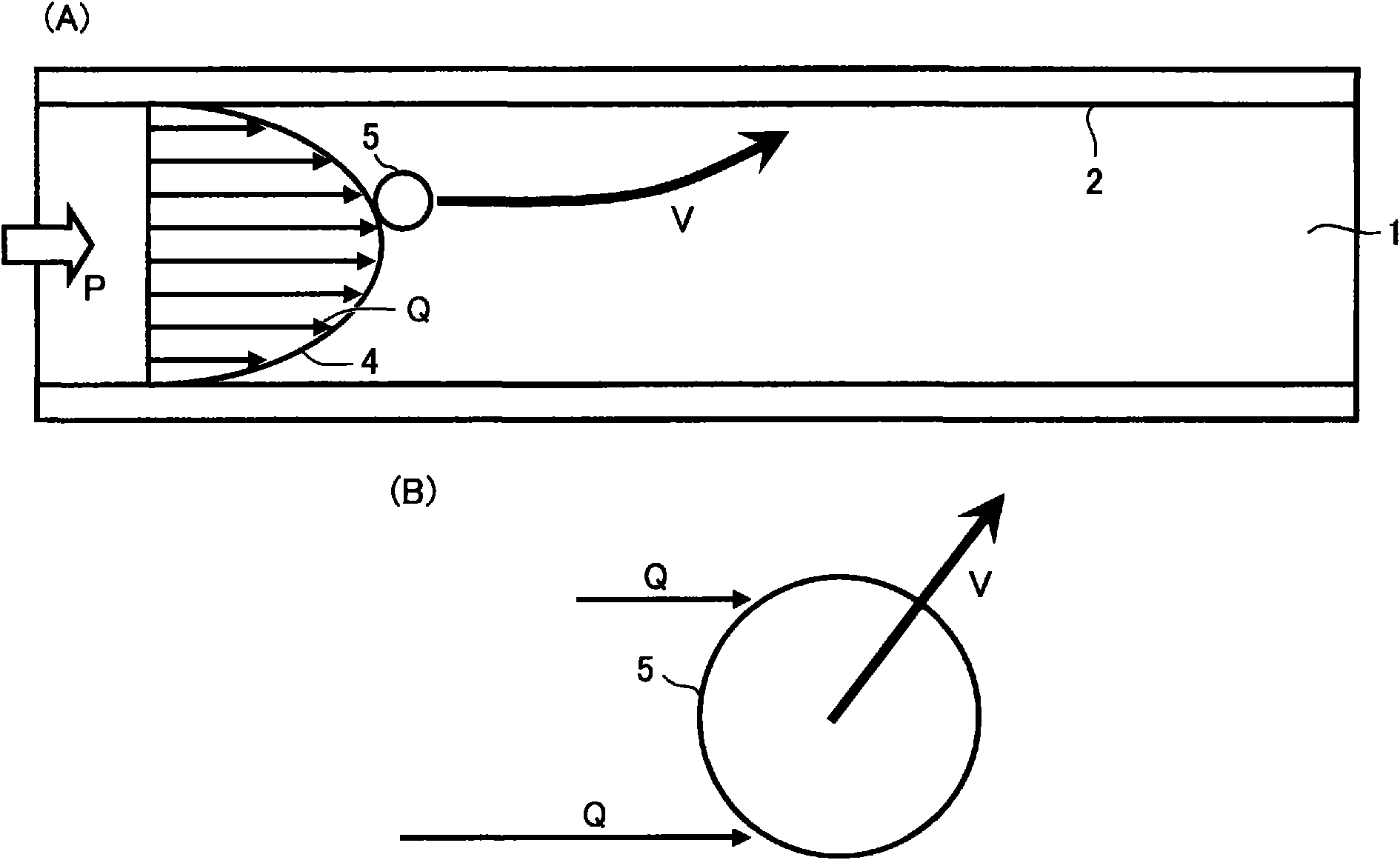

Dust flocculating passage, dust flocculating method, and vacuum cleaner

InactiveCN101528102AIncrease the probability of collisionShort intervalAuxillary pretreatmentSuction filtersFlocculationParticle collision

The present invention provides a dust flocculating passage, which is enabled with a simple structure to promote the flocculation of particles in dust by increasing the number of particle collisions, thereby to reduce the particle number and to enlarge the apparent particle diameter, and a dust flocculating method and a vacuum cleaner. The dust flocculating passage (10) comprises a passage (11) for a gas to pass therethrough, a wall (12) for forming the passage (11), and vortex generating means for generating vortexes in the gas flowing in the passage (11). The vortex generating means is so arranged on the inner face of the wall (12) as to give a heterogeneous velocity distribution to the gas flow near the wall (12). The vortex generating means includes either a turning portion (13) having a wall portion protruding from the inner face of the wall (12) into the passage (11) so as to turn the gas flow in the passage (11), or protrusions from the inner face of the wall (12) so as to make heterogeneous the velocity of the passing gas.

