Multilayer composite belt for brazing type heat exchanger and manufacturing method thereof

A multi-layer composite and heat exchanger technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of affecting the service life of heat exchangers, and heat exchangers whose anti-corrosion performance cannot reach high quality and other problems, to achieve the effect of ensuring service life, improving service life and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

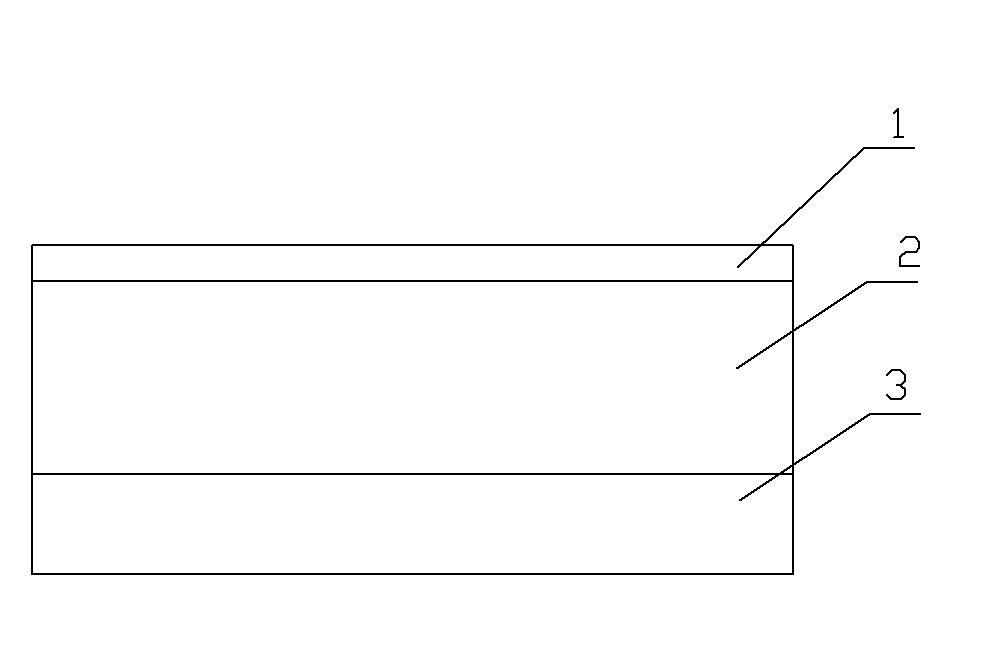

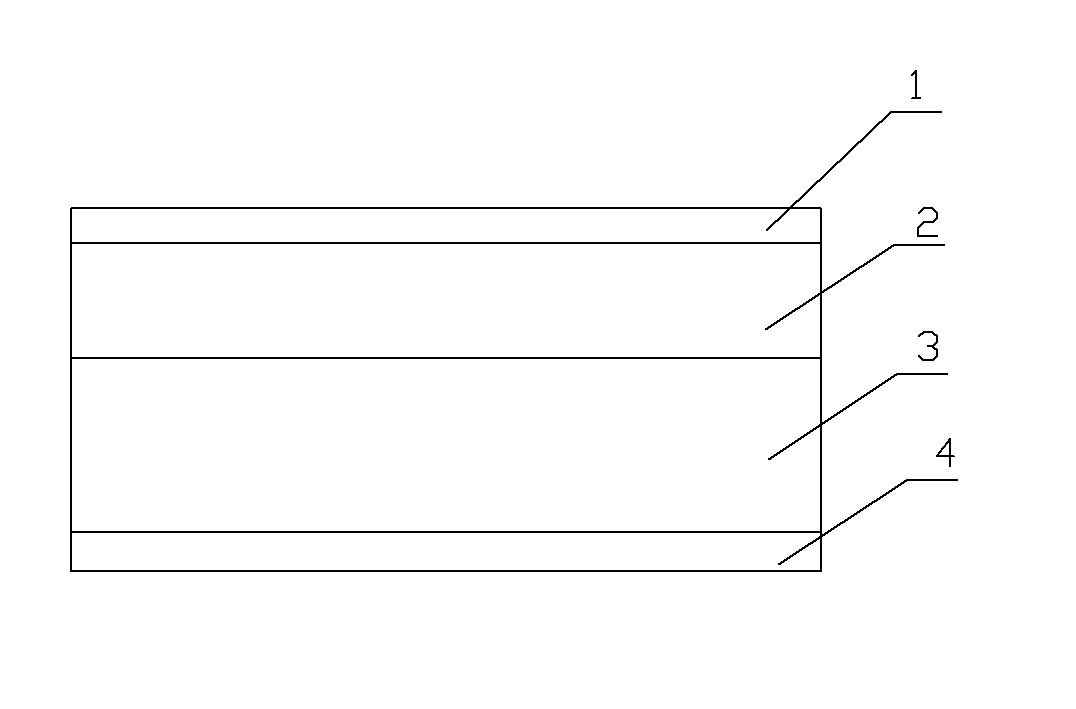

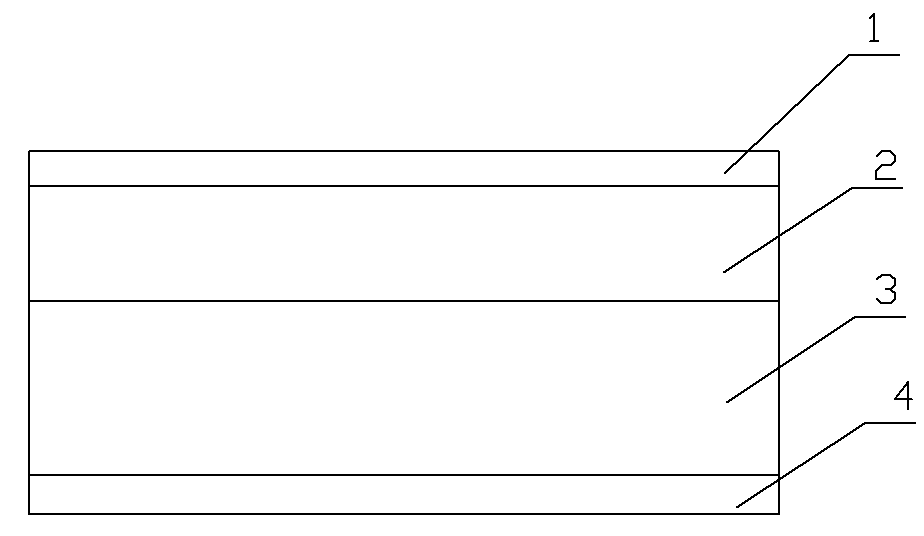

[0018] See figure 2 , a multilayer composite strip for a brazed heat exchanger, which includes a core alloy layer 2, and is covered with an anti-corrosion layer alloy layer 3 and a brazing alloy layer 1 on both sides of the core layer alloy layer 2, and on the anti-corrosion layer The outer side of the alloy layer 3 covers the brazing alloy layer 4 . See Table 1, the ratio of core layer alloy is 45%-70% (thickness composite ratio), the ratio of anti-corrosion layer alloy is 10%-35% (thickness composite ratio), and the ratio of brazing alloy is 5%-10% ( Thickness composite ratio); the core layer alloy is Al-Mn or Al-Mn-Mg alloy; the anti-corrosion layer alloy is pure aluminum alloy AA1050, AA1145 or AA7072 alloy; the brazing alloy is Al-Si alloy.

[0019] Table 1

[0020] alloy layer

Alloy (AA)

Composite ratio (%)

4045 or 4343

5-10%

Anti-corrosion layer alloy layer

1145 or 7072

20-35%

core alloy la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com