Patents

Literature

32results about How to "Reasonable flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

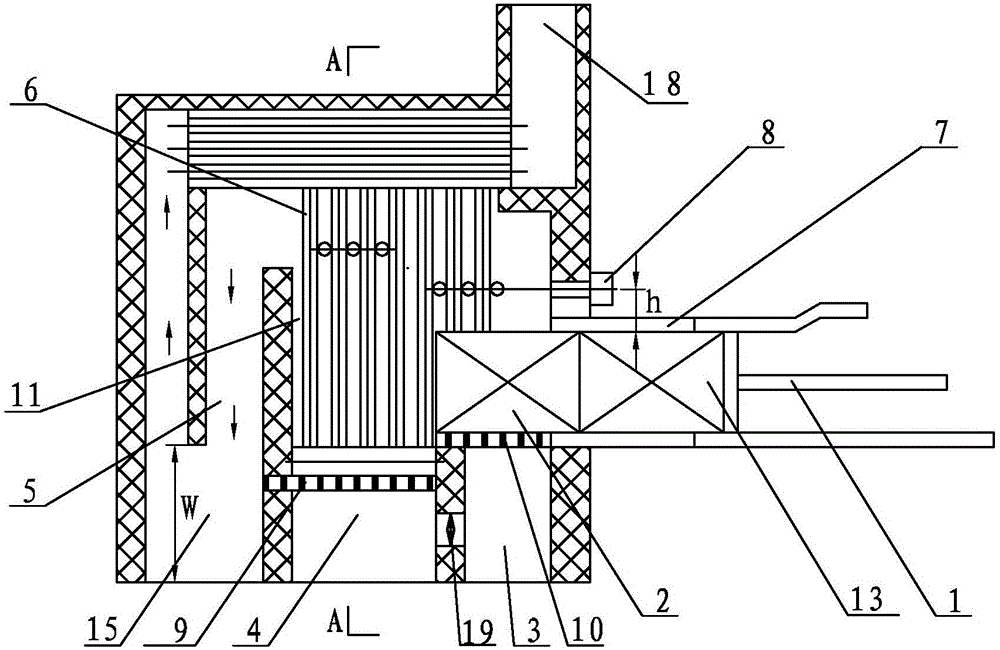

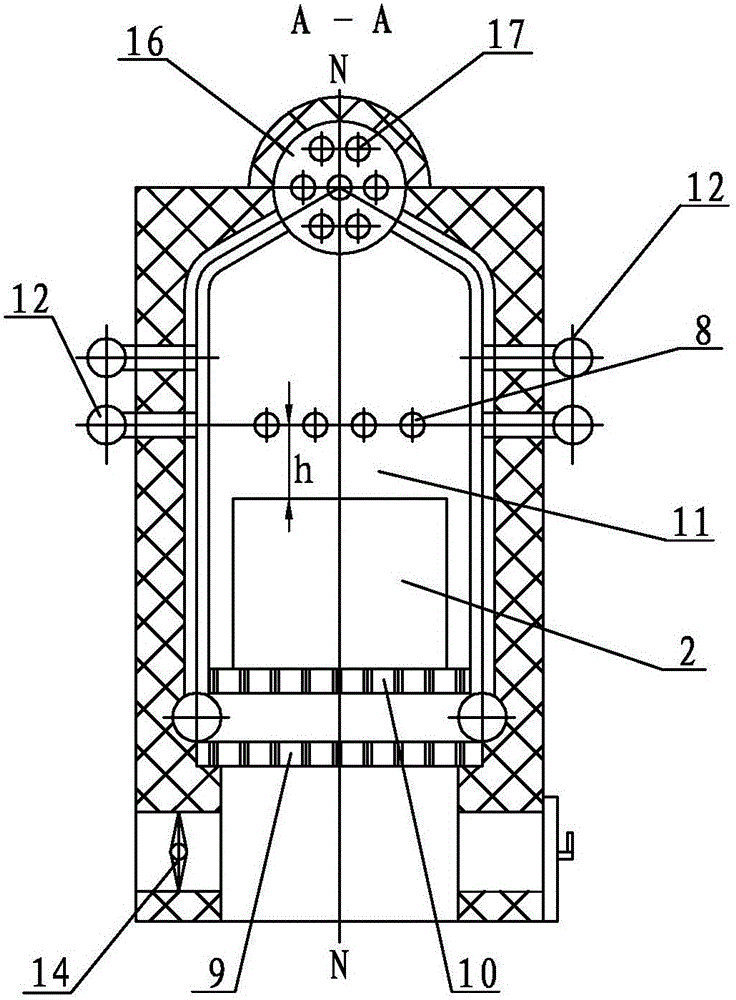

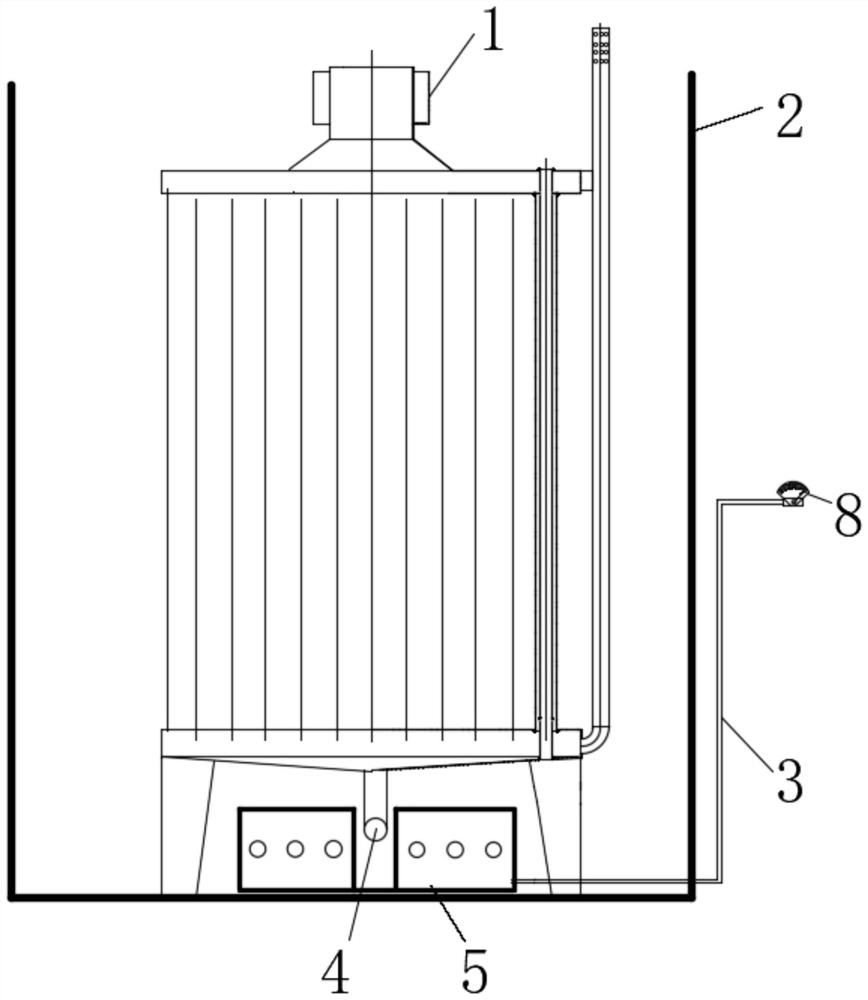

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

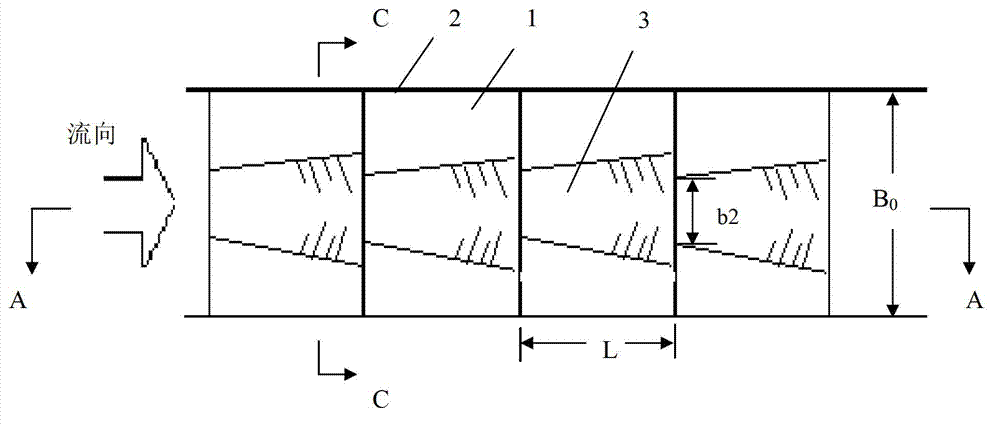

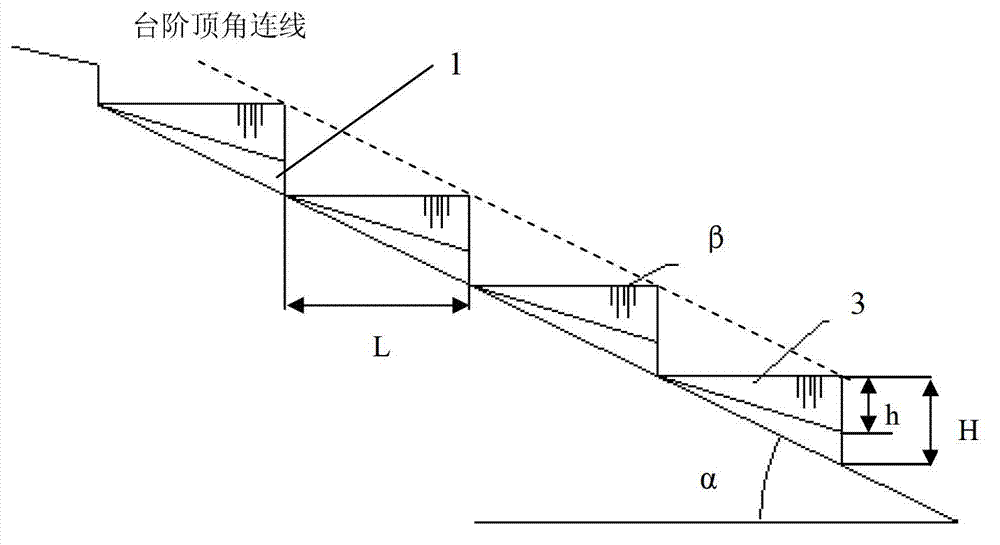

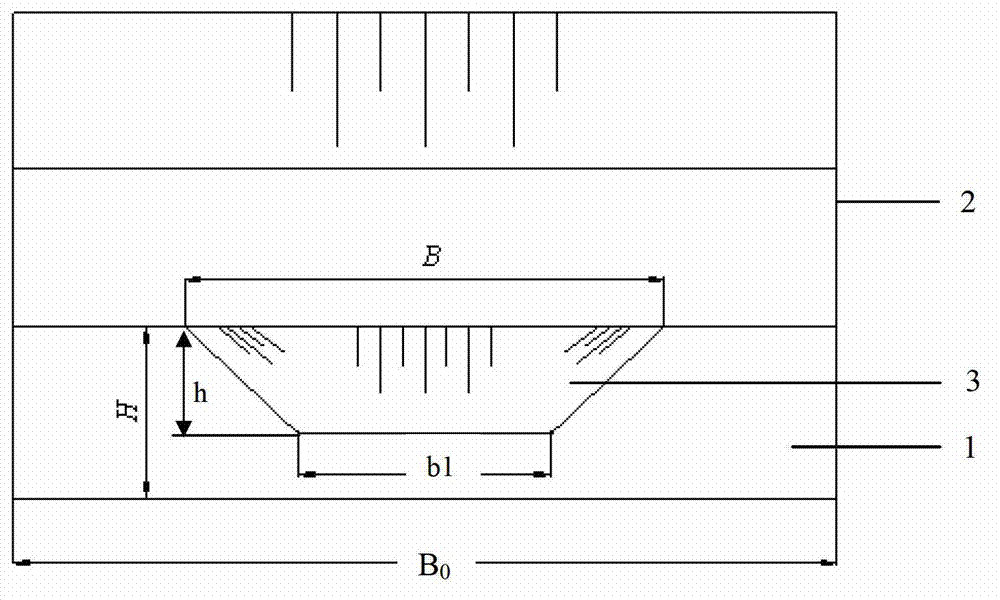

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

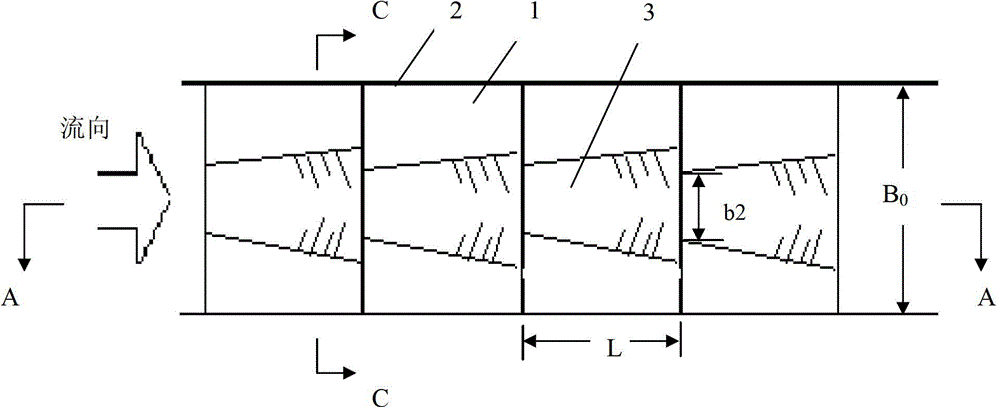

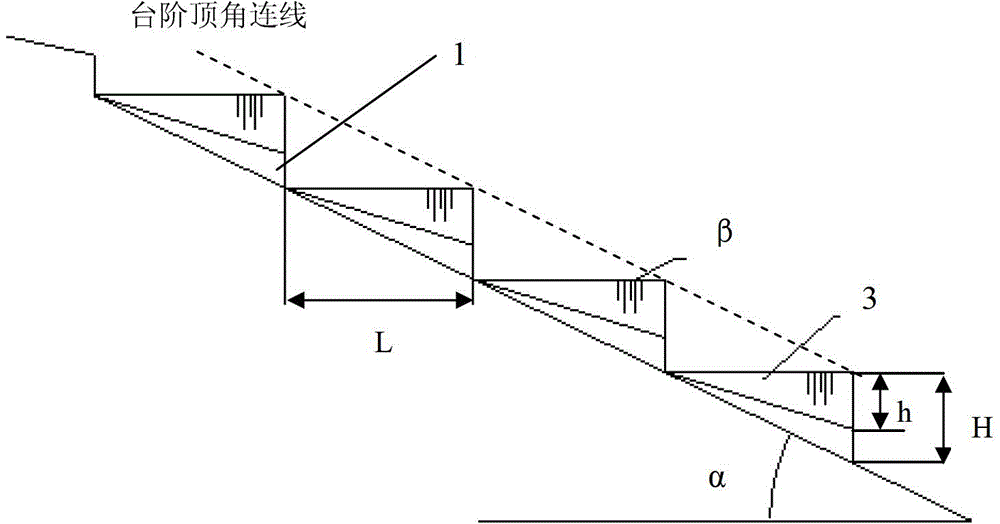

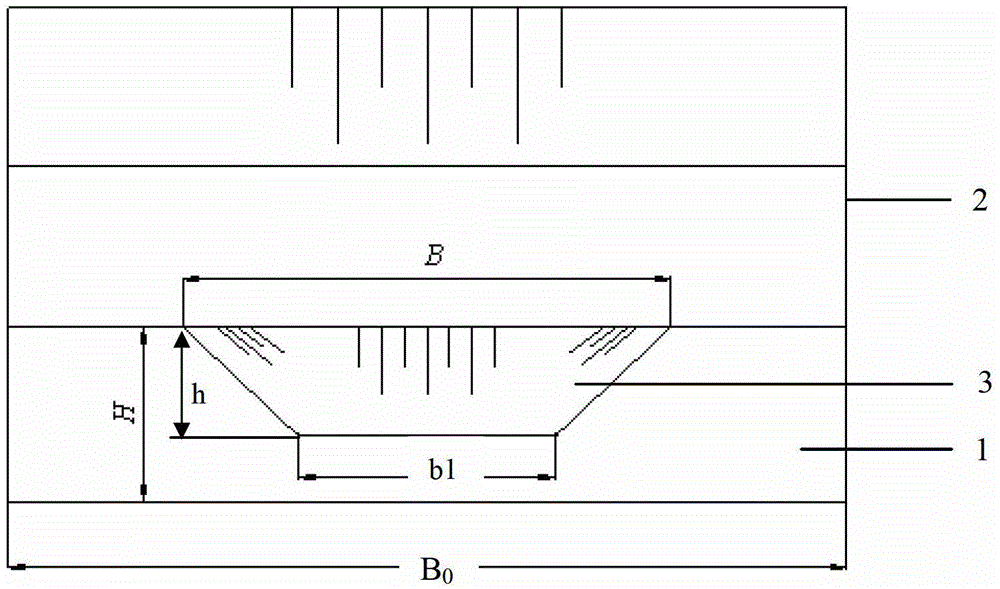

The invention discloses a debris-flow drainage canal with energy dissipation and drainage functions and an application of the debris-flow drainage canal with energy dissipation and drainage functions. The drainage canal comprises a fully-lining drainage canal bottom plate and drainage canal side walls on two sides of the drainage canal bottom plate; the drainage canal bottom plate is in the shape of continuously-connected multiple-stage steps, the steps are provided with grooves; the width of the grooves on the top surfaces of the steps increases gradually along the flow direction of the debris flow, and the width of the grooves on the vertical surfaces of the steps decreases gradually; and the maximum width of the grooves on the top surfaces of the steps coincide with the maximum width B on the vertical surfaces of the steps. Compared wit the prior art, the step shape design is adopted to dissipate the energy of the debris flow all the way and the groove design is adopted to drain the debris flow, so the debris-flow drainage canal disclosed by the invention has high efficiency and good drainage capacity. By adjusting the height and the length of the steps and the size and the shape of grooves, the debris-flow drainagedrainage canal can be used for preventing the debris flow with any gradient and any nature.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

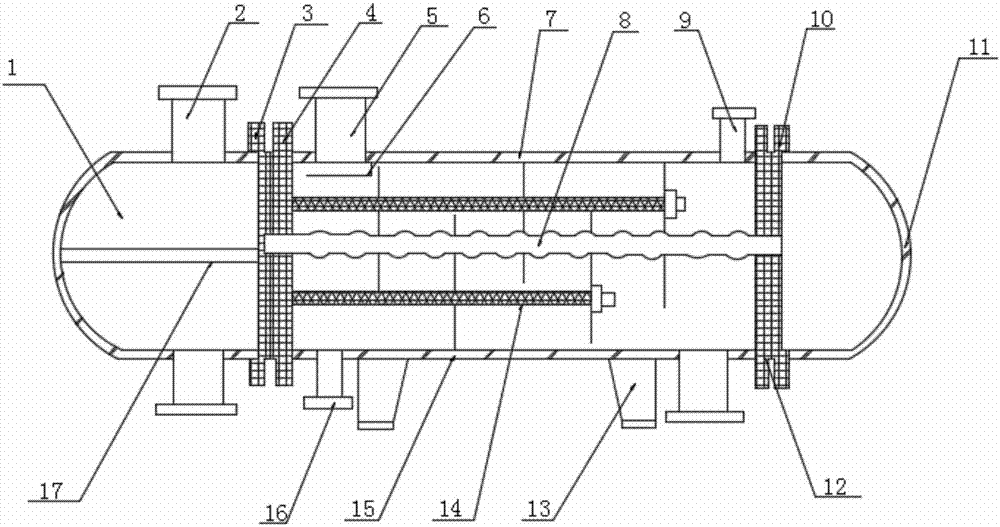

Shell-and-tube heat exchanger

InactiveCN107449298AReduce flow rateReduce designHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a shell-and-tube heat exchanger. The shell-and-tube heat exchanger comprises a tube body and a barrel body, wherein a tube pass connecting pipe and a shell pass connecting pipe are correspondingly arranged on the surface of the tube box; a tube plate is arranged at one side of the tube pass connecting pipe; a scour preventing device is arranged at the bottom part of the shell pass connecting pipe; a waved heat exchanging pipe is arranged in the barrel body, and an exhausting port is formed in the surface of the barrel body; one side of the exhausting port is provided with a spacer; a sealing head is arranged at one side of the barrel body, and a supporting seat is arranged at the bottom part of the barrel body; a pulling rod is arranged at the bottom part of the waved heat exchanging pipe, and a baffle plate is arranged at the bottom part of the pulling rod; a draining port is formed in one side of the supporting seat; a separating plate is arranged in the tube box; a filtering net is arranged on the top part of the scour preventing device, and a flowing limiting plate is arranged in the scour preventing device. With the adoption of the shell-and-tube heat exchanger, the problem that an undercooling layer with poor heat conducting performance is formed on the surface of the heat exchanger for a long term due to plenty of cooling water flows through a cooler when a pouring medium is poured into the shell-pass connecting pipe of an existing tube-and-shell heat exchanger, resulting in poor heat exchanging effect, can be solved.

