Patents

Literature

58 results about "Beta angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

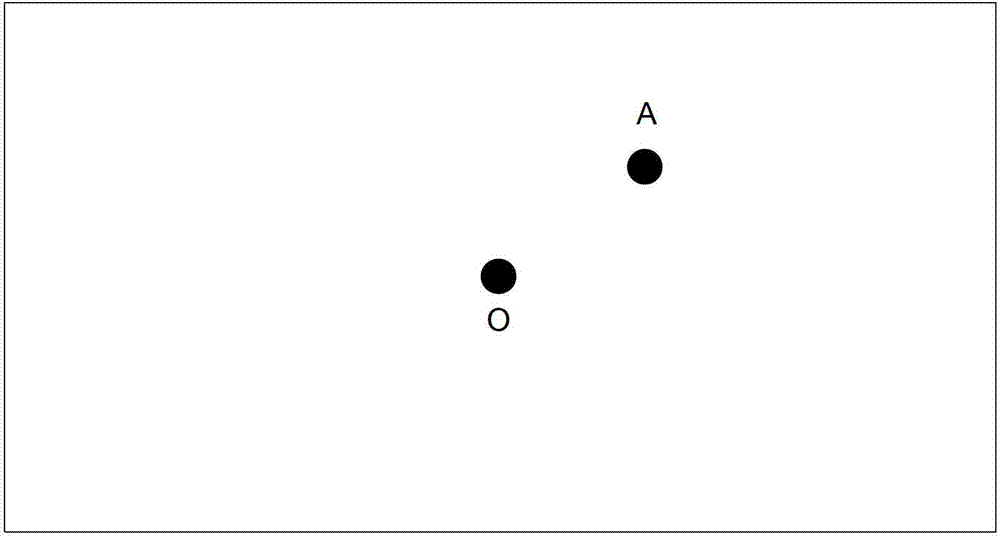

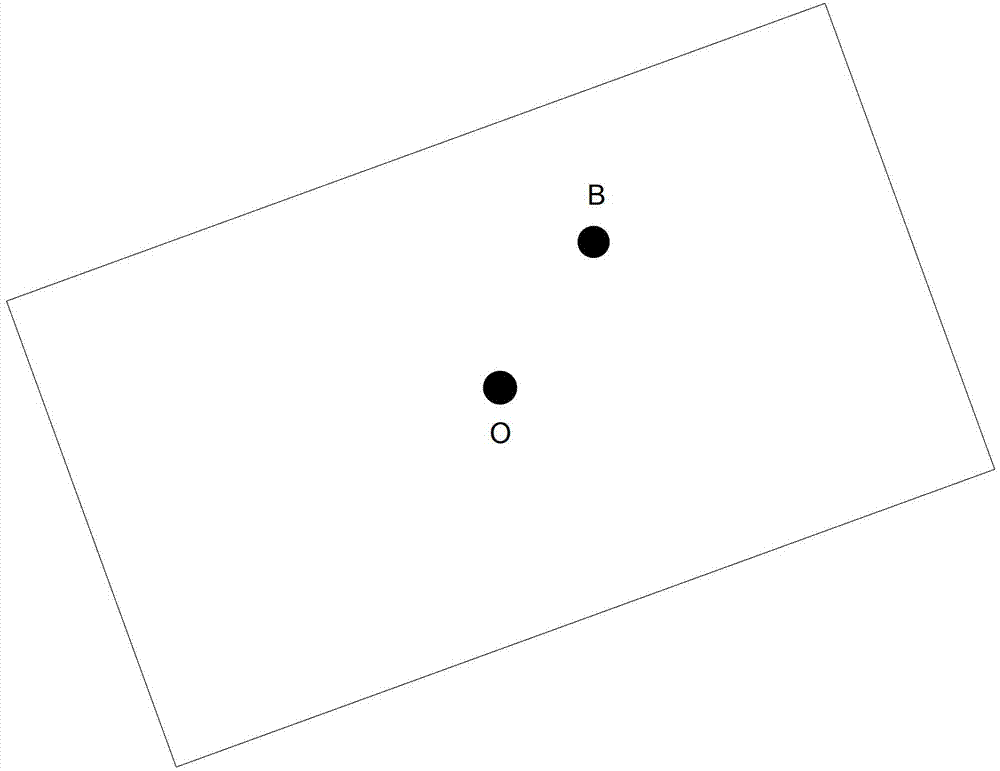

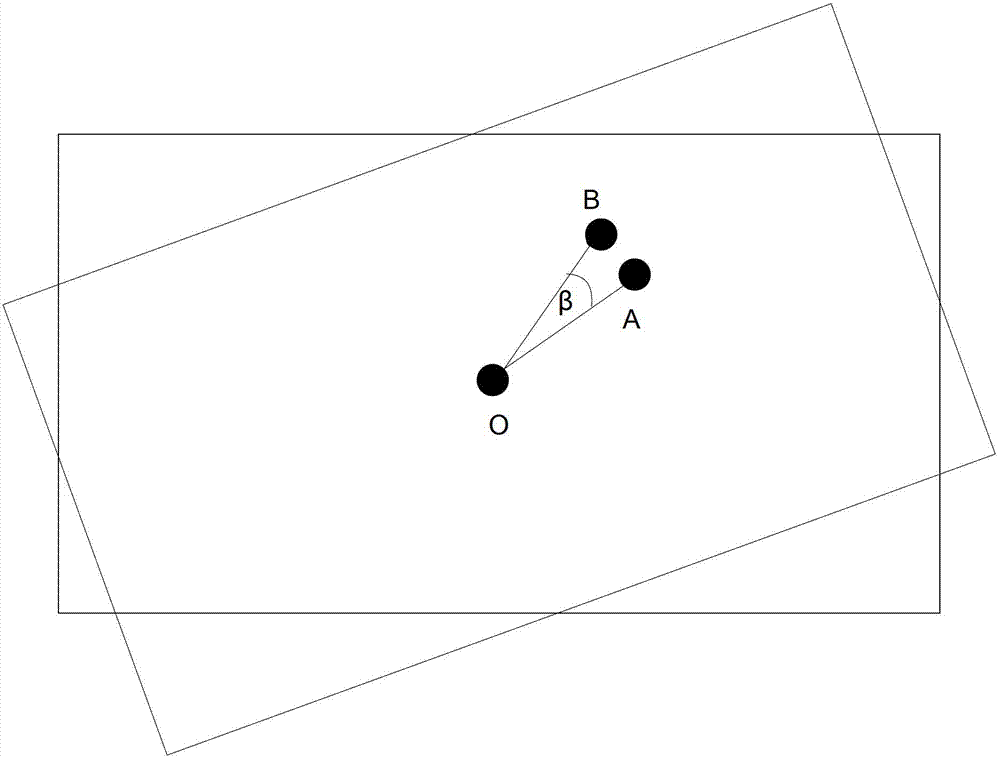

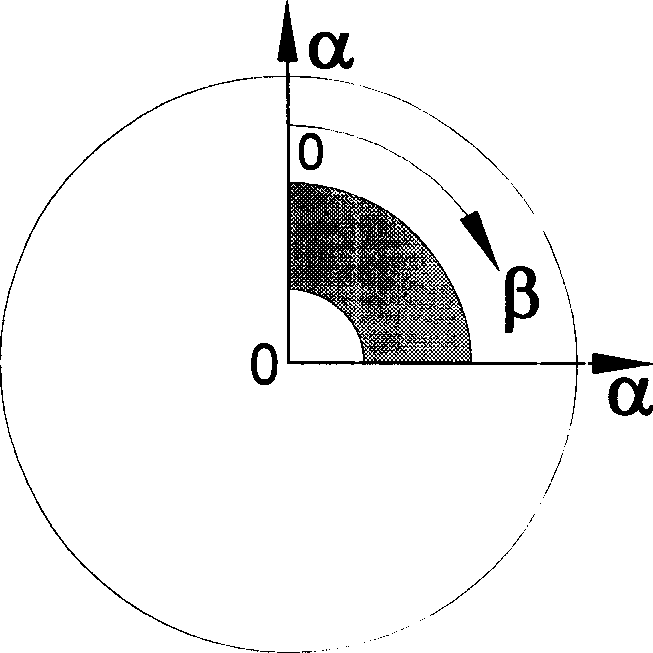

The beta angle (β) is a measurement that is used most notably in orbital spaceflight. The beta angle determines the percentage of time that a satellite in low Earth orbit (LEO) spends in direct sunlight, absorbing solar energy. The term is defined as the angle between the orbital plane of the satellite and the vector to the Sun (i.e., the direction from which the Sun is shining). The beta angle is the smaller of the two angles between the Sun vector and the plane of the object's orbit.

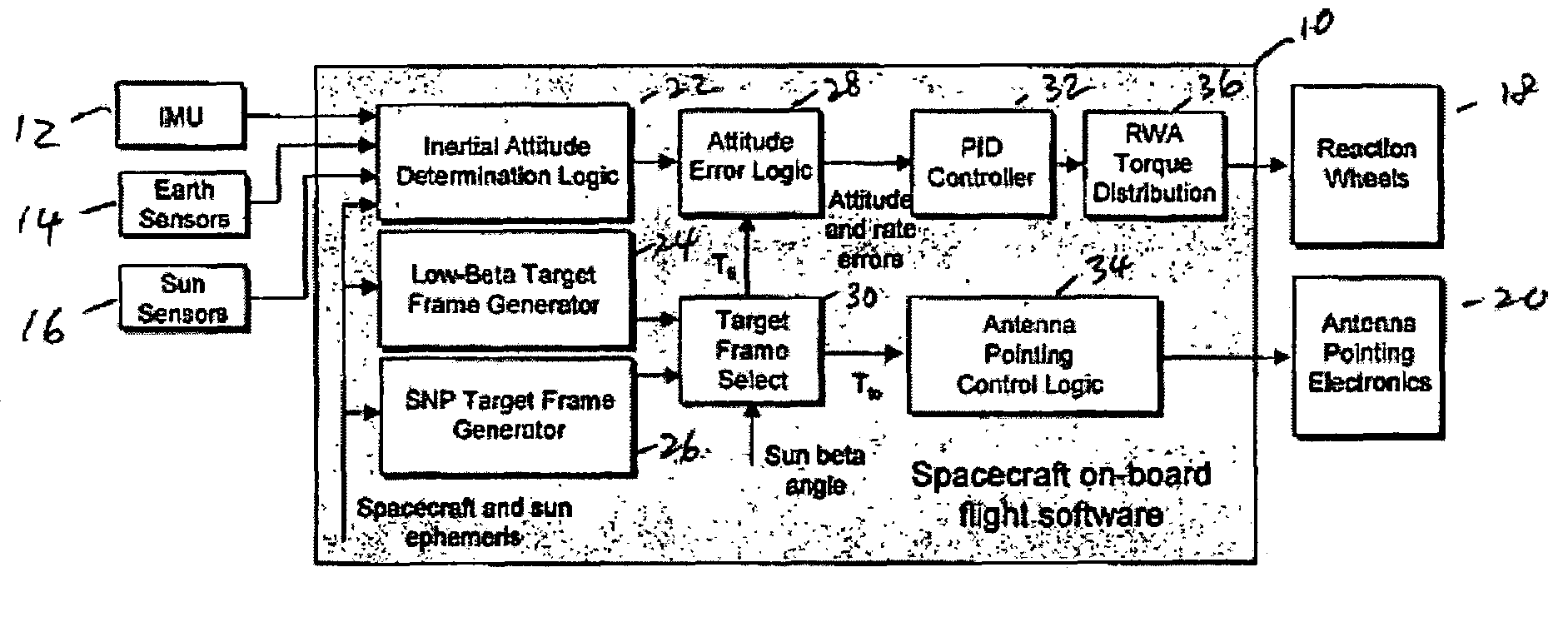

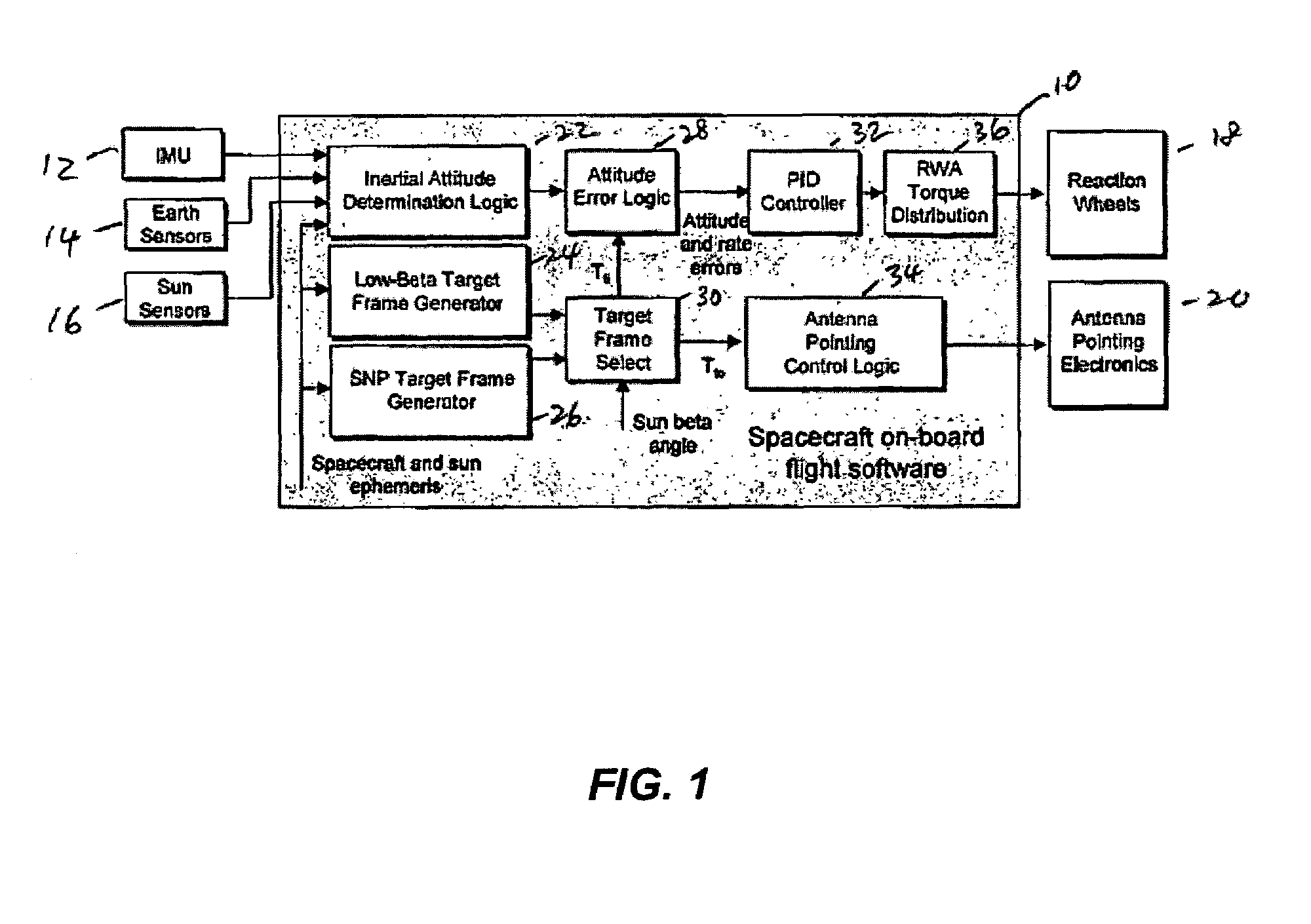

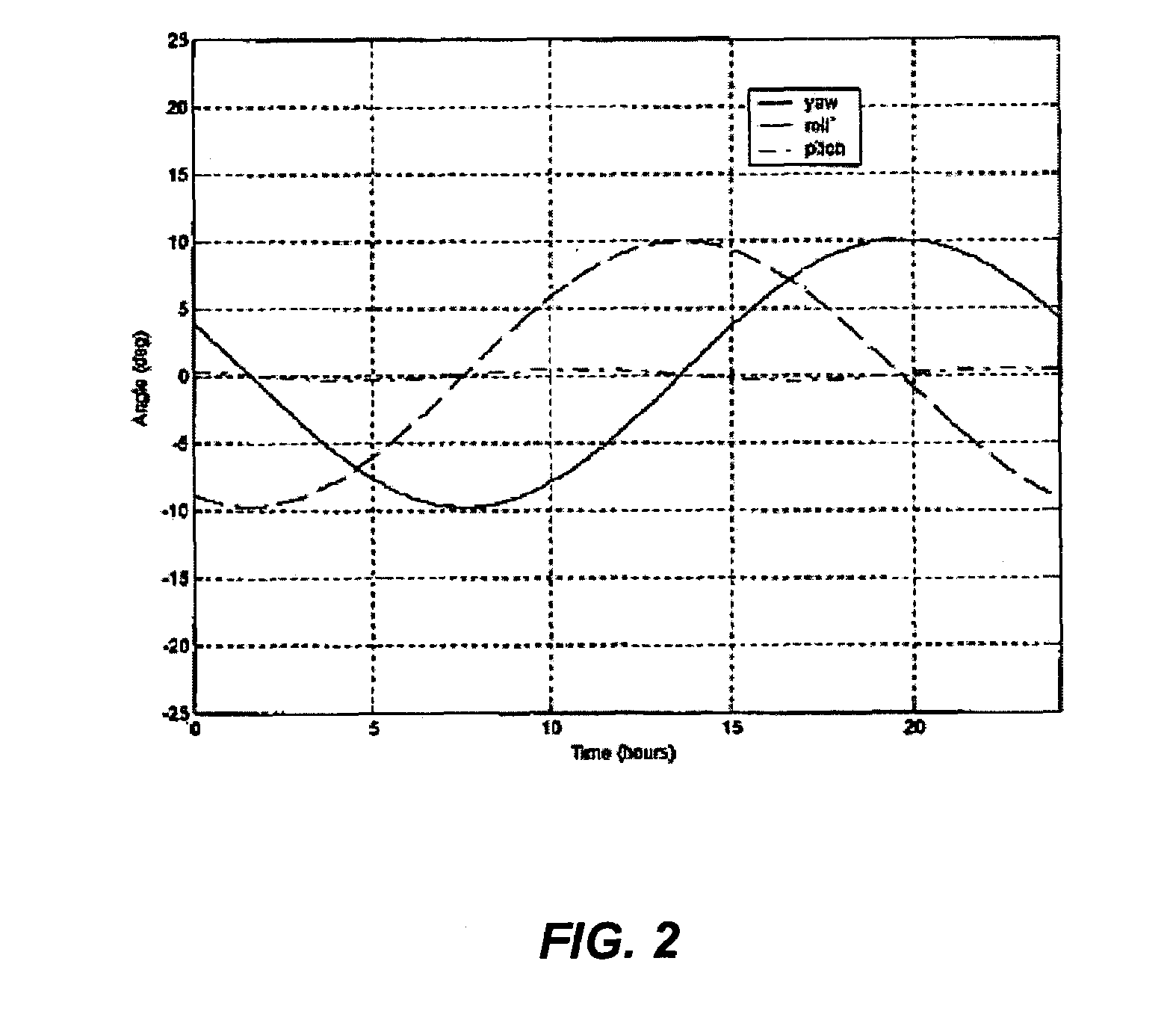

Attitude and antenna steering system for geosynchronous earth orbit (GEO) spacecraft

ActiveUS7357356B1High rateLarge rotation angleCosmonautic vehiclesRadio transmissionBeta angleGeosynchronous orbit

A system for providing attitude and antenna steering for a spacecraft is disclosed. The spacecraft has a number of reaction wheels and a number of antennas. The system includes control logic configured to: determine a beta angle, the beta angle being the angle between a sun vector and an orbit plane of the spacecraft, and alternately engage either a first mode or a second mode to provide attitude and antenna steering based on the beta angle.

