Composite microdisplacement oil jetter of IC engine with piezoelectric control

A technology of fuel injectors and internal combustion engines, which is applied in the direction of machines/engines, fuel injection devices, mechanical equipment, etc., and can solve problems such as difficulty in forming a homogeneous mixture, achieve reduced HC and NOx emissions, high control accuracy, and increase compression ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

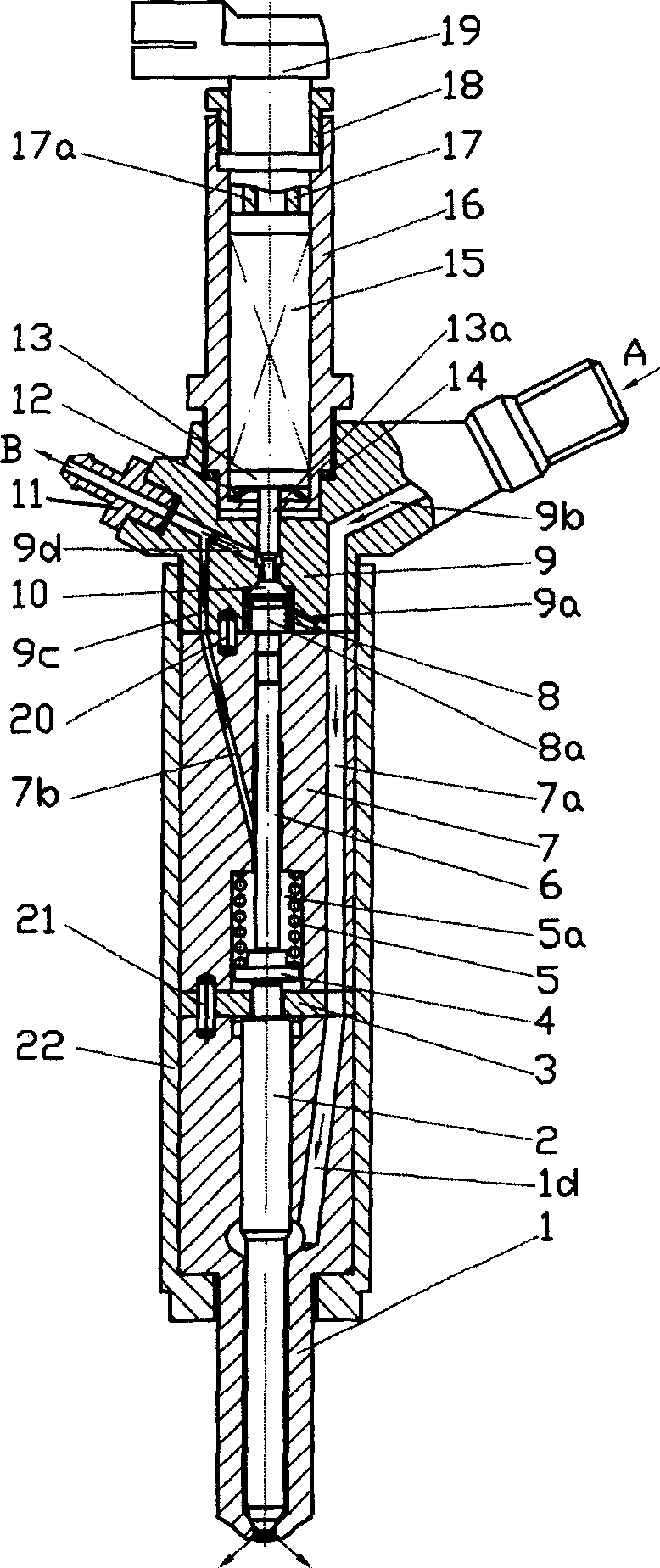

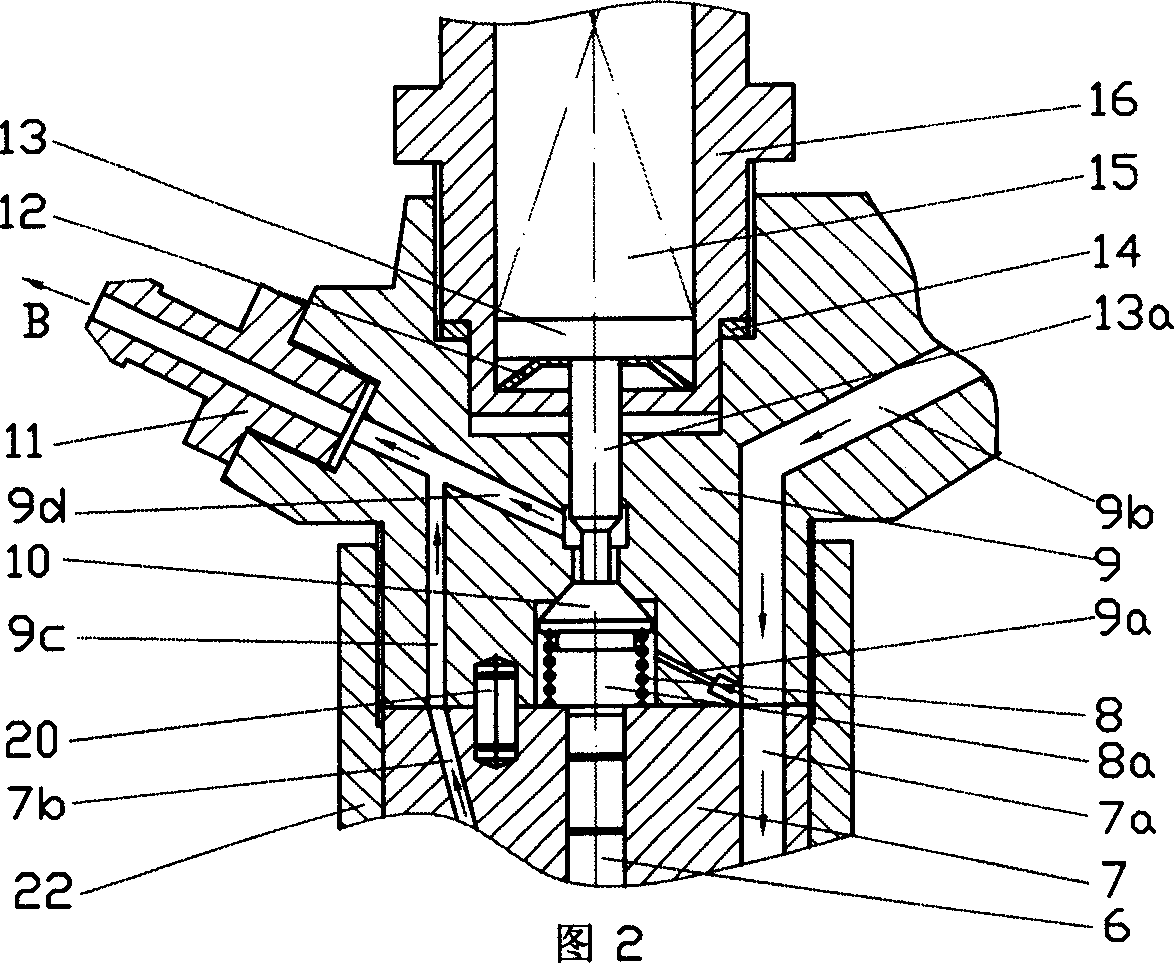