Owner:吴江华尔克斯机械设备有限公司

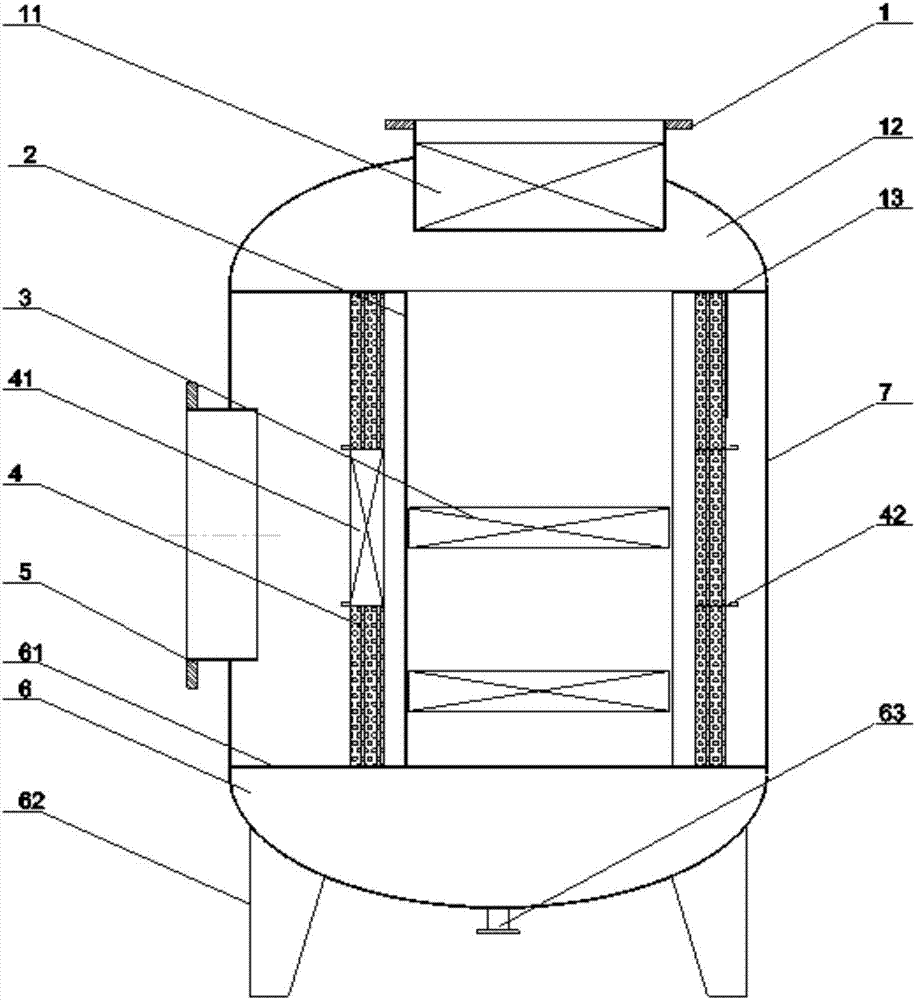

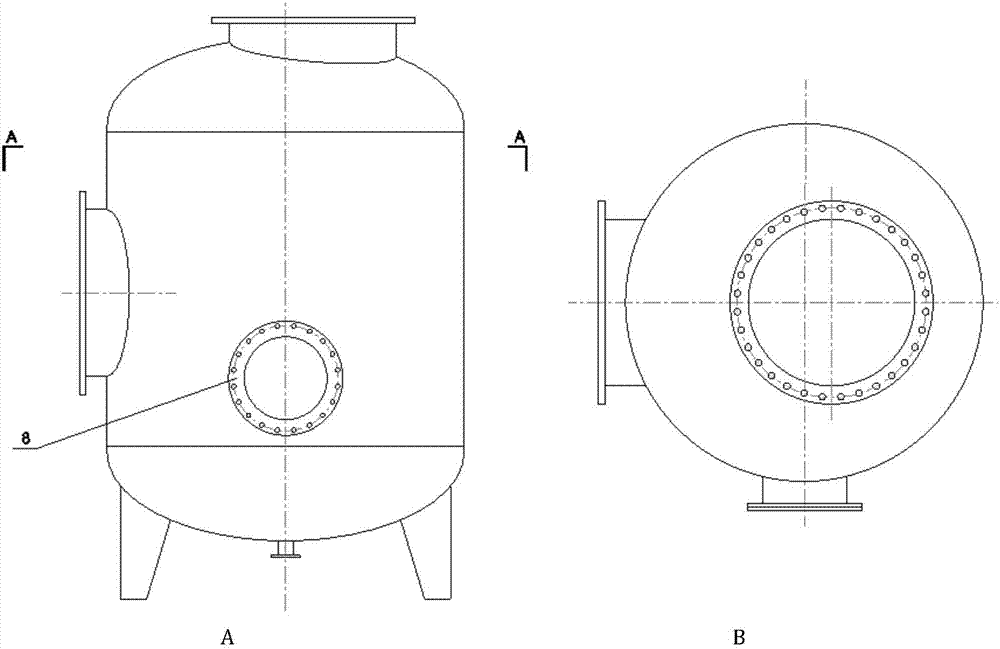

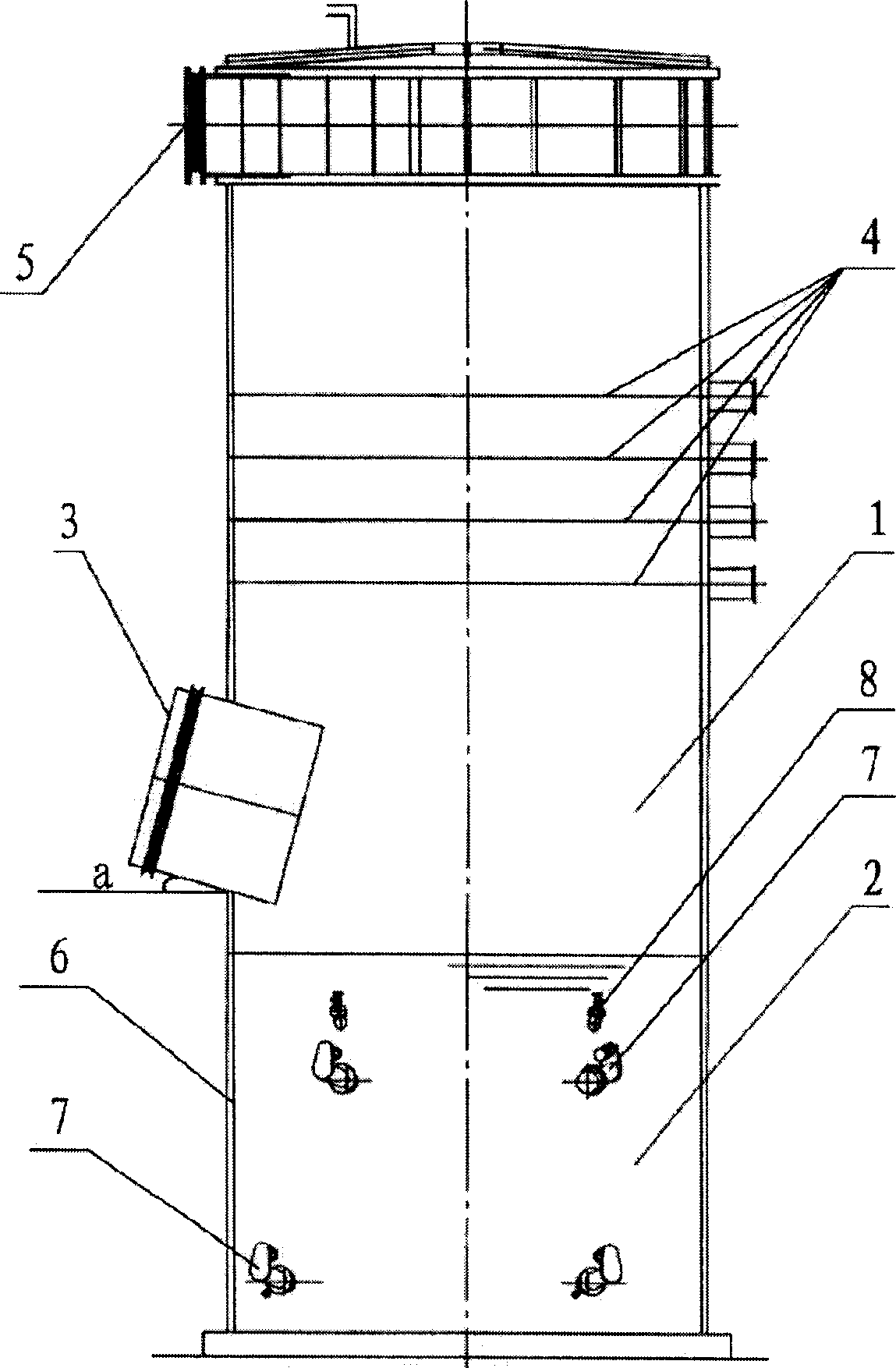

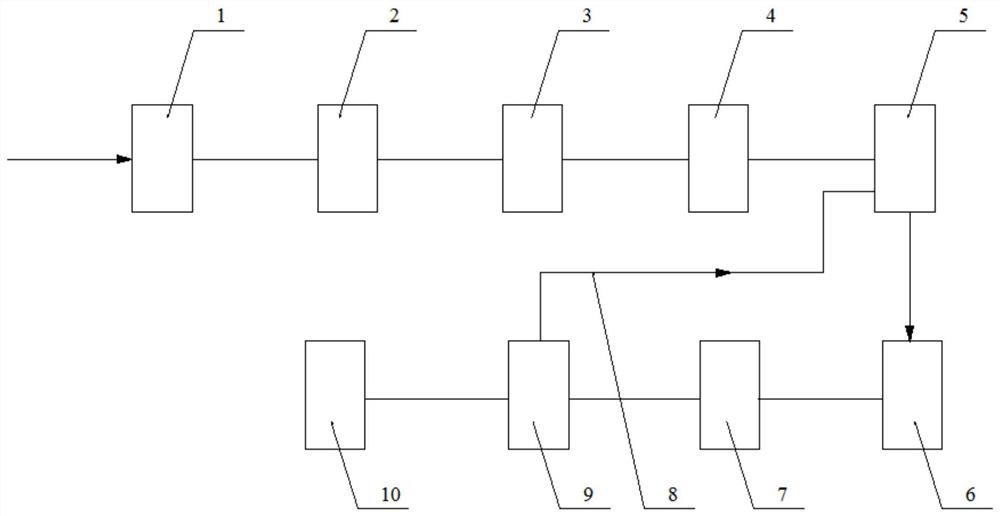

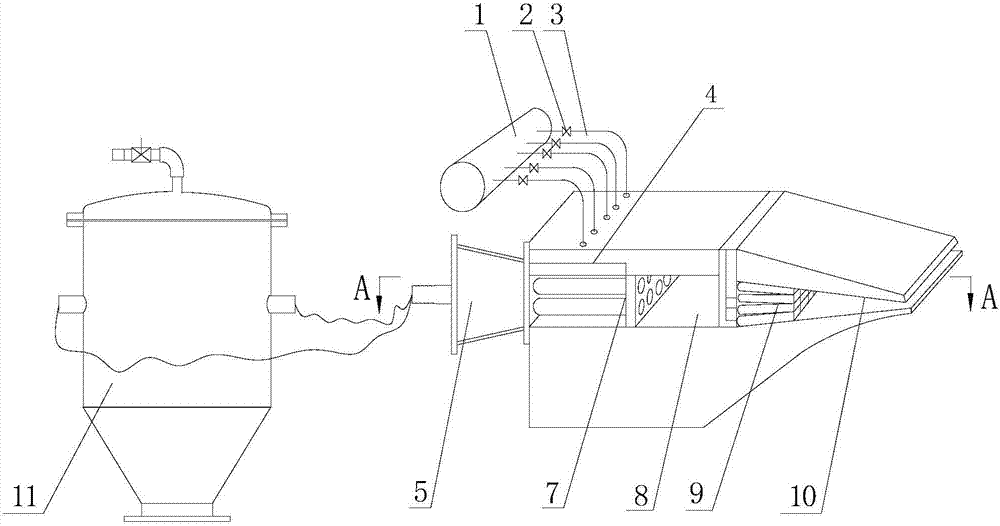

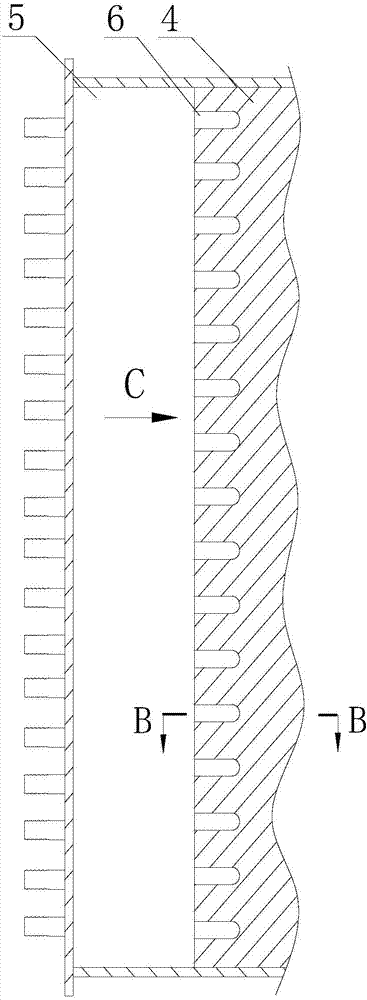

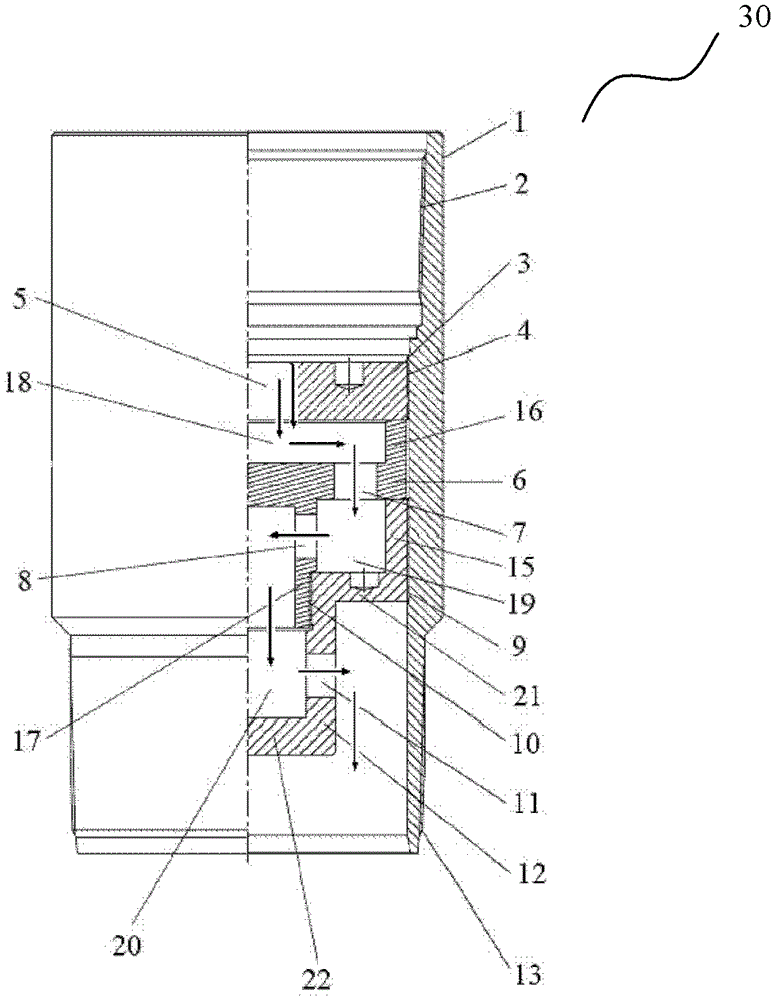

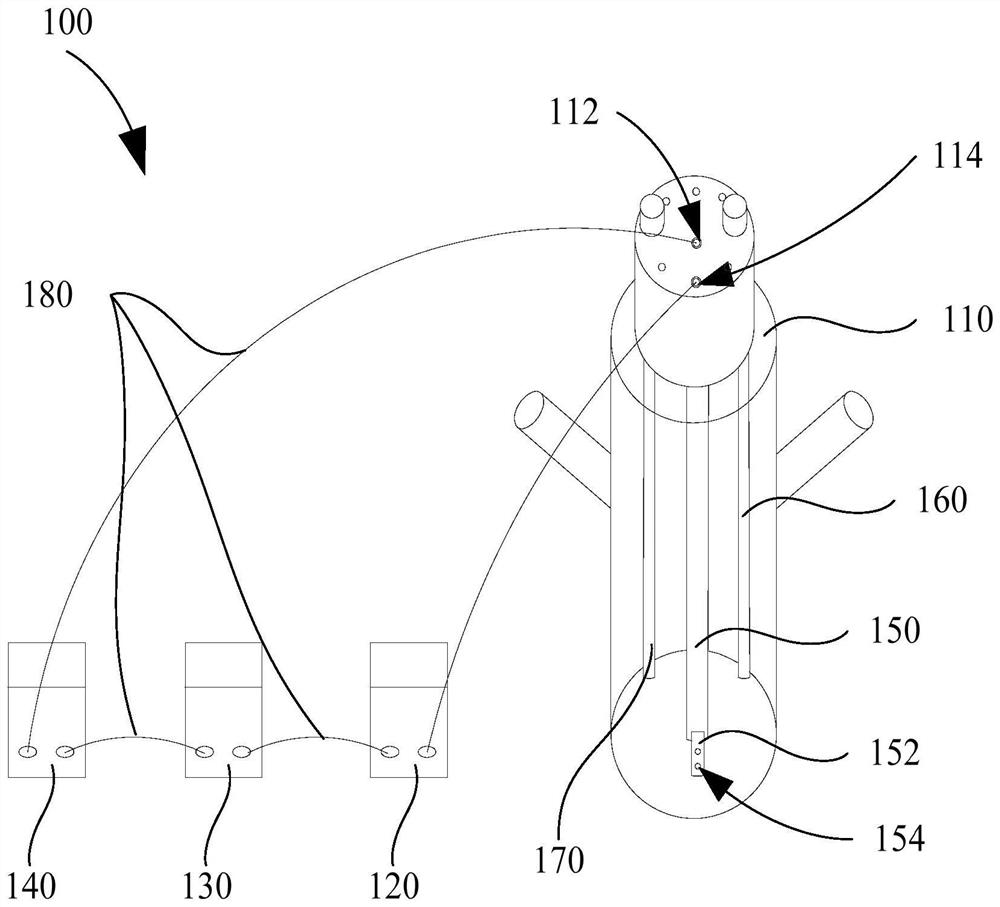

System and method suitable for low-pressure steam-water separation

ActiveCN107376519AReasonable flow rateIncrease total separation loadDispersed particle separationStream flowEngineering

The invention discloses a system and a method suitable for low-pressure steam-water separation. The system comprises a buffer chamber, a separation chamber and a hydrophobic chamber which are sequentially arranged in a housing from top to bottom, wherein a screen mesh separation system and a flow uniform-distribution barrel are sequentially arranged in a separator chamber; a team outlet is formed in a side surface of the housing; a non-uniform baffle plate for steam-liquid separation and flow-equalization is arranged in a barrel wall part of the flow uniform-distribution barrel; a uniform baffle plate for separation and diversion pressure-stabilization is horizontally arranged in a barrel chamber part. In the invention, a core concept of multi-stage distribution is adopted to realize optimal separation of low-pressure steam; a method integrated by the system is combined with the advanced steam-liquid separation technology to realize efficient steam-liquid separation with relatively low costs and meet requirements on humidity of steam entering a steam turbine.