Owner:SHARP KK

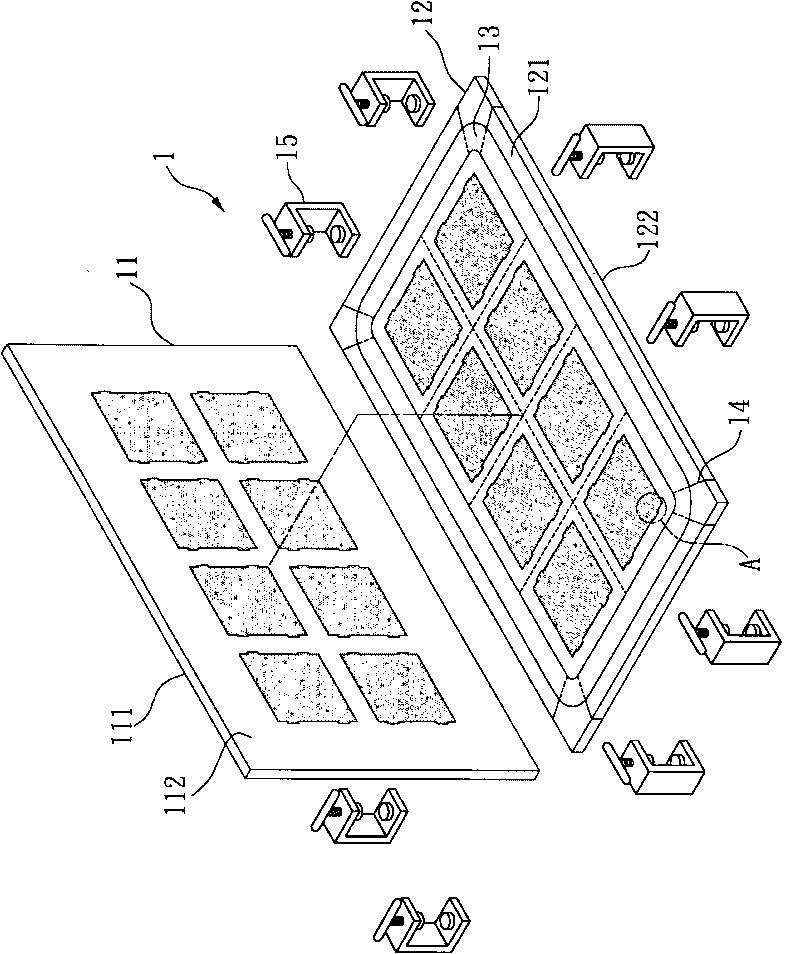

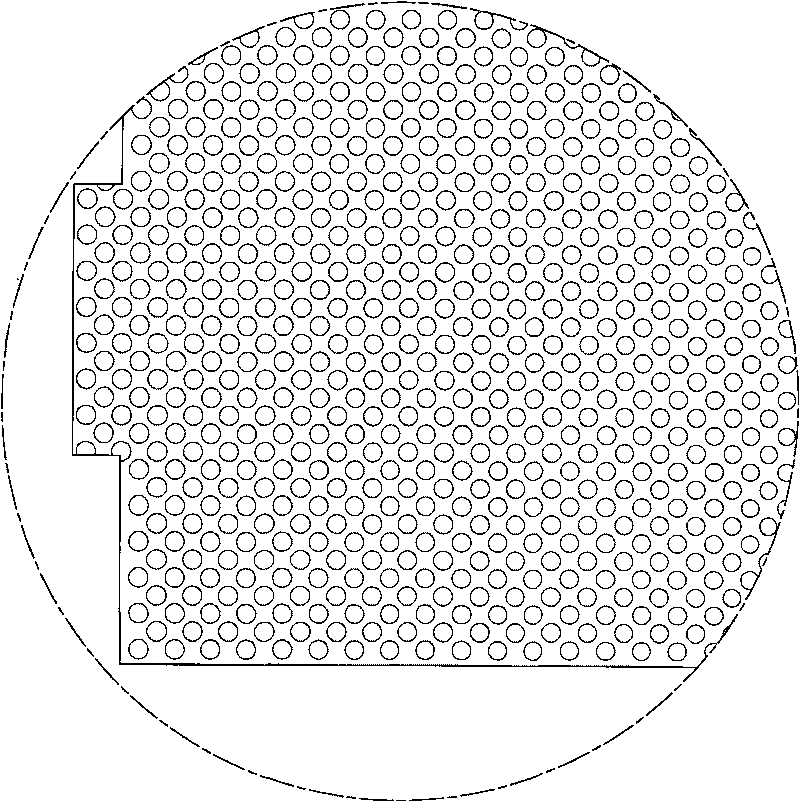

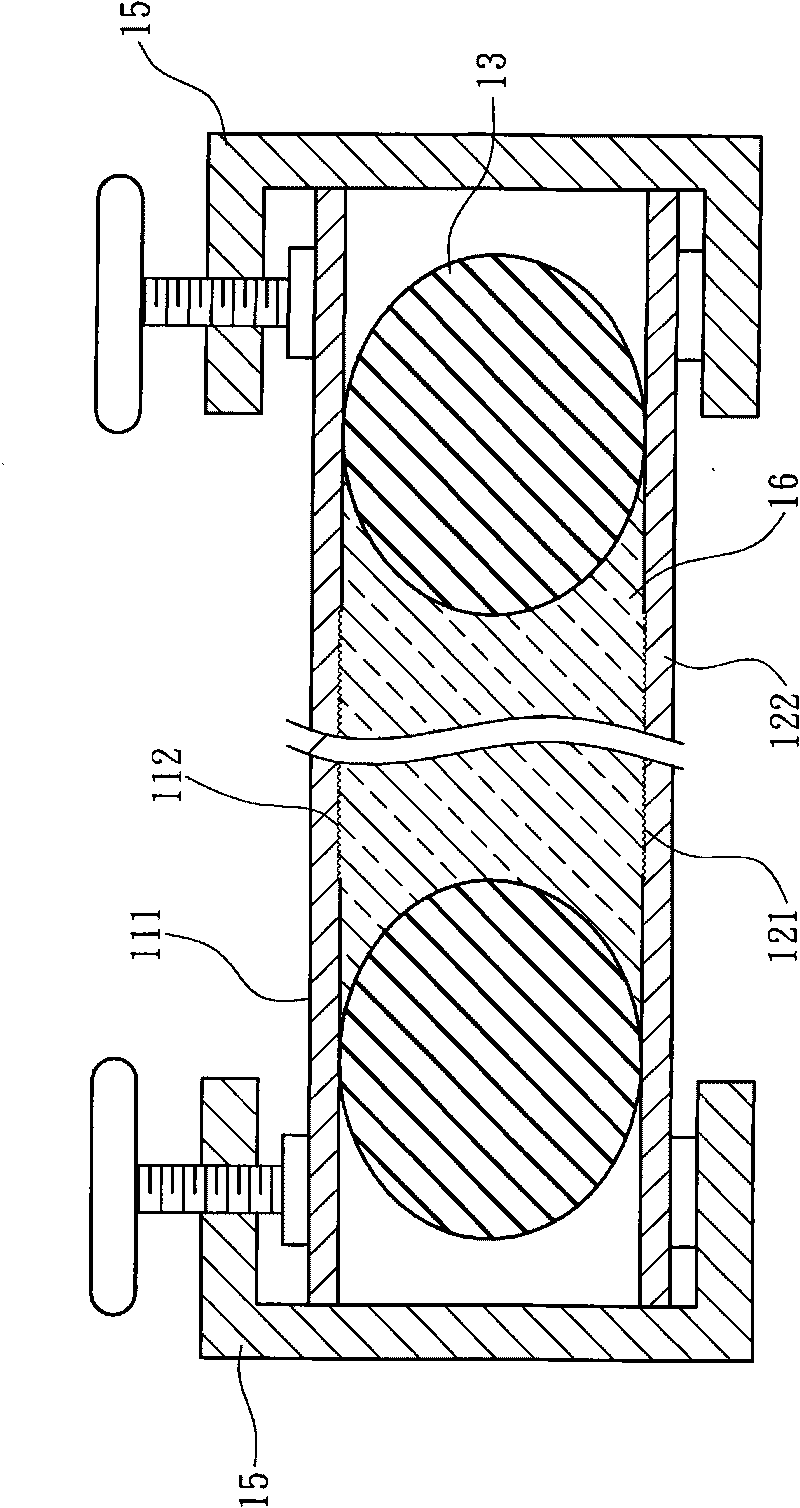

Manufacturing method of light guide plate and mould used by same

InactiveCN101733874ANo need to worryDon't Worry About UniformityAbrasion apparatusOptical articlesLight guideParticle collision

The invention relates to a manufacturing method of a light guide plate and a mould used by the same. The mould is a glass mould which comprises an upper mould, a lower mould, an elastic element, a fixed element and a clamping element. The manufacturing method of the light guide plate comprises the following steps of: firstly, sticking numerical plastic films with pre-made patterns to the upper mould and the lower mould; secondly, processing the glass mould by adopting a sand spraying technology according to the high-speed particle collision principle; and finally pouring the blended and filtered sizing; after pouring, fastening the upper mould and the lower mould in the glass mould subject to sand spraying by using the clamping element; carrying out curing and polymerization reaction; and then carrying out mould removable, cutting, quality control, package and subsequent manufacturing procedures to finally finish the manufacture of various light guide plates.

Owner:江俊慧

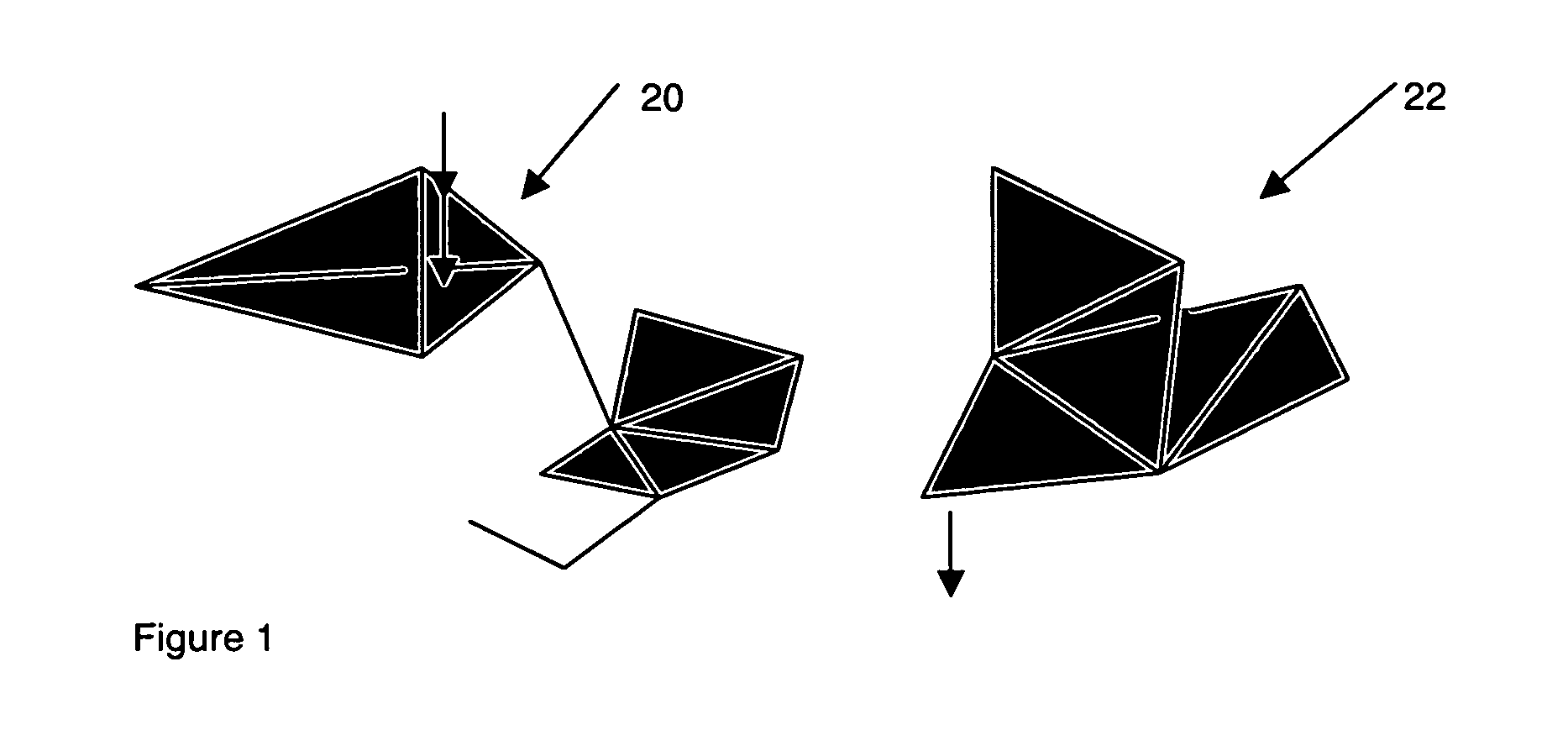

Structure surface wear simulation method based on discrete element method

The invention provides a structure surface wear simulation method based on a discrete element method. The structure surface wear simulation method includes the following steps that S1, the structure surface shape is obtained, and a target surface is divided into a triangular mesh composed of a plurality of triangular units; S2, discrete element simulation is conducted on the triangular units, the scattered particle collision processes of the triangular units are simulated, and thus the collision energy data of all the triangular units are computed and recorded; S3, the sizes of the materials stripped out of the surfaces of all the triangular units are computed according to the collision energy data obtained in S2, and thus the height variable quantity of the centers of mass of all the triangular units is obtained according to the material sizes; S4, the target surface is fitted again according to the height variable quantity of the centers of mass of all the triangular units obtained in S3. The structure surface wear simulation method based on the discrete element method provides reference for structural design, functional design, service life design and the like of scattered material processing equipment.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Method for coarsening surface by erosion of hard grains in high speed

