Patents

Literature

75results about How to "Improve flow pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

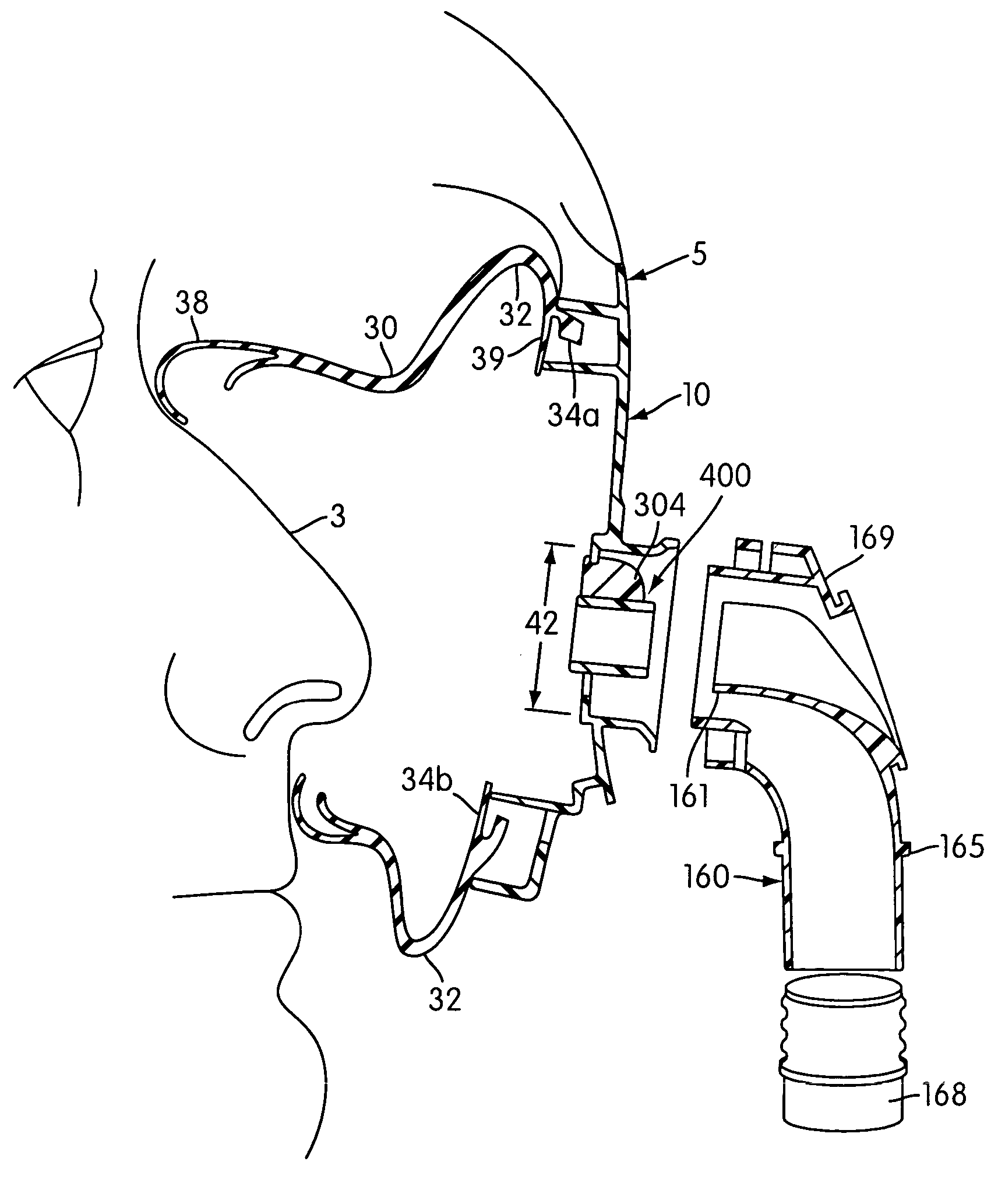

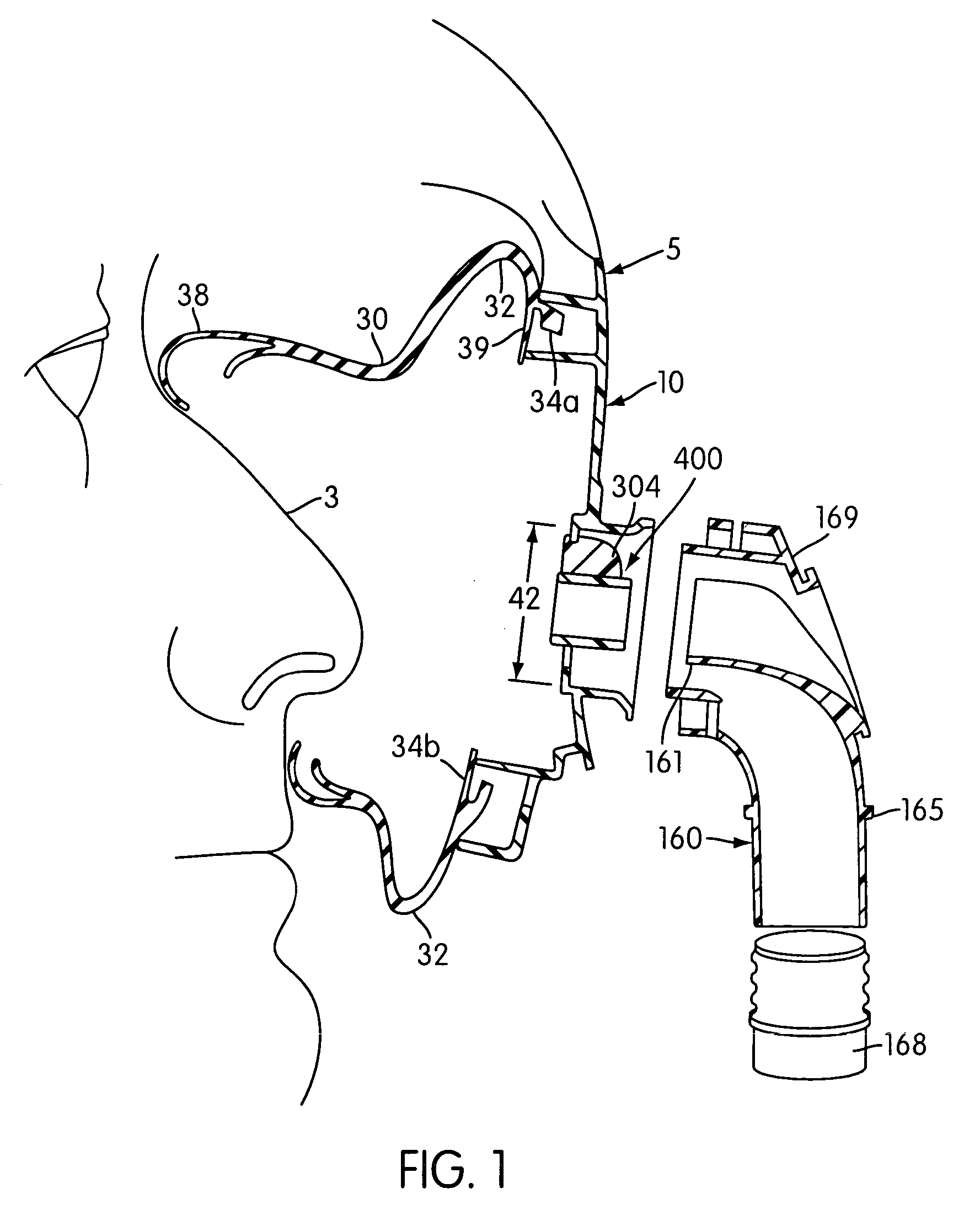

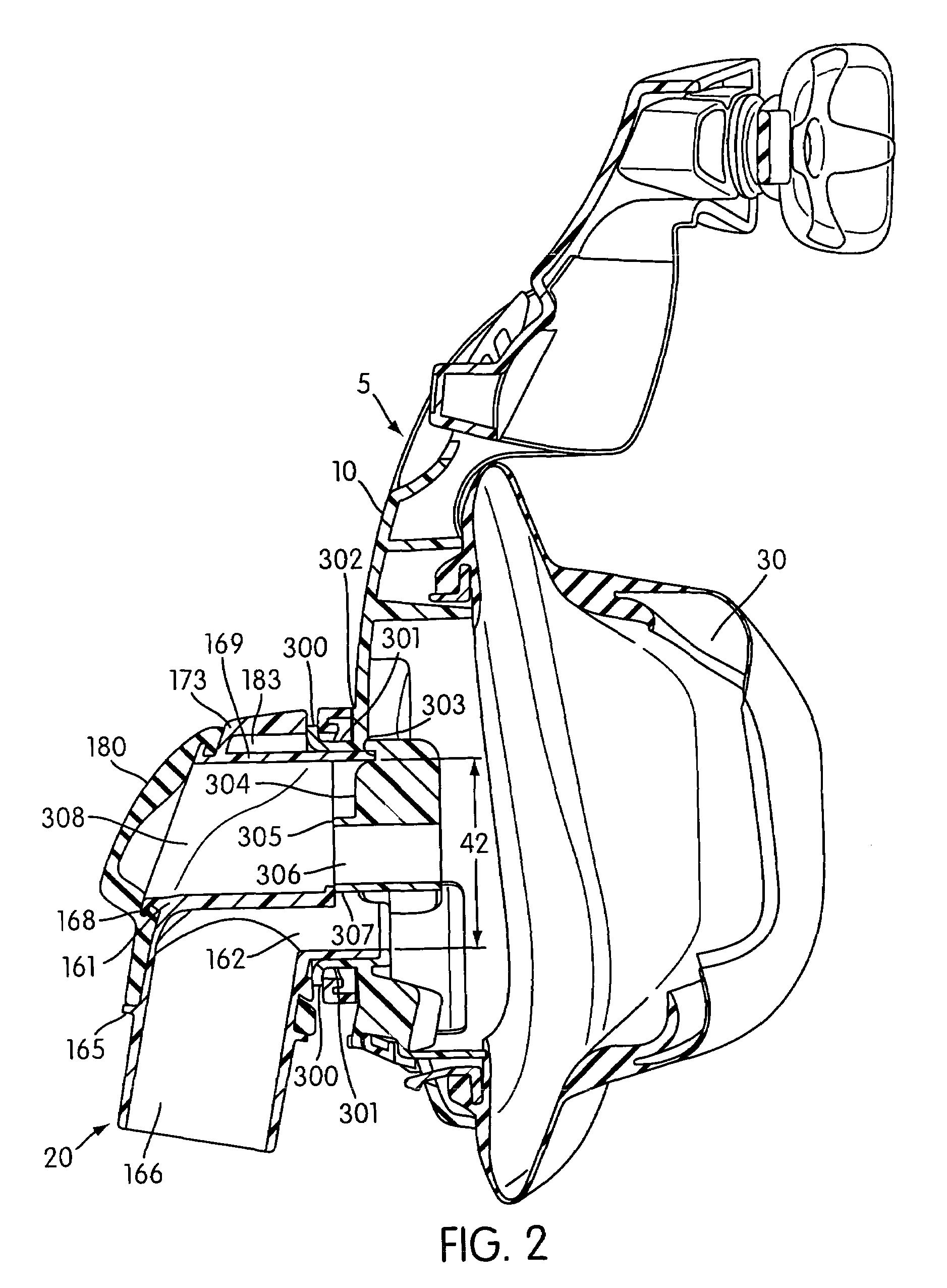

Elbow for mask assembly

InactiveUS7011090B2Improve flow patternEasy to disassembleBreathing masksRespiratory masksRespiratory maskBiomedical engineering

Owner:RESMED LTD

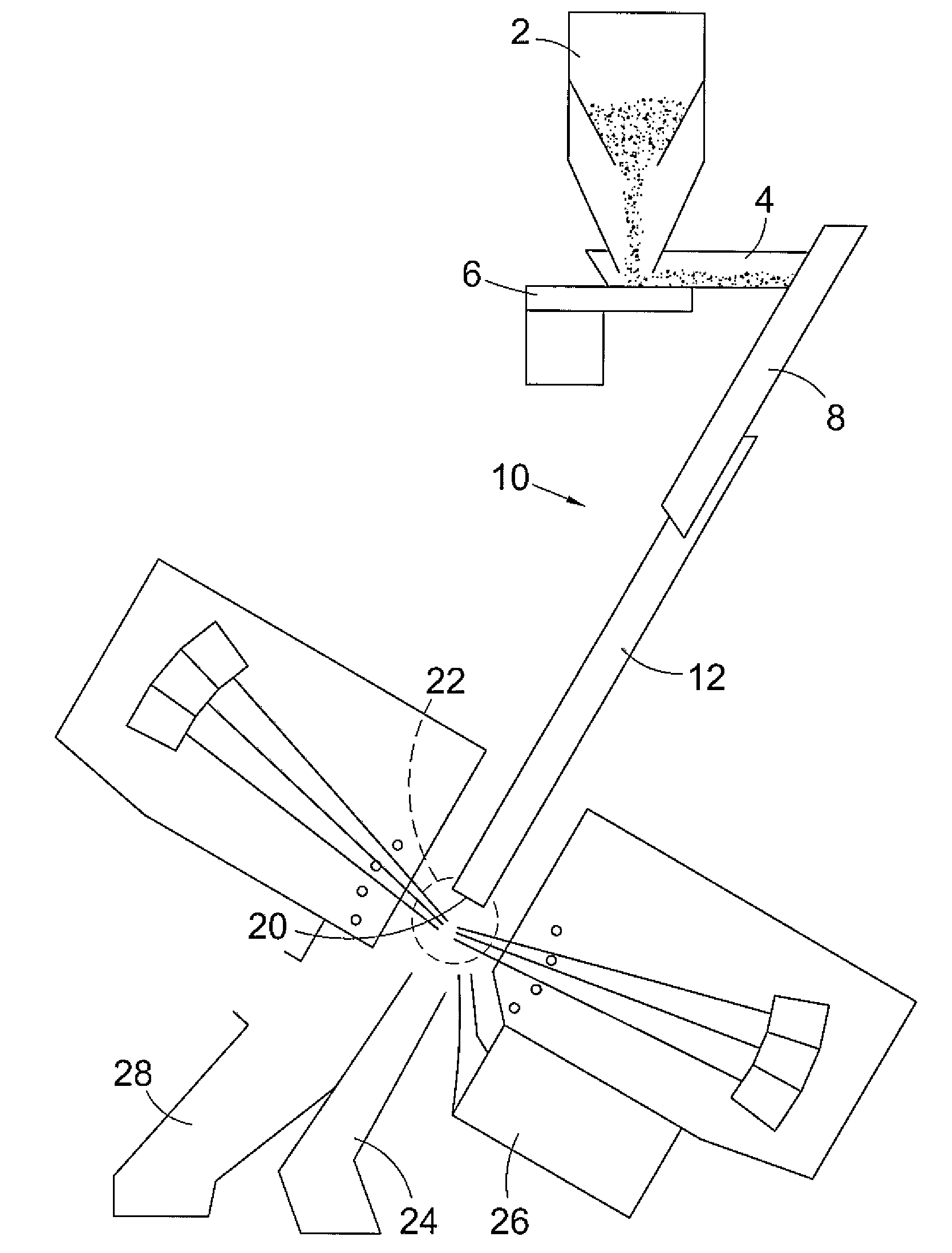

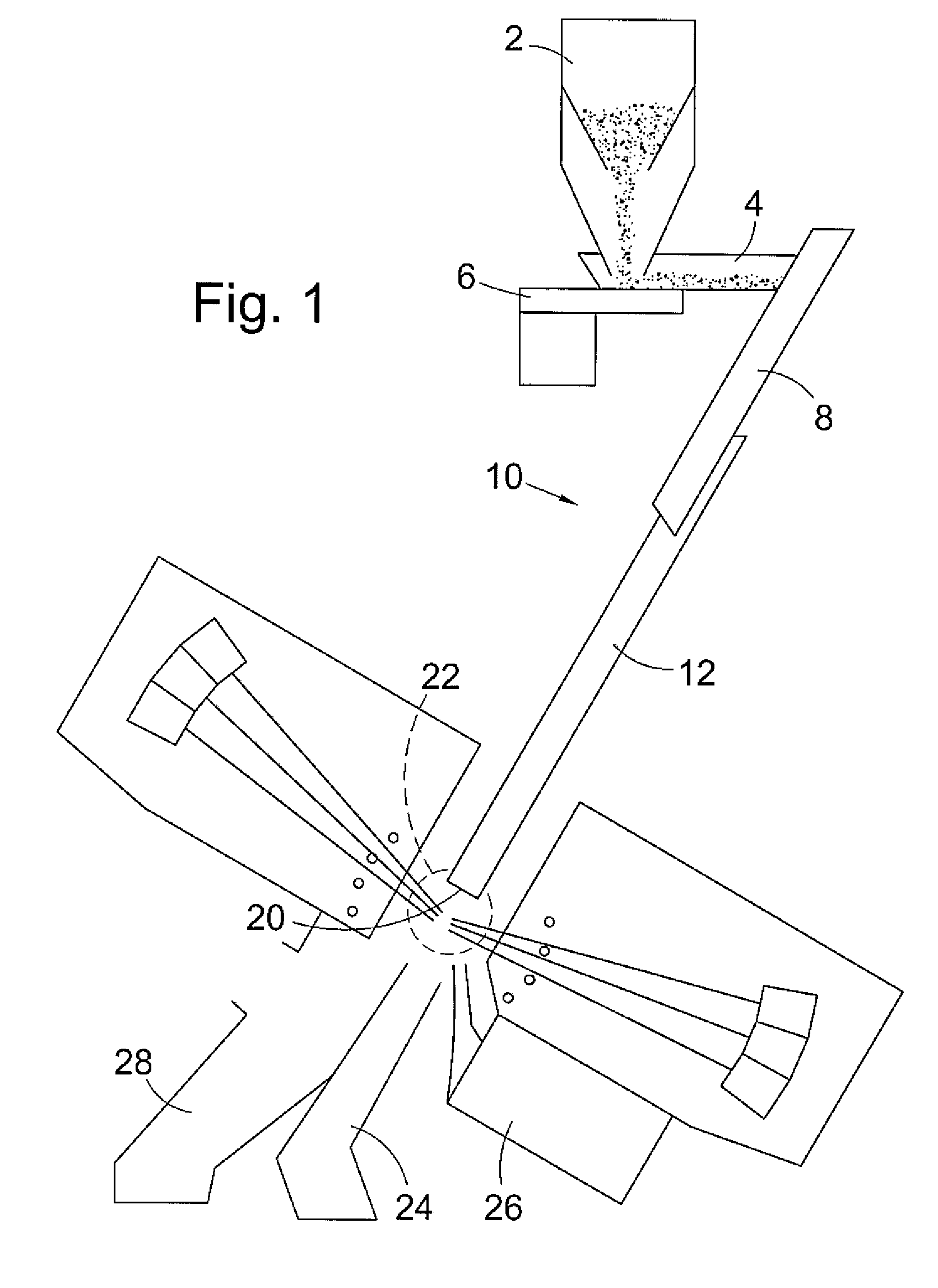

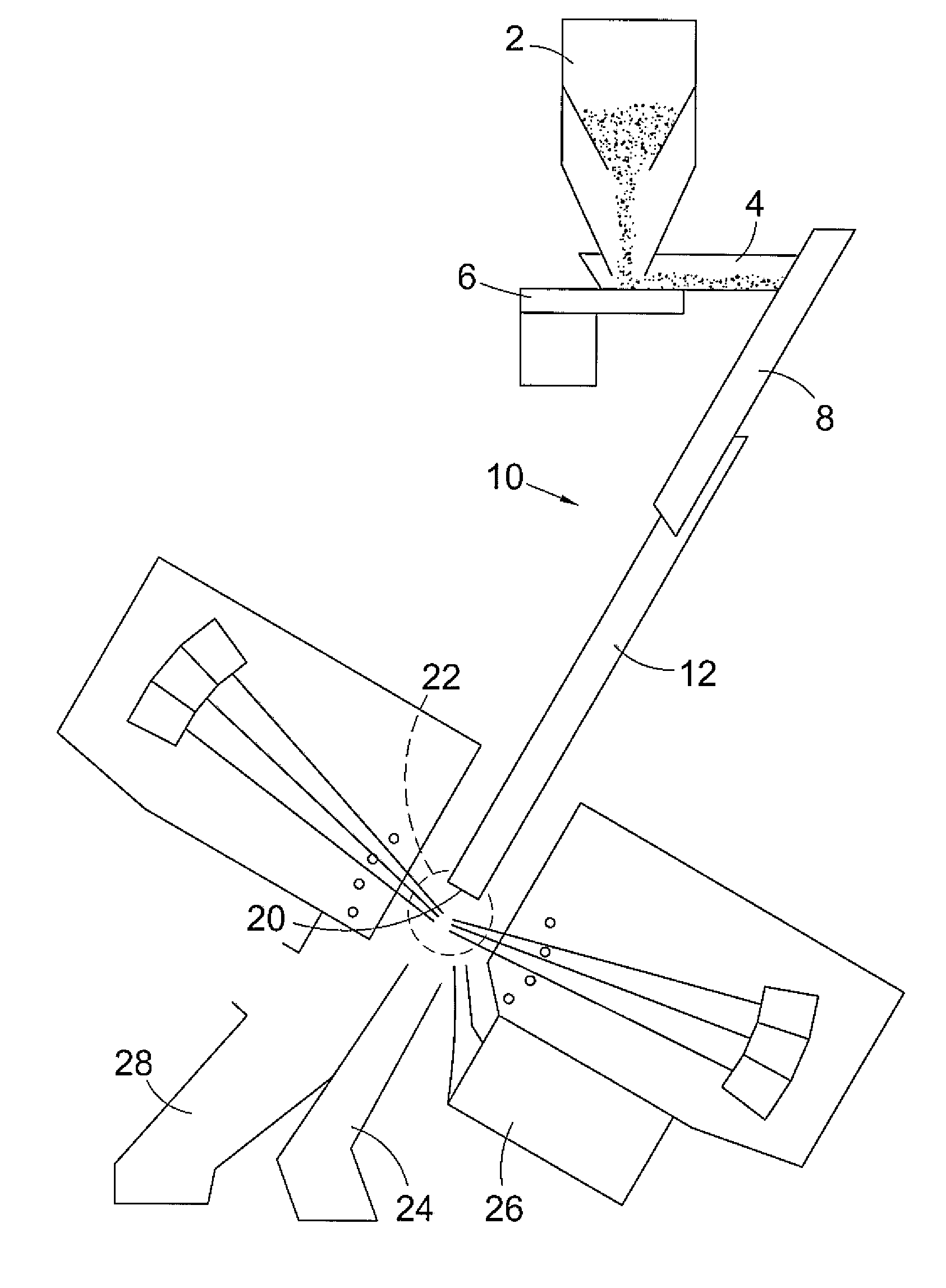

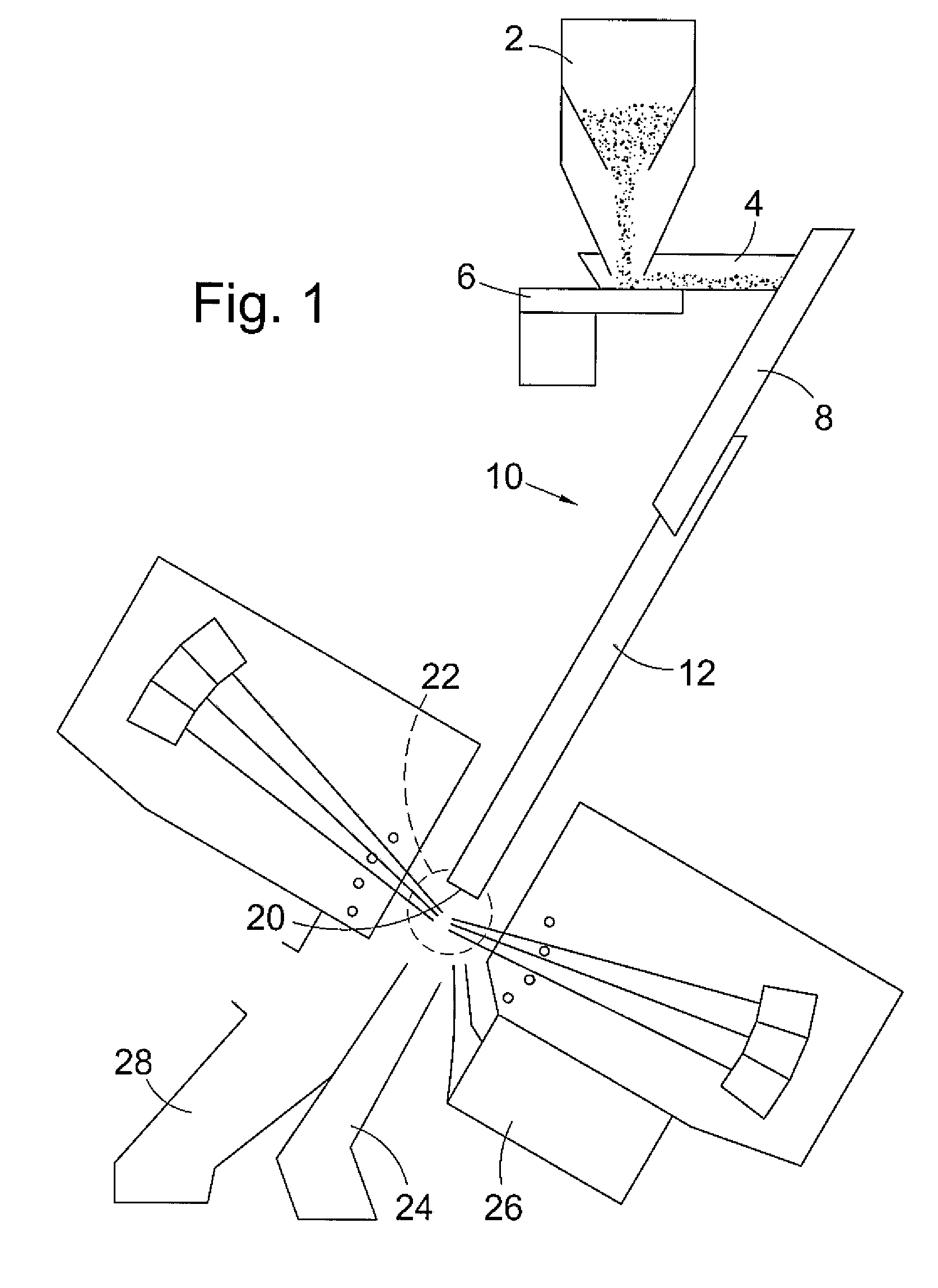

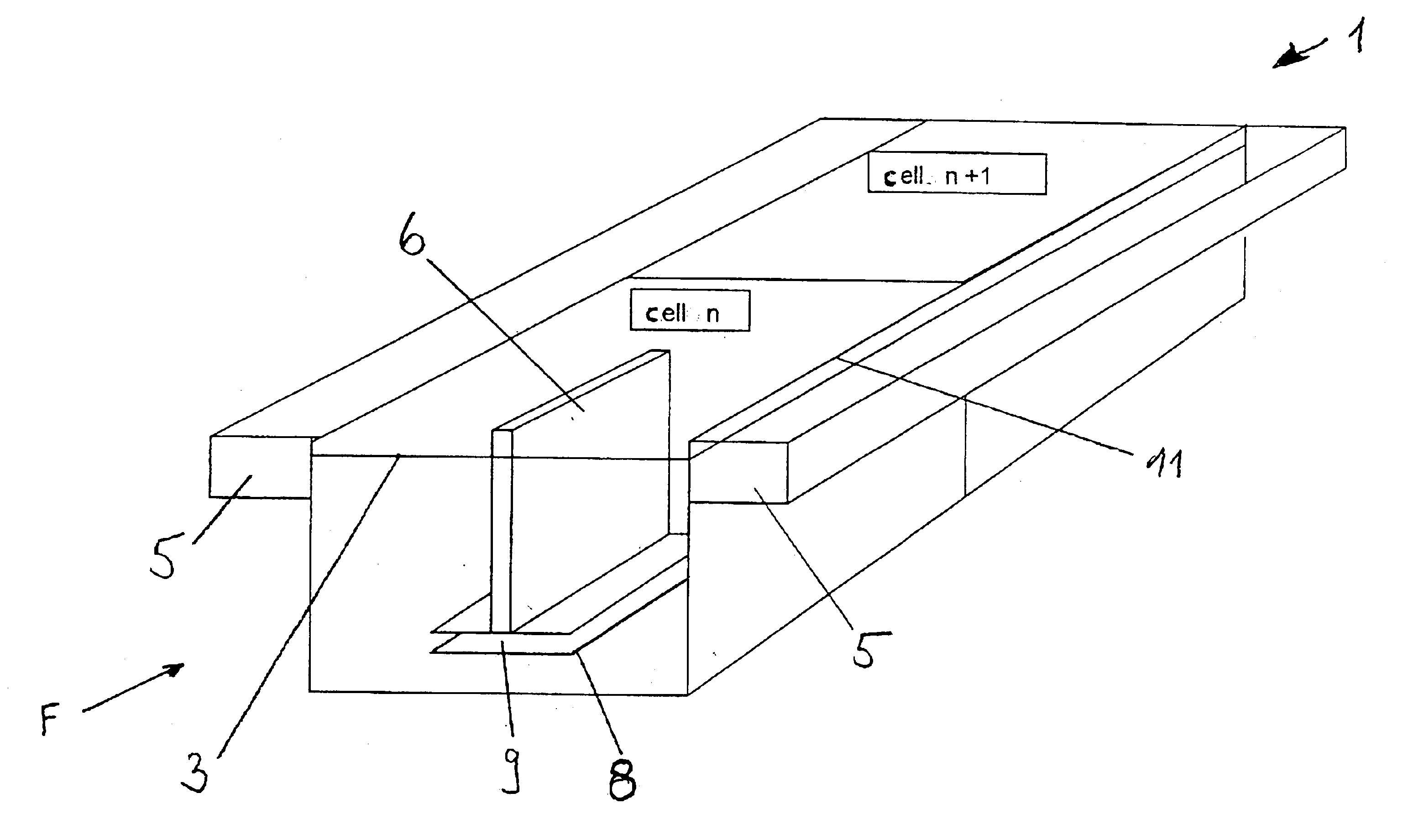

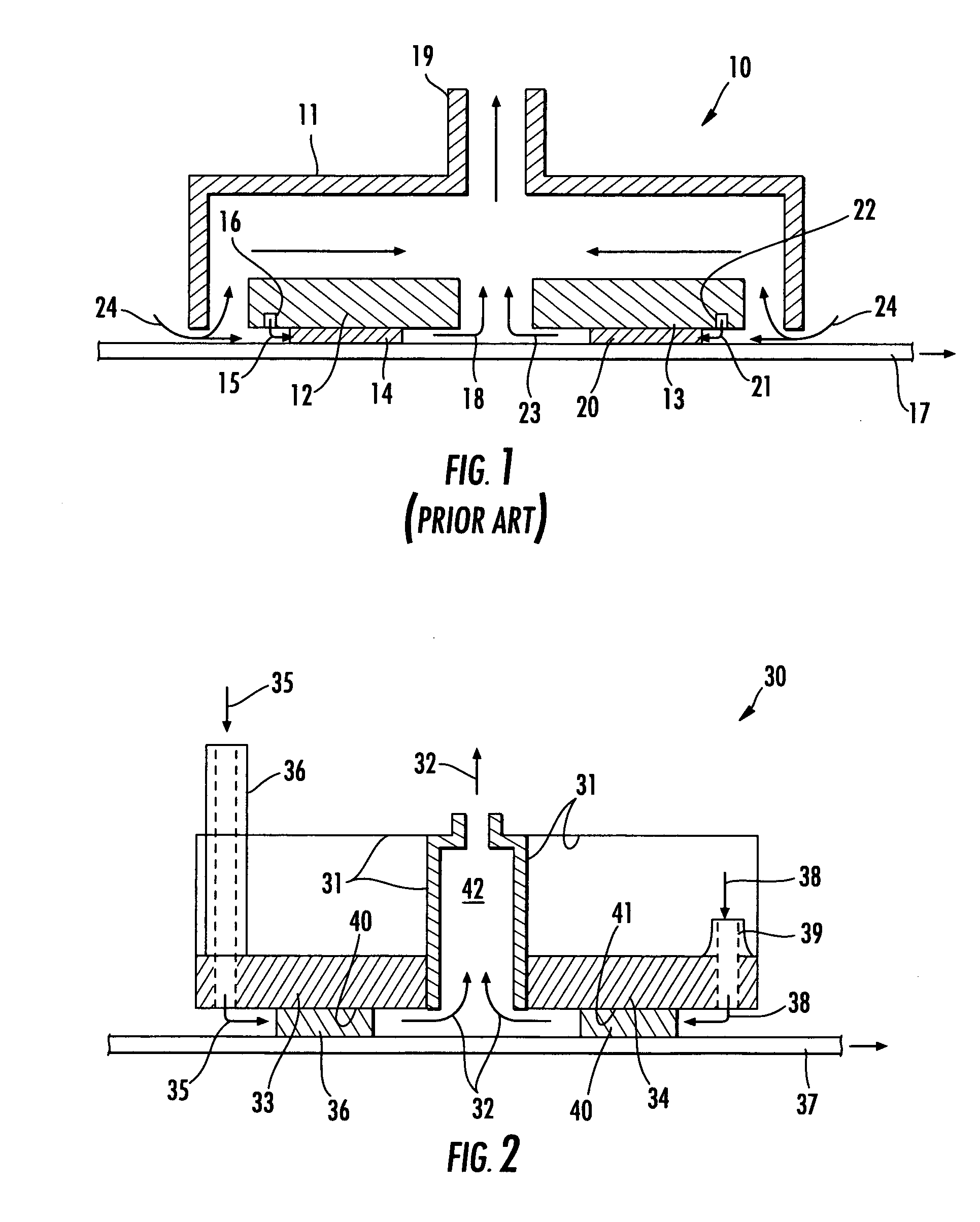

Chutes for Sorting and Inspection Apparatus

ActiveUS20100096300A1Restrict movementPromote differentiationStructural/machines measurementSortingEngineeringMechanical engineering

