Dust flocculating passage, dust flocculating method, and vacuum cleaner

A dust and flow path technology, applied in suction filters, separation methods, external electrostatic separators, etc., can solve the problems of complex structure, particle accumulation, increased occupation area, etc., and achieve the effect of increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1-1

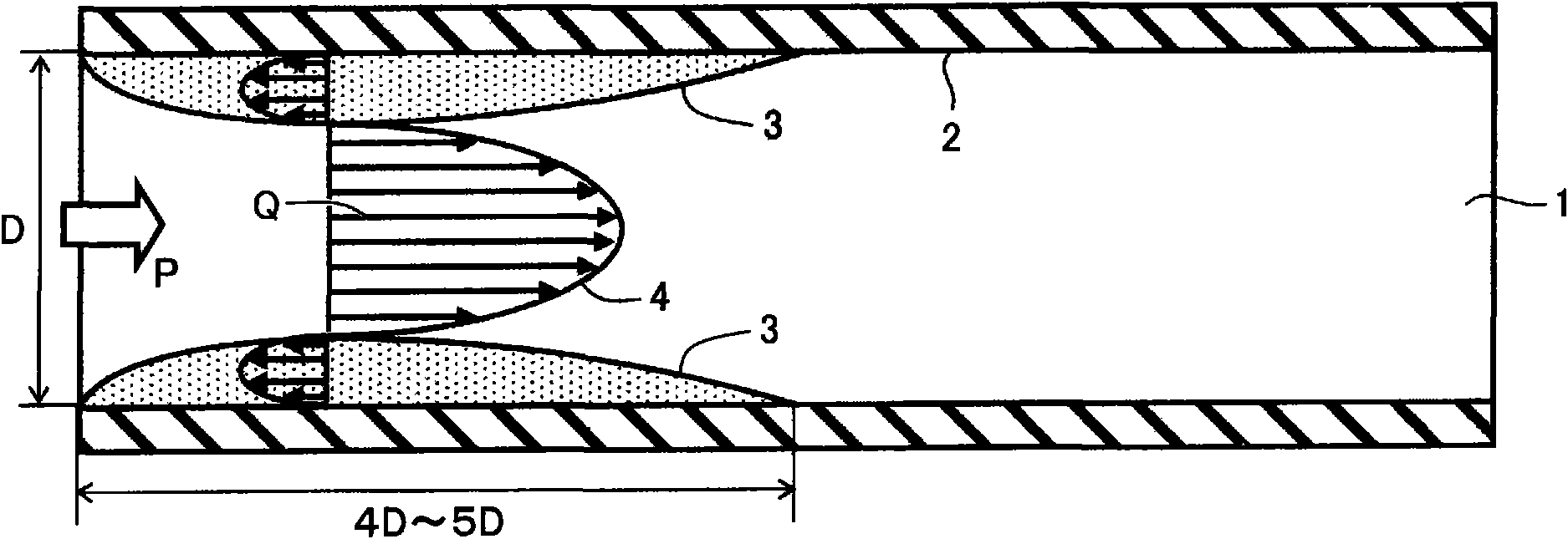

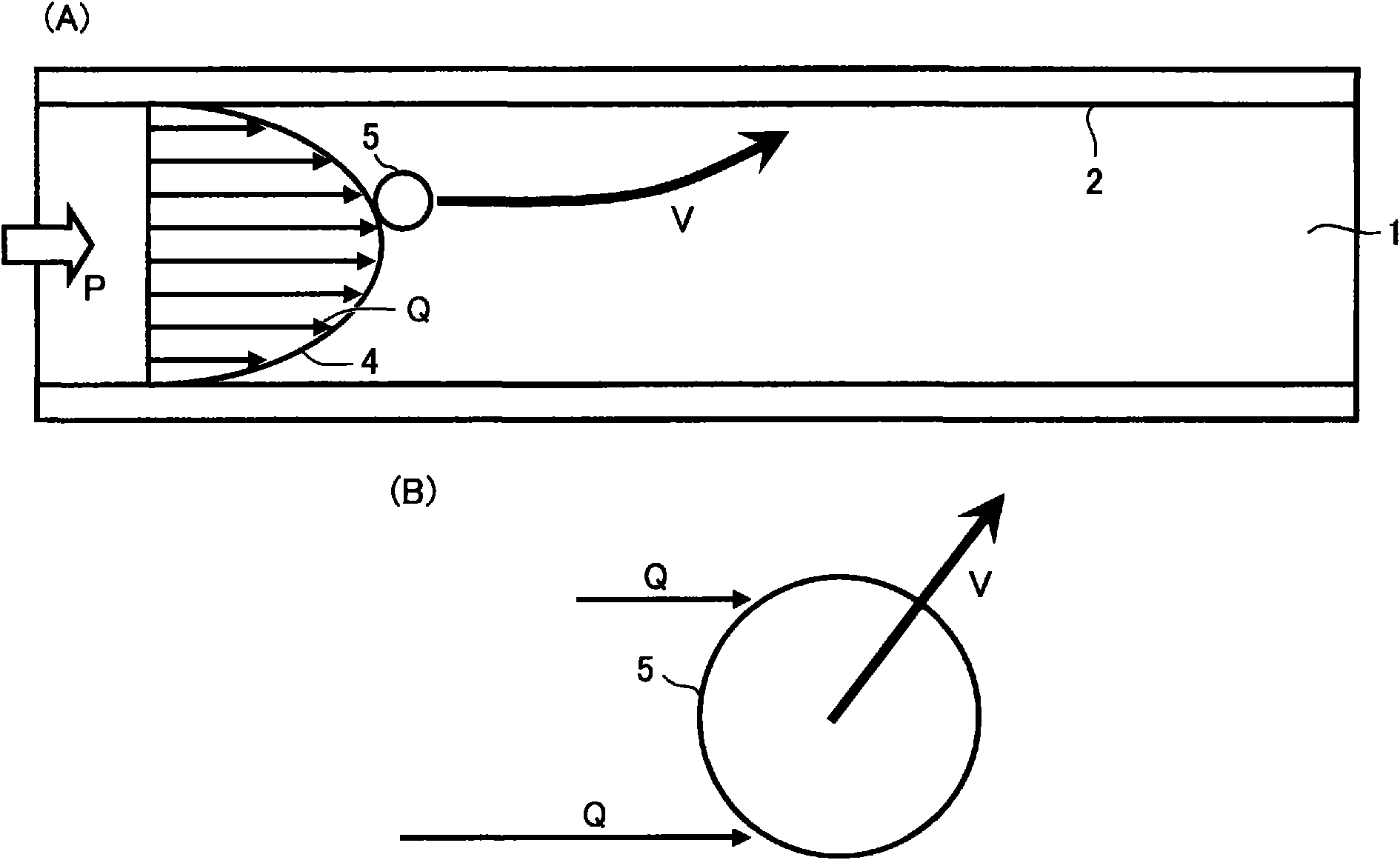

[0238] Figure 5 It is a figure which shows the dust aggregation path of Embodiment 1-1 of this invention.

[0239] Such as Figure 5 As shown, the dust aggregation passage 10 includes a flow passage 11, a wall 12, and a rotating portion 13 as a vortex generating mechanism. The flow path 11 is formed by a cylindrical wall 12 . Air or other fluid containing agglomerated particles (dust or other fine particles) flows through the flow path 11 driven by an unillustrated drive source (for example, a fan or blower).