Owner:LOCKHEED MARTIN CORP

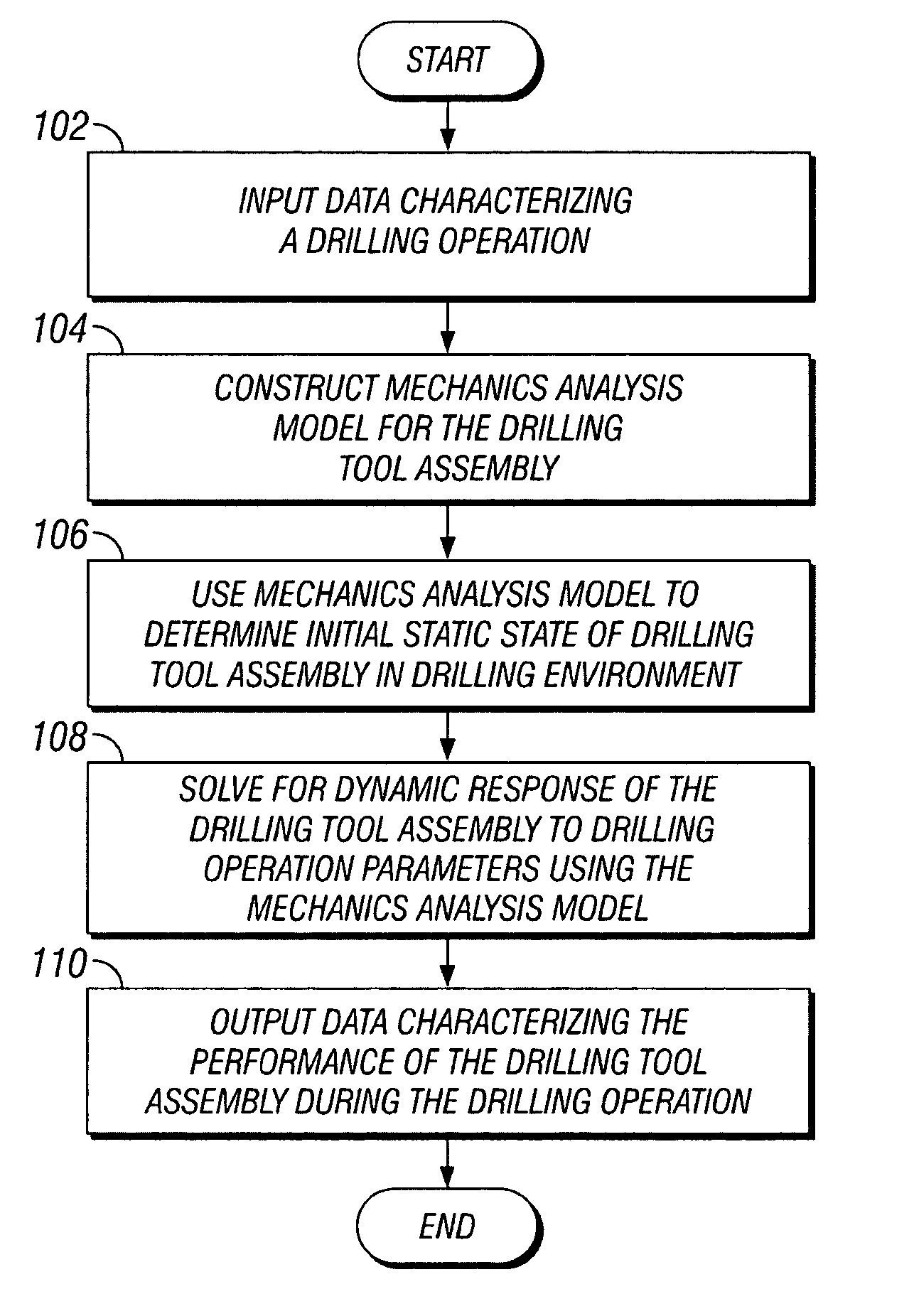

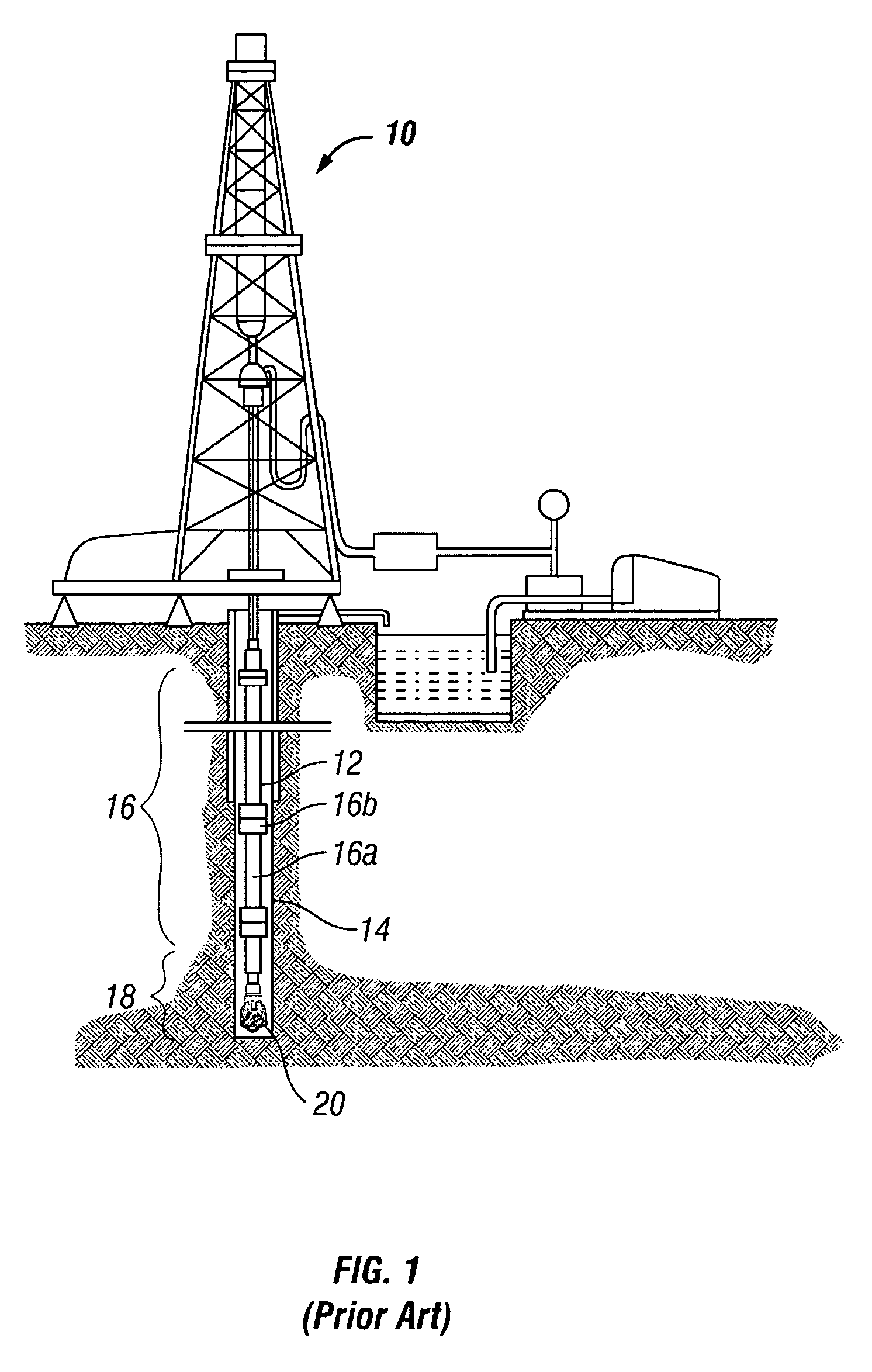

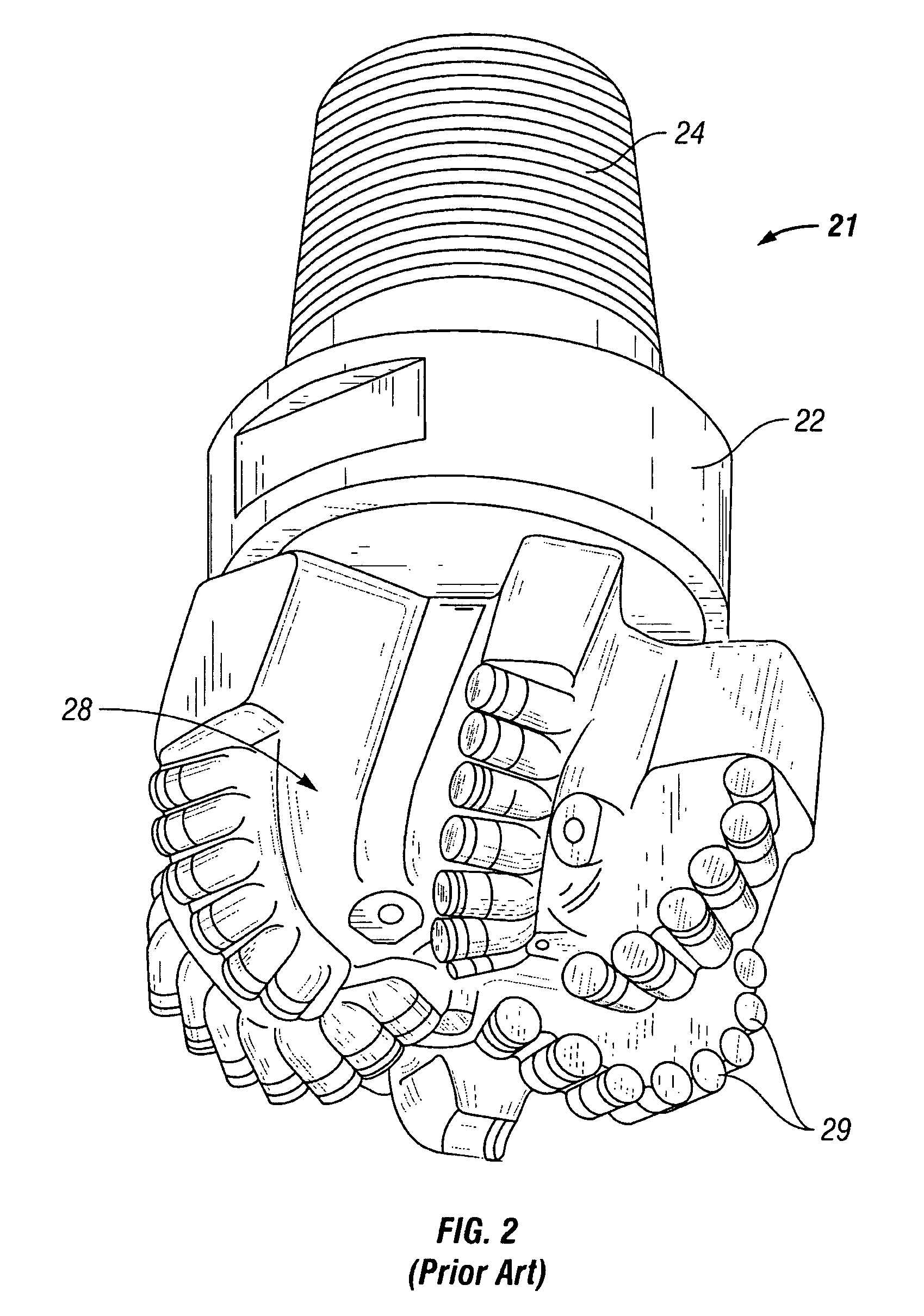

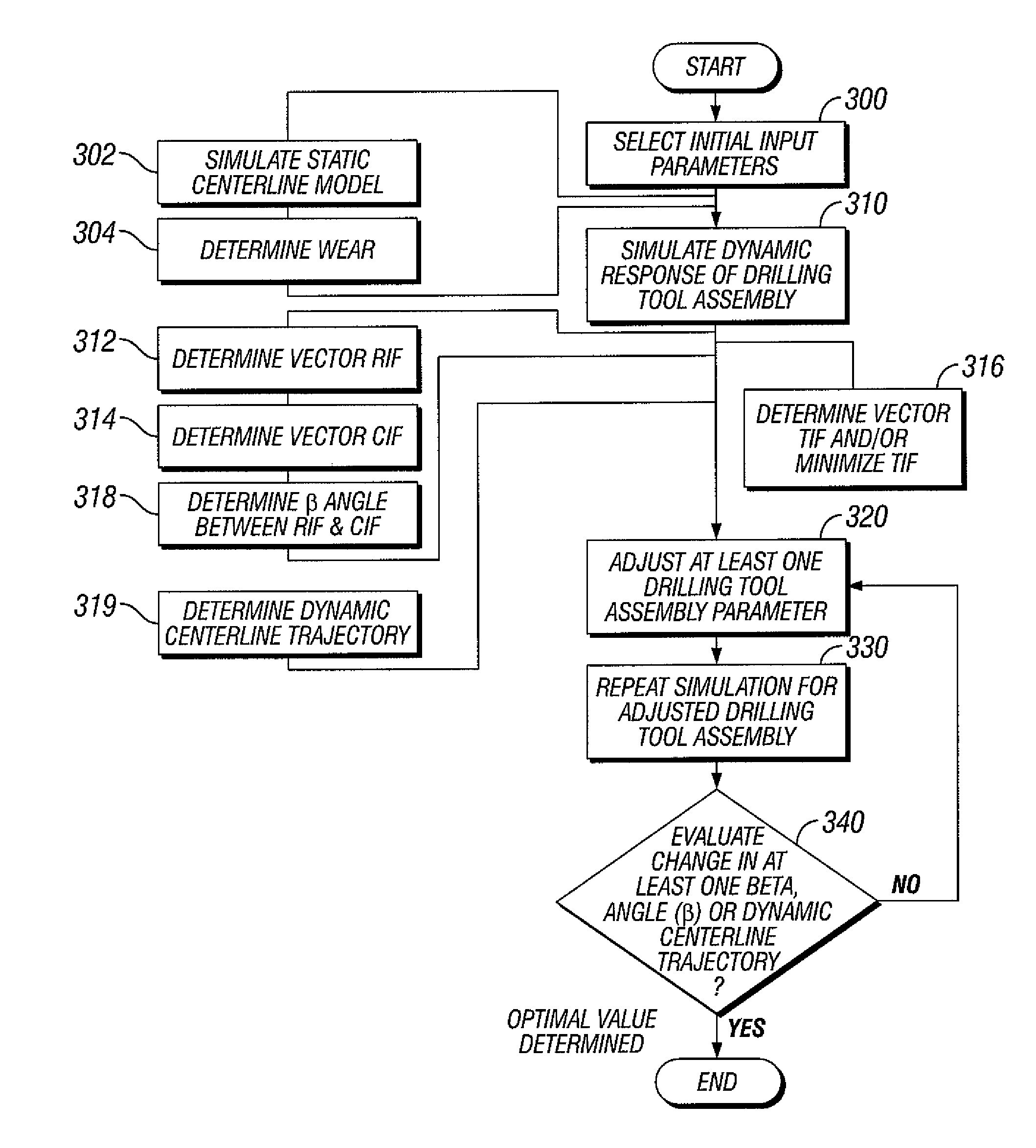

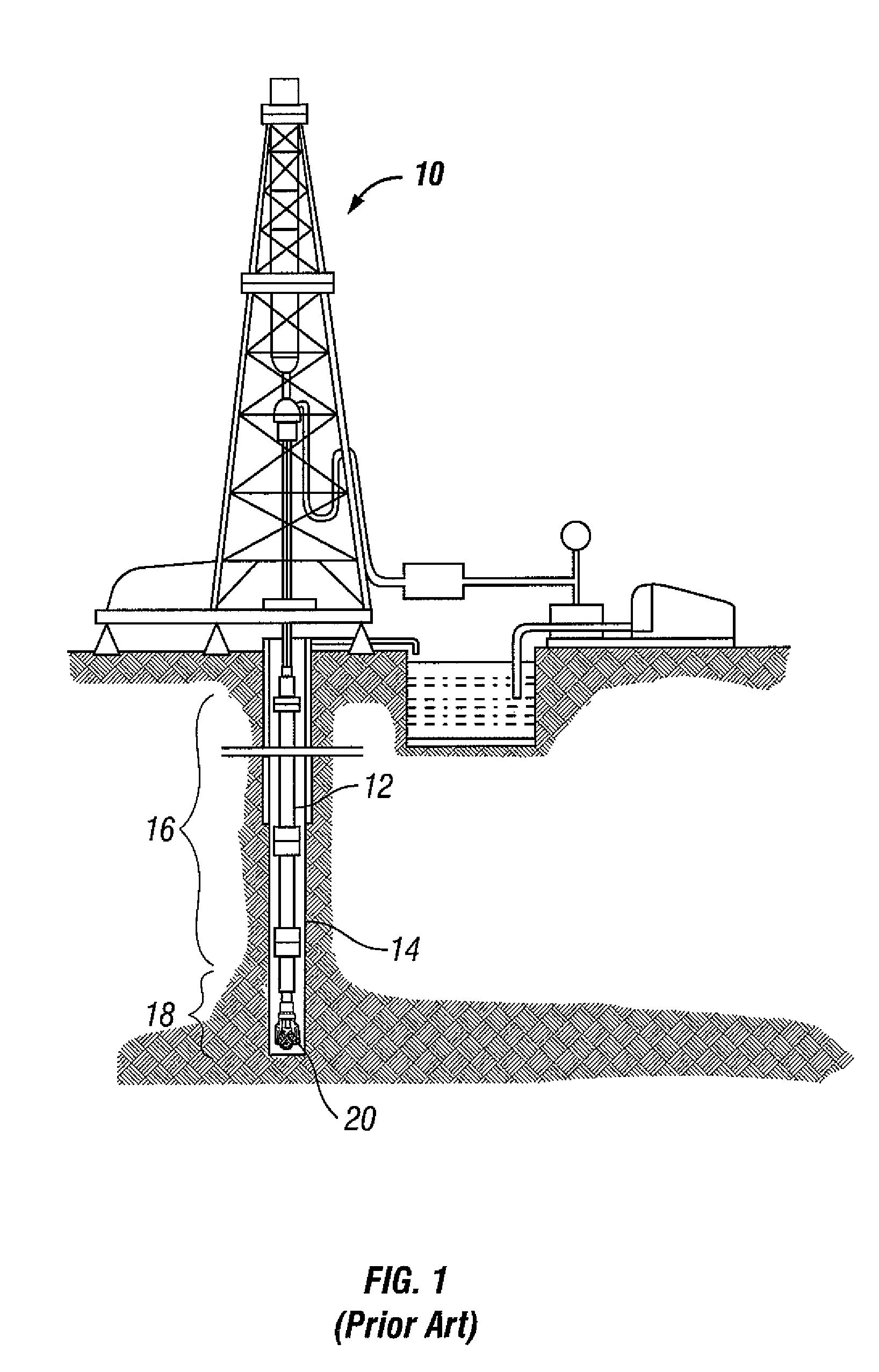

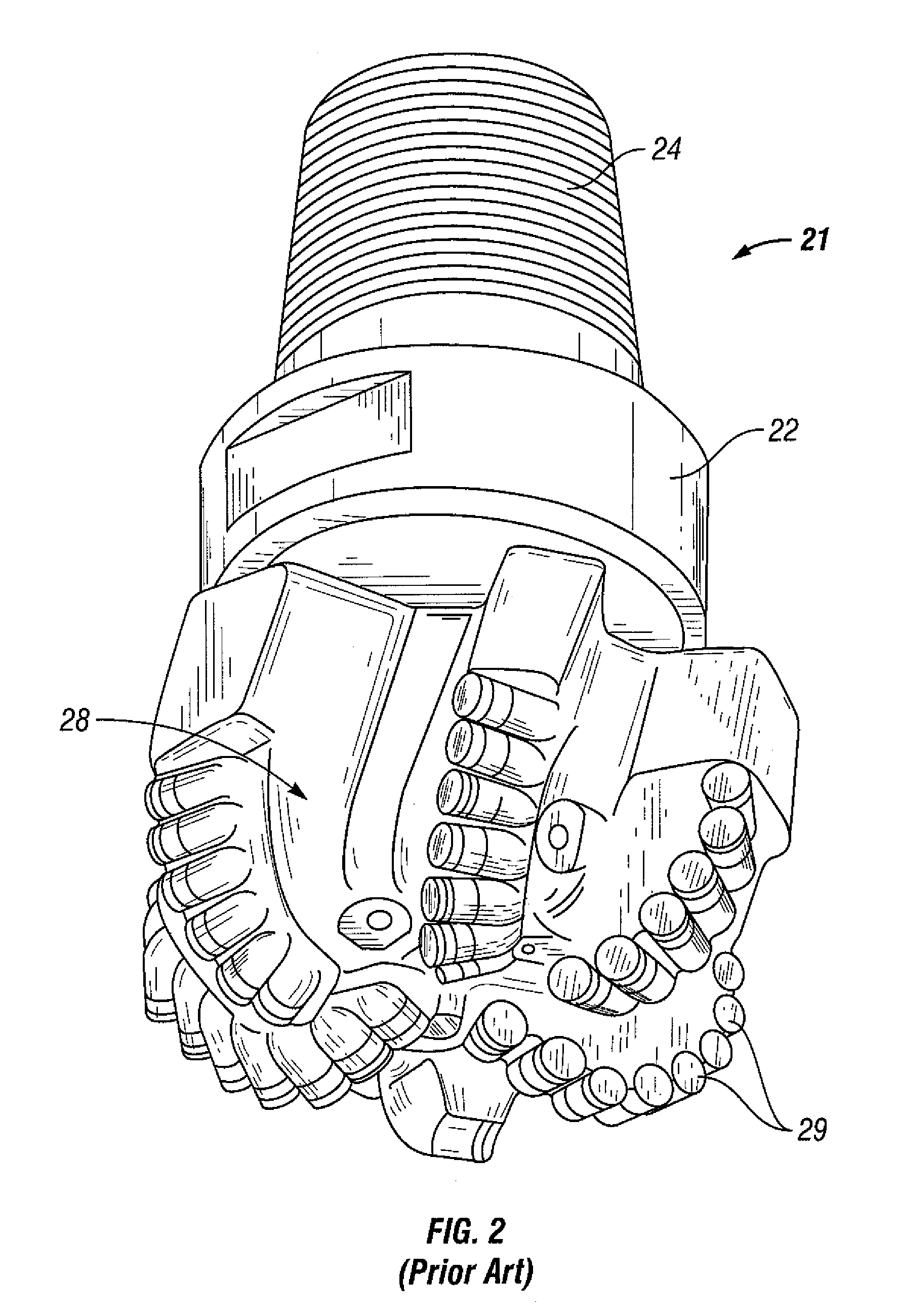

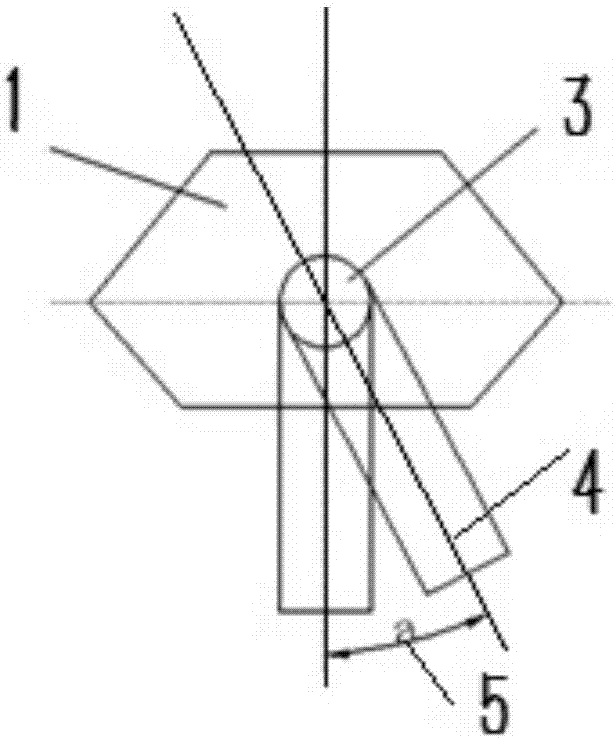

PDC drill bit with cutter design optimized with dynamic centerline analysis having an angular separation in imbalance forces of 180 degrees for maximum time

InactiveUS20060167669A1Improve accuracyWeakening rangeDrill bitsDesign optimisation/simulationBeta angleEngineering

A method for designing a fixed cutter drill bit, includes simulating the fixed cutter drill bit drilling in an earth formation, determining radial and circumferential components of imbalance forces on the drill bit and a Beta angle between the radial and circumferential components of the imbalance forces during a period of simulated drilling, and adjusting a value of at least one design parameter for the fixed cutter drill bit at least based upon the Beta angle. To facilitate drill bit design, the Beta angel can be displayed to a drill bit designer. To improve performance, the method can include repeating the simulating, determining, and adjusting to change a simulated performance of the fixed cutter drill bit. A drill bit may be made according to the design resulting from the method.

Owner:SMITH INT INC

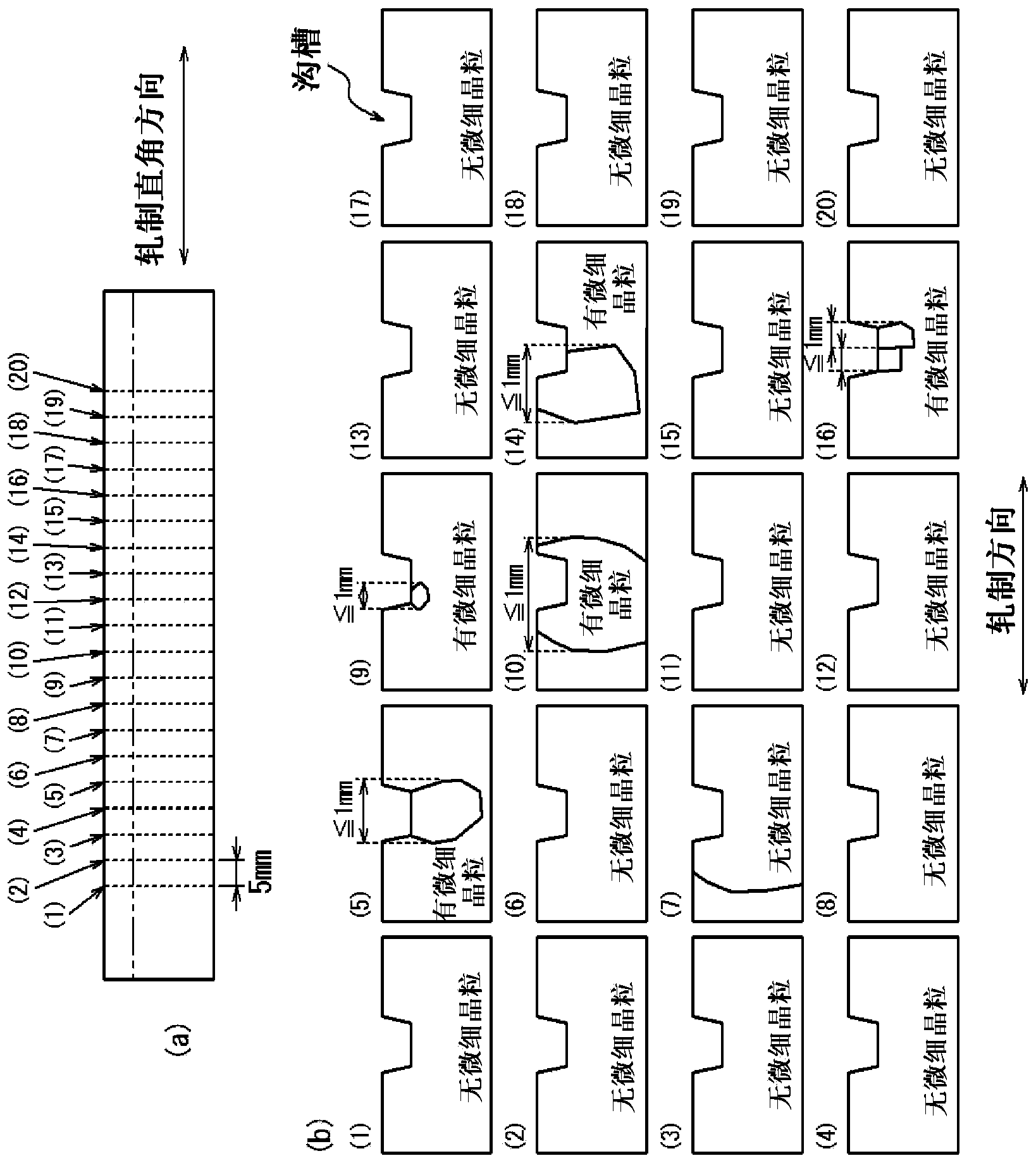

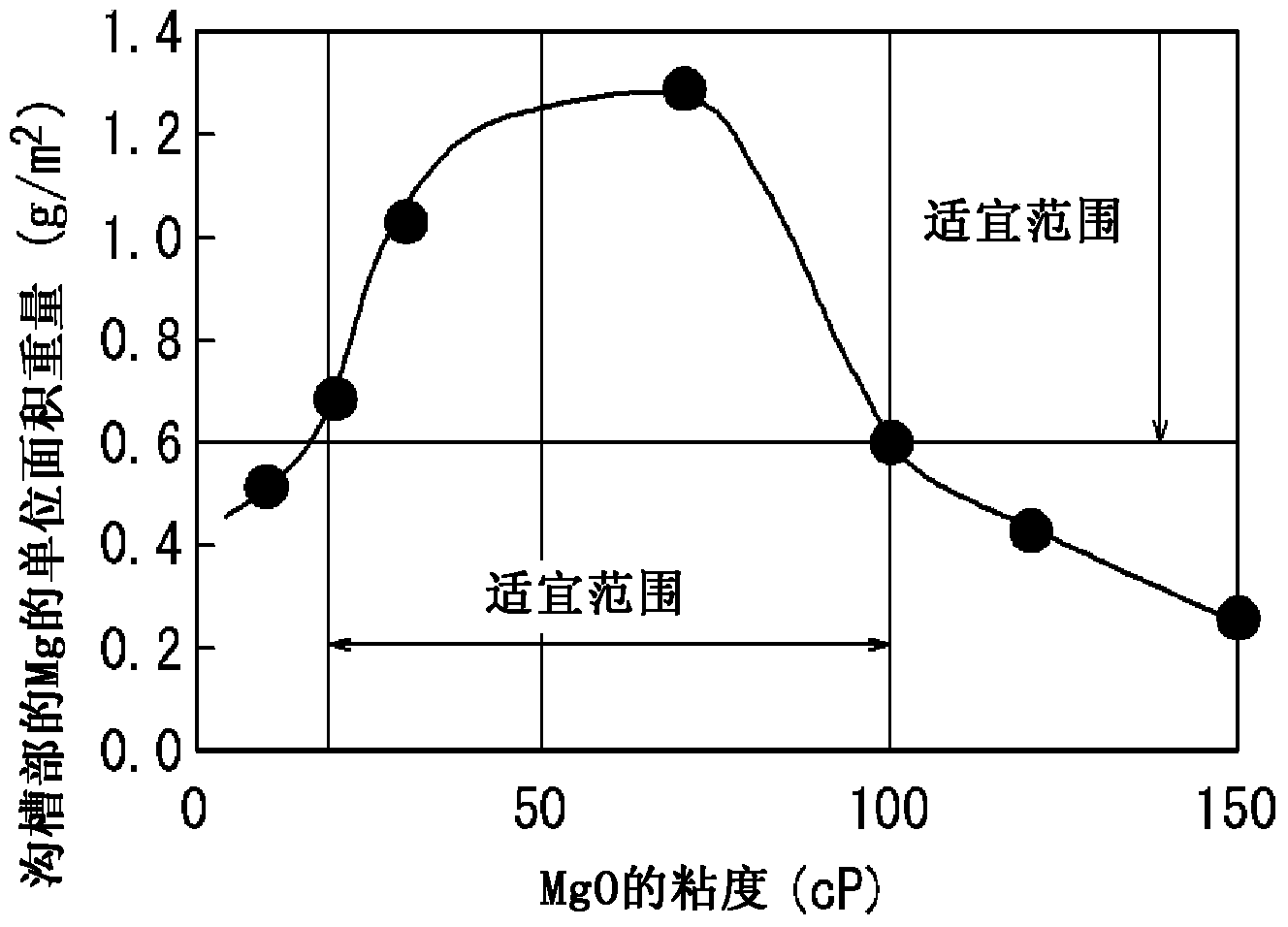

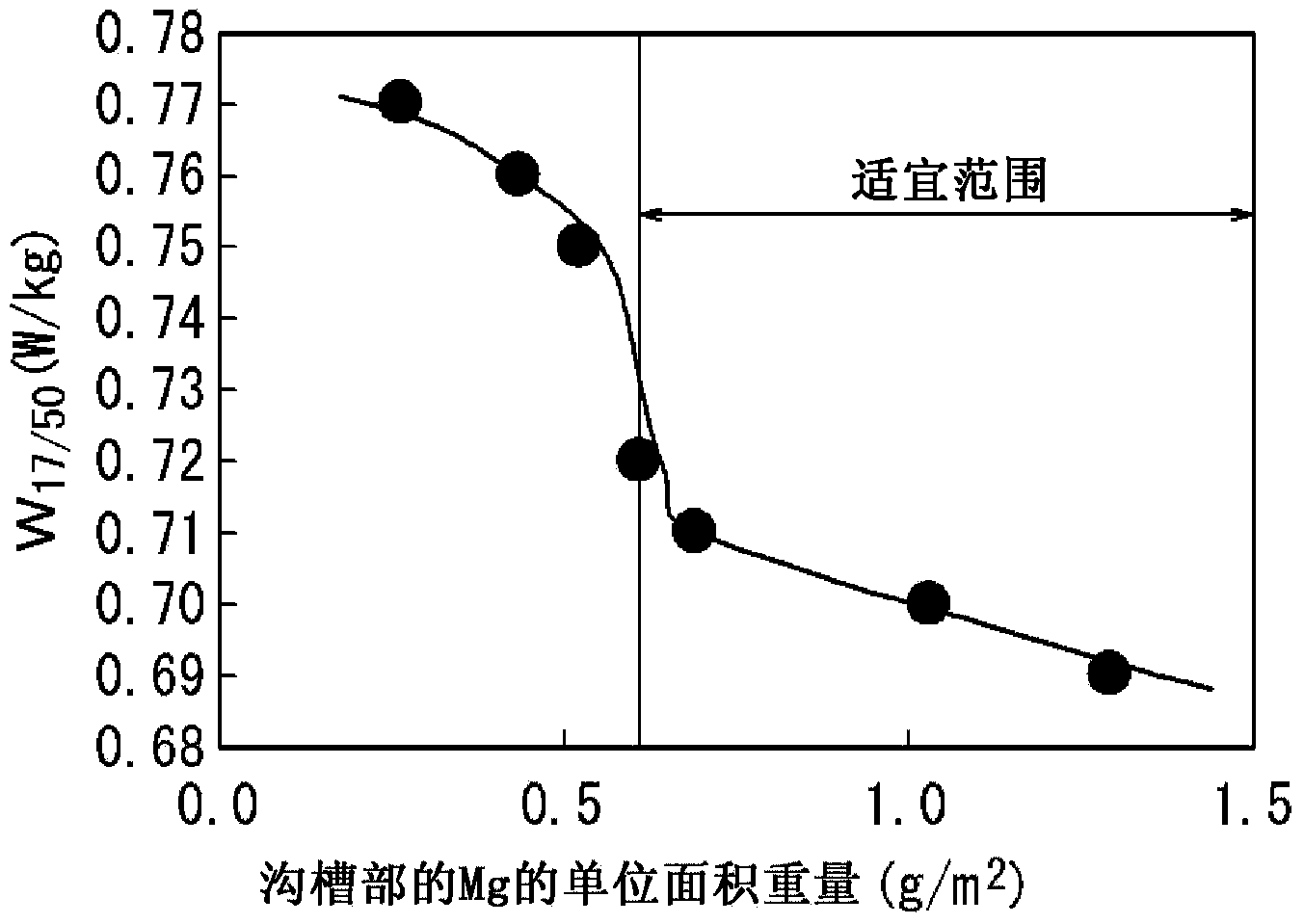

Grain-oriented electrical steel sheet and method for manufacturing same

ActiveCN104284994AReduce iron lossInorganic material magnetismThin material handlingBeta angleElectrical steel

Provided is a grain-oriented electrical steel sheet having a linear groove forming an angle of 45° or less with the direction perpendicular to the direction of rolling, wherein a grain-oriented electrical steel sheet having low iron loss characteristics, on which a magnetic domain subdivision treatment by chemical means is used, is provided by setting the incidence of microparticles having a length of 1 mm or less in the rolling direction in a bottom part of the groove to 10% or less (also including cases in which microparticles are not present), providing a forsterite coating in which the Mg weight per side of the steel sheet is at least 0.6 g / m2 in the groove, and setting the angle (beta angle) between a rolling surface and the <100> axis of a secondary recrystallized grain oriented in the rolling direction of the steel sheet to an average value of 3° or less.

Owner:JFE STEEL CORP

PDC drill bit with cutter design optimized with dynamic centerline analysis having an angular separation in imbalance forces of 180 degrees for maximum time

InactiveUS7831419B2Improve accuracyWeakening rangeDrill bitsDesign optimisation/simulationBeta angleEngineering

A method for designing a fixed cutter drill bit, includes simulating the fixed cutter drill bit drilling in an earth formation, determining radial and circumferential components of imbalance forces on the drill bit and a Beta angle between the radial and circumferential components of the imbalance forces during a period of simulated drilling, and adjusting a value of at least one design parameter for the fixed cutter drill bit at least based upon the Beta angle. To facilitate drill bit design, the Beta angel can be displayed to a drill bit designer. To improve performance, the method can include repeating the simulating, determining, and adjusting to change a simulated performance of the fixed cutter drill bit. A drill bit may be made according to the design resulting from the method.

