Rolled copper foil and manufacturing method of rolled copper foil

A technology of rolling copper foil and rolling surface, which is applied in the field of rolling copper foil, can solve the problems of reduced manufacturing efficiency of rolled copper foil, difficult rolling processing, difficult reduction, etc., and achieves low cost and excellent bending characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

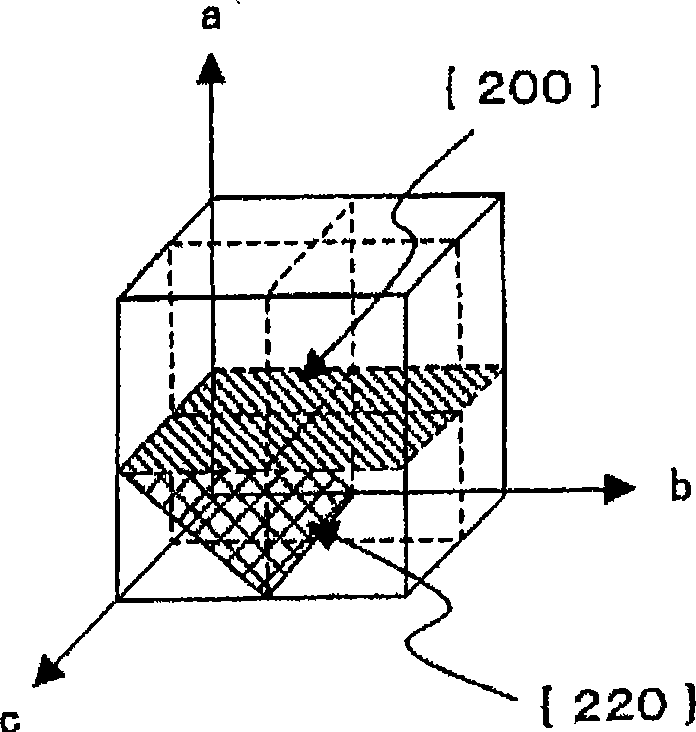

[0053] (Measurement of in-plane orientation)

[0054] The rolled copper foil of the present embodiment is a rolled copper foil before recrystallization annealing after the final cold rolling process, and is characterized in that the results obtained by X-ray diffraction pole pattern measurement based on the rolled surface are present in β At least 90±5 each of the angles 0 The α angle determined by the existence of the pole diagram = 45 0 {220} of the copper crystal obtained from the β-axis scan Cu Surface diffraction peaks and show 4th order symmetry. For example, the rolling direction of the copper foil measured by the pole diagram is set to β=0 0 , The centers of the 4th-order symmetric diffraction peaks are β≌0 0 , 90 0 , 180 0 , 270 0 , 360 0 .

[0055] In the results of the above-mentioned in-plane orientation measurement, {220}Cu plane diffraction peaks do not show each 90±5 0 In the case of 4th order symmetry, even if recrystallization annealing is performed, a rolled copp...

