Method for introducing waste and/or alternative fuels into a clinker production method and device for carrying out said method

An alternative fuel and production process technology, applied in clinker production, cement production, etc., can solve the problem that waste cannot be used directly, and achieve the effect of simple structure and avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

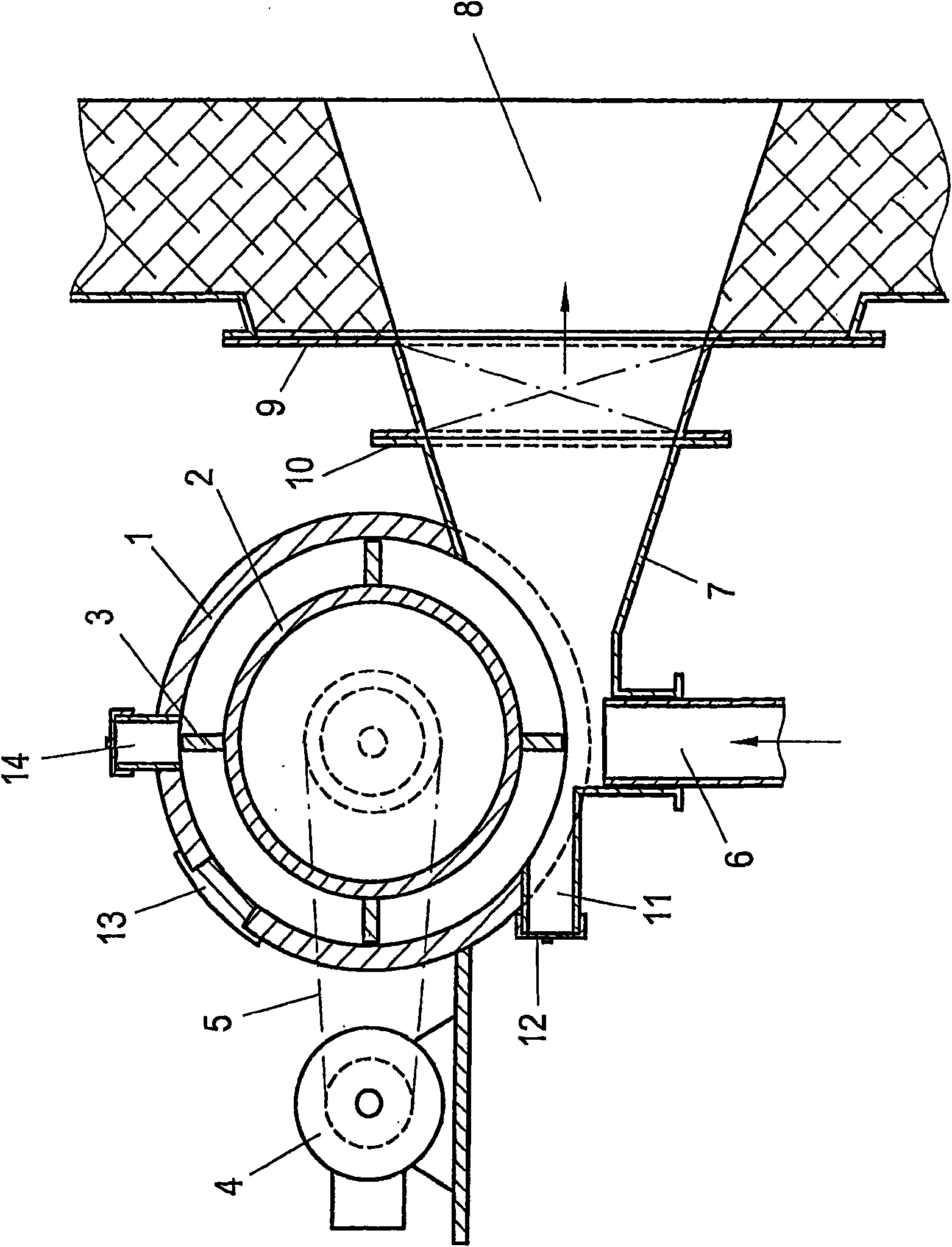

[0010] In the accompanying drawings, 1 represents the casing of the decomposition device. A rotor 2 comprising blades 3 designed as substantially axially parallel slats is mounted inside the tubular housing 1 and coaxially with it. The drive motor is schematically indicated at 4 and drives the rotor 2 at a high rotational speed via a drive belt indicated at 5, thus causing the blades 3 at the point of delivery of the material to be decomposed to impinge on said material at high speed. The delivery takes place via a connection or conduit 6, through which the pumpable substance is introduced. The solid part of the substance is broken up by the impingement of the rotating blades or slats 3 on the solid. The discharge takes place via the discharge cone 7 at the cooling end 8 of the tubular rotary kiln, the fixing of which can be achieved in a particularly simple and stable manner via the flange 9 . Reference numeral 10 denotes a slide, by means of which the outlet opening can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com