InactiveCN101003126ALarge particle sizeSpeed adjustable range is smallAbrasive feedersParticle collisionHigh pressure

A high-speed hard particle collision method for roughening the surface of workpiece features that the superfine hard particles are driven by the compressed air to impact on the surface of workpiece at sonic or supersonic speed to make said surface to be strongly and plastically deformed while the fine metallic particles to be separated from the surface, so roughening it.

Owner:BAOSHAN IRON & STEEL CO LTD

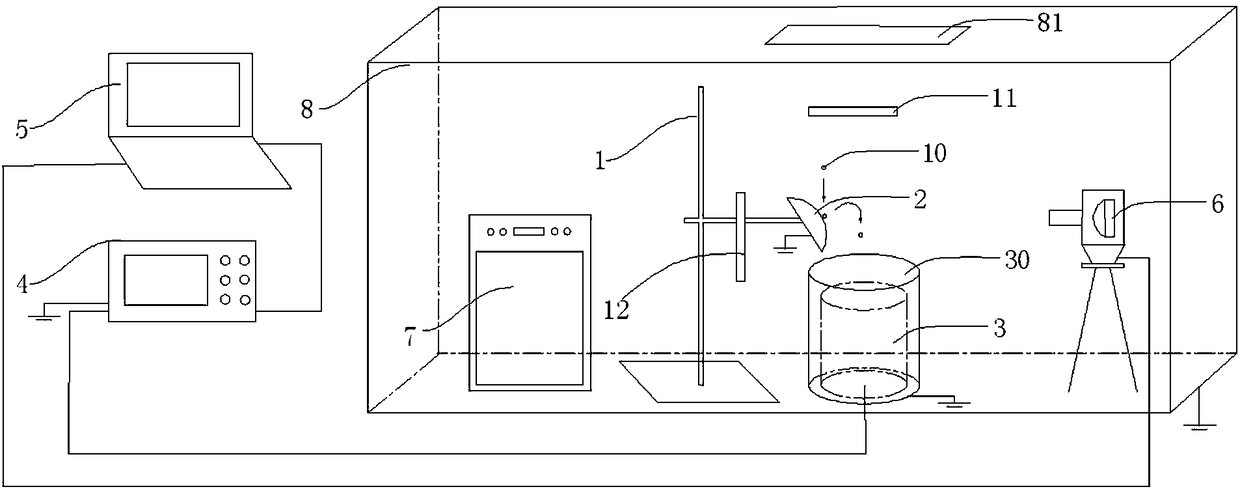

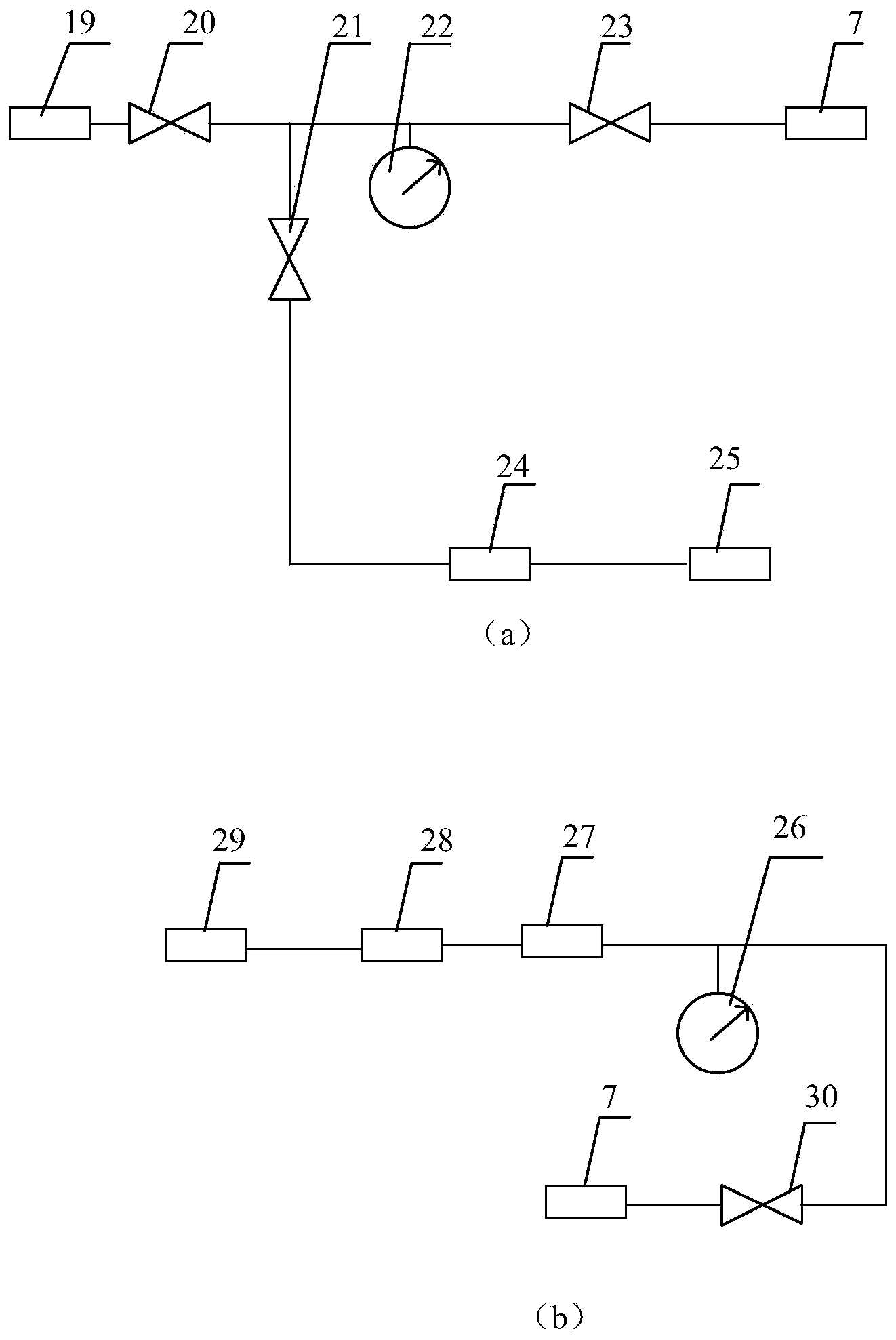

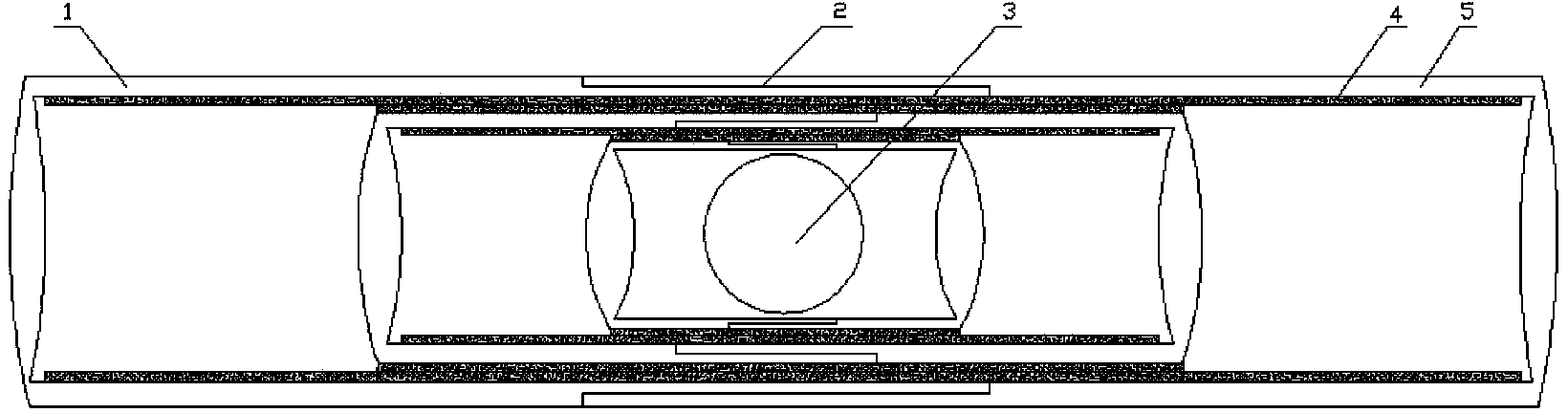

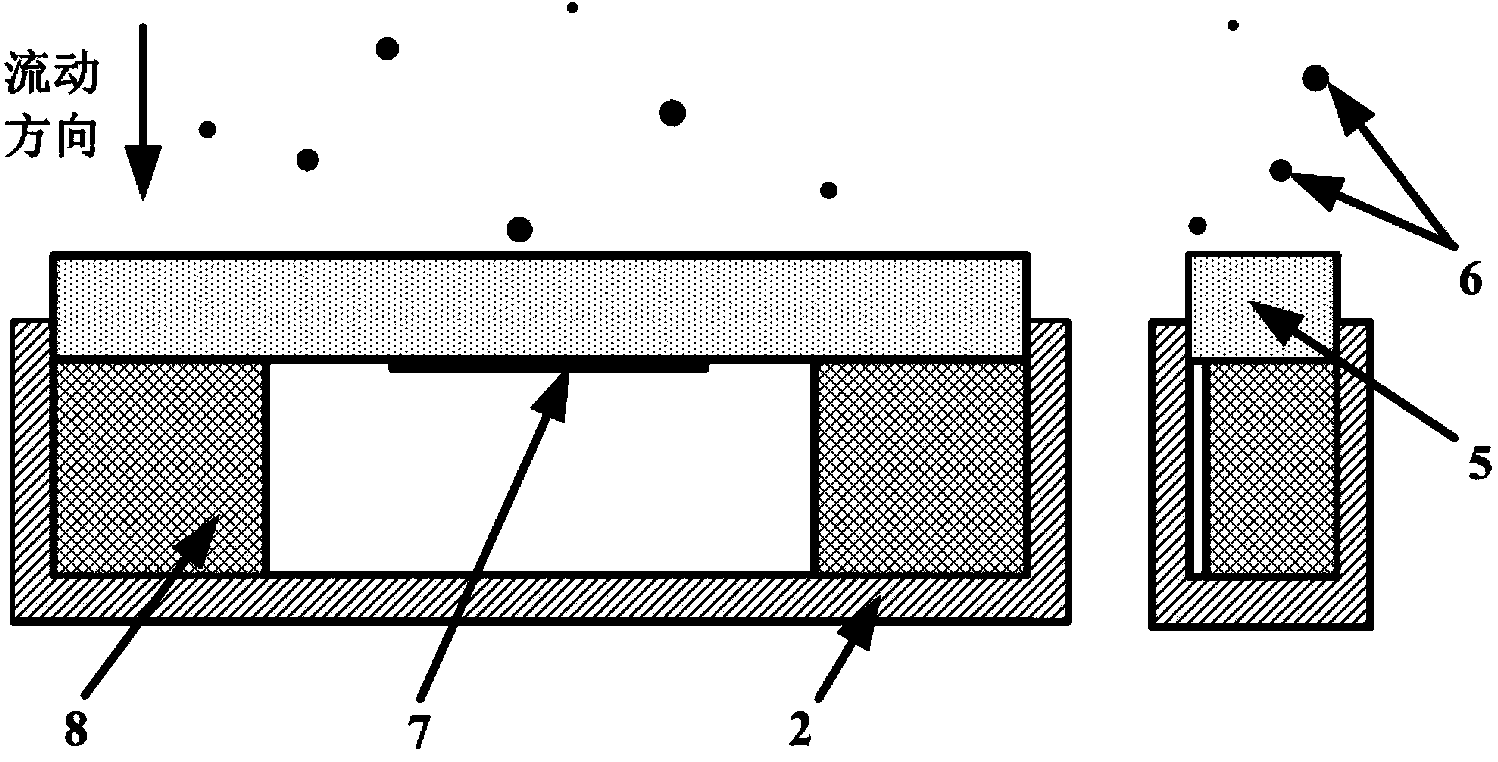

Experimental system and method for droplet-particle collision coagulation test

ActiveCN110006792AObtaining Particle-Droplet Collision BehaviorGet collision behaviorMaterial analysis by optical meansCondensation processImaging analysis

The invention discloses an experimental system and method for a droplet-particle collision coagulation test. The system mainly comprises a particle supply device, a droplet generating device, a particle recycling device, and an image collecting and processing system, the particle supply device realizes the supply of particles at different angles and different speeds, the droplet generating devicerealizes the micro-feeding of droplets and the addition of different heights, the particle recycling device realizes the recycling of falling particles and droplets, and the image collecting and processing system realizes the instantaneous capture and image analysis of particle motion trajectory, droplet deformation and a condensation process after the particles meet the droplets. The experimentalsystem disclosed by the invention has the advantages of convenient operation and low cost, can accurately control various parameters during the collision of the particles and the droplets, accuratelycaptures the droplet-particle collision process, records a deformation and spreading process when the droplets adsorb and capture the particles, and is suitable for dust fall capture related to wetdust fall, the collision condensation research on wet desulfurization during thermal power generation, etc.

