Patents

Literature

83results about How to "Increase the heat transfer surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

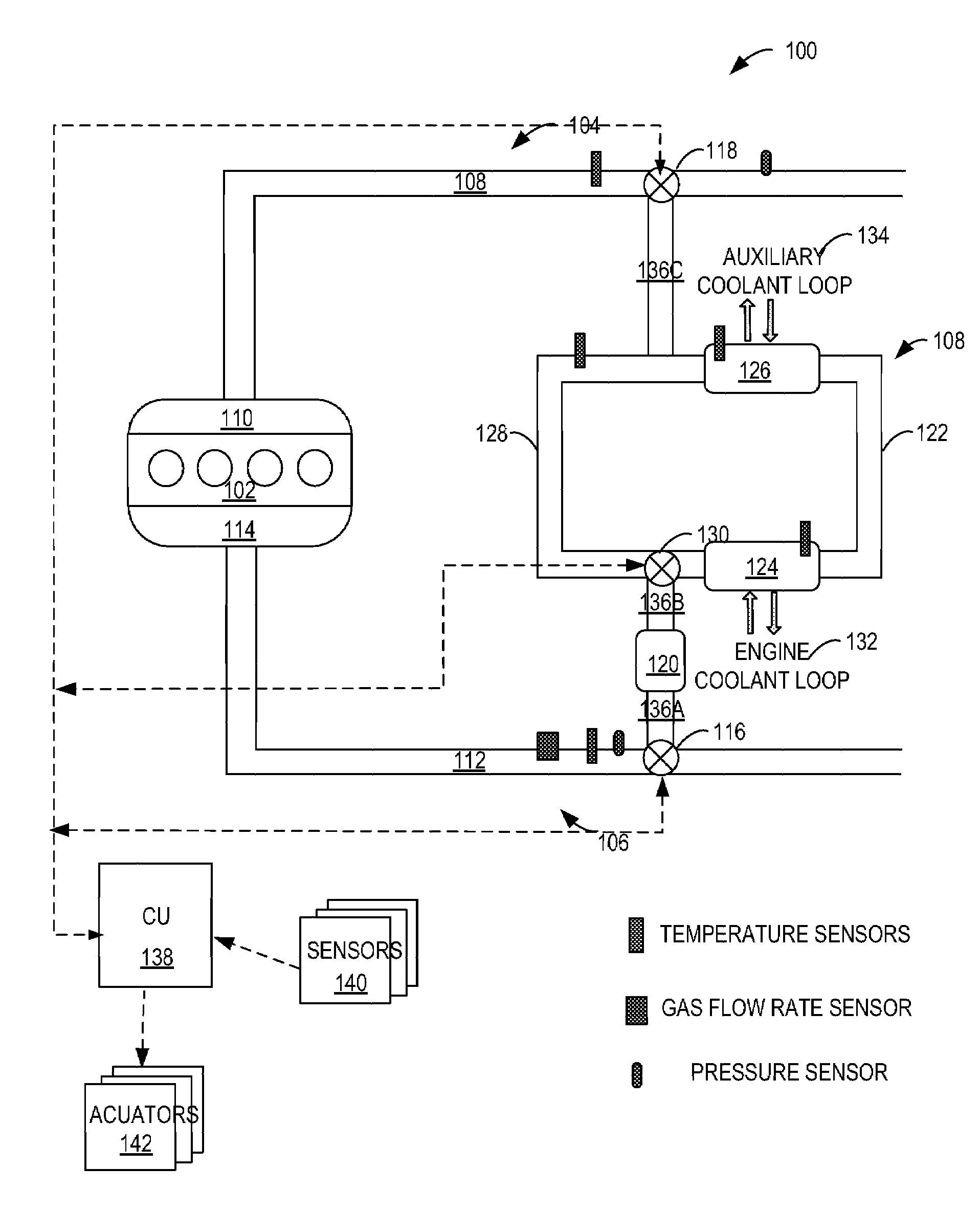

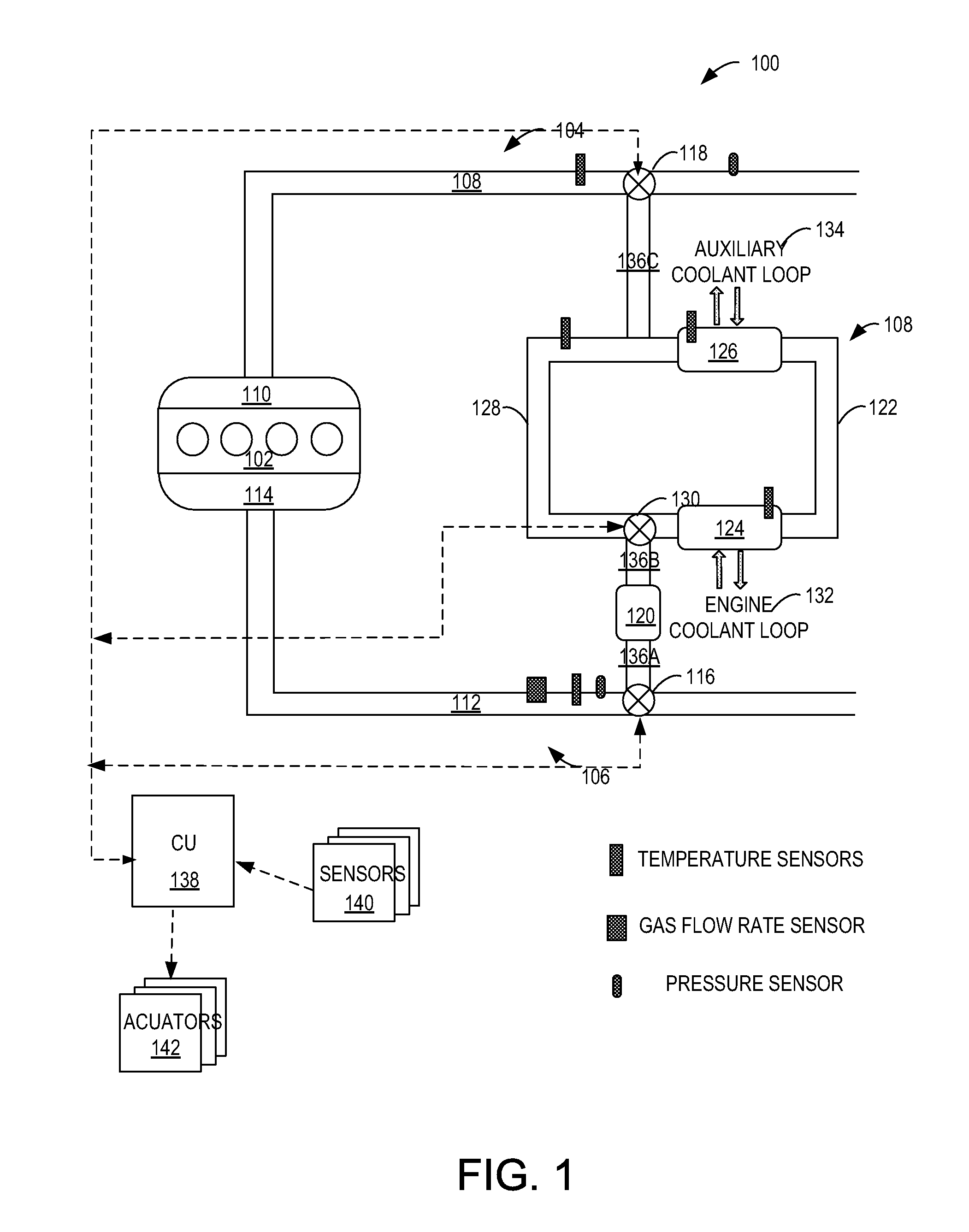

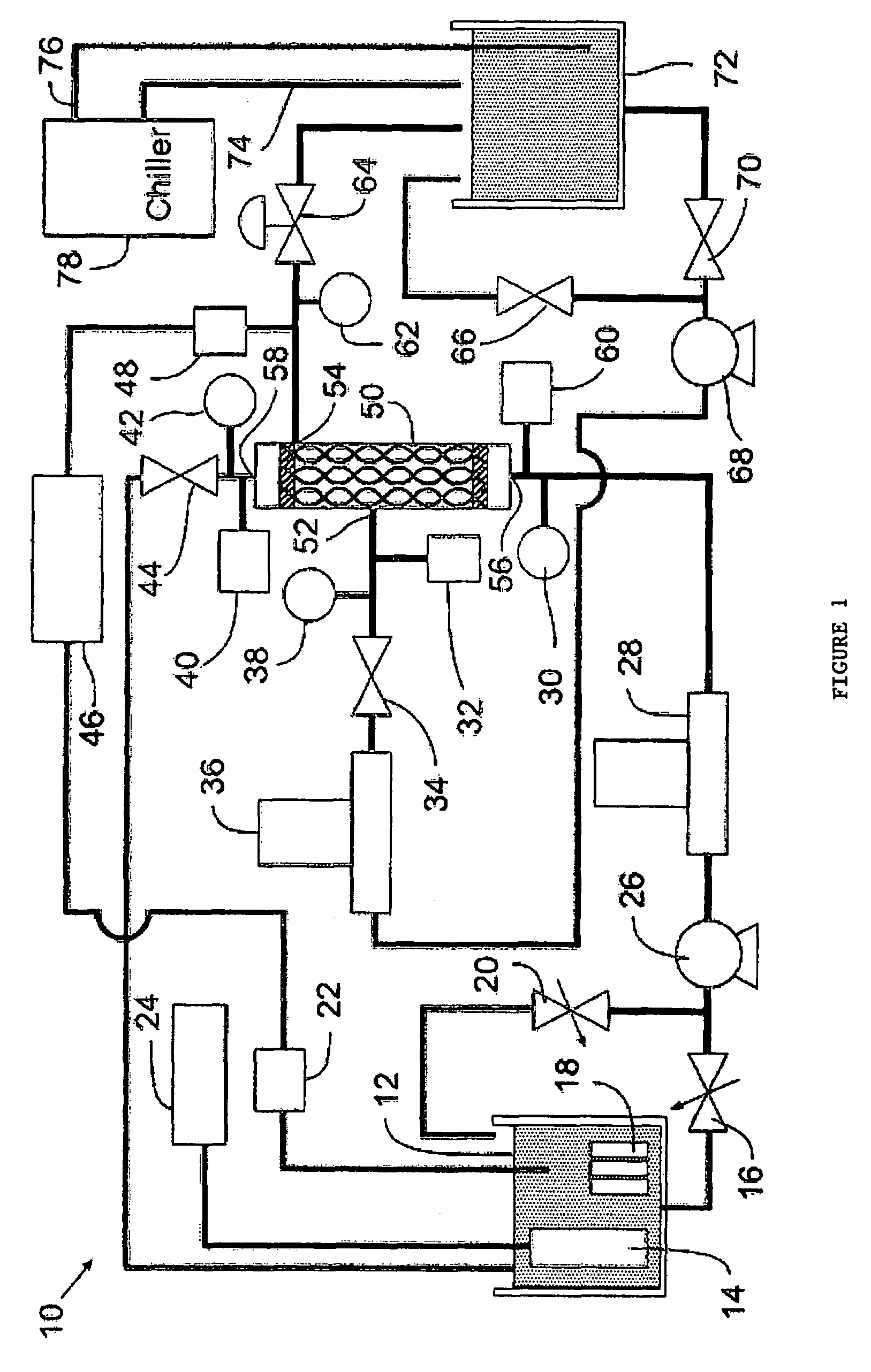

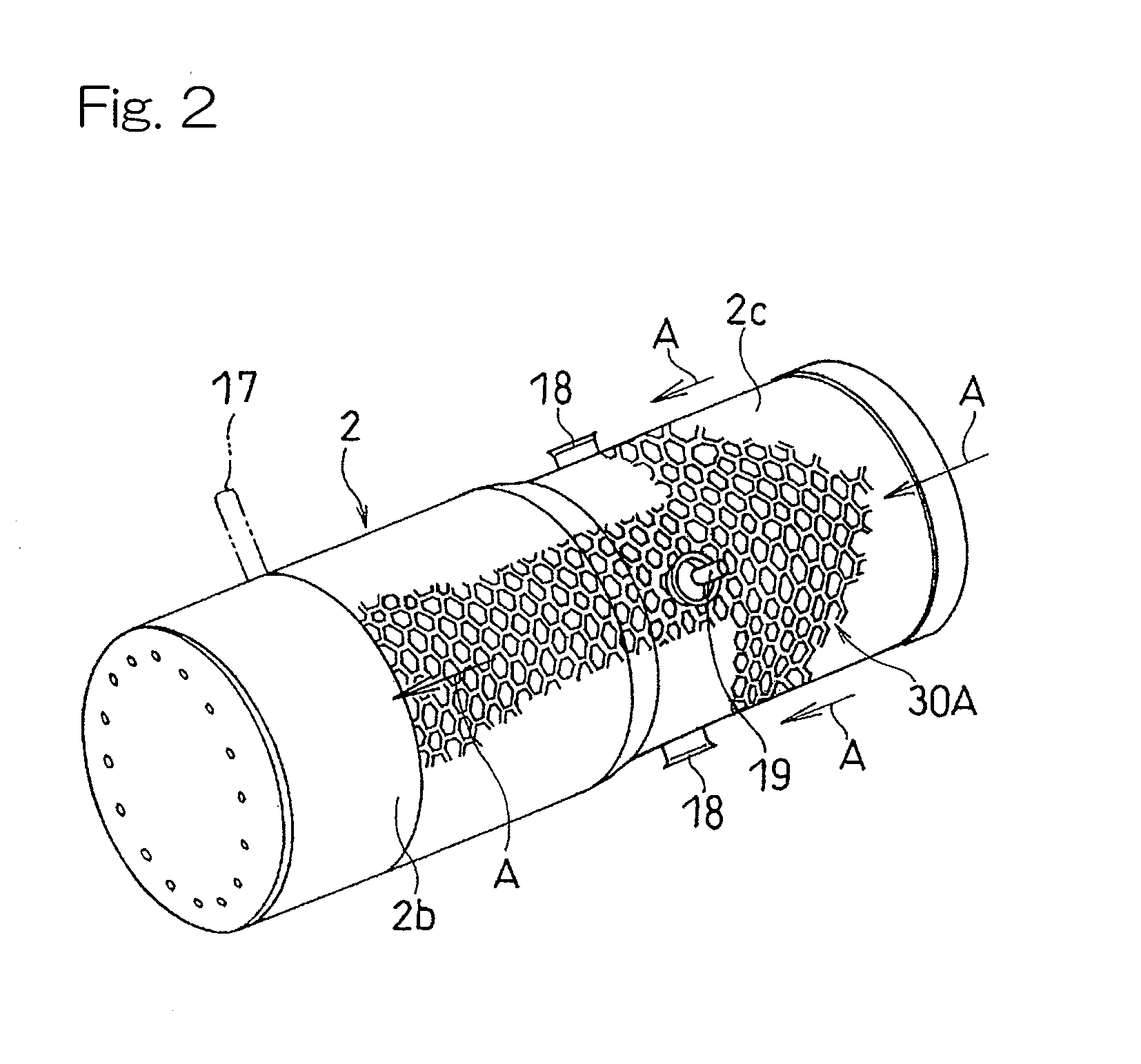

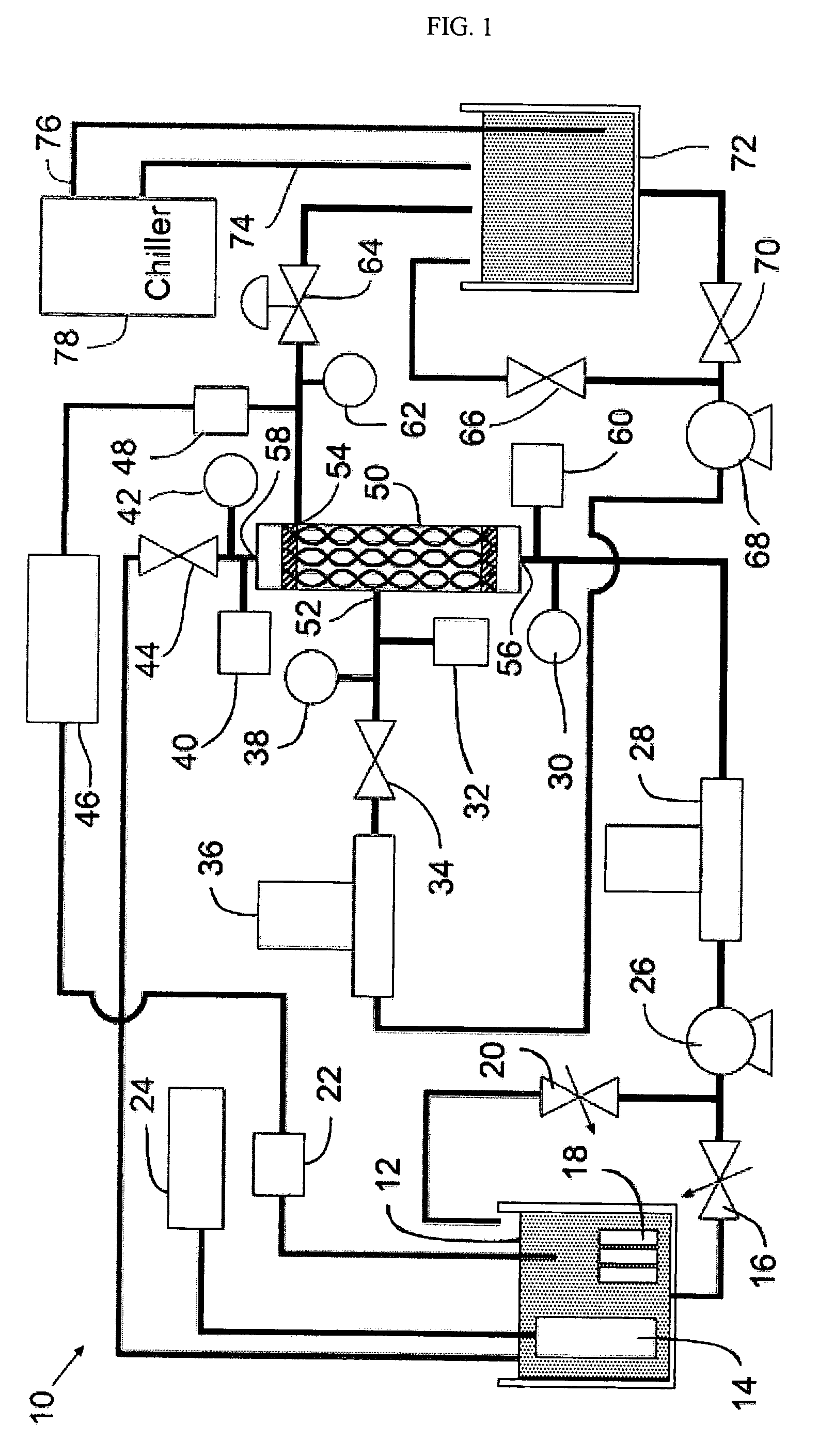

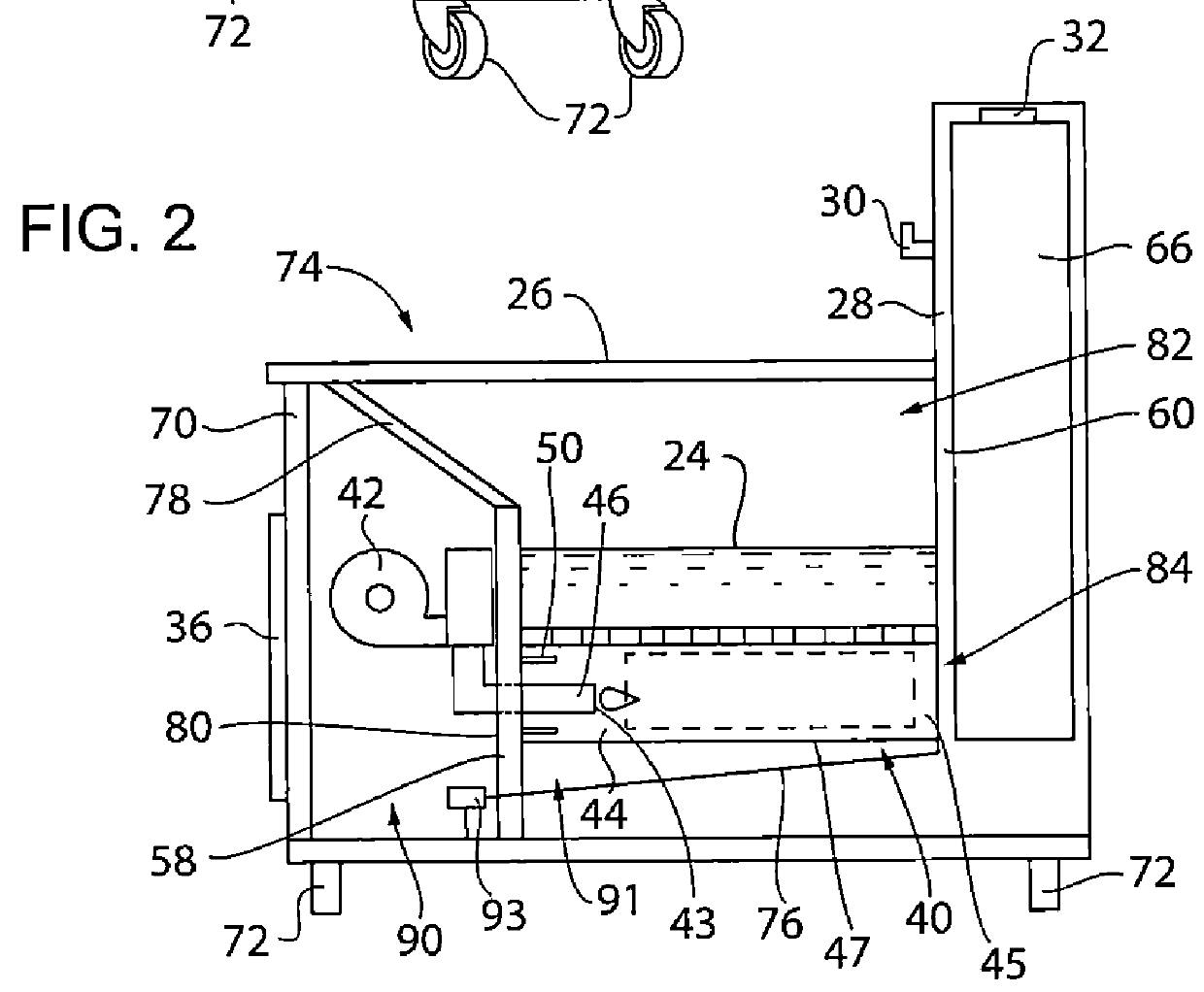

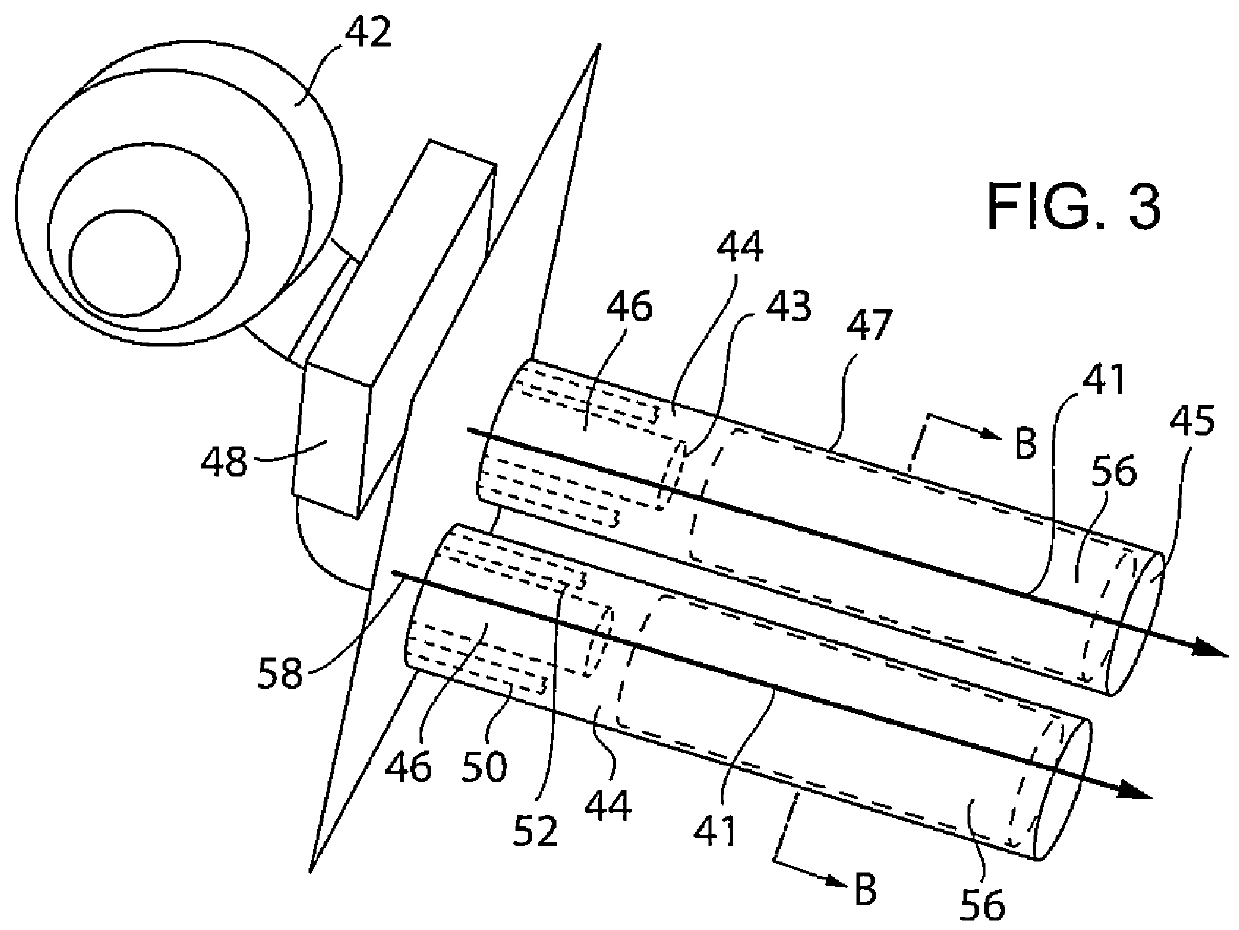

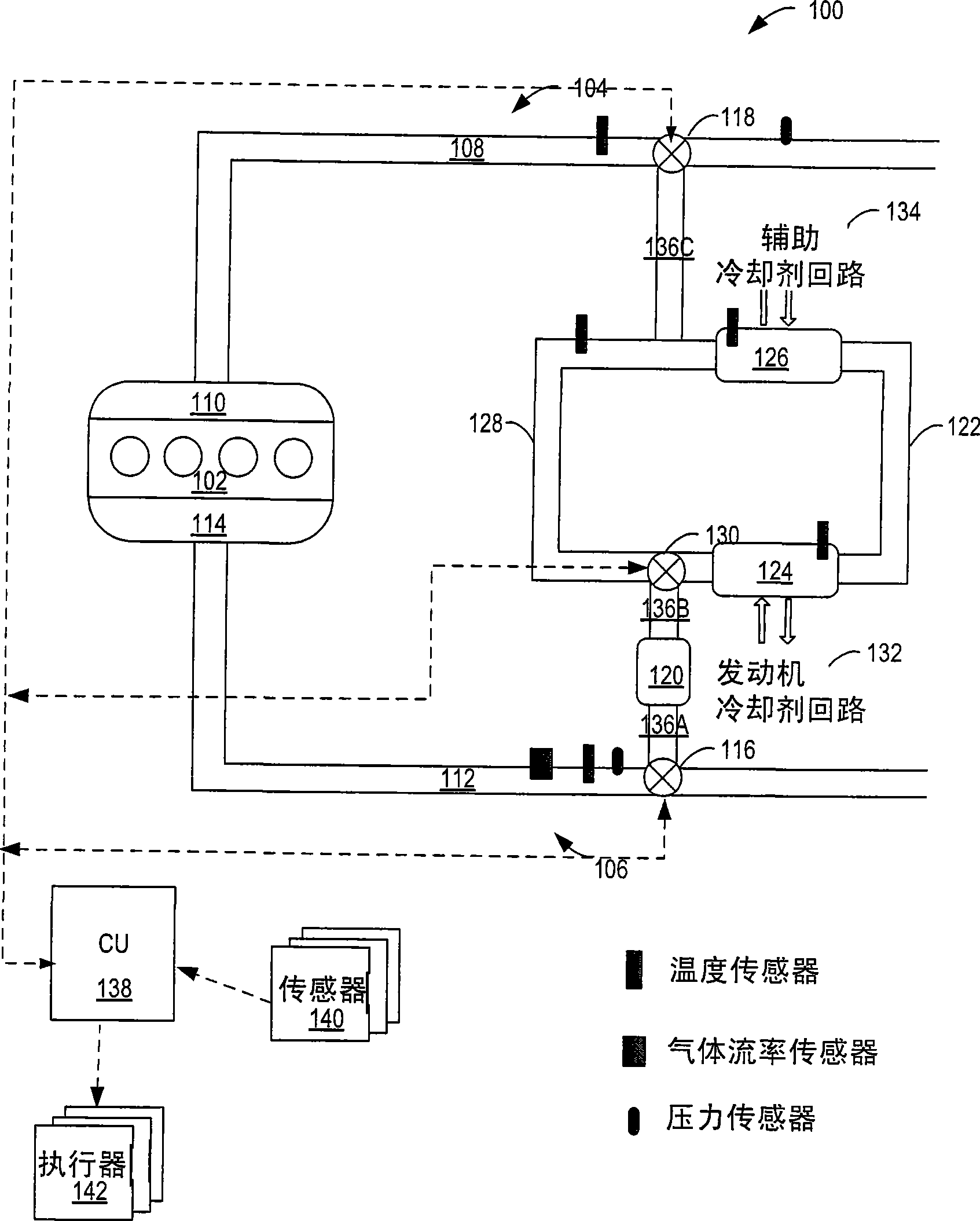

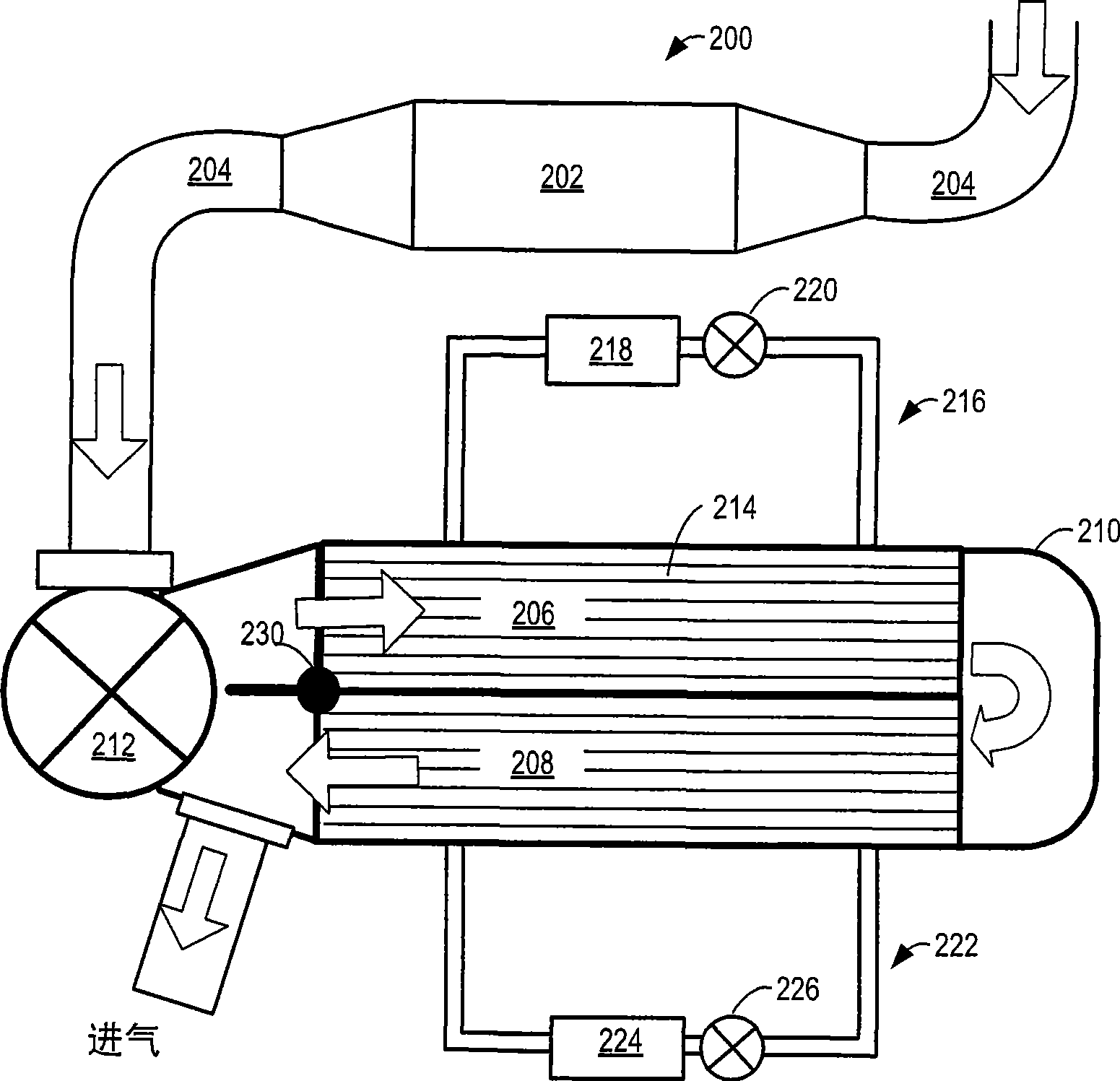

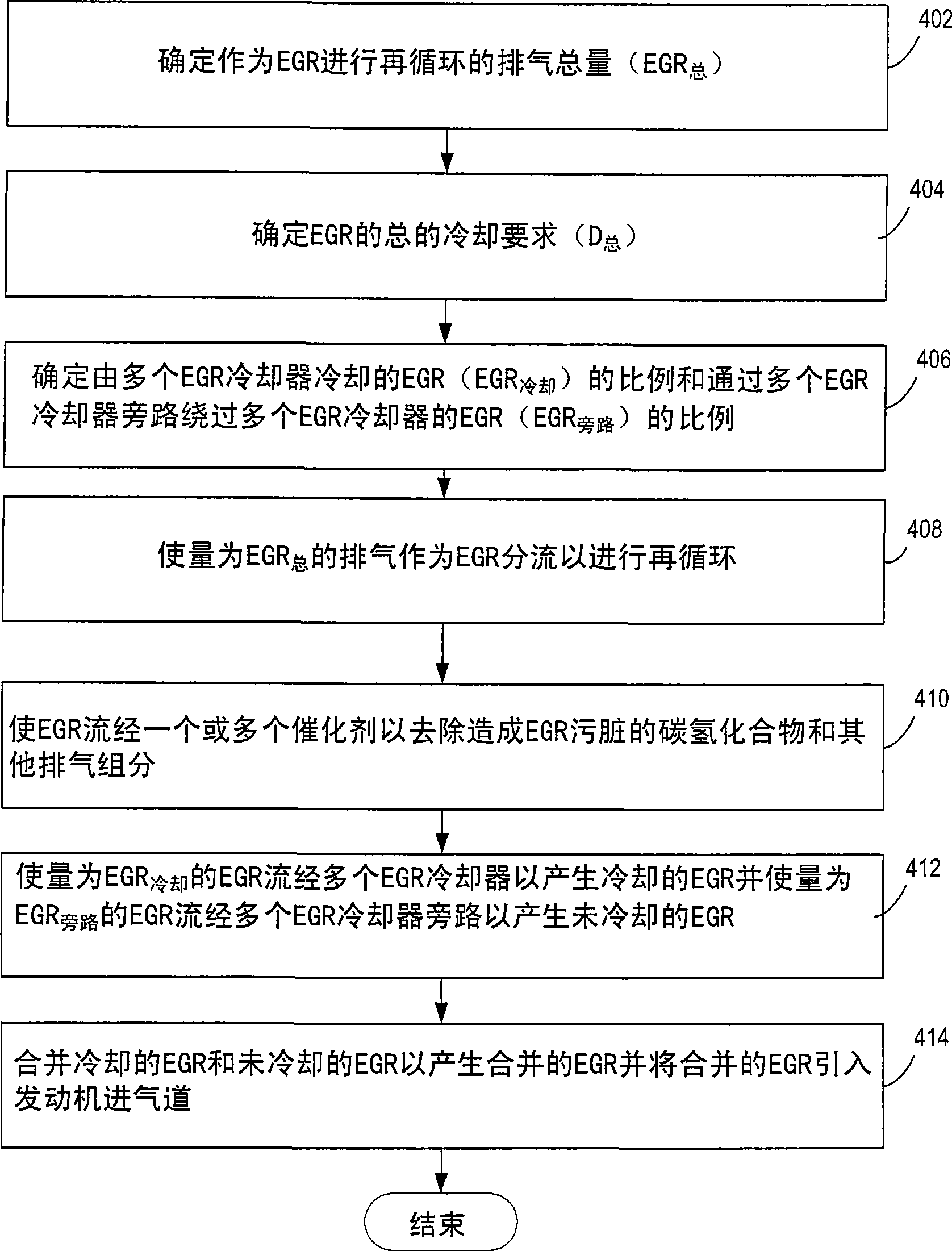

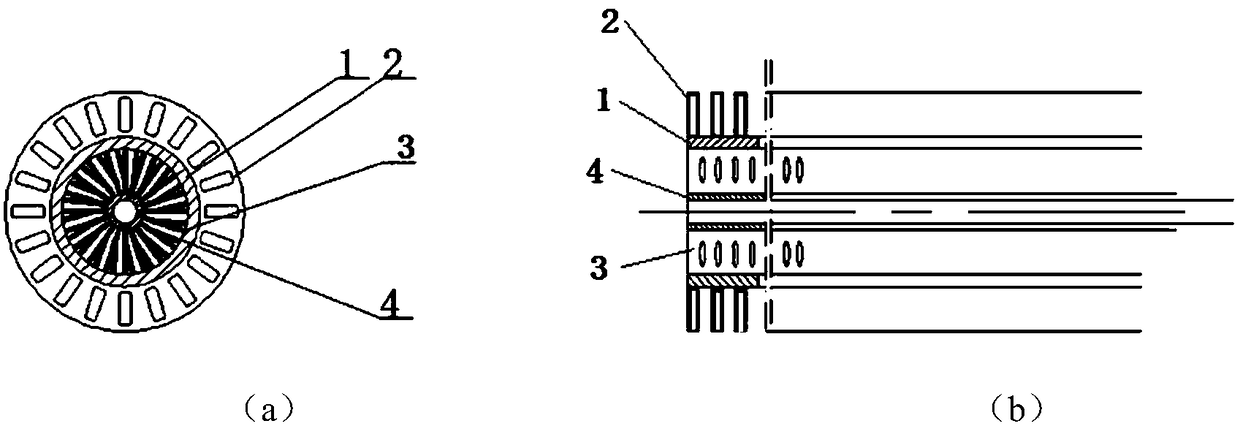

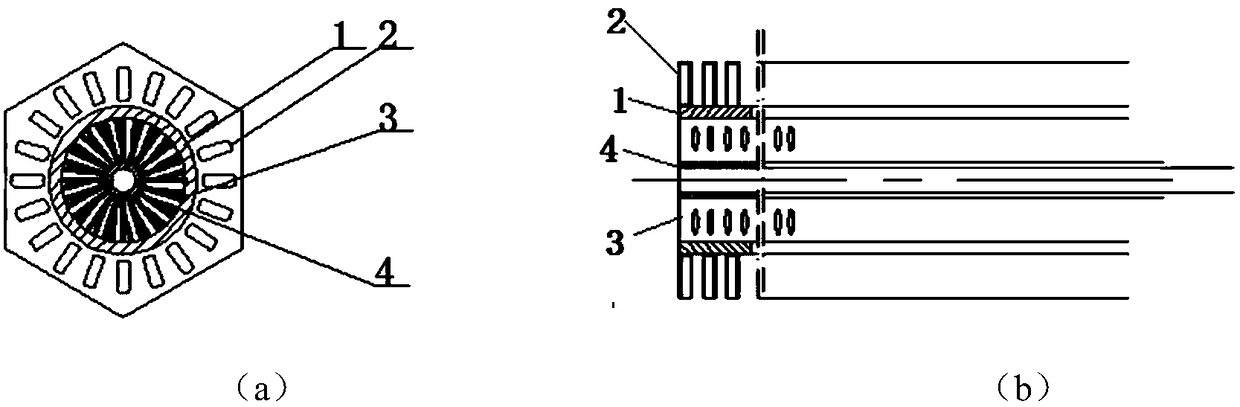

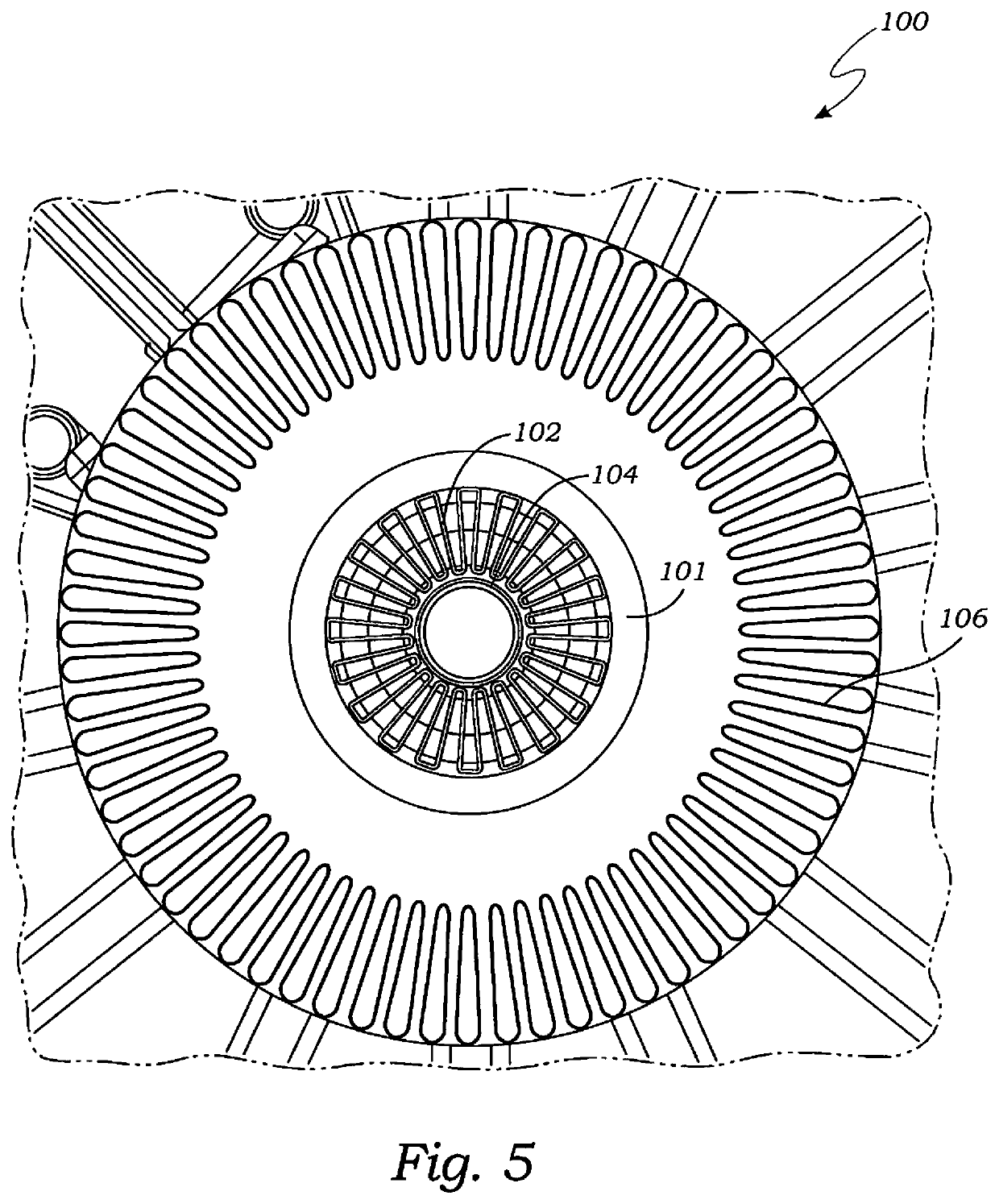

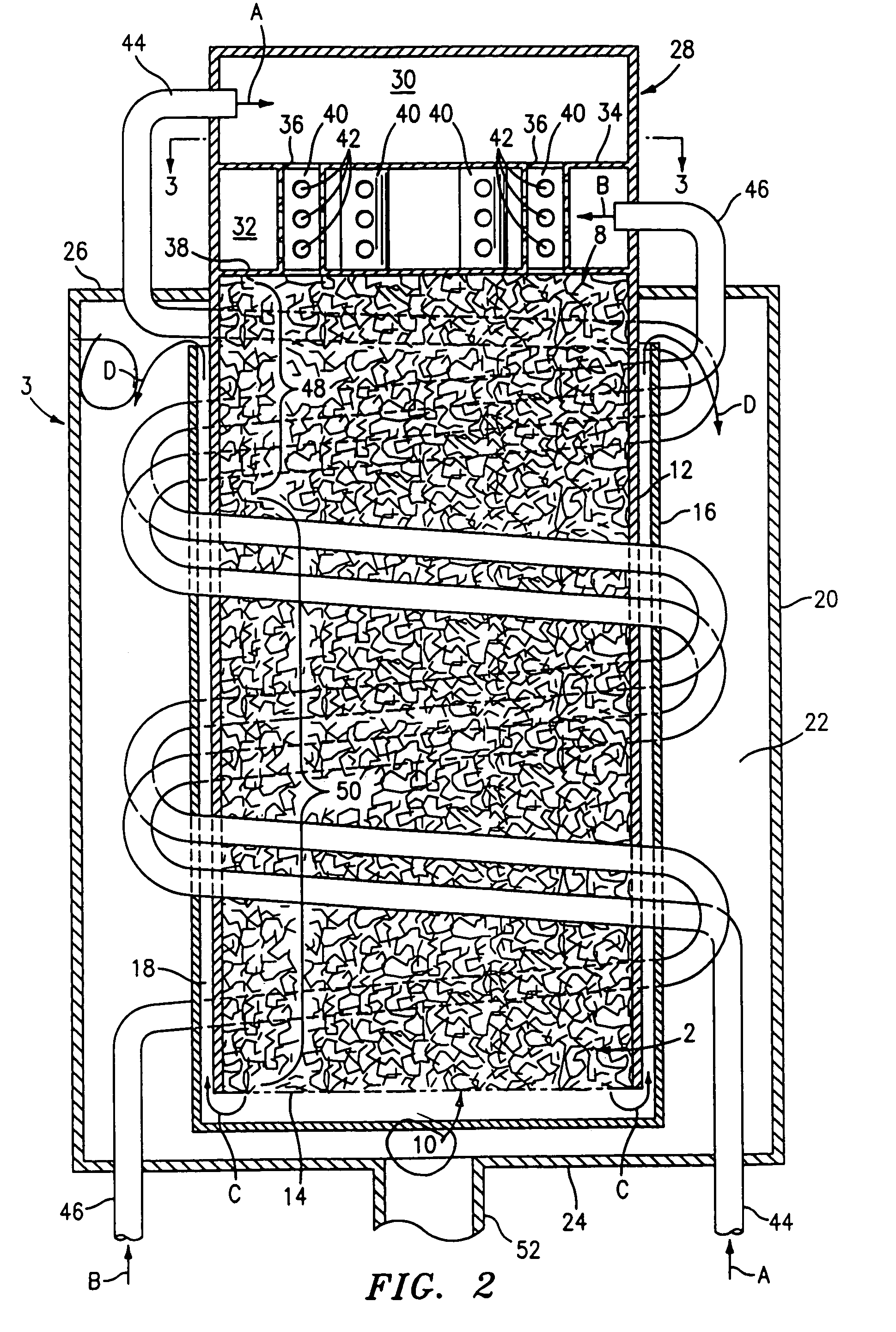

EGR Cooling System with Multiple EGR Coolers

ActiveUS7461641B1Avoiding EGR foulingIncrease the heat transfer surface areaInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringChiller

An EGR cooling system is provided. The EGR cooling system comprising a plurality of EGR coolers configured to cool the EGR to a plurality of successively lower temperatures, where at least one of the plurality of EGR coolers includes a finned EGR cooler that comprises a plurality of channels for dissipating heat in the EGR, the plurality of channels increasing heat