Owner:BUHLER UK LTD

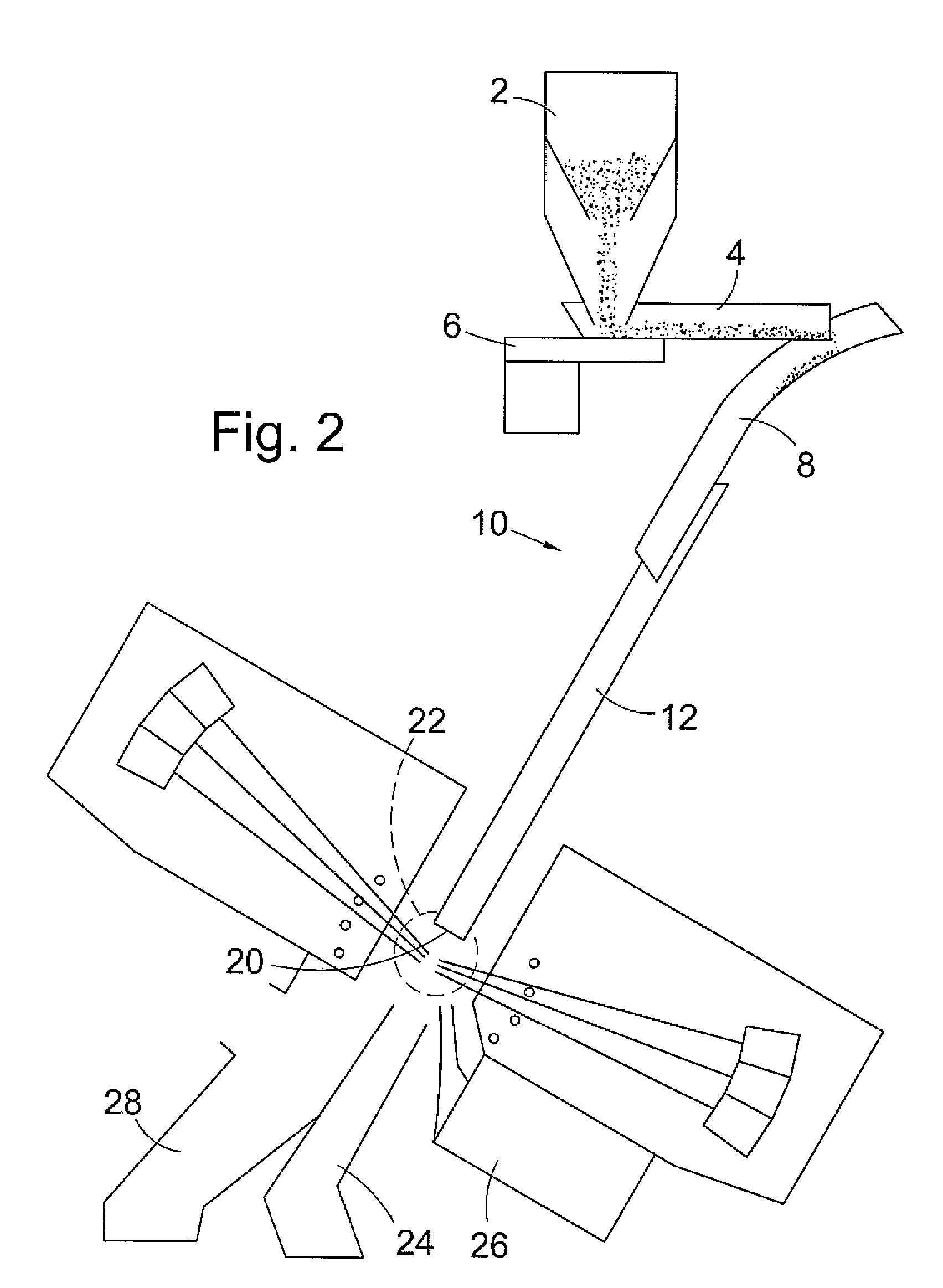

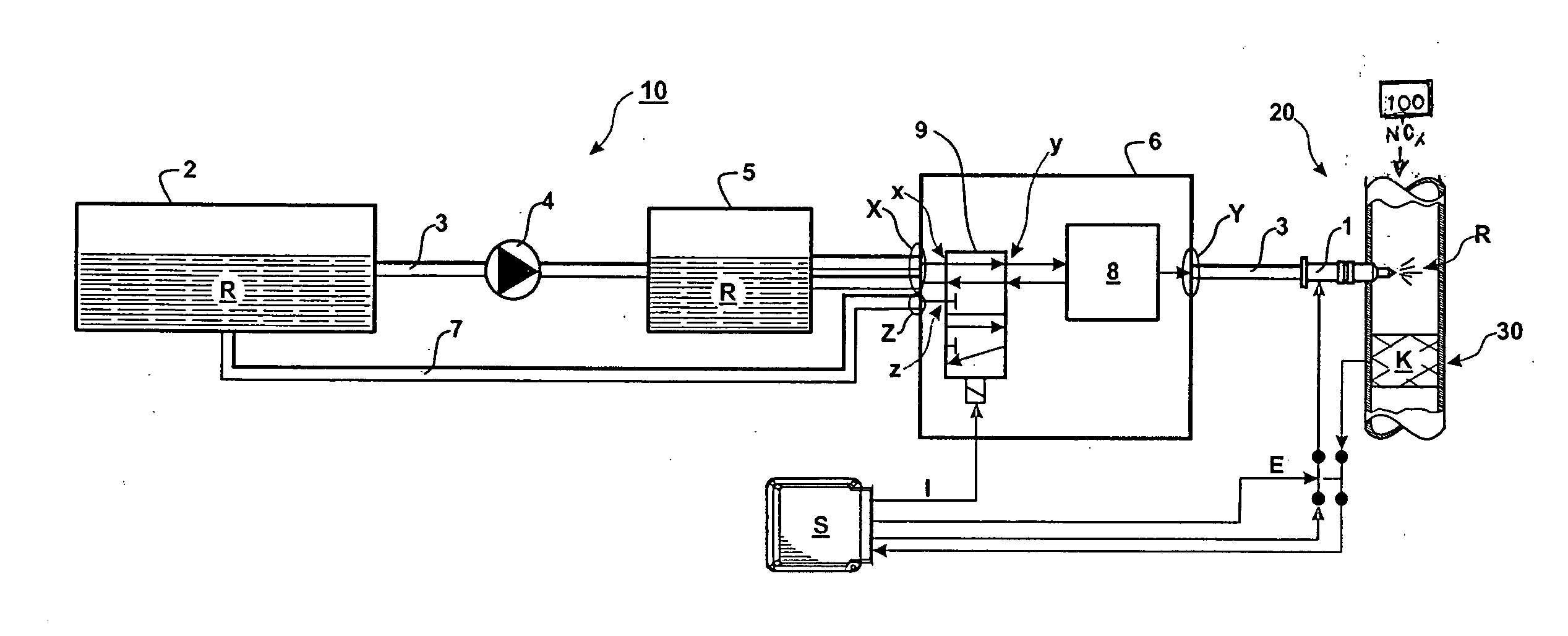

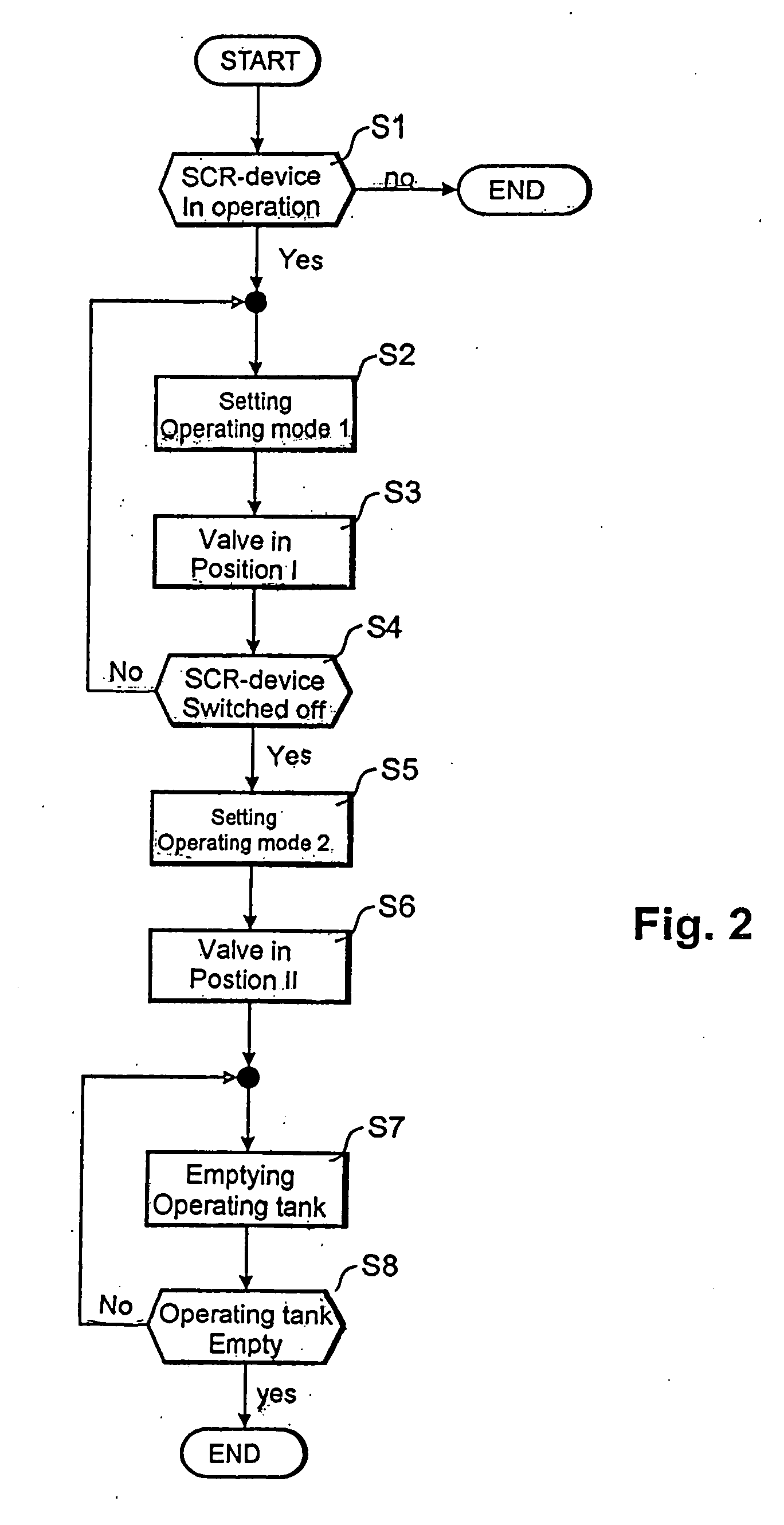

Supply arrangement for supplying an exhaust gas system with a solution including a reduction agent, an internal combustion engine, a generator uint and a method as well as a control arrangement therefor

ActiveUS20120031073A1Reduce arrangementParticularly safe and energy-efficientInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

In a supply arrangement for supplying a solution containing a reducing agent, in particular urea, to an exhaust gas system of an internal combustion engine wherein a supply line extending from a storage tank to an injector which is connected to the exhaust gas system includes an operating tank and a dosing arrangement, a return line extends between the dosing arrangement and the storage tank and the dosing arrangement includes a directional valve for directing solution to the injector during a first operating mode in which the engine is operating and, in a second operating mode in which the engine is shut down, directing the solution back to the storage tank for emptying the operating tank.

Owner:ROLLS ROYCE SOLUTIONS GMBH

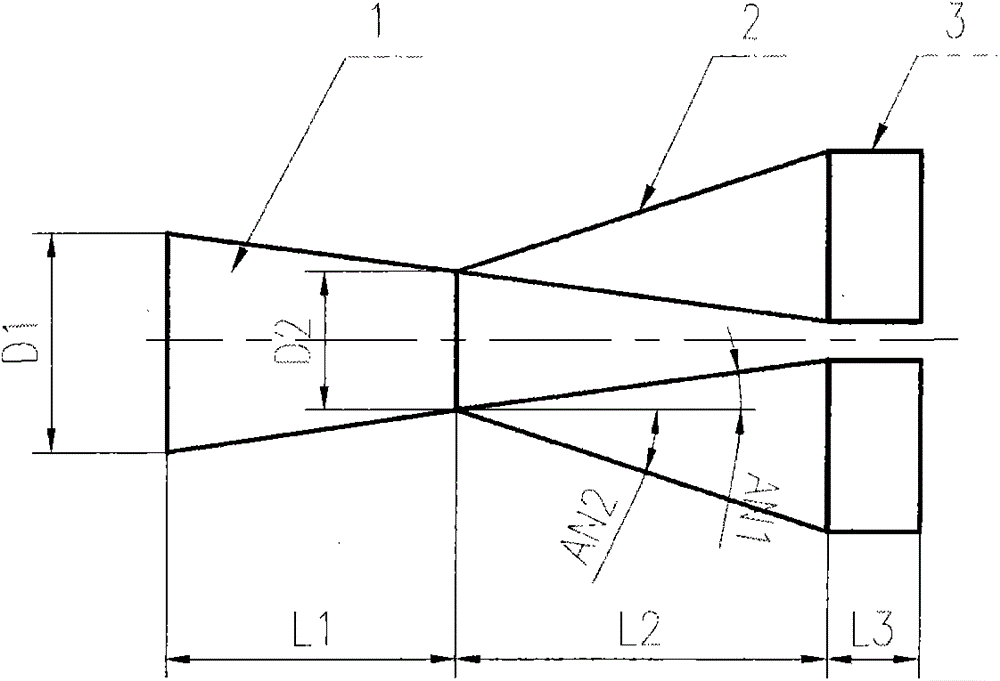

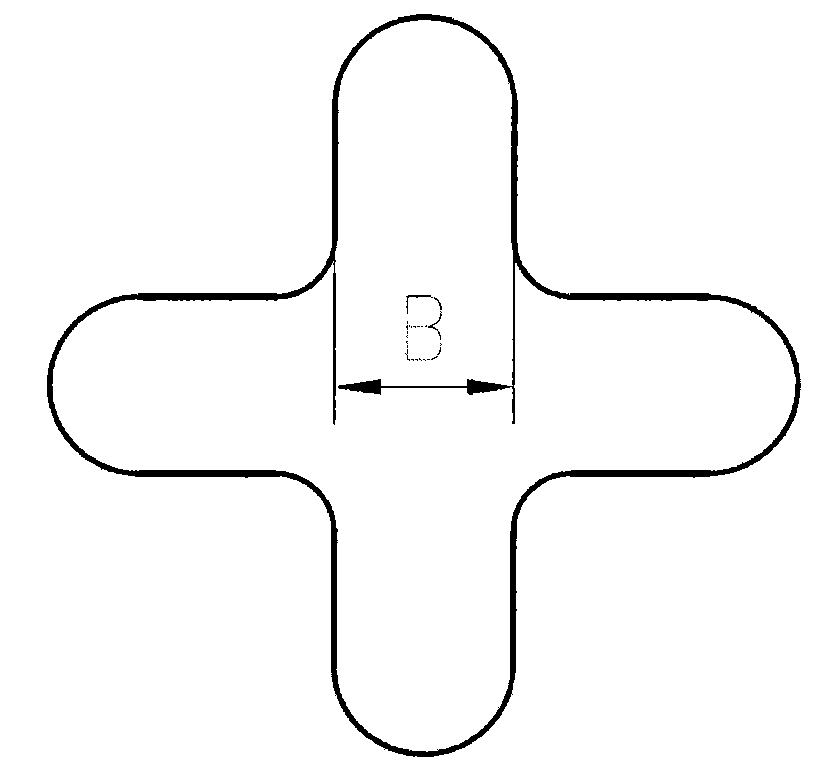

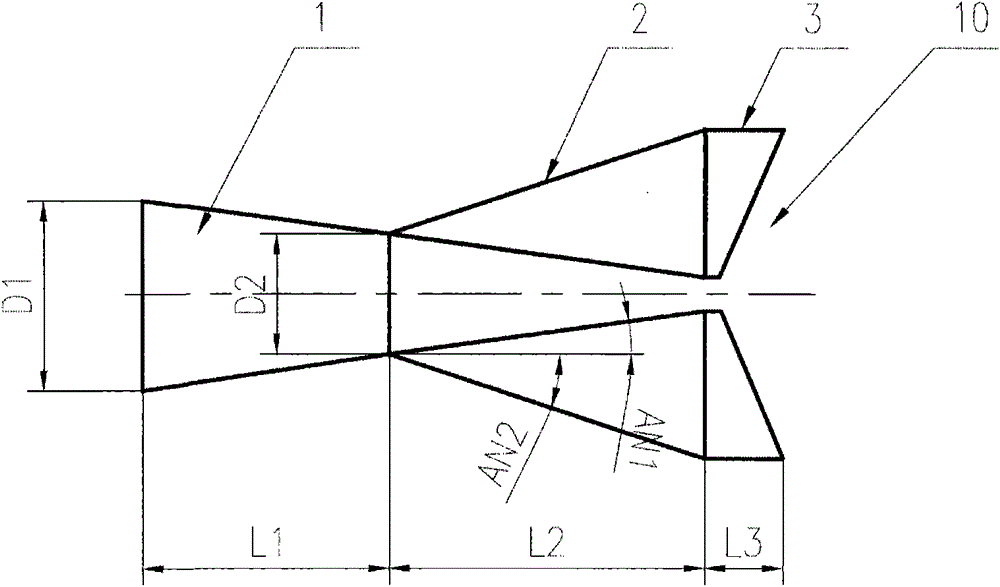

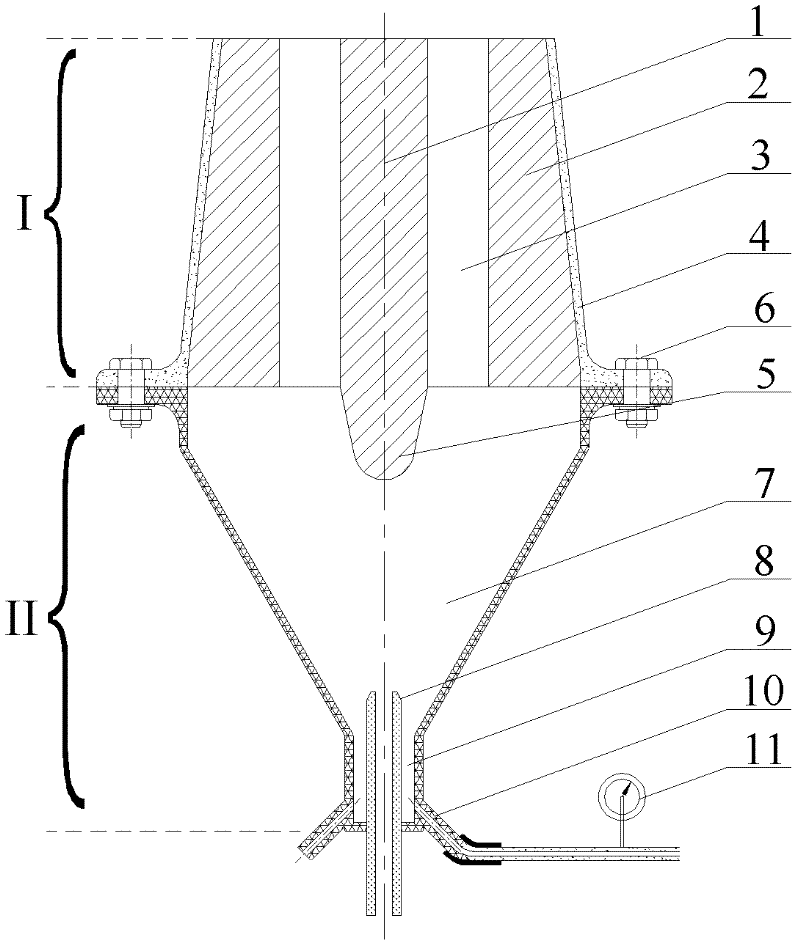

Chrysanthemum-shaped nozzle water injecting and air pumping device and an injection type mixer

The invention provides a subsonic velocity chrysanthemum-shaped nozzle and a water injecting and air pumping device, or an injection type mixer, or a steam injection pressurizing device or a steam injection water heater and other devices equipped with the nozzle. The chrysanthemum-shaped nozzle comprises an inlet section, an outlet section and an extending section which are sequentially connected to form a complete subsonic velocity chrysanthemum-shaped nozzle structure. The water injecting and air pumping device equipped with the subsonic velocity chrysanthemum-shaped nozzle comprises a 1) main stream inlet section, 2) the chrysanthemum-shaped nozzle, 3) a suction chamber and a secondary stream inlet connected with the suction chamber, 4) a diffusion chamber mixing section, 5) a throat part of a diffusion chamber, and 6) a diffusion section of the diffusion chamber. Compared with the existing a large amount of shrinkage tapered nozzles or straight tube shaped nozzles, and the water injecting and air pumping device and other devices equipped with the nozzle. According to the device, the injection coefficients are fundamentally greatly increased according to the mechanism; the working efficiency and adjustable main and secondary stream mixing ratio are greatly increased.

Owner:刘友宏

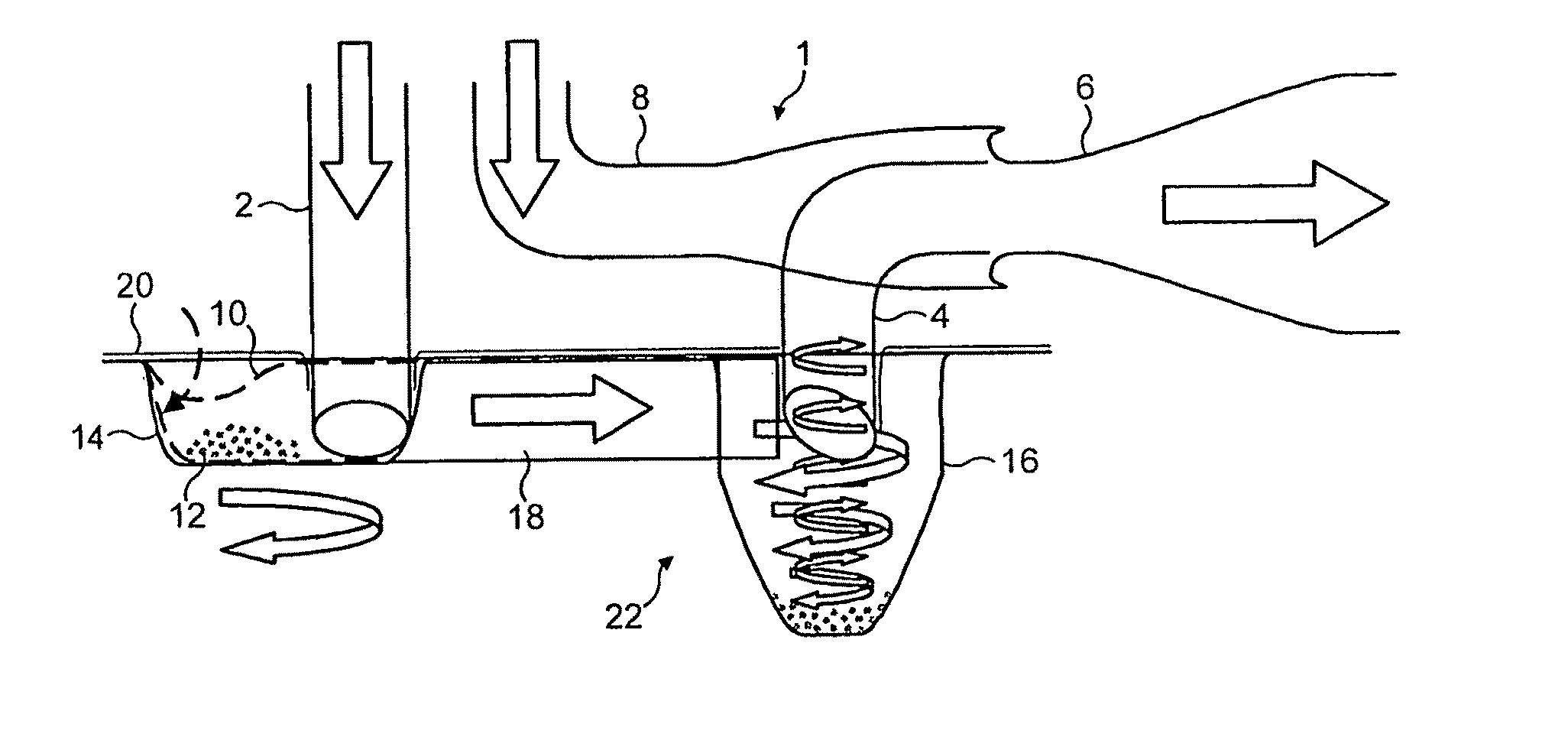

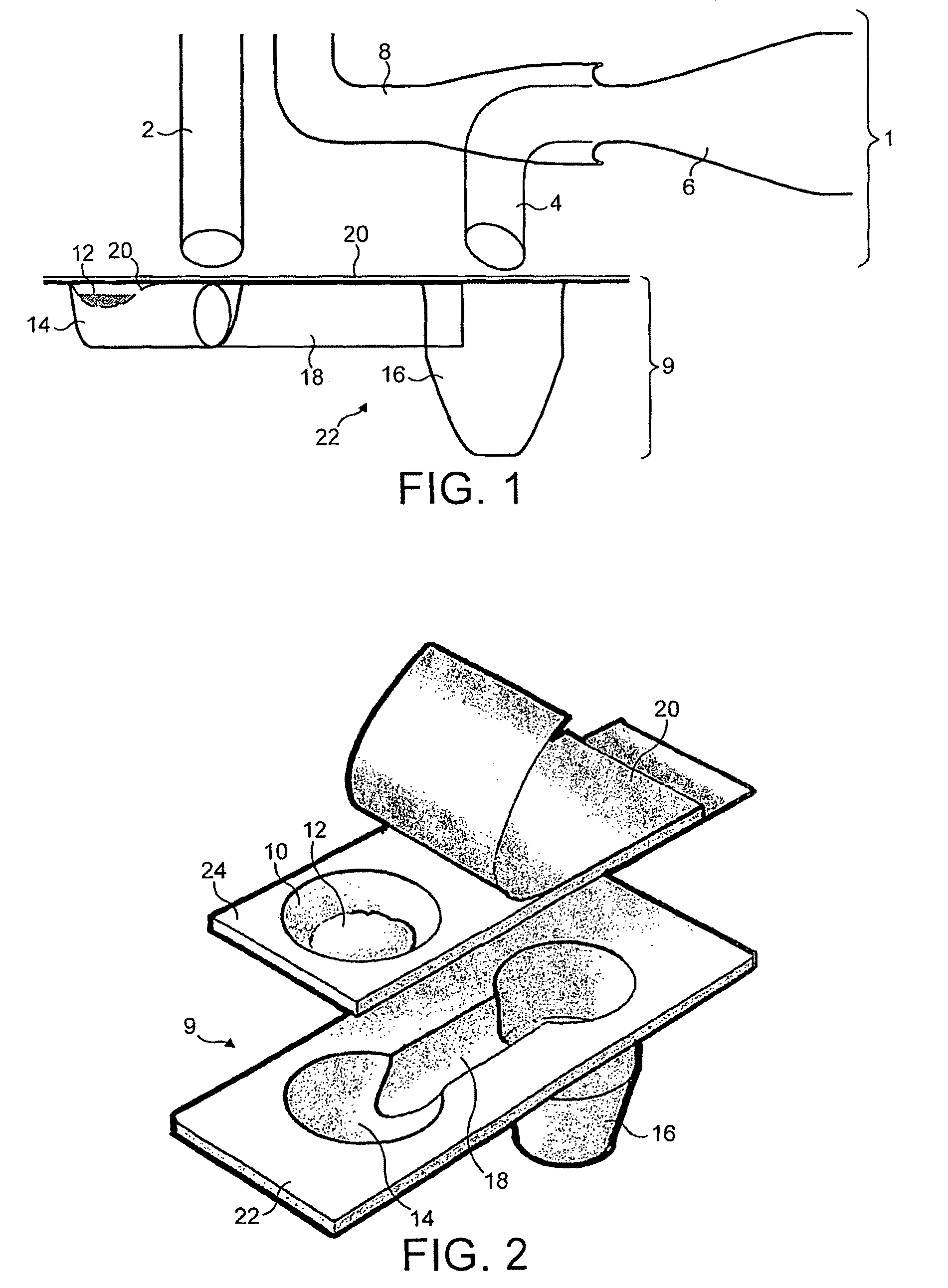

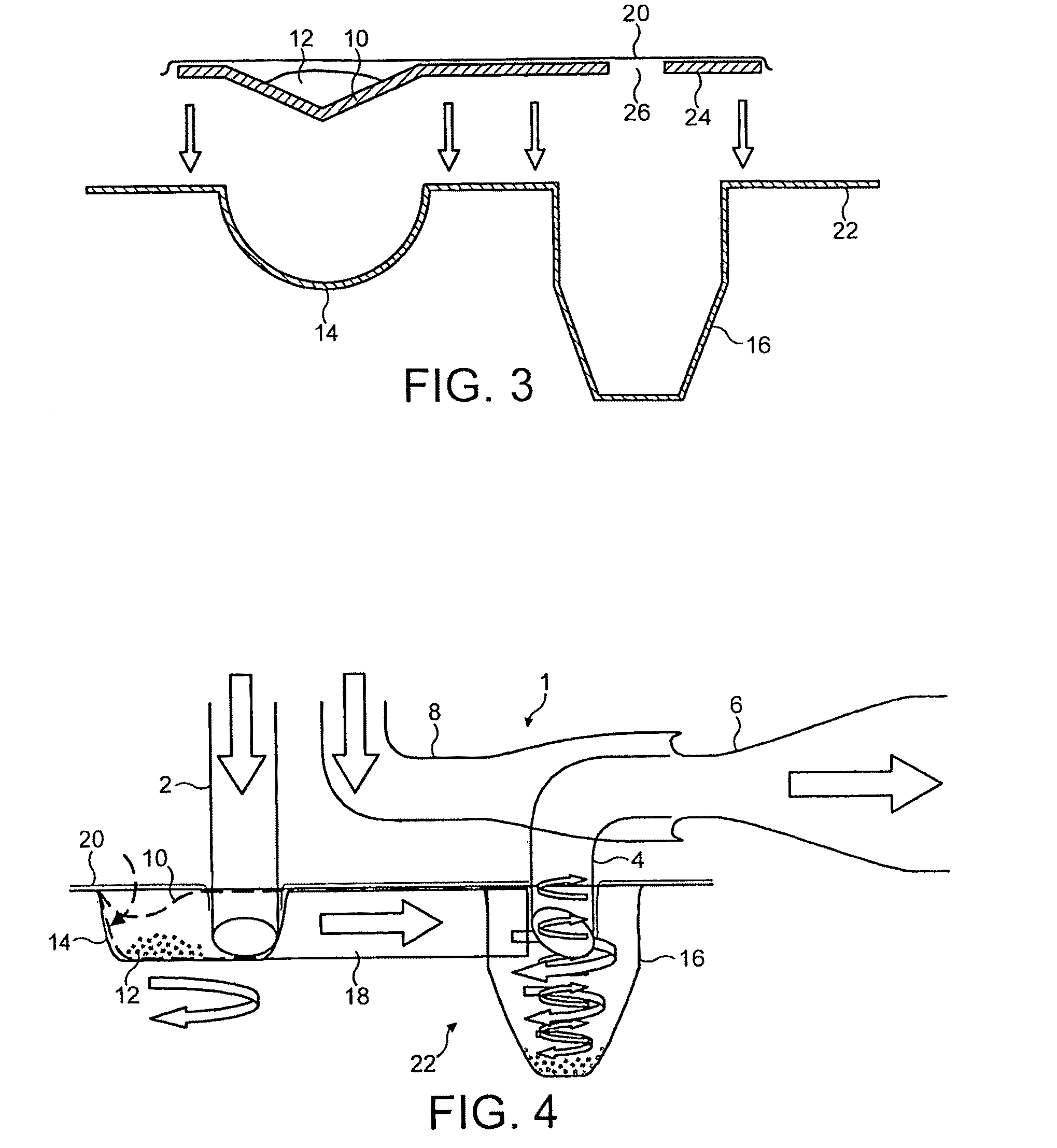

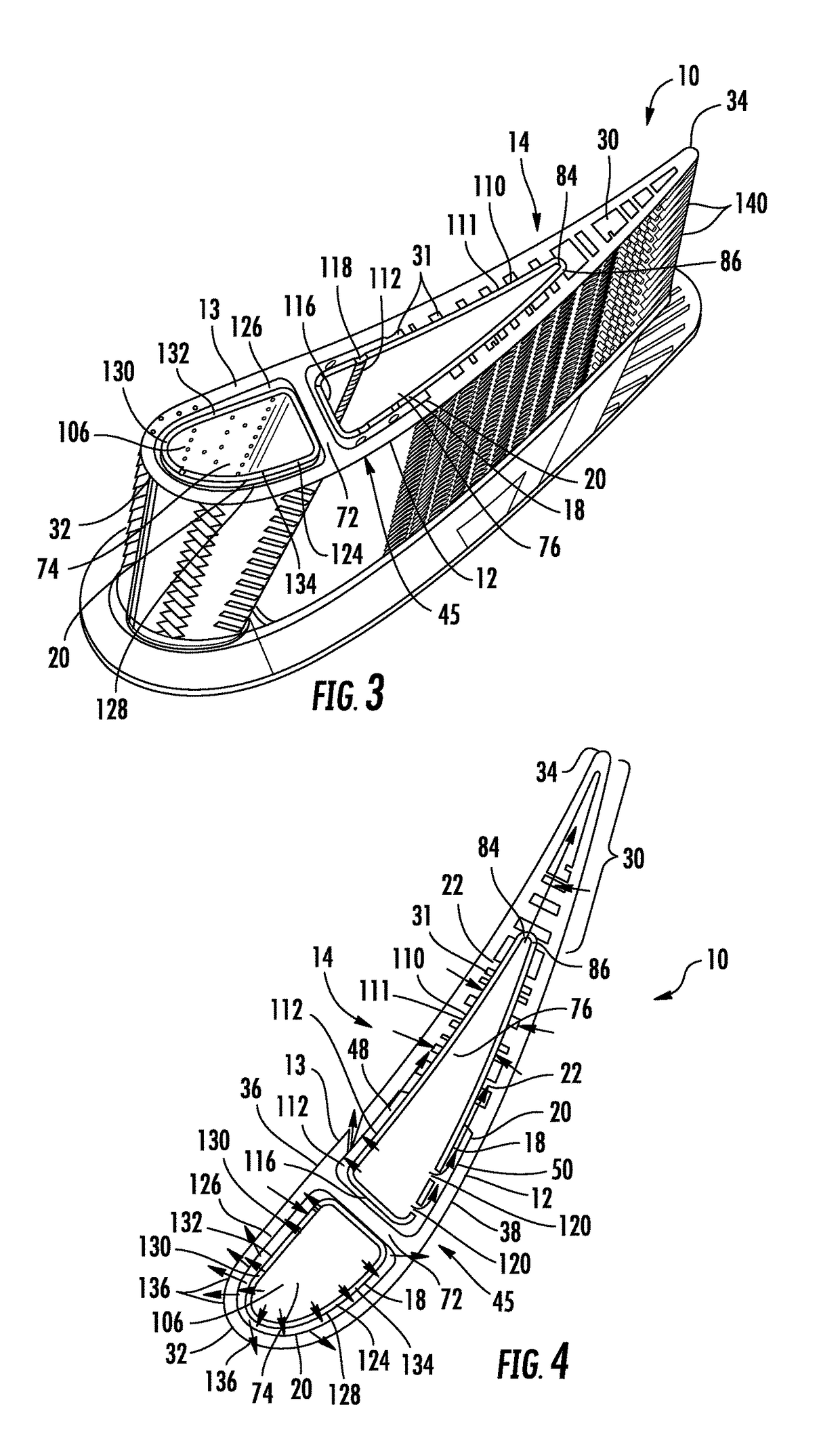

Dry powder inhalers

InactiveUS8261739B2Enhance protection against moistureEnhance contaminationRespiratorsLiquid surface applicatorsCycloneEngineering

A dry powder inhaler has a main airflow path including a cyclone chamber (16) having an air inlet and being so shaped that at least a part of the chamber decreases in cross-sectional area in a direction away from the air inlet, so as thereby in use to set up a reverse flow cyclone in the chamber. A bypass airflow path (8) bypasses the cyclone chamber and the main and bypass airflow paths communicate with a mouthpiece (6). The cyclone chamber may be provided by a part (22) which is removable from the rest of the inhaler for regular replacement thereof.

