Patents

Literature

61results about How to "Stable furnace temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

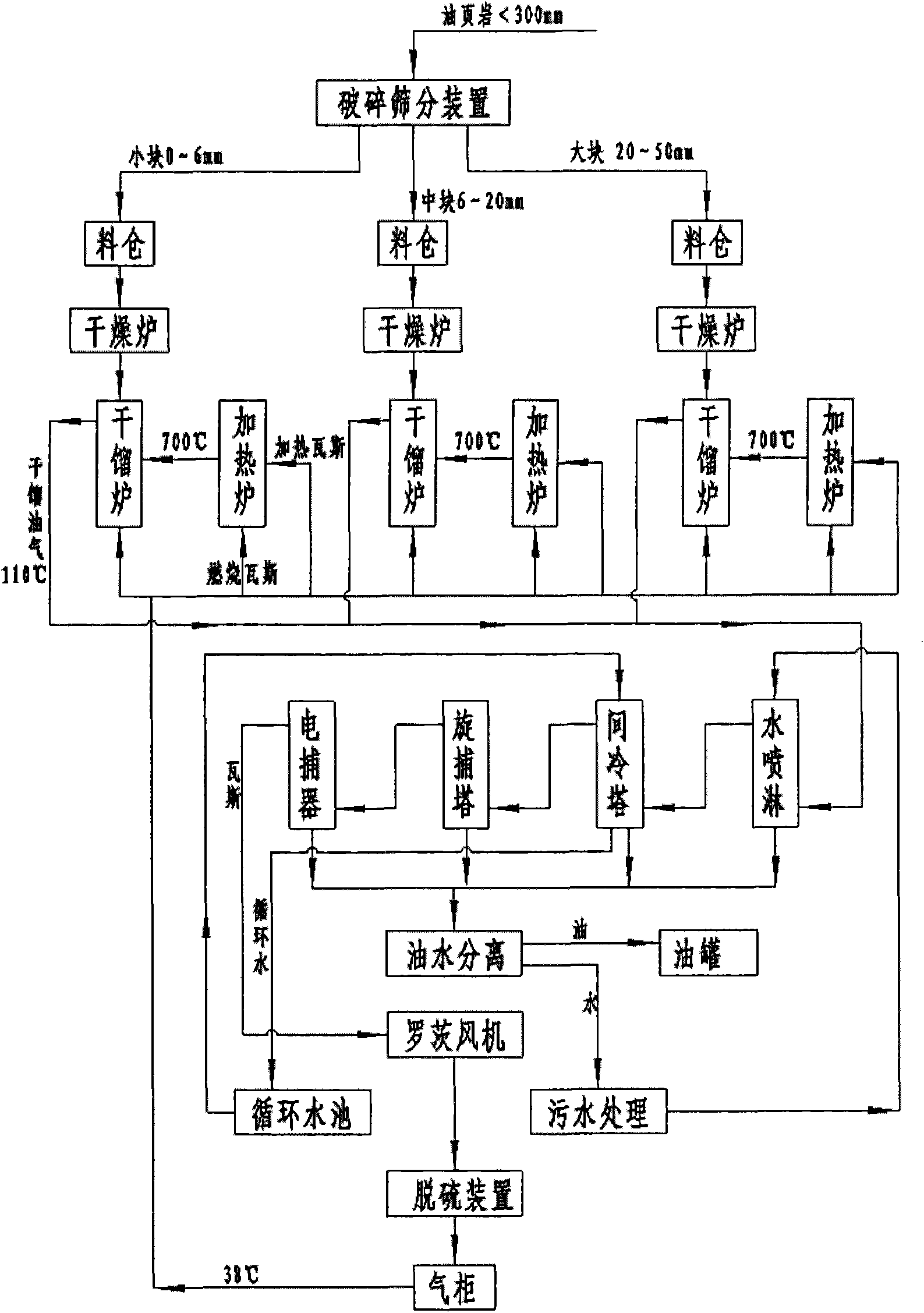

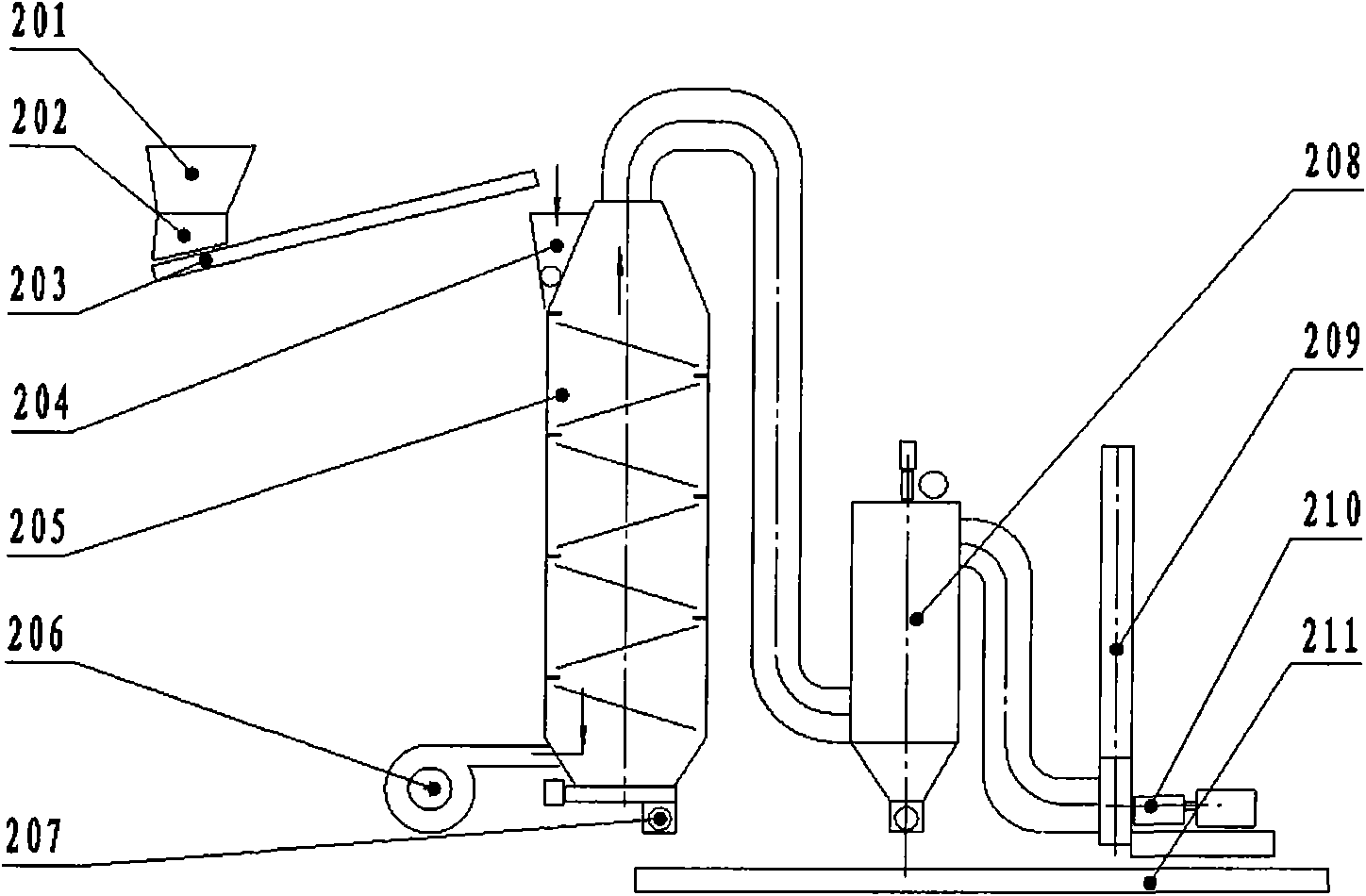

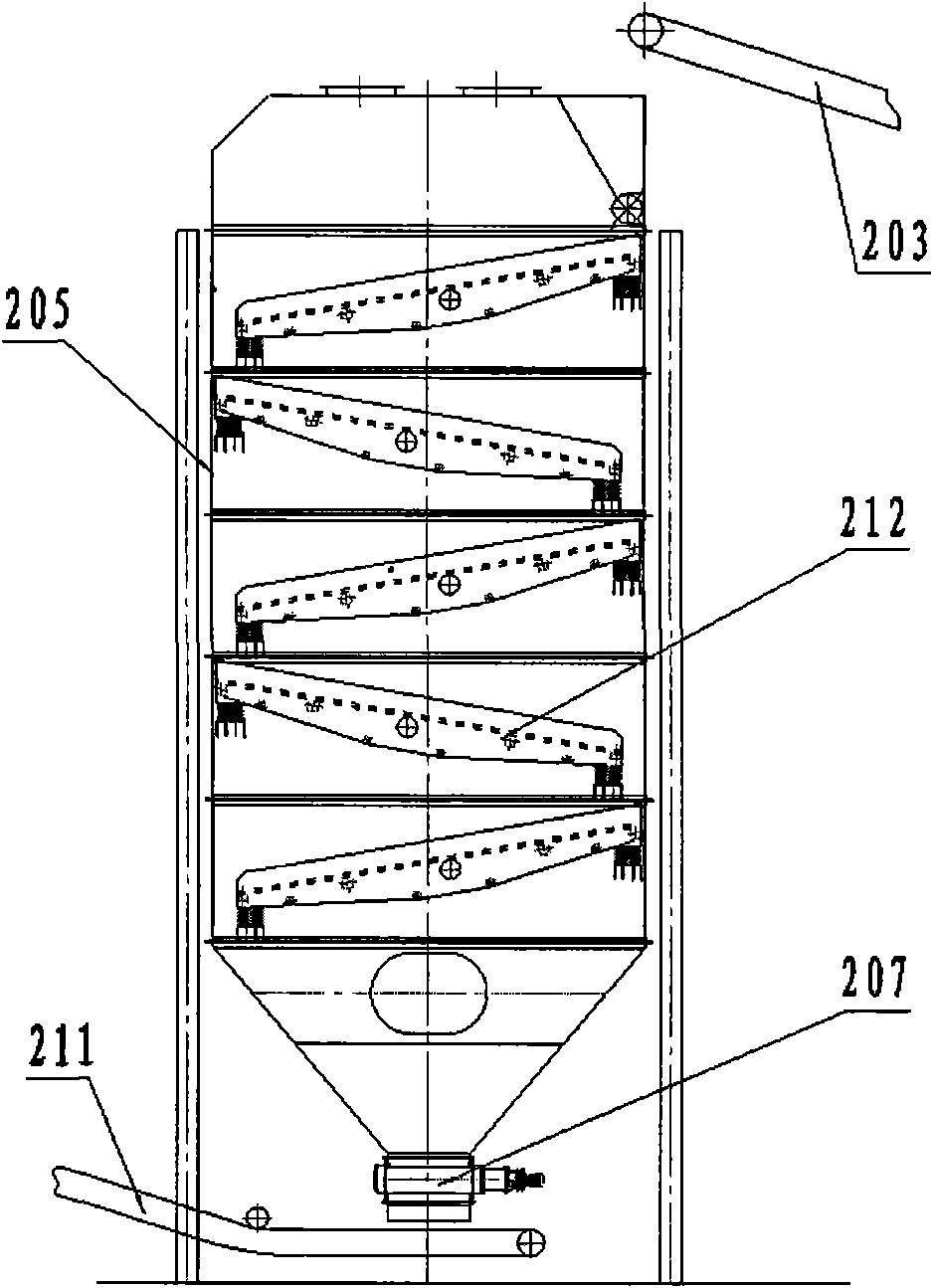

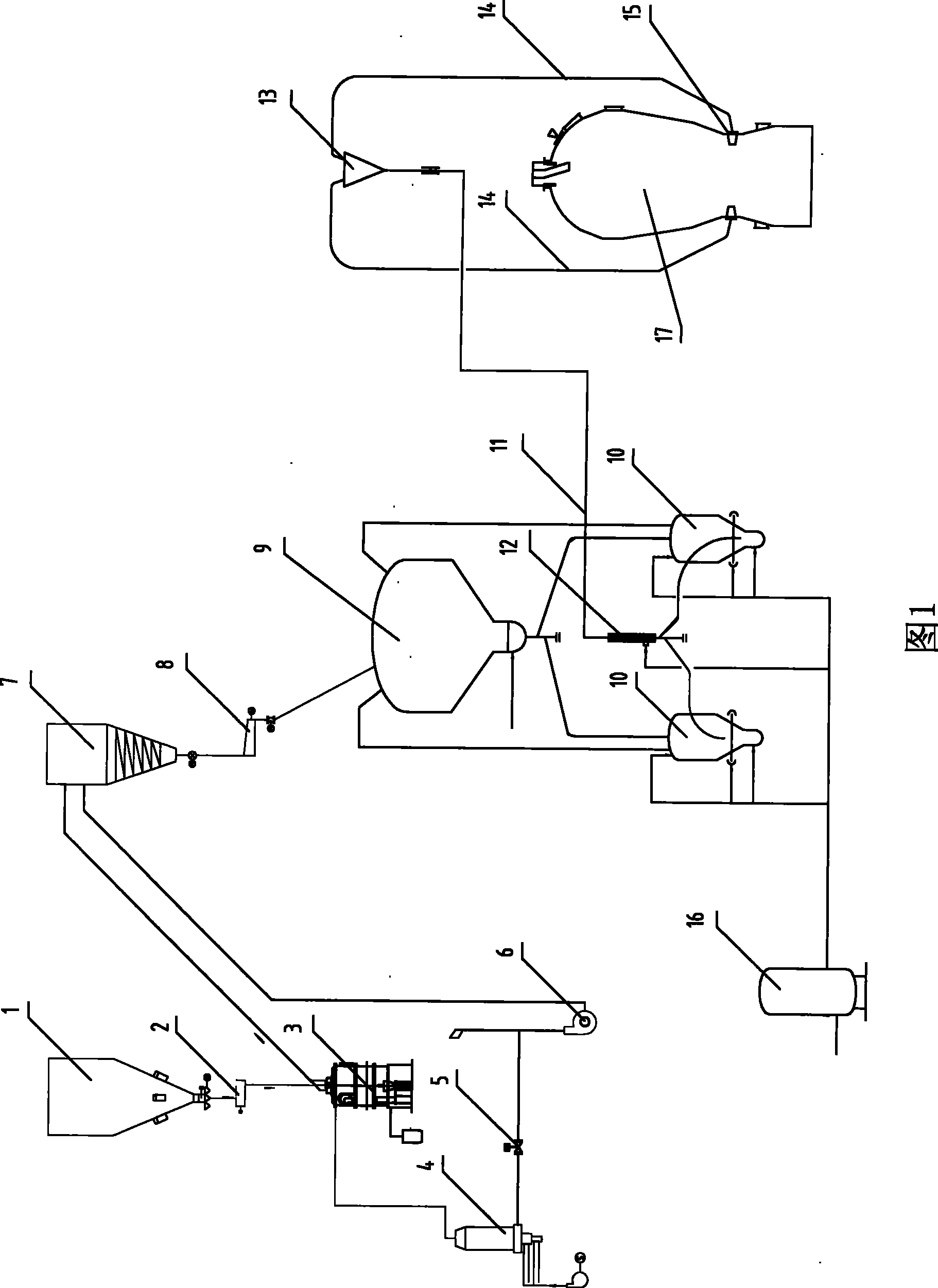

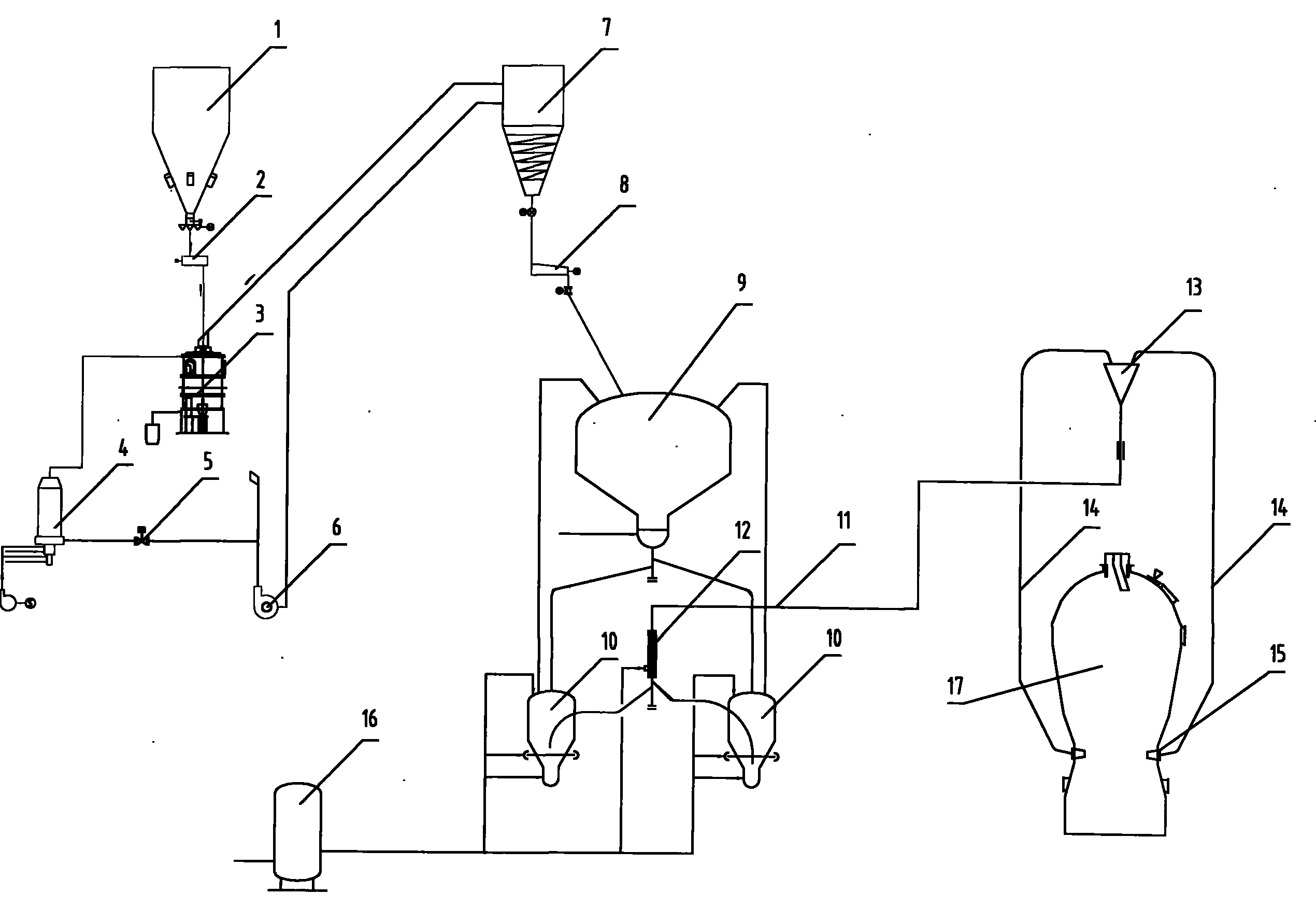

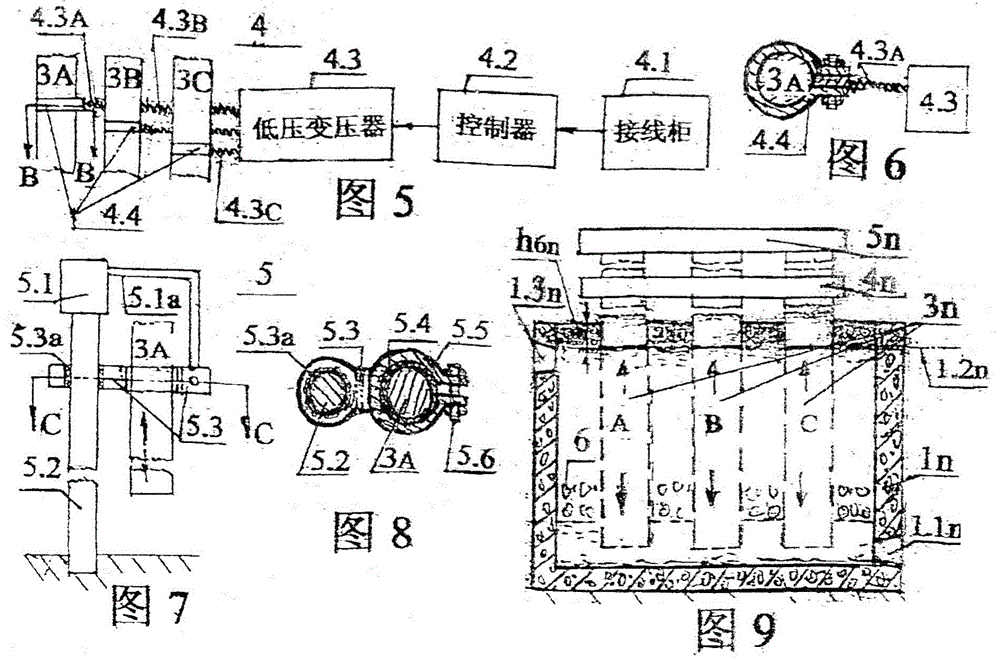

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

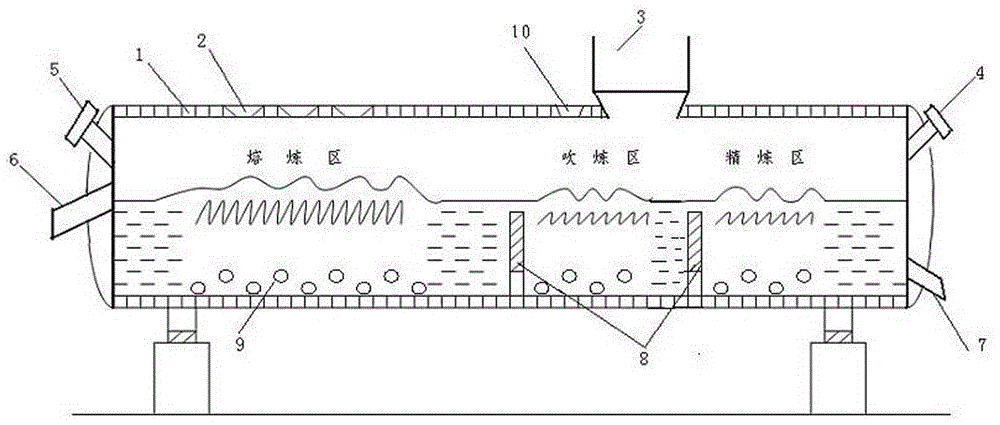

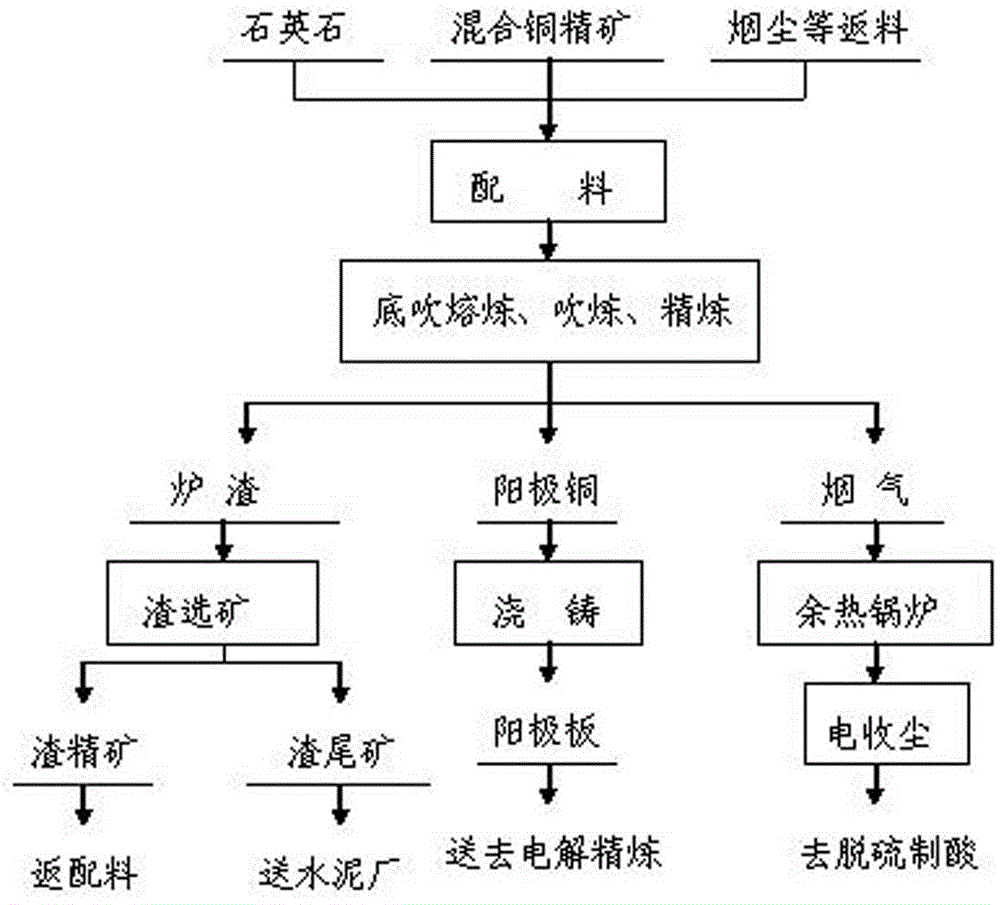

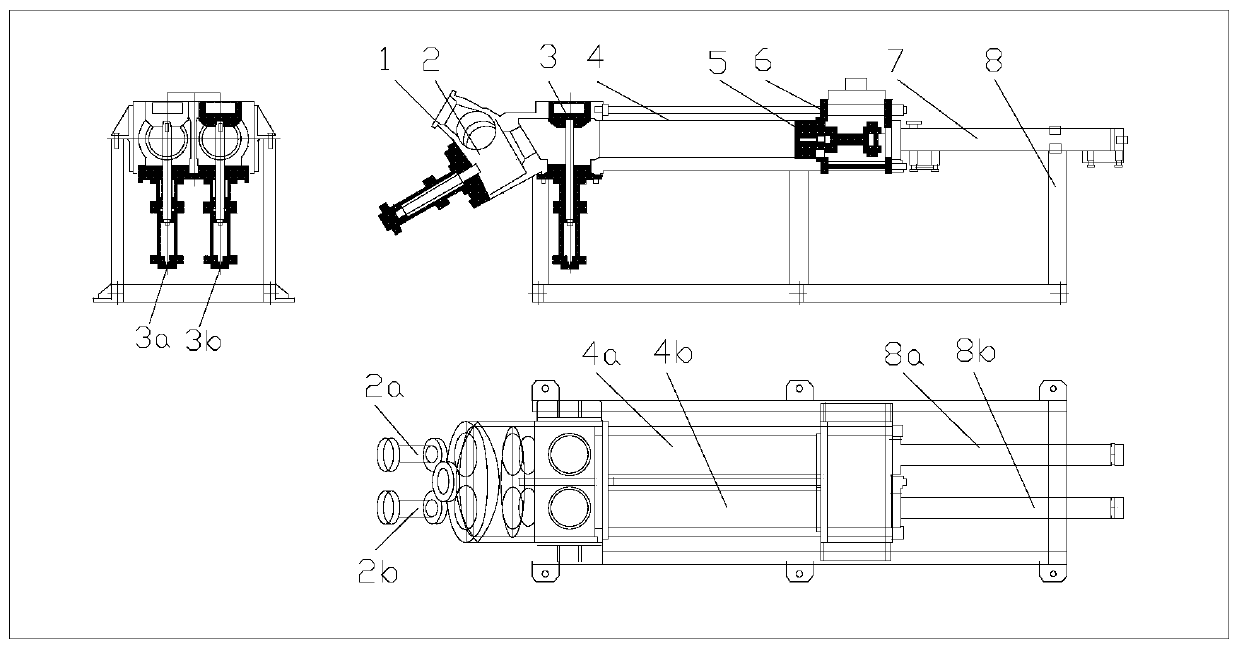

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

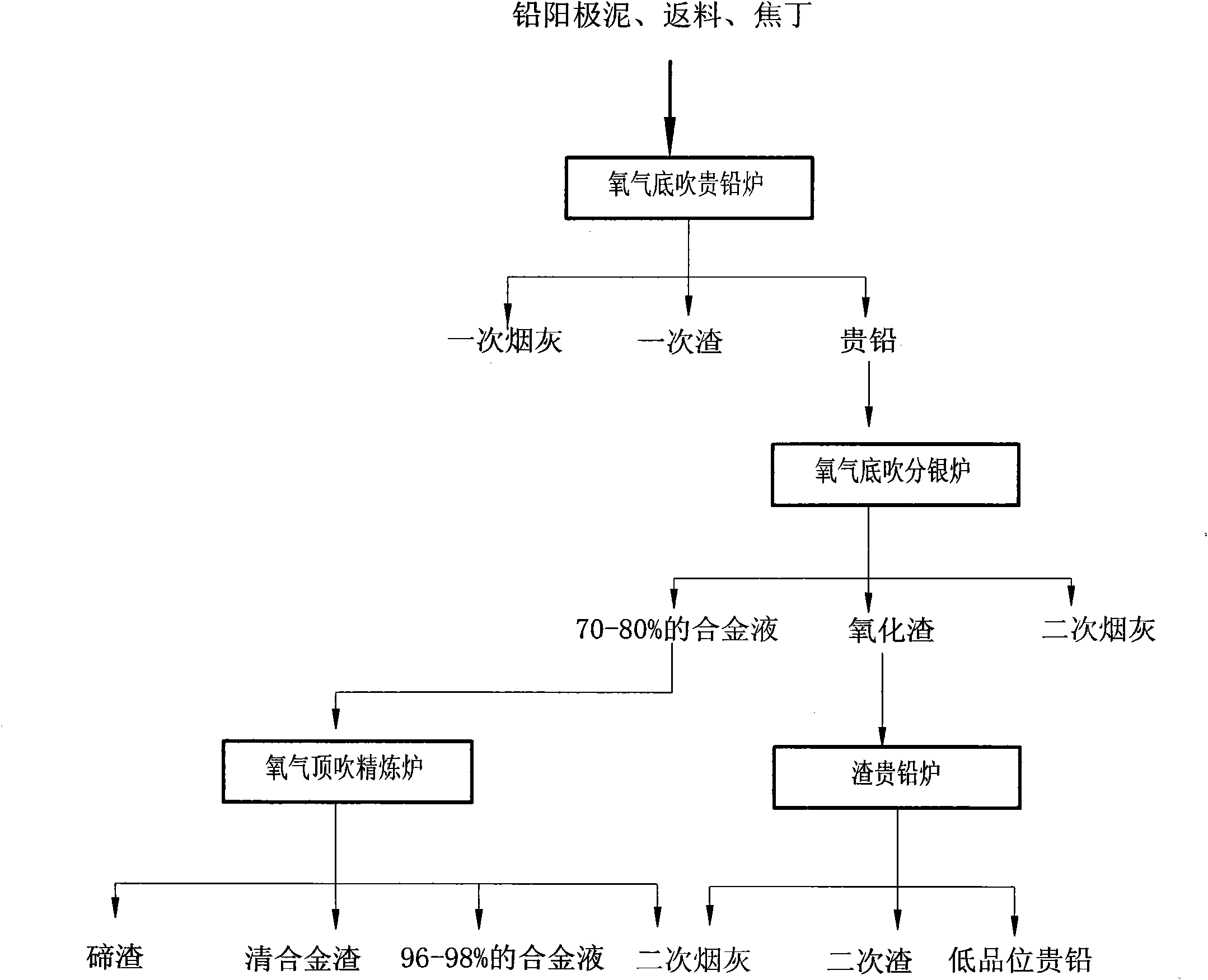

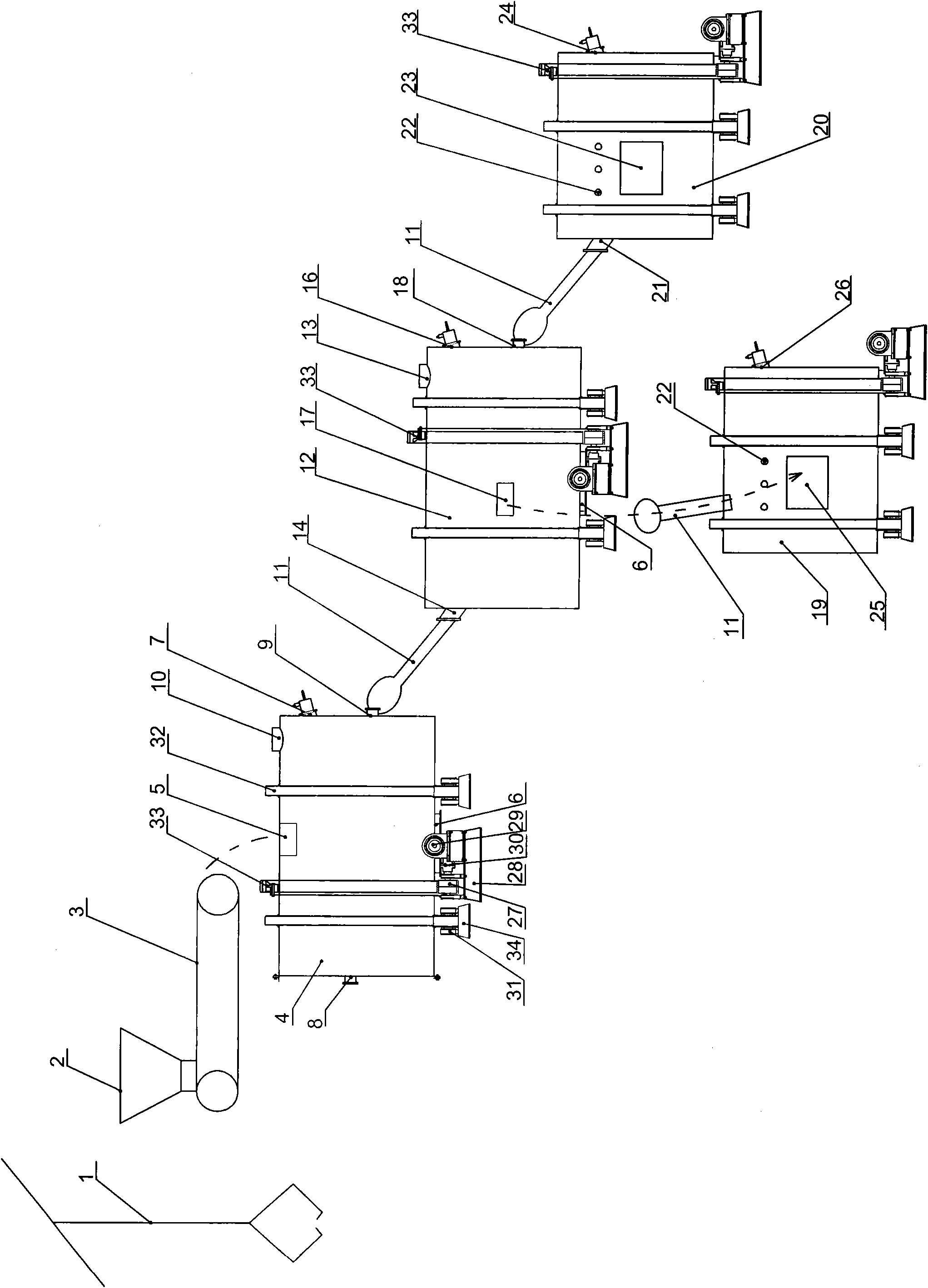

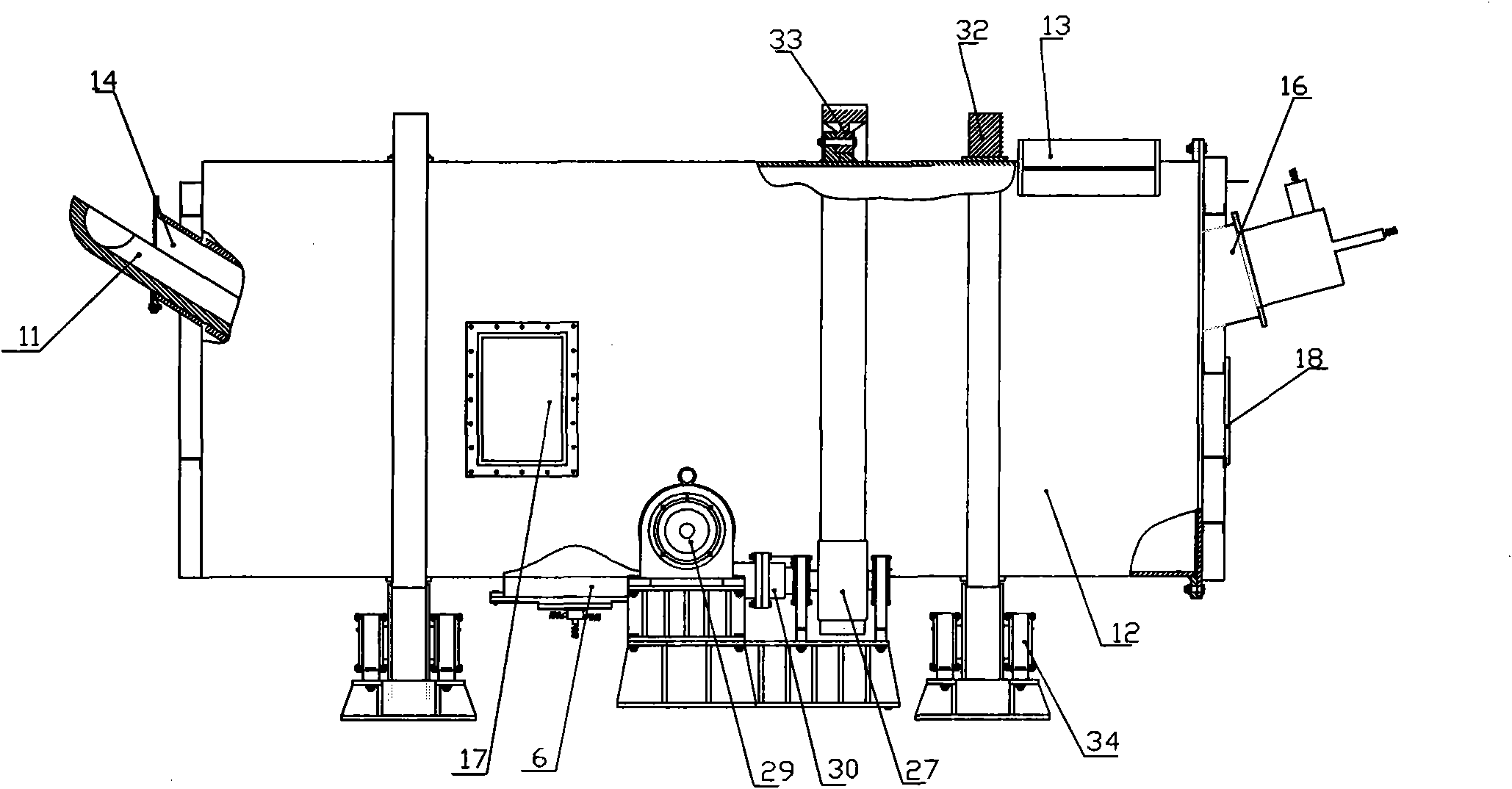

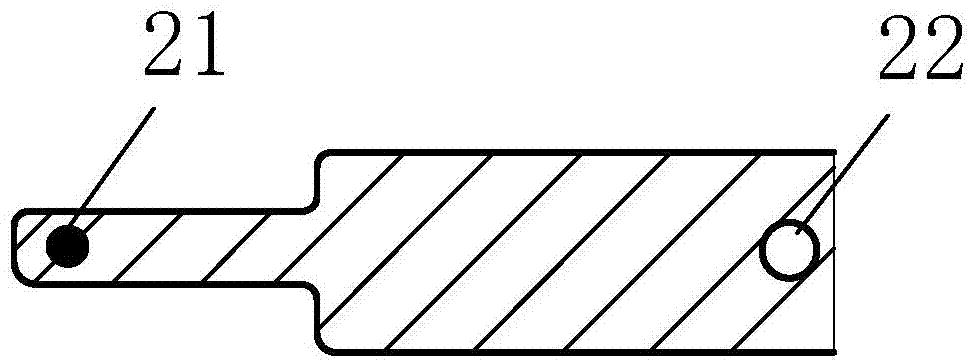

Method and device for continuously treating lead anode slime

ActiveCN101892388AEnables continuous processingShort processing cycleProcess efficiency improvementMelting tankSmelting process

The invention relates to a method and device for continuously treating lead anode slime by bath smelting. The method comprises the following steps: proportionally adding lead anode slime, recycled materials and nut coke as charging materials into an oxygen bottom blowing bullion lead furnace for smelting to generate bullion lead of which the bullion grade is 25-50%, primary slag and primary soot; adding the bullion lead into an oxygen bottom blowing silver-smelting furnace to react to generate oxidizing slag, secondary soot and alloy liquid of which the bullion grade reaches 70-80%; introducing the alloy liquid into an oxygen top blowing refining furnace to react to generate tellurium slag, clear alloy slag, secondary soot and alloy liquid of which the bullion grade reaches 96-98%; and discharging the oxidizing slag, then enabling the oxidizing slag to enter a slag bullion lead furnace, and adding the nut coke to react to generate low-grade bullion lead, secondary slag and secondary soot, wherein the low-grade bullion lead is returned for proportioning. The invention realizes the continuous treatment of the anode slime, strengthens the smelting process, improves the direct recovery rate of the bullion, lowers the production cost, reduces the environmental pollution, and shortens the treatment period of the anode slime.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

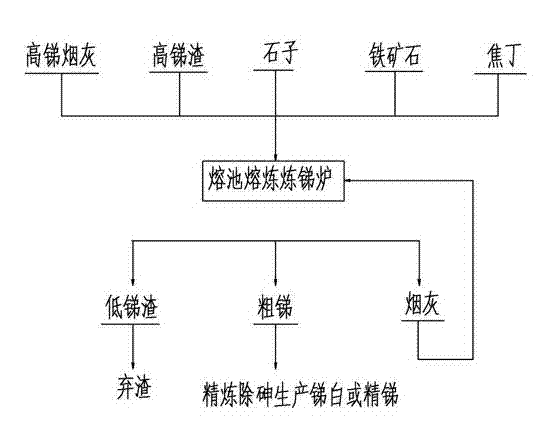

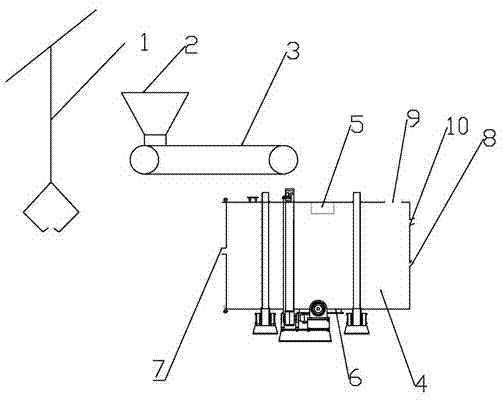