Owner:SMITH INT INC

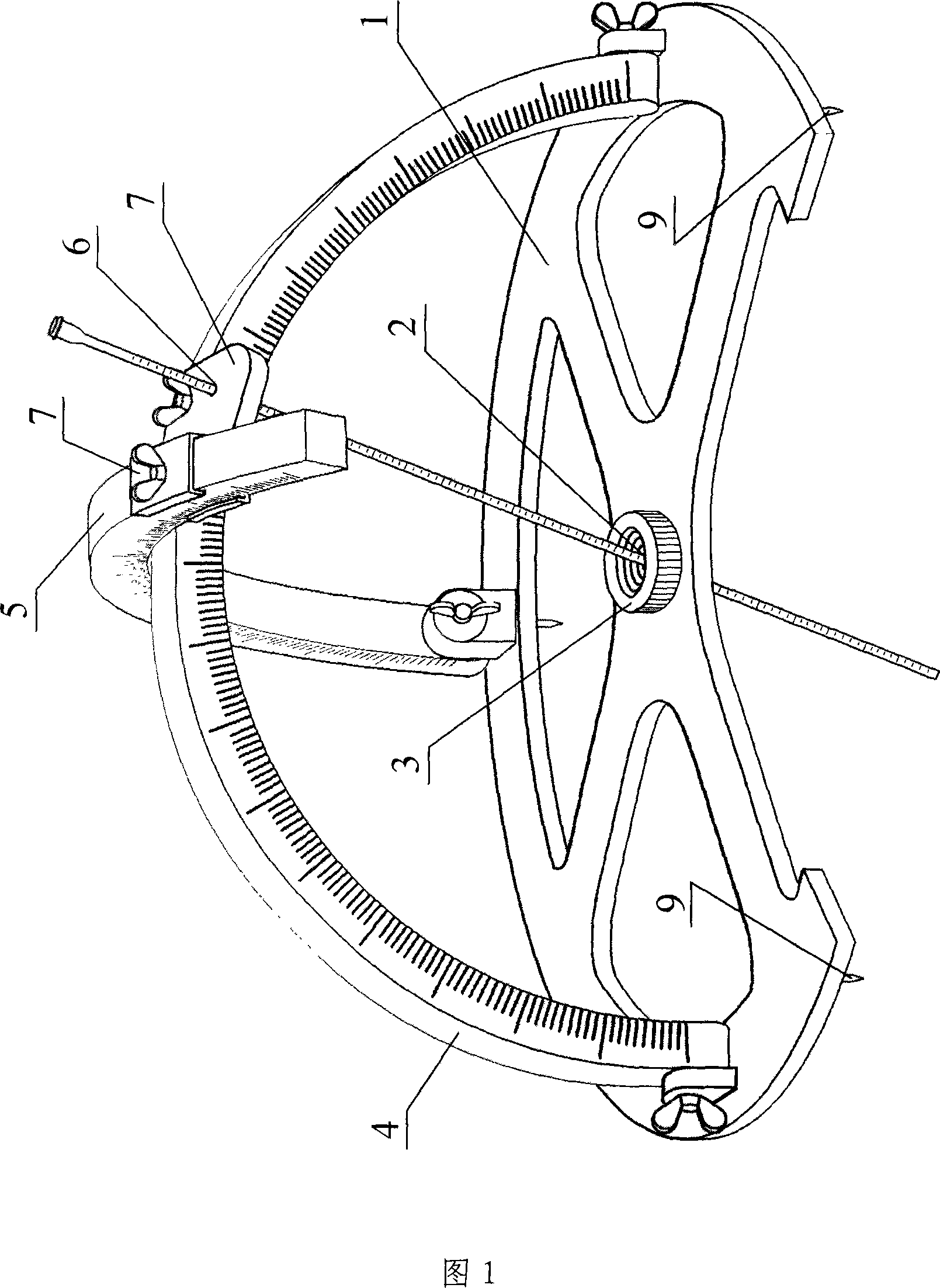

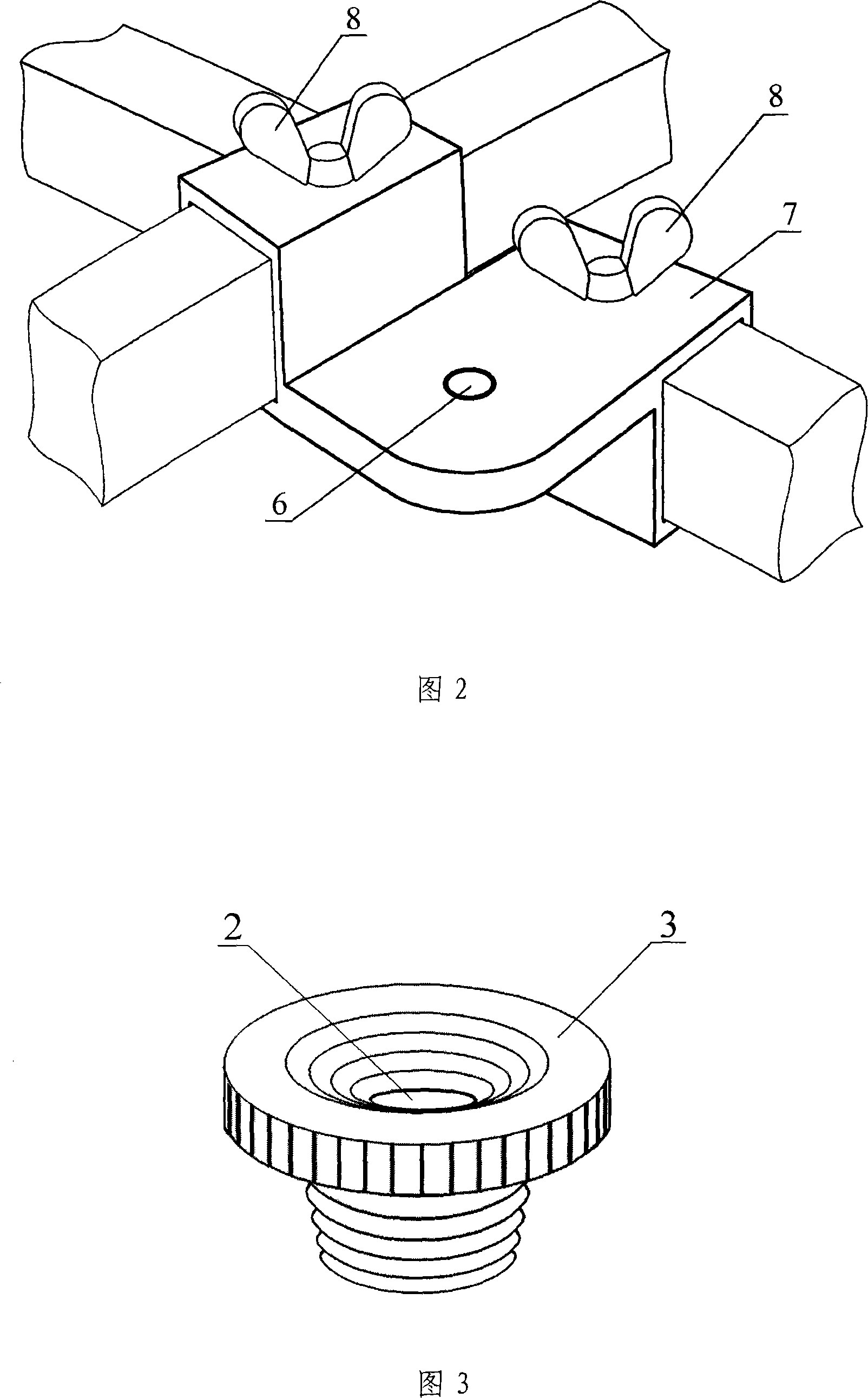

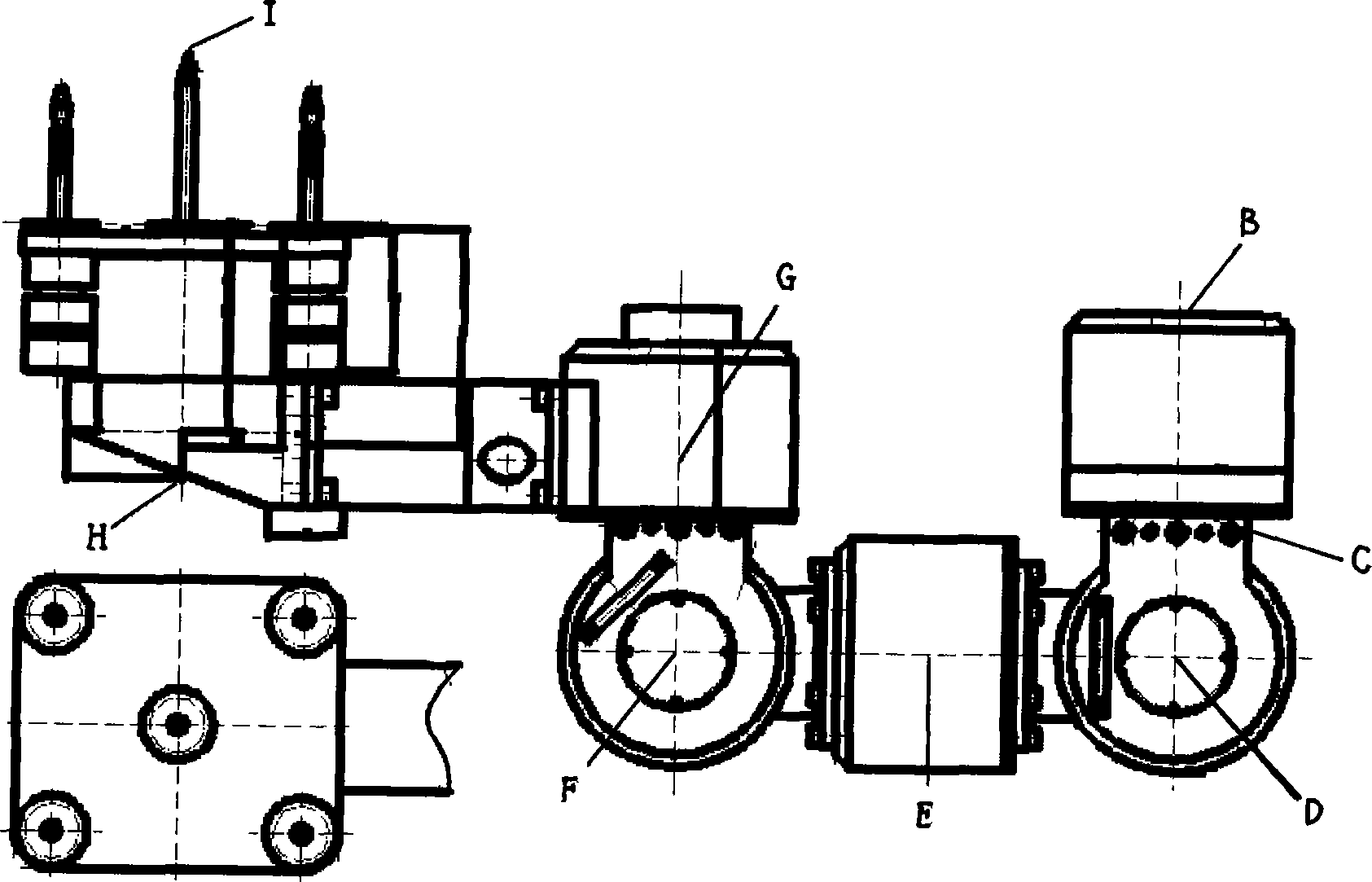

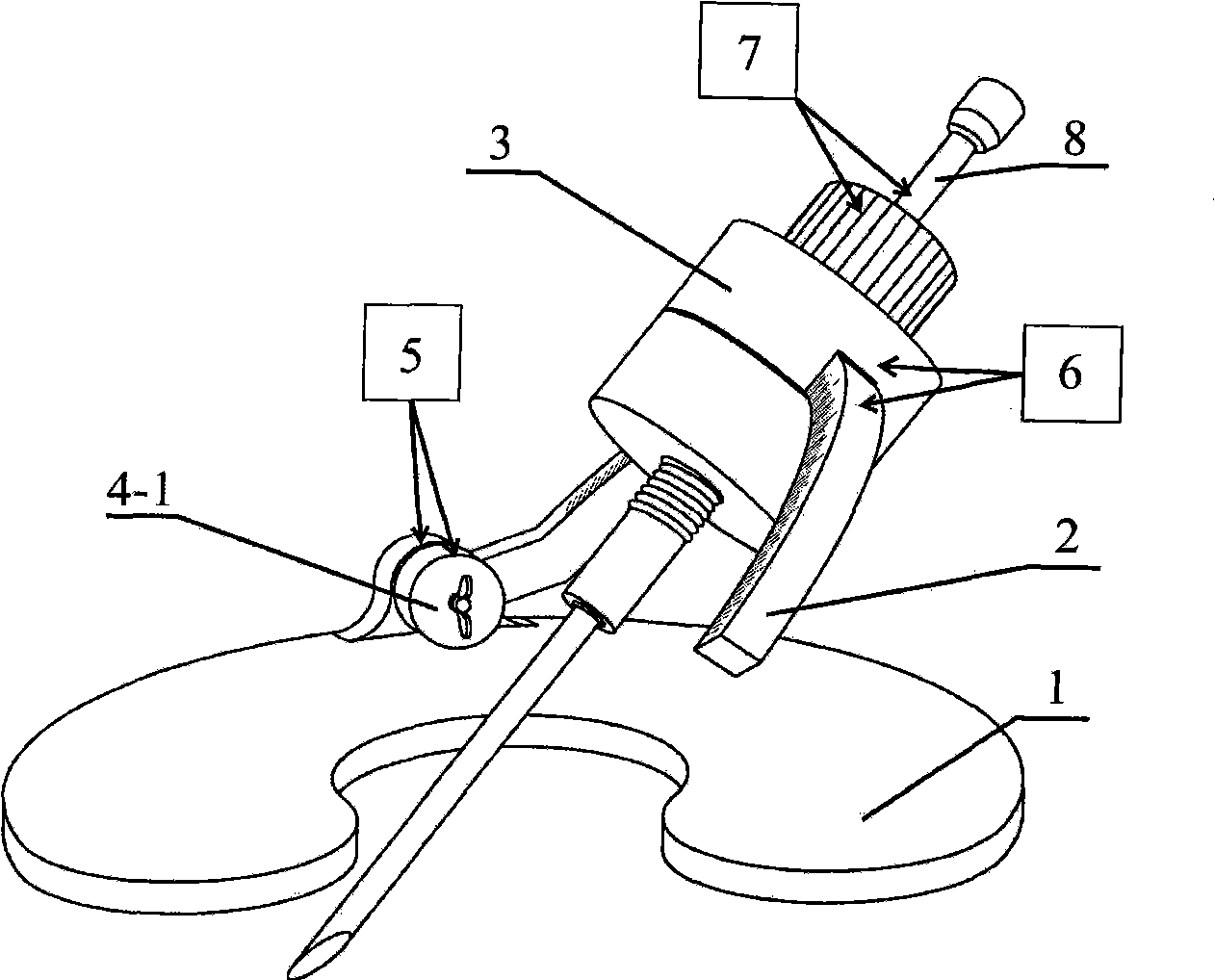

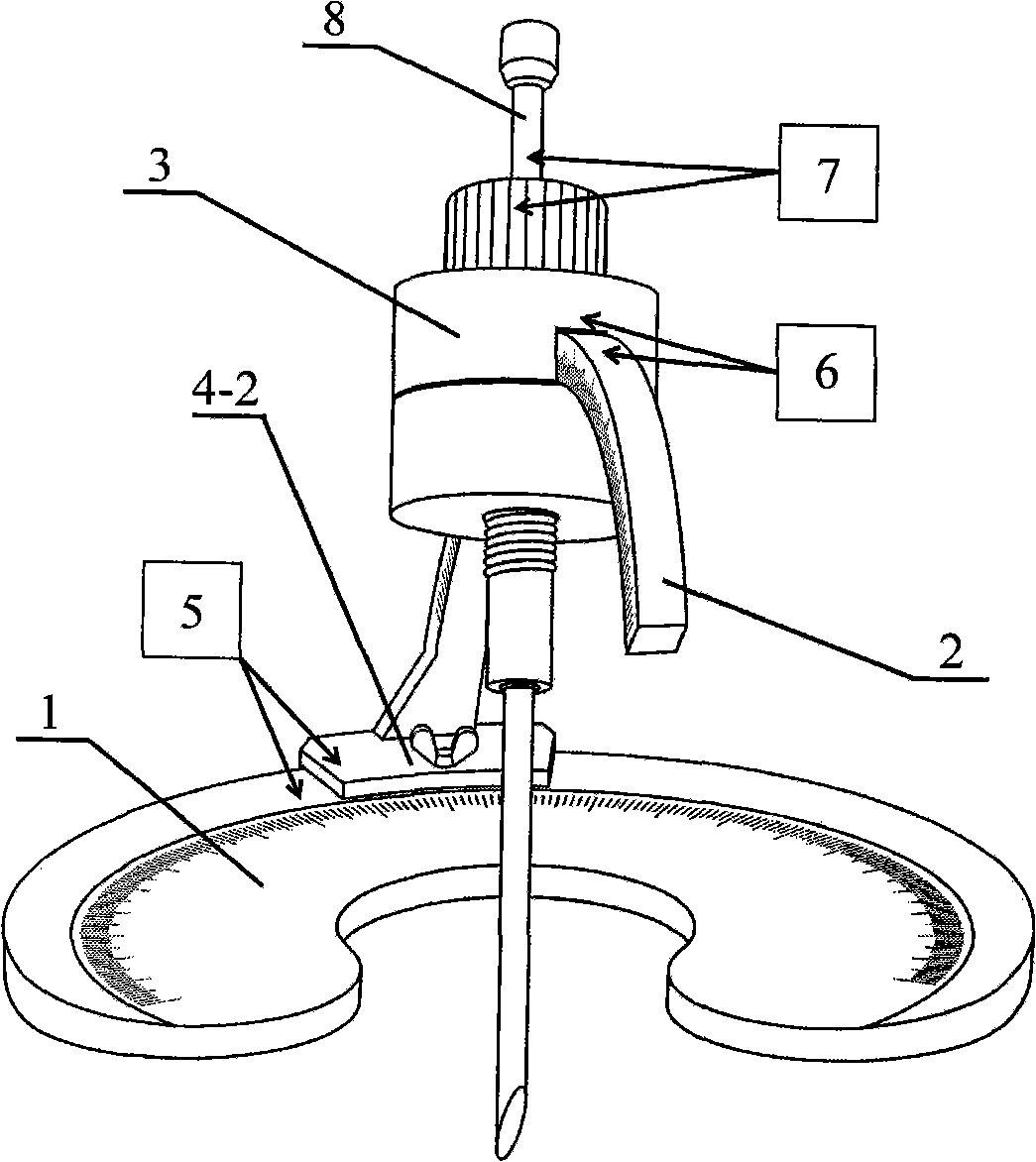

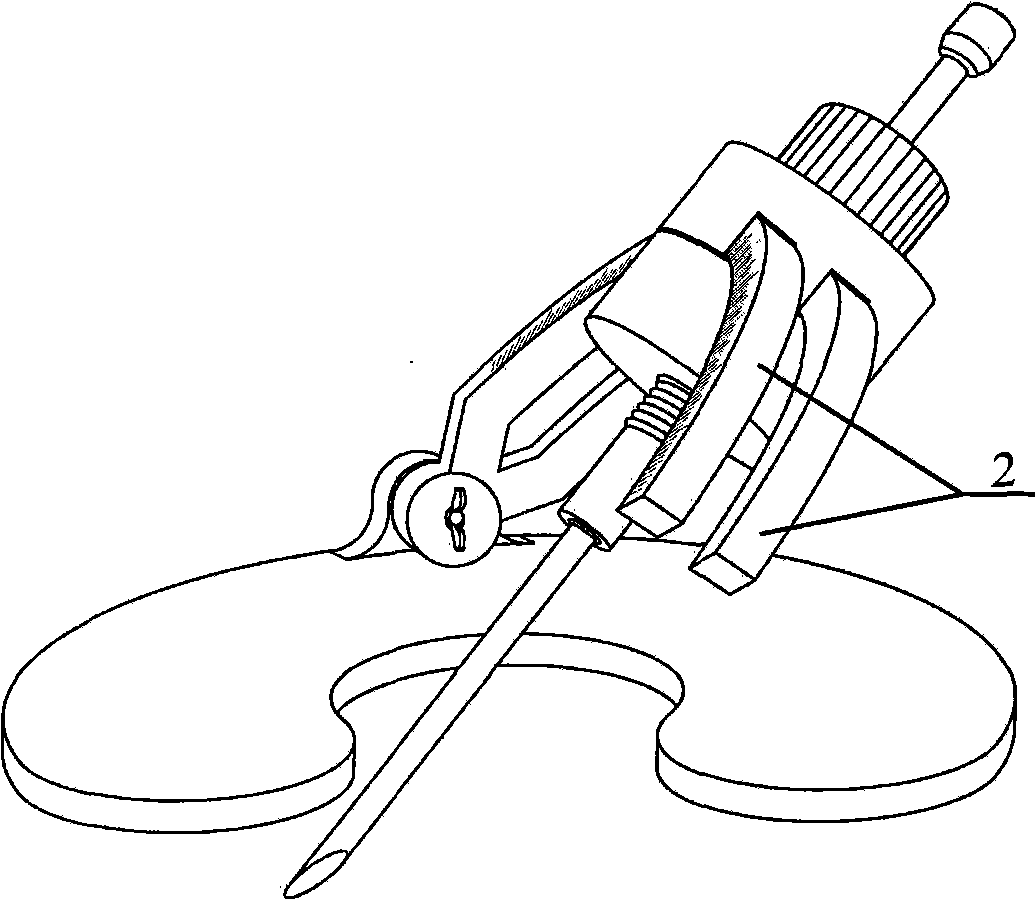

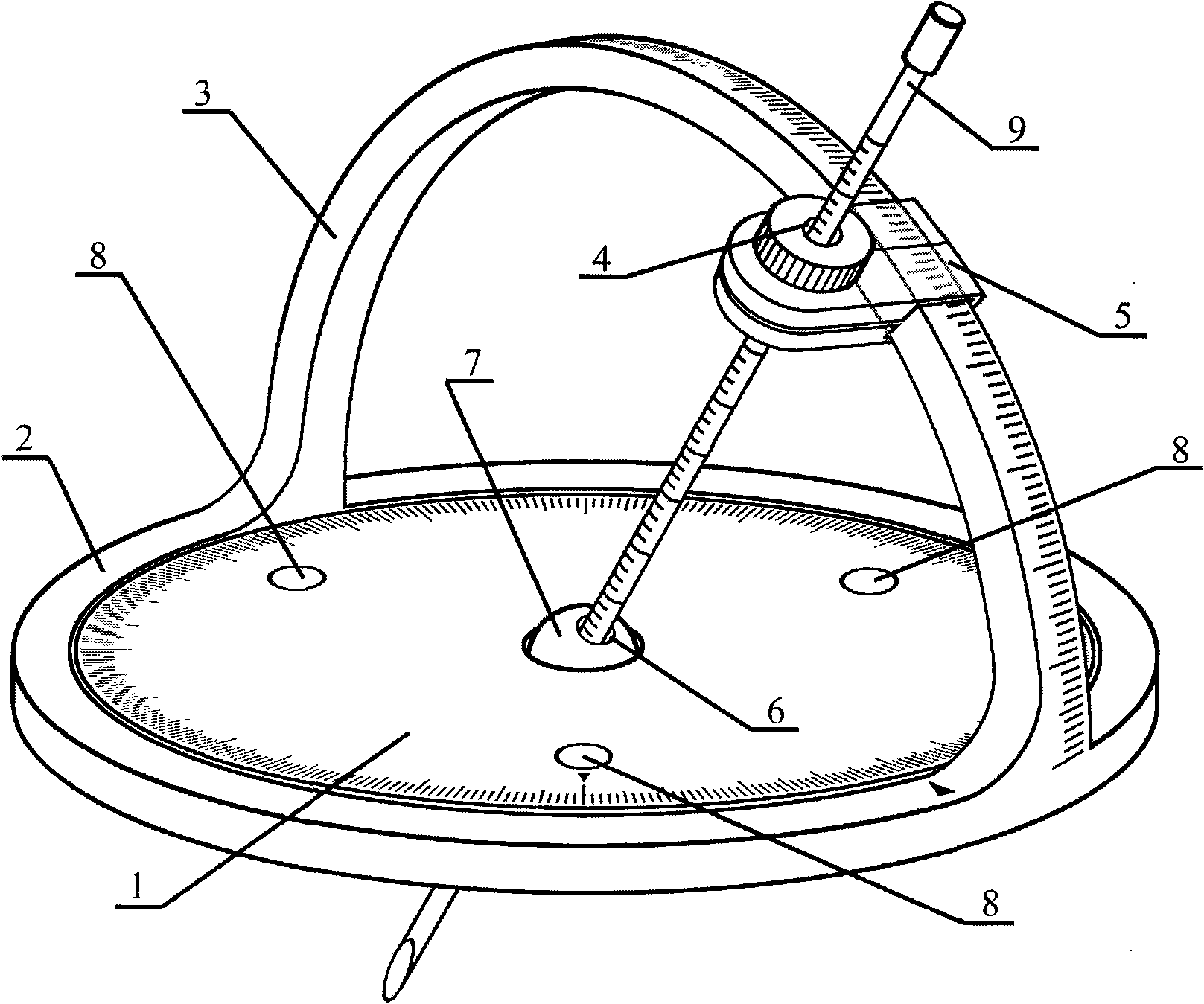

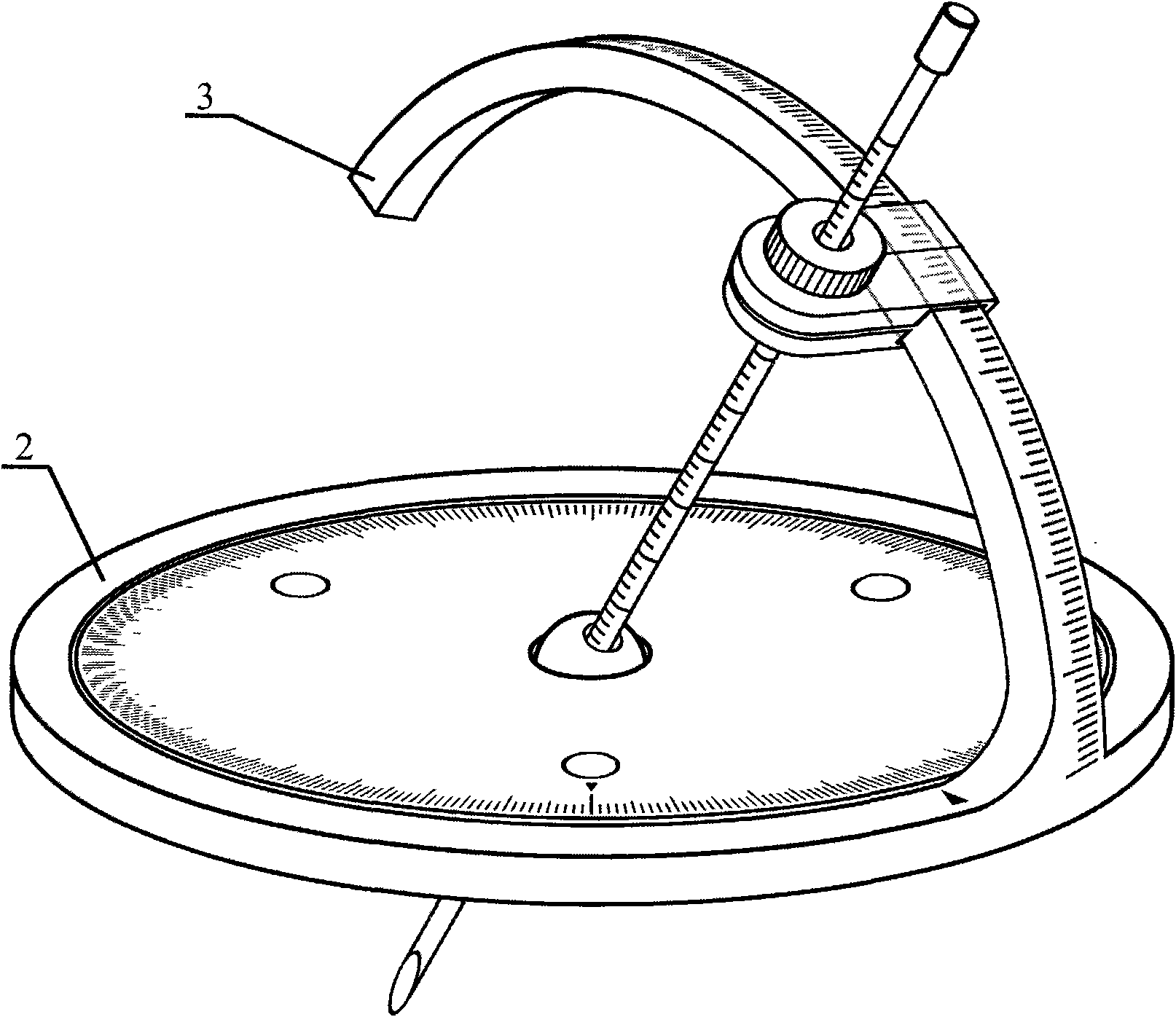

Structure simple stereoscopic director

InactiveCN101099692AReduce volumeSimple structureDiagnosticsInstruments for stereotaxic surgeryBeta angleEngineering plastic

The present invention provides a steric direction finder with simple structure. Said steric direction finder can be used for accurately feeding the operative instrument into targe point when the operation on human or animal cranium and brain can be made. Said invention includes the following several portions: base plate which is made up by using high-strength rare earth engineering plastics or other material and does not produce pseudoimage interference when the image scanning process is made, fixed nut with guide hole, bow-shaped alpha angle measurer with angular scale, bow-shaped beta angle measurer with angular scale and fastener for regulating tightness.

Owner:吕田明

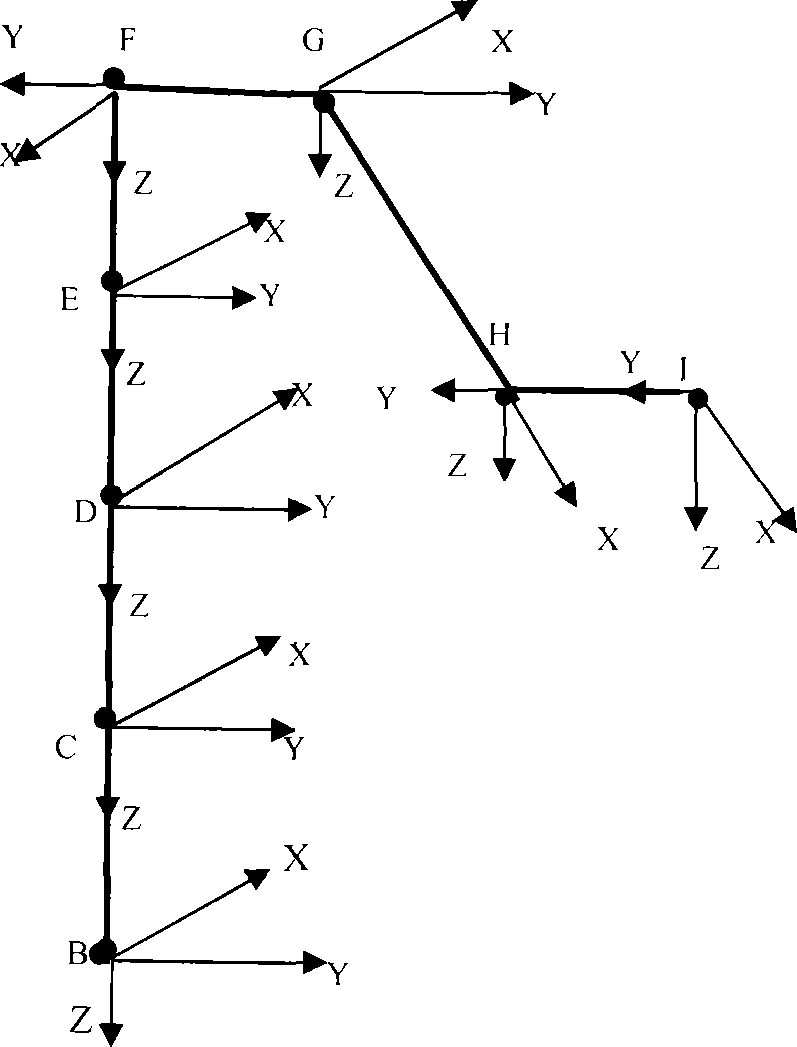

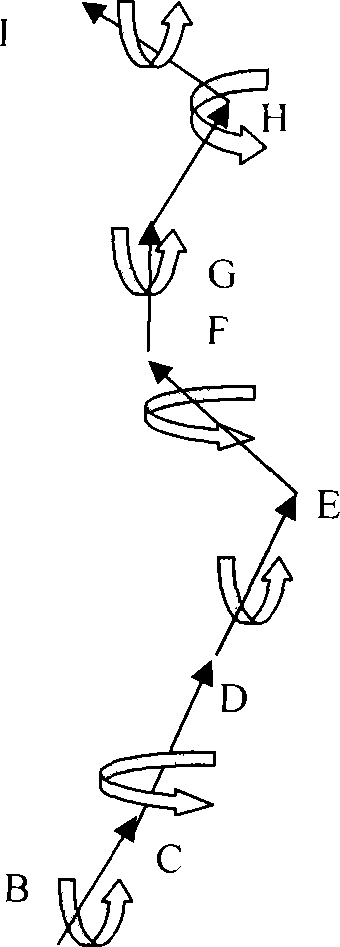

Kinematic inverse method for installation process of steam generator examining and repairing mechanical arm

InactiveCN101244561AAvoid kinematic equationsFast operationProgramme-controlled manipulatorComplex mathematical operationsBeta angleKinematics equations

The invention provides an inverse kinematical solution method during the installation process of an overhaul robot arm of a steam generator; wherein, the definitions of Alpha, Beta, and Gamma are as follows: at the initial stage, a base coordinate system is in the same attitude with a world coordinate system, then the base coordinate system revolves around the Y axis for the Alpha angle, next revolves around the X axis for the Beta angle, and finally revolves around the Y axis again for the Gamma angle, so as to obtain the ultimate attitude of the base coordinate system. The respective positions of the articulation points are: B point is the arithmetic endpoint of the robot arm, C, D, E, F, G, and H points are respectively the sixth to first articulation points, and I point is toe arithmetic endpoint; first, the coordinates of the articulation points of the robot arm are solved, and the coordinates of B, C and D points are resolved by means of the normal solutions during installation process; then, a vector HI is acquired based on the coordinate of I point and the attitude angles Alpha, Beta, and Gamma, so the coordinate of H point can be deduced; next, the coordinate of F point is solved; finally, the turn angles Theta (i) of the articulation points can be resolved (wherein, I=1, 2, 3, 4, 5, 6). The inverse kinematical solution method in the invention has the advantages of avoiding building up the kinematical equation of the robot arm, greatly reducing the amount of calculation, quickening the operational speed, and solving all the solutions.