Owner:CAMBRIDGE CONSULTANTS LTD

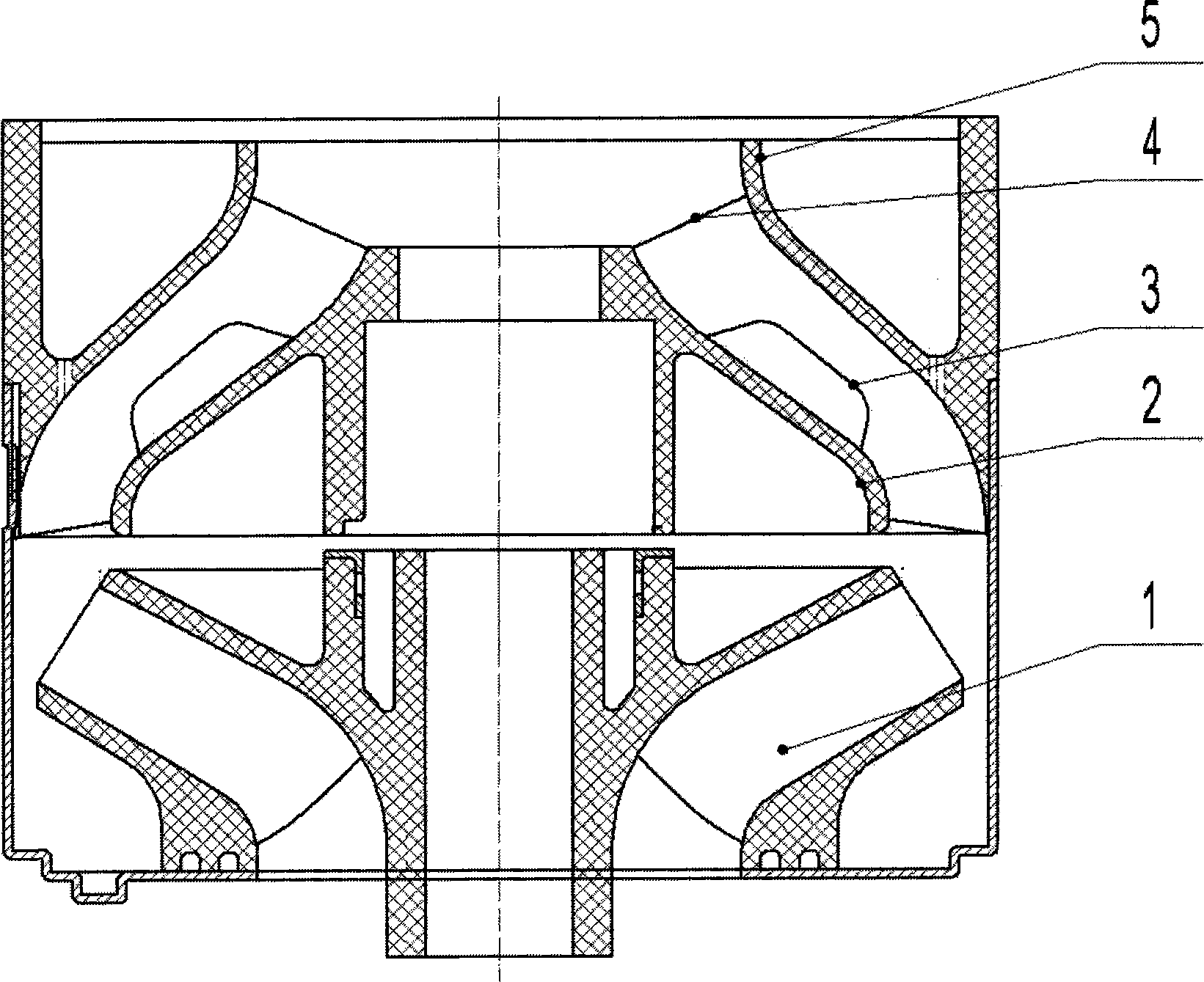

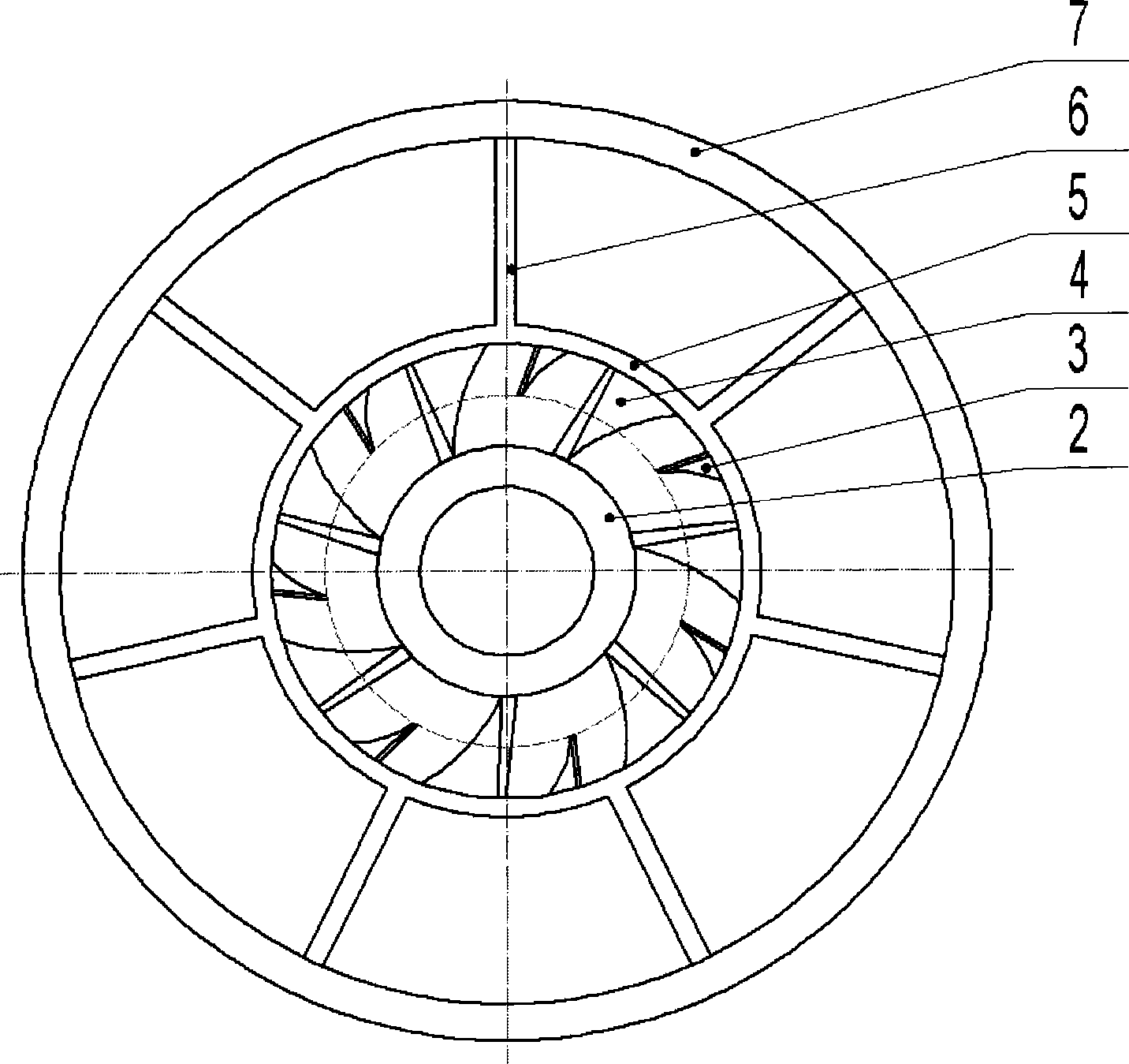

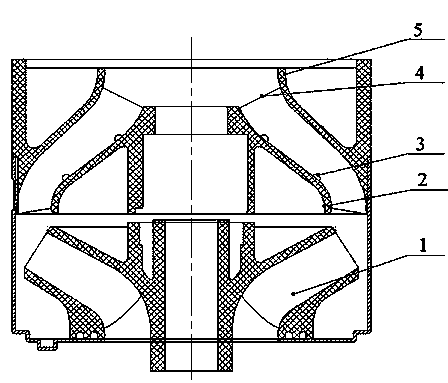

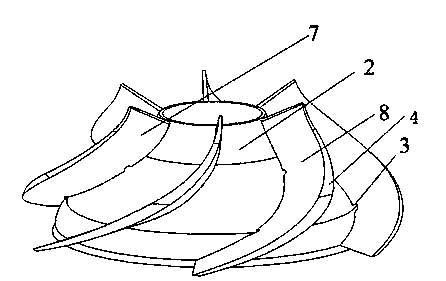

Space guide blade with auxiliary vanes

InactiveCN103591051AImprove overcurrent efficiencySimple structurePump componentsPumpsEngineeringMechanical engineering

The invention discloses a space guide blade which is used for a deep well centrifugal pump or other forms of multi-level centrifugal pumps and provided with auxiliary vanes. The auxiliary vanes are arranged in the middle of all runners of the space guide blade, the change rule of the auxiliary vanes in the axial direction conforms to the streamline shape of vanes of the space guide blade, the thickness of the auxiliary vanes is smaller than that of the vanes of the space guide blade, and the auxiliary vanes occupy small space. The space guide blade is simple in structure, the flowing form that the middle of the space guide blade is attached to a lower cover plate area of the space guide blade can be effectively improved, the probability of vortex and secondary flow is reduced, the hydraulic loss in the runners of the space guide blade can be reduced, and the overflowing efficiency of the space guide blade is improved.

Owner:JIANGSU UNIV

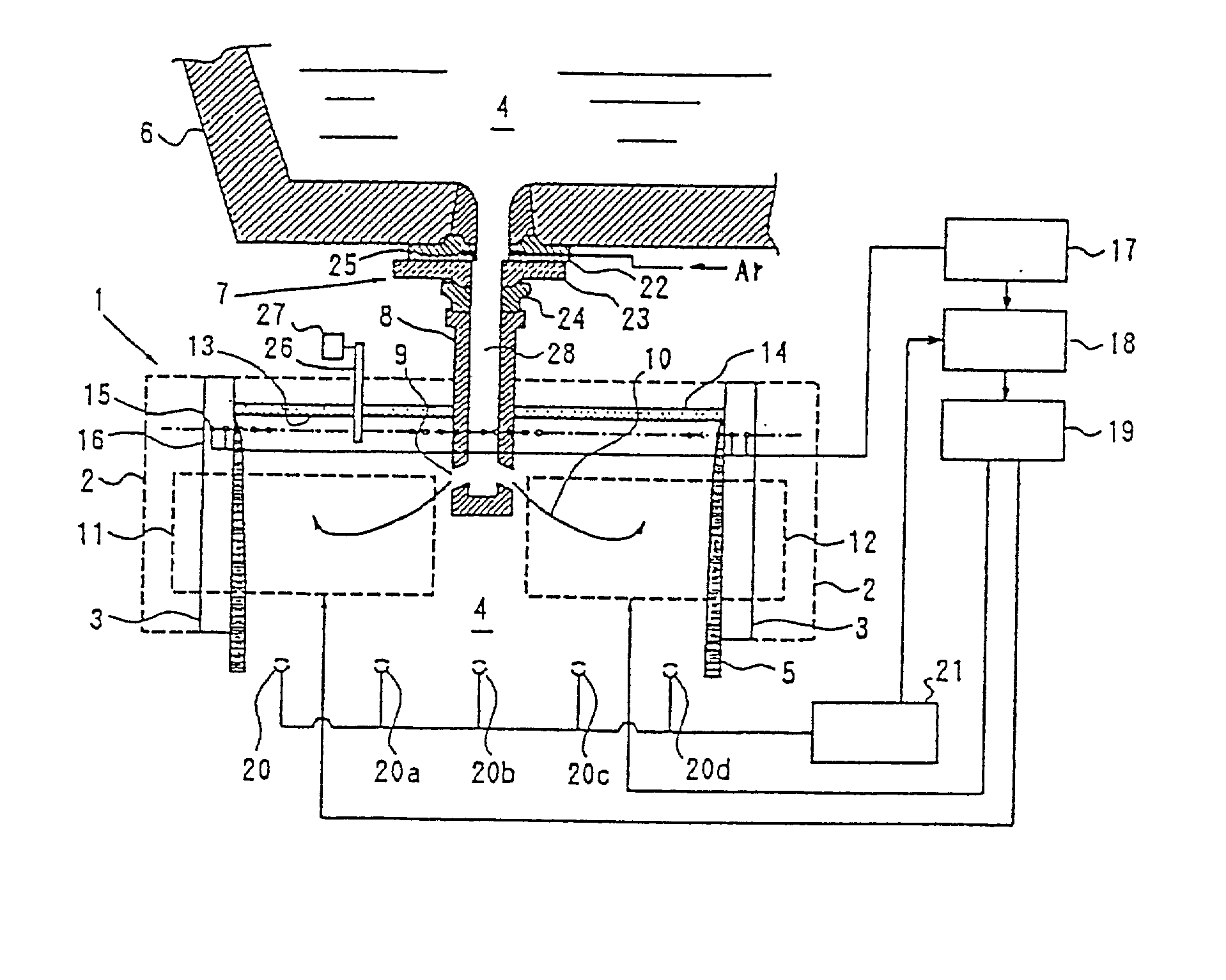

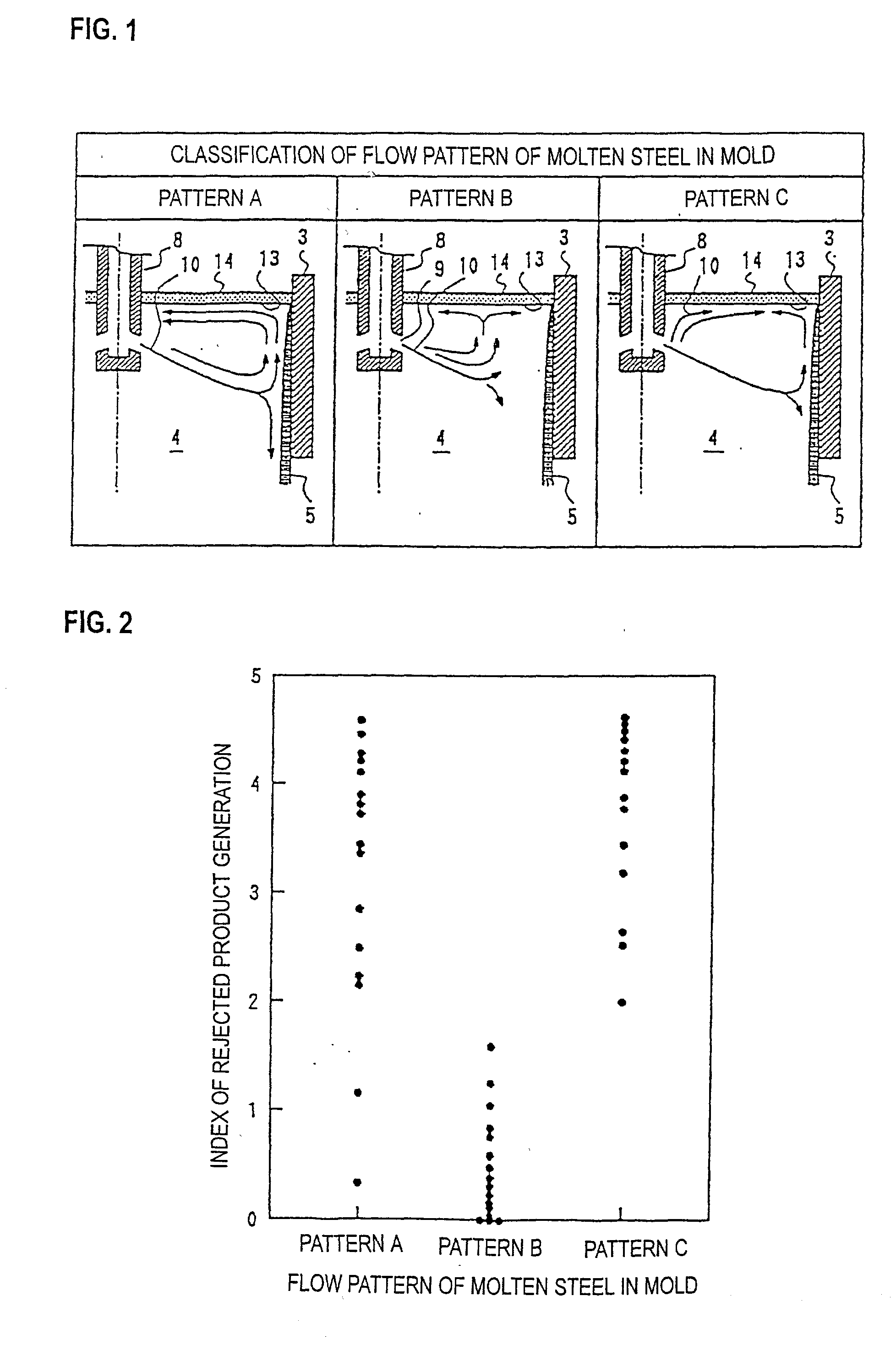

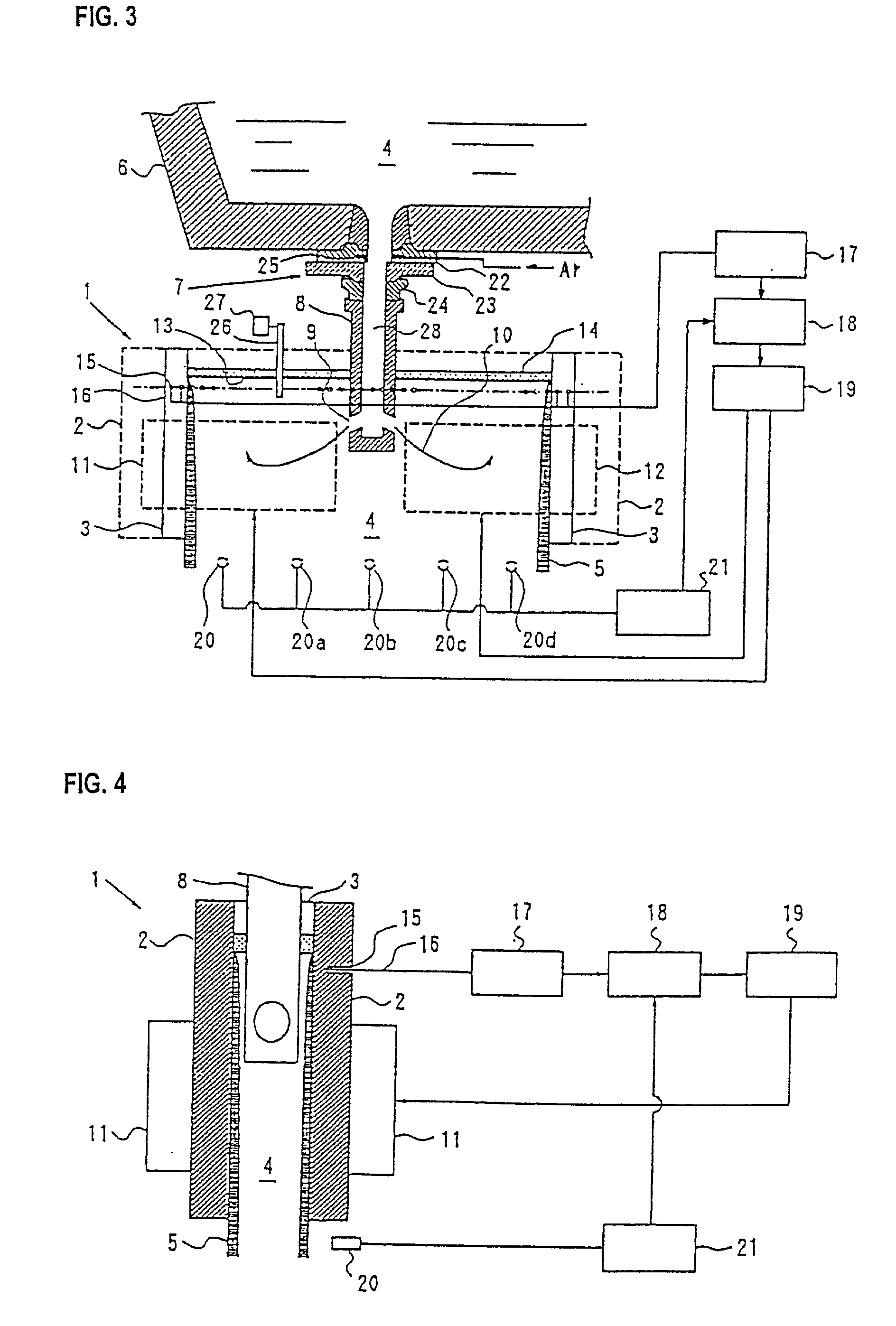

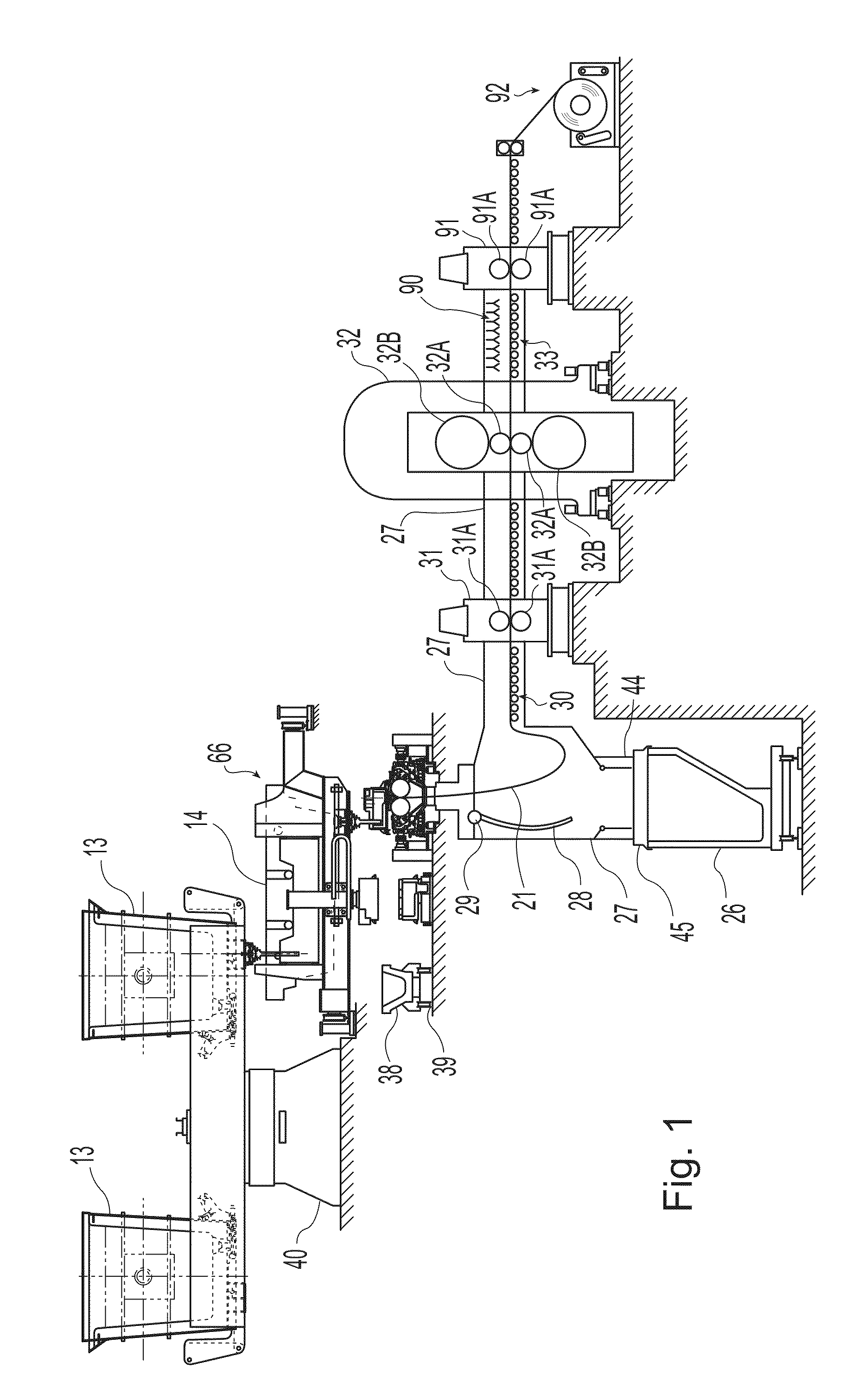

Method for estimating and controlling flow pattern of molten steel in continuous casting and apparatus therefor

InactiveUS20020079083A1Accurate estimateImprove flow patternCasting safety devicesMould controlling devicesTemperature measurementCopper

The method for controlling flow pattern of molten steel in continuous casting, comprises the steps of: (a) continuously casting a molten steel injected through an immersion nozzle; (b) measuring temperatures of a copper plate on longer side of the mold in width direction thereof at plurality of points; (c) detecting a flow pattern of the molten steel in the mold based on the time-sequential variations of temperatures of the copper plate at individual measurement points; and (d) controlling the flow pattern to establish a specified pattern on the basis of the detected result. The temperatures of mold copper plate are measured by plurality of temperature measurement elements buried in the rear face of the mold copper plate for continuous casting. The temperature measurement elements are arranged in a range of from 10 to 135 mm distant from the melt surface in the mold in the slab-drawing direction.

Owner:NIPPON KOKAN KK

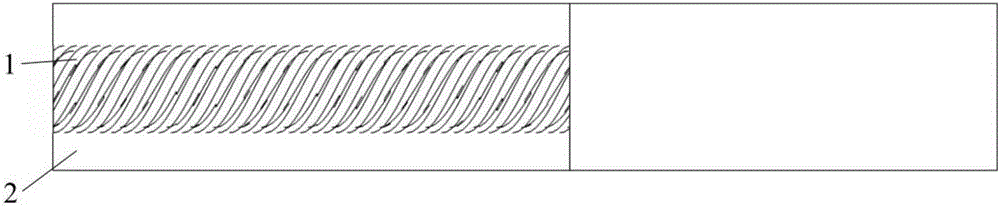

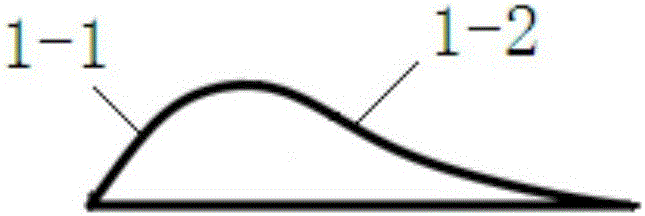

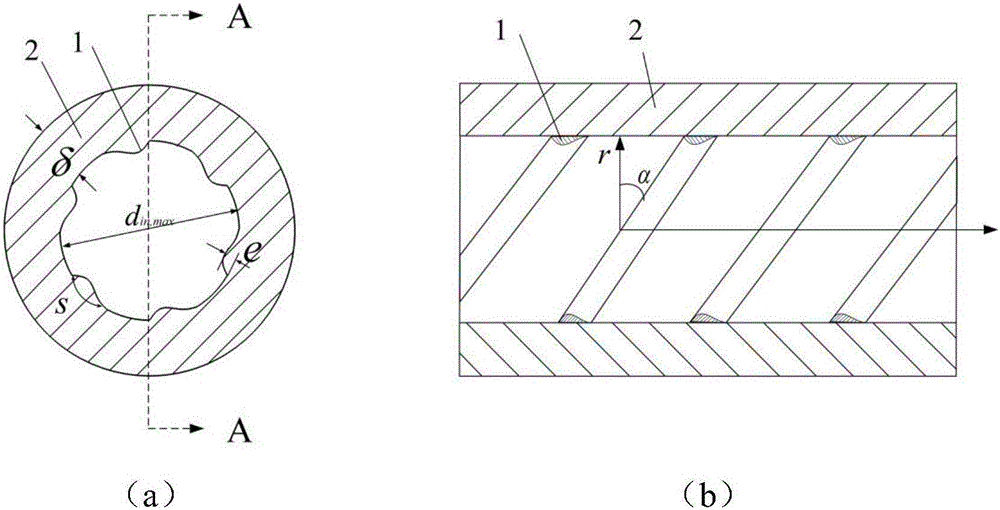

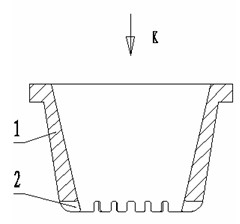

Boiler water-cooled wall inner threaded pipe with streamline-section inner ribs

ActiveCN105806127AImprove heat transfer performanceImprove heat transfer efficiencyCasings/liningsSteam boilersThreaded pipeEngineering

The invention discloses a boiler water-cooled wall inner threaded pipe with stream-line-section inner ribs. The boiler water-cooled wall inner threaded pipe comprises a pipe body and the ribs spirally arranged on the inner wall of the pipe body in the axial direction, wherein the cross sections of the ribs are in streamline shapes. The ribs which are spirally arranged are distributed at equal intervals, and the number of the ribs is 4 to 8. The included angle between the spiral direction of the ribs and a cross section is controlled within the range of 30 degrees to 60 degrees. The circumferential bottom width of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 4 mm to 10 mm. The height of the highest point of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 0.5 mm to 1.5 mm. The position of the highest point of the ribs is at the position of one third of the rib bottom width. By means of the novel boiler water-cooled wall inner threaded pipe, vortexes on the back flow sides of the ribs are avoided or reduced through the streamline inner ribs, so that the heat transfer capability of the inner wall face of the pipe is effectively improved, and the temperature level near rib roots on the back flow sides of the ribs is lowered. Therefore, the heat transfer performance of the boiler water-cooled wall inner threaded pipe can be further enhanced through the pipe shape.