Technology and device thereof adopting bottom blowing molten bath for antimony reduction and smelting

InactiveCN102758094ASpeed up smeltingEasy to handleProcess efficiency improvementMelting tankMolten bath

The invention belongs to the technical field of antimony smelting in the industry of non-ferrous metal metallurgy, and particularly relates to a technology and a device thereof adopting bottom blowing molten bath for antimony reduction and smelting in the process of antimony smelting, wherein the bottom blowing molten bath smelting technology is adopted, antimonial raw material and burden are uniformly blended according to a suitable proportion and fed into a molten bath antimony smelting furnace for smelting to carry out reduction and slag making reaction; oxygen, nitrogen, natural gas or coal gas are fed into the melt through a gas spray gun from the bottom part or bottom side part of the molten bath antimony smelting furnace; the gas is combusted to release heat, so as to ensure the temperature of the furnace, participate in the oxidation and reduction reaction of the burden, and vigorously blend the melt, as a result, the heat and mass transfer and reaction speed in the smelting furnace can be improved, the burden can be quickly reacted to produce lean antimony slag, crude antimony and flue gas, the antimony can be continuously processed, and the slag type with little corrosion on the refractory material is produced. The technology and the device have the advantages of low investment, energy consumption and cost, high automation degree and environmental protection.

Owner:HENAN YUGUANG GOLD & LEAD

Method for producing precipitated calcium carbonate

InactiveCN101648723AIncrease productionQuality improvementCalcium/strontium/barium carbonatesCalcium hydroxidePrecipitated calcium carbonate

The invention discloses a method for producing precipitated calcium carbonate, which comprises the following steps: crushing a limestone raw material; calcining the crushed limestone raw material after screening and water scrubbing; obtaining calcium oxide (CaO) after calcining; preparing calcium hydroxide by ashing the calcium oxide (CaO); generating liquid calcium carbonate by carbonizing the calcium hydroxide; and preparing calcium carbonate by dewatering and drying, wherein the drying method adopts an internally heated rotating furnace combining with a controllable temperature furnace in fluid bed, so the drying process has the advantages of no pollution, fast drying speed and good quality.