transfer surface area while having sufficient fin spacing to avoid clogging. The EGR cooling system may further comprise a catalyst configured to remove particle matters and / or hydrocarbons from the EGR, the catalyst positioned upstream of at least one of the plurality of EGR coolers.

Owner:FORD GLOBAL TECH LLC

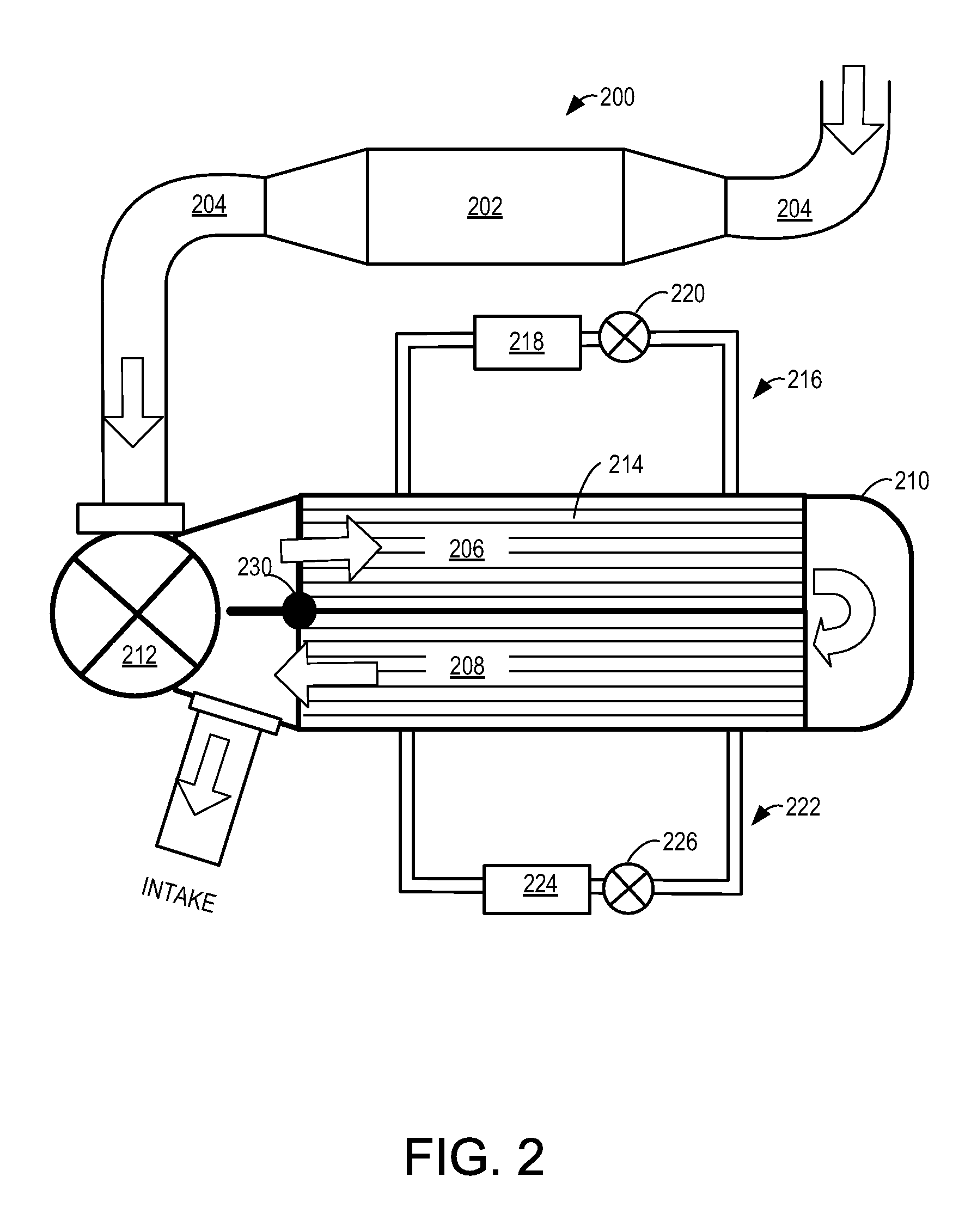

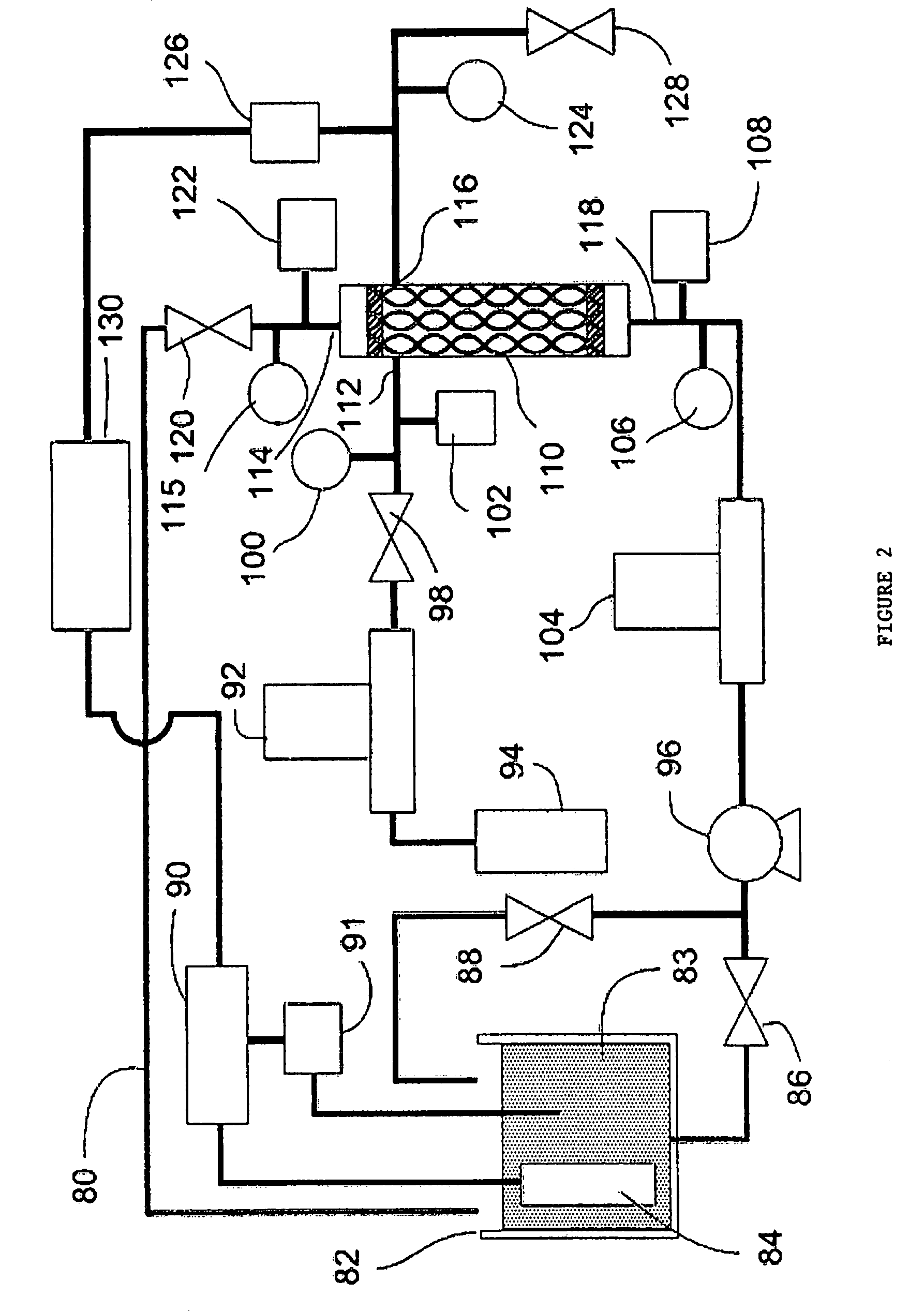

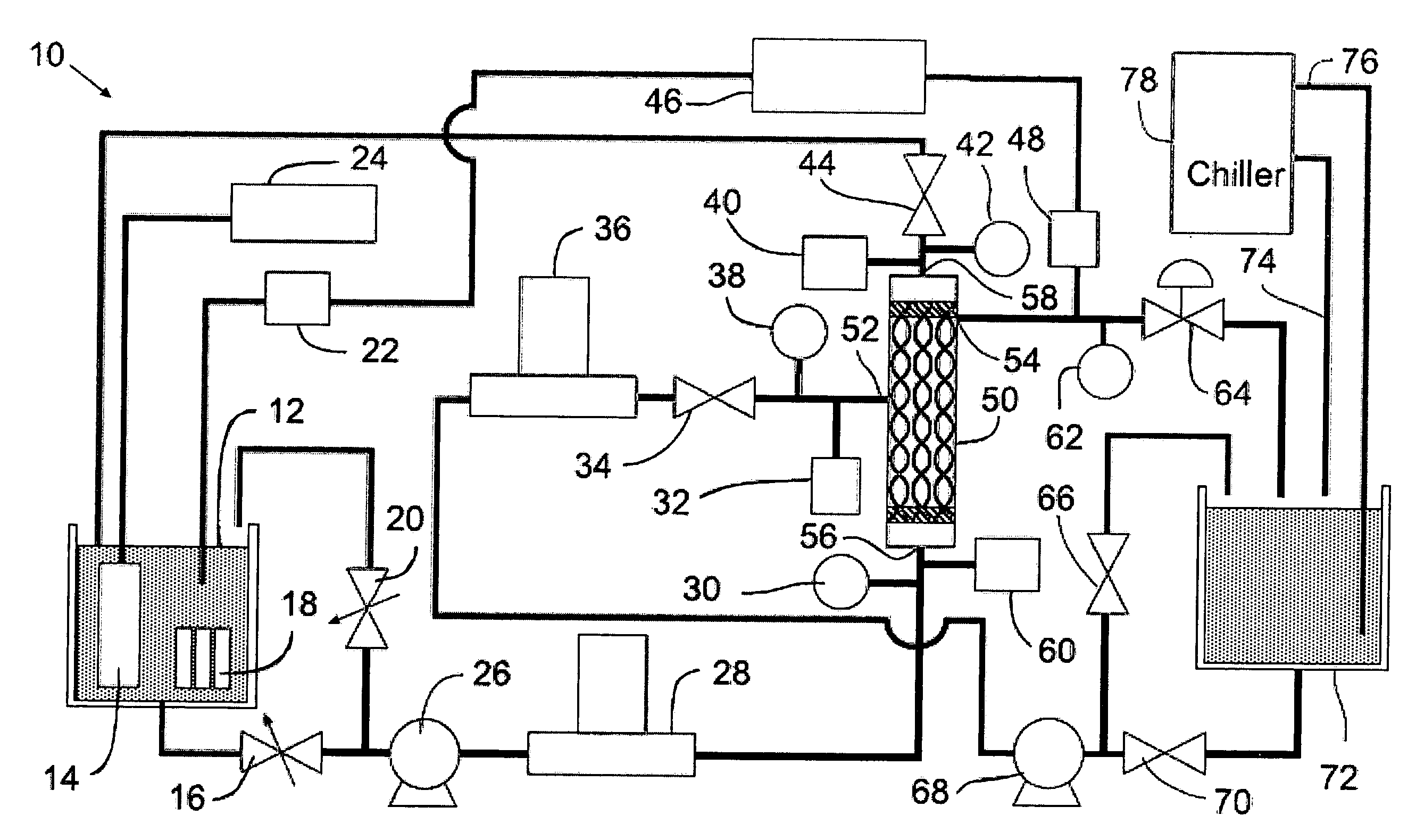

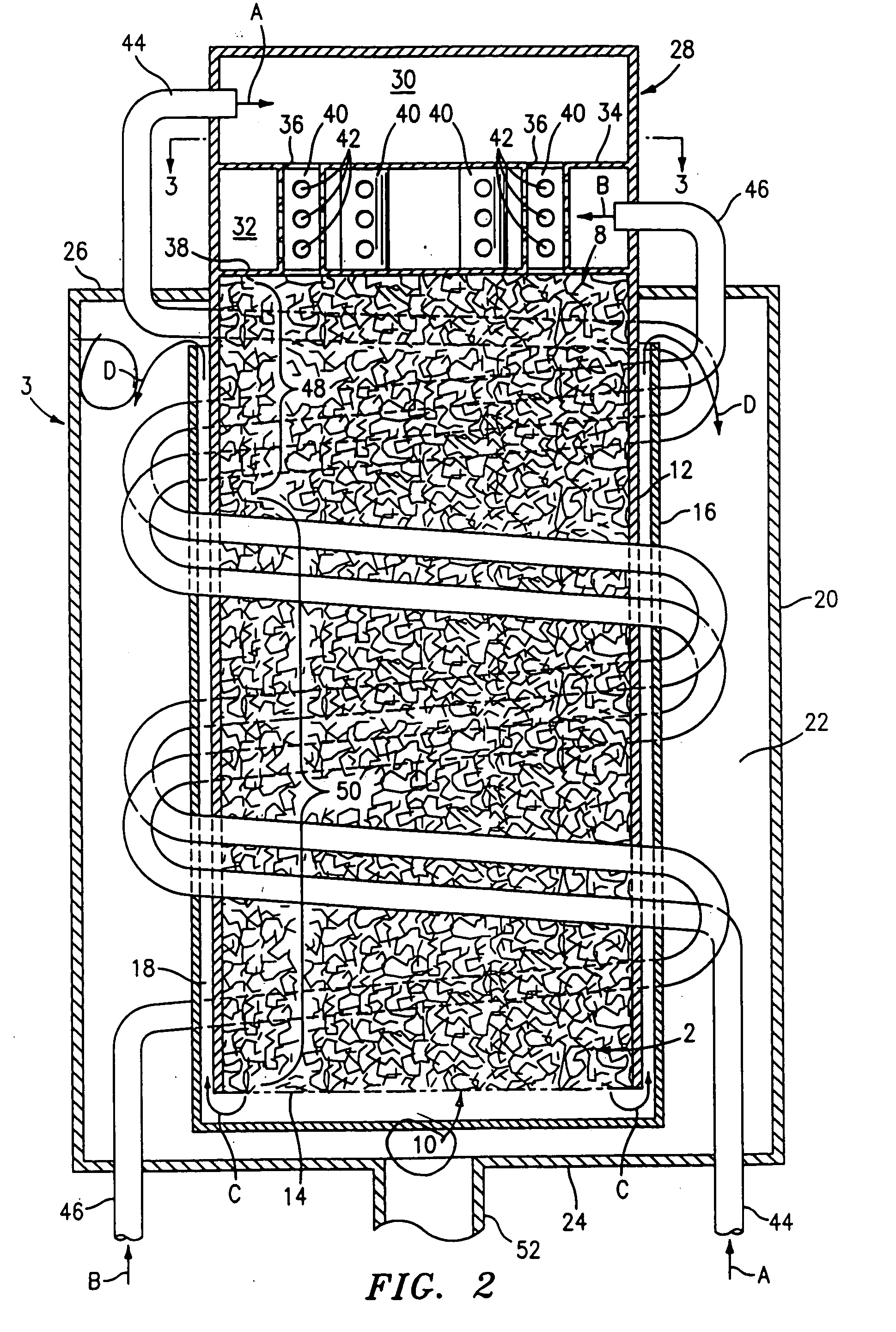

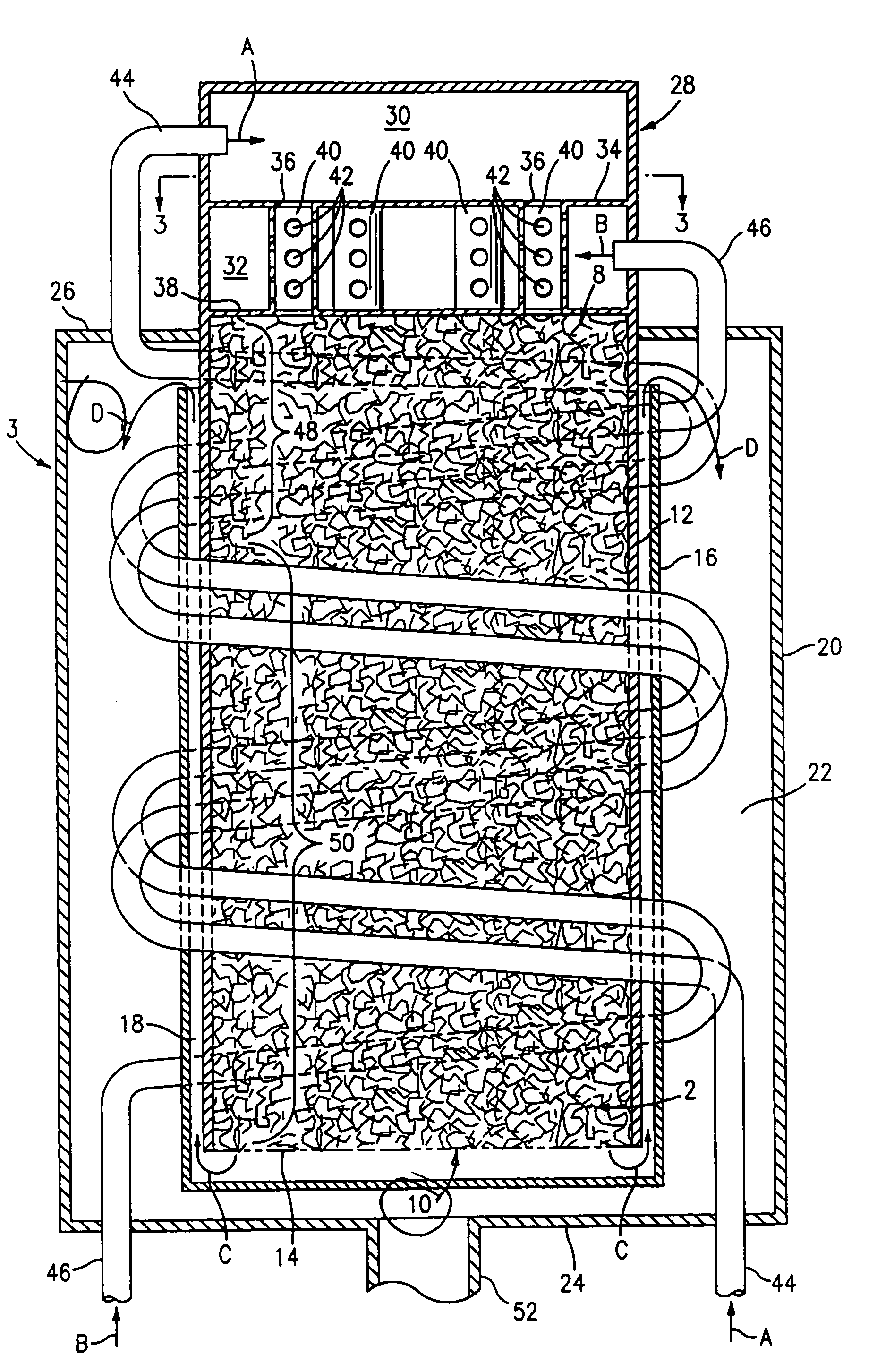

Apparatus for conditioning the temperature of a fluid

InactiveUS7249628B2High bulk densitySmall volumeTemperature control without auxillary powerTemperature control using analogue comparing deviceTemperature controlEngineering

This invention relates to an apparatus for conditioning the temperature of a fluid by utilizing a thermoplastic heat exchanger (50) comprised of a plurality of hollow tubes. The apparatus controls the temperature of a process fluid inside the heat exchanger (50) via a controller (46) by adjustment of a control valve (64) that regulates the flow of an exchange fluid. The apparatus can be used to maintain the temperature of a chemical bath (12) and also to prepare discreet dispensed volumes of temperature controlled liquid.

