Fixed grate boiler allowing square bundle of stalks to be combusted

A fixed grate and boiler technology, applied in the direction of combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of inability to ensure sufficient combustion of straw bales, high pollution emissions, and low boiler efficiency, so as to avoid incomplete combustion The effect of stability, low pollution emission and high boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

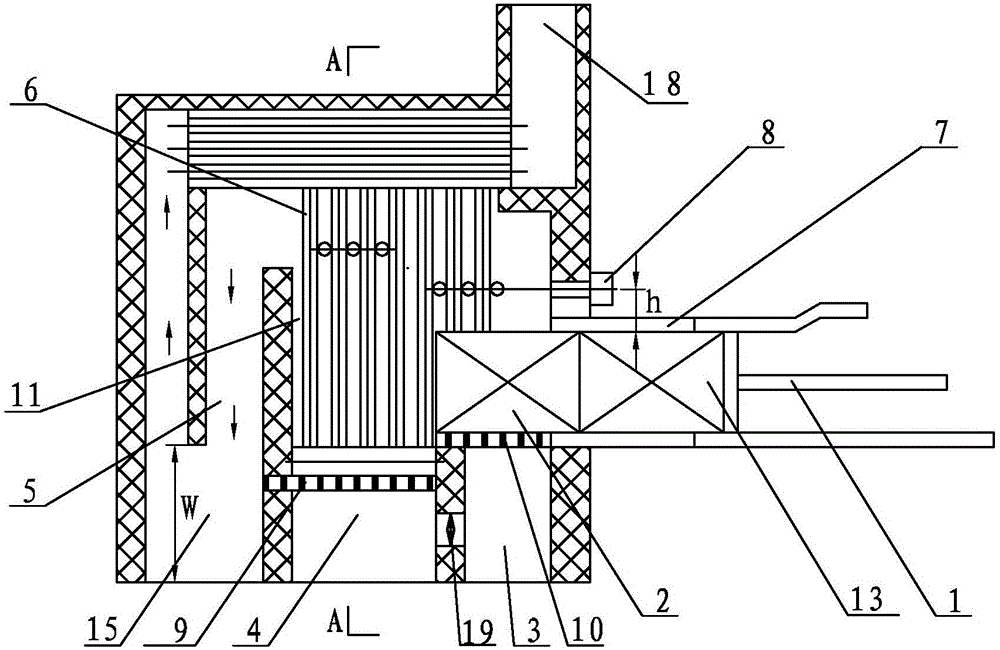

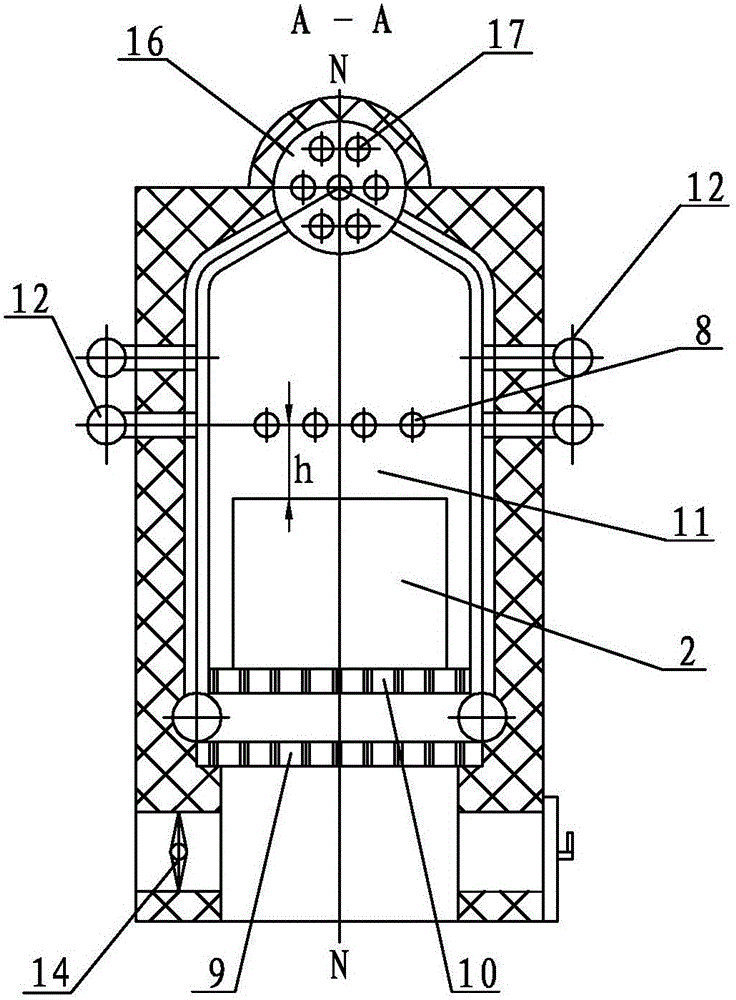

[0017] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes a feeding mechanism 1, a pre-combustion chamber 2, a first-stage primary air chamber 3, a second-stage primary air chamber 4, a burnout chamber 5, a water-cooled wall 6, a water-cooled jacket 7, and a turning furnace Row 9, fixed fire grate 10, stepped combustion chamber 11, air inlet adjustment baffle 14, settling chamber 15, steam drum 16, smoke pipe 17, middle adjustment baffle 19, reinforcement of the horizontal uniform distribution of the boiler front wall along the outlet The secondary air nozzle 8, the supplementary secondary air nozzle 12 arranged in symmetrical steps on both sides of the wall, the pre-chamber 2 is surrounded by a square water cooling jacket 7, the front of the pre-chamber 2 is connected to the feed port 13, the outlet of the pre-chamber 2 is connected to the stepped combustion The chamber 11 is connected, and the feeding mechanis...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 Describe this embodiment, the inner diameter of the water-cooling jacket 7 in this embodiment is the same as the cross-sectional size of the square bundle of straw, which is 440×350 mm. Avoid the spread of air in this area and prevent the flame from extending to this area; at the same time, the high water cooling ensures that the straw in this area does not catch fire. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the combustion zone of the stepped combustion chamber 11 of this embodiment is laid with a guard combustion belt, and the guard burner belt is to adjust the water cooling degree of the furnace, and the pouring refractory material laid on the furnace radiation heating surface, and the laying of the guard burner belt can control the water cooling of the furnace. The degree is less than 0.3. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com