Owner:SHANGHAI HUIMIN ENERGY TECH

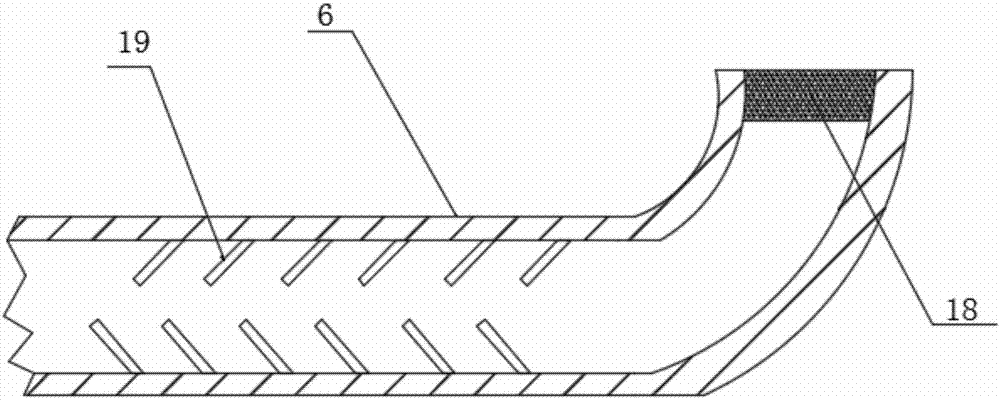

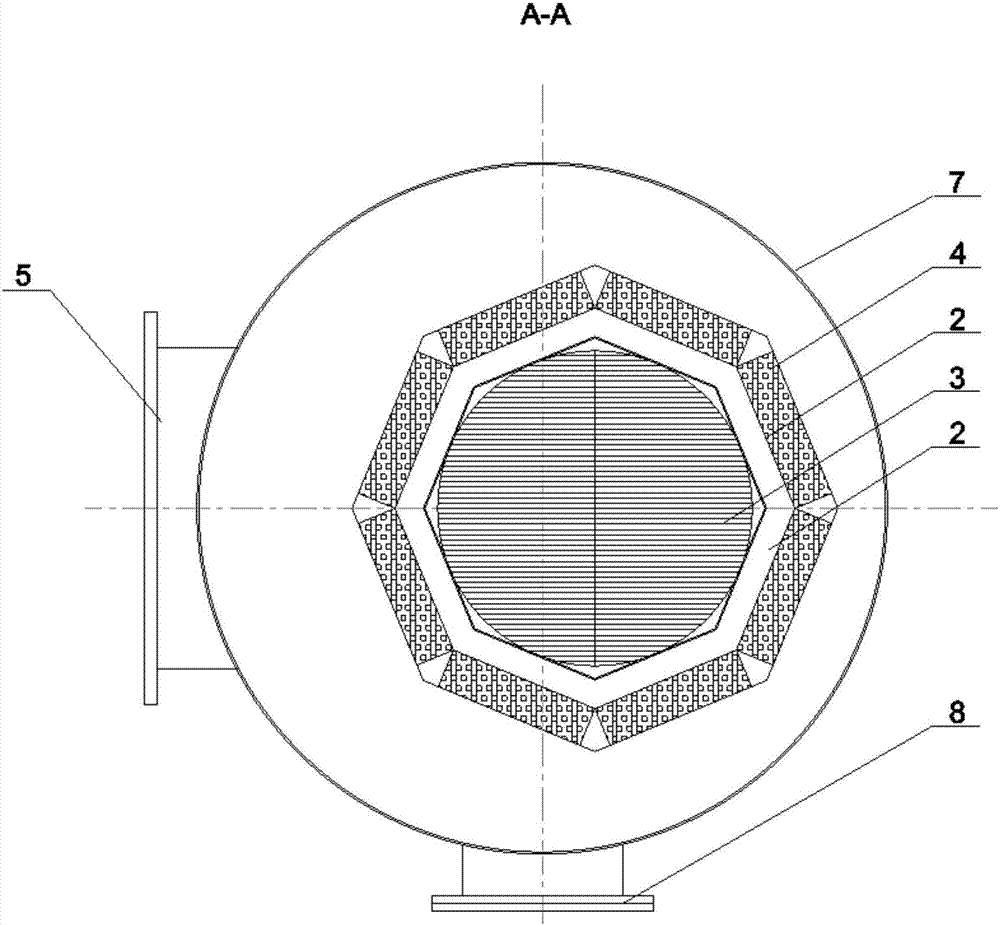

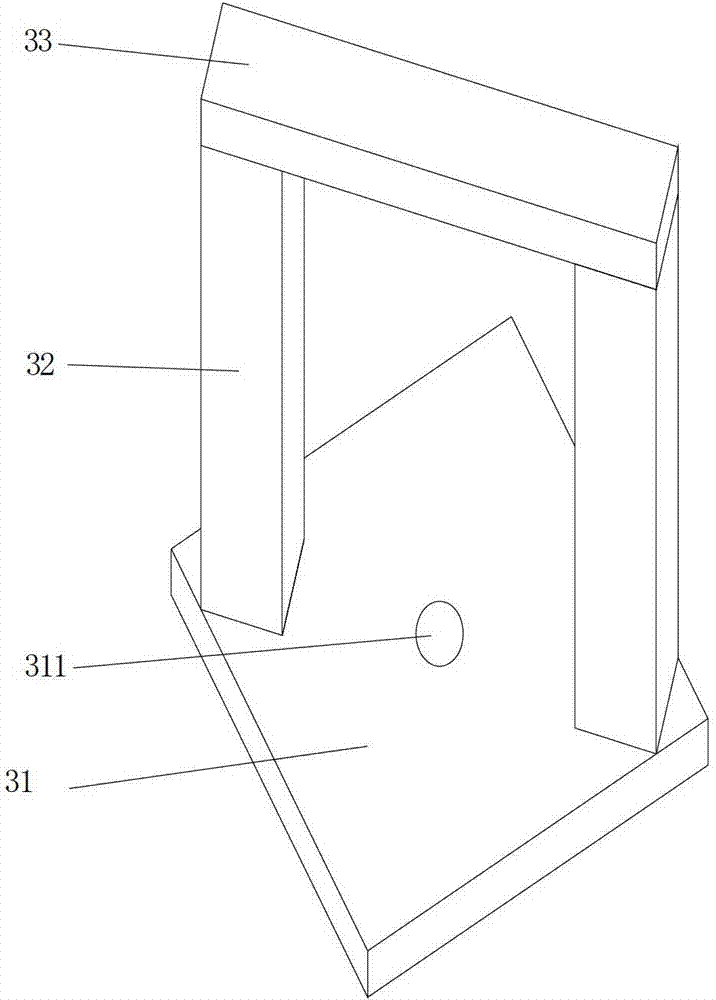

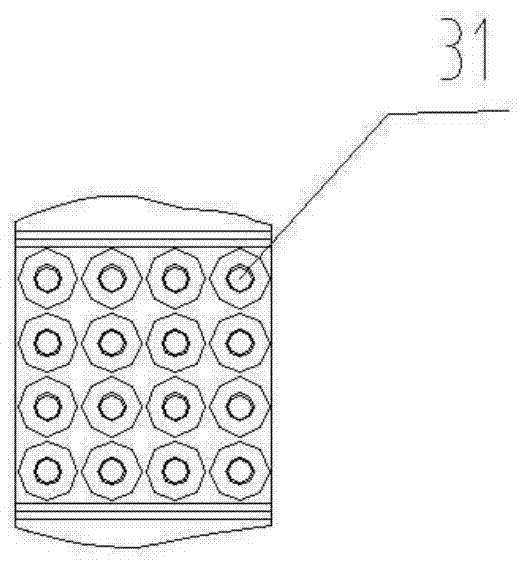

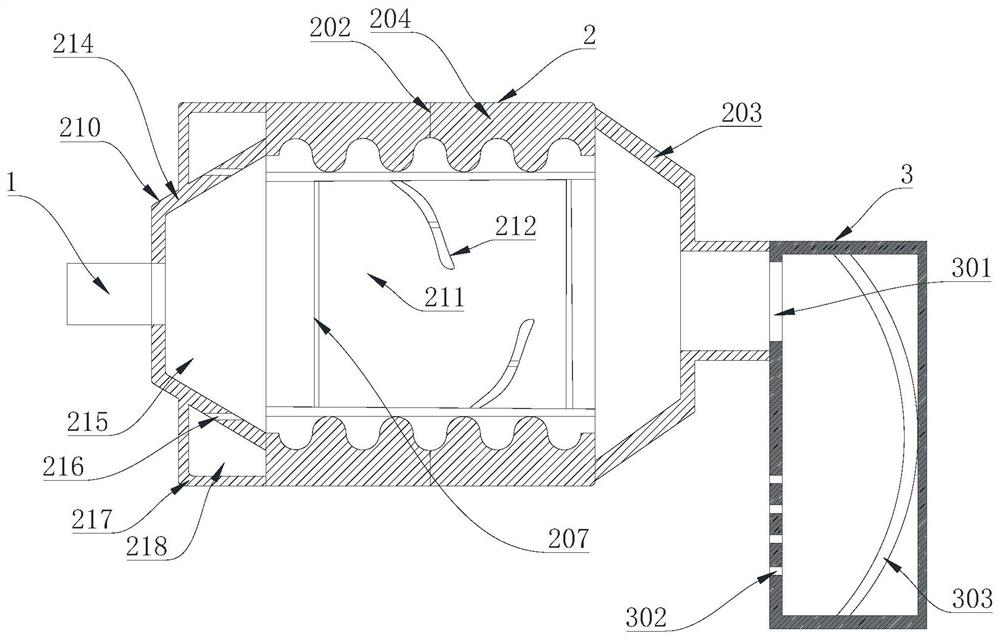

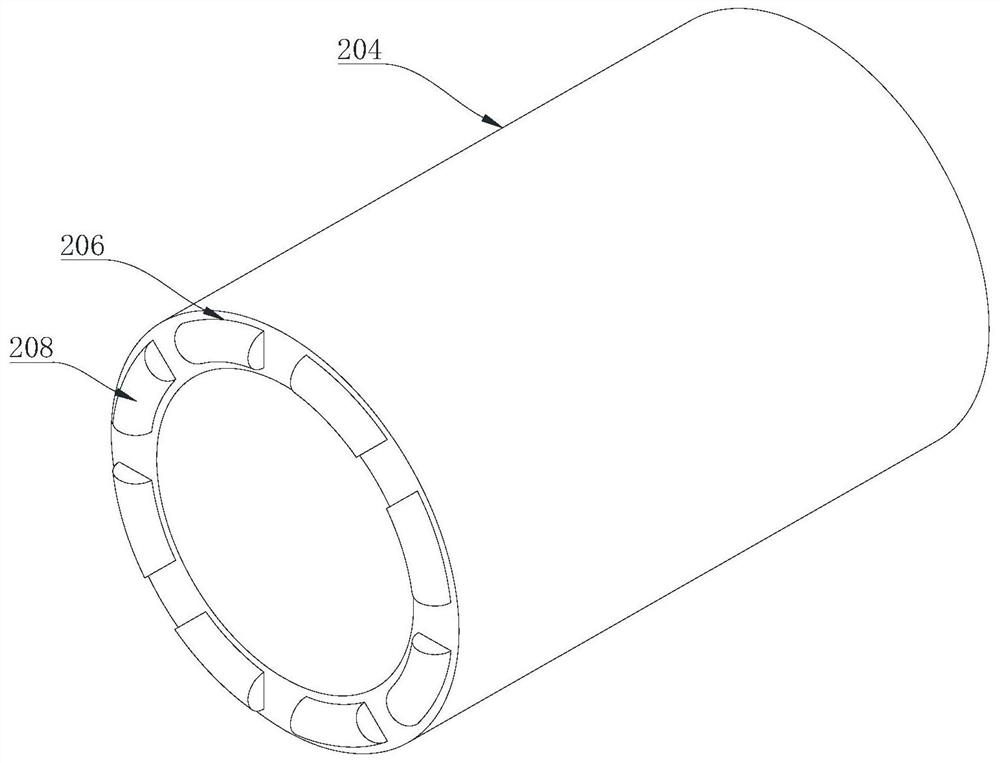

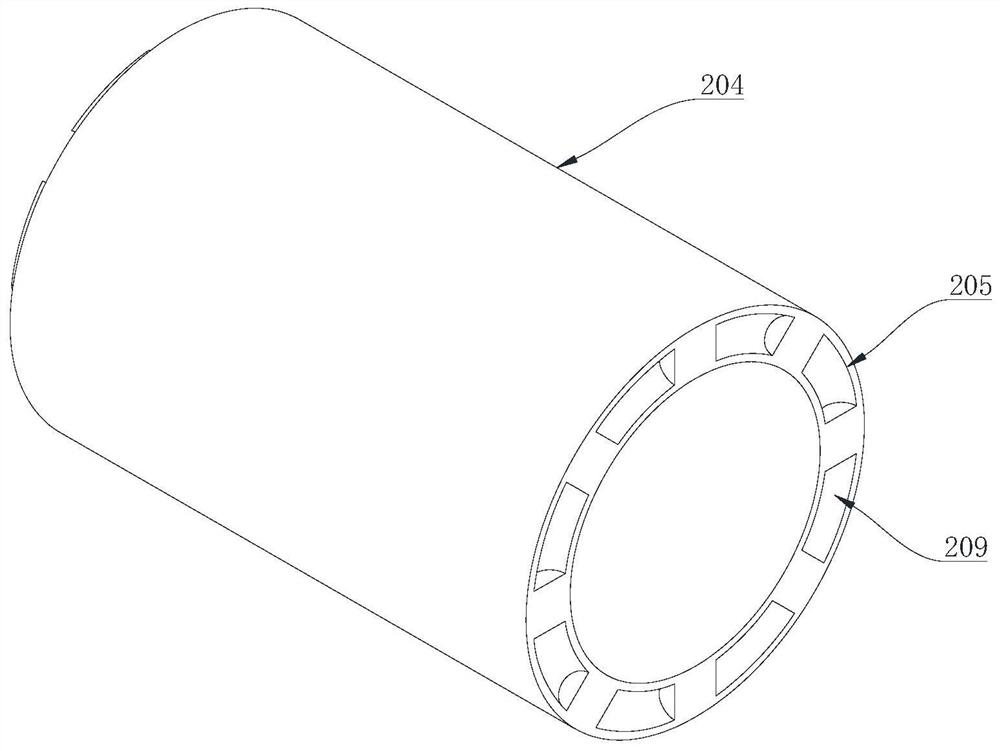

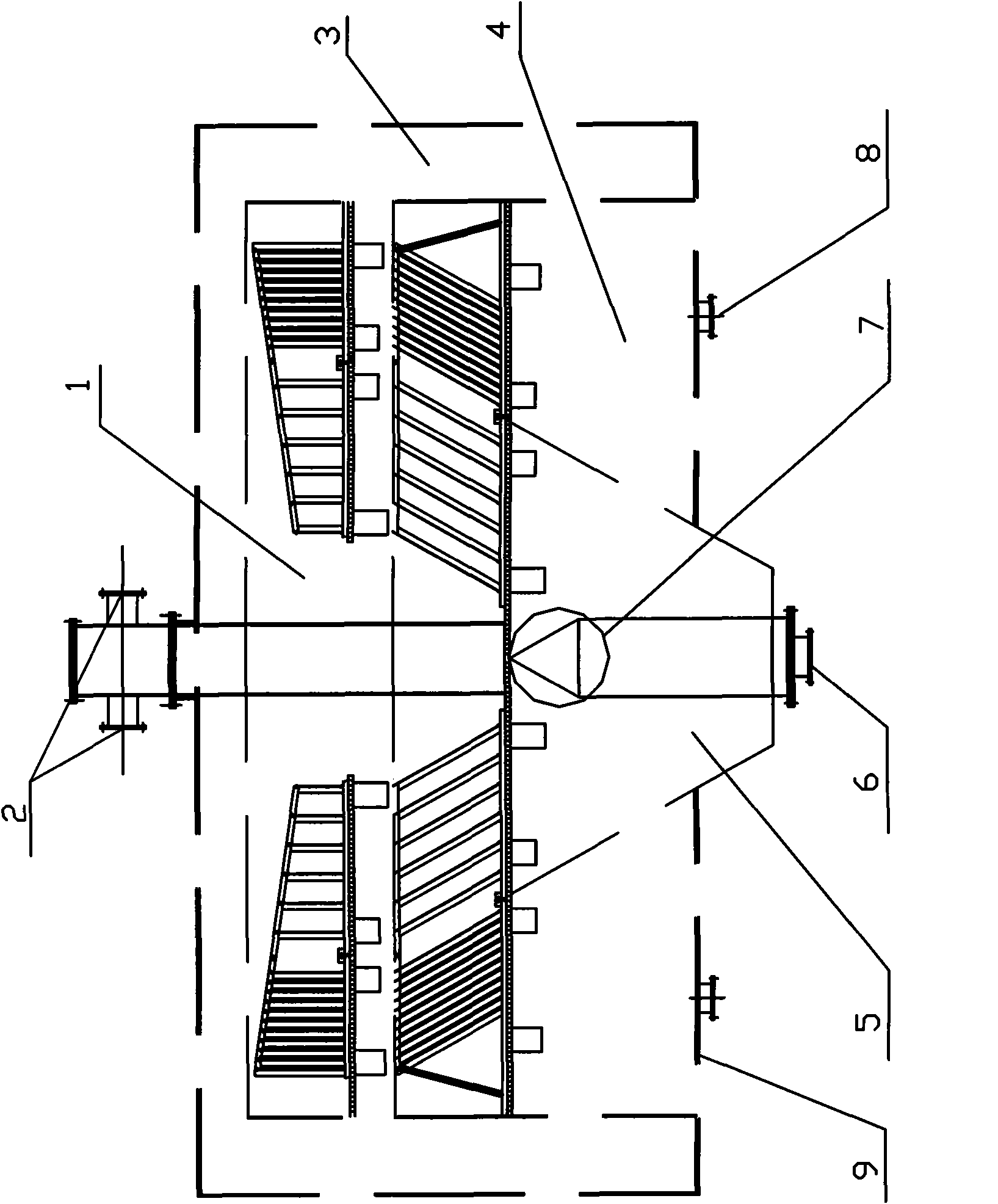

Combined body of composite type rotating sludge incineration kiln and reciprocating type sludge incineration kiln

InactiveCN104197339AImprove dehydration drying performanceExtend heat exchange timeIncinerator apparatusFlue gasEngineering

The invention discloses a combined body of a composite type rotating sludge incineration kiln and a reciprocating type sludge incineration kiln. A reverse interaction heat exchange mode is adopted for the moving direction of sludge materials of the composite type rotating sludge incineration kiln and the flow direction of high-temperature flue gas of a heat source, and the heat exchange ability is high; the inner wall of a cylinder is provided with a lifting plate which can lift the sludge materials to the portion above the inner side of the kiln cylinder, N times of curtains of the N sludge materials are formed in the cylinder of the rotating kiln, and the time for heat exchange of full contact of the high-temperature flue gas and the sludge materials is longer; meanwhile, the lifting plate absorbs heat of the high-temperature flue gas and transmits the heat to the sludge materials, and therefore the sludge dewatering and drying effect is better. According to the heat resource of the composite type rotating sludge incineration kiln in the structure of the combined body, the unburned sludge materials left by incineration in the composite type rotating sludge incineration kiln in the former working procedure continue to be incinerated in the reciprocating type sludge incineration kiln for providing all heat energy, a fuel oil and gas burner does not need to be used as an auxiliary heat source, and the operation cost is lower.

Owner:陆骏

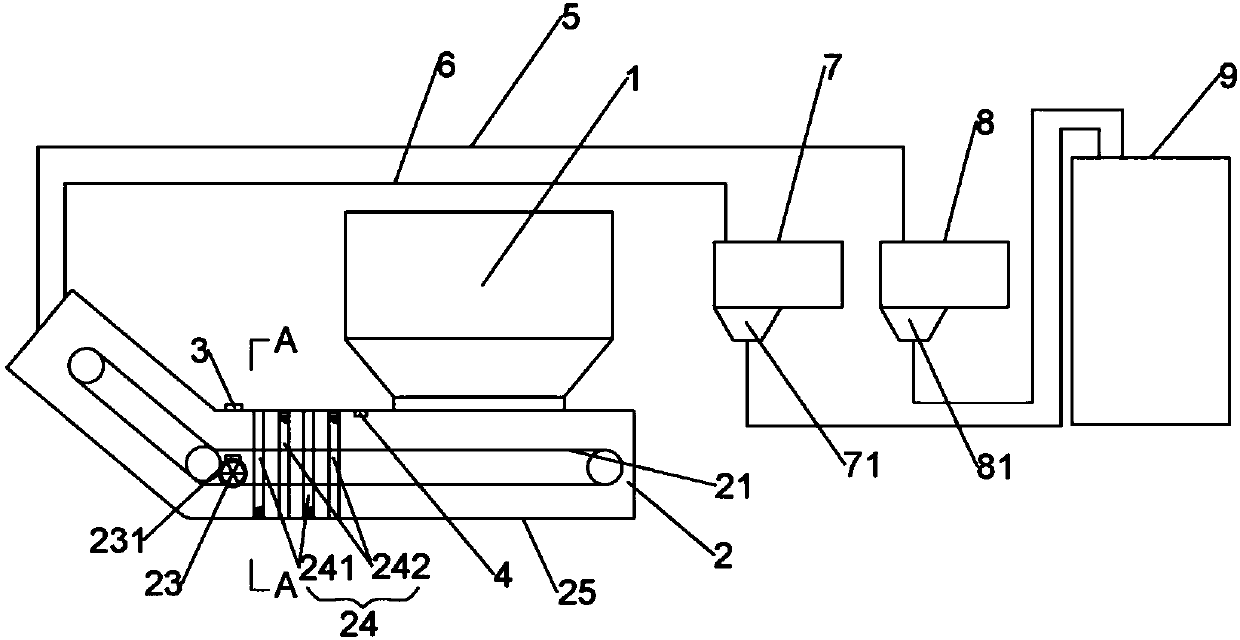

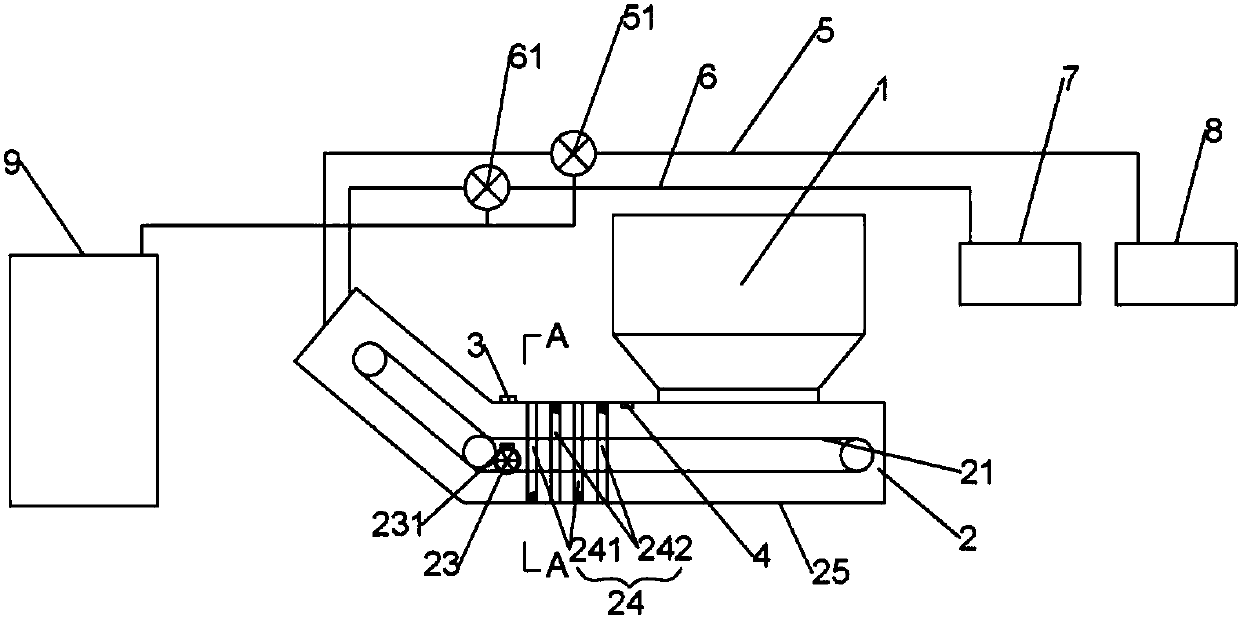

Slag sensible heat recycling system for air-cooling dry slag machine

ActiveCN107741021AAvoid influenceImprove efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

Environment-friendly heat and low temperature resisting meal box and production technology thereof

InactiveCN105820439AGood mechanical propertiesThe production process is simplePolypropyleneFire retardant