no. 2 approach

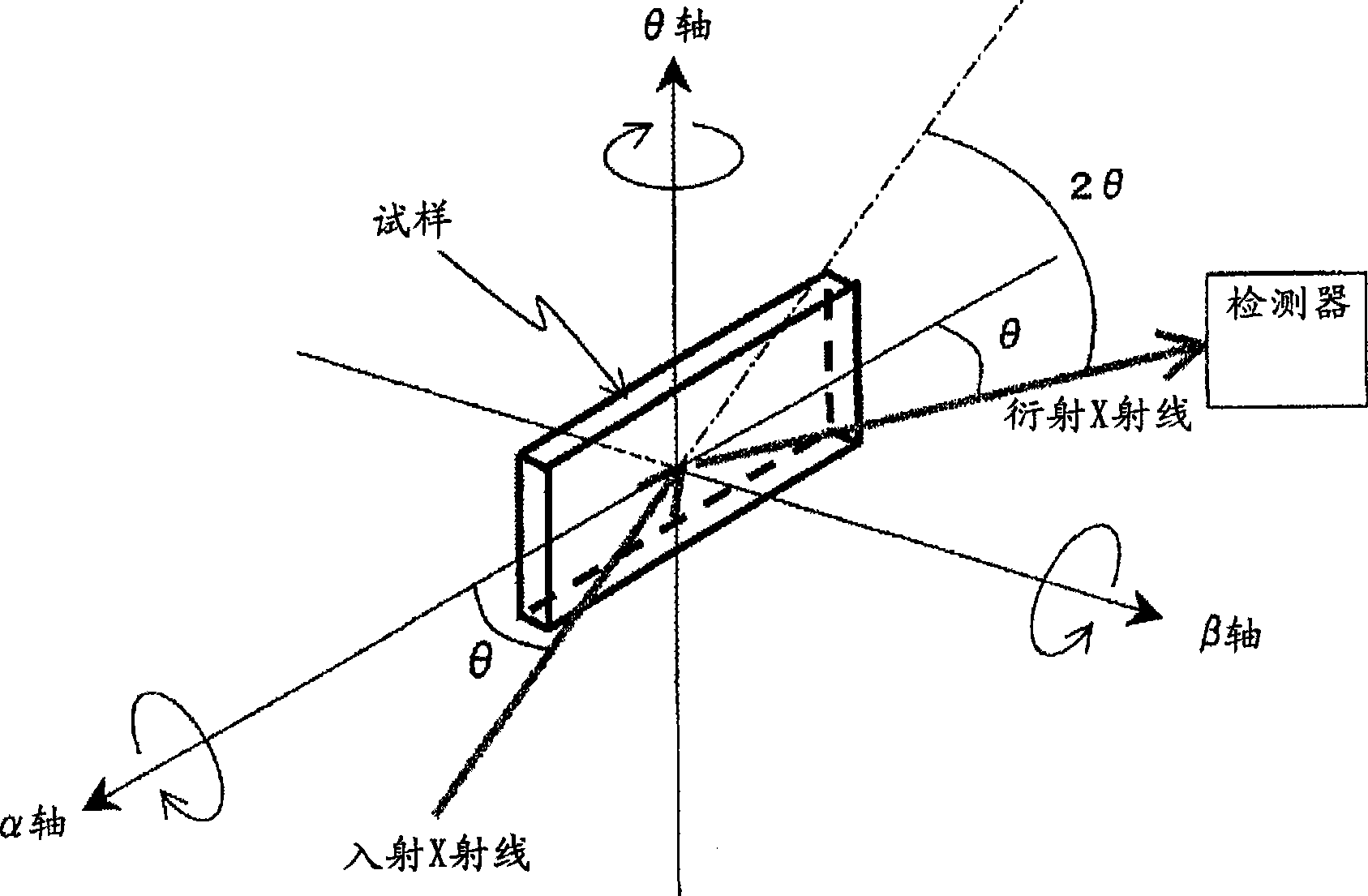

[0057] (Standardized strength)

[0058] The rolled copper foil of the present embodiment is a rolled copper foil before recrystallization annealing after the final cold rolling process, and is characterized in that it is measured by an X-ray diffraction pole diagram based on the above-mentioned rolled surface. The α angle measured by the pole diagram is the horizontal axis, and the copper crystal obtained by scanning the β axis at each α angle is {220} Cu When the normalized intensity of the surface diffraction peak is represented by a curve on the vertical axis, when α=25∽35 0 There is the maximum value P of the above-mentioned normalized intensity between α=40∽50 0 There is the maximum value Q of the above-mentioned standardized intensity between α=85∽90 0 Between the above-mentioned normalization intensity monotonously increase, the above-mentioned maximum value P and the above-mentioned maximum value Q, and the above-mentioned α=90 0 The value R of the above-mentioned normaliz...