Owner:徐铭

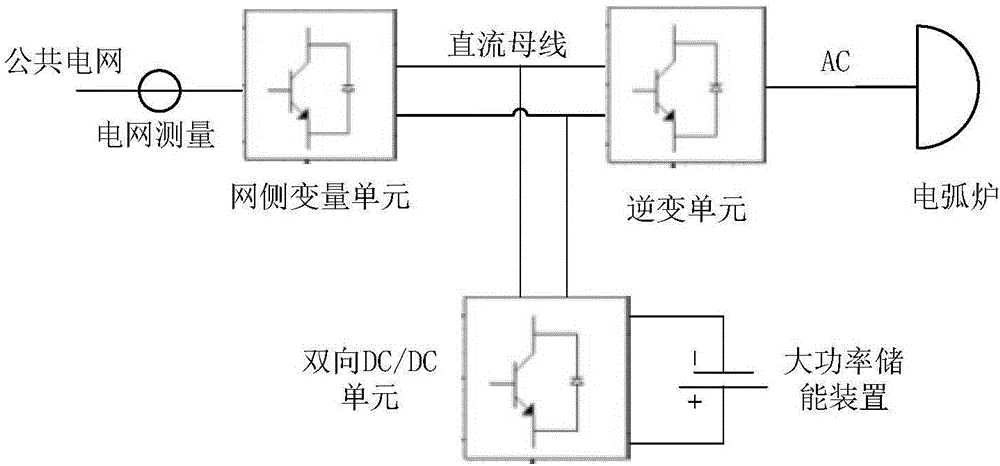

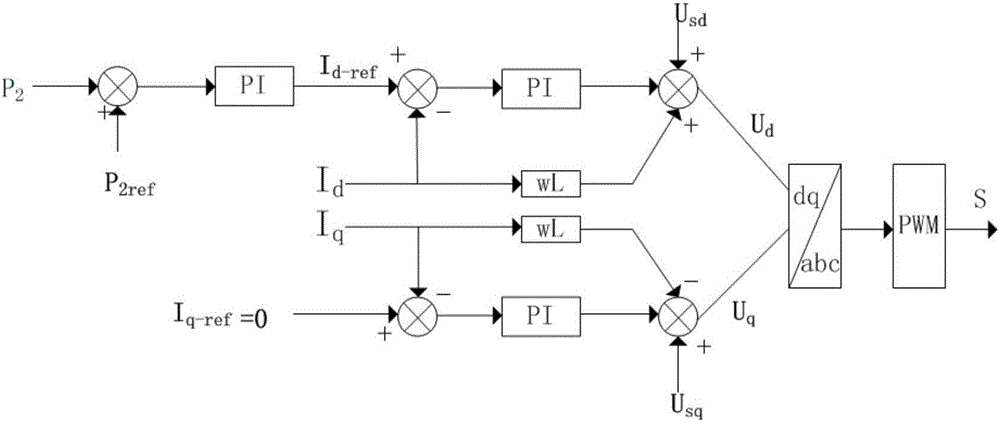

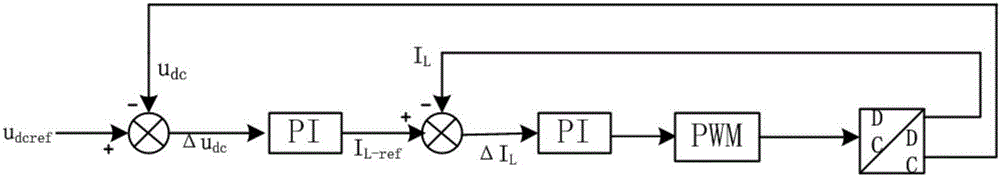

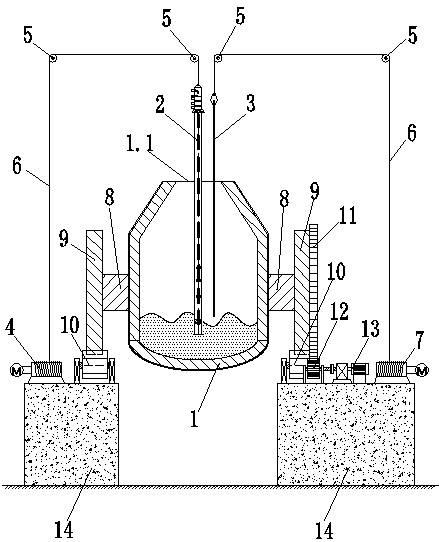

Energy storage-containing arc furnace energy-supply power system and control method thereof

PendingCN106849144AStable power supplyReduce shockPolyphase network asymmetry elimination/reductionAc network load balancingFurnace temperatureElectric arc furnace

The invention relates to an energy storage-containing arc furnace energy-supply power system and a control method thereof. The system comprises a power grid access and measuring unit, a network-side variable flow unit, a direct current bus, an energy storage power control unit, a high power energy storage device, an inverter unit and a main controller. According to the method, the power supply of an arc furnace is kept stable when a power grid is abnormal, the impact on the power grid is reduced, and the problems that the power factor of power grid access points is low and three phases are imbalanced caused by the arc furnace are solved. When the power grid voltage flickers and power fails in a short time, the power can be uninterruptedly and stably supplied to the arc furnace, so that the furnace temperature is stabilized and the quality of metallurgical products is ensured; meanwhile, the adverse effects on the power grid caused by factors of power fluctuation and low power factor of the arc furnace can be reduced.

Owner:SHENYANG POLYTECHNIC UNIV

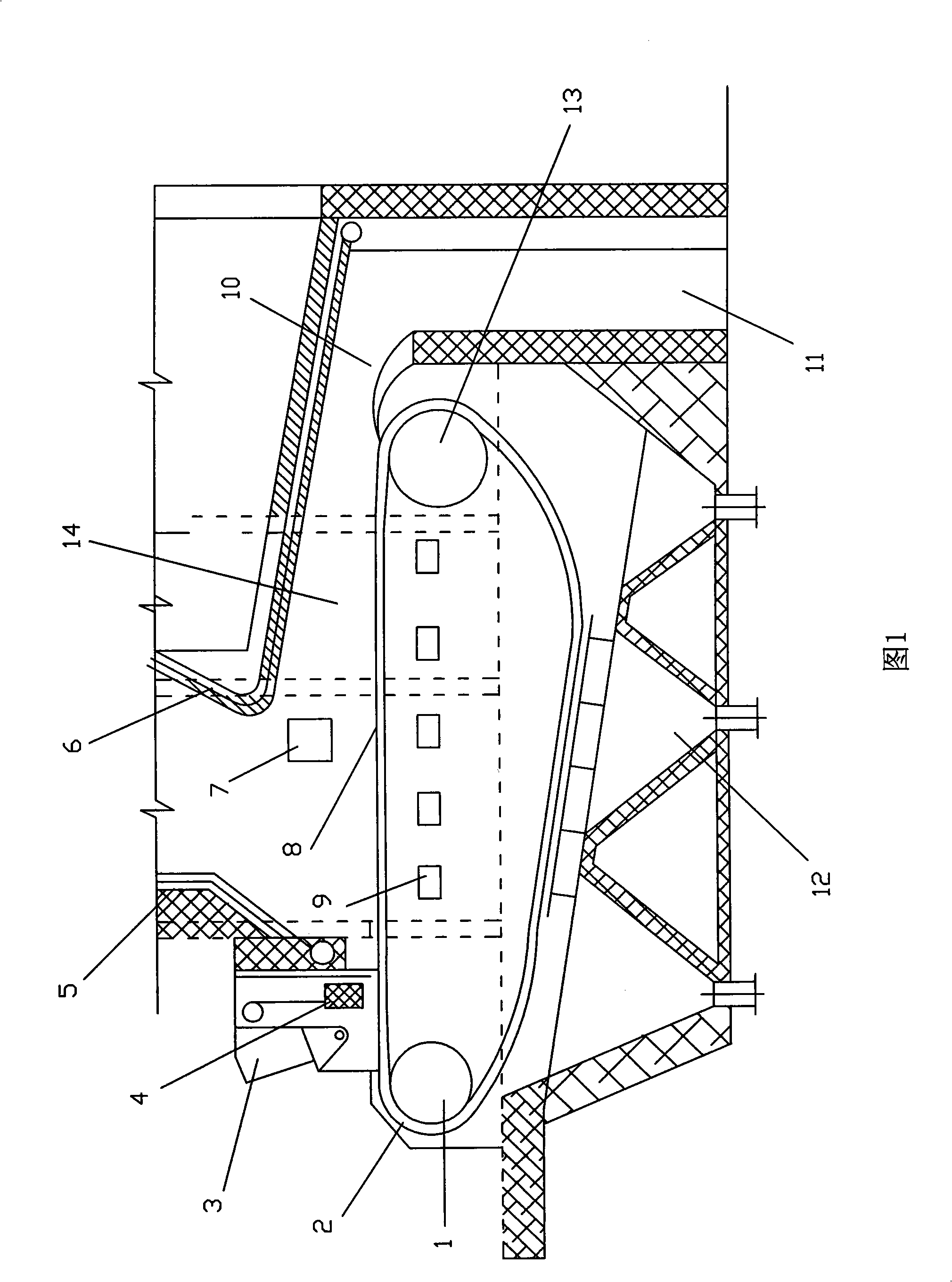

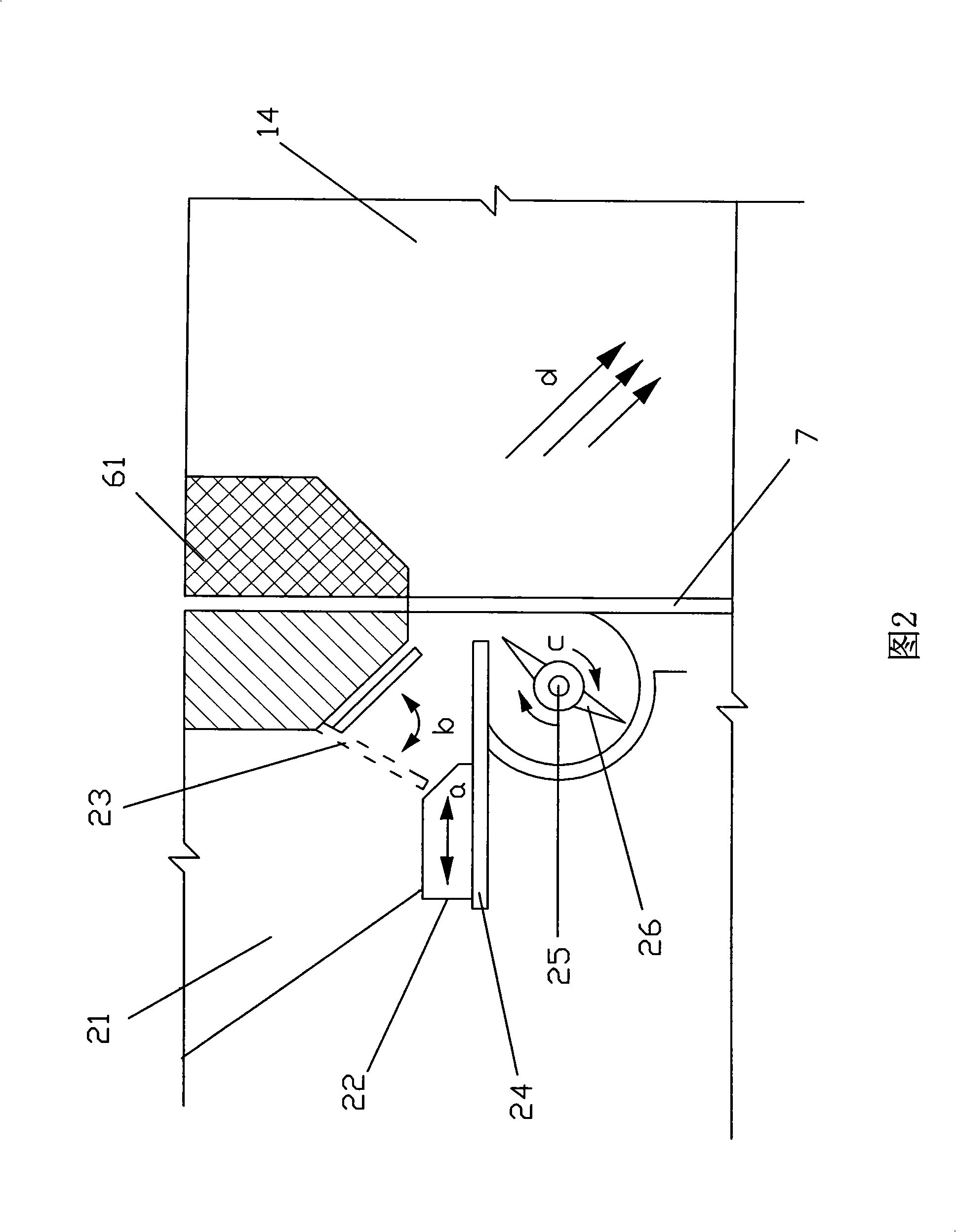

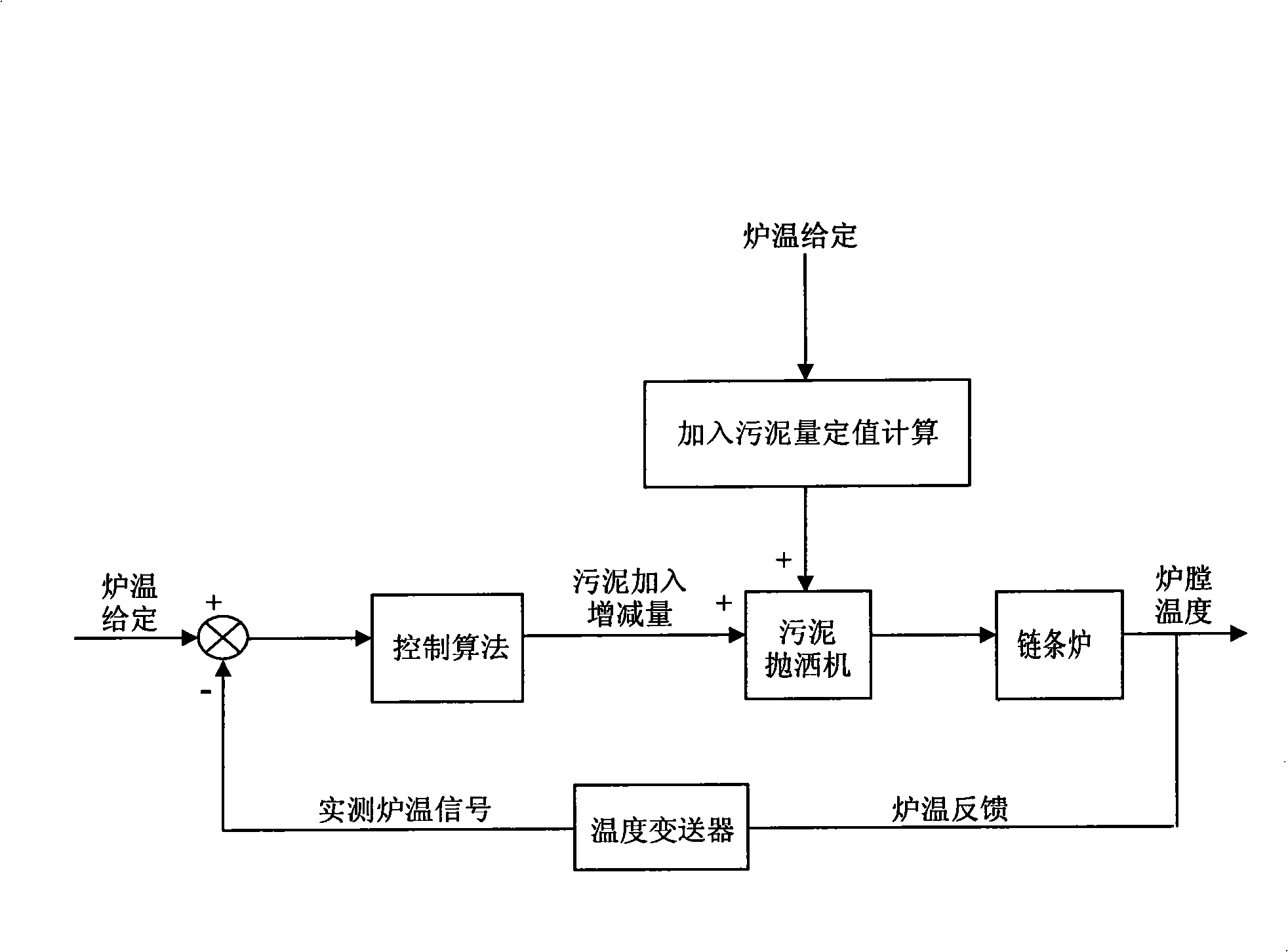

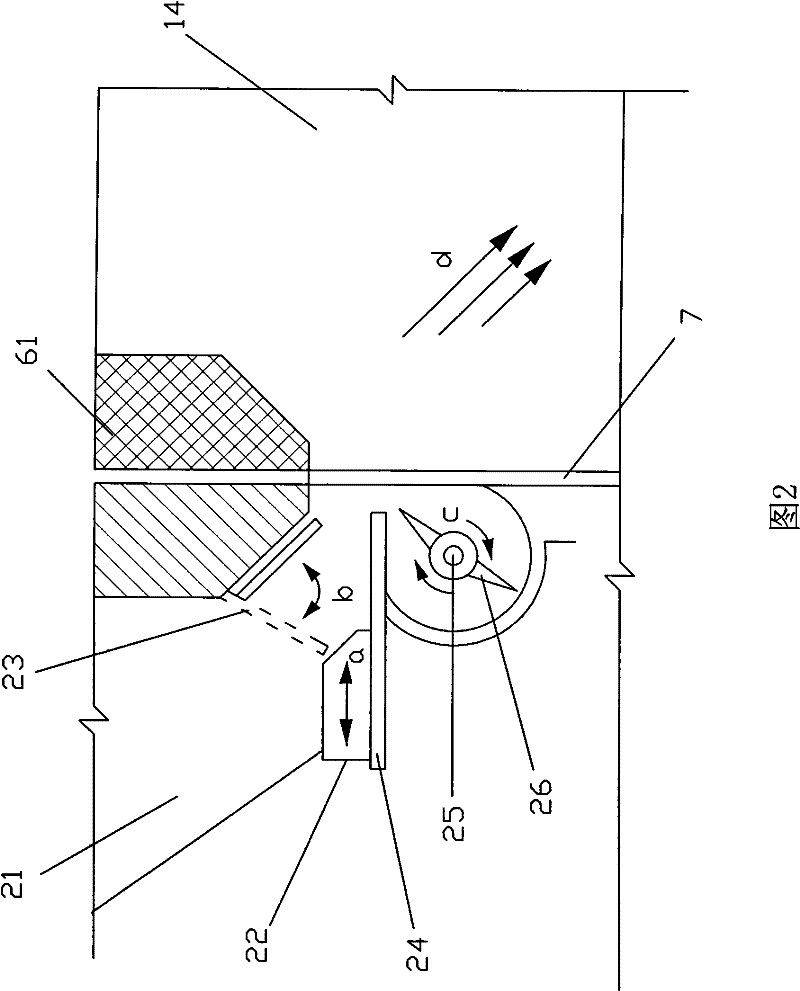

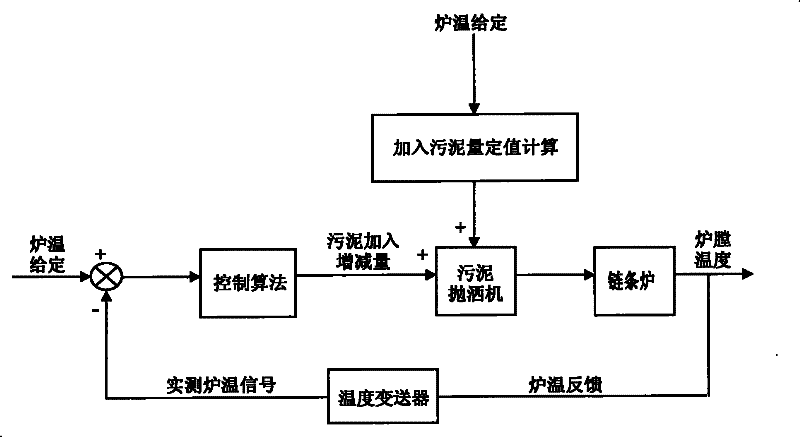

Method for burning sludge of chain furnace

InactiveCN101324337AEasy to control the amount addedHigh thermal efficiencyIncinerator apparatusHeating furnaceDewatered sludge

The invention discloses a method for burning sludge in chain grate. A sludge feeding port is arranged on rear arch on the side surface of the chain grate used in the method; and coal and sludge are respectively added into the furnace of the chain grate. The method comprises following steps: adding the coal into the grates of the chain grate through a coal valve from a coal scuttle in front of the chain grate; preheating, drying, and burning the coal sequentially along with the movement of the grates of the chain grate; uniformly adding the squeezed and dewatered sludge alone from the sludge feeding port into the chain grate, wherein the sludge falls onto the grates in a position in the vicinity to the rear arch at 1 / 2 to 3 / 4 the tail section of the furnace of the chain grate; and igniting and burning the sludge added in the position by the temperature of the tail section of the furnace of the chain grate when the coal burning is substantially ended, wherein the added amount of the sludge is calculated and adjusted in real time according to the heat value of the coal and the temperature when the added amount is stabilized. The chain grate can ensure complete burning of coal when used for burning various kinds of sludge with heat energy utilization value, thus effectively utilizing the heat value of the sludge and improving the heat efficiency of the chain grate.

Owner:ZHEJIANG HUAZHANG TECH

Combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke

InactiveCN103994442ARelieve pressureReduce generationIncinerator apparatusToxic gasCombustion chamber

Provided is a combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke. An incinerator hearth is composed of a first combustion chamber and a second combustion chamber, the first combustion chamber is a horizontal type combustion chamber, the second combustion chamber is a vertical type combustion chamber, heat insulation type combustion chambers are adopted by the whole first combustion chamber and the second combustion chamber of enough height, multiple primary air inlet chambers are adopted by the first combustion chamber to carry out chamber division and amount selected air supply according to needs, two rows of secondary air exhaust pipes which blow oppositely and are arranged at the connecting positions of the other two combustion chambers blow in secondary air, slaked lime adding devices are arranged out of the hearth at the horizontal height of the center of an upper boiler barrel and the hearth of the horizontal height at the center of a lower boiler barrel of a double-boiler-barrel vertical type waste heat boiler, and the slaked lime adding devices inject quantitative slaked lime into the hearth in the flow direction of the high temperature smoke between the upper boiler barrel and the lower boiler barrel. According to the combined type incinerating device capable of controlling the toxic gases and the heavy metal content in the waste incineration smoke, the structural characteristics of the combined type incinerating device is utilized, the controlling over all techniques and parameters is combined, source controlling over the toxic gases and heavy metal is achieved in an incineration process, the pressure of tail gas purification work is relieved fundamentally, and market needs are met.

Owner:上海煜工环保科技有限公司

Method for preventing and controlling flue gas pollutant and domestic refuse incineration system

PendingCN108826303AAdsorption reductionReduction of passive governance measuresEmission preventionCombustion technology mitigationCombustion chamberGreenhouse

The invention discloses a domestic refuse incineration system for preventing and controlling flue gas pollutant. A material grabbing hopper of a refuse storage vault feeds materials into a compressionand crushing system, the compression and crushing system is connected with a drying system through a conveying system, a refuse discharging opening of the drying system is connected with a refuse feeding opening of an integrated incinerator, a hot bad smell outlet of the drying system is connected with an air inlet of the integrated incinerator, a combustible gas outlet and a flue gas discharge opening of the integrated incinerator and a hot air outlet of a second-stage heat exchanger are connected with a second combustion chamber, and the second combustion chamber, a first-stage heat exchanger, a quick cooling chamber, the second-stage heat exchanger and a flue gas desulfurization device are connected in sequence; and a hot air outlet of the first-stage heat exchanger is connected to anair inlet of the drying system. The domestic refuse incineration system is rigorous and reasonable in structure, the flue gas pollutant can be prevented and controlled in key processes including refuse drying, gasification burnout, flue gas burning purification and flue gas cooling, heat energy, combustible gas and combustion-supporting air needed by the system in all processes are provided, and the direct cost is almost zero.