The invention discloses an environment-friendly heat and low temperature resisting meal box and a production technology thereof. The meal box is prepared from, by weight, 50-60 parts of polypropylene, 30-50 parts of a propylene-ethylene copolymer, 1-5 parts of a foaming agent, 10-15 parts of modified crop straw powder, 1-5 parts of compatilizer, 1-5 parts of antioxidant and 1-5 parts of fire retardant. The modified crop straw powder is a mixture of crop straw powder and nonionic surfactant, and the dosage of the nonionic surfactant accounts for 5-10% that of the modified crop straw powder. The meal box is easy to degrade and will not deform or send a smell (low smell) at high temperature, embrittlement of the material is avoided at low temperature, a good mechanical property can be kept at high and low temperature, and the preparing technology is simple.

Owner:SUZHOU FENGZE PLASTIC IND LIMITED

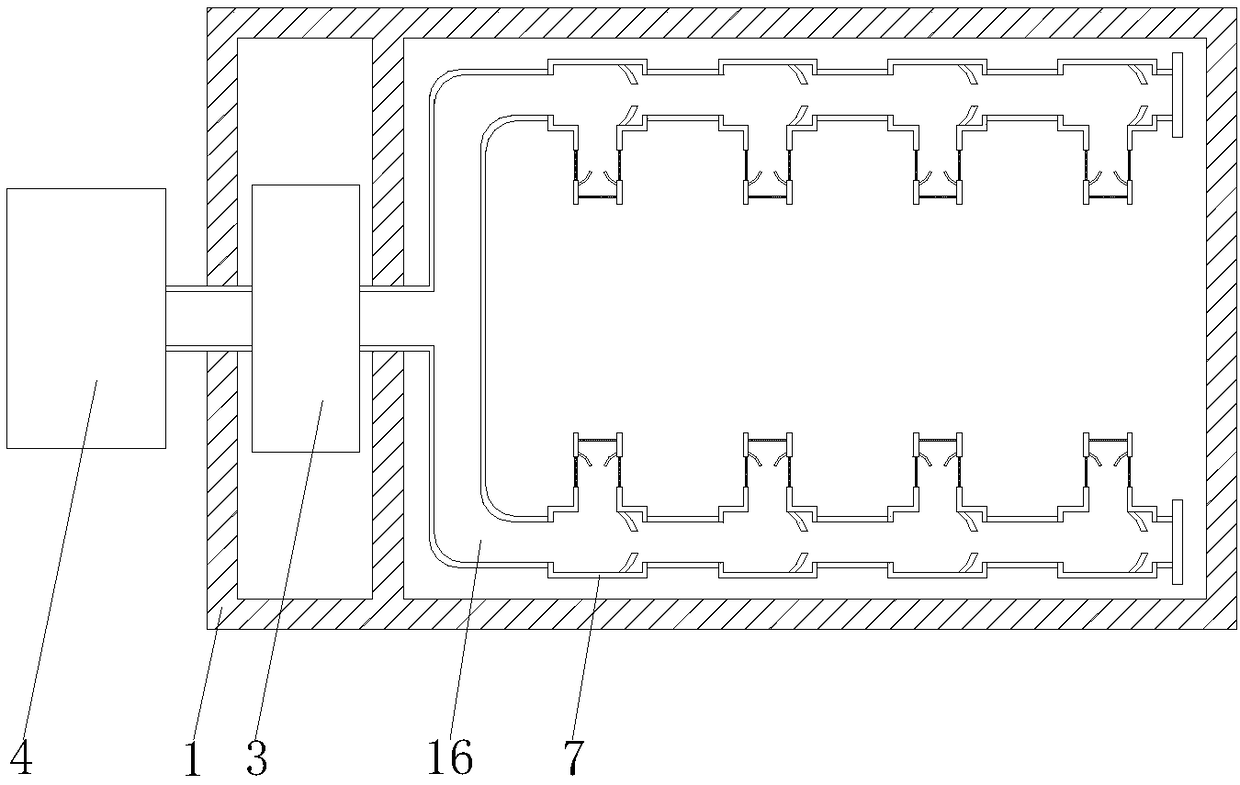

Refrigeration system low space area on ground of building hall

PendingCN108224647AHeight adjustableReasonable flow rateLighting and heating apparatusAir conditioning systemsCold airEngineering

The invention discloses a refrigeration system for a low space area on the ground of a building hall. The refrigeration system comprises a wall body; refrigeration equipment is fixedly arranged at thelower end of one side of the interior of the wall body; an air inlet and an air outlet are formed in the upper end and the lower end of the refrigeration equipment; the air outlet communicates with one end of a cold air pipe; the other end of the cold air pipe extends to the other side of the interior of the wall body; a sealing head is arranged at the end part of the other end of the cold air pipe; an air nozzle sleeves are arranged in the middle of the cold air pipe; the two ends of the air nozzle sleeves are connected to the cold air pipe in a threaded mode; the air nozzle sleeves communicated with the cold air pipe; first air deflectors are arranged in the air nozzle sleeves; air nozzles are arranged on the inner side surfaces of the air nozzle sleeves; and side ventilation openings are formed in the side surfaces of the air nozzles. The refrigeration system has the advantages that the cold air pipe, the air nozzle sleeves, the air nozzles and a hot air pipe are arranged, and therefore the problems that a traditional refrigeration system can hardly perform refrigeration in the low space area on the ground of the building hall, and refrigeration is not uniform can be solved.

