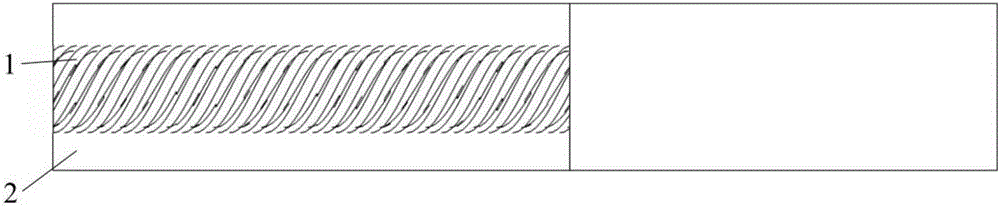

Boiler water-cooled wall inner threaded pipe with streamline-section inner ribs

An internally threaded tube, streamlined technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve problems such as affecting the safe use of internal threaded tubes, damage to heat transfer tubes, temperature differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

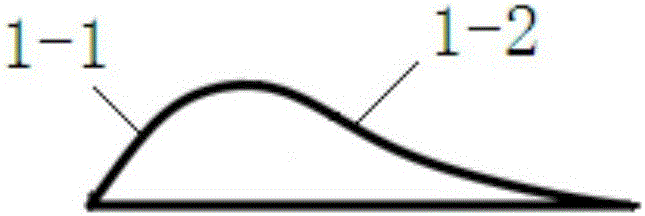

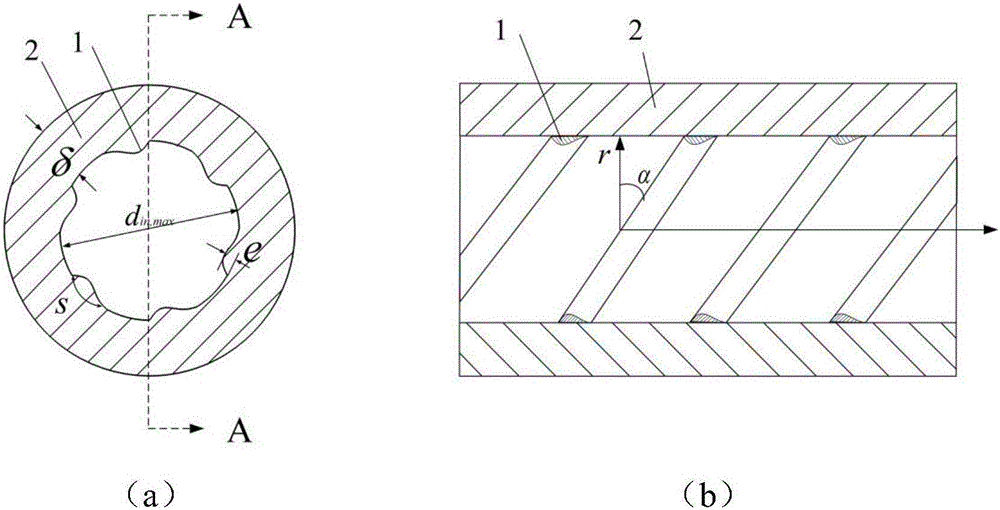

[0031] In this embodiment, the pipe length is taken as 2000mm, the number of thread heads is taken as six, the outer diameter of the pipe is 33.4mm, the largest inner diameter is 20.62mm, the smallest inner diameter is 18.12mm, the lead angle of the thread is 50 degrees, and the circumferential bottom width of the thread is 5.68mm. mm, the height of the highest point of the threaded rib is 1.25mm, the position of the highest point of the rib is at 1 / 3 of the axial bottom width; the thermal load of the inner wall is temporarily taken as 350kW / m 2 , the heat exchange tube is heated under this condition. The heat transfer performance curve of the novel heat transfer tube of this embodiment is as follows Figure 5 (a) and Figure 5 (b) shown. Depend on Figure 5 (a) and Figure 5 It can be seen from the curve in (b): on the cross-section at the same position under the same calculation conditions, the temperature of the inner wall surface of the new type of internally threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com