Patents

Literature

158 results about "Alpha angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

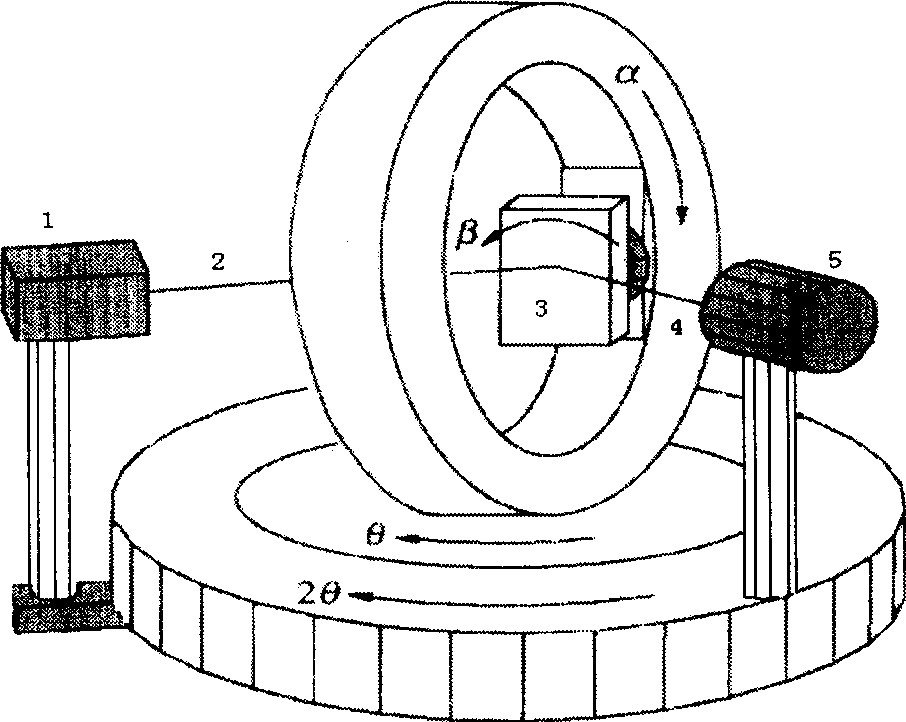

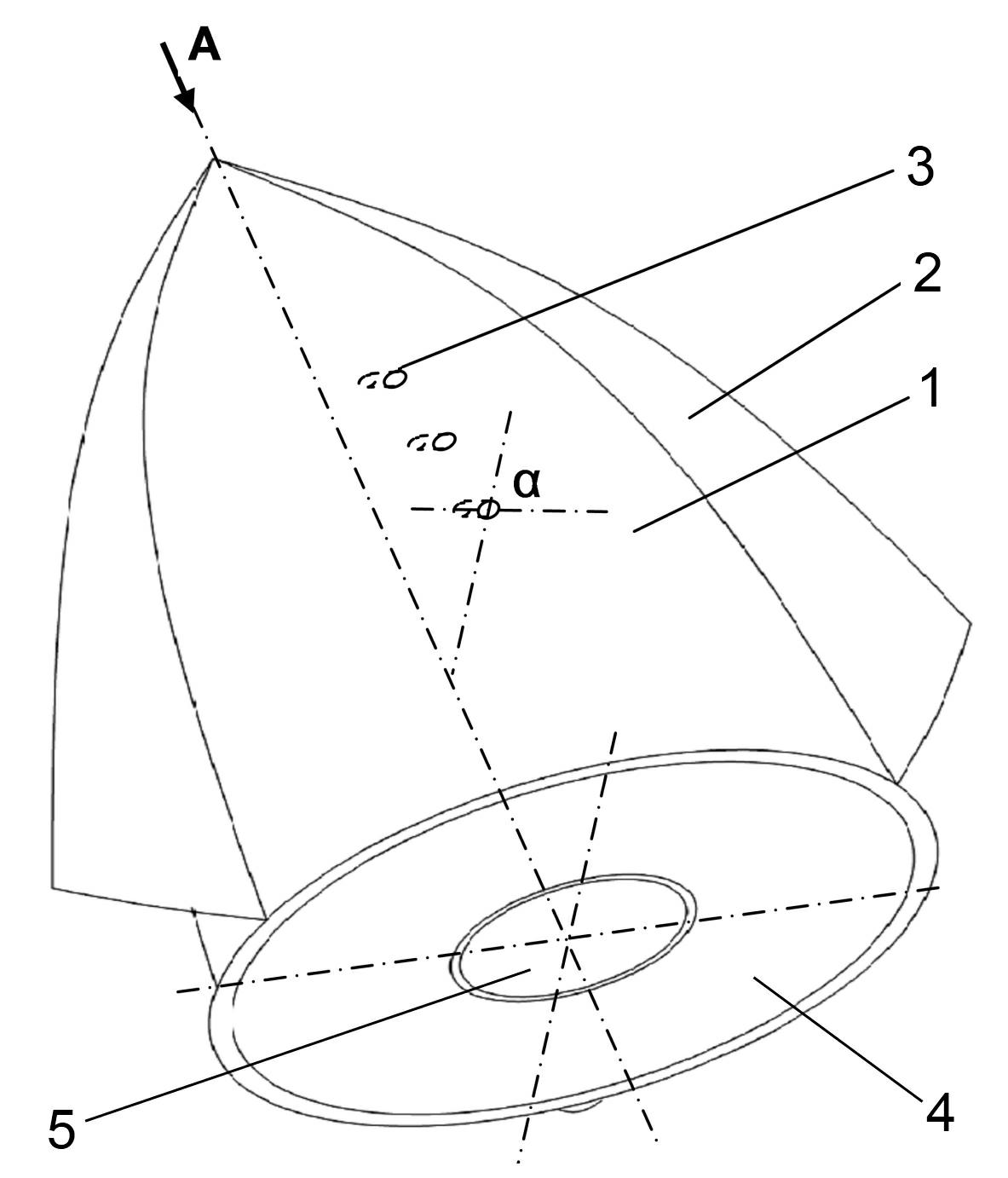

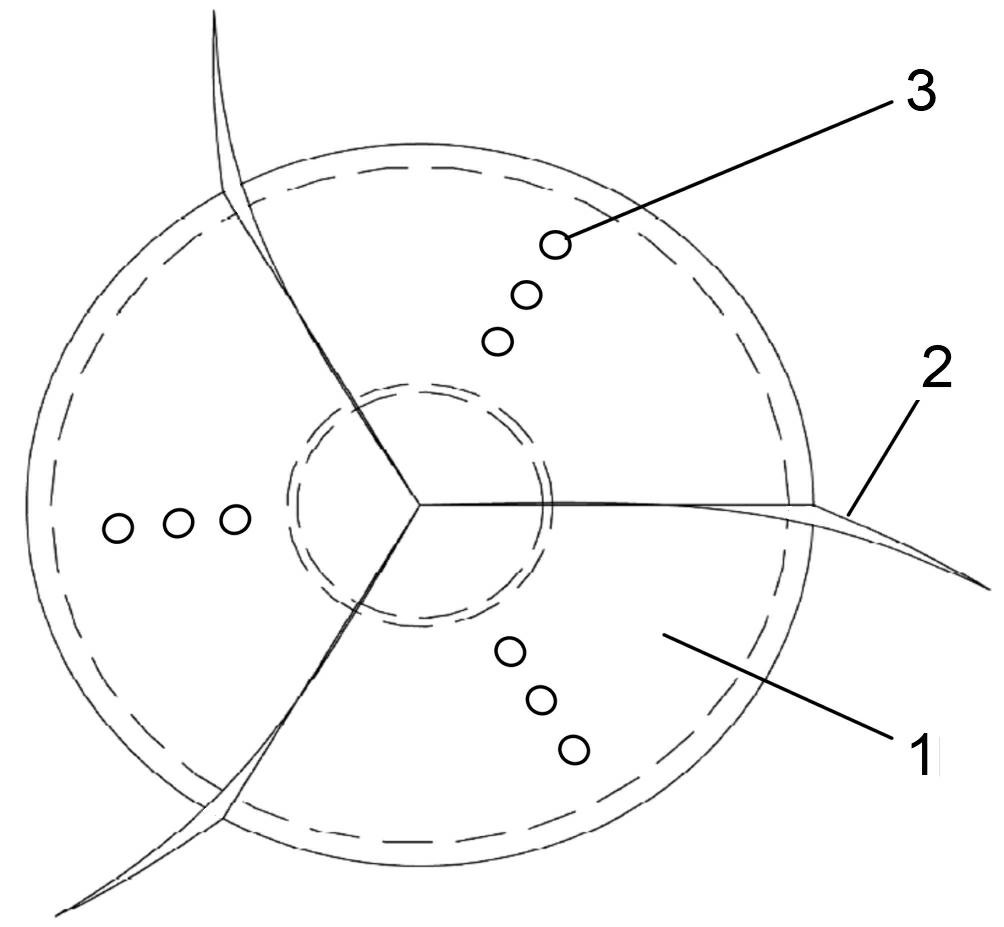

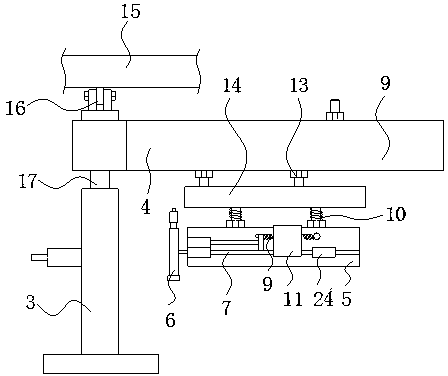

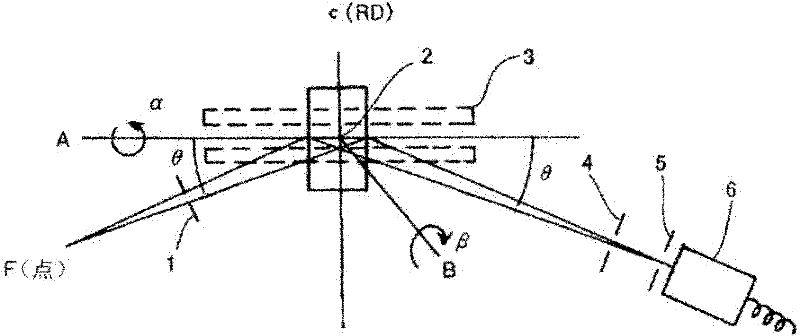

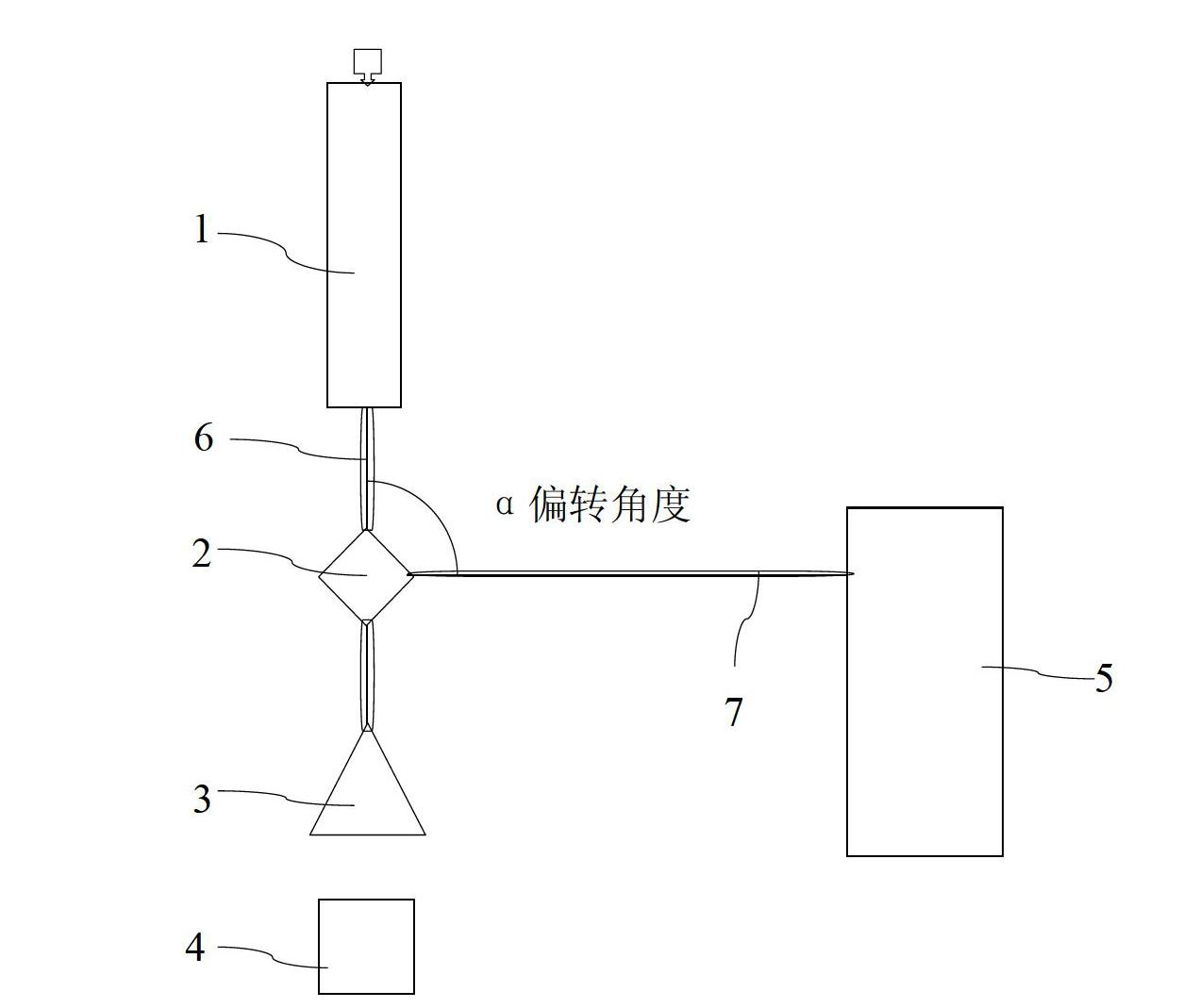

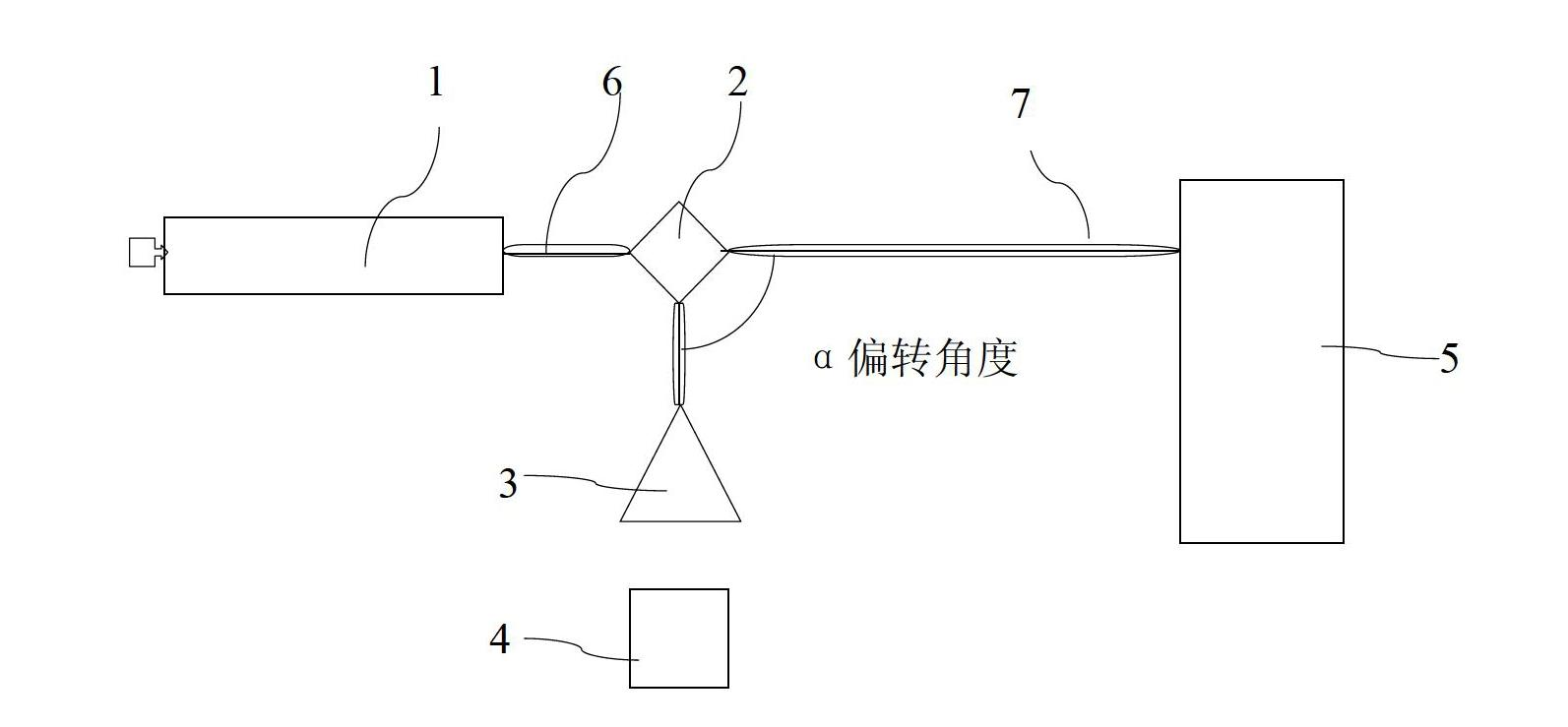

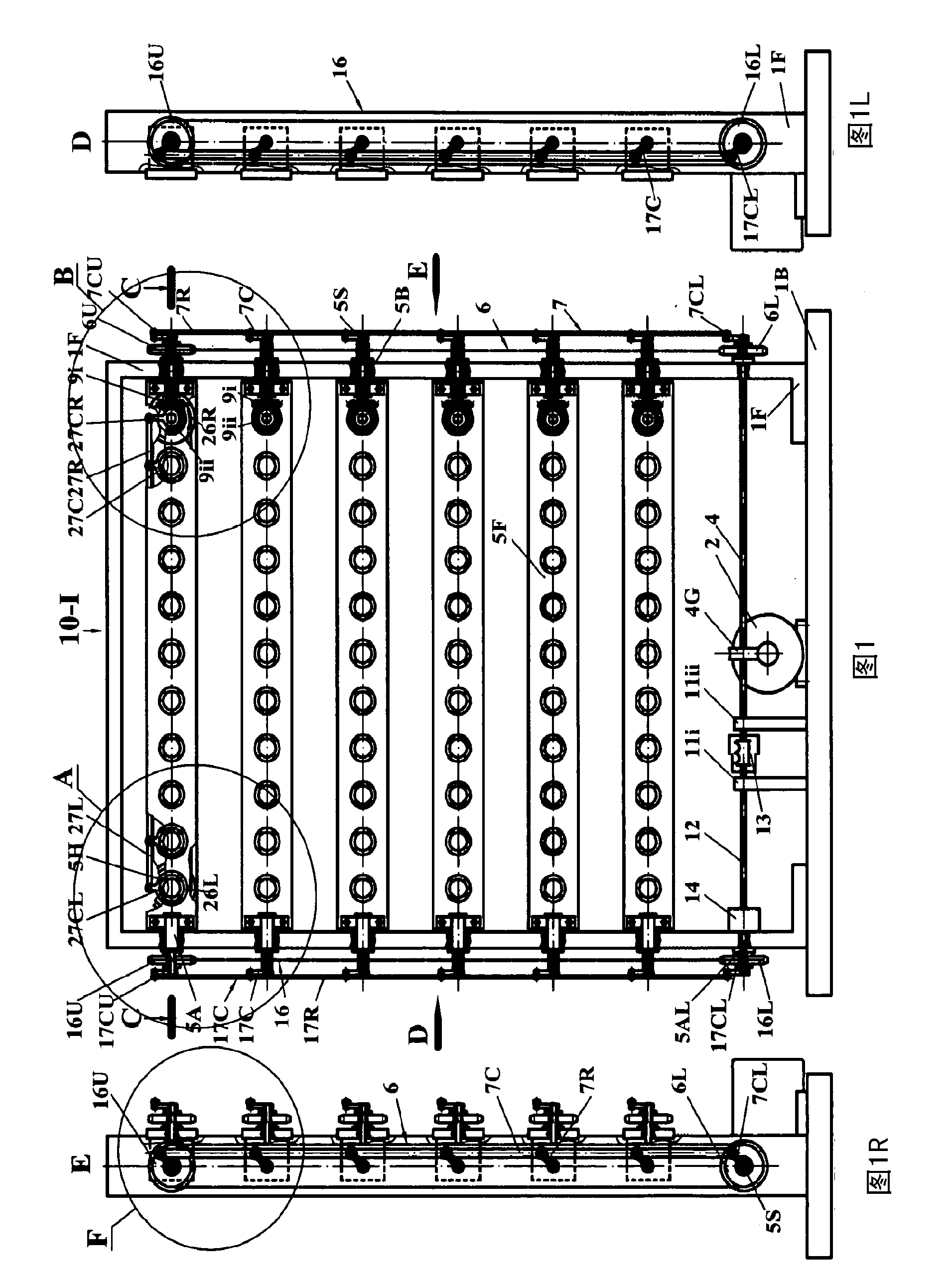

Light curtain array automatic scoring round target device and method

InactiveCN101149245AAchieving Stereoscopic Data AcquisitionRealize multivariate data collectionTarget detectorsSensor arrayExact location

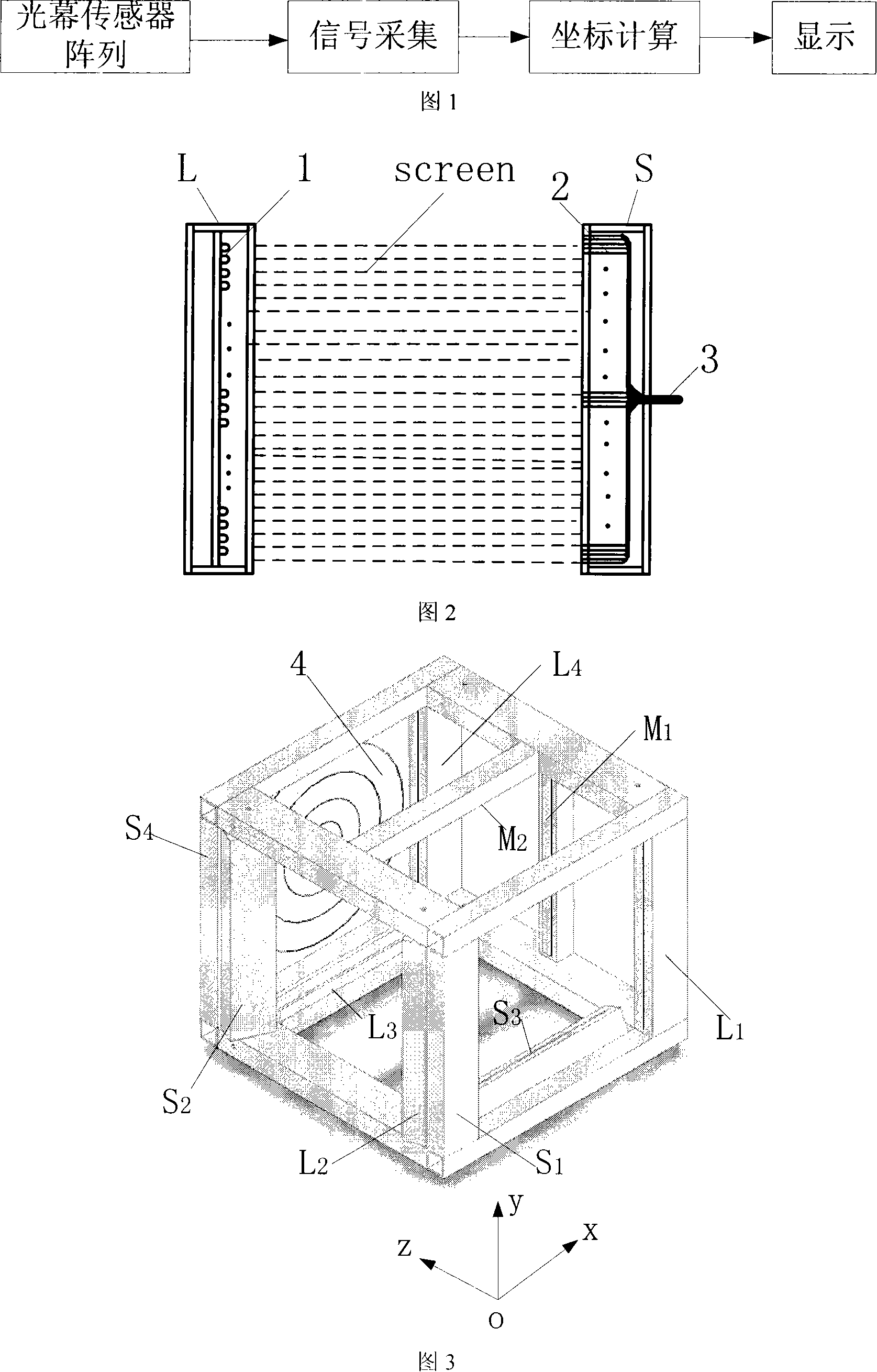

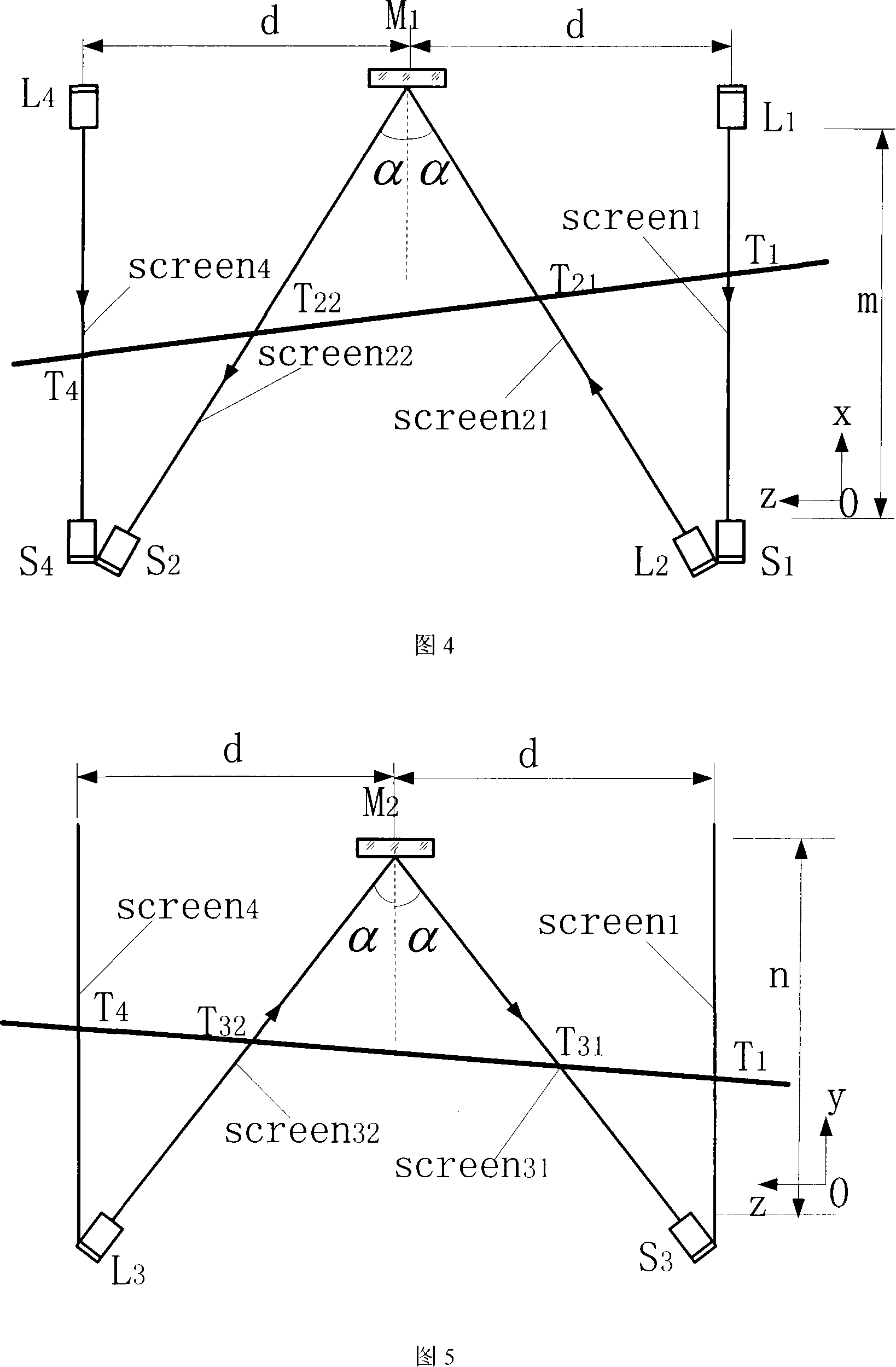

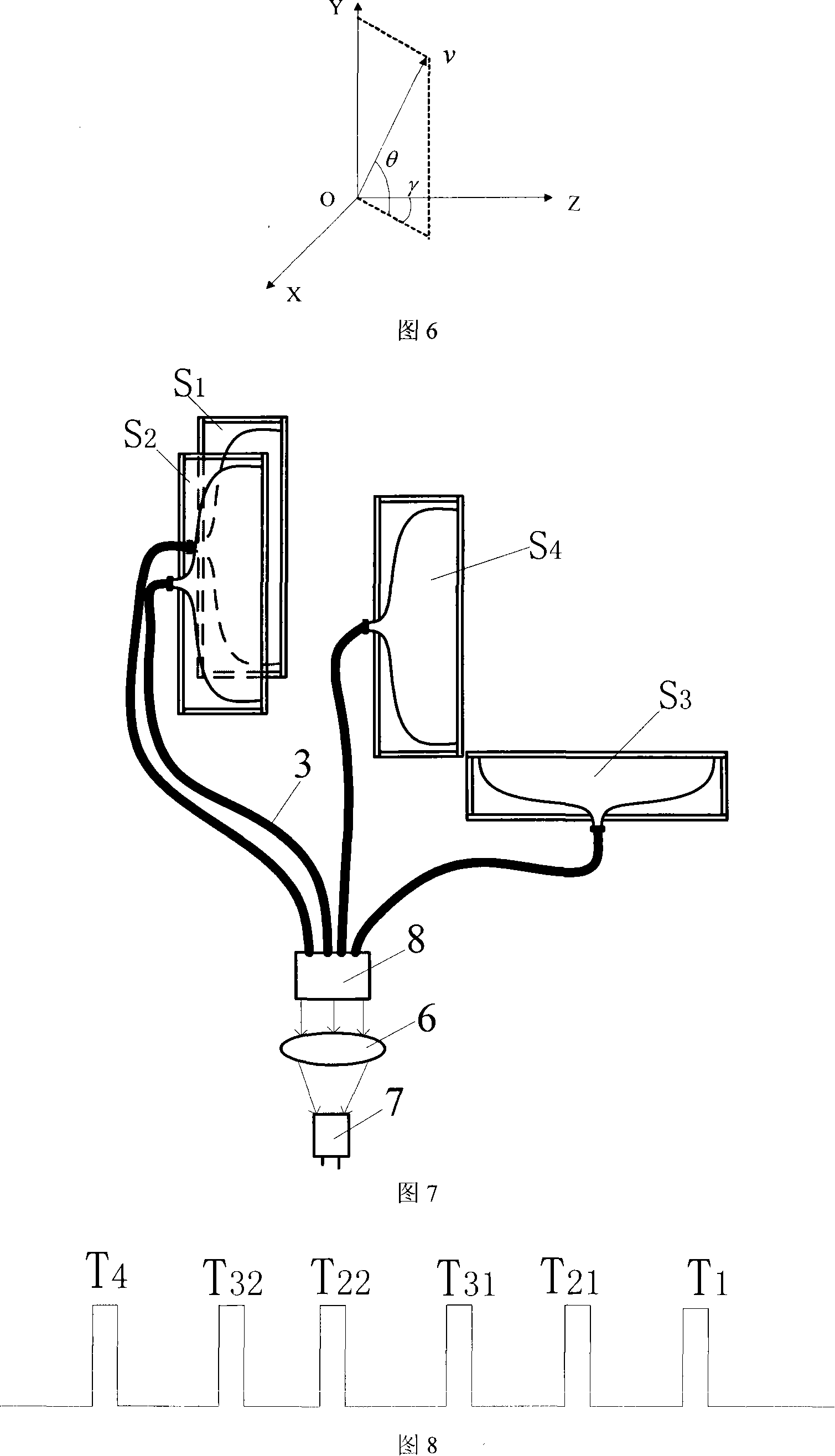

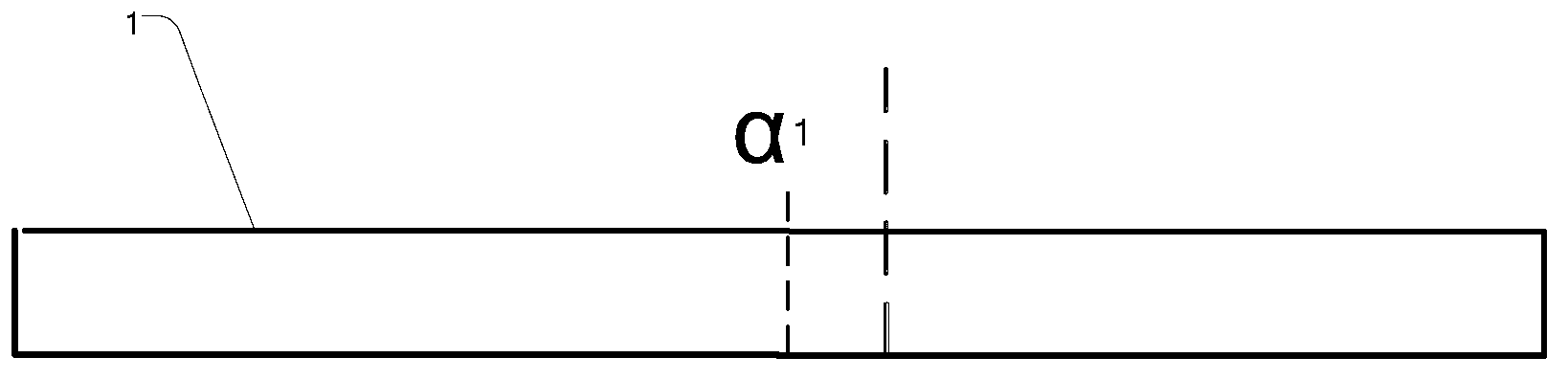

This invention discloses an automatic target-reporting method and system for indoor and outdoor bullet shooting. It includes veiling sensor array, signal collection, coordinates computation and display parts. The basic cell array of the veiling sensor is composed of a linear light source L and corresponding receiving device. The linear light source L is composed of light-emitting diodes that are arranged in line. The receiving device S is formed by the end face of optical fiber. The veiling sensor is three-dimensional frame structure. Two parallel veiling are used together in the X and Y computed coordinate directions. Each of them has two V shaped veiling which form alpha angle with the two parallel veiling. Thus, they form the special veiling sensor array. Only four sets of veiling basic cell arrays can fulfill the three-dimensional no touch measurement of the bullet. It can give the exact location and speed of the bullet on the target. The rate of false reporting rate is low. It will not be interfered by adjacent target.

