Patents

Literature

33results about How to "Ensure decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foaming coating, PVC foaming wallpaper and preparation method thereof

InactiveCN105062246AIdeal pore structureEnsure decompositionCovering/liningsFibre treatmentFoaming agentMicrosphere

The invention discloses a PVC foaming coating. The PVC foaming coating comprises, by weight, 330-350 parts of environmentally-friendly plasticizer, 360-390 parts of PVC paste resin, 15-18 parts of liquid stabilizer, 20-22 parts of AC foaming agent, 20-22 parts of microsphere foaming agent, 75-80 parts of titanium dioxide, 250-275 parts of ground calcium carbonate and 30-33 parts of matting agent. By means of the potassium / zinc liquid stabilizer, the AC foaming agent and the microsphere foaming agent, the foaming function of the PVC foaming coating can be effectively improved, the foaming ratio of PVC foaming wallpaper can be improved, and satisfactory foaming quality can be obtained.

Owner:NINGHAI CHANGHE ENVIRONMENTAL COATINGS

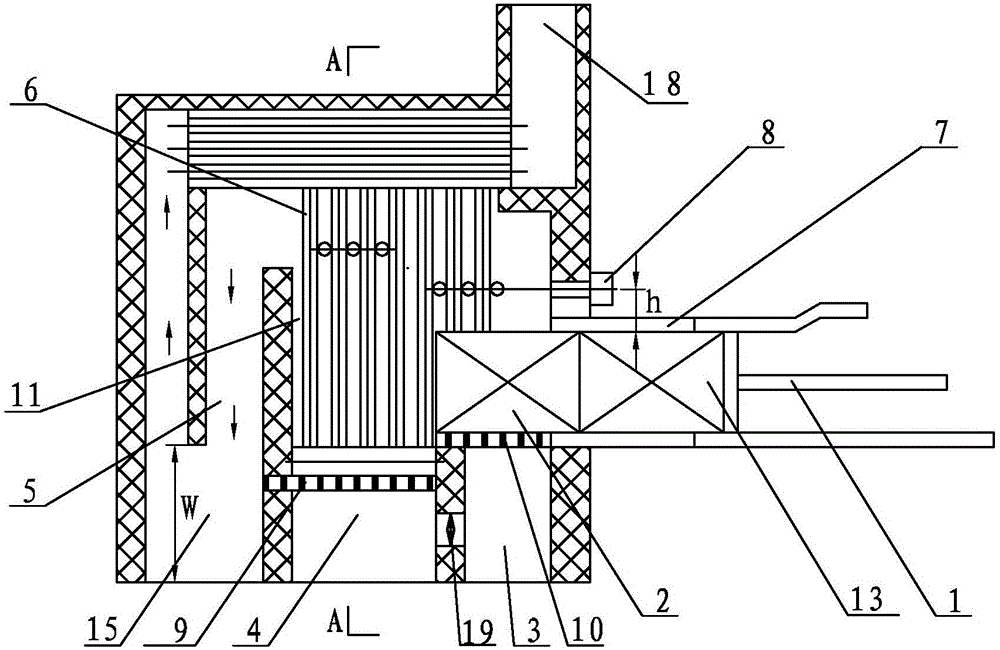

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

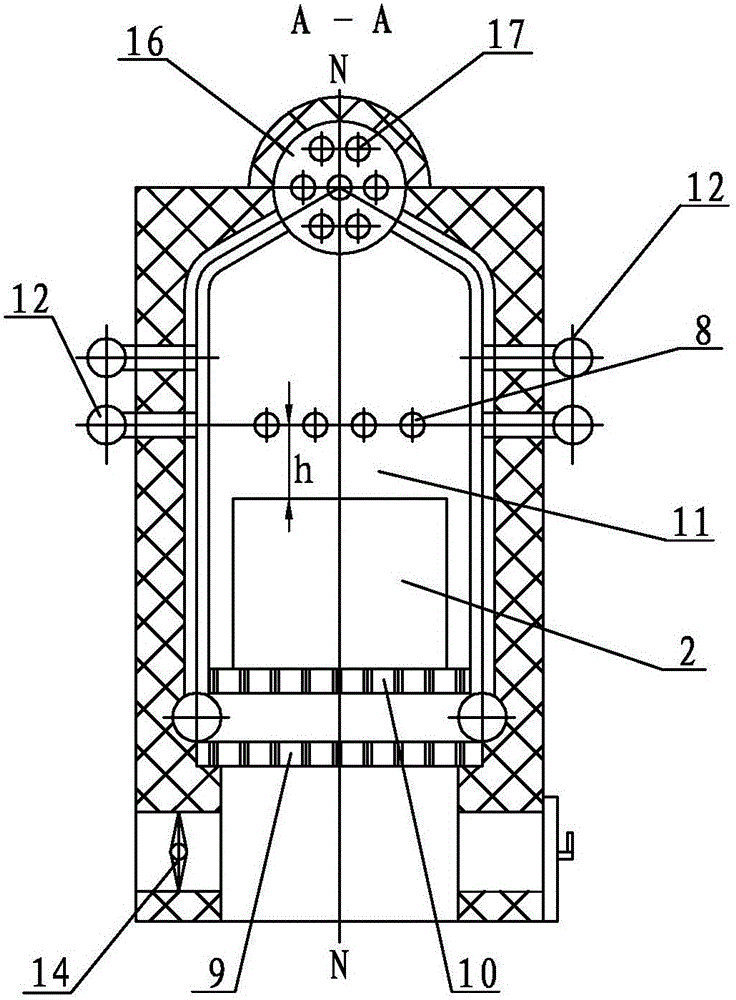

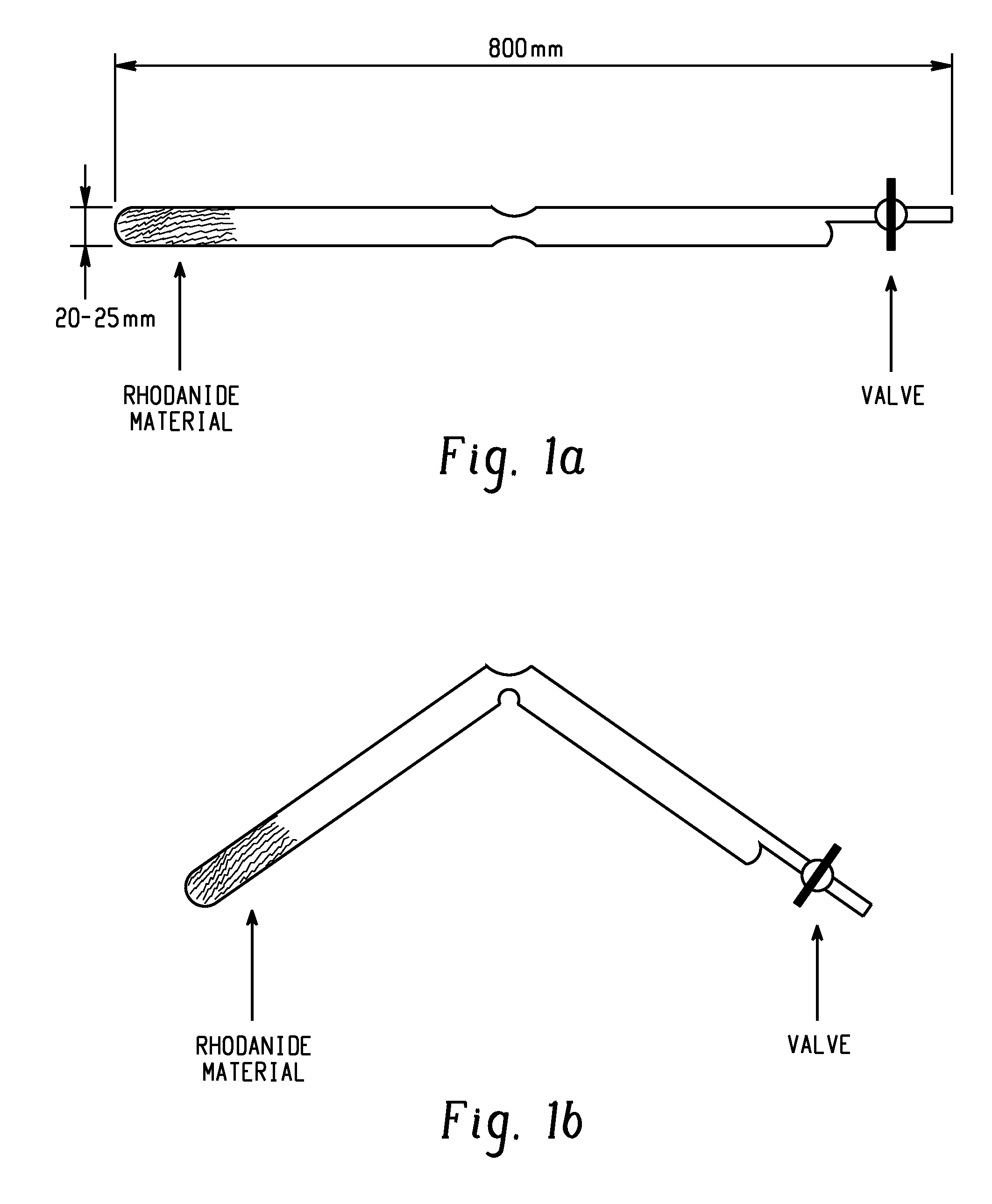

Carbon nitride preparation method

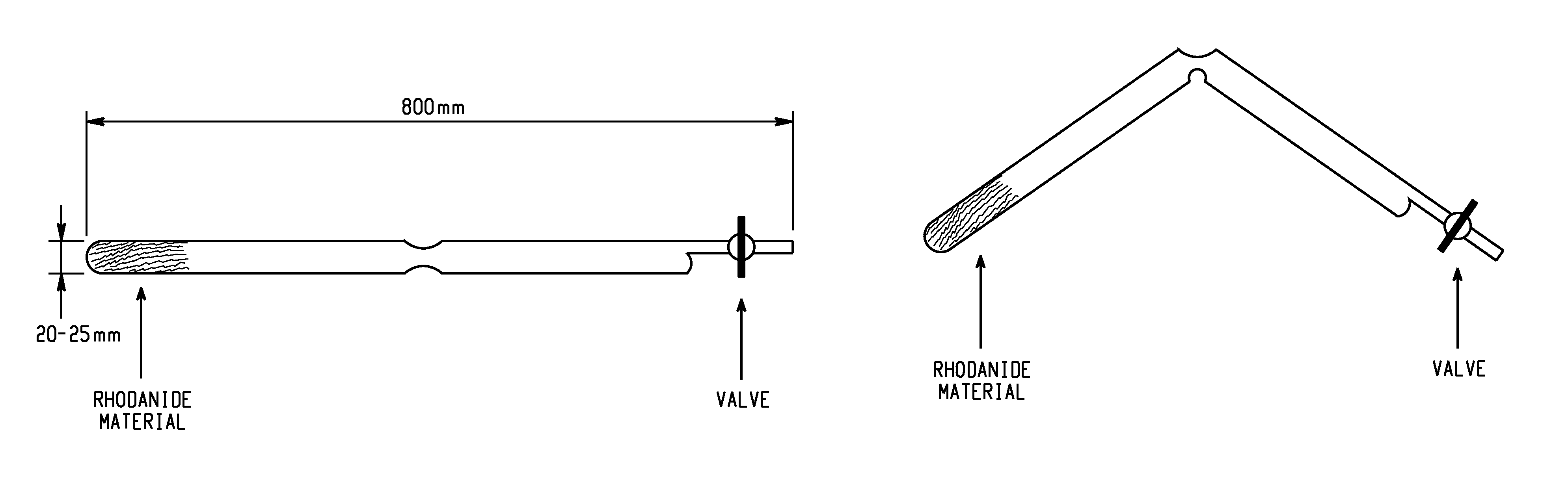

InactiveUS20100015030A1Simple and economically feasibleOutstanding propertyNitrogen-metal/silicon/boron binary compoundsThiocyanic acidCarbon nitrideNanotechnology

The present invention relates to a method for preparing carbon nitride material wherein organic rodanide is simply pyrolysed to give carbon nitride material in an efficient, economical and ecologically friendly manner. The present invention accomplishes preparation of graphitic carbon nitride materials having a carbon to nitrogen molar ratio of about 3:4. The employed starting materials are cheap and can be easily removed and / or washed away.

Owner:CARBODEON LTD OY

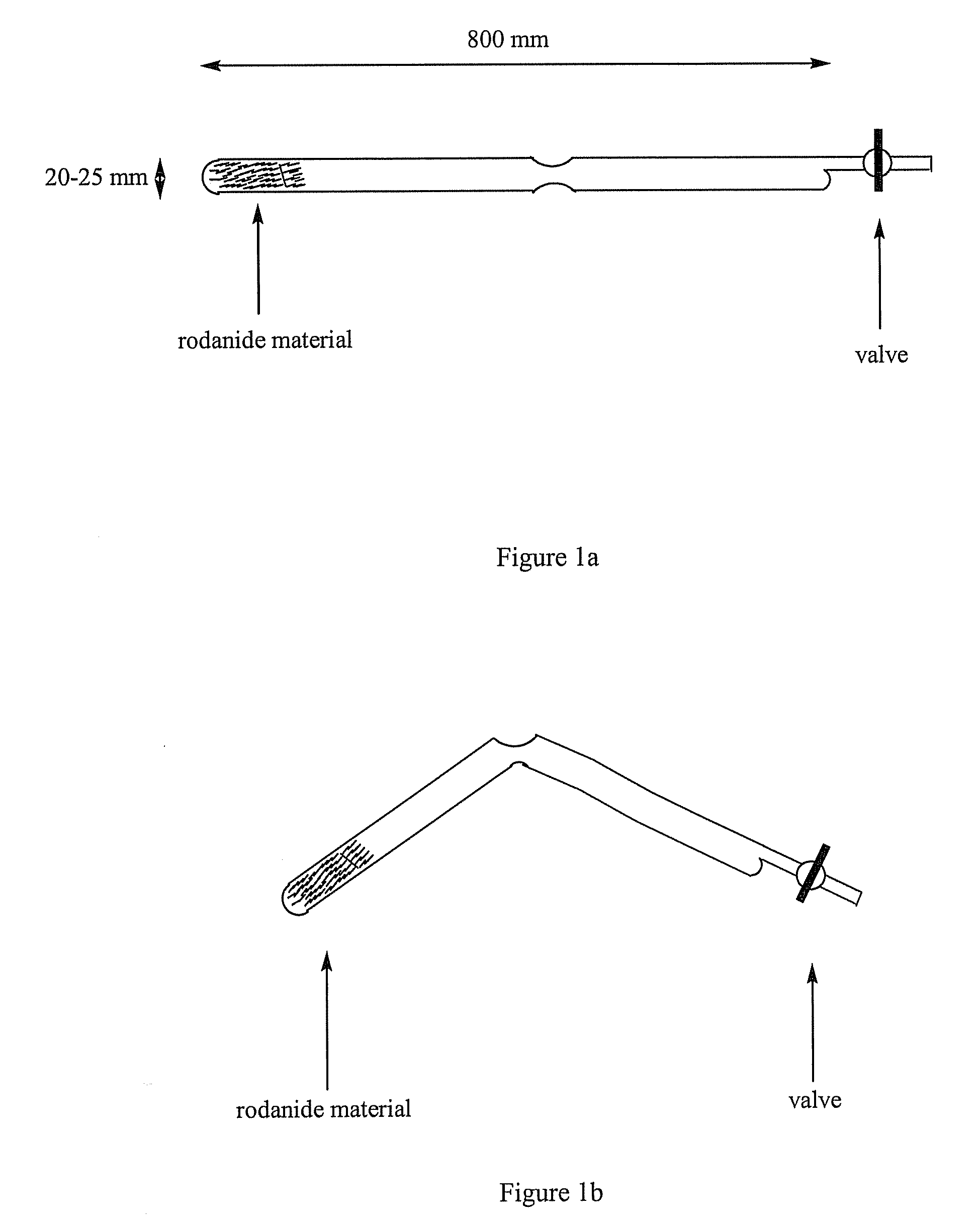

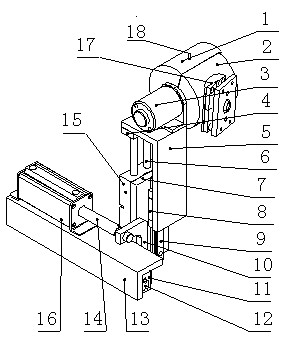

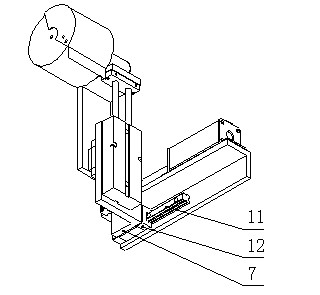

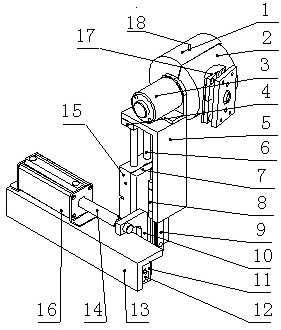

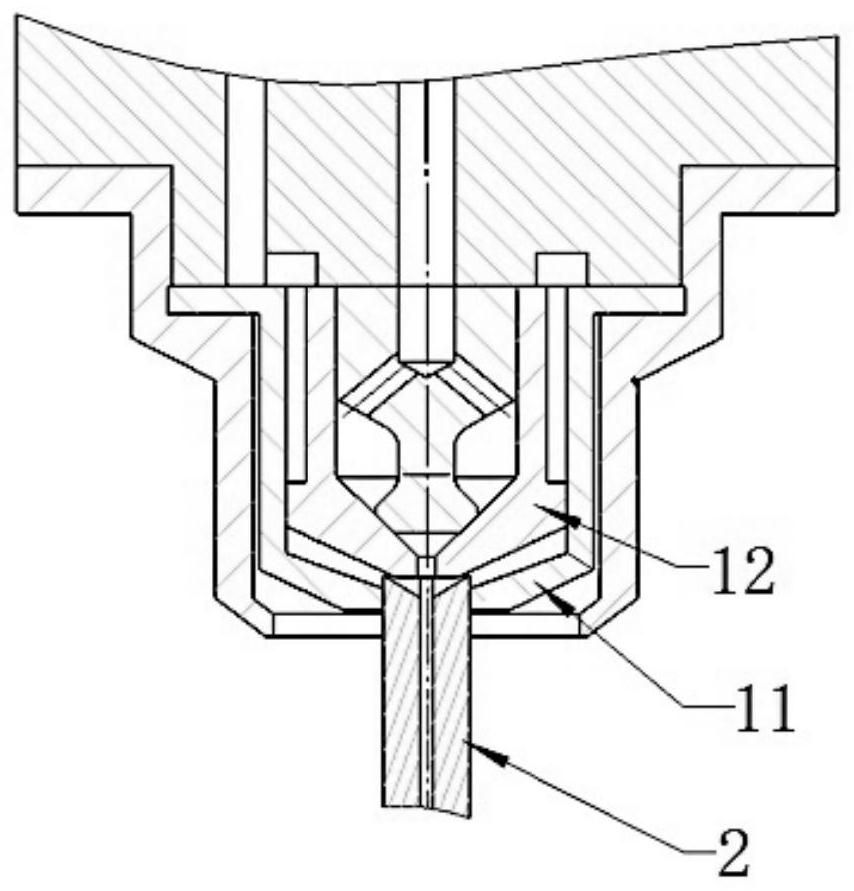

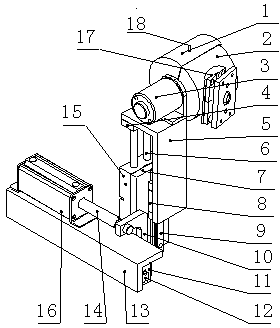

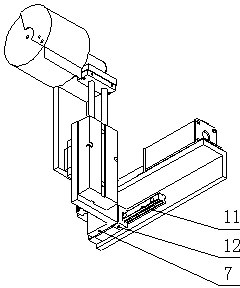

Special gluing head cleaning device for full automatic glue edge sealing production line and cleaning method thereof

InactiveCN102125904AExtended service lifeEnabling Bionic ExtrusionSpraying apparatusCleaning using toolsEngineeringExtrusion

The invention relates to a special gluing head cleaning device for a full automatic glue edge sealing production line and a cleaning method thereof. The device can not only realize the function of automatically cleaning a gluing head, but also decompose and clean gelatin in an electric cleaning device, the gluing head in the full automatic glue edge sealing production line is provided with the electric cleaning device, the electric cleaning device can be lifted longitudinally through a pneumatic lifting mechanism, the pneumatic lifting mechanism is connected with a pneumatic horizontal driving mechanism, and the pneumatic horizontal driving mechanism is used for driving the pneumatic lifting mechanism to move front and back. The special gluing head cleaning device has the following advantages: 1) reliability in cleaning the gluing head is realized; and 2) an elastic movable cover edge arranged on an outer casing can not only realize bionic extrusion and cleaning of a flexible moistureabsorption roller, but also thoroughly completely decompose and clean residual glue after the flexible moisture absorption roller is used for dry type cleaning of the gluing head.