Owner:CHINA UNIV OF MINING & TECH

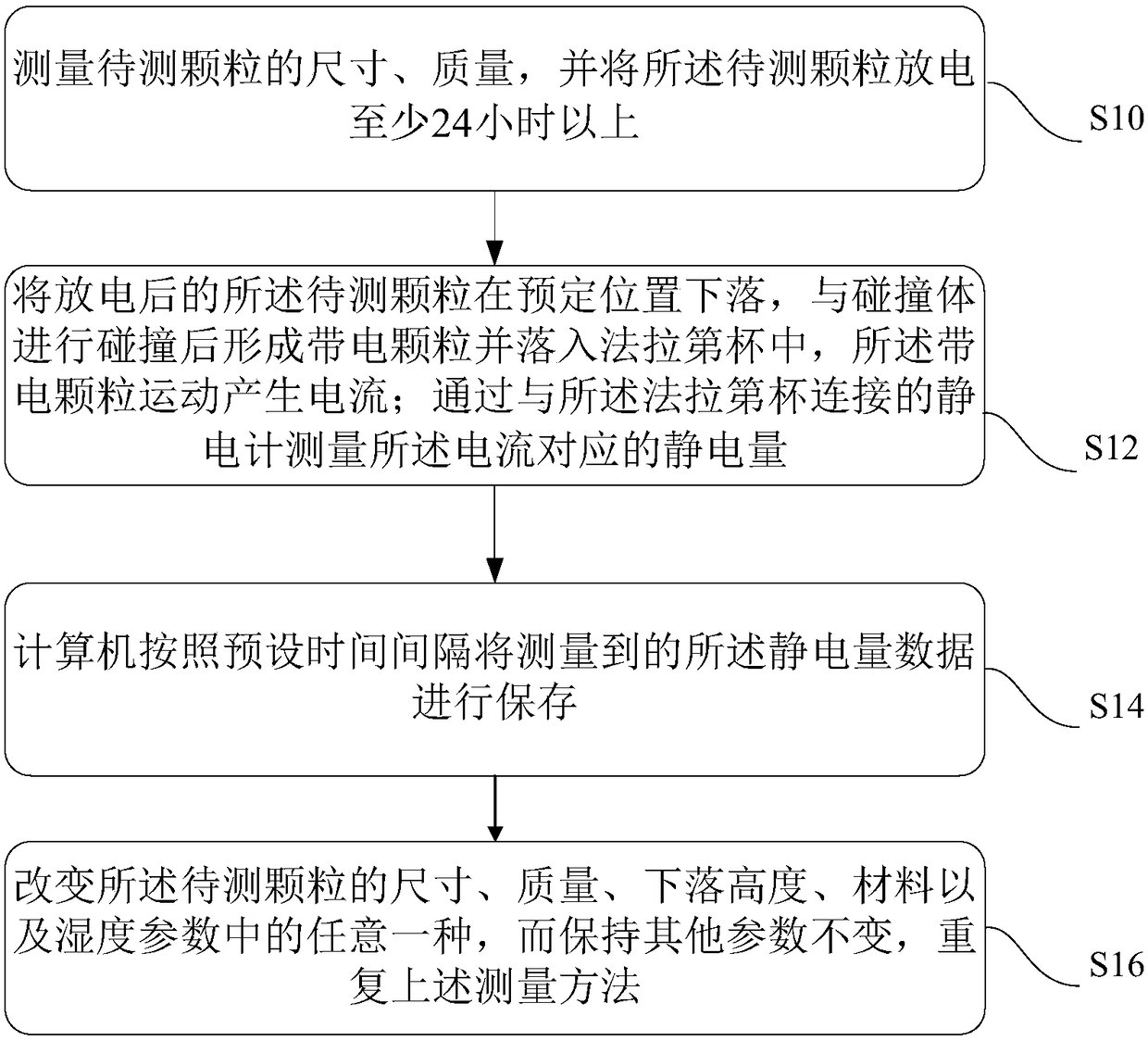

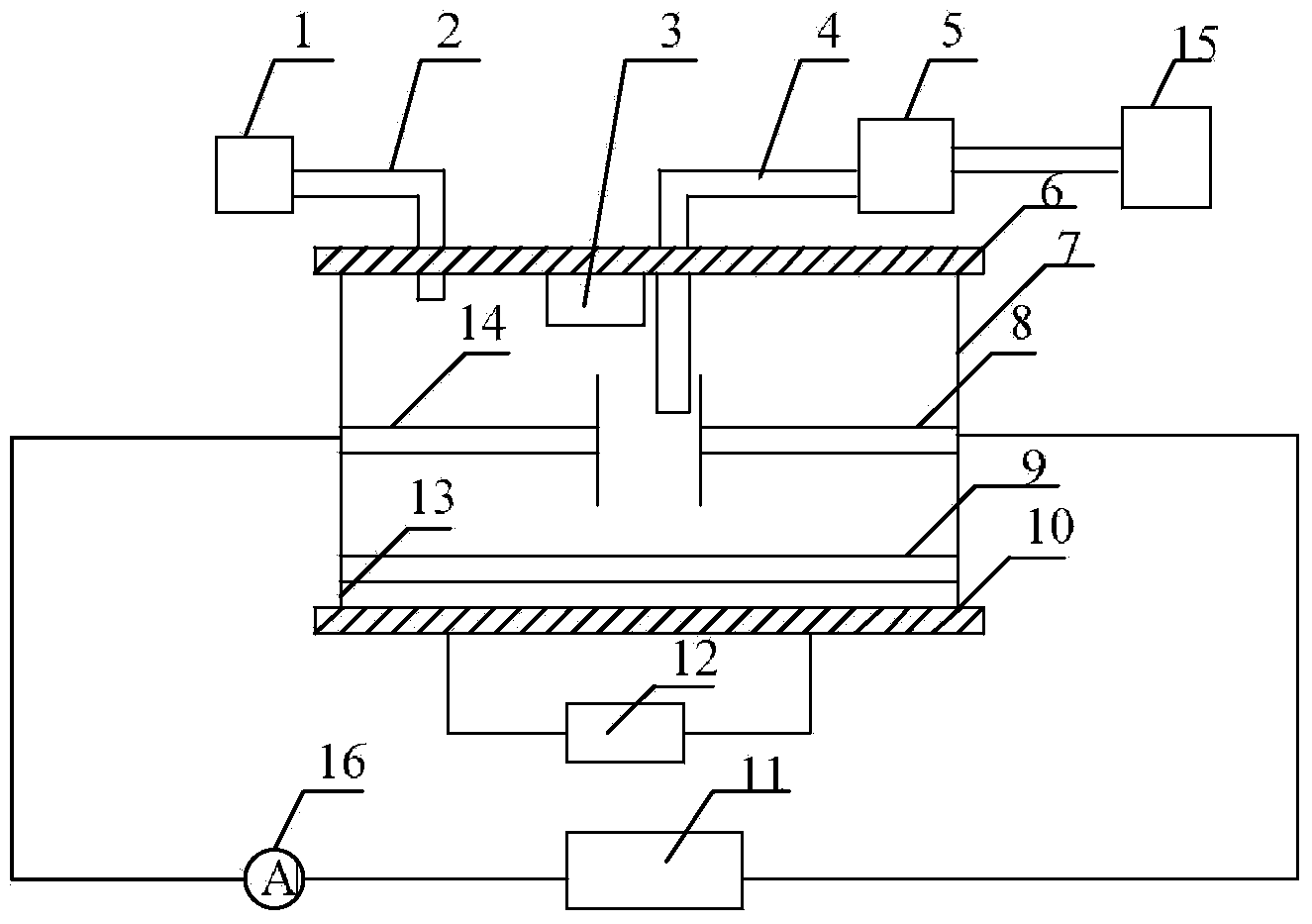

Electrostatic generation measuring device and method for collision particles

PendingCN108107282AMaterial analysis by electric/magnetic meansElectrical measurementsMeasurement deviceElectrometer

The invention discloses an electrostatic generation measuring device and method for collision particles. The device comprises a bracket, a collision body, a Faraday cup, an electrometer and a computer. The collision body is arranged on the bracket. The Faraday cup is located below the collision body. A particle to be measured forms a charged particle after colliding with the collision body and canfall into the Faraday cup, and the charged particle moves to generate a current. The electrometer is electrically connected with the Faraday cup, and is used for measuring the electrostatic capacitycorresponding to the current. The computer is electrically connected with the electrometer, and is used for recording the measured electrostatic capacity. Through the electrostatic generation measuring device and method for collision particles provided by the invention, the size of the static electricity generated by single particle collision can be obtained, the factors affecting electrostatic generation can be determined, and thus, actual production can be guided.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A novel method and an apparatus in converting unsorted municipal solid waste into geo-polymer pellets/briquettes and geo-polymer bricks/paver blocks

Apparatus and method in converting municipal solid waste into geo-polymer briquettes and geo-polymer bricks comprising bag opener cum crushers, magnetic separators for ferrous and eddy current separators for non-ferrous things; squeezer for removing liquid content; inter particle collision driers for drying; pulverizer for pulverizing, and devolatizing carbonization reactor for carbonisation of combustible MSW to produce solid char with low water content. Solid char is mixed with geo- polymer binding agent / starch / tar / to form combustible pellet / briquette. These highly combustible briquette / pellets have high calorific value. The pellet / briquette is formed by rotating combustible char at high rpm and compaction. Pellet has a water content of less than 5% by weight and fuel value of 5500 to 6500 KCAL This process produces non-combustible geo-polymer brick. The non-combustible MSW separated by a trommel is crushed by inter particle collision crusher and pan mixers mixing with geo-polymer binding agent / fly ash / quarry dust / chips or china clay and moulded.

Owner:NEWAY MSW IP HLDG LLP

Fixed time step dynamical solver for interacting particle systems

ActiveUS7813903B2Simple calculationMore cost-effectivelyComputation using non-denominational number representationDesign optimisation/simulationParticle collisionParticle position

The present invention is a particle position solver that allows particles to reach an end of a fixed time, time step in an invalid state and which are then pushed toward a valid state. This allows the solver to continue the simulation while the simulation results move toward a valid behavior. Particle collision calculations are simplified by adopting a non-sequential model ignoring some collisions or combining them. The speed of the simulation is also improved by performing some operations outside the solver calculation loop and by using specialized data structures.

Owner:AUTODESK INC

High-temperature gas breakdown characteristic detection device and method under VFTO condition

The invention provides a high-temperature gas breakdown characteristic detection device and method under the VFTO condition. The device achieves detection of the gas breakdown process under the VFTO condition. The device comprises a gas sealing chamber, a heating unit, a discharging unit, a spectrometer, a thermodetector, a gas inflating, deflating and recycling unit, a voltage source, a VFTO generation unit, an ampere meter and a computer. The method detects the gas breakdown process from the microcosmic viewpoint, the spectrometer is used for measuring light intensity and wave length in the breakdown process, the temperature of particles in the breakdown process is obtained, and the viscosity coefficient, the conductivity and the diffusion coefficient of the particles are further obtained. According to particle collision characteristics under the VFTO condition, a collision item of a Boltzmann equation is corrected.