Owner:XIAN TECHNOLOGICAL UNIV

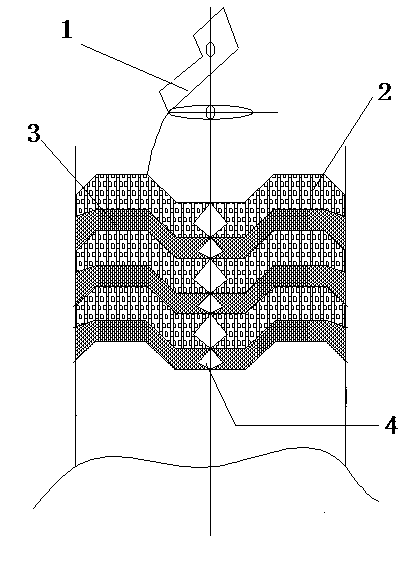

Seed crystal splicing method used for monocrystal-like silicone cast ingot

ActiveCN103060892AReduce generationPromote growthPolycrystalline material growthFrom frozen solutionsSolar batteryDislocation

The invention discloses a seed crystal splicing method used for monocrystal-like silicone cast ingot, and used for directional solidification method monocrystal-like silicone cast ingot. Seed crystal layers are formed by seed crystal closely arrayed. An alpha angle is formed between the tangential direction of at least one of spliced surfaces of every two blocks of seed crystal and the normal direction of a plane at the bottom of a crucible, wherein 0 degree < alpha <90 degrees. The seed crystal splicing method that the splicing surface is tangent to the normal direction of the plane at the bottom of the crucible, and the splicing surface does not coincides with the normal direction of the plane at the bottom of the crucible is adopted. The shape of the seed crystal is changed to reduce dislocation source and even the generation of polycrystalline grain boundaries, all-momocrystal is achieved, and monocrystal-like with less dislocation source grows. Therefore, dislocation defect of silicon slices is reduced, monocrystal area proportion is increased, photoelectric conversion efficiency of a solar battery is improved, the service life of the battery is prolonged, and therefore the performance of a photovoltaic device is improved.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

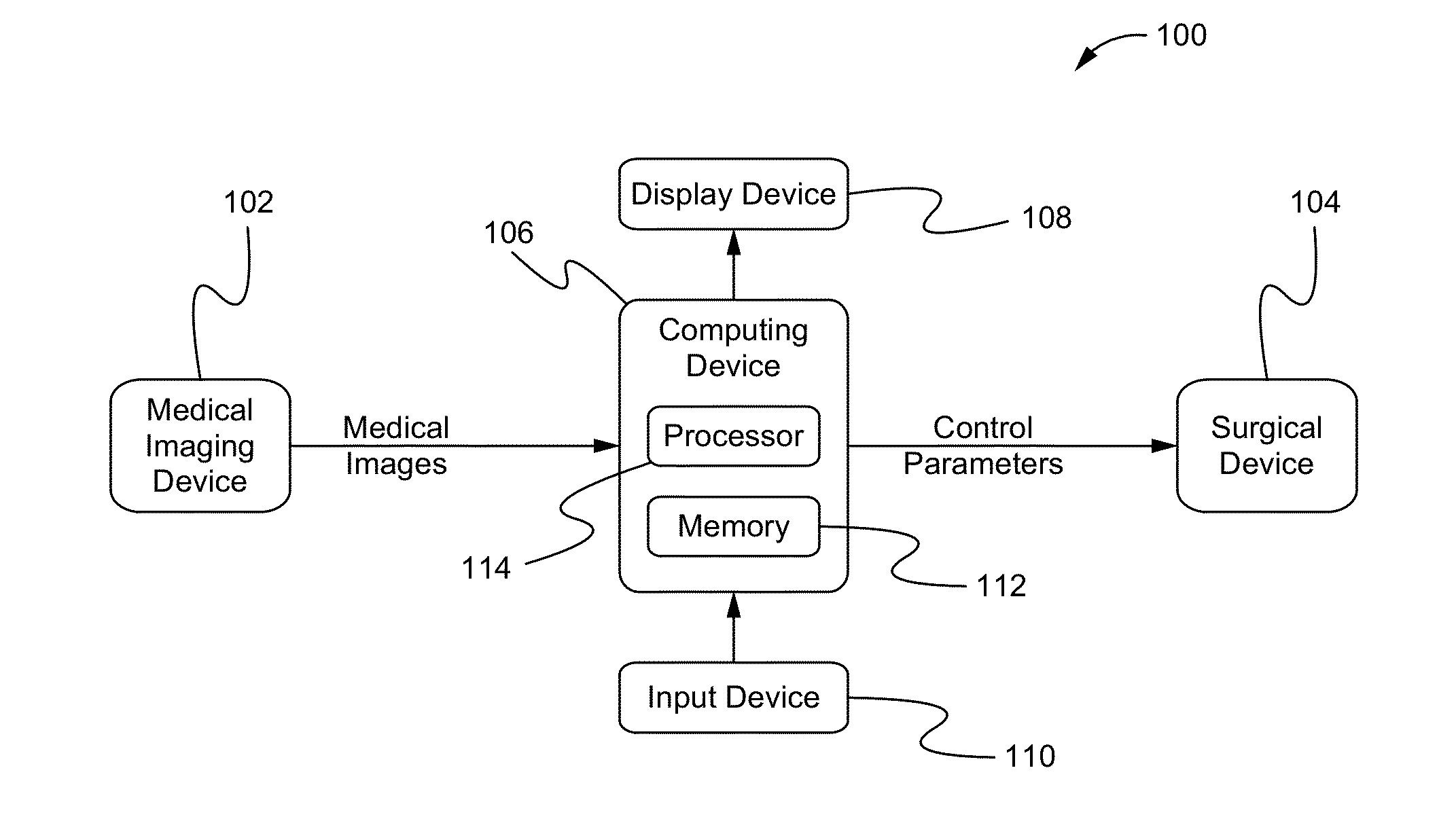

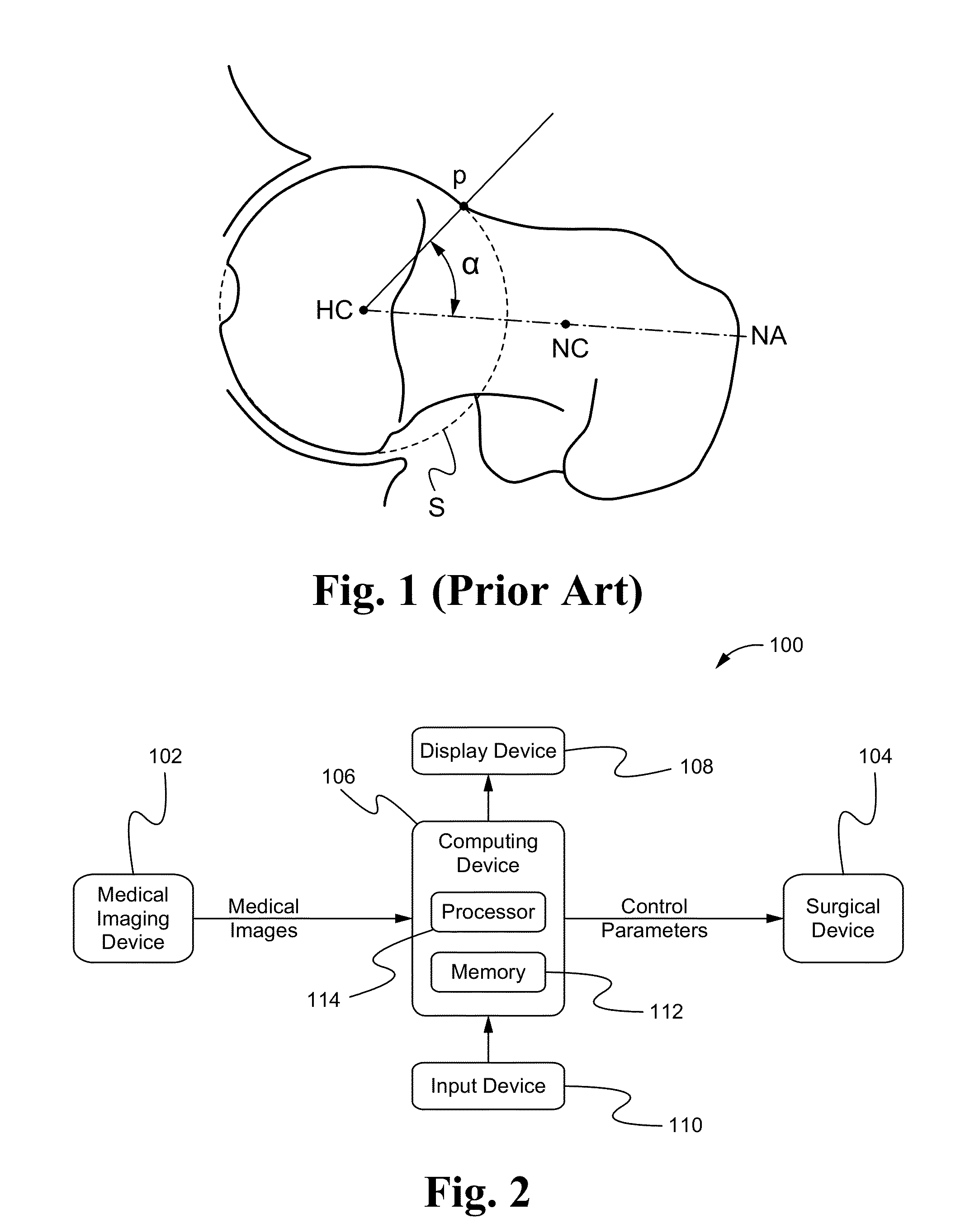

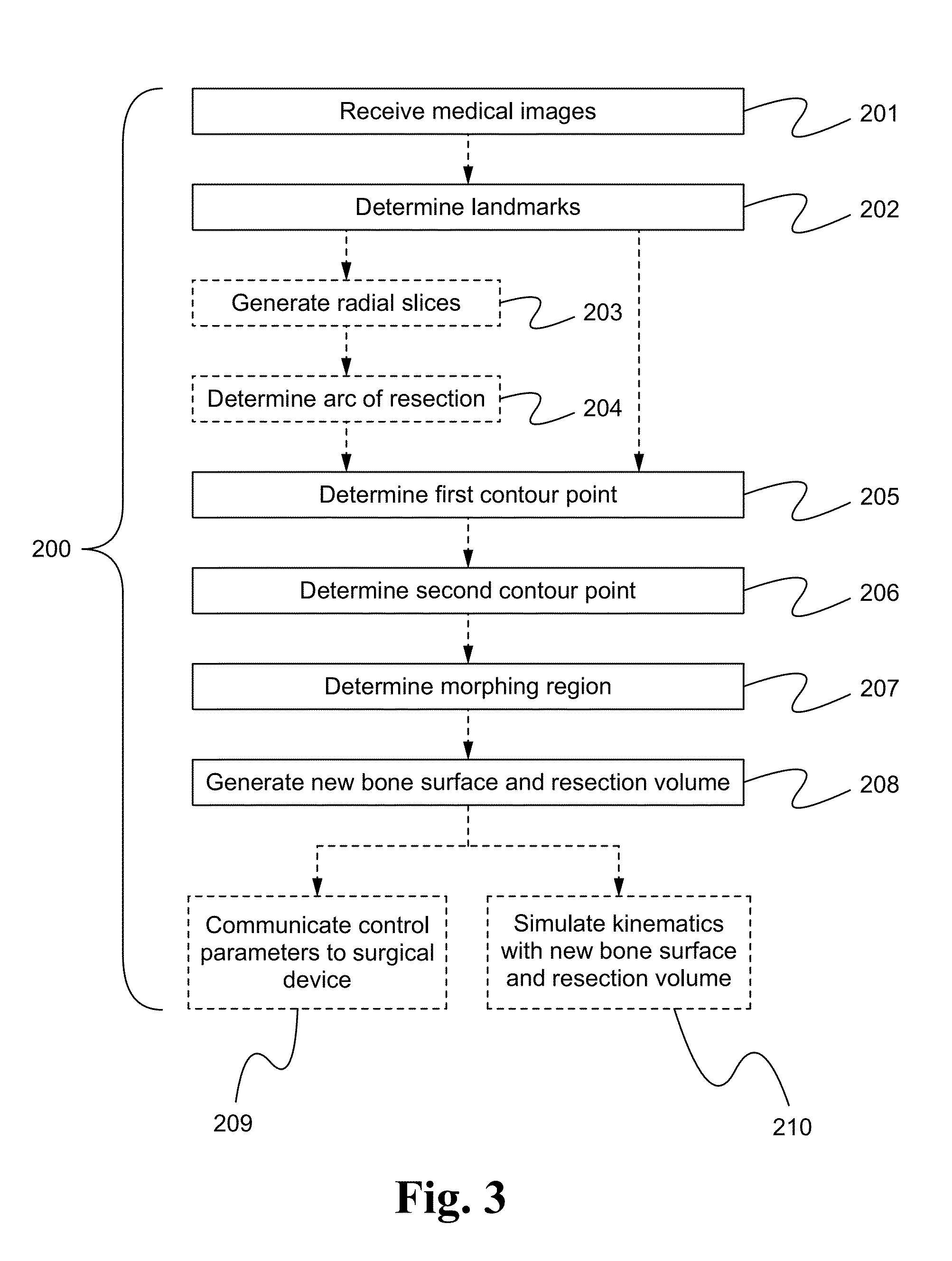

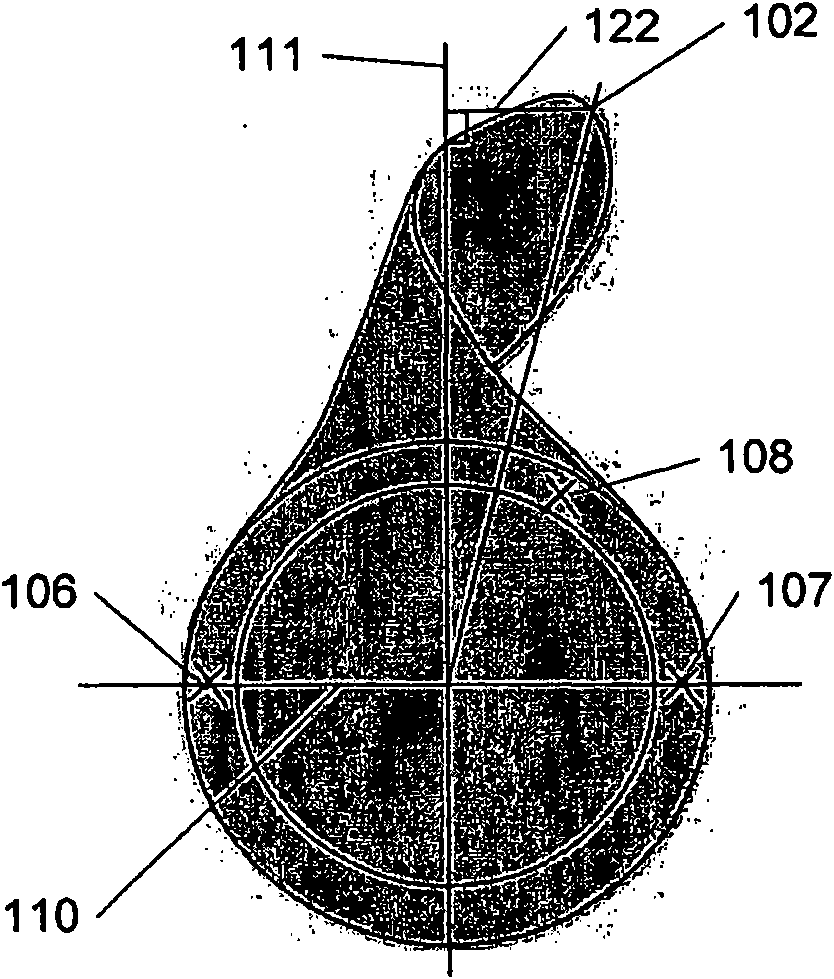

Computer-Aided Planning with Dual Alpha Angles in Femoral Acetabular Impingement Surgery

A method for determining a resection volume of a pathologic femur having a femoral head and a femoral neck is provided. The method may determine a first point of a desired contour based on a pathologic alpha angle of the pathologic femur, determine a second point of the desired contour based on a desired alpha angle of the pathologic femur, determine a third point of the desired contour on the femoral neck of the pathologic femur, and generate a resection volume of the pathologic femur based on the first, second and third points of the desired contour.

Owner:MAKO SURGICAL CORP

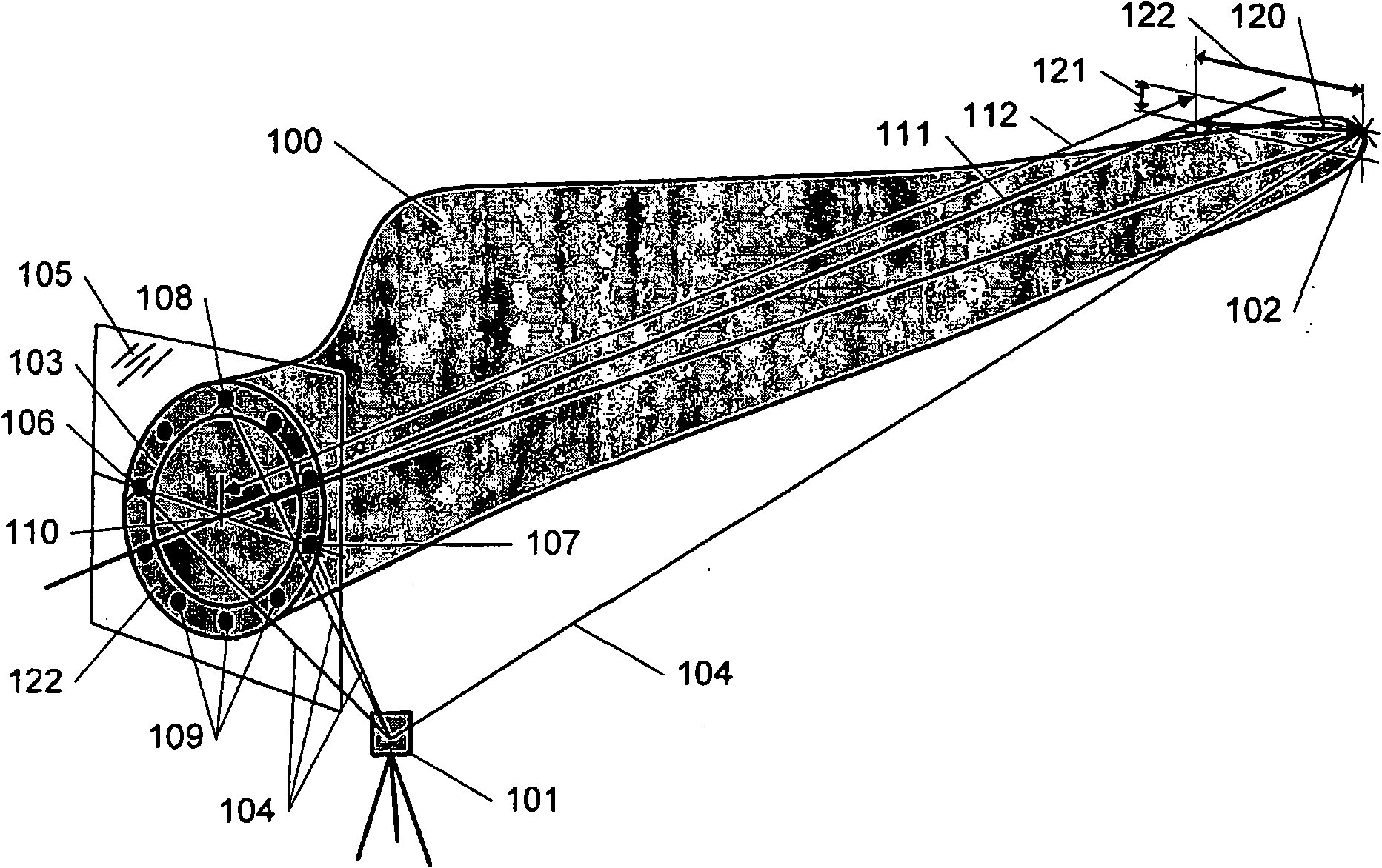

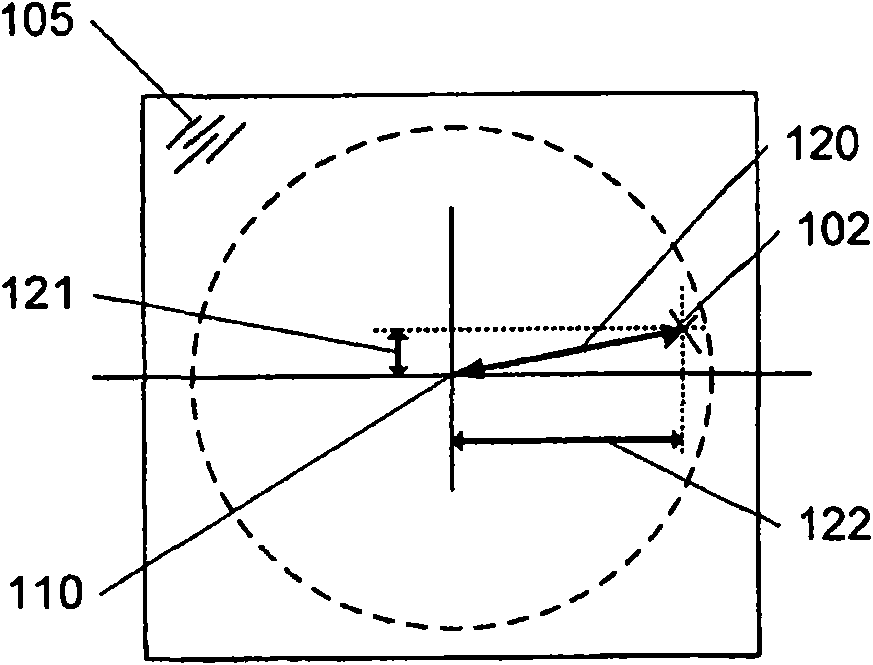

Measuring of geometrical parameters for a wind turbine blade

InactiveCN101680429ALow cost and fastReduce sources of errorSurveying instrumentsMachines/enginesTurbine bladeSurvey instrument

This invention relates to methods for measuring geometrical parameters of a wind turbine blade, the method comprising placing a surveying instrument with a view to the root of the blade and measuringthe blade. Methods are described for measuring parameters such as the blade length, the blade bending, the twist and the alpha-angle of the blade. This is accomplished by the use of a surveying instrument by which is measured a number of points or markings on the root of the blade, the blade tip and / or some reference markings on the blade. The invention further relates to the use of a surveying instrument for measuring and / or marking geometrical parameters on a wind turbine blade and for measuring deformations of a wind turbine blade.

Owner:LM GLASSFIBER

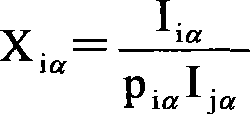

Method for quantitatively measuring remaining austenite in steel by X-ray diffraction polar diagram data

InactiveCN101446561AReduce mistakesMaterial analysis using radiation diffractionChemical compositionQuantitative determination

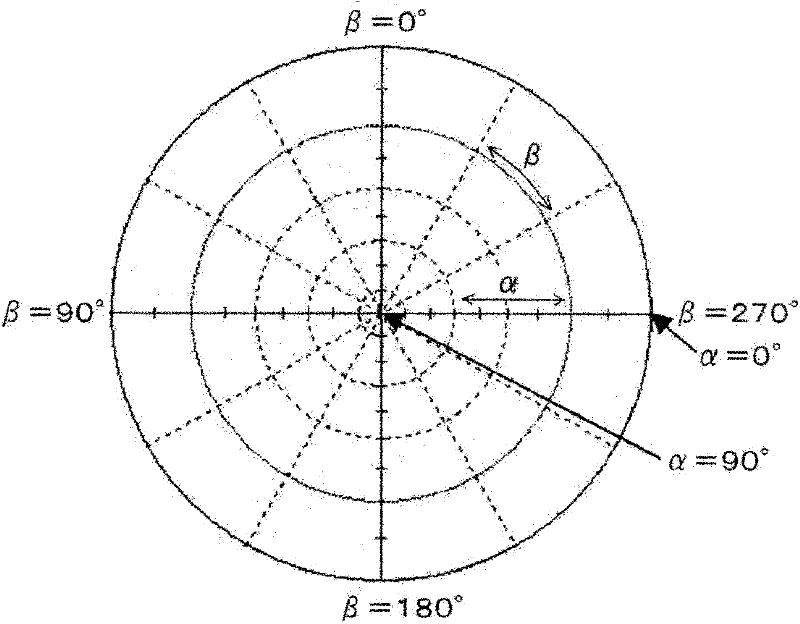

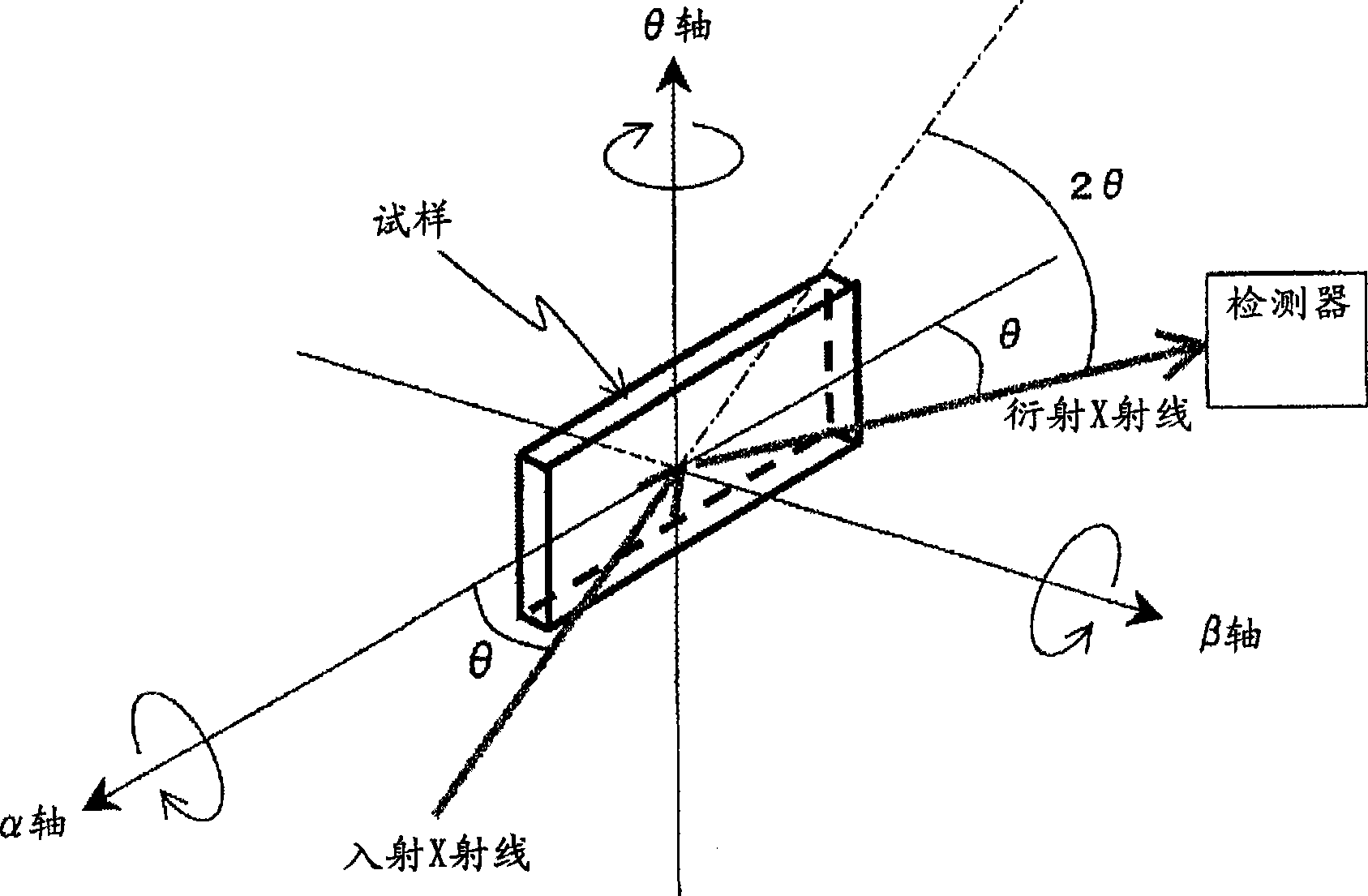

The invention relates to a method for quantitatively measuring remaining austenite in steel by X-ray diffraction polar diagram data. The method is as follows: a lumpy steel material sample to be measured and a pure martensite standard sample that the physical condition and chemical composition are the same as or similar to the physical condition and chemical composition of the sample to be measured are prepared for eliminating residual stress of the surfaces of the sample and the standard sample; the sample and the standard sample are put into a polar diagram measuring device respectively; the sample or the standard sample is placed at the positions of different alpha angles, and true diffraction intensities of different diffraction maximums are obtained; and the contents of martensite in sample i at each alpha angle are obtained with formulas; the contents of the austenite in the sample are calculated according to the contents of the martensite; the average value of the results of the contents of the austenite in the sample at each alpha angles is considered as the final result of the contents of austenite in the sample, and the measuring process is finished. By the measurement adopting the method of the invention, the effect of texture on measuring result can be effectively eliminated, and the difference between the measuring result and the true value is narrowed.