Owner:HARBIN ENG UNIV

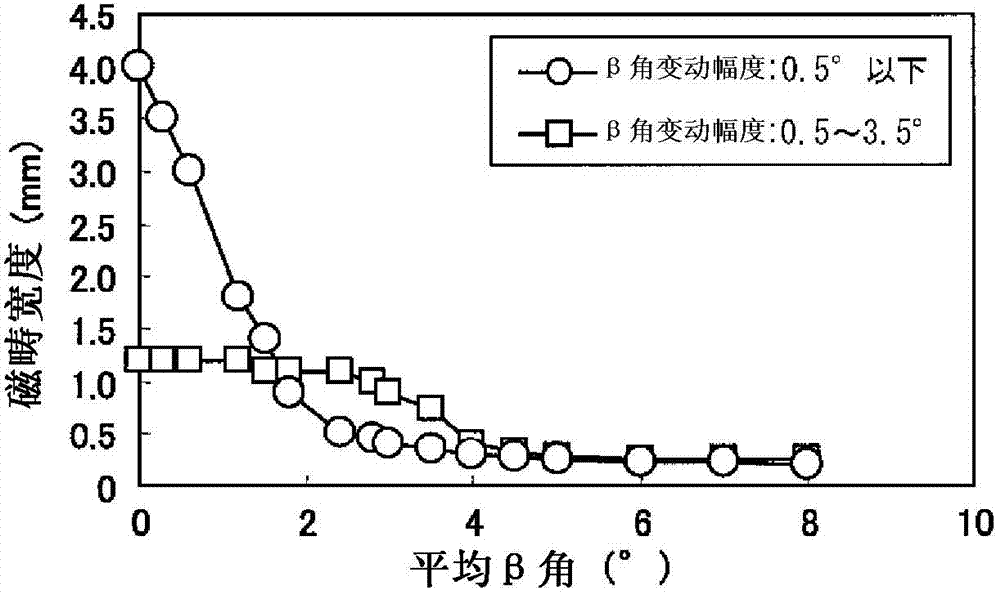

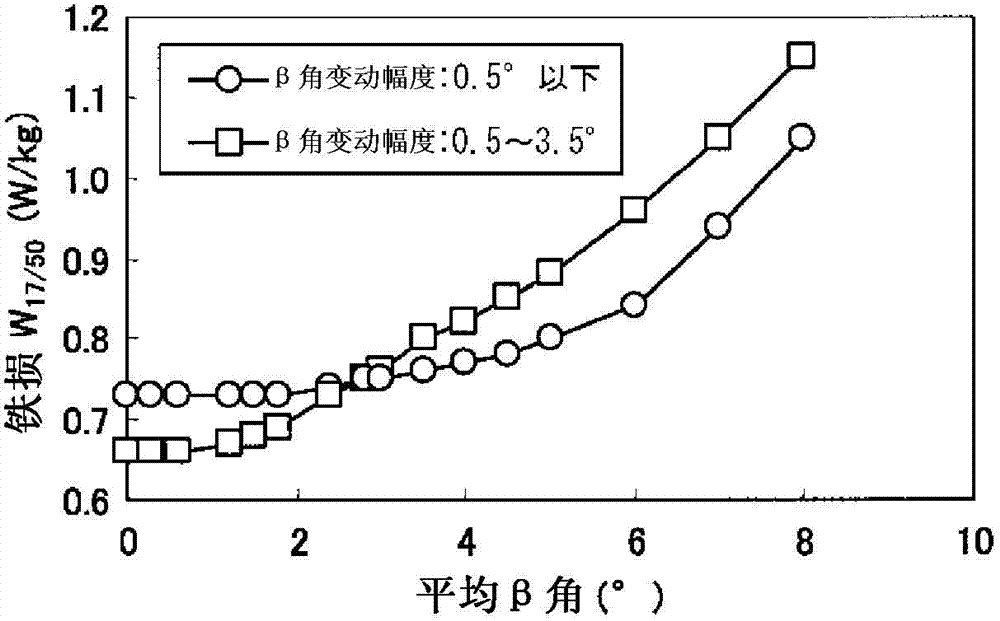

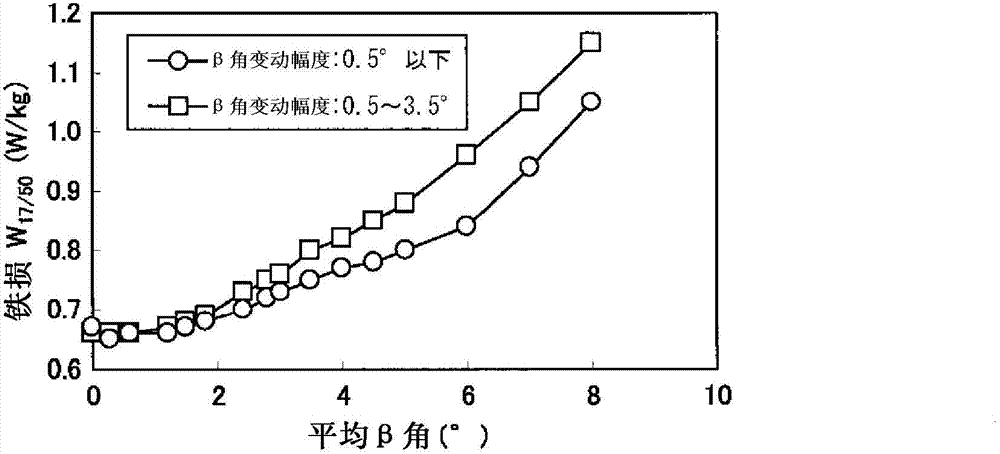

Grain-oriented magnetic steel sheet and process for producing same

InactiveCN103097563ADomain refinementGreat iron loss improvementInorganic material magnetismBeta angleSheet steel

A grain-oriented magnetic steel sheet having linear grooves for magnetic domain refinement which have been formed in a surface of the steel sheet is produced in accordance with the present invention so that the proportion of linear grooves under which crystal grains having a deviation in orientation from the Goss orientation of 10 degrees or more and having a grain diameter of 5 [mu]m or more are present is regulated to 20% or less, and that the crystal grains formed by secondary recrystallization are regulated so as to have an average beta angle of 2.0 degrees or less and the crystal grains formed by secondary recrystallization which have a grain diameter of 10 mm or more are regulated so as to have an average width of beta-angle fluctuations of 1-4 degrees. Due to the formation of the linear grooves for magnetic domain refinement, a grain-oriented magnetic steel sheet reduced in iron loss can be obtained.

Owner:JFE STEEL CORP

Stereotaxic apparatus capable of guiding in real time

InactiveCN101773410ALive bootFacilitate surgeryDiagnosticsInstruments for stereotaxic surgeryBeta angleStereotaxis

The invention provides a stereotaxic apparatus capable of guiding in real time, which comprises a stereotaxic apparatus and a sensor. The stereotaxic apparatus part comprises a chassis, a bow frame and a fastener, wherein the fastener is provided with a guide hole and has adjustable tightness; the sensor part comprises an alpha angle sensor, a beta angle sensor and a distance sensor. Because the sensor is arranged on the stereotaxic apparatus, and an operator can be guided in real time, thereby not only binging convenience for an operation, but also improving the operation quality.

Owner:吕田明

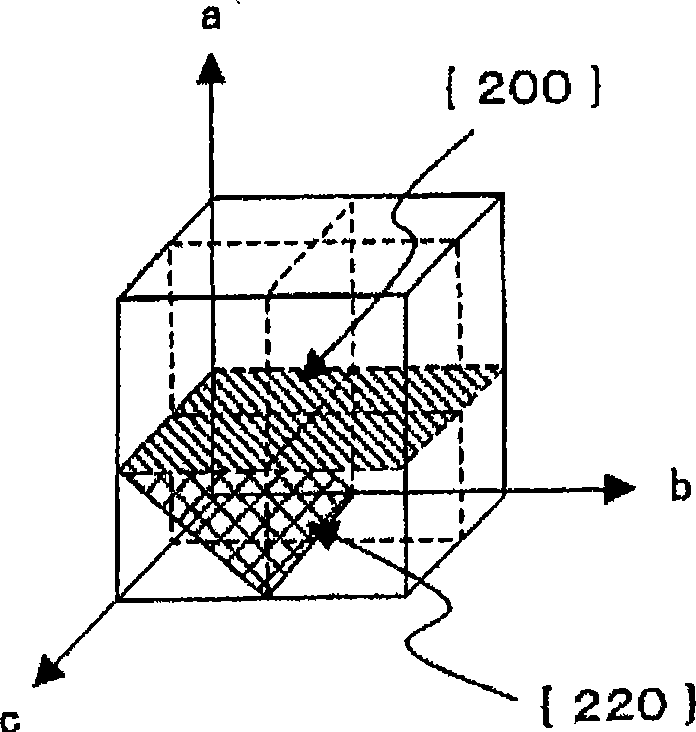

Rolled copper foil and manufacturing method of rolled copper foil

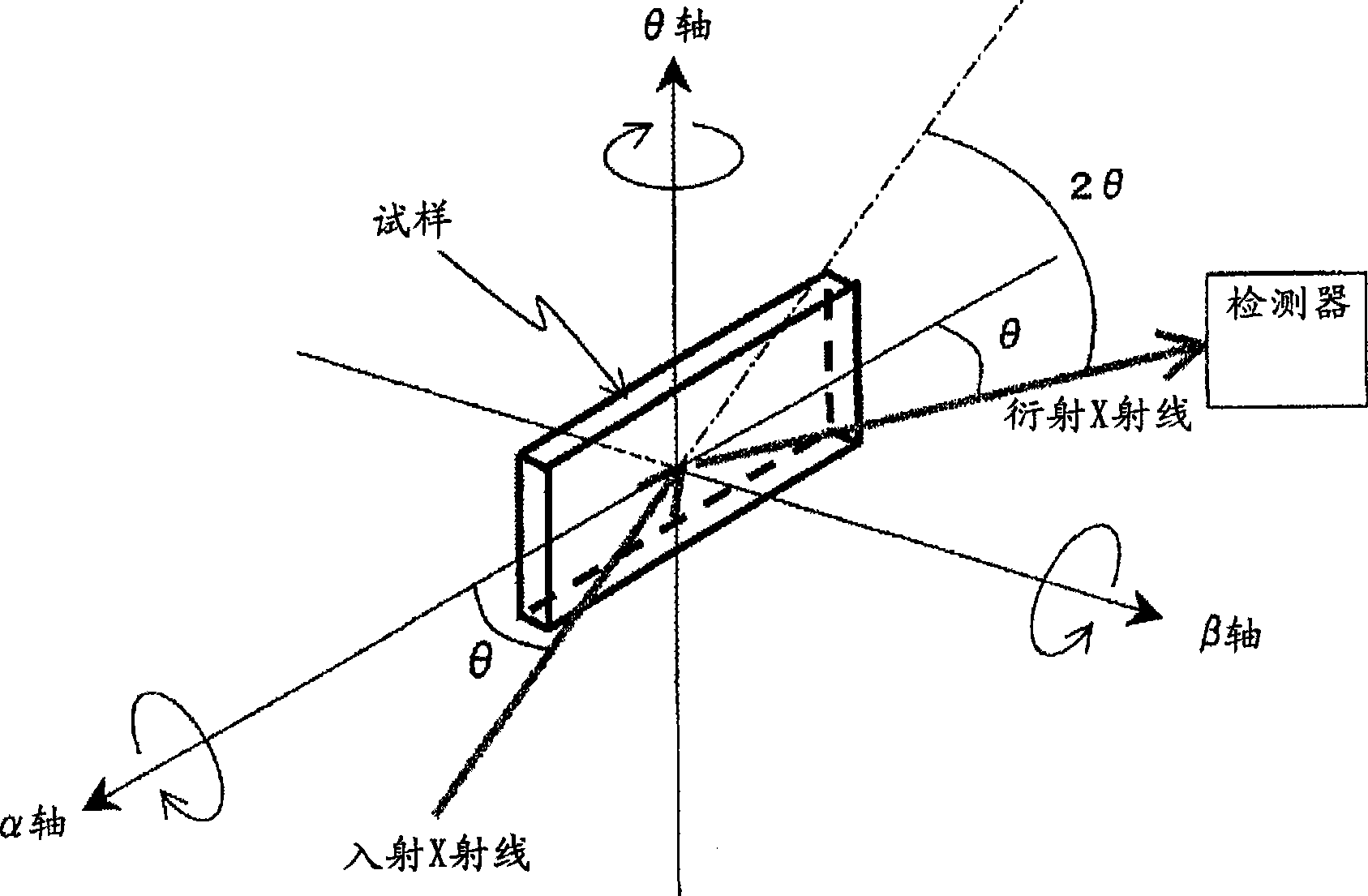

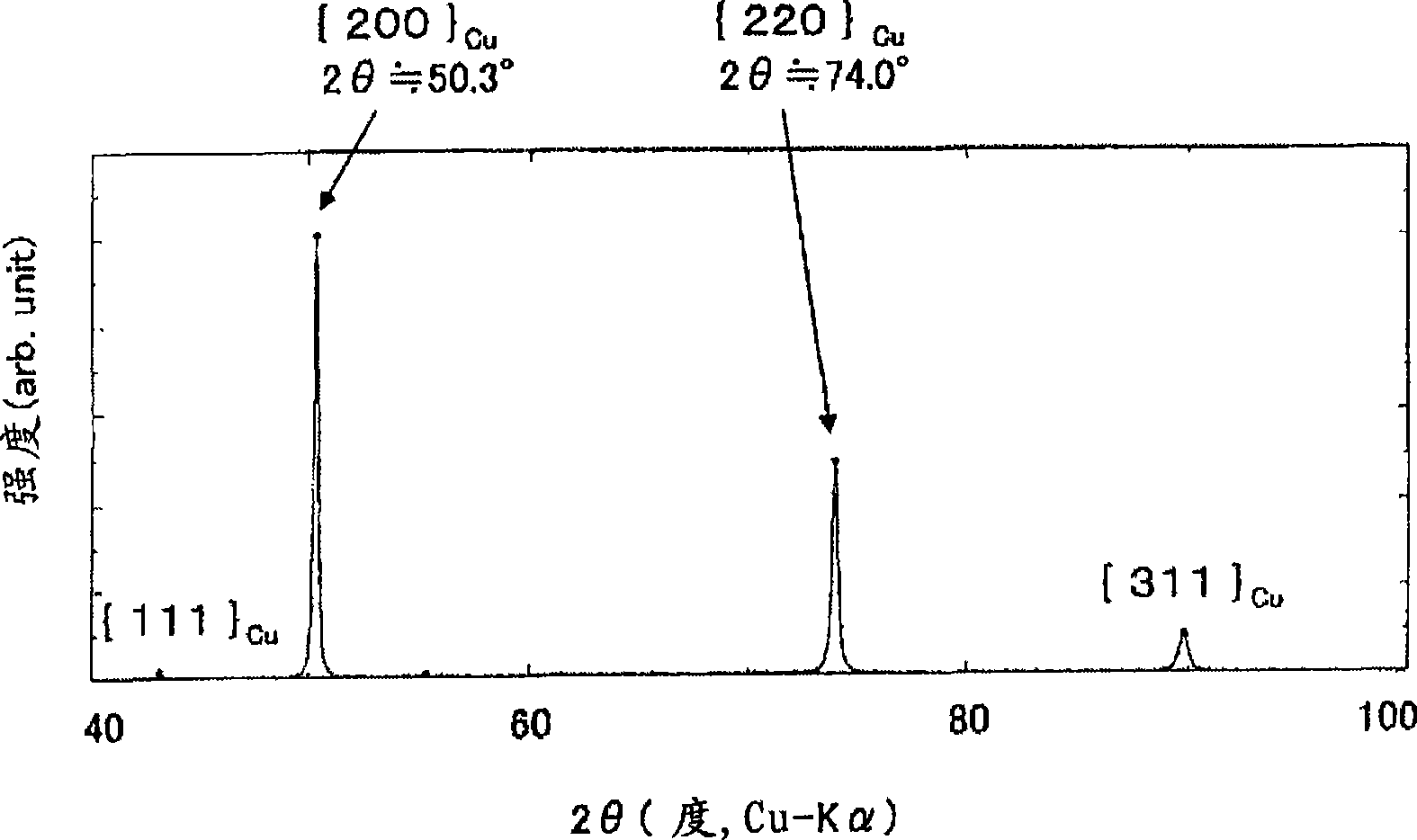

InactiveCN101481760AGood bending propertiesImprove bending characteristicsRoll mill control devicesMetal rolling arrangementsBeta angleX-ray

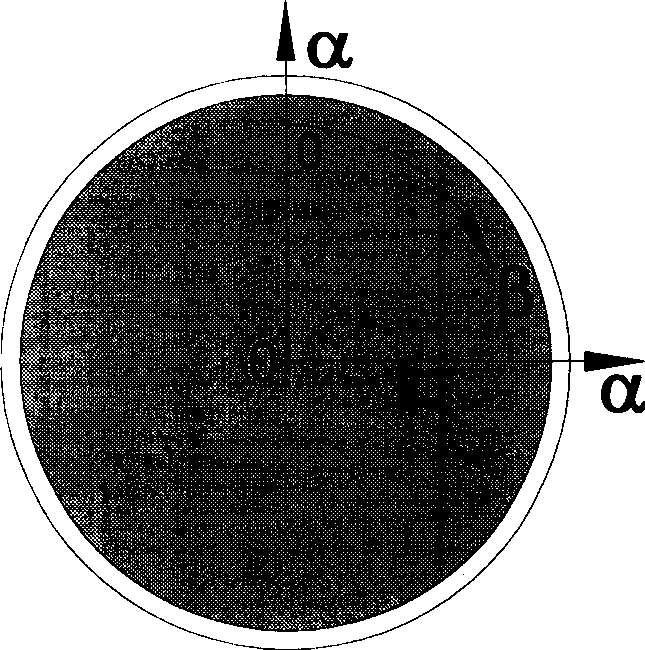

A rolled copper foil, according to the present invention, obtained after a final cold rolling step but before recrystallization annealing includes a group of crystal grains which exhibits four-fold symmetry in results obtained by X-ray diffraction (XRD) pole figure measurement with respect to a rolled surface. In the XRD pole figure measurement, at least four peaks of a {220}Cu plane diffraction of a copper crystal due to the group of crystal grains exhibiting the four-fold symmetry, which is obtained during beta axis scanning with an alpha angle set to 45 DEG , appear at intervals of 90 DEG +-5 DEG along the beta angle.

Owner:SH COPPER PROD CO LTD

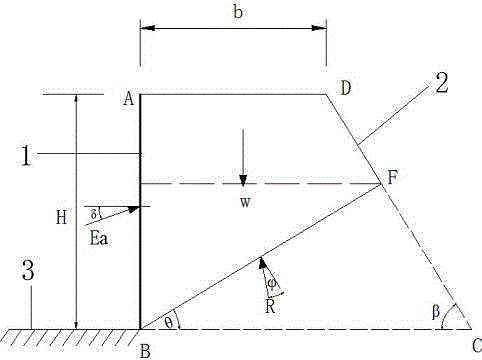

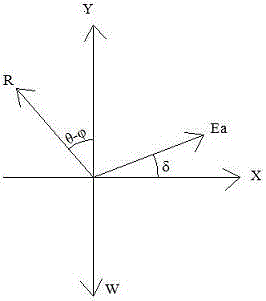

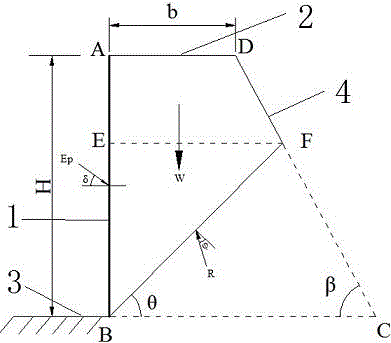

Method for calculating soil pressure of limited soil

InactiveCN106638537AEconomical, reasonable and practicalIn situ soil foundationBeta angleSoil science

The invention discloses a method for calculating soil pressure of limited soil. The method comprises the following steps: determining profile parameters of a foundation pit profile and limited soil, setting the included angle between a fracture plane of the limited soil and the horizontal direction, performing force analysis on a fractured slide body, obtaining the weight of the fractured slide body, establishing an equation set by utilizing known parameters according to static balance conditions in the horizontal direction and the vertical direction, substituting an expression of soil pressure of the limited soil, deriving a shearing damage angle for soil pressure of the limited soil, enabling a derivative equation to be zero, obtaining a shearing damage angle value, reversely substituting the shearing damage angle value into the expression of soil pressure of limited soil, calculating a numerical value, namely soil pressure, generated on a surrounding structure, of every linear meter of limited soil. According to the method disclosed by the invention, values of beta angles are different, different limited soil boundary conditions are contained, stress characteristics of limited soil are sufficiently taken into consideration, and a fracture plane direction angle of limited soil is derived, so that active pressure, which conforms to reality, of limited soil is calculated, and therefore, the method has a very good popularization application value.

Owner:南昌市政公用集团有限公司 +2

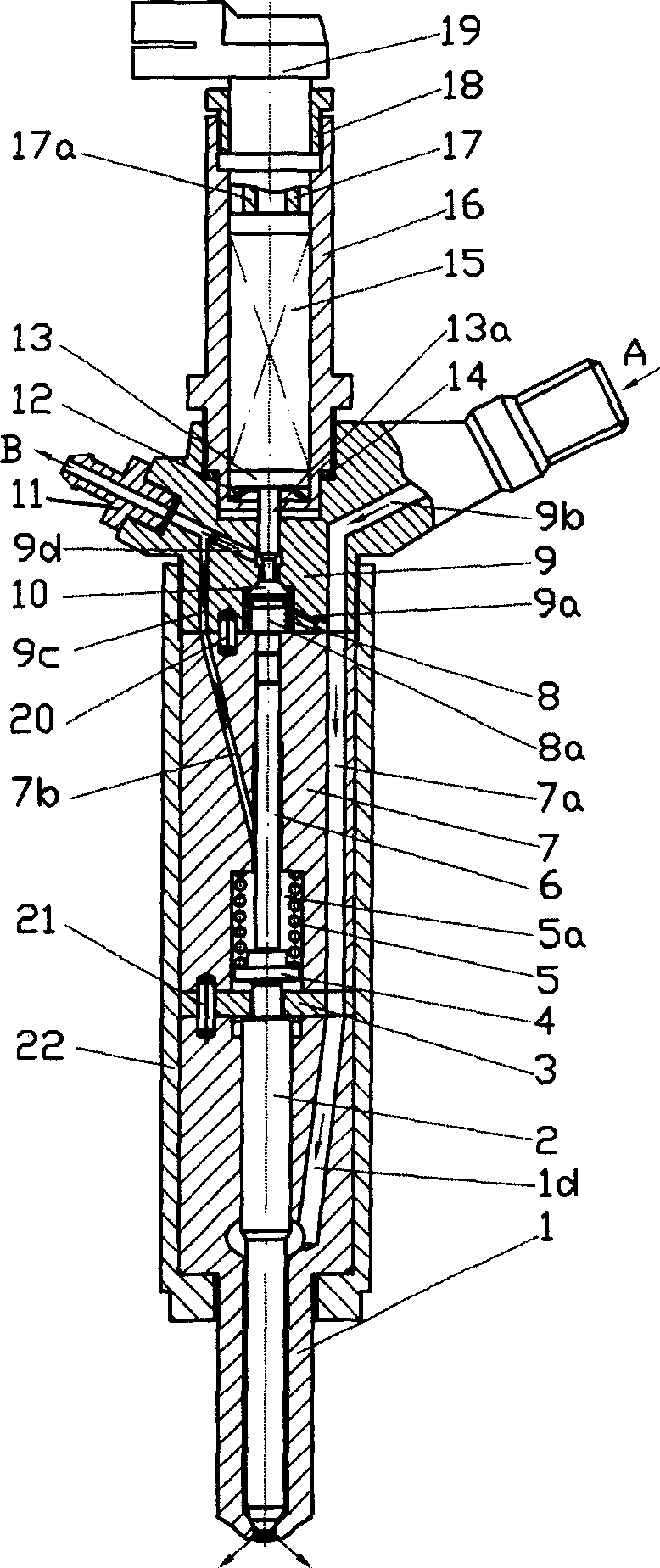

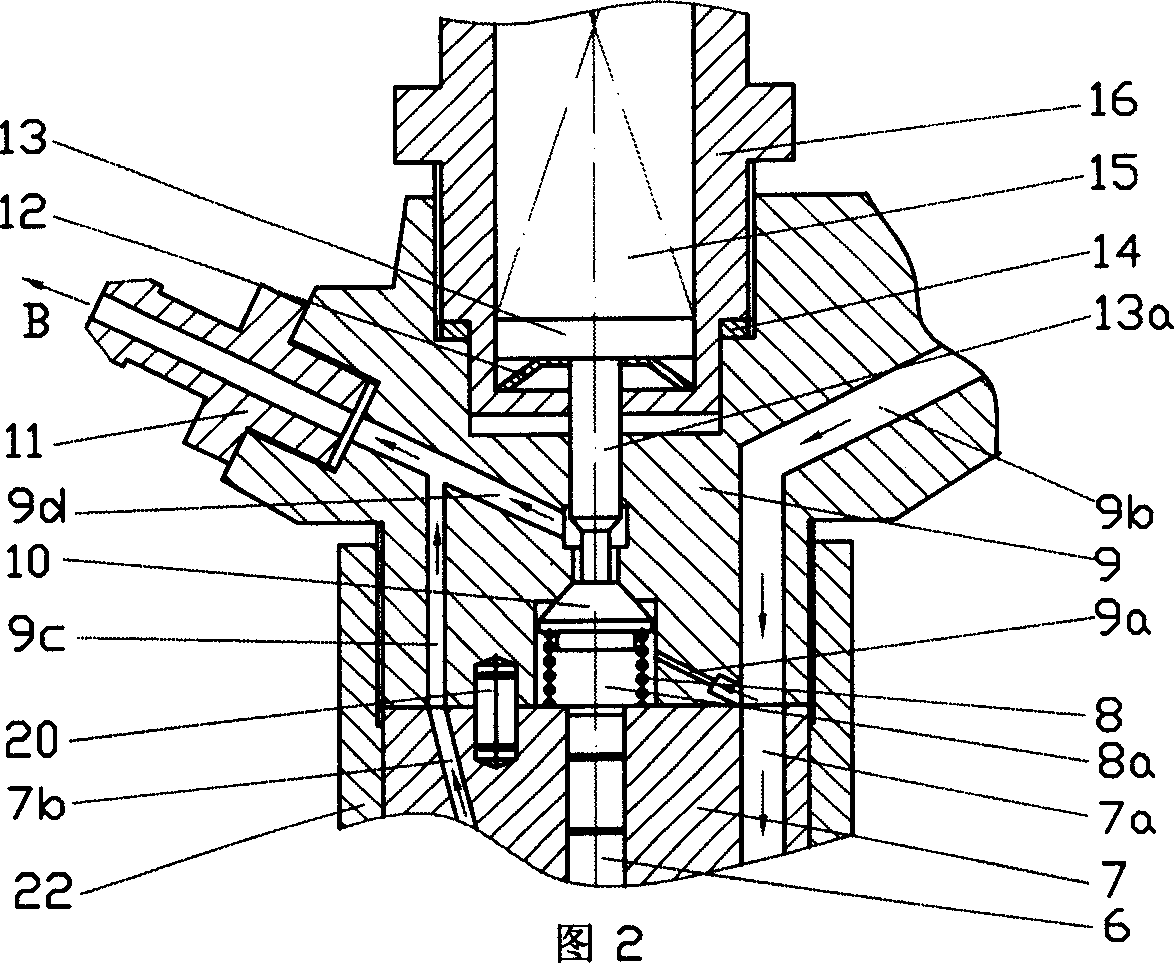

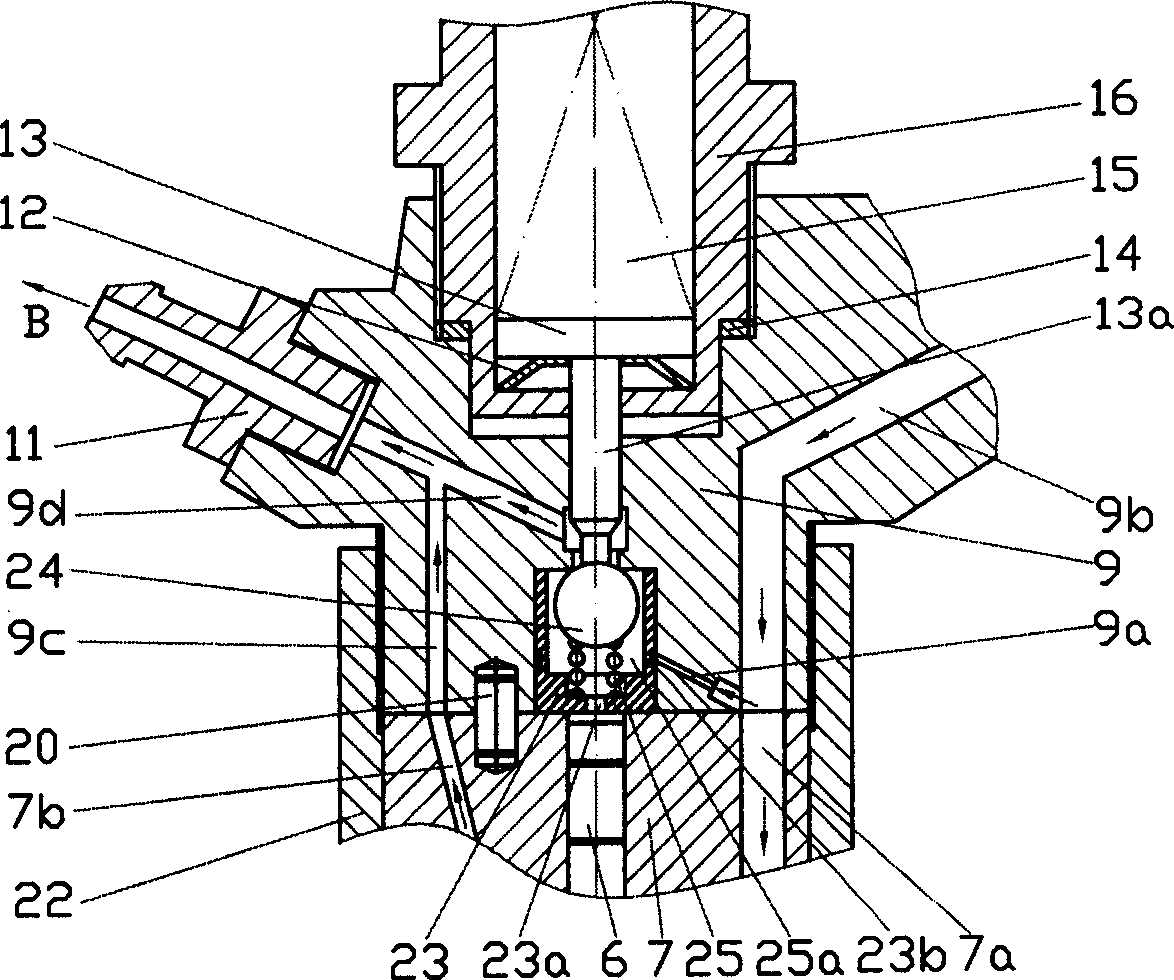

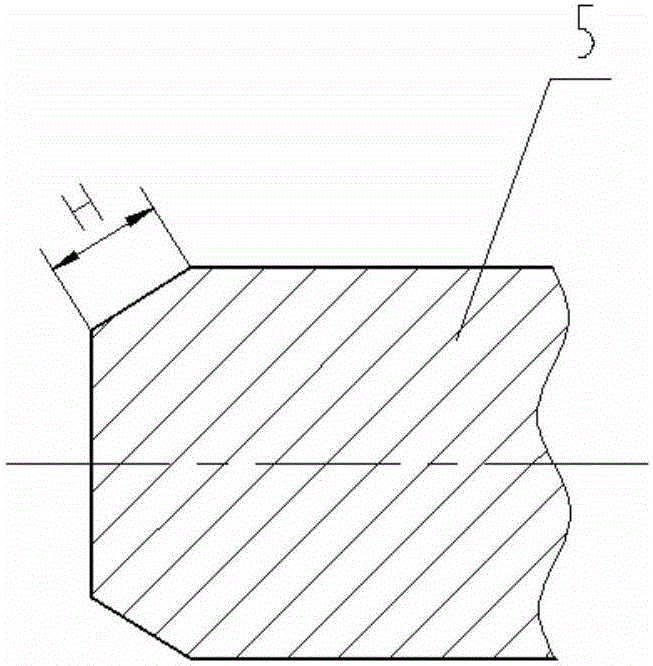

Composite microdisplacement oil jetter of IC engine with piezoelectric control

InactiveCN1818370AIncrease the compression ratioMeet different requirementsFuel injection apparatusMachines/enginesElectricityBeta angle