Owner:庞礴 +2

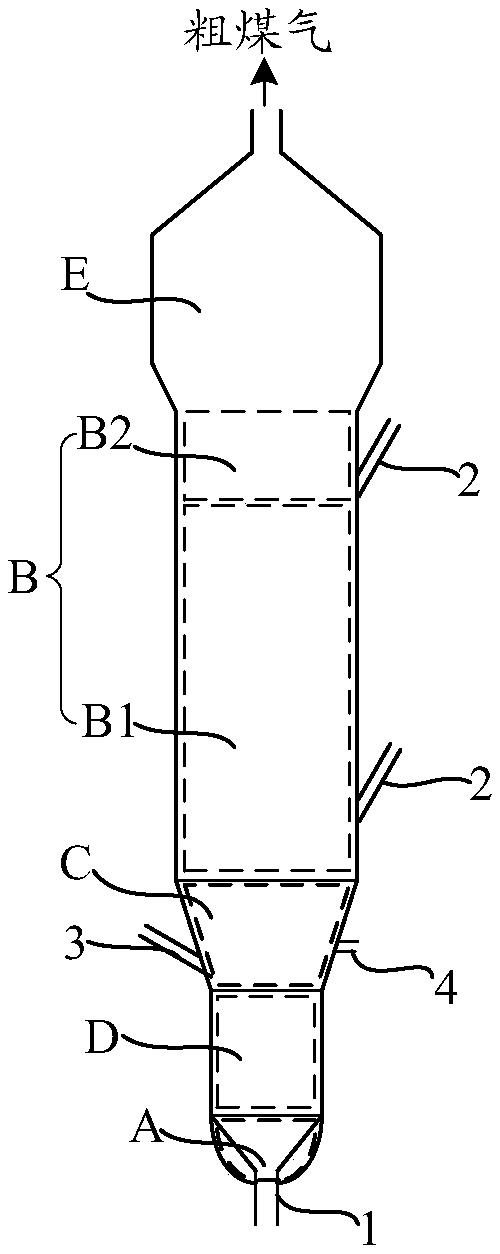

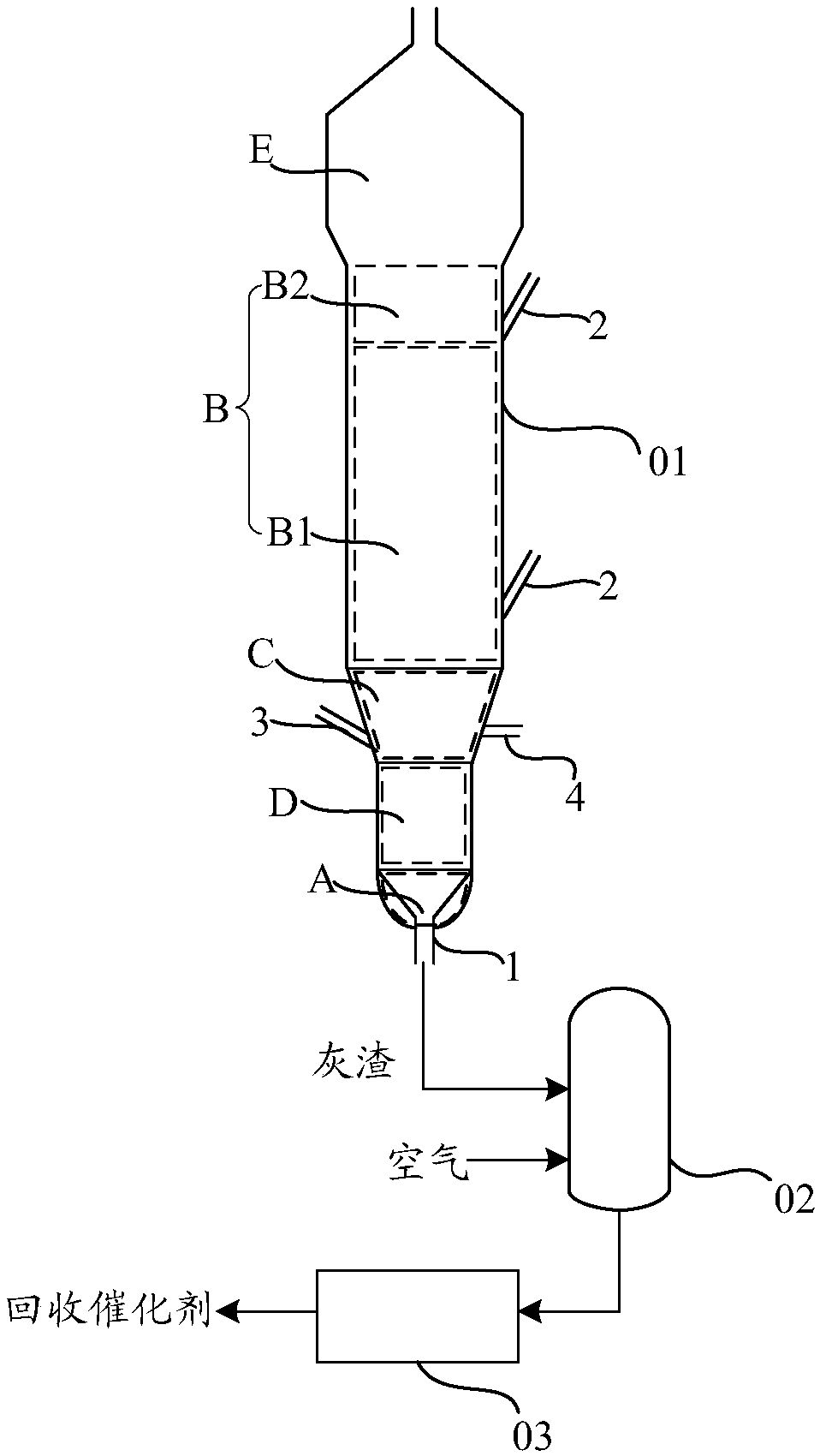

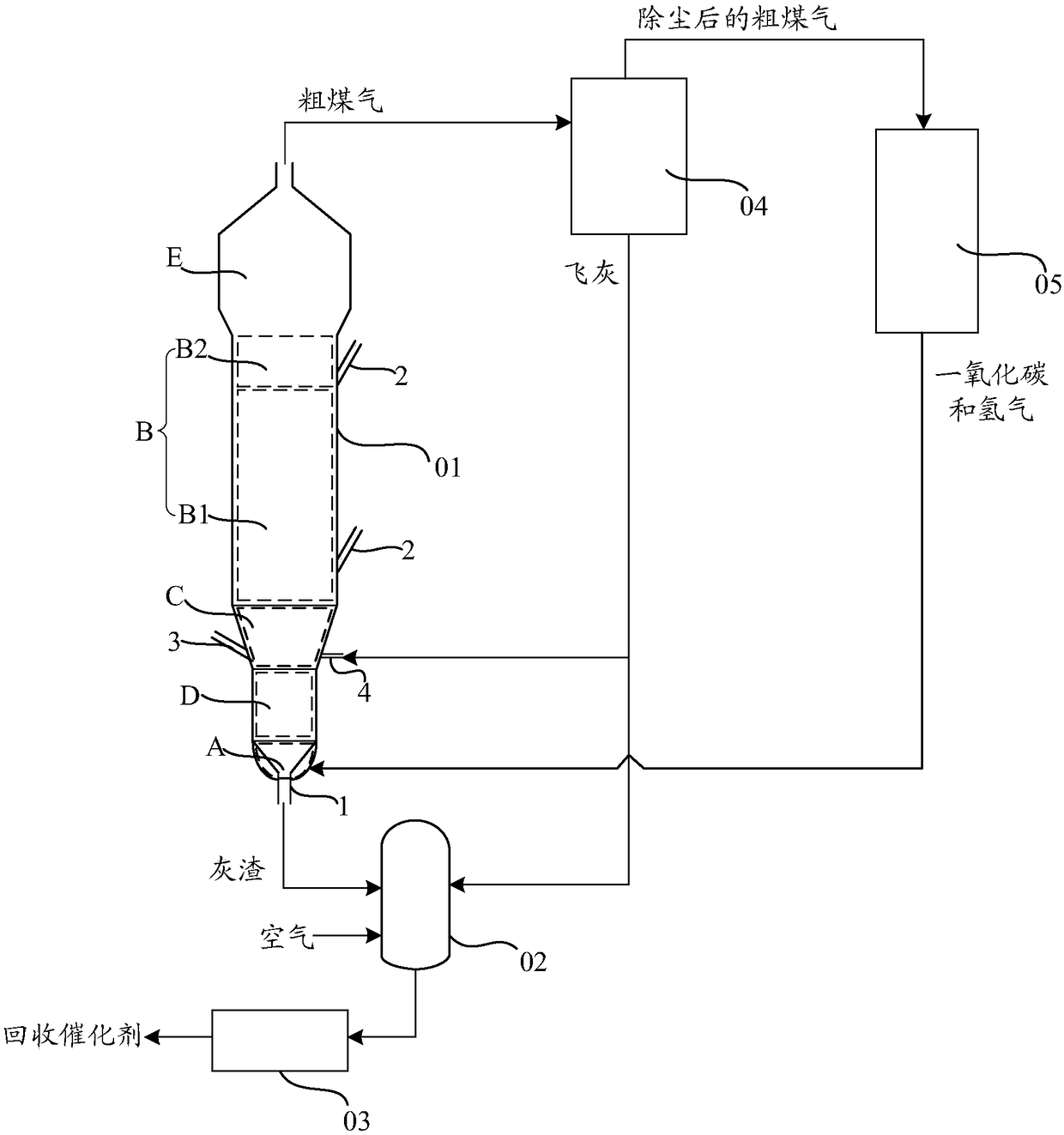

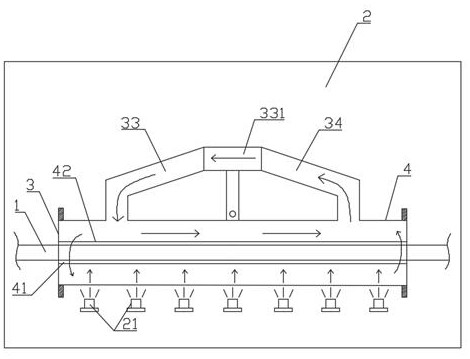

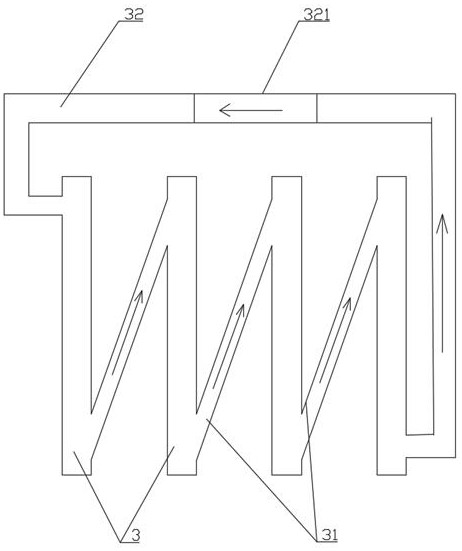

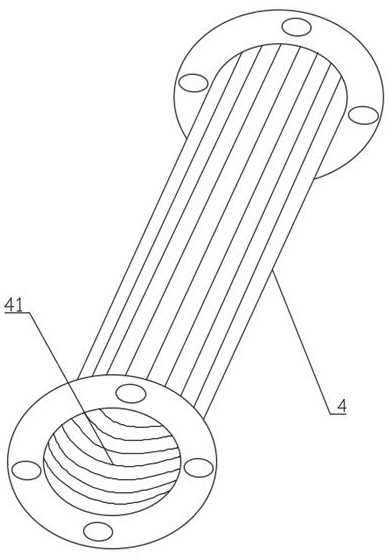

Fluidized bed gasifier, coal gasification system and method

InactiveCN108179032AHigh yieldStable furnace temperatureGasification processes detailsGranular/pulverulent flues gasificationSyngasFluidized bed gasifier

The invention relates to the technical field of coal gasification, in particular to a fluidized bed gasifier, a coal gasification system and a method, can satisfy the heat requirement of overall reaction in the furnace, have no need for introducing oxygen burning coal to provide heat, lower the risk of easy slagging in the gasifier due to introduction of oxygen, at the same time can promote forward overall reaction in the furnace, have no need for returning substantial synthesis gas to the furnace to increase the methane yield, and lower the risk of inhibition on overall reaction in the furnace caused by return of synthesis gas to the furnace. According to the fluidized bed gasifier, the bottom is a gas distribution plate area, a fluidized bed reaction area is disposed above the gas distribution plate area, a variable diameter section with a gradually enlarging inner diameter from the bottom up is disposed between the fluidized bed reaction area and the gas distribution plate area, thebottom of the fluidized bed gasifier is equipped with deslagging port, the side wall of the fluidized bed gasifier corresponding to the fluidized bed reaction area is equipped with coal inlets, and the lower part of the variable diameter section is equipped with a carbon carrier inlet.

Owner:ENN SCI & TECH DEV

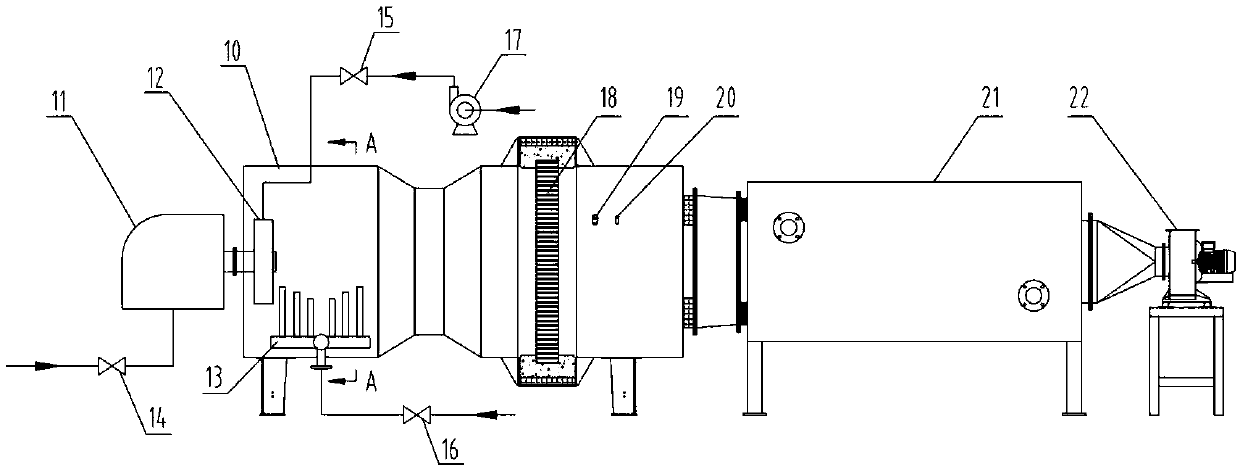

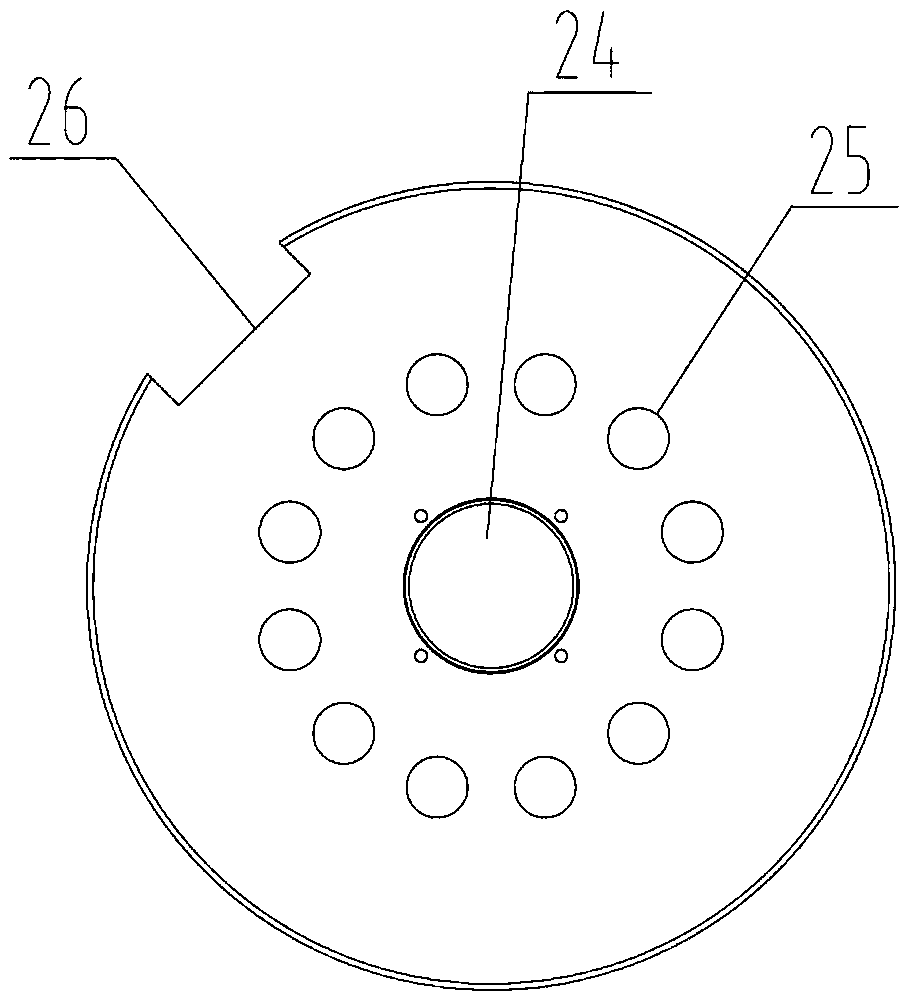

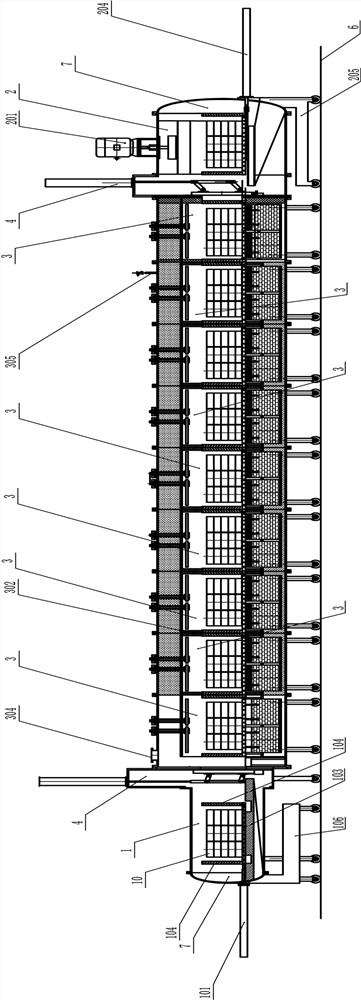

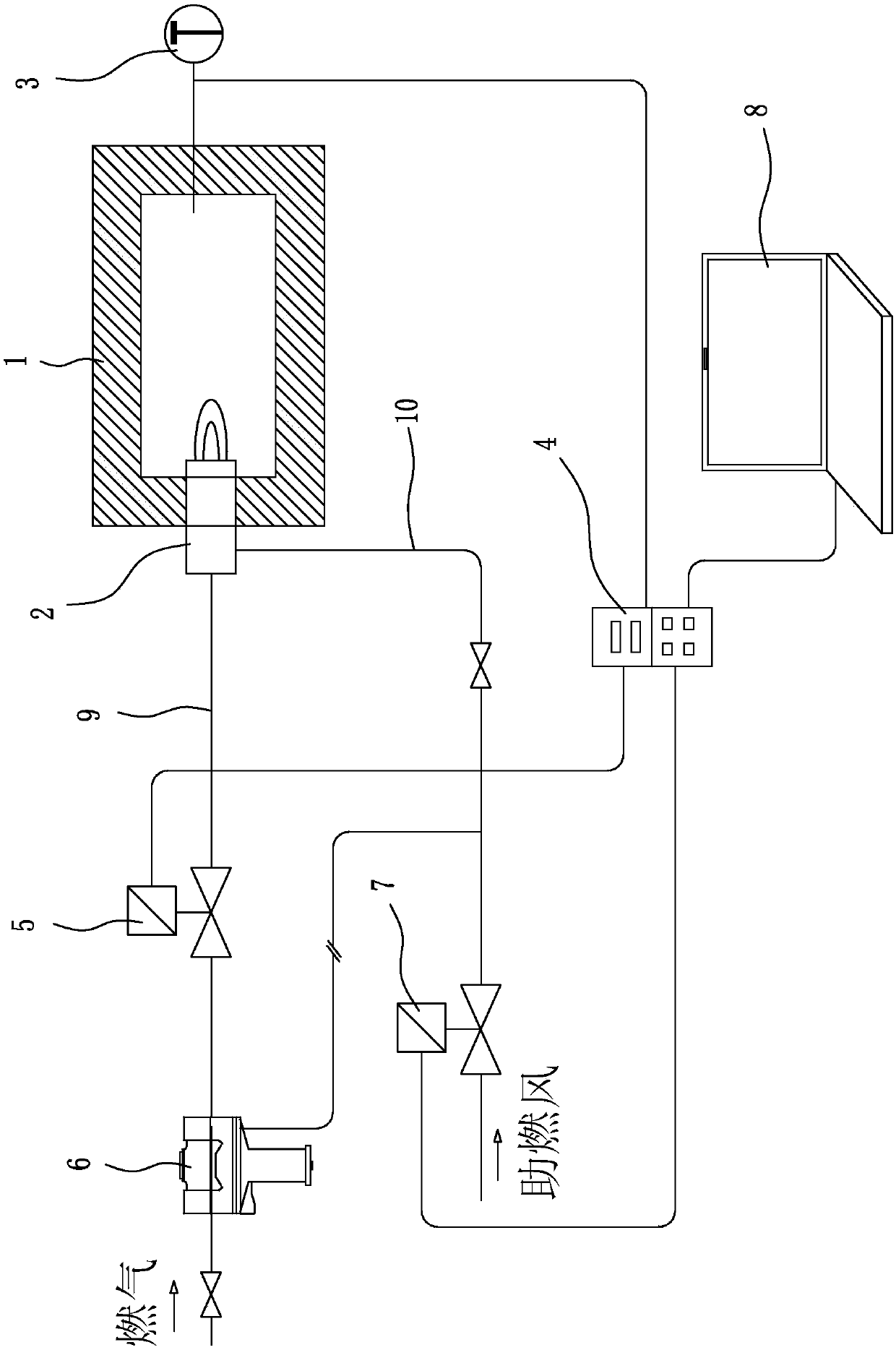

High-purity waste ammonia gas incinerating furnace, system and technology

ActiveCN109595568AReduce NOX generationKeep the oven warmIncinerator apparatusNitric oxideProcess engineering

The invention discloses a high-purity waste ammonia gas incinerating system. A high-purity waste ammonia gas incinerating furnace, a combustion device, an ammonia gas pipeline, a combustion supportingair pipeline, a fuel pipeline, a heat exchange device, a smoke discharging draught fan and a control device are included. The high-purity waste ammonia gas incinerating furnace comprises a furnace body, a first gas inlet distribution device, a second gas inlet distribution device and a fire barrier. The first gas inlet distribution device is connected with the ammonia gas pipeline through an ammonia gas pipeline connector, and the second gas inlet distribution device is connected with the combustion supporting air pipeline through an air supplementing port. When fuel generates flames in a hearth through a flame nozzle of the combustion device, the first gas inlet distribution device is used for distributing guided-in ammonia gas on the flame peripheries for sufficient combustion, and thesecond gas inlet distribution device is used for axially spraying guided-in combustion supporting air so that an air wall can be formed on the flame peripheries. Furthermore, a corresponding high-purity waste ammonia gas incinerating furnace and a corresponding incinerating technology are disclosed. Through the high-purity waste ammonia gas incinerating system, furnace and technology, in the heating power incineration process, generation of nitric oxide can be controlled while high-purity waste ammonia gas is completely combusted.