Owner:WUHAN IRON & STEEL (GROUP) CORP

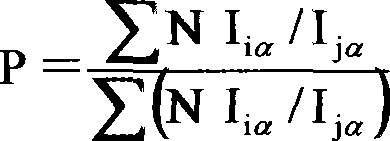

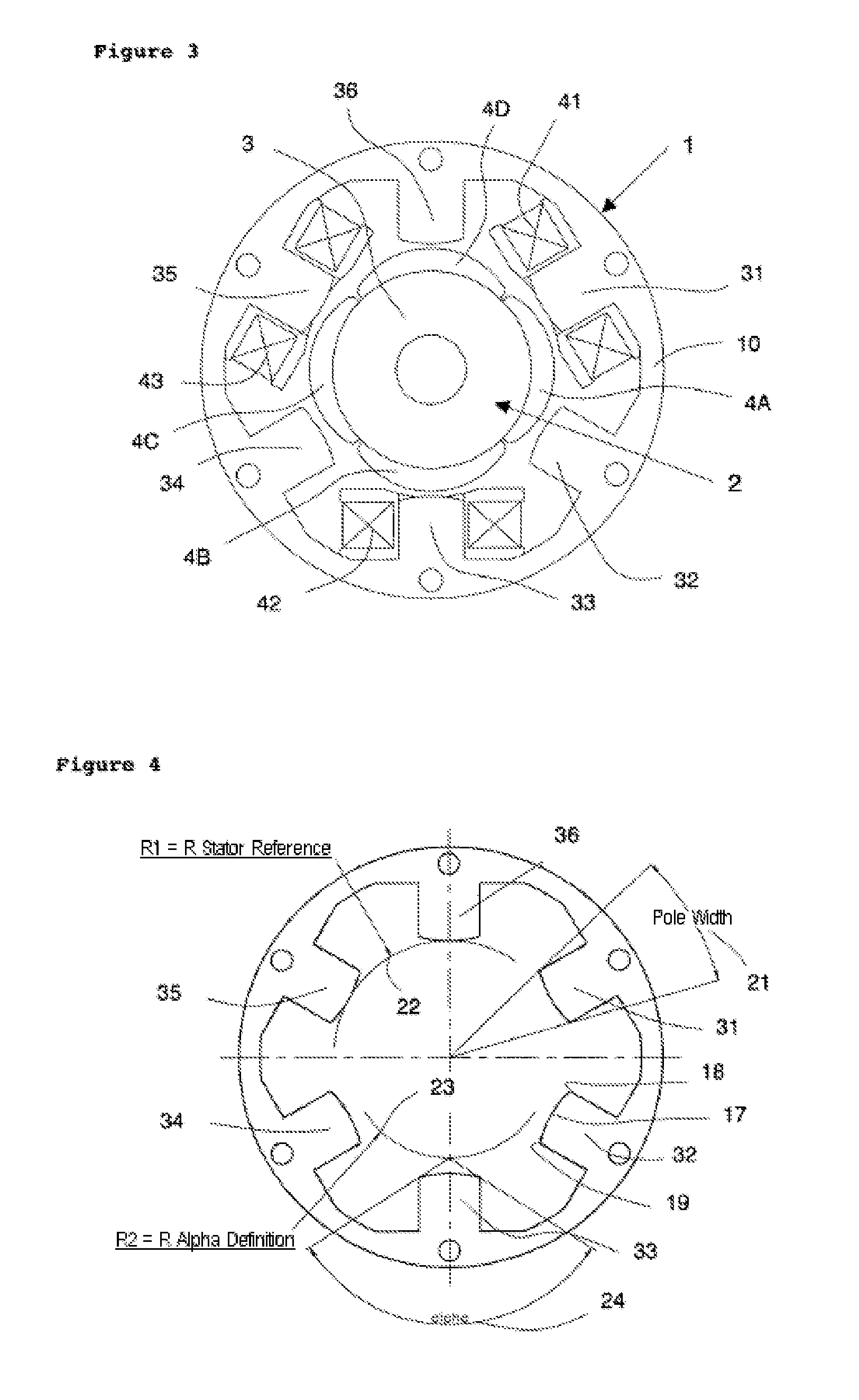

Permanent magnet assisted synchronous reluctance motor rotor which can be used in high-speed situation

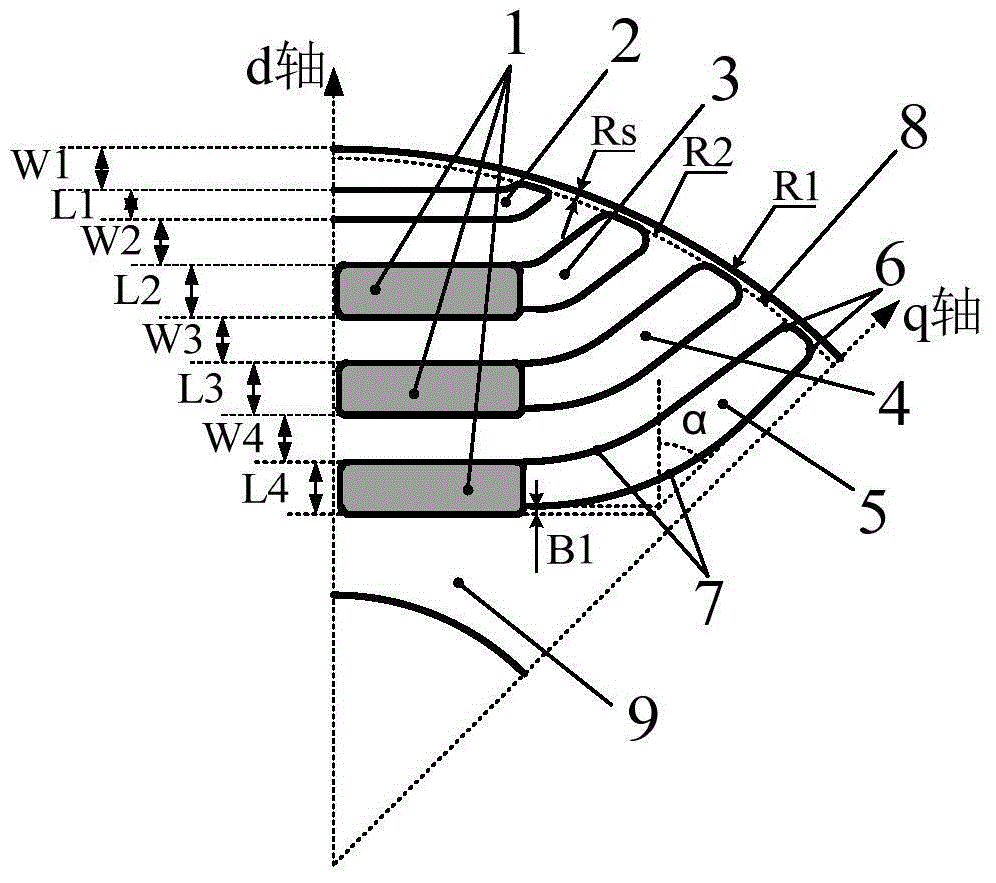

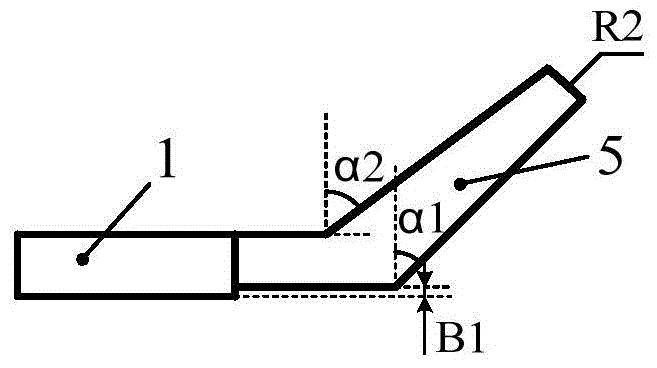

ActiveCN104901452ASafe high-speed operation capabilityMaximize output capacityMagnetic circuit rotating partsSynchronous machine detailsMagnetic barrierSynchronous reluctance motor

The present invention discloses a permanent magnet assisted synchronous reluctance motor rotor which can be used in a high-speed situation. The permanent magnet assisted synchronous reluctance motor rotor comprises a rotor core, magnetic barriers distributed on the rotor core and magnetic steels arranged in the magnetic barriers. Four layers of ship-shaped magnetic barriers are distributed under each pole of the rotor core, and each layer of magnetic barriers is formed by the connection closing of a straight line part which is in the middle and is perpendicular to a d axis direction and oblique straight line parts which are at two ends and are in an alpha angle direction with the d axis. According to the permanent magnet assisted synchronous reluctance motor rotor, the optimal design of the motor rotor is carried out, and thus a motor has the advantages of high efficiency, high torque density, high power factor, strong anti-demagnetization ability and convenient manufacture.

