Combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke

A technology for incinerating flue gas and toxic gases, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of substandard tail gas purification rate, expensive investment and operation costs, etc., and achieve small temperature fluctuations in the furnace and reduce pressure , to ensure the effect of stable furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

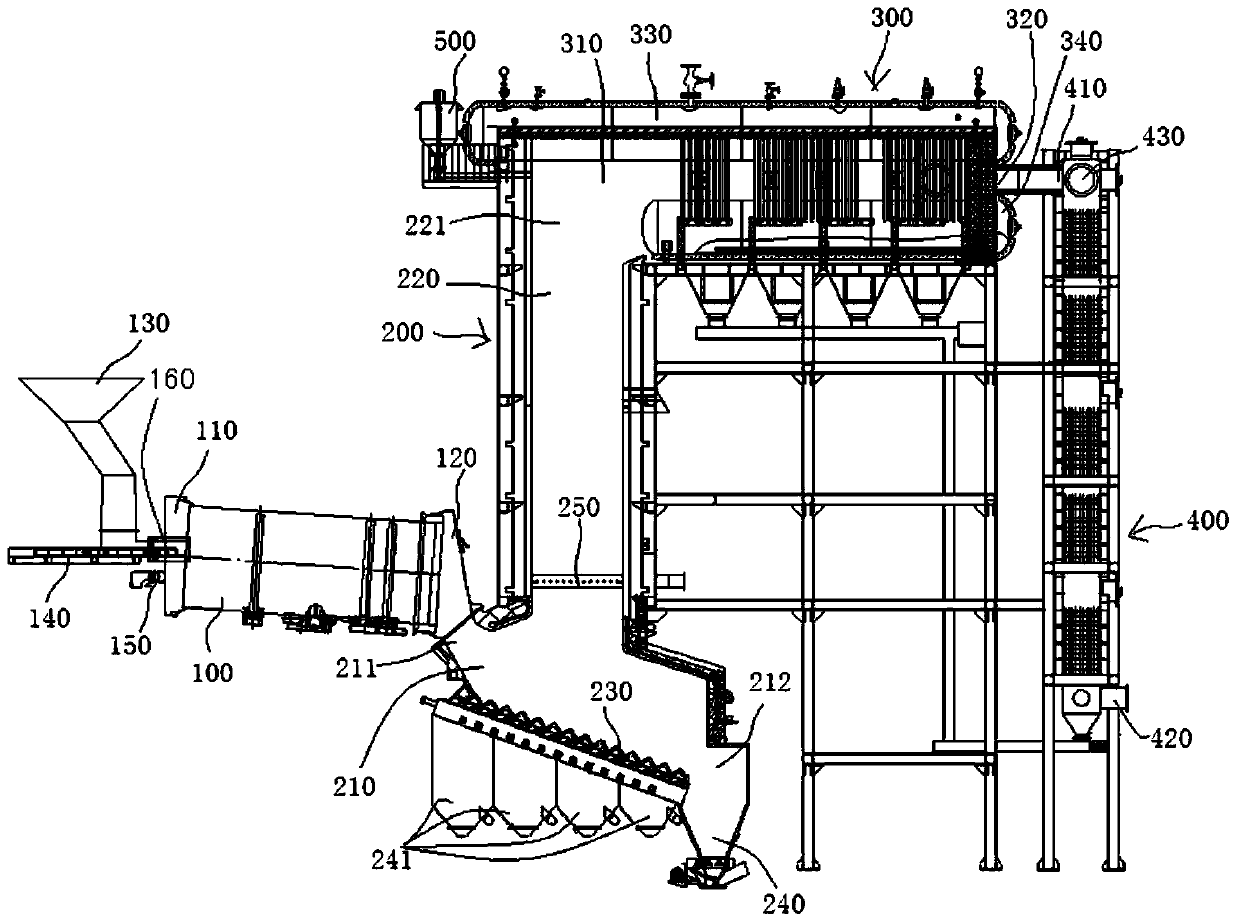

[0026] see figure 1 , the combined incineration device that can control the toxic gas and heavy metal content in waste incineration flue gas shown in the figure includes a rotary pyrolysis device 100, an incinerator 200, a double-drum vertical waste heat boiler 300 and an air Preheater 400.

[0027] The rotary pyrolysis device 100 has a feed end 110 and a discharge end 120. A waste feed bin 130 and a waste pushing device 140 are arranged at the feed end 110 of the rotary pyrolysis device 100. The waste to be incinerated Put the waste into the feeding bin 130, and send it into the rotary pyrolysis device 100 by the waste pushing device 140 through the feed port 160 of the feed end 110 of the rotary pyrolysis device 100 for pyrolysis.

[0028] The temperature of the pyrolysis flue gas used in the drying and pyrolysis process of the waste in the rotary pyrolysis device 100 is 500° C. Type pyrolysis device 100. During the pyrolysis process, the pyrolysis temperature in the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com