Owner:天津博帆科技发展有限公司

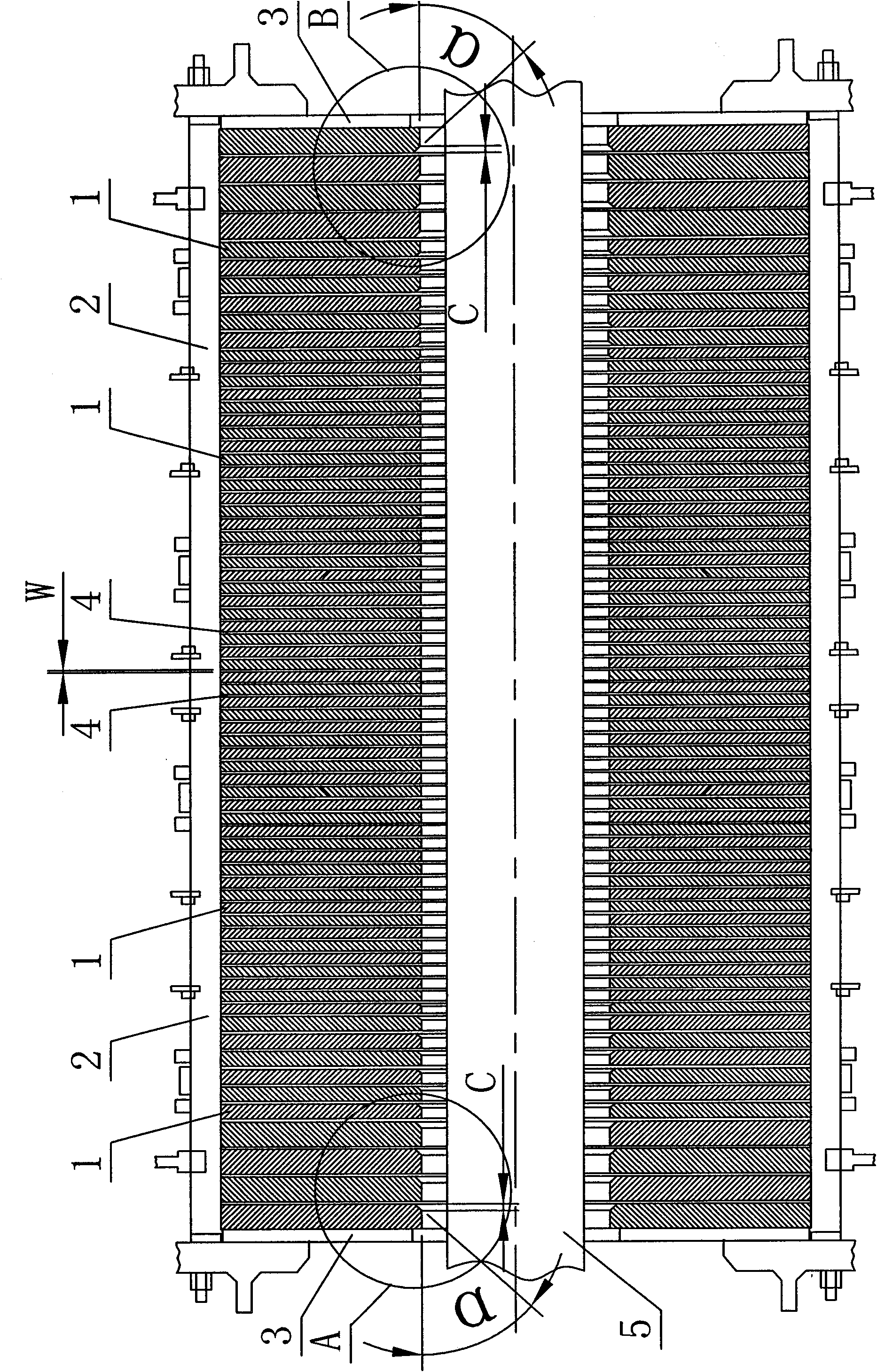

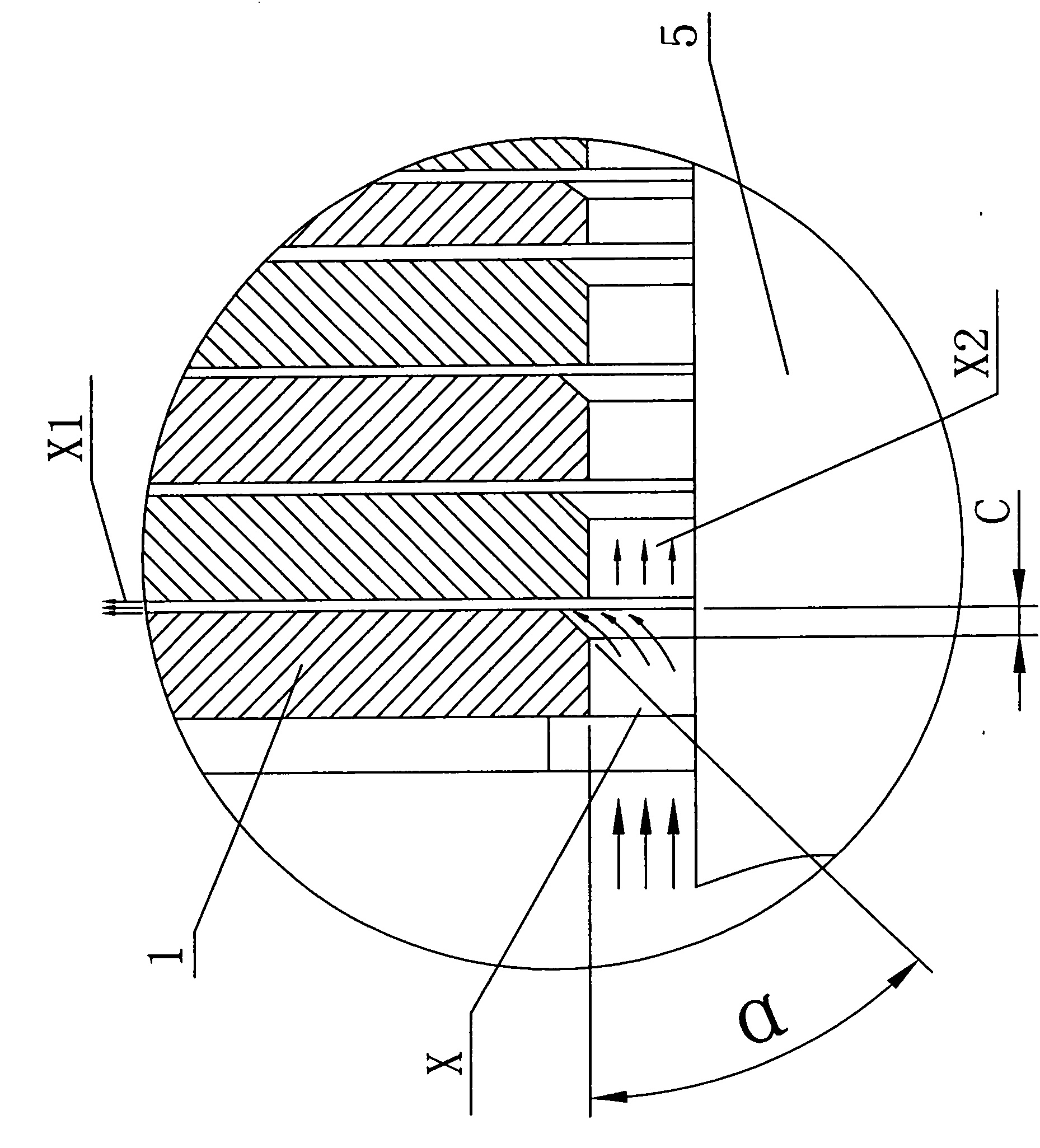

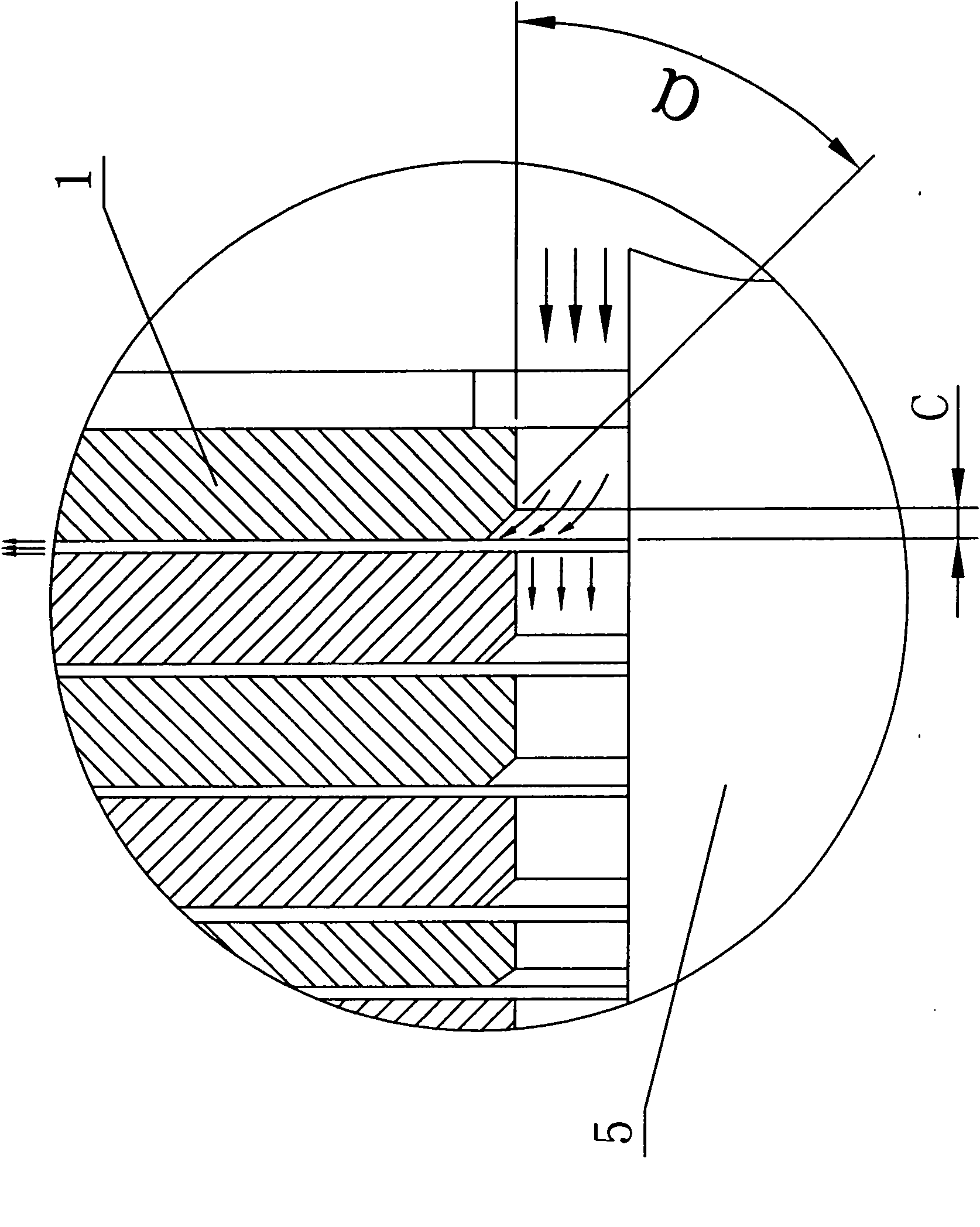

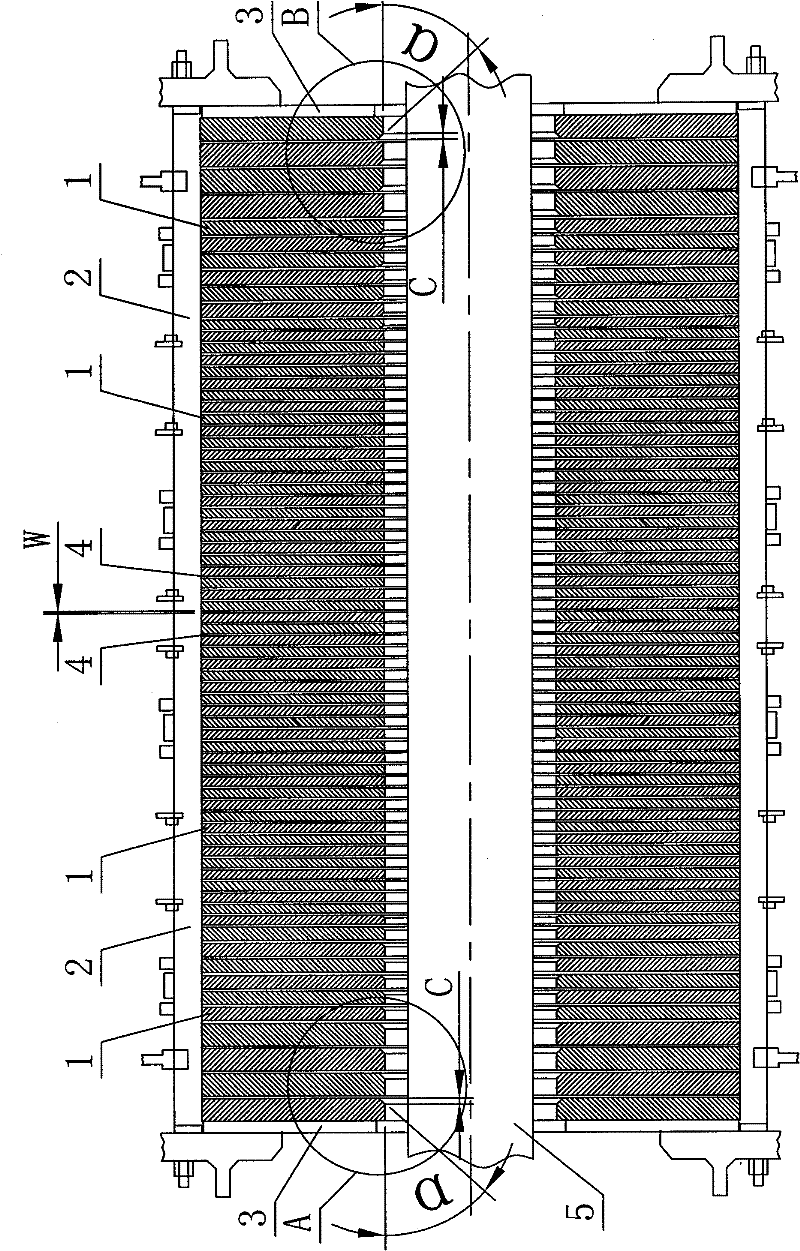

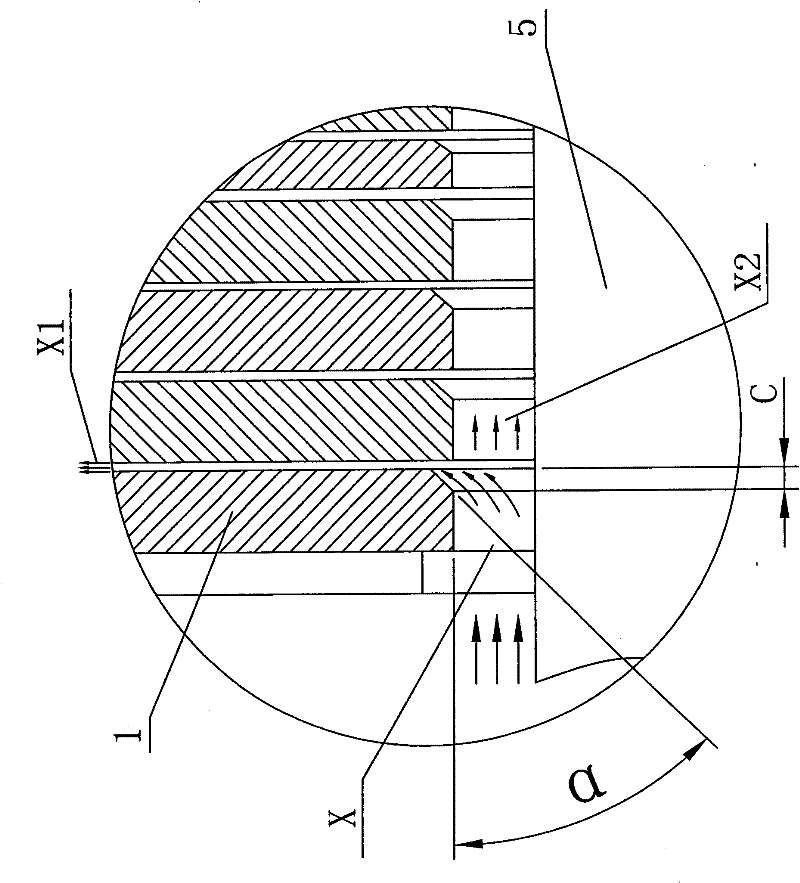

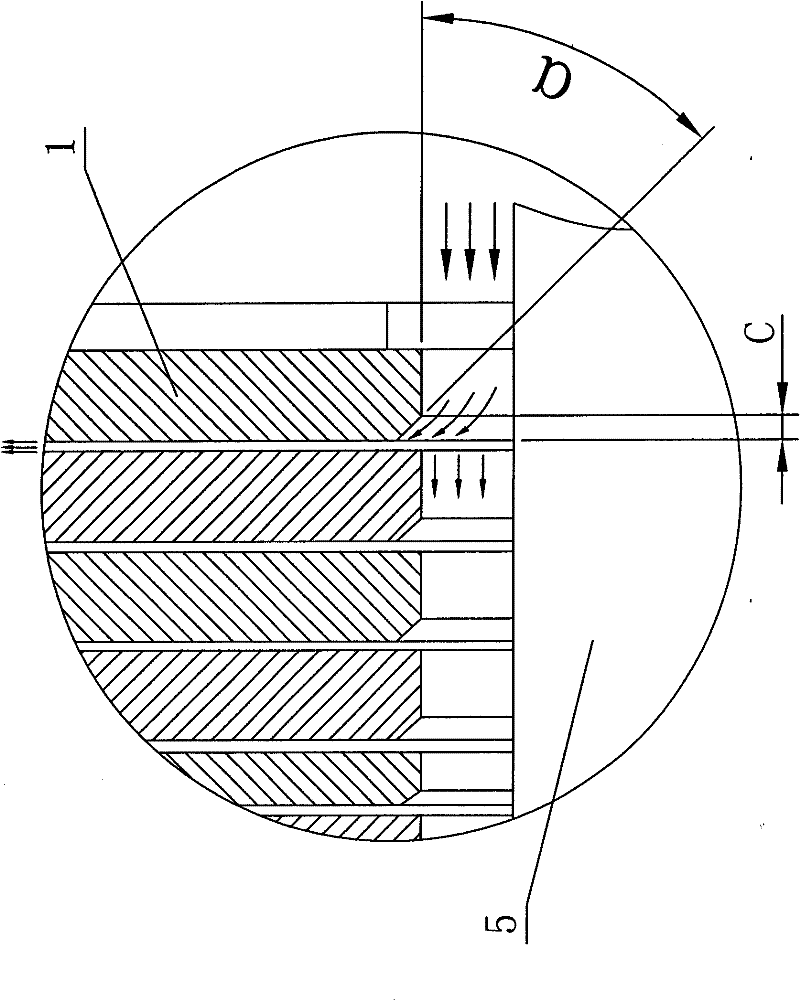

Large air-cooling steam turbo generator stator capable of improving aeration-cooling effect

ActiveCN101917074AHomogenization of temperature zonesIncrease heat loadMagnetic circuit stationary partsCooling effectEngineering

The invention discloses a large air-cooling steam turbo generator stator capable of improving aeration-cooling effect and relates to a large air-cooling steam turbo generator stator. For reducing the maximum temperature rise of an air-cooling steam turbo generator stator bar, the invention adopts the technical points that: an orifice of inner bores of iron core sections which are positioned at the two ends of a stator main body is provided with a chamfer angle (alpha) of between 60 and 75 DEG, the orifice is an axial opening close to one side of an axial midperpendicular plane of the stator main body, and the depth (C) of the chamfer angle is 6 to 12mm. The heat radiating efficiency of a motor cooling system can be effectively improved due to the adoption of the generator stator structure provided by the invention; and under the condition of a given inlet and fixed outlet pressure, when a chamber angle scheme is adopted, experiments prove that the maximum temperature is 3 DEG C lower than that of the conventional scheme after the temperature of the generator stator structure is solved, so the temperature of the hottest section of a motor is effectively reduced, and the whole temperature area of the motor is uniformized.