Owner:XI AN JIAOTONG UNIV

Chutes for sorting and inspection apparatus

ActiveUS8247724B2Promote differentiationImprove flow patternStructural/machines measurementSortingEngineeringMechanical engineering

Owner:BUHLER UK LTD

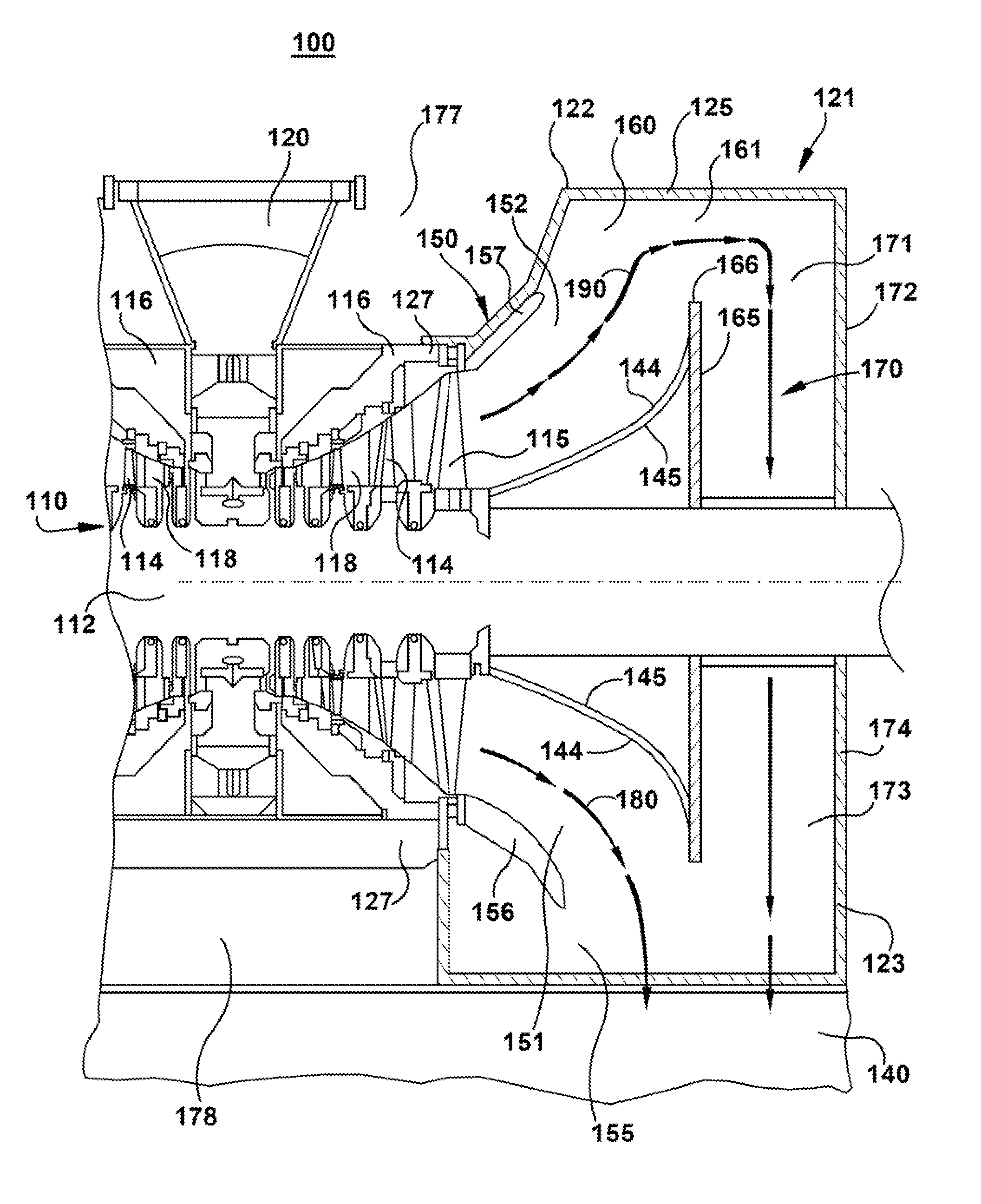

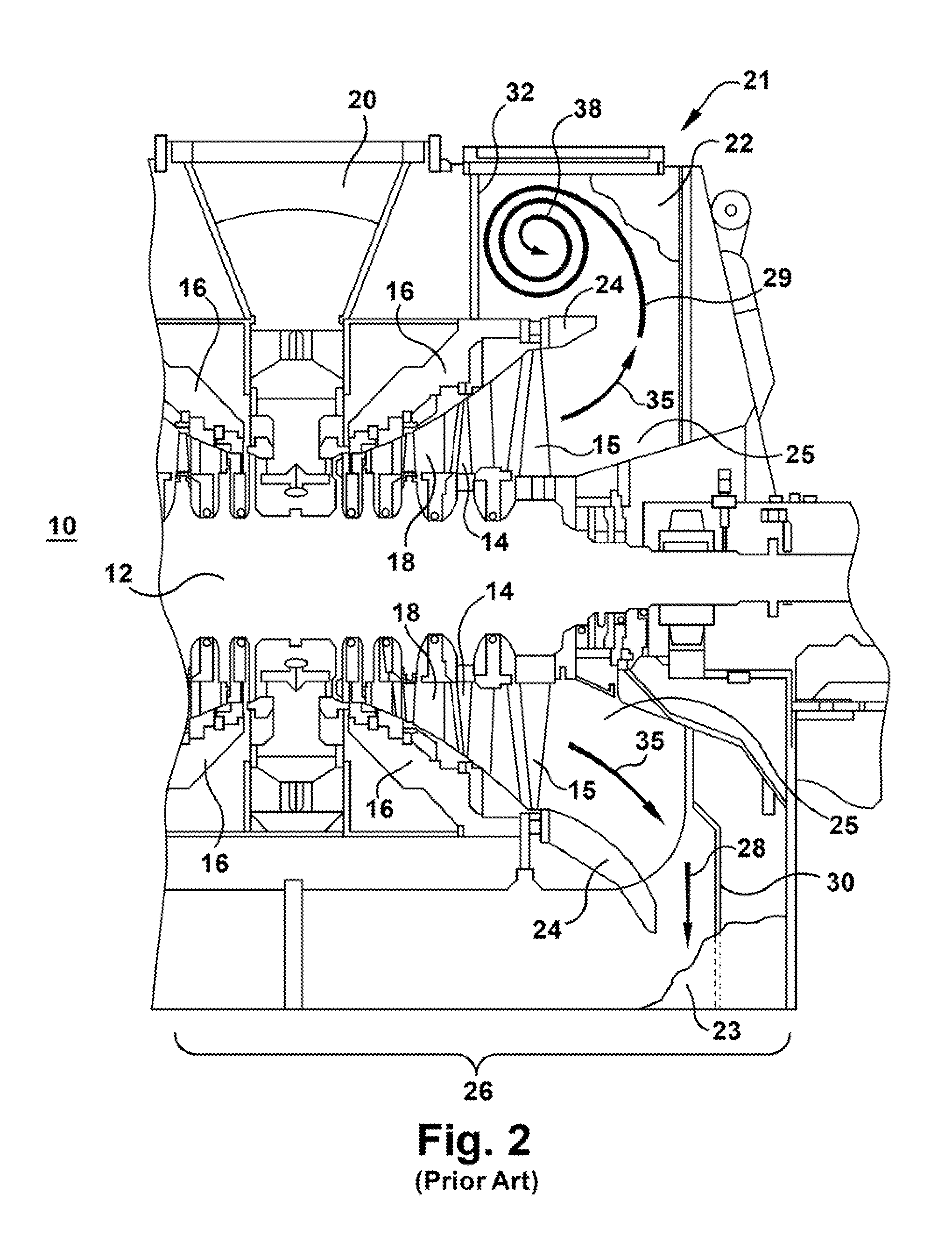

Radial channel diffuser for steam turbine exhaust hood

An exhaust hood for an axial steam turbine that includes a radial channel, downstream from the normal flow pattern. The radial channel guides the exhaust steam flow in upper half of the hood in the flow momentum direction. Due to this pattern of flow direction, vortex generation in upper exhaust hood is reduced and increased flow diffusion results. The geometric arrangement can eliminate the outer casing of the exhaust hood over the axial length of the turbine inner casing, allowing the turbine inner casing to be supported directly by a foundation for the steam turbine.

Owner:GENERAL ELECTRIC CO

Method for preparing chlorohydrocarbon

ActiveCN1762933AImprove reaction efficiencyShort reaction timePreparation by halogen halide additionAlkaneMetal catalyst

The present invention relates to chlorohydrocarbon preparing process, and is especially one telomerization process of preparing chlorohydrocarbon in the molecular expression CCl3CH2CHnClm, where n is 0, 1 or 2, and m=3-n, inside a tubular reactor, with chloroalkane or chloroalkene as main material and in the presence of composite Fe, Cr and Ni metal catalyst and dimethyl formamide as co-catalyst. The reacted mixture may be distilled to recover un-reacted material and co-catalyst and is decompression distilled to obtain final chlorohydrocarbon product. The telomerization process is simple, high in reaction efficiency and suitable for continuous industrial production.

Owner:BEIJING YUJI SCI & TECH +1

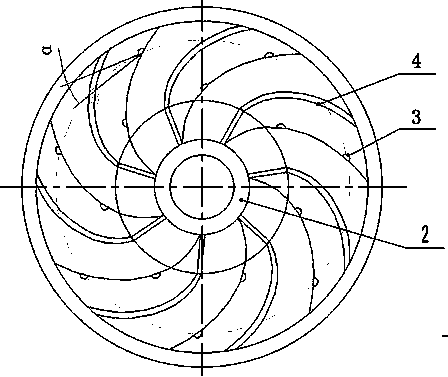

Guide vanes with vortex elimination and drag reduction holes

InactiveCN104047898AReduce lossesImprove overcurrent efficiencyPump componentsPumpsLow speedEngineering

The invention relates to spatial guide vanes with vortex elimination and drag reduction holes, wherein the spatial guide vanes are used for a deep-well centrifugal pump or multistage centrifugal pumps in other forms. One to three semicircular holes with the same size are arranged in the root portion of each of the spatial guide vanes and close to a lower cover plate, and the vortex elimination and drag reduction holes penetrate through the pressure faces and the suction faces of the guide vanes and are inclined. The guide vanes with the vortex elimination and drag reduction holes are simple in structure and convenient to machine, high-speed liquid flow flows to the suction faces from the pressure faces through the vortex elimination and drag reduction holes, low-speed liquid remaining near the suction faces can be dispersed, the form of flow of the suction faces of the guide vanes close to the lower cover plate area can be effectively improved, the probability of generating secondary flow and vortexes is reduced, hydraulic loss is reduced, and the overflow efficiency of the guide vanes is remarkably improved.

Owner:JIANGSU UNIV

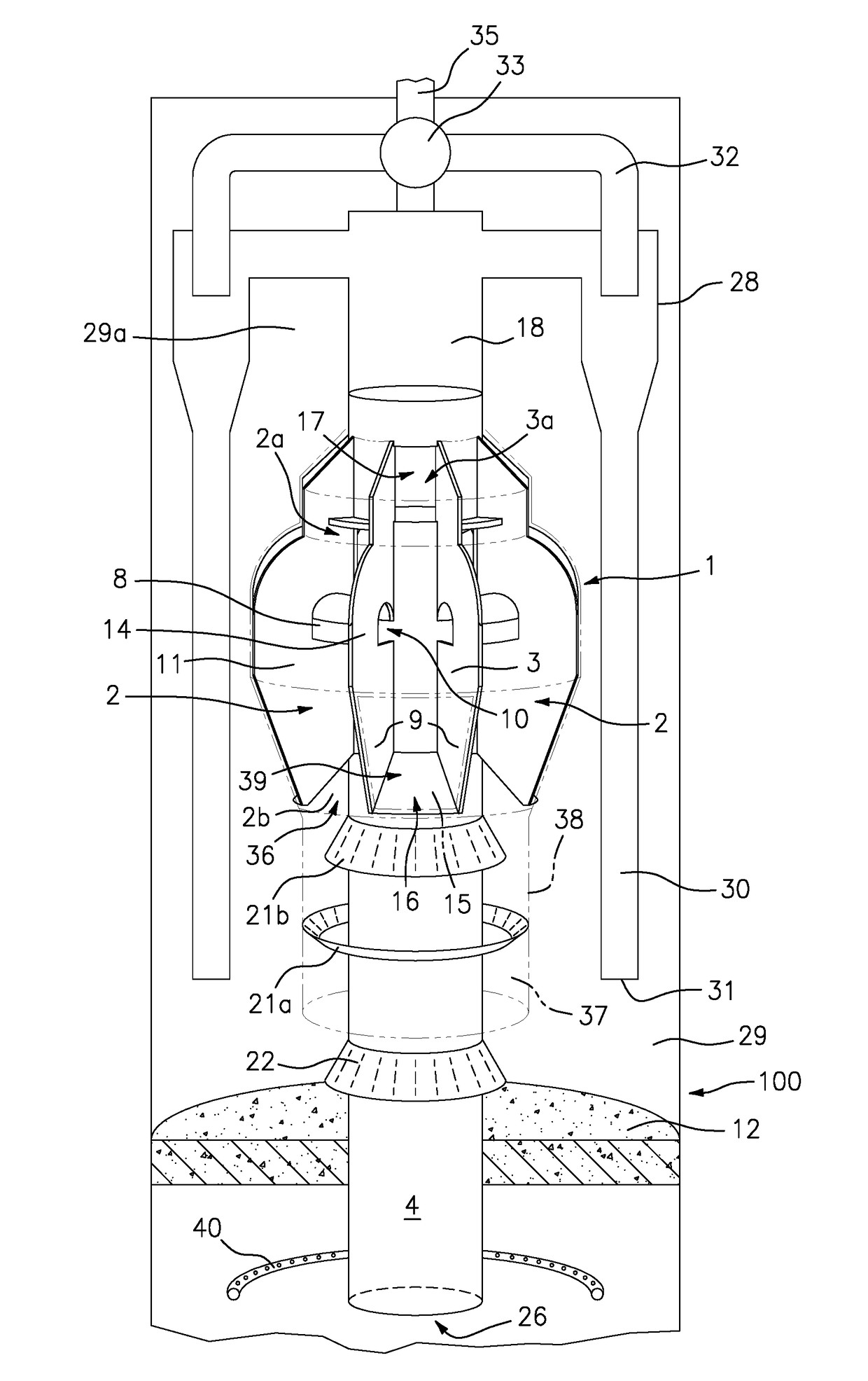

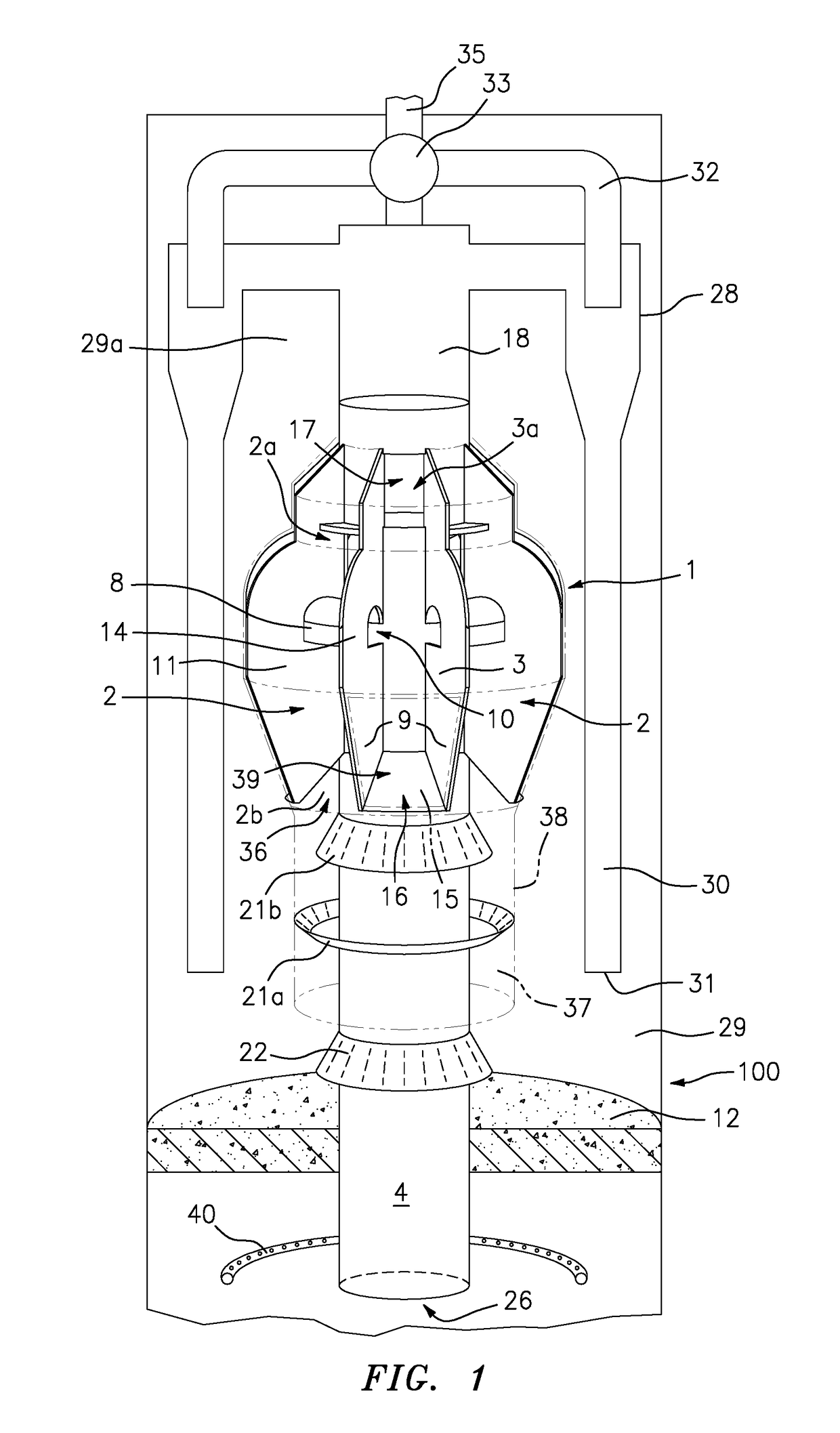

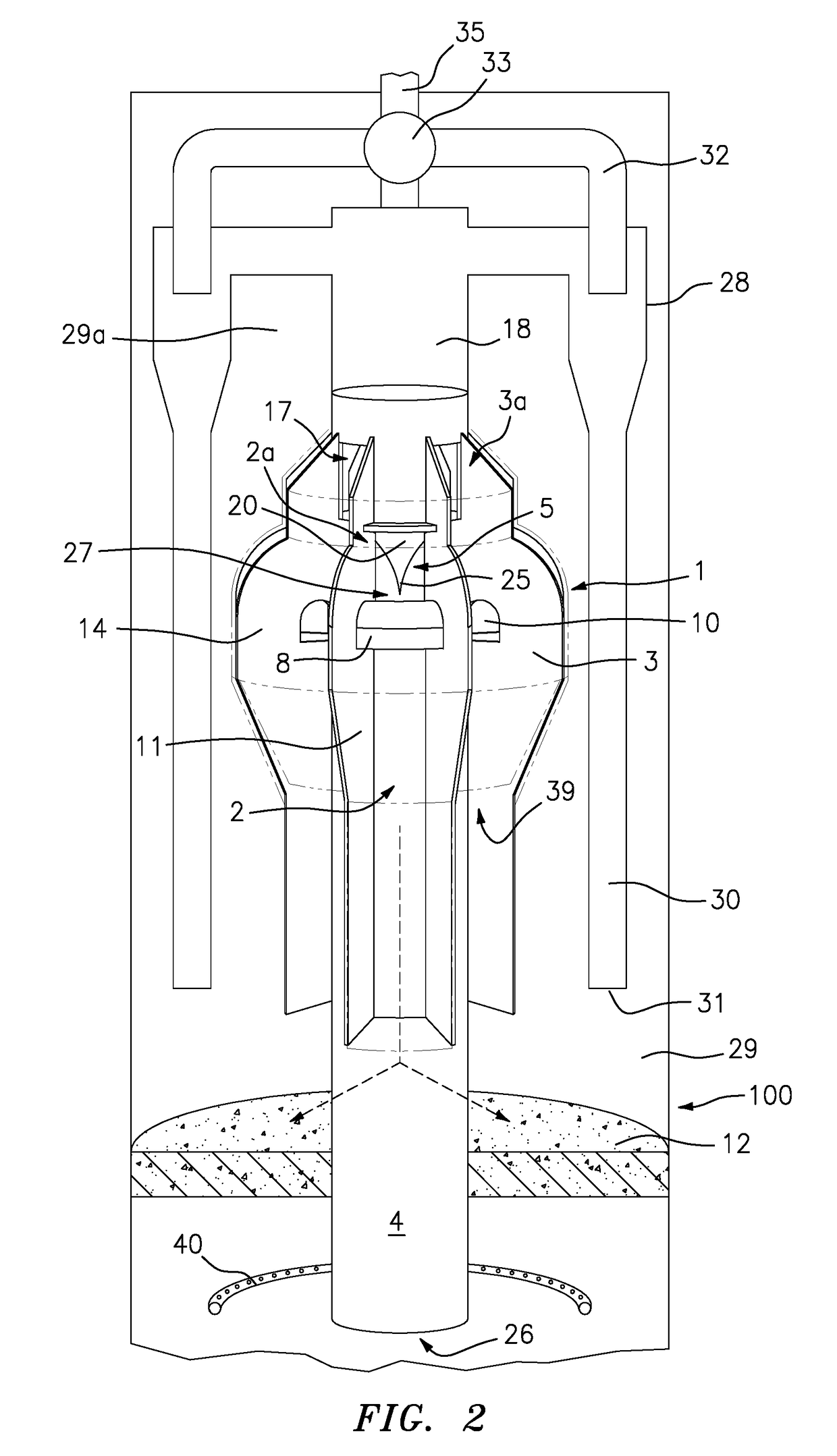

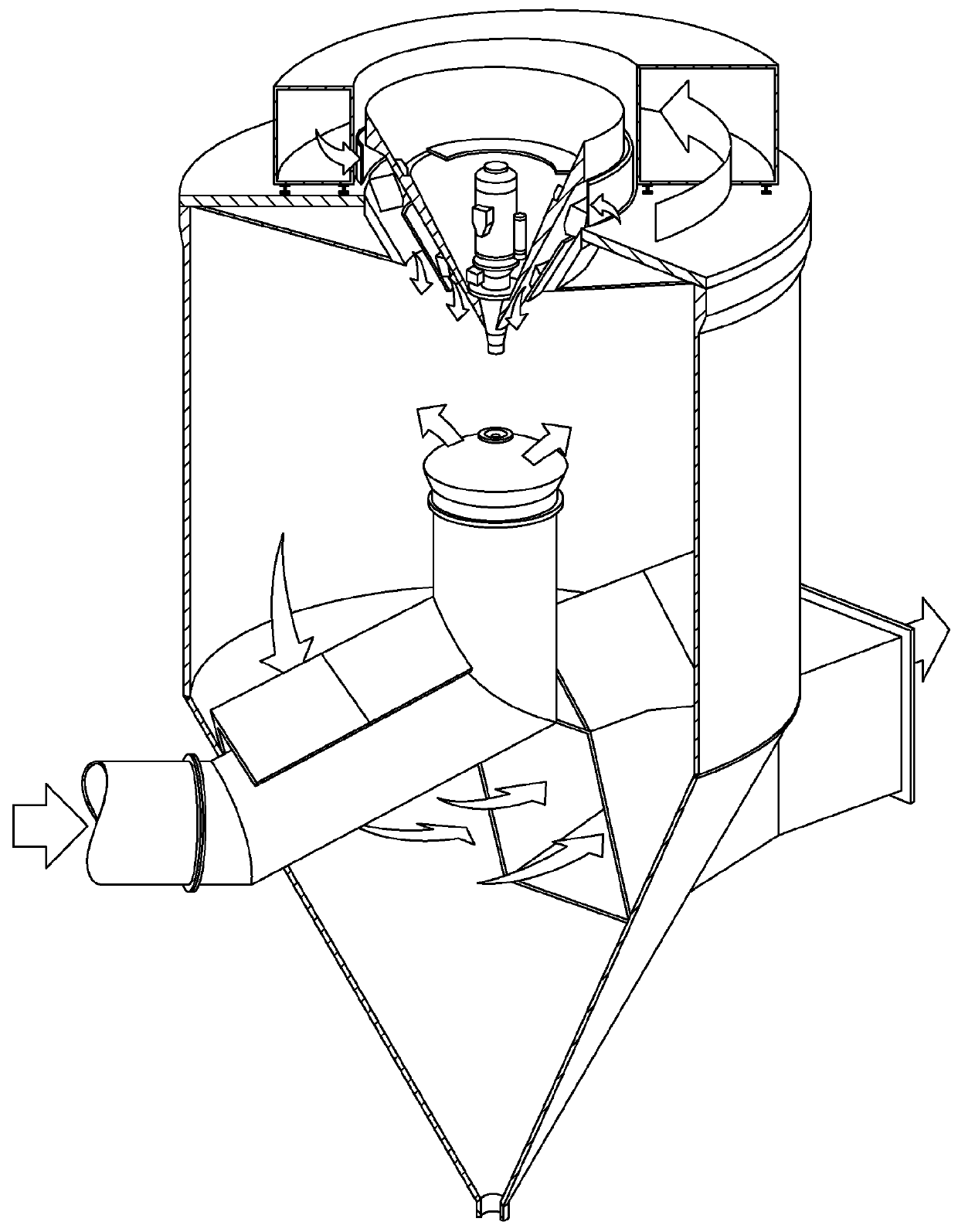

Riser separation system

ActiveUS20180216012A1Improve separationSmoothly flowCatalytic crackingDispersed particle separationProcess engineeringResidence time

The present disclosure is directed to an apparatus and a compact riser separation system for separating a gaseous mixture from a stream of particles entering from a central riser reactor used for cracking a hydrocarbon feed with the stream of particles. The apparatus provides improved gas solid separation efficiency and maximize containment of the hydrocarbon and minimize residence time in the separation system and thereby minimizing undesired post riser cracking reactions.