Owner:杭州精工机械有限公司

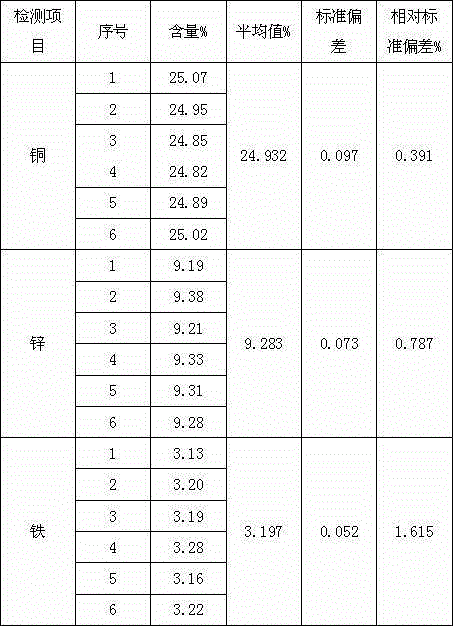

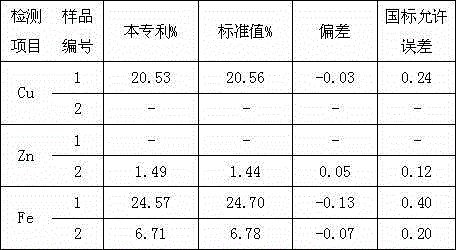

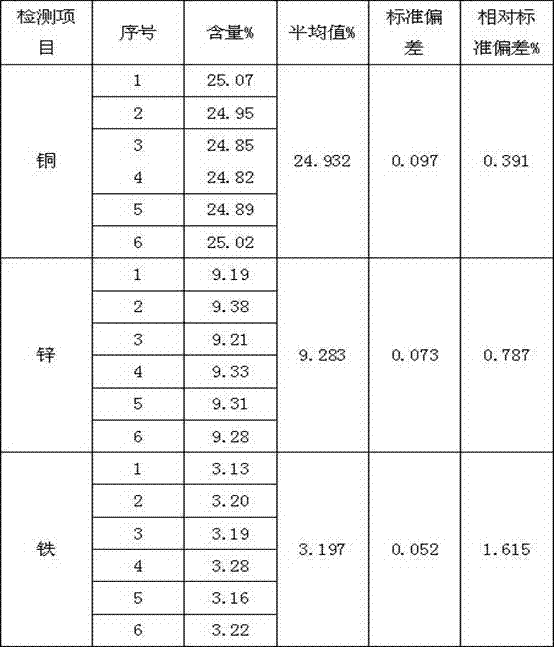

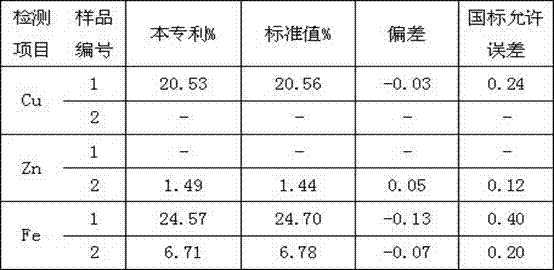

Rapid simultaneous detection method for content of copper, zinc and iron in gold mud

ActiveCN105044088AFill vacancyEnsure decompositionMaterial analysis by observing effect on chemical indicatorSal ammoniacComplex ions

The invention relates to a rapid simultaneous detection method for the content of copper, zinc and iron in gold mud. A sample is dissolved by utilizing nitric acid, aqua regia, sulfuric acid and nitric-sulfuric acid; after sulfuric acid is added for smoking, a copper-zinc-iron compound is decomposed to form a corresponding oxide, HAuCl4 is decomposed to form elemental gold, and H<n-1>[AgCln]<-n+1> is decomposed to form silver chloride; after sulfuric acid is added for dissolving salts, the copper iron zinc oxide is dissolved to form sulfate; after ammonia water is added, silver-copper-zinc is transformed into corresponding ammonia complex ions, iron is transformed into iron hydroxide precipitation, and gold and iron are filtered and then separated from filtrate; after the pH value of the filtrate is adjusted by adding sulfuric acid and ammonia water, sodium chloride is added for precipitation of silver, the silver is recovered by filtering, copper in the filtrate is detected by adopting iodometry, and zinc is detected by adopting an EDTA method; and iron is detected by using a potassium dichromate method. The sample consumption is less in a detection process, precious metals can be effectively classified and recovered, the detection process is simplified, the energy consumption is reduced, and the detection efficiency is improved.

Owner:山东黄金冶炼有限公司

Combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke

InactiveCN103994442ARelieve pressureReduce generationIncinerator apparatusToxic gasCombustion chamber

Provided is a combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke. An incinerator hearth is composed of a first combustion chamber and a second combustion chamber, the first combustion chamber is a horizontal type combustion chamber, the second combustion chamber is a vertical type combustion chamber, heat insulation type combustion chambers are adopted by the whole first combustion chamber and the second combustion chamber of enough height, multiple primary air inlet chambers are adopted by the first combustion chamber to carry out chamber division and amount selected air supply according to needs, two rows of secondary air exhaust pipes which blow oppositely and are arranged at the connecting positions of the other two combustion chambers blow in secondary air, slaked lime adding devices are arranged out of the hearth at the horizontal height of the center of an upper boiler barrel and the hearth of the horizontal height at the center of a lower boiler barrel of a double-boiler-barrel vertical type waste heat boiler, and the slaked lime adding devices inject quantitative slaked lime into the hearth in the flow direction of the high temperature smoke between the upper boiler barrel and the lower boiler barrel. According to the combined type incinerating device capable of controlling the toxic gases and the heavy metal content in the waste incineration smoke, the structural characteristics of the combined type incinerating device is utilized, the controlling over all techniques and parameters is combined, source controlling over the toxic gases and heavy metal is achieved in an incineration process, the pressure of tail gas purification work is relieved fundamentally, and market needs are met.

Owner:上海煜工环保科技有限公司

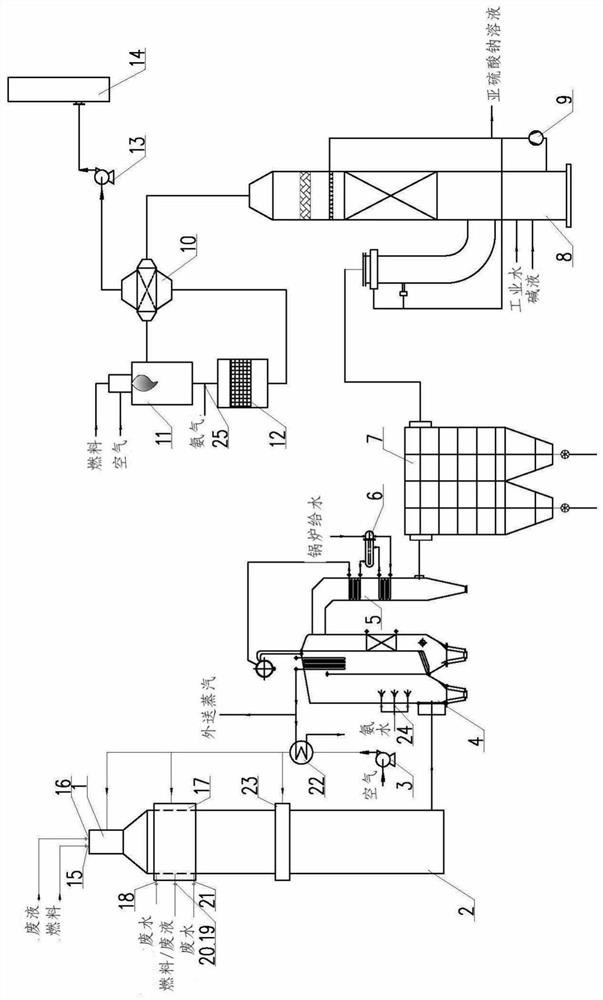

Incineration system for treating sulfur-containing, nitrogen-containing and salt-containing waste liquid

PendingCN113864789AAvoid cloggingAvoid corrosionEmission preventionIncinerator apparatusHazardous substanceSulfur containing

The invention discloses an incineration system for treating sulfur-containing, nitrogen-containing and salt-containing waste liquid. The system comprises an incinerator, a waste heat boiler, an economizer, a desulfurization tower and a denitration device, and the incinerator is provided with a waste liquid conveying pipeline and a fuel conveying pipeline; high-temperature flue gas generated after incineration of the incinerator enters the waste heat boiler from an outlet of the incinerator; the economizer is connected with the waste heat boiler, and after high-temperature flue gas treated by the waste heat boiler enters the economizer from an outlet of the waste heat boiler, heat continues to be recycled; the high-temperature flue gas treated by the coal economizer enters the desulfurization tower to be subjected to desulfurization treatment; and the high-temperature flue gas treated by the desulfurization tower enters the denitration device for denitration treatment. According to the invention, a process technical route of staged combustion-waste heat recovery-first desulfurization and then denitration is adopted, and toxic and harmful substances are oxidized and decomposed through high-temperature incineration; and by adopting the mode that the flue gas is desulfurized, heated and then denitrated, the blockage and corrosion of ammonium bisulfite and ammonium bisulfate to downstream equipment such as the coal economizer are avoided, and the environment-friendly emission requirement of NOx is met.

Owner:上海瑞鼎环境工程技术有限公司 +1

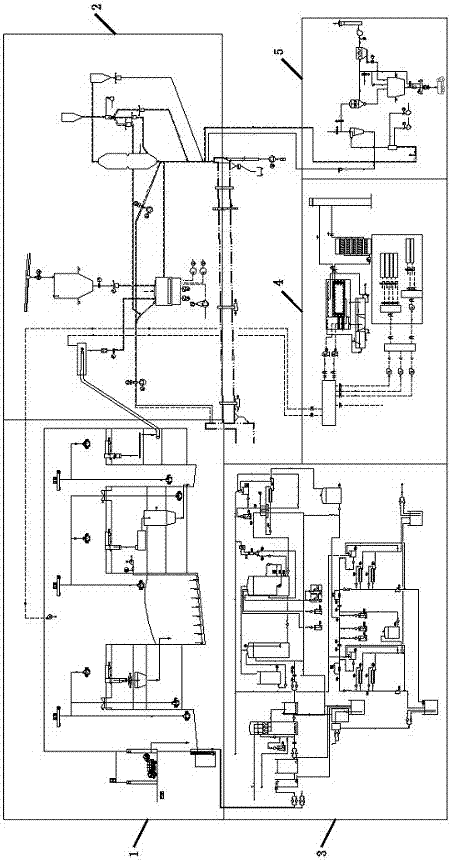

Method for synergistic treatment of urban and rural household garbage by cement kiln

ActiveCN107339702ALow moisture requirementsReduce preprocessingUsing liquid separation agentWater contaminantsWastewaterNational standard

The invention discloses a method for synergistic treatment of urban and rural household garbage by a cement kiln, and relates to the technical field of garbage treatment systems. The method comprises a household garbage pretreatment system, a household garbage incineration system, a household garbage leachate treatment system, a deodorizing system and a bypass exhaust system; and the household garbage pretreatment system and the household garbage incineration system, as main treatment links, can be constructed separately or constructed in a centralized manner according to the difference of construction conditions. The household garbage pretreatment system and the household garbage incineration system are matched with the household garbage leachate treatment system and the deodorizing system. The household garbage incineration system is also matched with the bypass exhaust system. The method is convenient to operate, stable in operation, low in investment and high in benefit, totally realizes harmless treatment to waste slag, waste water and waste gas, can totally achieve national standard requirements in environmental influence, and truly achieves harmlessness, recycling, volume reduction and environmental protection of household garbage.

Owner:蓝天众成环保工程有限公司 +2

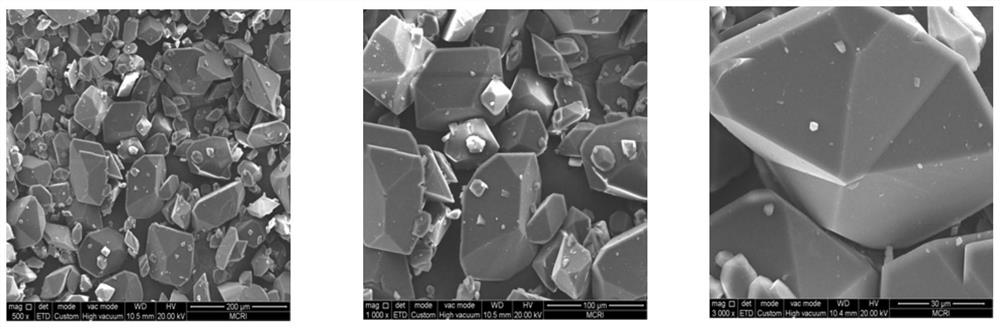

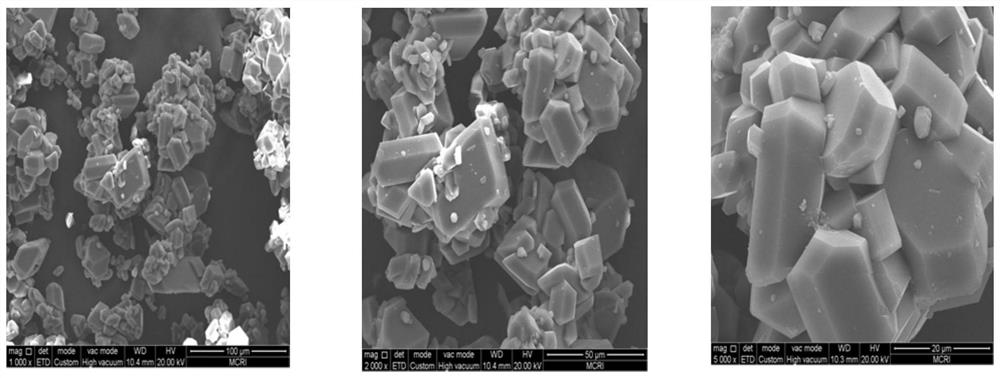

In-situ analysis method of HNIW crystal form crystal transformation rate in propellant powder

PendingCN112067596AImprove efficiencyLow detection limitPreparing sample for investigationRaman scatteringPhysical chemistryQuasicrystal

The invention provides an in-situ analysis method of HNIW crystal form crystal transformation rate in propellant powder, which comprises the following steps: step 1, placing a sample slice on a glassslide, step 2, determining a crystal area under an optical microscope, step 3, carrying out in-situ test on a crystal by microscopic Raman to obtain an HNIW Raman spectrogram, and step 4, performing standard crystal Raman data acquistion and crystal form identification, and counting the crystal transformation rate; 401, acquiring a standard Raman spectrogram of the standard crystal: preparing a standard epsilon HNIW crystal, a standard alpha HNIW crystal and a standard gamma HNIW crystal, placing the standard crystal under a microscope, and testing a Raman spectrum to obtain a crystal form standard Raman spectrogram; step 402, performing crystal form identification; and step 403, performing crystal transformation rate statistics. The method is high in efficiency, low in detection limit, accurate, reliable and feasible.