Owner:SHENYANG POLYTECHNIC UNIV

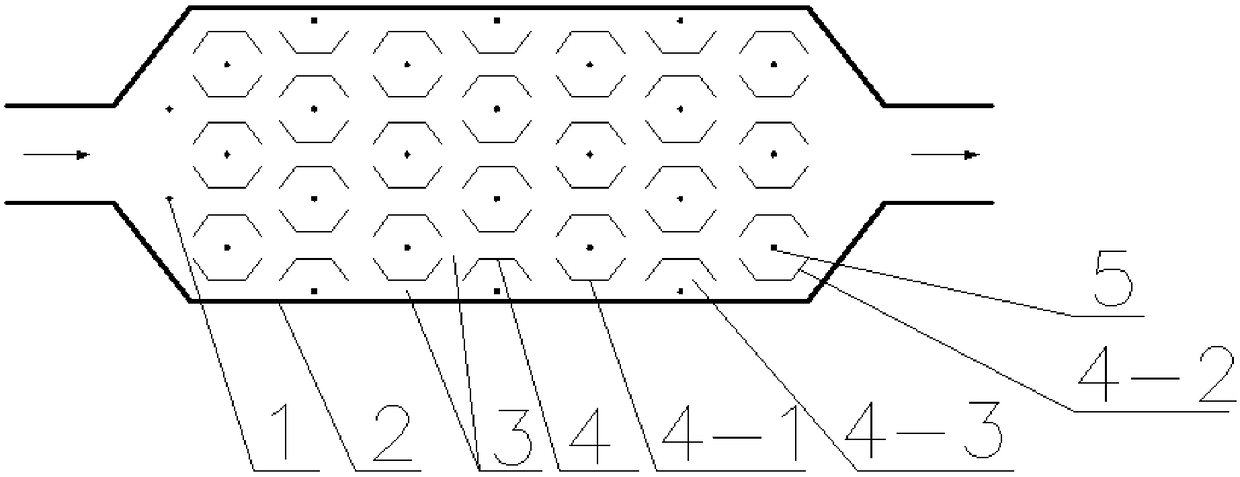

Industrial waste gas fine particulate matter removing device

ActiveCN108405184AExtended stayIncreased chance of collisionExternal electric electrostatic seperatorElectrode constructionsHoneycombExhaust fumes

The invention relates to the technical field of energy conservation and environment protection, in particular to an industrial waste gas fine particulate matter removing device. The industrial waste gas fine particulate matter removing device is a half honeycomb type dust collecting pole plate electric deduster, and comprises a shell, a first corona electrode and multiple half honeycomb dust collecting units. The industrial waste gas fine particulate matter removing device provided by the invention has a unique structure, so that a waste gas produces double vortexes in a passageway, the particle collision probability is effectively improved, the standing time of a waste gas flow carrying fine particulate matters is prolonged, and the removal efficiency of the fine particulate matters is improved compared with a conventional device.

Owner:江苏常诺能源环保科技有限公司

Nested collision damper

InactiveCN103453063AGuaranteed service lifeReduce the impactElastic dampersShock absorbersMomentumWorking environment

The invention provides a nested collision damper. The nested collision damper has the advantages that energy dissipation modes are various, and after friction layers are added into the nested collision damper on the basis that the original energy dissipation mode is kept, a friction energy dissipation mode becomes a main energy dissipation mode; impact on a system in a collision procedure can be effectively reduced while the momentum exchange and energy dissipated by collision cannot be reduced; energy of the system can be dissipated by collision which occurs on each layer of the nested particle collision damper, the quantity of nested layers can be freely increased or decreased according to the size and the shape of an actual structure, and accordingly the damper can be widely applied to various places, is convenient to install and simple in structure and can adapt to complicated working environments.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Comminution apparatus

InactiveUS7229037B1Small particle sizeEliminate useGas current separationCocoaParticulatesEngineering

These and other objects of the present invention are achieved by a comminution apparatus comprised of a housing member formed with co-planar circularly-shaped chambers in chordal juxtaposition to each other thereby forming a collision zone therebetween and wherein wheel members having radially disposed directional vanes are positioned for rotation in each cylindrically-shaped chamber and wherein an inlet fluid conduit or a slurry of particulate matter to be treated is in axial fluid communication with each wheel member and wherein each wheel member is caused to be rotated in a direction to accelerate the slurry towards the collision zone and to affect particle size reduction by particle collision and wherein an outlet conduit is in fluid communication with the collision zone for withdrawing a slurry of size reduced particles from the comminution apparatus.

Owner:HAYLES JR PETER E

A preparing method of coconut charcoal fiber

InactiveCN105442095AAdd anti-static functionProtect the environmentElectroconductive/antistatic filament manufactureCelluloseAntistatic agent

A preparing method of coconut charcoal fiber is disclosed. The method includes (1) a step of preparing master batch, namely a step of recovering waste coconut shells, extracting coconut shell cellulose by dipping, beating, removing impurities and airing, heating the coconut shell cellulose to 1200 DEG C, performing high-temperature carbonization to prepare coconut charcoal, smashing the coconut charcoal into nanometer powder by utilization of a particle collision principle and through a dry grinding manner, adding anionic antistatic agent powder into the coconut charcoal powder, and fully mixing to obtain the coconut charcoal master batch, and (2) a step of spinning the coconut charcoal fiber, namely a step of preparing the hollow type coconut charcoal fiber with a three-dimensional crimp configuration by melt spinning, drawing, sizing, crimping, oiling, cutting and packaging. The prepared coconut charcoal fiber has good antibacterial, far infrared and anion-releasing performances, and the like, and accords with functional, healthy and environment friendly ideas pursued in product development. For better application in development of home textile products, the antistatic property of the fiber is improved by adding the antistatic agent, thus improving product quality.

Owner:SHANGHAI SHUIXING HOME TEXTILE

On-line particle size distribution measuring device and method based on array sonic transducer

InactiveCN103411858ARealize online continuous measurementParticle size analysisParticle suspension analysisElectricityUltrasonic sensor

The invention discloses an on-line particle size distribution measuring device and method based on an array sonic transducer, which belongs to the technical scope of gas-solid two-phase flow on-line measurement. The on-line particle size distribution measuring device adopts the structure that a sound emission detection test piece with a plurality of sound emission detecting units is mounted on a gas-solid two-phase flow pipeline, a particle collision vibration member generates a sound emission signal, a piezoelectric film sensor detects the sound emission signal, sound insulation rubber is arranged between the vibration member and the sound emission detection test piece, and an embedded data processing module is adopted to process and analyze the sound emission signal to obtain the particle size distribution information. Each sound emission detecting unit can measure the particle size distribution of particles in the local space, and together with fusion of all local information in a pipeline, the integral particle size distribution of the particles in the pipeline can be obtained, thereby providing measurement data for powder flow behavior research and industrial field on-line diagnosis.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