Owner:普兰特换热设备(溧阳)有限公司

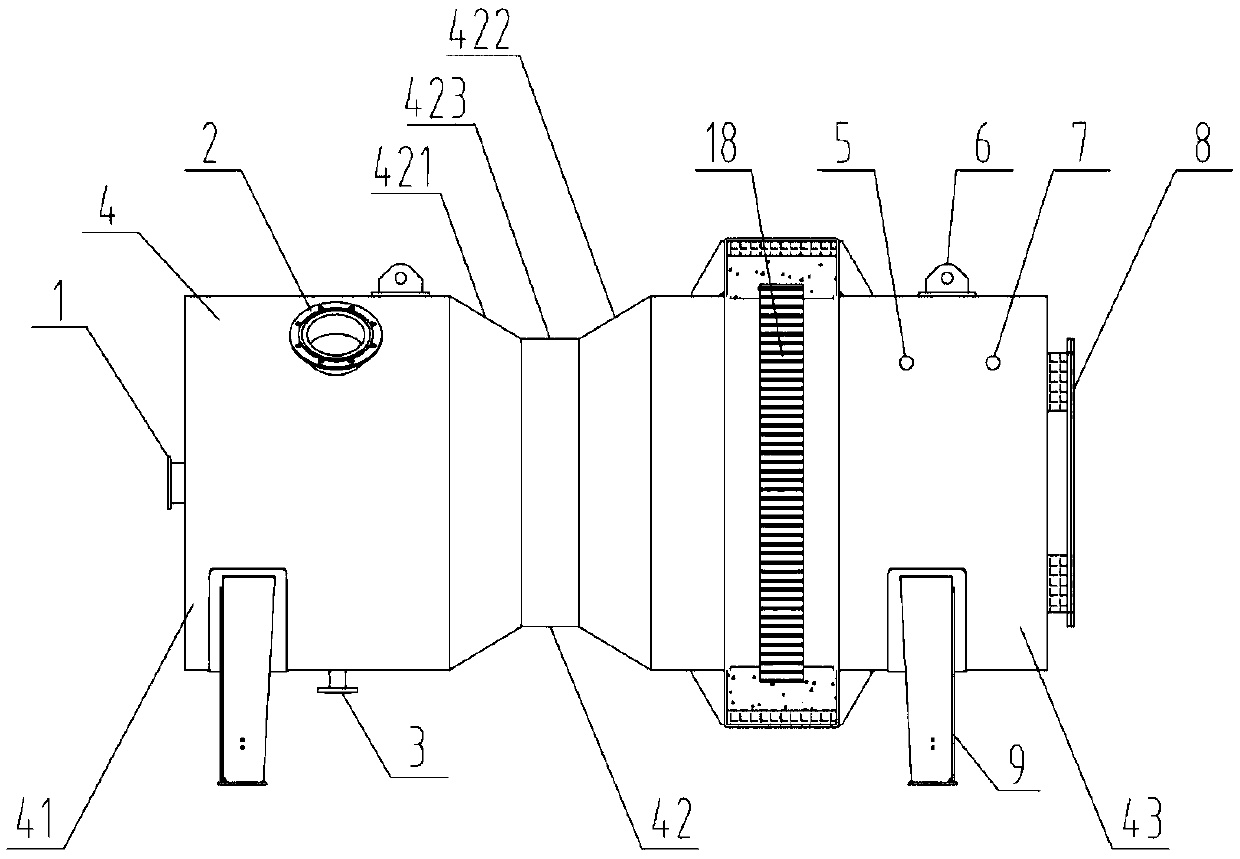

Immersed top-blown converter

PendingCN112877500AImprove reaction efficiencyStir violentlyManufacturing convertersEngineeringMechanical engineering

The invention discloses an immersed top-blown converter. The immersed top-blown converter comprises a top-blown converter body, wherein a material inlet and outlet is formed in the top of the top-blown converter body, and an immersed top-blown spray gun is inserted into the material inlet and outlet. The reaction efficiency of the converter is high, the immersed top-blown molten pool is used for smelting, materials can be continuously added into the converter, the blowing-out charging time is shortened, and the smelting operation rate is improved. Due to the fact that the immersed top-blowing spray gun can be directly inserted into the molten pool and a hydrocyclone is arranged in the immersed top-blowing spray gun, the molten pool is violently stirred by the immersed top-blowing spray gun, materials are mixed more evenly, and the reaction efficiency in the converter is improved. The top-blown converter is provided with a detection bar, a melt can be sampled and analyzed at any time, the blowing-out sampling frequency is reduced, the converter temperature is kept constant, and the service life of the converter is longer. A supporting ring and supporting roller combined structure is adopted for supporting the top-blown converter, and large and small gear transmission is adopted, so that transmission is more stable, and vibration impact on the converter body is overcome.

Owner:YIXING YAOYUAN TECH DEV CO LTD

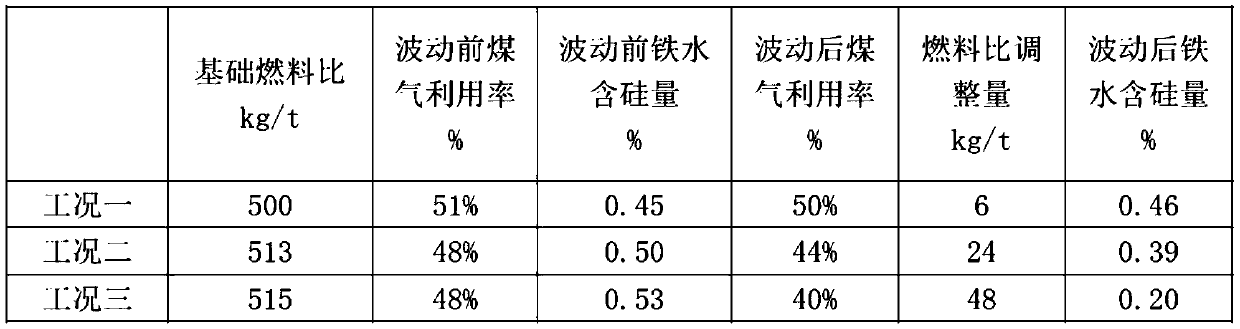

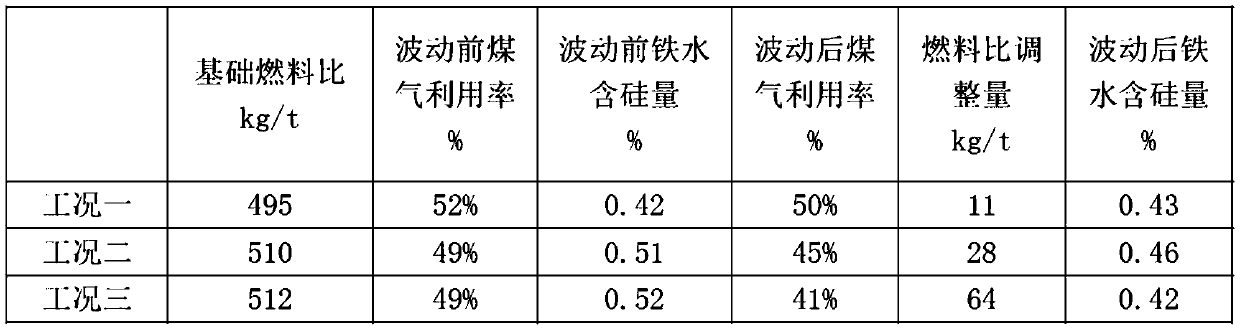

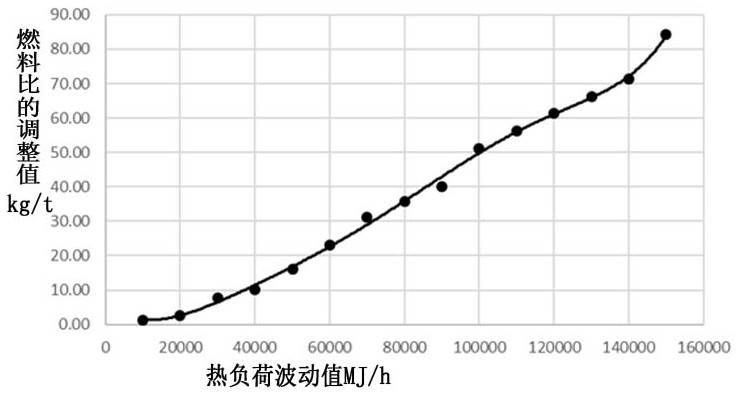

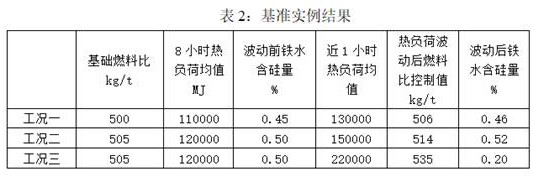

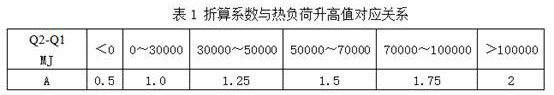

Furnace temperature control method for coping with fluctuation of blast furnace gas utilization rate

InactiveCN111041140AFurnace temperature remains stableGuarantee the quality of hot metalSteel manufacturing process aspectsBlast furnace detailsChemistryProcess engineering

The invention discloses a furnace temperature control method for coping with fluctuation of a blast furnace gas utilization rate. The furnace temperature control method comprises the following steps of acquiring a ton iron fuel ratio before fluctuation of the gas utilization rate, a carbon monoxide utilization rate before fluctuation and a carbon monoxide utilization rate after fluctuation; acquiring a fuel ratio control value by using the following formula FR = FR<1> + ((eta CO) <2>-(eta CO) <1>) x (0.0034 (eta CO) <2><2>-0.4177 (eta CO) <2> + 17.192), wherein in the formula, FR represents the fuel ratio control value, FR<1> represents a ton iron fuel ratio before fluctuation of a gas utilization rate, (eta CO) <1> represents the carbon monoxide utilization rate before fluctuation, and (eta CO) <2> represents the carbon monoxide utilization rate after fluctuation; and adjusting the blast furnace fuel ratio according to the fuel ratio control value. According to the furnace temperaturecontrol method for coping with the fluctuation of the blast furnace gas utilization rate, the fuel ratio control value after the fluctuation of the blast furnace gas utilization rate is quantified. When the furnace condition fluctuates and the gas utilization rate changes greatly, the fuel ratio control value can be quickly determined, the blast furnace fuel ratio is adjusted to keep the furnacetemperature stable, and the molten iron quality is guaranteed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

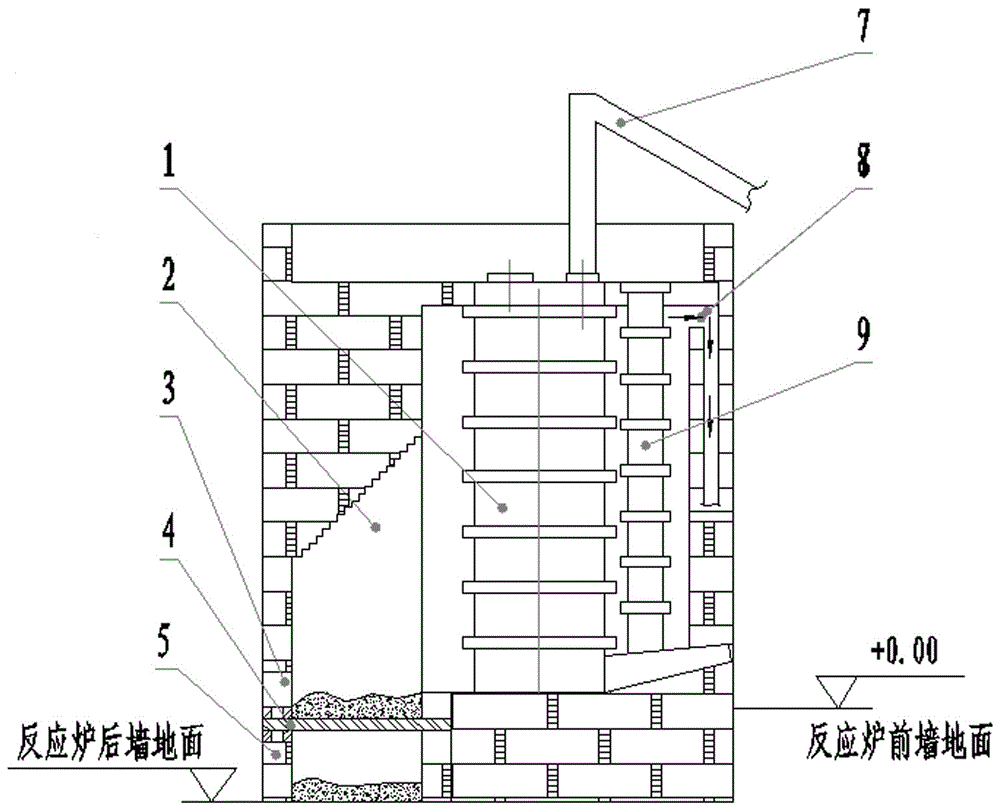

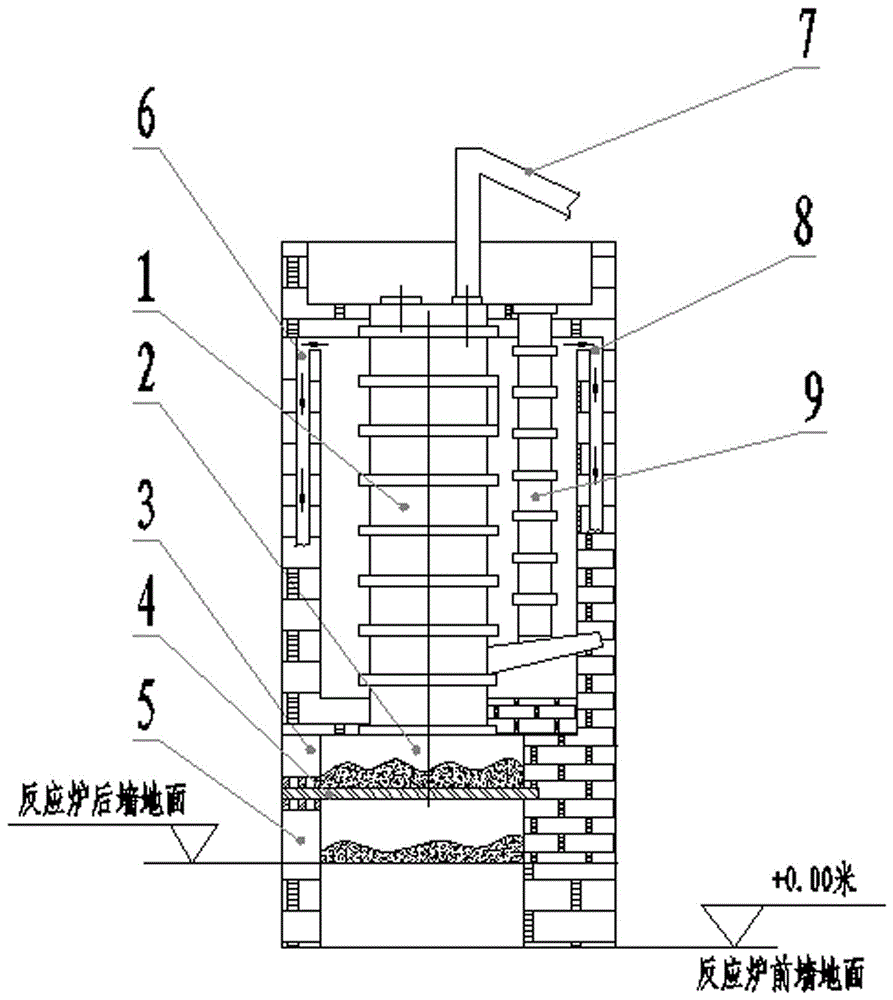

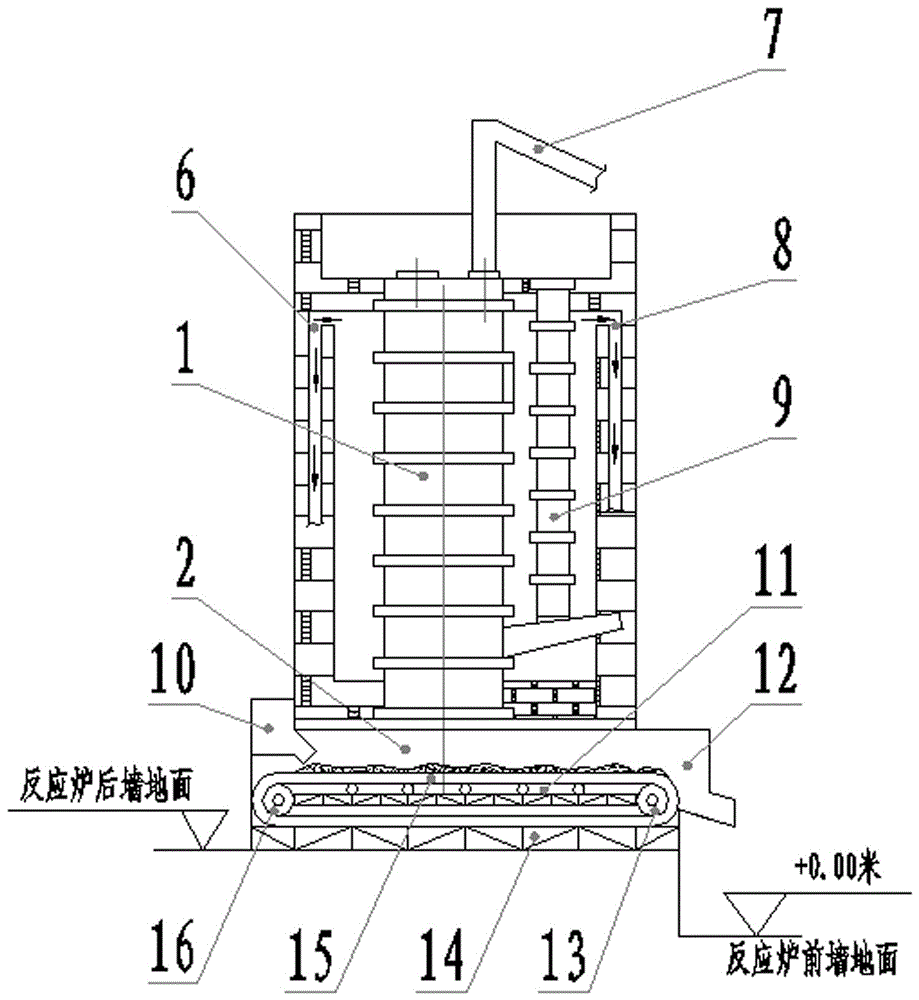

Energy-saving environment-friendly carbon bisulfide gasification reaction furnace

ActiveCN105948048ARealize online automatic controlReduce physical laborChemical industrySulfurHigh energy

The invention belongs to the technical field of coke-process carbon bisulfide production equipment, and aims to overcome the defects of high energy consumption, environment pollution caused by high exhaust emission, influence on production, large occupied area, high refractory material consumption for furnace construction and the like in the existing post external heating mode for the coke-process carbon bisulfide gasification reaction furnace. The invention provides an energy-saving environment-friendly carbon bisulfide gasification reaction furnace which comprises a furnace body and a sulfur gasification small furnace which are arranged in one closed cavity and connected with each other, wherein the top of the furnace body is provided with a carbon bisulfide recovery pipeline; the front wall and back wall of the closed cavity are symmetrically provided with a front smoke discharge channel and a back smoke discharge channel; and the bottom of the furnace body is provided with an external heating furnace. The front and back walls of the gasification furnace are symmetrically provided with the smoke discharge channels, and the external heating furnace is arranged on the bottom of the gasification furnace, thereby effectively solving the problems of high energy consumption, high pollution, large occupied area, high refractory material consumption for furnace construction and the like in the existing post external heating mode for the coke-process carbon bisulfide gasification reaction furnace.

Owner:阳城县绿色铸造研发中心 +1

Device for removing dioxin from flying garbage dust and treatment method of device

InactiveCN105889948AHigh degree of automationIncrease productionIncinerator apparatusNitrogenProduct gas

The invention relates to a device for removing dioxin from flying garbage dust and a treatment method of the device. According to the device, the discharge hole of a cabin is communicated with a thermolysis furnace; the thermolysis furnace is communicated with a nitrogen compensating tank, so that the thermolysis furnace is in a sealed environment in the presence of the protective nitrogen gas; a cooling pipeline a with a water jacket is connected to the upper end of the thermolysis furnace; the cooling pipeline a is communicated with a cooling dust collector; a cooling pipeline b with a water jacket is communicated with the upper part of the cooling dust collector; the cooling pipeline b is communicated with a cloth belt cooling dust collector a; a conveying pipeline is communicated with the lower end of the thermolysis furnace; a feeding hole communicated with a spiral conveying cooler is communicated to the lower end of the conveying pipeline; the discharge hole in the spiral conveying cooler is communicated with a pipeline; the pipeline is communicated with a cloth belt cooling dust collector b. The device can be adopted by a user for harmless thermolysis treatment on garbage flying ash, and is large in treatment capacity, high in automation degree and energy-saving, so that an environment can be free of dust or pollution.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