Owner:XIAN MODERN CHEM RES INST

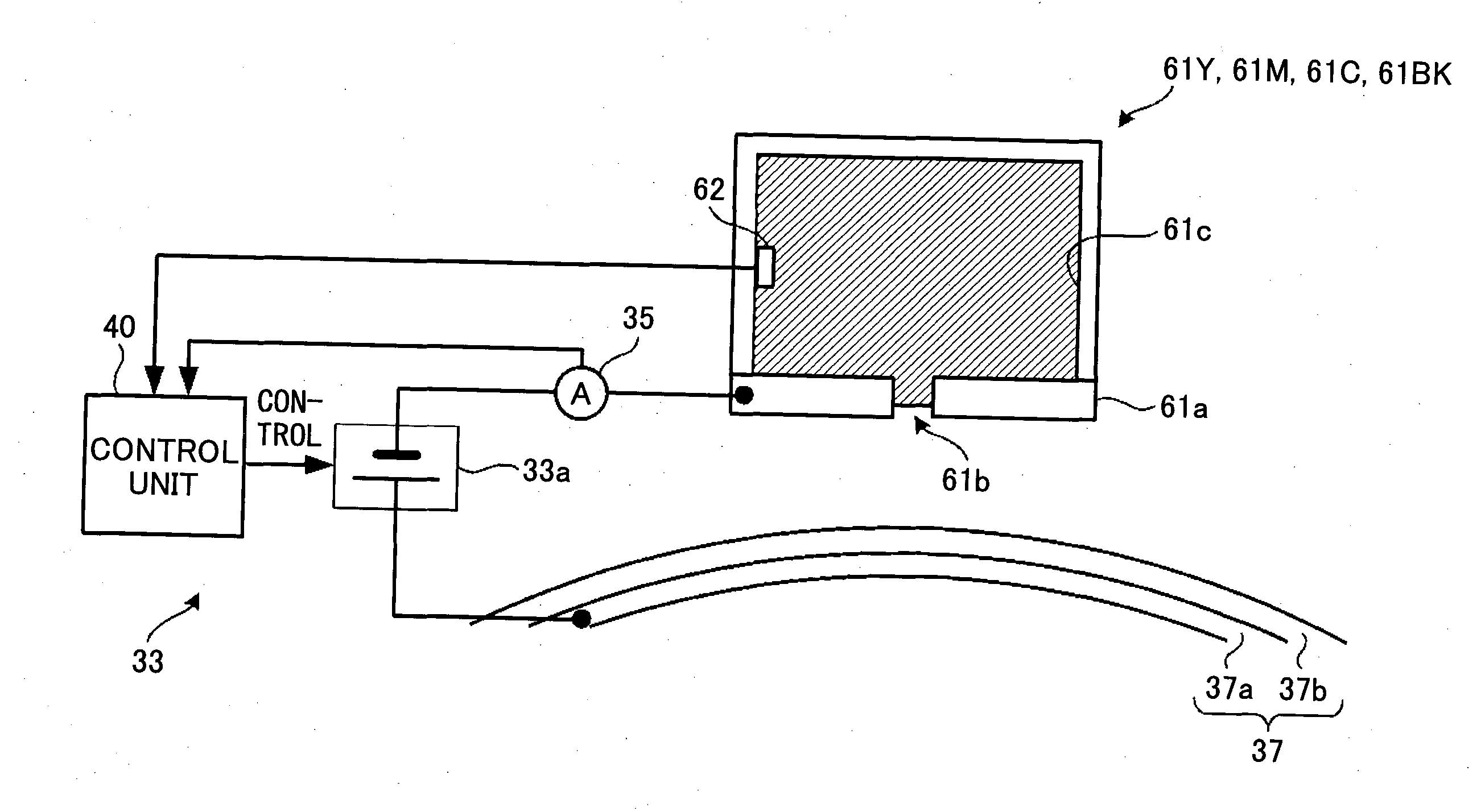

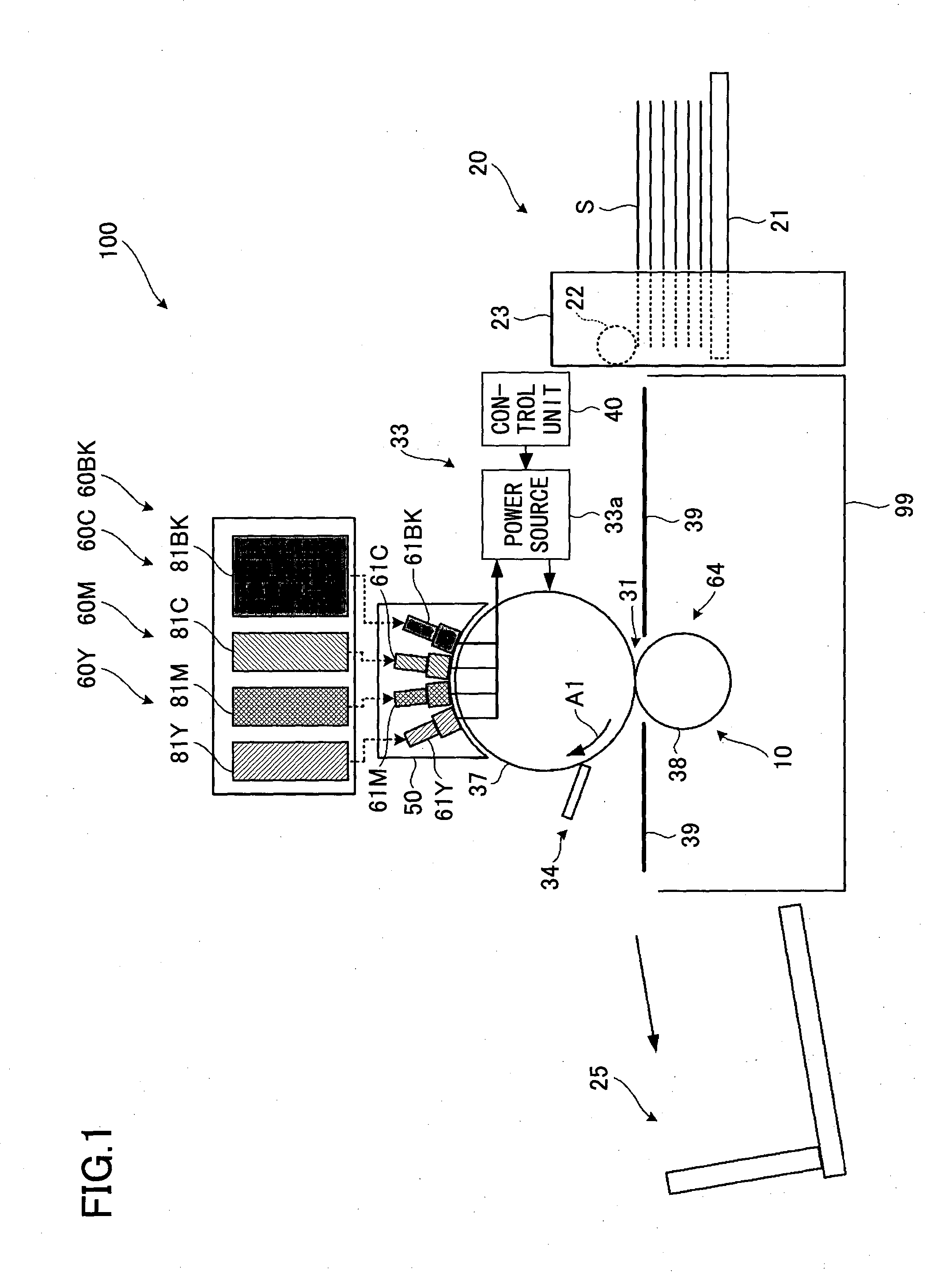

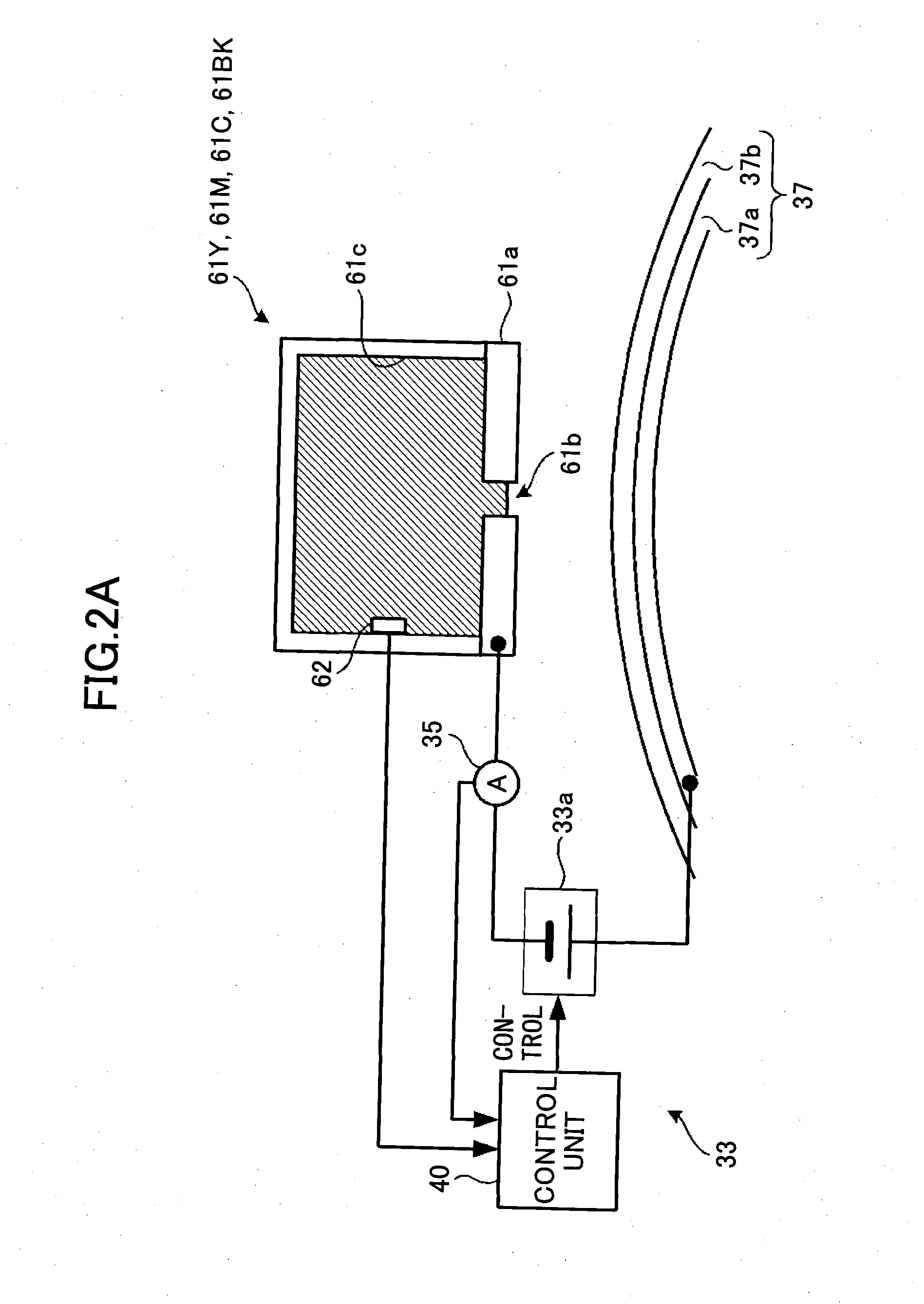

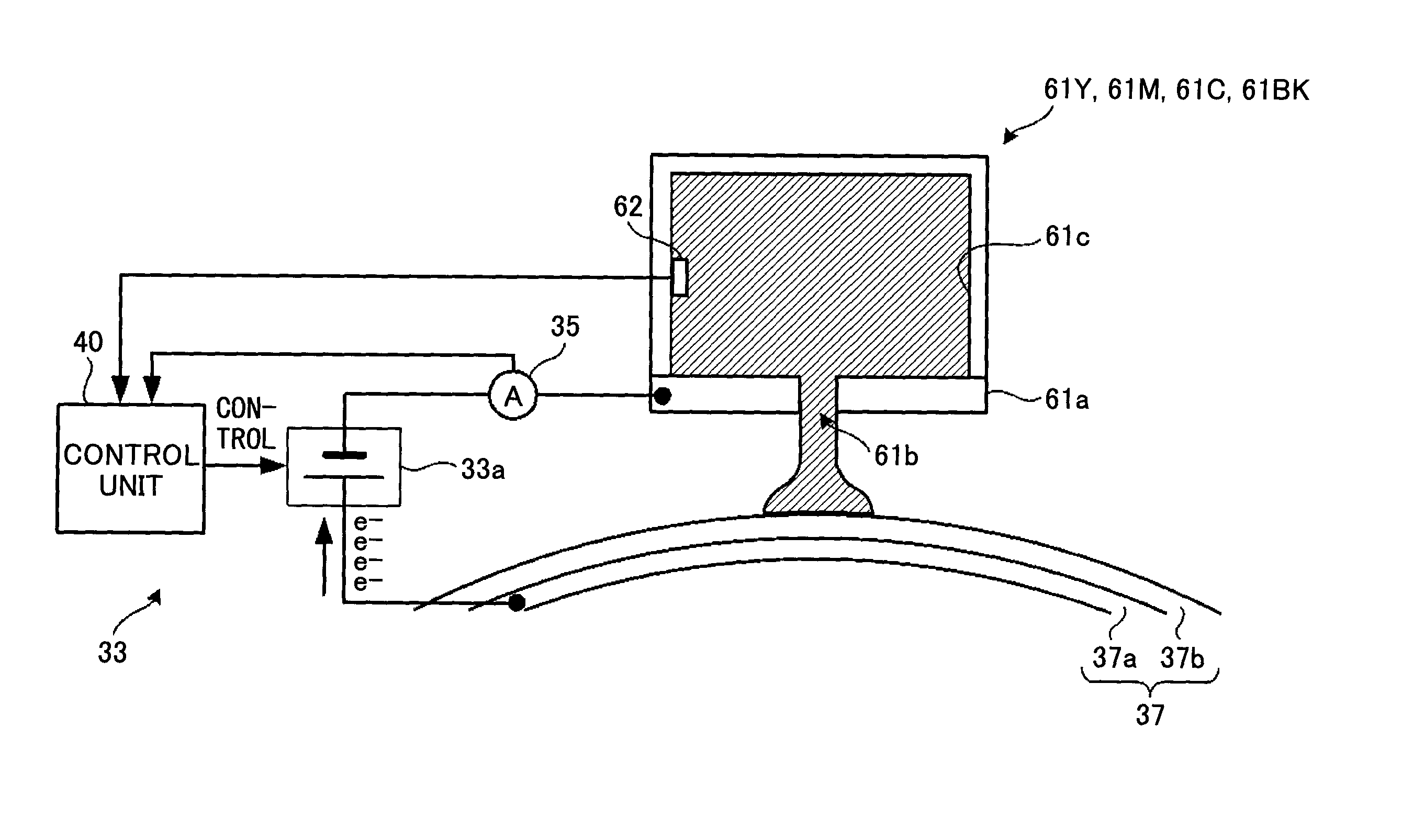

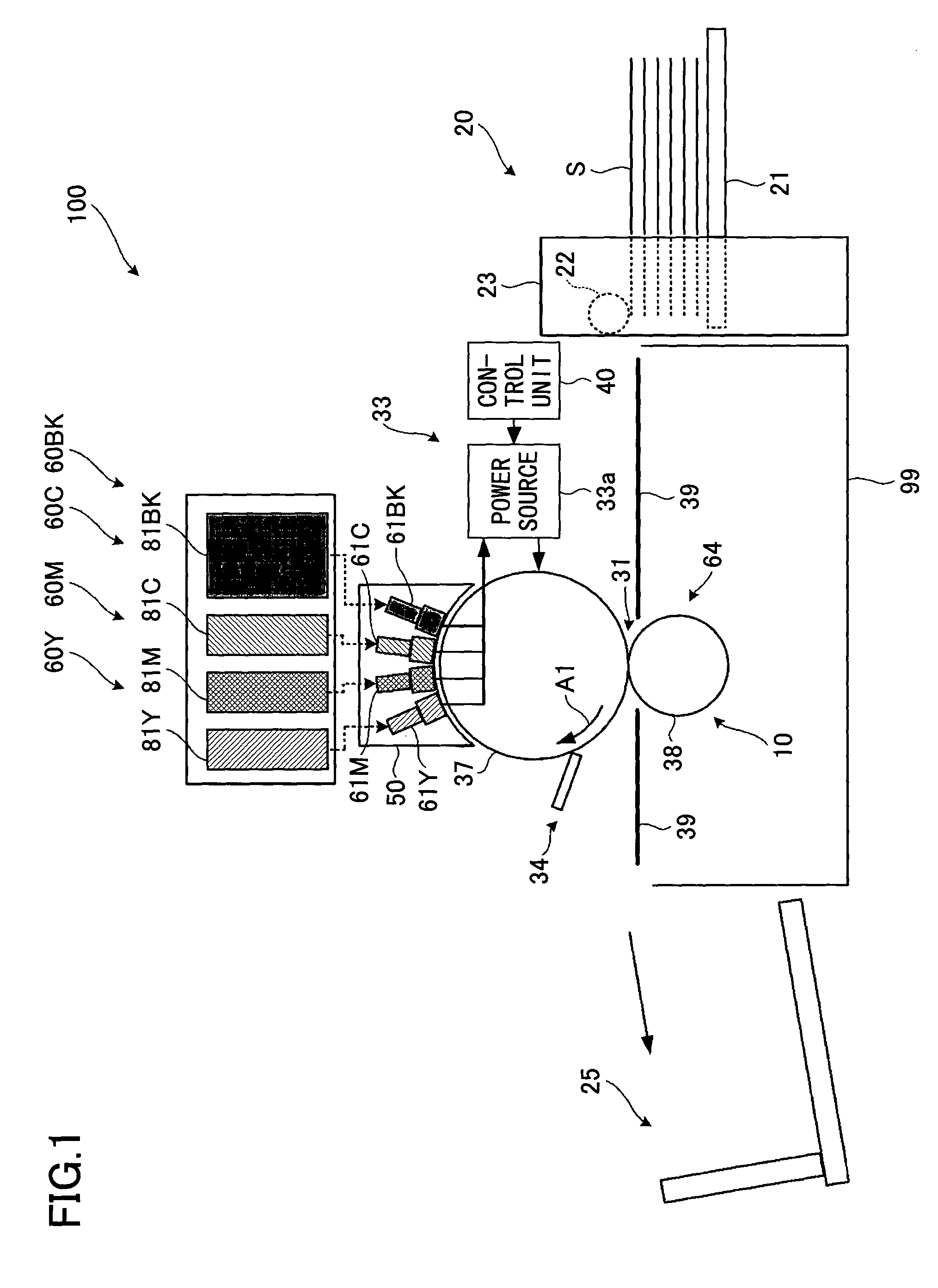

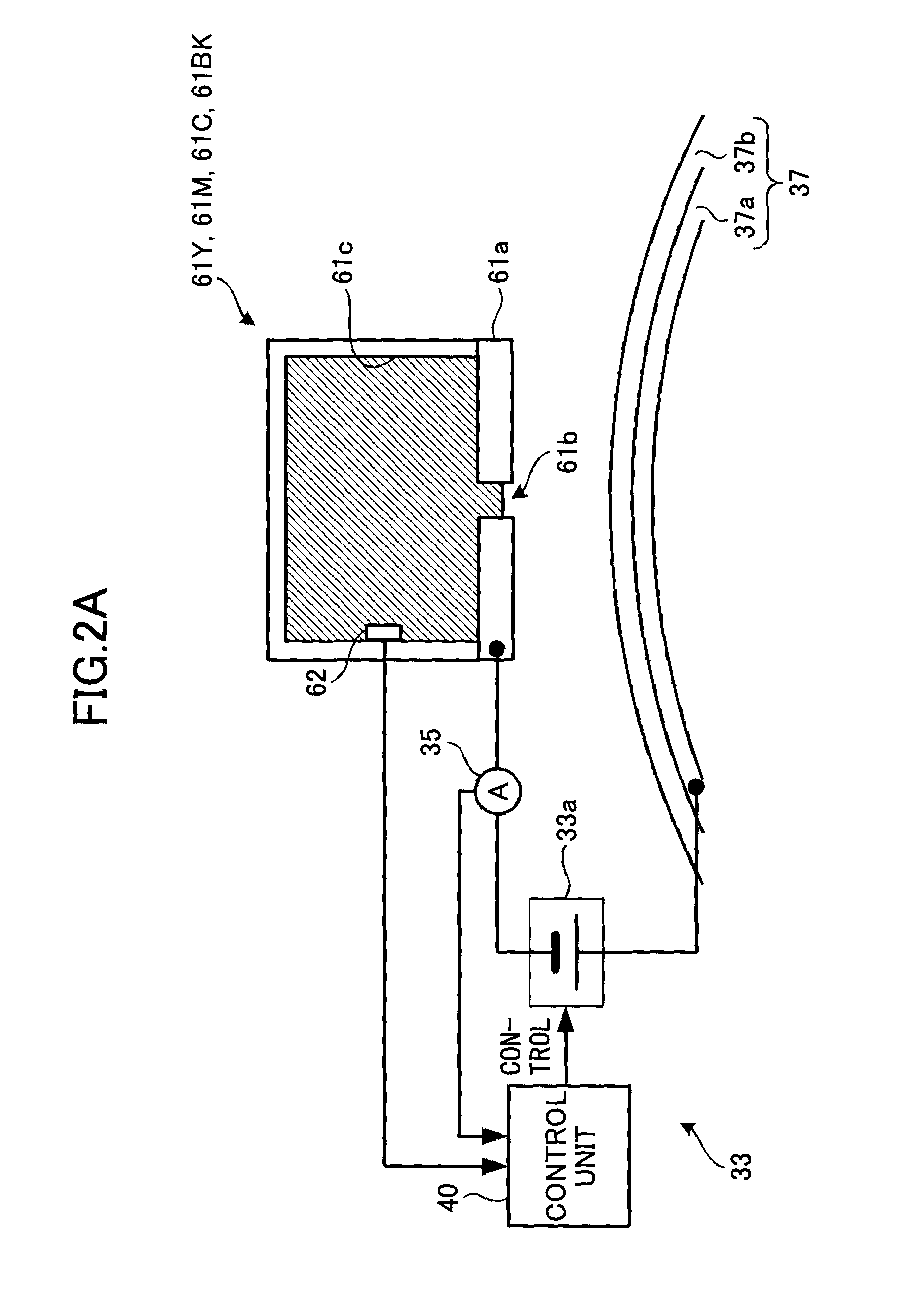

Image forming device, and image forming method

InactiveUS20130093810A1Suppress blurReduce energy consumption costsOther printing apparatusImage formationFluid level

An image forming device includes a head including a nozzle that discharges an electrically-conductive recording liquid in accordance with a driving signal; an intermediate transfer body on which the recording liquid discharged by the head is applied; a voltage apply unit that applies a voltage between the intermediate transfer body and the head, so as to decompose the electrically-conductive recording liquid by electrolysis; a transfer unit that transfers an image supported on the intermediate transfer body onto a recording material; and a discharging control unit that generates the driving signal that causes the electrically-conductive recording liquid to be discharged from the nozzle. The discharging control unit generates the driving signal so that a position of a meniscus is placed outside the nozzle during a time interval in which the recording liquid temporarily bridges between the head and the intermediate transfer body.

Owner:RICOH KK

Method for preparing carbon nitride C3N4

InactiveUS7708971B2Increase productionLow production costCyanogen compoundsNitrogen-metal/silicon/boron binary compoundsCarbon nitrideMaterials science

The present invention relates to a method for preparing carbon nitride C3N4 wherein alkali metal thiocyanate is simply pyrolysed to give carbon nitride C3N4 in an efficient, economical and ecologically friendly manner. The employed starting materials are cheap and formed side products are essentially non-toxic and can be easily removed and / or washed away.

Owner:CARBODEON LTD OY

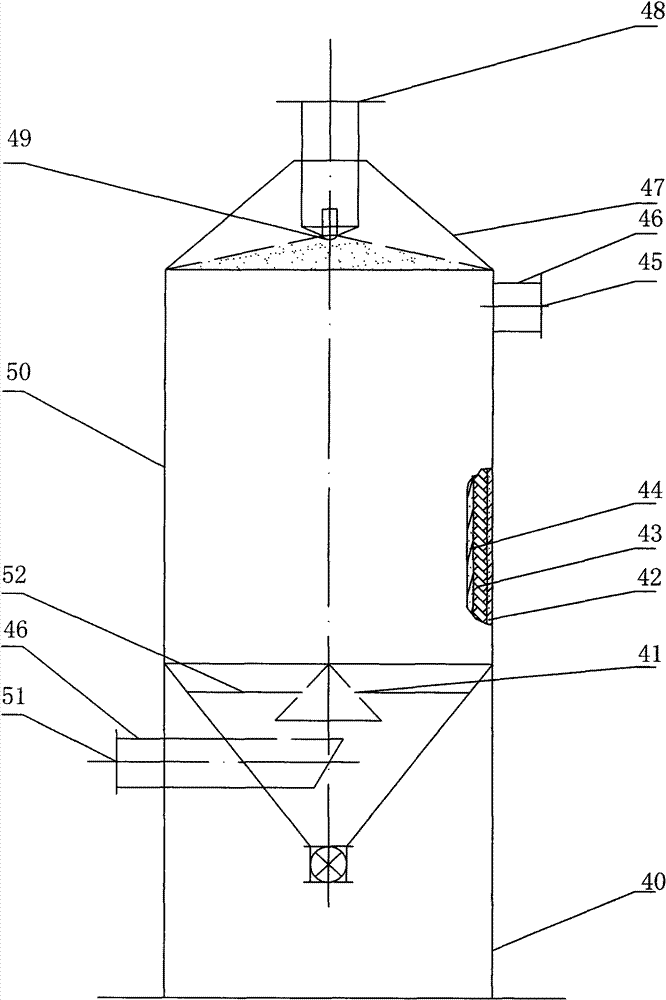

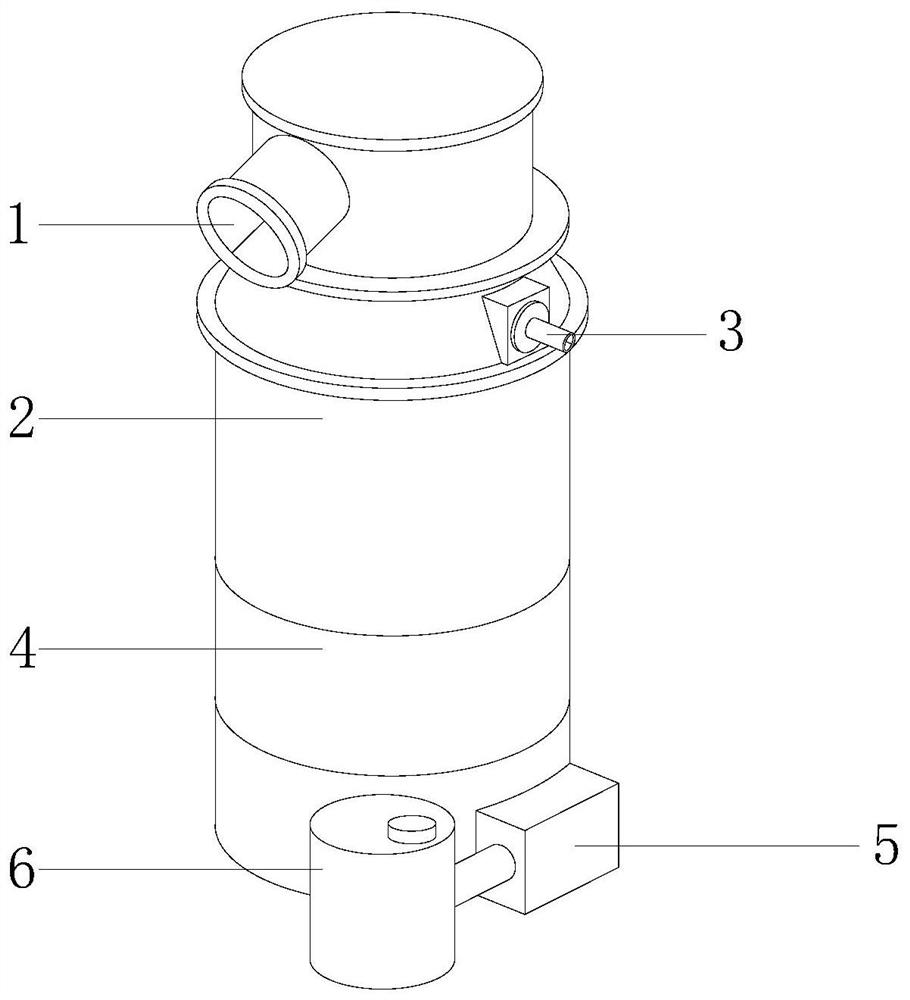

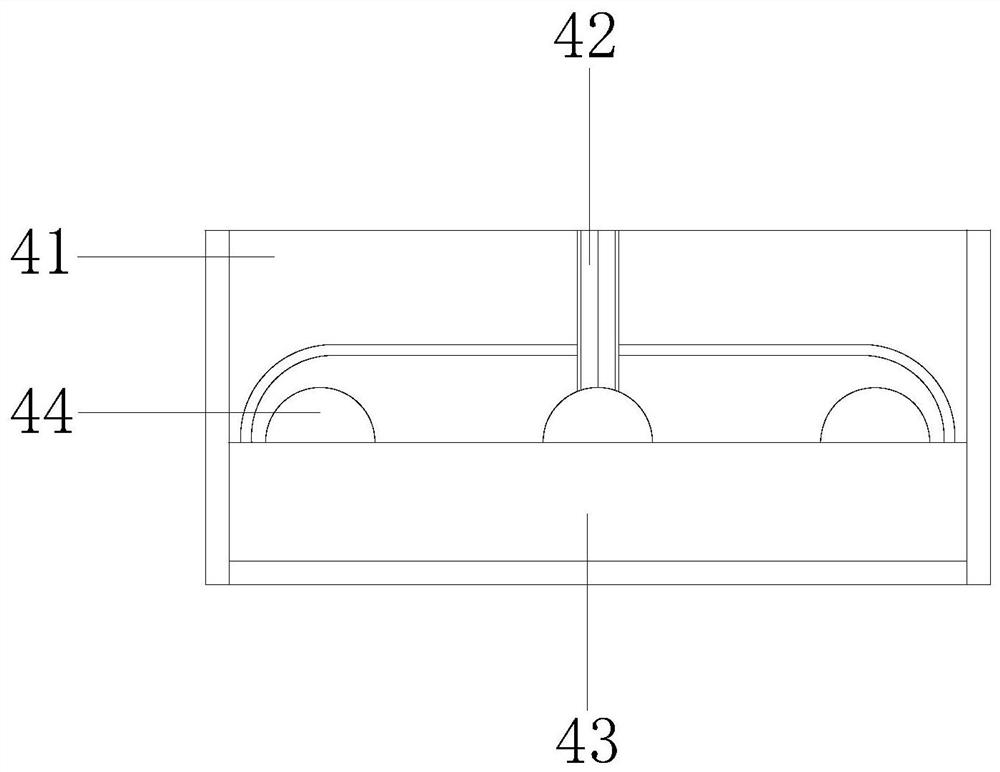

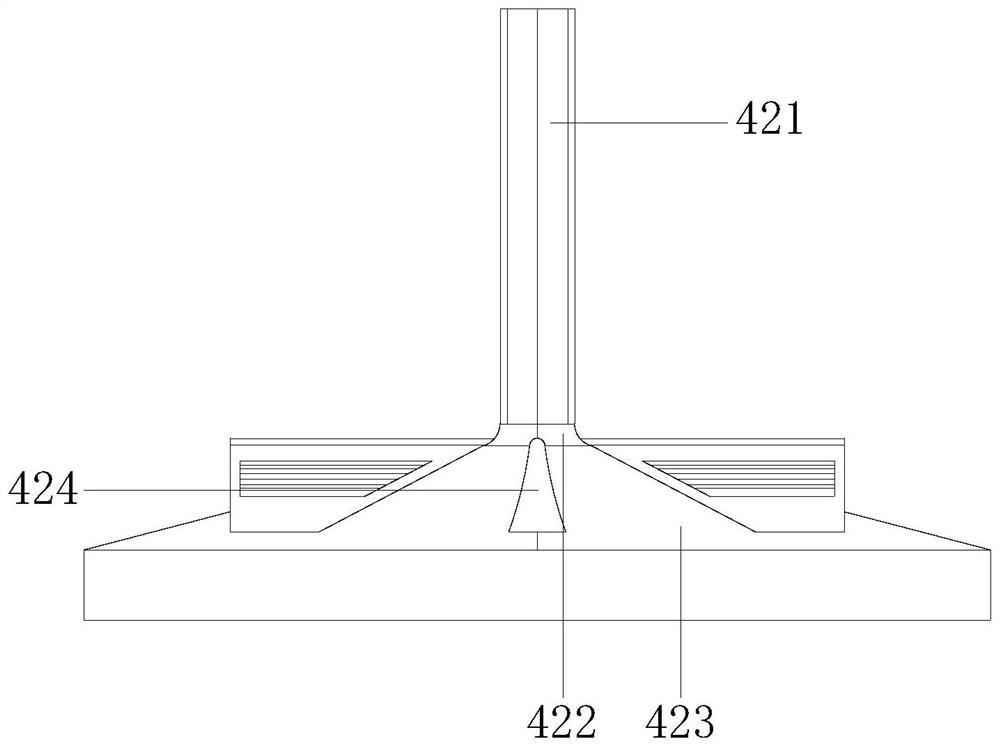

High-concentration saliferous liquid waste incinerator

InactiveCN110207137AReasonable structural designEnsure incinerationIncinerator apparatusLiquid wasteHigh concentration

The invention belongs to the technical field of environment-friendly engineering machinery, and particularly relates to a high-concentration salt-containing liquid waste incinerator. The incinerator comprises a vertical combustion furnace and a horizontal combustion furnace which communicates with each other, the vertical combustion furnace is positioned on the horizontal combustion furnace, the tail end of the vertical combustion furnace communicates with a secondary combustion furnace, an upper combustor is arranged in the vertical combustion furnace, a lower combustor is arranged in the horizontal combustion furnace, an auxiliary combustor is arranged in the secondary combustion furnace, and an atomizing spray gun communicates with the inner wall of the vertical combustion furnace; a horizontal chain plate transmission machine is arranged in the horizontal combustion furnace, a place for secondary combustion of liquid waste is provided, and the liquid waste is completely incinerated. The combustion system is divided into an upper part and a lower part, so that the consumption of fuel gas can be effectively saved, and the uniform distribution of the temperature in the combustionfurnace can be ensured. The tail of the combustion furnace is provided with the secondary combustion furnace, so that organic components in flue gas can be completely and effectively decomposed, and the treatment capacity of the incinerator can be improved.