Owner:SHANGHAI GIE EM

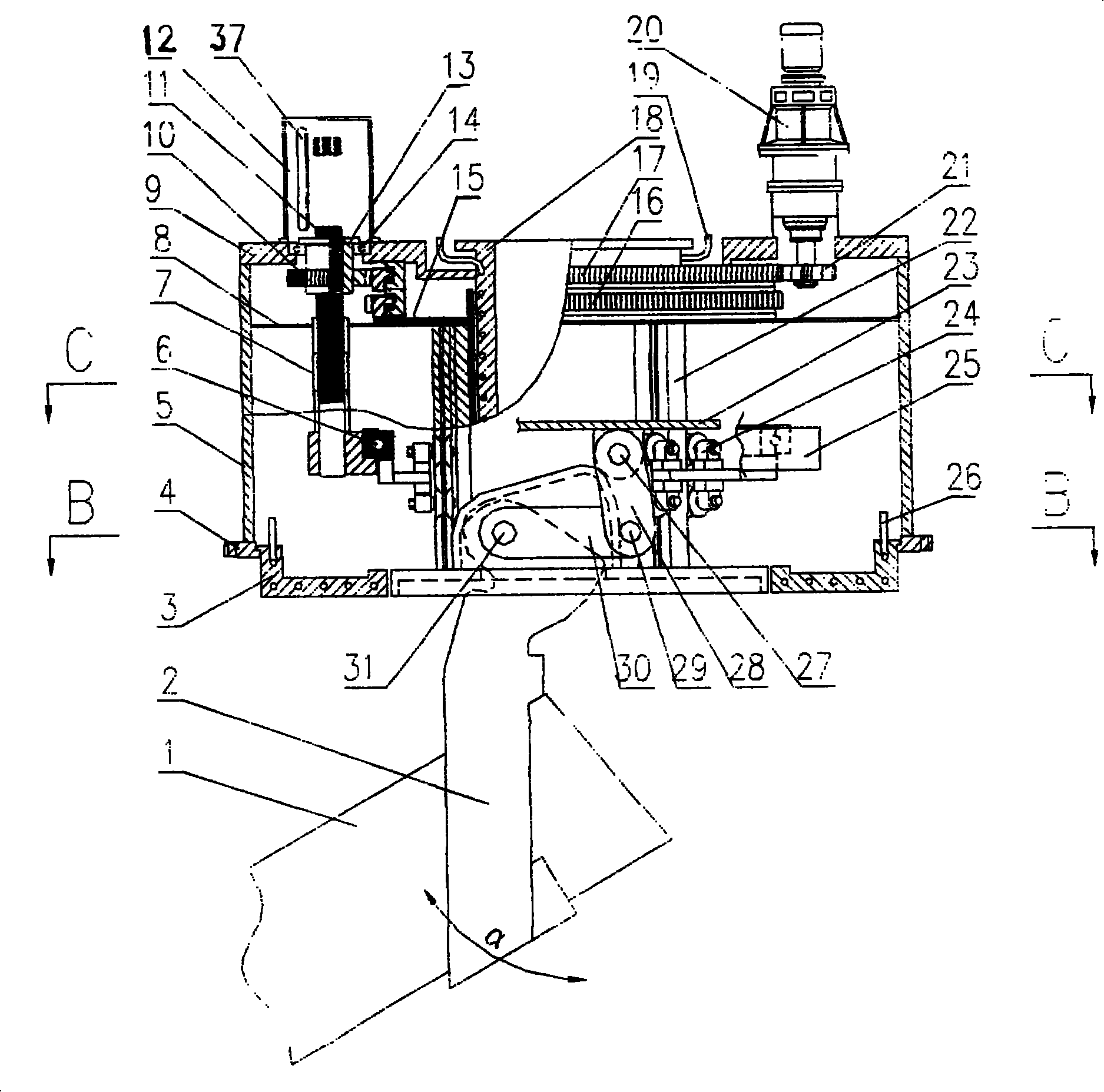

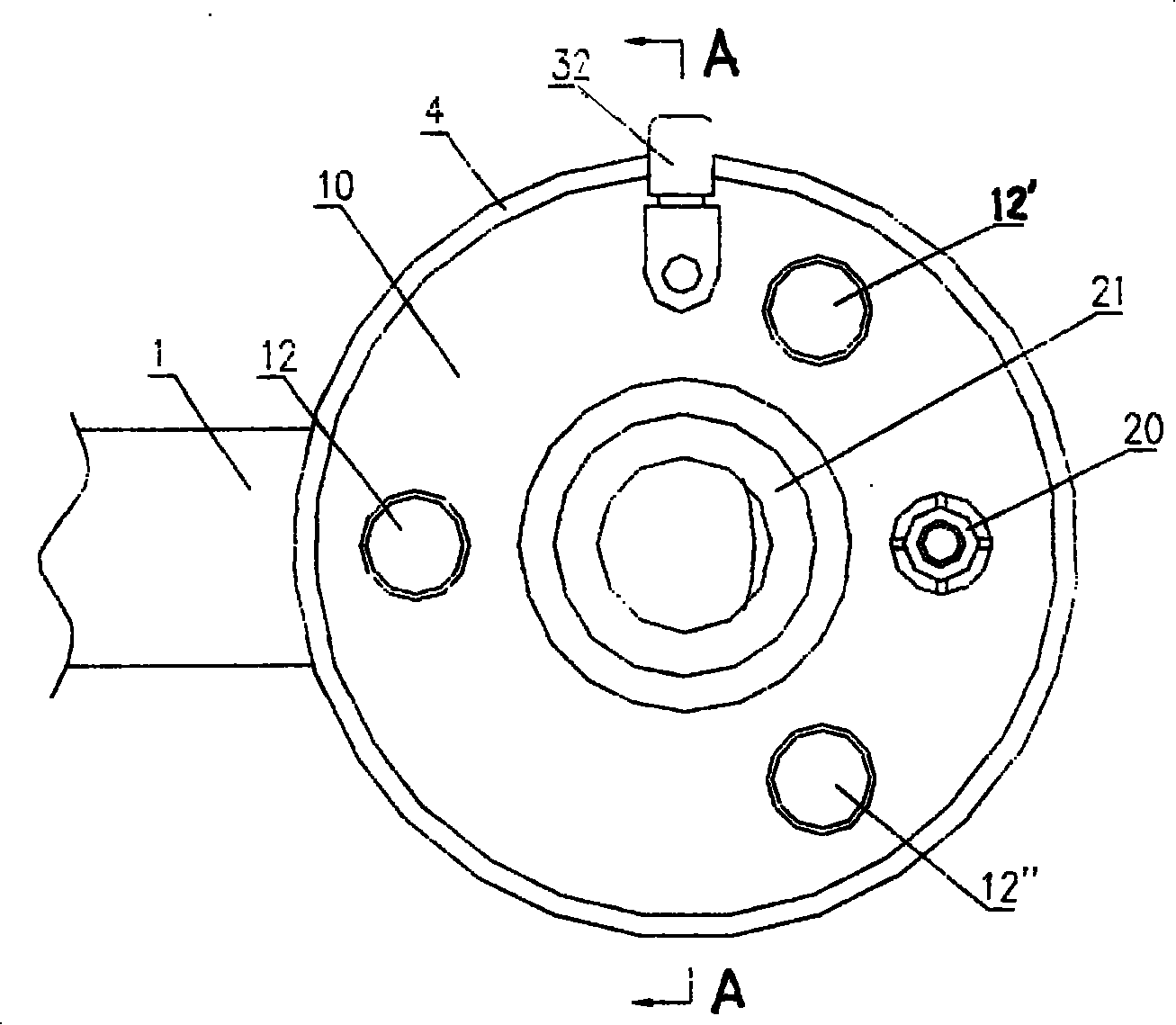

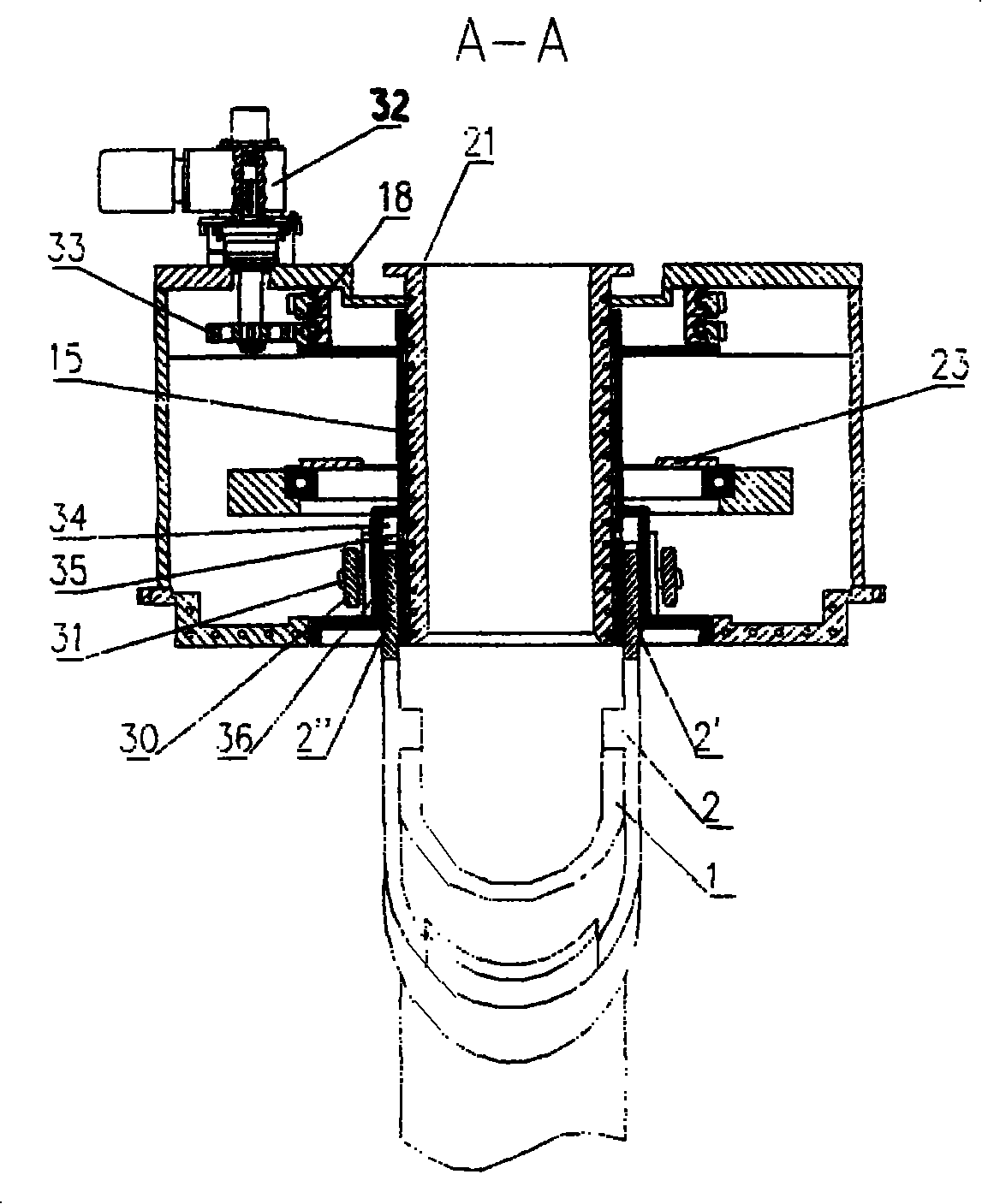

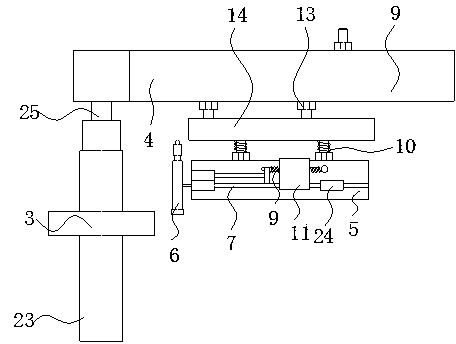

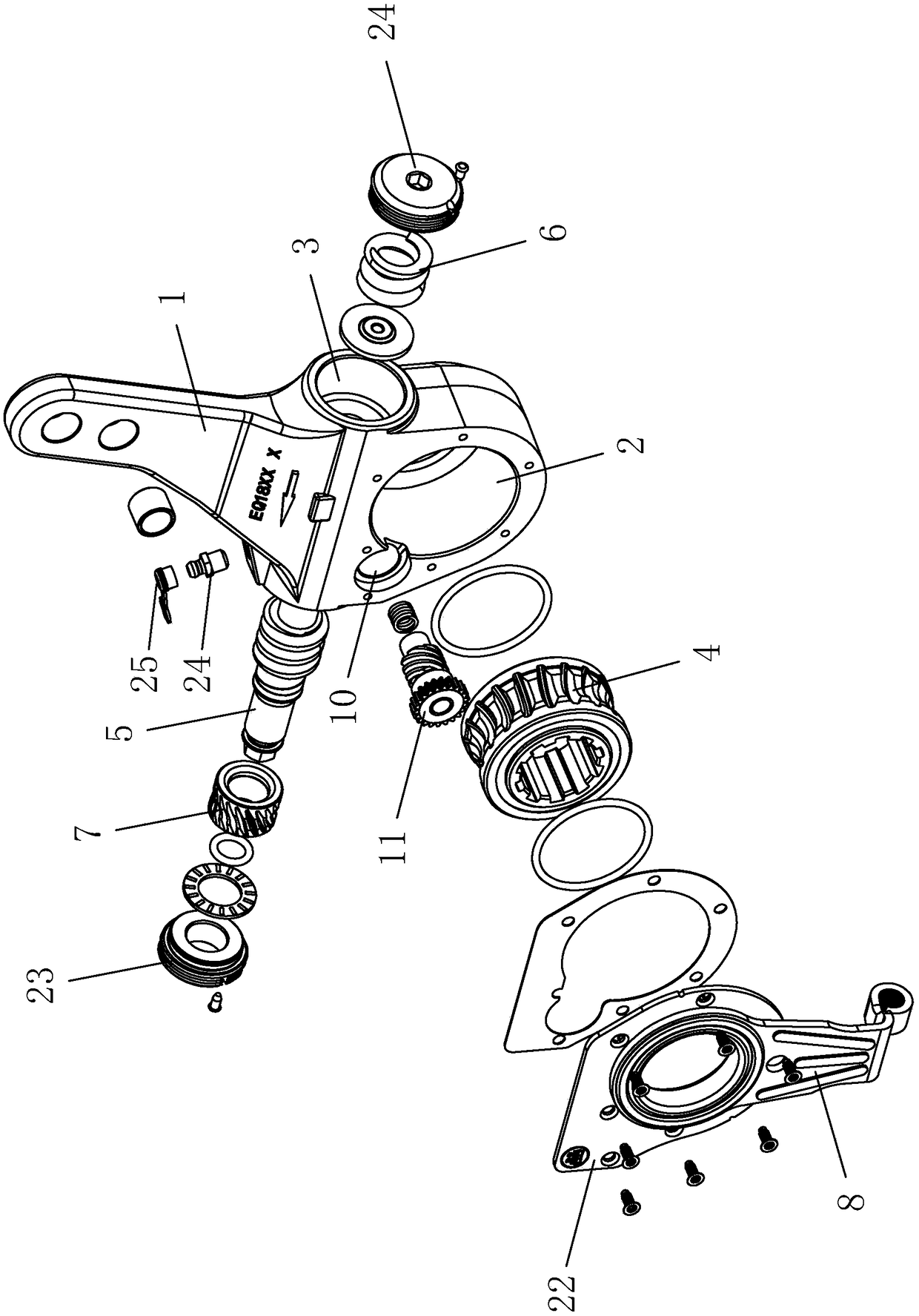

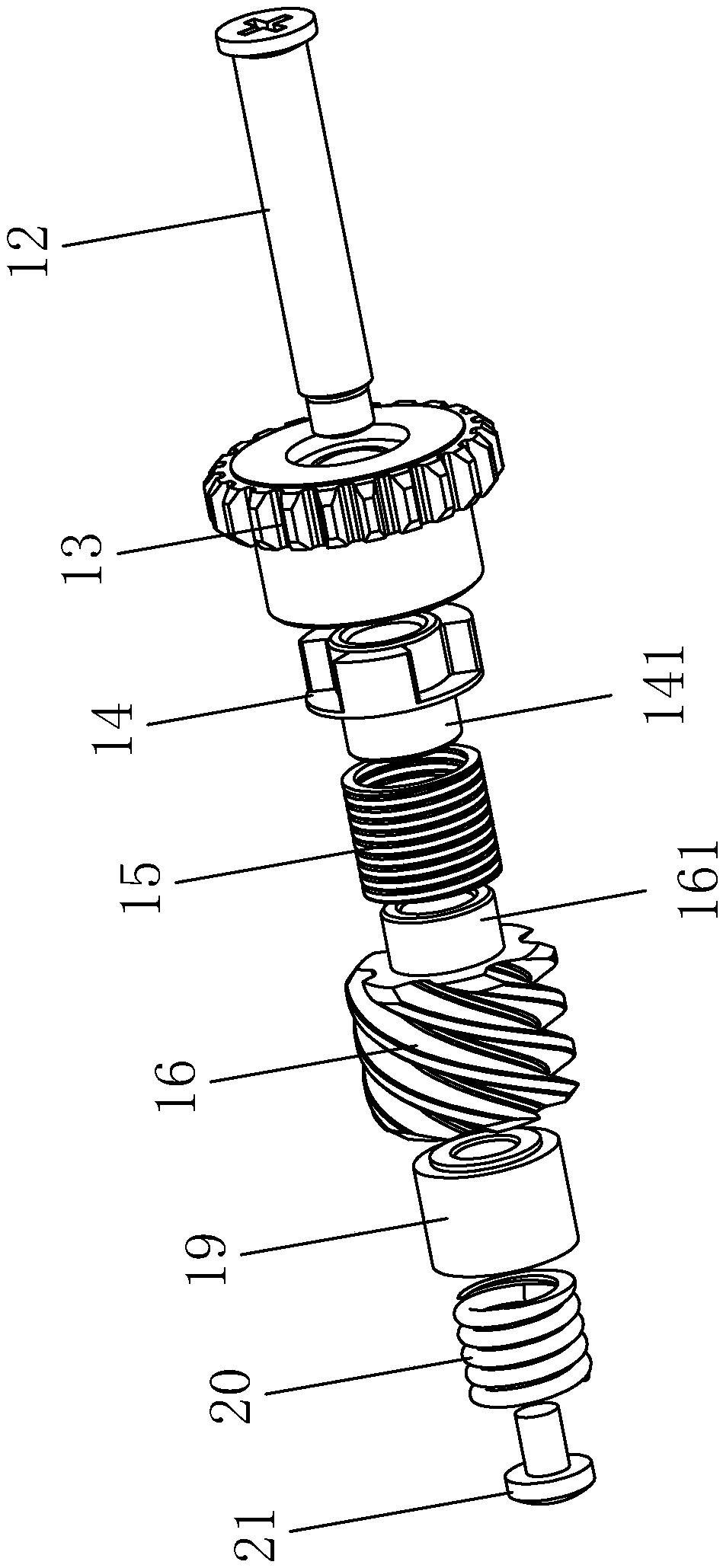

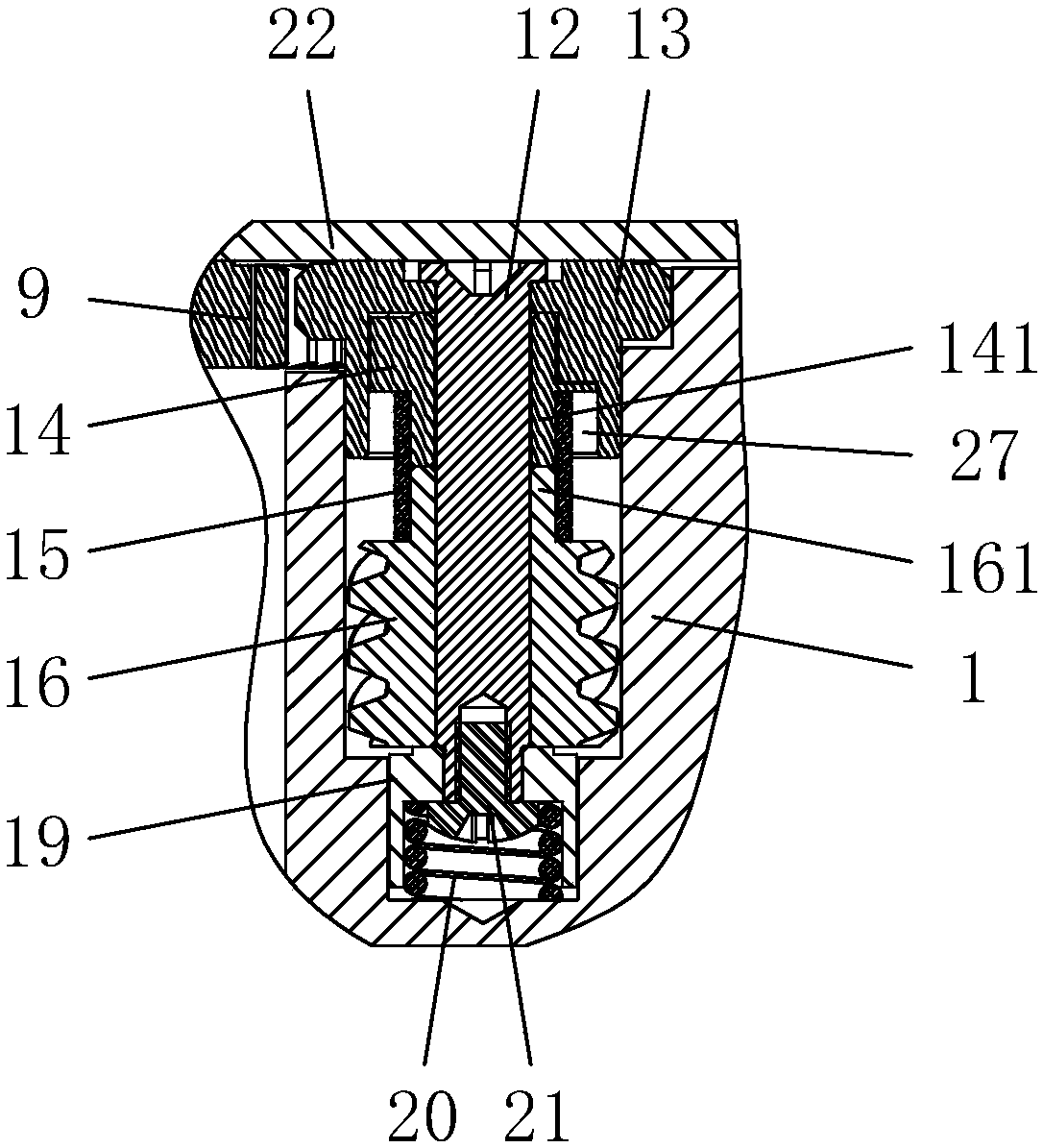

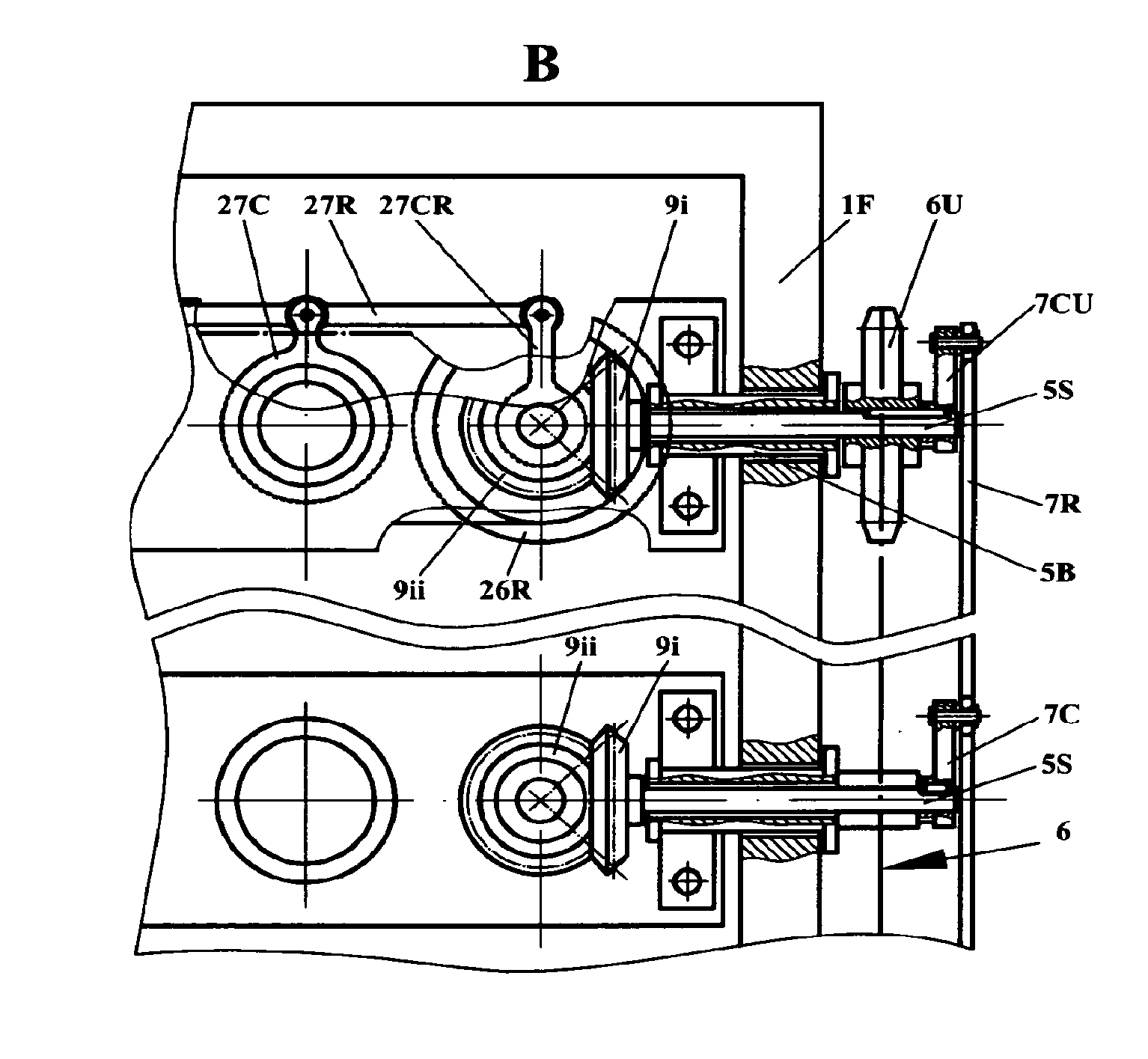

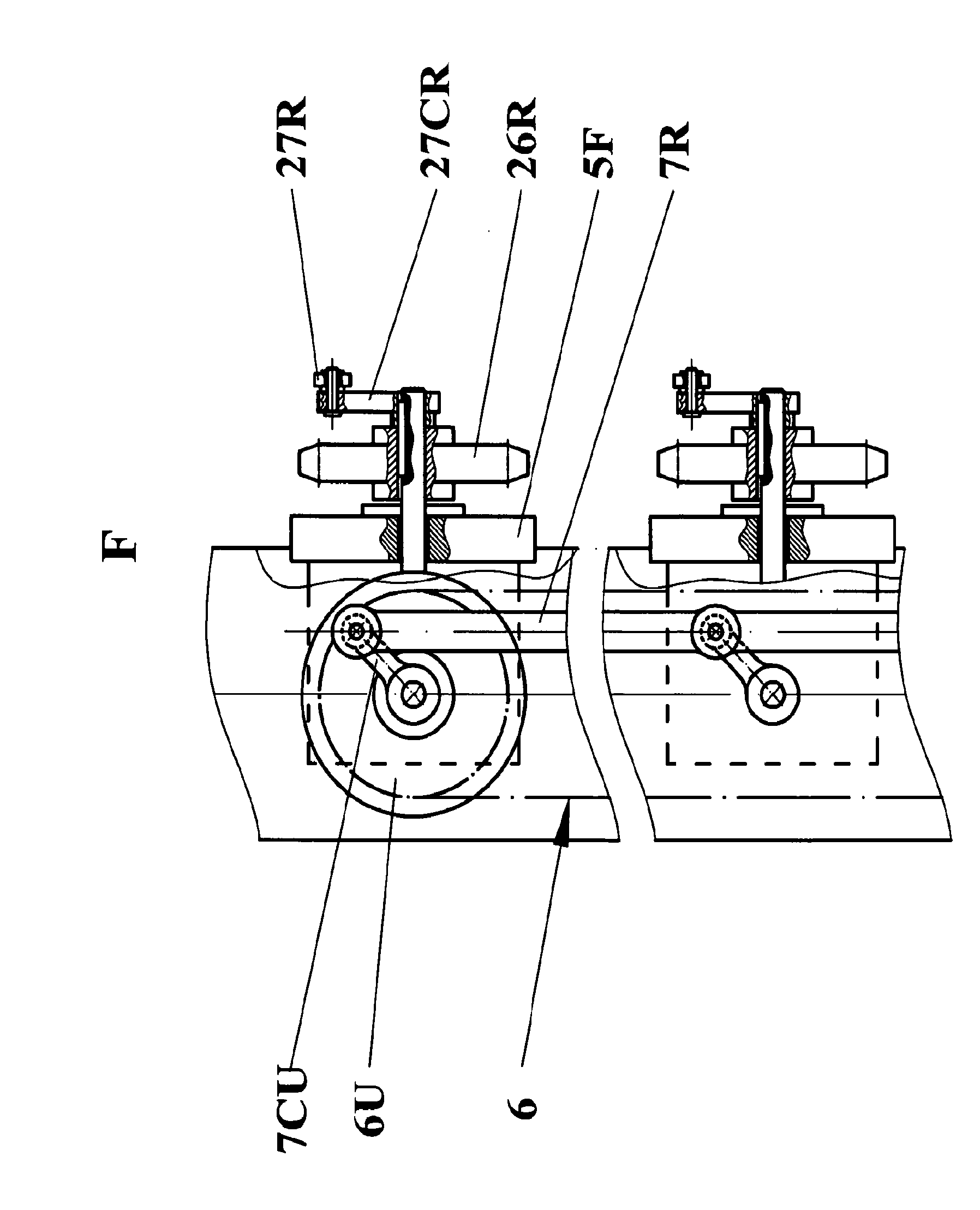

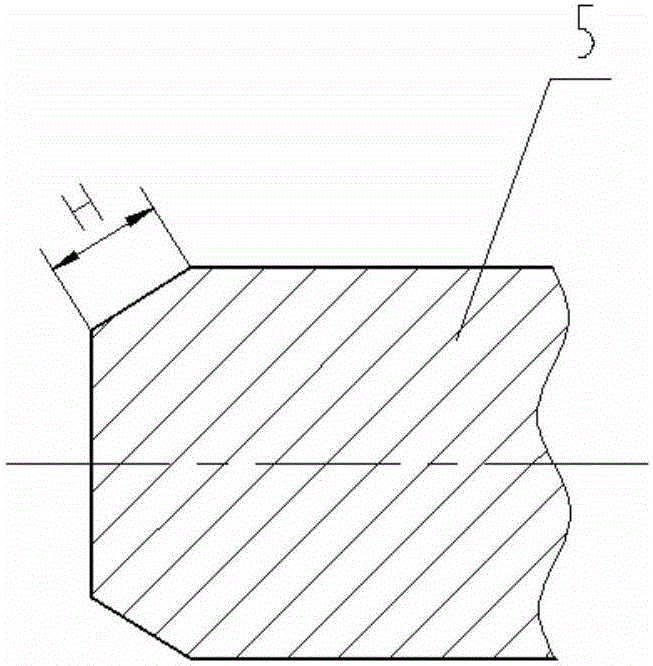

Blast furnace bellless furnace top distributor

ActiveCN101173321AExtended service lifeFully lubricatedBell-and-hopper arrangementBlast furnace detailsEngineeringShaft furnace

The invention discloses a bell-less top distributing gear of furnace, belonging to technical field of metallurgical industry. The invention adopts sealed cooling, a water-cooling venturi tube with pipe laying and a water-cooling chassis. A motor drives a chute to rotate and tilt; wherein, the motor drives the nut of the ball screw assembly to rotate and then drives the lead screw and the lifting rotary frame connected with the lead screw to move up and down in order to achieve chute to tilt for Alpha angle. The invention has the advantages of high coaxiality, high transmitting precision, long service life of the critical component, easy manufacture, light weight and low cost. The tilting Alpha angle of the chute and the stationarity of the tilting movement of the chute can be checked during the producing process of the furnace by the invention. The invention can be used in charging operation of furnace roof and also is suitable for shaft furnace or smelting reduction furnace which need to feed from the roof to the closed space and distribute regularly.

Owner:CISDI ENG CO LTD

Cleaning device of silt-blocked pipeline

The invention relates to a cleaning device of a silt-blocked pipeline, and belongs to the technical field of municipal engineering sewers. The cleaning device is characterized in that a spraying head shell is conical, a scraper and a high-pressure water spray hole are axially arranged on the outside surface of the spraying head shell, and a connection hole is formed in the center of a closing plate at the bottom of the spraying head shell; one end of a scarfer is provided with an outward convex step, the outside diameter of the outward convex step is larger than the inside diameter of the connection hole in the center of the closing plate, and the outward convex step is of a tee pipe shape; and one end, provided with the outward convex step, of the scarfer is placed in the inner cavity of the spraying head shell, and the other end of the scarfer is connected with a high-pressure water hose arranged outside the spraying head shell by a connection hole. The cleaning device has the benefits that the structure is simple, parts and components are few, and the use is convenient; the exposed part of the scarfer in the connection hole of the closing plate is connected and fastened with the high-pressure water hose; and because the spray hole direction has an alpha angle with the radial line direction of the spraying head, and inclines toward the rear part of the spraying head, the spraying head rotates and drills forwards simultaneously by virtue of reactive thrust of the high-pressure water spraying, the inner wall of the pipeline is cleaned through scraping and brushing due to the rotation of the scraper, and the pipeline is dredged by the forward drilling of the spraying head.

Owner:SHANGHAI KYOCERA ELECTRONICS +1

Pancake making device

InactiveCN103734210AAvoid breakingAvoid spillingOil/fat bakingPancakes bakingMechanical engineeringPhysics

A pancake making device comprises a support, wherein a scraper and a scraper lifting part which is used for driving the scraper to achieve a cyclical motion of rising and falling. The moving-track curve of the cyclical motion of rising and falling of the scraper comprises a rising part moving-track curve and a return part moving-track curve, wherein the return part moving-track curve comprises at least a return part moving-track curve I and a return part curve II. The alpha angle between the return part moving-track curve I and the time coordinate is larger than the beta angle between the return part moving-track curve II and the time coordinate. According to this arrangement, a plurality of functions such as the motion of rising and falling of the scraper, the transverse moving of a sub-scraper and the adjustment of heights of the scraper and the sub-scraper can be achieved. The pancake making device has the advantages of high integration and degree of automation, thereby effectively ensuring pancake making time by the scraper and uniformity of pancakes. Accordingly, pancakes made by the pancake making device are thin, tough and delicious. Compared with the prior art, cereal pancakes can be made by the pancake making device, which is an innovation in the industry.

Owner:尹相善

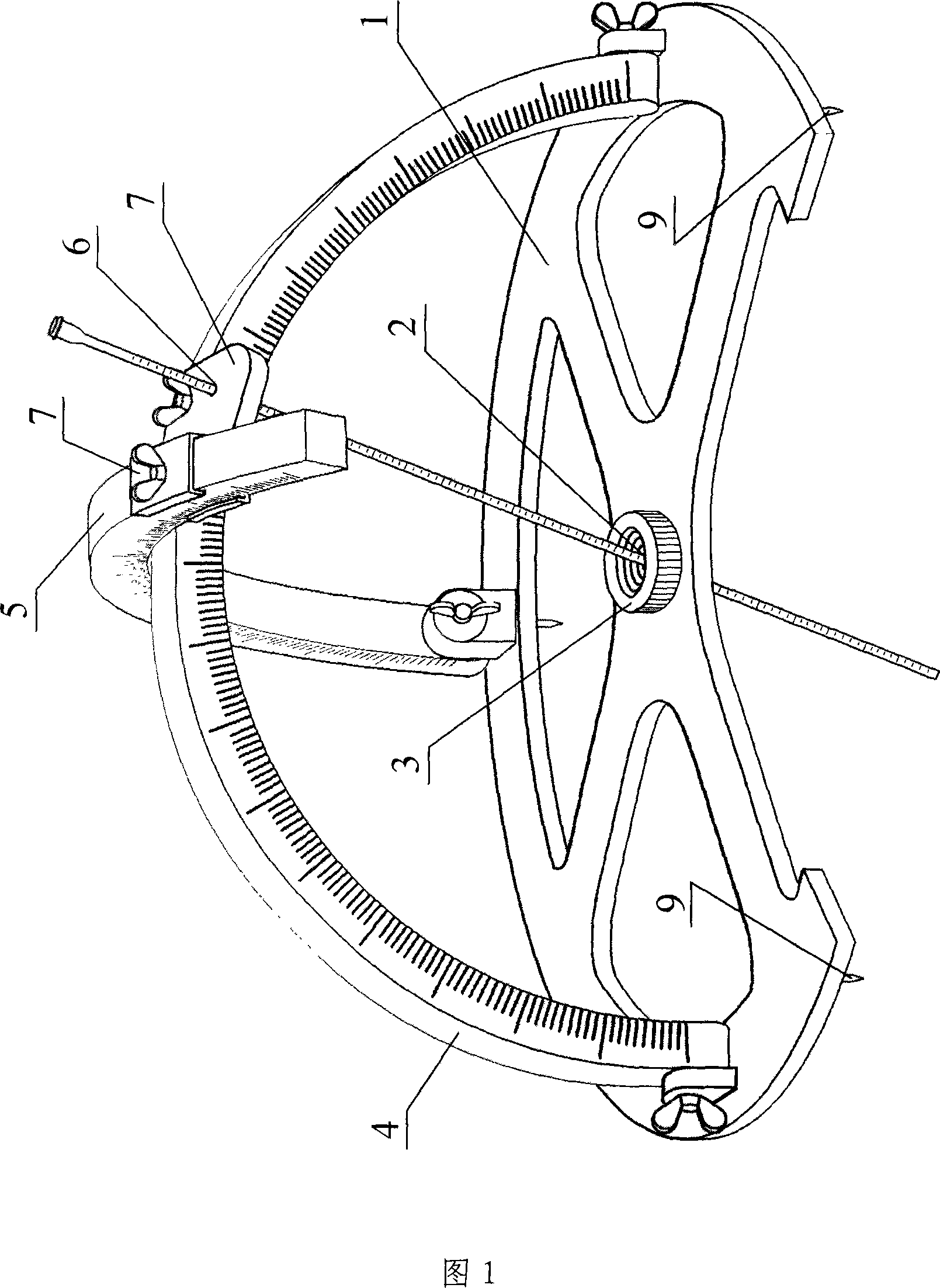

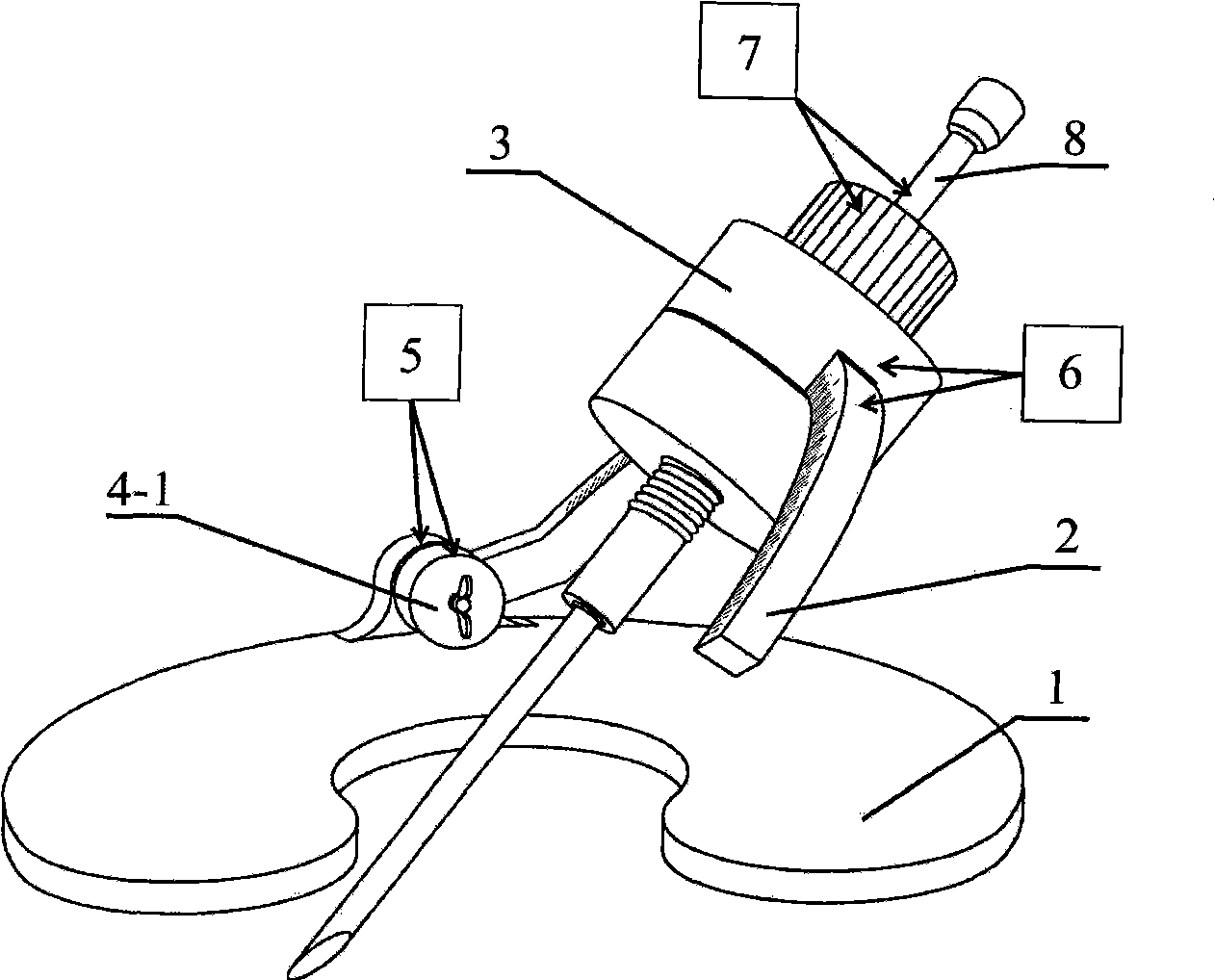

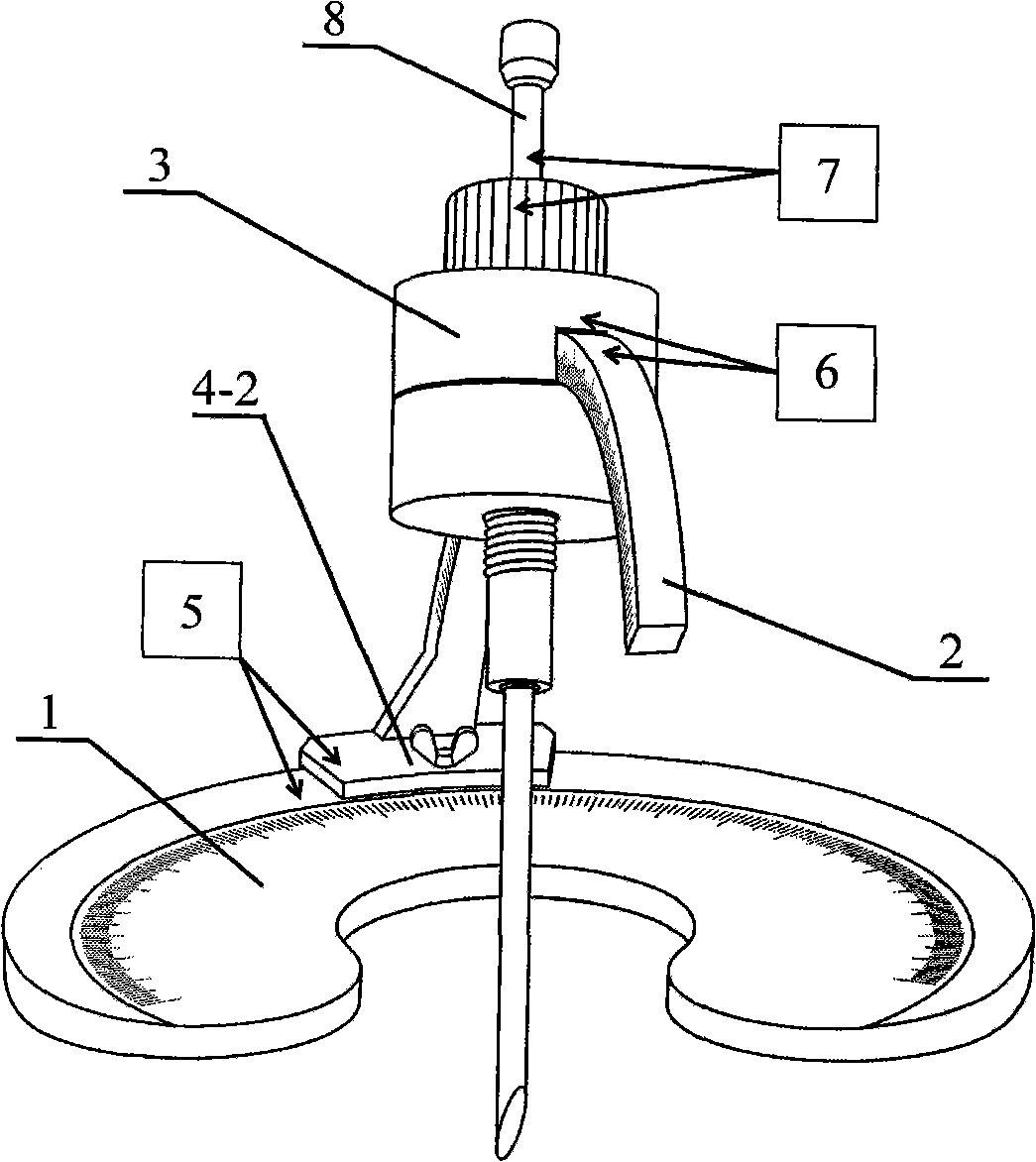

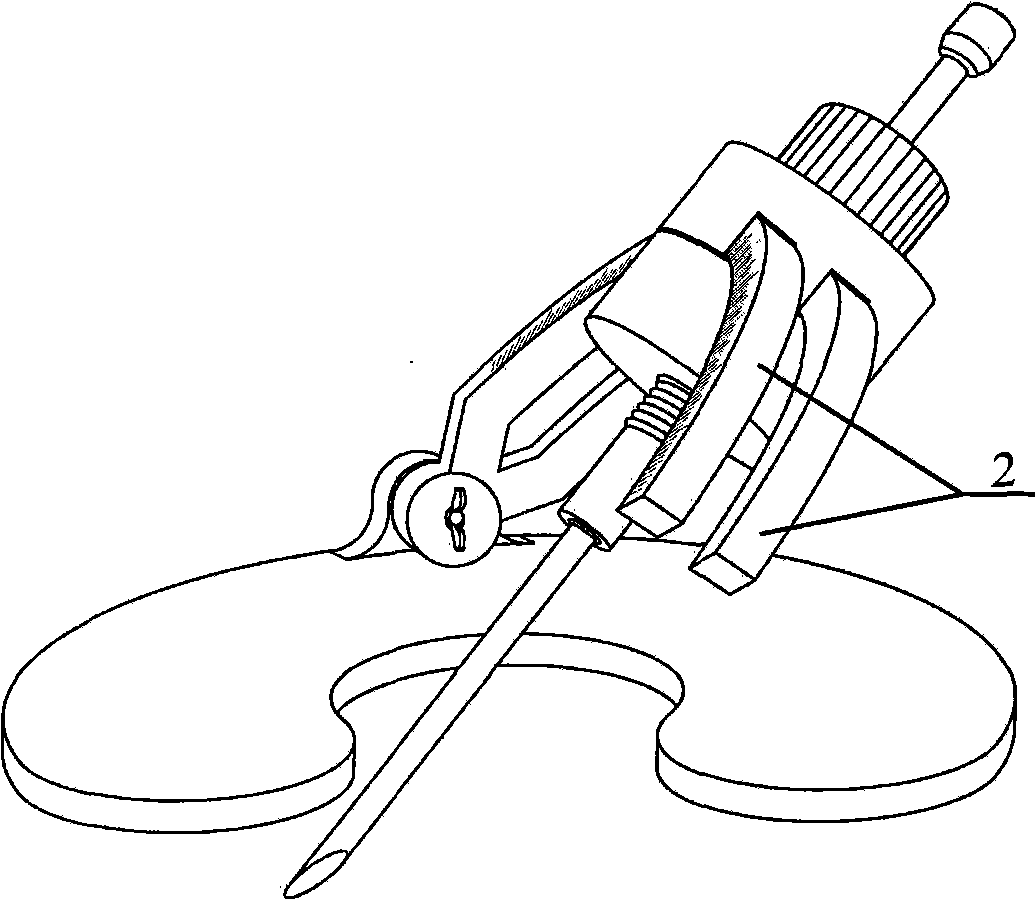

Structure simple stereoscopic director

InactiveCN101099692AReduce volumeSimple structureDiagnosticsInstruments for stereotaxic surgeryBeta angleEngineering plastic

The present invention provides a steric direction finder with simple structure. Said steric direction finder can be used for accurately feeding the operative instrument into targe point when the operation on human or animal cranium and brain can be made. Said invention includes the following several portions: base plate which is made up by using high-strength rare earth engineering plastics or other material and does not produce pseudoimage interference when the image scanning process is made, fixed nut with guide hole, bow-shaped alpha angle measurer with angular scale, bow-shaped beta angle measurer with angular scale and fastener for regulating tightness.

Owner:吕田明

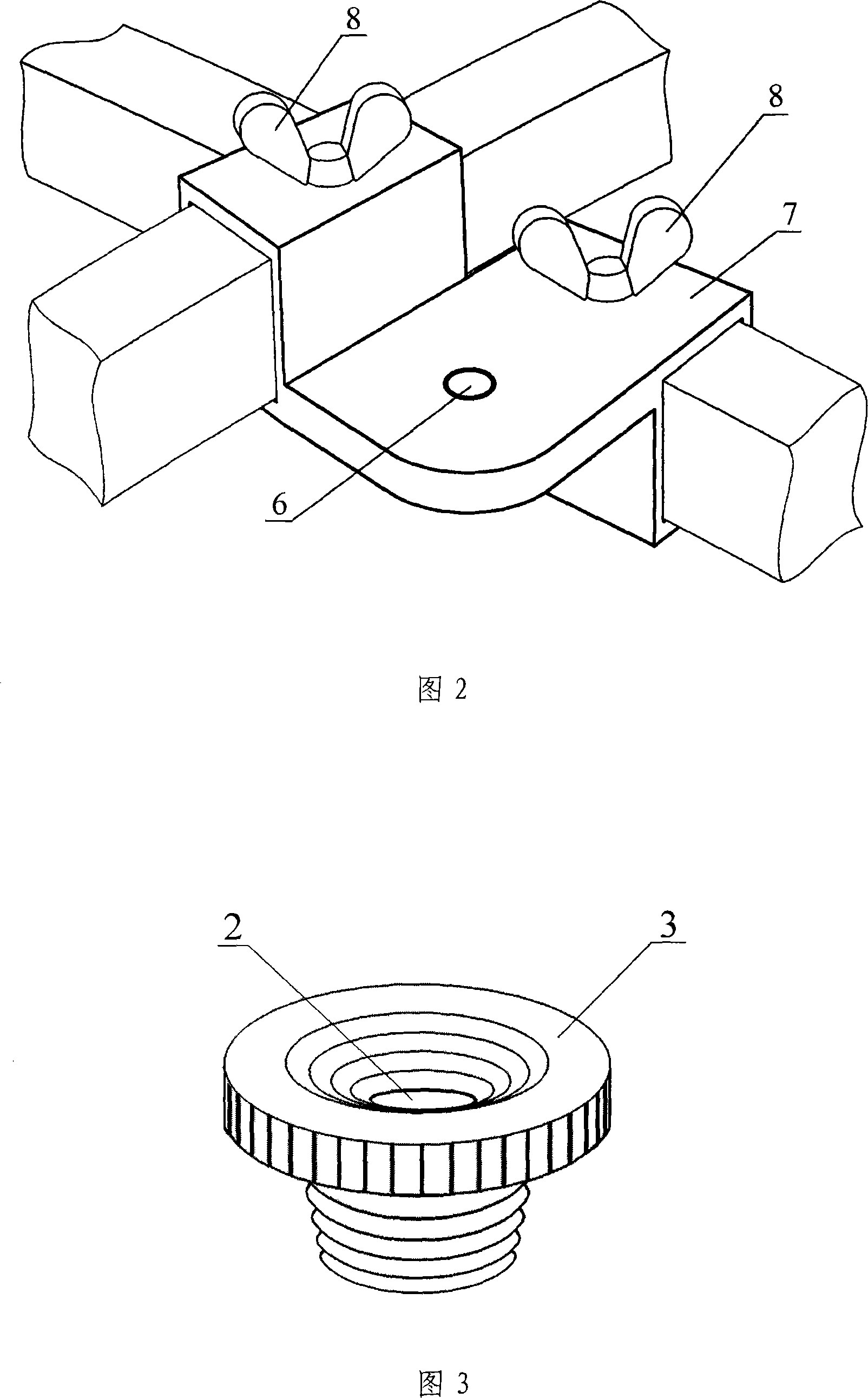

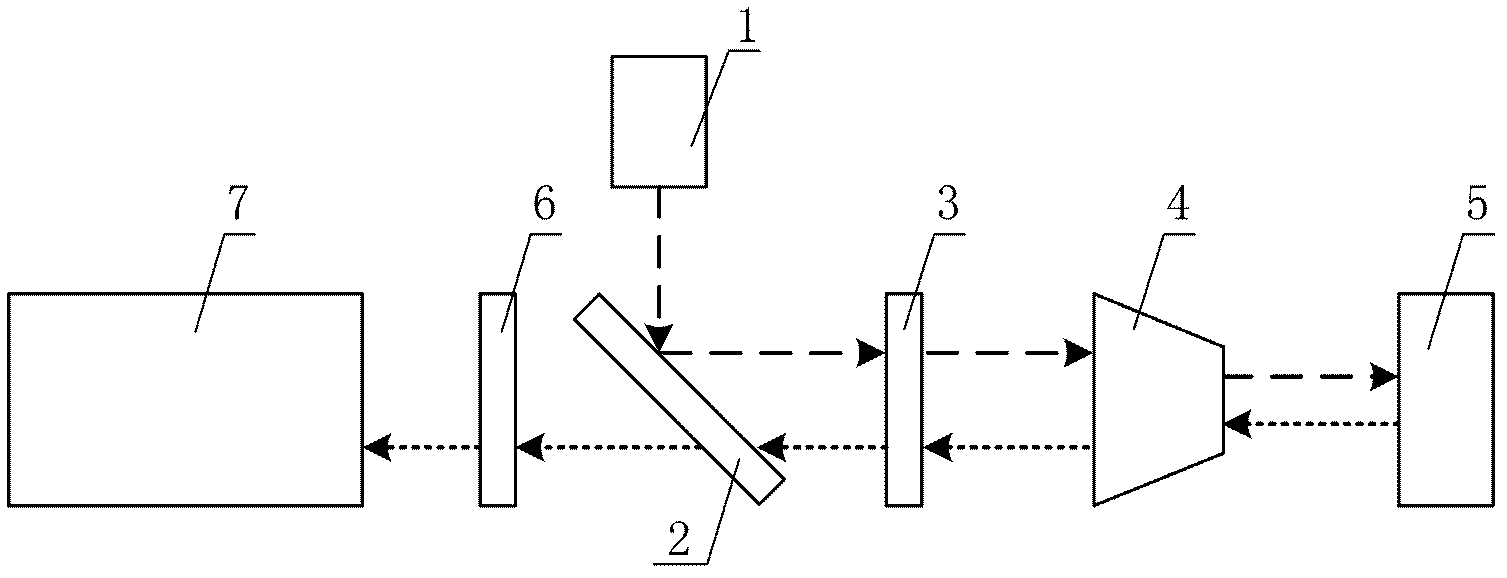

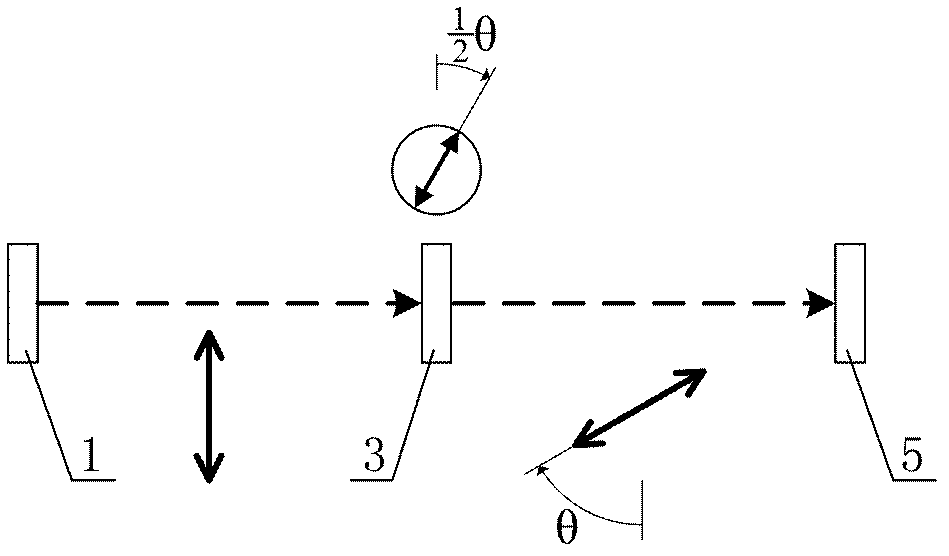

Micro-raman spectrum experiment apparatus for adjustable polarization direction continuous collaboration/covariation

The invention discloses a micro-raman spectrum experiment apparatus for adjustable polarization direction continuous collaboration / covariation. A micro-raman spectrum system is composed of a laser machine, an Edge optical filter, a microscope and a Raman spectrograph, a polarization collaboration / covariation adjusting module is composed of a half-wave plate and a polaroid sheet. The laser emitted by the laser machine is performed Edge optical filter reflection, half-wave plate transmission and microscope focusing incidence on the surface of the measured object. The diffusion light collected by the microscope transmits through the half-wave plate, the Edge optical filter and the polaroid sheet and then enters in the Raman spectrograph for photorecording the spectrum information. By setting the vibration detection angle of the polaroid sheet as zero or nonzero value-alpha, the fast optical axis angle of the half-wave plate is adjusted to be half of the rotation angle in the polarization direction, so that collaboration regulation or alpha angle covariation regulation of polarization direction of incidence light and scattered light can be realized. On the basis of unchanged functions and precision of the traditional micro-raman spectrum experiment system, the modularization and simplification of controlling polarization collaboration / covariation can be realized, and the manufacture cost can be reduced.