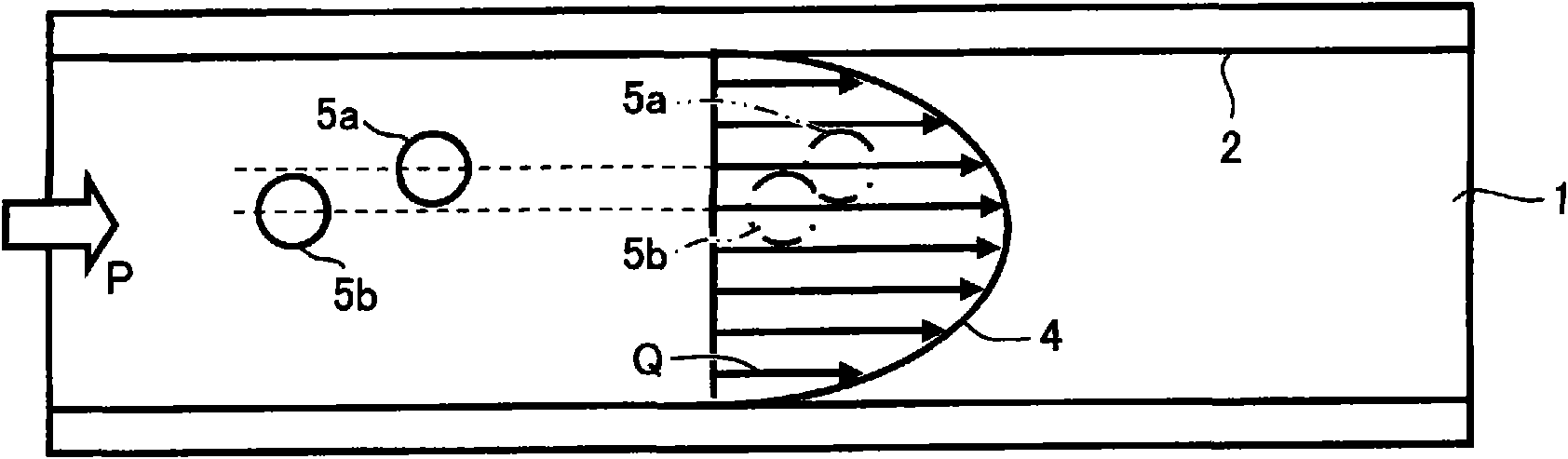

[0240] Figure 6 It is a figure which shows the front of the dust aggregation path of Embodiment 1-1 of this invention.

[0241] Such as Figure 5 and Figure 6 As shown, the rotating part 13 includes four surfaces as a wall part of the rotating part 13 : a surface 13 a , a surface 13 b , a surface 13 c , and a surface 13 d. The surface 13 a , surface 13 b , surface 13 c , and surface 13 d are arranged at intervals of 90° counterclockwise when viewed from the up...

Embodiment approach 1-2

[0267] Figure 9 It is a perspective view which shows the main part of a dust aggregation path as Embodiment 1-2 of this invention.

[0268] Such as Figure 9 As shown, the dust aggregation path 20 includes a flow path 21, a wall 22, and a rotating portion 23 as a vortex generating mechanism. The flow path 21 is formed by a cylindrical wall 22 .

[0269] Figure 10 It is a figure which shows the front of the dust aggregation path of Embodiment 1-2 of this invention.

[0270] Such as Figure 9 and Figure 10 As shown, the rotation part 23 includes four surfaces as a wall part of the rotation part 23 : a surface 23 a , a surface 23 b , a surface 23 c , and a surface 23 d. The surface 23 a , surface 23 b , surface 23 c , and surface 23 d are arranged at intervals of 90° counterclockwise when viewed from the upstream side of the flow path 21 . The respective surfaces are formed perpendicularly to the inner surface of the wall 22, are connected to each other at the center of...

Embodiment approach 1-3

[0287] Figure 12 It is a perspective view which shows the main part of the dust aggregation path of Embodiment 1-3 of this invention.

[0288] Such as Figure 12 As shown, in Embodiment 1-3, a rotating portion 33 is provided instead of the rotating portion 13 in Embodiment 1-1. Rotating part 33 becomes the shape that cuts through the center of the cross section of rotating part 13, so there is rotating part 33 on the inner surface of wall 32 of flow path 31 formed in dust condensing path 30, and there is no central part of flow path 31. There is a shape of the rotating part 33 . The flow path 31 is divided into four small flow paths by the rotating part 33 . Four small channels communicate at the center of the channel 31 .

[0289] Figure 13 It is a front view which shows the main part of the dust aggregation path of Embodiment 1-3 of this invention.

[0290] Such as Figure 13 As shown, for the height h calculated from the inner surface of the wall 32 of the rotating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com