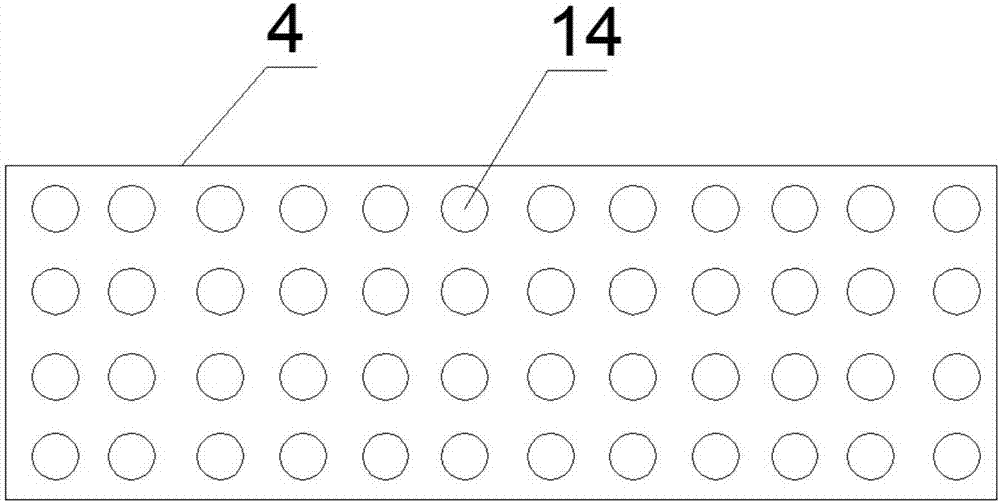

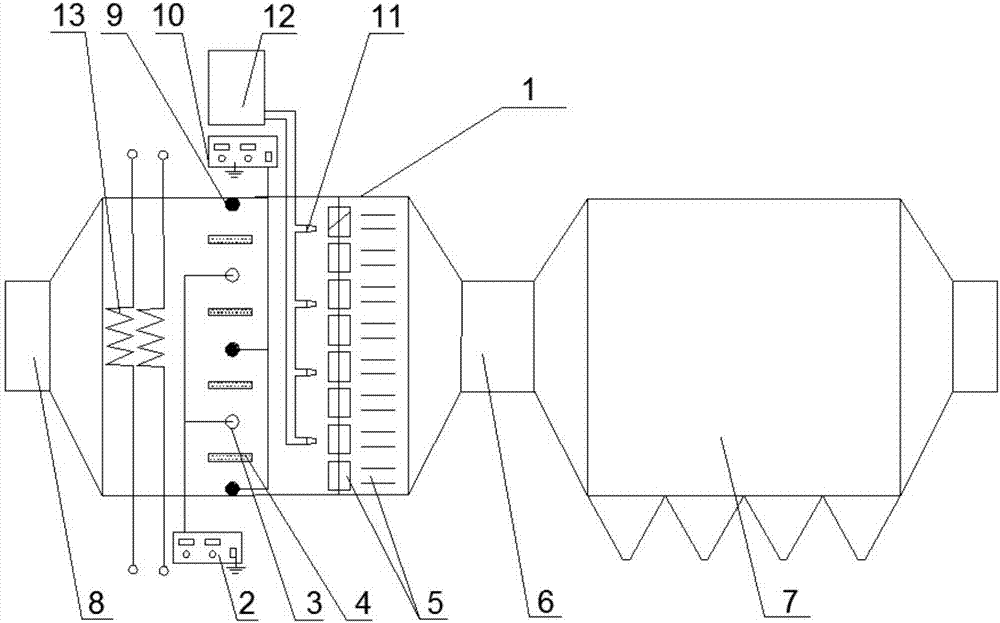

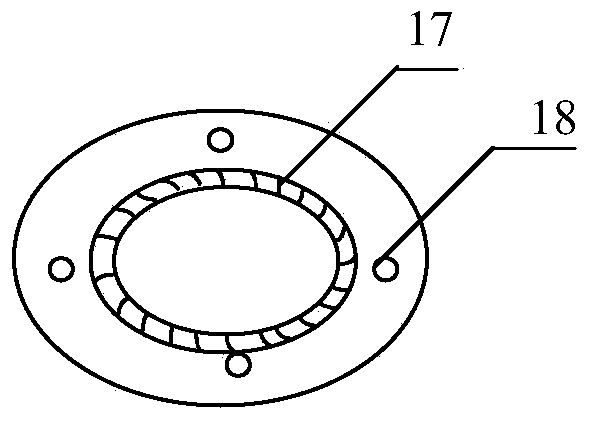

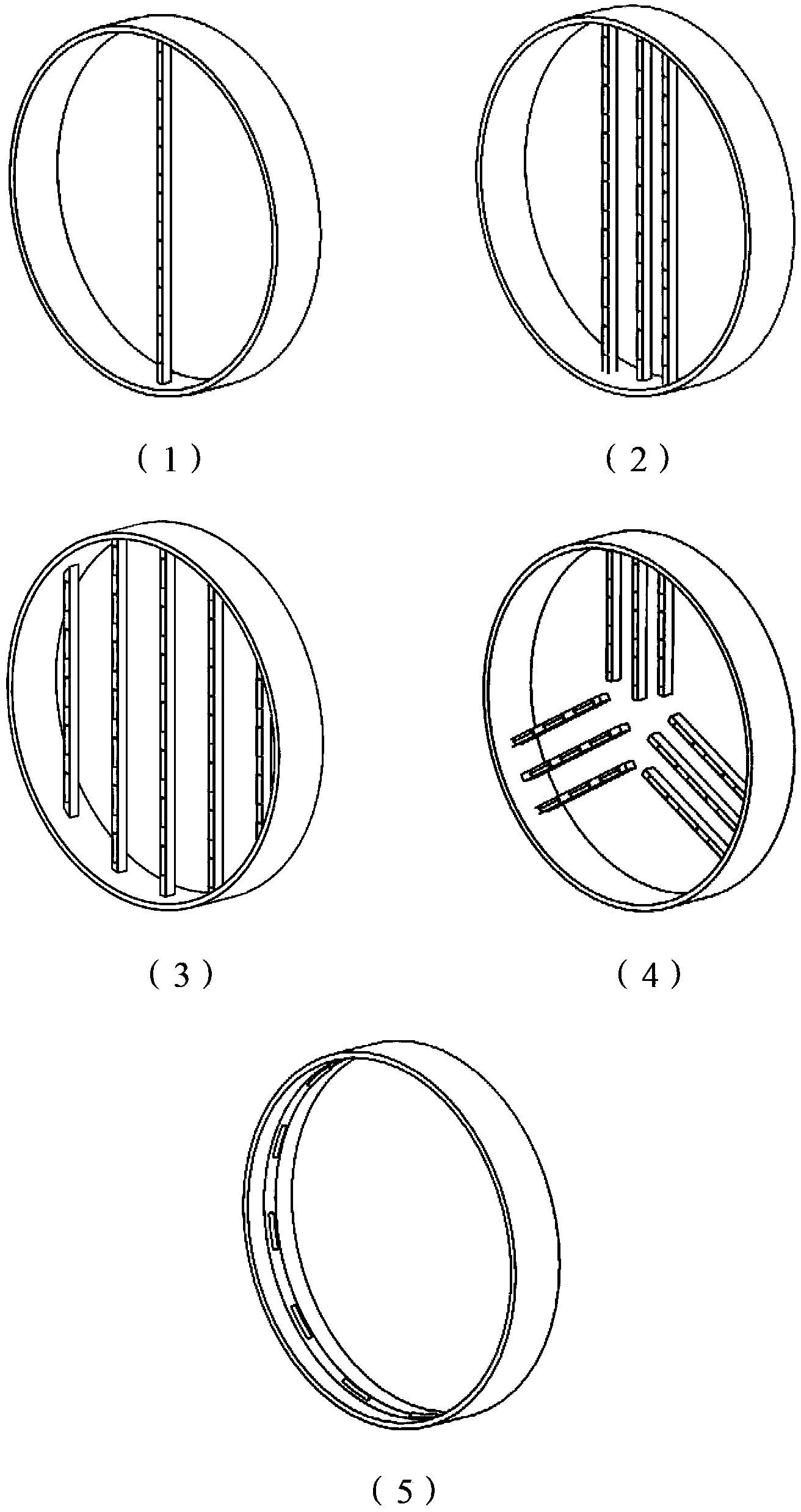

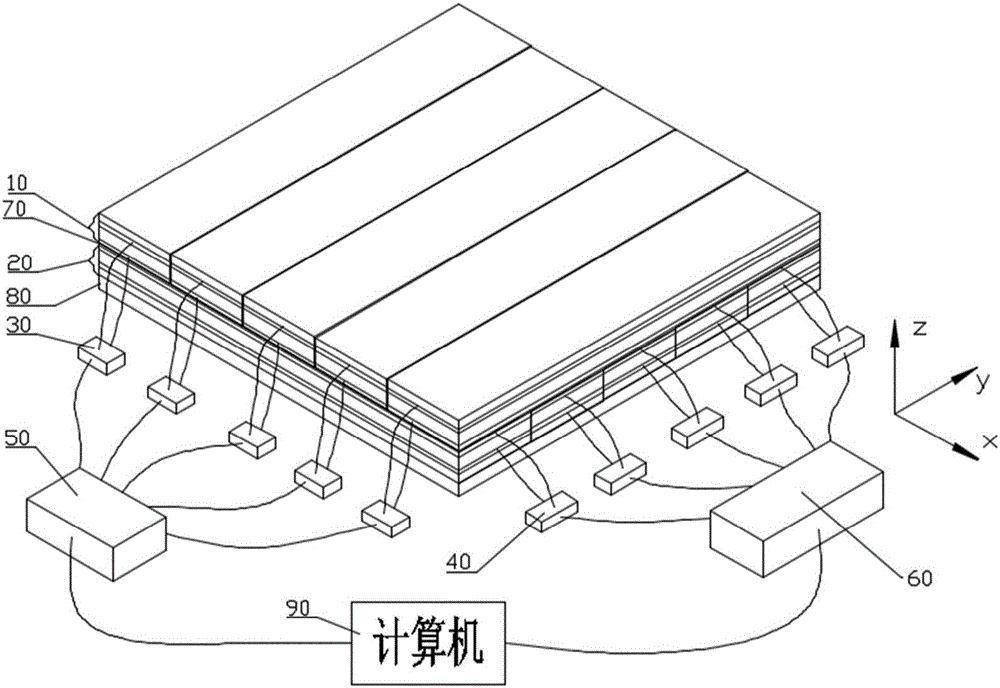

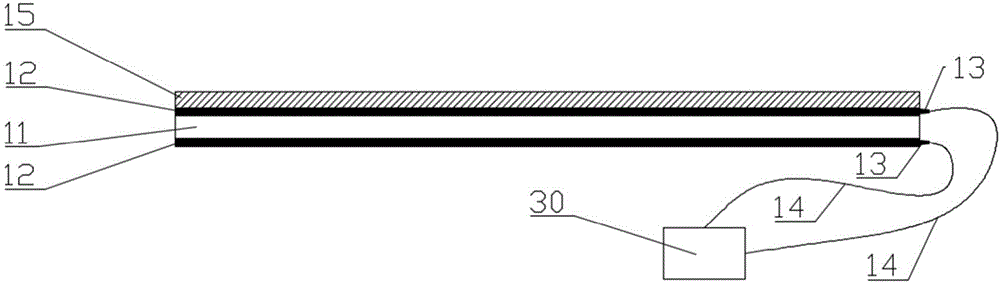

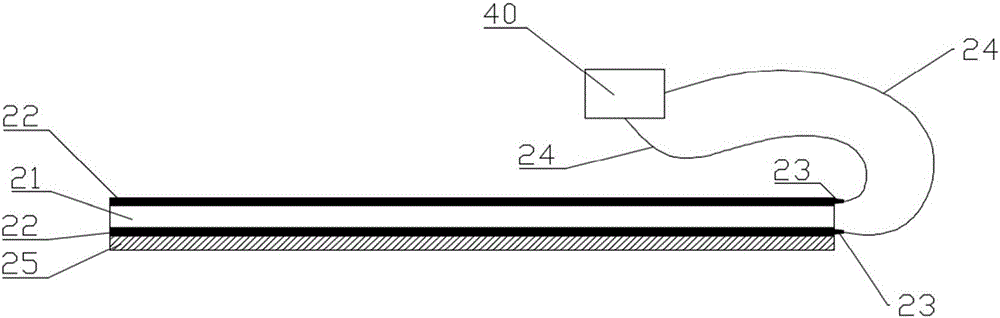

Double-layered crisscross-structure particle collision sensor based on PVDF (Polyvinylidene Fluoride)