no. 3 approach

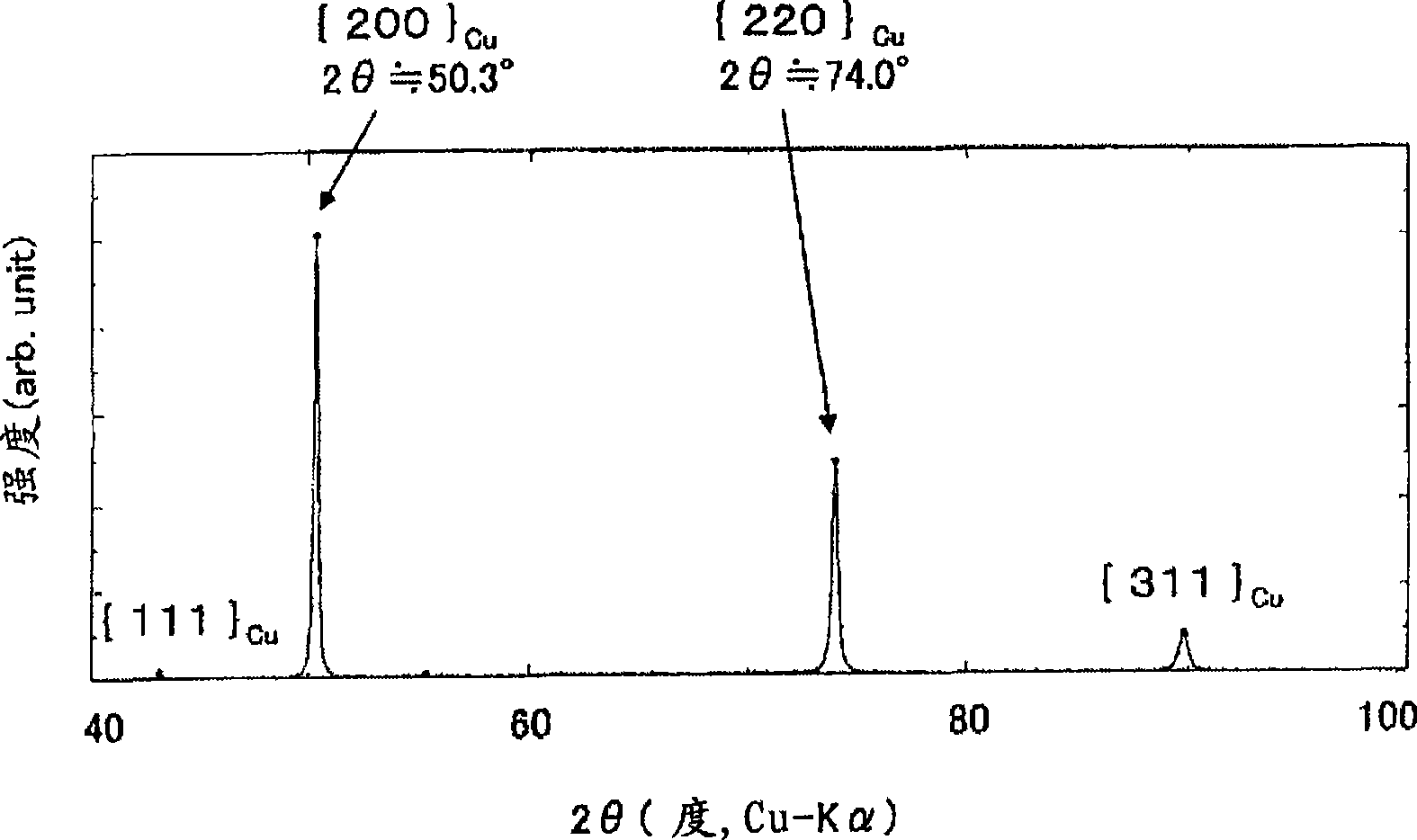

[0067] (2θ / θ measurement)

[0068] The rolled copper foil of the present embodiment is characterized in that, in the state before the recrystallization annealing after the final cold rolling step, the diffraction peak of the copper crystal is obtained by the X-ray diffraction 2θ / θ measurement of the rolled surface. The intensity I is "I{200} Cu ≥I{220} Cu ".

[0069] As described above, the rolled copper foil of the present invention is in the state before the recrystallization annealing after the final cold rolling process, {200} Cu The surface is oriented in the rolled surface of the copper foil. This means that there is a considerable amount of {200} on the rolled surface of the polycrystalline copper foil Cu Face-oriented grains. image 3 This is an example of the results of the X-ray diffraction 2θ / θ measurement of the rolled surface in the rolled copper foil of the present invention after the final cold rolling step and before the recrystallization annealing.

[0070] From i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com