The piezoelectric-controlled micro-displacement combined fuel injector for internal combustion engines belongs to a fuel-injector apparatus for the fuel system of internal combustion engines. Because of being controlled by a piezoelectric element, its fuel-injection correct time is easy to regulate. An internal tapered angle 2 alpha being offset from beta angle is disposed at the outlet of a fuel nozzle. An oil-guide slot is opened on an umbrella-injection internal tapered surface in order to control the appointed area where the oil beam can reach the combustion chamber easily.

Owner:侯德洋

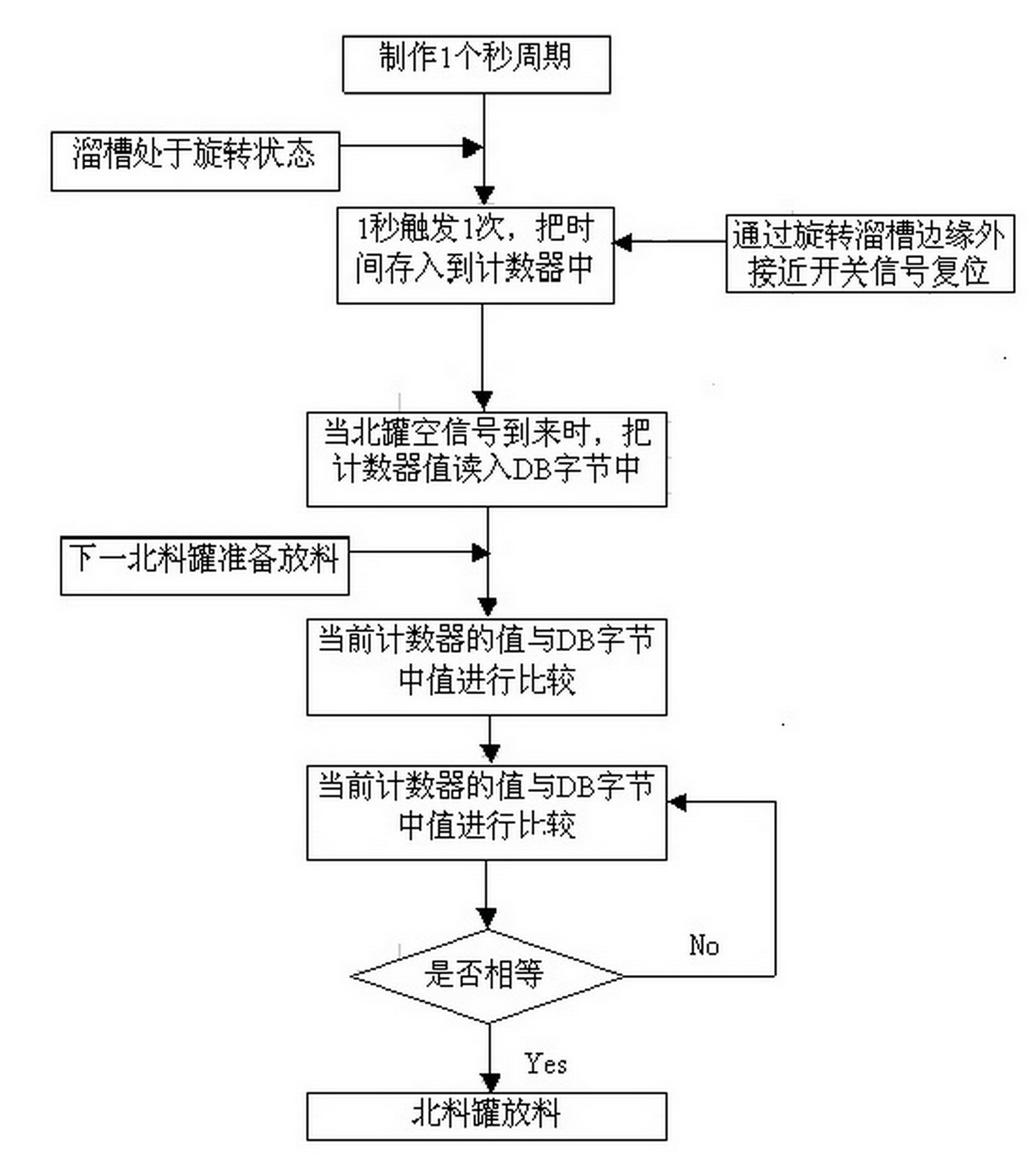

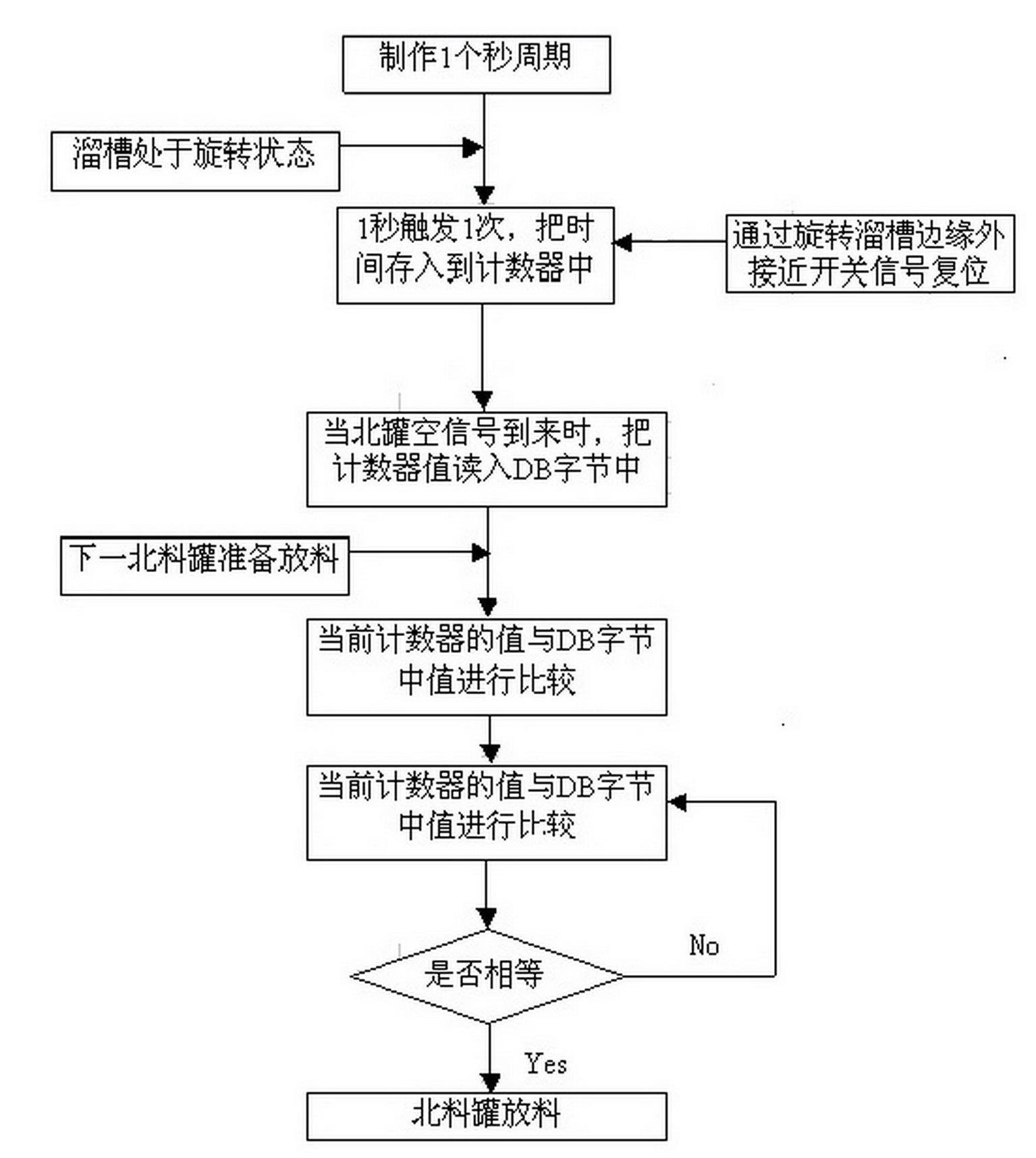

Uniform charging method of bell-less blast furnace

InactiveCN102010923AImprove standardizationMeet the production process requirementsBell-and-hopper arrangementProgram segmentBeta angle

The invention discloses a uniform charging method of a bell-less blast furnace. The method comprises the following steps: 1) an iron block is welded on the beta angle signaling device of a planetary gear reducer, the iron block is matched with a fixed approach switch to act; 2) a second period program segment is added in the blast furnace charging control program; 3) the running time of a rotary chute is continuously stored in the specified counter through second period counting in the production process, then the signals of the approach switch outside the edge of the beta angle signaling device are detected to perform zero clearing operation; and the counting and zero clearing operations are executed in cycles; 4) when a level gage detects the arrival of the empty signals of a stocking tank, the value of the counter is read in the define byte (DB); and 5) when the other charging conditions of the stocking tank for the next batch of material are provided, the step 3) is executed, the current value of the counter is compared with the value in the last recorded DB, if the two values are not equal, the comparison is performed repeatedly; and if the two values are equal, the charging operation of the stocking tank is performed.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

