Reaction furnace device for decomposing substances to be treated by utilizing high temperature steam and heat source

A steam heating device and decomposition treatment technology, applied in coking ovens, direct heating carbonization, special carbonization, etc., can solve the problems of poor thermal efficiency of cracking technology, high manufacturing cost, high sulfur content in oil products, carbon impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

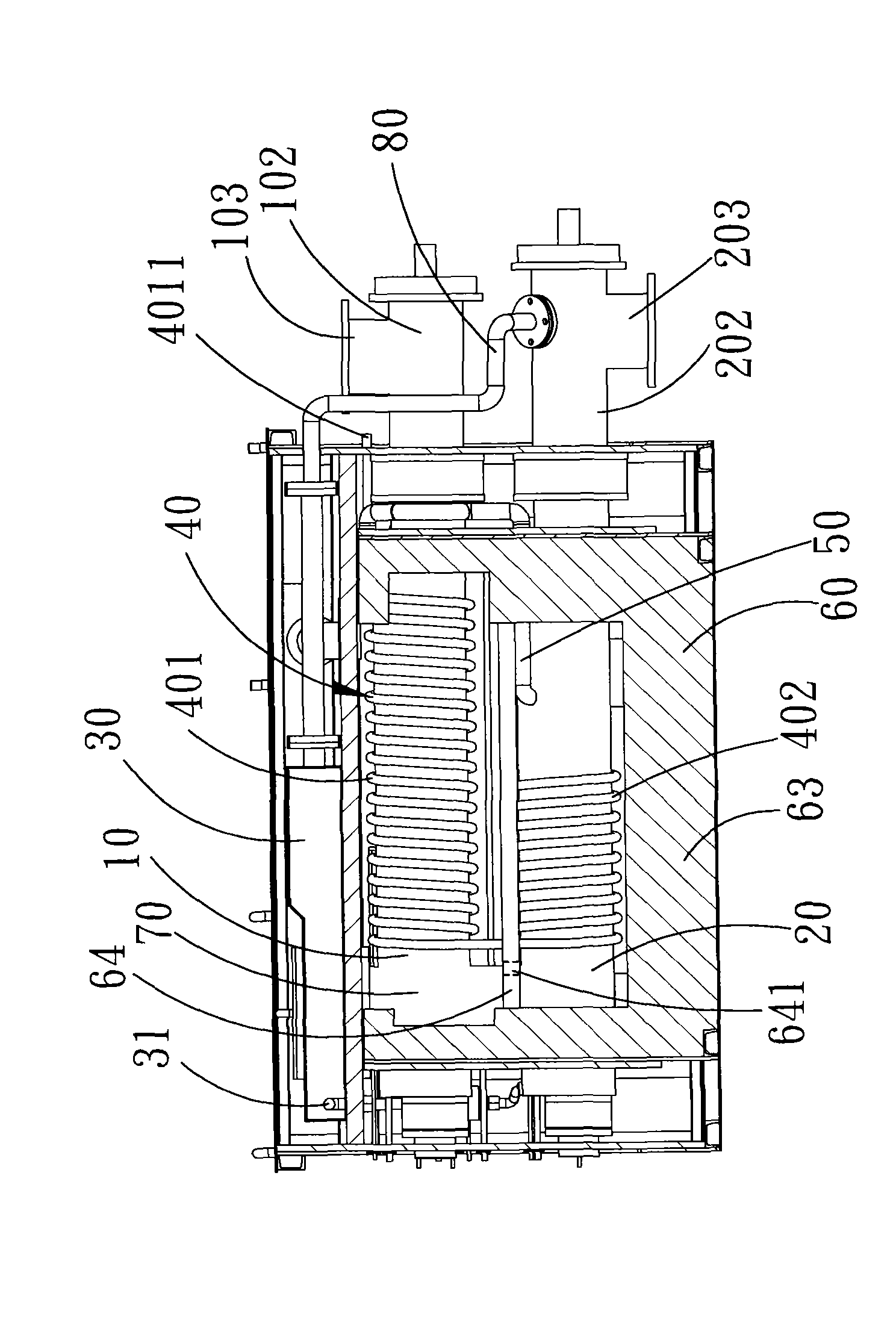

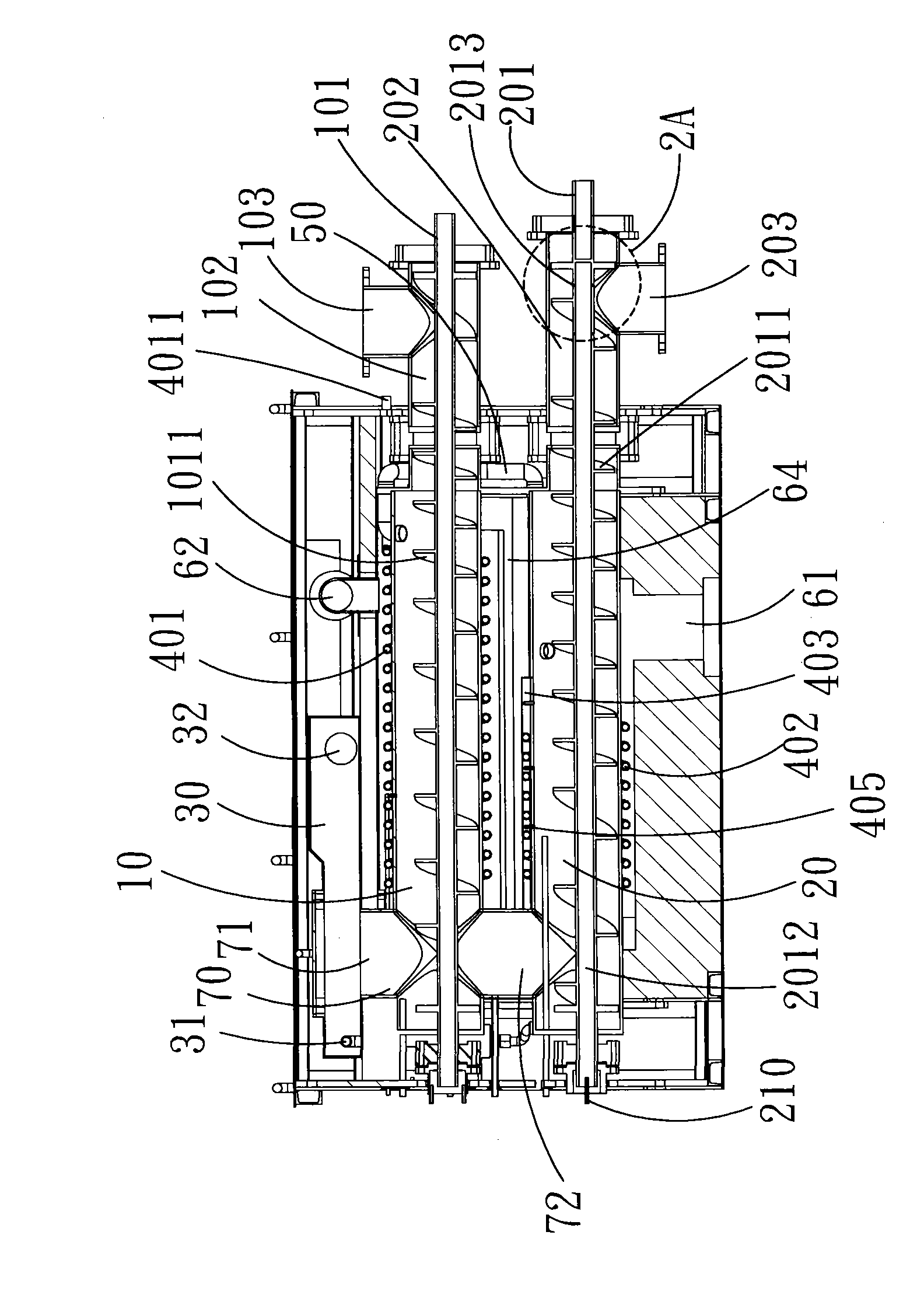