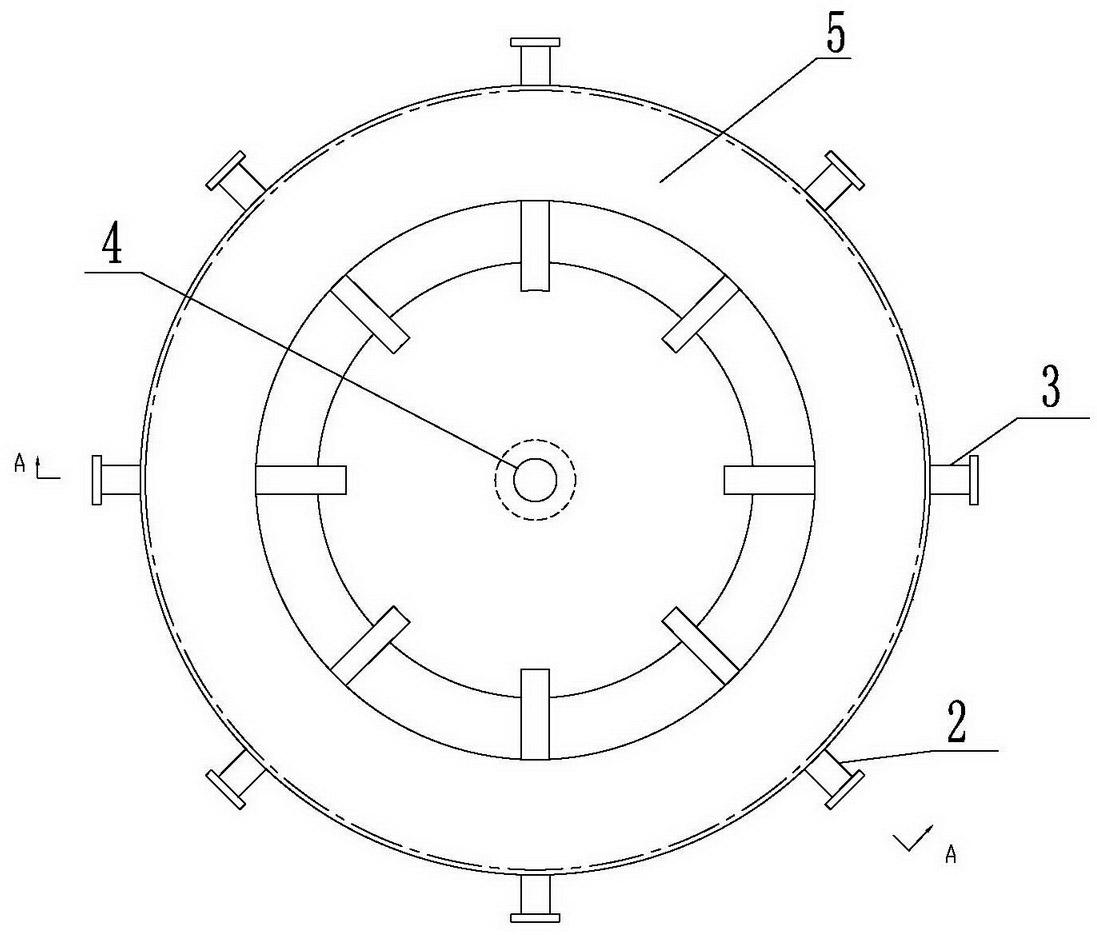

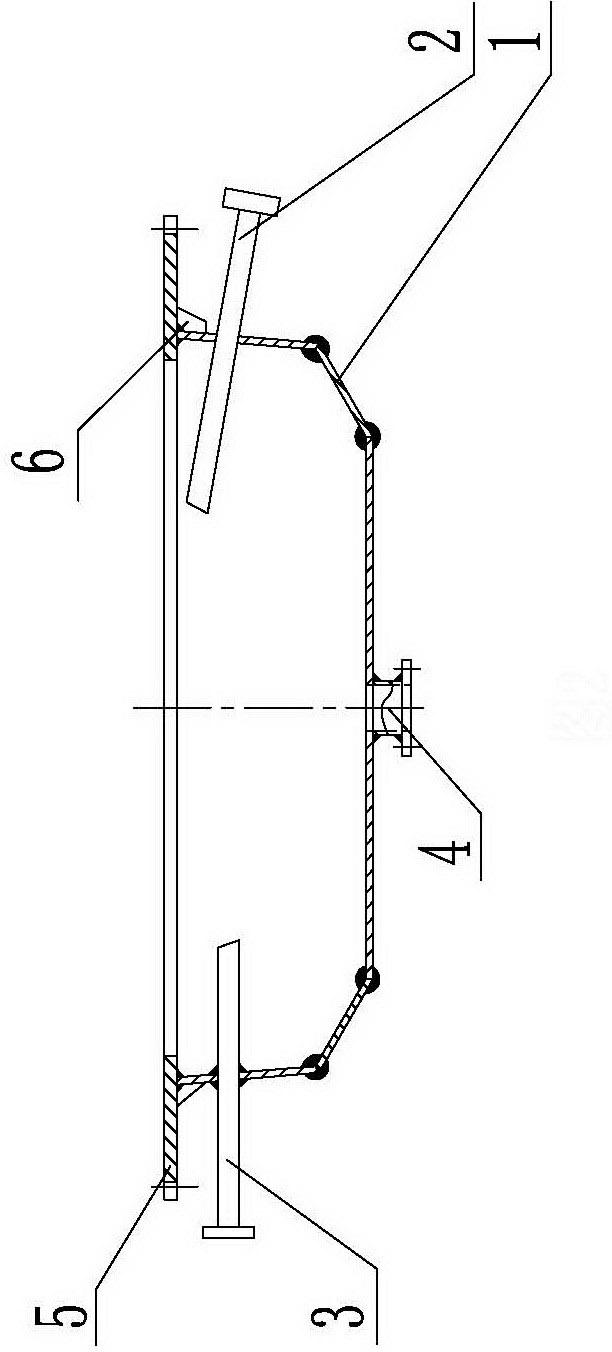

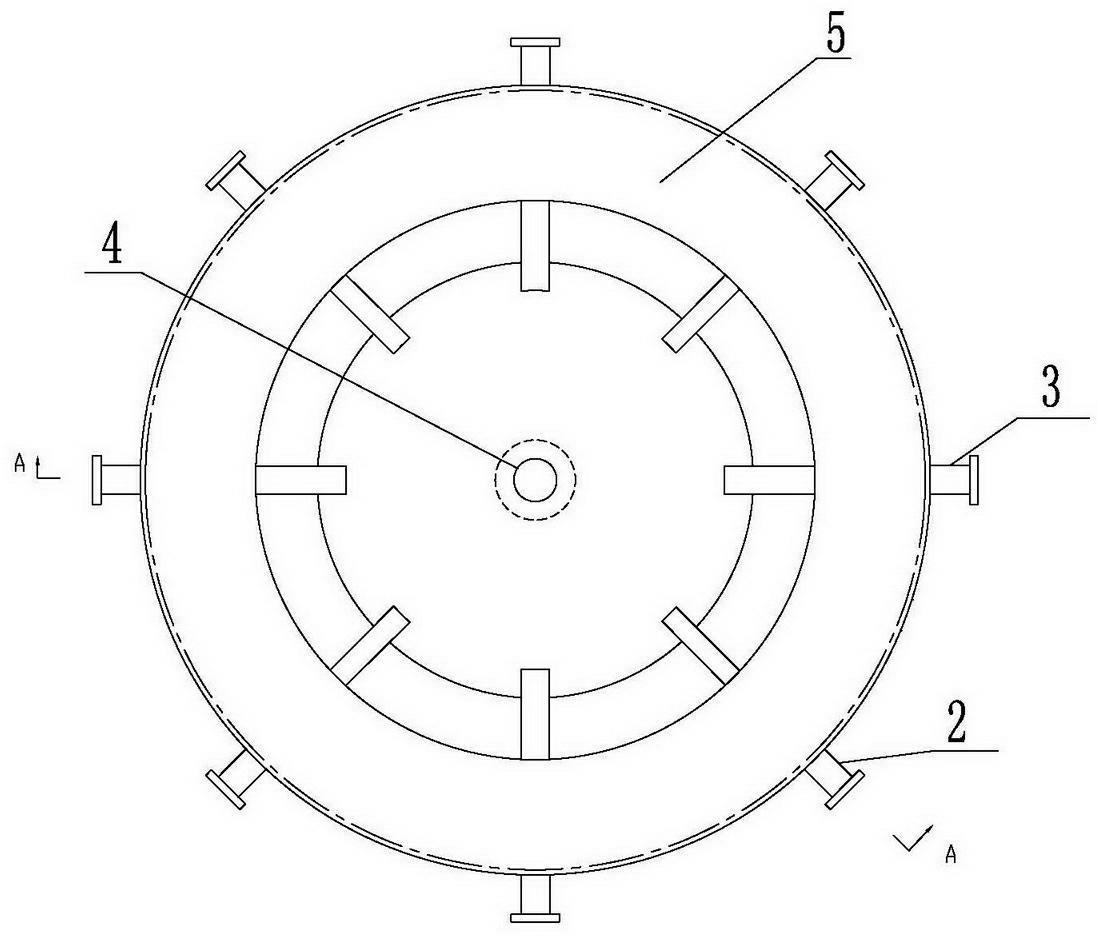

Novel furnace bottom distributor of sieve-plate-free fluidizing chlorination furnace

The invention discloses a novel furnace bottom distributor of a sieve-plate-free fluidizing chlorination furnace, which comprises a basin-shaped casing. A plurality of horizontal chlorine direct connection pipes and upward sloping chlorine oblique connection pipes are arranged along the lateral face of the casing, and the horizontal chlorine direct connection pipes and the upward sloping chlorineoblique connection pipes are distributed alternately. Due to the fact that the horizontal chlorine direct connection pipes and the upward sloping chlorine oblique connection pipes are distributed alternately, the chlorine oblique connection pipes also form a protective screen for the chlorine direct connection pipes while forming a self eddy protective screen, and thick calcium magnesium impurities and furnace clinkers are not apt to block the connection pipes. Simultaneously, airflow distribution can be even, the impurities are prevented from entering the connection pipes, so that certain fluidization speed is retained, furnace temperature is led to be stable, fluidization bed height is reasonable, stability and stability of production are improved, operation is easy and simple, chlorineunit consumption is reduced to 0.98t / t, sorting range of rich titanium material is improved, maximum content of the calcium magnesium impurities of the rich titanium material is improved to 4.5%-5%.

Owner:抚顺钛业有限公司

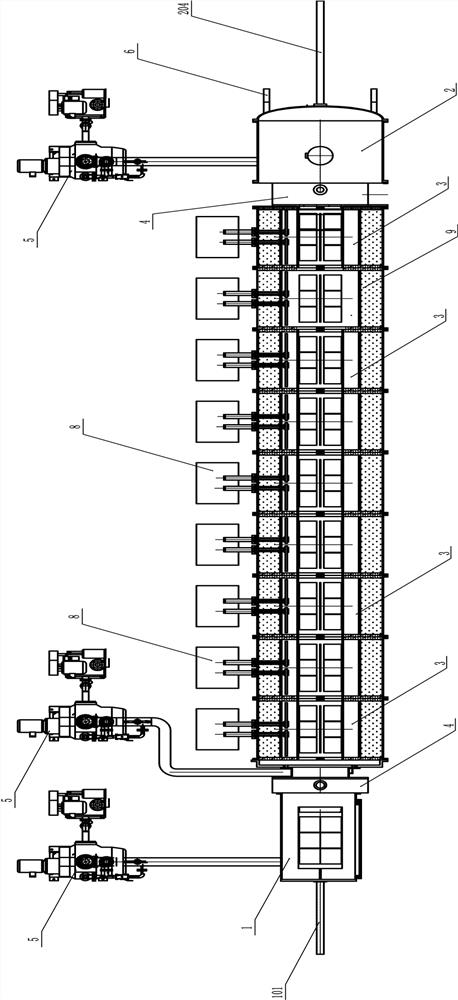

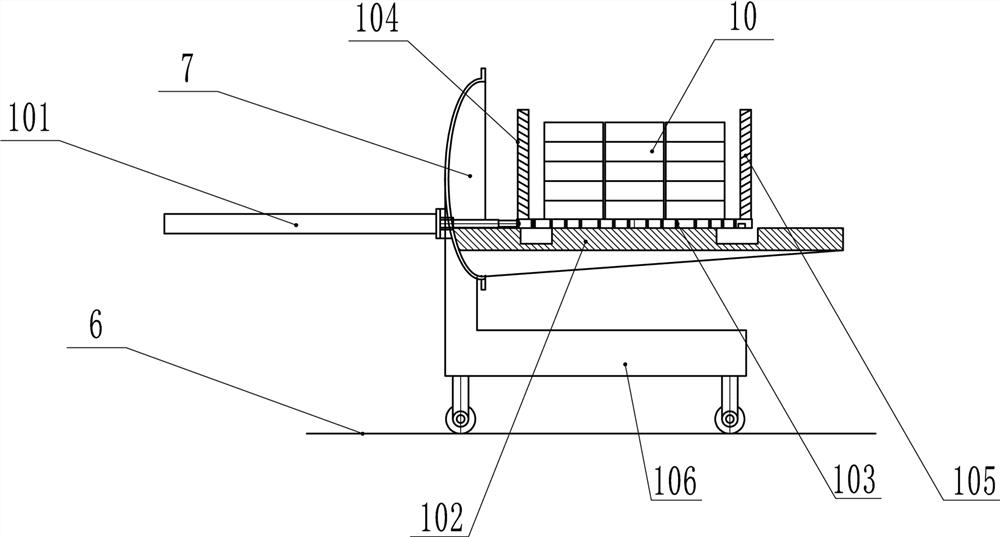

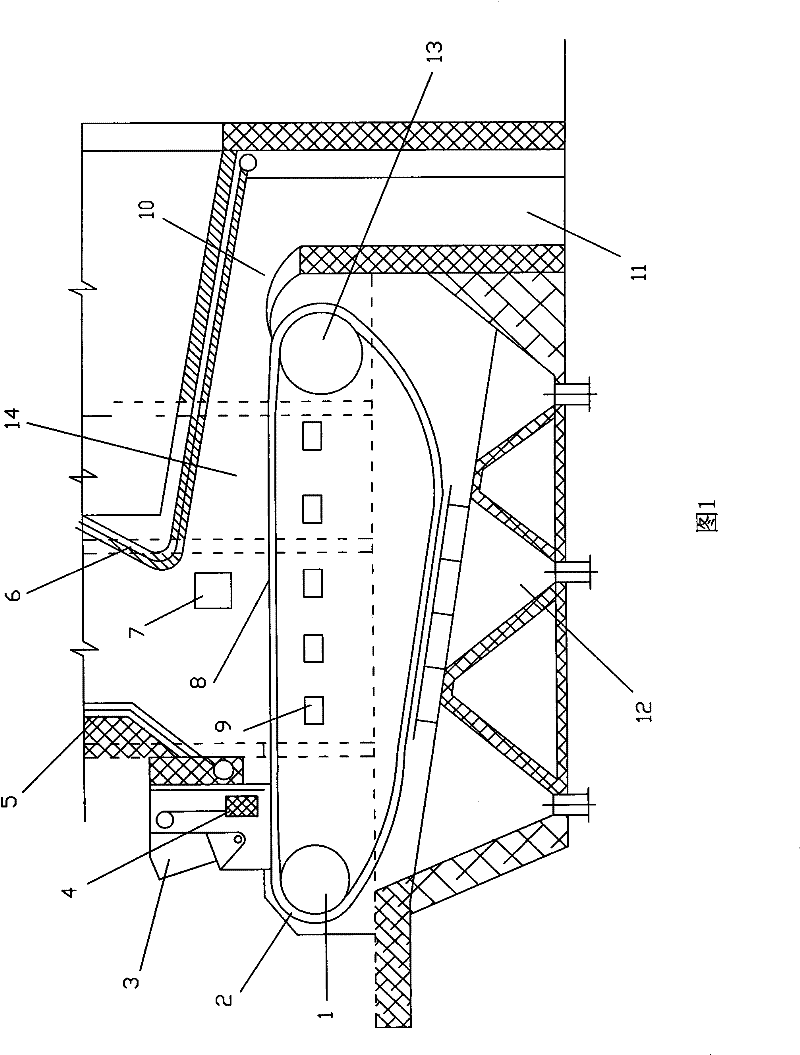

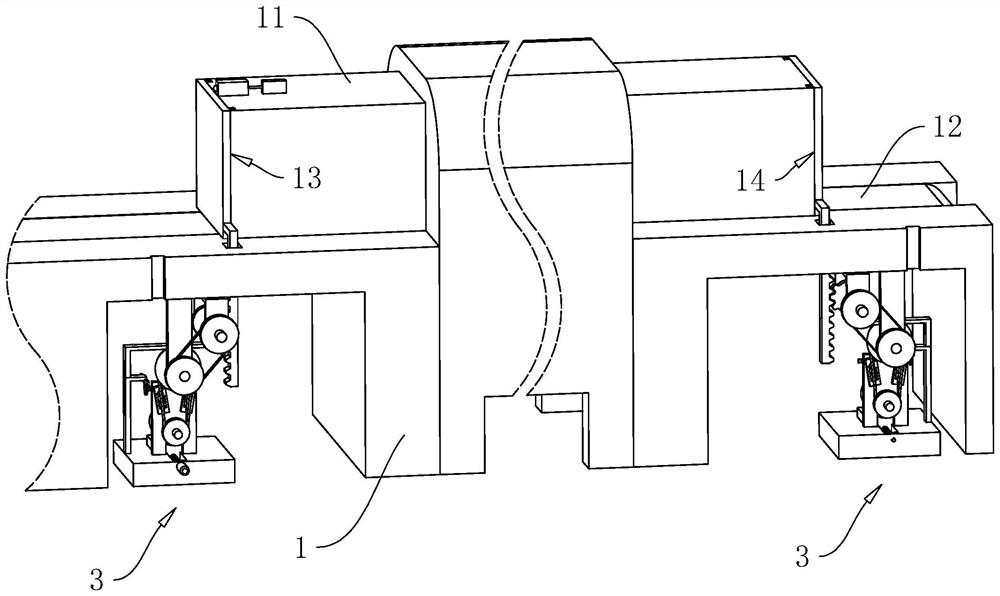

Continuous vacuum sintering furnace

InactiveCN112179128ANot easy to loseStable furnace temperatureCharge treatment typeFurnace typesCooling chamberMaterials science

The invention belongs to the technical field of sintering furnaces, and particularly relates to a continuous vacuum sintering furnace. The continuous vacuum sintering furnace comprises a vacuum furnace-entering preparation chamber, a sintering chamber with a plurality of temperature zones and an air cooling chamber which are sequentially communicated, wherein a gate valve is arranged at one end ofthe vacuum furnace-entering preparation chamber and one end of the air cooling chamber; the vacuum furnace-entering preparation chamber, the sintering chamber with the plurality of temperature zonesand the air cooling chamber respectively form three independent spaces through the gate valves; the vacuum furnace-entering preparation chamber, the sintering chamber and the air cooling chamber are respectively communicated with a vacuum unit and are respectively provided with a guide rail; a material pushing oil cylinder, a preparation chamber bracket and a sintering material frame are arrangedin the vacuum furnace-entering preparation chamber; and tray heat insulation plugs are arranged on two end sides of the sintering material frame. Since there is no partition in the sintering chamber,a vacuum unit is used in common, and there is no conveying mechanism in the sintering chamber, so that the overall complexity is greatly reduced, and the cost is reduced. Heating bodies are arranged at the periphery and the center of the interior of the sintering chamber, so that the heat transfer distance is shortened by one time, the temperature uniformity speed is increased, and the sintering time is shortened.

Owner:JIANGXI KAIYUAN AUTOMATIC EQUIP CO LTD

Excess air coefficient management system for kiln

PendingCN107655029AStable furnace temperatureImprove firing efficiencyFuel supply regulationControl devices for furnacesHearthPressure detection

The invention discloses an excess air coefficient management system for a kiln. The excess air coefficient management system comprises a burner arranged in the kiln, a thermocouple, a temperature control instrument, a fuel gas actuator, a fuel gas proportional valve, an air actuator and an industrial personal computer. The fuel gas actuator and the fuel gas proportional valve are connected to a fuel gas pipeline of the burner in series one after another. The air actuator is connected to an air pipeline of the burner in series. An air pressure detection device of the fuel gas proportional valveis connected with the air pipeline of the burner. The thermocouple, the industrial personal computer, the fuel gas actuator and the air actuator are connected with the temperature control instrument.According to the baking technology of green bricks, burner sets have different optimal air-fuel ratios during the different firing stages. Meanwhile, when the kiln is not in operation, the burner isin a low fire state, combustion-supporting wind can achieve automatic adjustment and the optimal ratio of fuel gas. The whole process is completely controlled by the program edited in advance, precisecontrol over excess air coefficients is achieved, the stability of temperature of the hearth is ensured, the firing efficiency is improved, and energy consumption is reduced.

Owner:MODENA TECH LTD

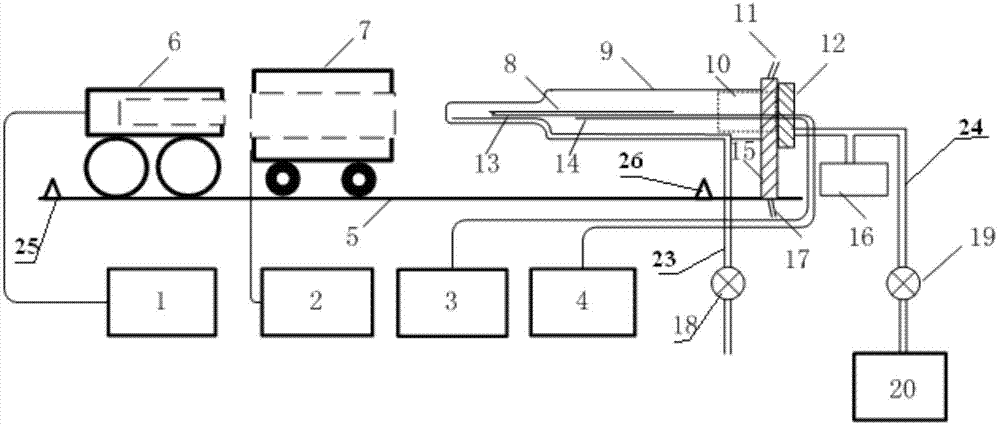

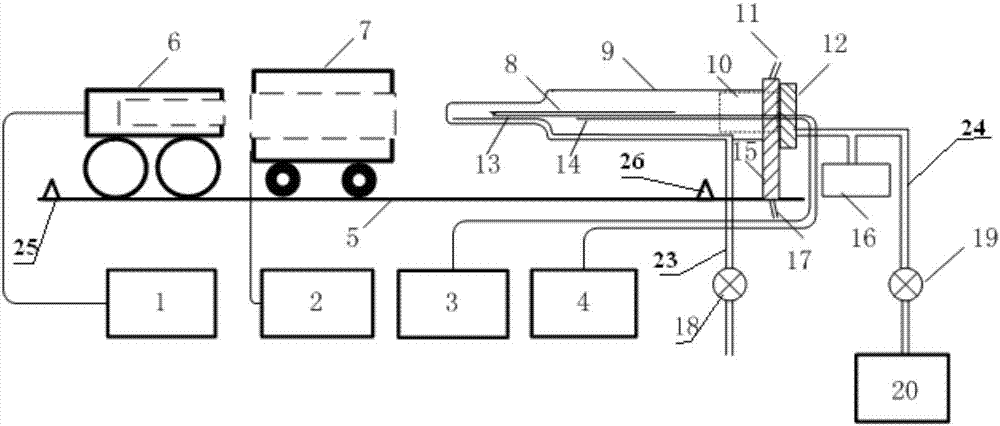

Device for semiconductor laser unit Zn impurity source diffusion and application thereof

ActiveCN104716027APrevent proliferationAvoid decompositionSemiconductor/solid-state device manufacturingHigh concentrationFurnace temperature

The invention relates to a device for semiconductor laser unit Zn impurity source diffusion. The device comprises a first diffusion heating furnace and a second diffusion heating furnace which are arranged on a track in sequence. The first diffusion heating furnace is in the shape of a groove with one end sealed. The second diffusion heating furnace is in the shape of a hollow-out ring. The position, at one end of the track, behind the second diffusion heating furnace is provided with a support. The support is provided with a quartz tube with one end sealed and the other end open. A first thermocouple and a second thermocouple are sequentially arranged in the quartz tube in the longitudinal direction. The front-half portion of a quartz boat is arranged on the first thermocouple. The rear-half portion of the quartz boat is arranged on the second thermocouple. According to the device, the separation of a diffusion source and a chip is adopted, a double-temperature area is adopted to control the temperature of the diffusion source and the temperature of the chip, and during the diffusion process, the temperature of the diffusion source and the temperature of the chip are controlled so that the stability of a furnace temperature can be guaranteed; GaAs on the surface layer of the chip of a laser unit is prevented from decomposing in large quantity under the diffusion temperature, so that a high-concentration surface layer which has the advantages of being bright in surface, even in distribution of the Zn concentration, good in repeatability, and free of damage is obtained.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