Owner:ENTEGRIS INC

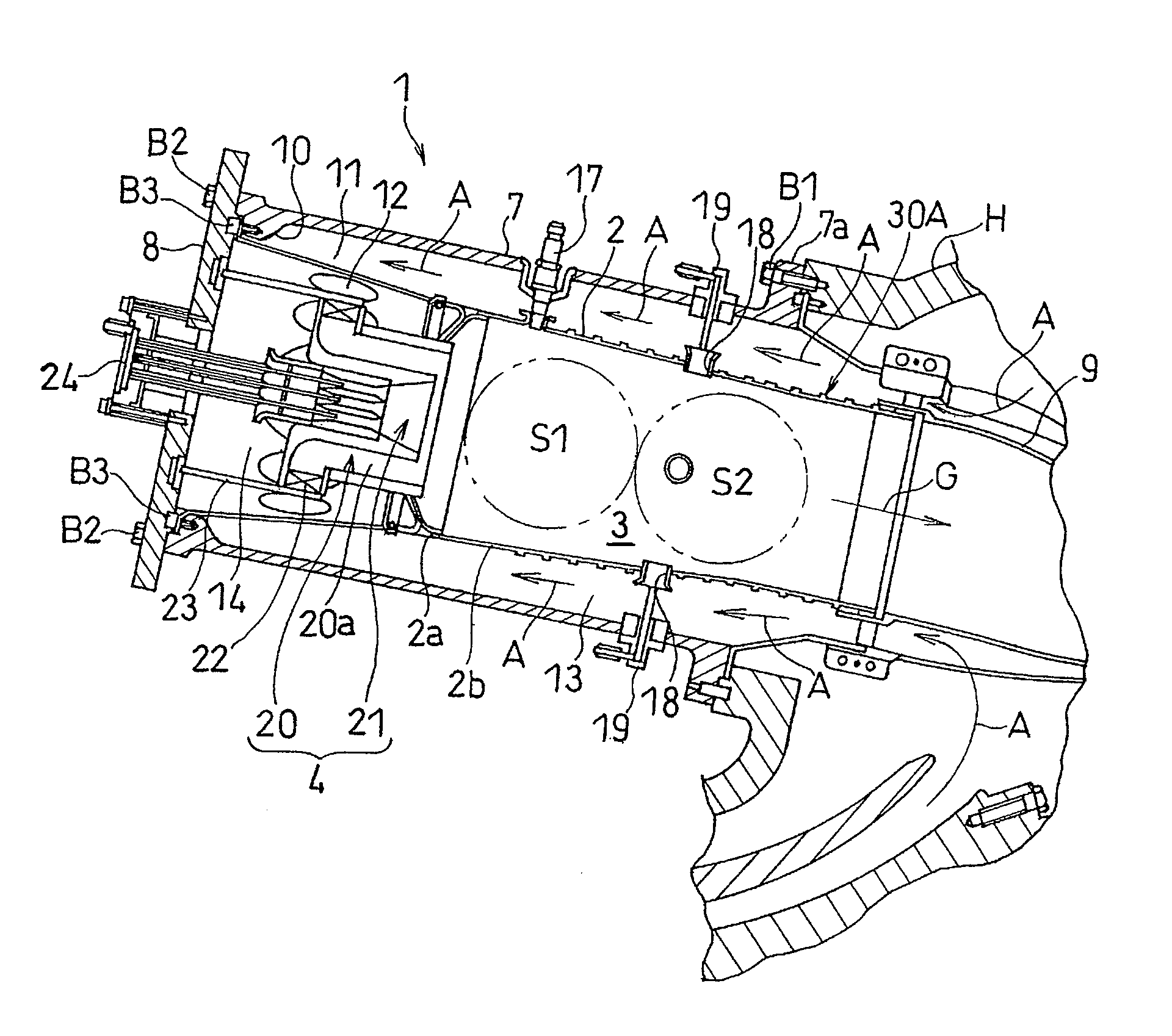

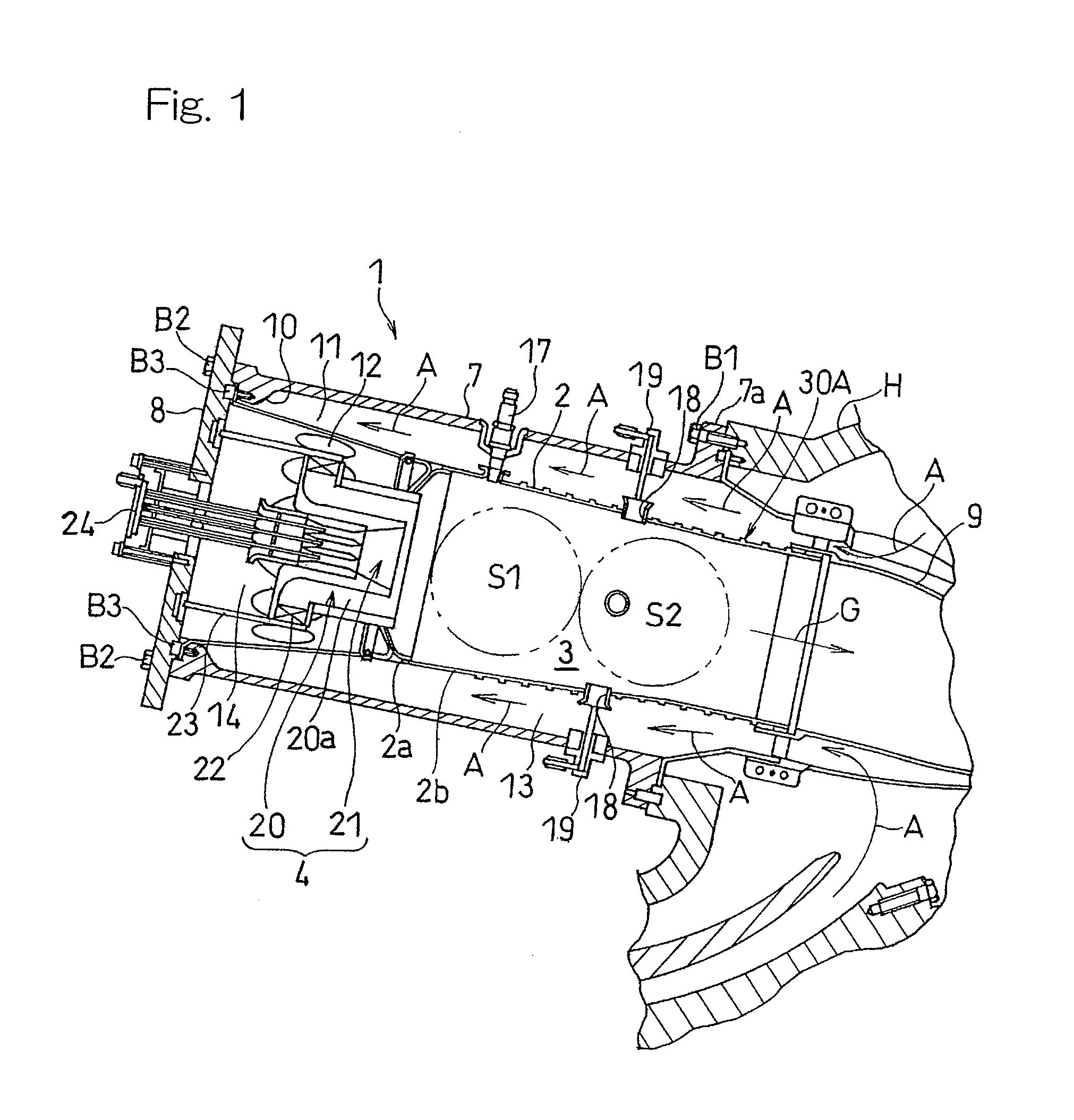

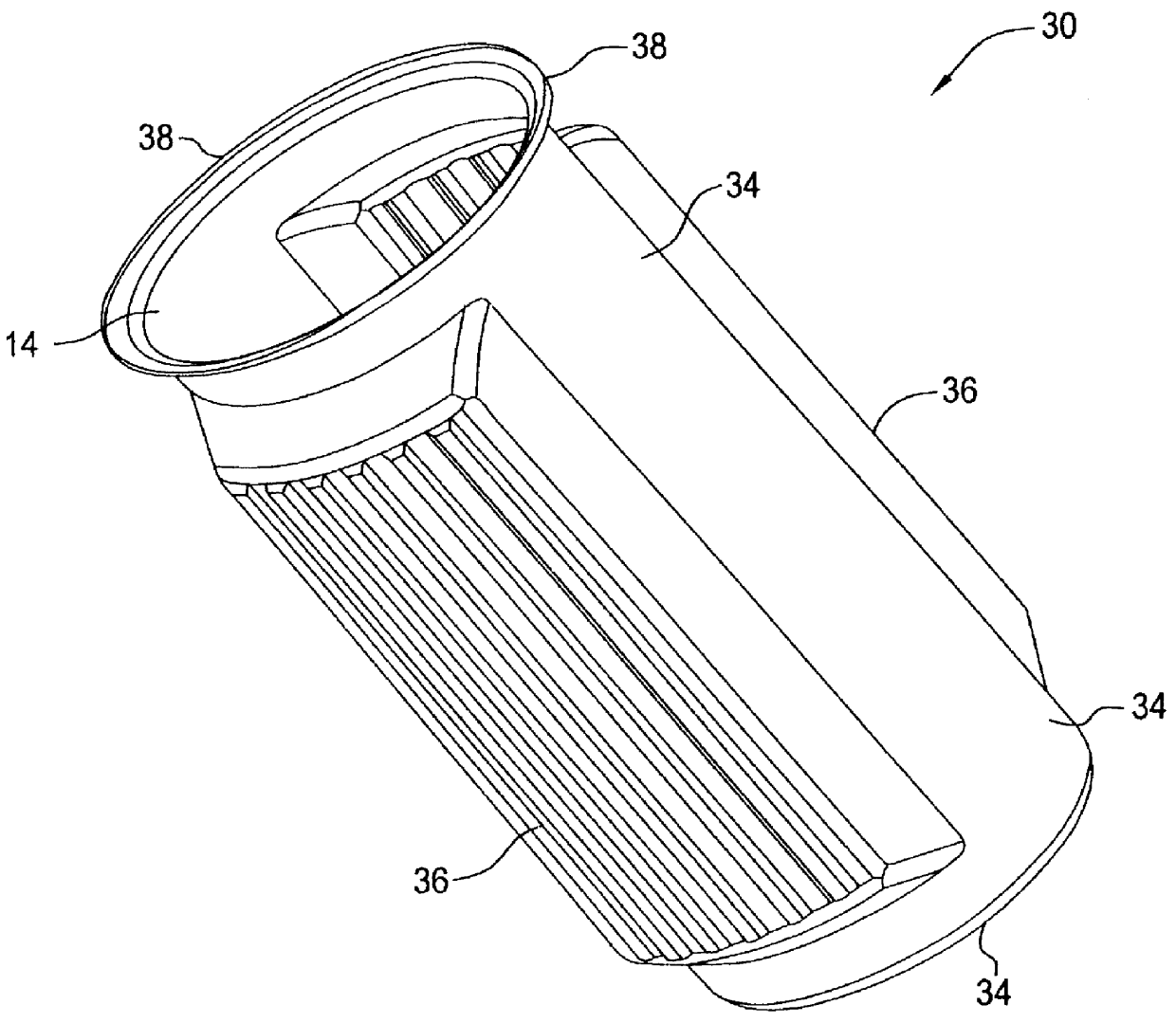

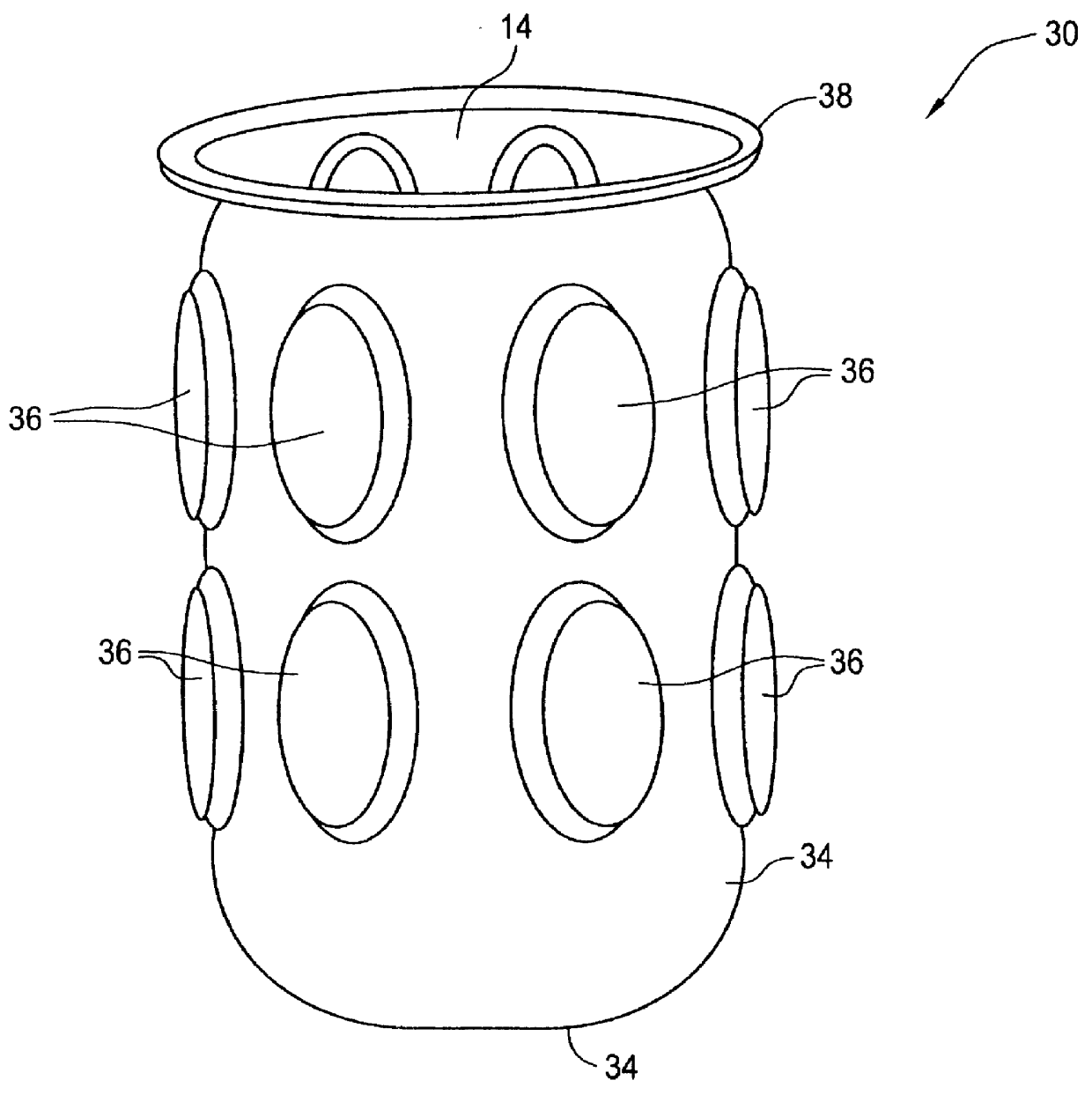

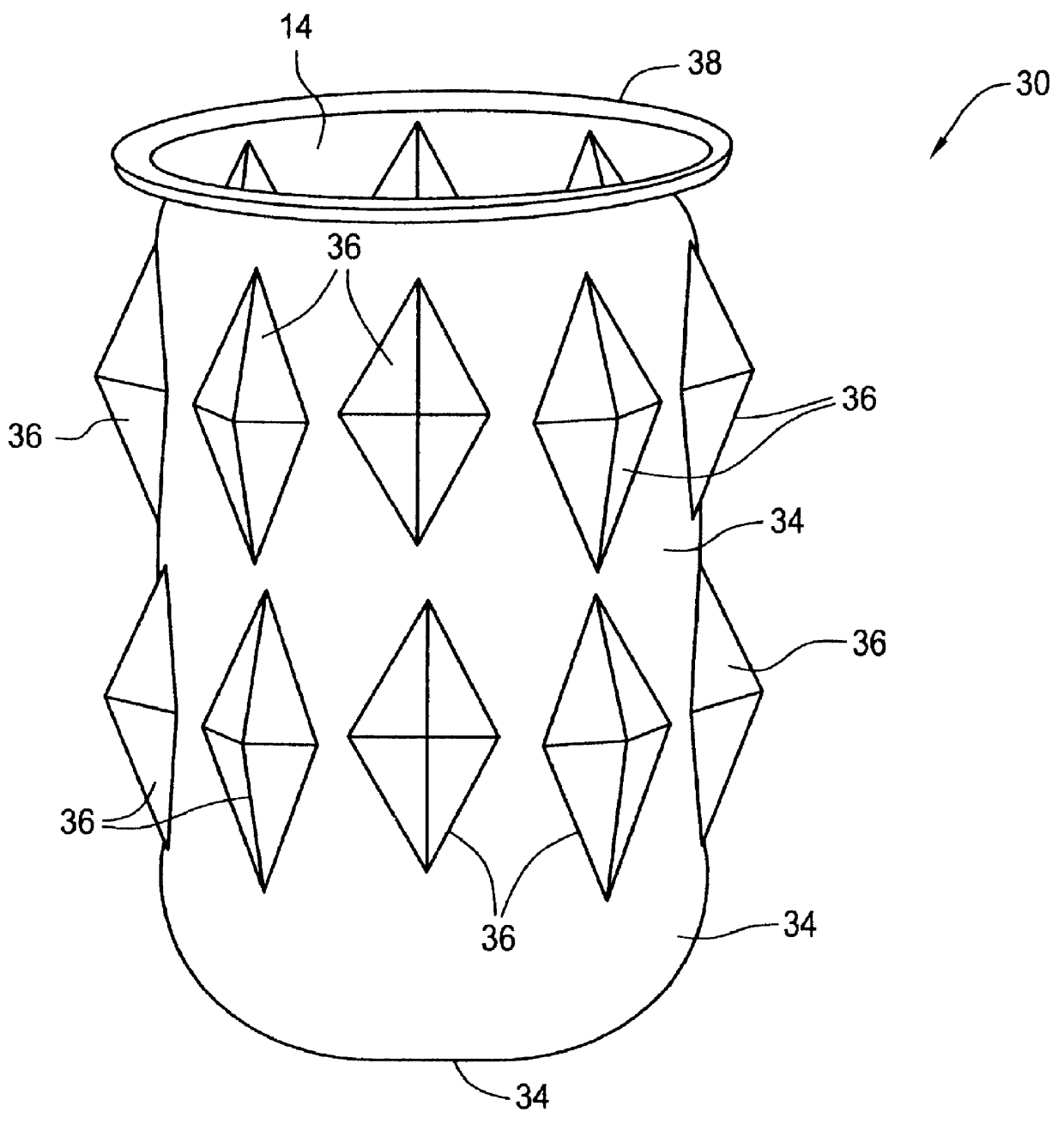

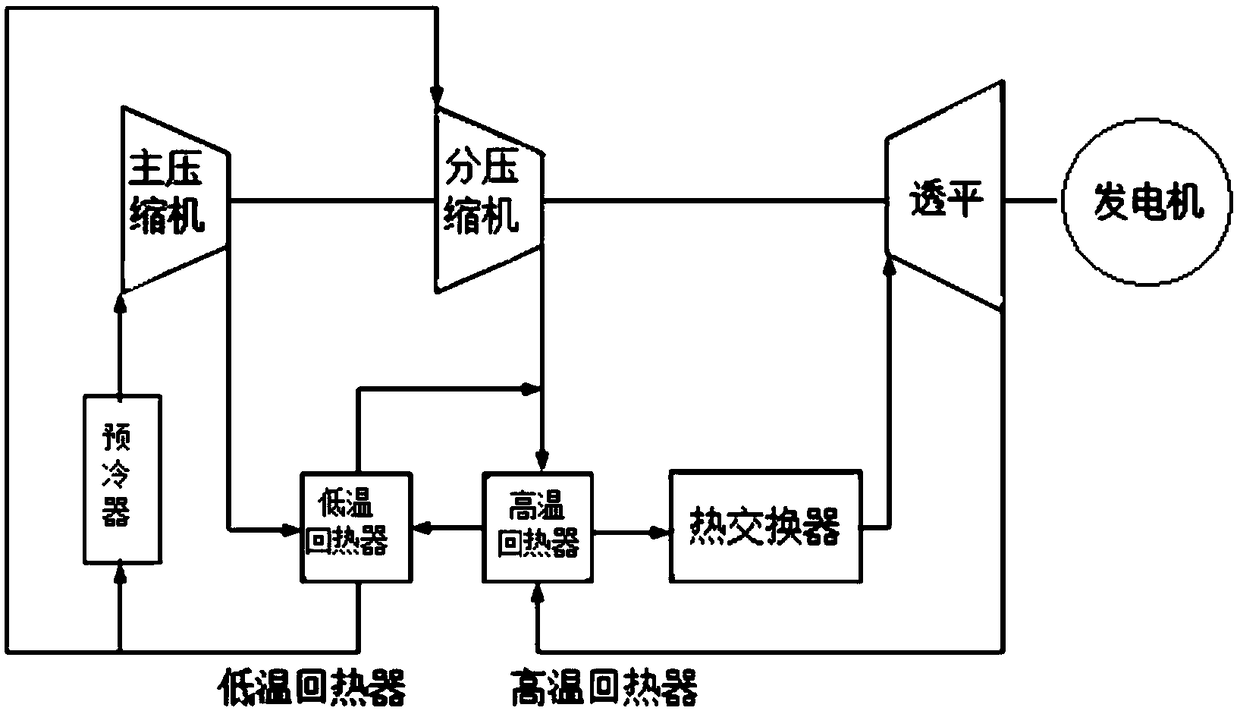

Cooling structure for gas turbine combustor

InactiveUS20110016869A1Increase the heat transfer surface areaImprove cooling effectContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

To provide a gas turbine combustor having an improved cooling structure effective to efficiently suppress a possible occurrence of buckling in the combustion liner while exhibiting a convection cooling effect to the combustion liner, the gas turbine combustor includes a combustion liner having a combustion chamber defined therein and an outer peripheral surface forming a path of a compressed air, and a heat transfer enhancement structure provided on the outer peripheral surface of the combustion liner. The heat transfer enhancement structure referred to above is of a honeycomb construction defined by ribs protruding outwardly from the outer surface of the combustion liner. The honeycomb construction may be of a geometry in which hexagonal shapes, rhombic shapes, parallelogrammic shapes, bent rectangular shapes or triangular shapes are deployed next to each other.

Owner:KAWASAKI HEAVY IND LTD

Self-cooling container with internal beverage vessel having a vessel wall with reversible wall bulges

InactiveUS6065300AMaximize capacityIncrease the heat transfer surface areaLighting and heating apparatusLarge containersAtmospheric airEngineering

A rapid refrigeration apparatus includes a container having a container upper end, a container wall with a container opening in the container upper end bordered by a container rim; a beverage retaining vessel extending within the container defining an annular refrigerant chamber between the container and the vessel containing a liquefied refrigerant and refrigerant vapor, and the vessel containing flowable vessel contents, the vessel being sized to fit at least partly through the container opening, the vessel including a vessel rim secured relative to the container rim, and a vessel wall including at least one reversible bulge; a lid sealingly secured to the container rim and including a lid opener mechanism for releasing the vessel contents from the vessel and container for consumption; the lid opener mechanism including a lid opener mechanism activation mechanism for voluntarily opening the lid opener mechanism at a selected moment in time; and a refrigerant release mechanism for releasing the refrigerant from the annular chamber into the atmosphere surrounding the apparatus; the refrigerant release mechanism including a refrigerant release mechanism activation mechanism for voluntarily opening the refrigerant release mechanism at a selected moment in time.

Owner:ANTHONY MICHAEL M

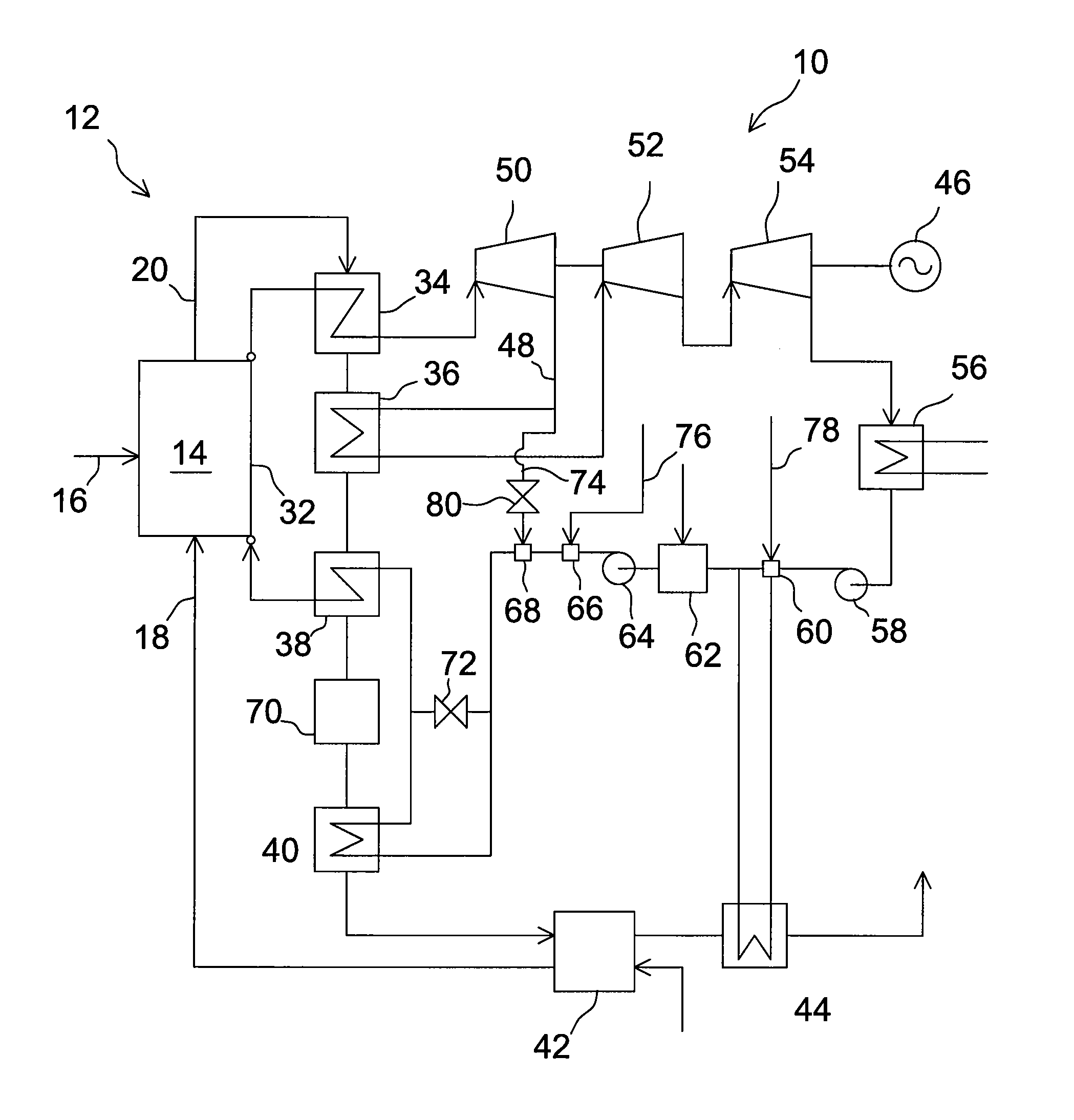

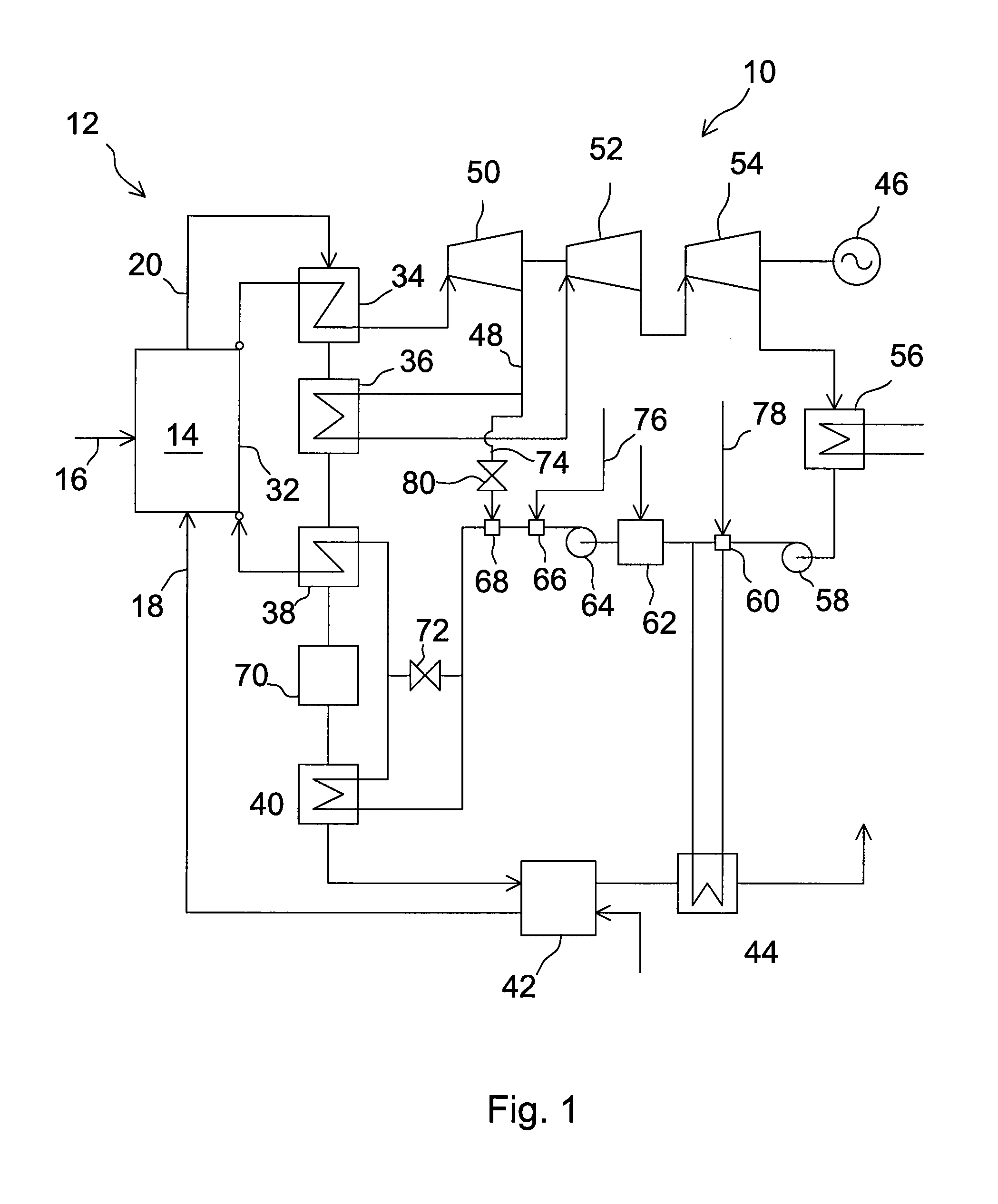

Method of Increasing the Performance of a Carbonaceous Fuel Combusting Boiler System

InactiveUS20110094228A1Increase powerImprove thermal efficiencySteam regenerationSteam useGas heaterProduct gas

A method of increasing the power of a carbonaceous fuel combusting boiler system includes the steps of (a) feeding carbonaceous fuel into a furnace of the boiler system, (b) feeding oxidant gas into the furnace for combusting fuel to produce exhaust gas, (c) discharging the exhaust gas from the furnace via an exhaust gas channel, (d) conveying a stream of feedwater from a boiler economizer arranged in the exhaust gas channel to evaporating and superheating heat exchange surfaces arranged in the furnace and in the exhaust gas channel for converting the feedwater to superheated steam, (e) expanding the superheated steam in a high-pressure steam turbine for generating power, (f) extracting steam from the high-pressure steam turbine at a decreased rate for preheating the feedwater, (g) conveying steam from the high-pressure steam turbine at an increased rate to a reheater arranged in the exhaust gas channel for generating reheated steam, (h) expanding the reheated steam in an intermediate pressure steam turbine for generating power, and (i) conveying the exhaust gas in the exhaust gas channel from the reheater through a boiler economizer to a gas heater. The heat exchange surface area of at least one of the reheater and the boiler economizer is increased and / or a high pressure economizer is added downstream of the boiler economizer and upstream of the gas heater.