ActiveCN106706177AReduce missed judgmentsReduce misjudgmentMowersForce measurement using piezo-electric devicesElectricityParticle collision

The invention discloses a double-layered crisscross-structure particle collision sensor based on PVDF (Polyvinylidene Fluoride). The double-layered crisscross-structure particle collision sensor comprises an x-directional sensor layer, an insulating sheet, a y-directional sensor layer and a supporting plate, which are stacked in sequence from top to bottom, wherein the x-directional sensor layer comprises a plurality of x-directional sensor units; the y-directional sensor layer comprises a plurality of y-directional sensor units; the parallel arrangement direction of the x-directional sensor units is vertical to that of the y-directional sensor units; the x-directional sensor units are connected to an x-directional electric signal processing device through respective x-directional electricsignal collectors in parallel; the y-directional sensor units are connected to a y-directional electric signal processing device through respective y-directional electric signal collectors in parallel, so that a structure of electrically connecting sensors on the same layer in parallel and mechanically connecting sensors of different layers in series is formed. The double-layered crisscross-structure particle collision sensor disclosed by the invention provides a double-layered crisscross structure for the particle collision sensor, particle collision position information can be obtained according to a multi-sensor fusing technology and the detection precision is improved; a novel design concept is provided for the particle collision sensor.

Owner:ZHEJIANG UNIV

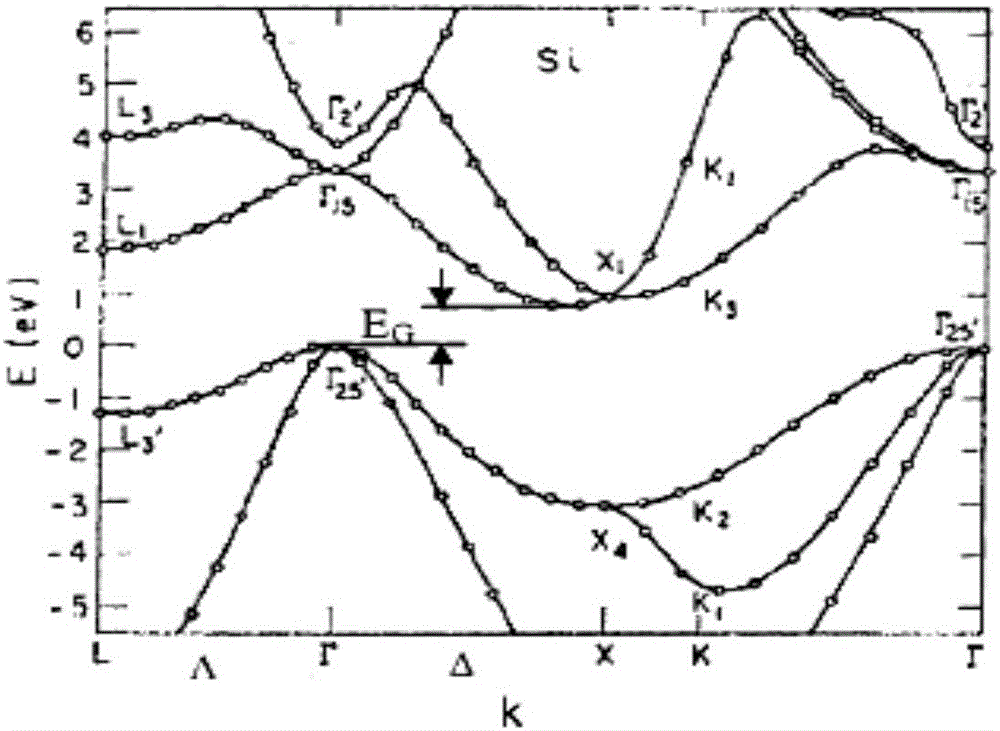

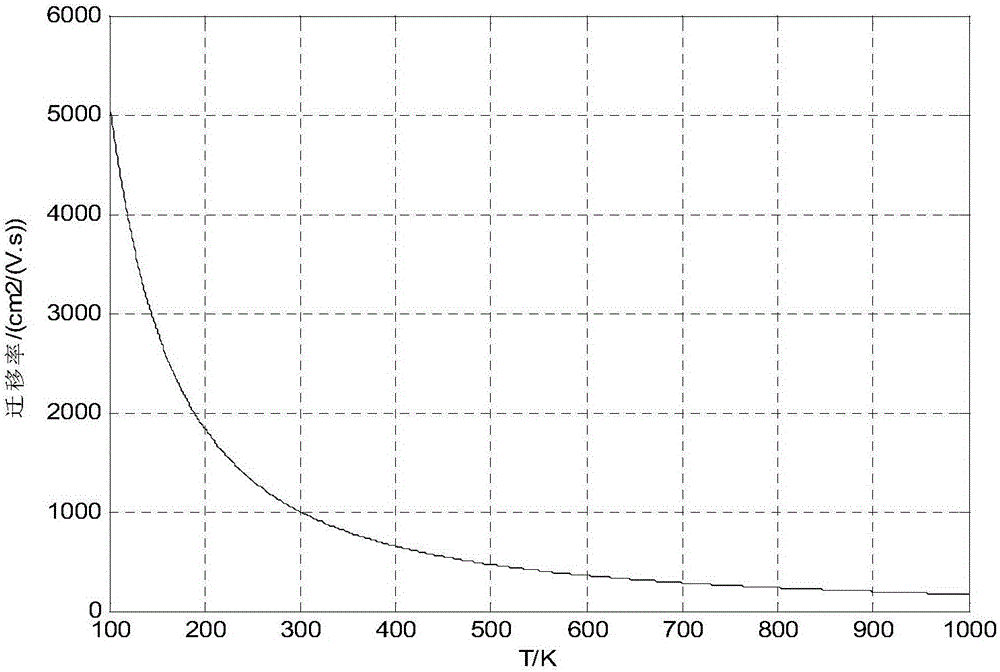

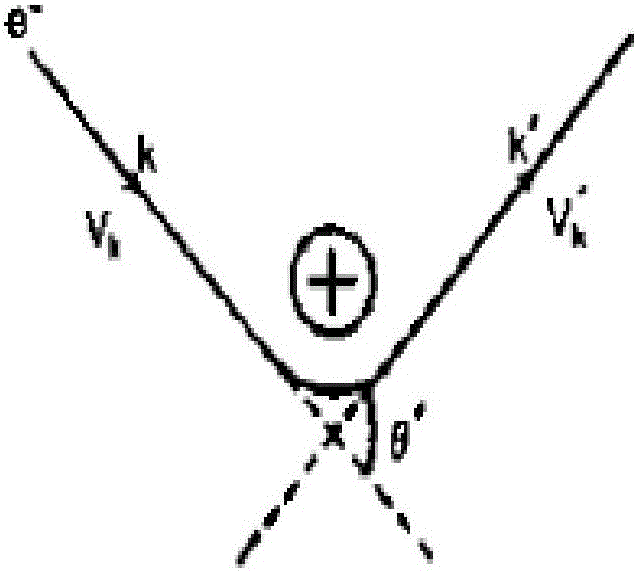

Monte Carlo simulation method for electronic transportation problem of n-type Si material

InactiveCN104992020AAvoid errorsSpecial data processing applicationsExperimental testingSemiconductor materials

The present invention discloses a Monte Carlo simulation method for the electronic transportation problem of an n-type Si material. The Monte Carlo simulation method comprises the following steps of: 1, determination of a carrier scattering mechanism and calculation of various scattering ratios under corresponding input conditions; 2, establishment of a carrier drift model and calculation of energy and a wave vector after carrier drift; 3, establishment of a carrier scattering model and selection of a scattering type; and 4, implementation of simulating an electronic transportation problem calculating program of the n-type semiconductor Si material by the Monte Carlo method. According to the present invention, an average rate and a drift mobility of the n-type Si material are simple, rapid and convenient to calculate; a series of problems of difficulty in testing, a large error and the like, which are caused by influence of the size of a semiconductor device and experiment conditions when an experimental testing method is used before, are avoided; moreover, the method has high popularization performance; and the carrier transportation or microscopic particle collision problem of other semiconductor materials also can be calculated by changing corresponding input parameters.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com