Owner:合肥仁德电子科技有限公司

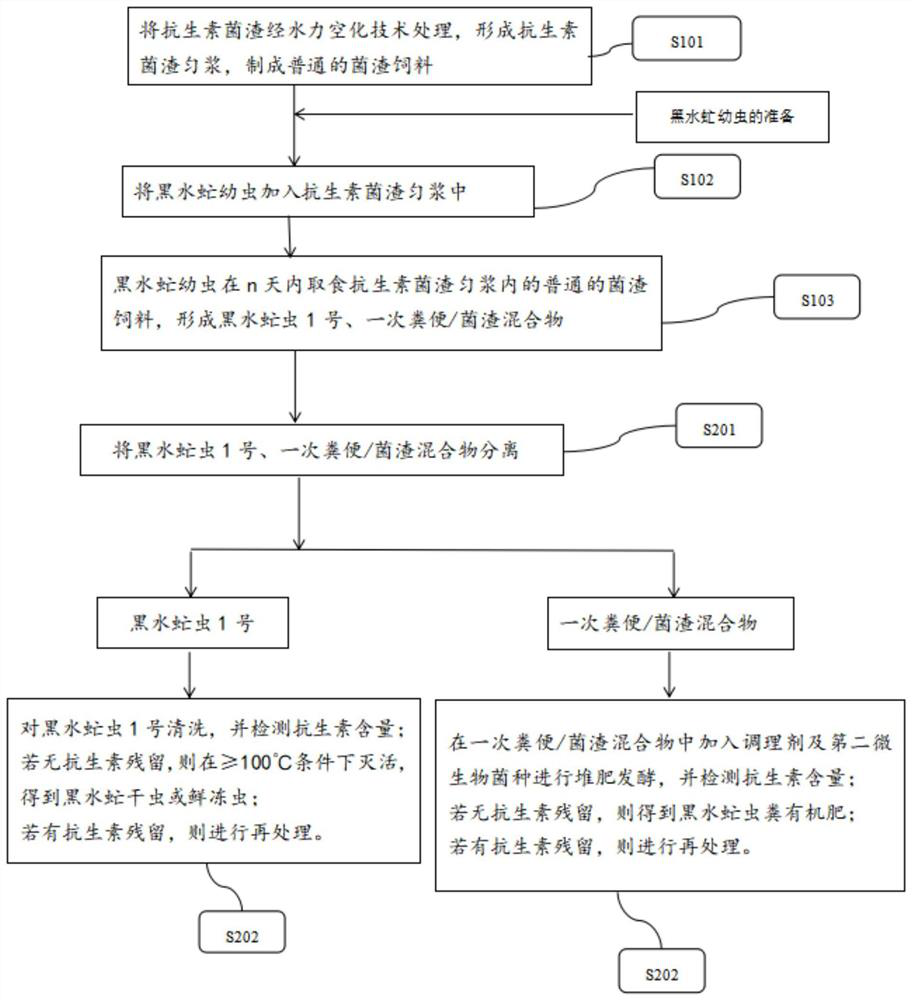

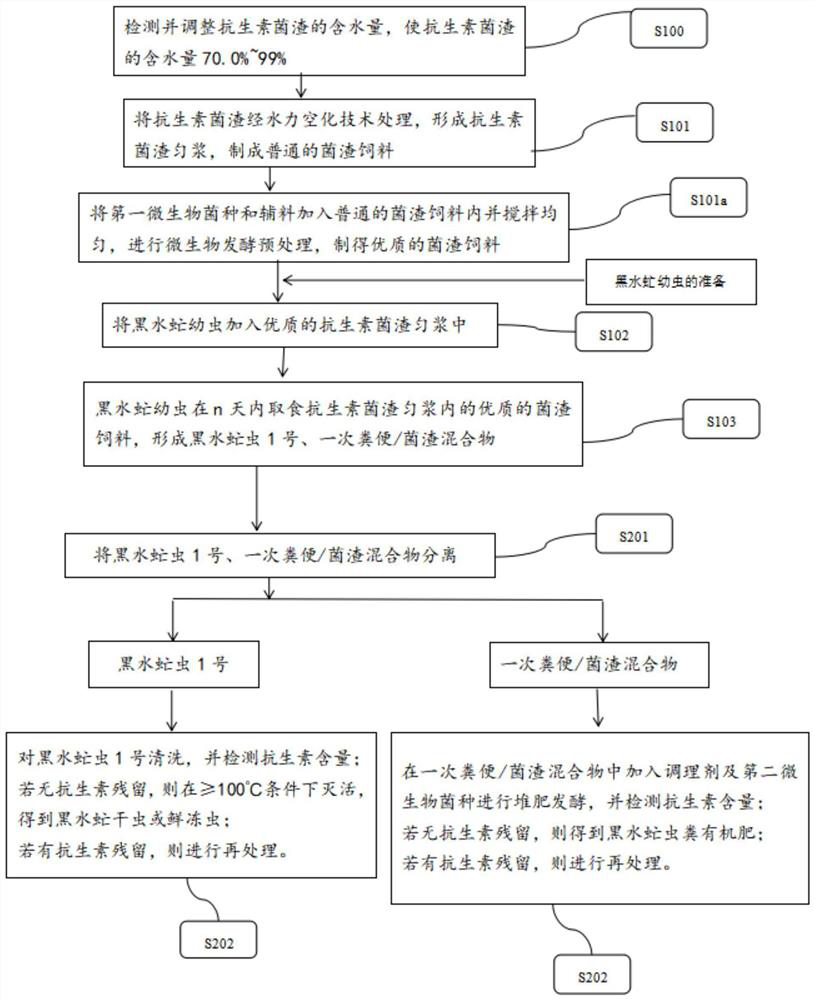

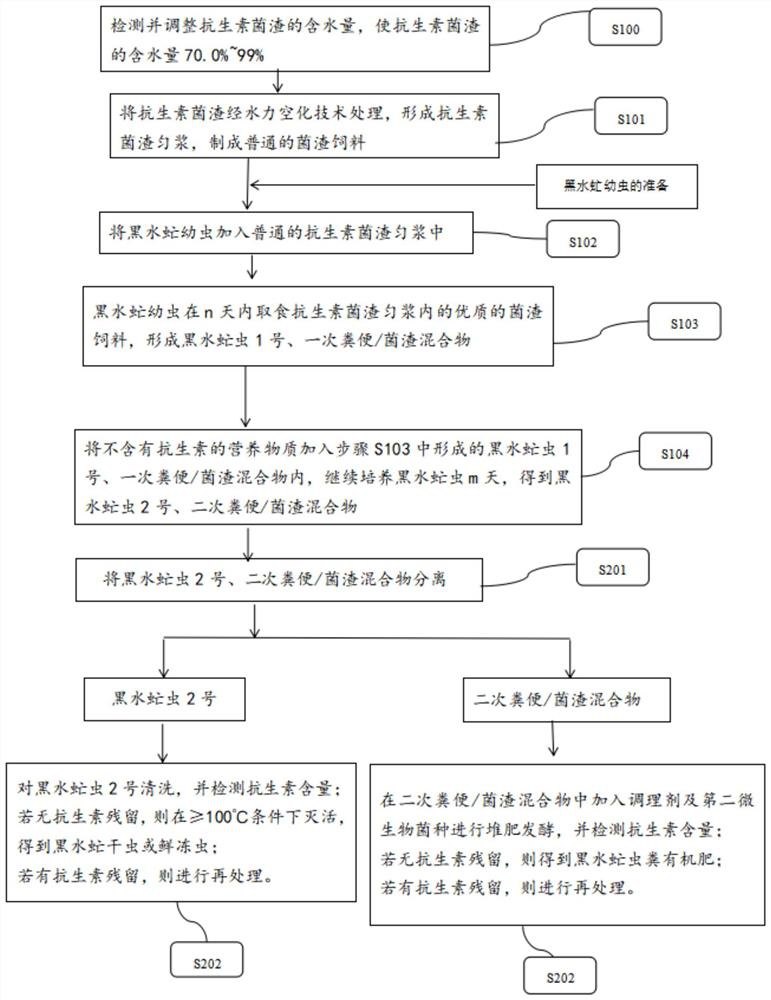

Treatment method of antibiotic mushroom dregs

ActiveCN112314533AHarmlessHigh degree of resource utilizationExcrement fertilisersBioloigcal waste fertilisersBiotechnologyHermetia

The invention provides a treatment method of antibiotic mushroom dregs. The treatment method comprises the steps of preparation of hermetia illucens larvae, pretreatment of the antibiotic mushroom dregs, treatment of the antibiotic mushroom dregs by the hermetia illucens larvae, and processing treatment of fecula and the hermetia illucens larvae. According to pretreatment of the antibiotic mushroom dregs, the antibiotic mushroom dregs are treated by a hydrodynamic cavitation technology to form antibiotic mushroom dreg homogenate so as to prepare common mushroom dreg feed. According to treatment of the antibiotic mushroom dregs by the hermetia illucens larvae, the hermetia illucens larvae are added into the antibiotic mushroom dreg homogenate; and the hermetia illucens larvae eat the commonmushroom dreg feed in the antibiotic mushroom dreg homogenate within n days to form hermetia illucens No.1 and primary excrement / mushroom dreg mixture; The treatment method of the antibiotic mushroomdregs is efficient, safe and reliable, and 95.0% or above of antibiotics in the antibiotic mushroom dregs can be treated.

Owner:湖南自然创造生物科技有限公司

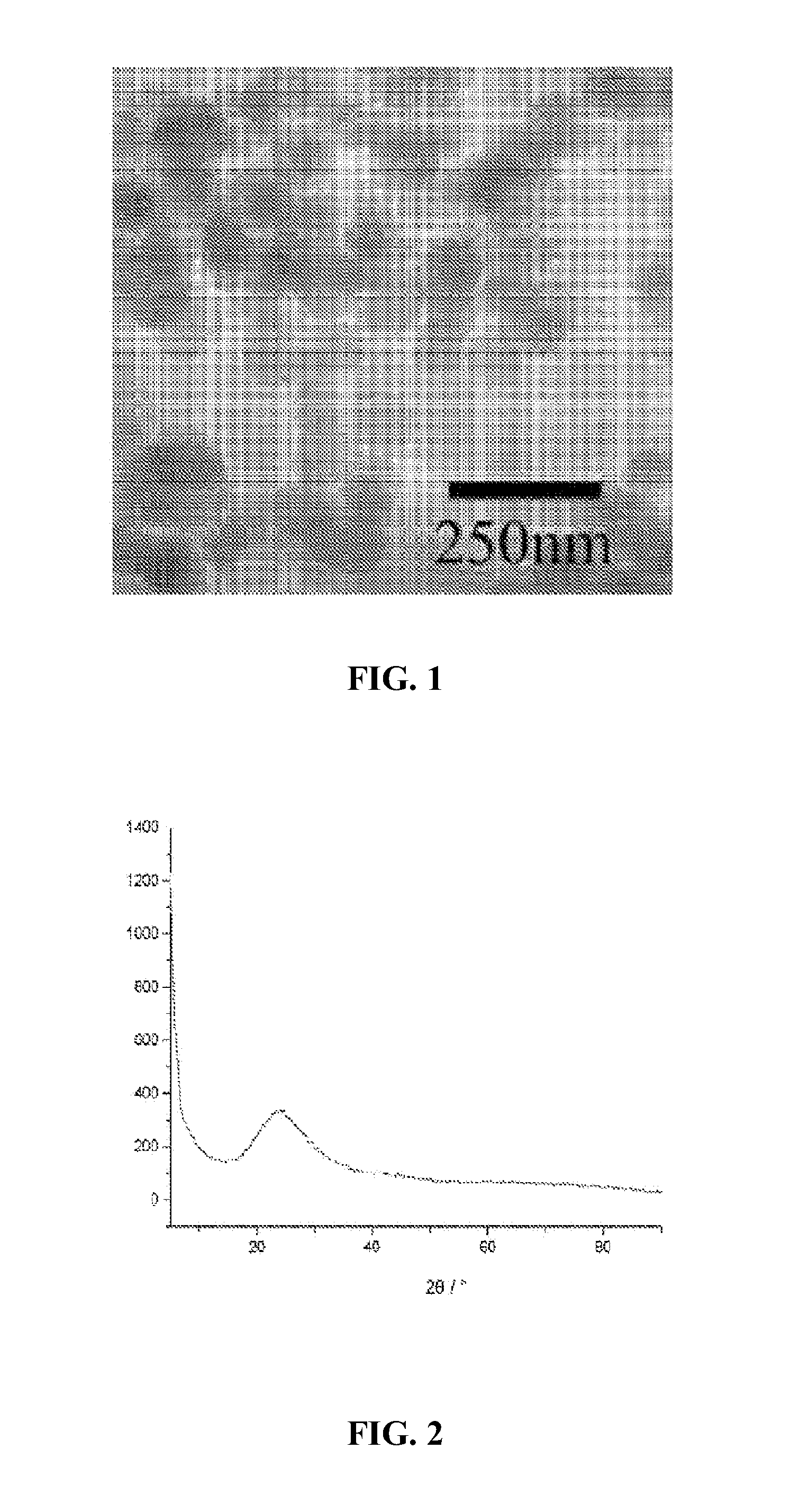

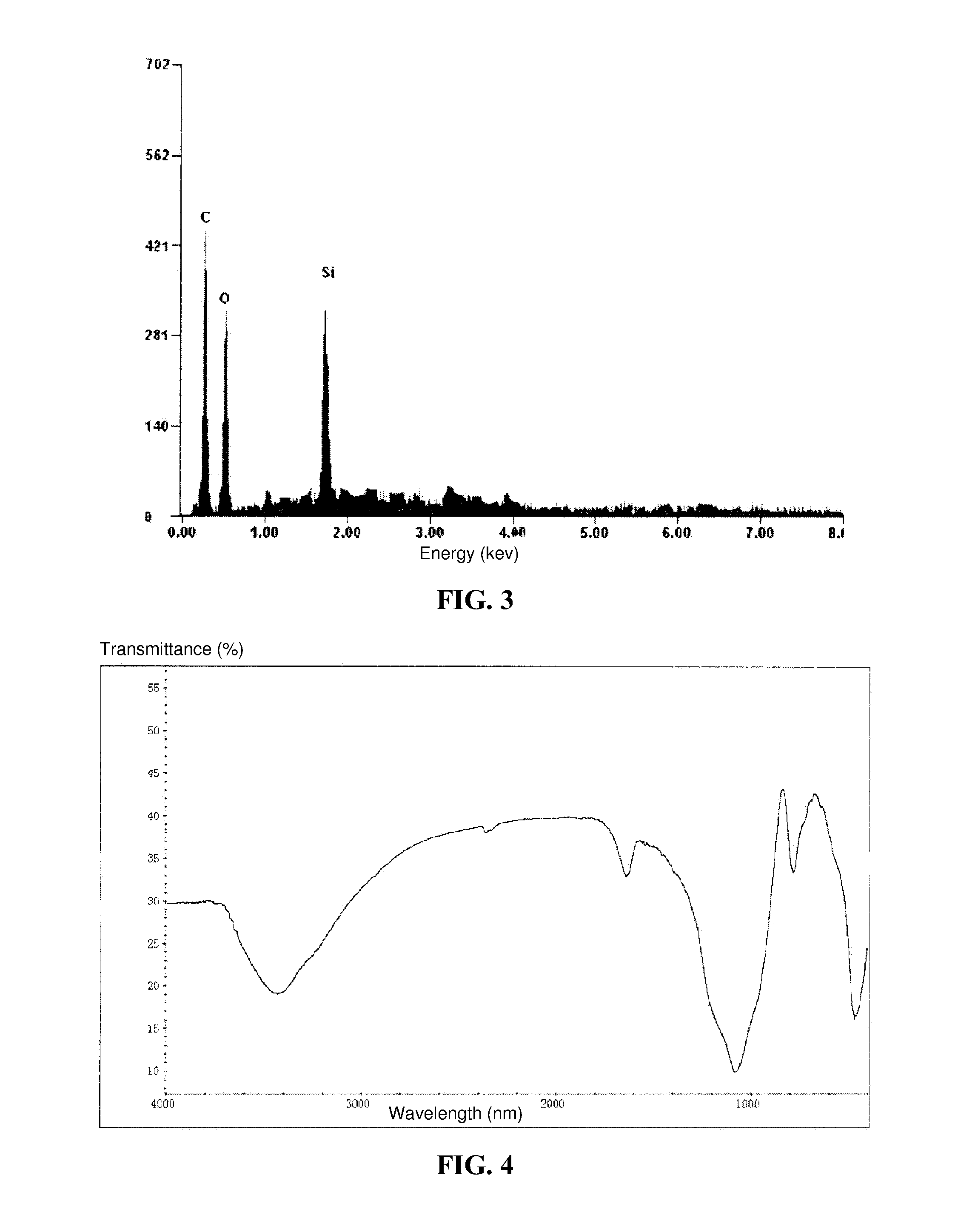

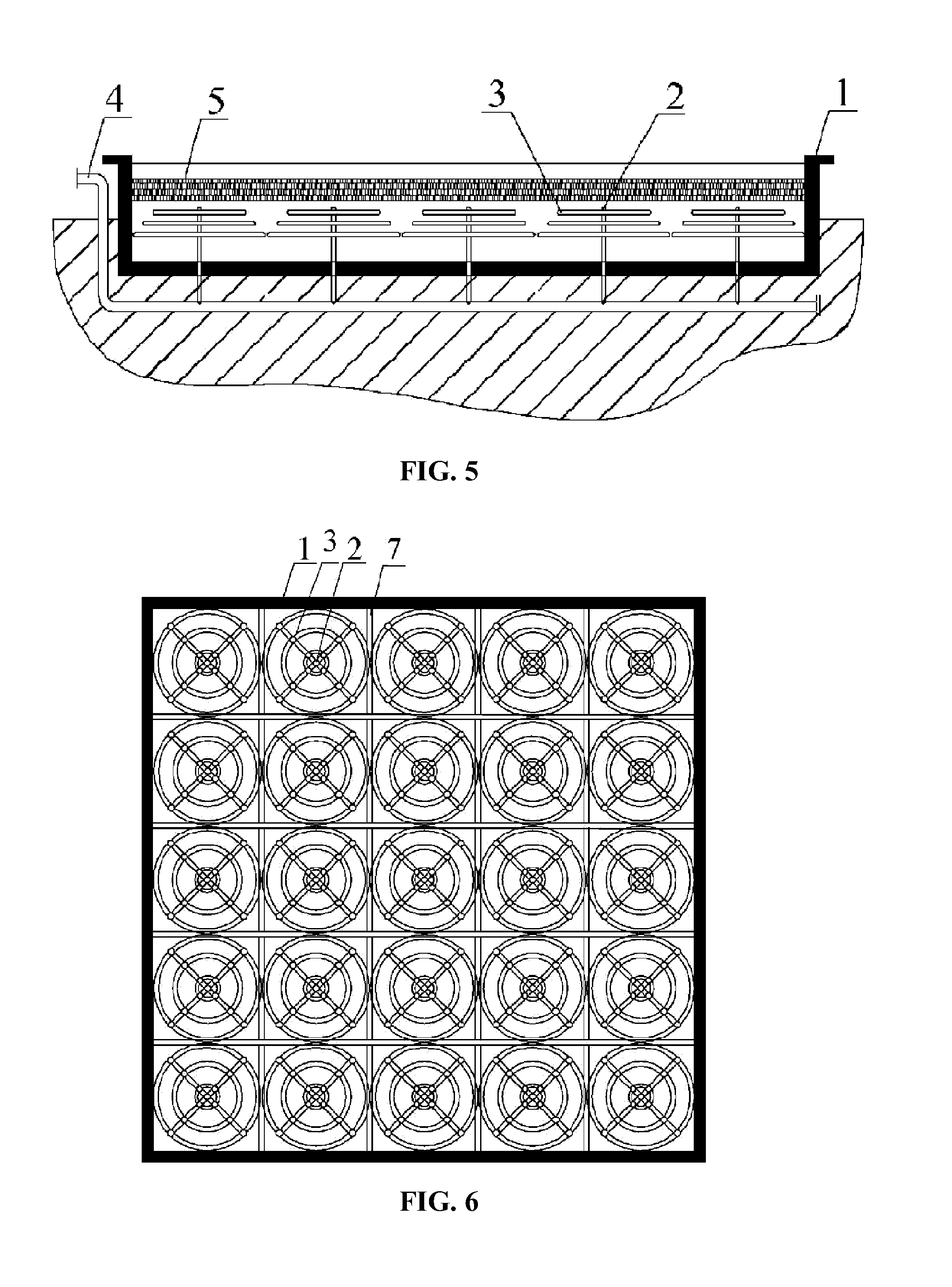

Method for preparing surface-modified nanosilicon dioxide from rice hulls

ActiveUS20150119595A1Increase equilibrium pressureImprove solubility of carbon dioxideSilicon organic compoundsSilicaPropanoic acidStrong acids

A method for preparing surface-modified nano silicon dioxide from rice hulls. The method includes: 1) pretreating rice hulls using a treating gas containing CO2 to remove metal ions, impurities, and dusts, and desiccating and grinding the rice hulls; 2) submerging the rice hulls into a dilute solution of phosphoric acid, boric acid, hydrochloric acid, formic acid, acetic acid, propionic acid, butyric acid, or a strong-acid-weak-base salt for between 4 and 8 hrs, controlling the immersion temperature not to exceed 10° C., leaching a resulting mixture, removing a filtrate, and desiccating the rice hulls; and 3) calcining the rice hulls in the absence of oxygen at a temperature of between 300 and 450° C.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Image forming device, and image forming method

InactiveUS8870350B2Suppress blurDischarging performanceOther printing apparatusImage formationEngineering

An image forming device includes a head including a nozzle that discharges an electrically-conductive recording liquid in accordance with a driving signal; an intermediate transfer body on which the recording liquid discharged by the head is applied; a voltage apply unit that applies a voltage between the intermediate transfer body and the head, so as to decompose the electrically-conductive recording liquid by electrolysis; a transfer unit that transfers an image supported on the intermediate transfer body onto a recording material; and a discharging control unit that generates the driving signal that causes the electrically-conductive recording liquid to be discharged from the nozzle. The discharging control unit generates the driving signal so that a position of a meniscus is placed outside the nozzle during a time interval in which the recording liquid temporarily bridges between the head and the intermediate transfer body.