Owner:TIANJIN UNIV

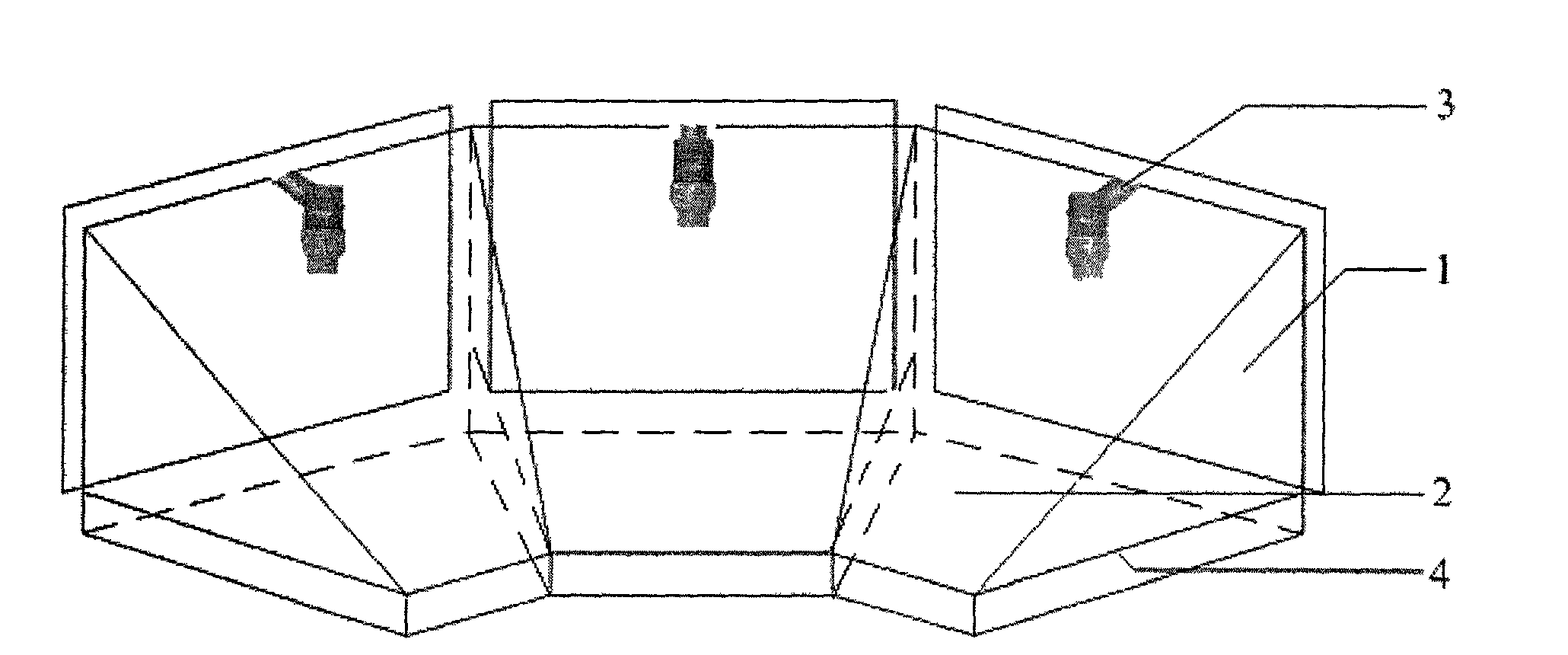

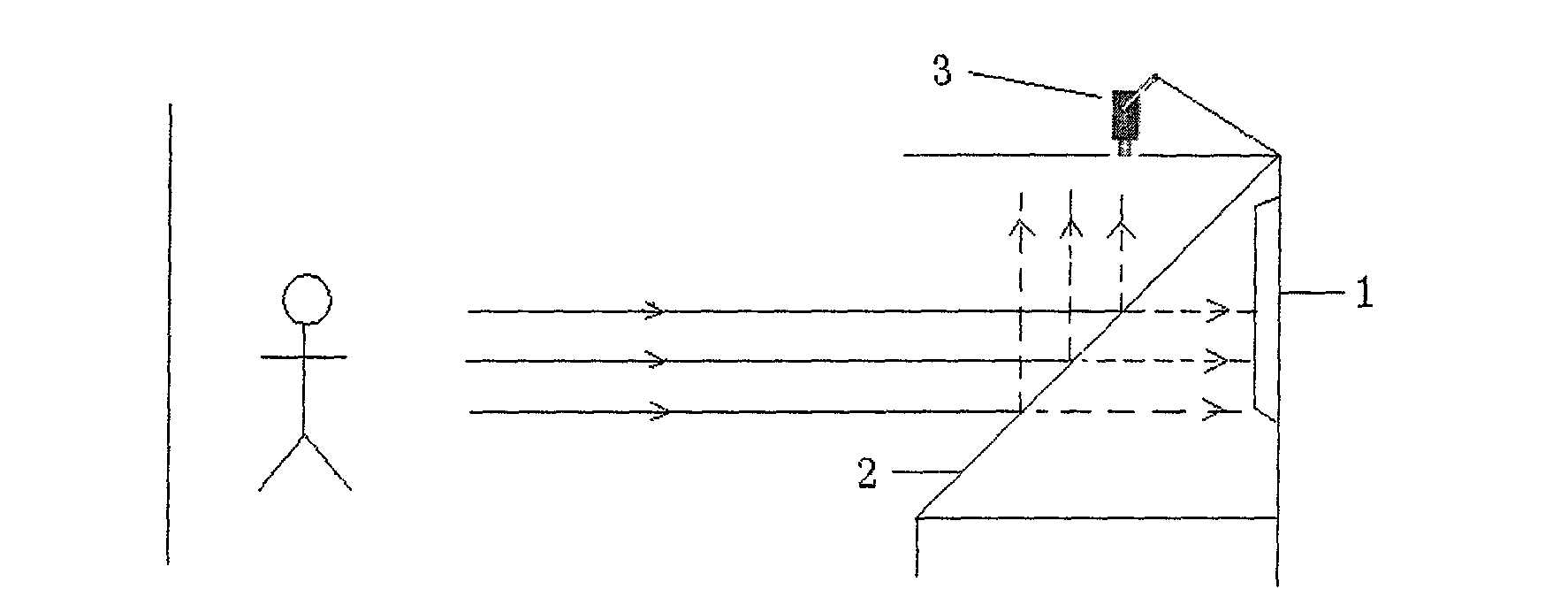

Tele-immersion teamwork device based on multi-camera acquisition

InactiveCN101581874AExpand field of viewImage data processing detailsStereoscopic photographyCamera lensMulti camera

A tele-immersion teamwork device based on multi-camera acquisition is disclosed, comprising; three cameras, three displays arranged at an alpha angle and semitransparent semireflecting mirrors which are respectively positioned in front of each display at an angle of 45 degrees and which are used for changing light path; the three cameras are respectively fixed directly above the semitransparent semireflecting mirrors with lenses thereof facing vertically downwards, projection of the lenses in the semitransparent semireflecting mirrors is coincided with that of eyes of a user in the semitransparent semireflecting mirrors when the user faces directly towards the display; wherein, alpha is larger than 90 degrees; the three cameras receive the same external triggering signal sent by an external host, and collect synchronous real images in an identical scene is performed by collecting lights reflected by the semitransparent semireflecting mirrors. The invention can collect front sight line of human, bringing people the sense of eye contact; in addition, two-dimensional video can be enabled to be more realistic when being viewed in three-dimensional scene.

Owner:BEIHANG UNIV

Coated member

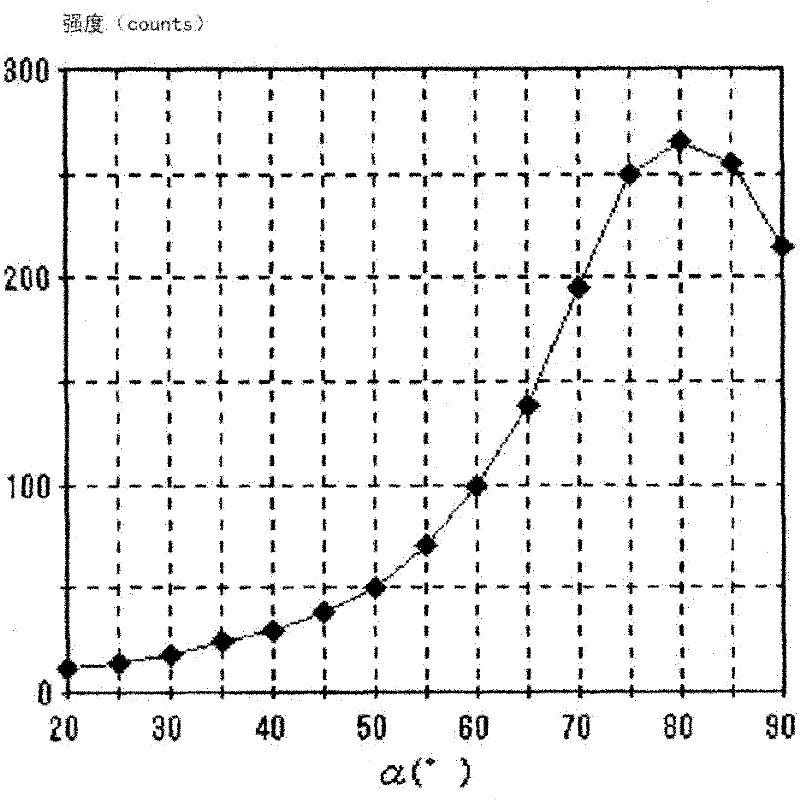

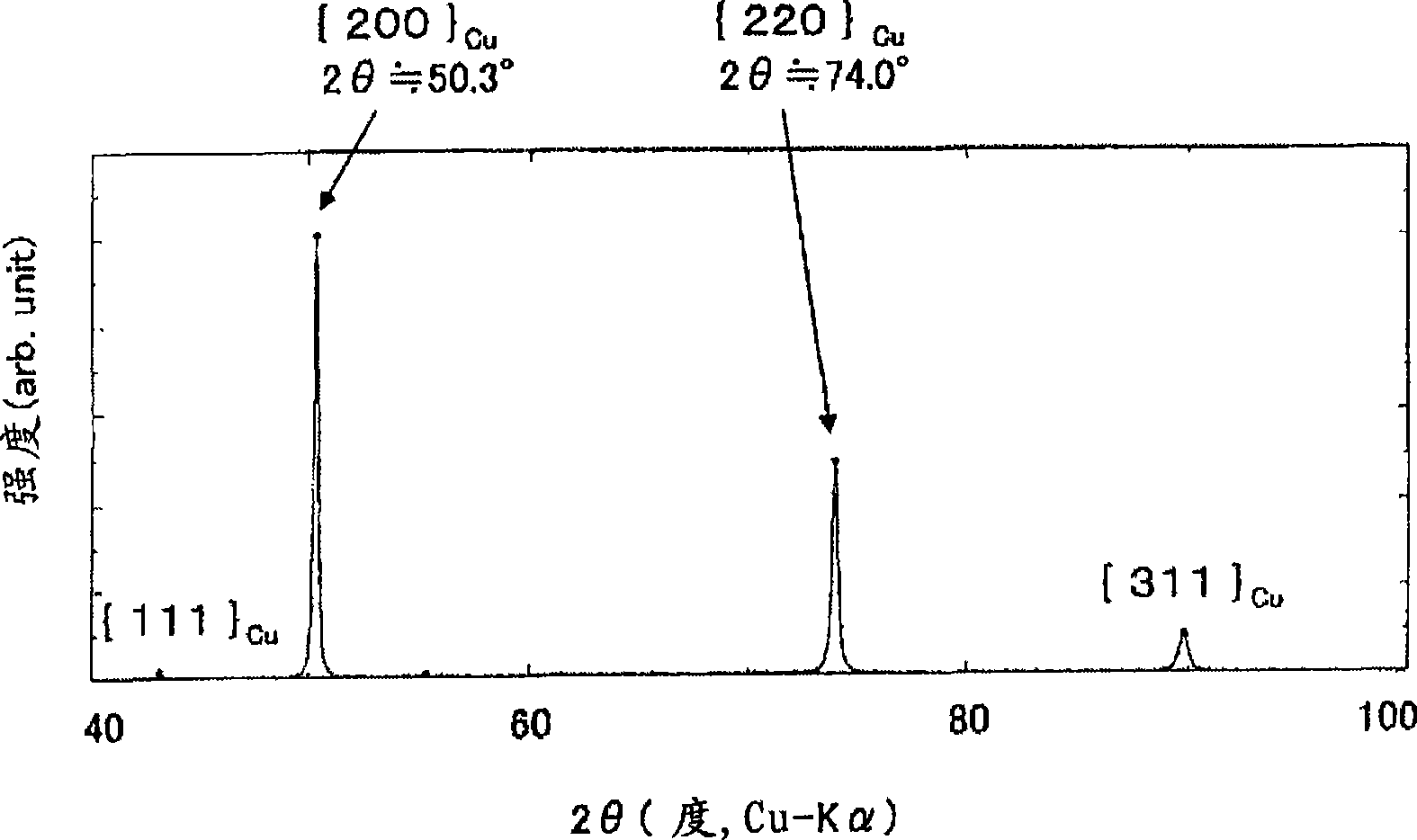

ActiveCN102099138AStrong adhesionImprove abrasion resistanceMilling cuttersVacuum evaporation coatingX-rayHardness

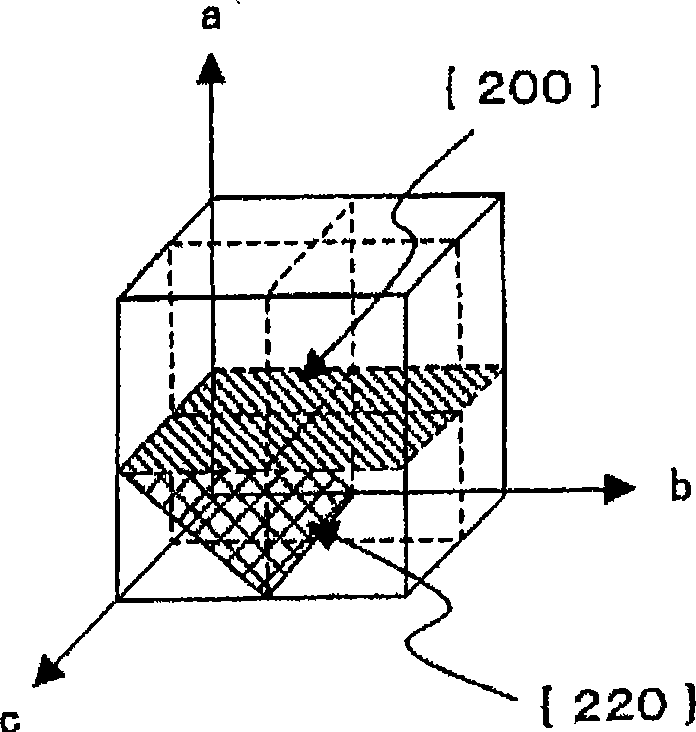

The invention provides a coated member for cutting tools which renders a long life possible under severe cutting conditions as in high-speed processing, high-feed-rate processing, cutting of works having enhanced hardness, and cutting of works difficult to cut. The coated member comprises a base having a surface coated with one or more coating films. At least one of the coating films is a hard film of a cubic metallic compound comprising at least one metallic element (M) selected from Al, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W and at least one element (X) selected from C, N, and O. In the pole figure for the (111) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG. In the pole figure for the (220) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG .

Owner:TUNGALOY CORP

Three-phase electric motor with a low detent torque

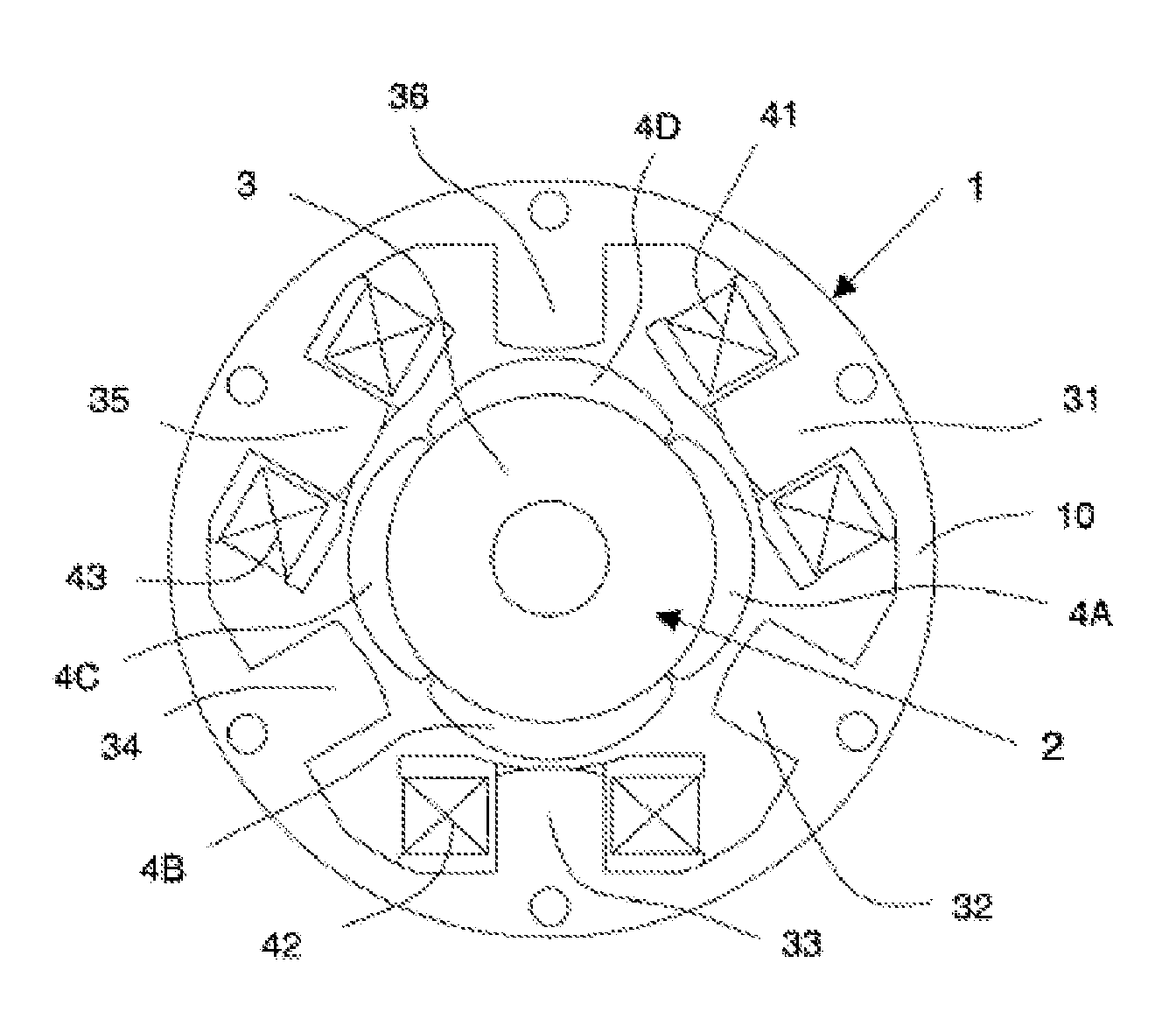

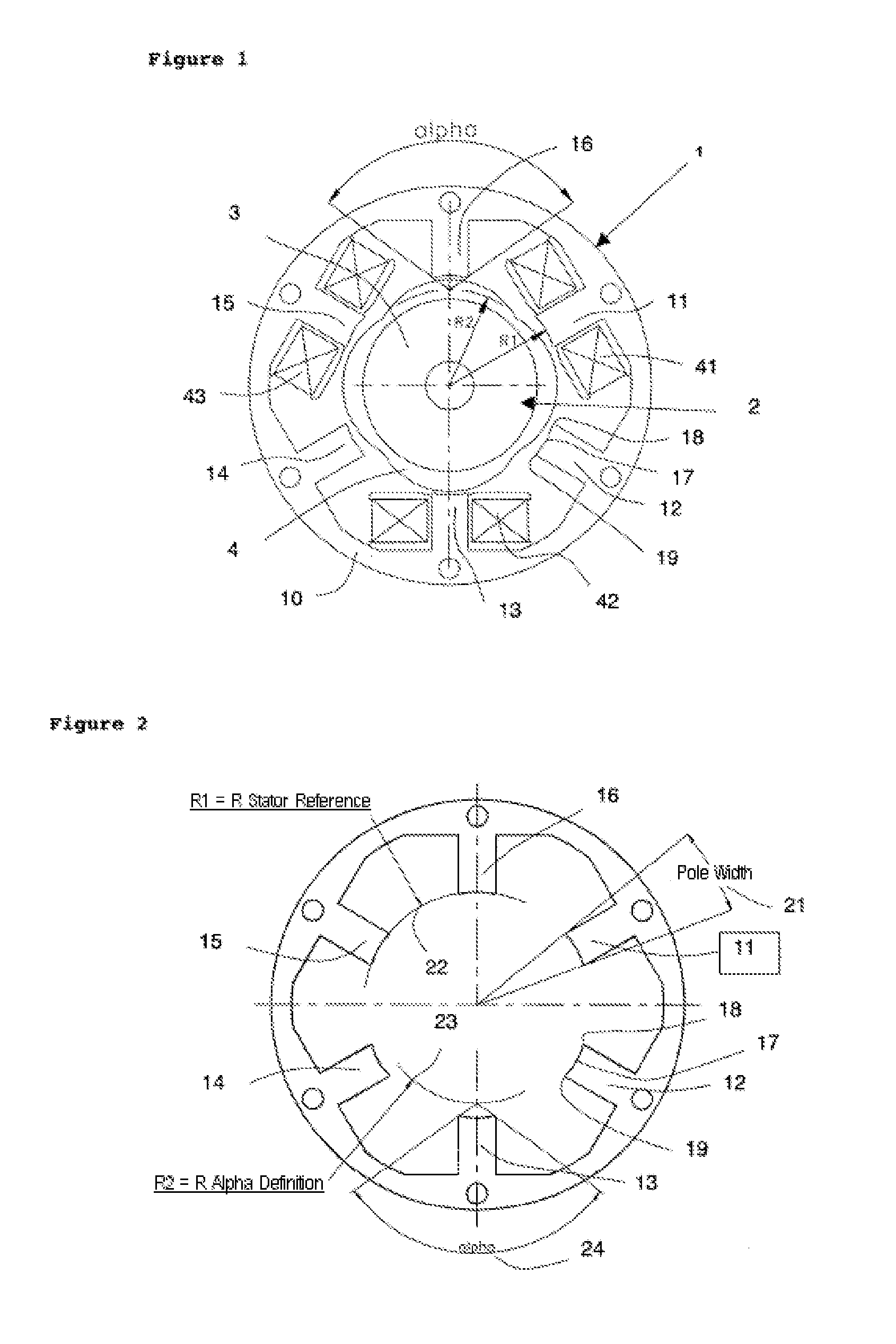

ActiveUS20120104905A1Reduce lossesHigh energyMagnetic circuit rotating partsMachines/enginesGear wheelElectric machine

The disclosure relates to a three-phase electric motor that uses high magnetic energy permanent magnets and that has a low detent torque. The motor consists of a rotor with N pairs of poles and of a stator portion with teeth extending radially from an annular gear. The teeth have windings and the ends thereof comprise an arc of circle, the middle of which is located on a radius R1 and two sides defining an alpha angle, the vertex of which is located on a radius R2. The ratio R2 / R1 is substantially equal to (1+ / −0.26 / N), and the alpha angle is between 110 and 135°.

Owner:MMT SA

New charging method of schreyerite smelting blast furnace

ActiveCN103981308AStable furnace temperatureIncreased CO2 contentBlast furnace detailsTruckSchreyerite

The invention provides a new charging method of a schreyerite smelting blast furnace. The double ring burden distribution of ores and coke in a 430m<3> blast furnace is characterized in that ores of each batch are added at two angles, then coke is added at two angles, and finally center coke is added, wherein the ore and coke burden distribution alpha angles are 27DEG and 33DEG, and an angle difference alphadelta is fixedly controlled at 6DEG; and after the double ring charging of the ores and coke is carried out five times, the center coke is added, the addition amount of the center coke accounts for 1 / 5 of the total amount of coke added in the five-time charging, and the center coke is added with the alpha angle of 16DEG and a beta angle rotating for 2-3 rings. The ores, coke and the center coke of the blast furnace are weighed and screened, are added to a truck, are sent to a furnace roof distributing device, and finally are added to the blast furnace.

Owner:XINJIANG BAYI IRON & STEEL

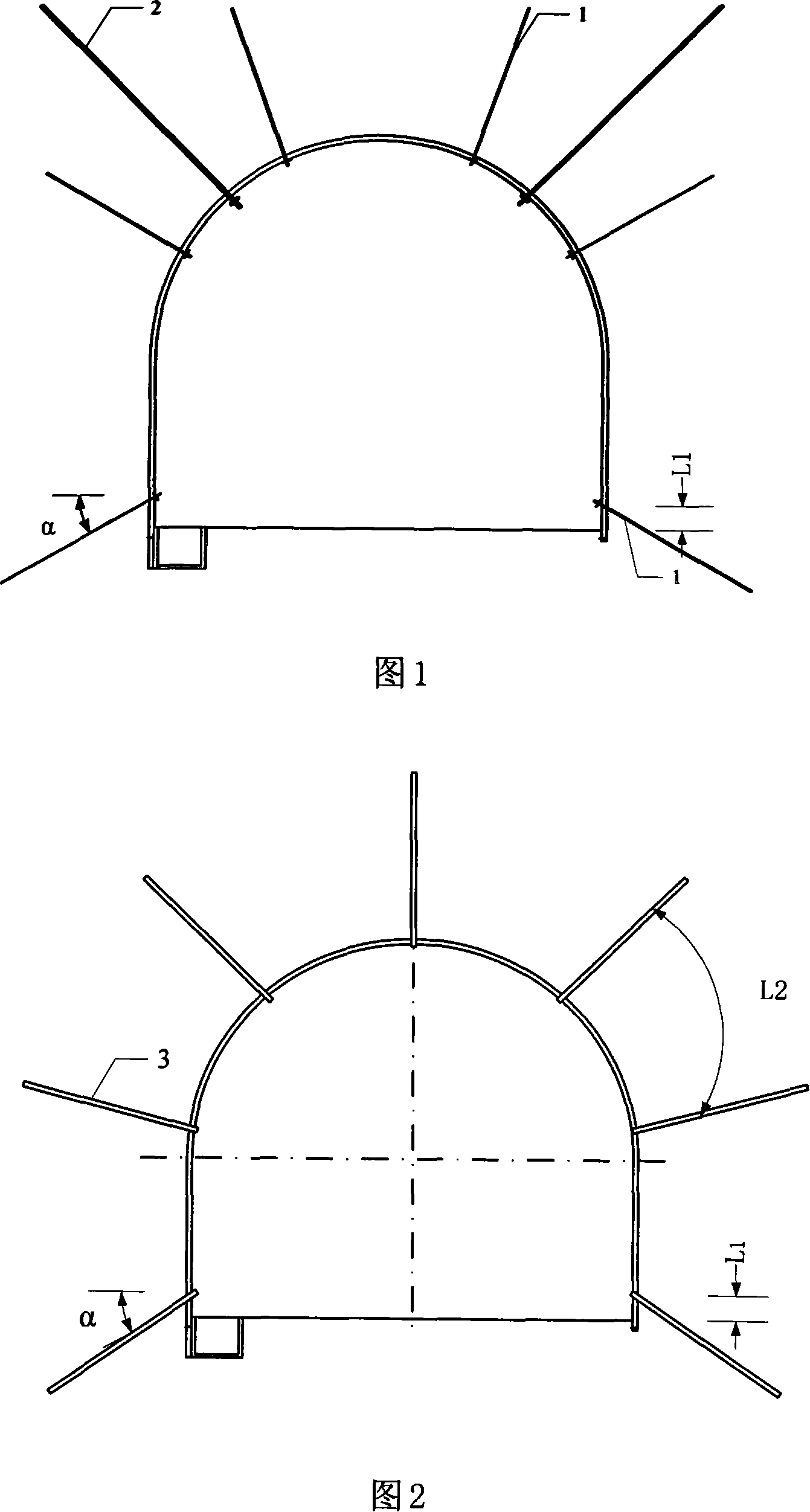

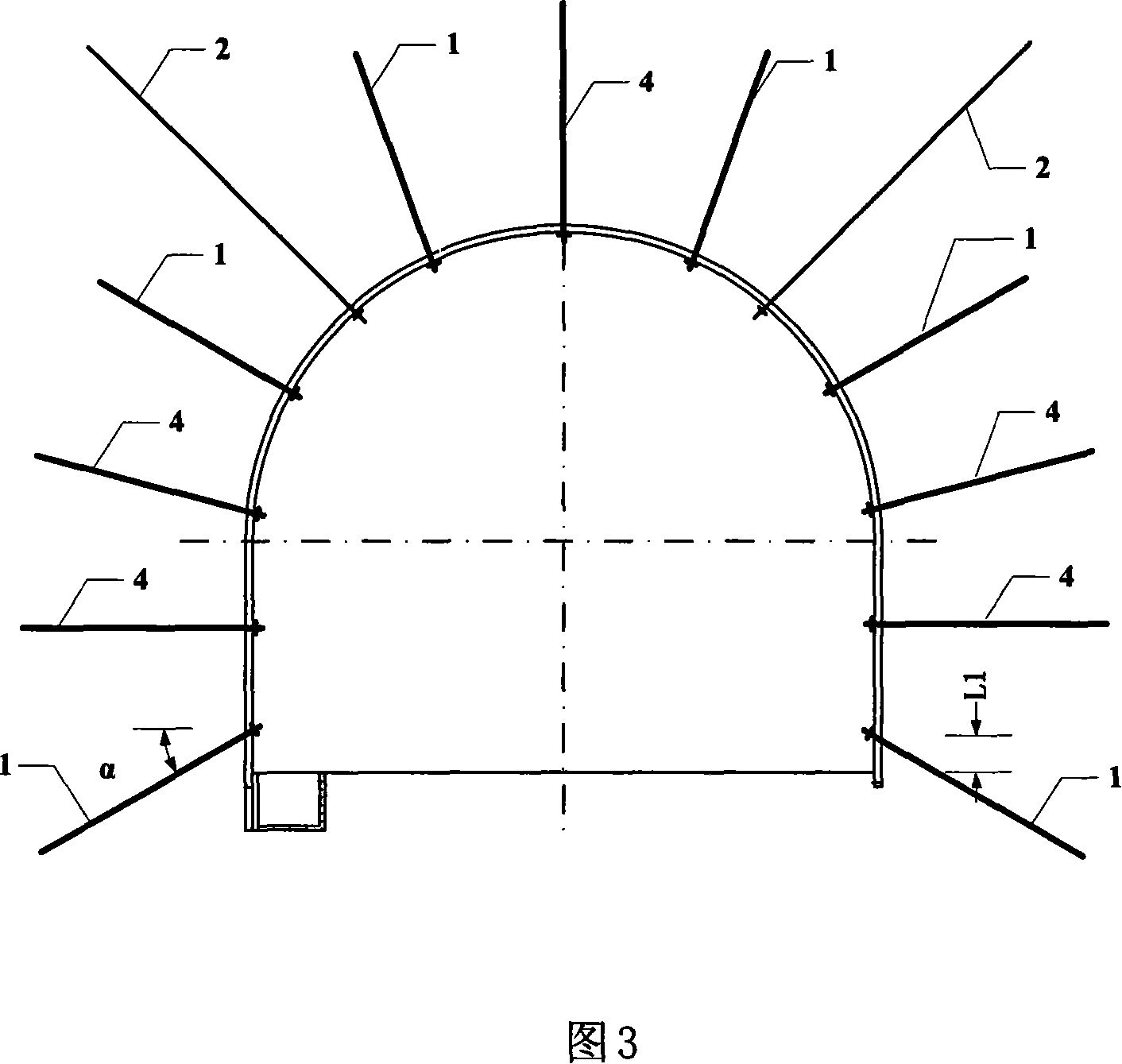

Method for controlling deformation of surrounding rocks of gallery influenced by overhead mining

InactiveCN101082281AImprove the quality of service periodImprove safety and reliabilityAnchoring boltsLevel lineRock bolt

A method to control the country rock distortion of the span mining tunnel adopts high-performance anchor to support on the weak structure of the fillet supporting which is easy to be damaged in the semicircular arch span mining tunnel. The small-bore anchor wires are adopted between the high-performance anchors for encryption supporting. A high-performance anchor with an alpha angle to the horizontal line is set on the tunnel base angle with a distance L1 to the base plate for supporting. An injected anchor is added with a 3-5 array pitch to the anchor and anchor wire supporting for injected supporting. Compared with the existing technology, it improves the safe reliability of the tunnel supporting greatly, eliminates the badly bleeding possibility during the tunnel driving and supporting and improves the quality of the tunnel service, which favors the safe production of the mine. It lightens the workers' working strength, reduces the tunneling cost, increases the mine economic performance, releases the syntaxial problem of mine development preparation and the working-face production and creates conditions for the high-efficient production and the sustainable development of the mine, which has the extensive practicability.