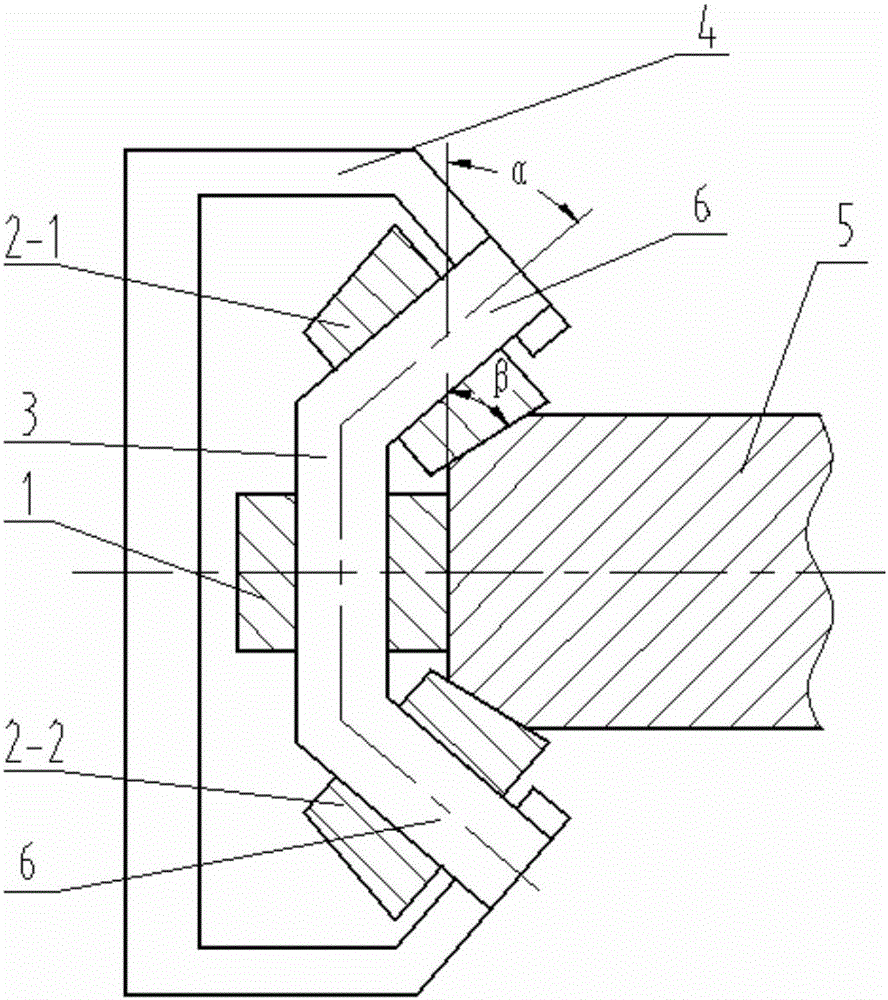

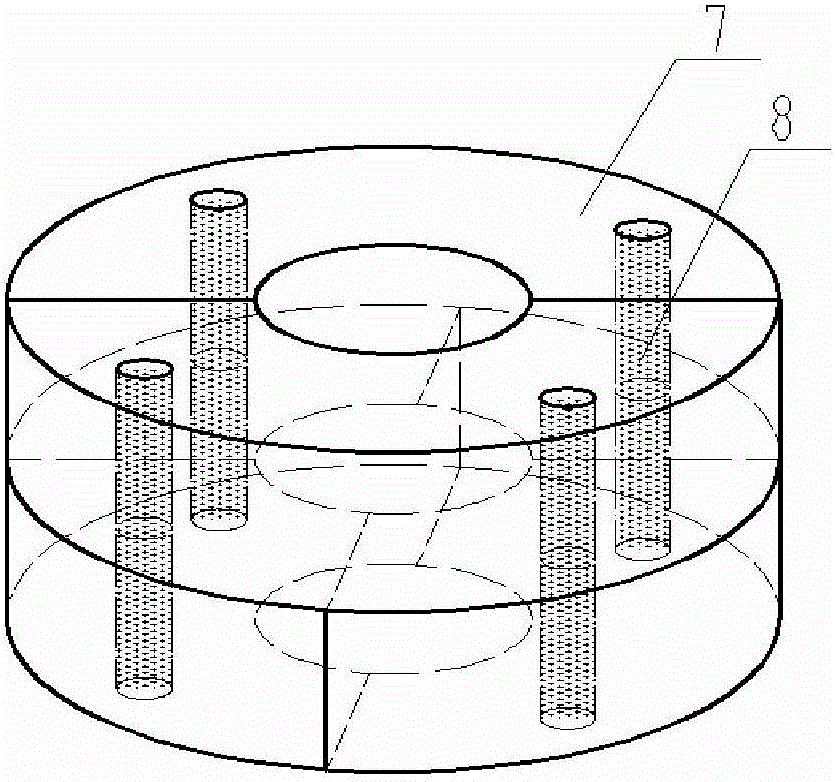

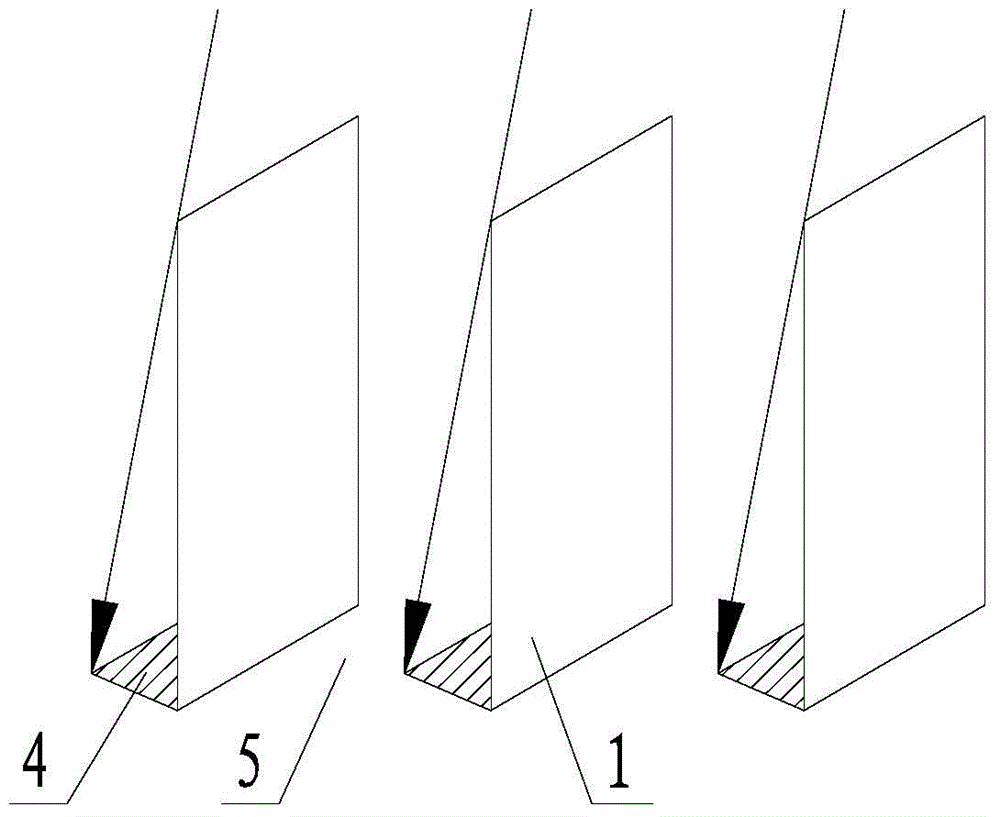

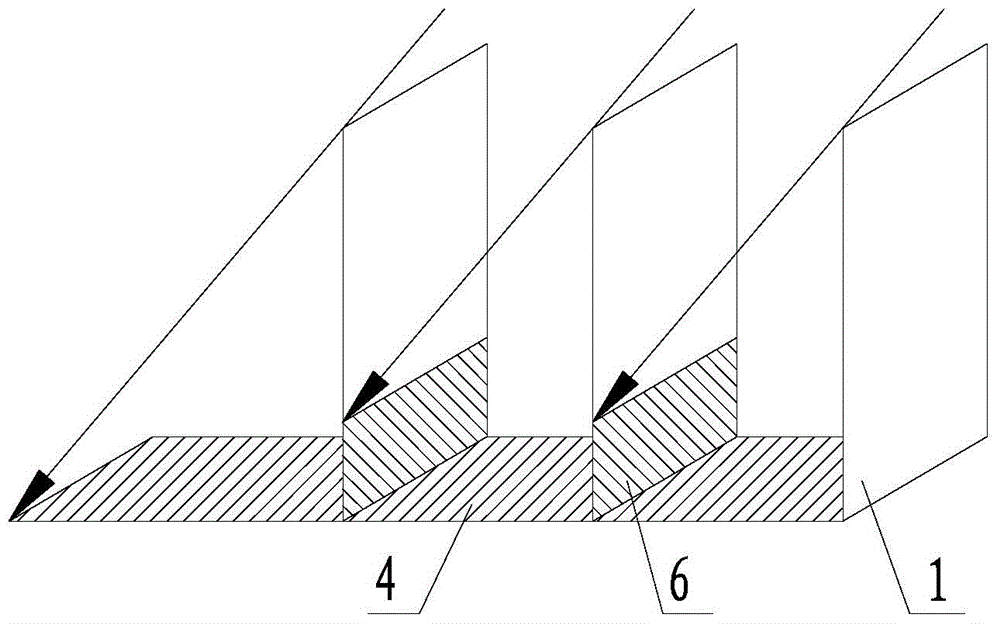

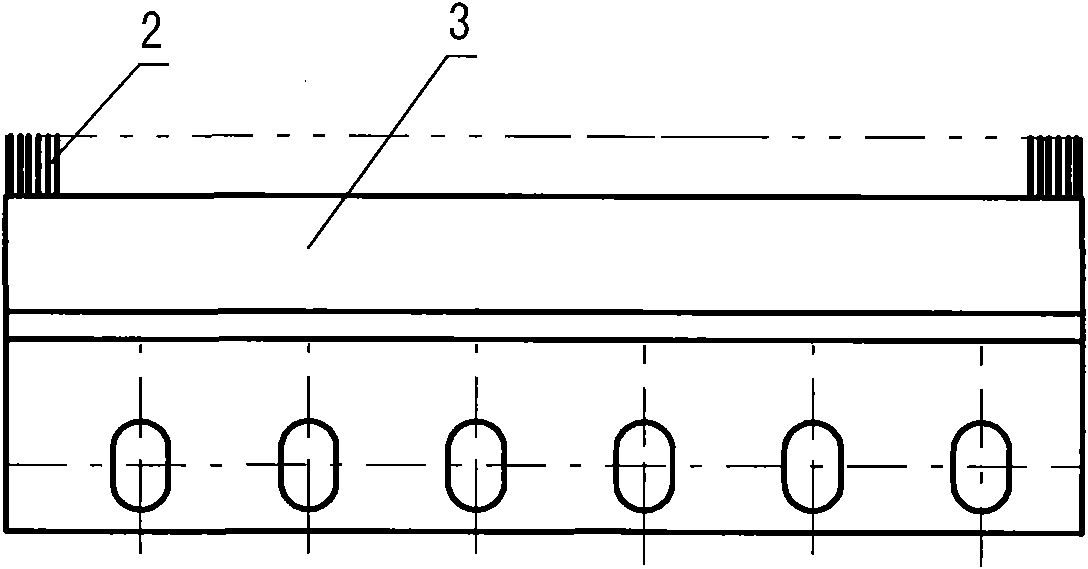

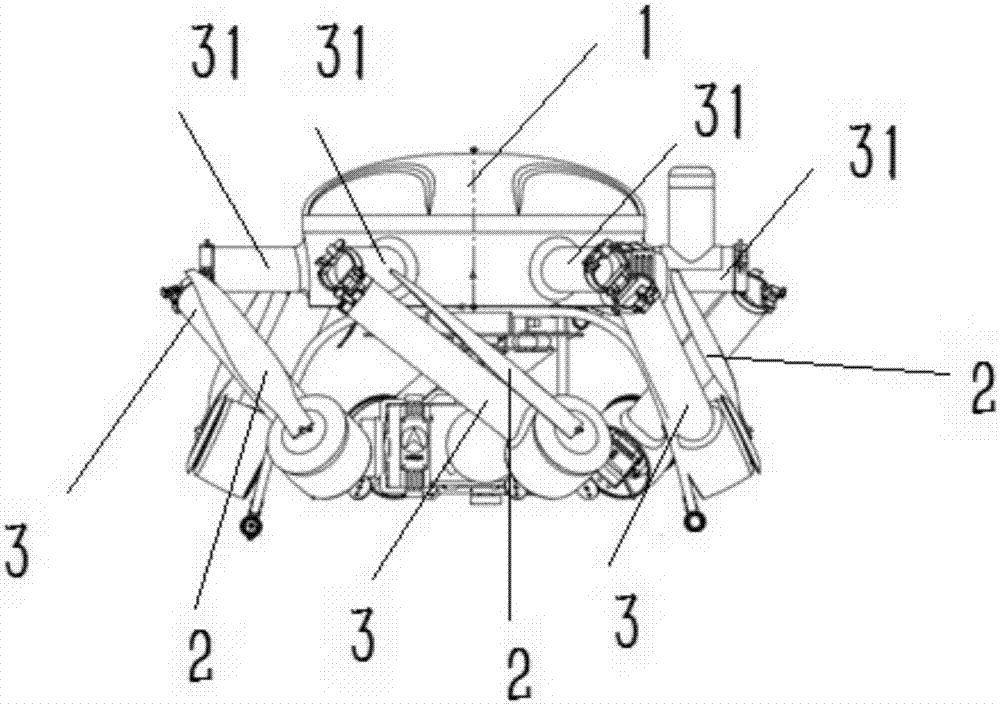

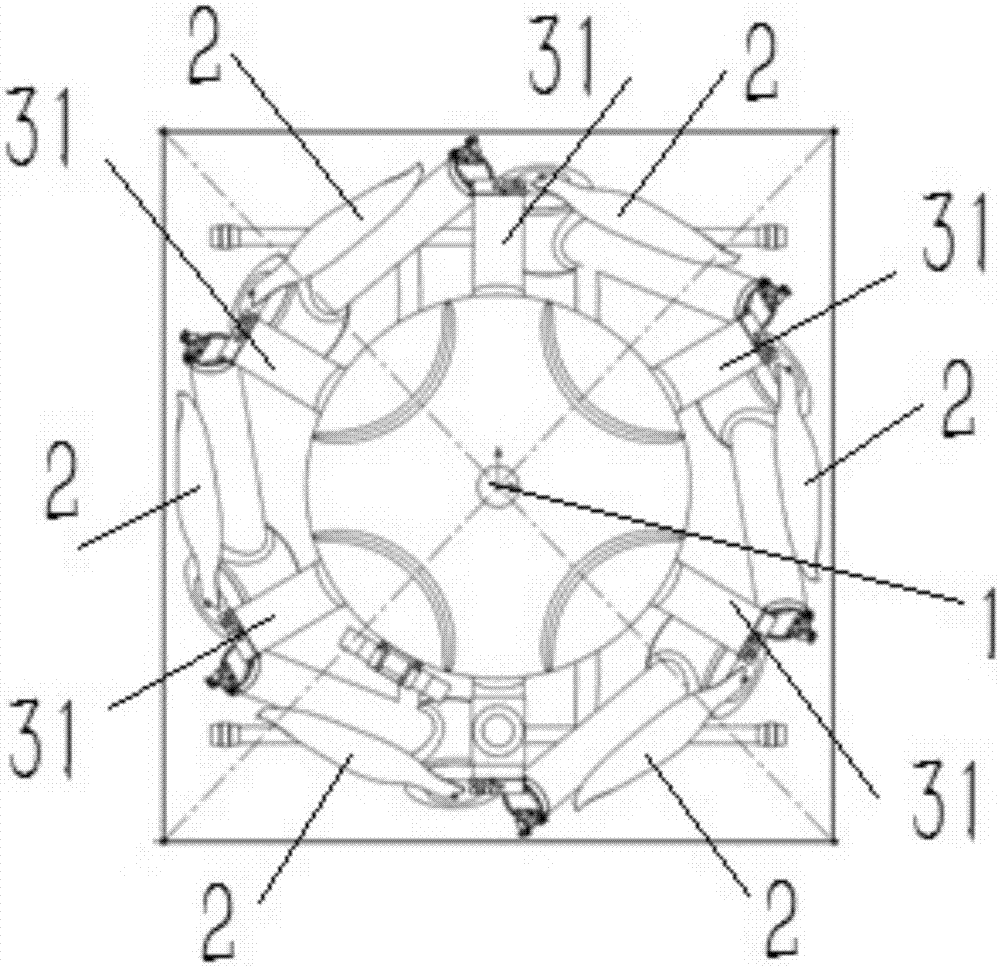

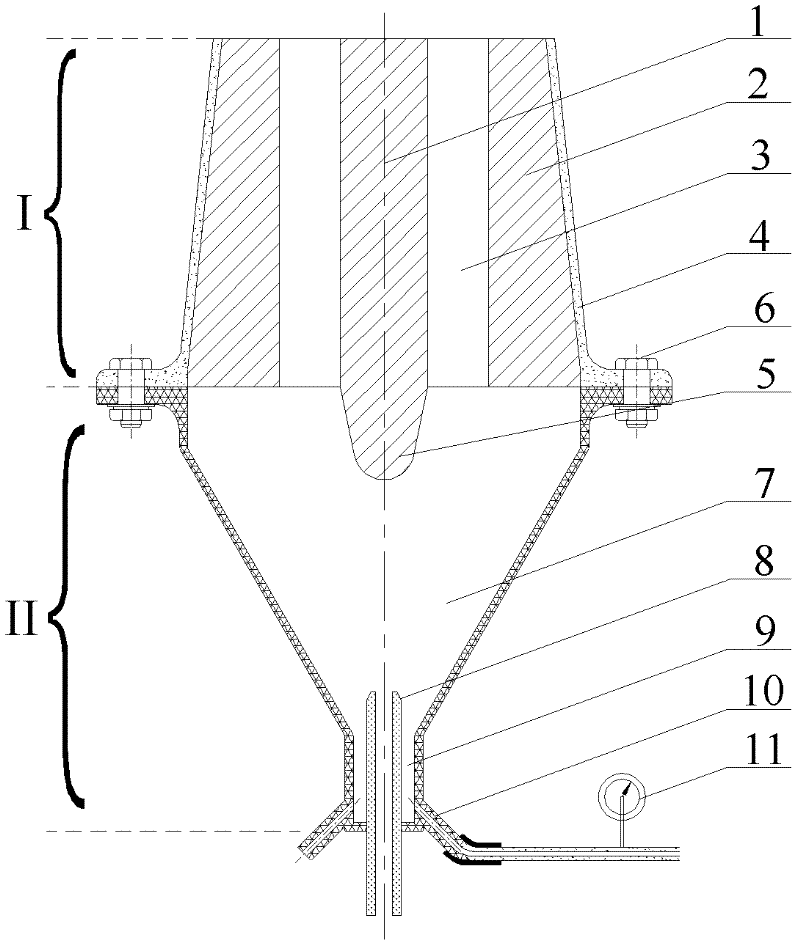

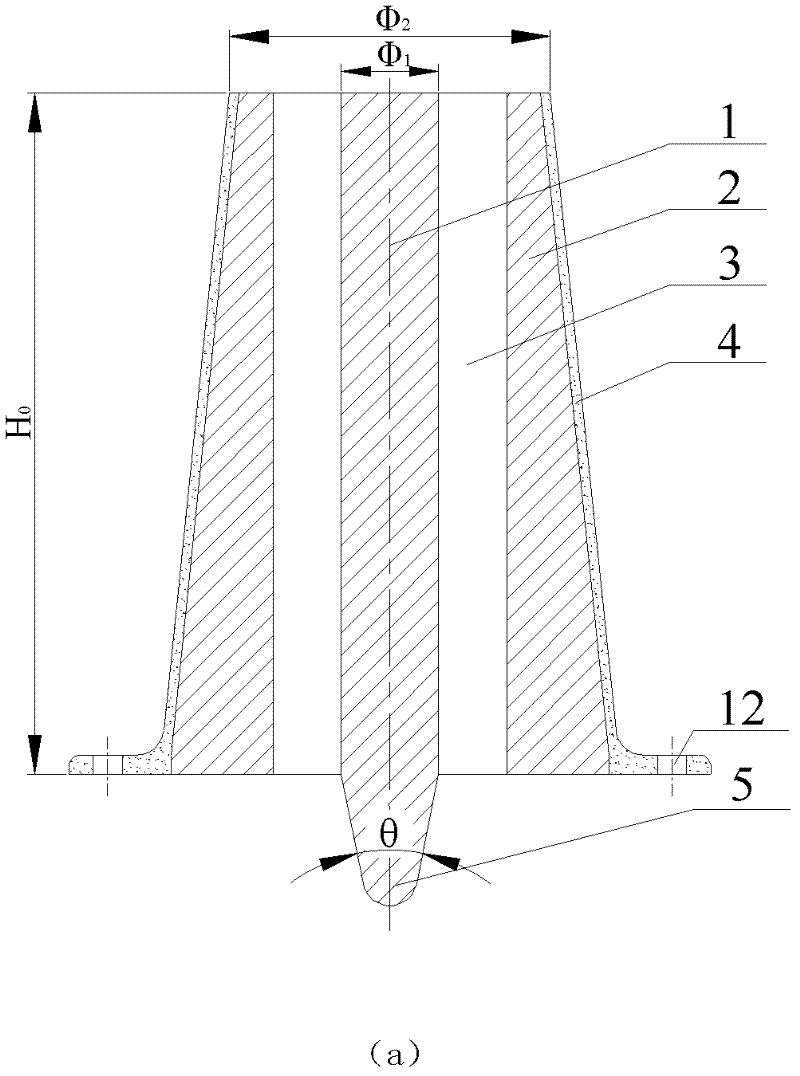

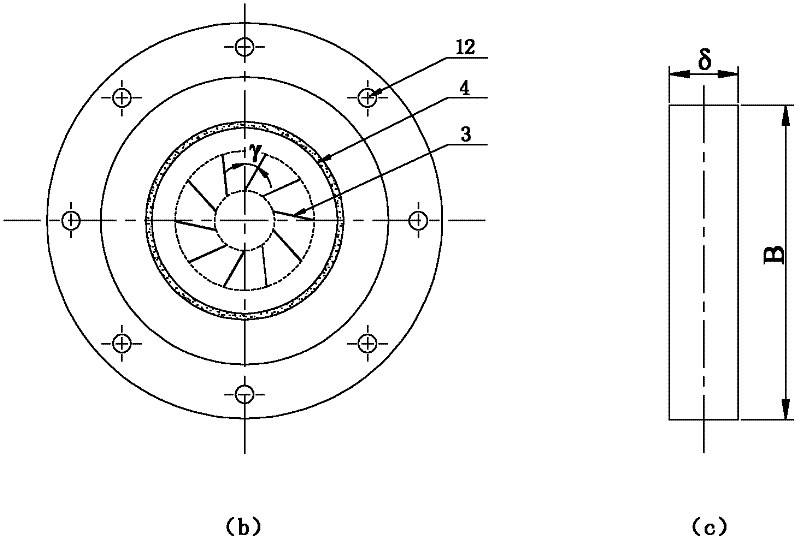

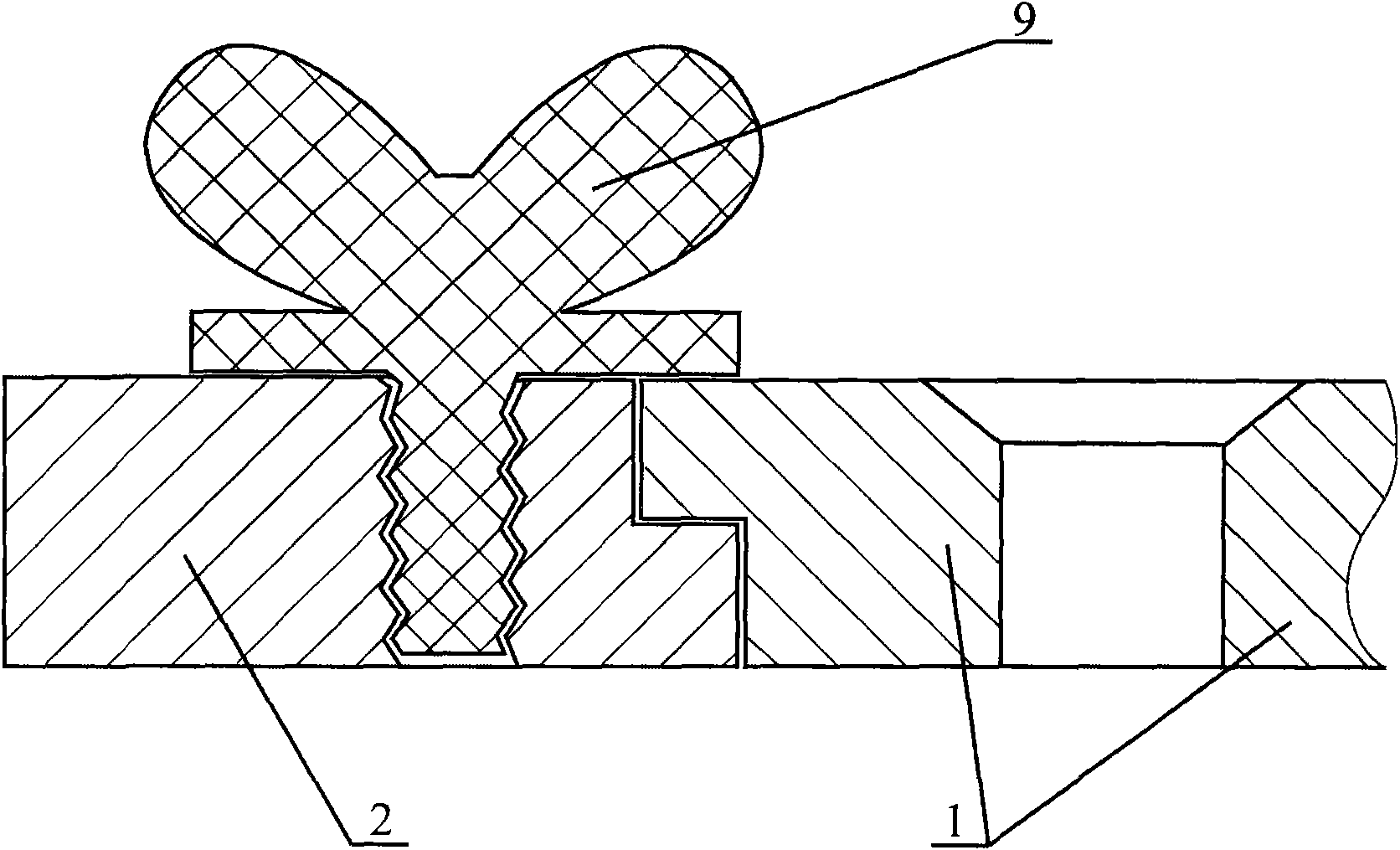

Integrated-shaft and three-roller corner rolling device for continuous casting billet corner rolling

The invention relates to the field of metal solidification and continuous casting, in particular to an integrated-shaft and three-roller corner rolling device for continuous casting billet corner rolling. The device comprises a middle positioning roller (1), an upper chamfer roller (2-1), a lower chamfer roller (2-2), a roller shaft and a roller supporting frame (4); the roller shaft comprises a middle roller shaft section (3) and chamfer roller shaft sections (6) at the two ends; the chamfer roller shaft sections (6) and the middle roller shaft section (3) are arranged in an alpha angle manner; the middle positioning roller (1) is mounted on the middle roller shaft section (3); the upper chamfer roller (2-1) and the lower chamfer roller (2-2) are respectively mounted on the chamfer roller shaft sections (6); the chamfer roller shaft sections (6) are connected with the roller supporting frame (4); the alpha angle is 0-45 degrees; a roller surface slant angle beta of each chamfer roller is 30-70 degrees; and the alpha angle is less than or equal to the beta angle. The device effectively avoids the defects of shear cracks arising from shear rolling, an optimized casting billet corner chamfer shape can be obtained, and split or surface upwarping of the edge of a plate is eliminated.

Owner:ZHONG NAT ENG & RES CENT

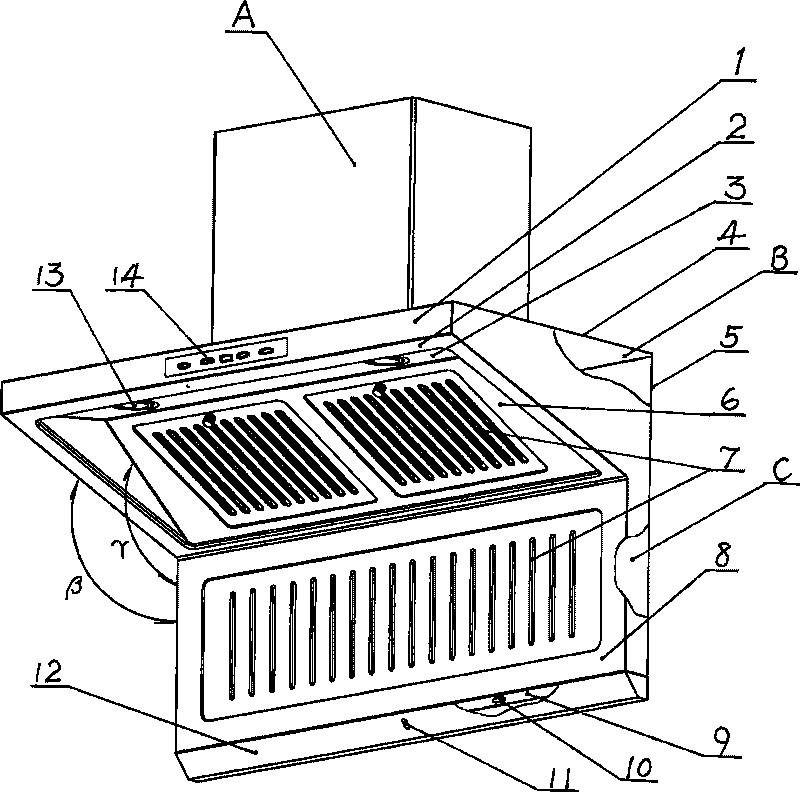

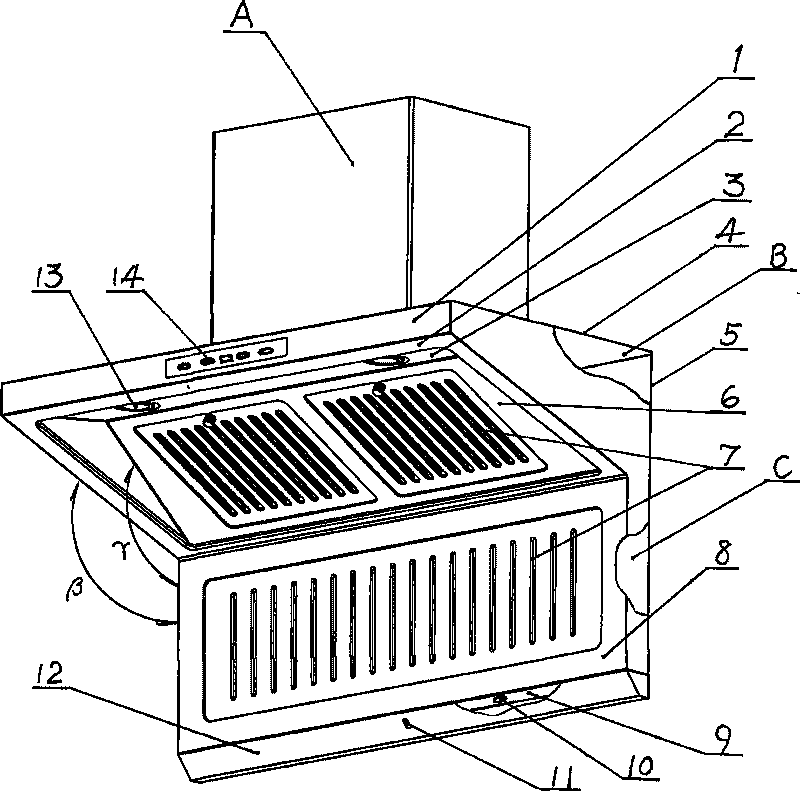

Integrally stretched body pushing double-suction type range hood

InactiveCN101726025ABeautiful appearance and high-gradeEasy to wipeDomestic stoves or rangesLighting and heating apparatusBeta angleSecondary emission

The invention relates to an integrally stretched body pushing double-suction type range hood which comprises a box and an integrally stretched body, wherein a motor, an air wheel, an air channel, an air outlet, a decorative cover and other parts are arranged in the box; the integrally stretched body is formed by combining a transverse cavity and a vertical cavity; and the transverse cavity and the vertical cavity are in a seamless integral structure. The range hood of the invention has luxurious and beautiful appearance, can not accumulate dirt, and can be cleaned conveniently. The stretched base surface and the back stretched surface of the transverse cavity respectively form a beta angle and a gamma angle with the front surface of the vertical cavity, wherein gamma is greater than 90 degrees and less than or equal to 125 degrees, and beta is less than gamma; and air inlet holes are arranged on the back stretched surface of the transverse cavity and the front surface of the vertical cavity, thereby possessing the efficacy of secondary emission of oil smoke generated by cooking. The novel range hood of the invention has the advantages of luxurious and beautiful appearance, very convenient maintenance and the like and can thoroughly clear the oil smoke generated by cooking.

Owner:贺滨

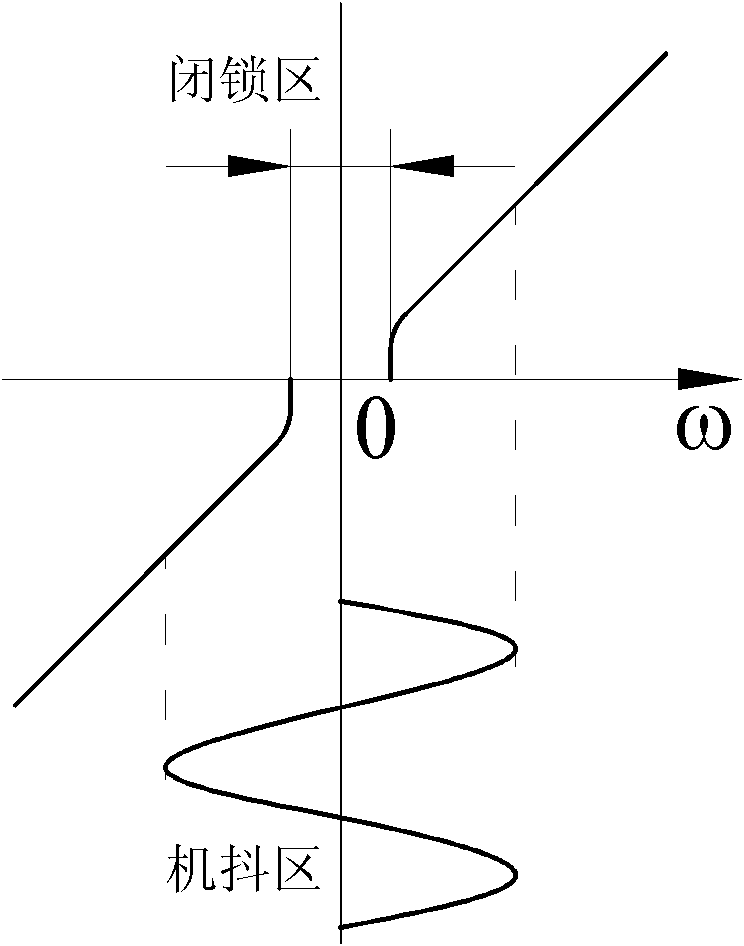

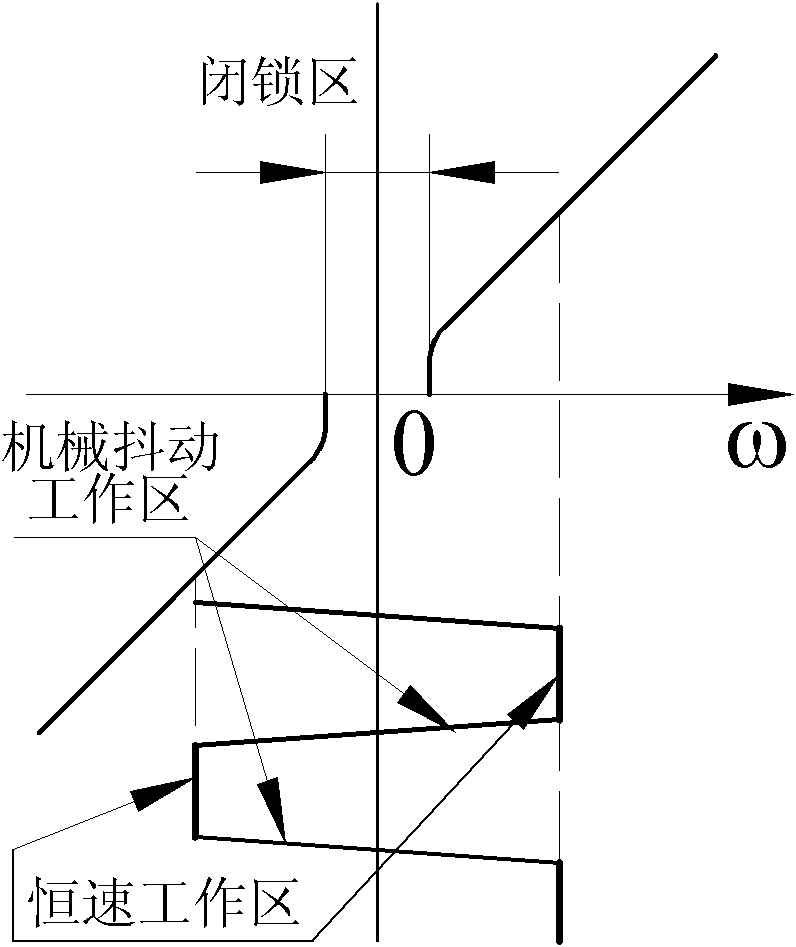

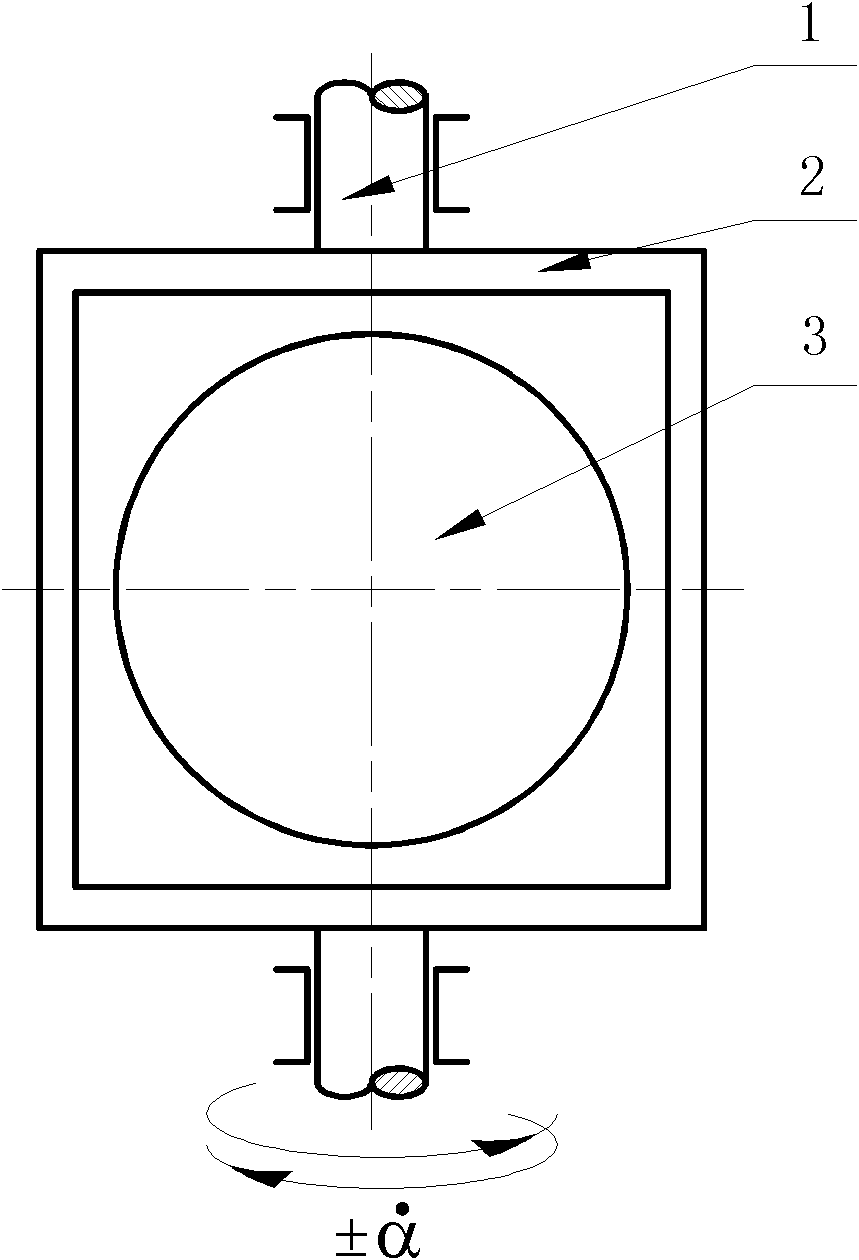

Laser gyro combined offset frequency method and combined device for inertial measurement of laser gyro

ActiveCN102109346AReduce interference errorsReduce positioning accuracyNavigation by speed/acceleration measurementsSagnac effect gyrometersBeta angleVertical axis

The invention provides a laser gyro combined offset frequency method, belonging to the technical field of inertial navigation equipment. The method comprises the following steps: combination with two-way constant speed and mechanical shaking is adopted; a 1-3 axis laser gyro group is arranged on a two-way constant-speed offset-frequency rotary platform rotating around a vertical axis, all sensitive axes of the laser gyro are deviated from a beta angle of a rotary axis of the offset-frequency rotary platform and are driven by the rotary platform to rotate, and a component (alpha & cosine beta)of the rotary angle speed (alpha &) on all the sensitive axes of the laser gyro is the offset-frequency angle speed of the laser gyro; and simultaneously, the rotary angle speed (alpha &) carries outrotary modulation on the error of the laser gyro axis. In the laser gyro combined offset frequency method adopting combination of two-way constant speed offset frequency and mechanical shaking offsetfrequency, not only is the accuracy guaranteed, but also the difficulties for design and manufacture are reduced. The laser gyro combined offset frequency method can be used for high-accuracy laser gyro strapdown inertial systems.

Owner:SHAANXI BAOCHENG AVIATION INSTR

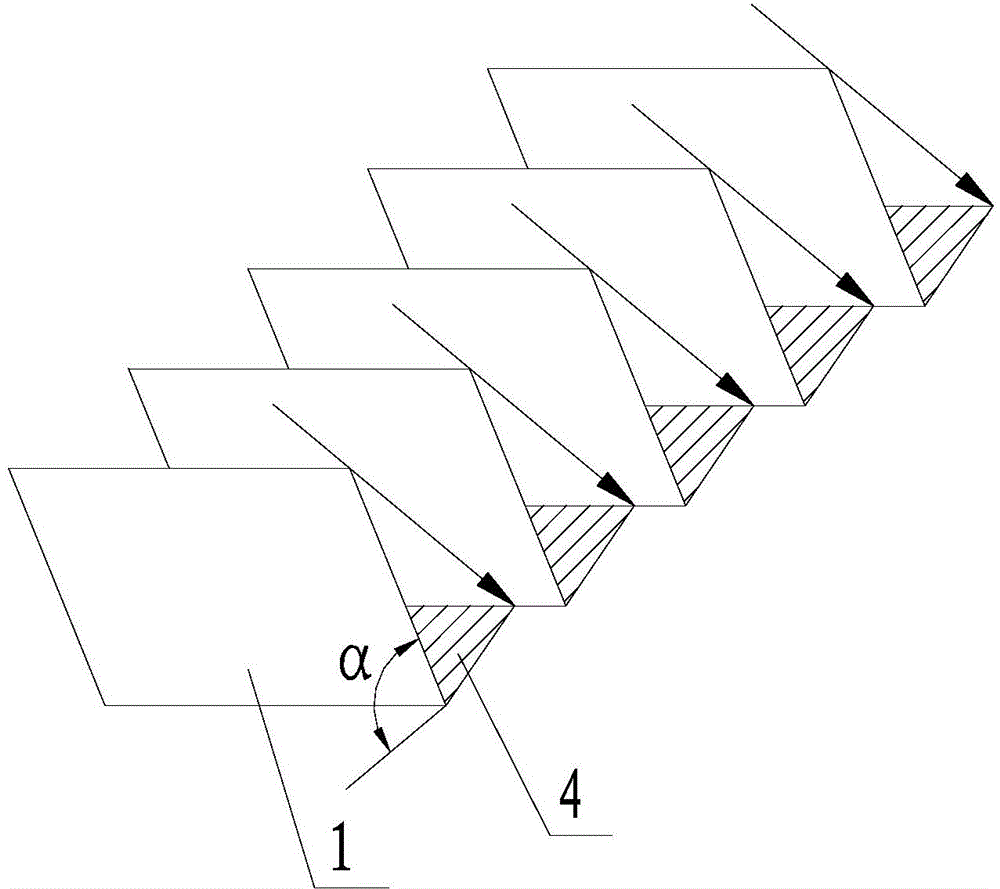

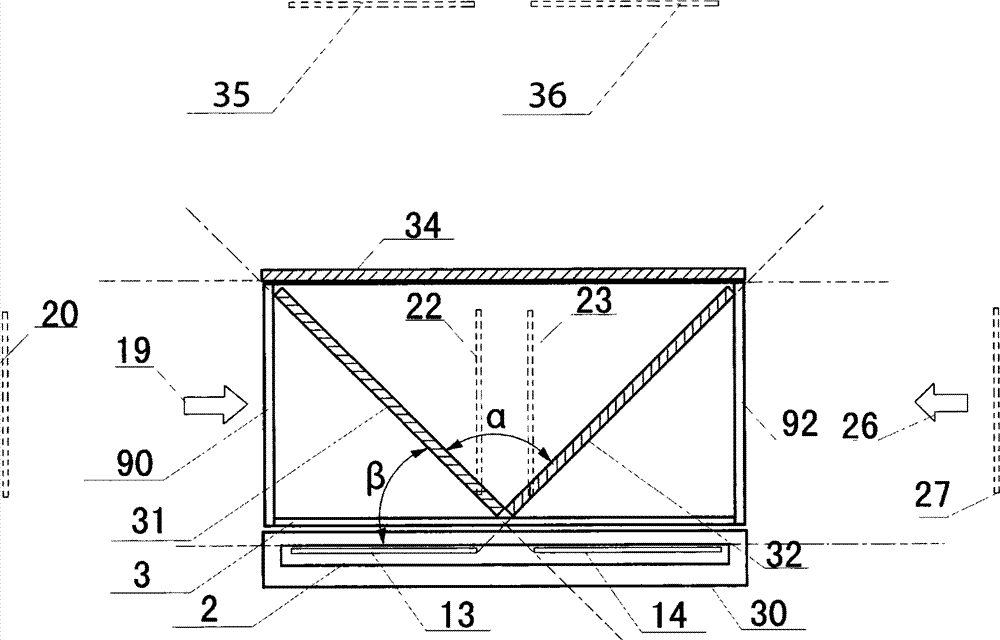

Array type photobioreactor light splitting method

ActiveCN105385563AImprove light splitting ratioImprove light utilization efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBeta angleElevation angle

The present invention discloses an array type photobioreactor light splitting method, and belongs to the technical field of microalgae culture. The array type photobioreactor light splitting method comprises that: 1, at least two photobioreactors are arranged on the ground in a front-rear parallel manner and in an array manner at a certain interval, wherein the orientations of the two photobioreactors are free; and 2, along with the changes of the sun altitude angle and the azimuth angle, at least one of the elevation angle alpha and the azimuth angle beta of the effective breeding surface of the photobioreactor is adjusted, such that the length of the vertical shadow produced after sunlight projects onto the photobioreactor is not less than the distance between the adjacent photobioreactor bottom edges in the vertical shadow length direction. According to the present invention, the alpha angle and / or beta angle is adjusted, such that the direct illumination does not produce the light leakage on the ground so as not to cause energy loss.