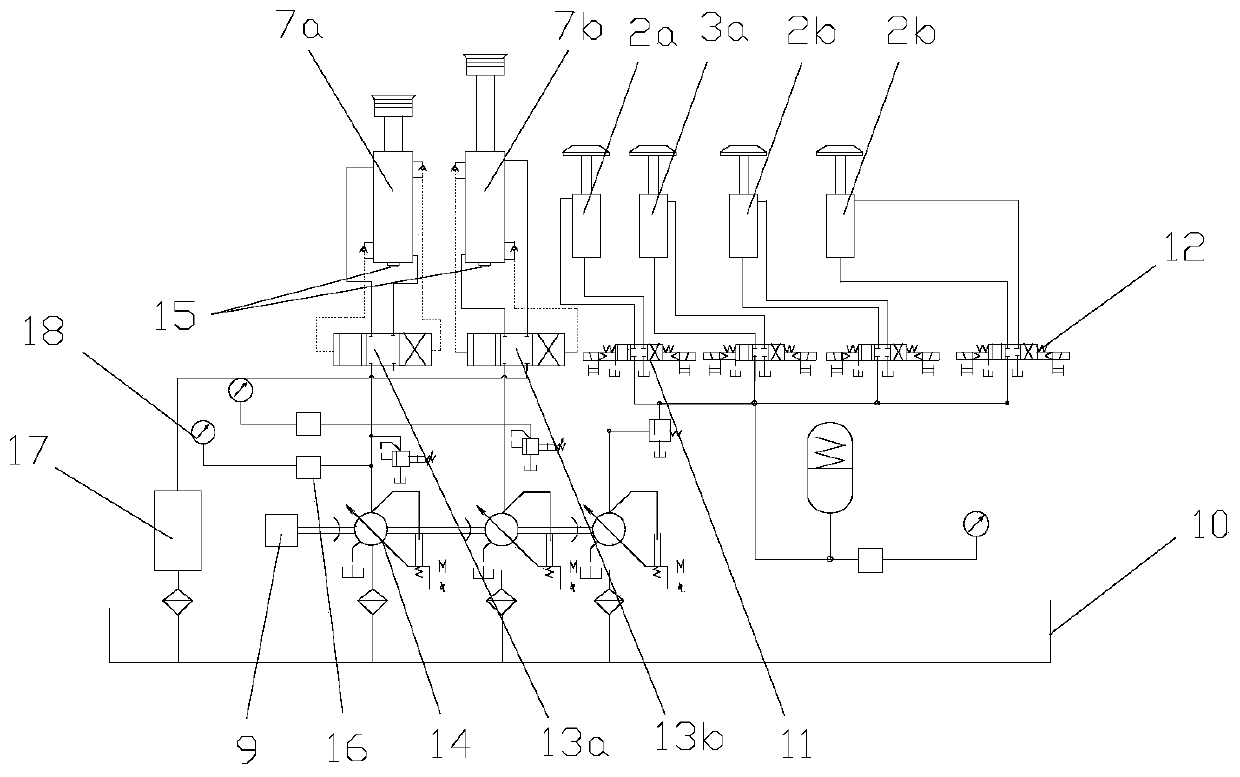

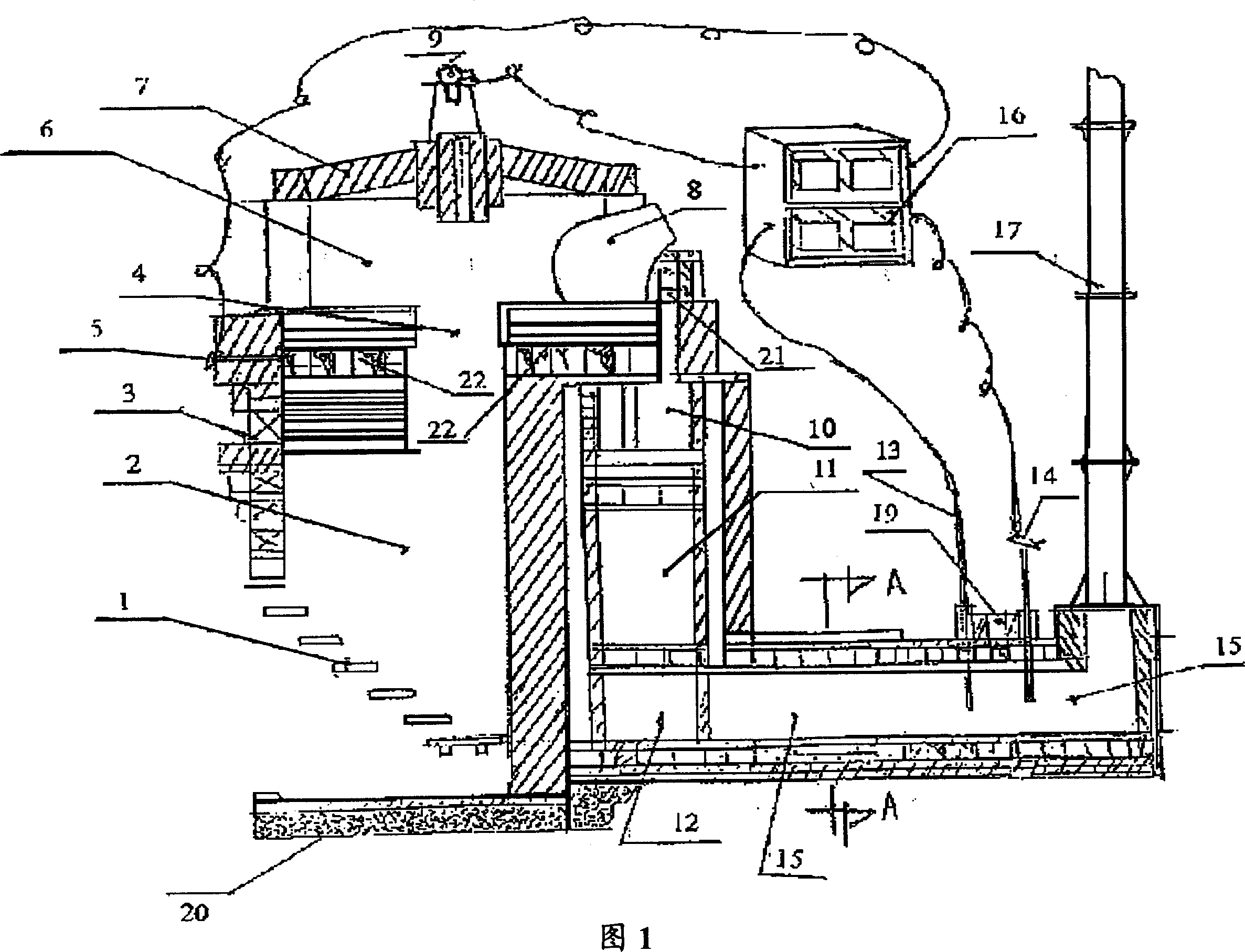

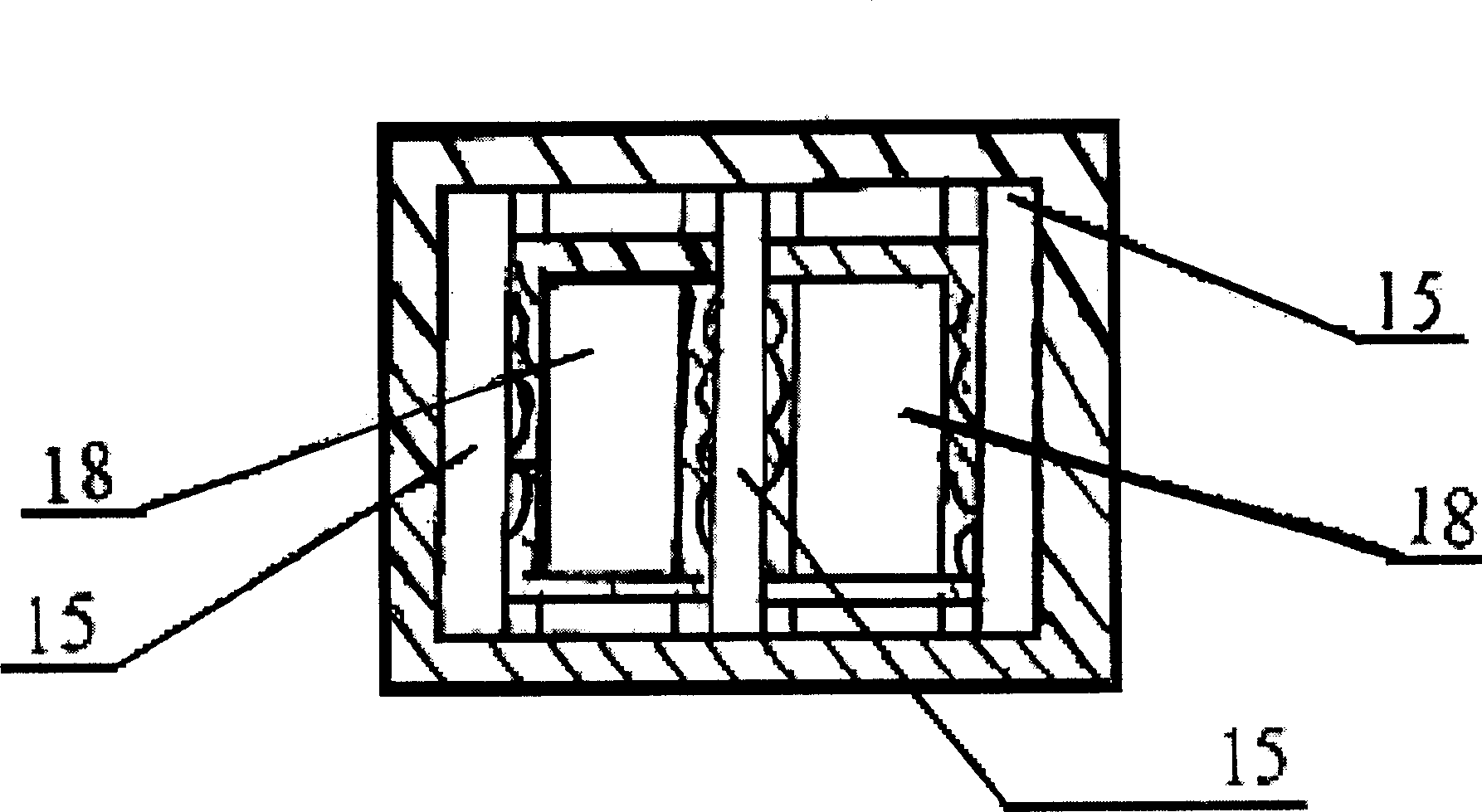

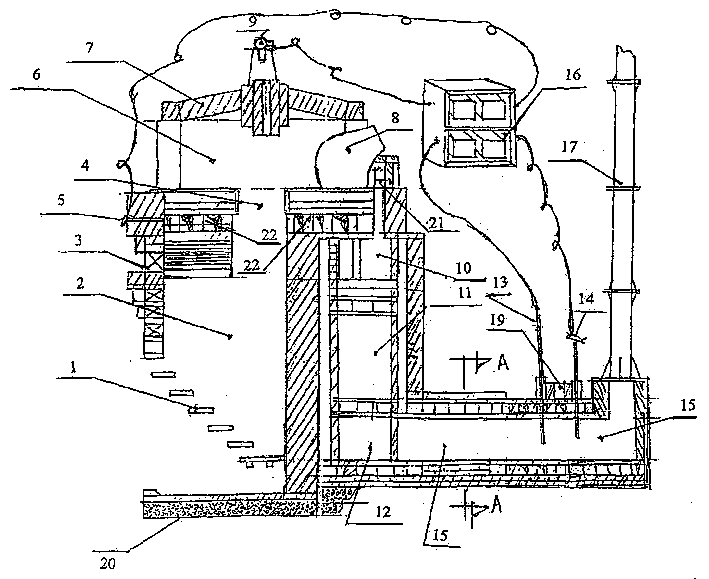

Constant-pressure constant-flow sludge pumping system

PendingCN110701032AStabilizationRealize continuous productionPump controlPositive-displacement liquid enginesEngineeringElectric control

The invention discloses a constant-pressure constant-flow sludge pumping system, relates to the technical field of sludge disposal equipment, and aims to solve the problem that an existing sludge pumping system cannot continuously convey sludge at constant pressure and constant flow. The system comprises a sludge plunger pump, a hydraulic system and an electric control system. The hydraulic systemcomprises a motor, three variable plunger oil pumps, an oil tank, a hydraulic control three-position four-way reversing valve for controlling the main oil cylinder, two first electromagnetic three-position four-way reversing valves for controlling discharge cone valves, and two second electromagnetic three-position four-way reversing valves for controlling feeding cone valves. The variable plunger oil pumps are located above the oil tank and connected with the oil tank through oil pipes. The electric control system comprises a PLC, a displacement sensor and a pressure transmitter, wherein thedisplacement sensor and the pressure transmitter are in control connection with the PLC. By means of the system, sludge can be continuously conveyed at constant pressure and constant flow, continuousproduction is achieved in the aspects of sludge carbonization and sludge thermal hydrolysis, the production efficiency is improved, the furnace temperature can be stabilized in the aspect of sludge incineration, and meanwhile, later tail gas treatment is stable.

Owner:XUZHOU SHENGYUAN ENVIRONMENTAL TECH CO LTD

Glass melting crucible furnace with dual flow directions

InactiveCN1396129AReasonable designExtend your lifePot furnacesGlass productionCombustion chamberPollutant emissions

A glass smelting crucible furnace with exhausting waste gas in forward direction and recovering heat energy in reverse direction features that its combustion box above grate has ash layer, fire layer, coal layer and air layer, its combustion chamber is composed of pre-burning flame nozzle and smelting chamber, and the fume flow through three fle layers, heat exchanger, and venting from chimney. Its advantages are high and stable furnace temp., low coal consumption no black smoke, and no environmental pollution.

Owner:李津贵

Production method of non-loose steel wire rope

ActiveCN111621635AUniform internal organizationHigh tensile strengthRope making machinesFurnace typesWire rodMegasonic cleaning

The invention provides a production method of a non-loose steel wire rope. The production method comprises the steps of wire rod forming: selecting 304 stainless steel wires with diameter of 5.5mm; surface treatment: soaking the wires in dilute hydrochloric acid to remove an oxide film; wire drawing: drawing the wires with the diameter of 5.5mm into 1.5mm steel wires; stranding: stranding a plurality of layers of steel wires into rope strands; rope laying up: stranding the rope strands around the center line of a rope core on a laying-up machine into a steel wire rope; heat treatment: puttingthe laid-up steel wire rope strand in a heat treatment furnace for heat treatment, and carrying out ultrasonic cleaning and cooling after heat treatment; and inspection: calculating the safety factorof the steel wire rope. The production method provided by the invention is not used in the steel wire rope at present, and the produced steel wire rope has the advantages that all layers of steel wires inside the steel wire rope are in close contact with each other, the non-looseness performance is excellent, the fatigue resistance is good, the stability is good, and the service life is long.

Owner:江苏亚盛金属制品有限公司

Method for burning sludge of chain furnace

InactiveCN101324337BHigh thermal efficiencyStable furnace temperatureIncinerator apparatusHeating furnaceDewatered sludge

Owner:ZHEJIANG HUAZHANG TECH

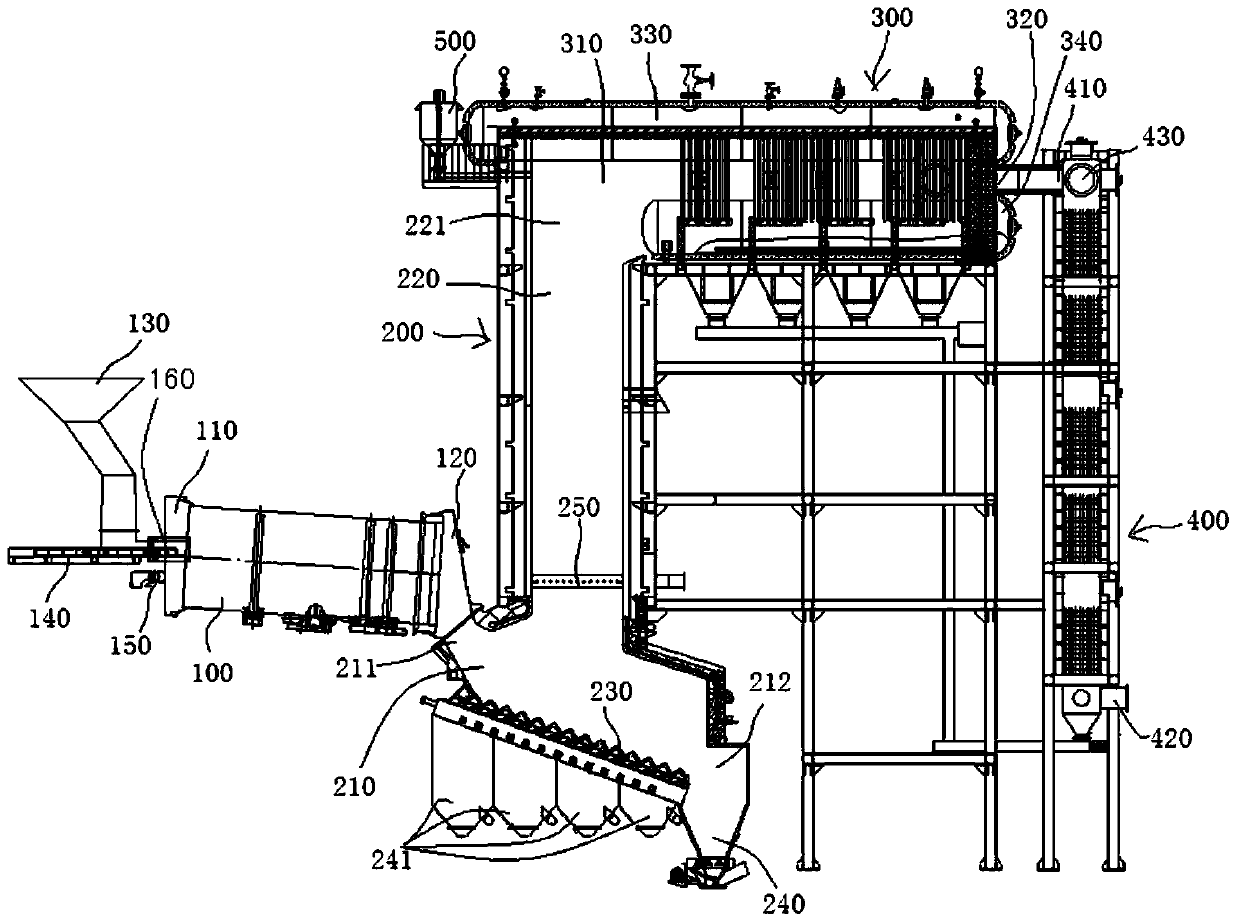

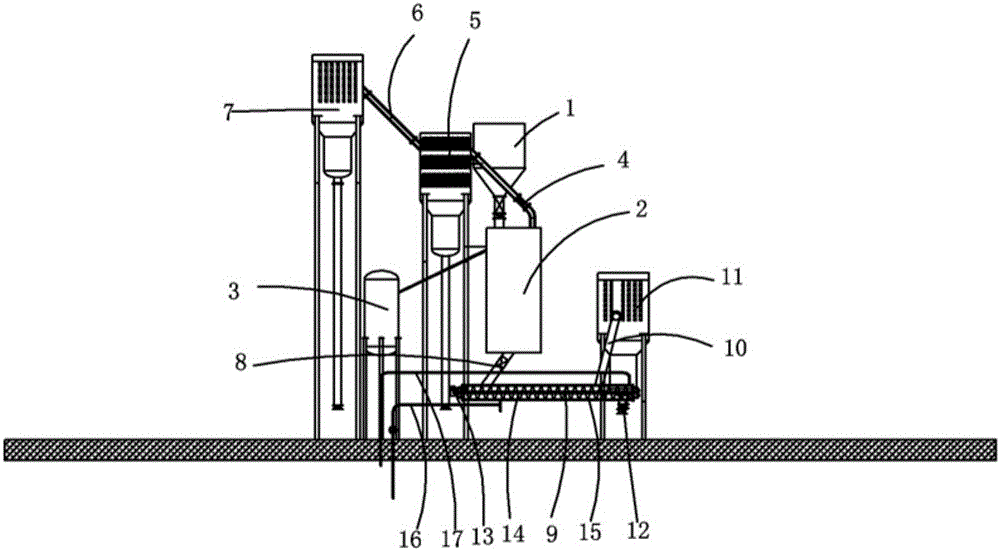

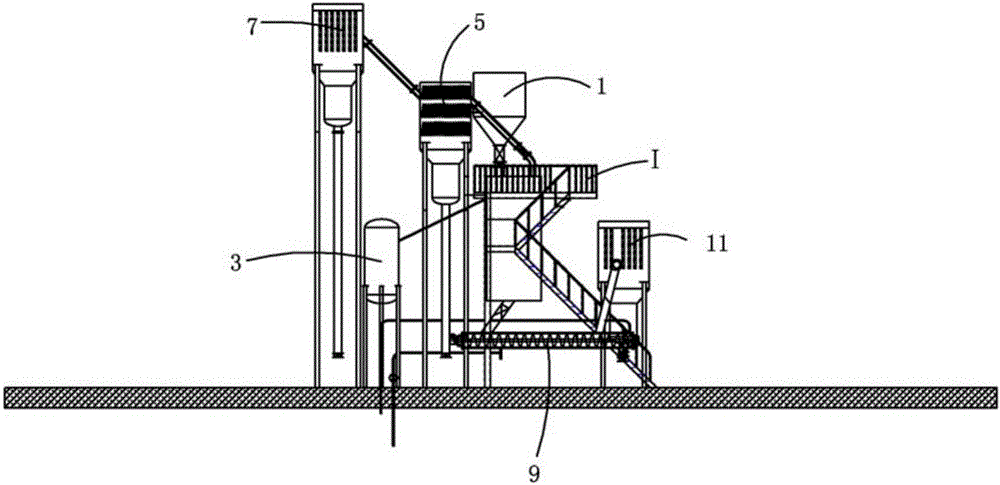

Coal fine preparation, blowing method and device from packed-bed smelting reduction furnace

The invention discloses a filling bed COREX stove braise preparing and blowing method which comprises the following steps of: a) putting mine run coal which is applicable to melting in the COREX stove and producing reducing gas into a run coal bin by crushing and screening the mine run coal into crushed coal; b) milling the crushed coal to minus 200 meshes and above 60 percent by a coal-milling device provided by a coal feeder and carrying out drying at the same time; and c) putting the finished braise into a pulverized coal bunker after the separation of gas and powder; loading the braise into 2 or 3 coal injecting tanks sequentially; transporting the braise to a distributor mechanism positioned at the top of a melting gasification furnace of the COREX stove by using pressured gas after the processes of pressurizing fluidization and gas supplement; distributing the braise to the blowing branch pipe which is led to the oxygen tuyere of the melting gasification furnace; spraying the braise into the melting gasification furnace by a coal injection gun. The method has the advantages that the in-place digestion and utilization of powder sifted range coal of the filling bed COREX stoveis realized; and the total coal consumption of the COREX stove can be reduced by replacing part range coal; therefore, the cost of production is reduced; more optimized COREX melting reduction process and more flexible operation are realized.

Owner:BAOSTEEL ENG & TECH GRP +1

Continuous hydrogen decrepitation method for rare earth permanent magnetic alloy

The invention provides a continuous hydrogen decrepitation method for a rare earth permanent magnetic alloy. The method is carried out in a continuous hydrogenation furnace provided with an activation chamber, a hydrogen absorption chamber, a first dehydrogenation chamber, a second dehydrogenation chamber and a cooling chamber. The continuous hydrogen decrepitation method comprises the following steps that the rare earth permanent magnetic alloy is activated in the activation chamber; selective hydrogen absorption is carried out in the hydrogen absorption chamber; circulating heating dehydrogenation is carried out in the first dehydrogenation chamber and the second dehydrogenation chamber; cooling is carried out, that is, forced cooling is carried out in the cooling chamber through argon. The heating dehydrogenation process in the first dehydrogenation chamber is divided into two stages; the temperature in the first stage ranges from 400 DEG C to 550 DEG C, and the temperature in the second stage ranges from 550 DEG C to 600 DEG C; the heating dehydrogenation process in the second dehydrogenation chamber is divided into two stages; and the temperature in the first stage ranges from 550 DEG C to 600 DEG C, and the temperature in the second stage ranges from 400 DEG C to 550 DEG C.