Owner:RICOH KK

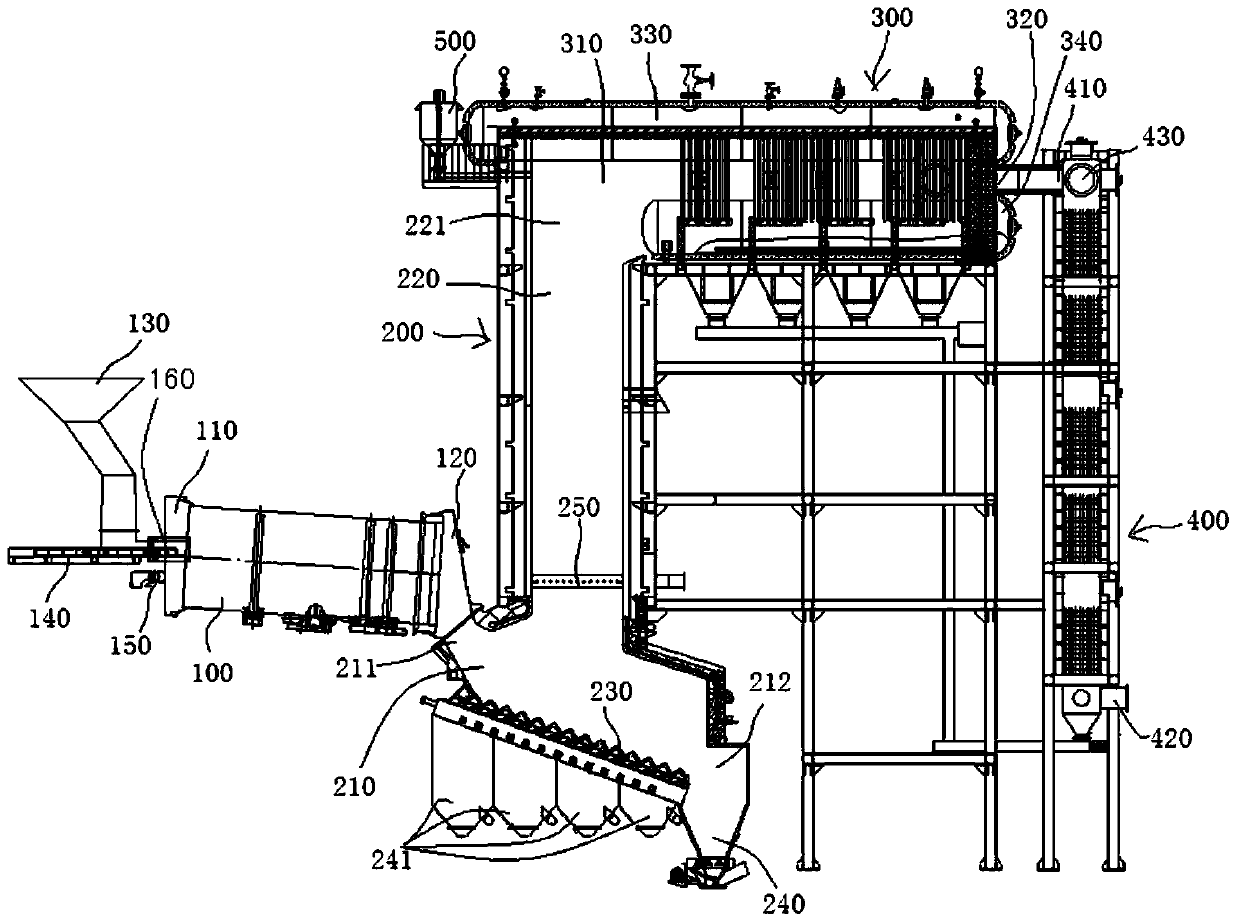

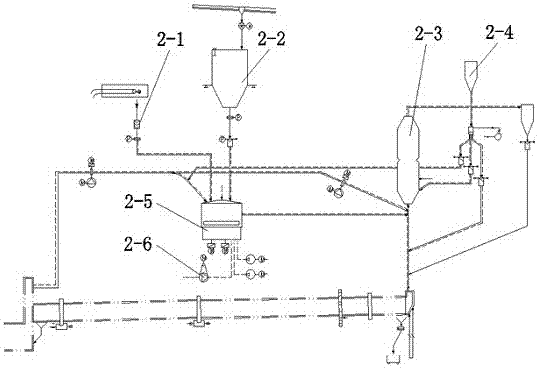

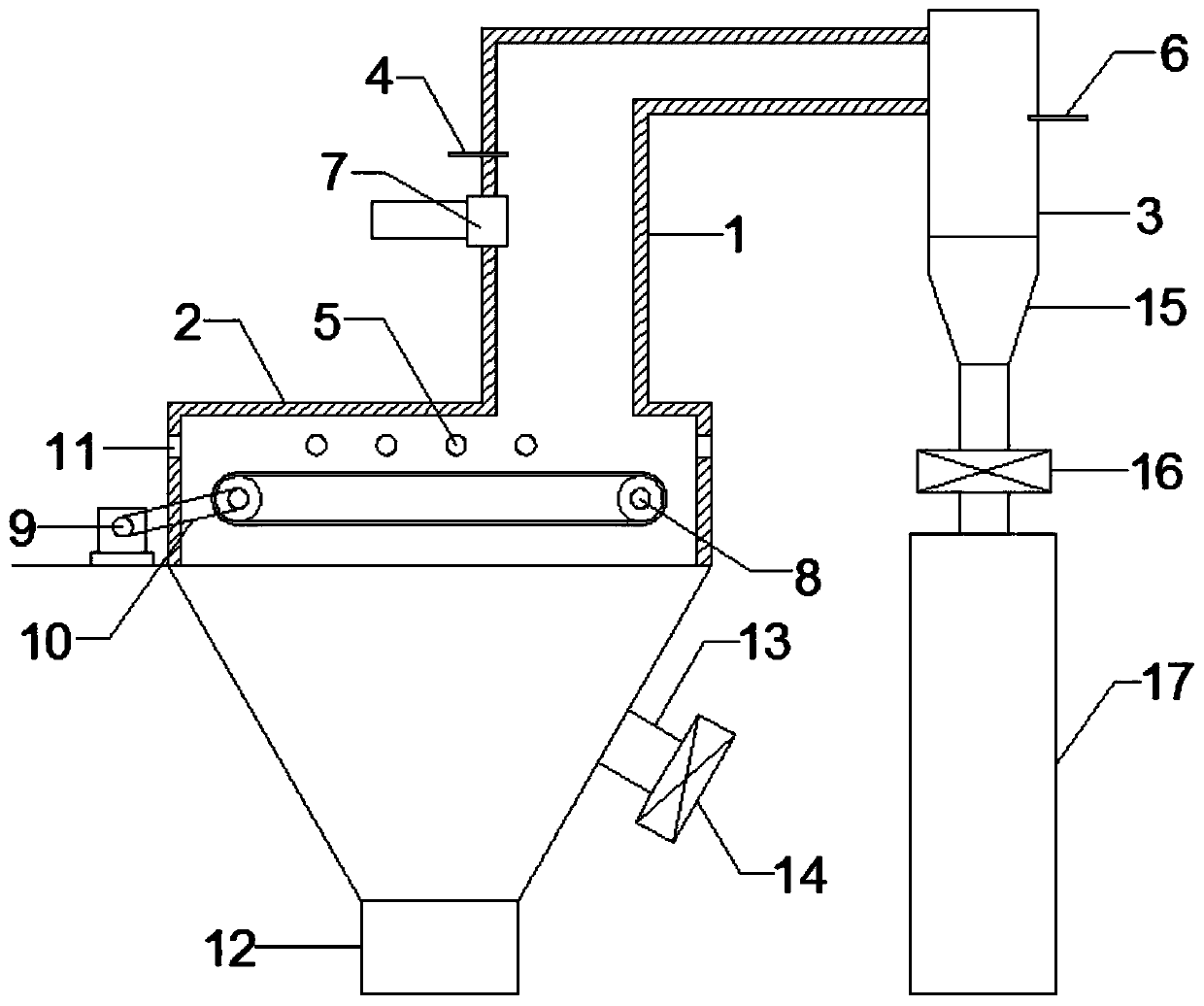

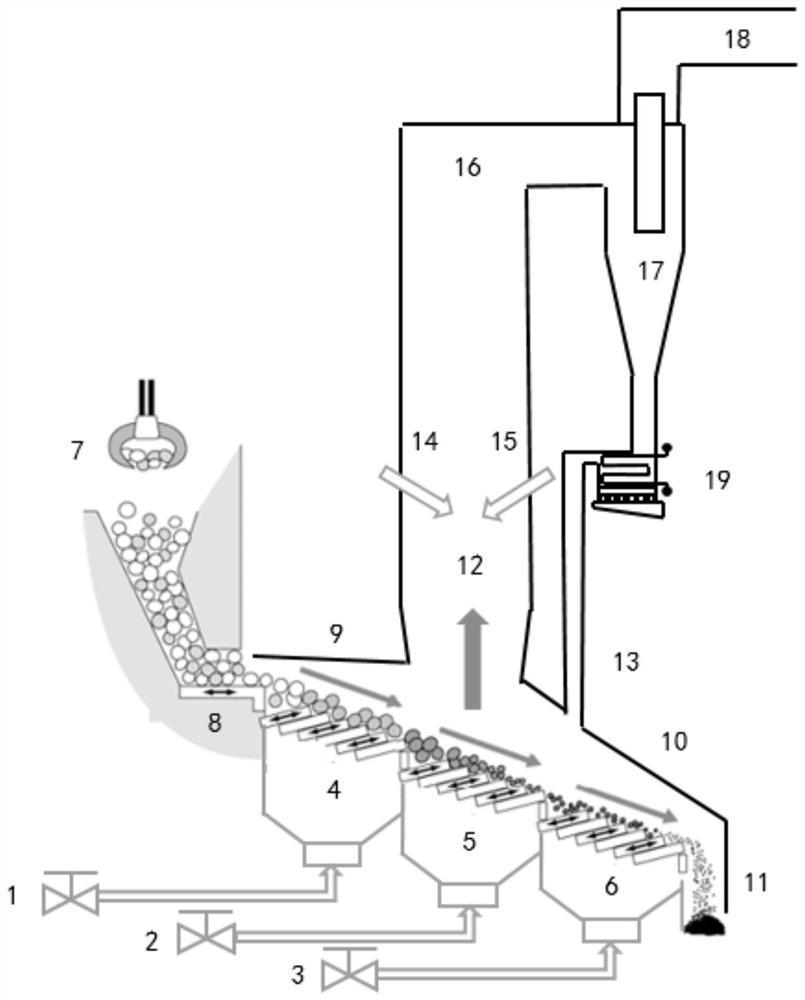

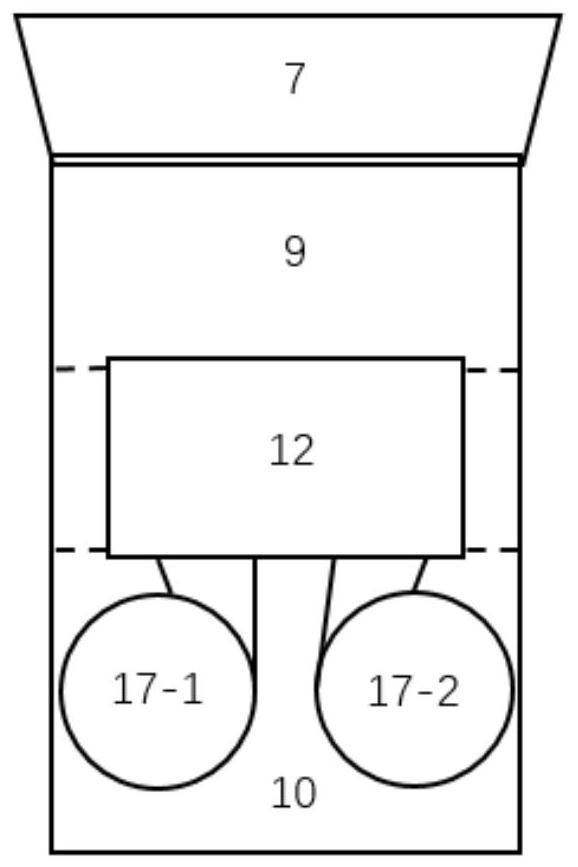

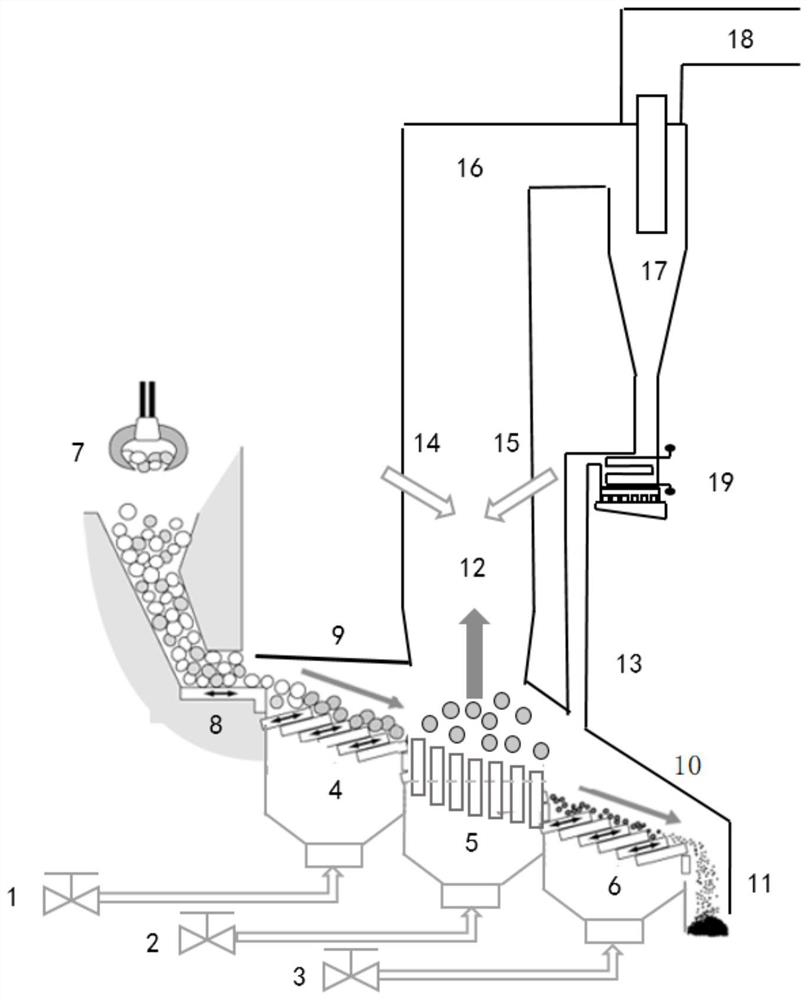

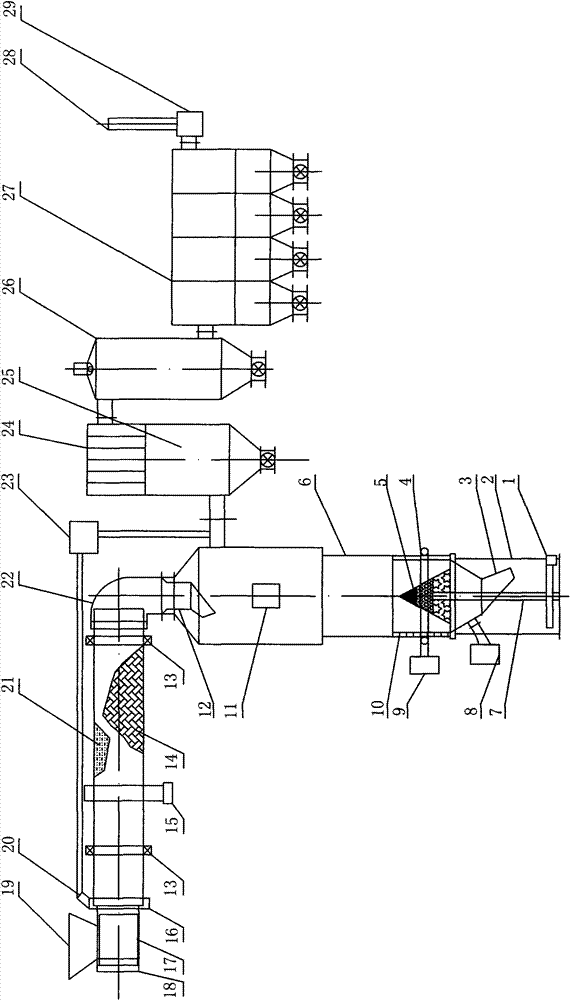

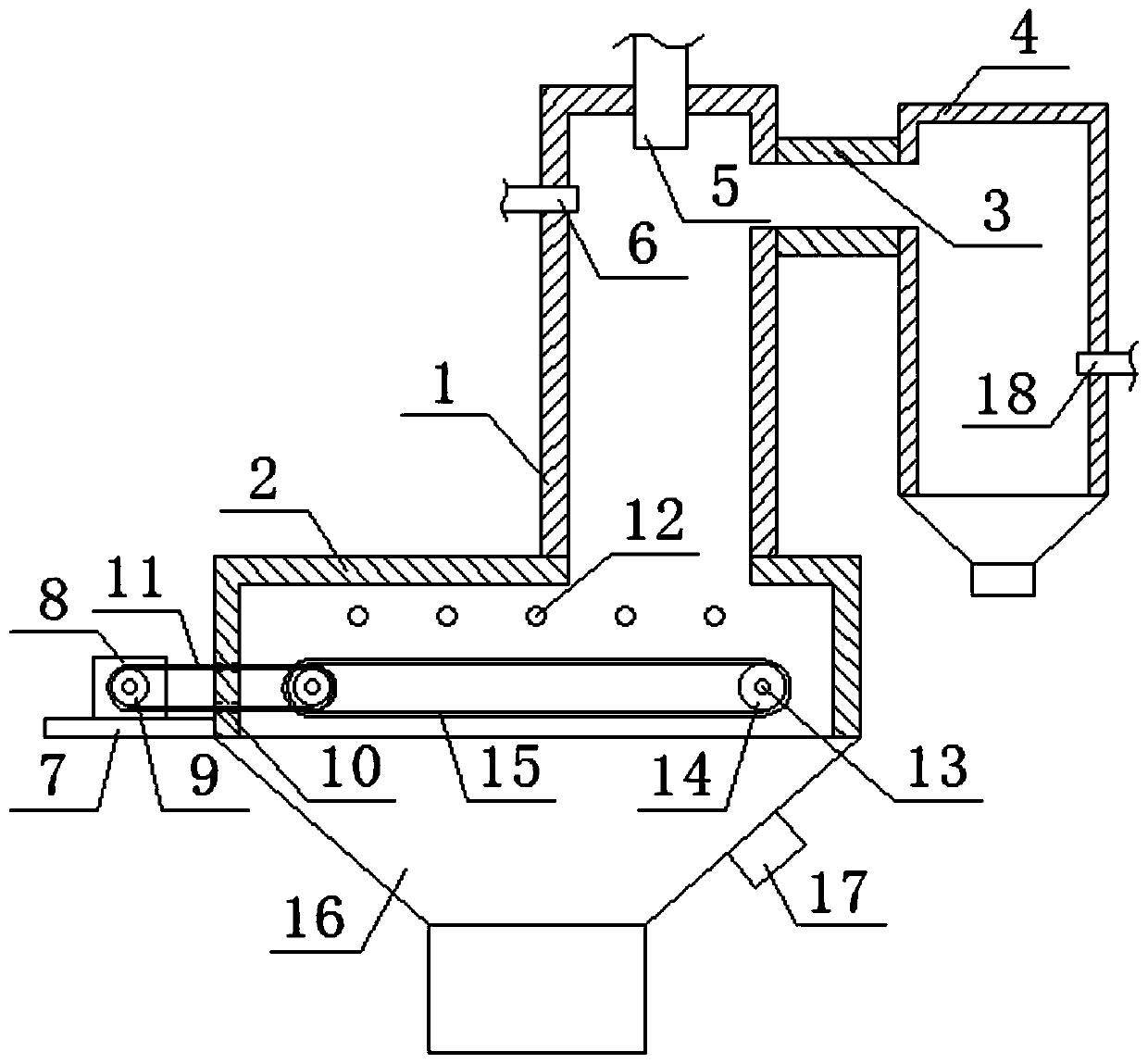

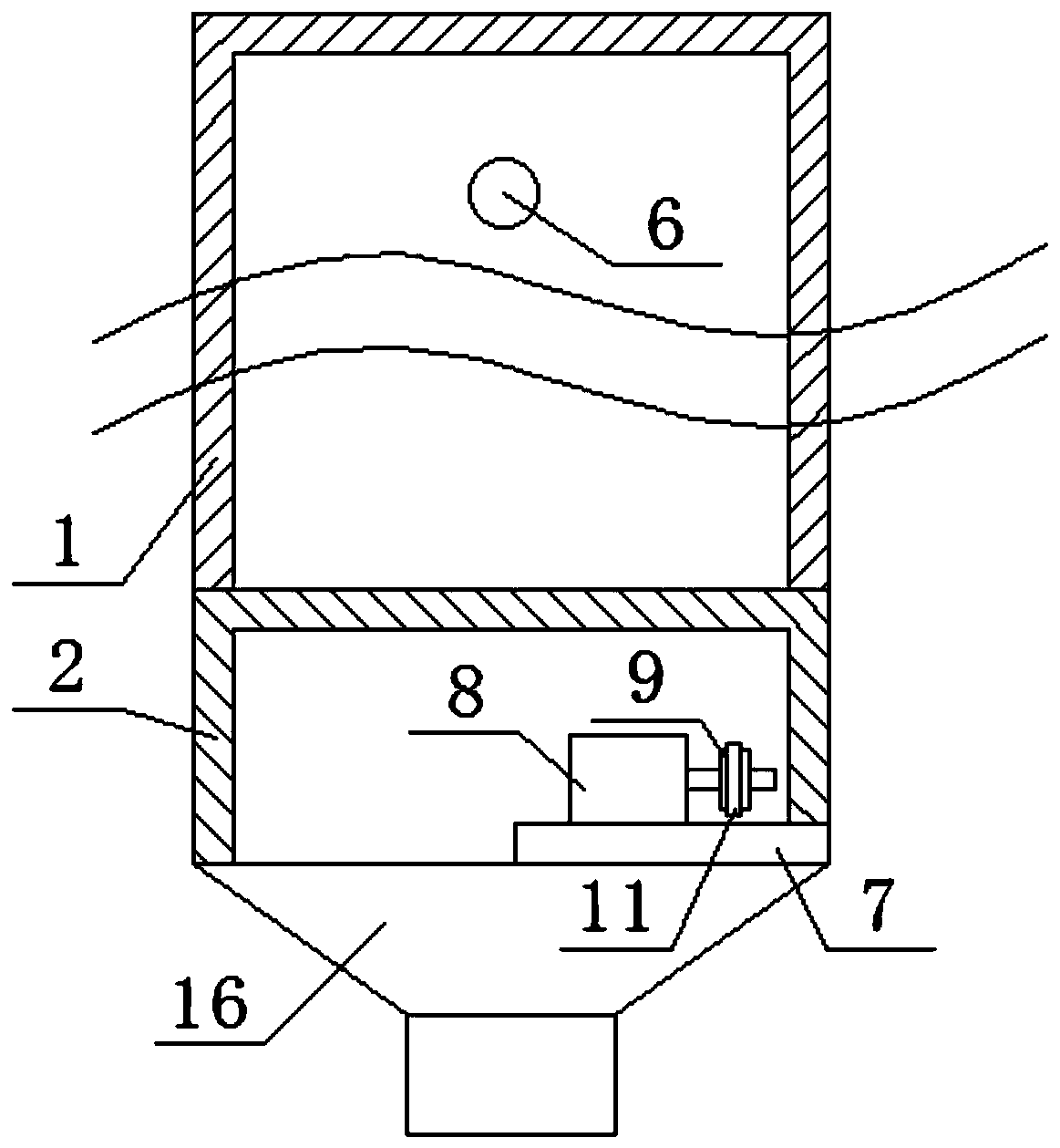

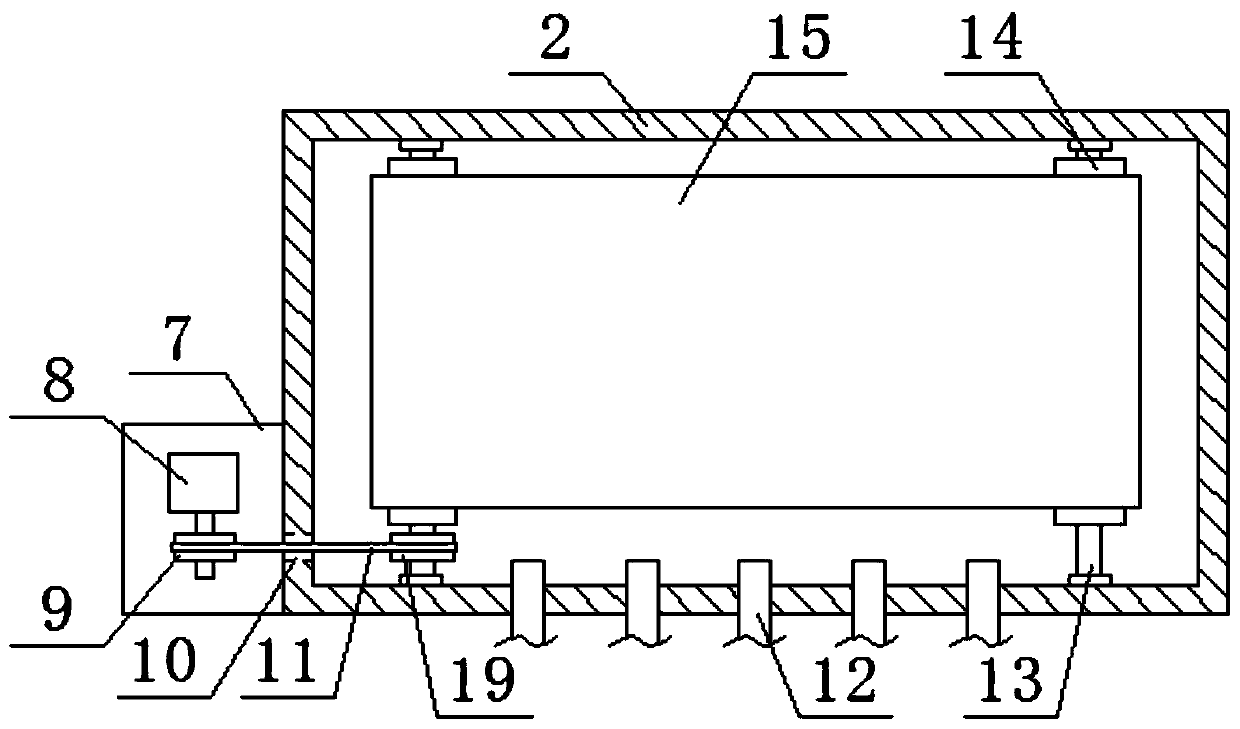

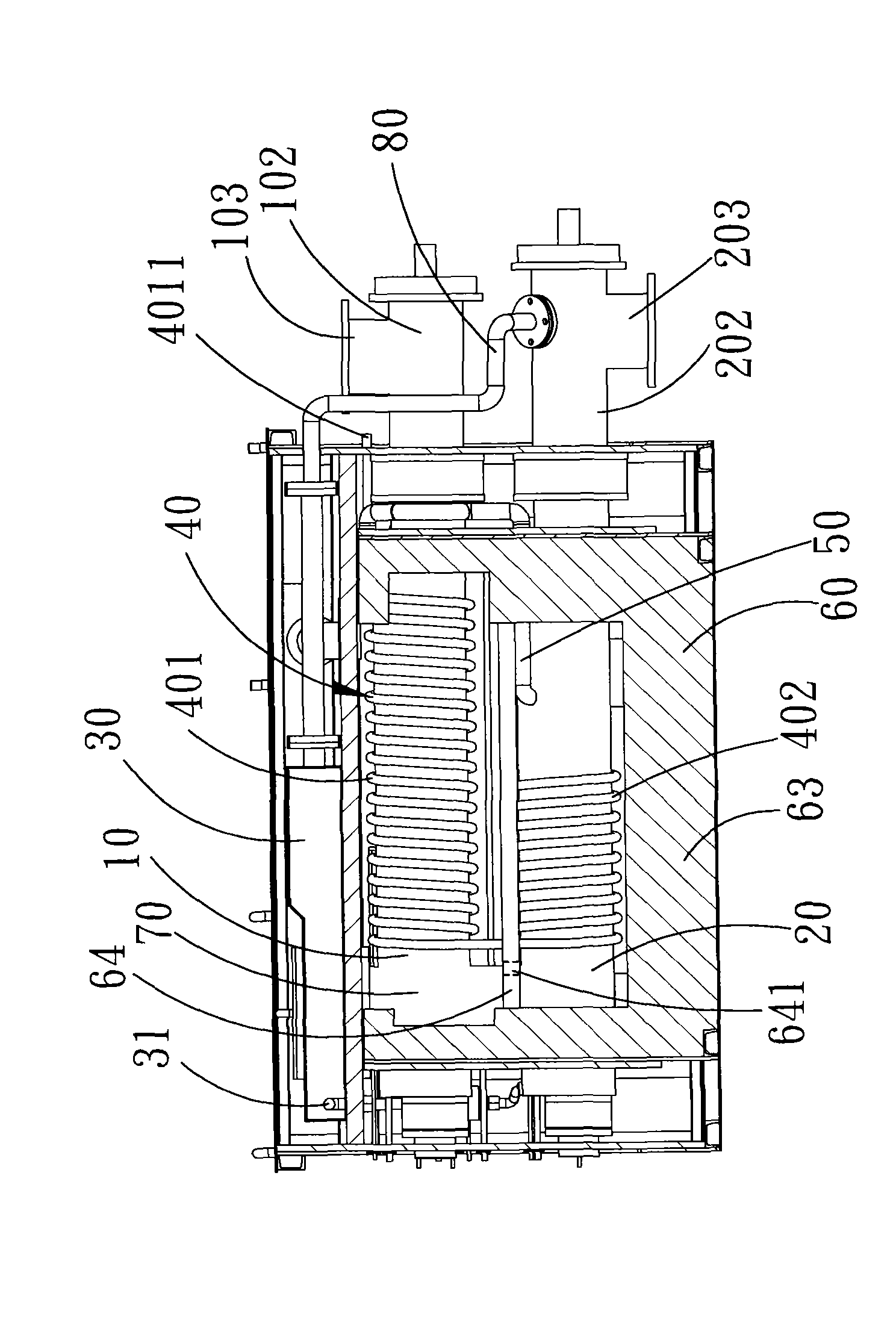

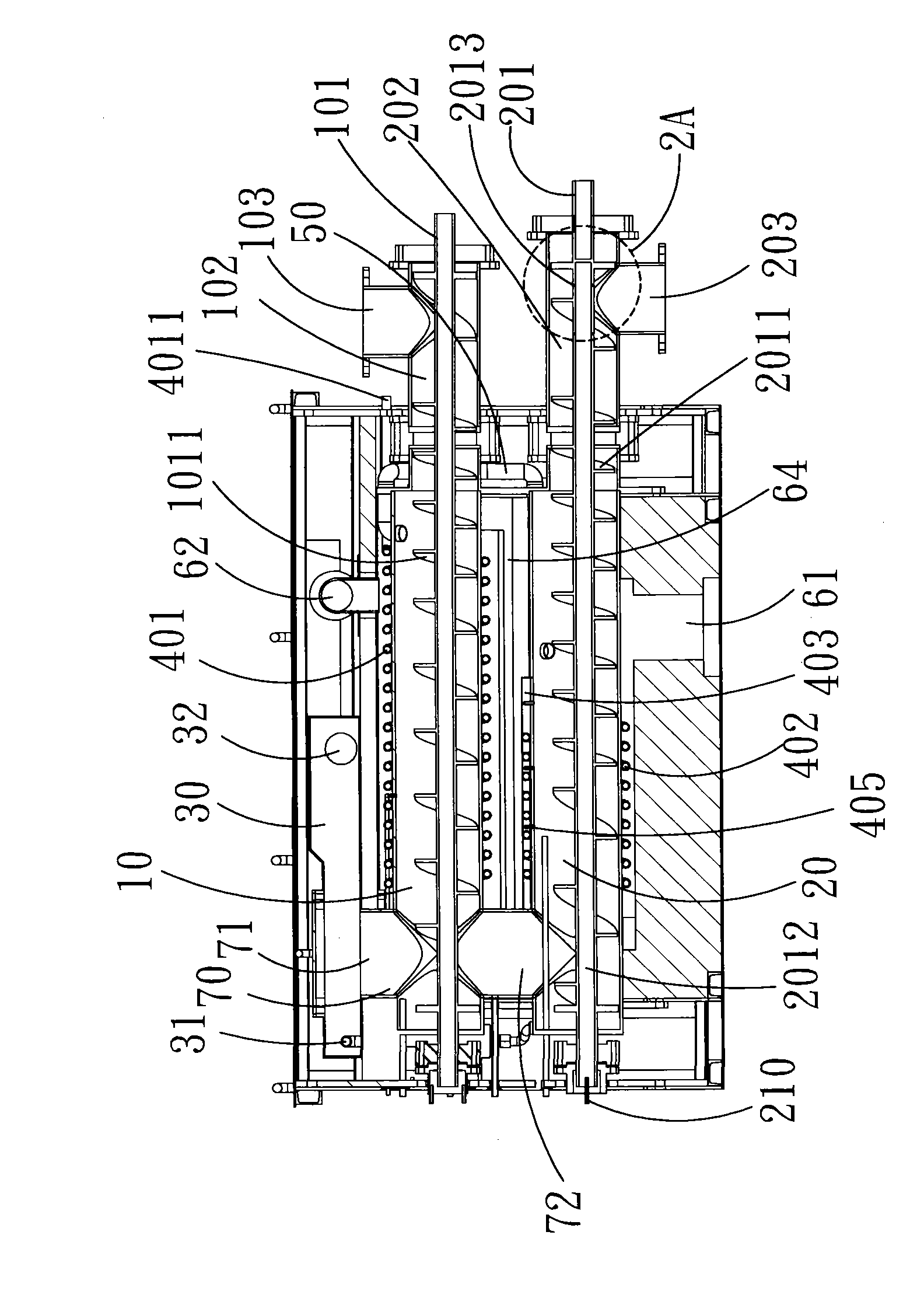

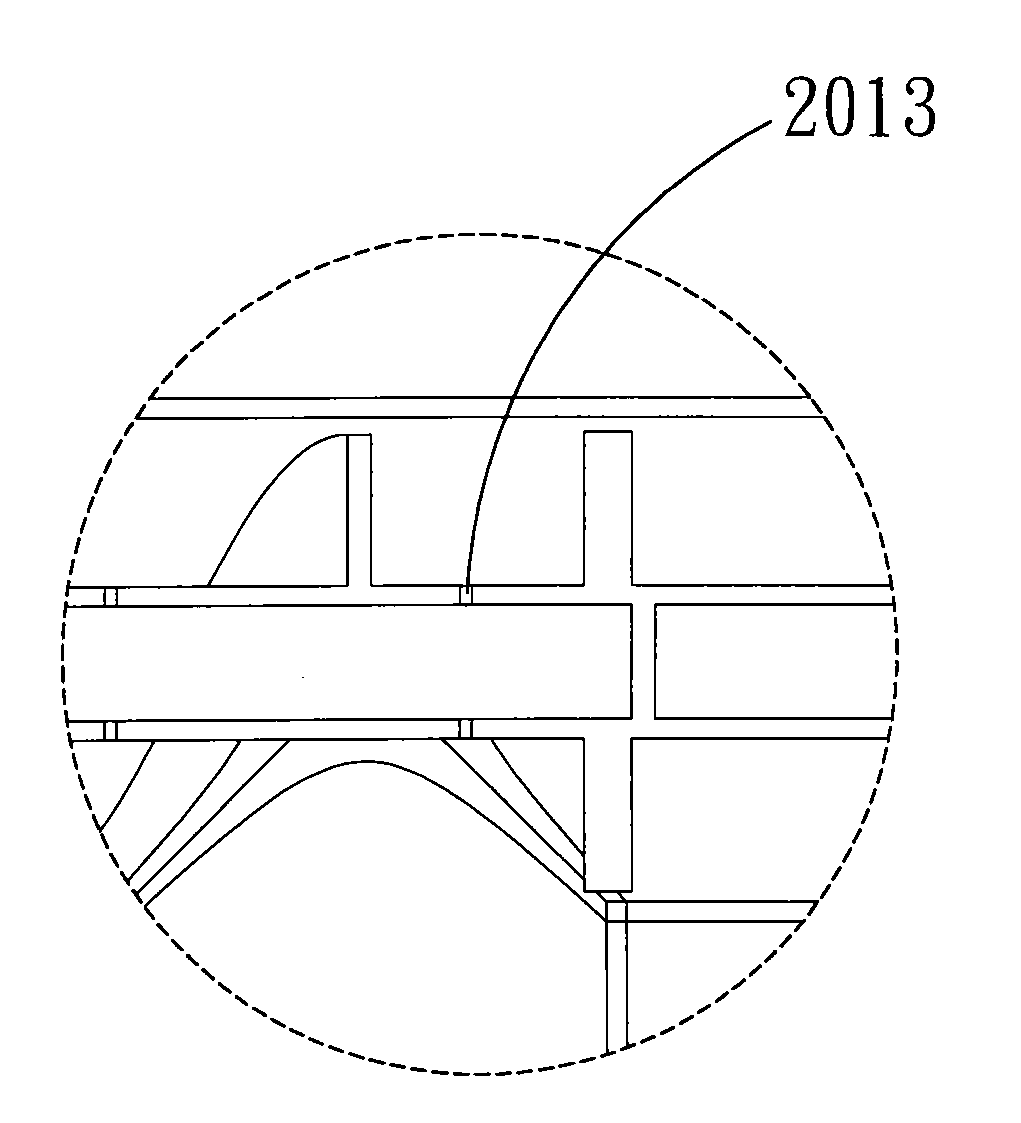

Circulating fluidized bed waste incineration boiler based on grate and working method thereof

The invention discloses a circulating fluidized bed waste incineration boiler based on a grate and a working method thereof and belongs to the technical field of household waste incineration flue gastreatment. A feeding system is connected with a grate drying section; the grate drying section, a fluidized combustion section and a grate burnout section are sequentially connected, and the lower parts of the grate drying section, the fluidized combustion section and the grate burnout section are respectively connected with a primary air system