Owner:HARBIN UNIV OF SCI & TECH

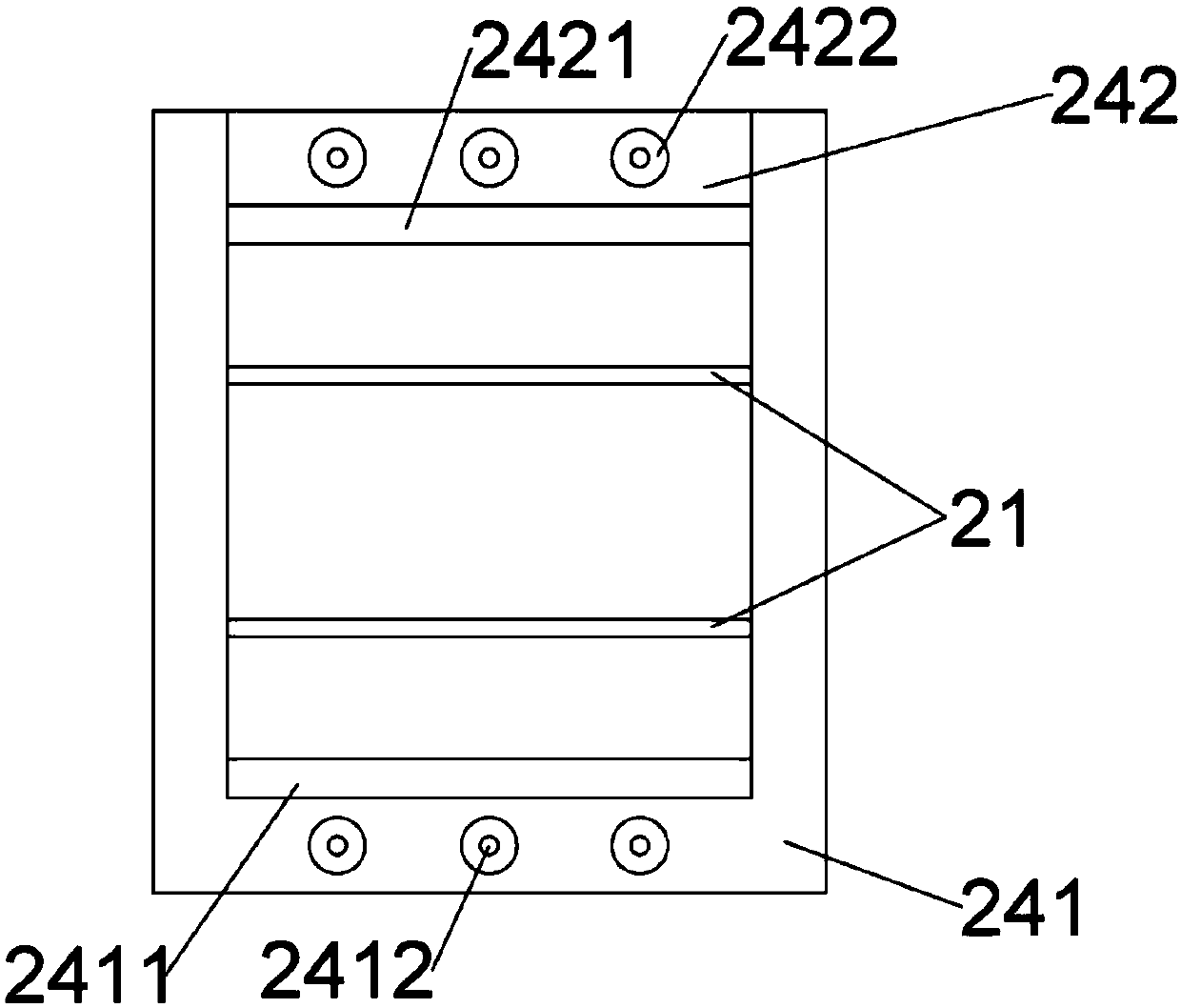

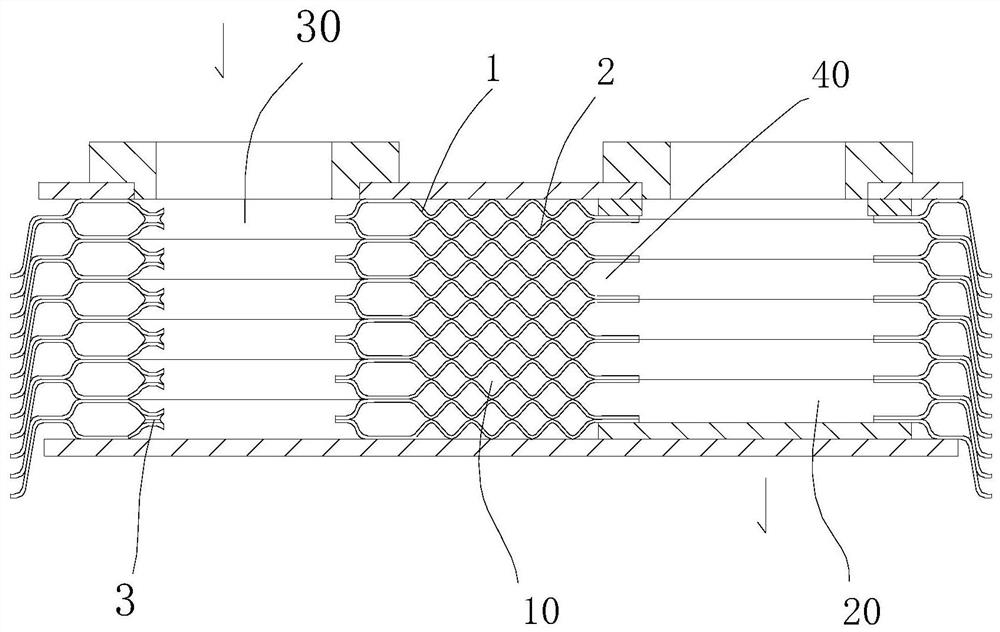

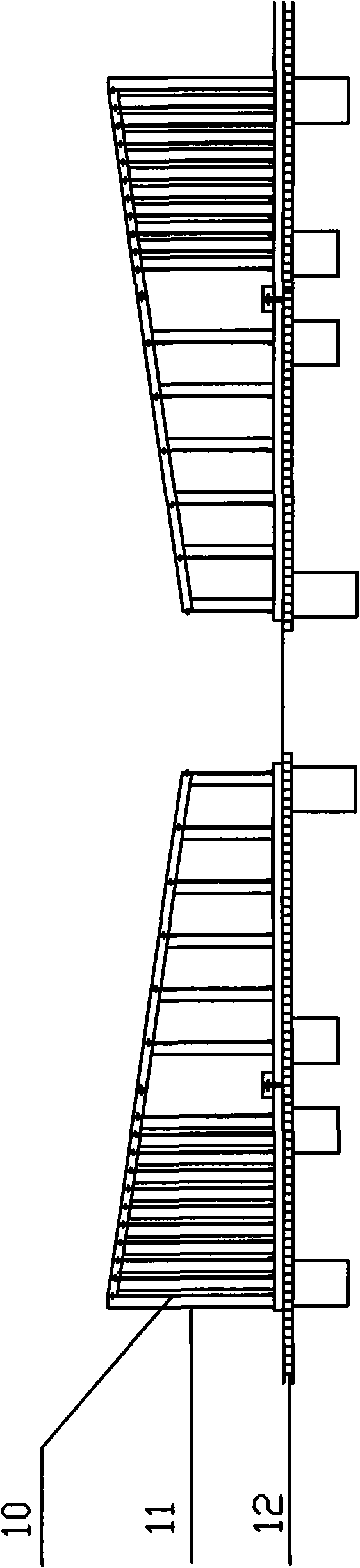

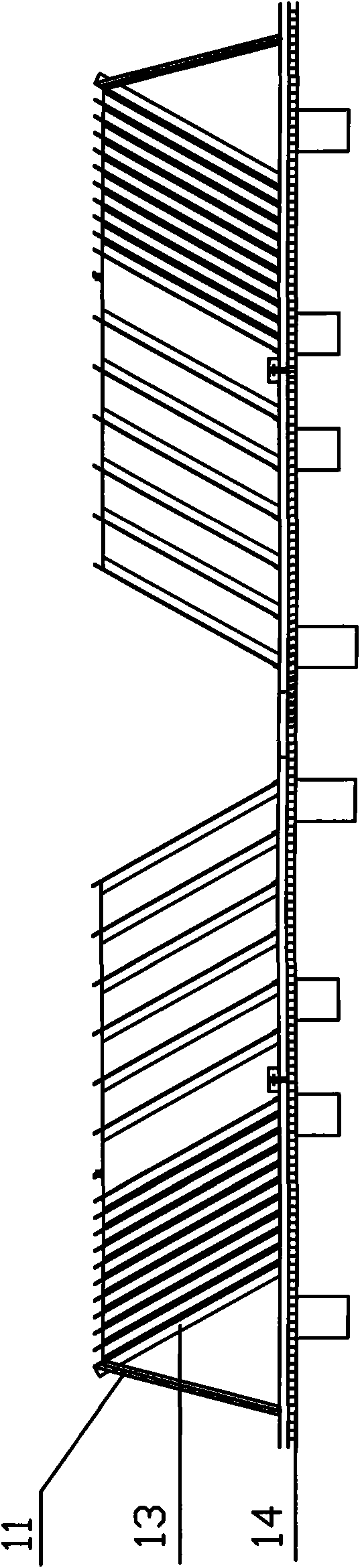

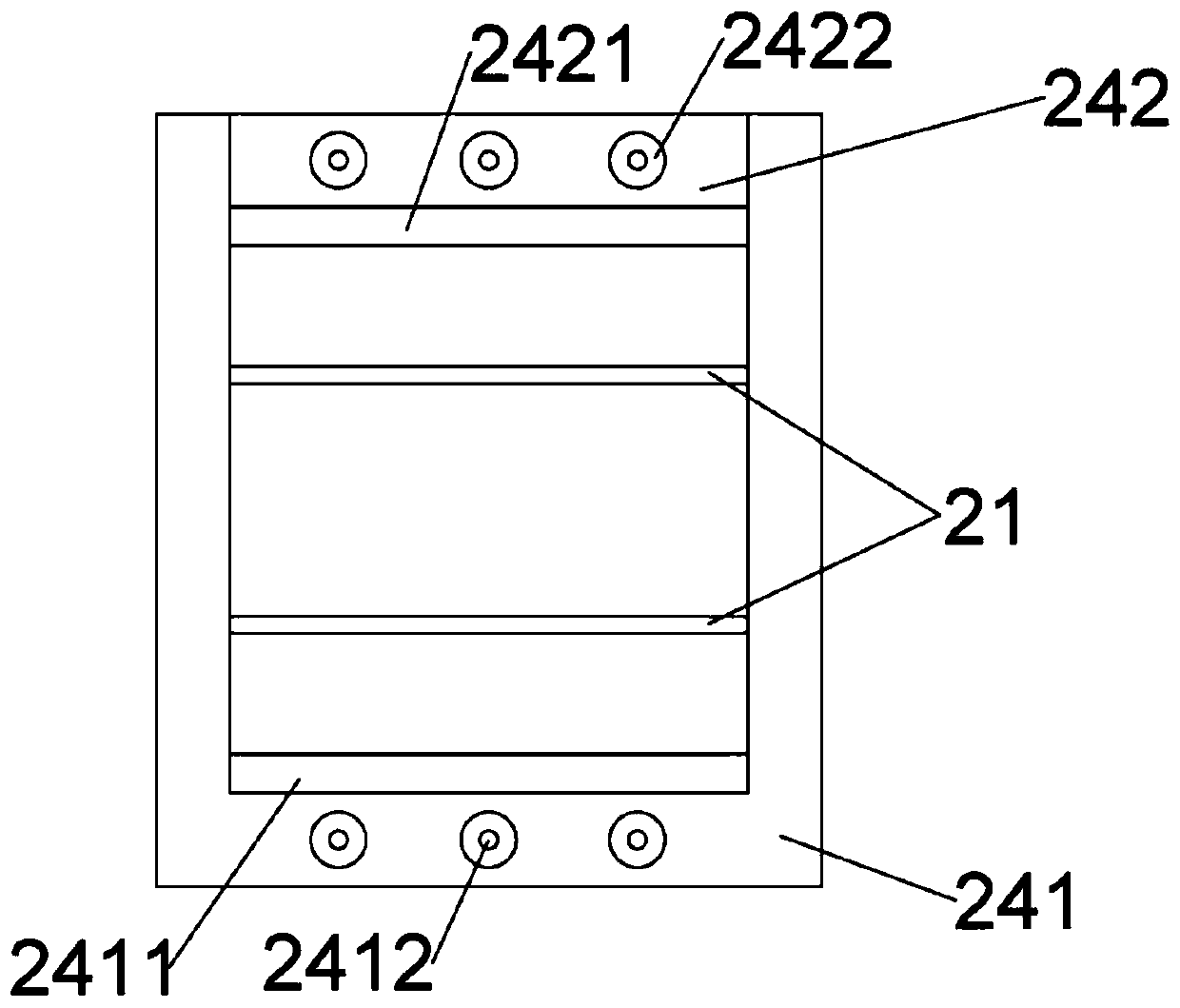

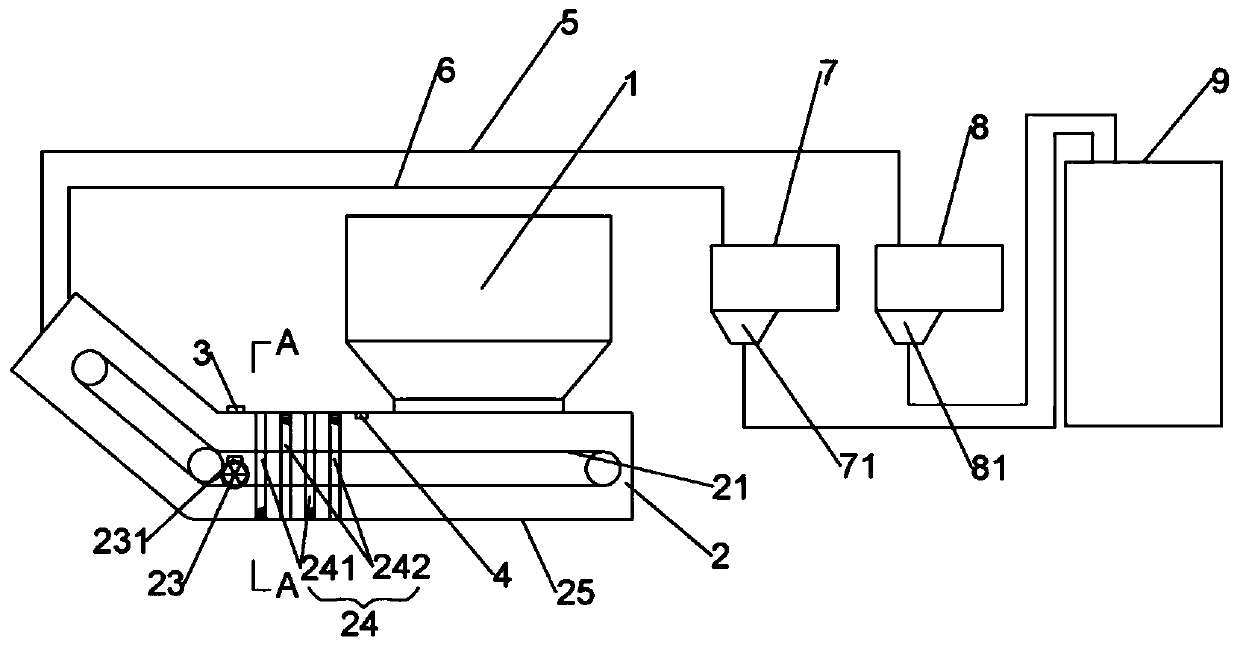

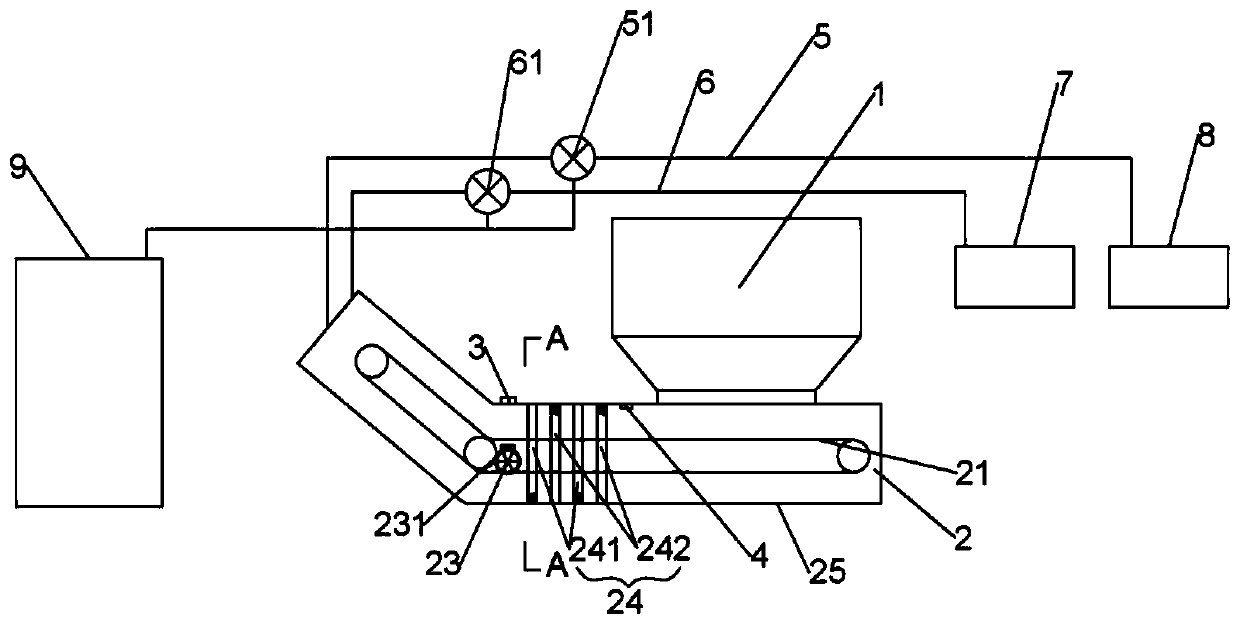

Dilution water addition device and method for adjusting cross-direction paper basis weight

InactiveCN105755886AGuaranteed performanceAvoid cross flowMachine wet endWater channelComputer module

The invention discloses a dilution water addition device and method for adjusting cross-direction paper basis weight.The device comprises a headbox, a dilution water header pipe, dilution water branch pipes and a concentration adjusting module; pulp distributing branch pipes are arranged in the headbox in a multi-column and side-by-side mode, the concentration adjusting module is arranged above the pulp distributing branch pipes and internally provided with multiple dilution water channels, and each dilution water channel is located above the corresponding column of pulp distributing branch pipes; multiple dilution water branch pipes are distributed on the dilution water header pipe, each dilution water branch pipe is communicated with a pulp distributing header pipe through the corresponding dilution water channel, and the flow direction of dilution water in each dilution water channel is opposite to that of pulp in the corresponding pulp distributing branch pipe.The method comprises the steps that the dilution water provided by the dilution water header pipe is distributed through the dilution water branch pipes and then enters the pulp distributing header pipe through the dilution water channels, and the dilution water is sent out by the pulp distributing branch pipes after being mixed with the pulp which is about to enter the pulp distributing branch pipes.By means of the dilution water addition device and method for adjusting the cross-direction paper basis weight, addition of the dilution water does not affect the outlet flow rates of the pulp distributing branch pipes, and the transverse flow phenomenon is effectively avoided.