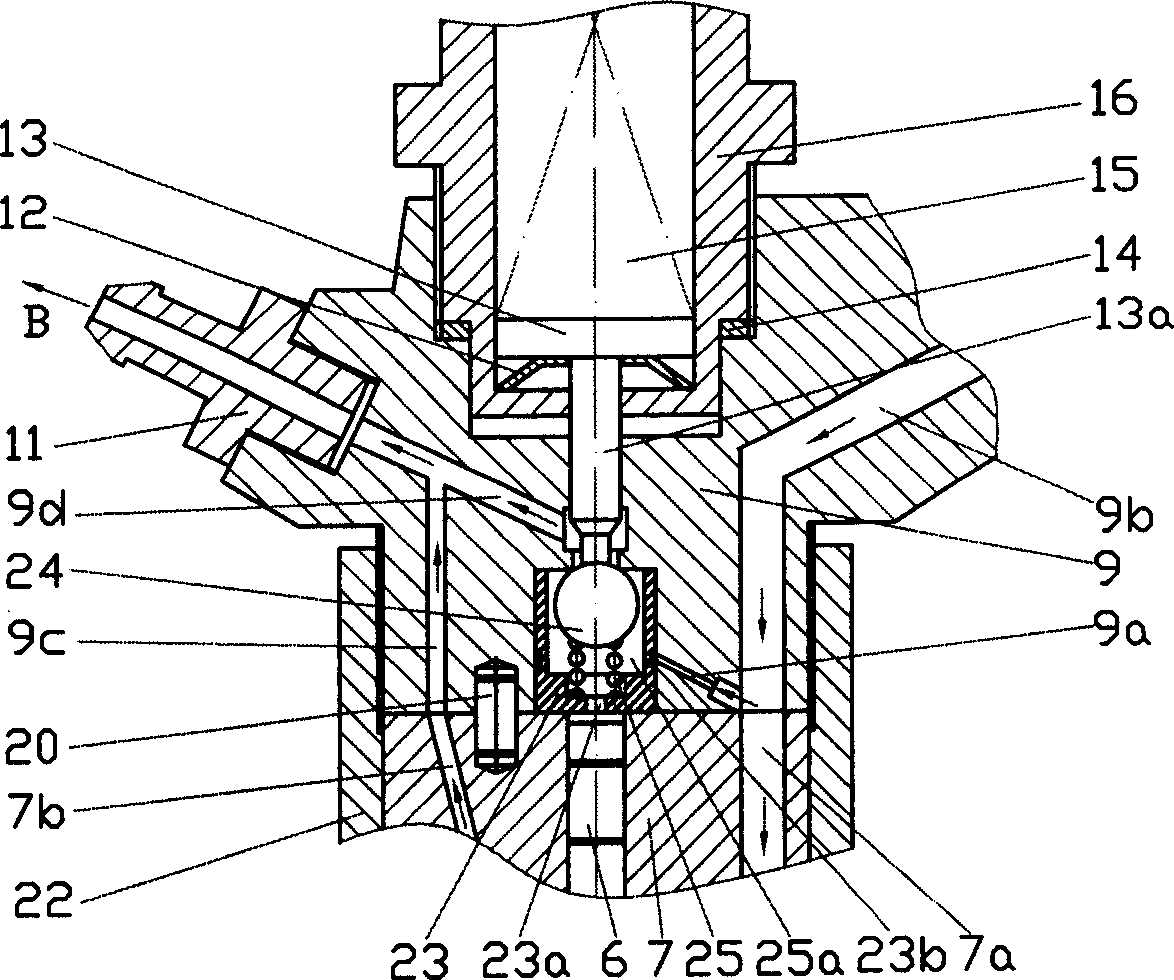

[0022] exist figure 1 , In the embodiment shown in 2, the fuel injector body consists of an upper body 16, a middle body 9 and a lower body 22 which are screwed together, and the upper body 16 is sequentially equipped with a disc spring 12, a piston with a piston rod 13a 13 and piezoelectric stack 15, piezoelectric stack 15 is electrically connected with electric socket 19 by lead wire 117 and lead wire 217a, and parts such as piezoelectric stack 15 are fastened in upper body 16 by compression sleeve 18. When upper body 16 is installed on middle body 9, seal gasket 14 should be added, and piston rod 13a should be movably inserted in the corresponding hole of middle body 9.

[0023] The middle body 9 is provided with a high-pressure oil inlet A, a high-pressure oil inlet passage 9b, a small high-pressure oil passage 9a and a high-pressure oil chamber 8a, as well as an oil return passage 19c, an oil return passage 29d, an oil return joint 11 and an oil return port B. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com