through air volume adjusting devices; the grate burnout section is connected with a slag discharge pipe; a front arch of the grate is positioned above the grate drying section, and a rear arch of the grate is positioned above the grate burnout section;a hearth is connected with a secondary air system; the upper part of the hearth is connected with a horizontal flue; the horizontal flue is connected with an inlet of a material returning system; a material returning outlet of the material returning system is connected with a material returning port of the boiler through a material returning pipe; and a smoke outlet of the material returning system is connected to a tail flue. The stability of feeding and slag discharging is improved, so that the combustion is uniform and stable, the emission of harmful pollutants is reduced, the combustion efficiency of the boiler is improved, and the risk of blowing out is avoided.

Owner:HUANENG CLEAN ENERGY RES INST

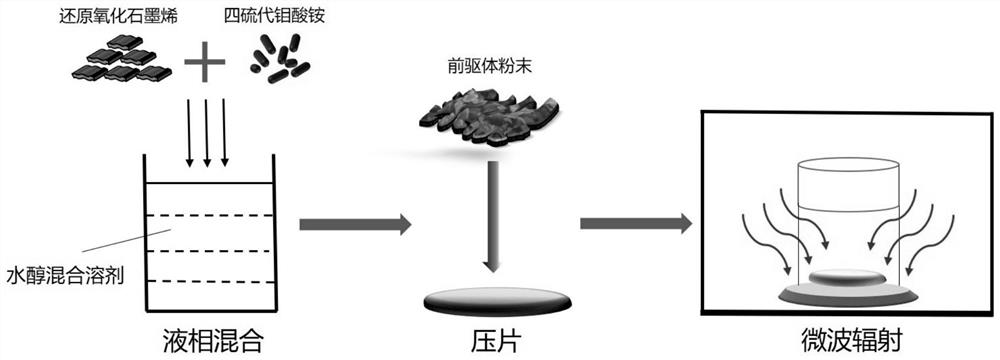

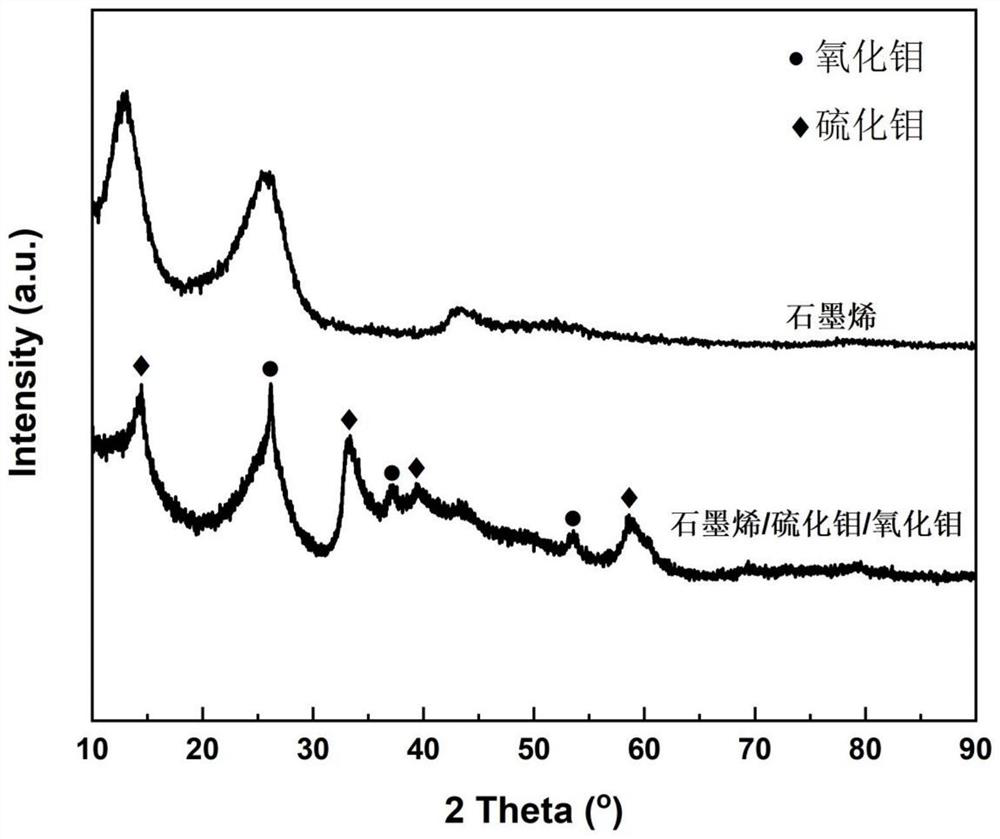

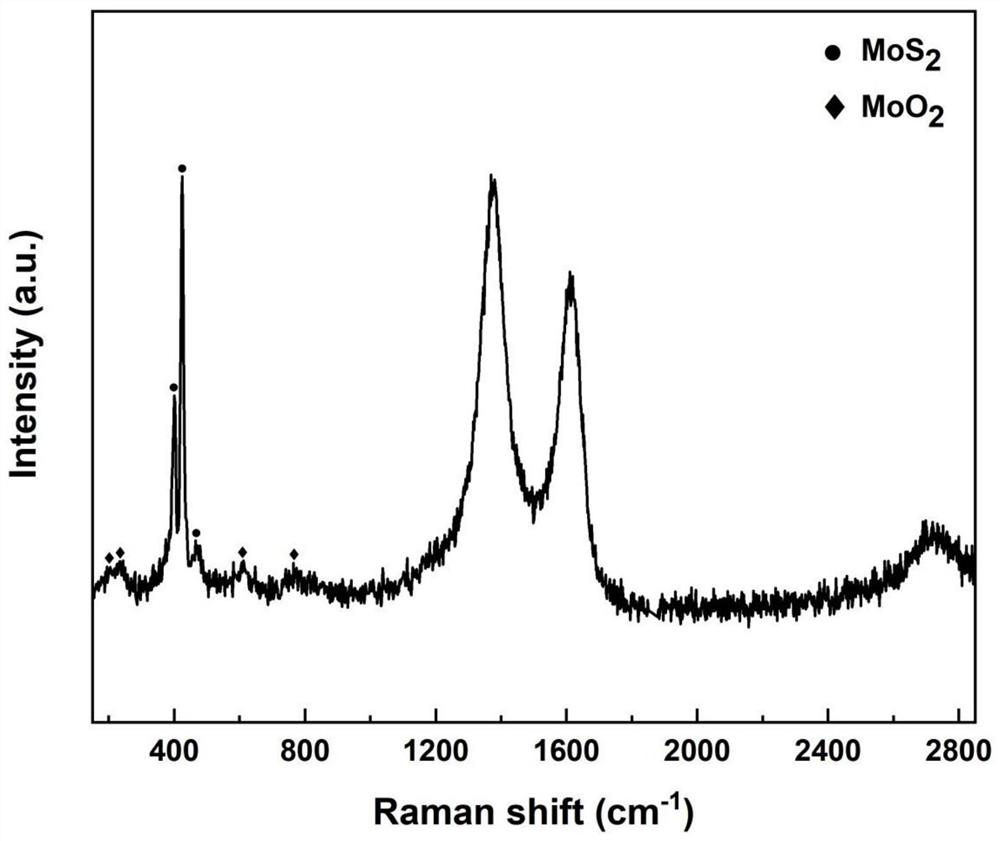

Microwave preparation method and application of graphene/molybdenum sulfide/molybdenum oxide heterostructure catalyst