Owner:SANVAC BEIJING MAGNETICS +1

Furnace temperature control method for coping with blast furnace thermal load fluctuation

ActiveCN114134267AStable furnace temperatureQuality assuranceBlast furnace detailsTemperature controlFurnace temperature

The invention relates to the field of blast furnace temperature control, in particular to a furnace temperature control method for coping with blast furnace thermal load fluctuation, which accurately reflects fuel ratio adjustment quantity under different thermal load change values according to change characteristics of actual operation parameters of blast furnace production so as to ensure the stability of furnace temperature level and fully utilize in blast furnace thermal system adjustment. And the blast furnace operation can be guided when the furnace condition of the blast furnace fluctuates greatly. According to the utilization of the method, when the furnace condition fluctuates, a basis can be effectively provided for blast furnace recovery operation, operation errors are reduced, and the recovery rhythm is accelerated.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

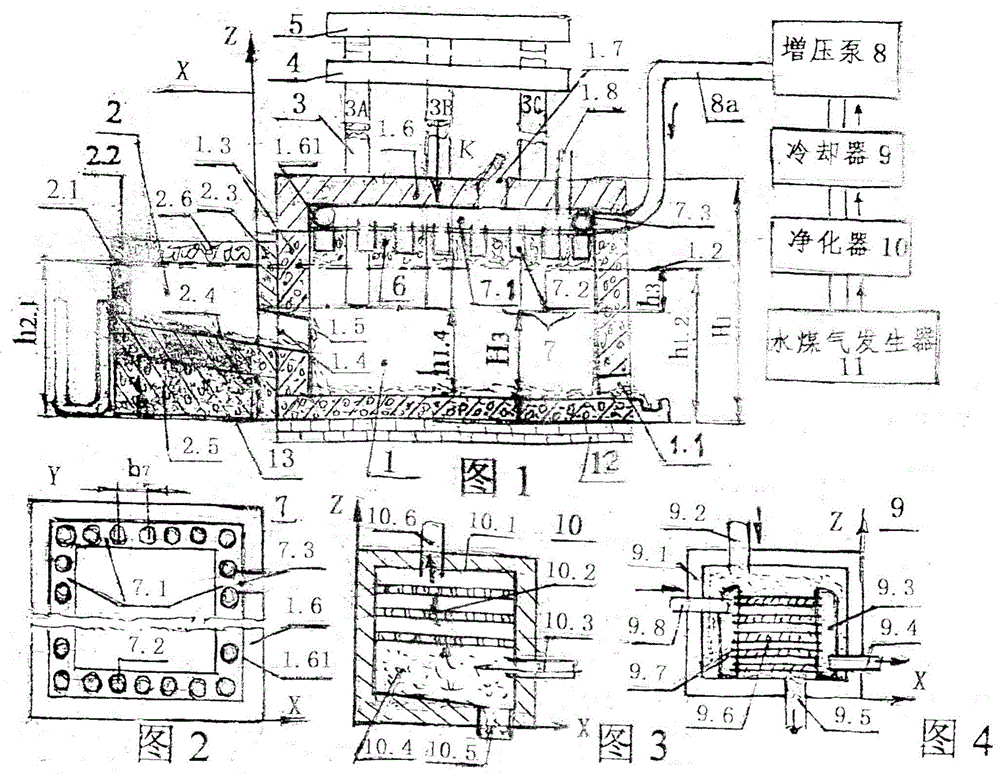

Combined protection smelting furnace and smelting method

ActiveCN104482764BHigh recovery rateImprove pollutionIncreasing energy efficiencyFurnace typesDecompositionAlternating current

The invention discloses a combined protection smelting furnace and a smelting method. The combined protection smelting furnace consists of a big furnace body, a small furnace body and a water gas system, wherein the big furnace body is heated by alternating current, water gas is injected into the big furnace body, ores are arranged in the big furnace body, and the small furnace body is communicated with the big furnace body; the water gas system is provided with a water gas generator, a purifier, a cooler and a pressure-increasing pump. The water gas of which the pressure is increased is led into a rectangular annular pipe and a plurality of vertical spraying pipes above the big furnace body, and is sprayed into the ores during smelting. Carbon oxide and hydrogen in the water gas reduce metal oxides in the ores into metal, so that the metal recovery rate is greatly improved; inert gases in the water gas protect the reduced metal against decomposition, so that residual metal in exhausted tail gas after smelting is none, and air is not polluted; metal content in waste residue is greatly reduced, and the requirement of environment friendliness on a building material is met; the small furnace body can increase the space and time for metal deposition of slag liquid, and the improvement of metal recovery rate is promoted; the smelting process is continuously and automatically performed, so that compared with the current method that smelting and emission are performed one furnace by one furnace by continuously increasing and reducing an alternating-current electrode, the smelting method has the advantages that about 15 percent of electric energy is saved and the efficiency is greatly improved, and the method can be used for smelting various metals, such as copper, from the ores.

Owner:深圳市原性环保科技有限公司

A kind of device and application of semiconductor laser zn impurity source diffusion

ActiveCN104716027BAvoid decompositionStable furnace temperatureSemiconductor/solid-state device manufacturingFurnace temperatureHigh concentration

The invention relates to a device for semiconductor laser unit Zn impurity source diffusion. The device comprises a first diffusion heating furnace and a second diffusion heating furnace which are arranged on a track in sequence. The first diffusion heating furnace is in the shape of a groove with one end sealed. The second diffusion heating furnace is in the shape of a hollow-out ring. The position, at one end of the track, behind the second diffusion heating furnace is provided with a support. The support is provided with a quartz tube with one end sealed and the other end open. A first thermocouple and a second thermocouple are sequentially arranged in the quartz tube in the longitudinal direction. The front-half portion of a quartz boat is arranged on the first thermocouple. The rear-half portion of the quartz boat is arranged on the second thermocouple. According to the device, the separation of a diffusion source and a chip is adopted, a double-temperature area is adopted to control the temperature of the diffusion source and the temperature of the chip, and during the diffusion process, the temperature of the diffusion source and the temperature of the chip are controlled so that the stability of a furnace temperature can be guaranteed; GaAs on the surface layer of the chip of a laser unit is prevented from decomposing in large quantity under the diffusion temperature, so that a high-concentration surface layer which has the advantages of being bright in surface, even in distribution of the Zn concentration, good in repeatability, and free of damage is obtained.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Mesh belt type sintering furnace

PendingCN113865338AStable furnace temperatureQuality improvementFurnace doorsFurnace typesPowder metallurgyEngineering

The invention discloses a mesh belt type sintering furnace. The mesh belt type sintering furnace comprises a rack, a furnace body is arranged on the rack, a conveying belt is rotationally installed on the rack, a feeding port and a discharging port are formed in the two ends of the furnace body respectively, the conveying belt penetrates through a furnace cavity of the furnace body through the feeding port and the discharging port, baffles are arranged on the portions, at the discharging port and the feeding port, of the furnace body, the two baffles shield the feeding port and the discharging port respectively, and two driving mechanisms used for driving the two baffles to be opened intermittently are arranged on the rack. According to the mesh belt type sintering furnace, when an installed powder metallurgy mold is conveyed to the feeding port through the conveying belt, the driving mechanism moves the baffle to open the feeding port, and after the mold enters the furnace cavity of the furnace body, the driving mechanism moves the baffle to shield the feeding port, interaction between external cold air and hot air in the furnace cavity of the furnace body during working of the furnace body is reduced, so that the temperature of the furnace in the furnace cavity of the furnace body is relatively stable, and the quality of finally sintered and molded parts is improved.

Owner:浙江孚菱机械有限公司

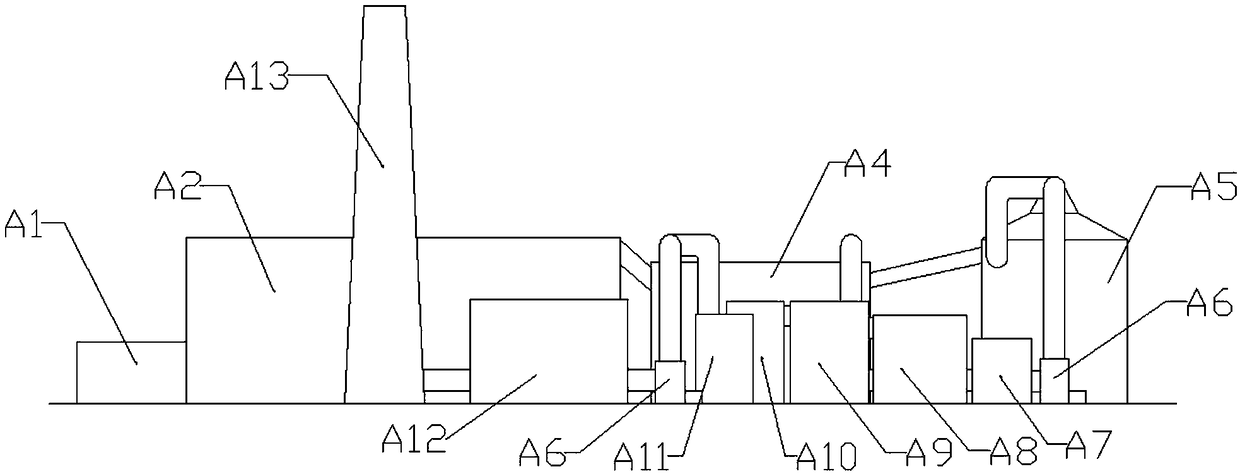

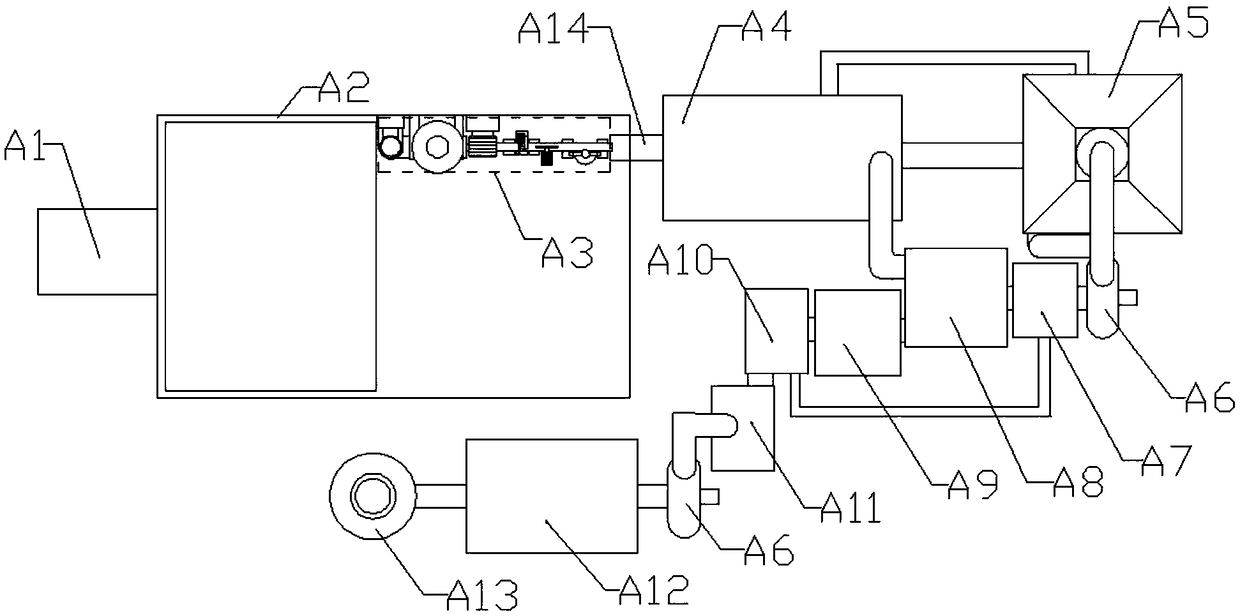

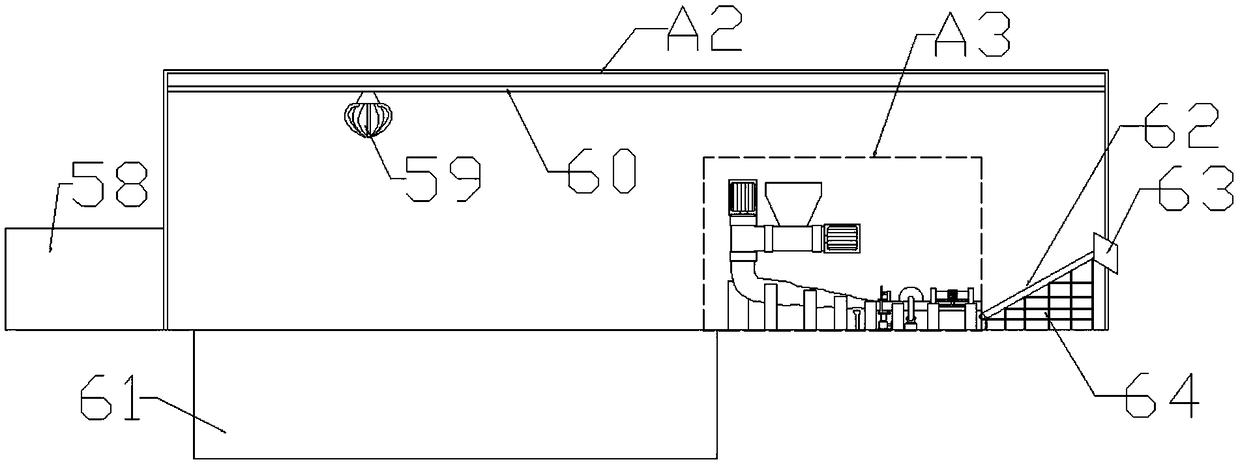

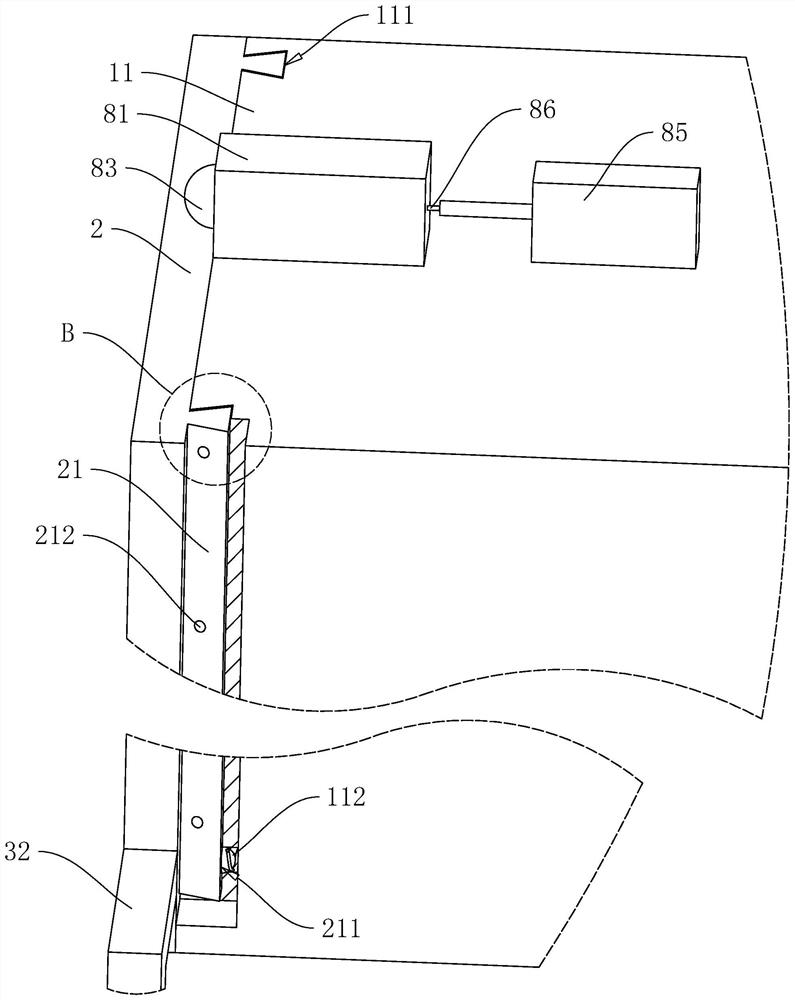

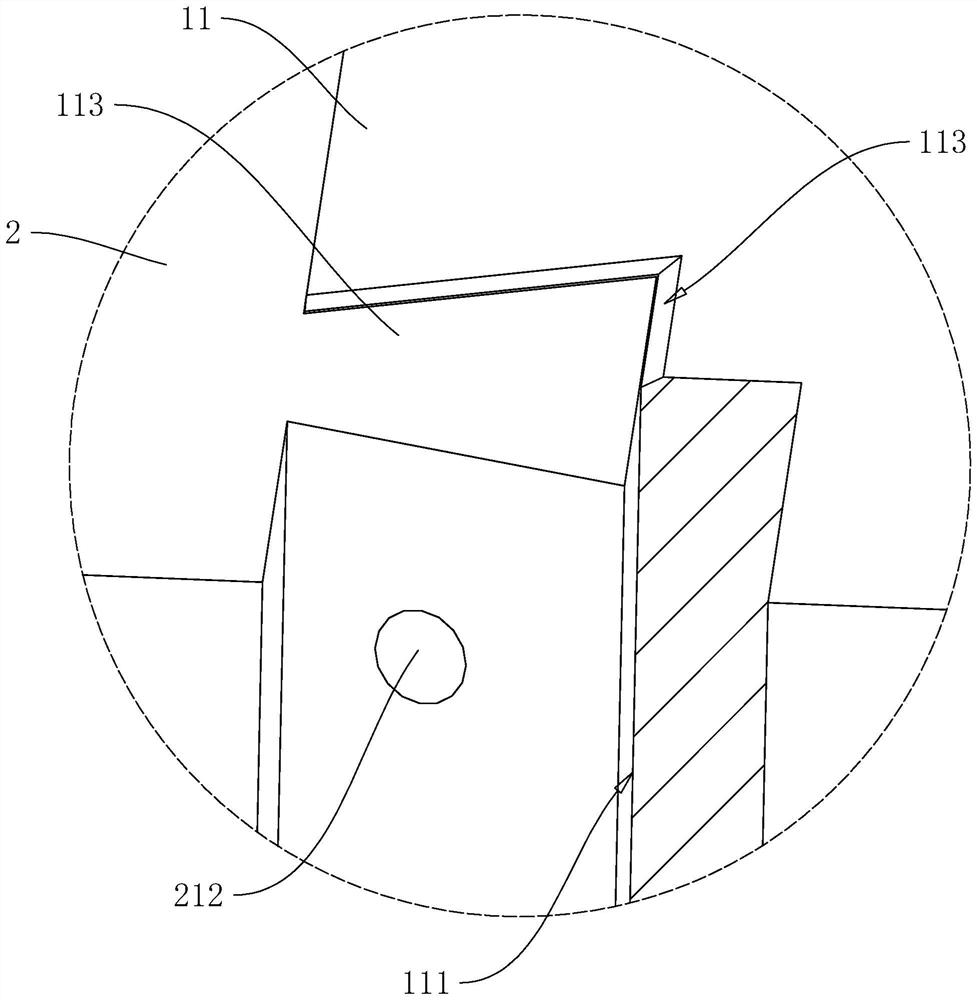

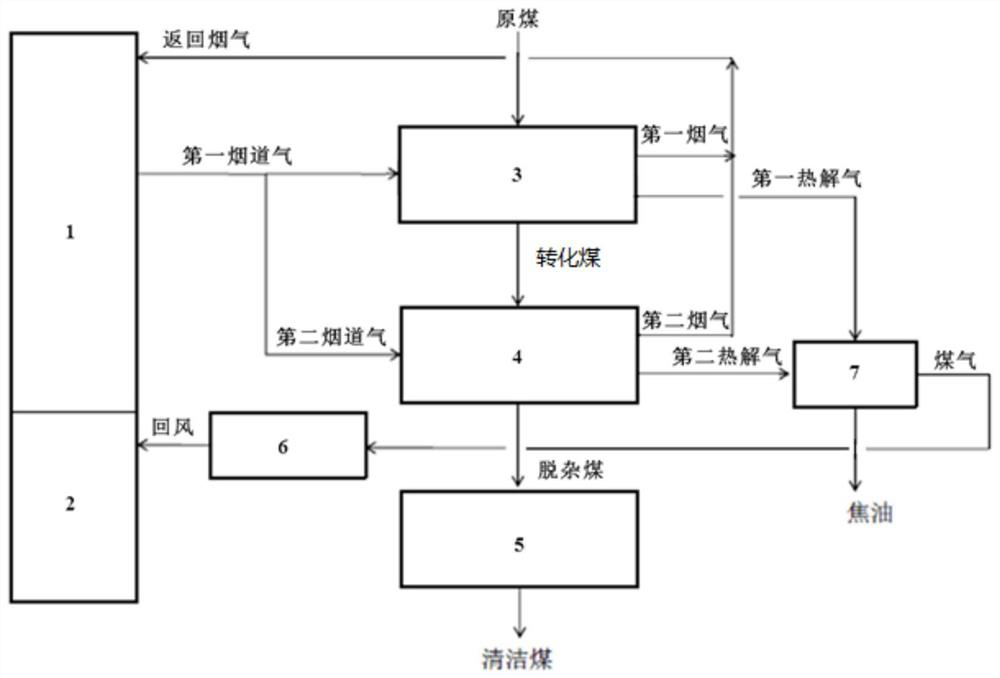

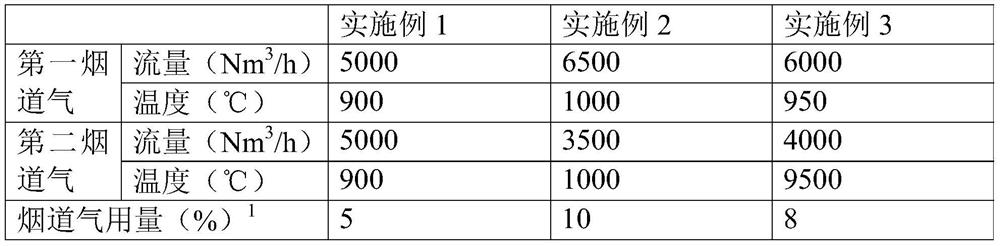

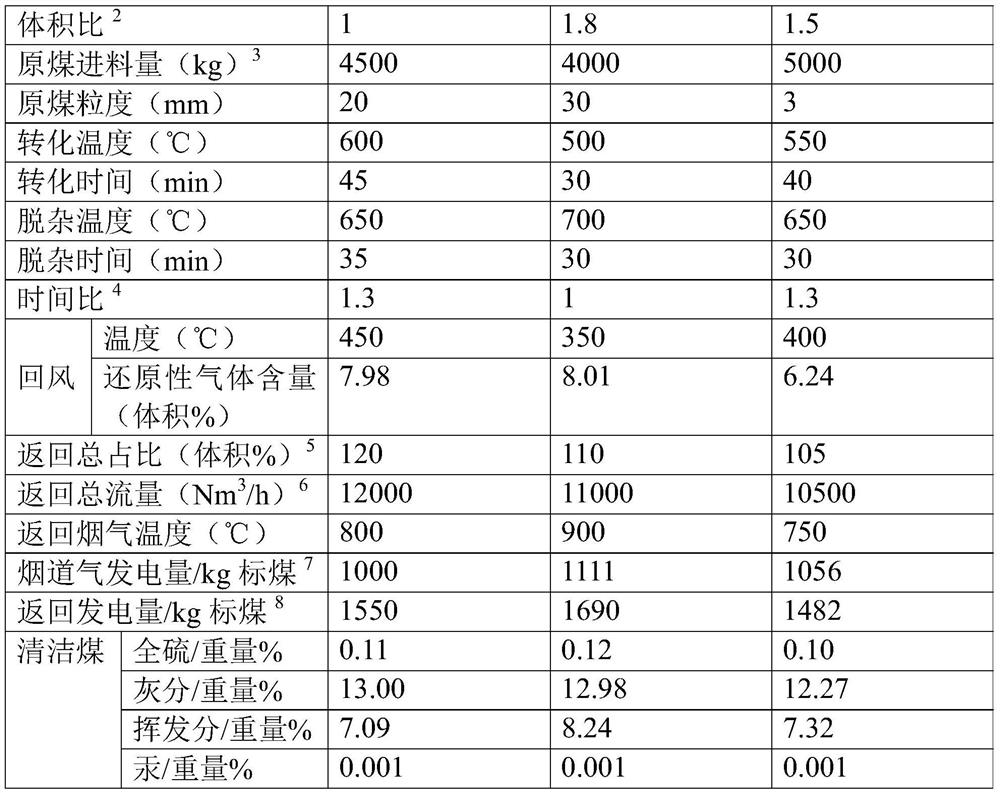

Method and system for producing clean coal by coupling power generation in a power plant

ActiveCN109929571BRealize segmental heatingEasy to produceSolid fuelsIndirect heating destructive distillationCombustorFlue gas

The invention relates to the field of power generation coupling of power plants and clean coal production, and discloses a method and system for power generation coupling production of clean coal in power plants. The method comprises: (1) indirectly heating the raw coal with the first flue gas at 800-1200° C. The second flue gas at 800-1200°C of the power plant boiler indirectly heats the converted coal to remove impurities from the coal to obtain the second flue gas, the second pyrolysis gas and the impurity-removed coal; (3) the first pyrolysis gas After merging with the second pyrolysis gas, tar is removed to obtain tar and coal gas; the coal gas is returned to the burner of the power plant boiler in the form of return air, and the first flue gas and the second flue gas are combined into return flue gas and sent to the power plant boiler Used for power generation; (4) dry-cooling the de-miscellaneous coal to obtain clean coal. While realizing the normal power generation and production of the power plant, low-rank raw coal is produced into clean coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com