Owner:FOSTER WHEELER ENERGY CORP

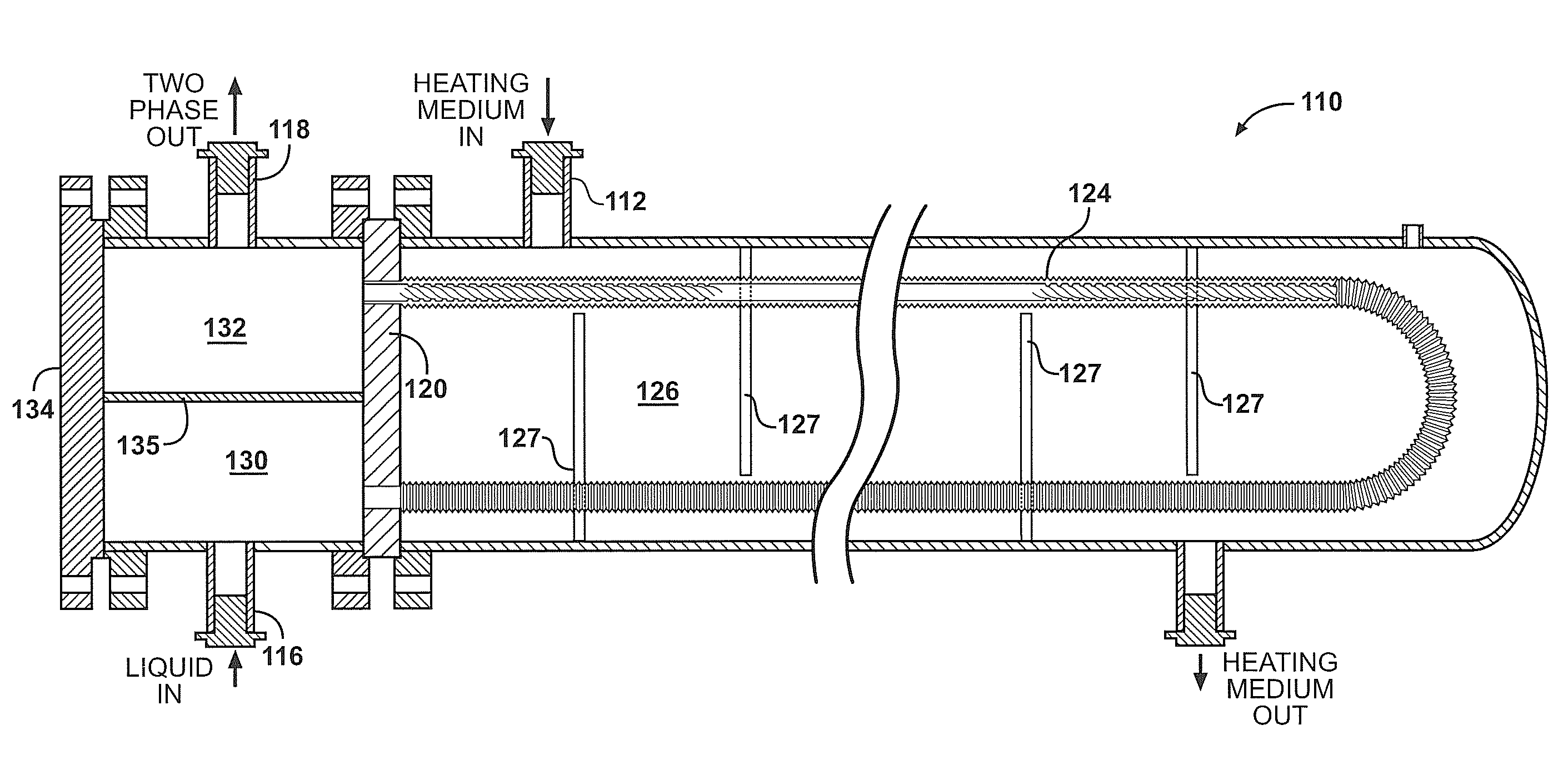

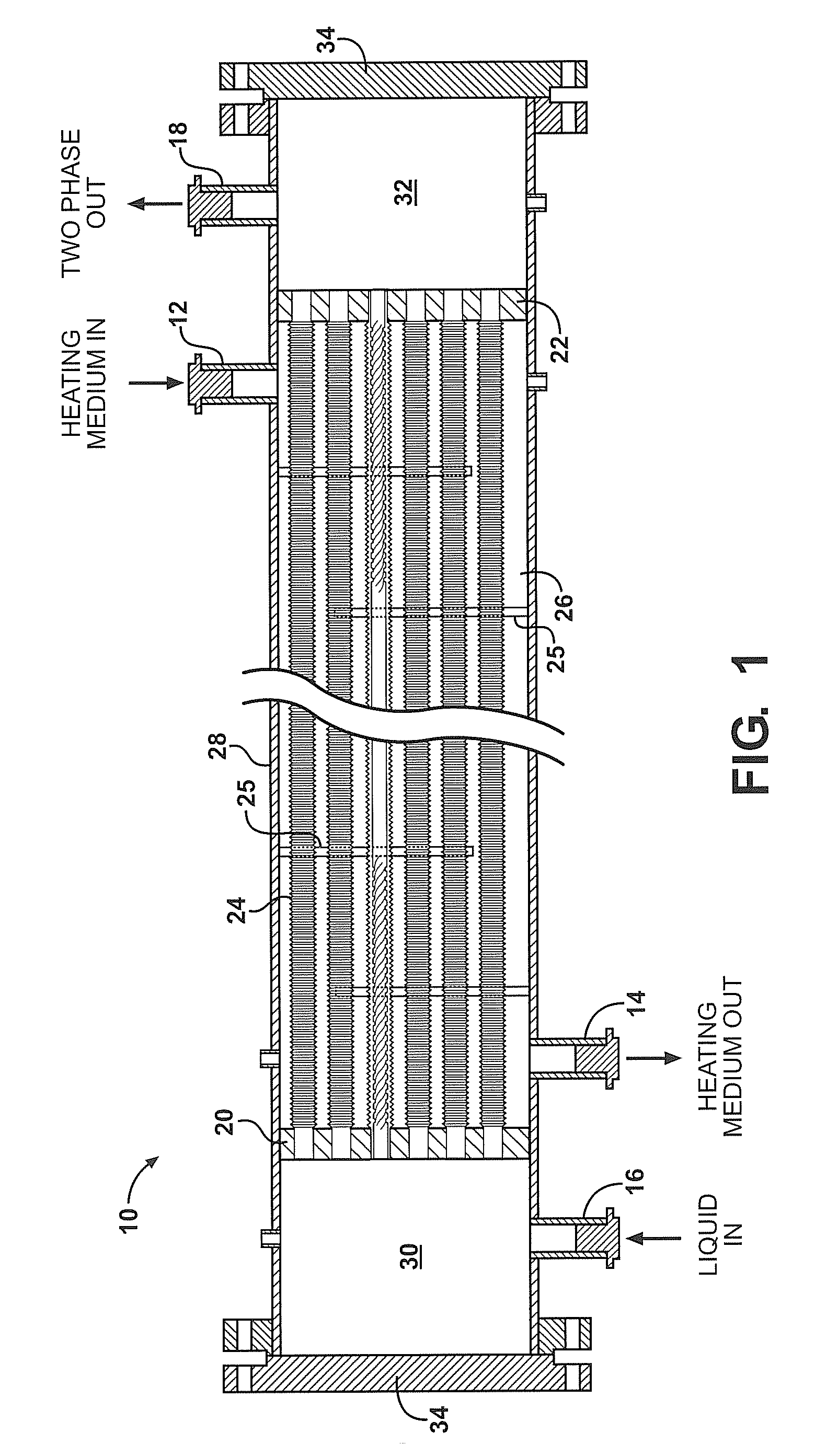

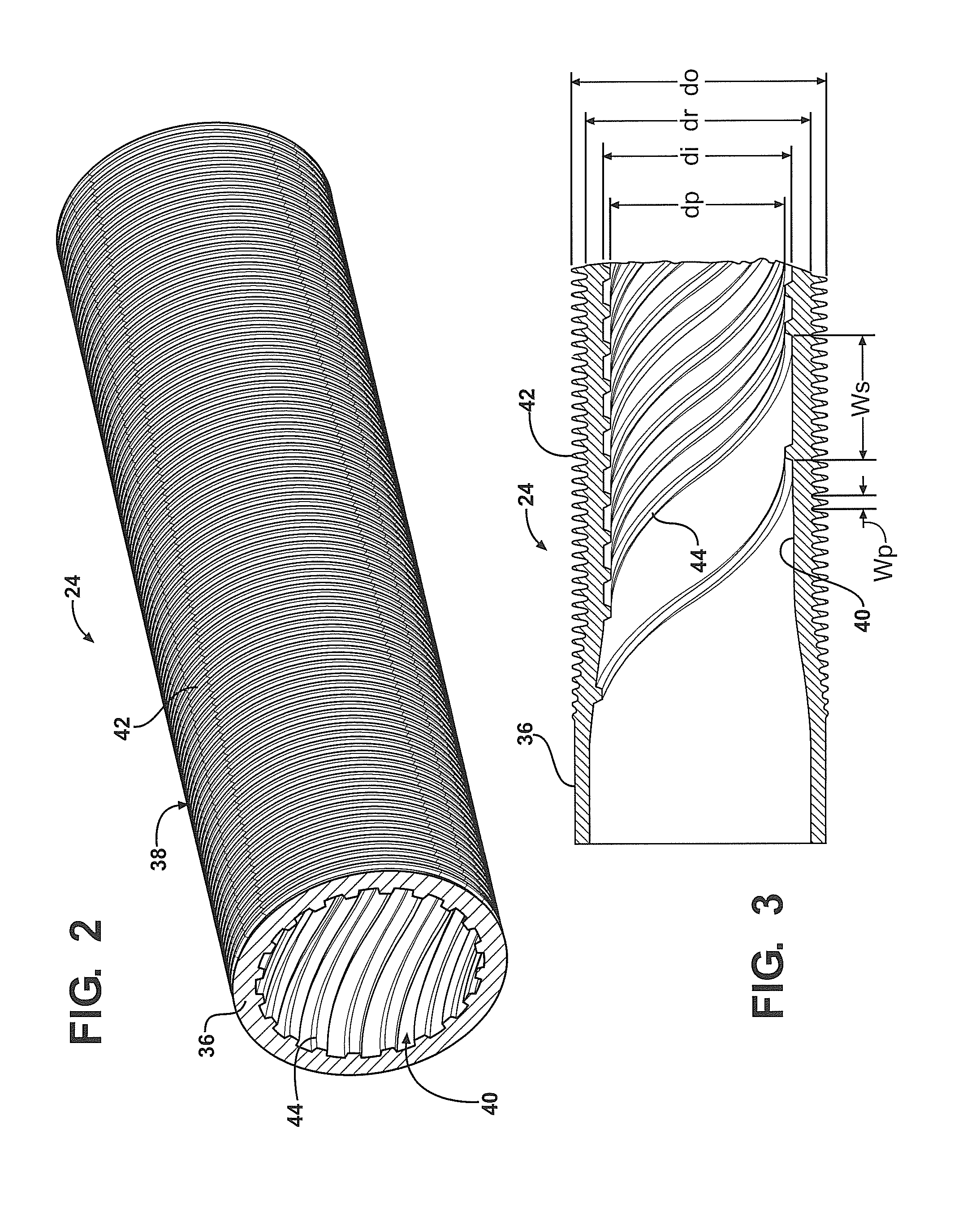

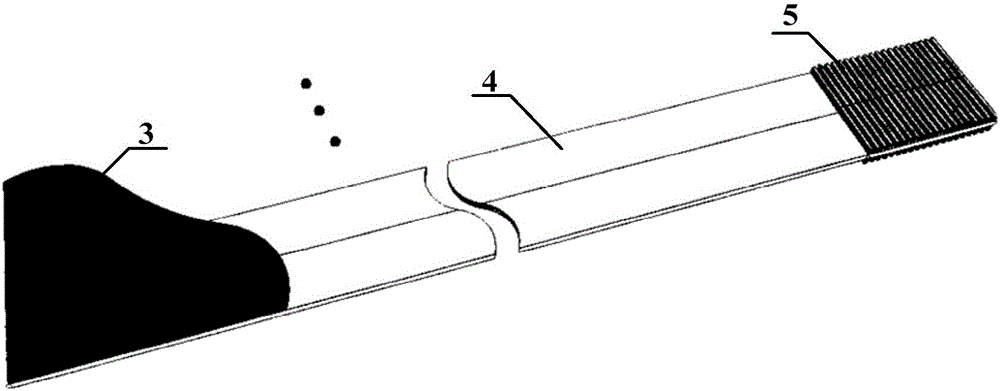

Dual enhanced tube for vapor generator

InactiveUS20110083619A1Increase the heat transfer surface areaImprove heat transfer efficiencyHeat exhanger finsWater-tube boilersElectricityEngineering

A heat exchange assembly for generating steam from a second medium to be used to drive a steam turbine for generating electricity or for other process, includes a tube having a longitudinal axis and an inner wall and an outer wall. The outer wall includes a plurality of spaced fins oriented generally perpendicular to the longitudinal axis. The inner wall defines a preheat zone and a dual phase zone. The preheat zone defines a helical rib configured to provide swirling motion and increase heat transfer surface area to liquid entering the tube increasing heat transfer from the tube to the liquid. The dual phase zone is spaced from the preheat zone and defines a helical rib configured to provide swirling motion to steam and liquid passing through the dual phase zone increasing heat transfer from the tube to the steam and liquid while preventing vapor stagnation and film boiling.

Owner:HAMON RES COTTRELL

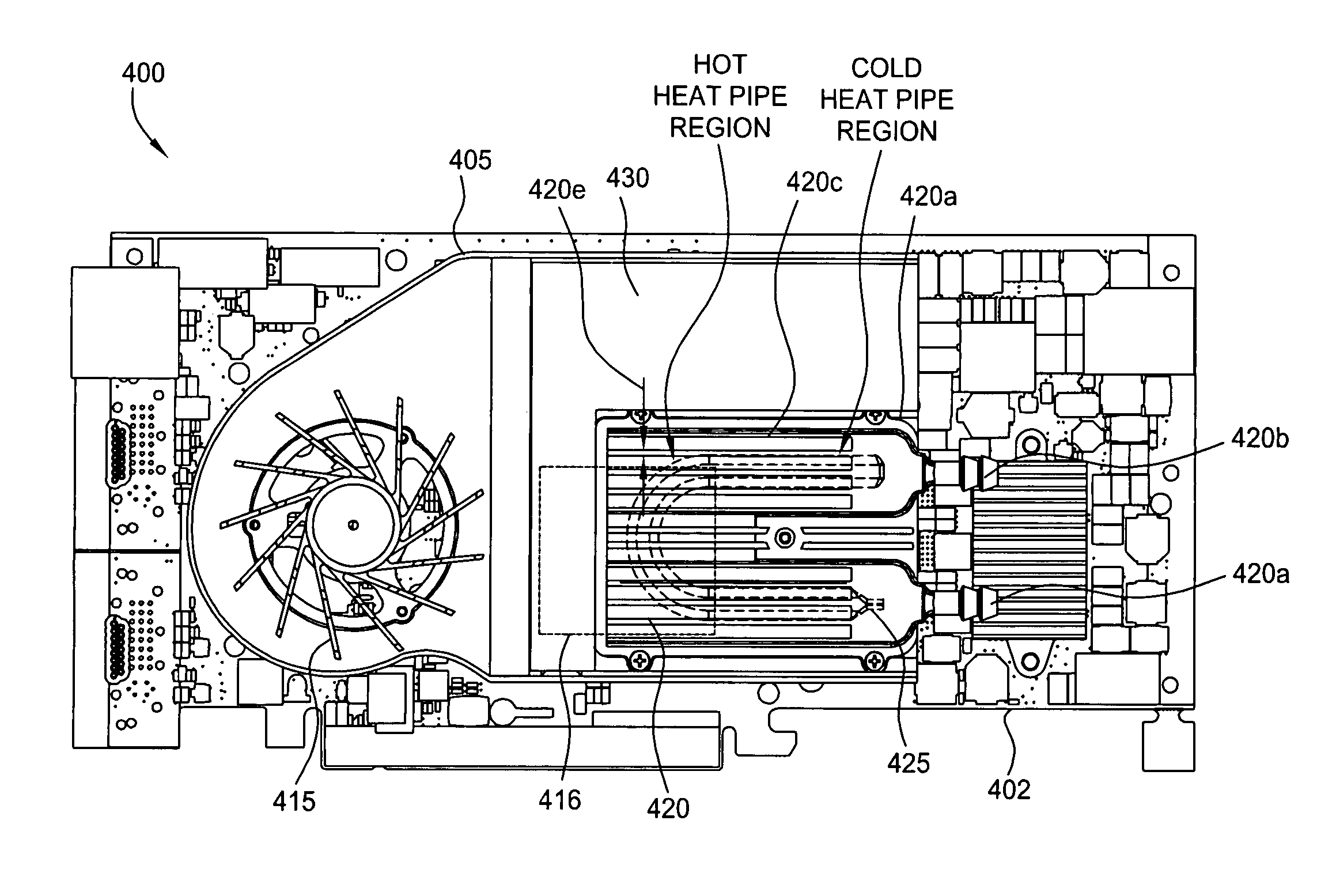

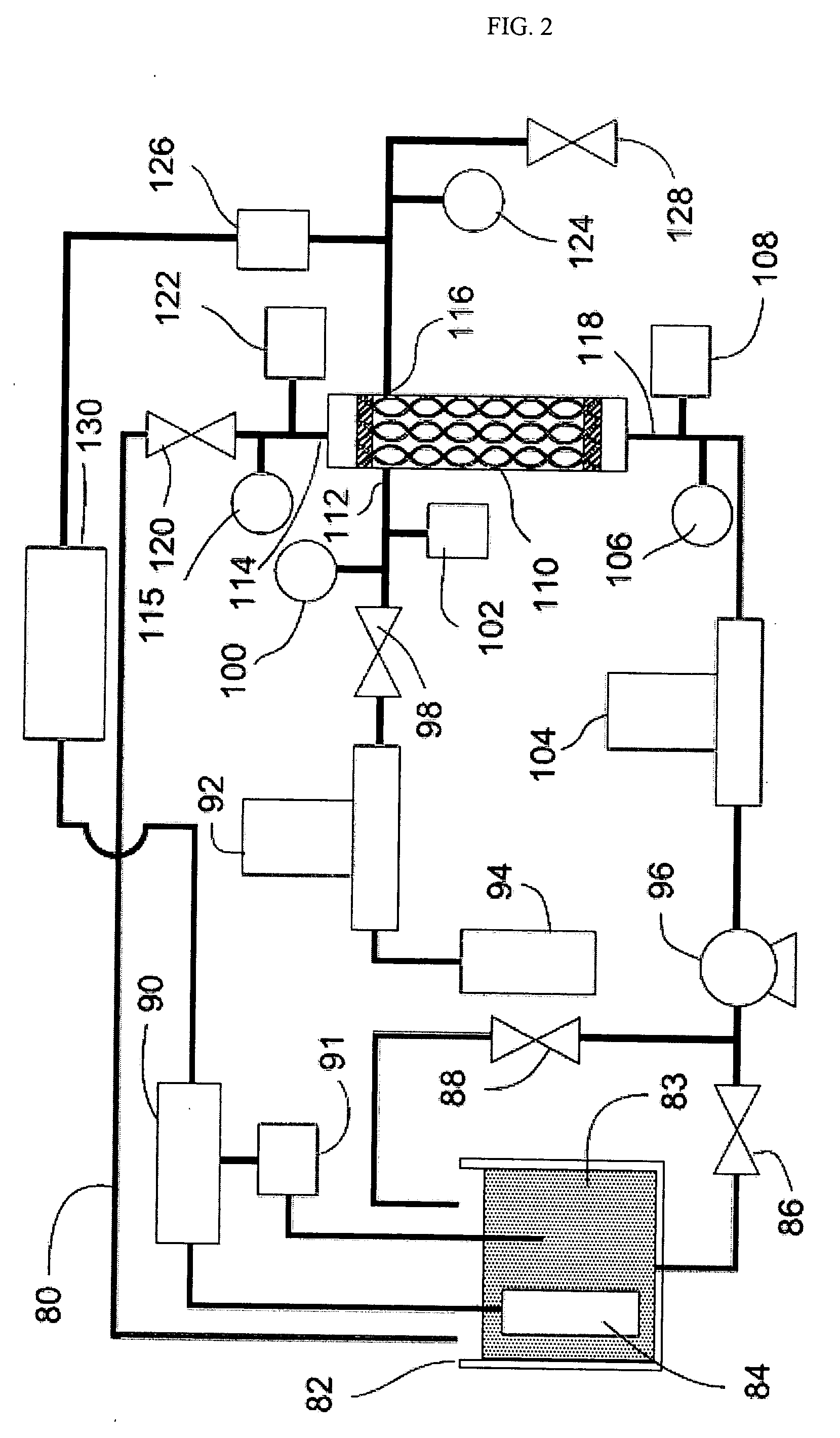

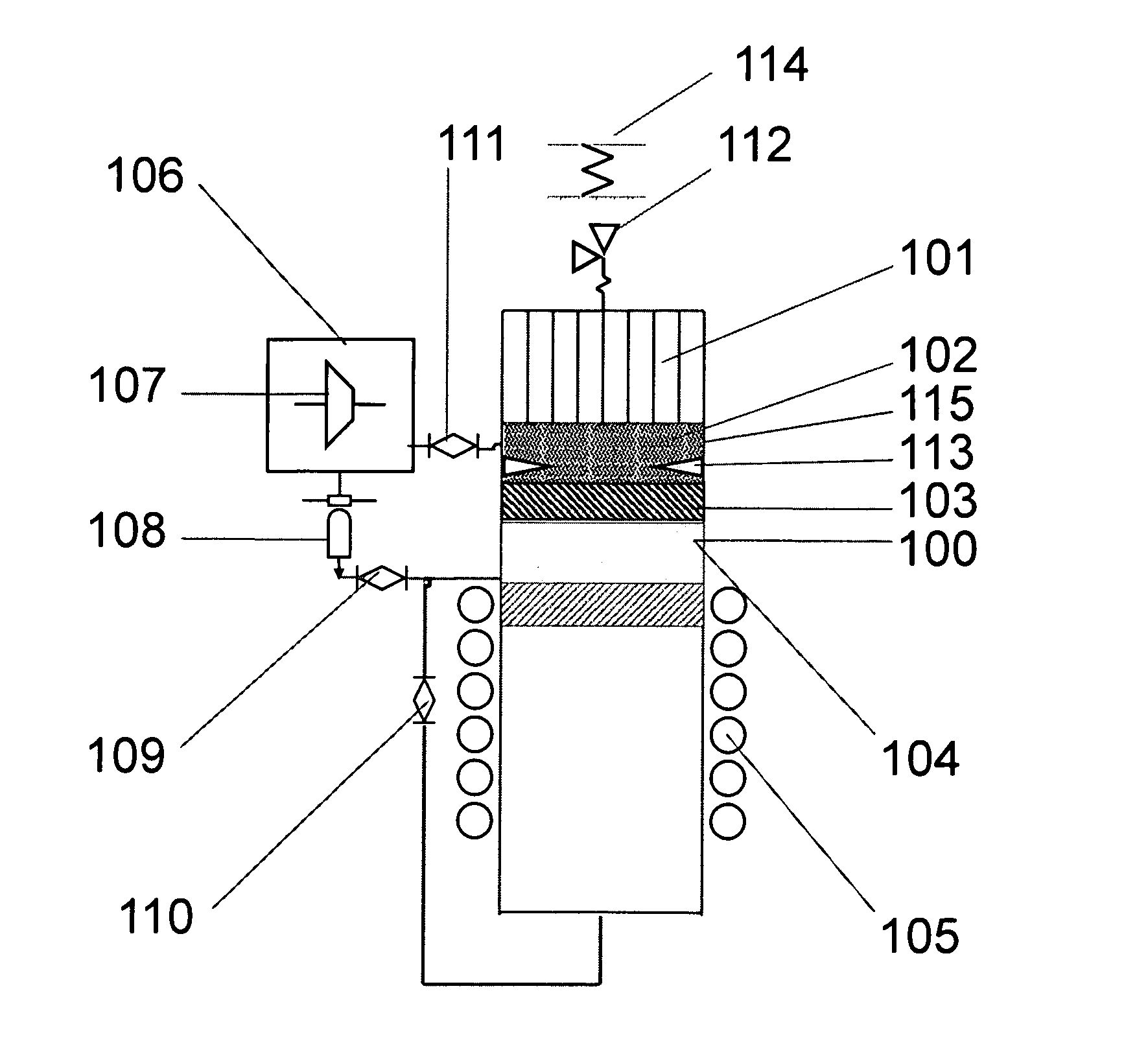

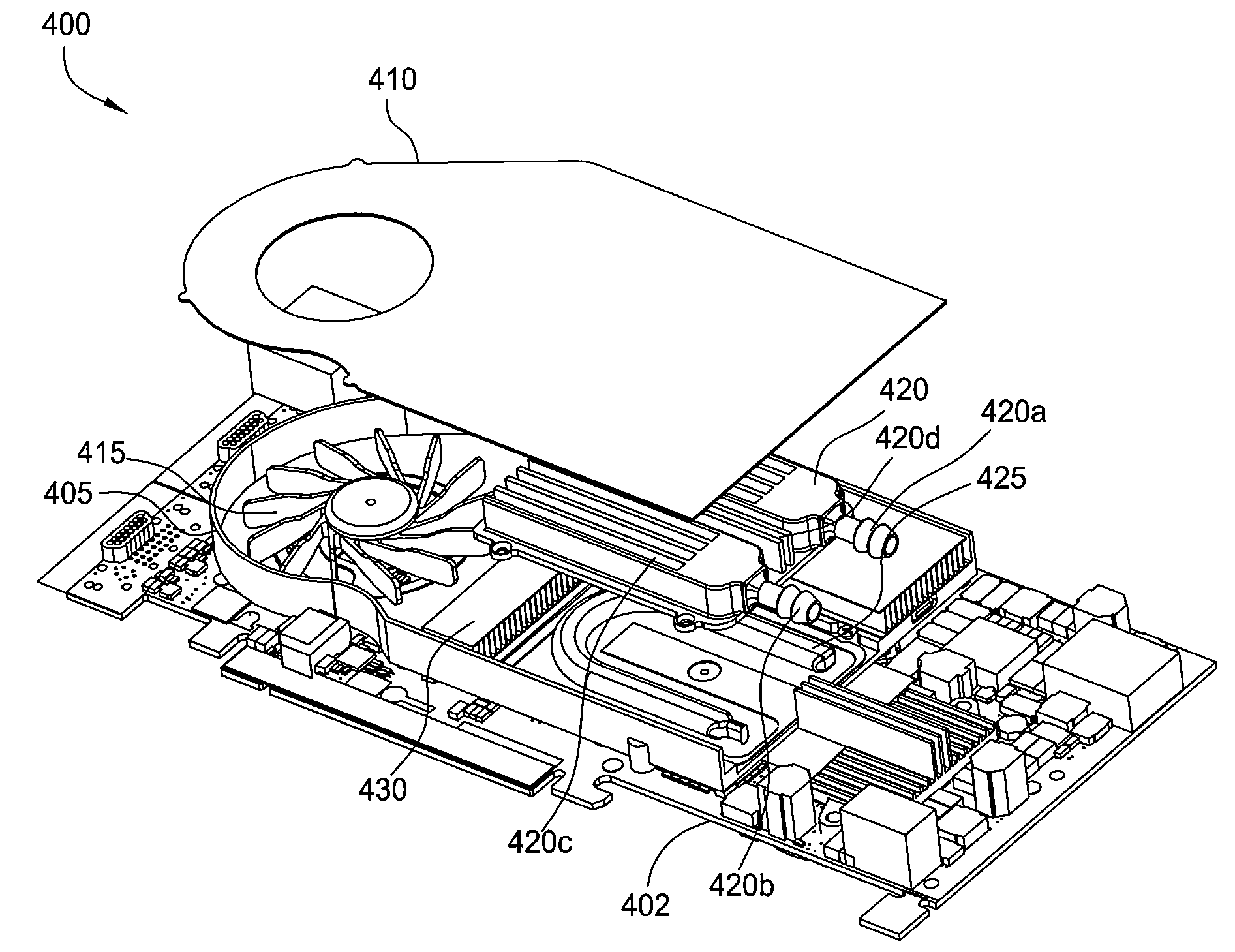

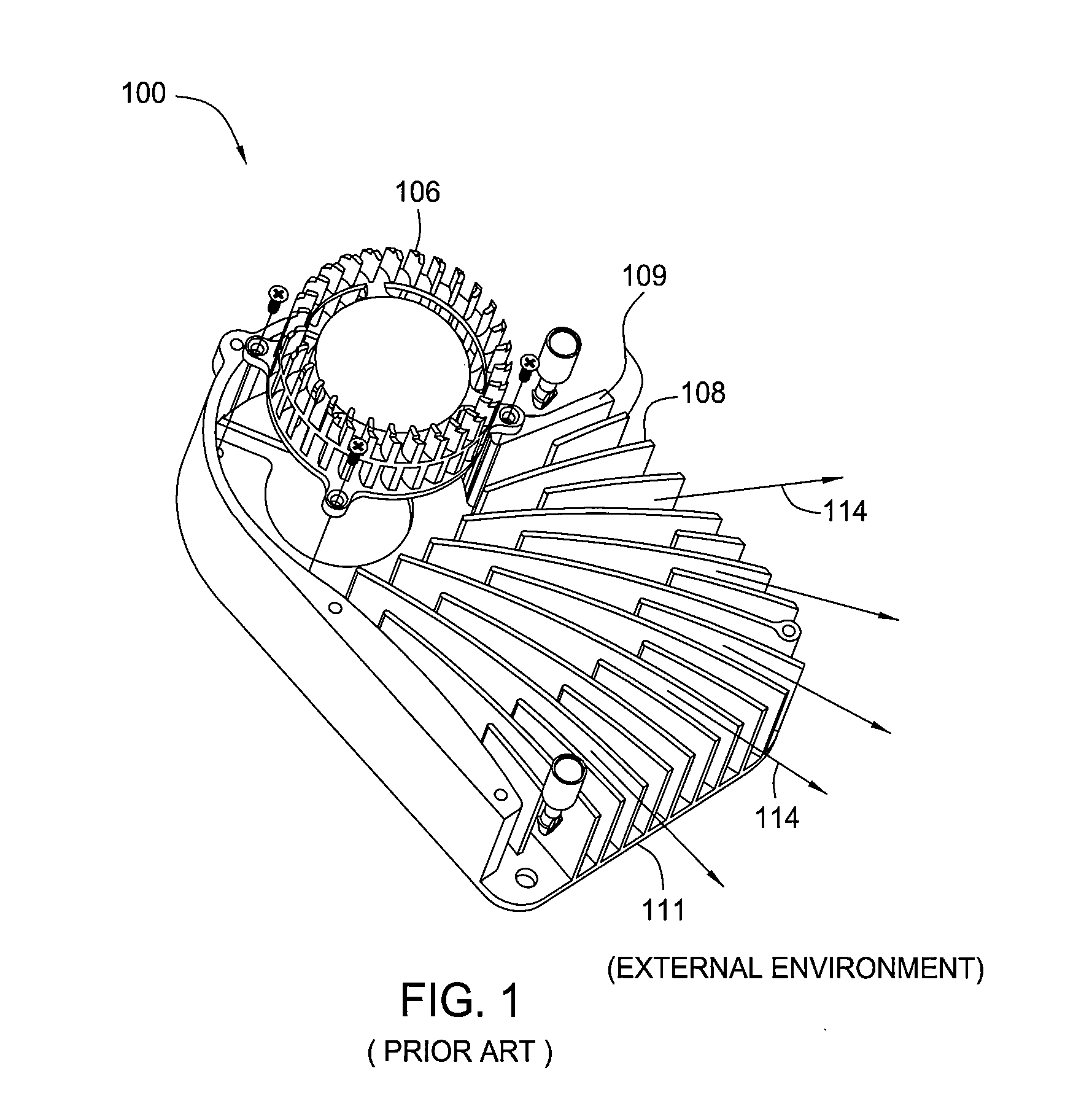

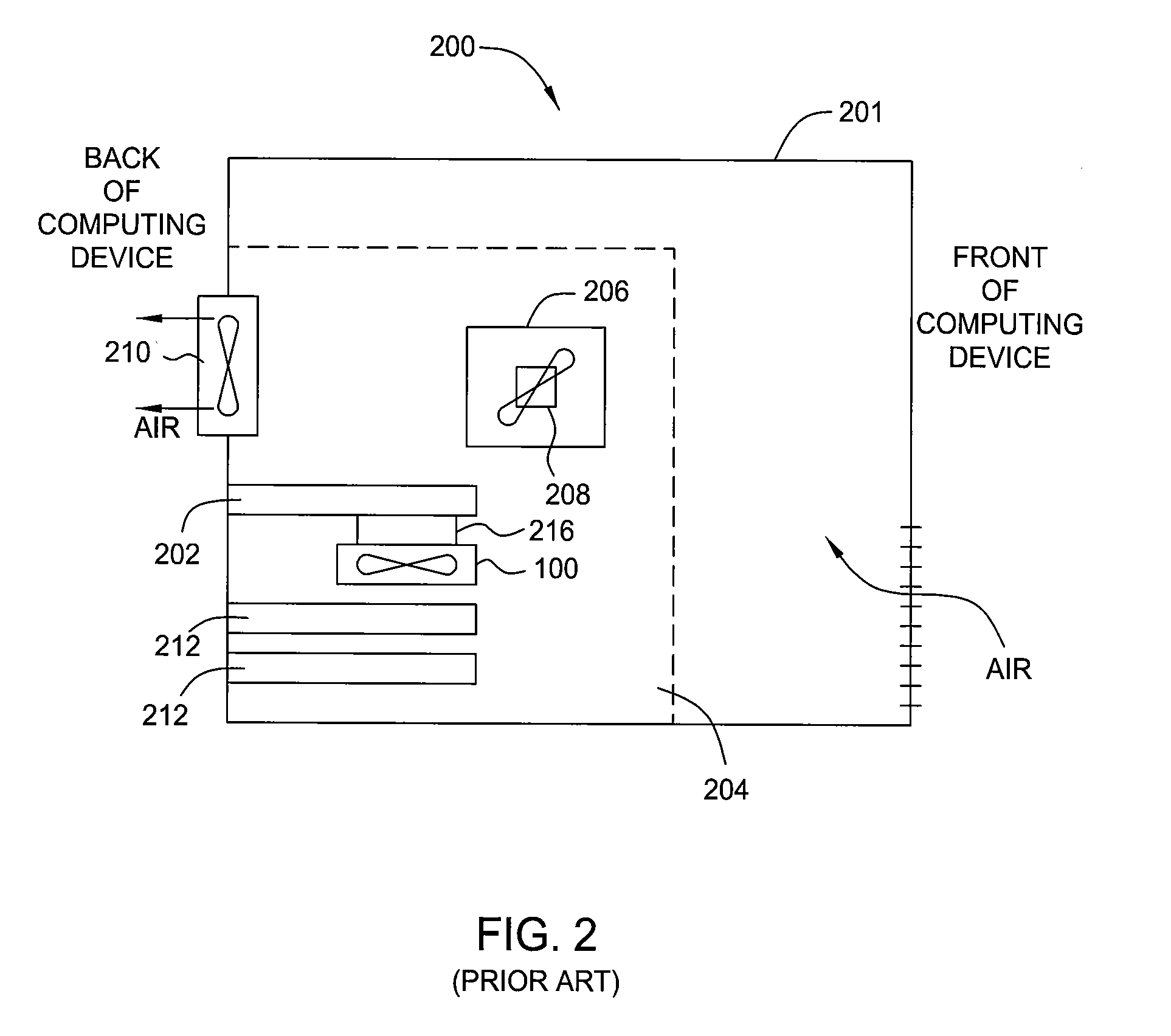

Embedded heat pipe in a hybrid cooling system

ActiveUS20070125522A1Remove heatIncrease the heat transfer surface areaSemiconductor/solid-state device detailsSolid-state devicesEnhanced heat transferEngineering

One embodiment of a system for cooling a heat-generating device includes a base adapted to be coupled to the heat-generating device, a housing coupled to the base, a liquid channel formed between the base and the housing, where a heat transfer liquid may be circulated through the liquid channel to remove heat generated by the heat-generated device, and a heat pipe disposed within the liquid channel, where the heat pipe increases the heat transfer surface area to which the heat transfer liquid is exposed. Among other things, the heat pipe advantageously increases the heat transfer surface area to which the heat transfer liquid is exposed and efficiently spreads the heat generated by the heat-generating device over that heat transfer surface area. The result is enhanced heat transfer through the liquid channel relative to prior art cooling systems.