Owner:TECH PRECESS TECH INC

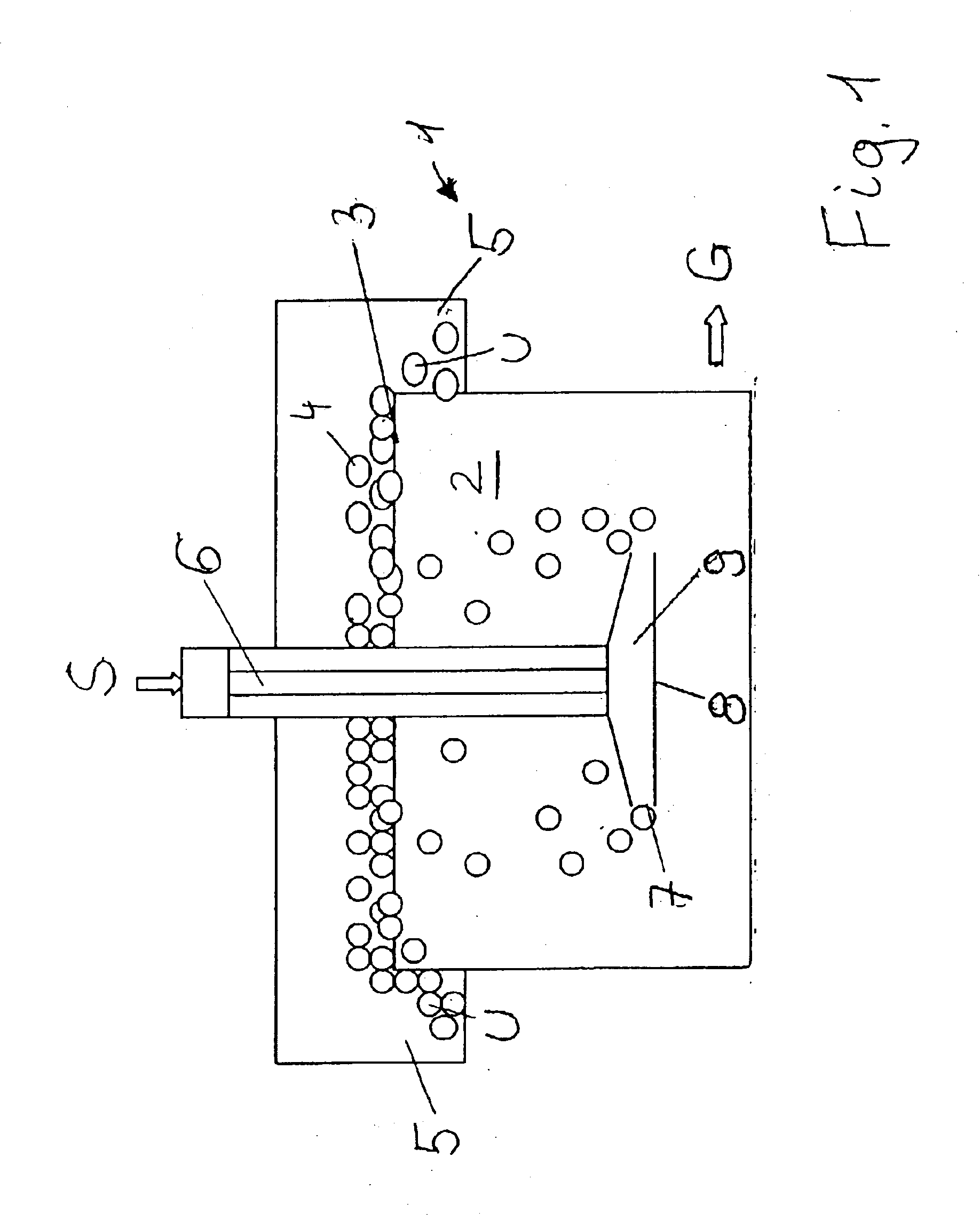

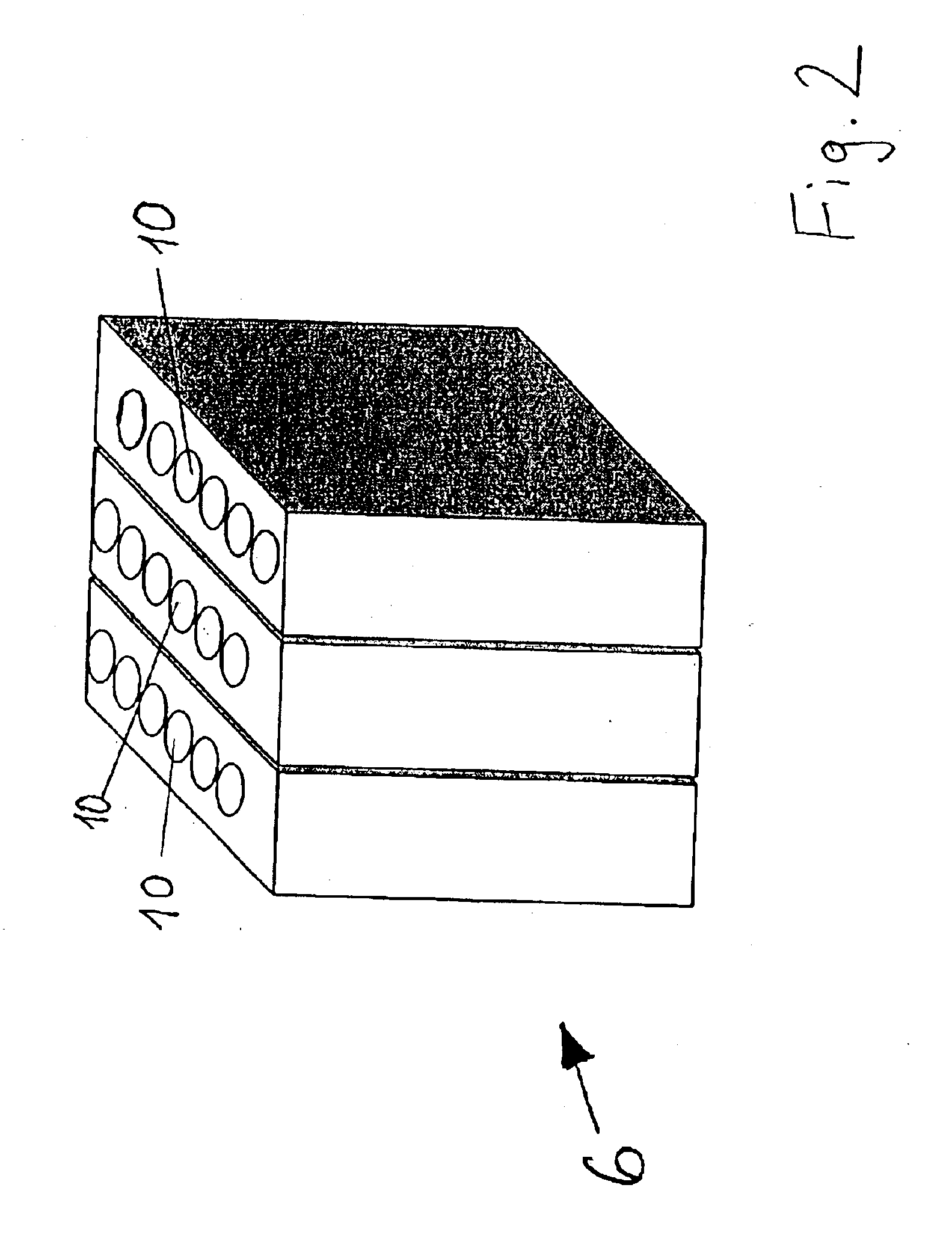

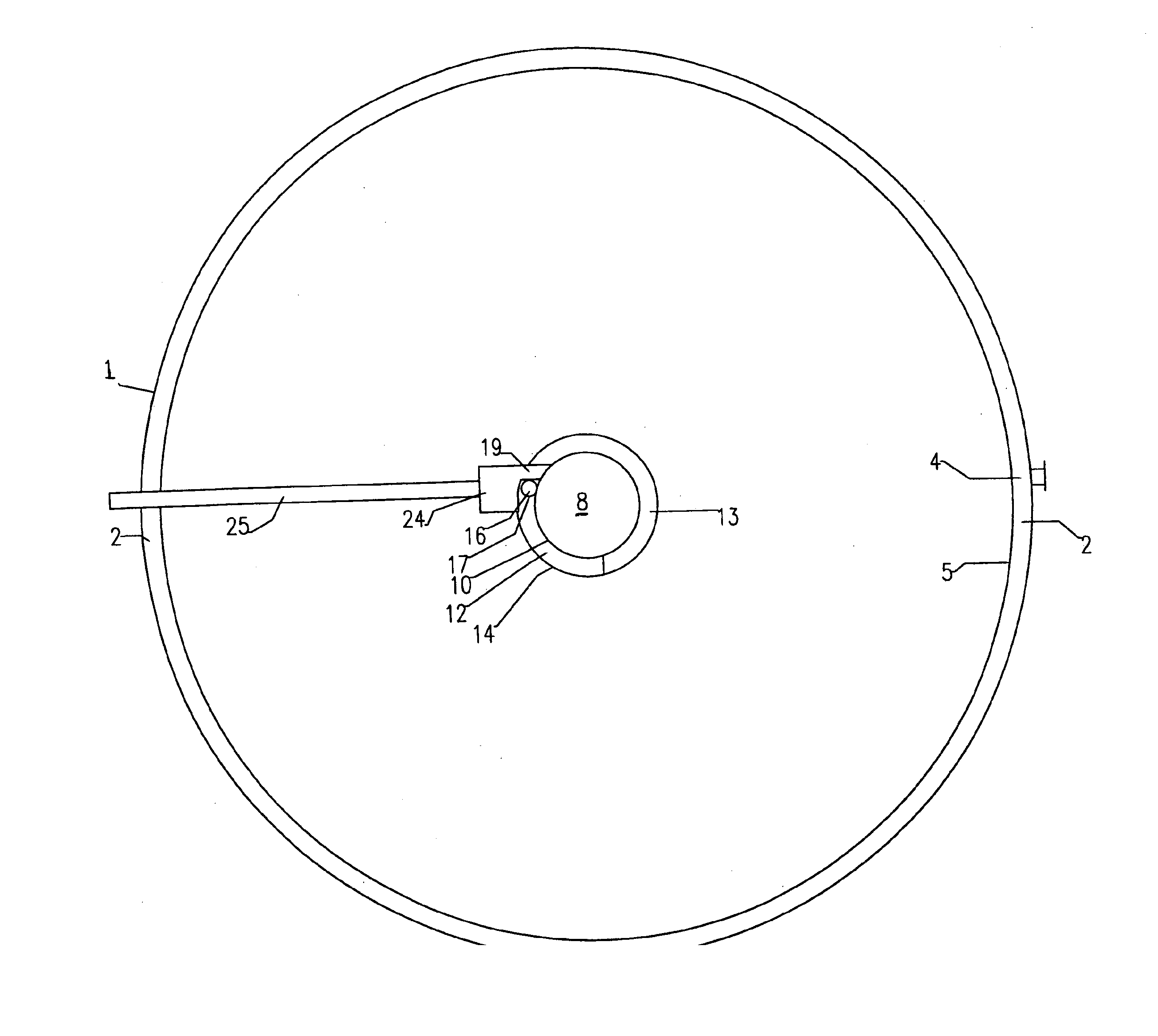

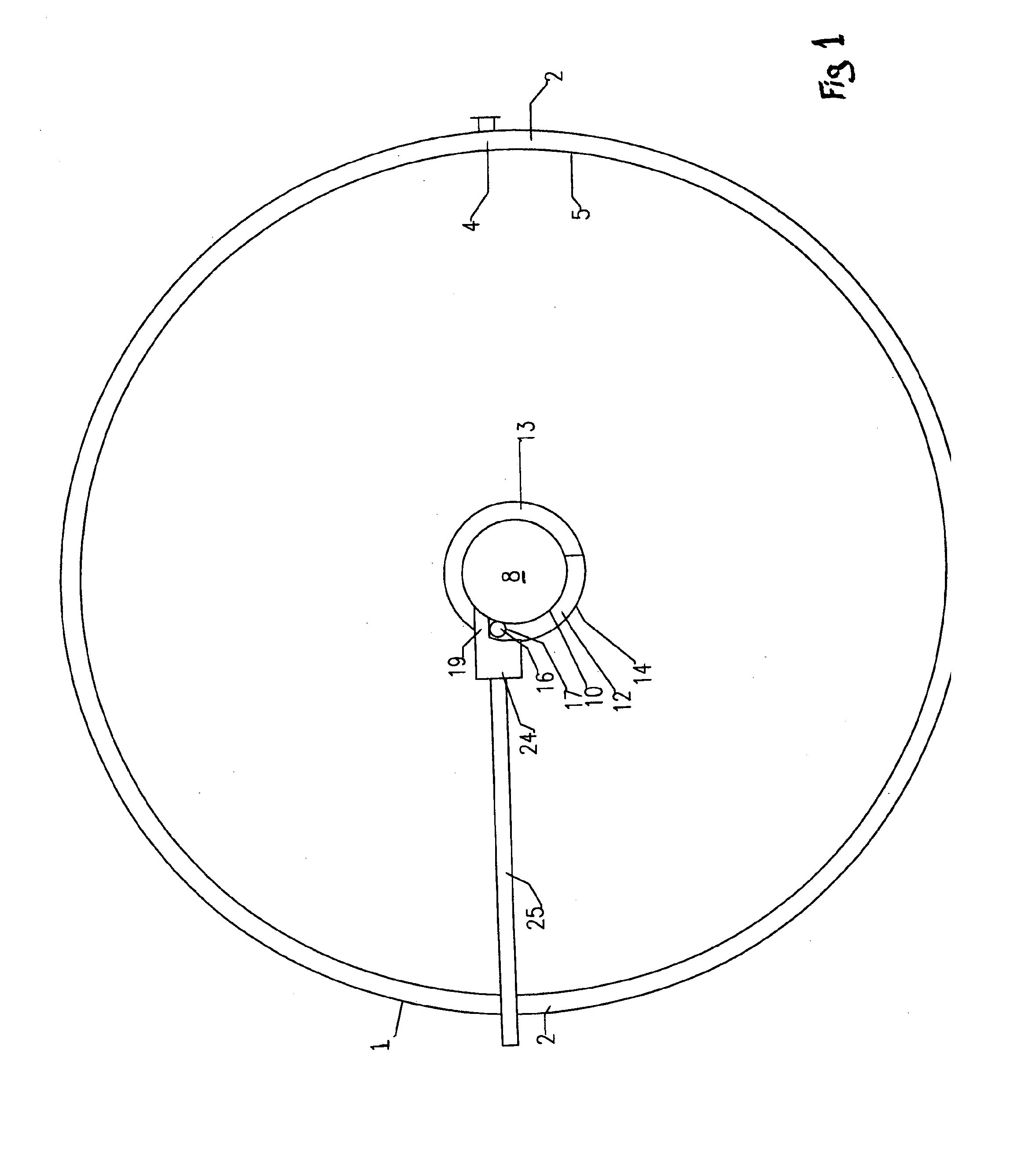

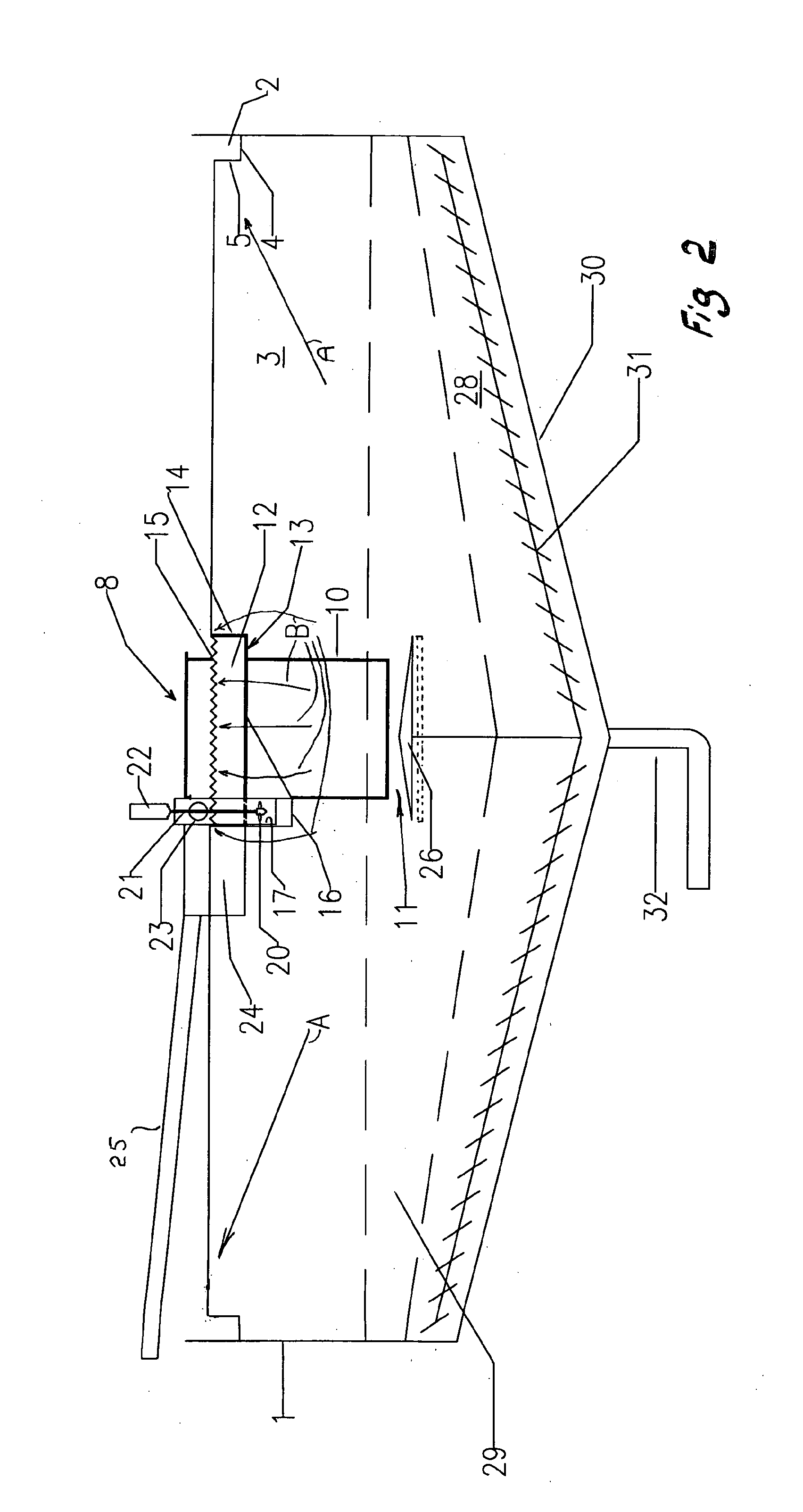

Device for separating solids from liquids by means of flotation

The invention relates to a device for separating solids from liquids by means of flotation, particularly for separating impurities and ink particles from fibre suspensions, with several injectors 10, which are provided inside a flotation cell 1. It is mainly characterised by the injectors 10 being arranged in one row.

Owner:ANDRITZ AG

Method for preparing chlorohydrocarbon

ActiveCN100361944CImprove reaction efficiencyShort reaction timePreparation by halogen halide additionAlkaneMetal catalyst

Owner:BEIJING YUJI SCI & TECH +1

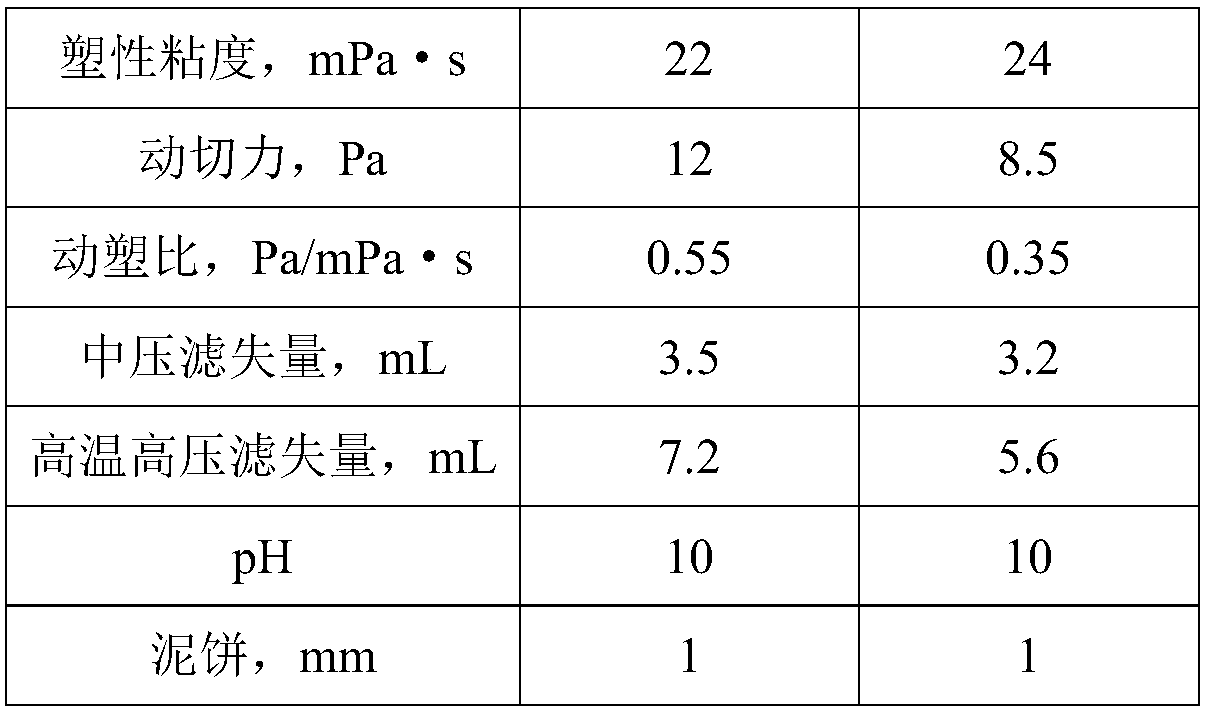

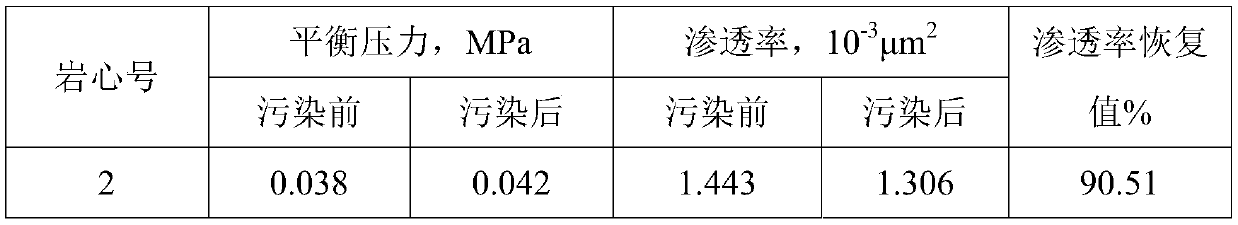

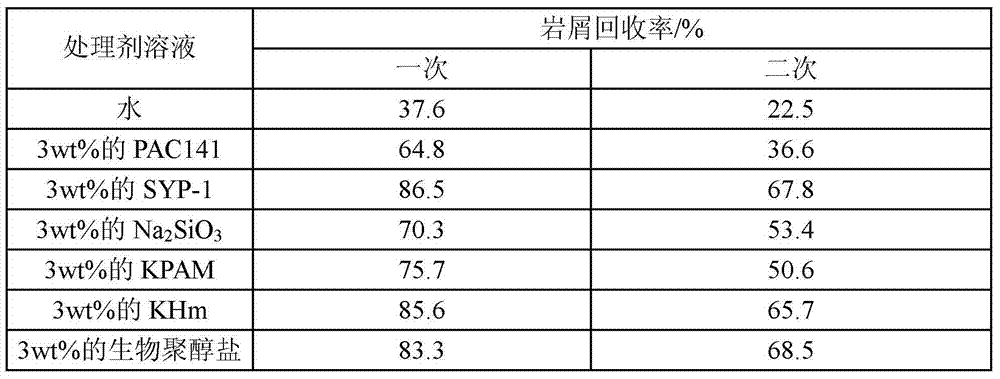

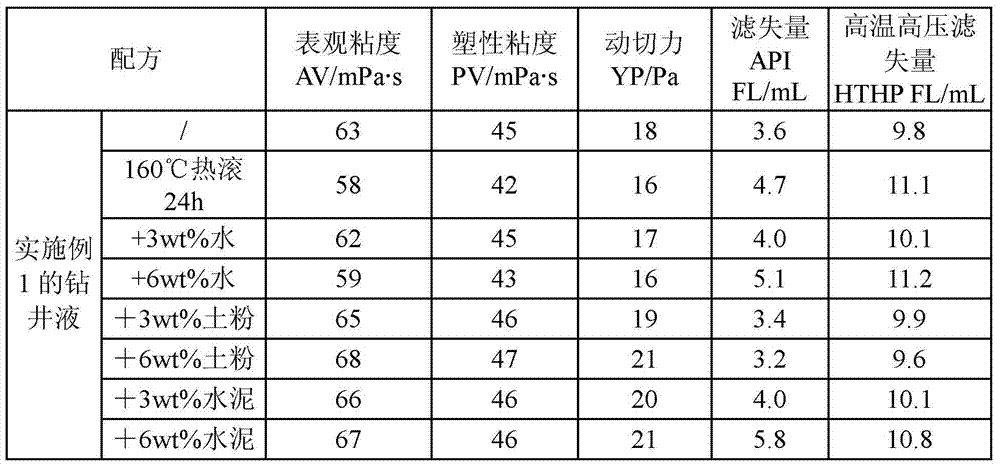

Strong-inhibition high-blocking-performance double-protection drilling fluid, preparation method thereof and drilling composition

The invention relates to strong-inhibition high-blocking-performance double-protection drilling fluid, a preparation method thereof and a drilling composition. The drilling fluid is mainly composed of, by weight, 2-3 parts of bentonite, 0.3-0.5 part of polyacrylamide potassium salt, 0.2-0.4 part of polyanionic cellulose, 2-3 parts of pre-gelatinized starch, 2-3 parts of emulsified paraffin, 2-3 parts of blocking agent, 0.04-0.06 part of xanthan gum, 0.1-0.3 part of pH regulator, 0-2 parts of weighting agent and 1-2 parts of rock debris. The drilling fluid is mainly compounded by water, the polyacrylamide potassium salt, polyanionic cellulose, the pre-gelatinized starch, emulsified paraffin, the blocking agent, the xanthan gum and the rock debris; the raw materials present good inhibiting performance and blocking performance on fractured mudstone strata at low using amount, so that the drilling fluid can effectively avoid accidents like well leakage and well collapse, and safety and success rate of drilling construction are improved.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

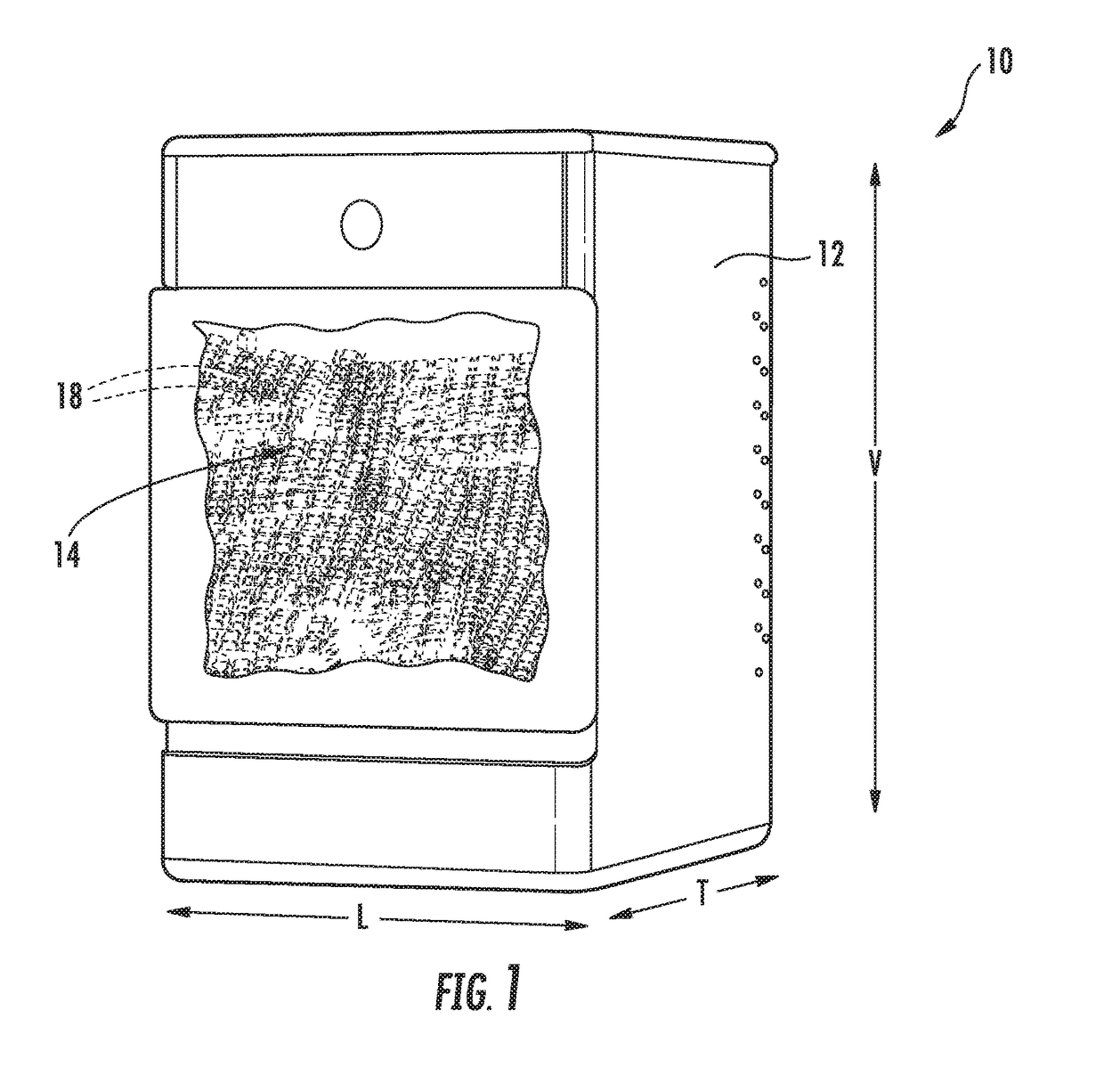

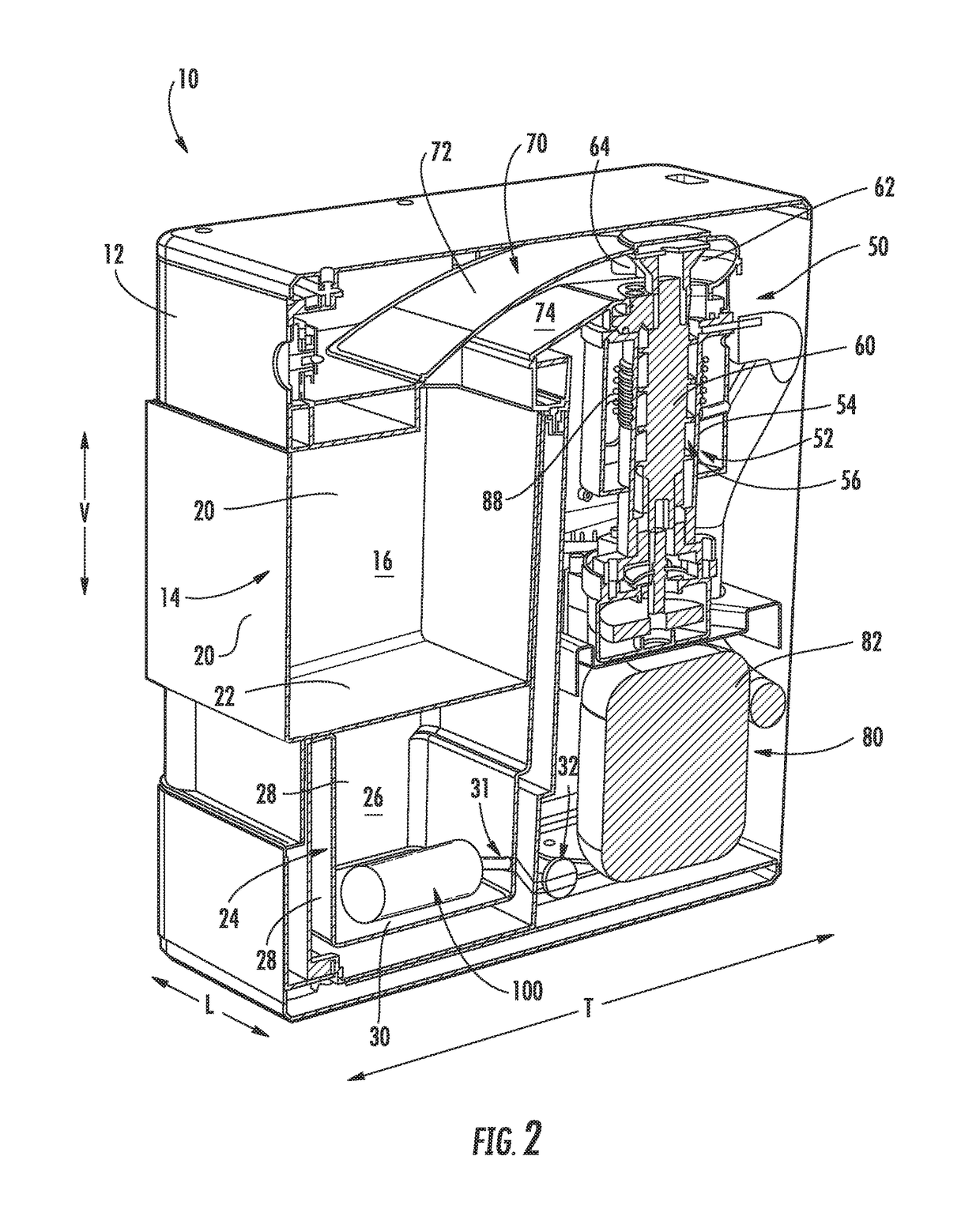

Filters for Non-Plumbed Appliances

InactiveUS20180001240A1Prevent from flowImprove flow patternLighting and heating apparatusIce productionEngineeringStreamflow

A filter for a non-plumbed appliance is provided. The filter includes a filter housing having a sidewall extending along a longitudinal direction between a first end wall and a second end wall. A flow distribution channel is also defined by the sidewall of the filter housing, the flow distribution channel extending outwardly from the sidewall along the radial direction and along the longitudinal direction between the flow aperture and the first end wall of the filter housing. The flow distribution channel equalizes the pressure gradient on the outer surface of the filter media, resulting in an improved flow pattern, increased clogging resistance, and improved filter performance capacity.

