High-temperature treatment process for oily sludge

A high-temperature treatment and process technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the secondary pollution of dust and flue gas, incomplete disposal, and high cost problems, to avoid damage to system equipment and avoid harmful gases from escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

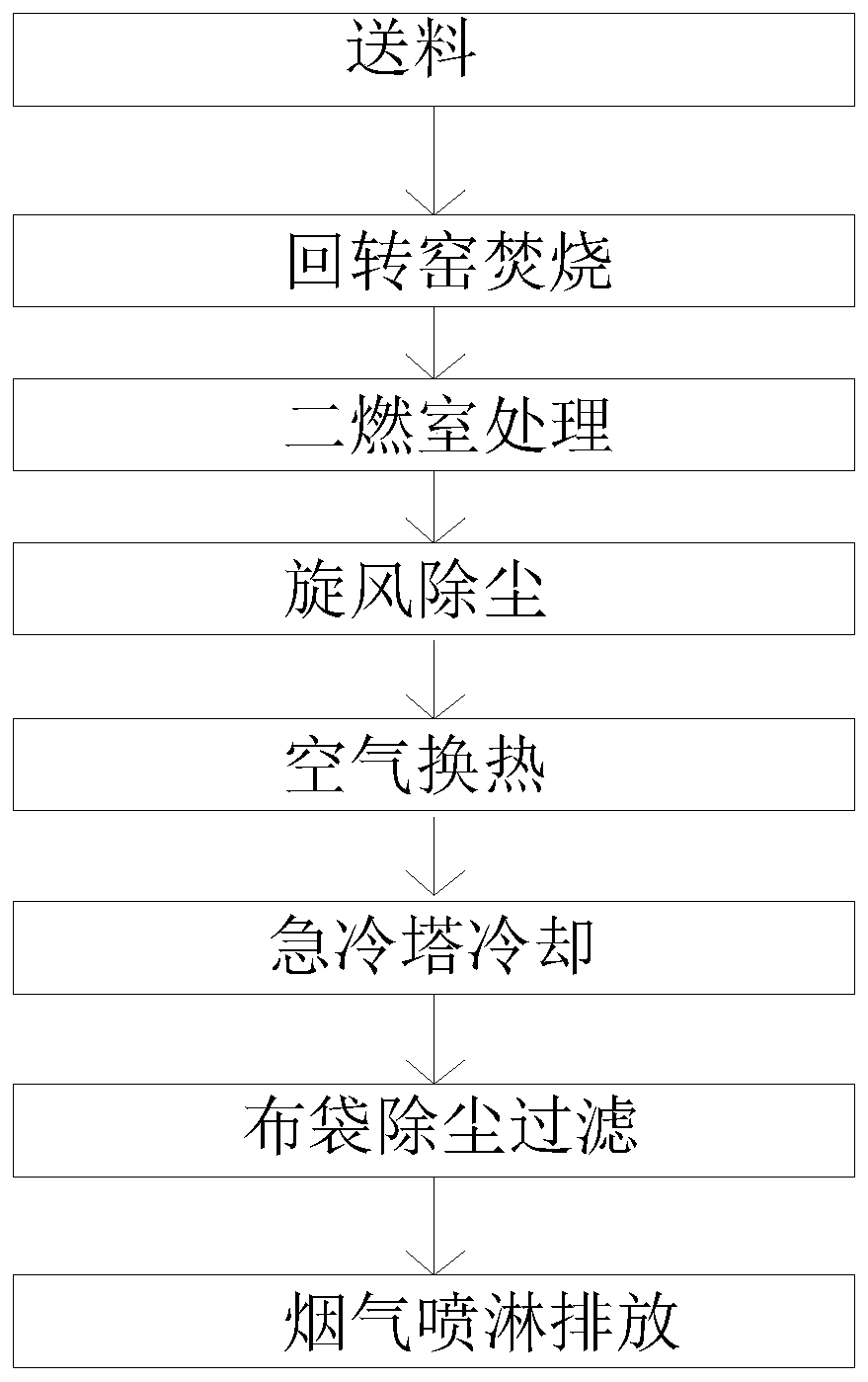

[0029] Such as figure 1 As shown, a high-temperature treatment process for oily sludge includes the following steps:

[0030] 1) Feeding: the materials are fed to the rotary kiln using belt conveyor and double screw conveyor;

[0031] 2) High temperature treatment of the rotary kiln: The materials entering the rotary kiln slowly move to the tail of the rotary kiln with the rotation of the sloped cylinder, completing the whole process of drying, organic matter desorption and thermal stability;

[0032] 3). Treatment in the second combustion chamber: the high-temperature treated materials are discharged from the kiln tail, cooled by the outer jacket, and then dropped into the excavator and transported inside and outside. The materials entering the kiln head are pyrolyzed at high temperature and precipitated by organic and heavy metal substances. The aerosol form is combusted by the second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com