Owner:CHINA UNIV OF MINING & TECH

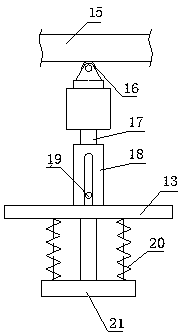

Stereotaxic apparatus capable of guiding in real time

InactiveCN101773410ALive bootFacilitate surgeryDiagnosticsInstruments for stereotaxic surgeryBeta angleStereotaxis

The invention provides a stereotaxic apparatus capable of guiding in real time, which comprises a stereotaxic apparatus and a sensor. The stereotaxic apparatus part comprises a chassis, a bow frame and a fastener, wherein the fastener is provided with a guide hole and has adjustable tightness; the sensor part comprises an alpha angle sensor, a beta angle sensor and a distance sensor. Because the sensor is arranged on the stereotaxic apparatus, and an operator can be guided in real time, thereby not only binging convenience for an operation, but also improving the operation quality.

Owner:吕田明

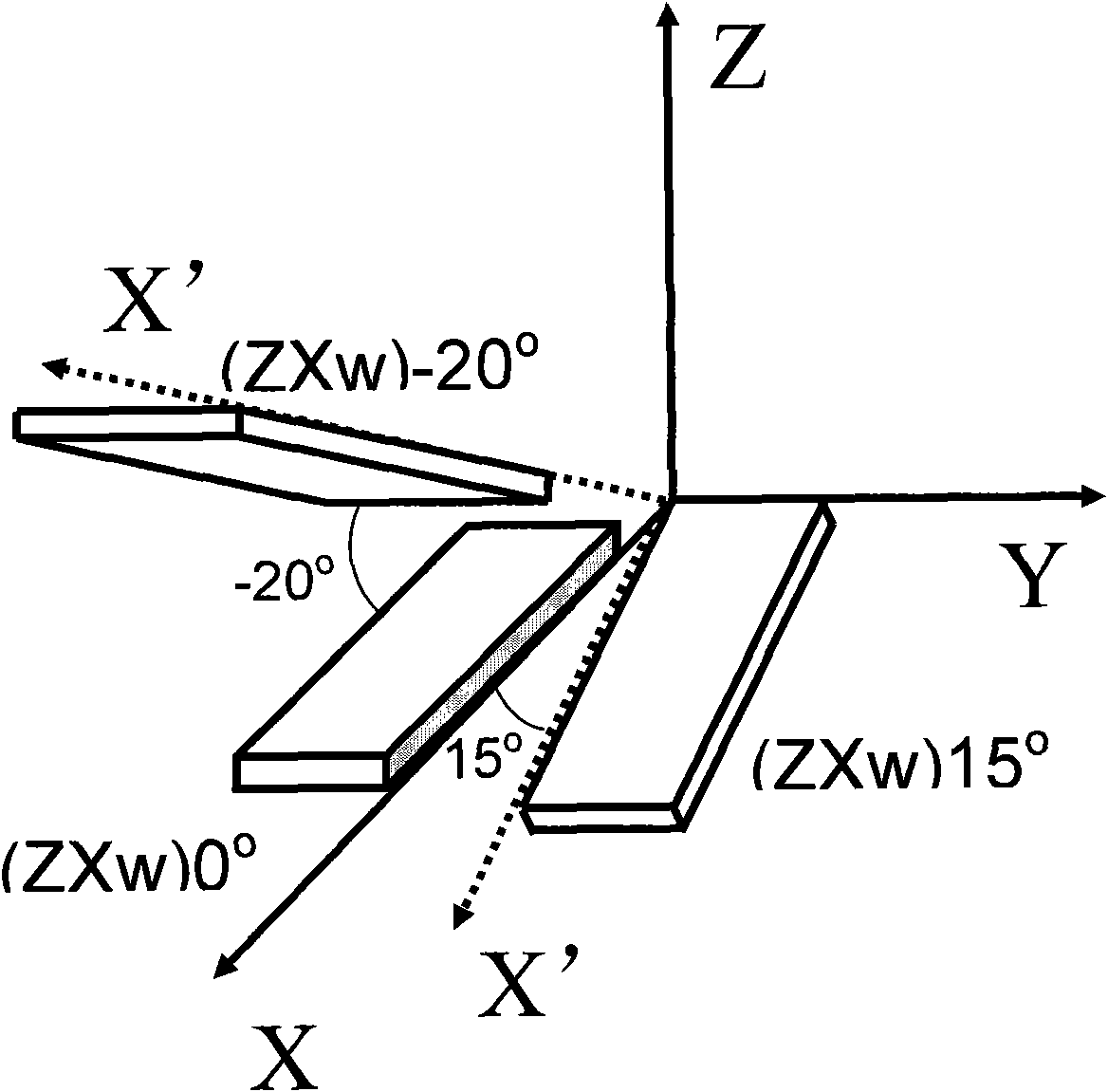

NdCa4O(BO3)3 crystal zero frequency temperature coefficient cut and application

ActiveCN101847975AImprove frequency temperature stabilityReduce mechanical wear and tearImpedence networksNarrow rangePlatinum

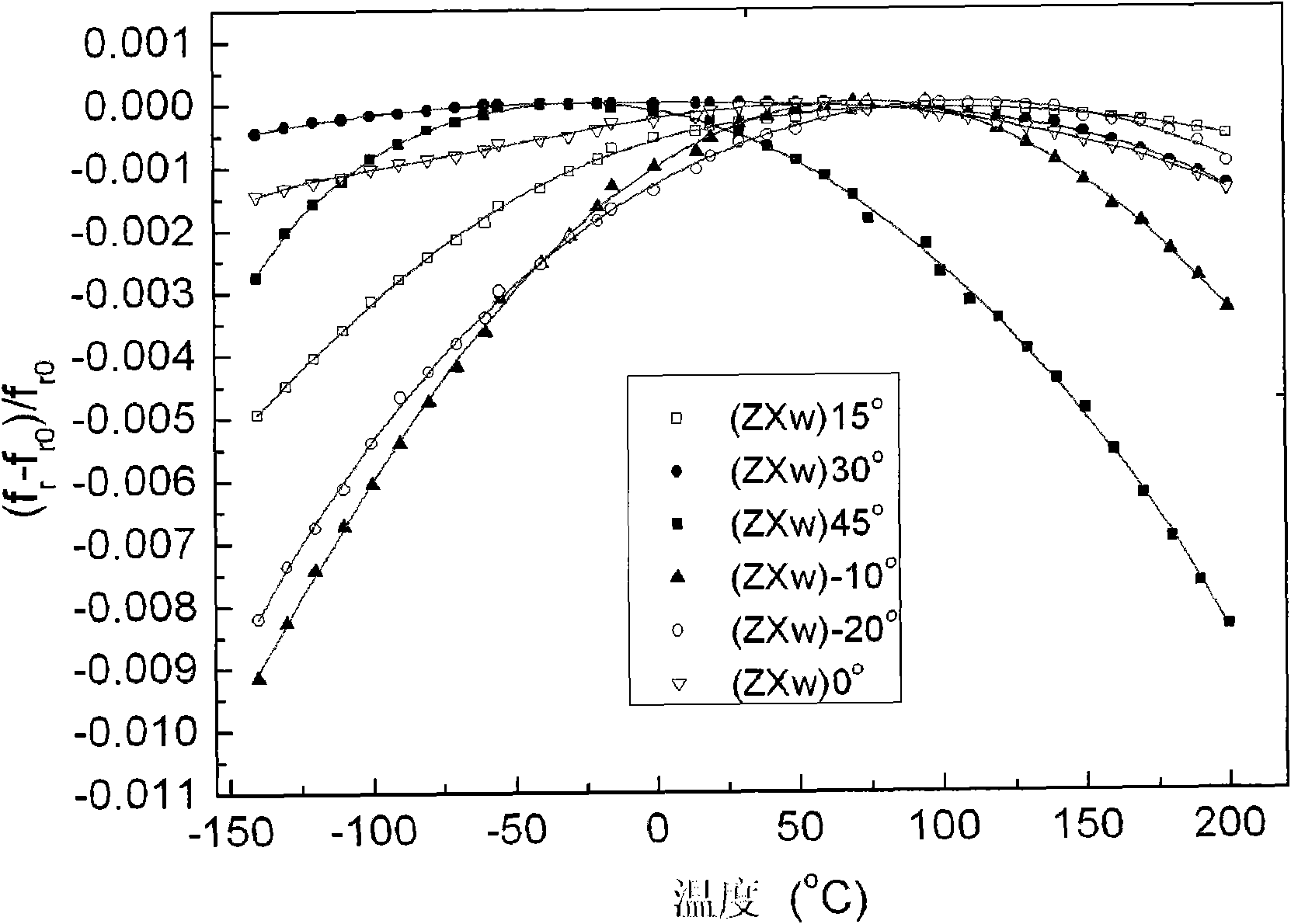

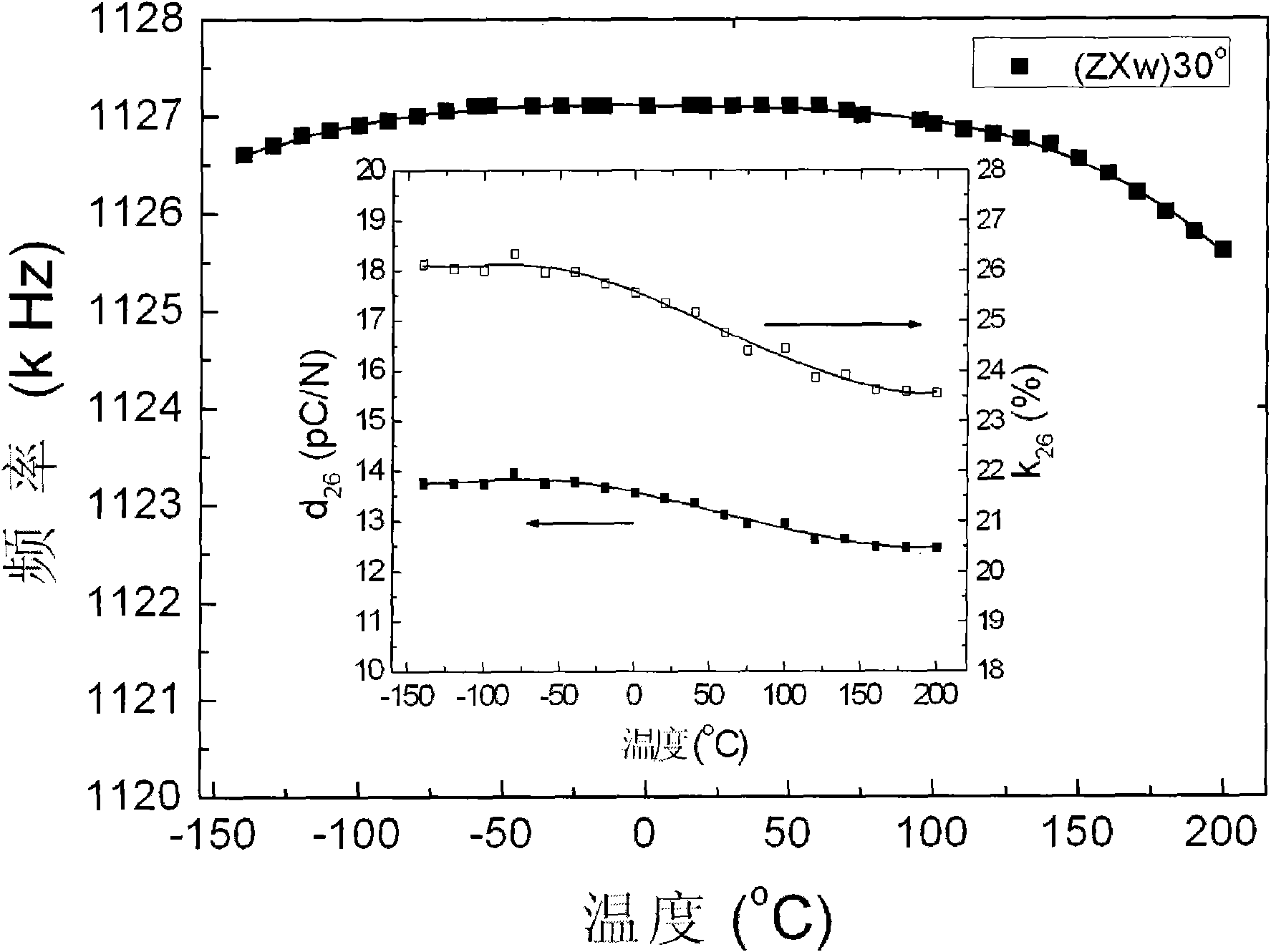

The invention relates to an NdCa4O(BO3)3 crystal zero frequency temperature coefficient cut and application. A crystal rotates with an alpha angle and is recorded as (ZXw) alpha, wherein alpha is no less than 20 degrees below zero and no more than 45 degrees; and the dimensional proportion of the cut is shown that thickness:width:length=1:(2-3):(6-10). Platinum electrode is plated on an NdCa4O(BO3)3 crystal cut in the width direction with the electrode thickness of 200-220nm; and by adopting a mode of width shearing vibration, the temperature stability of a crystal resonant frequency is controlled to be 0-25ppm / DEG C within a range from 140 DEG C below zero to 200 DEG C. The invention solves the problems of lower electromechanical coupling coefficient (smaller than 8 percent) of quartz crystals as well as stable crystal frequency and narrower range of crystals of lithium tantalate, lanthanum galium silicate single and the like and is suitable for manufacturing a frequency controller used in a wide temperature range.

Owner:山东本源晶体科技有限公司

Rolled copper foil and manufacturing method of rolled copper foil

InactiveCN101481760AGood bending propertiesImprove bending characteristicsRoll mill control devicesMetal rolling arrangementsBeta angleX-ray

A rolled copper foil, according to the present invention, obtained after a final cold rolling step but before recrystallization annealing includes a group of crystal grains which exhibits four-fold symmetry in results obtained by X-ray diffraction (XRD) pole figure measurement with respect to a rolled surface. In the XRD pole figure measurement, at least four peaks of a {220}Cu plane diffraction of a copper crystal due to the group of crystal grains exhibiting the four-fold symmetry, which is obtained during beta axis scanning with an alpha angle set to 45 DEG , appear at intervals of 90 DEG +-5 DEG along the beta angle.

Owner:SH COPPER PROD CO LTD

Automatic gap adjusting arm of automobile brake and rotation angle control device thereof

The invention relates to an automatic gap adjusting arm of an automobile brake and a rotation angle control device thereof. A first through hole, a second through hole and a third through hole are formed in a shell, a turbine is installed in the first through hole, a first worm matched with the turbine is installed in the second through hole, the rotation angle control device is installed in the third through hole, and the rotation angle control device comprises a mandrel and further comprises a transmission gear, a pulling block, tension springs and a second worm which are sequentially connected to the mandrel in a sleeving manner; the left-handed tension spring is adopted as a one-way clutch, infinite equal dividing can be carried out in the circumferential direction, infinite adjustment can be carried out during work, the conditions that in the prior art, the rotation angle of an adjustment arm is greater than a set value alpha angle but cannot be large enough to drive a one-way ratchet tooth to be meshed to a next tooth, and compensation can only be made by other mechanisms slowly are avoided, quick adjustment to the set value alpha angle can be achieved, the problem of lag ofthe automatic adjustment function of the adjustment arm is avoided, and the driving safety is ensured; and the quantity of accessories is small, machining and manufacturing are simple, and the manufacturing cost is low.

Owner:BPW (MEIZHO) AXLE CO LTD

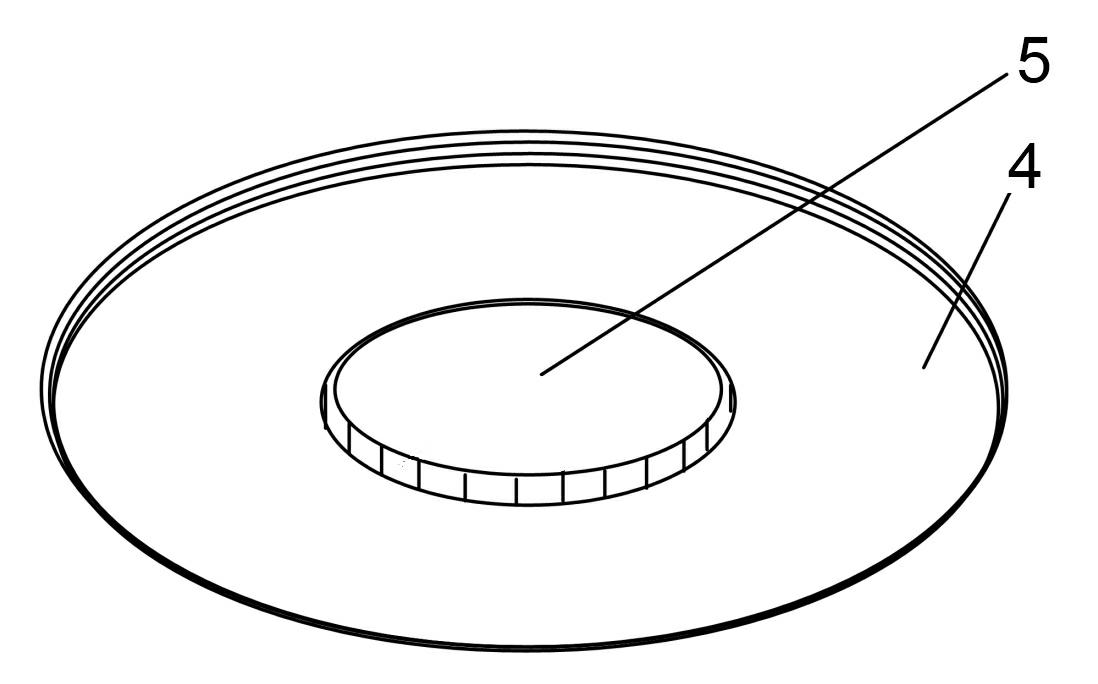

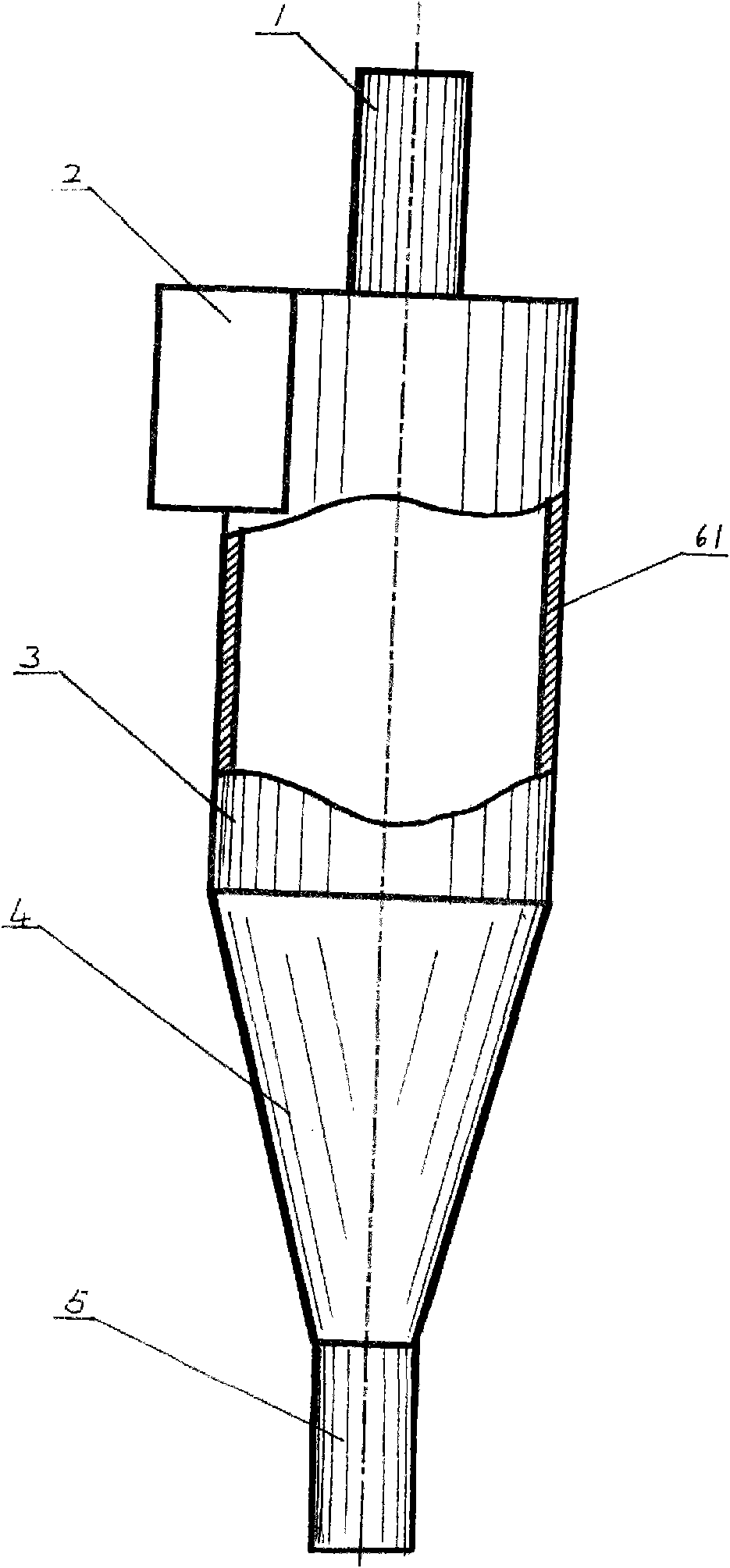

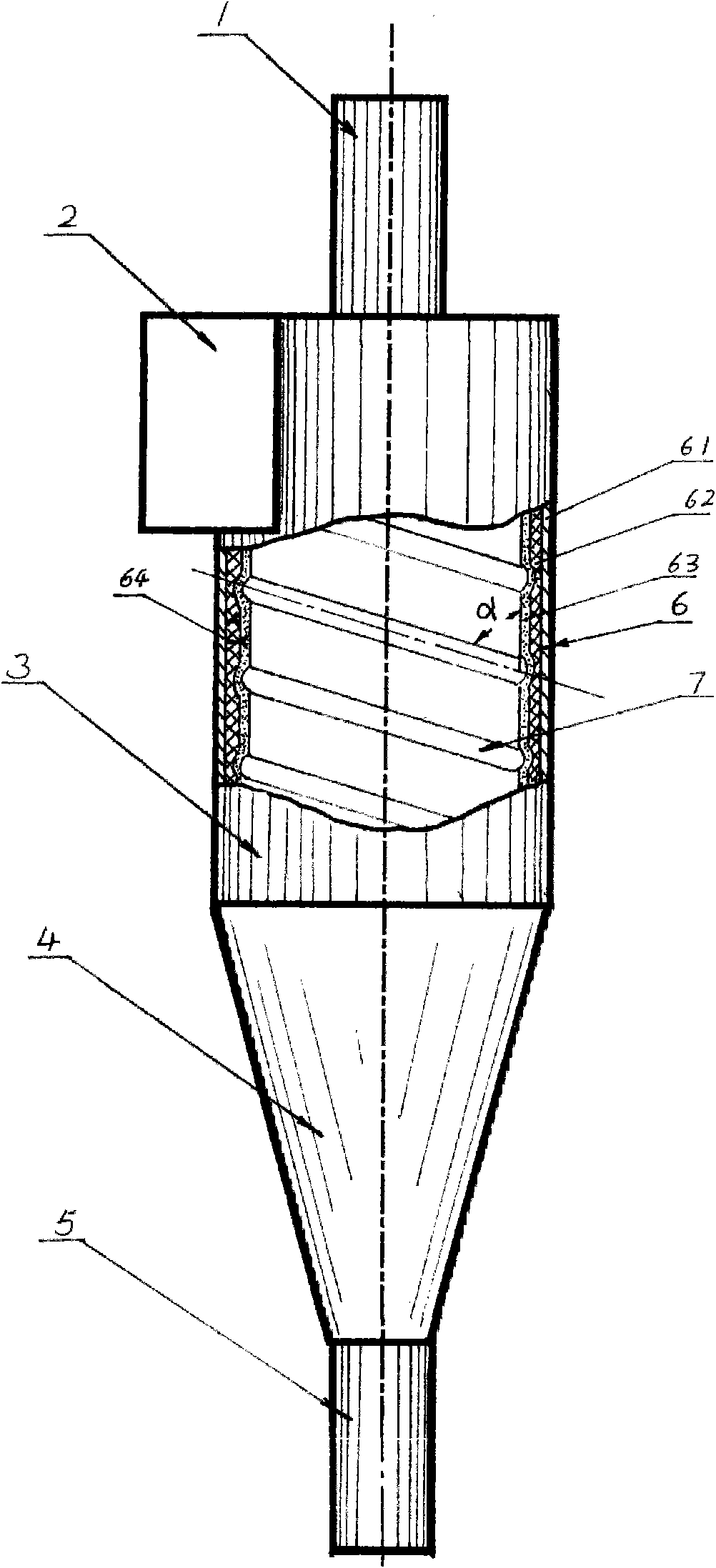

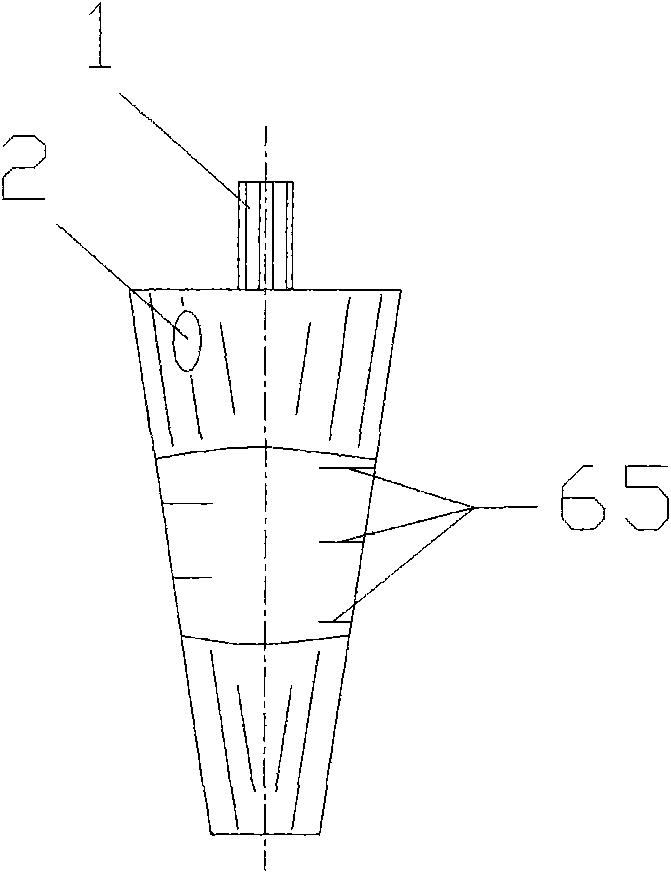

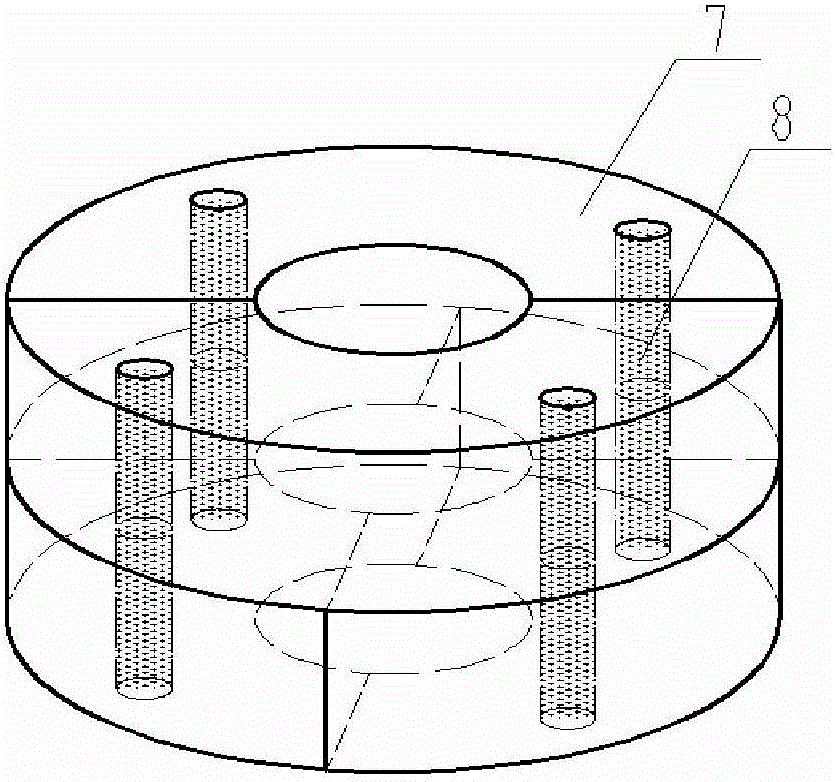

Cyclone separator with grooved wall surface

InactiveCN101898175AImprove separation efficiencyParticle cutting particle size reductionReversed direction vortexCycloneVolumetric Mass Density

The invention relates to a cyclone separator with a grooved wall surface for heterogeneous system separation, which mainly and sequentially comprises a riser (1), a system inlet (2), a cylinder body (3), a cone body (4) and a tail pipe (5) from top to bottom, wherein a groove channel (7) is arranged on an inner wall (6) according to a medium flowing direction with larger system density, the groove channel (7) forms an alpha angle with a fluid flowing direction, and the cross section of the groove channel (7) is in a semicircular shape, an arc shape, a triangular shape or other geometrical shapes. The invention has the advantages of simple structure, convenient construction and large operation elasticity, is easy to reform the original structure, can obviously reduce cutting grain diameter sizes and greatly increases heterogeneous separation efficiency.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

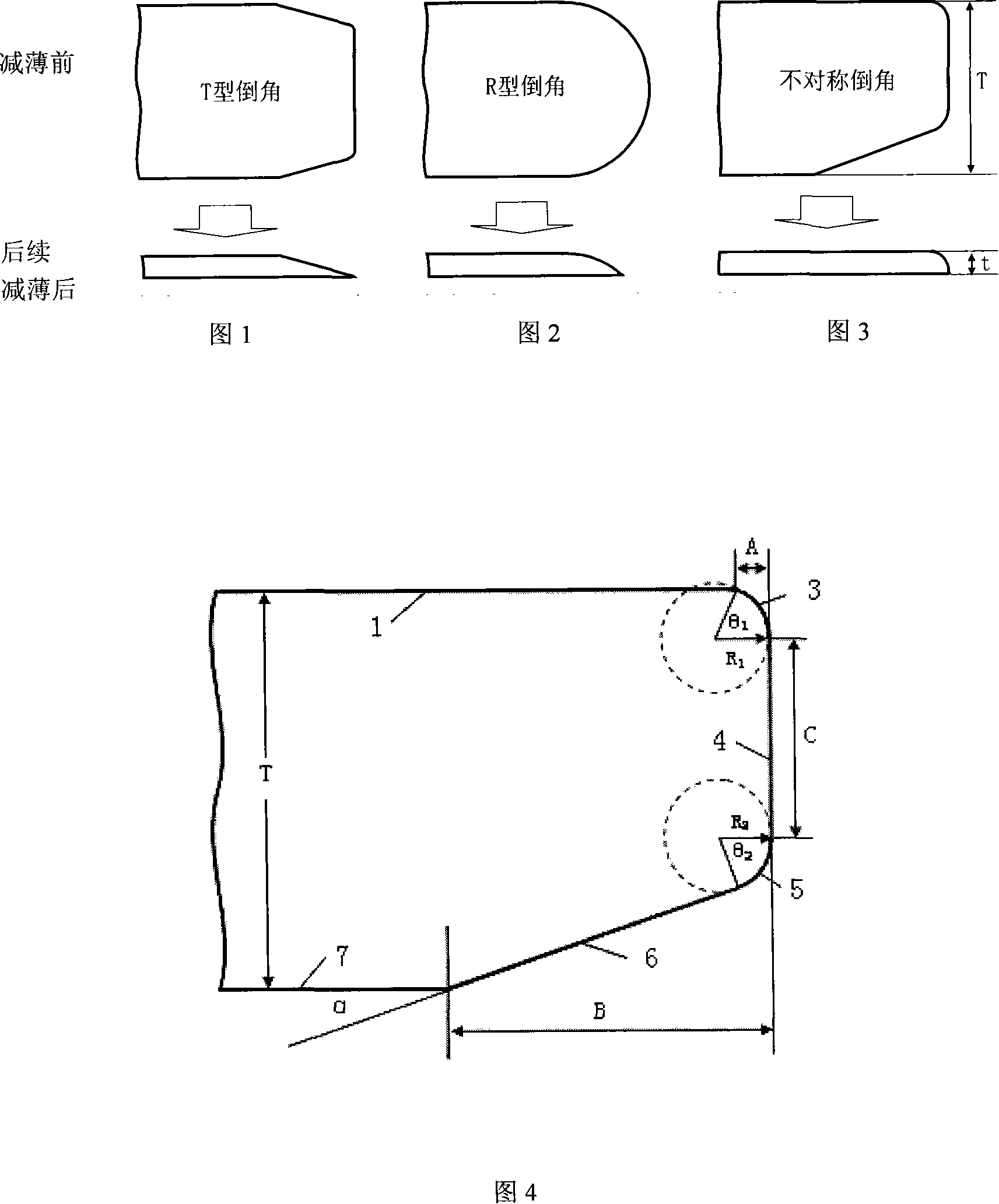

Silicon slice with asymmetry edge contour and manufacturing method thereof

ActiveCN101226904AReduce pollutionLess prone to edge damageSemiconductor/solid-state device detailsSolid-state devicesAcute angleSilicon chip