Owner:HAIER US APPLIANCE SOLUTIONS INC

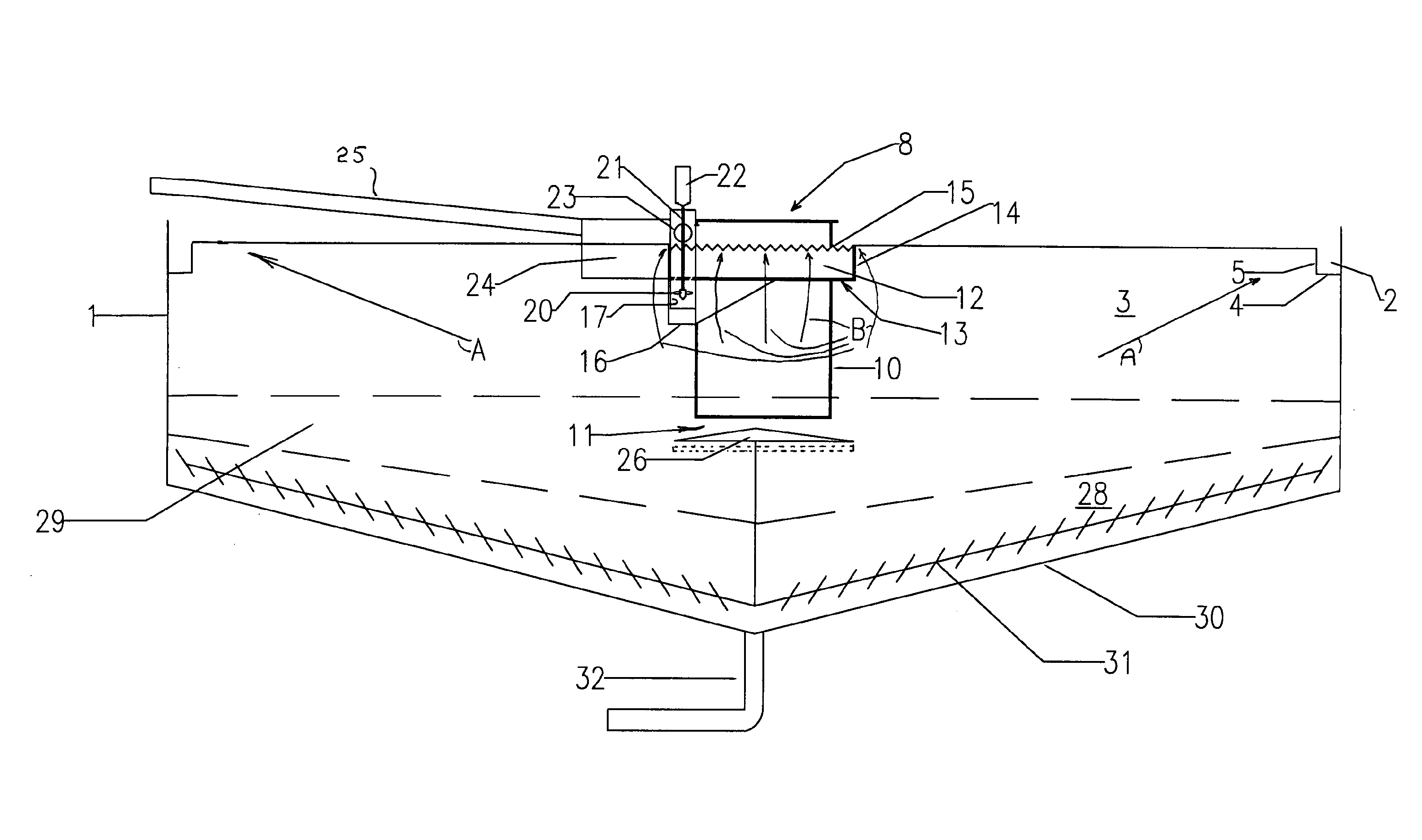

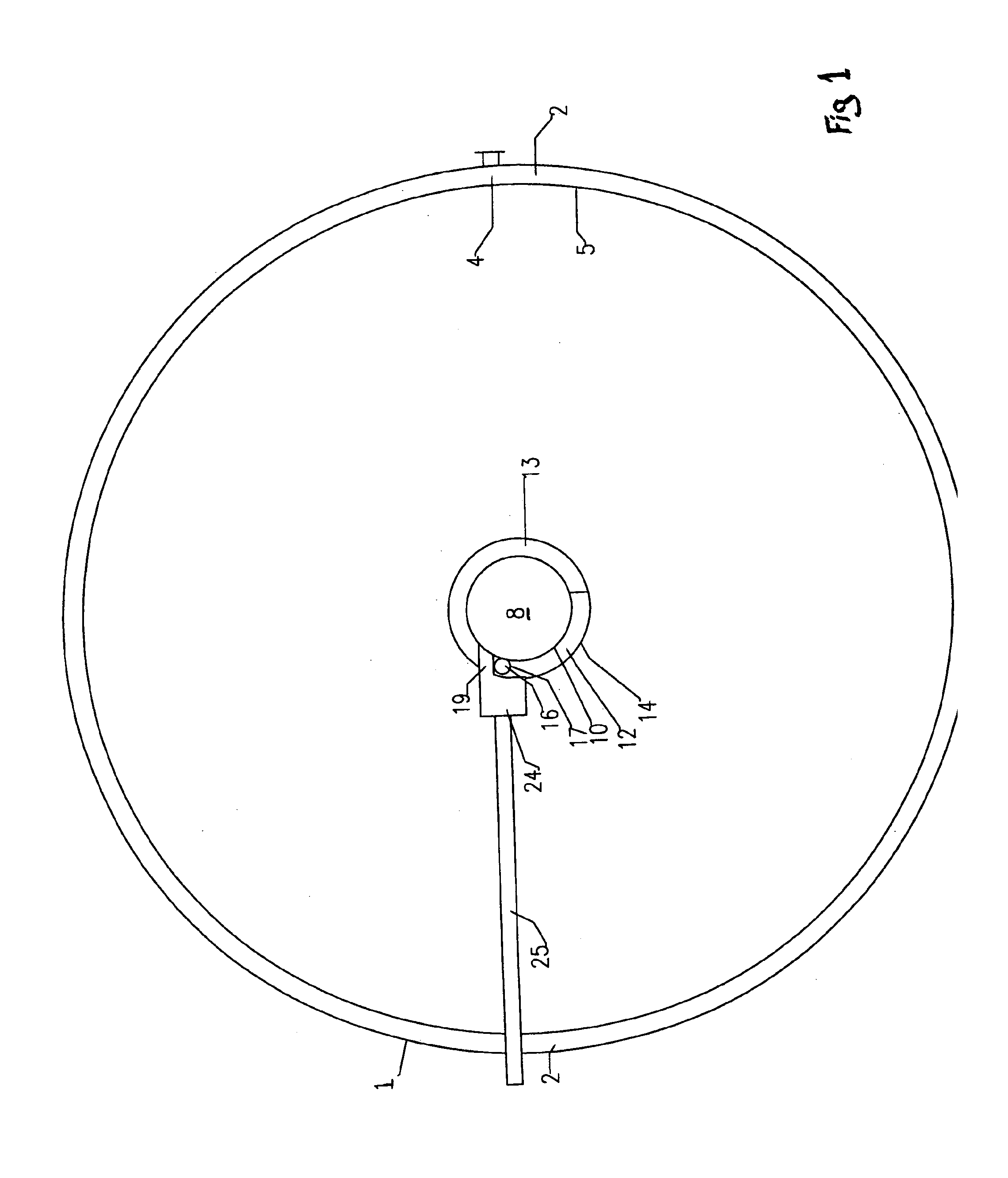

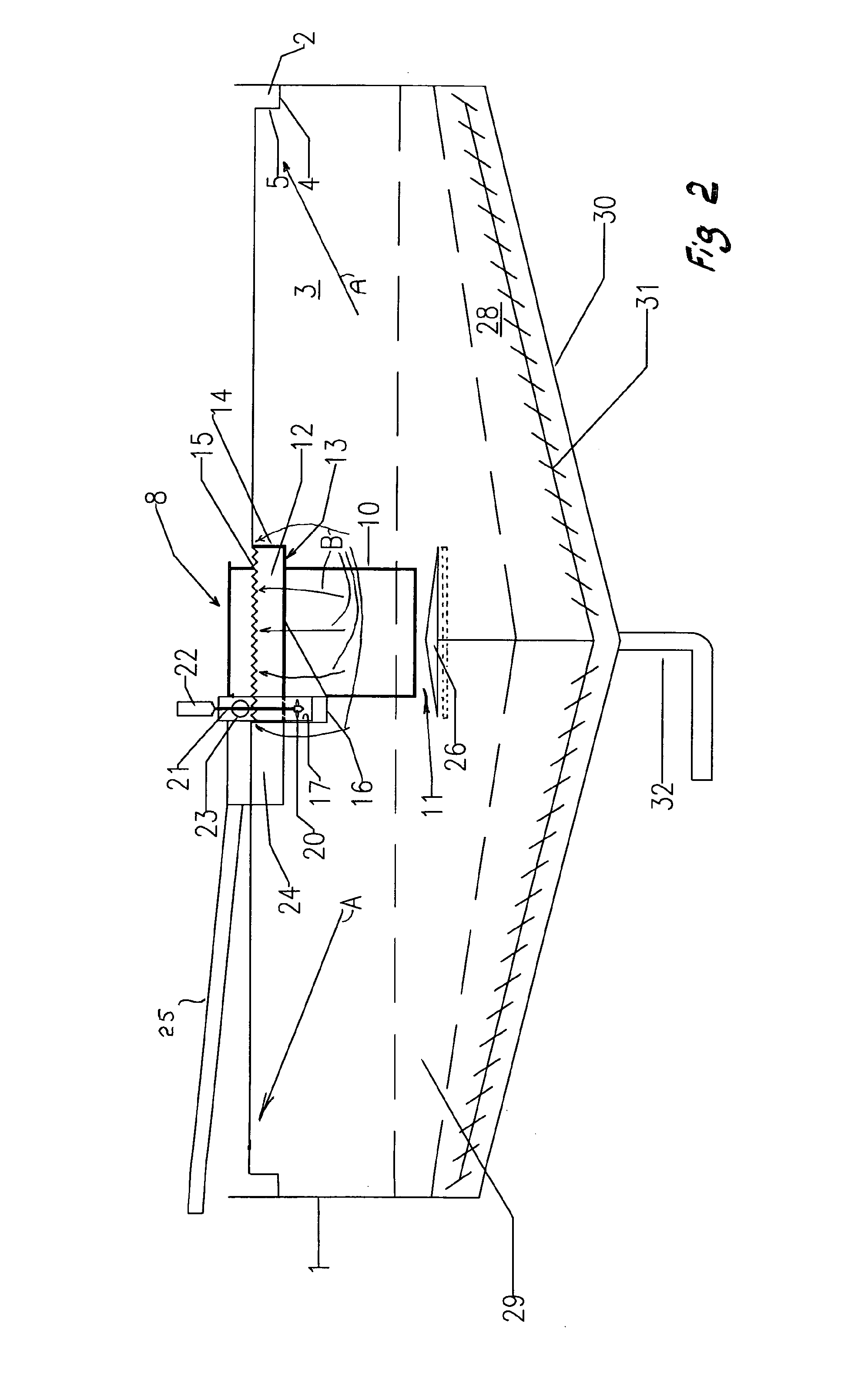

"improvement in or relating to thickeners having self-diluting feedwell"

ActiveUS20100300546A1Improve flow patternReduce consumable costsLiquid separation auxillary apparatusLarge containersImpellerDrive shaft

A thickening tank has a peripheral overflow launder and a centrally disposed feed well. Feedstock slurry is fed to a mixing box which also receives supernatant liquid and is supplemented by flocculated material flowing into the interior of the feed well onto a distributor baffle plate. The supernatant liquid is delivered at a controlled rate from a receiving vessel formed by an upright cylinder provided at its lower end with an impeller of a lift pump which is operated by a controller positioned at the upper end of a vertical drive shaft extending axially through the receiving vessel. The feed well is surrounded by a second launder which is closed at its base and formed with a cup. The lower end of the receiving vessel is spaced from the floor of the cup to draw supernatant liquid exclusively from the second launder rather than from the thickener tank.

Owner:TAKRAF

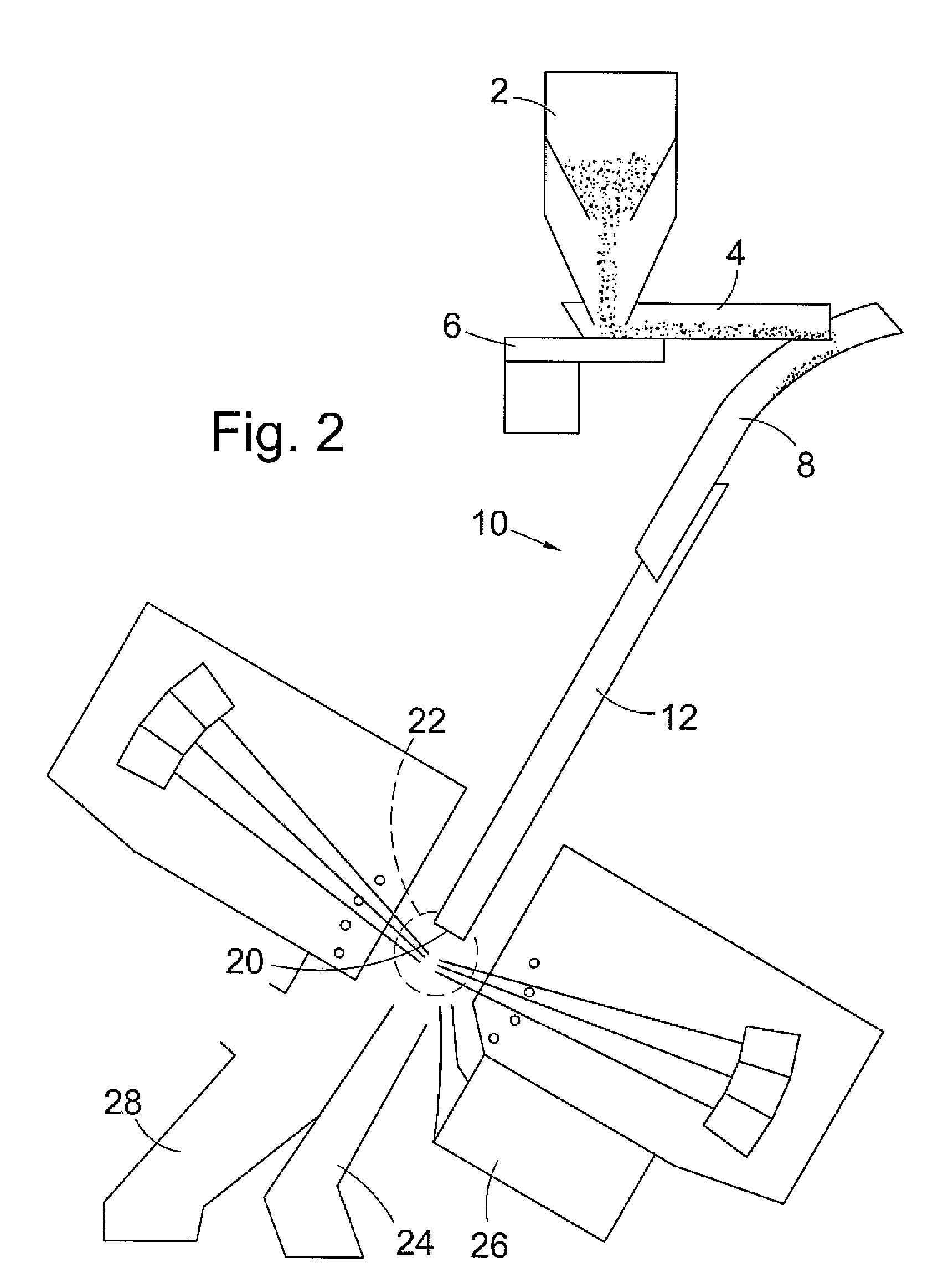

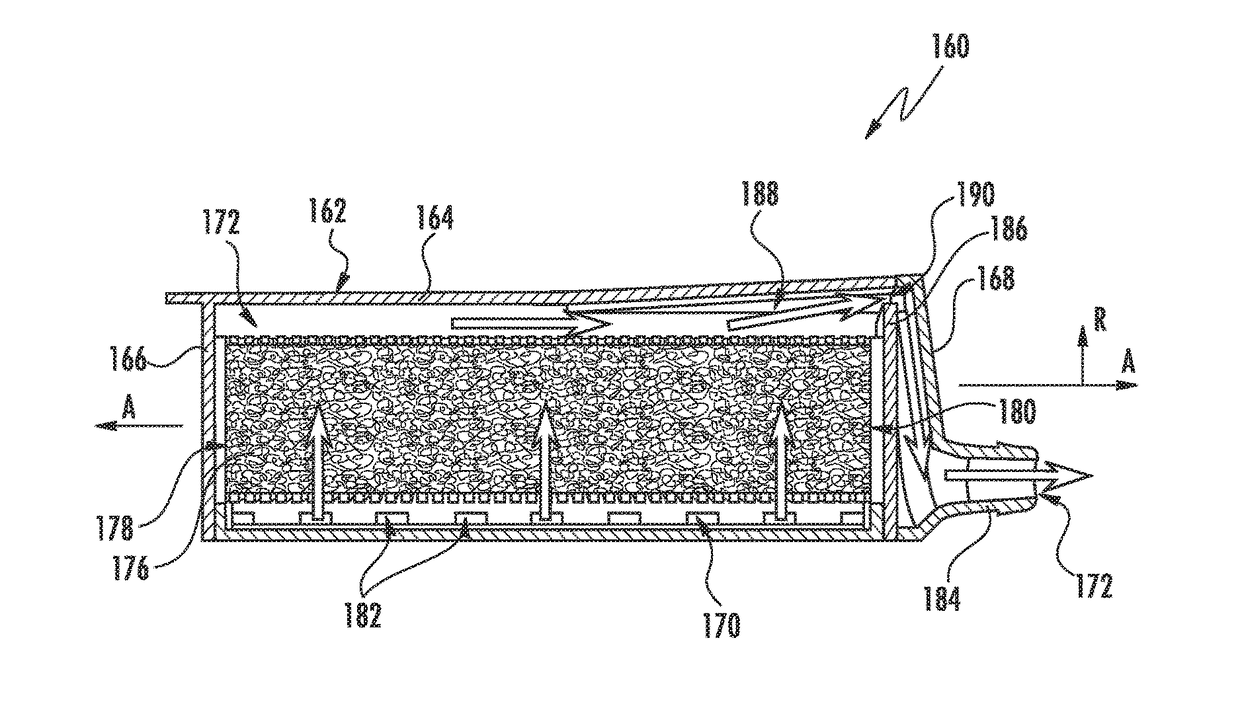

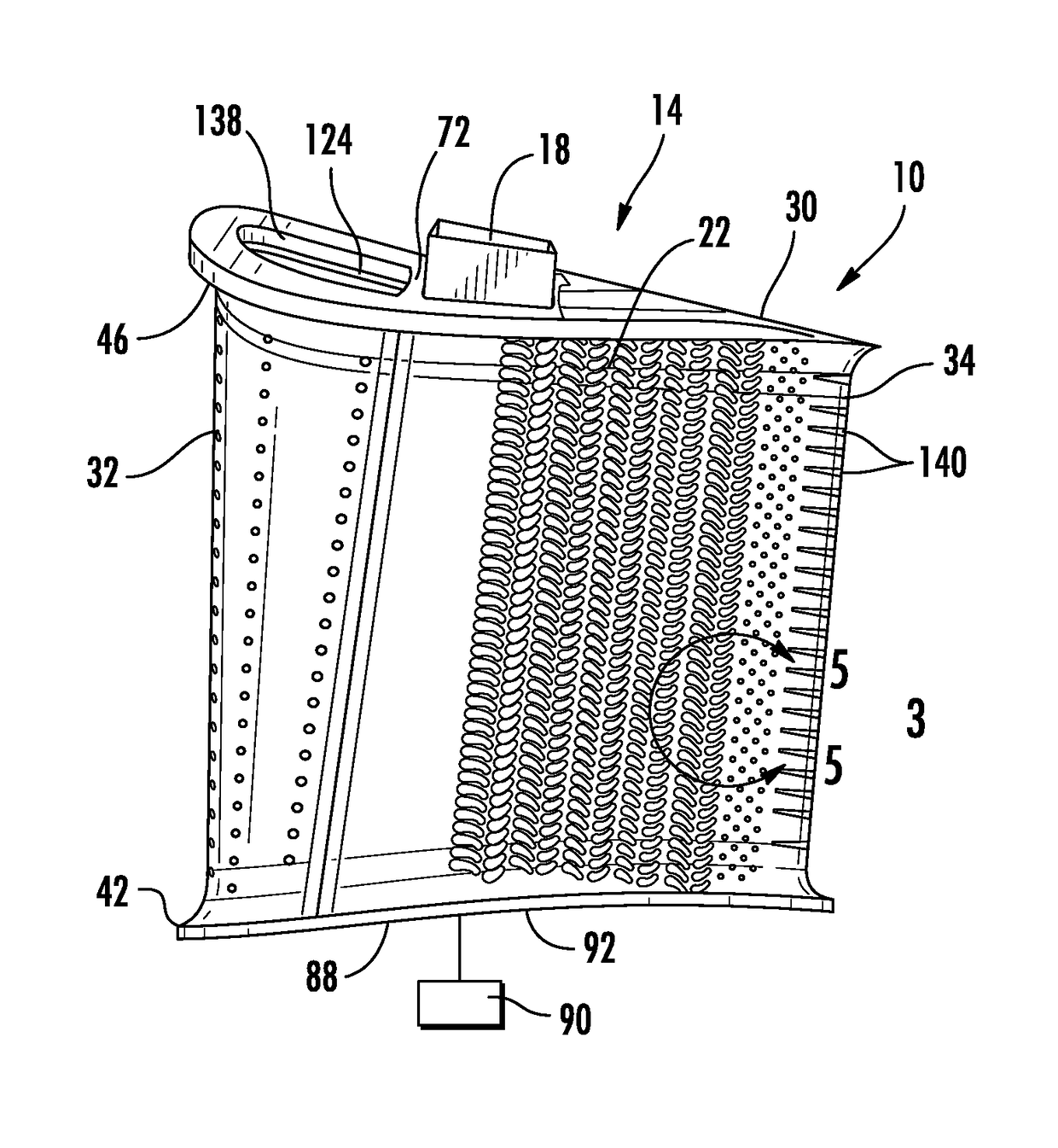

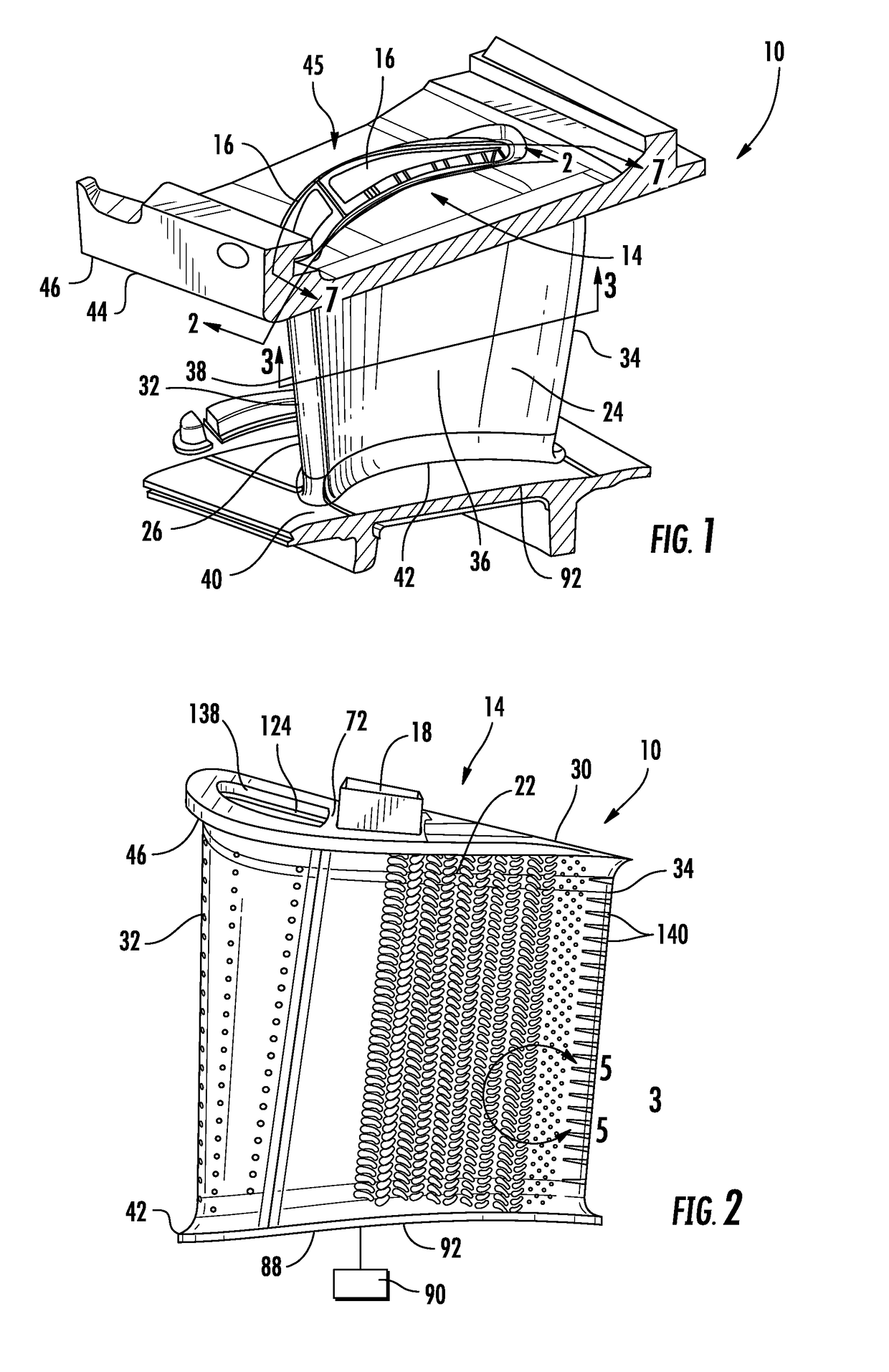

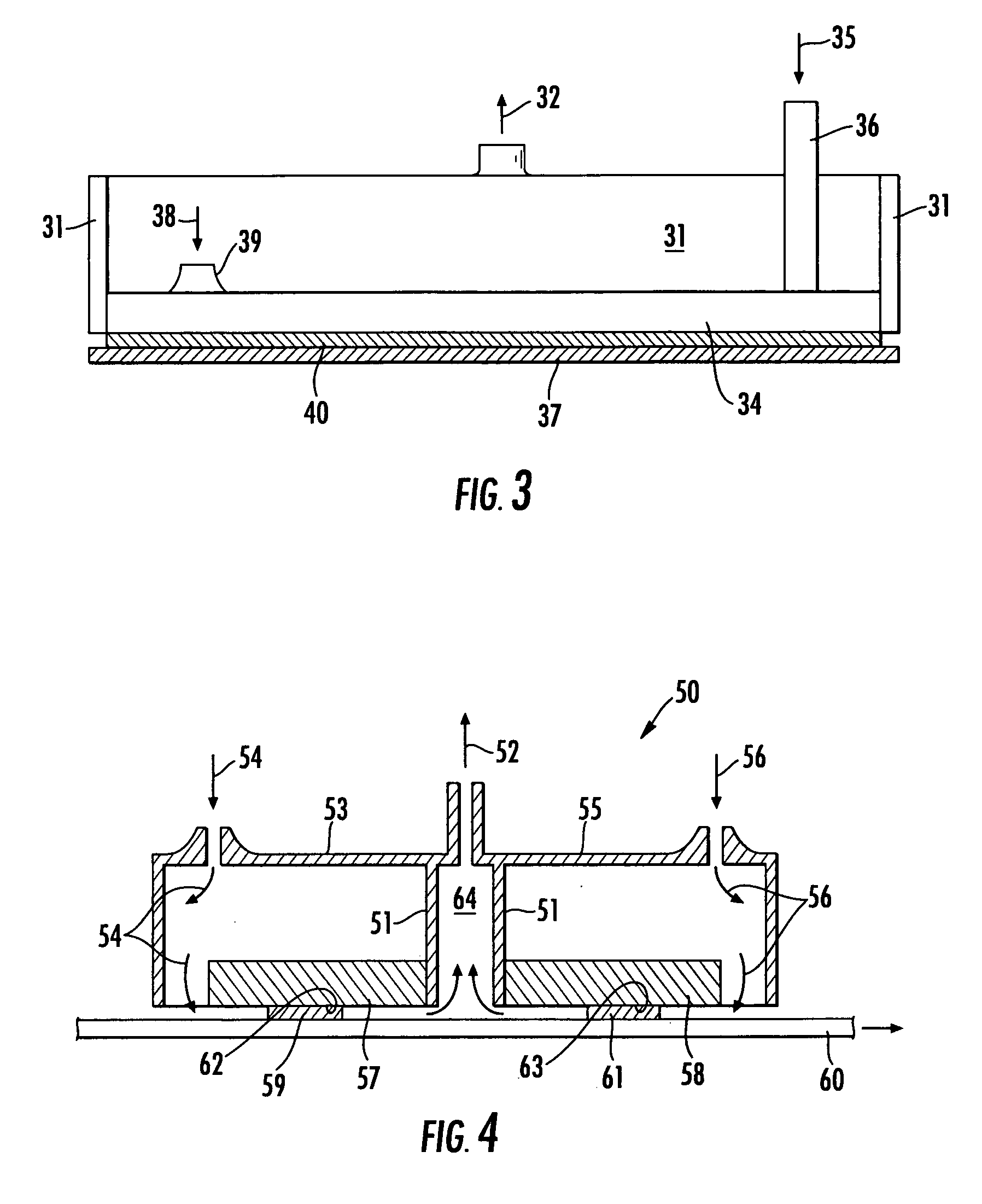

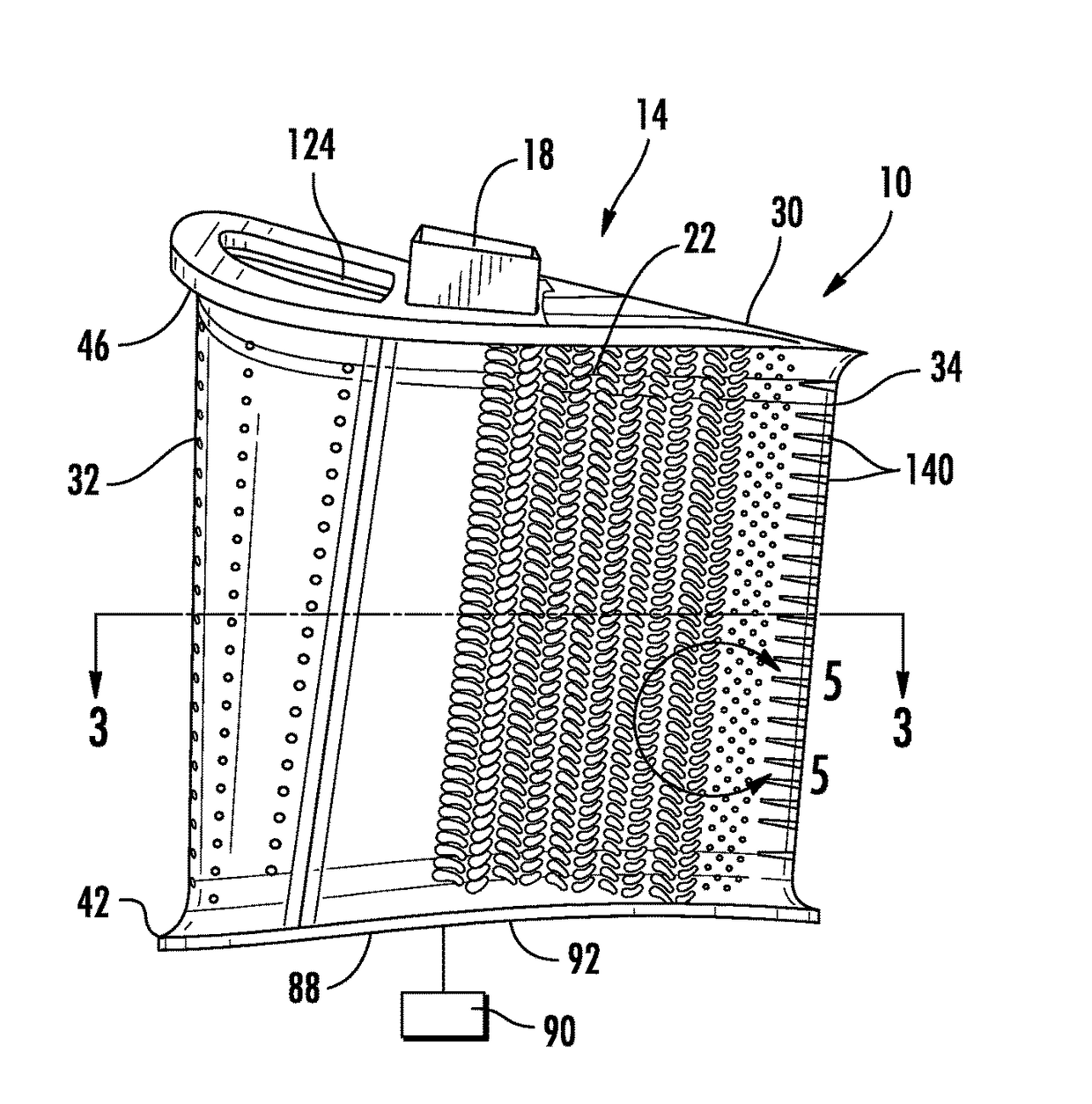

Internal cooling system with insert forming nearwall cooling channels in an aft cooling cavity of a gas turbine airfoil including heat dissipating ribs

InactiveUS20180045059A1Improve flow patternIncrease surface areaEngine fuctionsBlade accessoriesCooling fluidCooling channel

An airfoil (10) for a gas turbine engine in which the airfoil (10) includes an internal cooling system (14) with one or more internal cavities (16) having an insert (18) contained within an aft cooling cavity (76) to form nearwall cooling channels having enhanced flow patterns is disclosed. The flow of cooling fluids in the nearwall cooling channels (20) may be controlled via a plurality of cooling fluid flow controllers (22) extending from the outer wall (12) forming the generally hollow elongated airfoil (26). In addition, heat may be extracted in the midchord region (150) via one or more heat dissipating ribs (152) extending partially between an inner surface (144) of the suction side (38) and the insert (18). In at least one embodiment, the heat dissipating ribs (152) may extend in a generally chordwise direction and be positioned from an inner diameter (92) to an outer diameter (98) of the airfoil (10) between the cooling fluid flow controllers (22) and a rib (72) separating forward and aft cooling cavities (74, 76).

Owner:SIEMENS AG

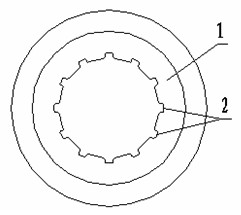

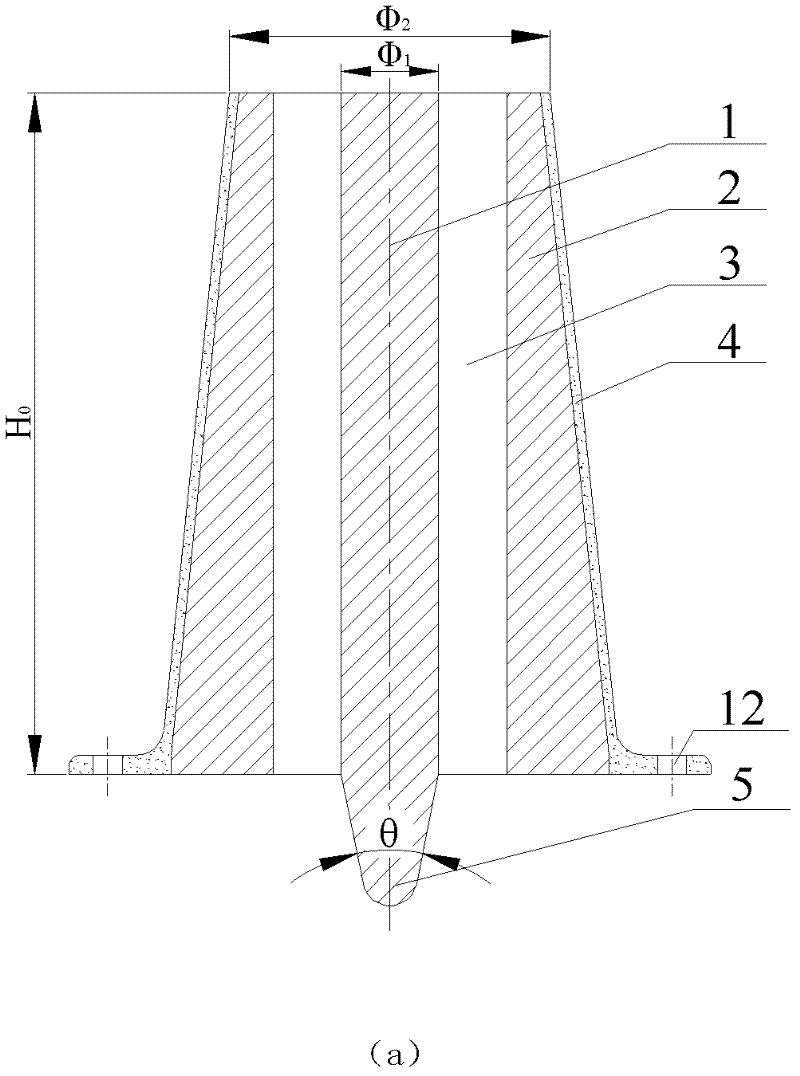

Flow guide cylinder used for czochralski silicon single crystal growth finance

InactiveCN102011175AImprove stabilityImprove flow patternPolycrystalline material growthBy pulling from meltEngineeringSingle crystal

The invention discloses a flow guide cylinder used for a czochralski silicon single crystal growth finance. The flow guide cylinder comprises a flow guide cylinder body, wherein the flow guide cylinder body has a conical cylindrical structure which has a large upper part and a small lower part; and a plurality of shunt grooves are uniformly reserved on the lower end part of the flow guide cylinder body annularly. The flow guide cylinder used for the czochralski silicon single crystal growth finance has a simple structure and a reasonable design, is safe to use, can effectively improve the growth efficiency of silicon single crystals, and can be widely used in czochralski silicon single crystal growth equipment.

