Nested collision damper

A damper, nested technology, used in shock absorbers, shock absorbers, elastic shock absorbers, etc., can solve the problems of main system shock, insufficient friction, and insufficient use of friction energy consumption, etc. The effect of slowing down the impact and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

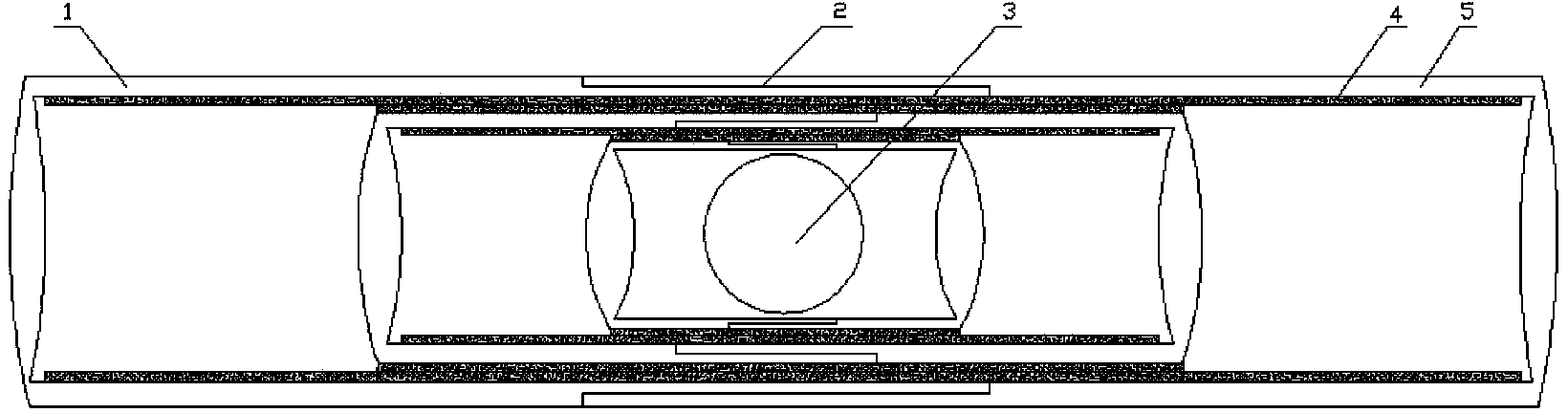

[0017] figure 1 It is a structural schematic diagram of the embodiment of the nestable crash damper involved in the present invention.

[0018] like figure 1 As shown, a nestable impact damper in this embodiment mainly includes: original impact steel balls; upper and lower covers of each nesting layer; friction layer; filling particles.

[0019] The first layer of impactor [3] can directly select 10mm steel balls, and thread the upper and lower end caps, so that the upper and lower end caps are connected with threads [2]. Among them, metal particles or other powders that are prone to plastic deformation are filled, the particle size is about 0.1mm, and the filling rate is 40%. The inner and outer sides of the upper and lower bottom surfaces are processed into arcs to increase plastic deformation. After installation, paste or fill in the friction layer on the outside, and you can choose a friction plate or coating with a rough surface. After a period of use, the friction la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com