Special gluing head cleaning device for full automatic glue edge sealing production line and cleaning method thereof

A kind of cleaning equipment and fully automatic technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems that cannot be solved, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

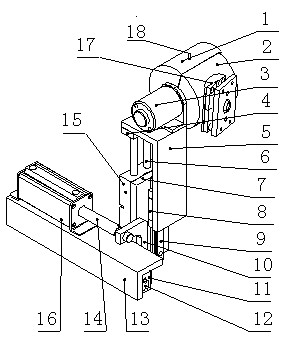

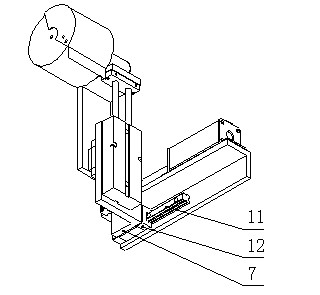

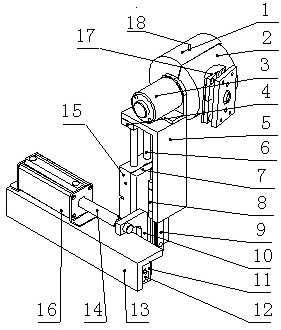

[0010] Embodiment 1: with reference to attached figure 1 and 2 . Glue head cleaning equipment for automatic rubber edge banding production line, which includes glue head 17. The glue head 17 in the fully automatic rubber edge banding production line is equipped with an electric cleaning head 2, and the electric cleaning head 2 passes through the pneumatic lifting mechanism 5 Up and down, the pneumatic lifting mechanism 5 is connected with the pneumatic horizontal driving mechanism 13 and the pneumatic horizontal driving mechanism 13 drives the pneumatic lifting mechanism 5 to move back and forth. The lifting cylinder 15 in the pneumatic lifting mechanism 5 is connected to the transition plate 10, the piston rod 6 in the lifting cylinder 15 is connected to the back of the top plate of the inverted L-shaped plate, and the front of the top plate of the inverted L-shaped plate is equipped with an electric cleaning head 2. Between the 15 cylinder bodies of the lifting cylinder a...

Embodiment 2

[0012] Embodiment 2: On the basis of Example 1, the cleaning method for the special glue head of the automatic rubber material edge banding production line, (1) After the glue head 17 completes the glue of each hollow glass, the PLC controller instructs the pneumatic horizontal drive mechanism The horizontal drive cylinder 16 in 13 drives the pneumatic lifting mechanism 5 to move horizontally, and at the same time, the lifting cylinder 15 in the command pneumatic lifting mechanism 5 drives the electric cleaning head 2 on which the flexible moisture-absorbing roller rises or falls and is in a pressure phase with the glue head 17 (2) The PLC controller instructs the electric cleaning head 2 to work. After the flexible moisture-absorbing roller in the electric cleaning head 2 cleans the glue on the glue head 17, the PLC controller instructs the booster pump to pass the colloid decomposition liquid in the liquid storage tank through The electromagnetic reversing valve and the fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com