Owner:JIANGSU HUASHENG TIANLONG PHOTOELECTRIC

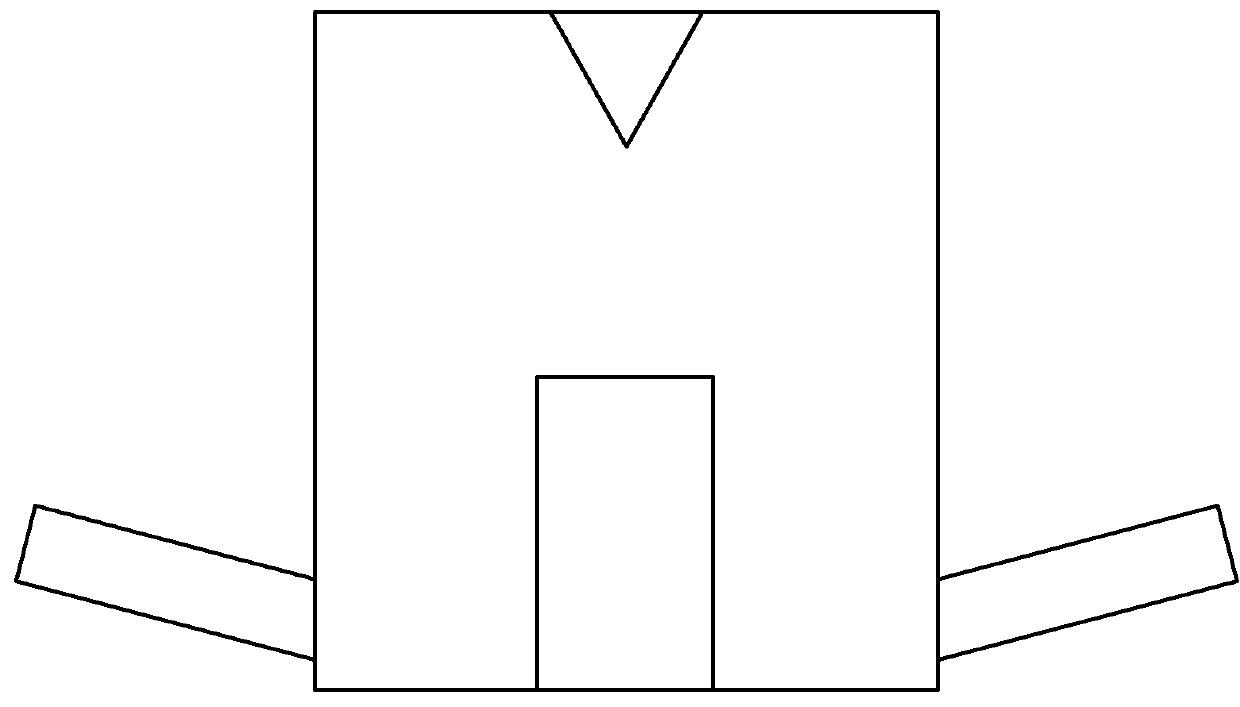

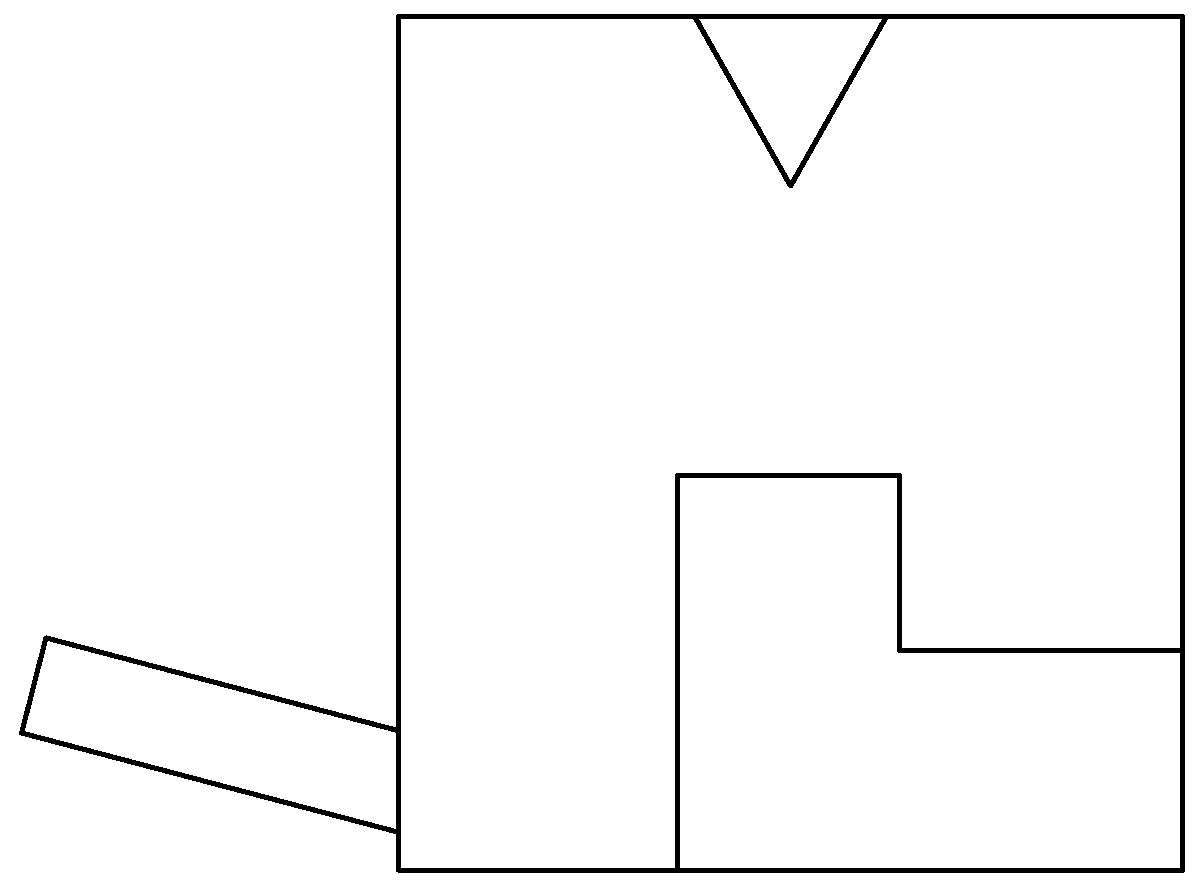

Spray dryer absorption apparatus with flat-bottomed chamber

ActiveUS9227157B2Reduced support structureAvoid excessive heightCombination devicesGas treatmentParticulatesChemical reaction

In the application a spray dryer absorption apparatus for treating a stream of flue gas containing acidic components is disclosed. The apparatus comprises a chamber having vertical cylindrical walls, said chamber comprises (i) an inlet for a flue gas stream containing an acidic component, (ii) an atomizer for spraying droplets of an absorbent slurry into said flue gas stream to effect a chemical reaction between the droplets and the acidic component of the flue gas, thereby forming a particulate reaction product, and (iii) an outlet for the treated flue gas and entrained particulate reaction product, wherein the bottom of the chamber having vertical cylindrical walls is substantially horizontal and impervious to gases. The apparatus of the invention has the advantage of a simplified geometry accounting for lower building and maintenance costs.

Owner:GEA PROCESS ENG

Thickeners having self-diluting feedwell

ActiveUS8440087B2Improve flow patternReduce consumable costsLiquid separation auxillary apparatusLarge containersImpellerDrive shaft

A thickening tank has a peripheral overflow launder and a centrally disposed feed well. Feedstock slurry is fed to a mixing box which also receives supernatant liquid and is supplemented by flocculated material flowing into the interior of the feed well onto a distributor baffle plate. The supernatant liquid is delivered at a controlled rate from a receiving vessel formed by an upright cylinder provided at its lower end with an impeller of a lift pump which is operated by a controller positioned at the upper end of a vertical drive shaft extending axially through the receiving vessel. The feed well is surrounded by a second launder which is closed at its base and formed with a cup. The lower end of the receiving vessel is spaced from the floor of the cup to draw supernatant liquid exclusively from the second launder rather than from the thickener tank.

Owner:TAKRAF

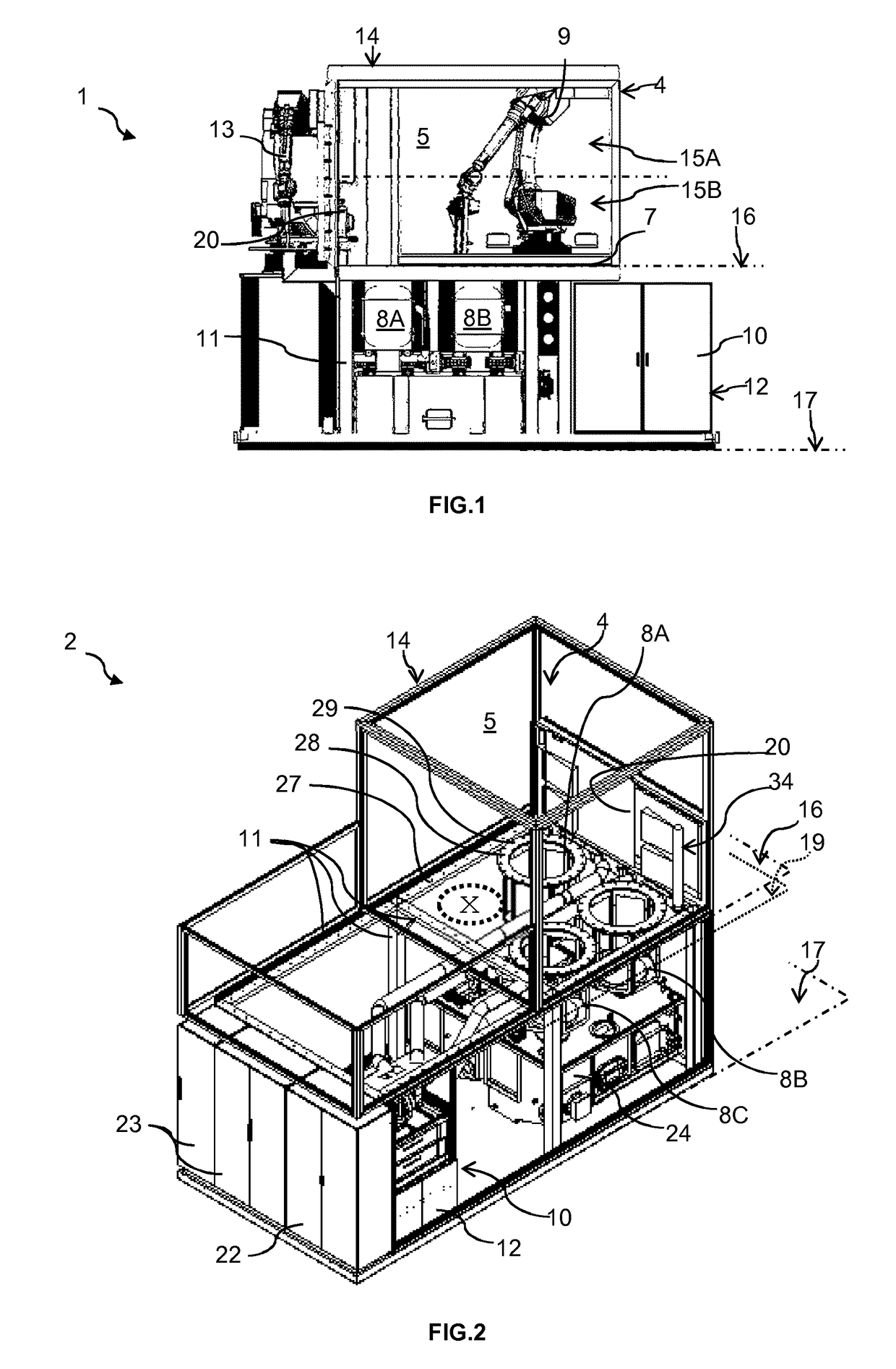

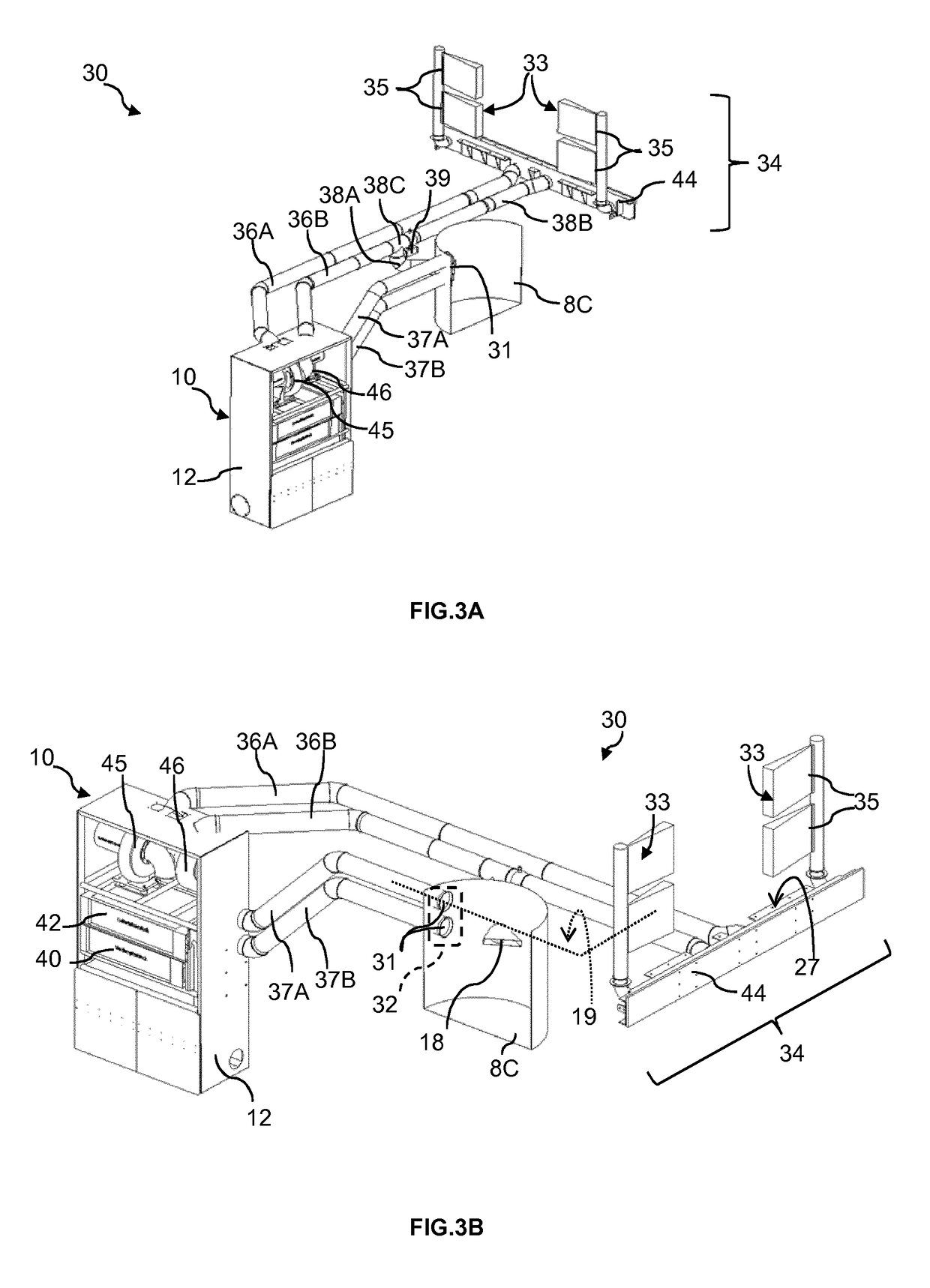

Industrial cleaning installation with vapour condensation and related methods

InactiveUS20190054511A1Easy maintenanceSimplifies retrofitting operationDispersed particle separationDirt cleaningSteam condensationWaste management

An industrial installation and process are provided for cleaning workpieces, in particular engine components or transmission components. The installation has a housing enclosing a workspace and an industrial robot mounted inside the housing, in particular on a platform. An air recirculation device having a vapour condenser and ductwork with one or more intakes for admitting vapour-charged air from the workspace and one or more exits for returning dehumidified air to the workspace. The vapour condenser preferably includes a heat recovery unit. The vapour condenser is arranged at a level below the top of the housing, preferably below the platform and / or each of the one or more intakes is arranged at a level below the upper half of the workspace, preferably on or below the platform.

Owner:ELWEMA AUTOMOTIVE

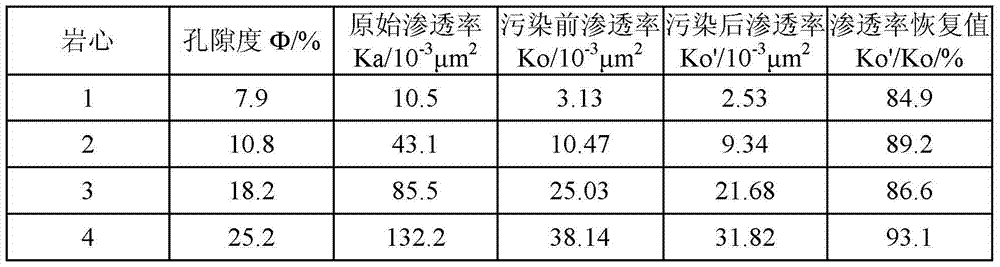

A Drilling Fluid Suitable for Tight Sandstone Reservoirs

ActiveCN105295872BImprove the lubrication effectAvoid harmDrilling compositionLiquid densitySodium Bentonite

Owner:PETROCHINA CO LTD

A device for blowing and spraying powder at the bottom of a ladle in a cyclone-protected gas storage chamber

The invention discloses a ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber, and belongs to the technical field of steel smelting. The ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber comprises a slit-type powder injection component I and the whirlwind-type flow-smoothing gas storage chamber II.A fire-resistant material is filled into the slit-type powder injection component. Multiple slits are distributed uniformly in the fire-resistant material. A middle axle plane which passes through ends which belong to the slits and are close to an axle center, and a vertical plane where the slits are arranged form an included angle gamma. The bottom of the whirlwind-type flow-smoothing gas storage chamber is connected with a whirlwind-type accelerating chamber. A low end of the whirlwind-type accelerating chamber is provided with a whirlwind-type gas flow conveying pipes. The whirlwind-type gas flow conveying pipes are arranged at both sides of a power-gas flow conveying pipe and form respectively beta angles with the power-gas flow conveying pipe. The ladle bottom blowing power injectiondevice with the whirlwind-type flow-smoothing gas storage chamber can reduce obviously a degree of powder-gas flow pulsation, accumulation of falling powder, and resistance to a powder-gas flow when the powder-gas flow is fed into the slits, can improve obviously a uniform flow conveying rate of the powder-gas flow in the slits. The ladle bottom blowing power injection device with the whirlwind-type flow-smoothing gas storage chamber has the advantages of stable blowing, small pulsation, low corrosion on fire-resistant materials, safe and reliable characteristics, feasibility for continuous and stable blowing and long service life of fire-resistant materials.

Owner:NORTHEASTERN UNIV LIAONING

Process and apparatus for atmospheric pressure plasma enhanced chemical vapor deposition coating of a substrate

InactiveUS20090142511A1Eliminate air pollutionImproving uniformity of and chemistryLiquid surface applicatorsElectric discharge tubesGas phaseCoating system

Process and apparatus for atmospheric pressure plasma enhanced chemical vapor deposition coating using a first and second electrode, the second electrode being positioned apart from the first electrode thereby creating a volume space between the first and second electrodes which volume space is covered by a duct sealed to the electrodes. Gas is flowed from the volume space between the first and second electrodes at the same or at a greater rate than the sum of the gaseous coating precursor mixtures of the first and second electrodes.In addition, an improved electrode assembly for use in an atmospheric pressure plasma enhanced chemical vapor deposition coating system that includes a means for distributing a gaseous coating precursor mixture to emerge from an electrode assembly. The improvement relates to a gas distributing subassembly of the electrode assembly.

Owner:DOW GLOBAL TECH LLC

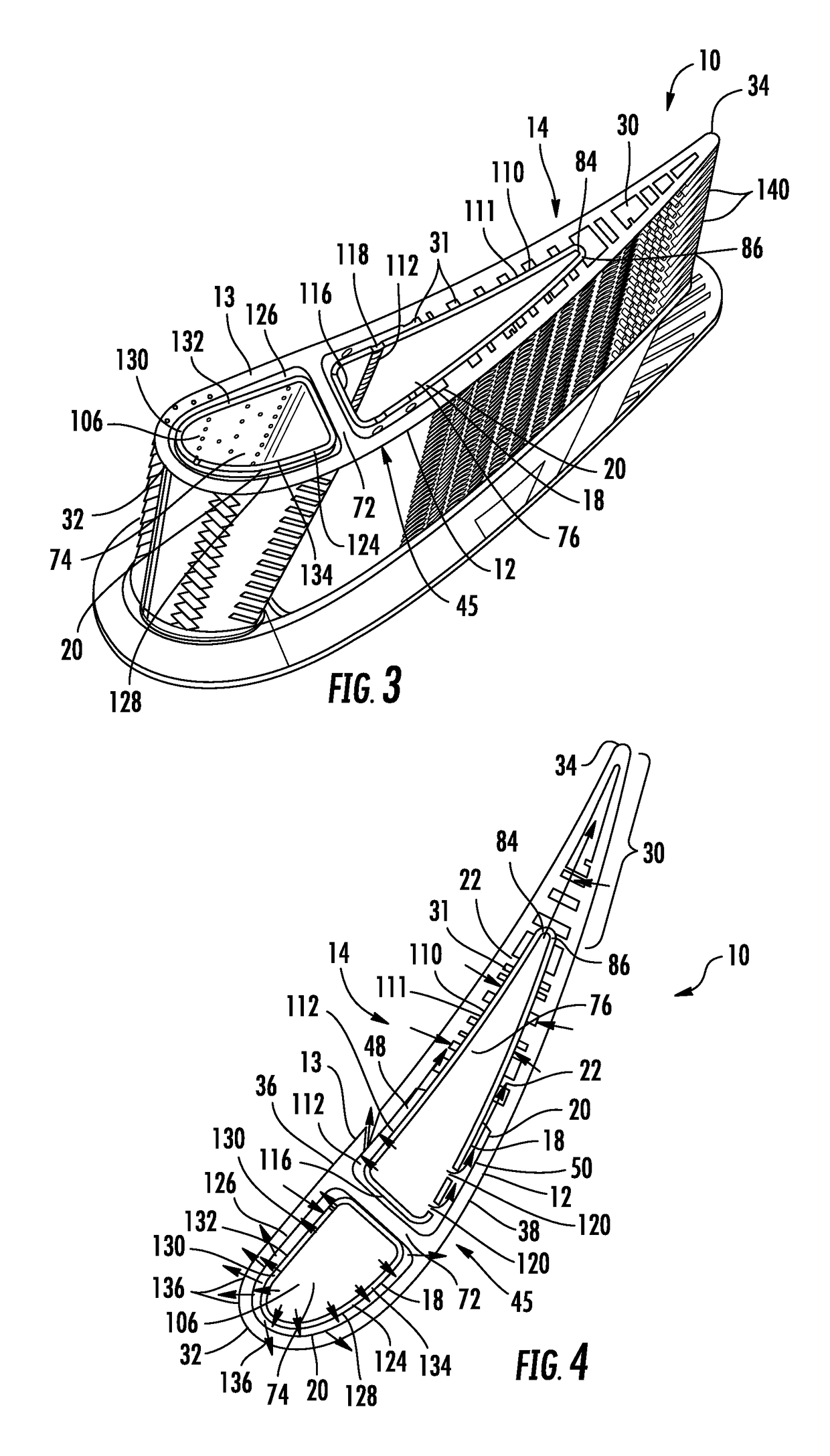

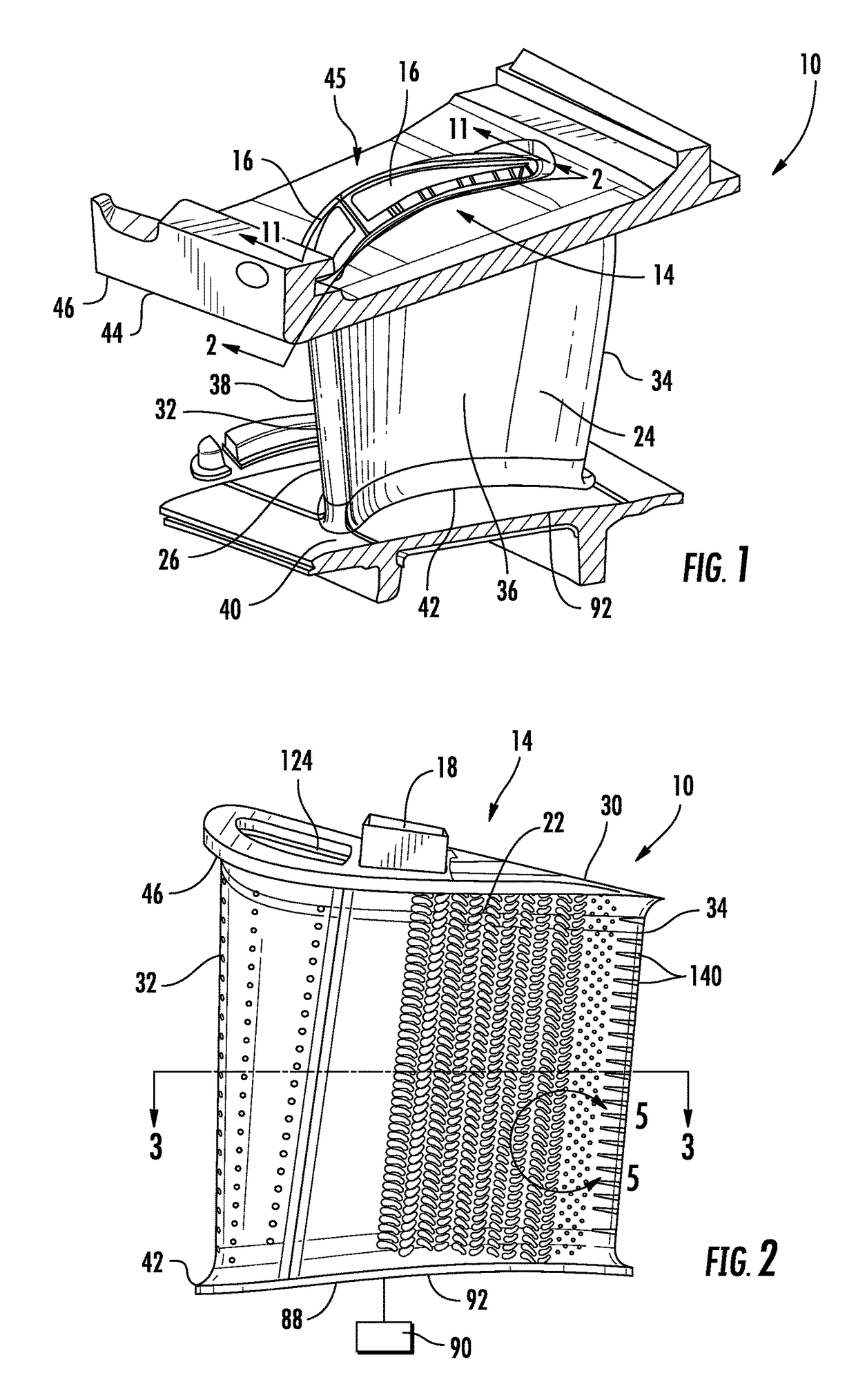

Internal cooling system with insert forming nearwall cooling channels in an aft cooling cavity of an airfoil usable in a gas turbine engine

InactiveUS9863256B2Improve flow patternImprove efficiencyEngine manufactureEngine fuctionsTrailing edgeCooling fluid

An airfoil (10) for a gas turbine engine in which the airfoil (10) includes an internal cooling system (14) with one or more internal cavities having an insert (18) contained within an aft cooling cavity (76) to form nearwall cooling channels having enhanced flow patterns is disclosed. The flow of cooling fluids in the nearwall cooling channels may be controlled via a plurality of cooling fluid flow controllers (22) extending from the outer wall (24) forming the generally hollow elongated airfoil (26). The cooling fluid flow controllers (22) may be collected into spanwise extending rows. In at least one embodiment, the cooling fluid flow controllers (22) may be positioned within a pressure side nearwall cooling channel (48) and a suction side nearwall cooling channel (50) that are both in fluid communication with a trailing edge channel (30). The trailing edge channel (30) may also include cooling fluid flow controllers (22) extending between the outer walls (12, 13) forming the pressure and suction sides.