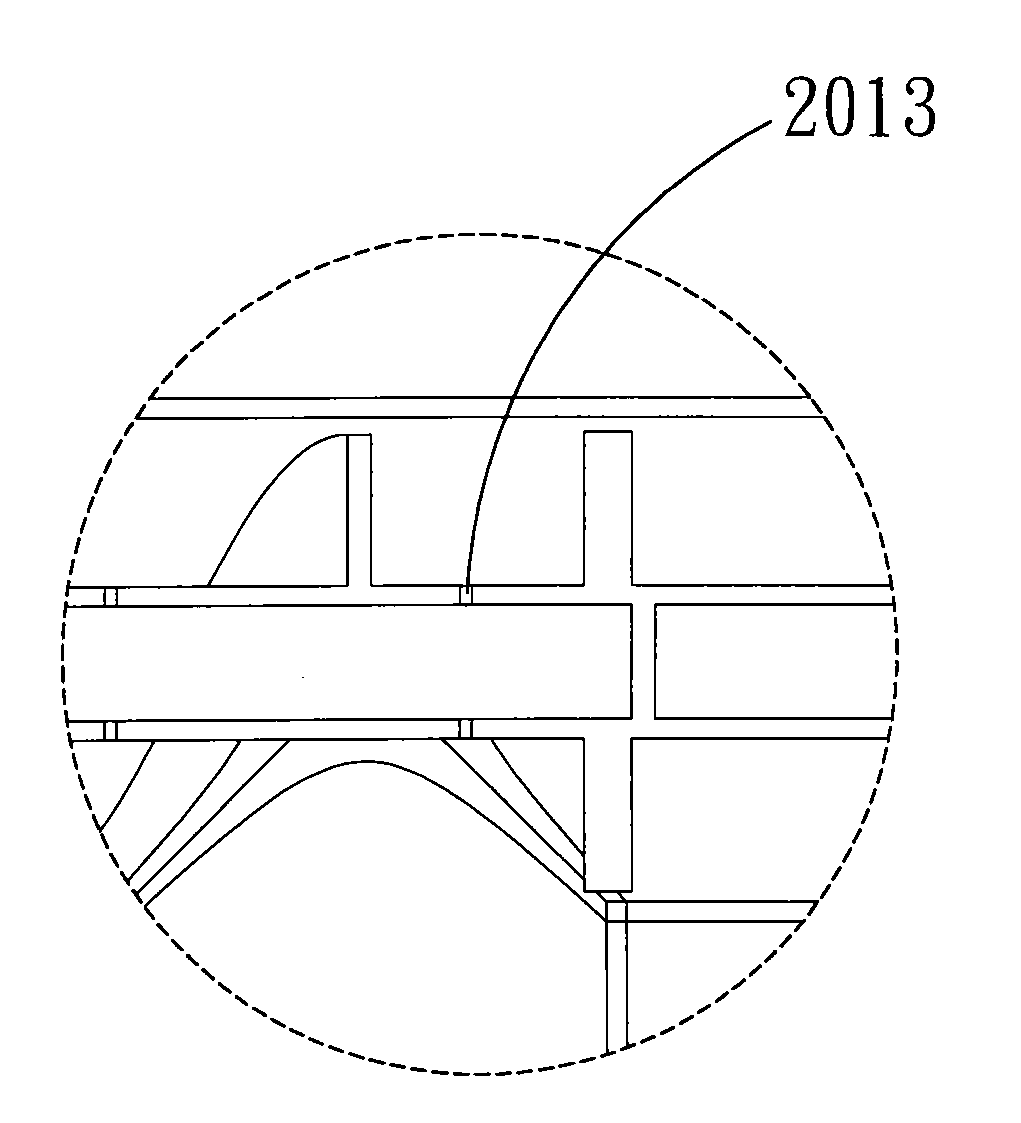

[0047] The present invention provides a reaction furnace device that utilizes high-temperature steam and heat sources to decompose processed objects. Please refer to Figure 1 to Figure 4 Shown is the reaction furnace device that the present invention is widely used in decomposing organic matter (so-called organic matter includes dioxin) or mercury-containing matter or petrochemical matter or dioxin-containing matter or volatile matter or general garbage into carbides.

[0048] As a preferred embodiment of the present invention figure 1 , figure 2 as well as Figure 2A As shown, the reaction furnace device includes a combustion chamber 60, in which a first reaction chamber 10, a second reaction chamber 20, a first steam conduit 50 and a steam heating device 40 are arranged. An oil-gas reaction chamber 30 is arranged outside the chamber 60 .

[0049] The aforementioned combustion chamber 60 has an inlet 61 (such as figure 2 shown), an exit 62 (such as figure 2 Shown), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com