Owner:NVIDIA CORP

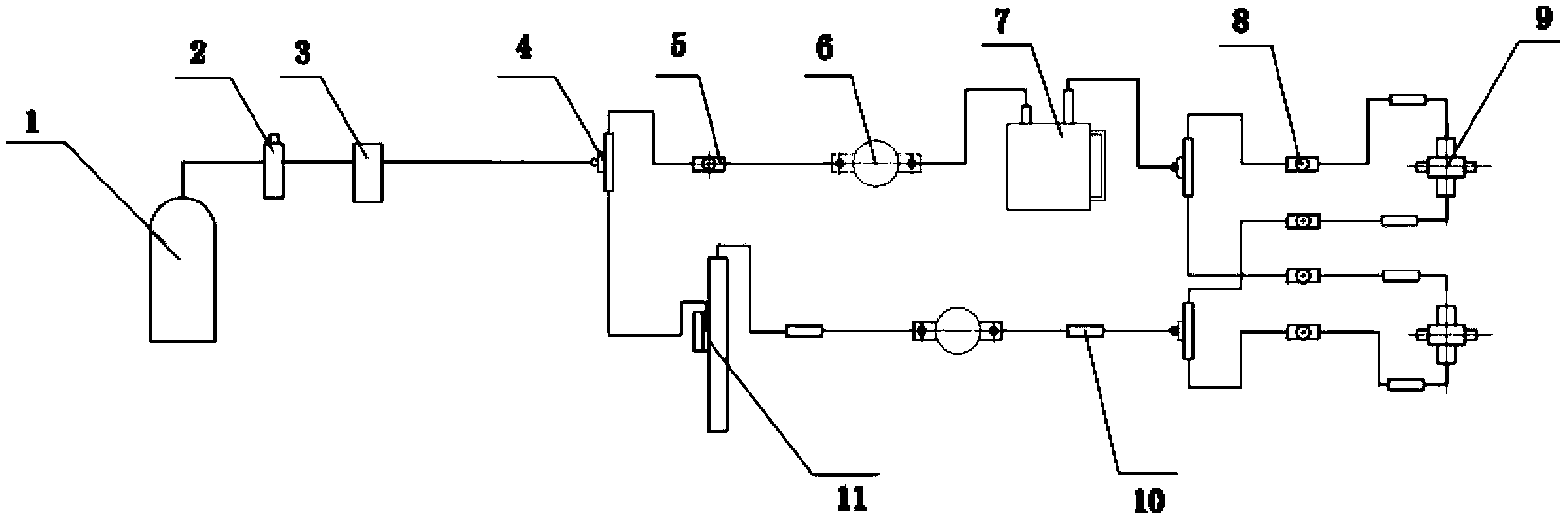

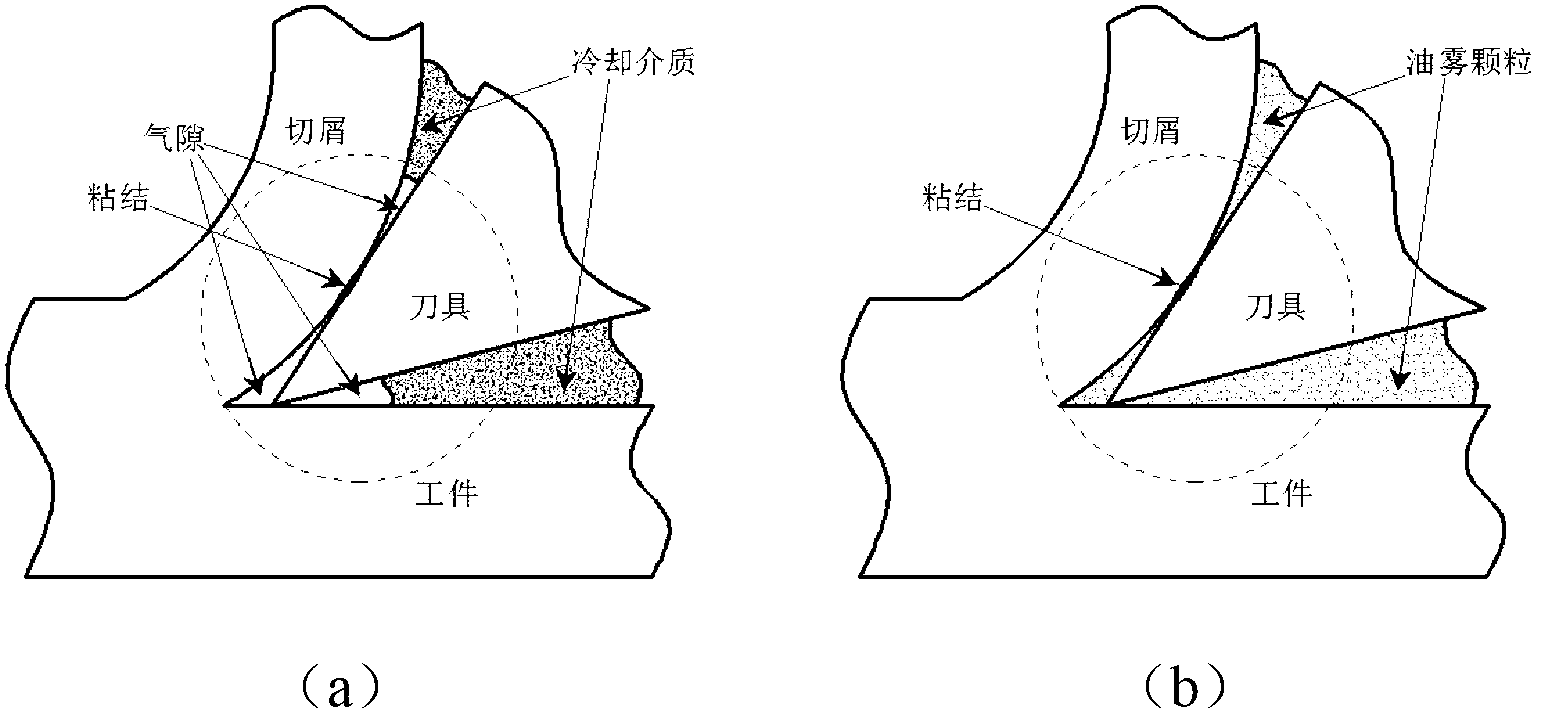

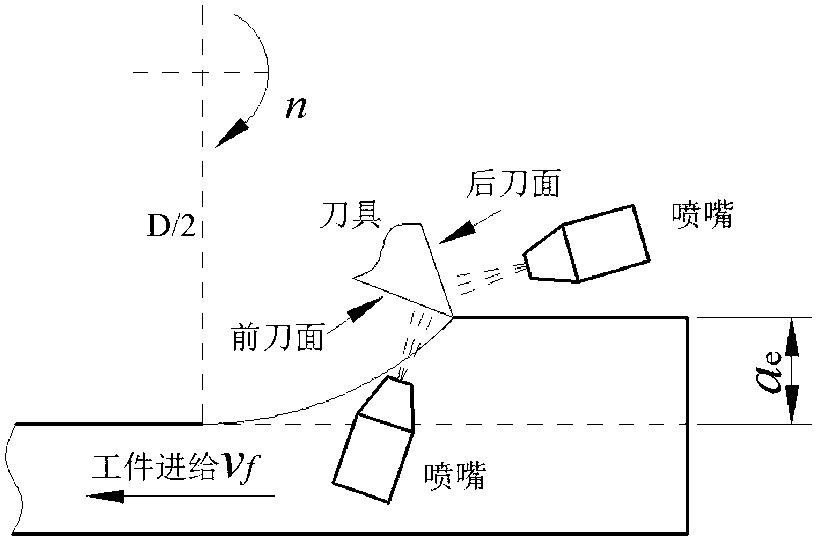

Method and device for forming high-pressure and low-temperature jet flow by cutting coolant

ActiveCN103286629AIncreased durabilityReduce cutting temperatureMaintainance and safety accessoriesJet flowSpray nozzle

The method discloses a method and device for forming high-pressure and low-temperature jet flow by cutting coolant. The method includes that compressed air stored inside an air storage tank is filtered and dried and connected to a tee joint through a hose to divide an output pipe into two branches, air in one branch is cooled by a cooling device to become low-temperature high-pressure air, and inputted into an air inlet end of a pneumatic spray nozzle after being connected with one or more than one tee joint, the air in the other branch is inputted into a well-sealed cutting fluid storage container after pressure in the air is regulated by a pressure regulating valve, the cutting fluid is pressed out, and connected into liquid inlet ends of a plurality of pneumatic spray nozzles after passing one or more than one tee joint prior through the hose, the air and the liquid are mixed outside a jet nozzle to produce high-speed jet flow. By the method, usage amount of cooling lubricating liquid is reduced, cooling and lubricating functions of fluid medium are fully performed, cutting temperature is greatly lowered, and tool durability is conspicuously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

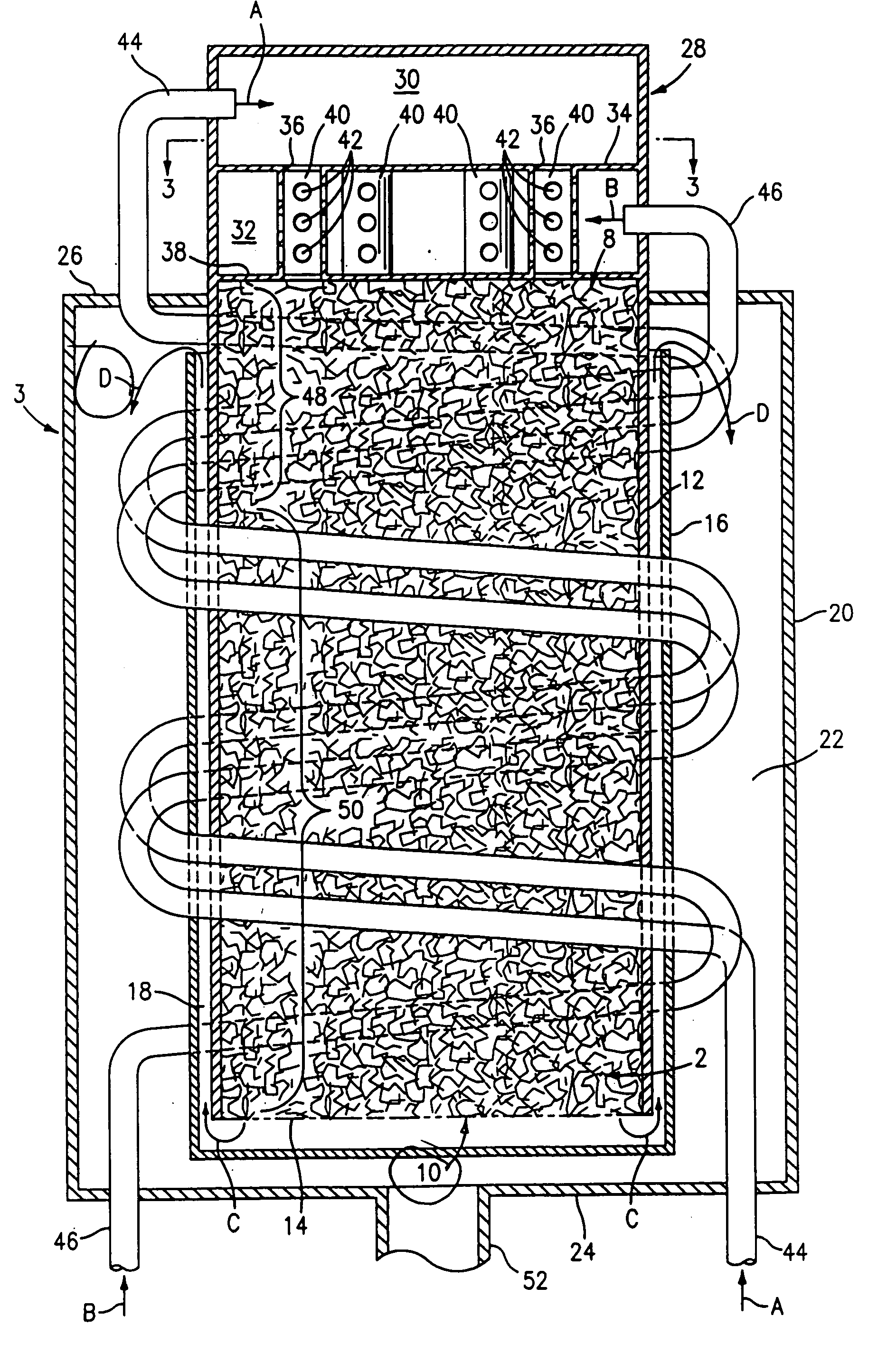

Apparatus for conditioning the temperature of a fluid

InactiveUS20070289732A1High bulk densityImprove traffic distributionTemperatue controlStationary tubular conduit assembliesTemperature controlEngineering

This invention relates to an apparatus for conditioning the temperature of a fluid by utilizing a thermoplastic heat exchange apparatus comprised of a plurality of hollow tubes. The apparatus controls the temperature of a process fluid inside the heat exchanger by adjustment of a control valve that regulates the flow of an exchange fluid. The apparatus can be used to maintain the temperature of chemical baths and also to prepare discreet dispensed volumes of temperature controlled liquid.

Owner:PILLION JOHN E +3

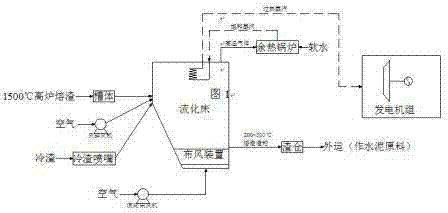

Heat recovery method for blast furnace slag

ActiveCN102851416ASmall particle sizeReduce mutual adhesionIncreasing energy efficiencyClinker productionThermal energyRecovery method

The invention belongs to the energy recycling field and particularly relates to a heat recovery method for blast furnace slag in metallurgy and steel industries. The heat recovery method includes that: step one, high pressure air on the lower portion of a tank blows the blast furnace slag melt into pieces to complete granulation when the blast furnace slag melt enters a fluidized bed through the tank; step two, granulated slag particle stream in the step one meets and collides with cold slag sprayed by a cold slag nozzle at a high speed in the fluidized bed; step three, the slag particles after collision are violently mixed with cold air for heat exchange through an air distributing device, and slag beads are cooled; and step four, the cooled slag beads are transported out as the raw material of cement, heated heat exchange air enters a waste heat boiler, saturated steam stream produced by the waste heat boiler is further heated to become superheated steam when passing the top of the fluidized bed, and then the superheated steam enters a generating set to generate electricity. The heat recovery method has the advantages that the granulation efficiency is high, mutual adhesion of slag particles is reduced, and the like.

Owner:SCIMEE TECH & SCI CO LTD

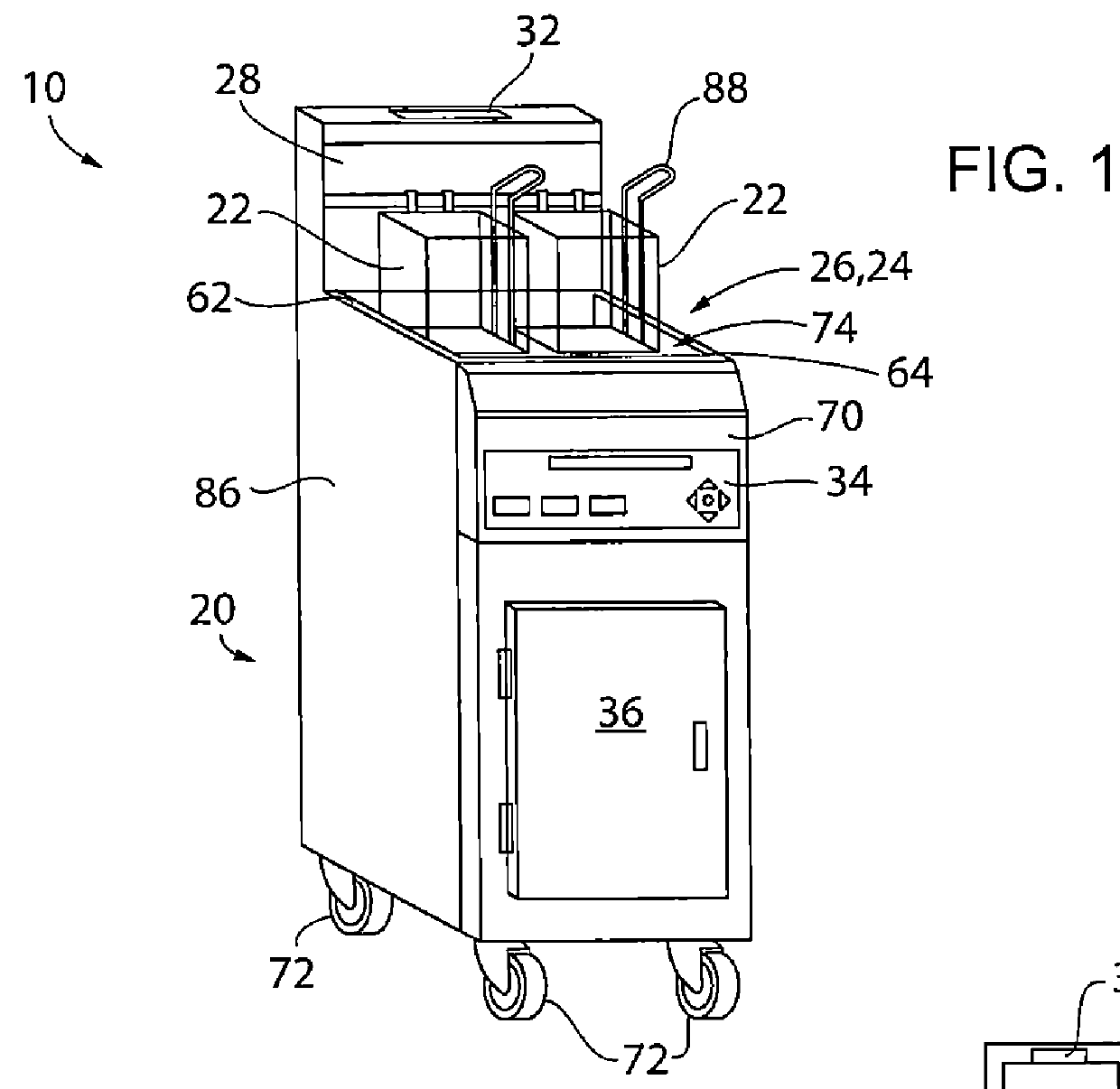

Gas Heat Exchanger with Baffle for Deep Fat Fryer

ActiveUS20180271326A1Save energyLow costBurner material specificationsStationary conduit assembliesEngineeringHeat exchanger

The present invention provides a deep fat fryer providing an oil vat for holding hot oil. The hot oil of the vat is heated by a heat exchanger system that includes a pair of heat tubes. Heat transfer along a length of the heat tubes is facilitated by a heat conductive baffle substantially filling the interior of the heat tubes in volume and length. Heated air and gas are forced through the dense and elongated baffle to facilitate heat transfer to the walls of the heat tubes.

Owner:ALTO SHAAM

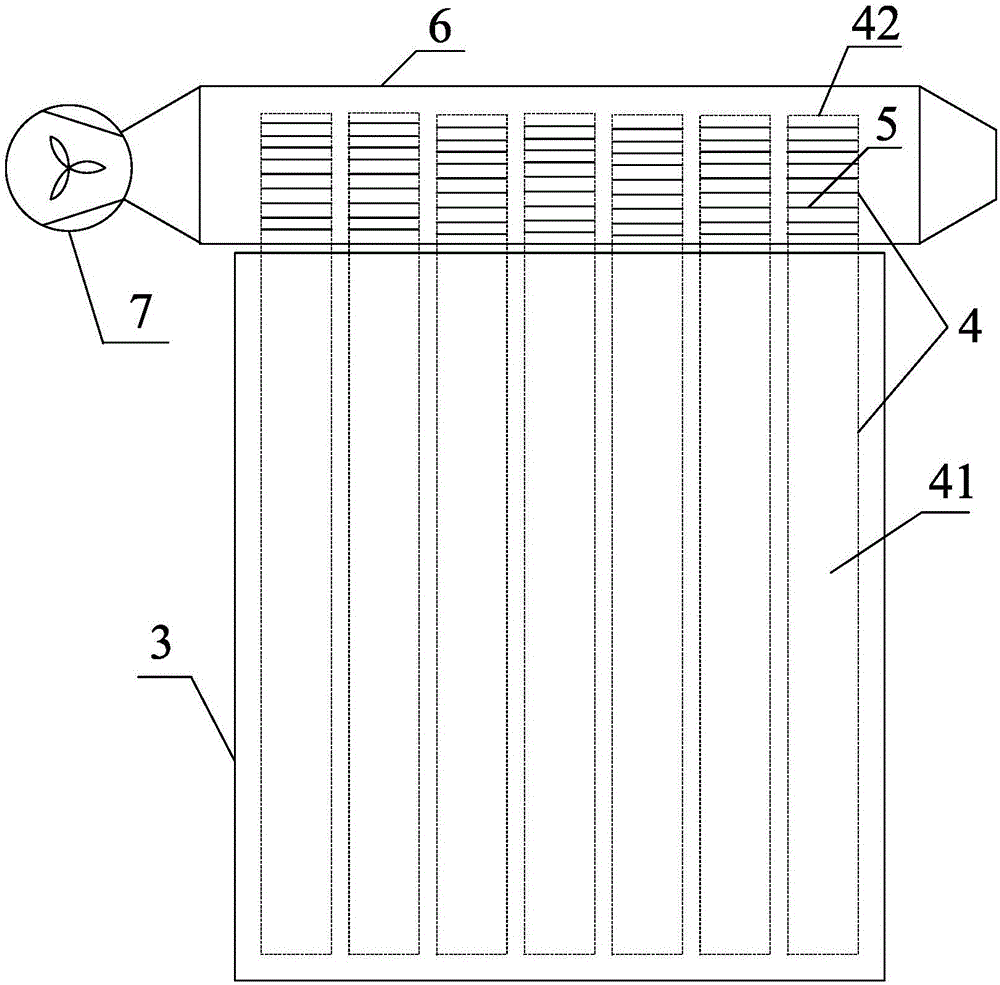

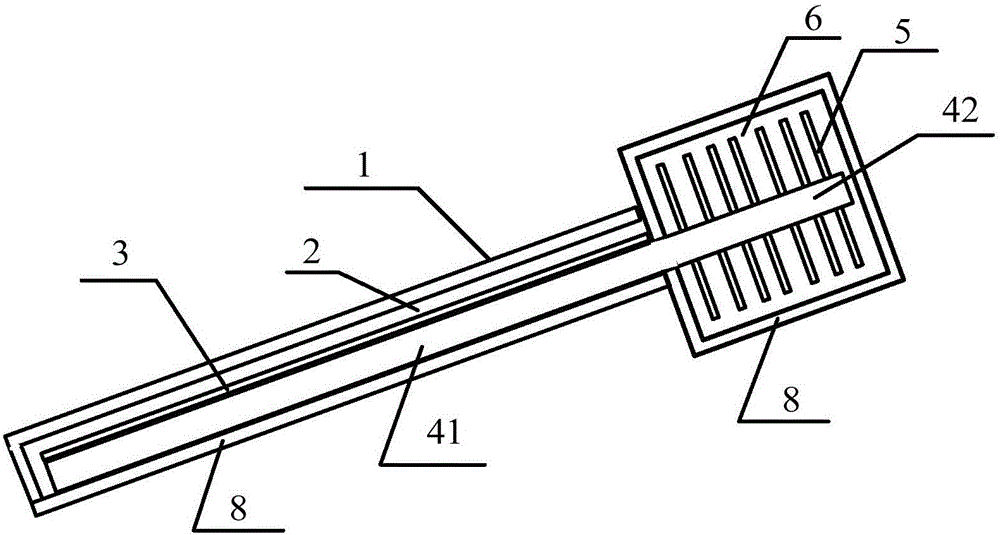

Heat-pipe type panel solar air collector and heating method thereof

InactiveCN105066471AImprove transfer efficiencyEfficient heat transportSolar heating energySolar heat devicesGlass coverSolar air collector

The invention relates to a heat-pipe type panel solar air collector and a heating method thereof. The collector comprises a solar panel heat collection and heat transmission section and an air ventilation heat exchange section. The solar panel heat collection and heat transmission section comprises tempered glass, an efficient heat absorption coating, a heat insulation air layer and a panel heat pipe evaporation section. The back of the efficient heat absorption coating and the obverse side of the panel heat pipe evaporation section are combined organically. The tempered glass covers the outer surface of the panel heat pipe evaporation section organically combined with the efficient heat absorption coating. The heat insulation air layer is arranged between the efficient heat absorption coating and the tempered glass, and the distance from the front of the efficient heat absorption coating to the inner surface of the tempered glass ranges from 20 mm to 50 mm. The air ventilation heat exchange section comprises an air duct, a fan and a panel heat pipe condensation section. The panel heat pipe condensation section is arranged in the air duct, and the fan is arranged on one side of the air duct. The collector has the advantages of being high in heat exchange efficiency, high in reliability, simple in structure, convenient to mount, free of maintenance and long in service life.