Owner:SIEMENS AG

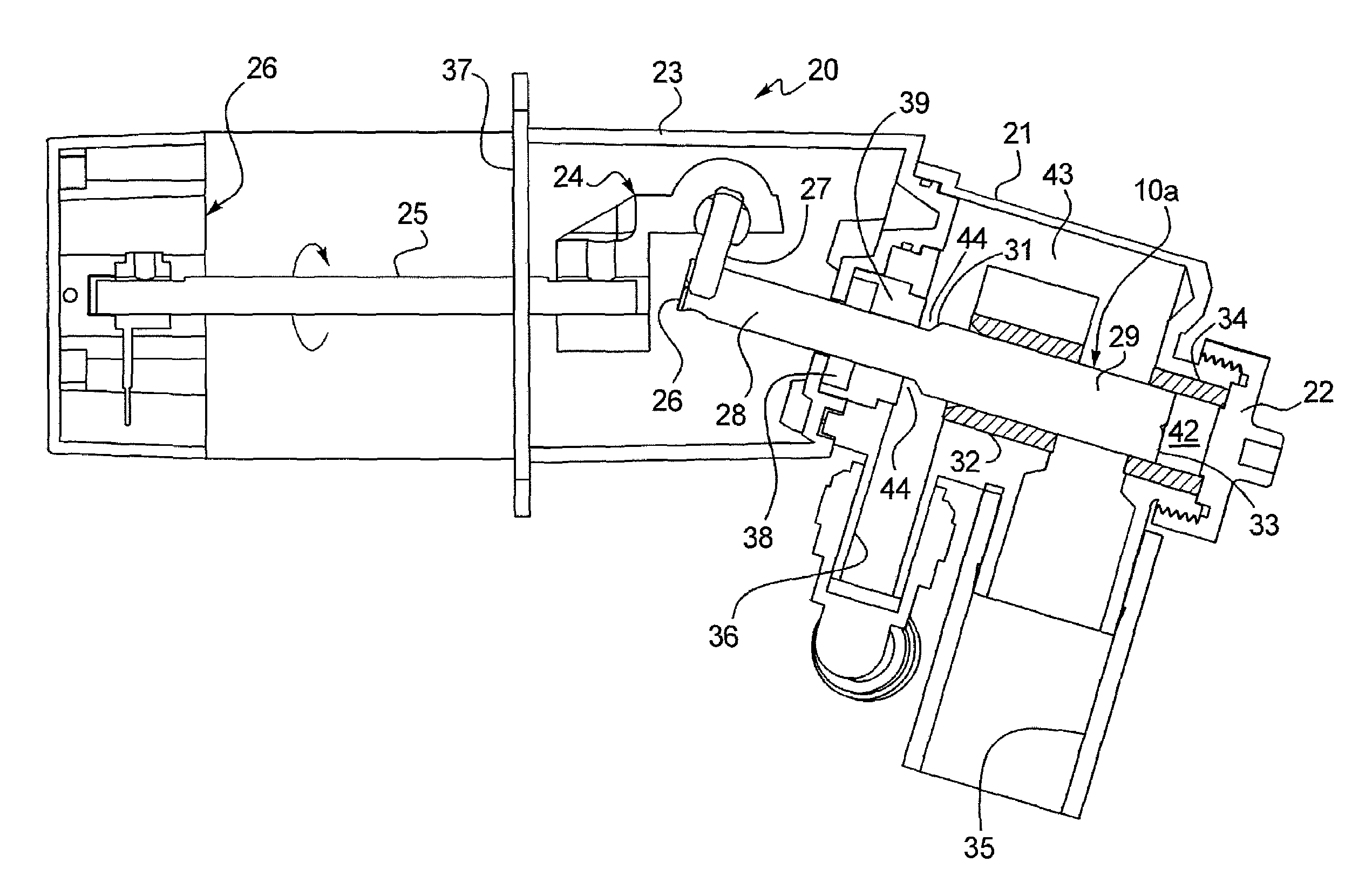

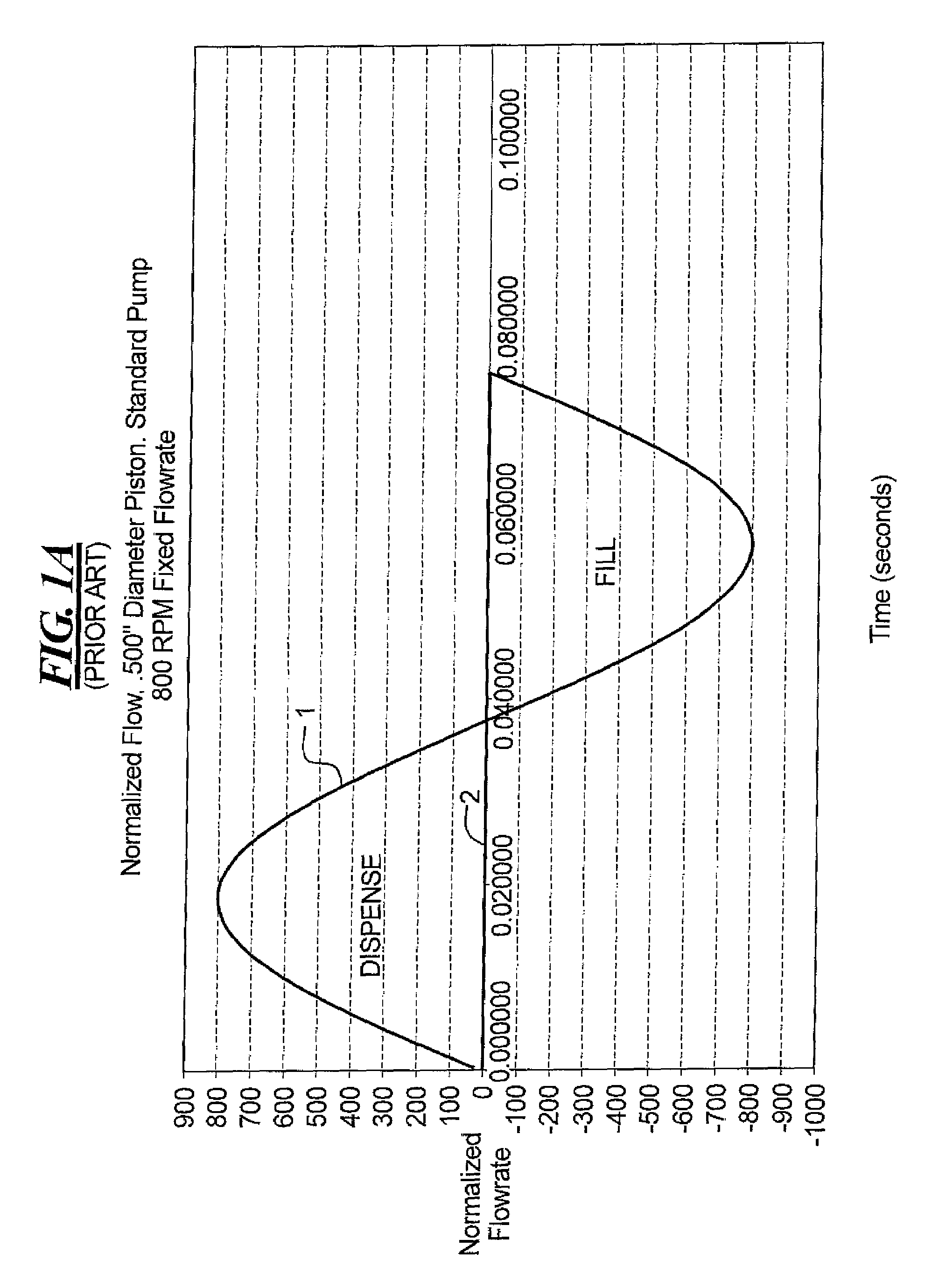

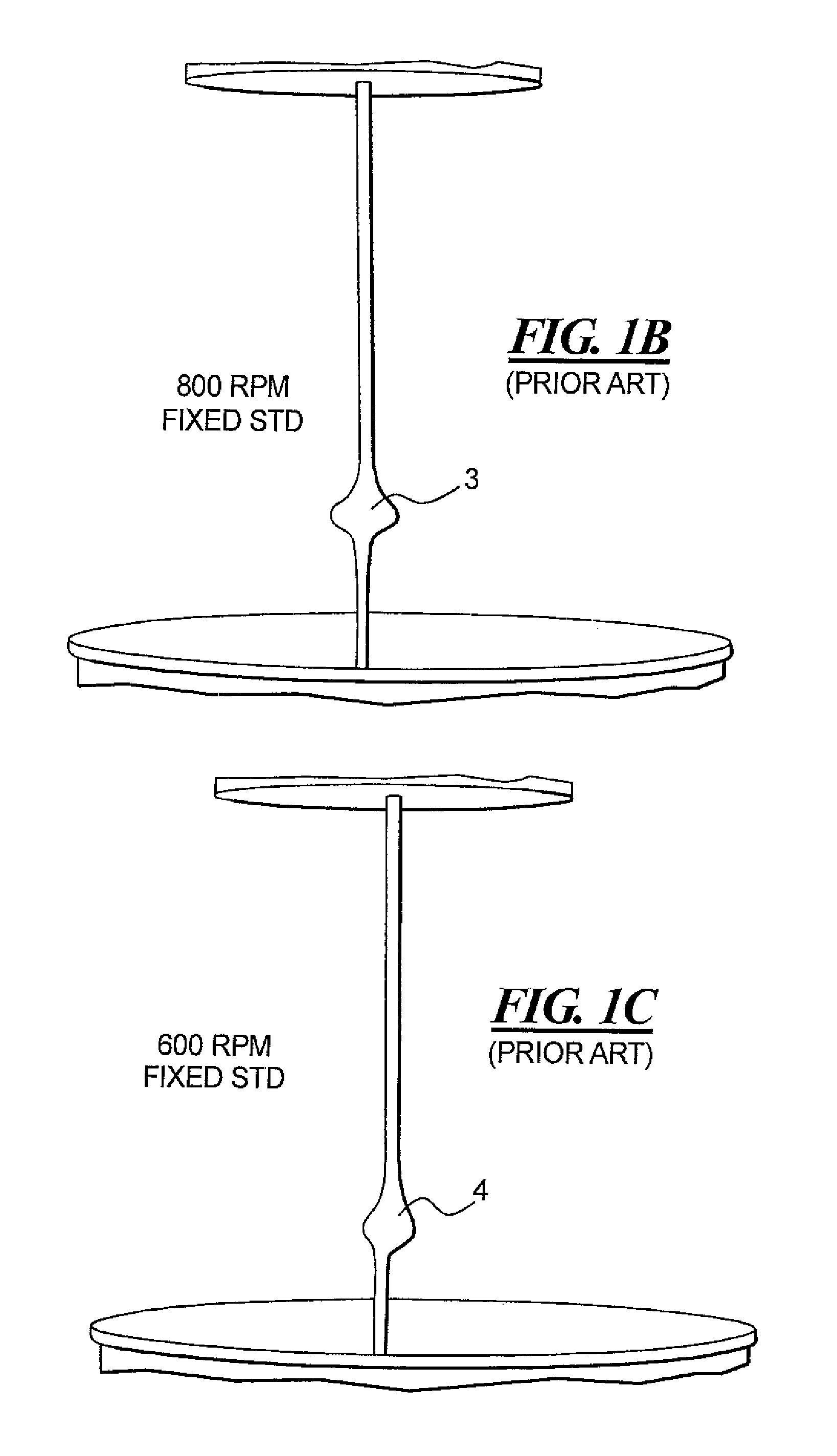

Nutating pump with reduced pulsations in output flow

ActiveUS7648349B2Improve flow patternReducing eliminating occurrencePositive displacement pump componentsPiston pumpsPump chamberEngineering

A nutating pump is disclosed which has a modified piston and housing or casing that provides two distinct pump chambers or areas. Output from the first pump chamber is delivered during a first half of the dispense cycle or the piston movement cycle. A substantial portion of this output is held for delivery by the second chamber during a second part or half of the dispense cycle. Thus, the output generated by the pump is not altered or reduced, it is delivered over the entire piston movement cycle as opposed to prior art pumps which deliver all of the fluid during a first half or first portion of the piston movement cycle. In this way, superior pulse modification is achieved as fluid is delivered across the entire piston movement cycle as opposed to a first half or first portion of the piston movement cycle. In additional embodiments disclosed, two distinct chambers are also provided but each chamber generates its own output as the piston includes two machined or flat sections for active pumping. Thus, each chamber generates its own positive output flow but the flow from each chamber is delivered during a different half of the piston movement cycle. Thus, the flow is still distributed throughout the entire piston movement cycle. In the first embodiment with a first and second chamber, the second chamber essentially acts as a holding station for fluid to be delivered during a second half of the piston movement cycle.

Owner:FLUID MANAGEMENT LLC

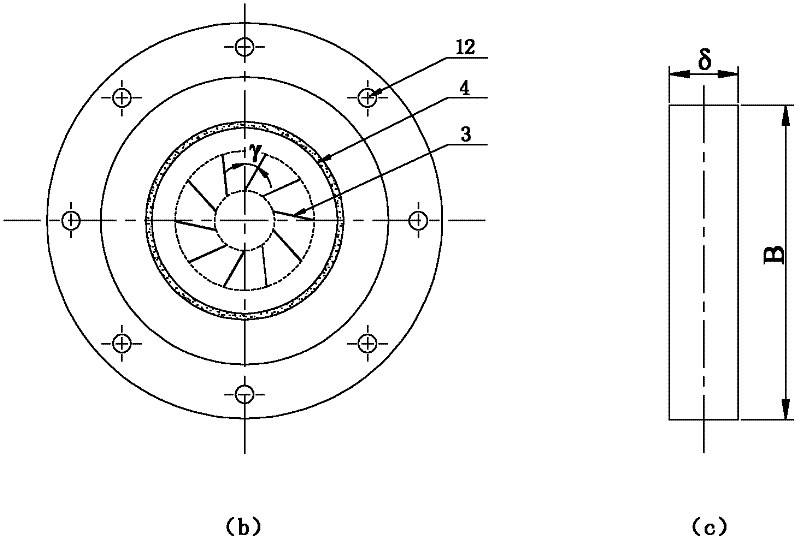

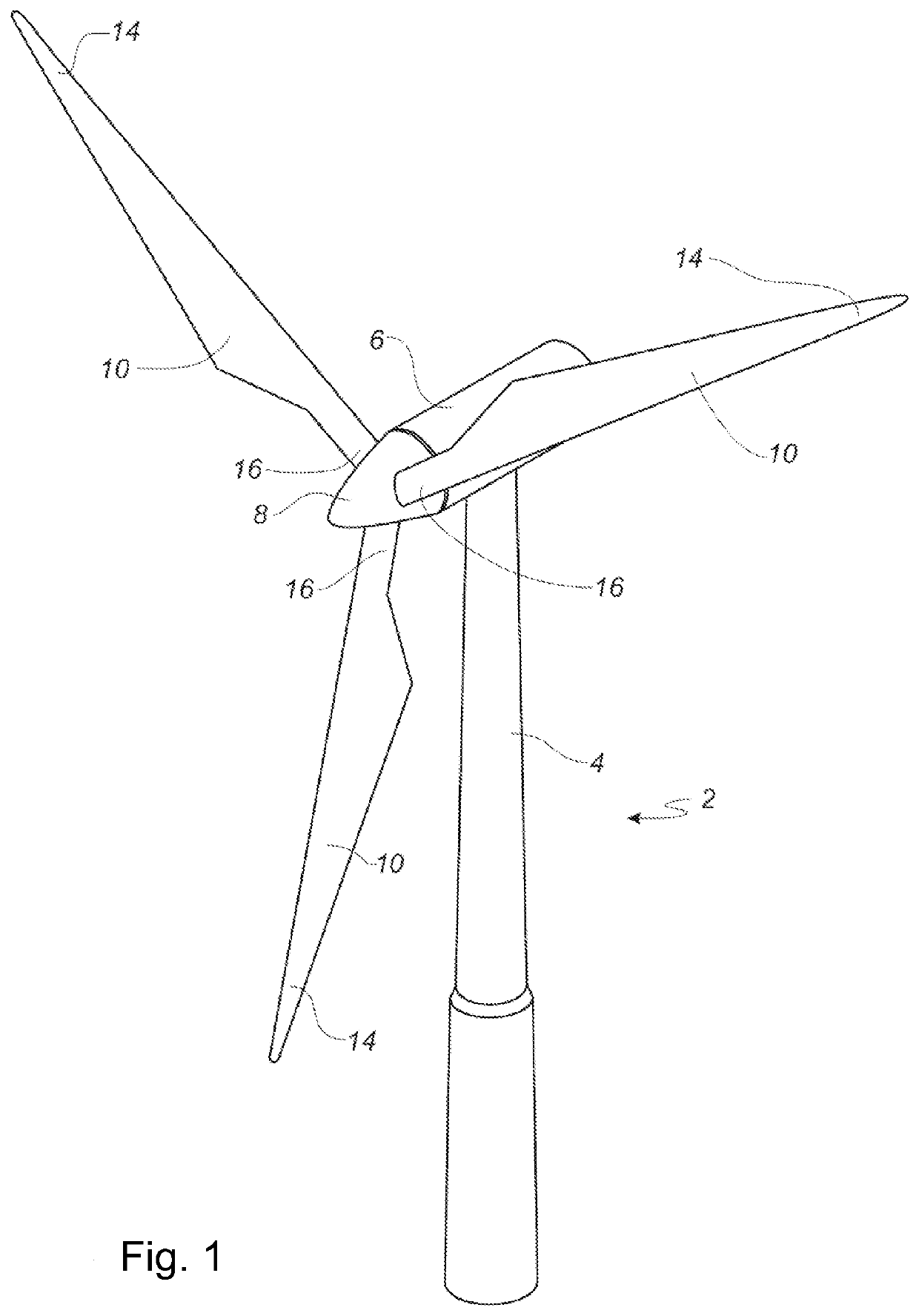

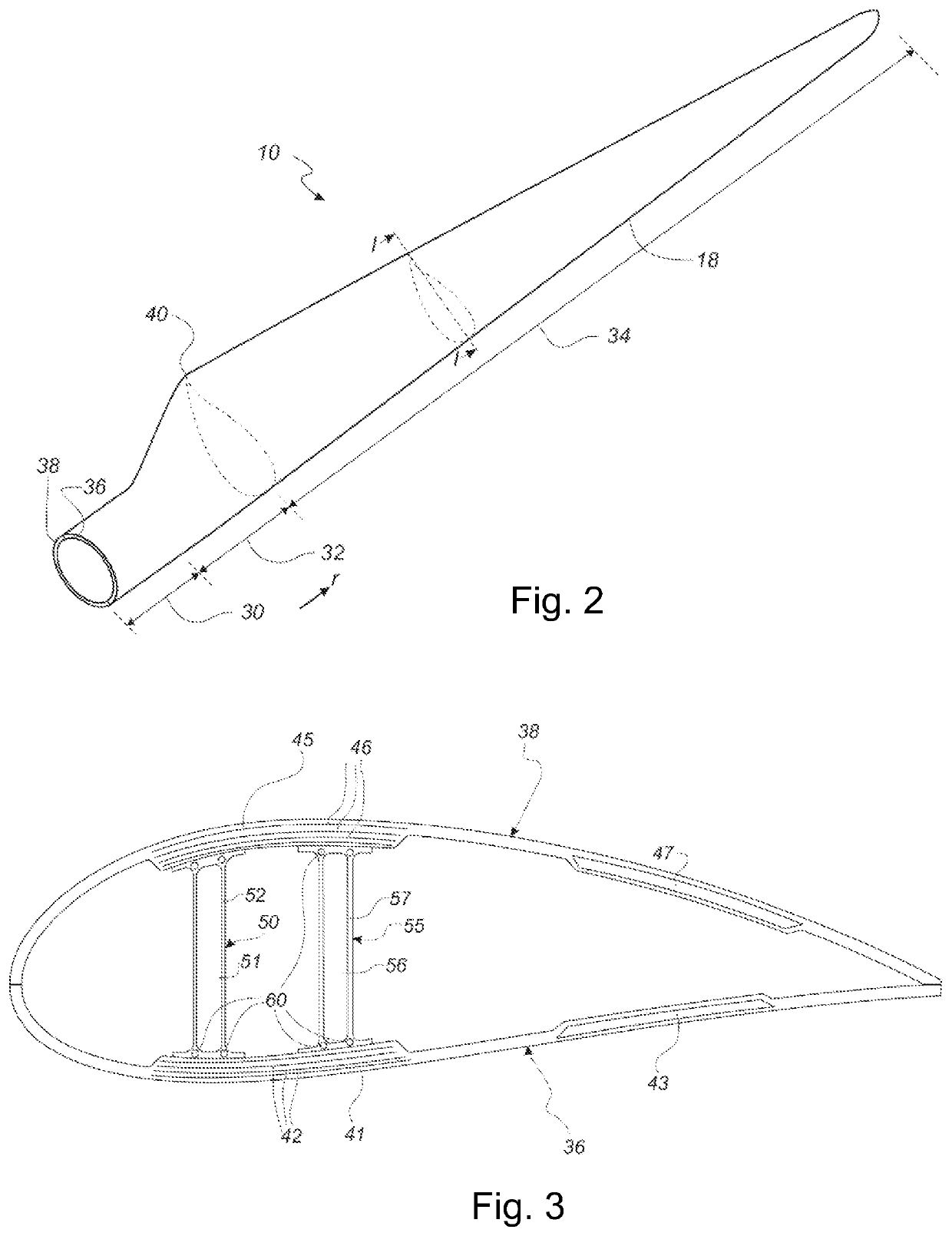

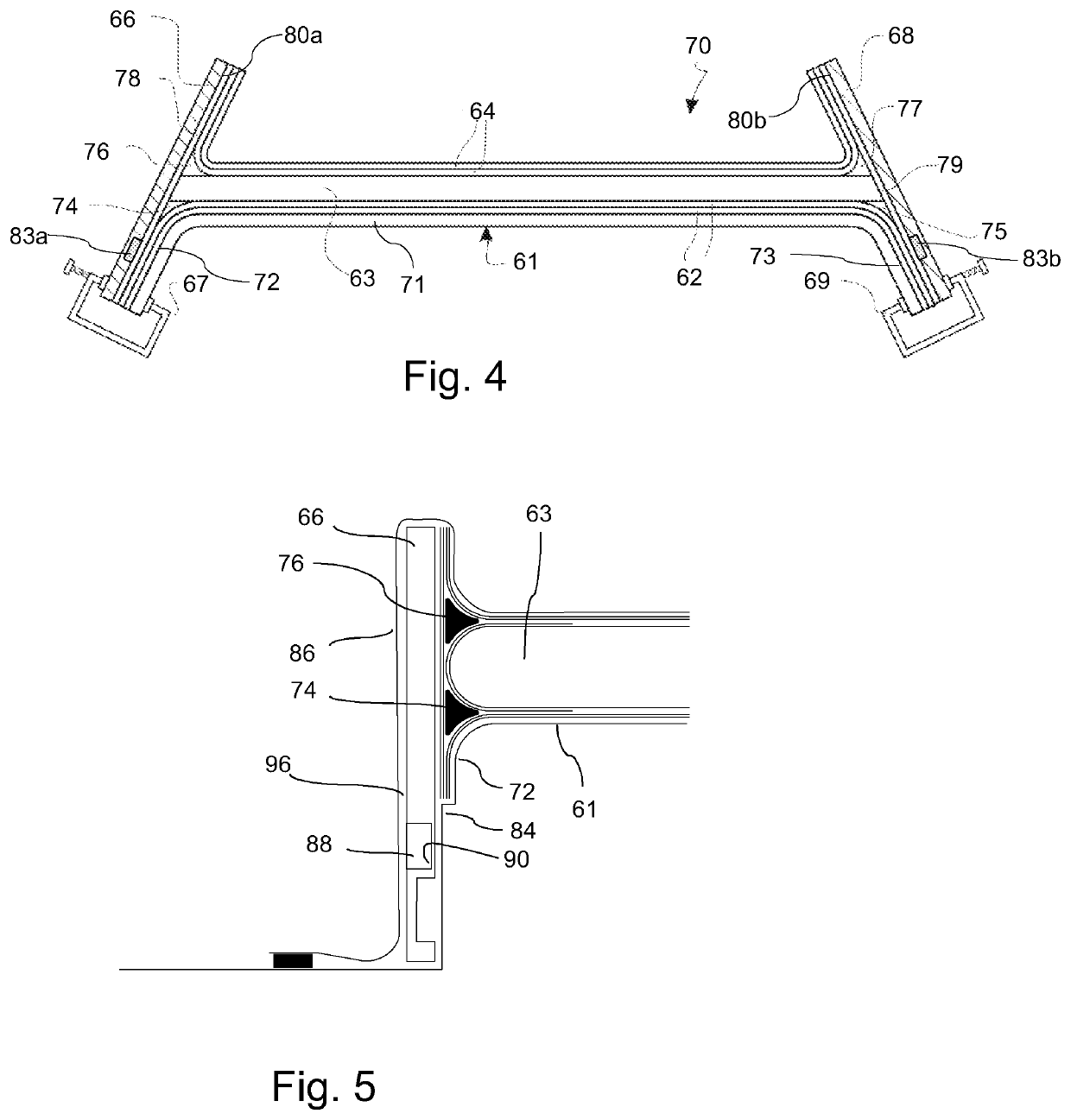

Method and system for manufacturing a shear web for a wind turbine

ActiveUS20200023557A1Easy to doImprove flow patternFinal product manufactureWind energy generationFiberTurbine blade

The present invention relates to a method and to a mould system (70) for manufacturing a shear web for a wind turbine blade as well as to a backing plate (66) for such method and mould system. The method involves arranging one or more fibre layers on top of a web mould part (61), arranging backing plates (66) at each end to create a mould cavity between the first and second backing plate (66, 68) and the web mould part (61). Each backing plate (66, 68) comprises an inner moulding surface (80), outer surfaces (98, 100) and a channel (82) or groove (83) extending between at least one of the outer surfaces (98, 100) and the inner moulding surface (80). Resin is supplied to the mould cavity via each channel or groove of the first and second backing plate (66, 68), and subsequently the resin is cured or hardened to form the shear web.

Owner:LM WIND POWER US TECH APS

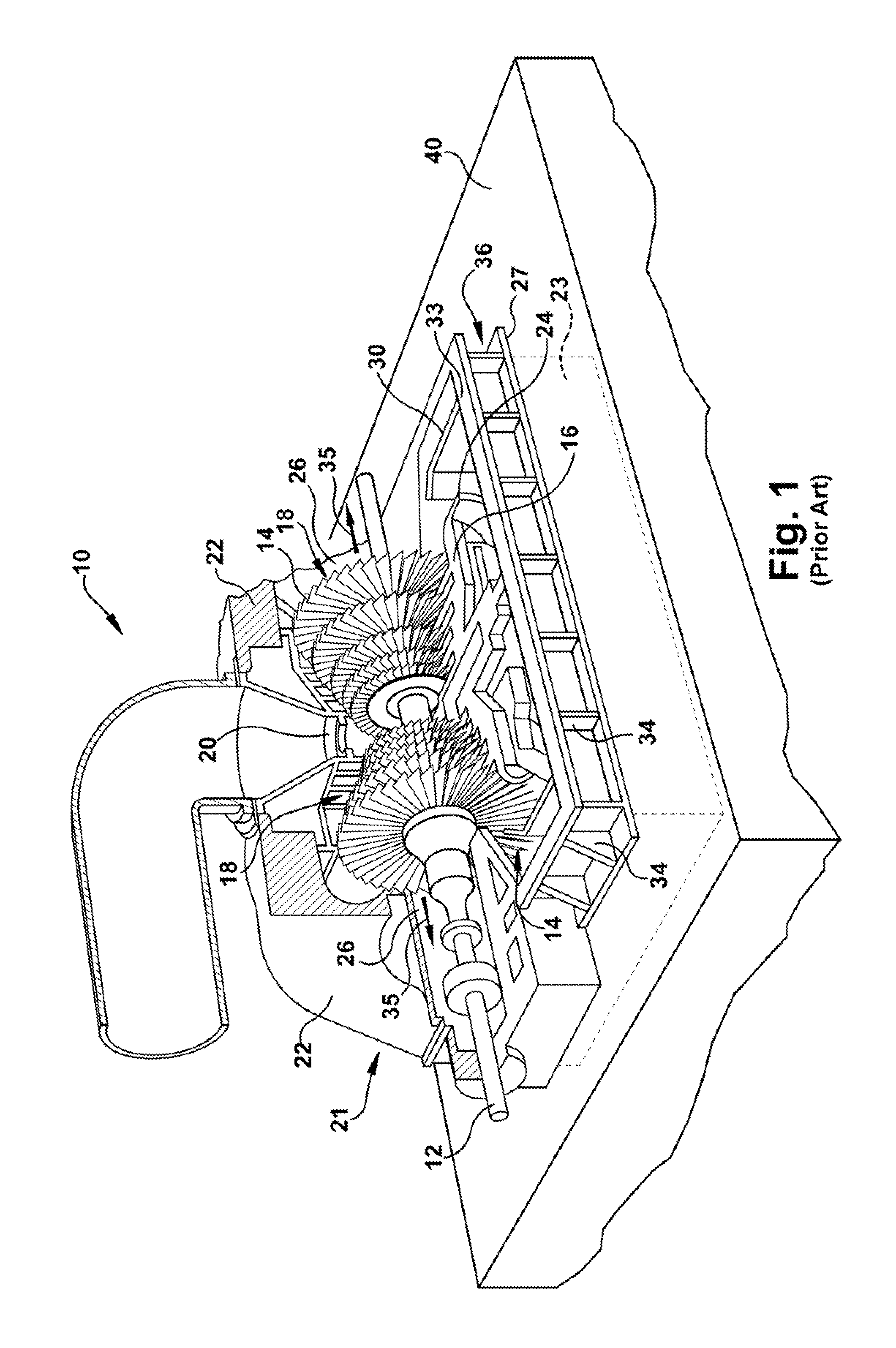

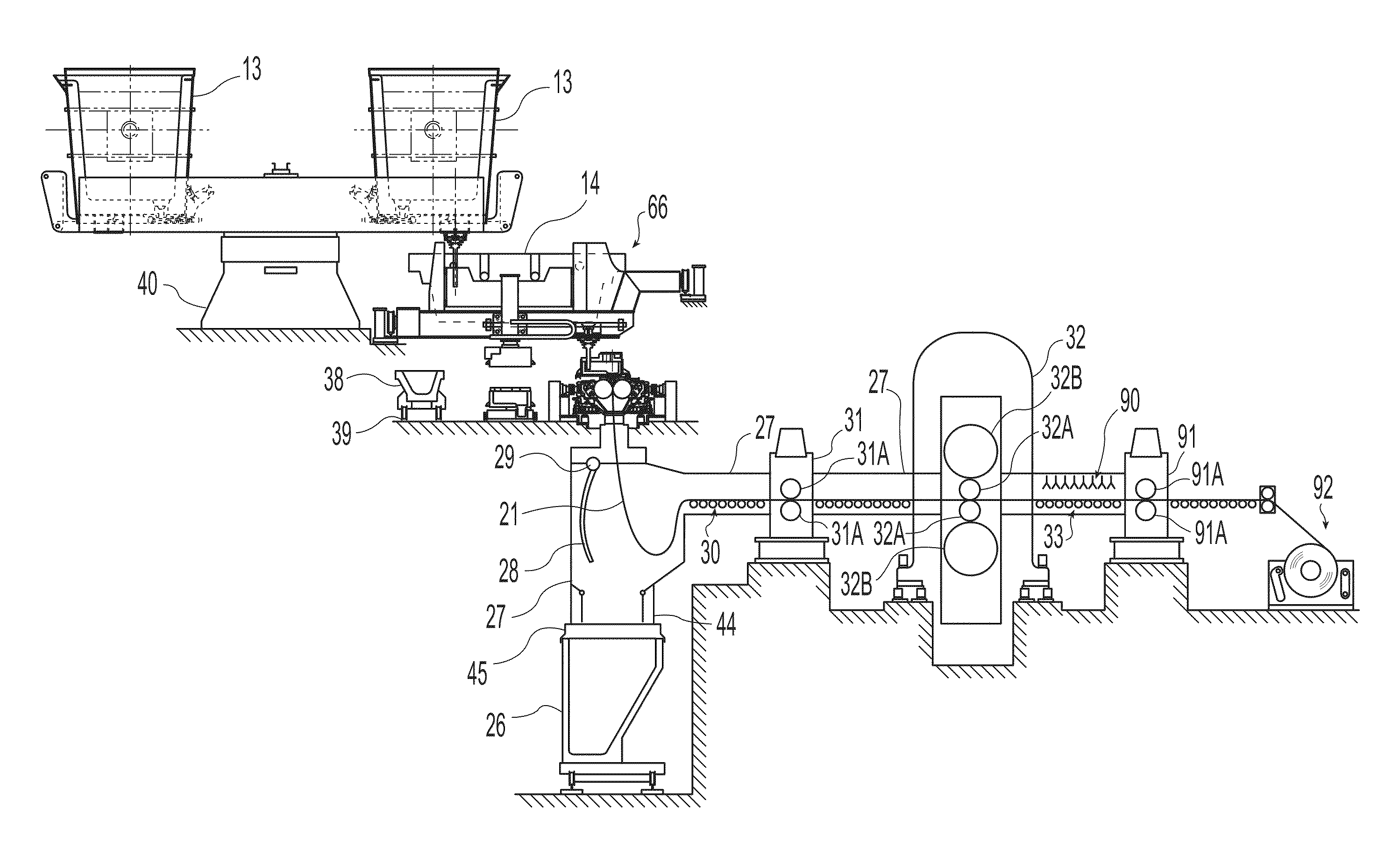

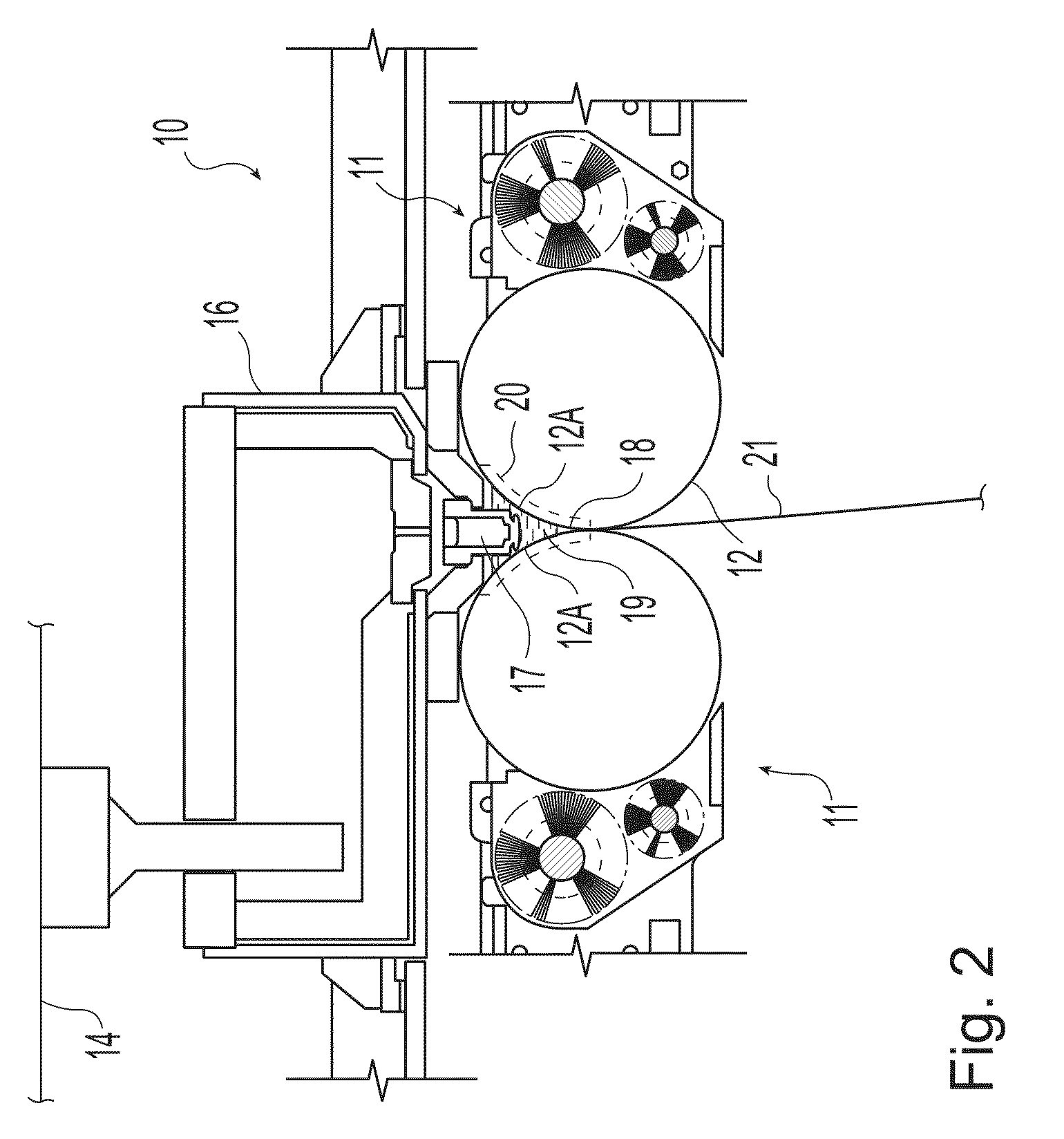

Strip casting apparatus with improved side dam

Apparatus for continuously casting metal strip includes a pair of counter-rotatable casting rolls laterally positioned to form a nip there between through which thin strip can be cast, a pair of confining side dams adjacent the ends of the casting rolls capable of confining a casting pool of molten metal supported on the casting rolls above the nip, each side dam having a surface capable of contacting the molten metal of the casting pool, with unraised portions and raised portions to form troughs with the unraised portions as base between the raised portion of the side dam and the casting surfaces of the casting rolls to guide the flow of molten metal, and a metal delivery system disposed above the nip and capable of discharging molten metal to form the casting pool supported on the casting rolls.

Owner:NUCOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com