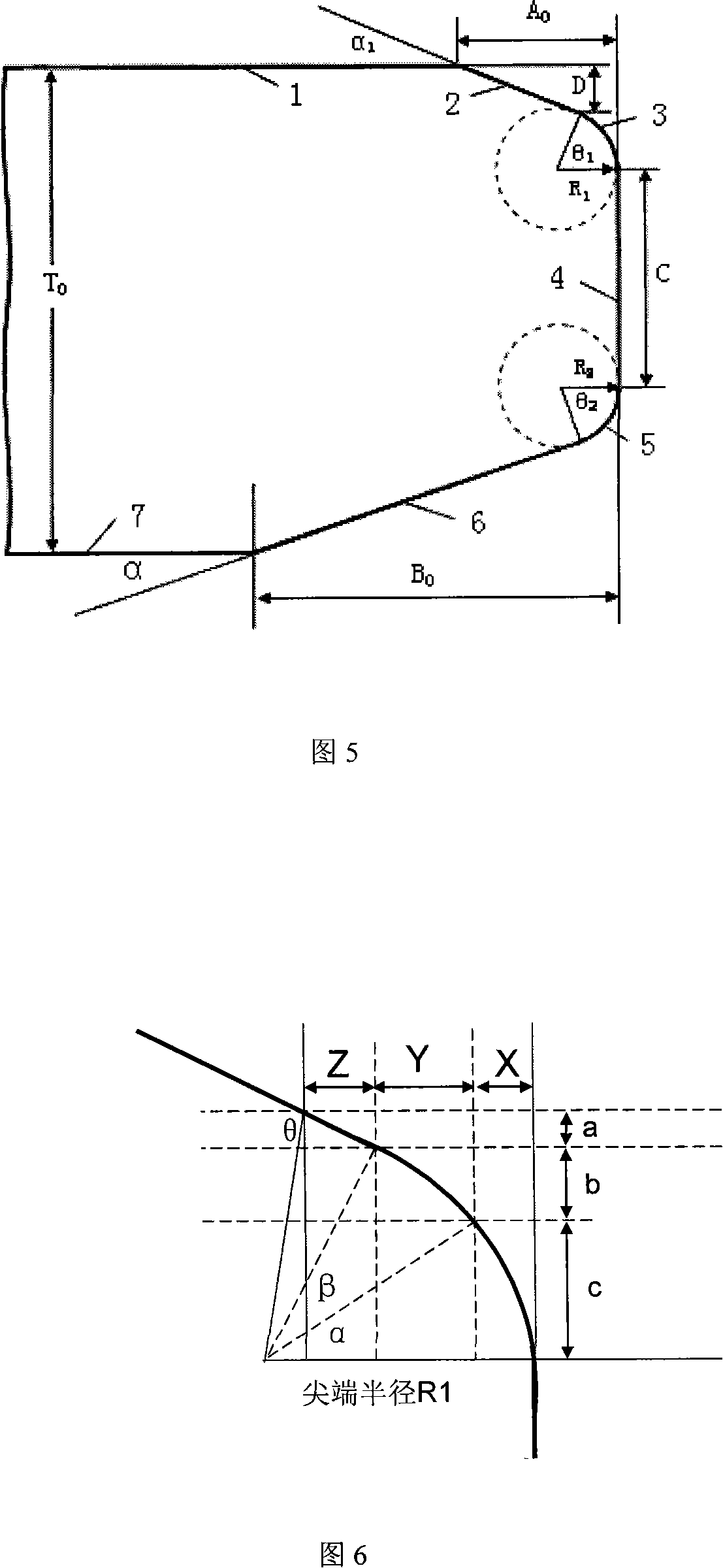

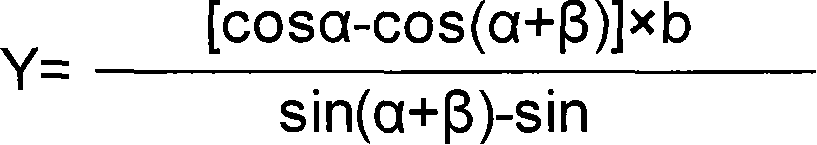

The invention relates to a silicon chip with asymmetry edge profile and a manufacturing method. The edge profile of the silicon chip comprises a profile from the upper surface of the silicon chip to the lower surface of the silicon chip via twisting the front end surface of the silicon chip. The front end surface of the silicon chip is a straight line, the transitional edge profile between the upper surface of the silicon chip and the front end surface of the silicon chip is a passage of circular arc EP1, the circular arc EP1 is tangent with the front end surface of the silicon chip and is intersecting with the upper surface of the silicon chip. The transitional edge profile between the lower surface of the silicon chip and the front end surface of the silicon chip are a long sloping side and a passage of circular arc EP2, the long sloping side and the lower surface of the silicon chip are with alpha angle, the circular arc EP2 is respectively tangent with the long sloping side and the front end surface of the silicon chip. The steps of the manufacturing method of the silicon chip comprise cutting film, chamfering hob and reserving polishing surplus on the upper surface, grinding the upper and lower surface, conducting etching treatment and polishing the upper surface to remove the reserved polishing surplus. After thinning process in the next phase, the edge of the silicon chip does not form an acute angle, the probability of damaging the edge is reduced and the percent of pass of the finished product is increased.

Owner:宁夏中欣晶圆半导体科技有限公司

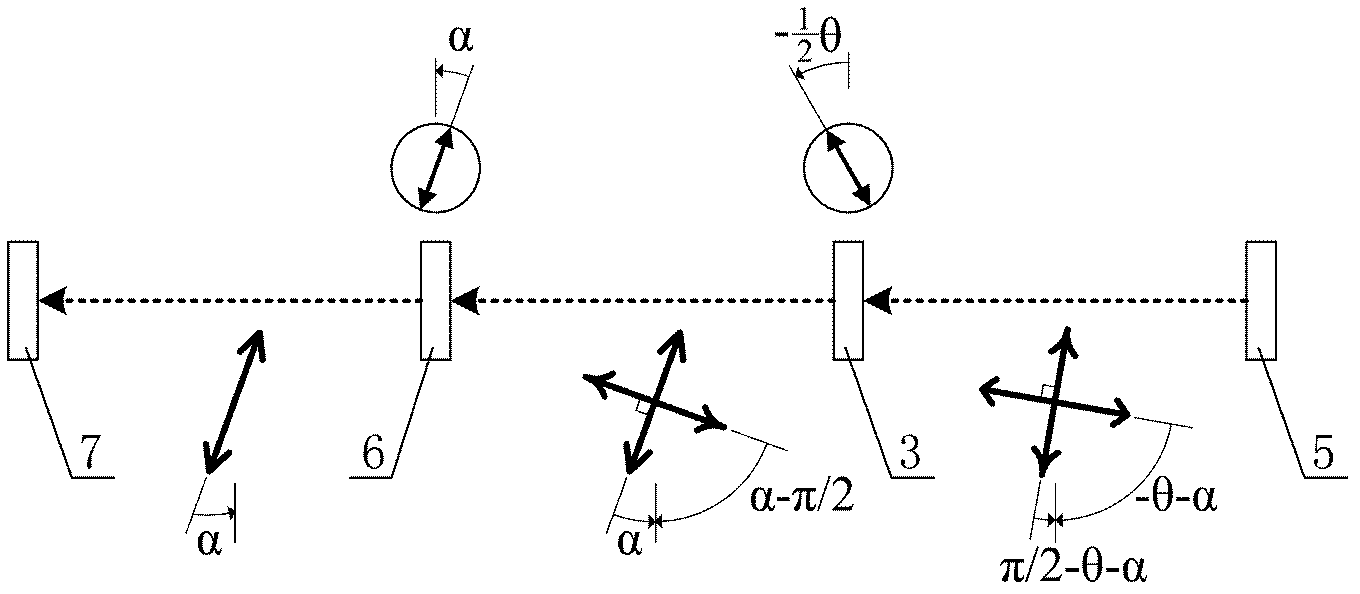

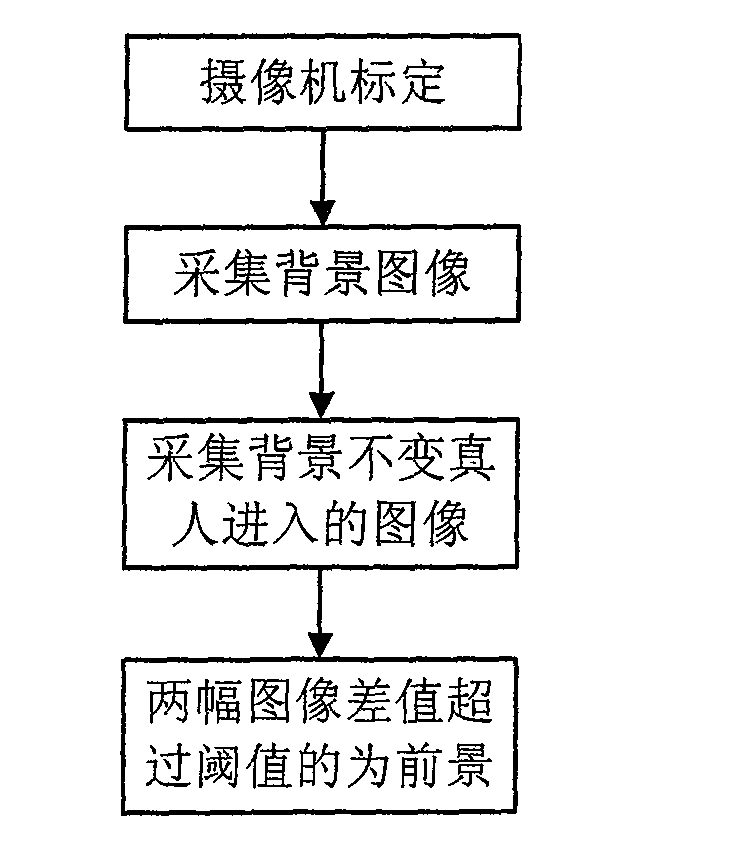

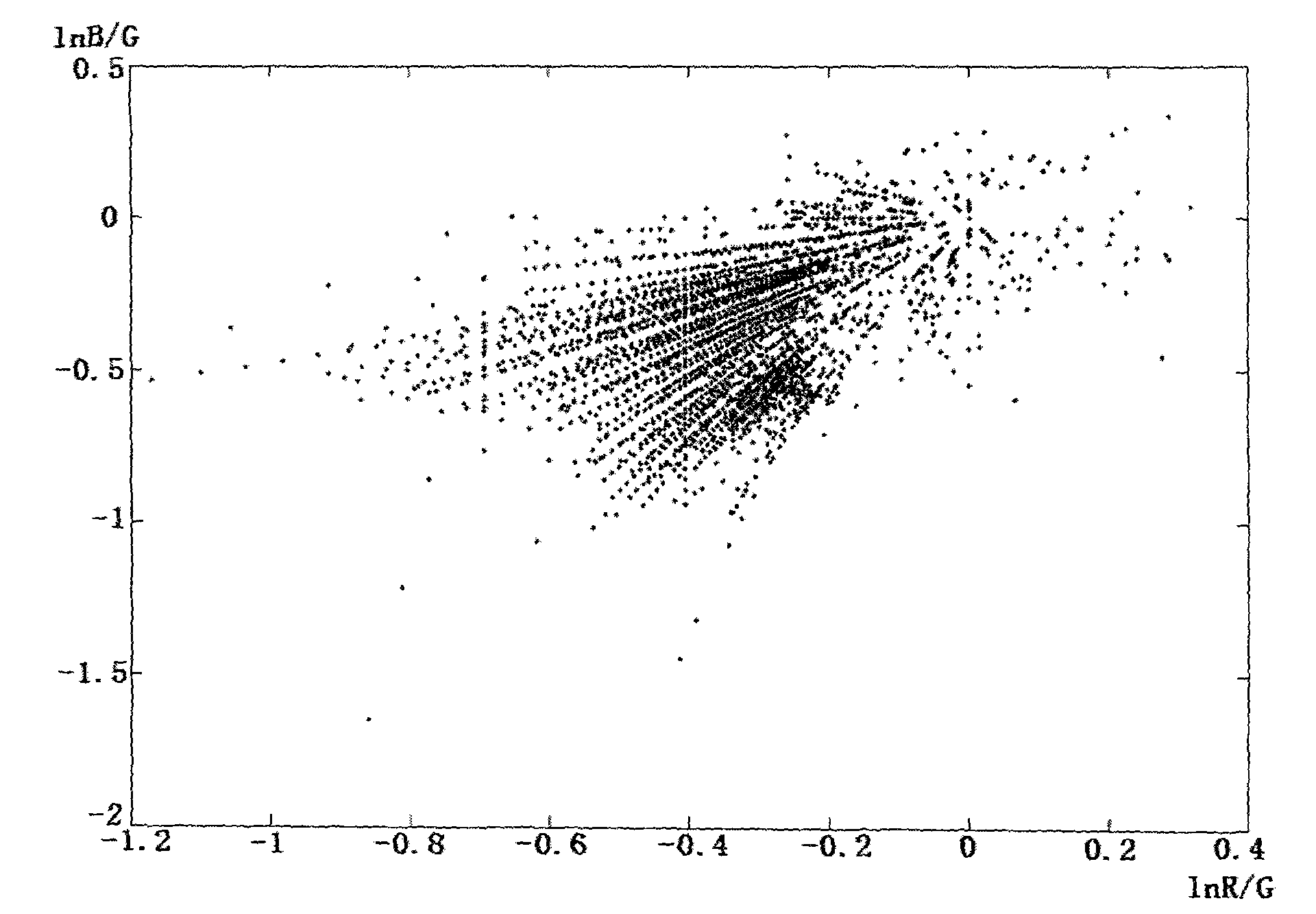

Calibration method for extracting illumination-insensitive information from visible images

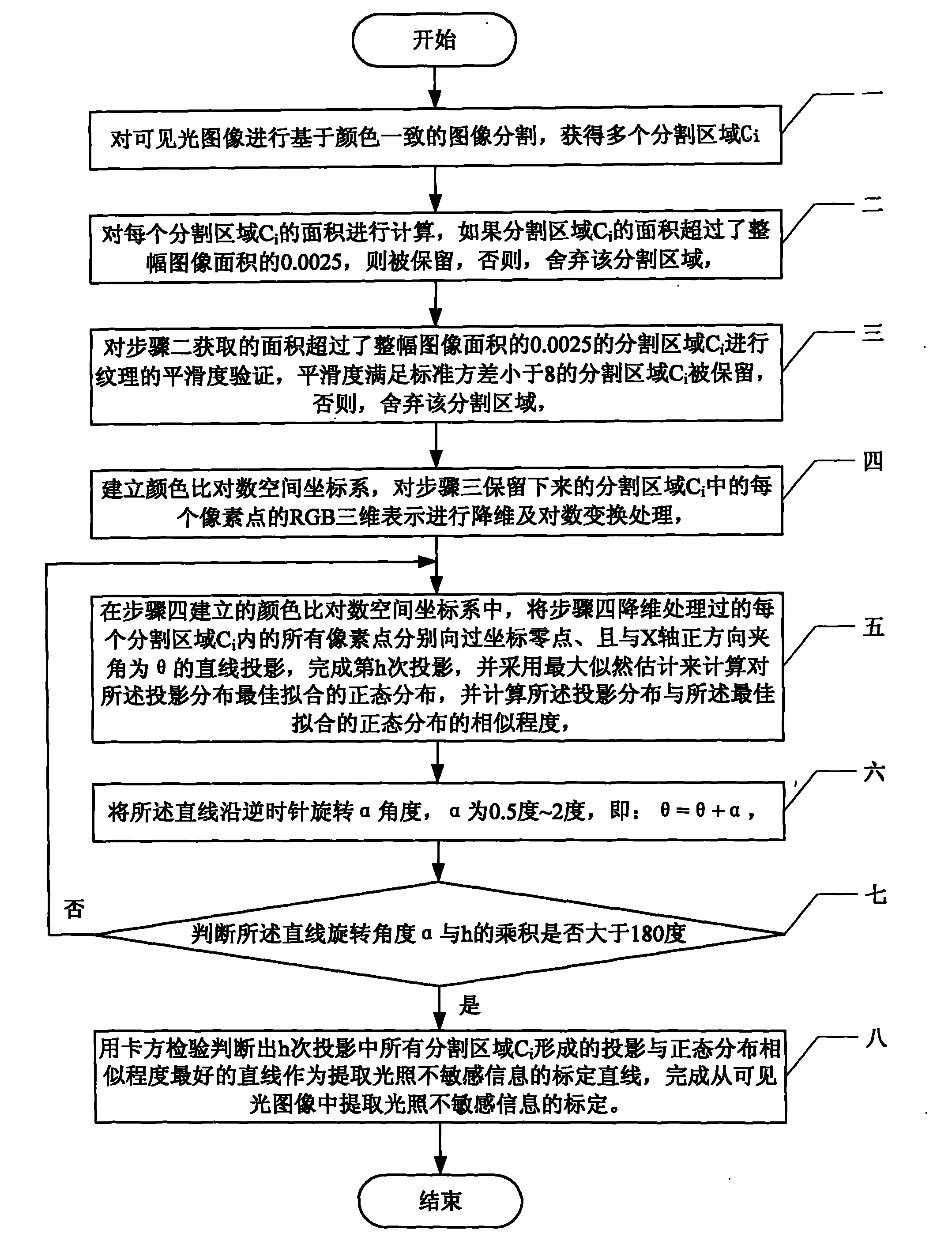

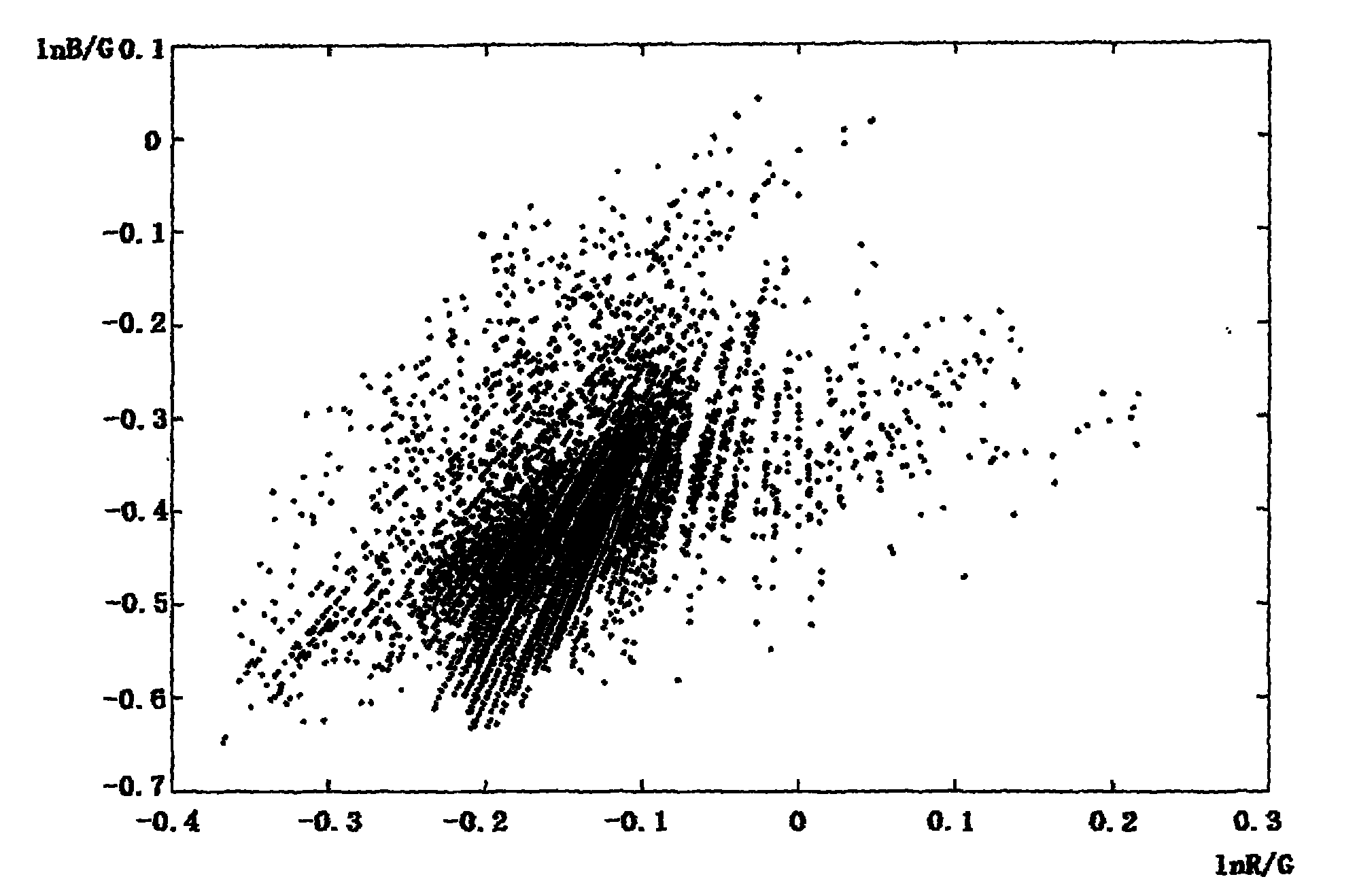

A calibration method for extracting illumination-insensitive information from visible images belongs to the image processing field. The invention aims to solve the problem that online calibration based on single image is not stable enough when gray information with constant one-dimensional illumination is extracted to calibrate the light sensation components of the camera. The method comprises the following steps: 1. segmenting the visible images based on color consistency; 2. keeping the zones with area in excess of 0.0025 of the area of the whole image; 3. keeping the zones with good smoothness; 4. establishing a space coordinate system of color matching numbers; 5. carrying out projection to the straight line which passes through the zero point of the coordinate and forms an included angle theta with the forward direction of the X axis, calculating normal distribution through best fit by adopting maximum likelihood estimation and calculating the similarity degree; 6. rotating alpha angle; 7. judging whether the product of alpha and h is more than 180 degrees, if so, carrying out the step 8, if not, carrying out the step 5; and 8. deciding the straight line with the best similarity degree as the calibration straight line for extracting the illumination-insensitive information through chi-square test.

Owner:HARBIN INST OF TECH

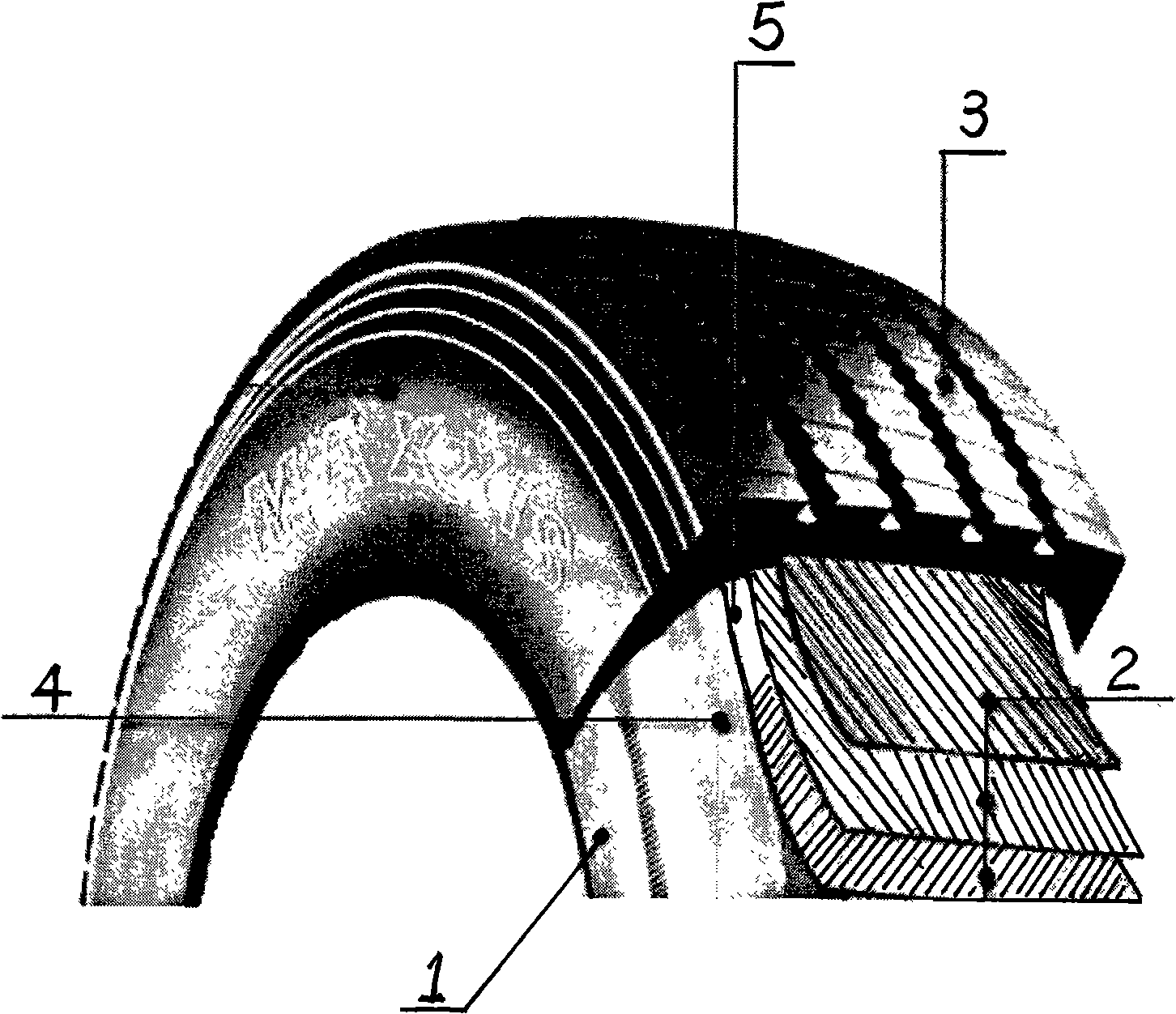

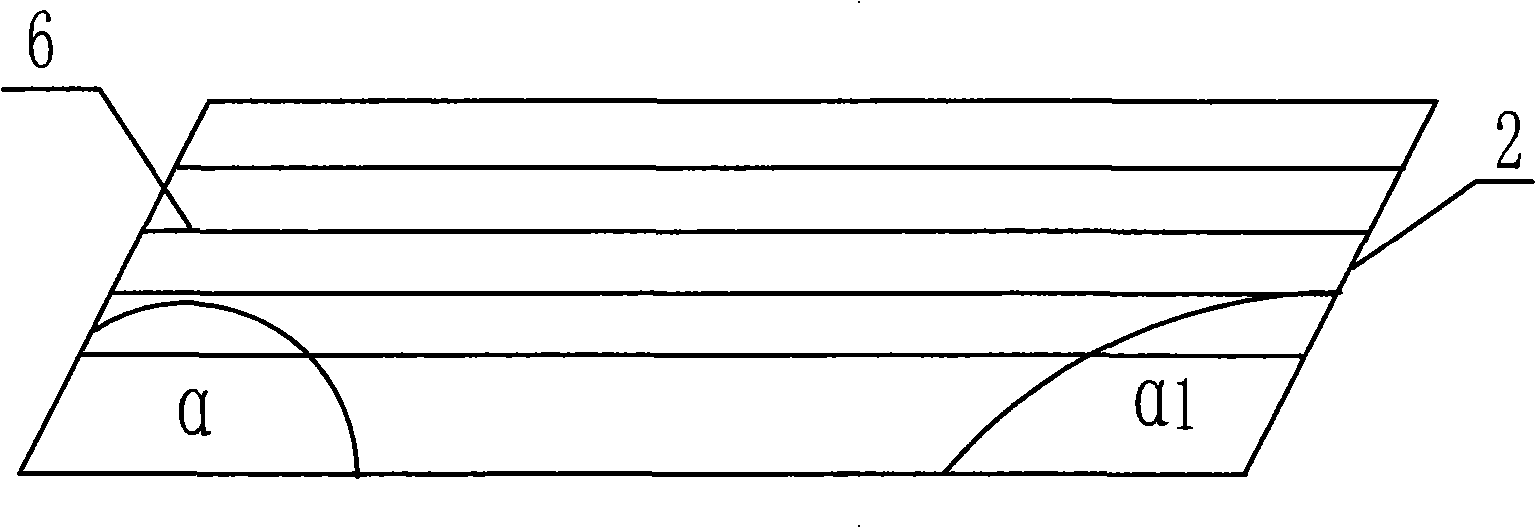

Renewing preparation method for radial tire steel wire cord layer fracture

The invention relates to the repair of a tire, in particular to a method for retreading and preparing the broken retread of the steel cord layer of a radial ply tire, which is characterized in that: recombination is carried out to carcass compound 4 is brushed on the polished coarse and cottony pitting surface of the tire body 1 in the first step; heads and ends of an Alpha angle and Alpha 1 of the first steel cord layer 2 are connected with each other to complete a bonding of the steel cord layer 2; the steel cord layer 2 is pressed layer by layer; each two steel cord layers 2 are bonded with each other by middle glue 3. The method has the advantages of simple operation, low cost, waste utilization and energy saving, can raise the utilization rate of the used tire by from 10 percent to above 20 percent, raise the service life of the retread from original 70 percent of the new tire to above 90 percent and save the energy consumption by 30 percent and the utilized materials are only 20 to 30 percent of the new tire. The cost is not increased on the basis of the original retread. The price for using the retread can be saved by above 50 percent compared with the price of the new tire.