Owner:赵耀华

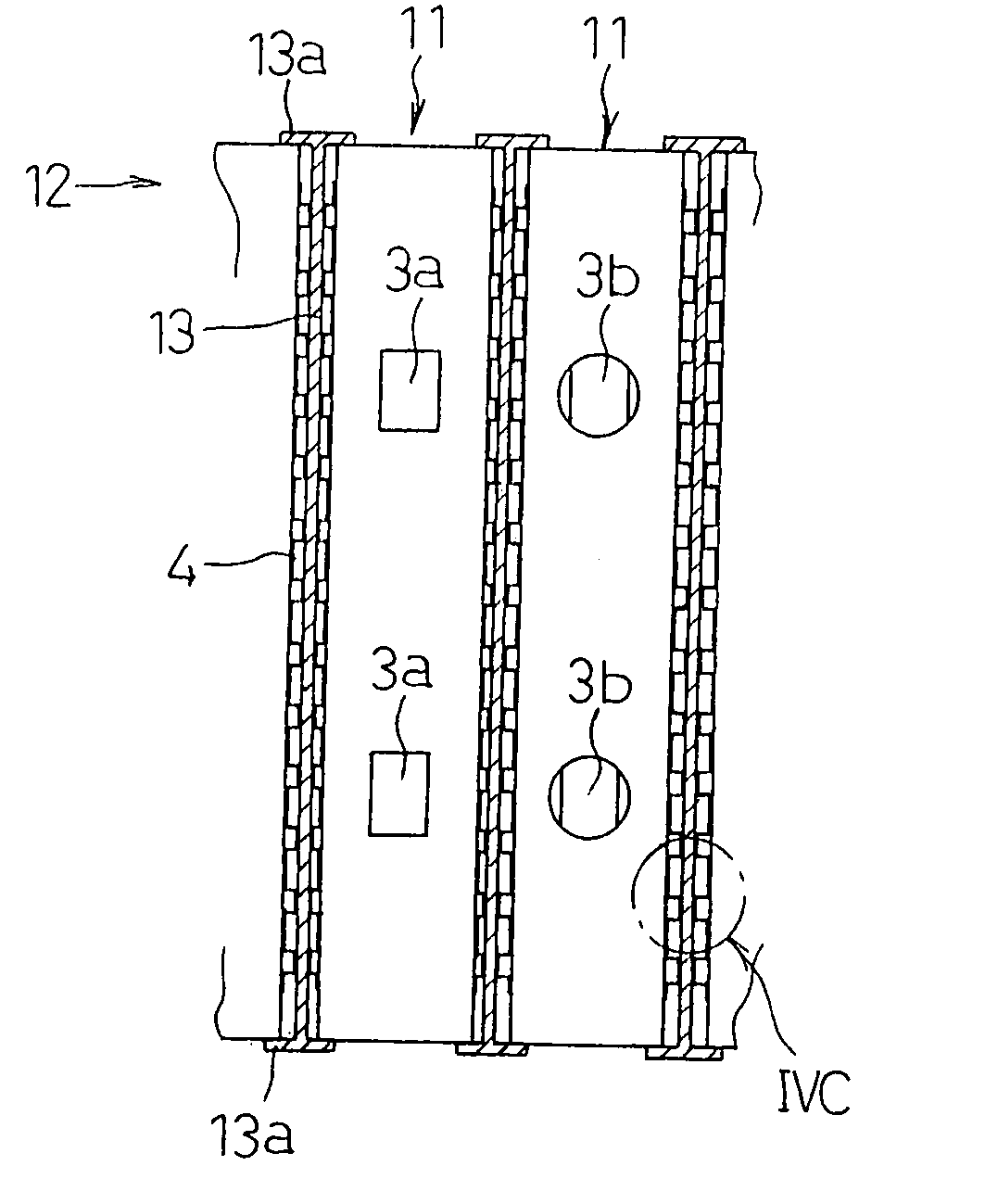

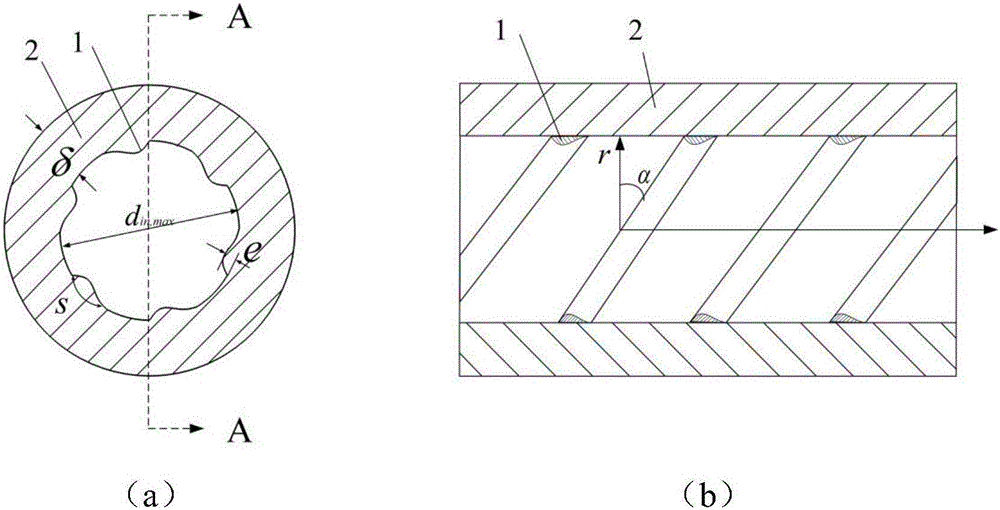

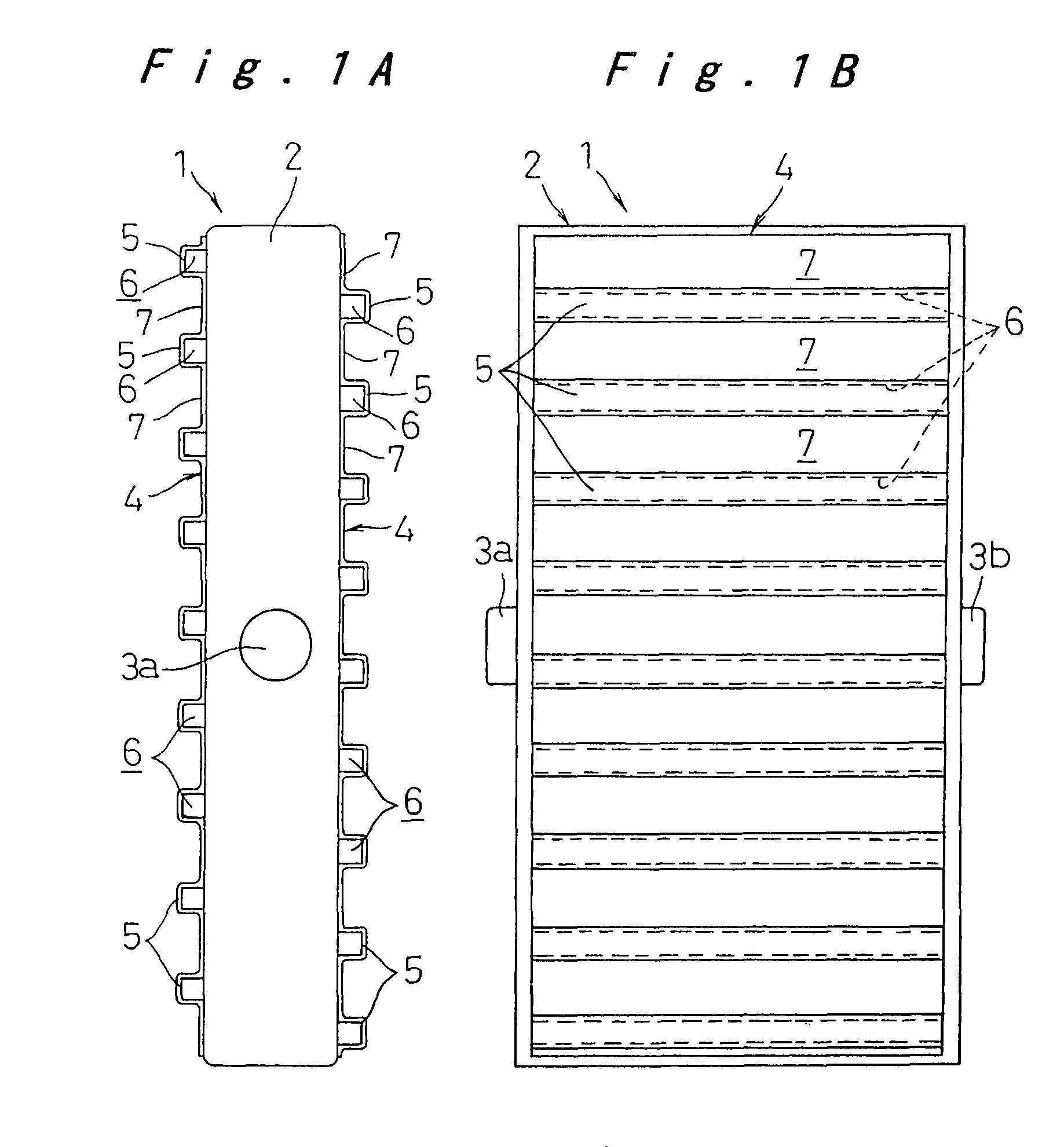

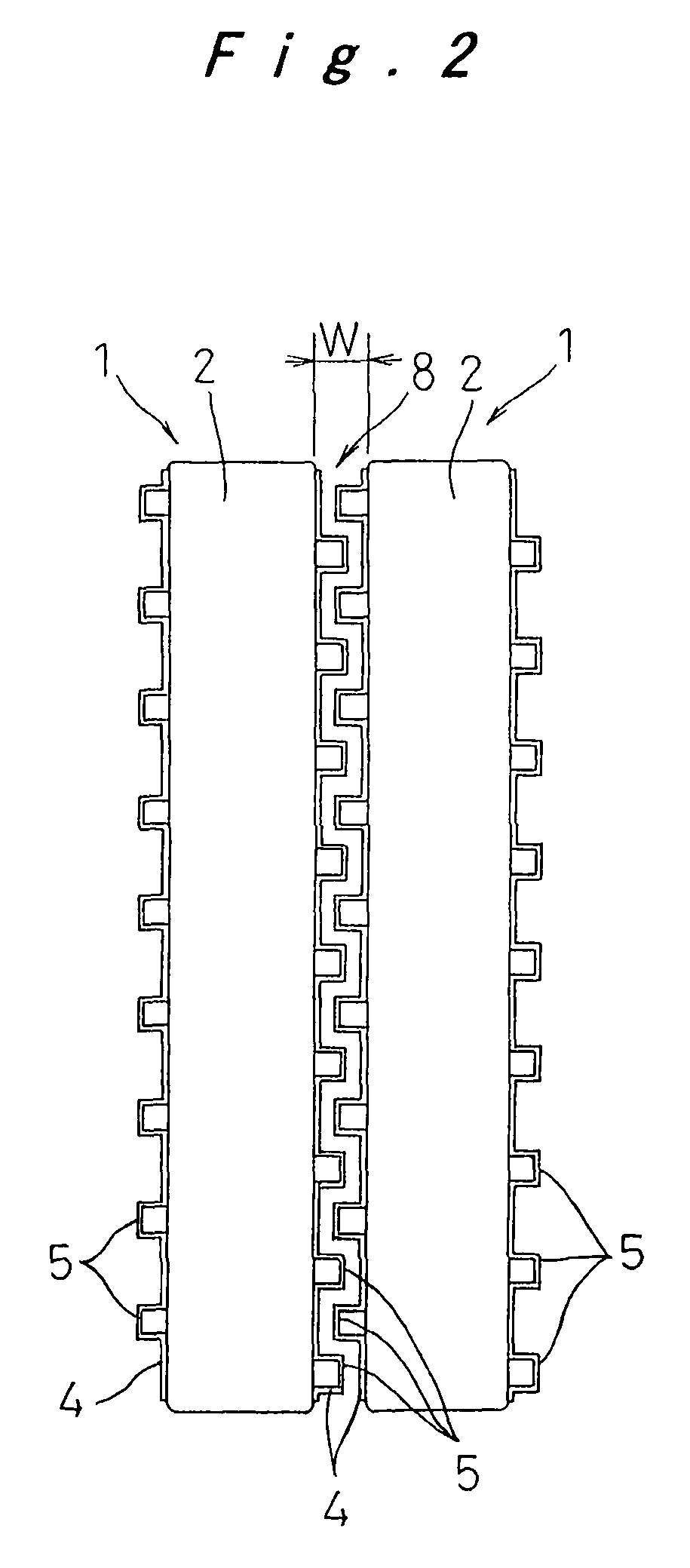

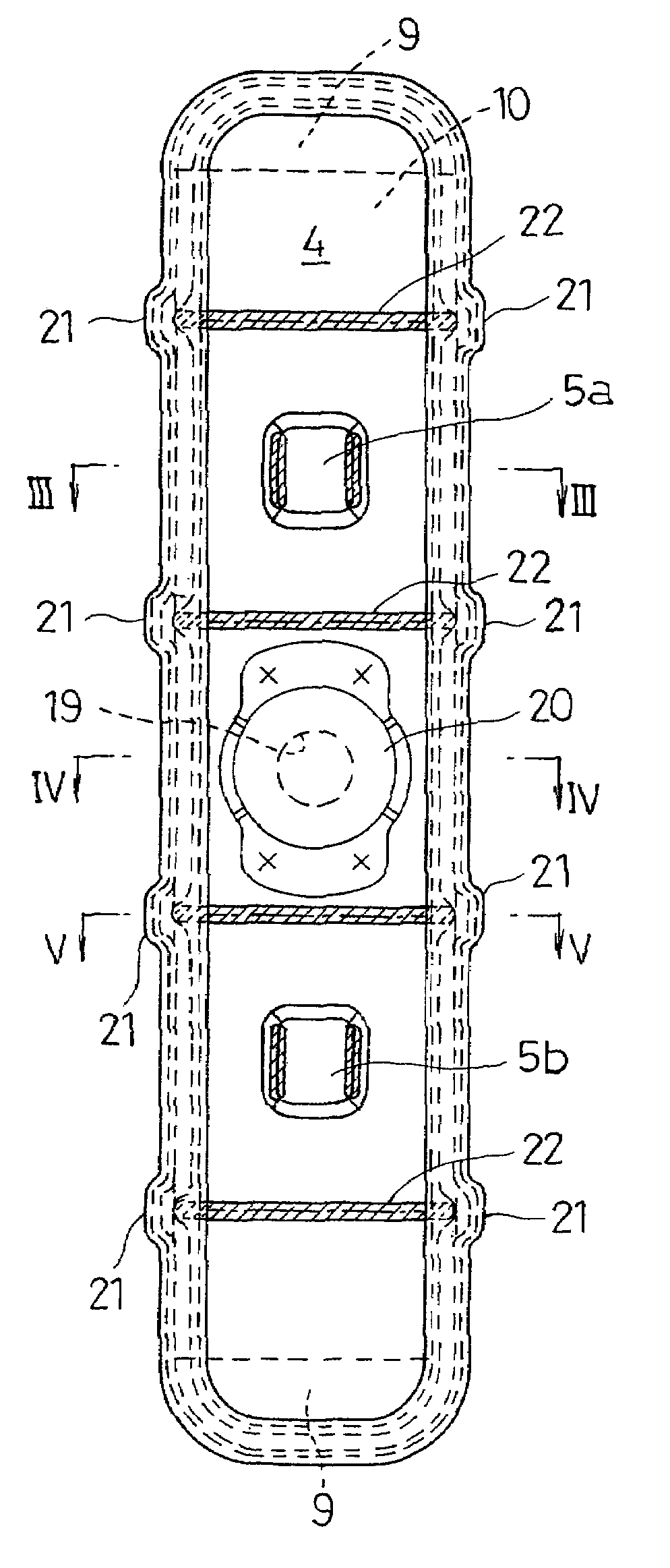

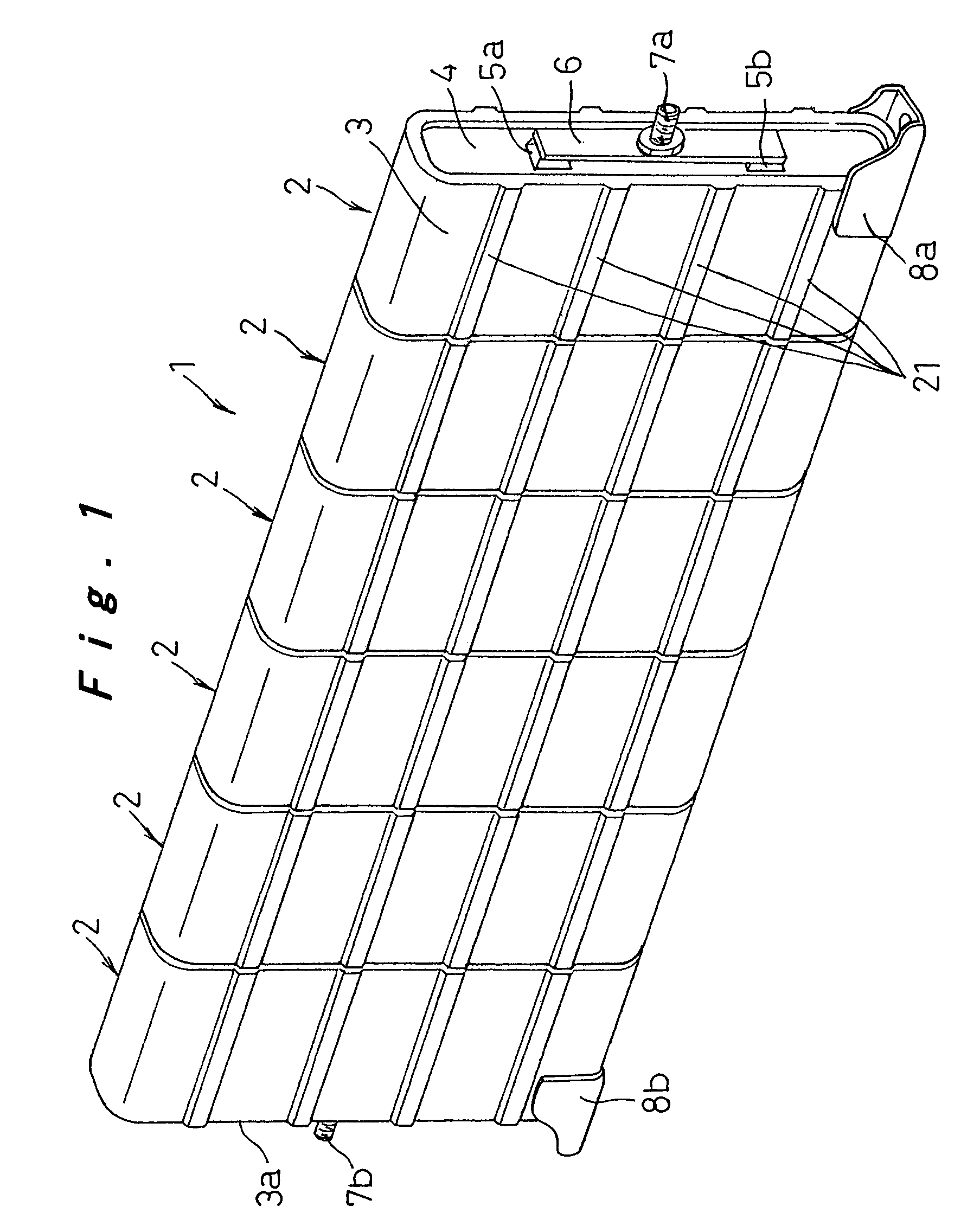

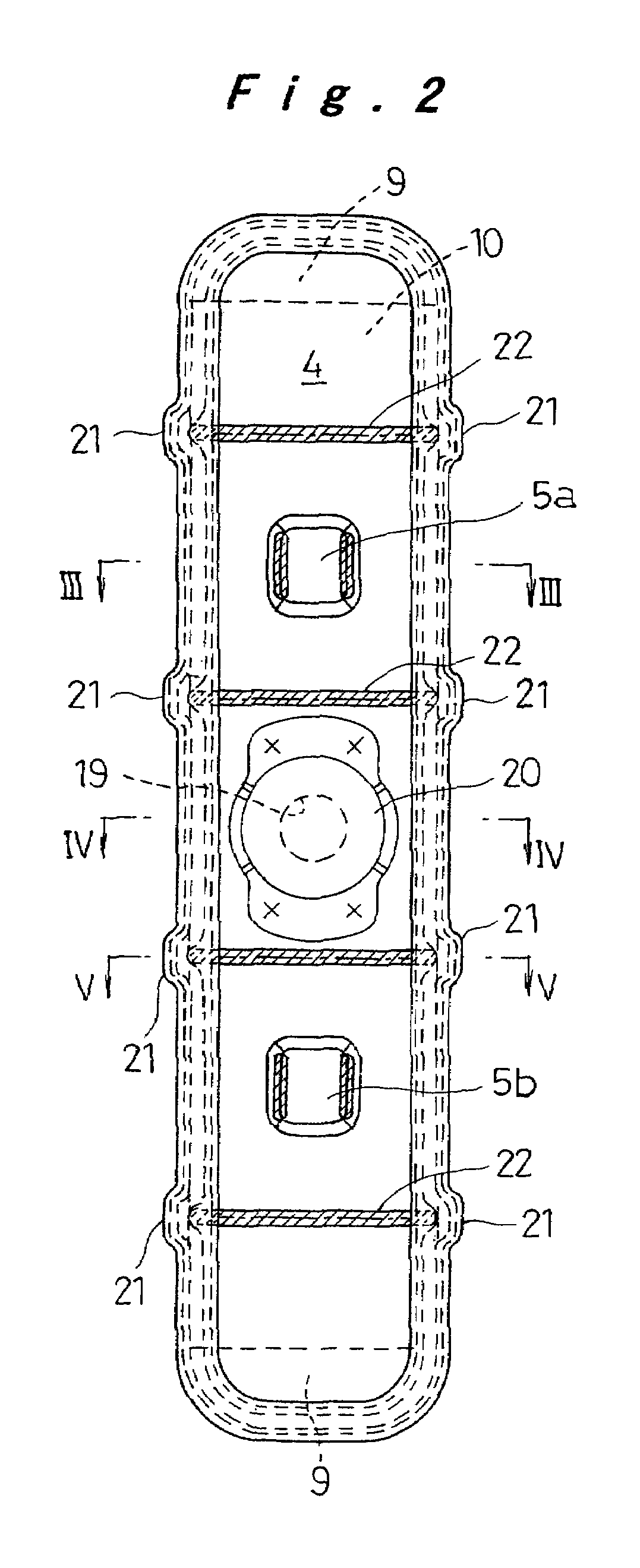

Prismatic sealed rechargeable battery, battery module, and battery pack

ActiveUS20070134550A1Improve cooling effectIncrease powerPrimary cell to battery groupingCharging stationsElectrolyteElectrical and Electronics engineering

A prismatic sealed rechargeable battery includes a substantially prismatic battery case that accommodates an electrode plate assembly and an electrolyte solution. The battery case is formed of metal. On a side face of the battery case, a thin plate is provided which has a plurality of protruding portions formed in parallel at appropriate intervals. The protruding portion and the side face form spaces opened at both ends therebetween. The thin plate is bonded to the side face of the battery case by making flat portions between the protruding portions into surface-contact with the side face, thereby improving cooling capability of the battery.

Owner:PANASONIC CORP +1

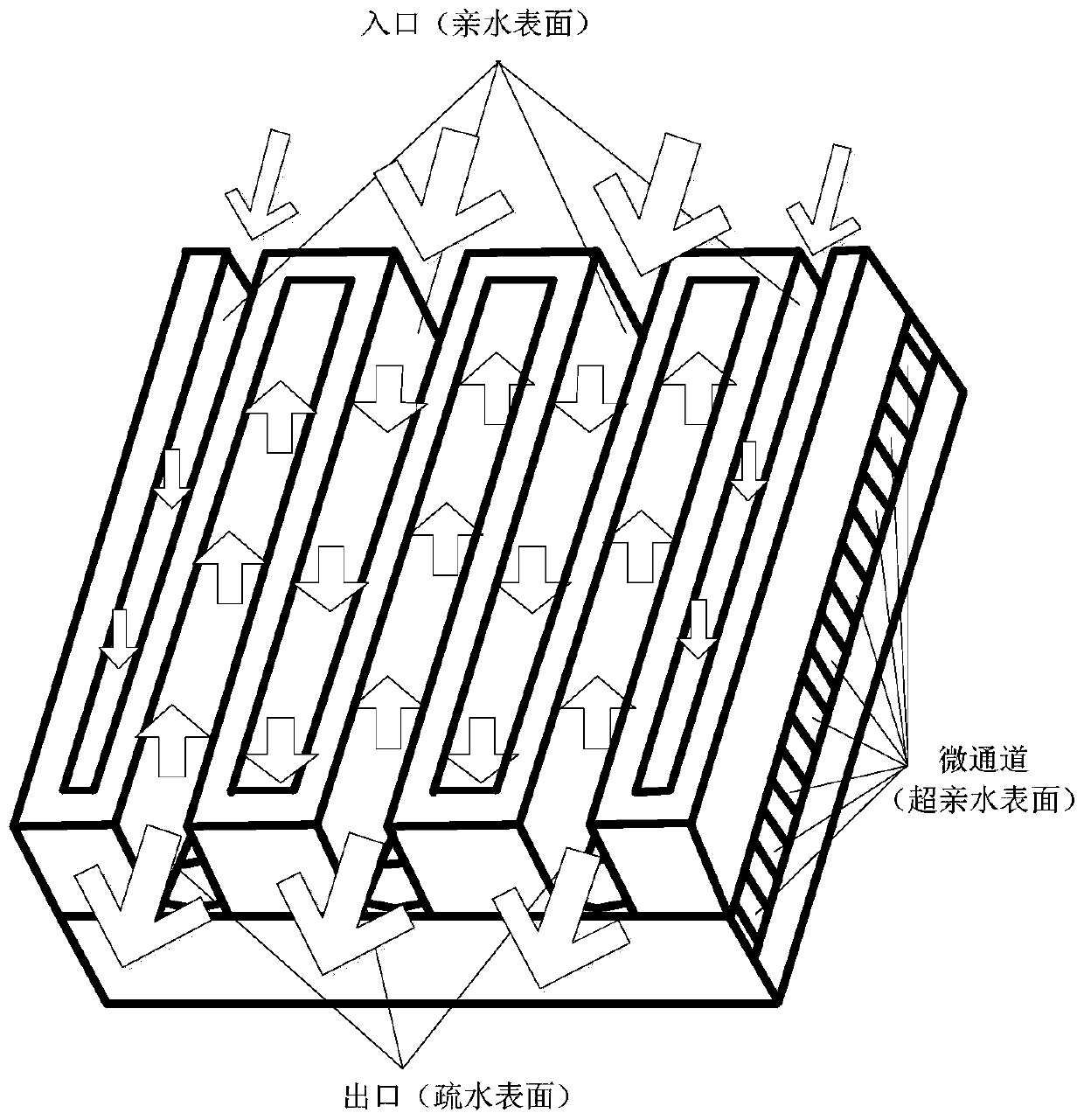

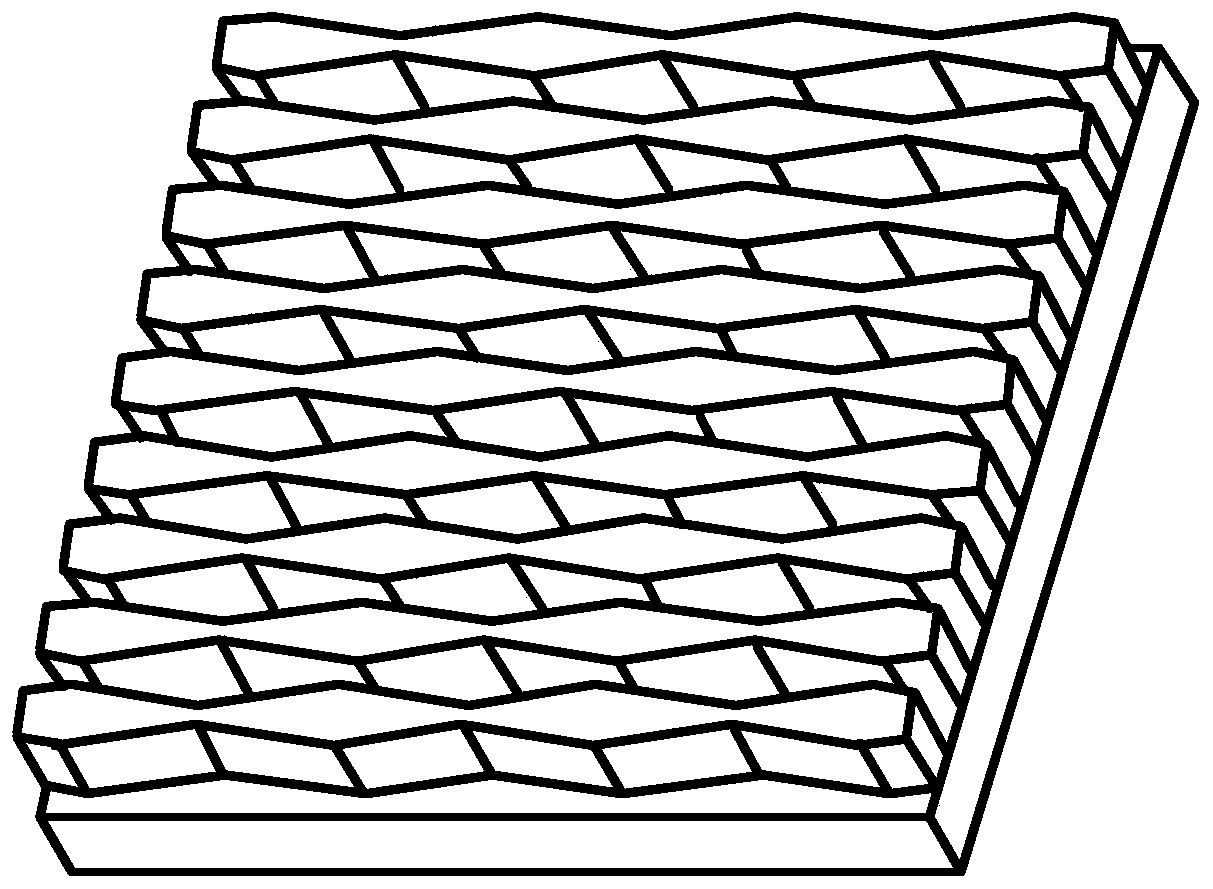

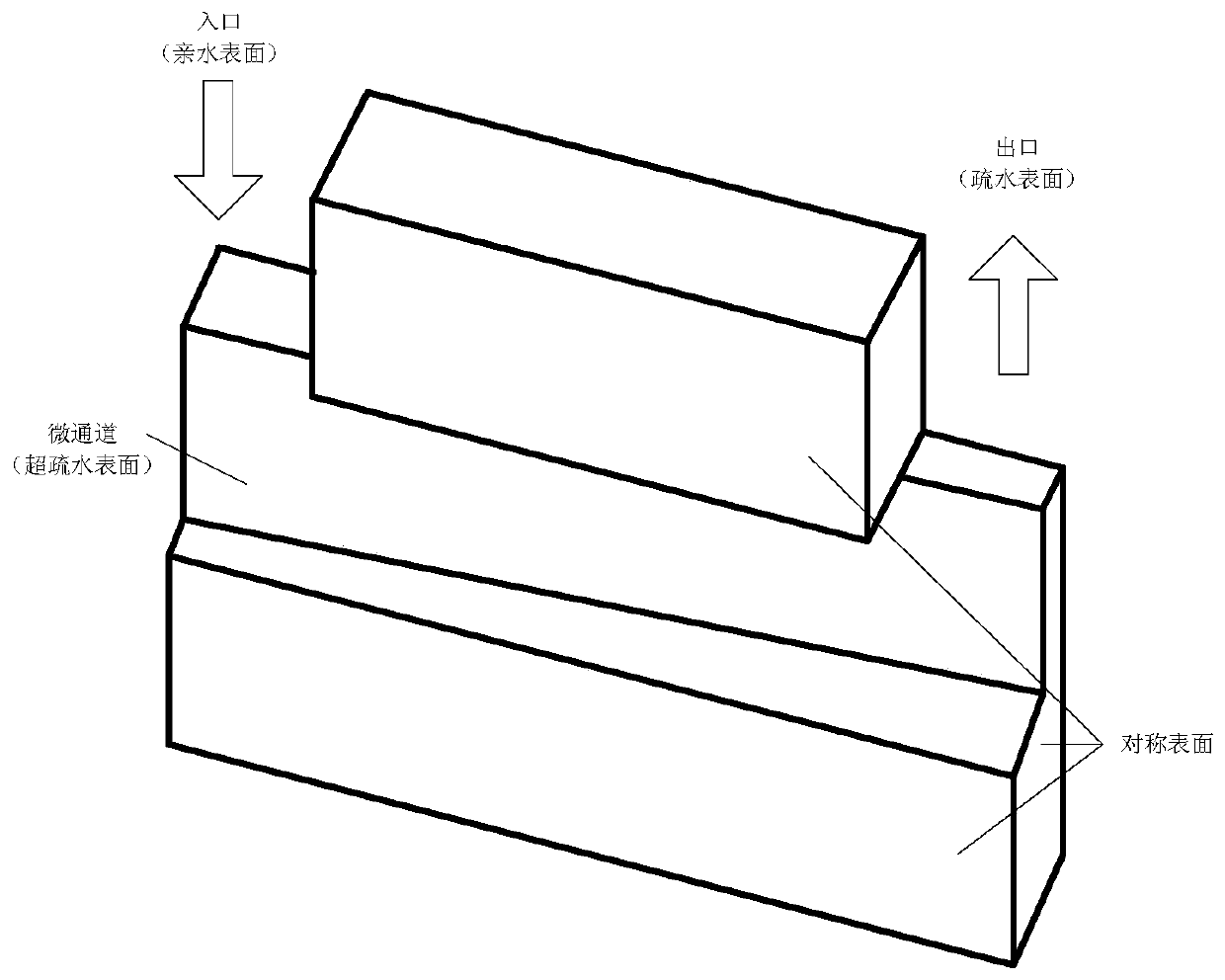

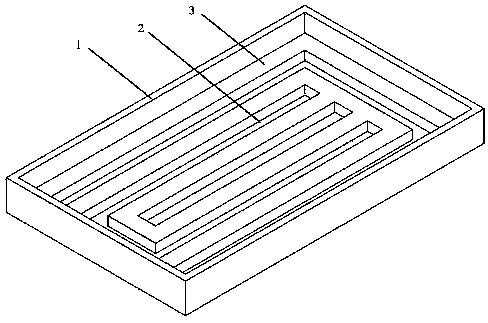

Low-resistance enhanced heat transfer structure based on nanometer super-wetting interface

ActiveCN110425914AShorten the length of the runnerReduce thicknessCoatingsModifications by conduction heat transferIsosceles trapezoidEnhanced heat transfer

The invention discloses a low-resistance enhanced heat transfer structure based on a nanometer super-wetting interface. The low-resistance enhanced heat transfer structure comprises a lower embedded microchannel layer and an upper manifold channel layer, wherein embedded microchannels are perpendicular to manifold channels; the lower embedded microchannel layer consists of a plurality of embeddedmicrochannel units; the cross section of each embedded microchannel of each unit is a rectangular divergent cross section along the flowing direction of a cooling working medium; the shape of each embedded microchannel of each unit is isosceles trapezoid; the upper manifold channel layer is composed of the S-shaped manifold channels; and two adjacent S-shaped manifold channels form inlets and outlets of the manifold channels. According to the low-resistance enhanced heat transfer structure, a microchannel radiator is constructed by utilizing a layered flow structure, the heat transfer characteristic and the resistance characteristic can be simultaneously improved by combining the microchannel radiator with the nano super-wetting interface and the divergent microchannel section, and the low-resistance enhanced heat exchange of the microchannel radiator is achieved under the condition of higher heat dissipation efficiency.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

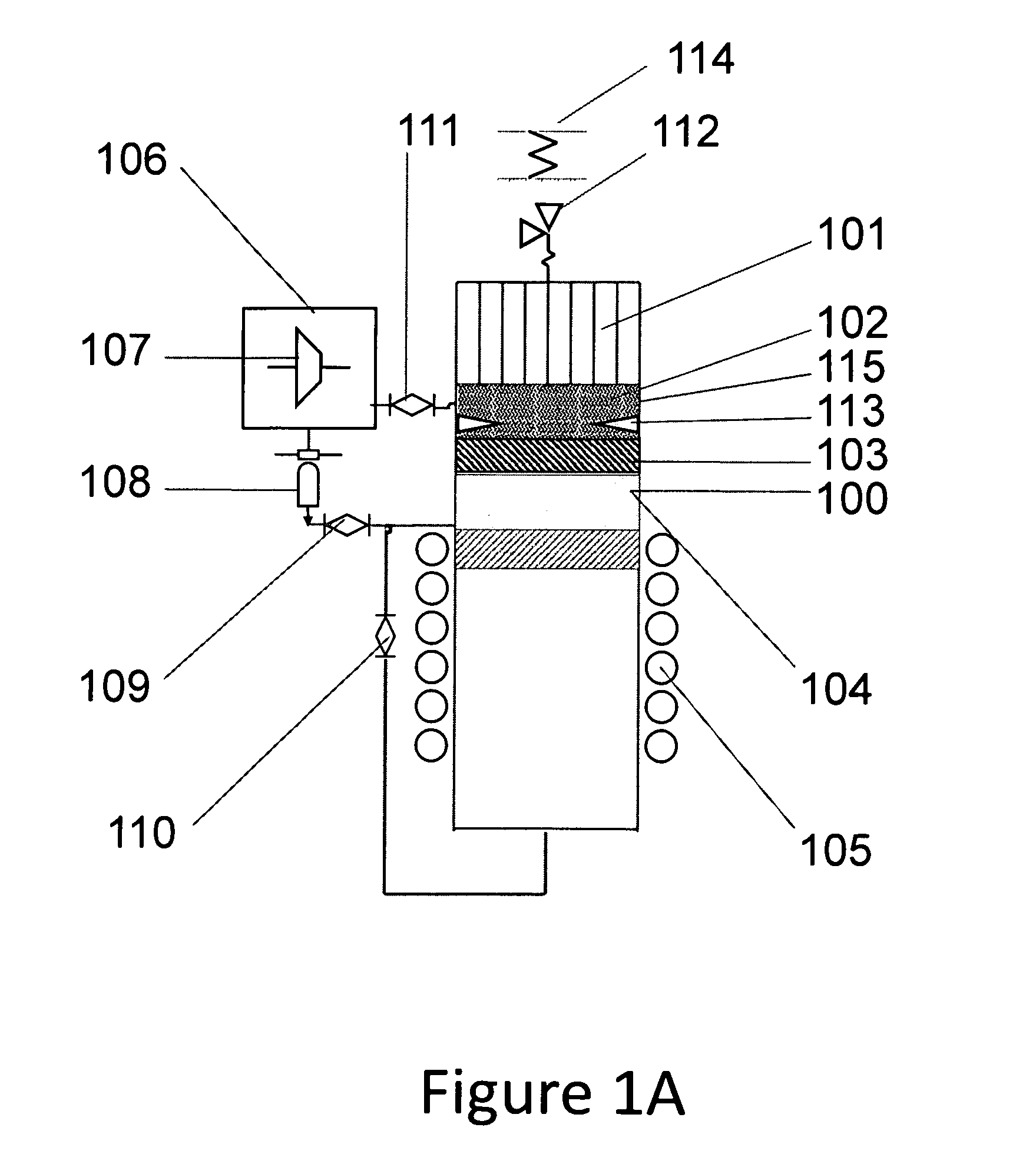

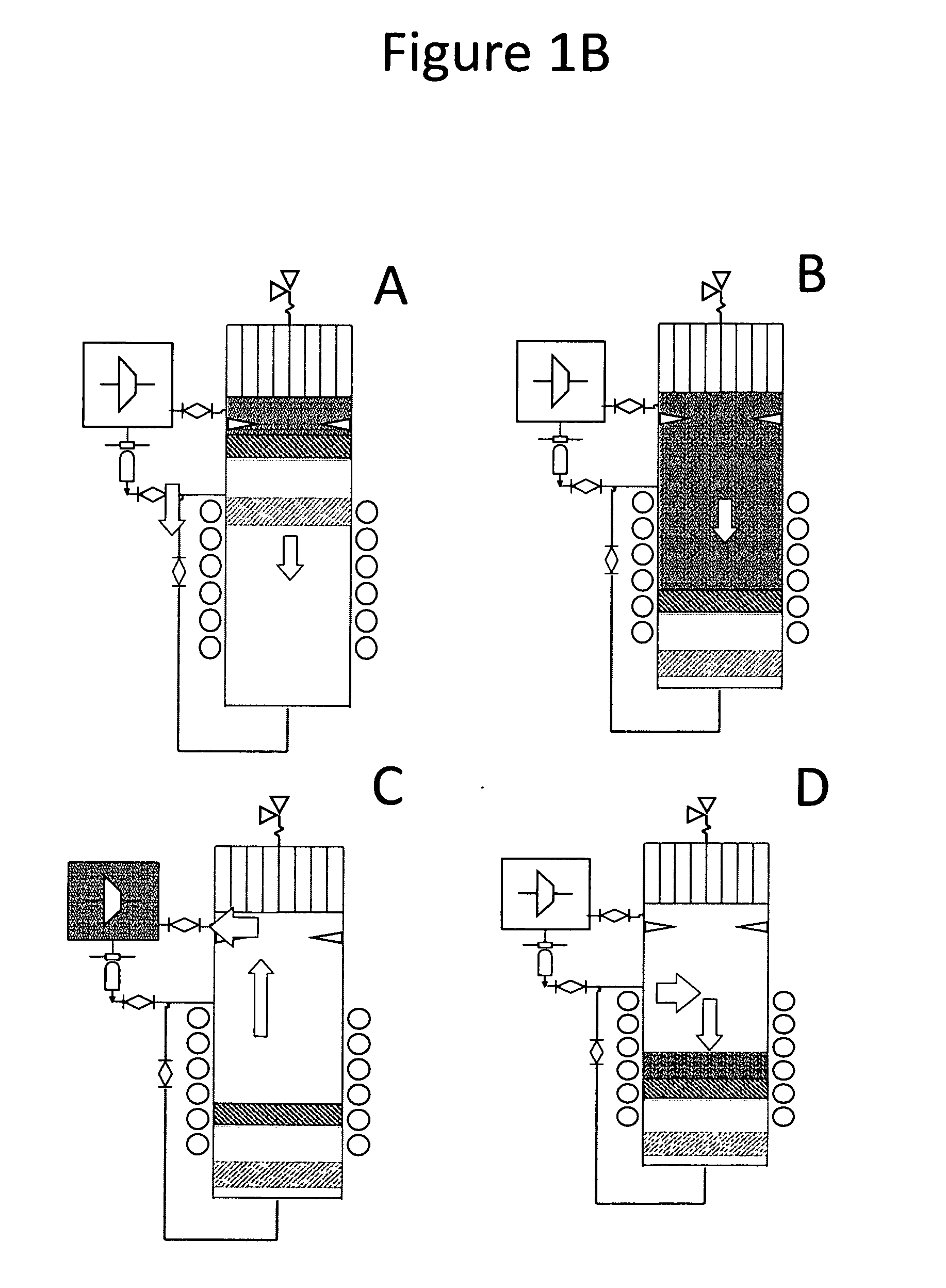

Methods of pulsed nuclear energy generation using piston-based systems

InactiveUS20130005200A1High heat transfer rateIncrease heatNuclear energy generationPropulsive elements of non-rotary typeWorking fluidNuclear engineering

The invention describes a method of nuclear energy transformation into electric and / or mechanical energy by triggering criticality in a working cylinder by an approach of a piston with a neutron reflector layer to fissile heat elements. Optionally, liquid moderator should fill the heating element to provide for an additional condition of such triggering. The pulse reaction initiates a heat cycle by expanding working fluid, extracting mechanical work and compressing the working fluid using lower amount of energy. The energy released in reaction can drive a column of water as a liquid piston propelling a highly efficient hydraulic turbine and producing a simple economical method of energy conversion. The piston movements can also be converted in laser and electromagnetic pulses. Self-regulation of nuclear reaction by a reflector piston linked to a resilient spring can be used in marine propulsion. In one method, the approach of the reflector piston triggers a reaction that evaporates water in the pressure chamber and produces a reactive thrust in a noozle. A fraction of the steam is diverted to produce steam bubble envelope on the surface of the vessel to minimize drag. Another fraction of the diverted steam drives a pump, pumping sea water into the heating elements. Other practical and novel applications of the method are disclosed.