Owner:ENN SCI & TECH DEV

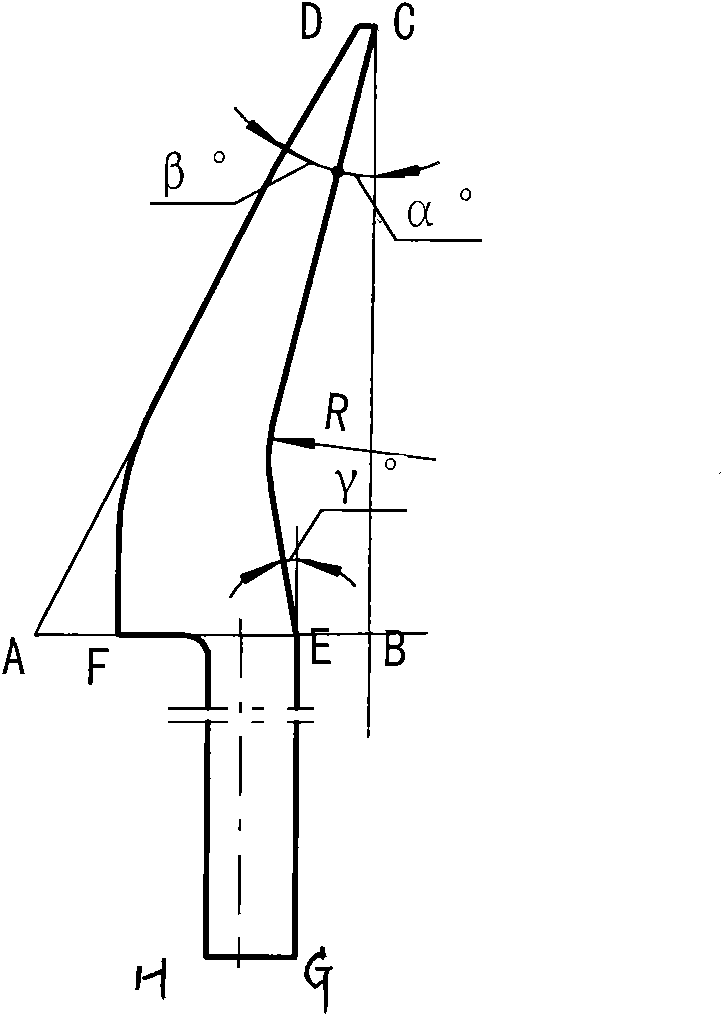

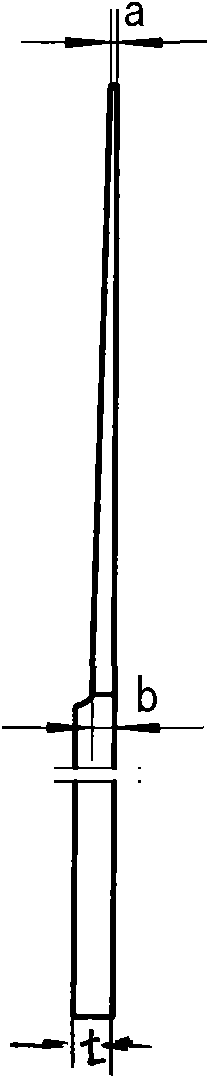

Teeth-like self-cleaning top comb for cotton comber

The invention relates to a teeth-like self-cleaning top comb for a cotton comber. Tooth sheets (2) are connected between a straight panel and a bent plate (3); the cross section of the tooth sheets (2) is of a wedge shape, wherein an alpha angle is 11 to 13 degrees; a beta angle is 17 to 19 degrees; and a gamma angle is 9 to 11 degrees; C and E are connected through an arc, the value of R is 2.3 to 3 mm, and edges of the C and the E are clearance angles and have no burr; the values of the C and D are 0.200 to 0.05 mm, the BC value of a working height of a tooth sheets section is 5.5+ / -0.015 mm, the value of AB is 3 mm, the value of BE is 0.6 to 0.8 mm, and the value of BF is 2.06 mm; and the alpha value of the lower end of the tooth sheets section thickness is 0.06 to 0.08 mm, and the beta value of the upper end of the tooth sheets section thickness is 0.20 to 0.25 mm. The top comb has the good carding effect, and self-cleans carded neps, flocks and impurities in the process of carding, so that the use performance of the top comb is improved and the working efficiency is improved.

Owner:何银康

Method for compensating infrared photography positioning by using acceleration sensor

The invention discloses a method for compensating infrared photography positioning by using an acceleration sensor, which comprises the following steps of: S1, acquiring the rotation angle beta which is relative to a horizontal direction, of a wireless control device through a gravitational acceleration sensor; S2, acquiring the position B point (XO, YO) of a target positioning point which is not corrected through a camera; S3, correcting the target positioning point through an infrared photography positioning unit; and S4, acquiring a corrected target positioning point A (X0cosbeta-Y0sinbeta, Y0cosbeta+X0sinbeta) so that the wireless control device can accurately position the target positioning point under the condition of rotating at the beta angle relative to the horizontal direction. According to the invention, the target positioning point is corrected through the infrared photography positioning unit so that the wireless control device can accurately position the target positioning point under the condition of rotating at the beta angle relative to the horizontal direction.

Owner:CHINA HUALU GRP

Quick detection method for punching steel plate polar diagram data

InactiveCN1425913AConsistent accuracyReduce data volumeMaterial analysis by transmitting radiationBeta angleSheet steel

The quick detection method for punched steel plate polar diagram data belongs to the field of X-ray detection technology. From eight polar diagrams of different crystal plane indexes {110}, {200}, {211}, {220}, {310}, {222}, {321} and {400}, 2-6 is selected as the tested polar diagrams. In 2D X-ray detection system, the polar diagram data in some alpha angle and some beta angle ranges. There data are utilized to ensure the consistency of the polar diagram method and traditional measurement method. The present invention has detection period only one percent of that in traditional detection method and has raised in-situ measurement precision. The present invention is suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

Method for portable folding novel multi-rotor unmanned aerial vehicle

InactiveCN107472508ALower the altitudeReduce the length and width dimensions in the horizontal directionFuselagesAir-flow influencersBeta anglePropeller

The invention provides a method for portable folding a novel multi-rotor unmanned aerial vehicle. Firstly, foldable propellers are folded to the direction of a vehicle body, the folded foldable propellers are aligned with corresponding foldable vehicle arms; the foldable vehicle arms are coaxially hinged to vehicle arm bases, at the moment, the vehicle arms are rotated and folded so as to be perpendicular to the vehicle arm bases, and the foldable vehicle arms form an alpha angle with the vertical direction; and the foldable vehicle arms continuously rotate for a beta angle to the direction of the vehicle body, and the portable folding of the vehicle arms is completed. According to the method for portable folding the novel multi-rotor unmanned aerial vehicle, the dimensions of the length and the width of the multiple rotors after being folded can be greatly compressed by adopting a method that folding of the vehicle arms in a tilt space is matched with folding of the propellers, meanwhile, relative to vertical folding of the vehicle arms, the requirements for the height of an undercarriage can be lowered greatly, the dimension of the overall vehicle after being folded is reduced to a largest extent, and the portability of product transporting is improved effectively.

Owner:TIANJIN AEROSPACE ZHONGWEI DATA SYST TECH CO LTD

A device for blowing and spraying powder at the bottom of a ladle in a cyclone-protected gas storage chamber

The invention discloses a ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber, and belongs to the technical field of steel smelting. The ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber comprises a slit-type powder injection component I and the whirlwind-type flow-smoothing gas storage chamber II.A fire-resistant material is filled into the slit-type powder injection component. Multiple slits are distributed uniformly in the fire-resistant material. A middle axle plane which passes through ends which belong to the slits and are close to an axle center, and a vertical plane where the slits are arranged form an included angle gamma. The bottom of the whirlwind-type flow-smoothing gas storage chamber is connected with a whirlwind-type accelerating chamber. A low end of the whirlwind-type accelerating chamber is provided with a whirlwind-type gas flow conveying pipes. The whirlwind-type gas flow conveying pipes are arranged at both sides of a power-gas flow conveying pipe and form respectively beta angles with the power-gas flow conveying pipe. The ladle bottom blowing power injectiondevice with the whirlwind-type flow-smoothing gas storage chamber can reduce obviously a degree of powder-gas flow pulsation, accumulation of falling powder, and resistance to a powder-gas flow when the powder-gas flow is fed into the slits, can improve obviously a uniform flow conveying rate of the powder-gas flow in the slits. The ladle bottom blowing power injection device with the whirlwind-type flow-smoothing gas storage chamber has the advantages of stable blowing, small pulsation, low corrosion on fire-resistant materials, safe and reliable characteristics, feasibility for continuous and stable blowing and long service life of fire-resistant materials.

Owner:NORTHEASTERN UNIV LIAONING

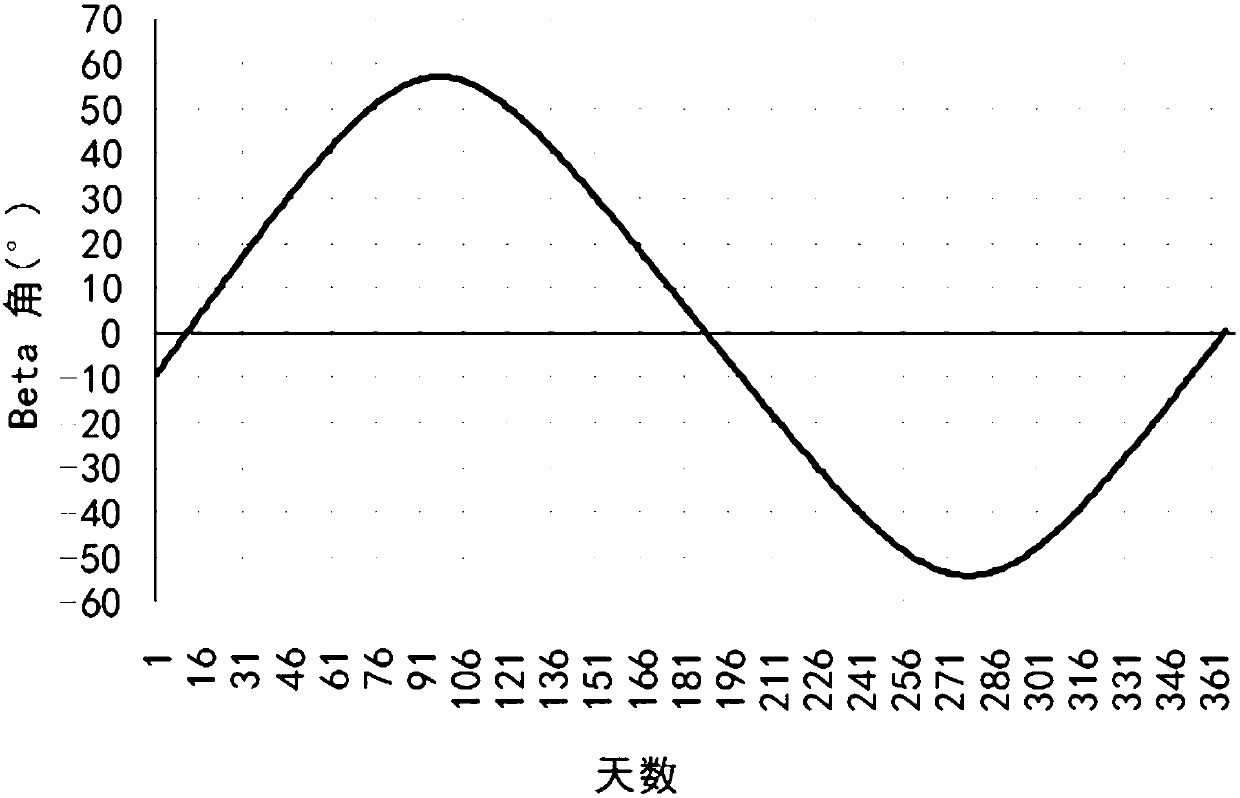

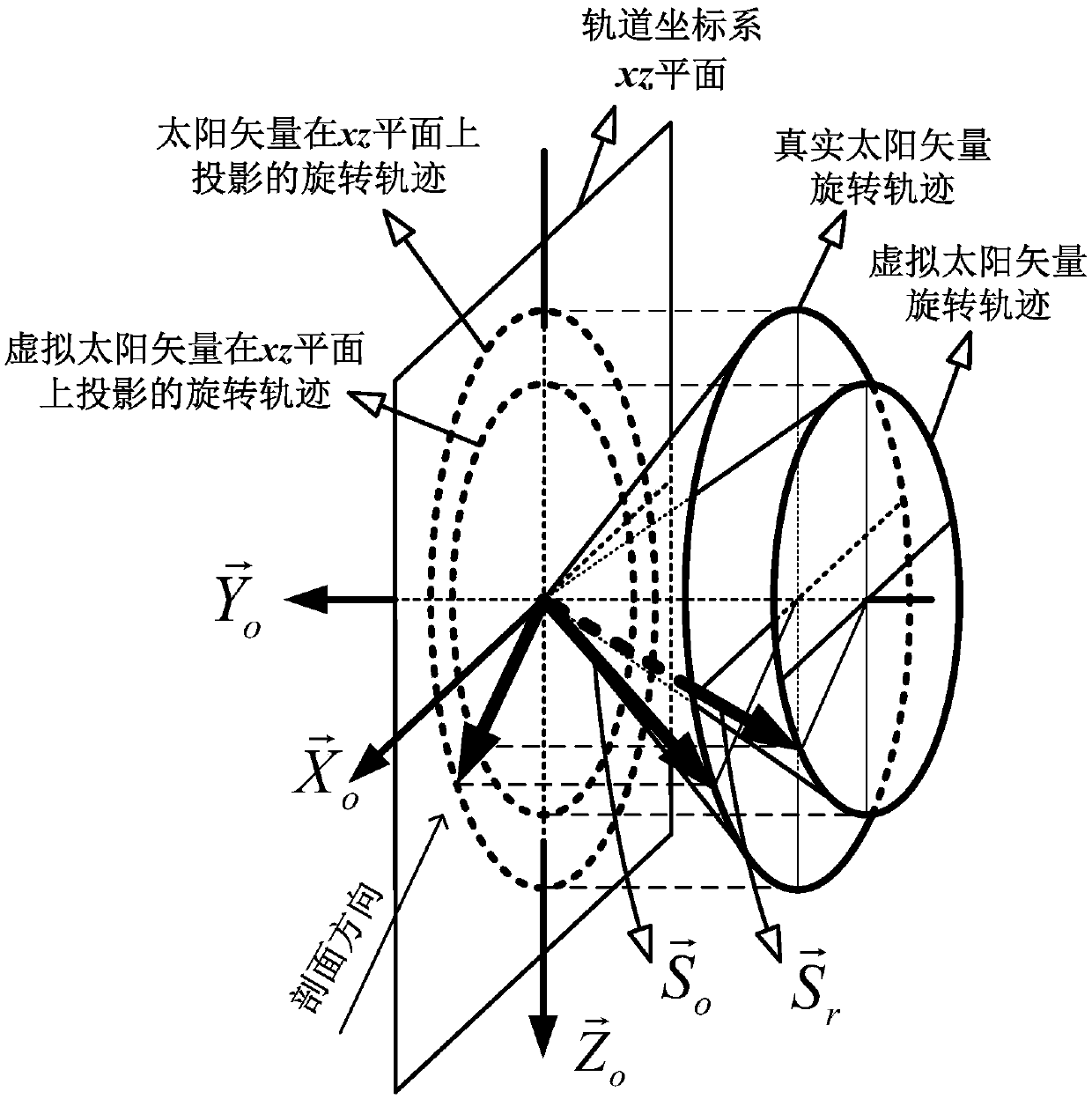

Yaw maneuvering control method and system of spacecraft by using virtual sun vector

ActiveCN108657467ANarrow downShorten speedCosmonautic vehiclesSpacecraft guiding apparatusBeta angleAttitude control system

The invention relates to a yaw maneuvering control method and system of a spacecraft by using a virtual sun vector. The yaw maneuvering control method comprises the steps that a vector expression of areal sun vector in an orbit coordinate system of the spacecraft is obtained; the included angle between the real sun vector and an orbital plane is calculated according to the expression of the realsun vector, and a Beta angle of the real solar vector is obtained; a threshold valve interval for one or more Beta angles is preset, the corresponding relationship between a Beta angle of the virtualsun vector and the Beta angle of the real solar vector which are set in the preset threshold valve interval is set; when the Beta angle of the real sun vector enters into the set threshold valve interval, the virtual sun vector is started to be calculated in real time according to the Beta angles of the real sun vector and the virtual sun vector; a target yaw angle of the spacecraft is calculatedaccording to the virtual sun vector; and according to an own attitude control system of the spacecraft, a yaw maneuvering angle of the spacecraft is controlled in real time to track the target yaw angle, and the yaw maneuvering control of the spacecraft implemented by using the virtual sun vector is realized.

Owner:TSINGHUA UNIV

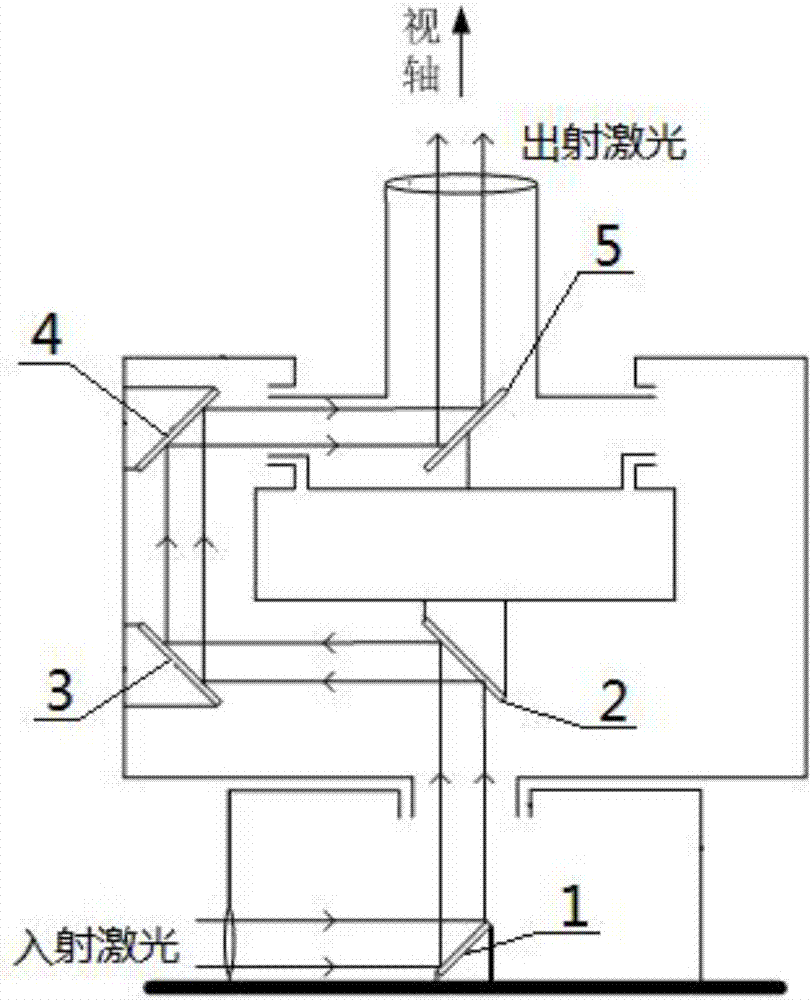

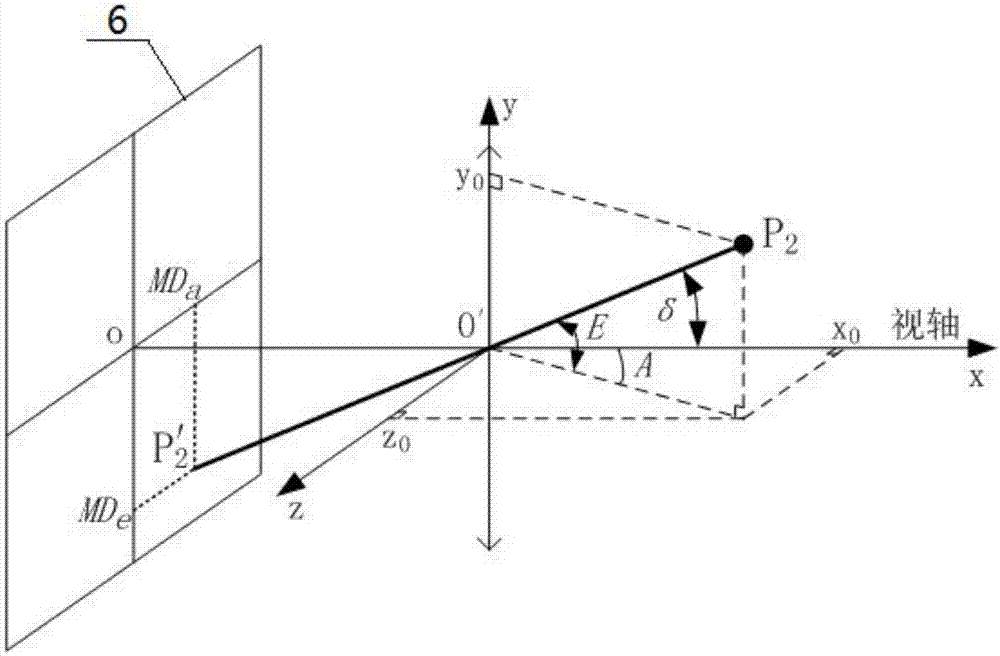

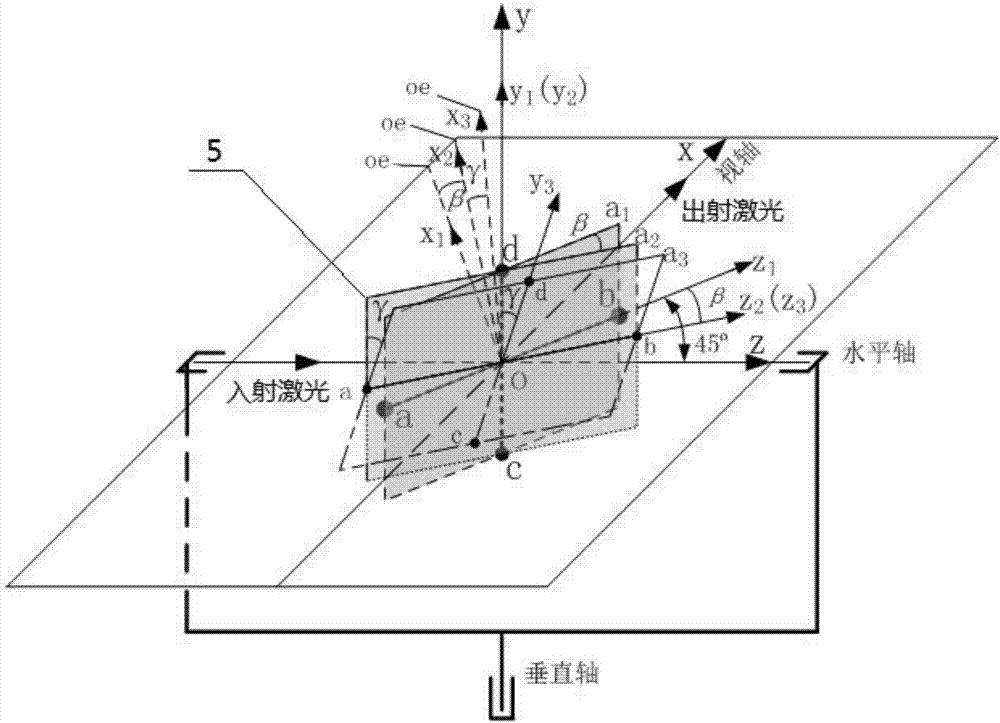

High-precision adjustable Kuder mirror control angle solving method

The method for solving the control angle of the high-precision adjustable Kudt mirror relates to the field of measurement, and can obtain an accurate expression of the control angle of the adjustable Kudd mirror. The method is as follows: in the laser emitting system, the incident laser light is reflected by multiple Kudd mirrors and adjustable Kudd mirrors, and the outgoing laser direction is parallel to the direction of the visual axis, and finally points to the space target located on the extension line of the visual axis of the imaging optical system. ; When the azimuth angle of the space object deviated from the visual axis is A, and the pitch angle deviated from the visual axis is E, by adjusting the adjustable Kudd mirror to rotate β angle around its own azimuth axis, and then rotate γ angle around its own pitch axis, Make the outgoing laser point to the space target again; the solution formulas of the β angle and γ angle are shown in formula (2) and formula (3), and A and E are known: Using formulas (2) and (3) to solve the control angle of the adjustable Kudt mirror can achieve extremely high pointing accuracy of the outgoing laser light under any turntable tracking error.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Stereospecific instrument with convenient operation

InactiveCN101564321AEasy qualityFew partsDiagnosticsInstruments for stereotaxic surgeryBeta angleEngineering

The invention provides a stereospecific instrument which has convenient operation and can convey operating instruments to target points when carrying out operations on cranium and brain to humans or animals. The stereospecific instrument comprises a bottom chassis with an Alpha angle graduated scale, a chassis frame, an arch-shaped bracket with Beta angle graduated scale and a fastening piece which is provided with a lead hole and has adjustable tightness; the central part of the chassis is provided with a spherical hinge, and the center of the spherical hinge is provided with the lead hole and two or more than two fixing holes are also arranged near the spherical hinge; the arch-shaped bracket is fixedly connected with the chassis frame; the chassis is sleeved in the chassis frame and can rotate in the chassis frame; and the fastening piece is sleeved on the arch-shaped bracket and can slide on the arch-shaped bracket. The stereospecific instrument has the advantages of less parts for hinge connection, compact structure, high stability and reliability, simple operation and easy guarantee for operation quality.

Owner:吕田明

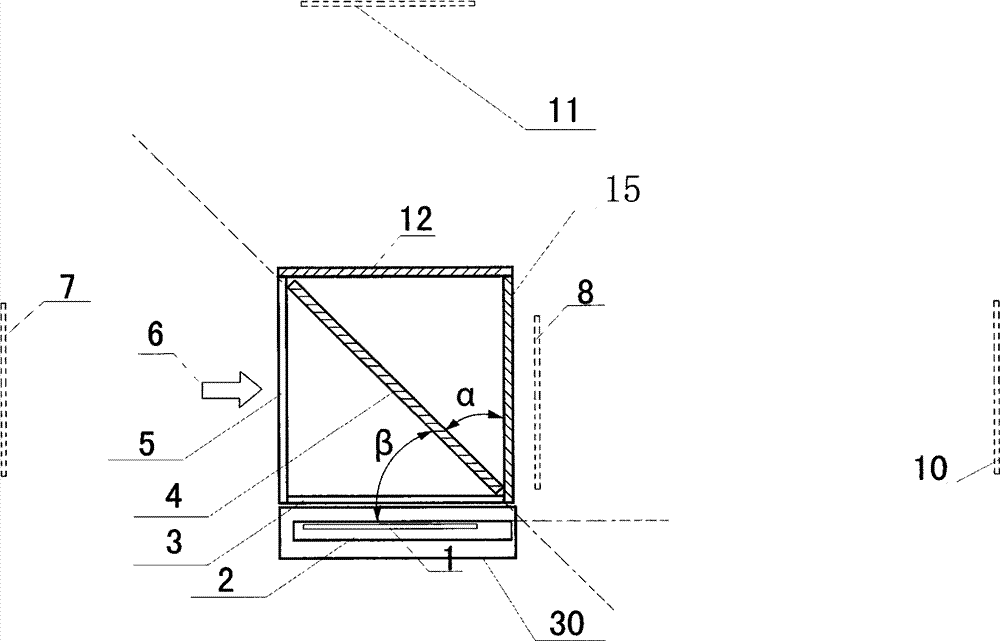

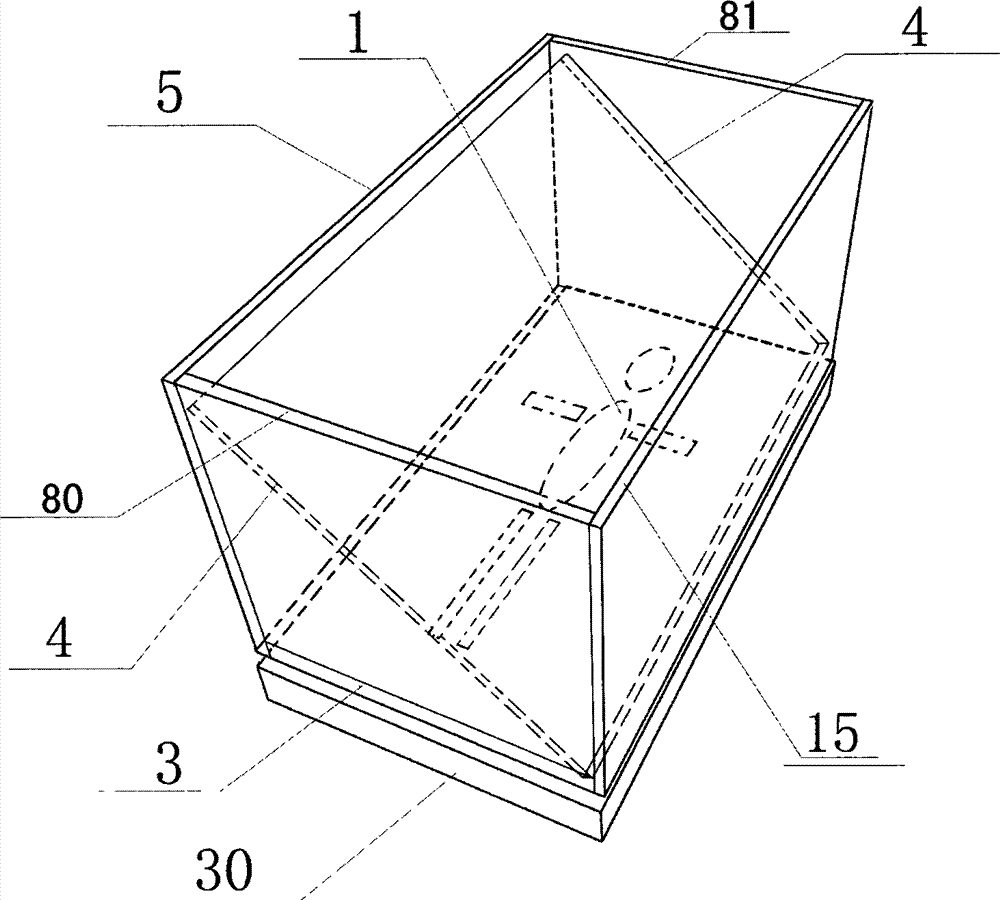

Multilayer transparent imaging device

InactiveCN104330884AObvious sense of distanceStrong three-dimensional senseOptical elementsBeta angleComputer science

The invention relates to reflection imaging, and relates to an imaging device that at least two layers of transparent images can be displayed in the same direction, and two layers or more than two layers of transparent images can be seen from multiple directions. The imaging device comprises a display screen and reflection boards which are used for enabling the display screen to be reflected by the corresponding reflection surfaces of the reflection boards so that the image in the display screen can be imaged at the corresponding position. The imaging device is characterized by comprising at least one set of display screen. Each set at least comprises one display screen. There are at least three reflection boards, wherein an alpha angle is formed between the reflection surface of at least one reflection board and the reflection surface of another reflection board, the alpha angle is greater than or equal to 30 degrees and less than or equal to 90 degrees, a beta angle is formed between the reflection surface of at least one reflection board and the display surface of the display screen, and the beta angle is greater than or equal to 30 degrees and less than or equal to 60 degrees. The reflection boards are total reflection boards or semitransparent reflection boards. Reflection thin films are coated on the reflection boards and used for enhancing light ray reflection capacity of the reflection boards.