Owner:惠树良

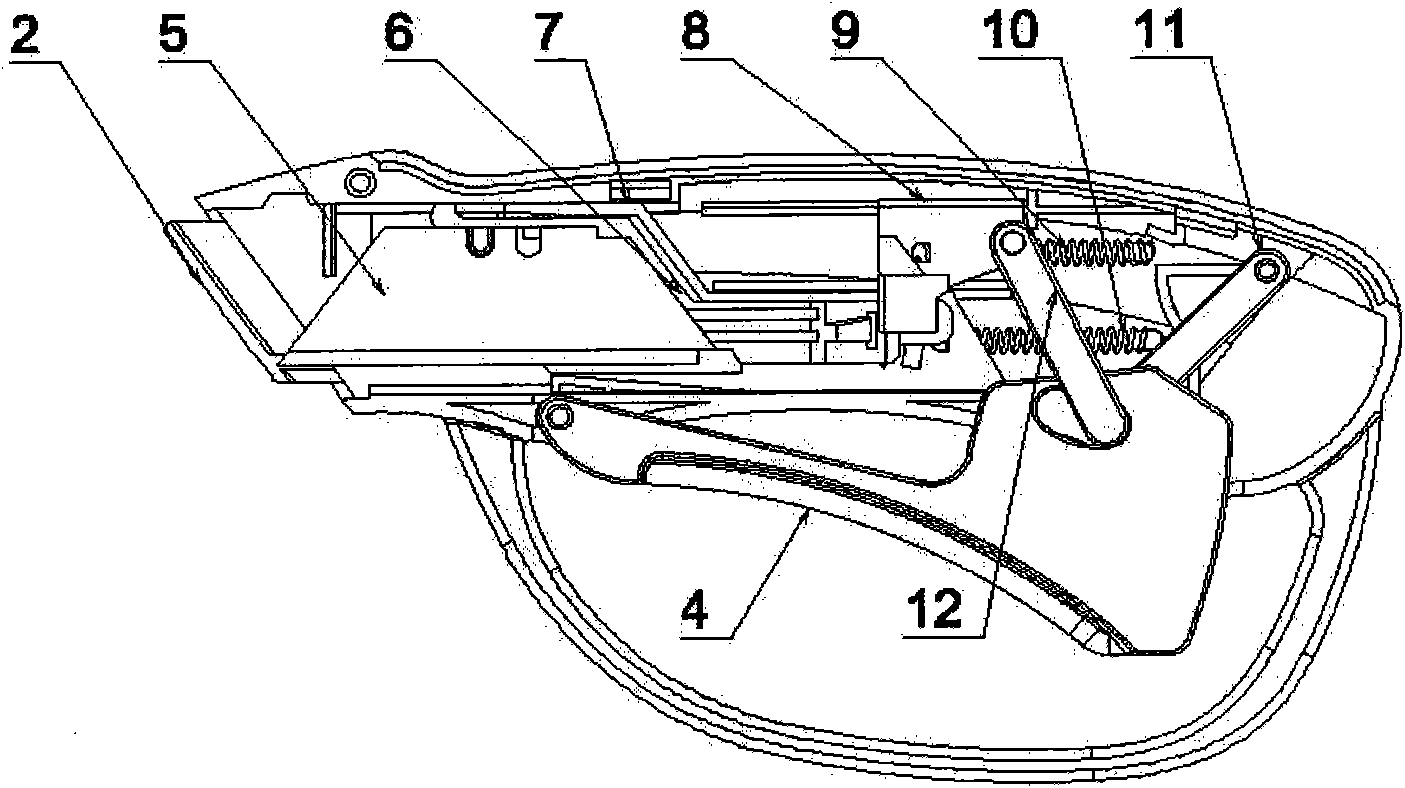

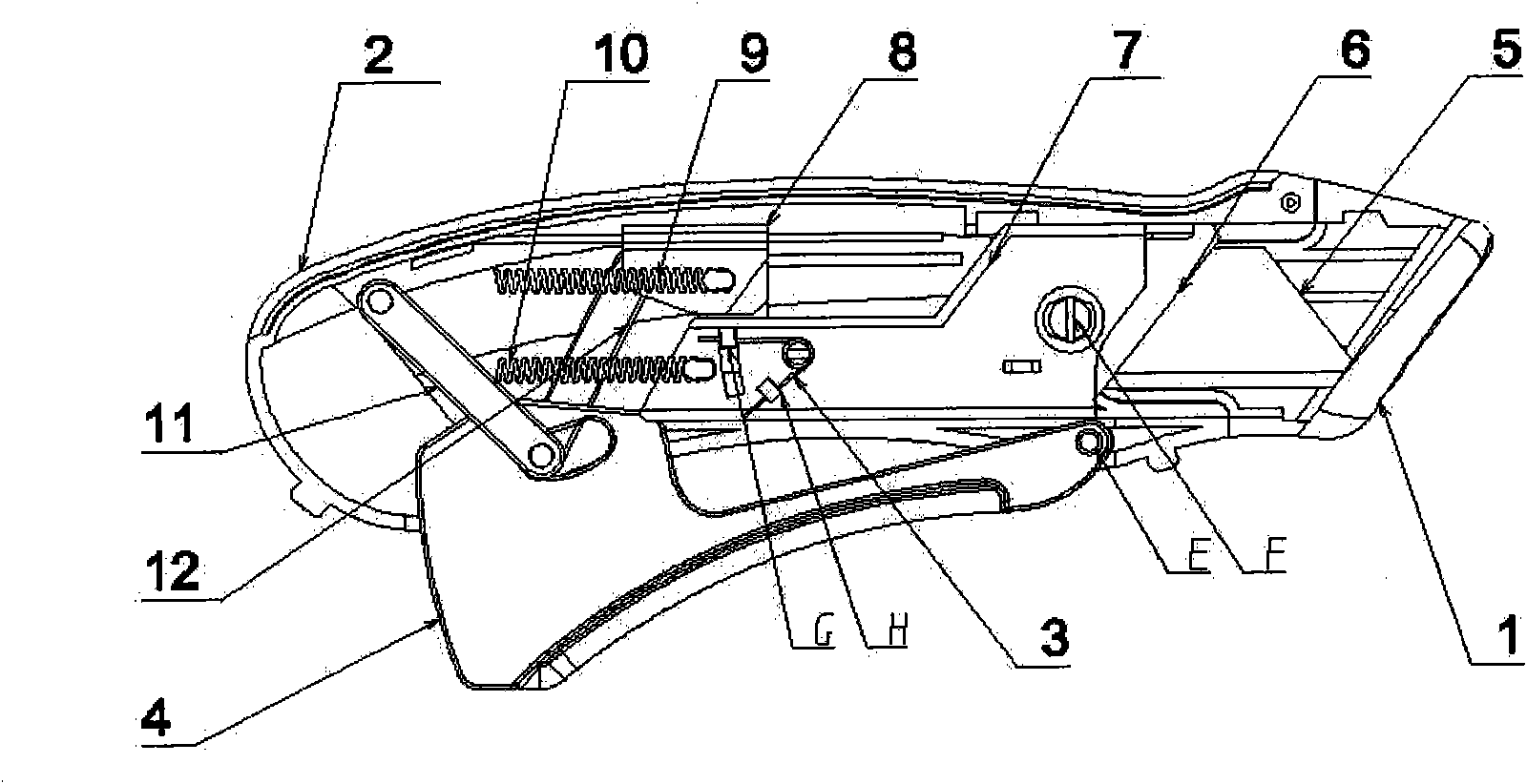

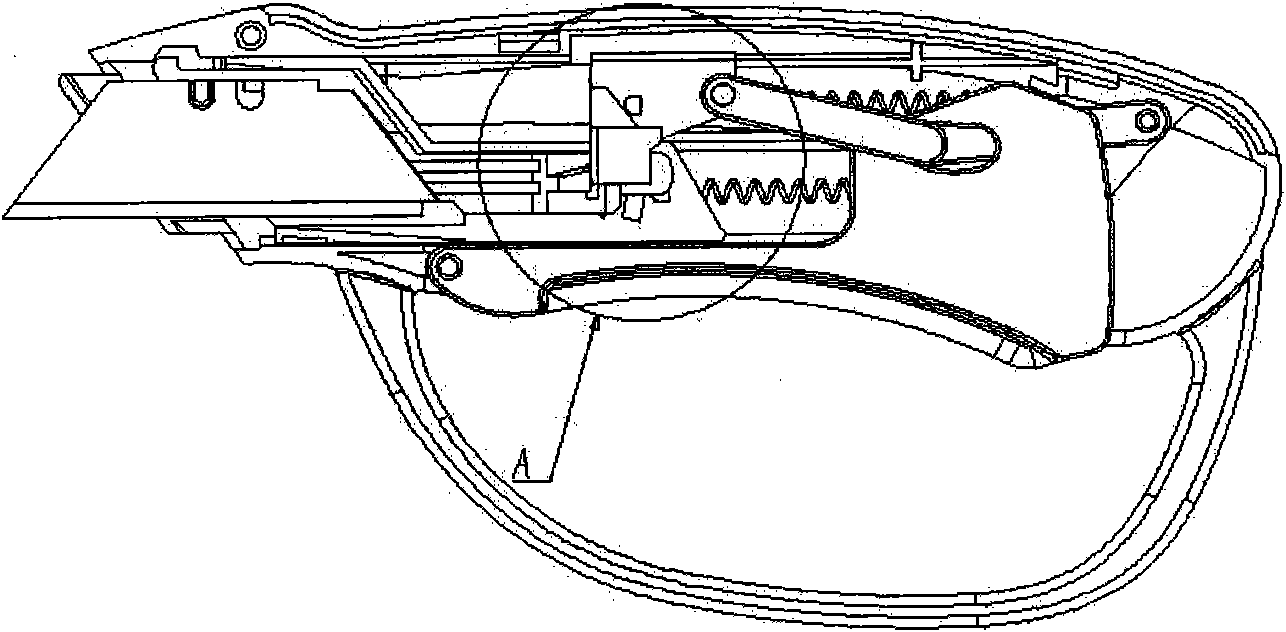

Safety cutter

InactiveCN101885183ACause some damagesRealize the cutting functionMetal working apparatusKnife bladesSupport point

The invention belongs to the technical filed of tools, which relates to a safety cutter and is characterized in that two ends of a tension spring 1 in a cutter shell cavity are respectively connected with a shell and a slide fastener; two ends of a tension spring 2 are respectively connected with the shell and a slide rest; one end of a trigger is connected with the shell through a supporting point E; one end of a connection rod 2 is connected with the slide fastener, and the other end is connected with one end of a connection rod 1 through a round hole above the trigger; the other end of the connection rod 1 is connected with the shell; the slide rest is connected with a cylindrical embossment F on a rotary tool rest in a button placement mode and can rotate for an alpha angle around the cylindrical embossment F; two ends of a torsional spring are respectively connected with a salient point G of the rotary tool rest and a salient point H of the slide rest; and the slide fastener is connected with the slide rest in a slide mode, and can be jointed or separated with the abutting side of the rotary rest. The invention has the beneficial effect that a blade can automatically stretch out under the driving of the squeezed trigger, realize the cutting function, and is convenient to use; and when the cutting operation ends, the blade can automatically retract into the shell at once even the trigger is not loosened, thereby having no potential safety hazard.

Owner:MERIDIAN INT

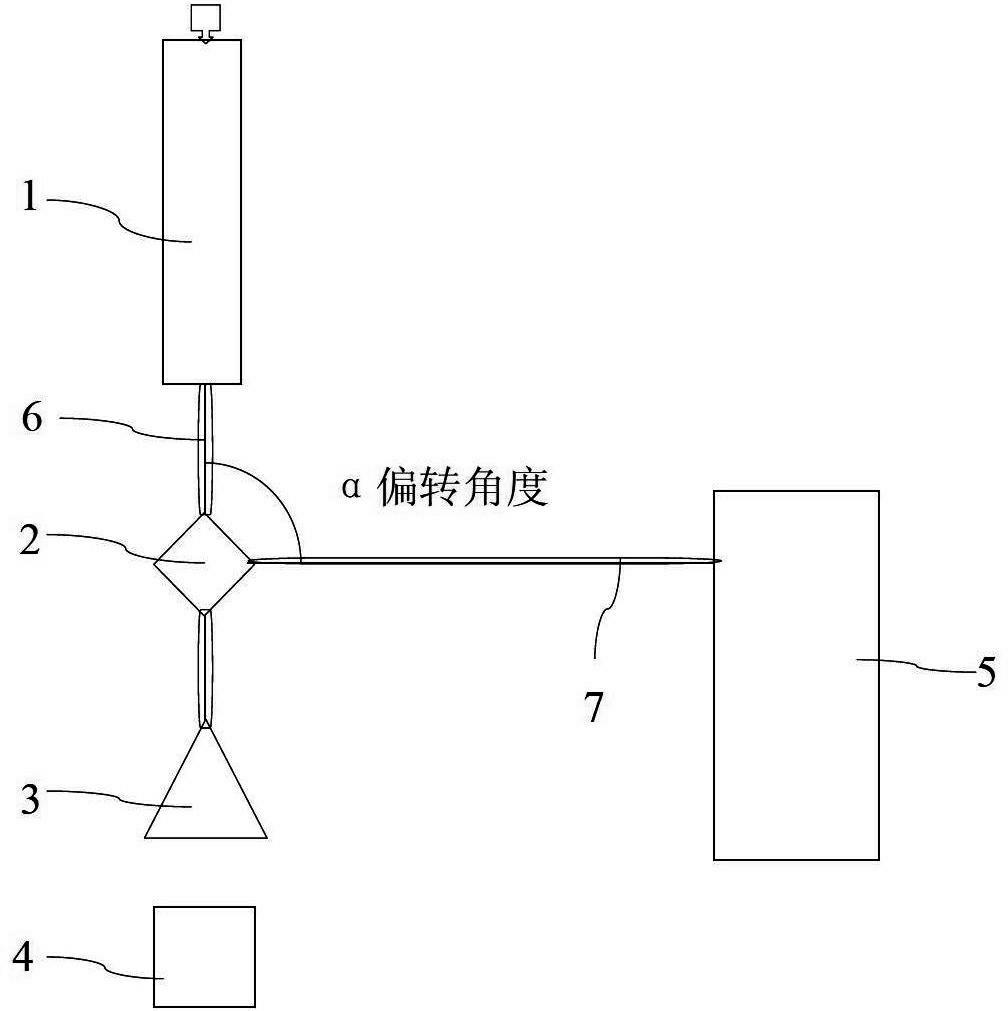

Electron linear accelerator having dual purposes and dual-purpose method of electron linear accelerator

InactiveCN102647849ASolve the conflicting problem of beam spot size requirementsRealize "one machine with two uses"Linear acceleratorsX-rayDual purpose

Disclosed is an electron linear accelerator having dual purposes and a dual-purpose method of the electron linear accelerator. The electron linear accelerator comprises an accelerating tube, a scanning box, an industrial computed tomography (CT) and a beam deflection system, wherein the beam deflection system comprises a front quadrupole magnet, a deflection magnet, a rear quadrupole magnet and a scanning magnet; the front quadrupole magnet is arranged behind the accelerating tube, the deflection magnet is arranged behind the front quadrupole magnet, and the rear quadrupole magnet and the scanning magnet are arranged behind the deflection magnet; the industrial CT is arranged behind the rear quadrupole magnet and the scanning box is arranged behind the scanning magnet; and the deflection magnet is controlled to be opened or closed, and electronic beam current is selected for moving forwards in a linear mode or for deflecting at an alpha angle, so that the electronic beam current selectively enters the scanning box or the industrial CT. The electron linear accelerator having dual purposes and the dual-purpose method of the electron linear accelerator solve the problem that the requirements of dual purposes on electron beam spot sizes are contradictory. Under the condition that all performances meet the requirements, the cost is reduced. The electron linear accelerator having dual purposes and the dual-purpose method of the electron linear accelerator not only perform electron beam irradiation by using different energy but also generate X rays with different energy, and perform CT imaging.

Owner:HARBIN ENG UNIV

Non-shielding fracture reduction forceps

InactiveCN105011992APrevent slippageRealize the purpose of reset without occlusionSurgical forcepsFracture reductionForceps

The invention discloses non-shielding fracture reduction forceps. The non-shielding fracture reduction forceps comprise a right forceps piece (1) and a left forceps piece (2) hinged to the right forceps piece (2) through a pin (3). A left clamping arm is formed at the front end of the right forceps piece (1), and a right handle is formed at the rear end of the right forceps piece (1). A right clamping arm is formed at the front end of the left forceps piece (2), and a left handle is formed at the rear end of the left forceps piece (2). The non-shielding fracture reduction forceps are characterized in that the left clamping arm is divided into a left bent arm (5) and a left clamping section (10), the left bent arm (5) is bent continuously in the horizontal direction to form an arc shape and is bent continuously by an alpha angle in the perpendicular direction; the right clamping arm is divided into a right bent arm (4) and a right clamping section (11), the right bent arm (4) is bent continuously in the horizontal direction to form an arc shape and is bent continuously by an alpha angle in the perpendicular direction; an operation cavity (12) is formed between the left clamping arm and the right clamping arm; the inner side of the left clamping section (10) and the inner side of the right clamping section (11) are each one third of a circular arc face, a clamping cavity (13) is formed between the left clamping section (10) and the right clamping section (11), and the longitudinal section of the clamping cavity (13) is two thirds of the circular arc shape.

Owner:陈志力

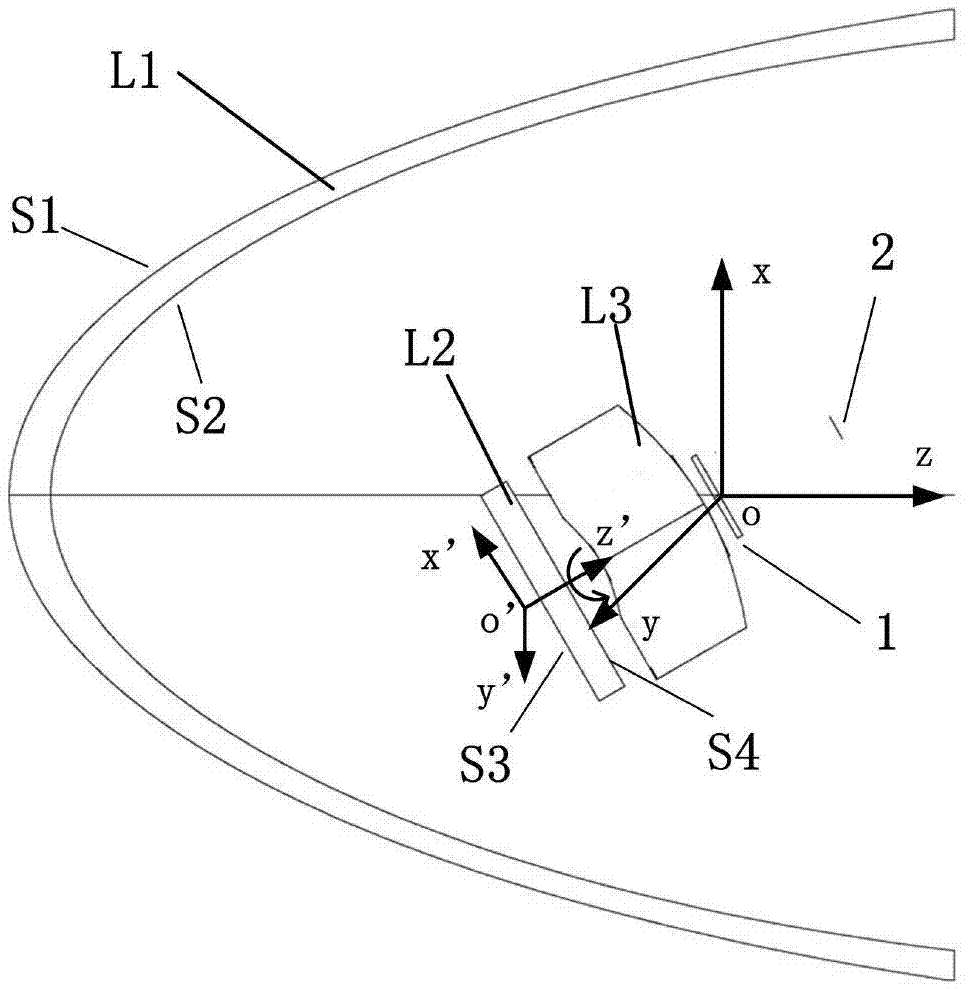

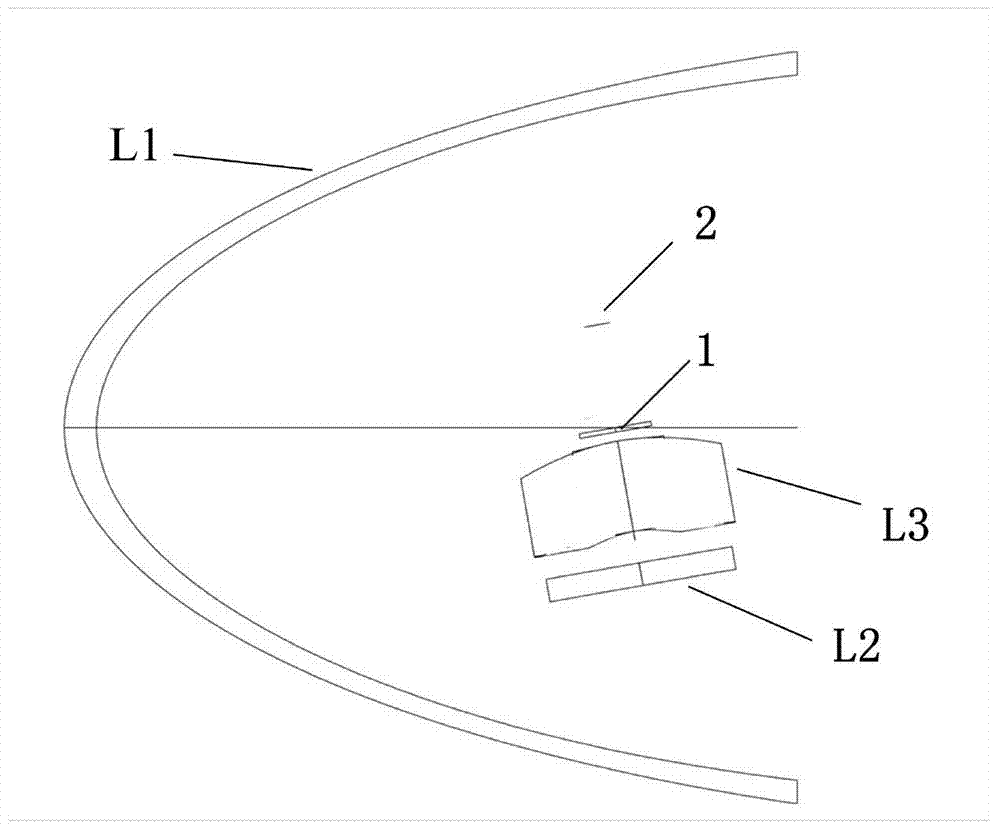

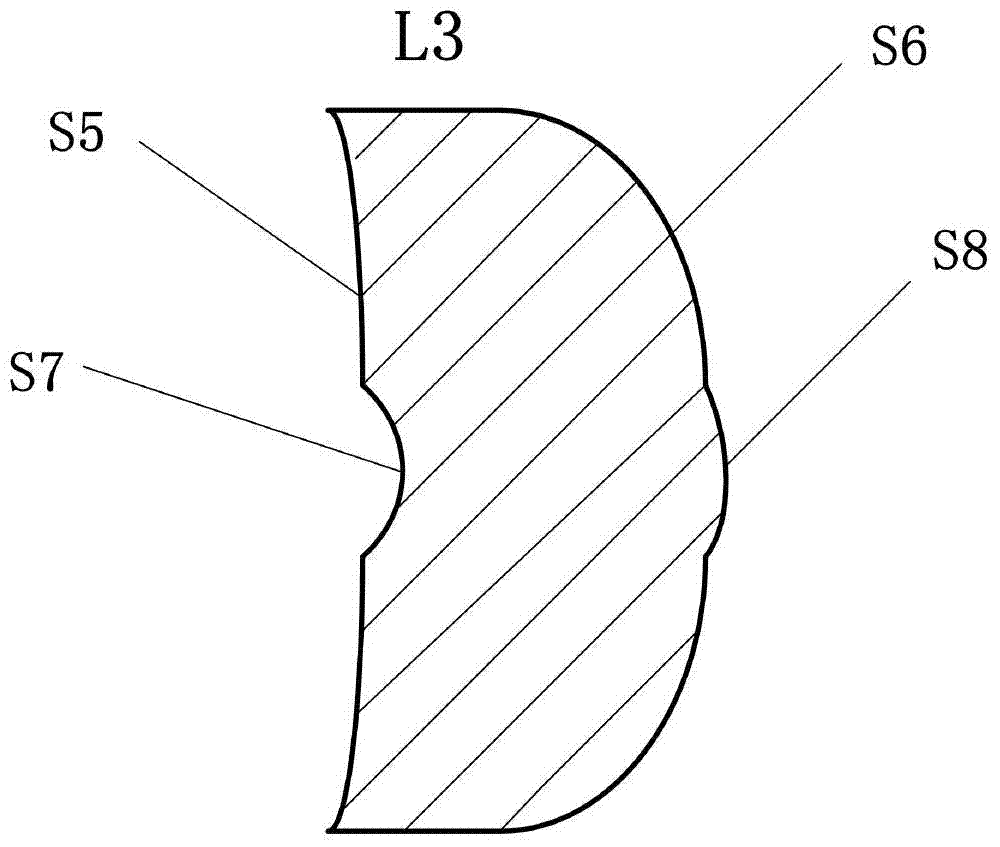

Compact large-framework-angle conformal optical system

The invention provides a compact large-framework-angle conformal optical system. After light passes through a rectifying cover and reaches a cylindrical-surface correcting lens, the phase position of the light can be corrected through the cylindrical-surface correcting lens, the light passing through the cylindrical-surface correcting lens is emitted out through an imaging lens set, and the light emitted out through the imaging lens set is subjected to eco-planar imaging on a detector after passing through a diaphragm; the cylindrical-surface correcting lens, the imaging lens set and the diaphragm rotate around a rotating center of an optical axis of the rectifying cover, an alpha angle is formed between the cylindrical-surface correcting lens and the z axis, as well as between the imaging lens set and the z axis, and between the diaphragm rotate and the z axis, meanwhile, the cylindrical-surface correcting lens rotates around the optical axis z' of itself, the rotating angle in the clockwise direction is beta, beta=f(alpha), and when different target view fields are imaged through the optical system and the optical system respectively rotates at the angle of alpha and at the angle of beta, complete imaging of objects in the target view fields is achieved. The requirement for performing detection and tracking objectives within the range of a large framework angle (>=100 degrees) can be met by the system, and the optical system can be extensively used.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Riddling machine system

A riddling machine for making champagne is proposed, comprising: a base, main motor, main shaft driven by the motor, pivotal parallel frames each fixed to a first half- axle and a second hollow half-axle revolvably mounted, and an inner shaft enclosed into the second half-axle, bevel gears including a driving wheel coupled to the inner shaft, and a driven wheel rotatably mounted on the frame furnished with bottle holders and controllably rotatable within an ALPHA angle range and with means revolving the holders driven by the driven wheel, a first gear means for conveying rotation from the main shaft to the inner shafts, an intermediate shaft controllably engaged / disengaged with the main shaft, and connected through a braking muff to an intermediate axle, and a second gear means for providing a controllable tilt angle BETA of the frames driven via the intermediate axle,; and conveying rotation to the first half-axles of frames.

Owner:艾尔・塞恩特

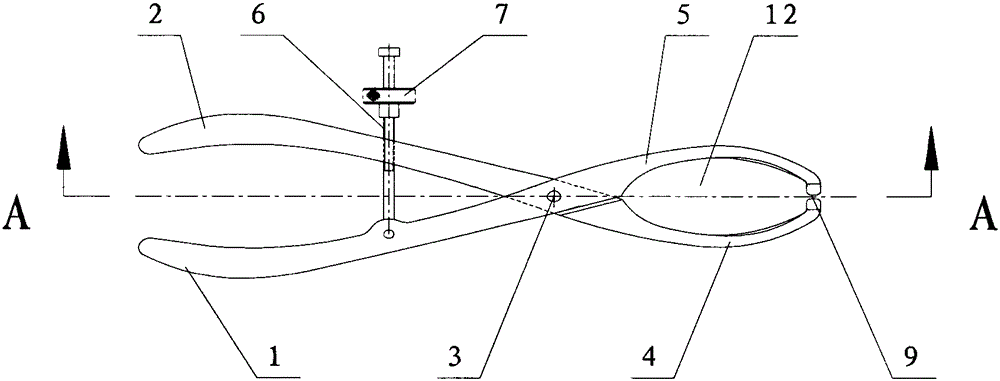

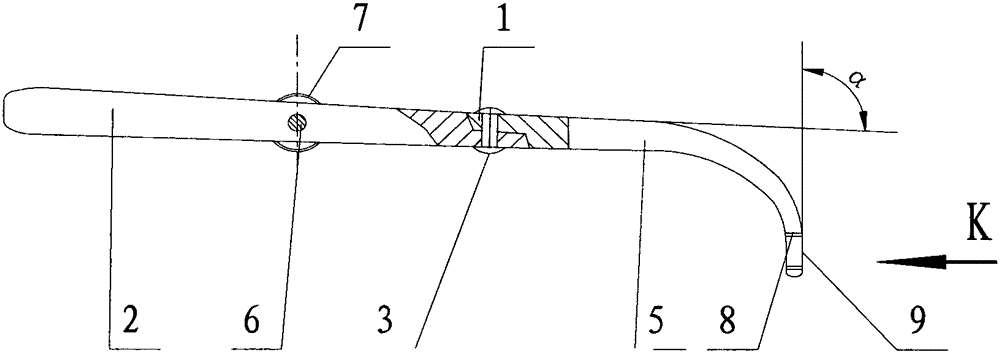

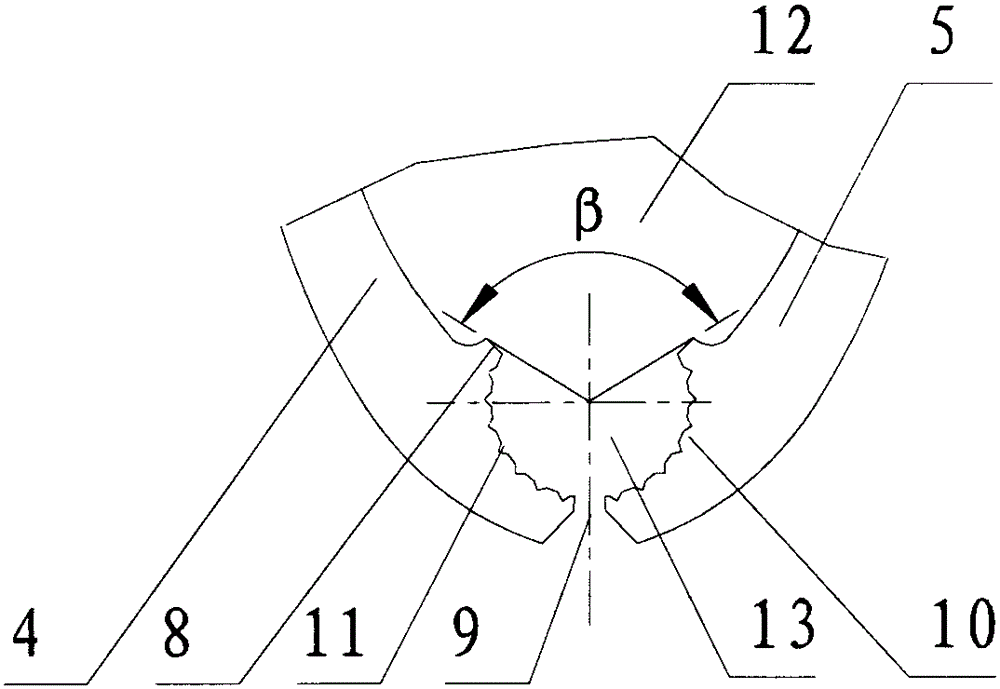

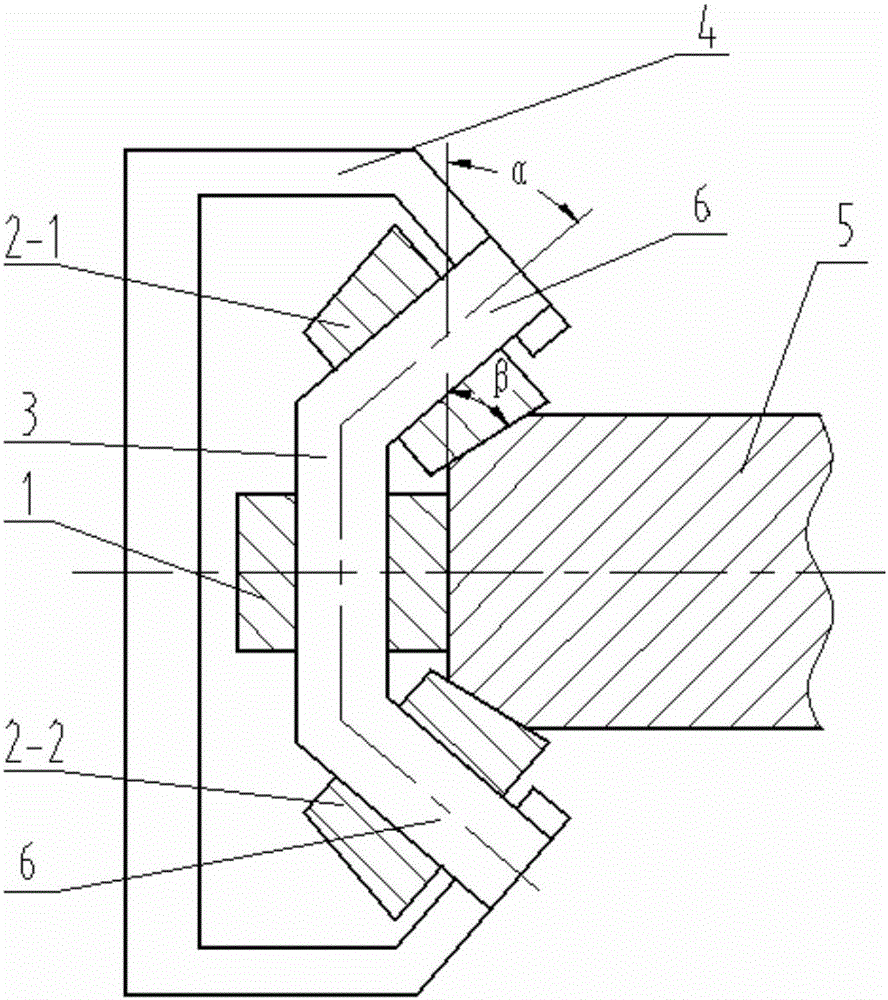

Integrated-shaft and three-roller corner rolling device for continuous casting billet corner rolling

The invention relates to the field of metal solidification and continuous casting, in particular to an integrated-shaft and three-roller corner rolling device for continuous casting billet corner rolling. The device comprises a middle positioning roller (1), an upper chamfer roller (2-1), a lower chamfer roller (2-2), a roller shaft and a roller supporting frame (4); the roller shaft comprises a middle roller shaft section (3) and chamfer roller shaft sections (6) at the two ends; the chamfer roller shaft sections (6) and the middle roller shaft section (3) are arranged in an alpha angle manner; the middle positioning roller (1) is mounted on the middle roller shaft section (3); the upper chamfer roller (2-1) and the lower chamfer roller (2-2) are respectively mounted on the chamfer roller shaft sections (6); the chamfer roller shaft sections (6) are connected with the roller supporting frame (4); the alpha angle is 0-45 degrees; a roller surface slant angle beta of each chamfer roller is 30-70 degrees; and the alpha angle is less than or equal to the beta angle. The device effectively avoids the defects of shear cracks arising from shear rolling, an optimized casting billet corner chamfer shape can be obtained, and split or surface upwarping of the edge of a plate is eliminated.

Owner:ZHONG NAT ENG & RES CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com