Owner:MAYBURD ANATOLY

Compact light weight autothermal reformer assembly

InactiveUS20050072048A1Light weightCompact and light in weightCombination devicesCatalytic gas-gas reactionSteam reformingAlloy

A fuel gas-steam reformer assembly, preferably an autothermal reformer assembly, for use in a fuel cell power plant, includes a catalyst bed which is formed from a cylindrical monolithic open cell foam body. The foam body is preferably formed from a high temperature material such as stainless steel, nickel alloys and iron-aluminum alloys, or from a ceramic material. The foam body includes open cells or pores which are contained within the metal or ceramic lattice. The lattice is coated with a porous wash coat which serves as a high surface area substrate onto which catalysts used in the reformer are applied. The foam body has an inlet end into which a mixture of fuel, steam and air is fed to begin the reforming process. An inlet portion of the foam body may be provided with an iron oxide and / or noble metal catalyst and the remainder of the foam body may be provided with a nickel and / or noble metal catalyst. An advantage of including an autothermal reformer in a fuel processing system is the compactness of the autothermal reformer. The inclusion of the foam catalyst bed rather than the traditional catalyzed pellet bed allows the reformer to be made even more compact and light weight.

Owner:HYAXIOM INC

Embedded Heat Pipe In A Hybrid Cooling System

ActiveUS20090001560A1Remove heatIncrease the heat transfer surface areaSemiconductor/solid-state device detailsSolid-state devicesEnhanced heat transferEngineering

One embodiment of a system for cooling a heat-generating device includes a base adapted to be coupled to the heat-generating device, a housing coupled to the base, a liquid channel formed between the base and the housing, where a heat transfer liquid may be circulated through the liquid channel to remove heat generated by the heat-generated device, and a heat pipe disposed within the liquid channel, where the heat pipe increases the heat transfer surface area to which the heat transfer liquid is exposed. Among other things, the heat pipe advantageously increases the heat transfer surface area to which the heat transfer liquid is exposed and efficiently spreads the heat generated by the heat-generating device over that heat transfer surface area. The result is enhanced heat transfer through the liquid channel relative to prior art cooling systems.

Owner:NVIDIA CORP

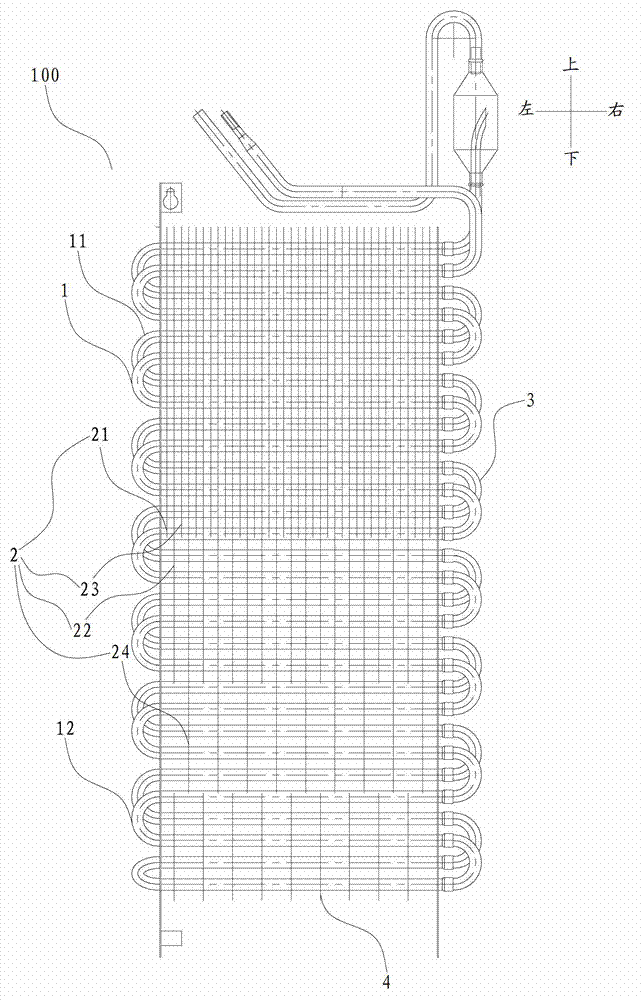

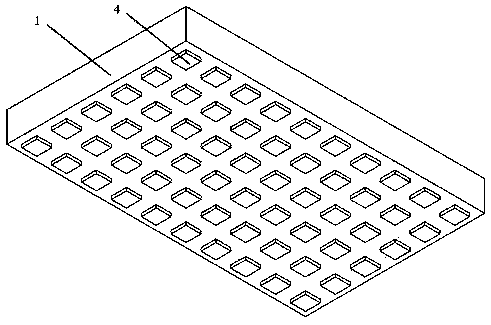

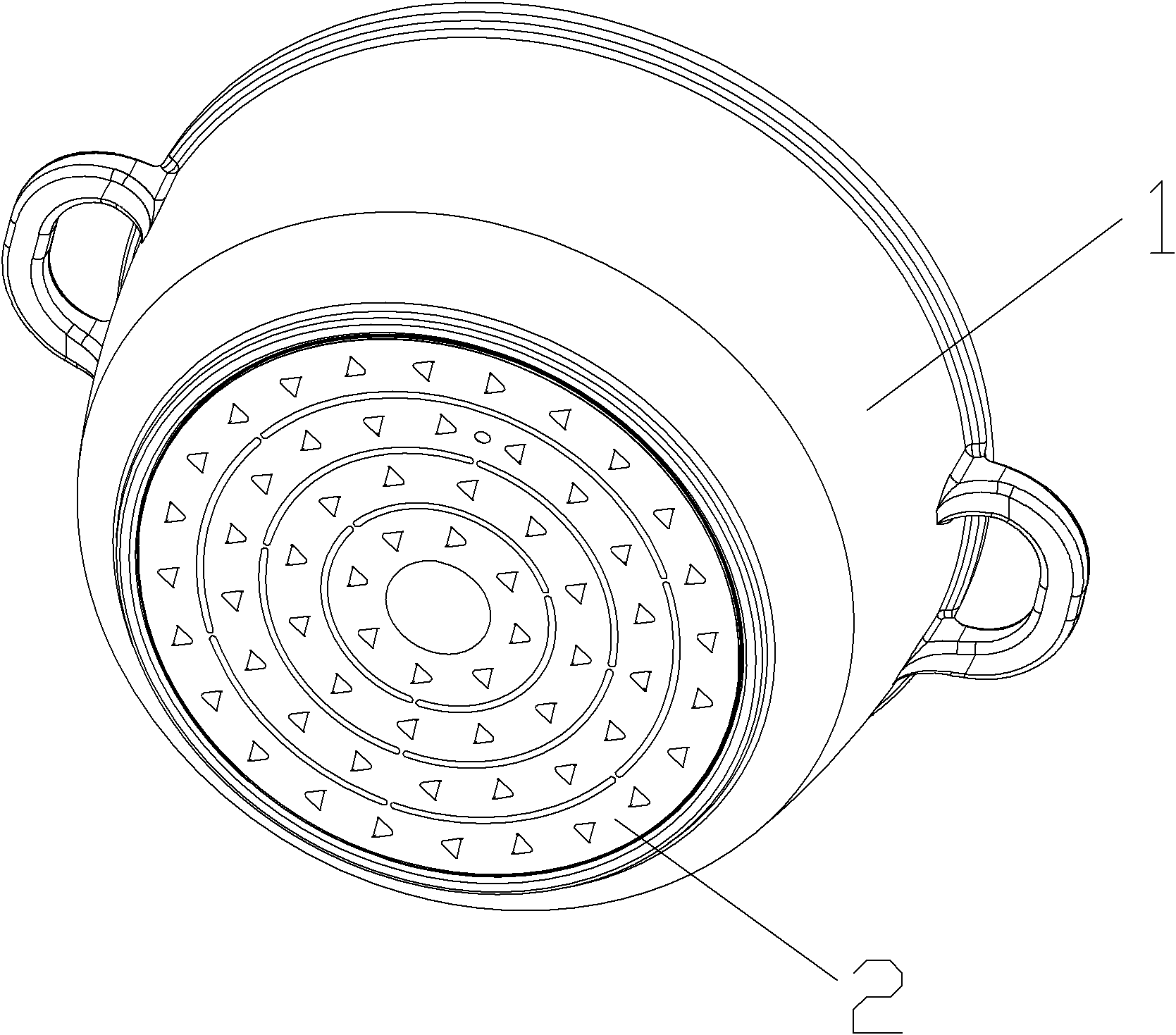

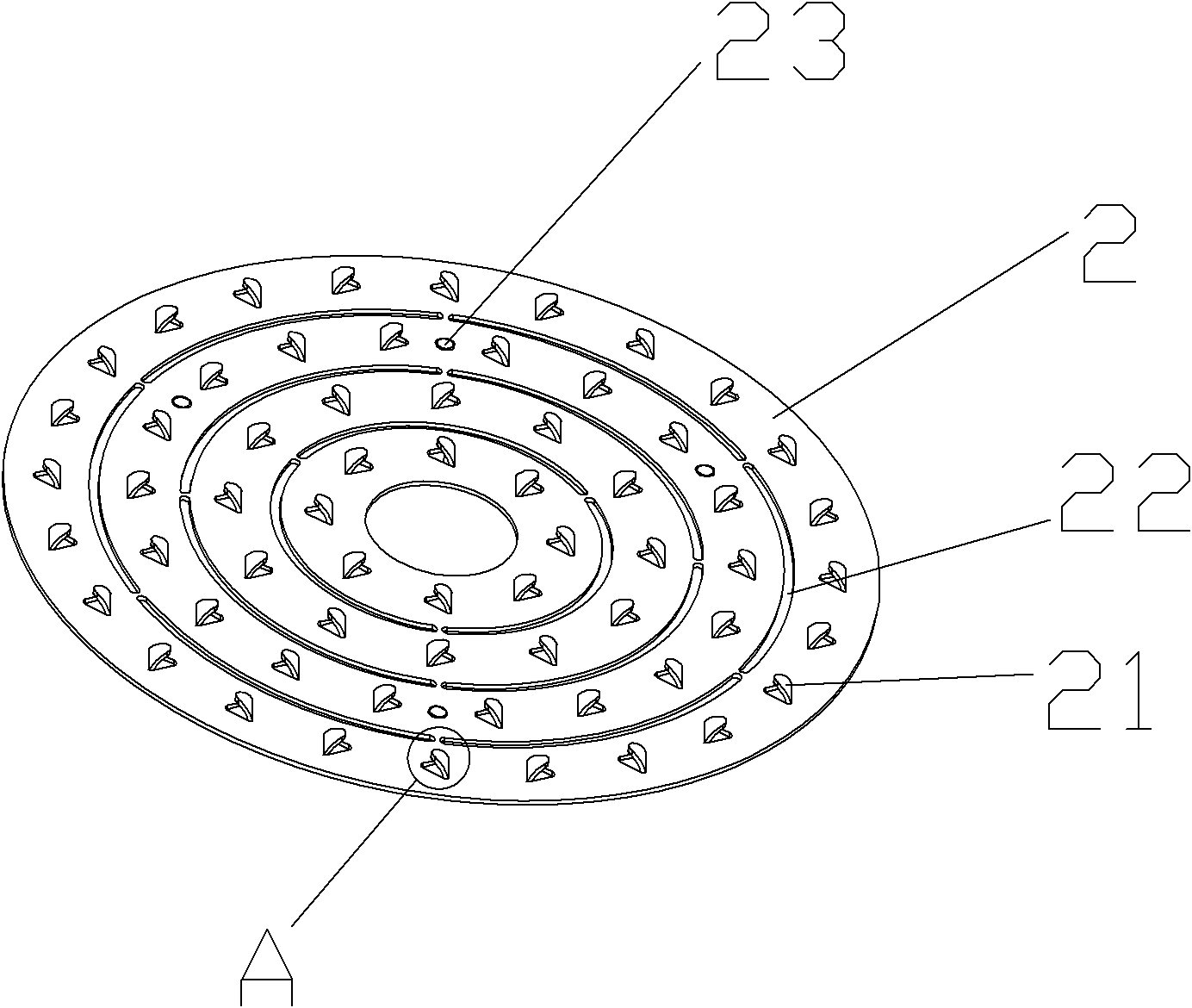

Fin evaporator applied to refrigerator, manufacturing method and refrigerator with fin evaporator

ActiveCN102967088AImprove heat transfer effectIncrease the heat transfer surface areaEvaporators/condensersRefrigeration devicesEngineeringRefrigerated temperature

The invention discloses a fin evaporator applied to a refrigerator, a manufacturing method and the refrigerator with the fin evaporator. The fin evaporator applied to the refrigerator comprises a plurality of evaporating pipes, multiple groups of fins and multiple U-shaped connecting pipes, wherein the evaporating pipes are respectively U-shaped and mutually and vertically arranged at intervals; the fins are horizontally arranged side by side, the evaporating pipes penetrate the fins sequentially, each group of fins comprise a plurality of sub-fins arranged side by side, and the lengths of every two adjacent sub-fins are unequal; and the evaporating pipes are sequentially connected through the connecting pipes. According to the fin evaporator provided by the invention, as the plurality of U-shaped evaporating pipes are adopted and penetrate the multiple groups of the fins, the matching of the fins and pipelines of the U-shaped evaporating pipes are more tight, so that the heat exchange effect of the fin evaporator is improved; and as the sub-fins in different lengths are arranged, the heat exchange superficial area of the fin evaporator is increased, so that the heat exchange efficiency of the fin evaporator is effectively improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

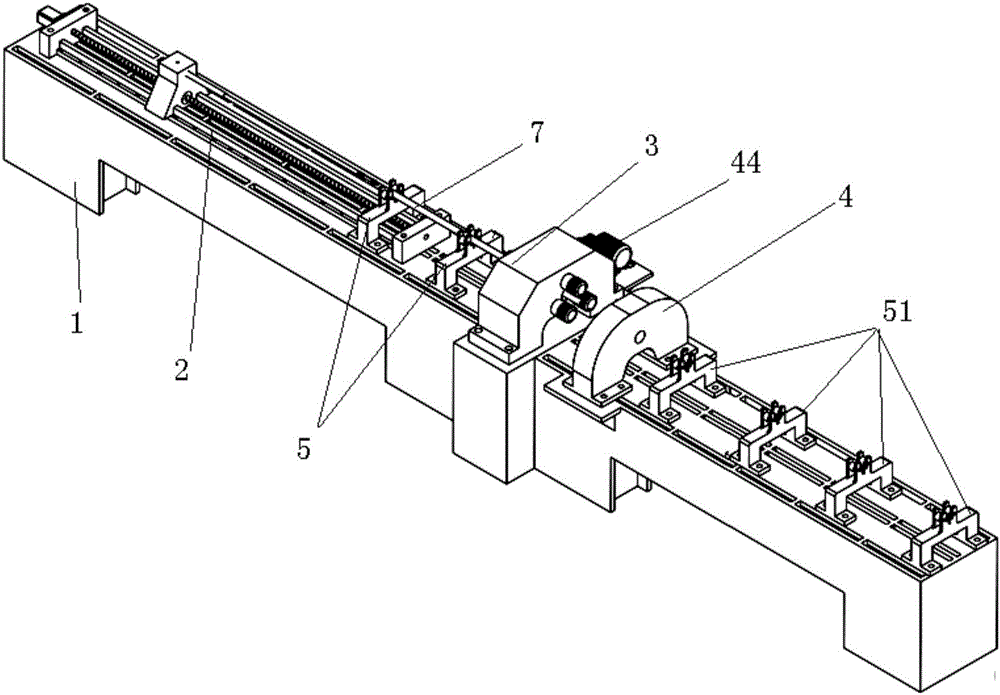

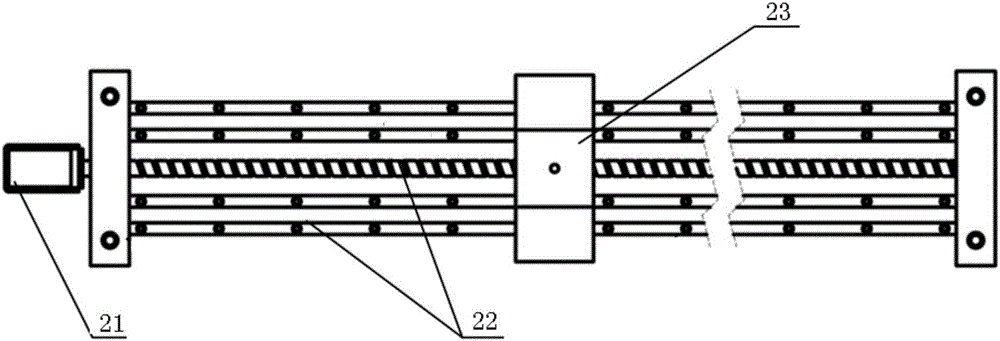

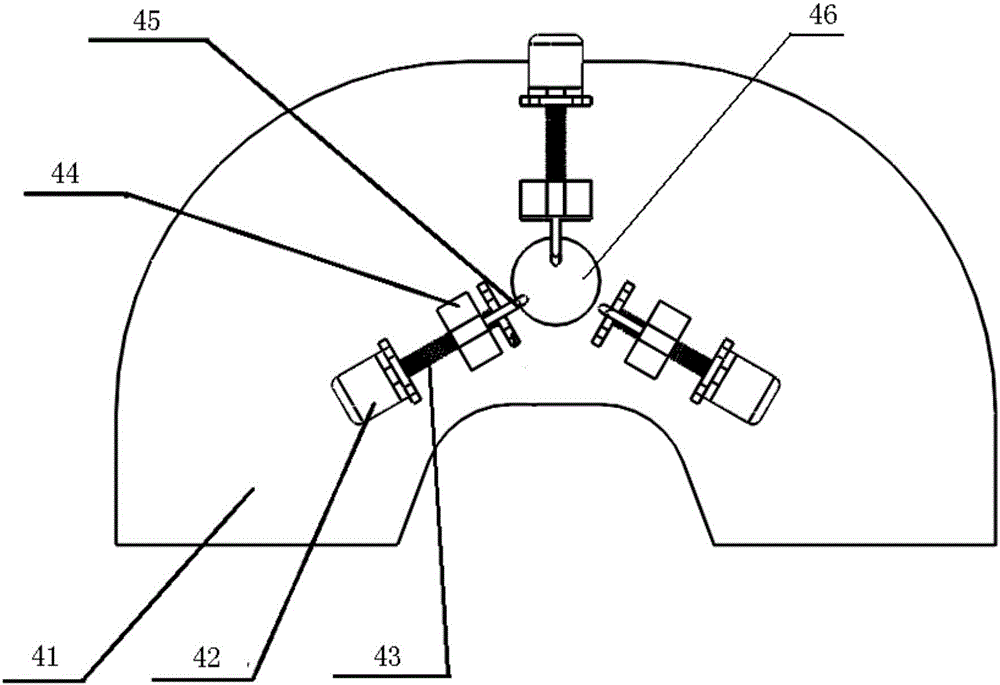

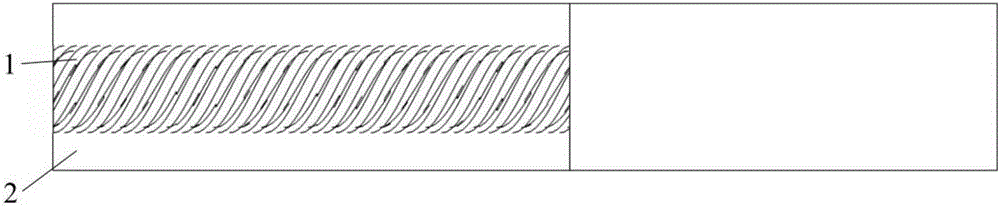

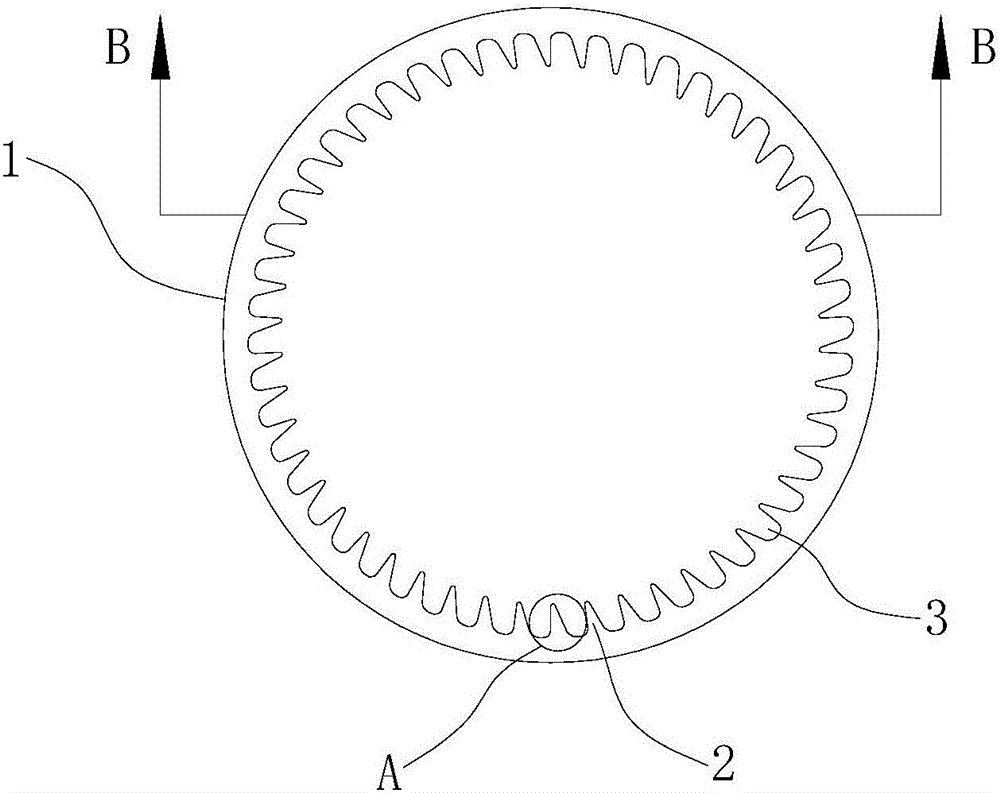

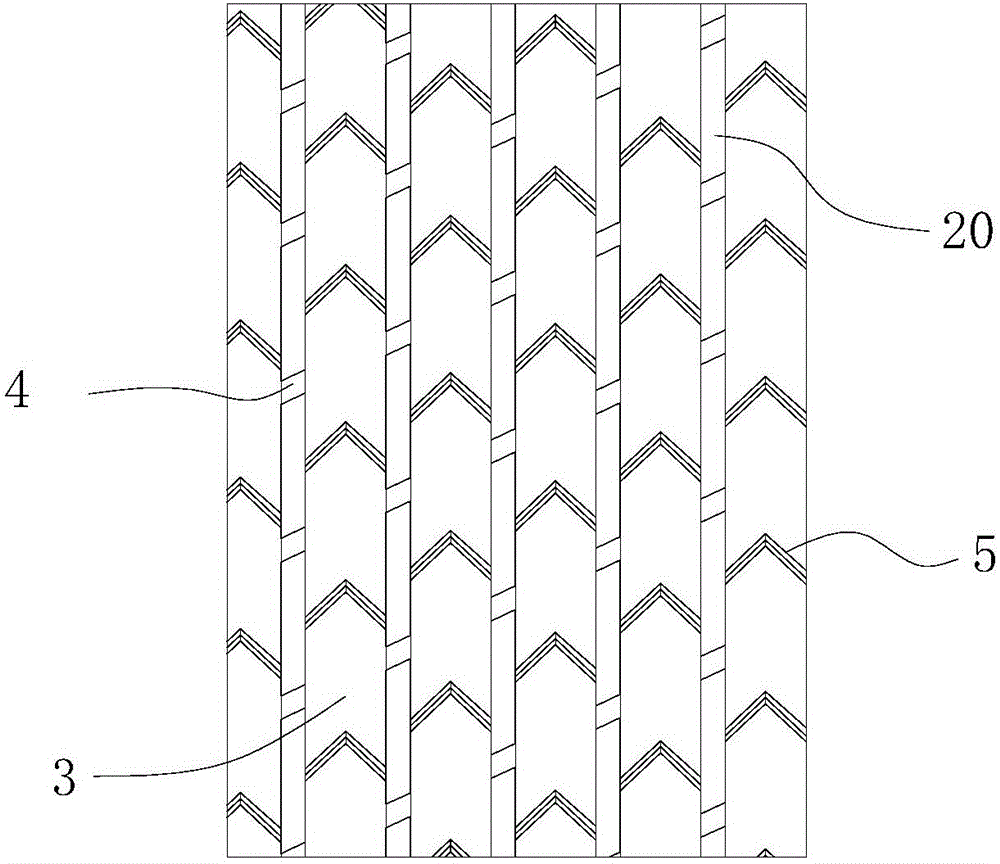

Rolling and ploughing-extrusion device and method for manufacturing three-dimensional internal and external finned tubes

ActiveCN106391914AIncrease the heat transfer surface areaImprove heat transfer coefficientHeat exchange apparatusEngineeringScrew thread

The invention discloses a rolling and ploughing-extrusion device and method for manufacturing three-dimensional internal and external finned tubes. The device comprises a rack, an adjusting pull rod mechanism, left brackets, a rotatable roller handpiece, an external fin ploughing tool and right brackets. The roller handpiece is provided with external thread roller mechanisms for forming external thread structures on the outer surfaces of metal tubes, and an internal thread roller core mechanism for forming internal thread structures on the inner surfaces of metal tubes. The external thread roller mechanisms are symmetrically distributed on the periphery of the internal thread core mechanism and form roller stations for metal tubes. When metal tubes pass through the roller stations, thread structures are formed on the inner surfaces and the outer surfaces of metal tubes under the rolling action of the external thread roller mechanisms and the internal thread core mechanism. When the device is adopted for machining heat tubes, internal fin structures and external fin structures can be formed at a time, clamping time is effectively shortened, production efficiency is improved, and production cost is lowered.

Owner:SOUTH CHINA UNIV OF TECH

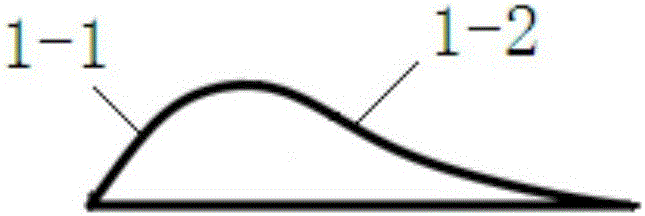

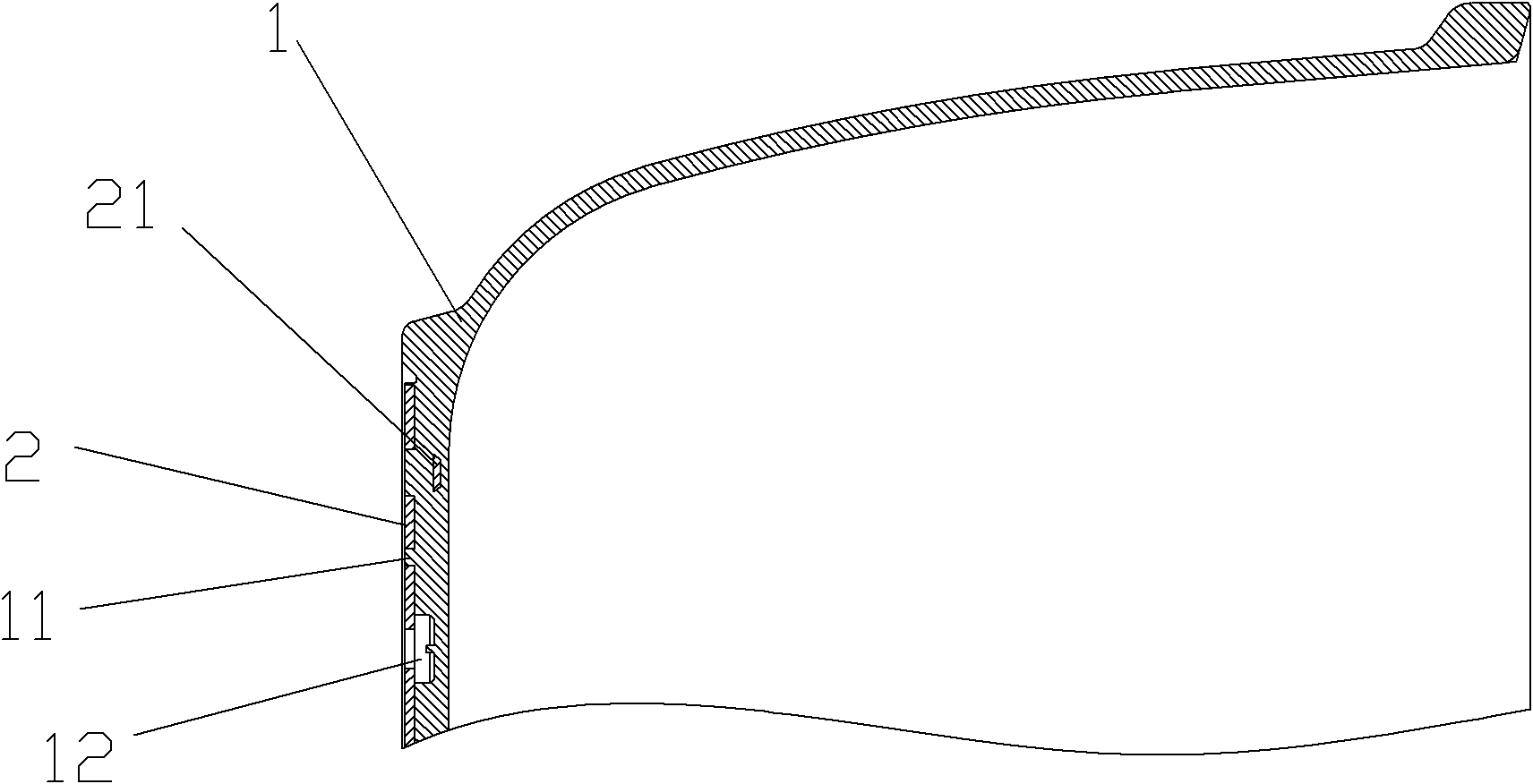

Boiler water-cooled wall inner threaded pipe with streamline-section inner ribs

ActiveCN105806127AImprove heat transfer performanceImprove heat transfer efficiencyCasings/liningsSteam boilersThreaded pipeEngineering

The invention discloses a boiler water-cooled wall inner threaded pipe with stream-line-section inner ribs. The boiler water-cooled wall inner threaded pipe comprises a pipe body and the ribs spirally arranged on the inner wall of the pipe body in the axial direction, wherein the cross sections of the ribs are in streamline shapes. The ribs which are spirally arranged are distributed at equal intervals, and the number of the ribs is 4 to 8. The included angle between the spiral direction of the ribs and a cross section is controlled within the range of 30 degrees to 60 degrees. The circumferential bottom width of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 4 mm to 10 mm. The height of the highest point of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 0.5 mm to 1.5 mm. The position of the highest point of the ribs is at the position of one third of the rib bottom width. By means of the novel boiler water-cooled wall inner threaded pipe, vortexes on the back flow sides of the ribs are avoided or reduced through the streamline inner ribs, so that the heat transfer capability of the inner wall face of the pipe is effectively improved, and the temperature level near rib roots on the back flow sides of the ribs is lowered. Therefore, the heat transfer performance of the boiler water-cooled wall inner threaded pipe can be further enhanced through the pipe shape.

Owner:XI AN JIAOTONG UNIV

Prismatic sealed rechargeable battery, battery module, and battery pack

ActiveUS8124270B2Increase powerImprove cooling effectPrimary cell to battery groupingCharging stationsRechargeable cellEngineering

A prismatic sealed rechargeable battery includes a substantially prismatic battery case that accommodates an electrode plate assembly and an electrolyte solution. The battery case is formed of metal. On a side face of the battery case, a thin plate is provided which has a plurality of protruding portions formed in parallel at appropriate intervals. The protruding portion and the side face form spaces opened at both ends therebetween. The thin plate is bonded to the side face of the battery case by making flat portions between the protruding portions into surface-contact with the side face, thereby improving cooling capability of the battery.

Owner:PANASONIC CORP +1

EGR cooling system with multiple EGR coolers

InactiveCN101413466ASolve assembly problemsDoes not increase size significantlyInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringHeat sink

An EGR cooling system is provided. The EGR cooling system comprising a plurality of EGR coolers configured to cool the EGR to a plurality of successively lower temperatures, where at least one of the plurality of EGR coolers includes a finned EGR cooler that comprises a plurality of channels for dissipating heat in the EGR, the plurality of channels increasing heat transfer surface area while having sufficient fin spacing to avoid clogging. The EGR cooling system may further comprise a catalyst configured to remove particle matters and / or hydrocarbons from the EGR, the catalyst positioned upstream of at least one of the plurality of EGR coolers. The inventive EGR cooling system can satisfy the EGR cooling requirement of high load engine without notably incereasing the size of the EGR cooling system and can reduce the dirty of the EGR.

