Recycling system of blast furnace slag heat

A technology of heat energy recovery and blast furnace slag, applied in the direction of improving energy efficiency, recycling technology, furnaces, etc., can solve environmental pollution and other problems, achieve high granulation efficiency, increase heat transfer surface area, and reduce slag flow deflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

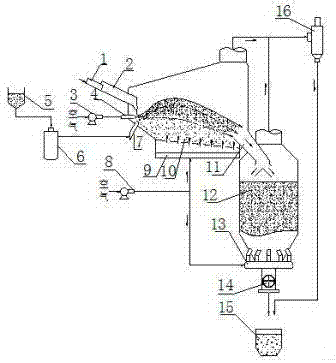

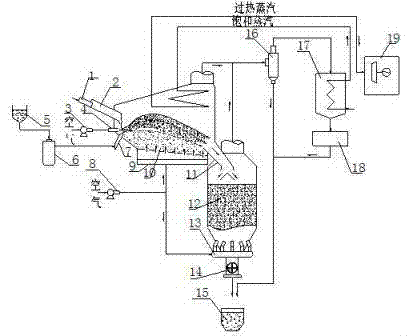

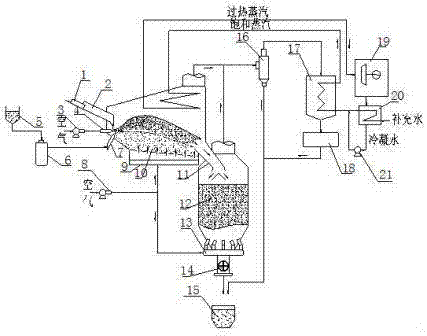

[0036] as attached figure 1 As shown, a blast furnace slag heat energy recovery system of the present invention includes a granulation unit, a fluidized bed slag particle collision unit, an air heat exchange unit, a superheated steam recovery unit, and a slag discharge unit. The granulation unit is composed of a slag tank 1. Diversion tank 2, wind crushing fan 3, and wind crushing nozzle 4. The slag tank 1 is placed above the diversion tank 2 with a certain slope, and the high-pressure air generated by the wind crushing fan 3 is in the lower part of the diversion tank 2. It is ejected from the blasting nozzle 4, and the outlet of the diversion groove 2 is inserted into the fluidized bed 10; the slag particle collision unit of the fluidized bed consists of a cold slag nozzle 7, a cold slag bucket 5, a slag sprayer 6, a fluidized bed fan 8, and a fluidized bed Bed 10, air distribution plate device 9, slag bead chute 11, cold slag nozzle 7 is set at the lower part of wind crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com