Owner:梁雁飞

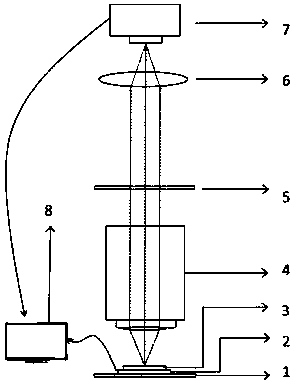

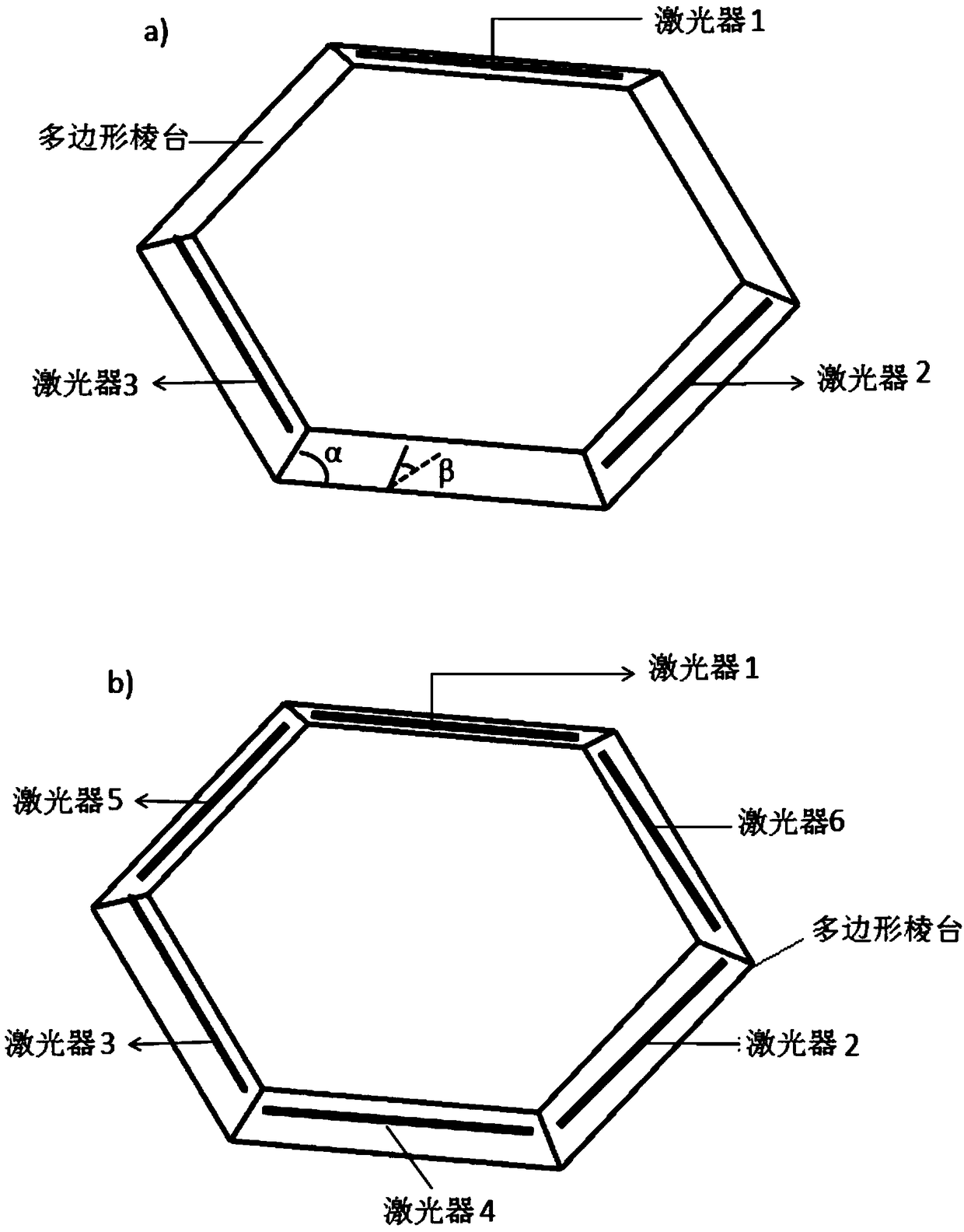

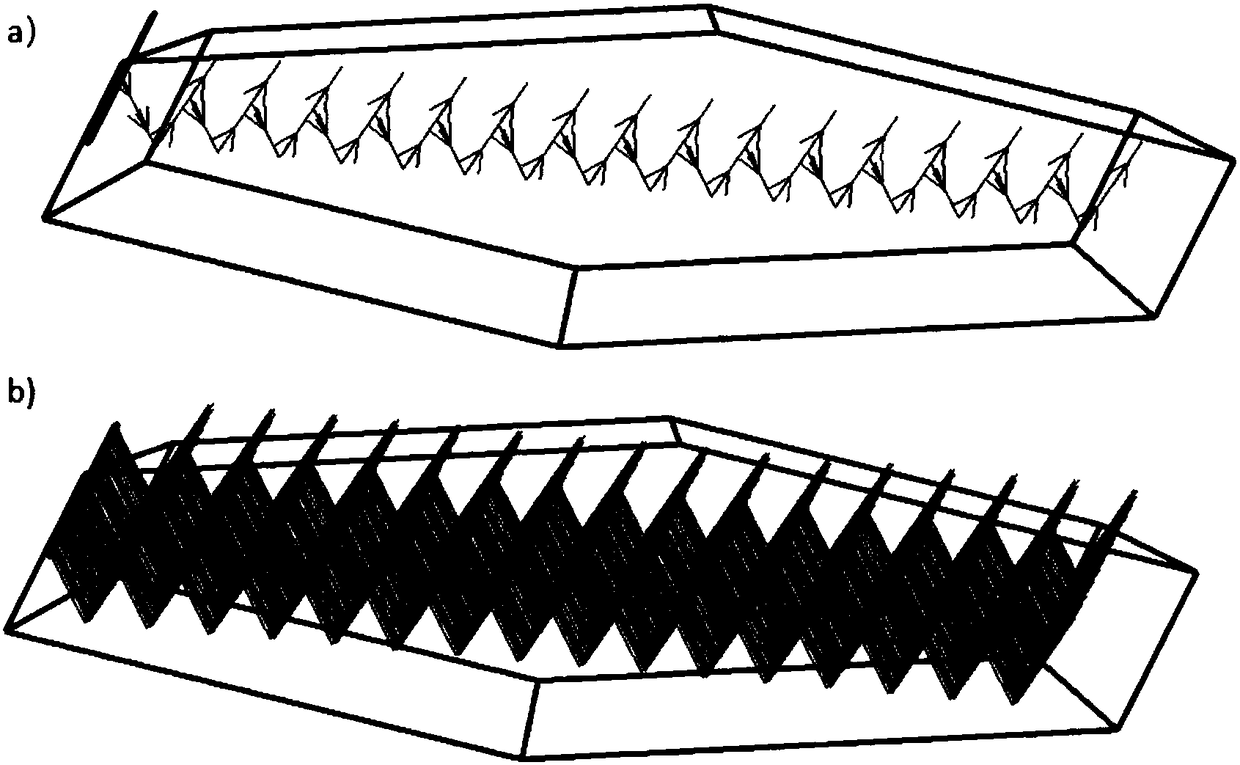

Illumination super-resolution fluorescence microscopic imaging method and device for microstructure light

ActiveCN108227174AQuick responseReduce volumeMicroscopesFluorescence/phosphorescenceBeta anglePolygonal line

The invention relates to an illumination super-resolution fluorescence microscopic imaging method and device for microstructure light and belongs to the field of optical super-resolution microscopic imaging and fluorescence detection. A microstructure light generation device is composed of a polygonal frustum of a prism and multiple linear lasers; the polygonal frustum of a prism is made of a transparent material, the area of the lower bottom surface is larger than that of the upper bottom surface, the included angle between each side surface and the bottom surface of the polygonal frustum ofa prism is beta, two or more side surfaces of the polygonal frustum of a prism are provided with the linear lasers, all the linear lasers can be reflectively transmitted at the beta angle in a zigzagshape between the upper and lower bottom surfaces of the frustum of a prism, partial light can be reflected and leak every time that light is vibrated to the upper bottom surface, and finally clear strip structure light can be generated on the upper surface of the device. The illumination super-resolution fluorescence microscopic imaging method and device for the microstructure light can be applied to a super-resolution fluorescence microscopic system.

Owner:BEIJING UNIV OF TECH

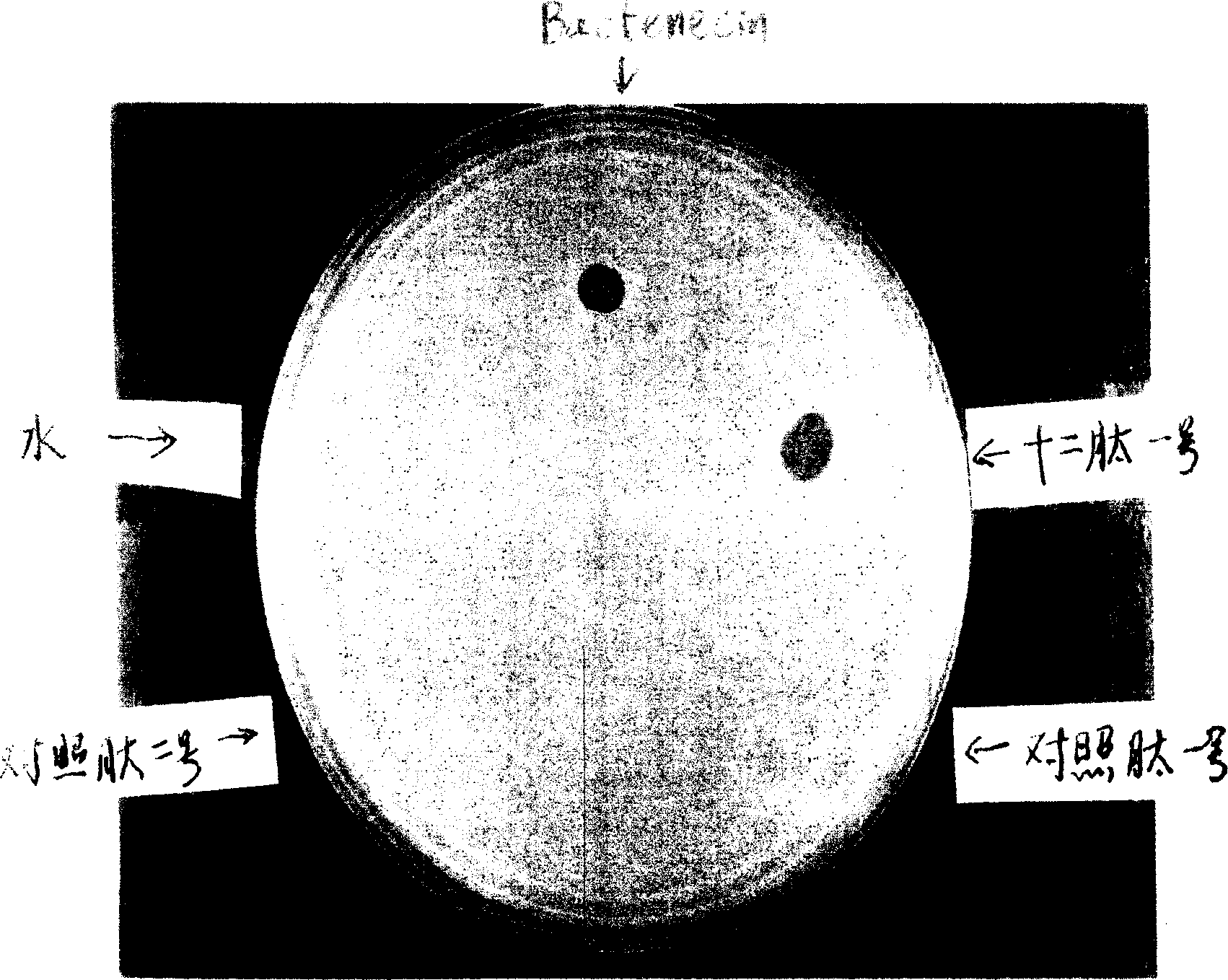

Active antibiotics dodeca peptide

The present invention relates to the amino acid sequence with the structure characteristics of dodecapeptide. It features that the amino acid constituting dodecapeptide are divided into three parts; 4 amino acids at amino terminal, 4 central amino acids and 4 amino acids at carboxy termin, which can form stable alpha-helix and beta-angle to destroy the cell membrane, so playing its antibacterial role. It can also be used to synthesize relative isomer to increase its stability in human body and its possibility of using it as gastrointestinal medicine.

Owner:高华 +2

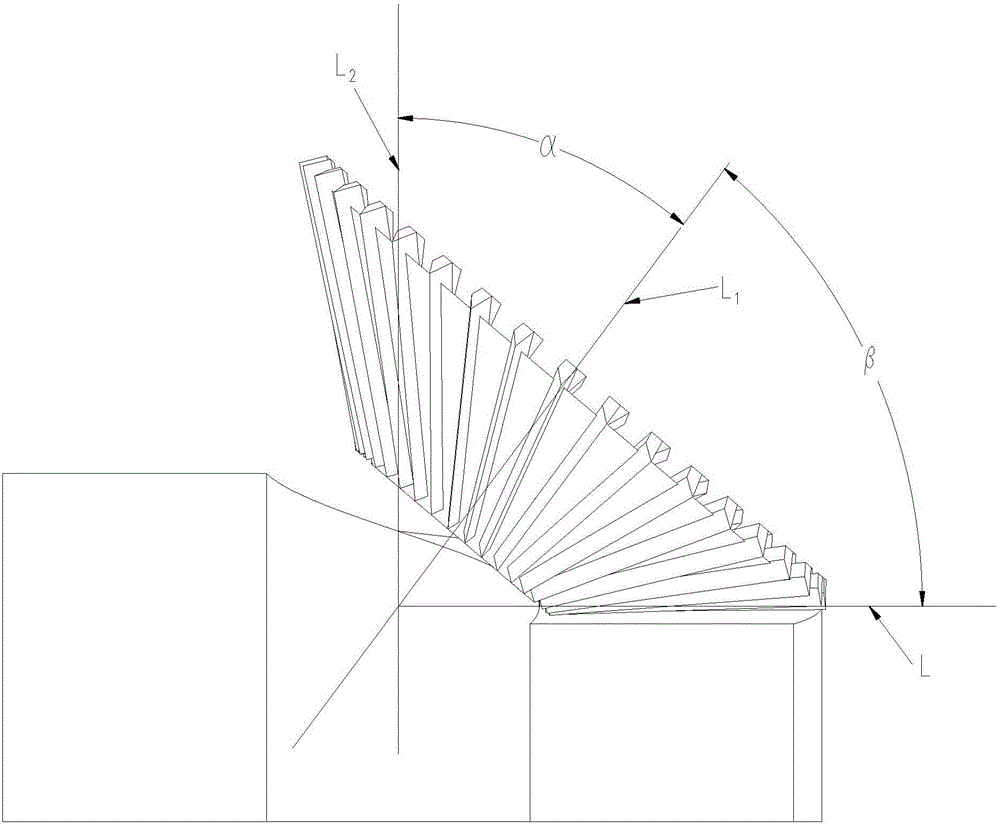

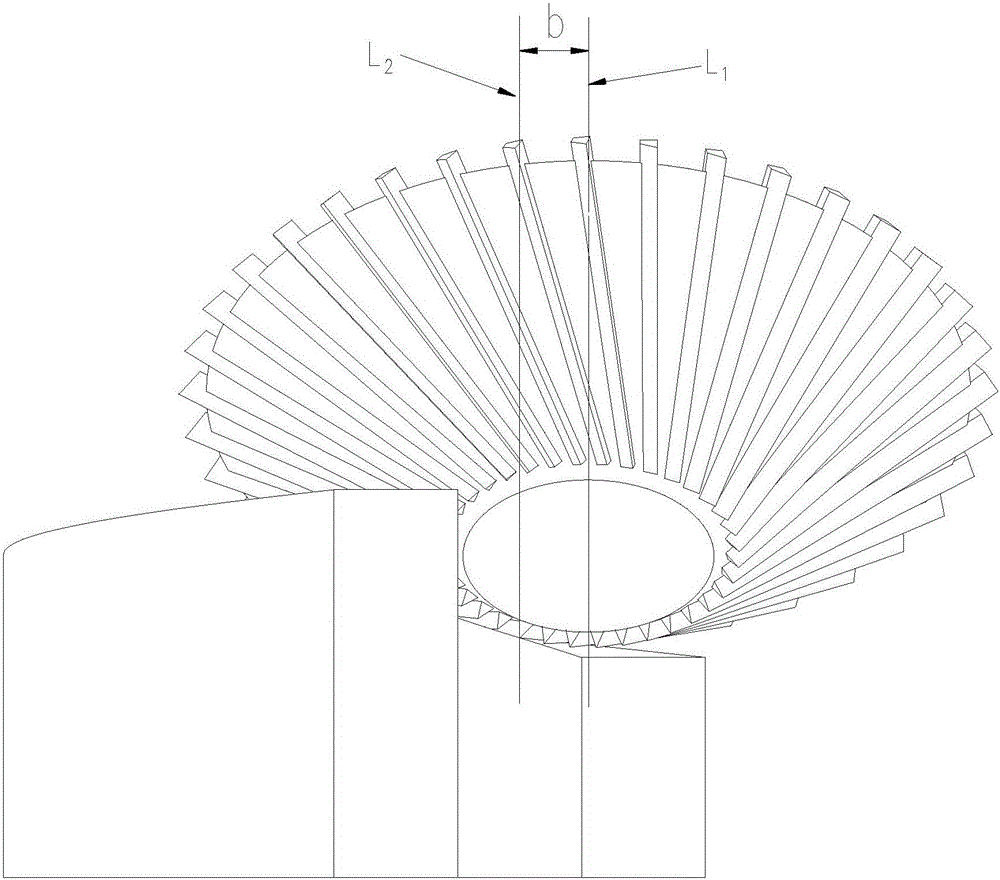

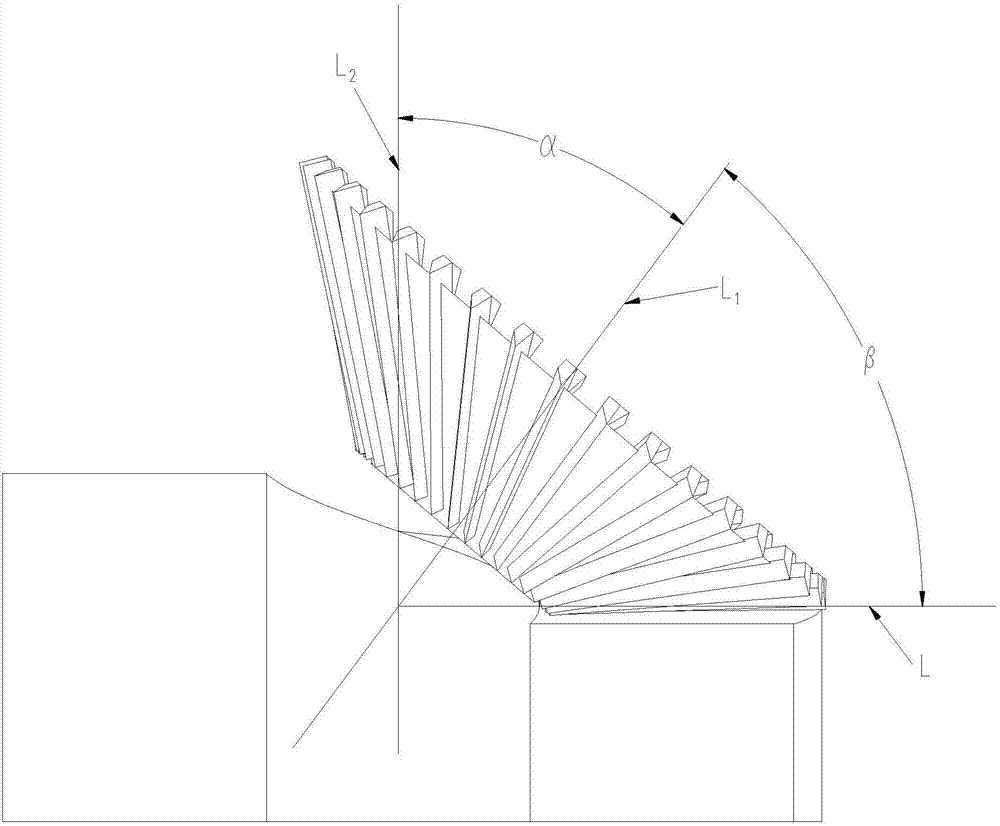

Processing method of right-angle helicoidal surface

The invention provides a processing method of a right-angle helicoidal surface. The processing is carried out through utilizing a single-blade double-curved surface profile-shaped milling cutter. The processing method comprises the steps of during the right-angle helicoidal surface processing process through the single-blade double-curved surface profile-shaped milling cutter, maintaining the axis of the single-blade double-curved surface profile-shaped milling cutter and the axis of the right-angle helicoidal surface to form an alpha-degree angle, and maintaining the distance between the axis of the single-blade double-curved surface profile-shaped milling cutter and the axis of the right-angle helicoidal surface to be b till the processing of the right-angle helicoidal surface is over, wherein alpha is 90 to beta; beta is an include angle between a generating line of the single-blade double-curved surface profile-shaped milling cutter and the axis of the single-blade double-curved surface profile-shaped milling cutter; beta angle is calculated through the formula that beta equals to arctan (2pi*c / h); h is the lead of the right-angle helicoidal surface; c is the minimum distance between the generating line of the single-blade double-curved surface profile-shaped milling cutter and the axis of the single-blade double-curved surface profile-shaped milling cutter; and c equals to b. According to the processing method, the right-angle helicoidal surface with a relatively small error can be processed on a milling machine.

Owner:CHONGQING JIANSHE IND GRP

Processing method of right-angle helicoid

The invention provides a processing method of a right-angle helicoidal surface. The processing is carried out through utilizing a single-blade double-curved surface profile-shaped milling cutter. The processing method comprises the steps of during the right-angle helicoidal surface processing process through the single-blade double-curved surface profile-shaped milling cutter, maintaining the axis of the single-blade double-curved surface profile-shaped milling cutter and the axis of the right-angle helicoidal surface to form an alpha-degree angle, and maintaining the distance between the axis of the single-blade double-curved surface profile-shaped milling cutter and the axis of the right-angle helicoidal surface to be b till the processing of the right-angle helicoidal surface is over, wherein alpha is 90 to beta; beta is an include angle between a generating line of the single-blade double-curved surface profile-shaped milling cutter and the axis of the single-blade double-curved surface profile-shaped milling cutter; beta angle is calculated through the formula that beta equals to arctan (2pi*c / h); h is the lead of the right-angle helicoidal surface; c is the minimum distance between the generating line of the single-blade double-curved surface profile-shaped milling cutter and the axis of the single-blade double-curved surface profile-shaped milling cutter; and c equals to b. According to the processing method, the right-angle helicoidal surface with a relatively small error can be processed on a milling machine.

Owner:CHONGQING JIANSHE IND GRP

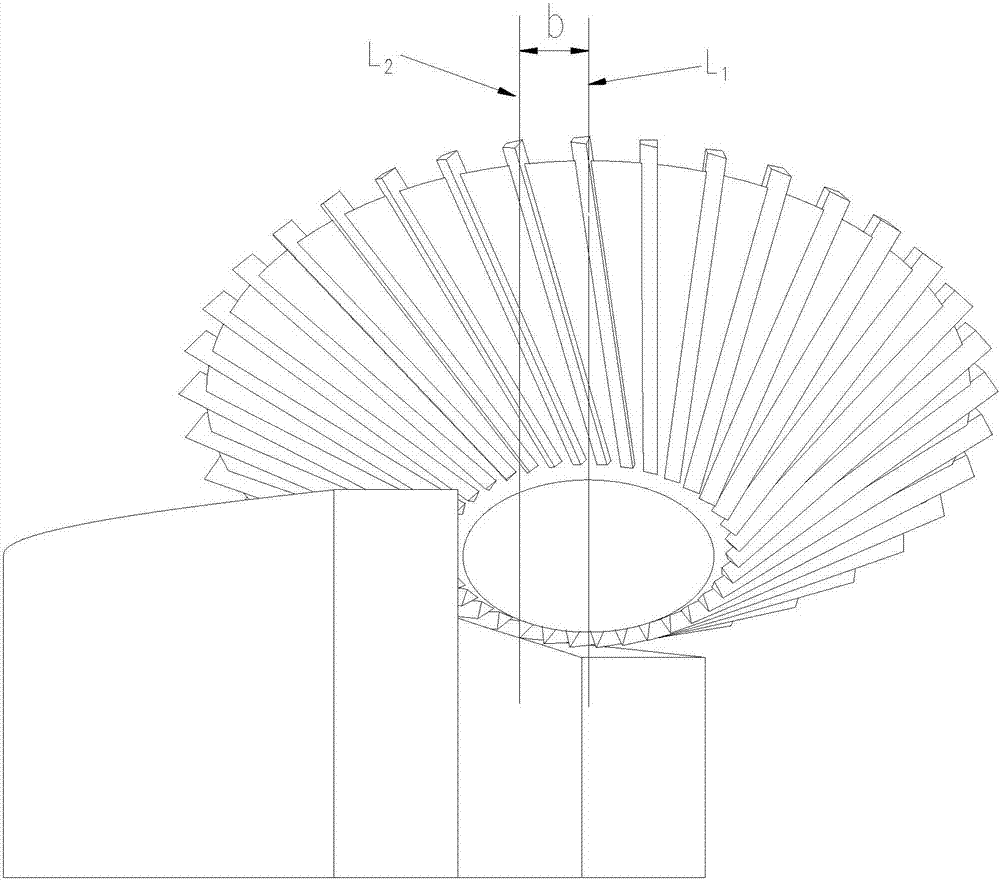

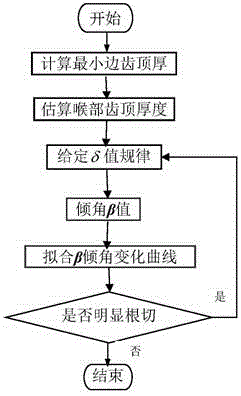

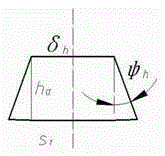

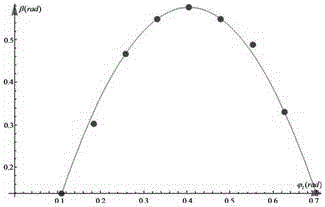

Method for determining beta angle changing curve of planar double enveloping worm

ActiveCN105422794AImprove accuracyImprove controllabilityPortable liftingGearing elementsHelical lineThroat

The invention discloses a method for determining a beta angle changing curve of a planar double enveloping worm. The method includes the steps that a space coordinate system is established according to a beta angle changing planar double enveloping worm forming principle, the beta value is set to be a function of worm gear turn angle phi<2>, and beta angle changing addendum thickness equation delta and tooth surface undercutting discriminant equation r1 are derived on the basis of an envelope method principle; the minimum side addendum thickness value delta<min> meeting the requirement of no sharpening is calculated according to worm parameters; the addendum thickness is made to change regularly and linearly in the worm helical line direction from side teeth to throat teeth; multiple worm gear turn angles phi<2> are obtained according to an equal difference rule to obtain the corresponding thickness values so as to form feature points (phi<2>, delta (beta)); the beta value which each point corresponds to is obtained through the beta angle changing addendum thickness equation, the beta curve is fitted, the fitted beta curve is substituted into the tooth surface undercutting discriminant equation, and an undercutting line is drawn on a worm tooth surface graph; and the undercutting ratio is estimated, if the design requirement is met, the operation is finished, if the design requirement is not met, throat addendum thickness delta<h> is reduced or the addendum thickness change rule is changed to a cosine rule, and the operation returns to the step 3.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com