Owner:FORD GLOBAL TECH LLC

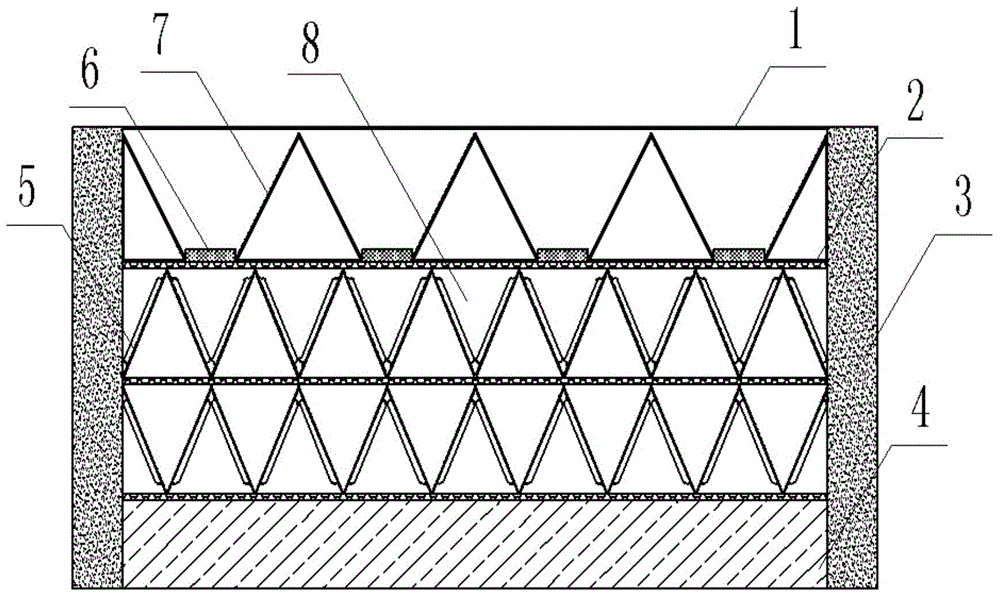

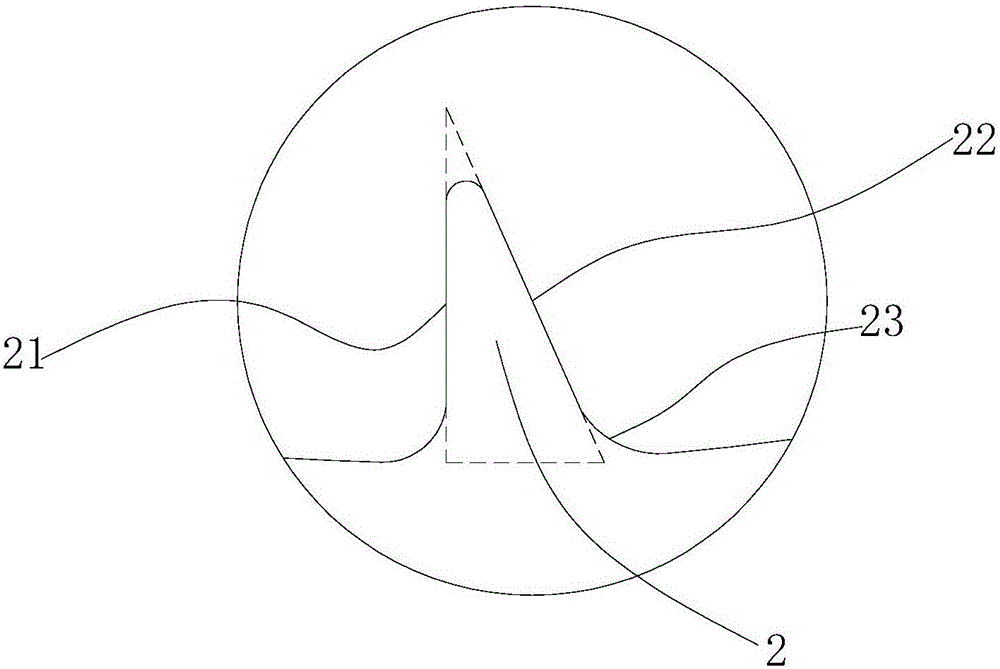

Novel solar energy photovoltaic photo-thermal integrated device

InactiveCN104935239AImprove absorption rateLower working temperaturePV power plantsPhotovoltaic energy generationEngineeringSolar cell

The invention provides a novel solar energy photovoltaic photo-thermal integrated device comprising a frame heat insulation layer, a pedestal heat insulation layer, a glass cover plate, and solar cell sheets, water cooling channels, air channels and a heat collection plate arranged in a sealed spaced formed by the frame heat insulation layer, the pedestal heat insulation layer and the glass cover plate; the heat collection plate is fixed on the frame heat insulation layer; the solar cell sheets are fixed on the heat collection plate; the water cooling channel is arranged between two adjacent solar cell sheets and on the heat collection plate; the air channels are arranged below the heat collection plate; the water cooling channel has a triangle section; two side wall of the water cooling channel are coated with a light selective absorption coating. The novel solar energy photovoltaic photo-thermal integrated device uses cooling water and air for simultaneous heat exchange, and obtained hot water and hot air can be applied to life water, home heating and greenhouse; work temperature of the solar cell sheets can be better ensured, heat can be fully absorbed, thus maximizing energy benefit.

Owner:JIANGSU UNIV

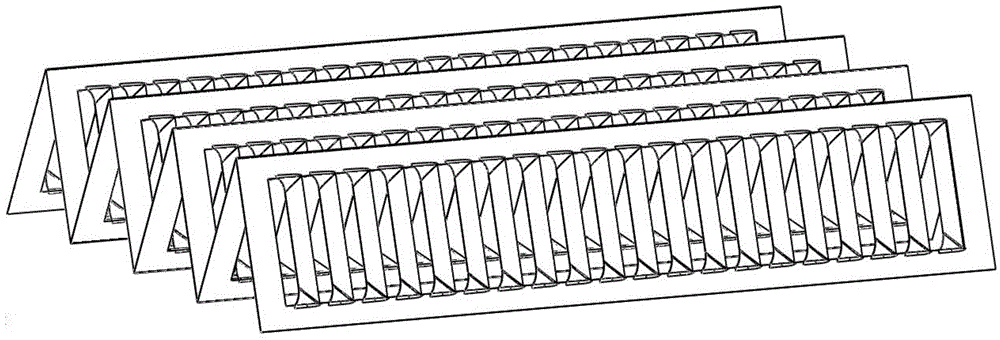

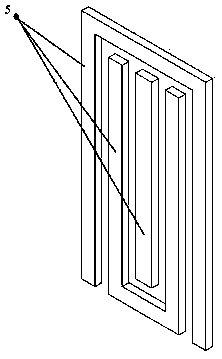

Compact type gas-gas heat exchange tube and manufacturing and use methods thereof

PendingCN109059601ARealize complete countercurrent heat exchangeFull turbulenceStationary tubular conduit assembliesHeat transfer modificationEngineeringTemperature difference

The invention provides a compact type gas-gas heat exchange tube which comprises a heat transfer tube, an inner fin set and an outer fin set. The heat transfer tube is used for separating fluid insideand outside the tube and transferring heat between the fluid inside and outside the tube in a convection heat conduction mode; the inner fin set is used for expanding the inside heat exchange surfaceof the heat transfer tube, forming miniature fluid channels, separating the fluid in the tube, making the fluid flow in the axial direction of the heat transfer tube and meanwhile generating a turbulent flow effect and enhancing a convection heat exchange effect; the outer fin set is used for expanding the outside heat exchange surface of the heat transfer tube, forming miniature fluid channels,restraining the fluid outside the tube to reversely flow in the axial direction of the heat transfer tube and meanwhile generating the turbulent flow effect and enhancing the convection heat exchangeeffect; and holes are formed in fins of the inner fin set or / and the outer fin set. The invention further provides manufacturing and use methods of the compact type gas-gas heat exchange tube. Complete reverse flow efficient heat transfer is achieved under the heat exchange working condition of the limited space and the small tube number average temperature difference, the equipment spatial size is reduced, and meanwhile the weight of each area is reduced, so that the total weight and the manufacturing cost are reduced.

Owner:SHANGHAI POWER EQUIP RES INST

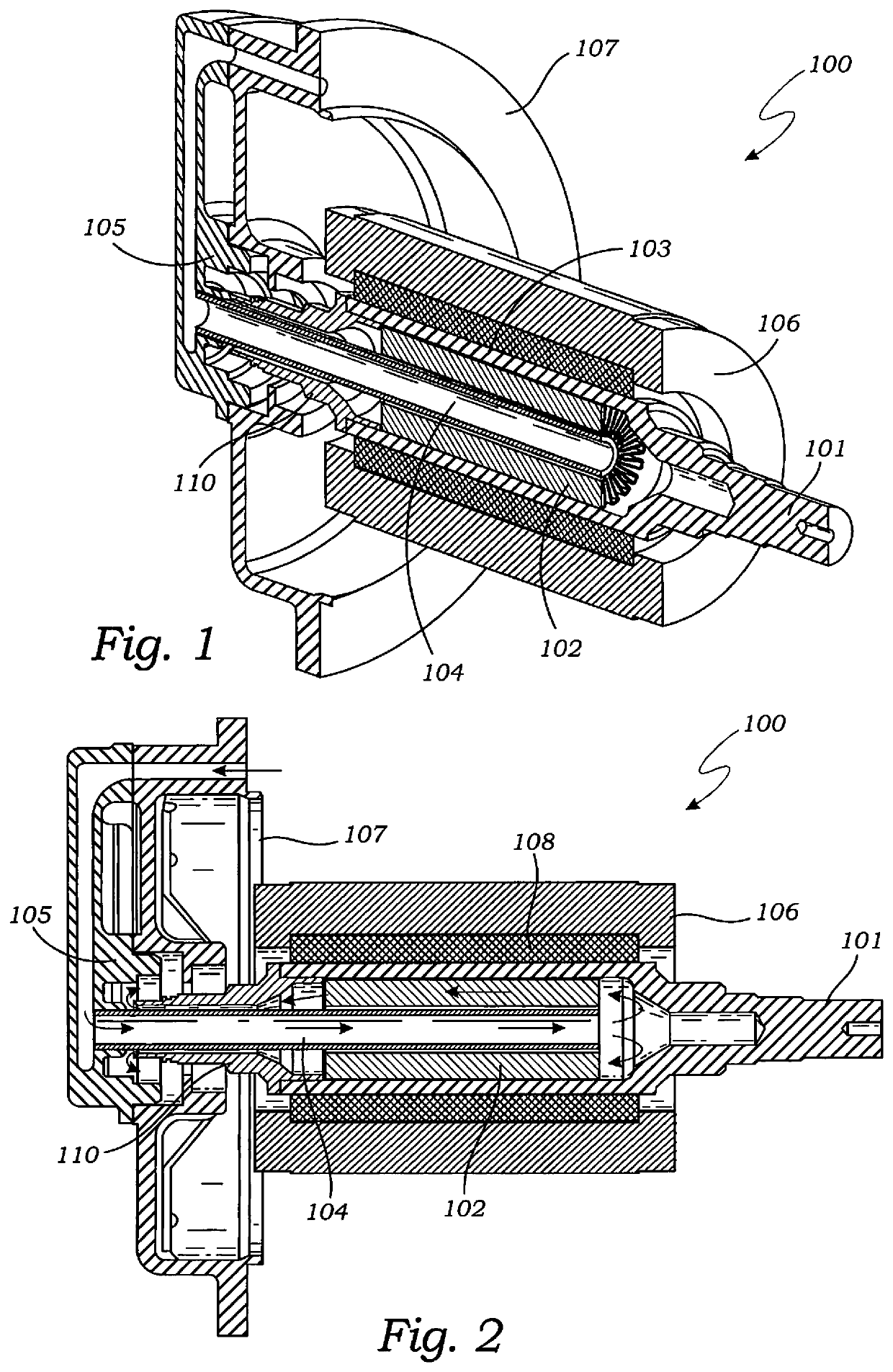

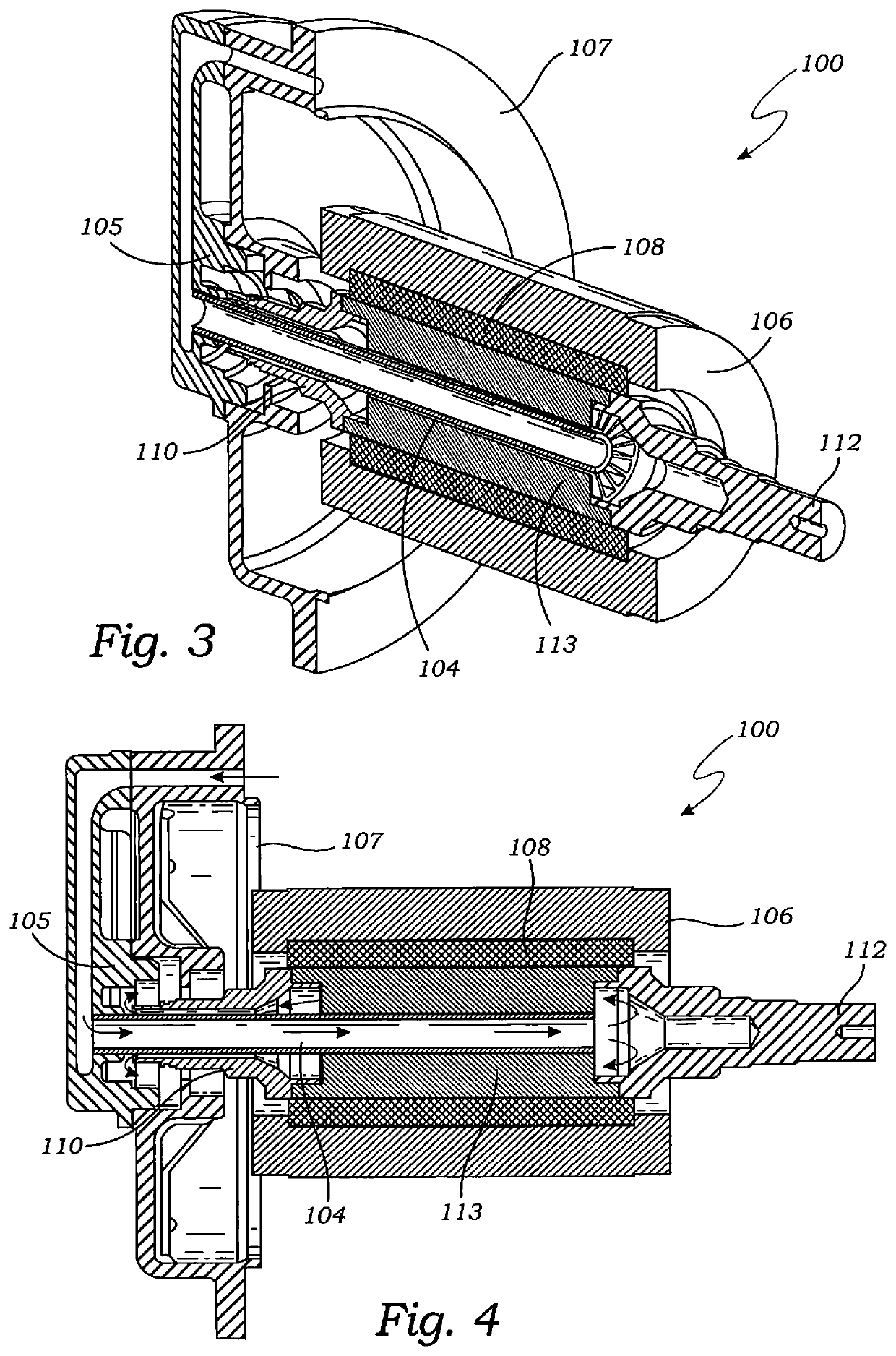

Electric motor with liquid cooled rotor

InactiveUS20200251963A1Increase exposureImprove power density and efficiencyMagnetic circuit rotating partsCooling/ventillation arrangementElectric driveEngineering

An electric drive motor with an improved liquid cooling system featuring a hollow rotor shaft configured to allow liquid coolant to flow in and out of the rotor shaft through an aperture in one distal end following a path influenced by a coolant tube such that the liquid coolant is directed to flow past a plurality of internally located heat dissipation fins which are in thermal communication with the rotor shaft thereby increasing the heat dissipation, performance, and power density.

Owner:WOODY GEORGE R +2

Heat-pipe-based enhanced radiating mobile phone sleeve

PendingCN109151139AEnhanced convective heat transferAvoid accumulationModifications by conduction heat transferTelephone set constructionsAgricultural engineeringMobile phone

The invention discloses a heat-pipe-based enhanced radiating mobile phone sleeve which is used for sleeving the exterior of the mobile phone and comprises a thermally conductive mobile phone sleeve case and heat pipes, wherein the heat pipes are uniformly embedded on the inner bottom surface of the mobile phone sleeve case. The inner bottom surface is uniformly provided with grooves for embeddingthe heat pipes. The bottom of the groove is provided with an elastic heat conduction pad. The invention provides the heat-pipe-based enhanced radiating mobile phone sleeve, wherein the process is simple, the mobile phone still has a good heat dissipation path after the mobile phone sleeve is installed, and heat accumulation is avoided.

Owner:SOUTH CHINA UNIV OF TECH

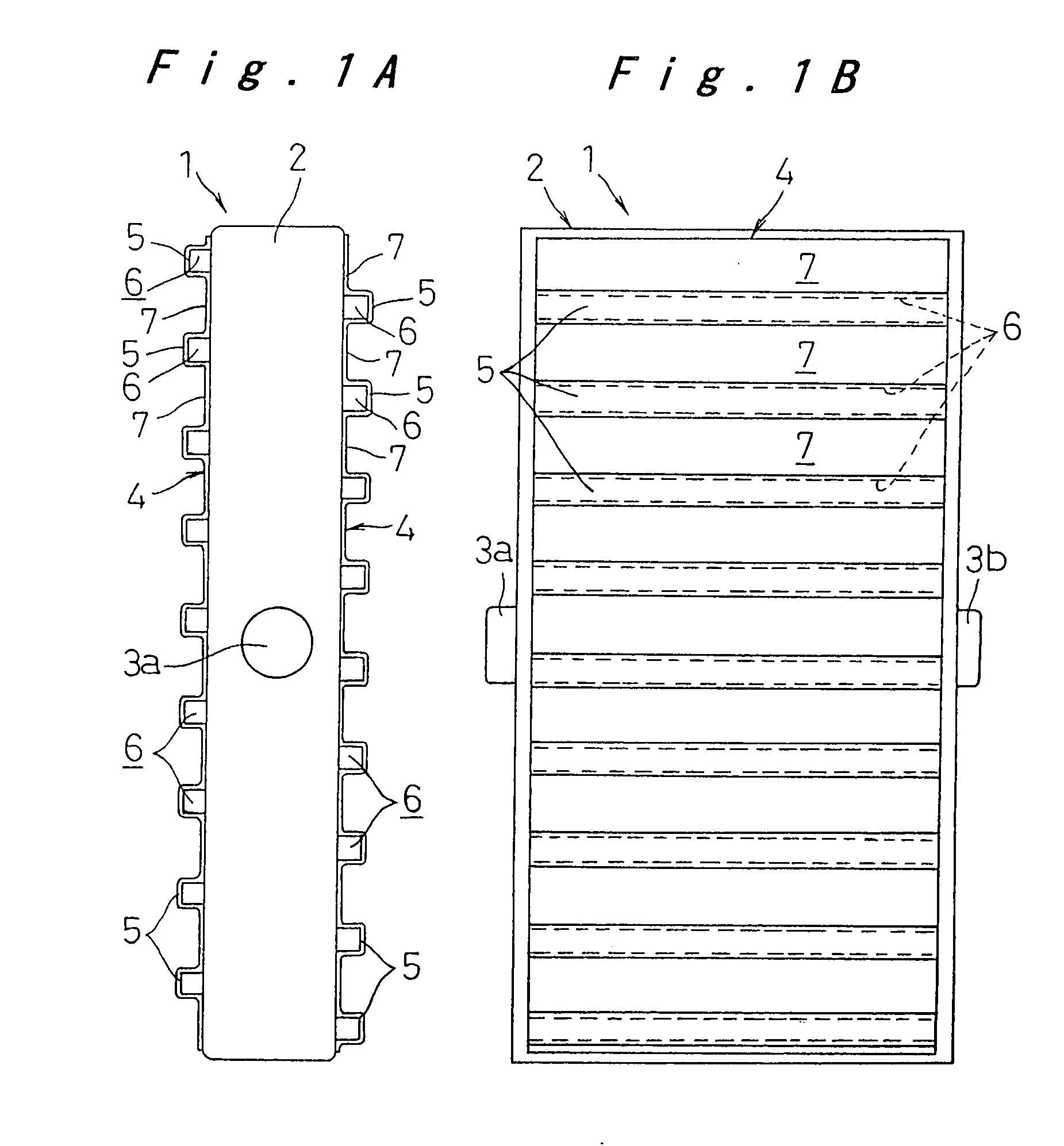

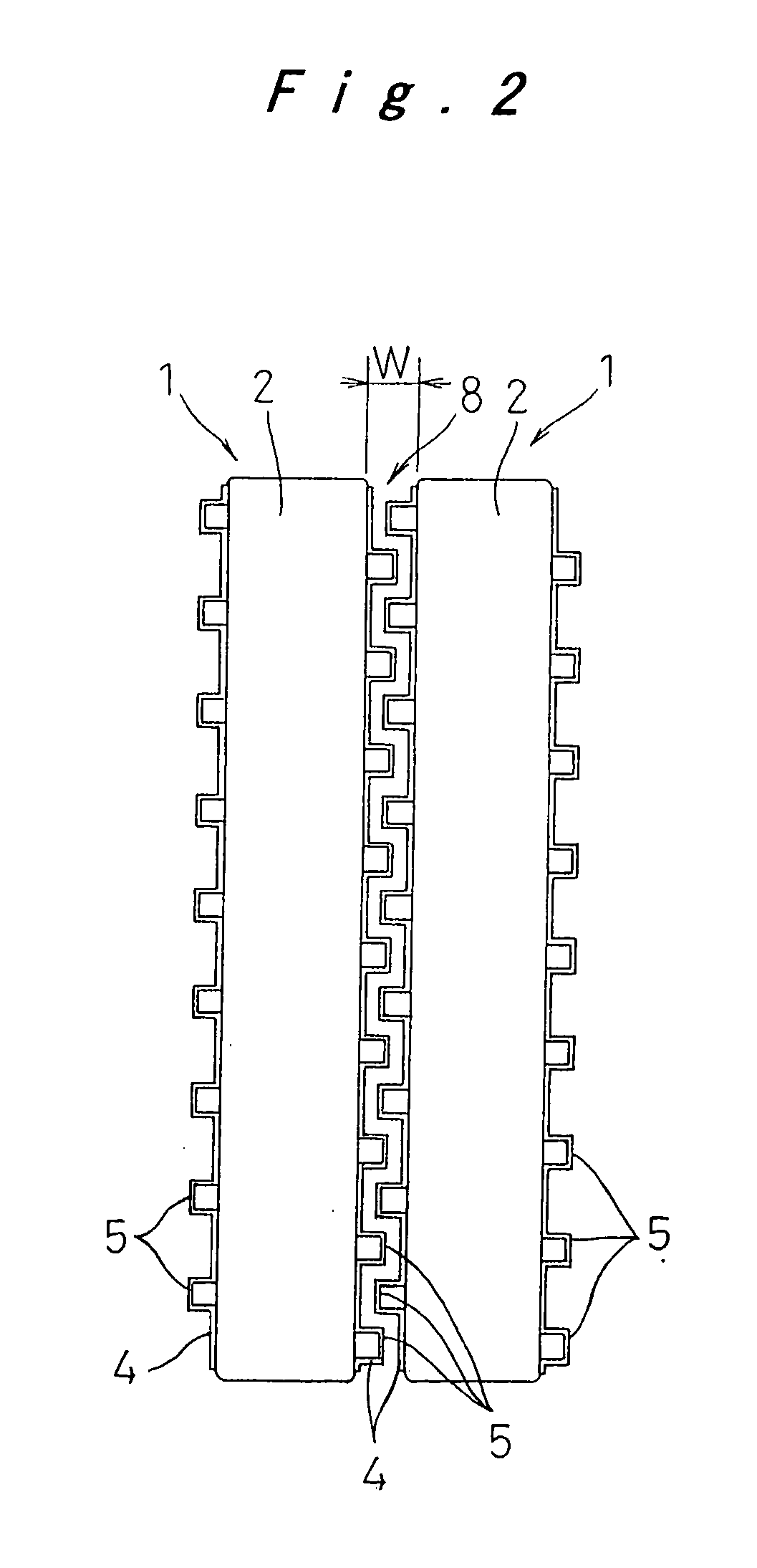

Sealed rechargeable battery and battery module

ActiveUS7393611B2Improve volume efficiencyHigh outputFinal product manufactureSmall-sized cells cases/jacketsRechargeable cellMechanical engineering

A sealed rechargeable battery includes: a metal case having an elliptical or rectangular cross section; a metal sealing plate for sealing an opening at one end of the case; and an electrode plate assembly being housed in the case with an electrolyte solution. In this configuration, a plurality of projecting ridges are formed in a continuous or discontinuous manner on both longer side faces of the case between a bottom face and the opening so as to enhance the cooling performance and to improve the strength of the side faces of the case.

Owner:PANASONIC CORP +1

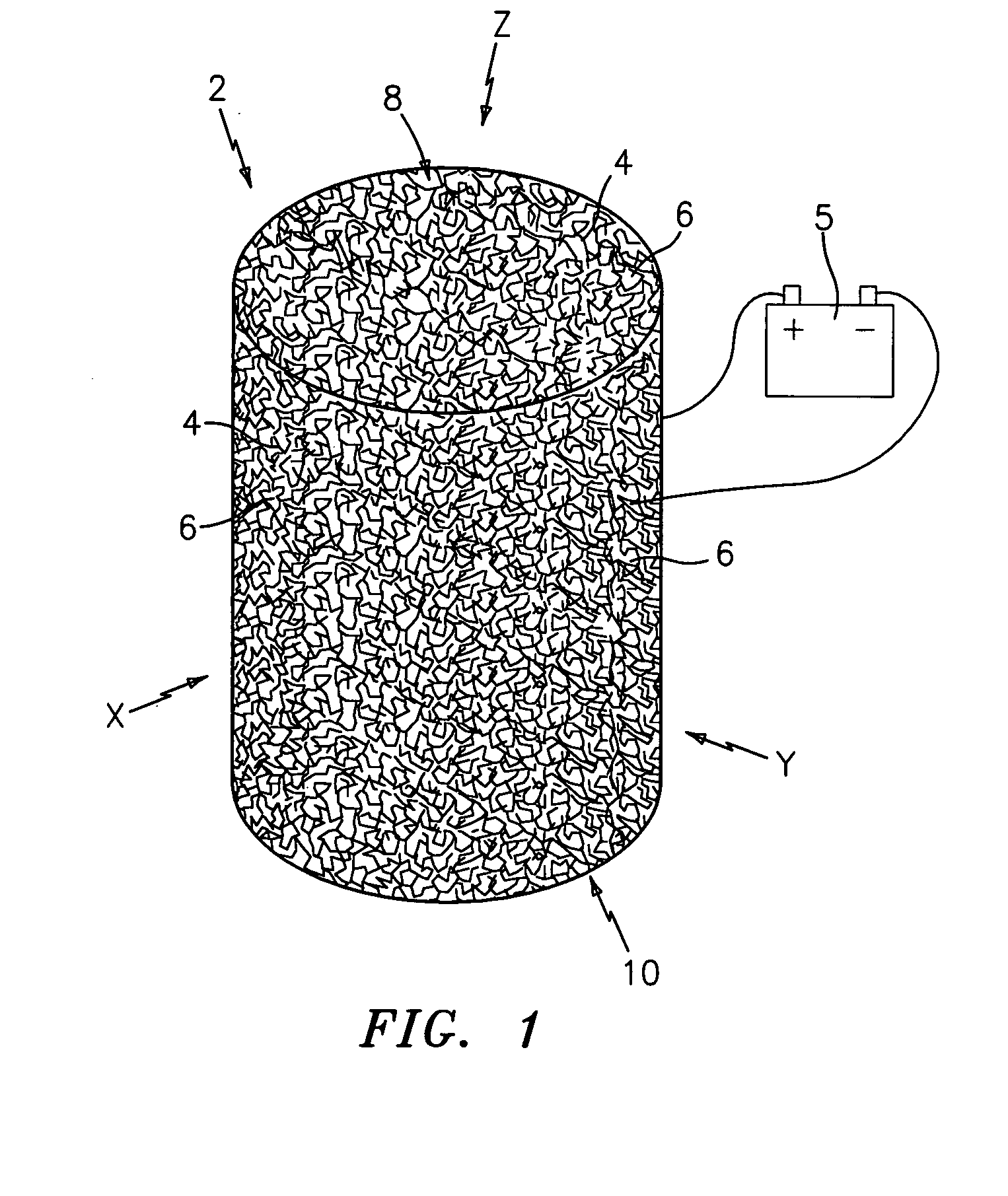

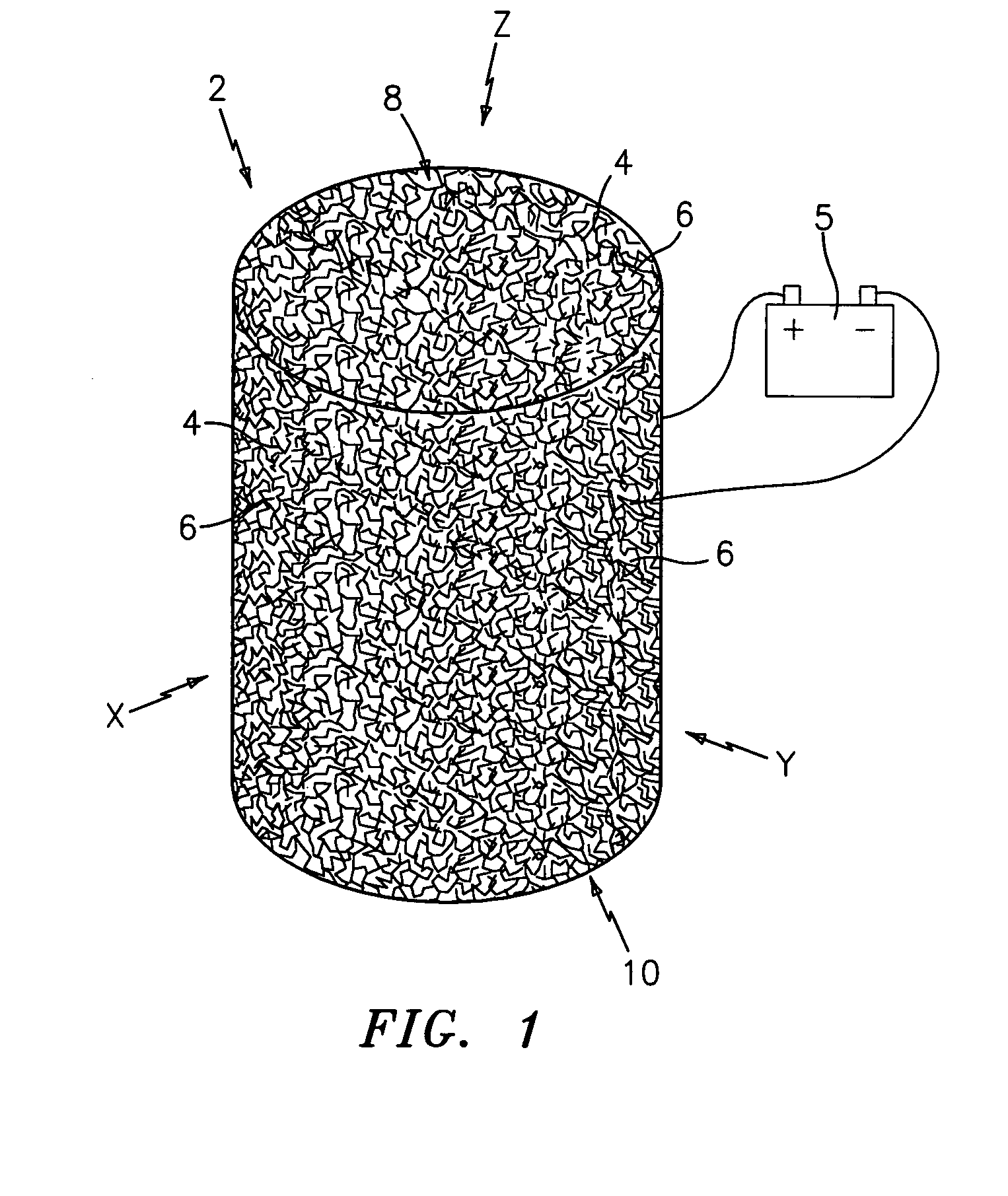

Compact light weight autothermal reformer assembly

InactiveUS6969411B2Increase the heat transfer surface areaCompact and light in weightCatalytic gas-gas reactionCombination devicesSteam reformingFuel cells

A fuel gas-steam reformer assembly, preferably an autothermal reformer assembly, for use in a fuel cell power plant, includes a catalyst bed which is formed from a cylindrical monolithic open cell foam body. The foam body is preferably formed from a high temperature material such as stainless steel, nickel alloys and iron-aluminum alloys, or from a ceramic material. The foam body includes open cells or pores which are contained within the metal or ceramic lattice. The lattice is coated with a porous wash coat which serves as a high surface area substrate onto which catalysts used in the reformer are applied. The foam body has an inlet end into which a mixture of fuel, steam and air is fed to begin the reforming process. An inlet portion of the foam body may be provided with an iron oxide and / or noble metal catalyst and the remainder of the foam body may be provided with a nickel and / or noble metal catalyst. An advantage of including an autothermal reformer in a fuel processing system is the compactness of the autothermal reformer. The inclusion of the foam catalyst bed rather than the traditional catalyzed pellet bed allows the reformer to be made even more compact and light weight.

Owner:HYAXIOM INC

Heat exchange copper tube provided with straight internal threads

ActiveCN106595372AAvoid leaningIncreased fluid turbulenceCoatingsHeat transfer modificationEngineeringScrew thread

The invention relates to the technical field of heat exchange copper tubes and particularly discloses a heat exchange copper tube provided with straight internal threads. The heat exchange copper tube provided with the straight internal threads comprises a copper tube body. A plurality of right-angled teeth are arranged on the inner side of the copper tube body in the circumferential direction. The two side edges of each right-angled tooth are a supporting straight edge and an expanding bevel edge intersecting with the supporting straight edge, wherein the extension line of the supporting straight edge passes through the center of the circle of the copper tube, the supporting straight edge is connected with the expanding bevel edge in a circular arc transmission on the top of the right-angled tooth. The addendum angle of each right-angled tooth is 45 degrees. The right-angled teeth are stretched along the axis of the copper tube to form straight racks. A straight tooth groove is formed between every two adjacent straight racks. A spiral guide groove penetrating the straight racks is formed in the copper tube body. The spiral guide groove extends from one end of the copper tube body to the other end of the copper tube body. A turbulence tooth group is further arranged on the inner side of the copper tube body, and the turbulence tooth group and the spiral guide groove extend in a double-helix shape. The turbulence tooth group comprises a plurality of turbulence tooth teeth located in the straight tooth grooves. By the adoption of the heat exchange copper tube provided with the straight internal threads, tooth patterns can be prevented from being damaged in the tube expanding process, the flowing resistance is reduced, the flowing turbulence degree is increased, the heat exchange efficiency is improved, and the heat exchange copper tube provided with the straight internal threads is convenient to machine.

Owner:ZHEJIANG NAILE COPPER +1

Cookware for electromagnetic oven as well as dedicated fixture and producing process thereof

InactiveCN102151066AReduce distortionReduce chance of unevennessCooking vesselsHeat conductingEngineering

The invention relates to the technical field of cookware, and particularly relates to cookware for an electromagnetic oven as well as a dedicated fixture and a producing process thereof. The cookware comprises an aluminum pot body and an iron bottom plate which are cast into a whole, as well as at least one bolt, wherein a plurality of hooks are arranged on the iron bottom plate, and are embedded into the bottom of the aluminum pot body; a plurality of strip holes are formed on the iron bottom plate; strip ribs formed when aluminum materials are filled into the strip holes are arranged at the bottom of the aluminum pot body; and the nut of the bolt is embedded to the bottom of the aluminum pot body, while the screw part is positioned in a positioning hole formed on the iron bottom plate. Compared with the conventional similar cookware, the cookware for the electromagnetic oven has a firmer structure, longer service life and a better heat conducting effect.

Owner:DONGGUAN EONTEC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com