Owner:SOUTH CHINA UNIV OF TECH

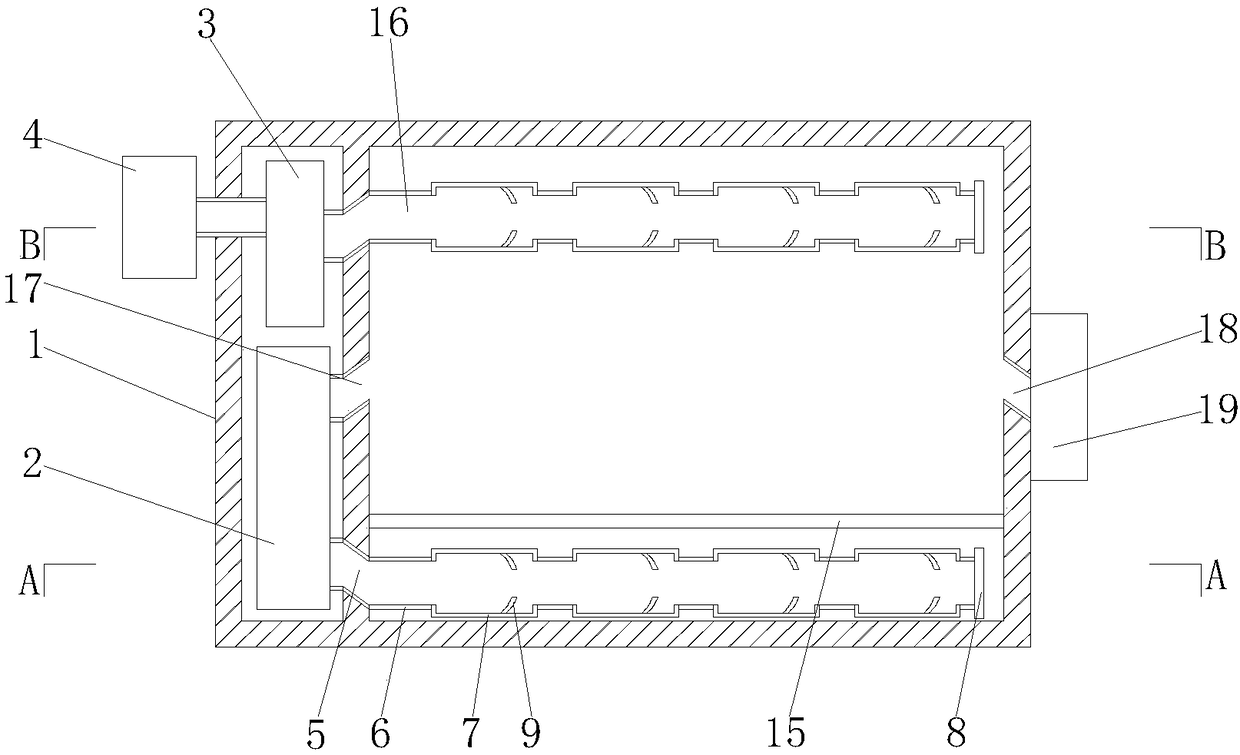

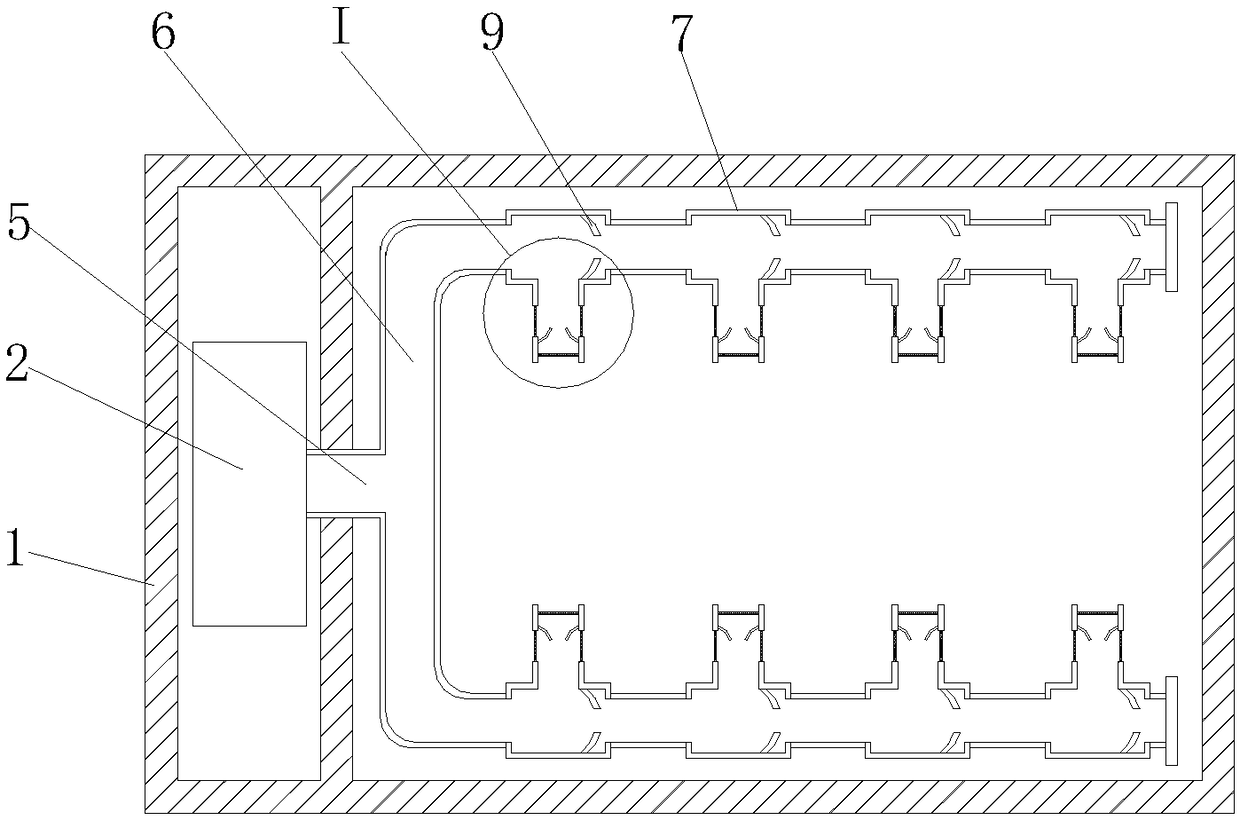

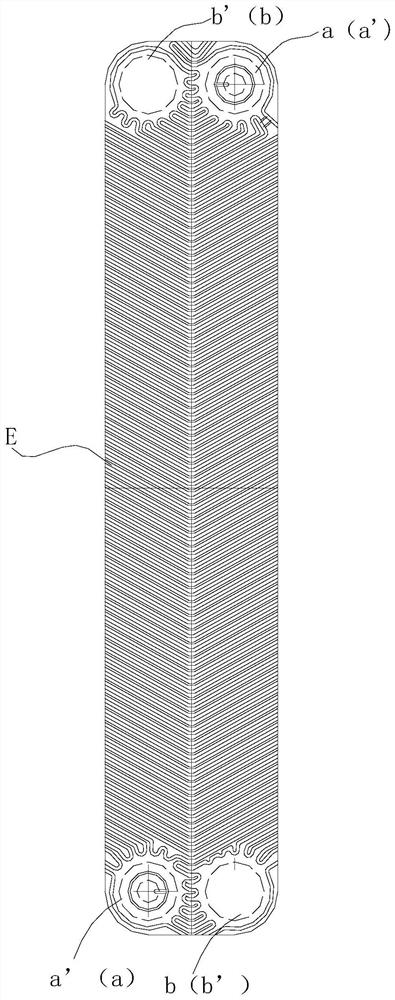

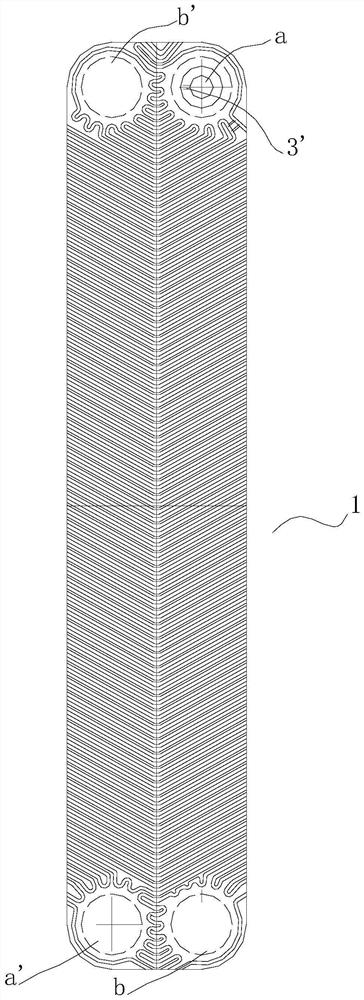

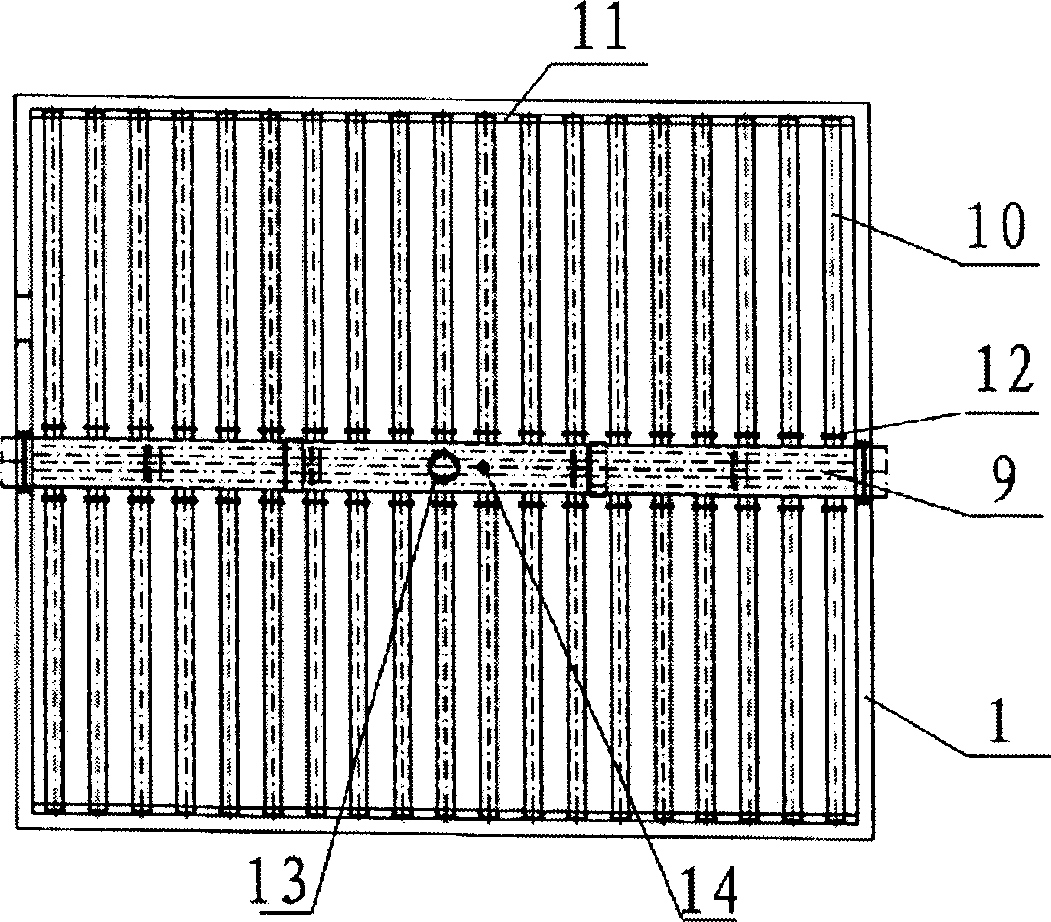

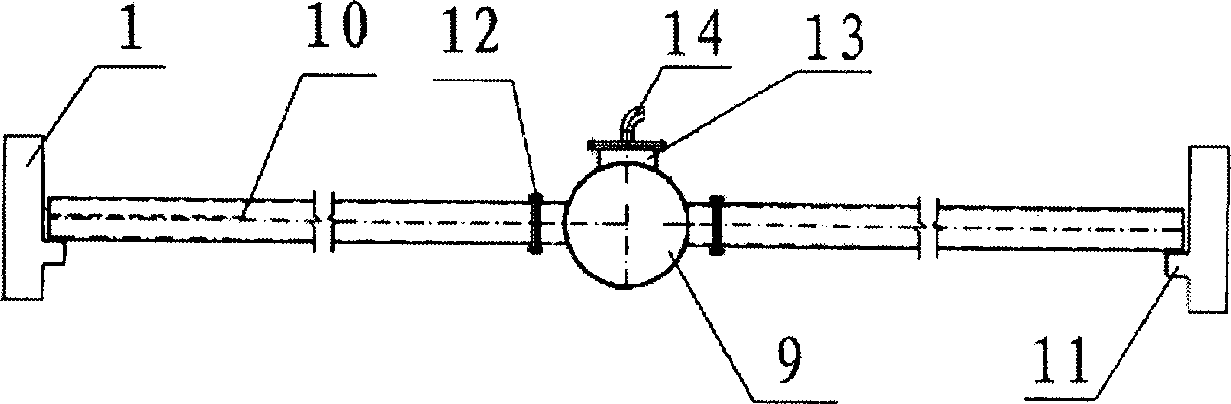

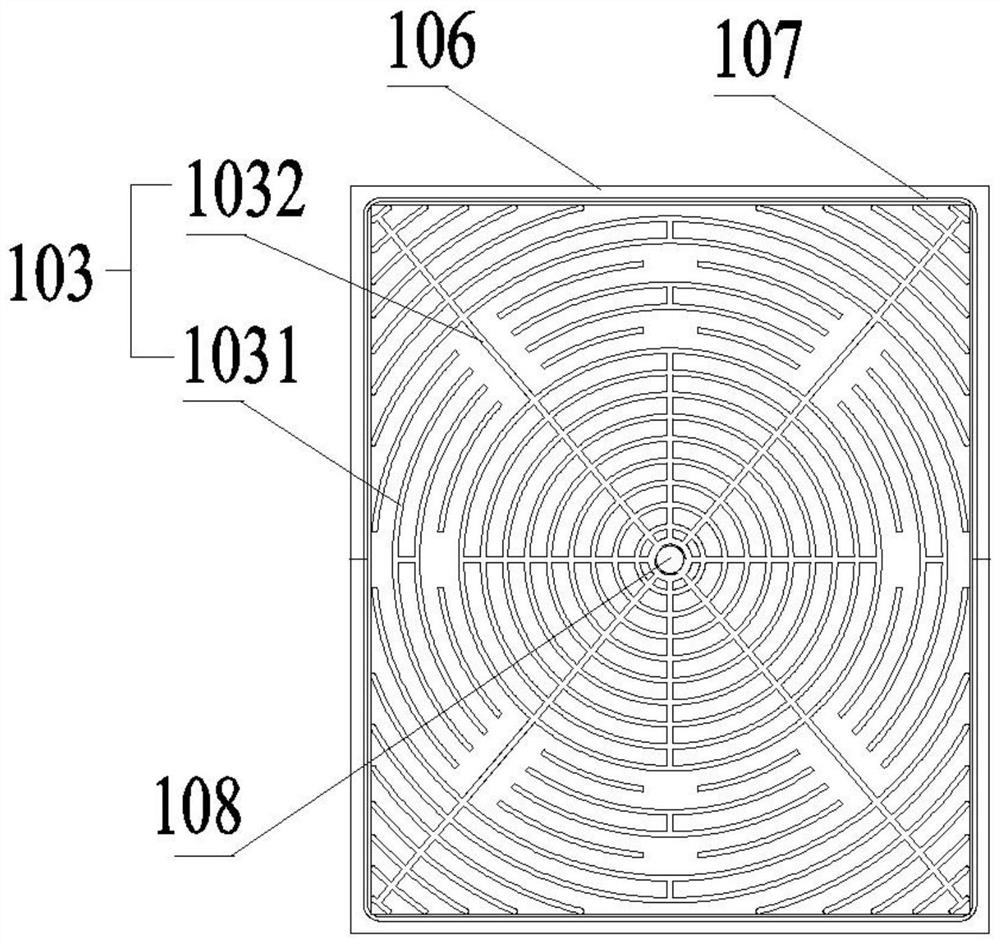

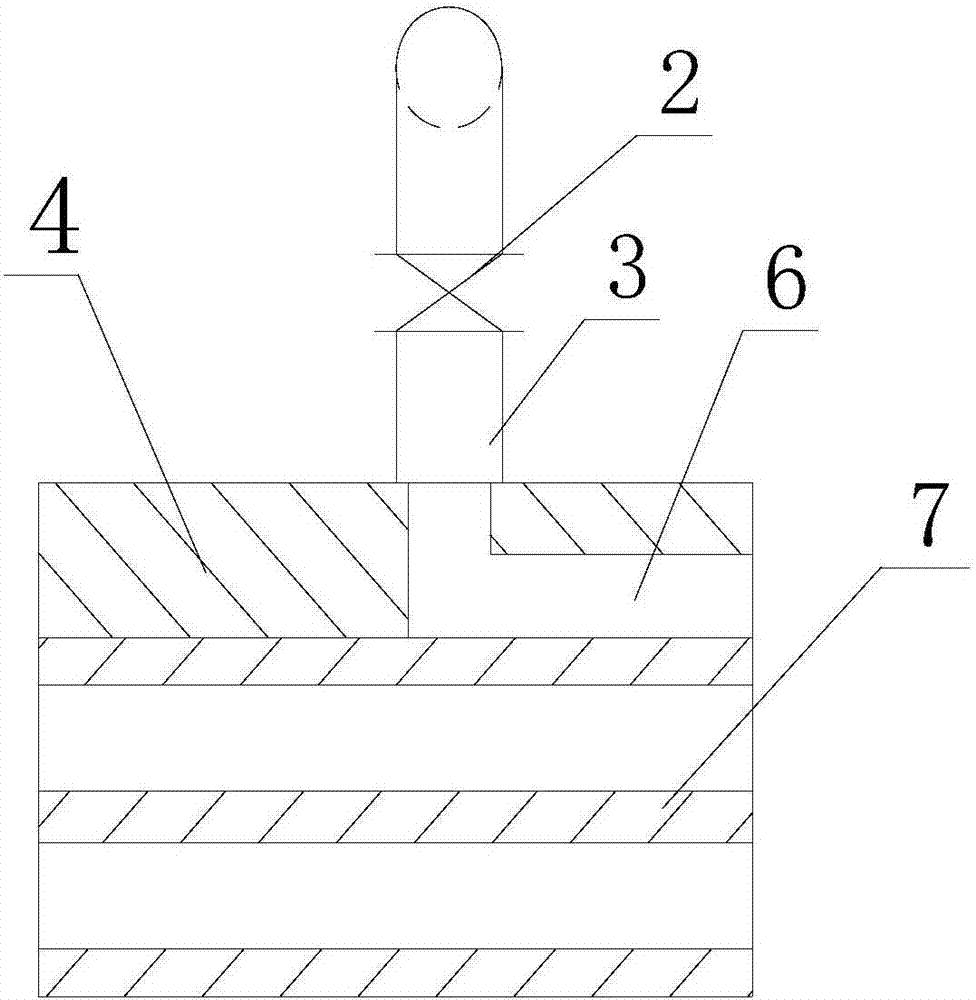

A plate evaporator

ActiveCN110500814BFully contactedImprove heat transfer efficiencyEvaporator accessoriesEvaporators/condensersHeat flowEngineering

The invention relates to a plate type evaporator, which comprises a series of heat exchange plates stacked at intervals between the first heat exchange fins and the second heat exchange fins (2) to form an interlaced , isolated heat exchange channels; the first surface (6) of the first and second heat exchange plates has a heat exchange area (E); the first surface (6) is respectively provided with four corner holes corresponding to the cold / heat medium Liquid inlet channel or liquid outlet channel; at least one groove (3') is provided on the edge of the first liquid inlet hole (a) for cold medium inlet in the four corner holes, and the groove (3') starts from the first inlet The edge of the liquid hole (a) extends all the way to the heat exchange channel; the first surface (6) is centrosymmetric except for the four corner holes, but the arrangement of the center points of the four corner holes also satisfies centrosymmetry; the first and second heat exchange The plates are punched separately from the same substrate. Copper foil is applied on the first surface of each heat exchange plate, the heat exchange plates are stacked in sequence, and the copper foil is heated to melt to form a permanent bond between the first and second heat exchange plates.