ActiveCN113368877AEvenly dispersedEfficient preparationCatalyst activation/preparationPositive electrodesPtru catalystGraphene flake

The invention discloses a microwave preparation method and application of a graphene / molybdenum sulfide / molybdenum oxide heterostructure catalyst. The method comprises: respectively dispersing reduced graphene oxide powder and ammonium tetrathiomolybdate powder in ethanol and deionized water with the same volume to obtain corresponding dispersion liquids, mixing the two dispersion liquids, and performing stirring and ultrasonic treatment to obtain a mixed dispersion liquid; stirring, heating and drying the mixed dispersion liquid to obtain precursor powder, and then tabletting the precursor powder to obtain precursor tablets; and carrying out microwave radiation treatment on the precursor tablet, wherein the ammonium tetrathiomolybdate of the precursor tablet is decomposed and subjected to an in-situ reaction with the graphene oxygen-containing functional group to generate a molybdenum sulfide-molybdenum oxide heterostructure on the graphene sheet layer so as to obtain the graphene / molybdenum sulfide / molybdenum oxide heterostructure catalyst. Compared with a hydrothermal synthesis method or a high-temperature calcination method which is long in time consumption, high in energy consumption and high in danger, the method is simple and rapid in preparation process and high in safety coefficient.

Owner:XI AN JIAOTONG UNIV

Carbon nitride preparation method

InactiveUS7807124B2Outstanding propertyImprove propertiesNitrogen-metal/silicon/boron binary compoundsThiocyanic acidCarbon nitrideNanotechnology

The present invention relates to a method for preparing carbon nitride material wherein organic rodanide is simply pyrolyzed to give carbon nitride material in an efficient, economical, and ecologically friendly manner. The present invention accomplishes preparation of graphitic carbon nitride materials having a carbon to nitrogen molar ratio of about 3:4. The employed starting materials are cheap and can be easily removed and / or washed away.

Owner:CARBODEON LTD OY

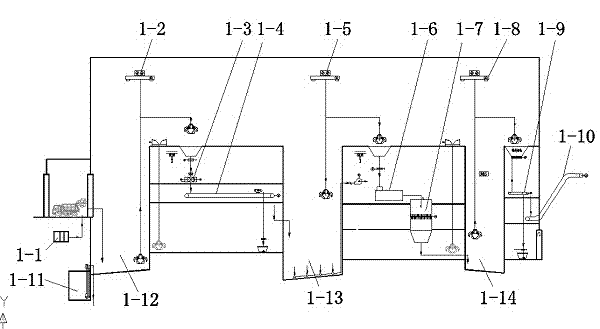

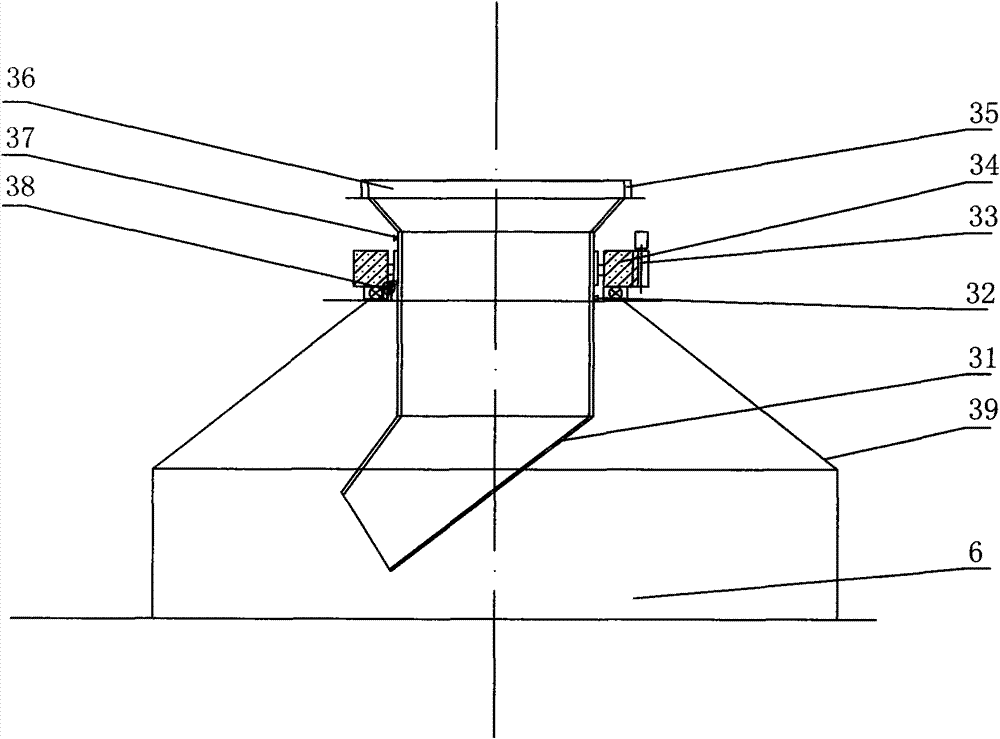

Household garbage vertical burning rotary grate furnace system

The invention relates to a household garbage vertical burning rotary grate furnace system, which comprises a discharge transmission device, a bracket, a slag discharge pipe, an annular air duct, a multilayer tower grate, a burning furnace main body, a transmission upright post, a draft fan, a Roche fan, a rotary feed distribution device, a garbage feed dryer, a cam device, a feed transmission device, a fuel gas connecting hood, a feeding outer cylinder, a feeder, a feeding hopper, a fuel gas circuit pipe, a fuel gas connecting hood, a feed connecting hood and a secondary blower, wherein the bracket supports the burning furnace main body; the lower part of the burning furnace main body is provided with the multilayer tower grate; the lower part of the multilayer tower grate is connected with the slag discharge pipe; the discharge transmission device is connected with the multilayer tower grate through the transmission upright post; the top over of the burning furnace main body is provided with the rotary feed distribution device; the annular air duct is arranged on the burning furnace main body at the position where the multilayer tower grate is arranged; the garbage feed dryer is provided with the cam device and the feed transmission device; a garbage transmission pipe is connected with the rotary feed distribution device through the fuel gas connecting hood; the feeding hopper is connected with the garbage transmission pipe through the feeding outer cylinder and the feeder; the fuel gas circuit pipe is connected with the garbage transmission pipe and the connector of the feeding outer cylinder through the fuel gas connecting hood; and the fuel gas circuit pipe is connected with the gas outlet of the burning furnace main body through the secondary blower.

Owner:陈仲伟

A garbage pyrolysis gasifier

ActiveCN111457382BAvoid carbonizationNormal rotationDigital data processing detailsIncinerator apparatusCombustorPlastic waste

The invention discloses a garbage pyrolysis gasification furnace, the structure of which comprises an inlet, a pyrolysis furnace, a gas outlet pipe, a turning mechanism, a steam inlet, and a burner. Embedded with an air outlet pipe, the plastic waste inside the turning mechanism is pyrolyzed, and the plastic waste in the middle is moved upward through the structure of the plate body, and at the same time, the melted plastic waste in the middle is flowed downward through the inlet and flow ports, and the upward flow is carried out. The middle and lower flow circulates, and at the same time, through the sliding of the sliding plate, the flow tube inside the supporting plate makes the molten garbage in the middle flow down, avoiding the carbonization of the external plastic garbage in the first step, and the steam is transmitted through the transmission tube, to the center The molten plastic waste inside is pyrolyzed, and at the same time, after the expansion body is heated and expanded, the connecting rod protrudes from the inside of the hollow ball, increasing the contact surface with the melted plastic waste, thereby ensuring that the plastic in the center is decomposed.

Owner:中开水生态治理有限公司

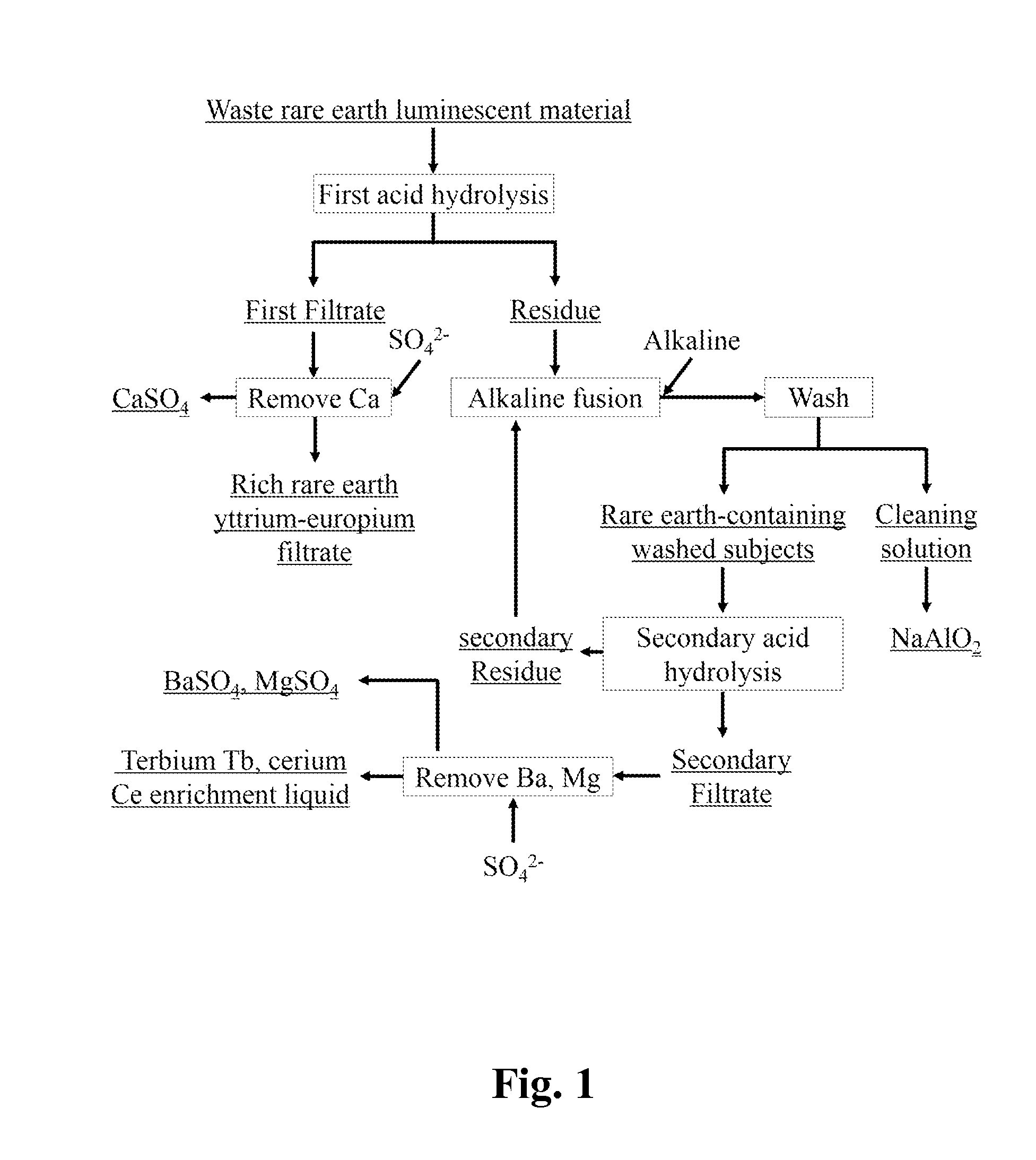

Method for Treating Waste Rare Earth Luminescent Material Using Dual Hydrochloric Acid Dissolution

InactiveUS20150225813A1Improve decomposition rateSimple separation and enrichmentRare earth metal compoundsProcess efficiency improvementSodium aluminateRare earth

The invention belongs to the field of recycling of resources, in particular to a method for waste rare earth luminescent material by dual hydrochloric acid. First hydrochloric acid was used to dissolve the red phosphor powder (Y2O3:Eu) priority, and yttrium-rich rare earth chloride solution and residue were obtained after filtered. Residue's major components were green and blue phosphor powder, and the removal of Ca2+ in filtrate was conducted by using Na2SO4, and CaSO4 precipitation separation was conducted to get rich rare earth chloride solution, europium and yttrium. Residue was mixed with alkali to perform alkaline fusion at high temperature to decompose green and blue powder, then sodium aluminate, magnesium, barium and rare earth oxides were obtained. Alkaline fusion products were washed with water, and filtered, and then sodium aluminate solution and residues containing rare earth oxides were obtained.

Owner:UNIV OF SCI & TECH BEIJING

Waste liquid incineration equipment for pesticide production

InactiveCN111550813AEnsure decompositionSimple structureIncinerator apparatusCombustorCombustion chamber

The invention belongs to the technical field of incineration equipment, particularly relates to waste liquid incineration equipment for pesticide production. The following scheme for solving the problem of incomplete incineration in the prior art is provided, the waste liquid incineration equipment comprises a first combustion chamber, a second combustion chamber is fixedly mounted at the bottom of the first combustion chamber, one end of a channel is fixedly mounted on one side of the first combustion chamber, an auxiliary combustion chamber is fixedly installed at the other end of the channel, a first combustor is fixedly installed in the center of the top of the first combustion chamber, a high-pressure nozzle is fixedly installed on one side, away from the channel, of the first combustion chamber, the first combustor and the high-pressure nozzle extend into the first combustion chamber separately, and a supporting plate is fixedly installed at the bottom of one side of the second combustion chamber. The waste liquid incineration equipment for pesticide production is simple in structure, reasonable in design and convenient to operate, incineration disposal can be carried out onhigh-concentration pesticide waste liquid, the waste liquid disposal effect can be ensured, and the waste liquid incineration equipment is environmentally friendly and high in practicability.

Owner:ANHUI YINONG CHEM

A Rapid Joint Measurement Method of Copper, Zinc and Iron Content in Gold Mud

ActiveCN105044088BFill vacancyDo not interfere with determinationMaterial analysis by observing effect on chemical indicatorSilver copperPrecipitation

Owner:山东黄金冶炼有限公司

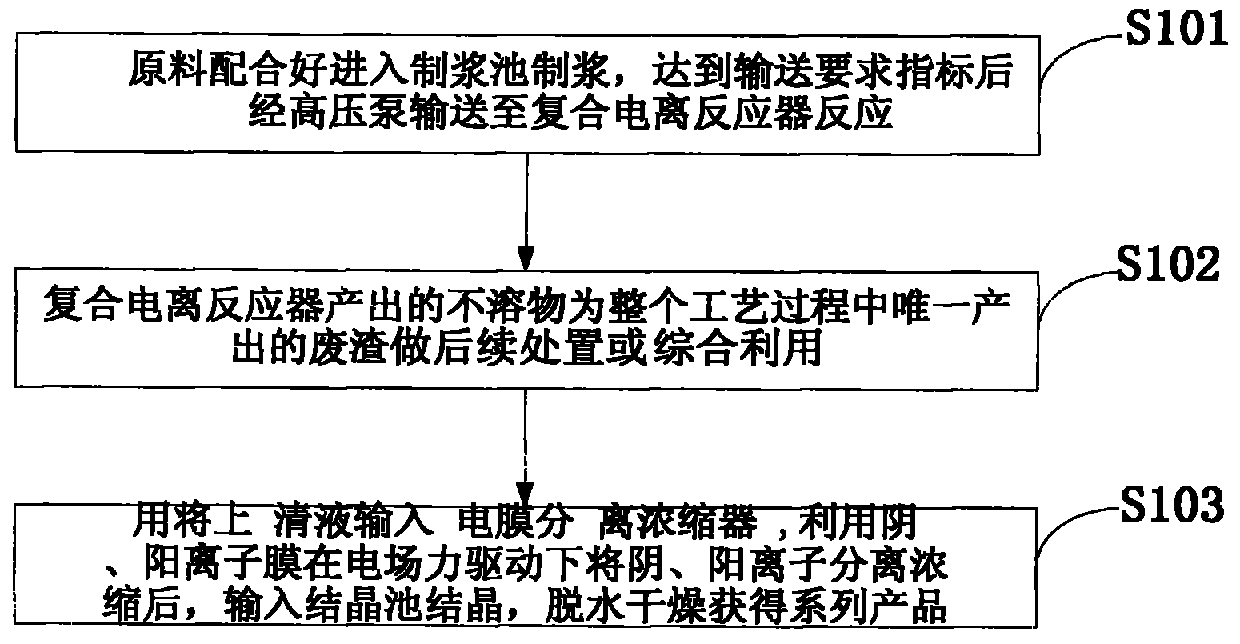

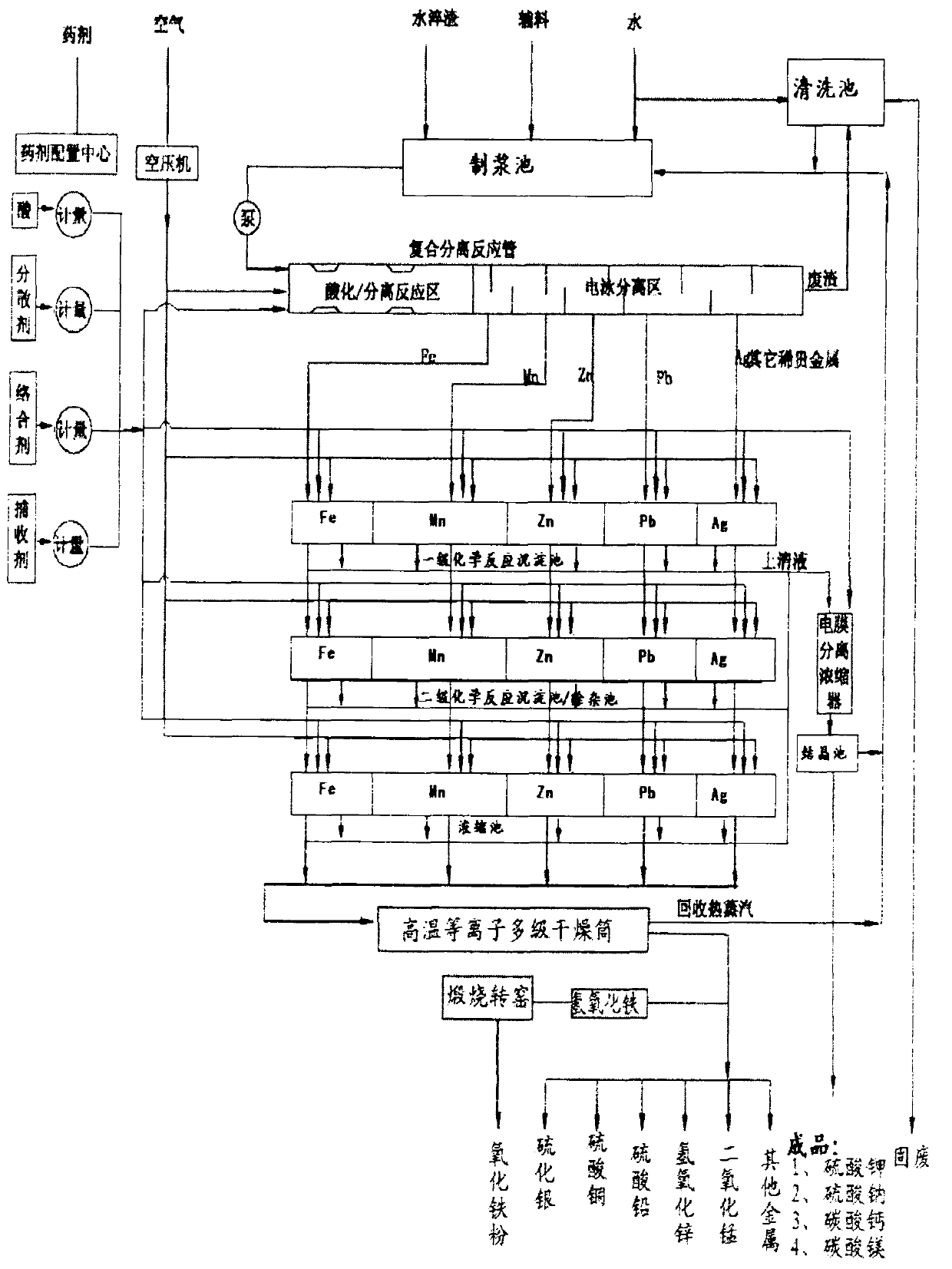

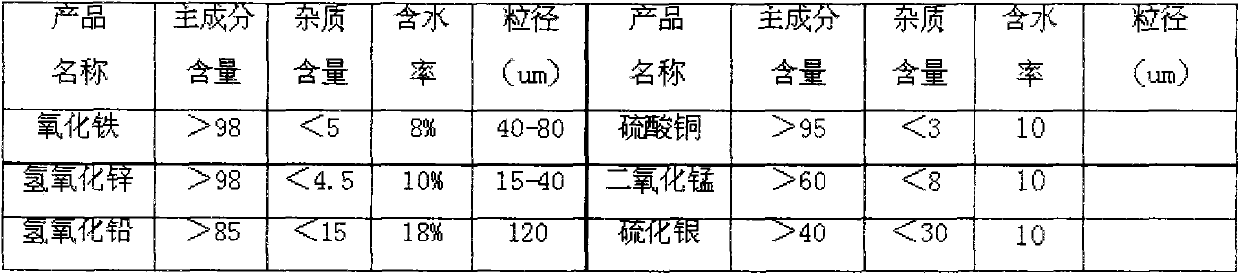

Comprehensive recycling method for solid waste water-quenched slag

InactiveCN103433270AEnsure decompositionAchieve the purpose of separationSolid waste disposalSlagSlurry

The invention discloses a comprehensive recycling method for solid waste water-quenched slag. The method comprises the following steps of (1) slurrying proportioned raw materials in a slurrying tank, and conveying slurry to a composite ionization reactor for reacting by a high-pressure pump after the slurry meets conveying required indicators; (2) carrying out subsequent treatment or comprehensive utilization on insolubles, which are produced from the composite ionization reactor and are the only produced waste residue of a whole process flow; (3) inputting a supernatant into an electric-membrane separation and concentration device, inputting the supernatant into a crystallizing tank for crystallizing after anions and cations are subjected to separation and concentration by using anion and cation membranes under the drive of electric field force, dehydrating and drying, thereby obtaining a series of products. According to the method, advanced processes of treating waste with waste are adopted, no waste gases, waste water and waste residues are discharged during comprehensive recycling, and the amount of solid waste digestion is 1,300 tons per day, so that the requirements on clean production and environmental protection are met. In addition, process procedures of the method all use electric energy, the aims of treating waste with waste, low cost and no pollution are realized, the technology is mature, and the process is reliable.

Owner:李戈登

proton conducting membrane

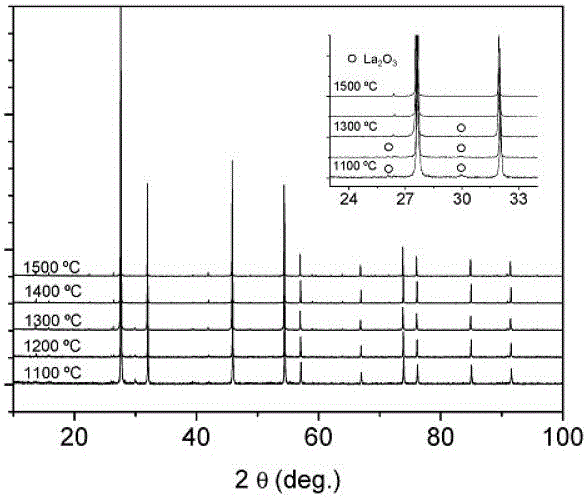

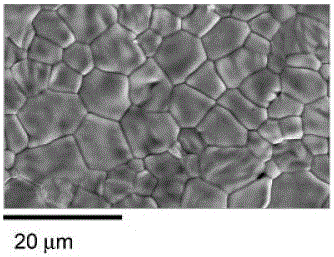

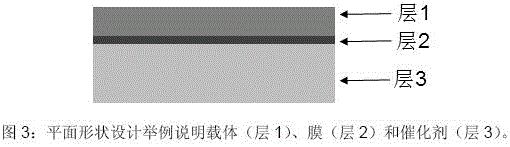

ActiveCN102812587BPromote decompositionEnsure decompositionHydrogenHydrocarbon by dehydrogenationProtonMembrane configuration

Accordingly, a first aspect of the present invention is to provide a reactor comprising a first zone containing a dehydrogenation catalyst, a second zone separated from the first zone by a proton-conducting membrane containing the formula (I) LnaWbO12-y Shown composite metal oxide; Wherein, Ln is Y, or a kind of in No. 57~71 elements; Molar ratio a:b is 4.8~6, is preferably 5.3~6; Y is to make molecular formula (I) uncharged Number, such as y satisfying 0≤y≤1.8.

Owner:普罗迪亚股份有限公司

A method for adjusting the flow rate of parallel fuel nozzles after welding

ActiveCN112178694BAvoid decompositionEnsure decompositionContinuous combustion chamberAbrasive agentStructural engineering

The invention provides a method for adjusting the flow rate of a parallel fuel nozzle after welding. First, the actual size of the spray hole of the main nozzle of the nozzle is measured; according to the measured actual size of the spray hole of the main nozzle of the nozzle, a straight grinding rod is selected as an adjustment tool; Among them, the diameter of the straight grinding rod is smaller than the actual size of the nozzle hole of the main nozzle of the nozzle; apply abrasive on the straight grinding rod, and then use the straight grinding rod to repair the main nozzle of the nozzle; when the main nozzle of the nozzle is not blocked, the fuel The nozzle is subjected to flow test until the flow test of the fuel nozzle is qualified; the present invention selects an adjustment tool in combination with the actual size of the nozzle main nozzle orifice, and uses a straight grinding rod with a diameter smaller than the actual size of the nozzle main nozzle nozzle to conduct the nozzle main nozzle nozzle hole. The repair and repair process can effectively avoid damage to the nozzle sub-nozzle, ensure the effective and qualified flow of the parallel fuel nozzle, avoid the decomposition of the fuel nozzle, the adjustment process is less difficult, and the performance of the fuel nozzle is ensured.

Owner:AECC AVIATION POWER CO LTD

Special gluing head cleaning device for full automatic glue edge sealing production line and cleaning method thereof

InactiveCN102125904BEnabling Bionic ExtrusionExtended service lifeSpraying apparatusCleaning using toolsProduction lineMoisture absorption

The invention relates to a special gluing head cleaning device for a full automatic glue edge sealing production line and a cleaning method thereof. The device can not only realize the function of automatically cleaning a gluing head, but also decompose and clean gelatin in an electric cleaning device, the gluing head in the full automatic glue edge sealing production line is provided with the electric cleaning device, the electric cleaning device can be lifted longitudinally through a pneumatic lifting mechanism, the pneumatic lifting mechanism is connected with a pneumatic horizontal driving mechanism, and the pneumatic horizontal driving mechanism is used for driving the pneumatic lifting mechanism to move front and back. The special gluing head cleaning device has the following advantages: 1) reliability in cleaning the gluing head is realized; and 2) an elastic movable cover edge arranged on an outer casing can not only realize bionic extrusion and cleaning of a flexible moistureabsorption roller, but also thoroughly completely decompose and clean residual glue after the flexible moisture absorption roller is used for dry type cleaning of the gluing head.

Owner:杭州精工机械有限公司

Reaction furnace device for decomposing substances to be treated by utilizing high temperature steam and heat source

ActiveCN102115672BEnsure decompositionQuick breakdownDirect heating destructive distillationSpecial form destructive distillationCombustion chamberEngineering

The invention discloses a reaction furnace device for decomposing substances to be treated by utilizing high temperature steam and a heat source. In the reaction furnace device, hot air is introduced into a combustion chamber; a second reaction chamber and a steam heating device encircling the second reaction chamber are heated first and then a first reaction chamber and a steam heating device encircling the first reaction chamber are heated, so that the temperature of the second reaction chamber is higher than that of the first reaction chamber; and the high temperature steam is introduced into the second reaction chamber and is mixed and reacted with the substances to be treated in the second reaction chamber, second mixed gas is generated and introduced into the first reaction chamber and is mixed and reacted with the substances to be treated, and the generated first mixed gas is introduced into an oil gas reaction chamber. Two-stage treatment that the first and second reaction chambers have different treatment temperatures and treatment time is created by the single heat source, and the substances to be treated are completely decomposed; and the oil gas treatment chamber provides a stable environment, so that the oil gas is quickly decomposed and is reacted with carbon particles to form fuel gas, and the carbon particles are reduced to be deposited in an oil product.

Owner:江宏

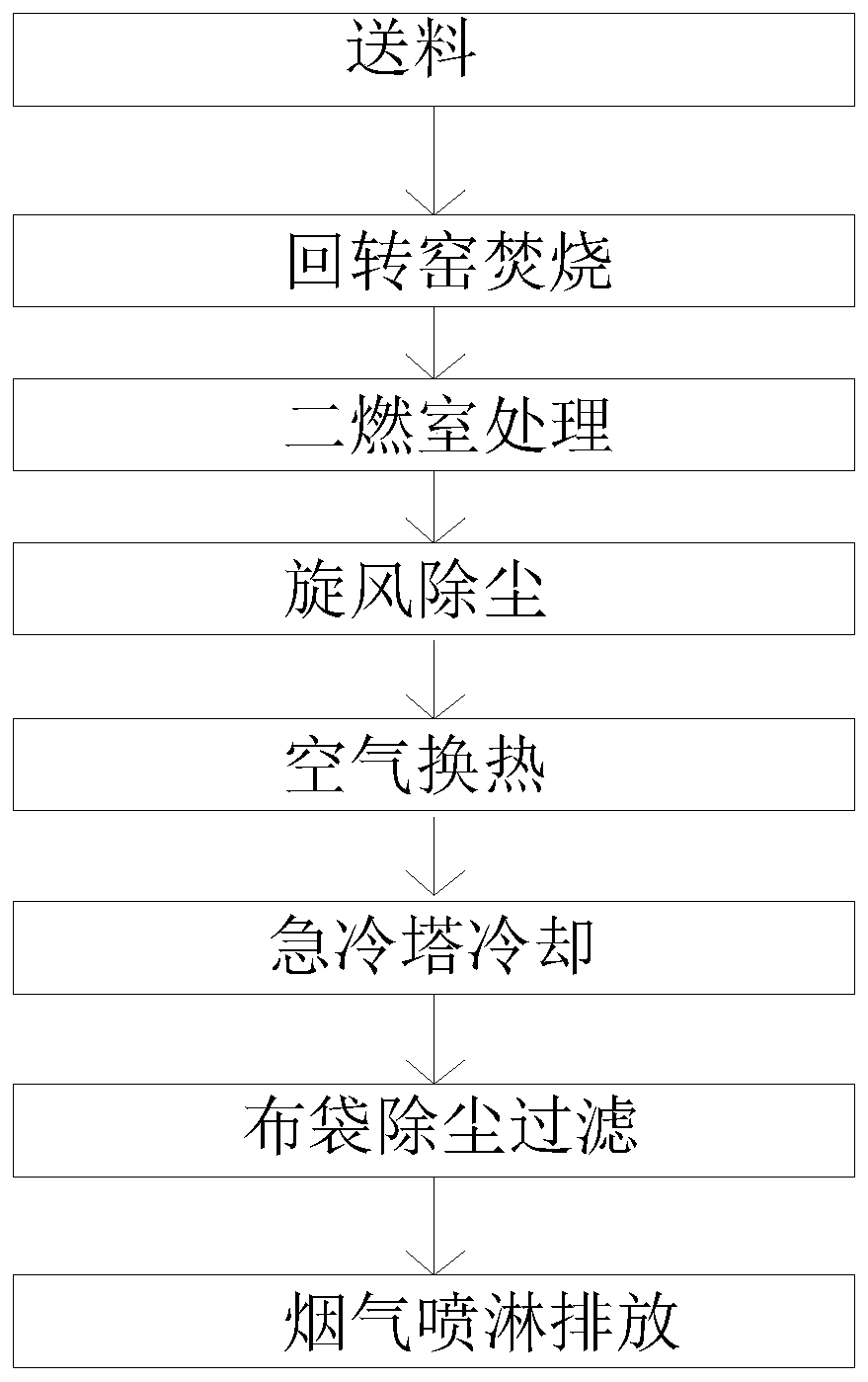

High-temperature treatment process for oily sludge

InactiveCN111072254APrevent escapeFully vaporized and volatilizedCombination devicesSludge treatment by de-watering/drying/thickeningCombustion chamberSludge

The invention discloses a high-temperature treatment process for oily sludge. According to the technical scheme, the process comprises the following steps: 1) a feeding step, namely a step of feedingmaterials into a rotary kiln by utilizing a belt conveyor and a double-screw conveyor; 2) a step of high-temperature treatment in the rotary kiln, namely a step of allowing the material entering the rotary kiln to slowly move to the tail part of the rotary kiln along with the rotation of a cylinder with the gradient, so that the whole process of drying, organic matter desorption and thermal stabilization is completed; (3) a step of treatment in a secondary combustion chamber, namely a step of discharging the material subjected to high-temperature treatment from the kiln tail, cooling the material through an outer jacket, enabling the cooled material to fall into a soil discharging machine for outward transportation, and performing combustion treatment on organic and heavy metal substancesseparated out after high-temperature pyrolysis in an aerosol form along with flue gas in a kiln head and a kiln body secondary combustion chamber; 4) a step of flue gas filtration for dust removal; and 5) a step of a step of flue gas spraying and discharging. According to the scheme, pollutants are thoroughly oxidized and decomposed, it can be guaranteed that the emission value of the pollutants such as dust, sulfur dioxide and dioxin reaches the emission standard, and economic benefits are good.

Owner:苏州同和环保工程有限公司

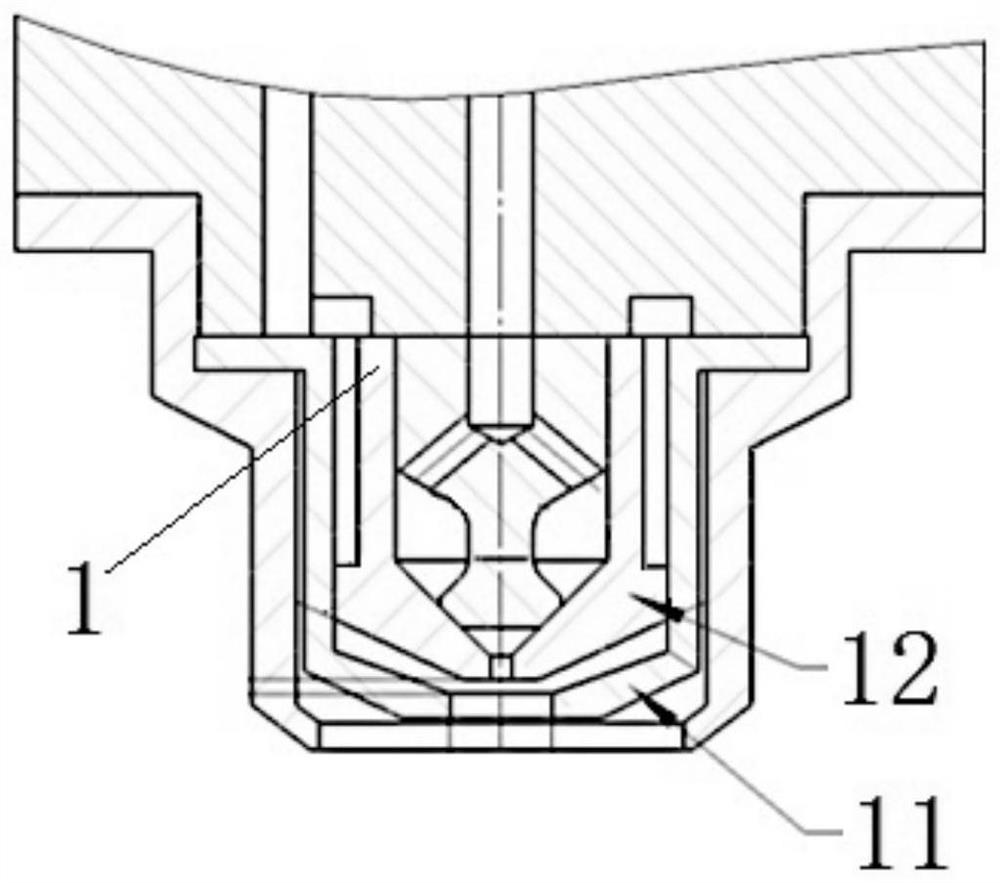

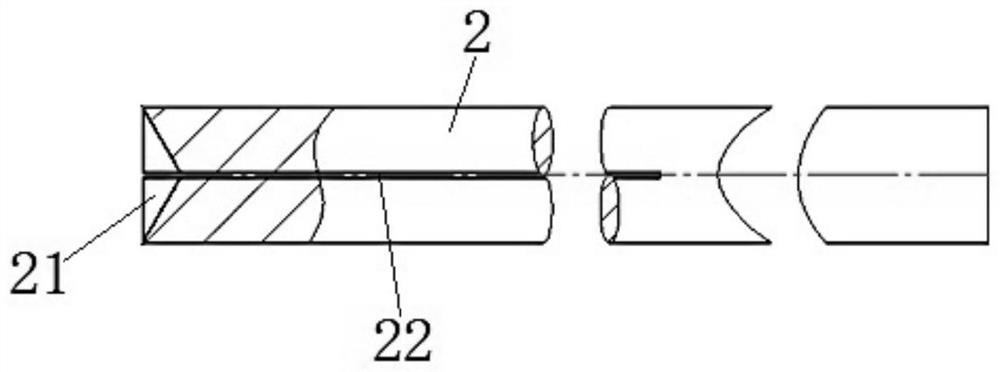

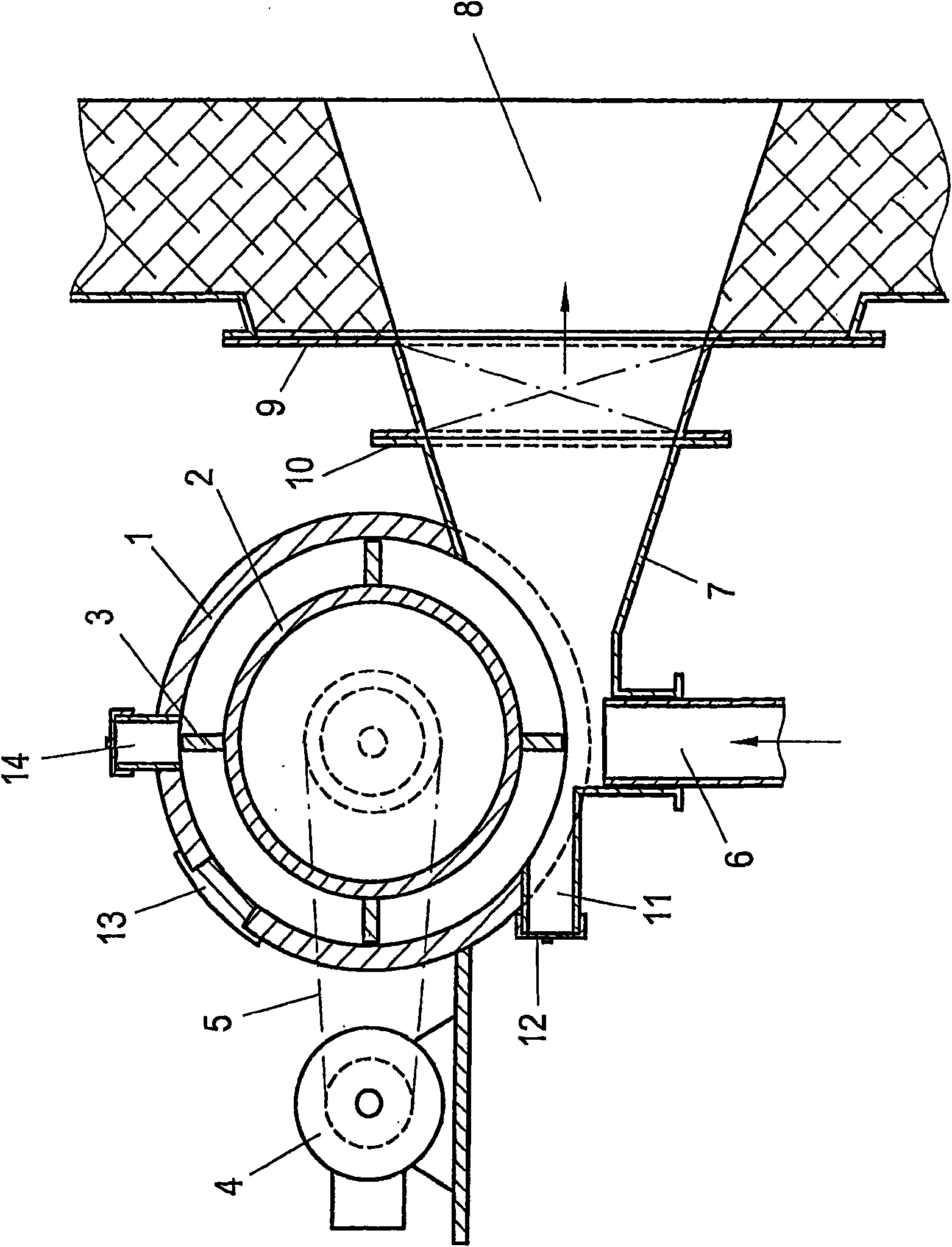

Method for introducing waste and/or alternative fuels into a clinker production method and device for carrying out said method

InactiveCN101528626AAvoid overall overheatingSimple structureClinker productionAlternative fuelsSludge

The invention relates to a method for introducing waste and / or alternative fuels into a clinker production method. The invention is characterized in that the starting materials are subjected, as sludges or in suspended form as a pumpable compound, to mechanical deagglomeration. The pumpable compound is ejected into rising pipes, pre-calcining furnaces and / or the rotary kiln. The device for carrying out the method is characterized by a tubular housing (1) having a rotor (2) that is received so that it can be rotated in relation to the axis of the tube in a substantially concentric manner and can be driven to rotate. Said rotor has rotor blades (3) that sweep over the space between the rotor shaft and the housing wall, a plurality of lines or openings (6, 7, 11, 14) being adjacent to the jacket of the tubular housing (1) and at least one line (6) being arranged together with the sludge supply and at least one being off-set in the circumferential direction.

Owner:HOLCIM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com