Owner:江苏远卓设备制造有限公司

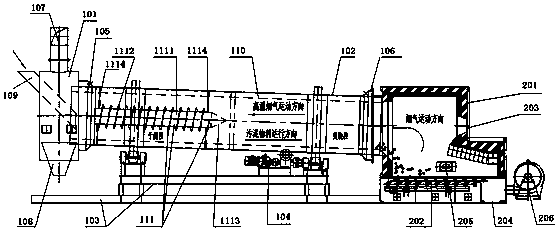

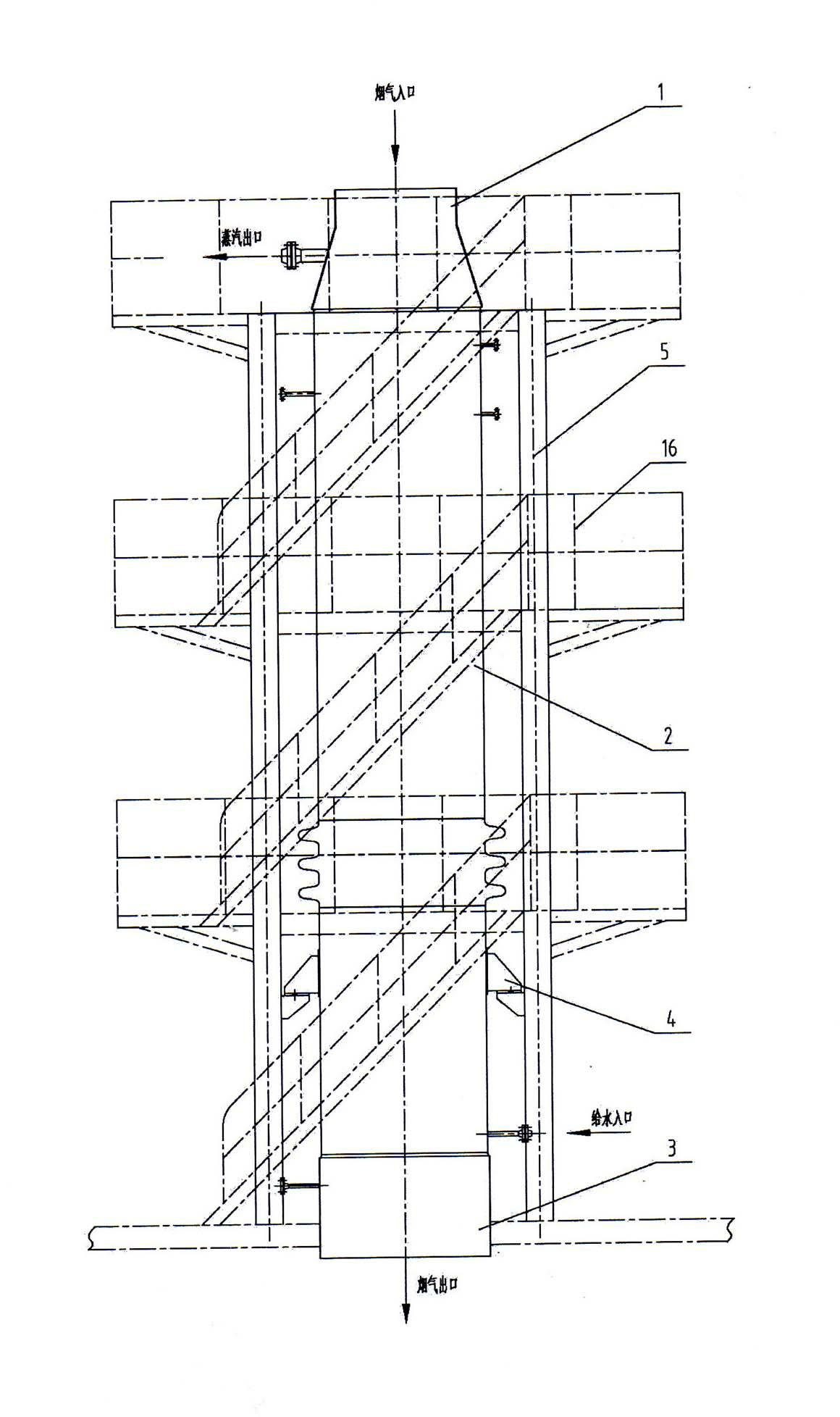

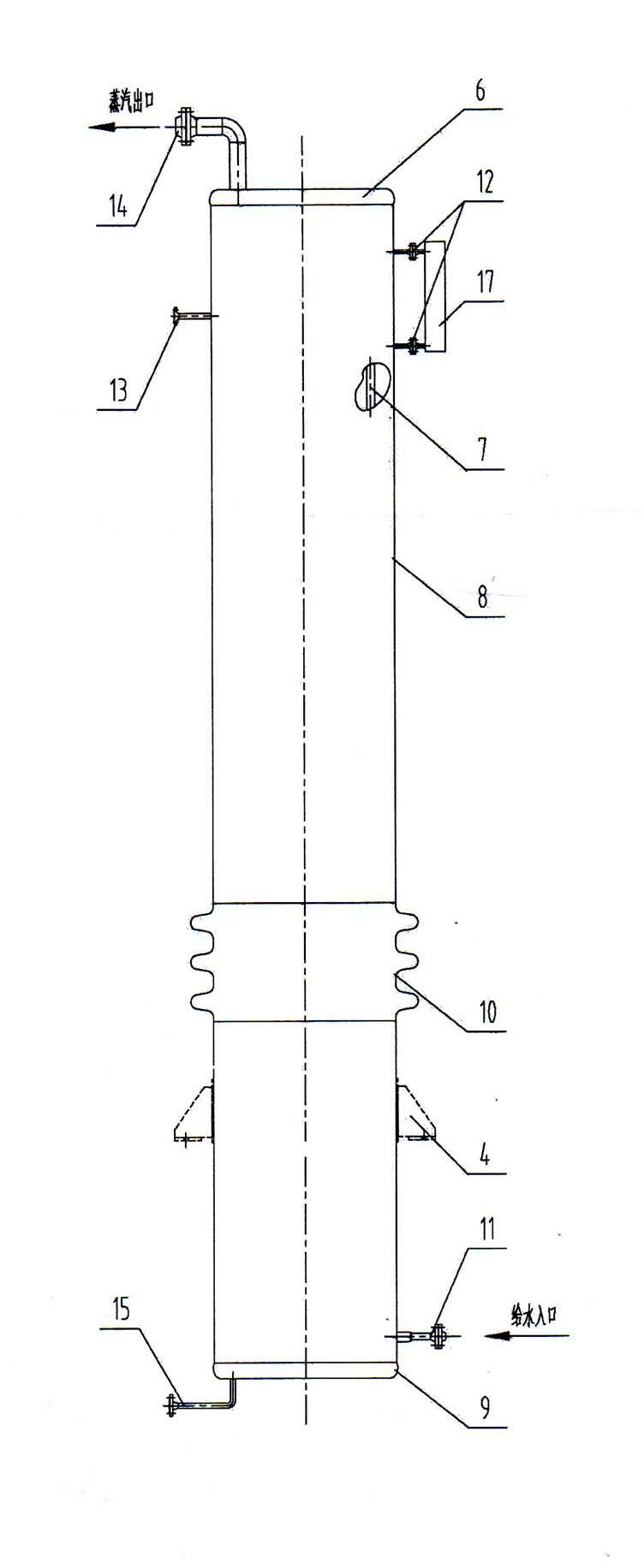

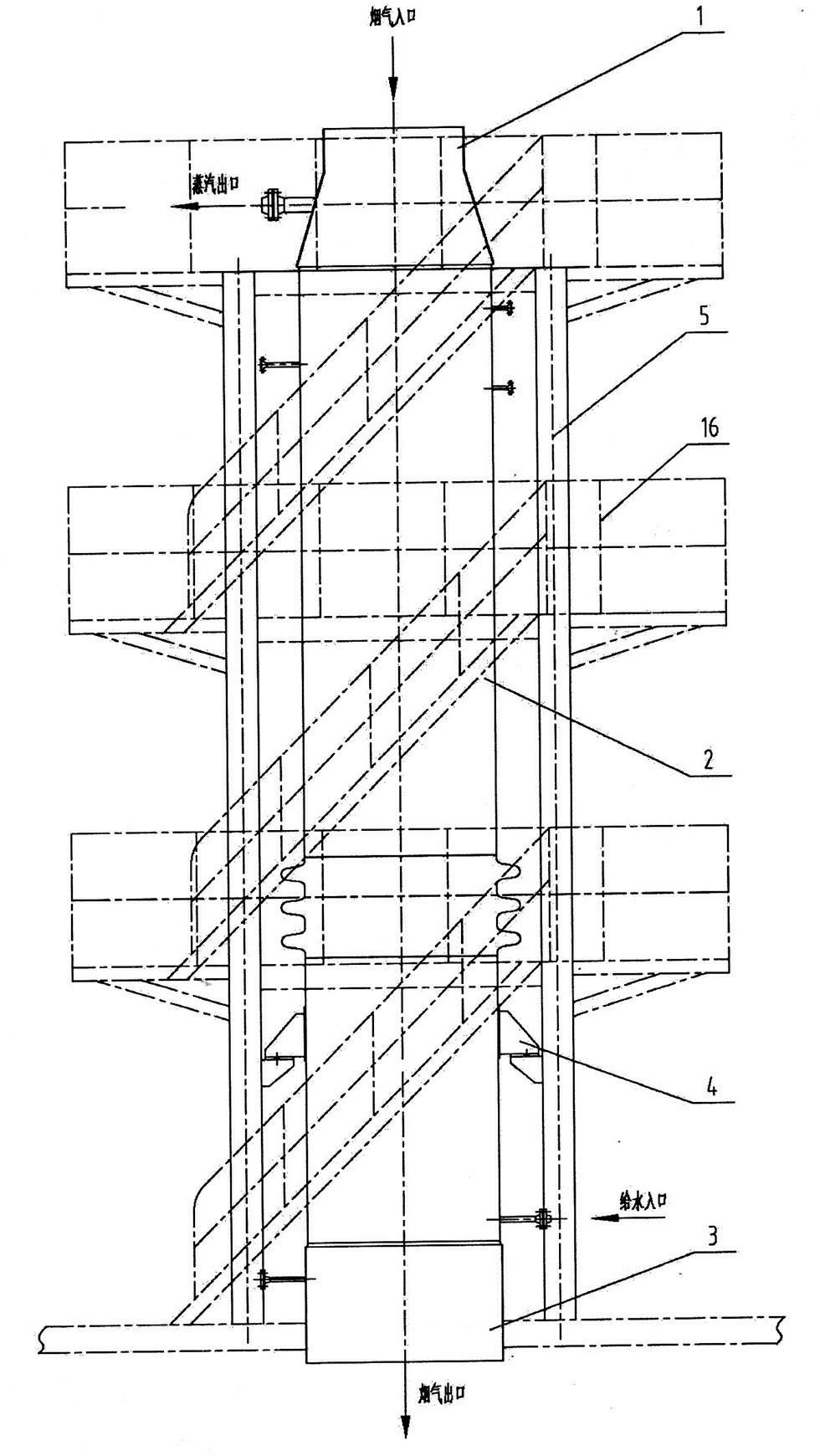

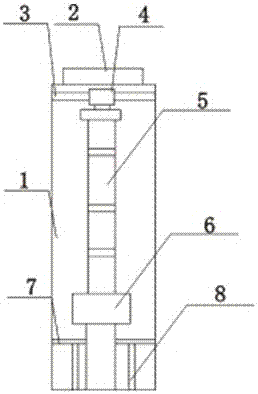

Vertical smoke tube exhaust-heat boiler

InactiveCN102384460AReasonable flow rateEfficient heat transferBoiler flue tubes/fire tubesSteam generation using hot heat carriersFlue gasVertical cylinder

The invention relates to a vertical smoke tube exhaust-heat boiler. In the vertical smoke tube exhaust-heat boiler, a boiler cylinder is a vertical cylinder body; pipe plates are arranged at openings at upper and lower ends of the boiler cylinder; two ends of a vertical smoke tube are fixedly arranged on through holes corresponding to the upper pipe plate and the lower pipe plate to form a smoke tube bundle; a flue gas inlet smoke box is arranged at the upper end of the boiler cylinder, a flue gas outlet smoke box is arranged at the lower end of the boiler cylinder, and the flue gas inlet smoke box, the flue gas outlet smoke box and the boiler cylinder are connected together; a water supply hole communicated with a cavity of the boiler cylinder is formed on the lower part of the wall of the boiler cylinder; a steam outlet communicated with the cavity of the boiler cylinder is formed on the upper part of the upper pipe plate, and a connection pipe passing through the flue gas inlet smoke box is arranged on the steam outlet; a support is arranged on the outer wall of the boiler cylinder, so that the boiler cylinder is fixed on a steel frame by the support; and the steel frame corresponds to the boiler cylinder and is fixed on a foundation. The vertical smoke tube exhaust-heat boiler has the characteristics of efficient heat transfer, automatic ash removal, modularization and low exhaust gas resistance.

Owner:DALIAN EAST NEW ENERGY DEV

Square absorption tower for wet method desulfurization of flue gas

ActiveCN1843581AAvoid badReasonable distribution of flow fieldDispersed particle separationFlue gasPulp and paper industry

The invention relates to a smoke wet sulfur trioxide square adsorption tower. Wherein, the lower section of tower is a cycle slurry tank and the upper section is a washing reaction section; the sections of upper and lower sections are both rectangle and vertically connected; the lower part of upper section is connected to the smoke inlet tube; the middle part of upper section is mounted with spray tubes; the tangent part of top of tower is connected to the smoke outlet; a mixer and a vent tube are inserted into the lower cycle slurry tank. The invention can avoid the slurry deposition of slurry to improve the efficiency of desulfuration and apply the installment of said adsorption tower.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

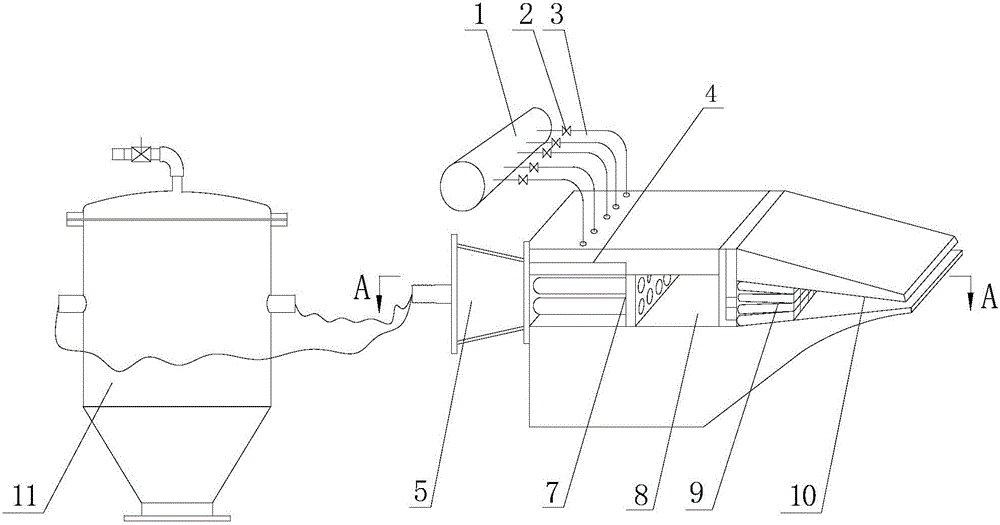

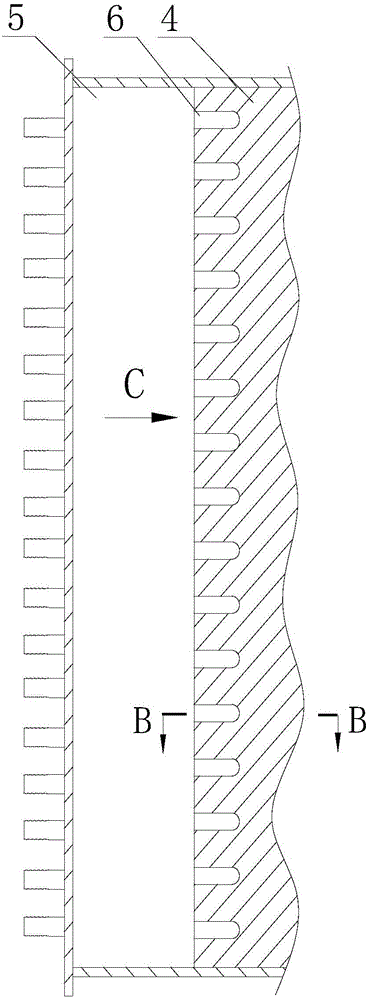

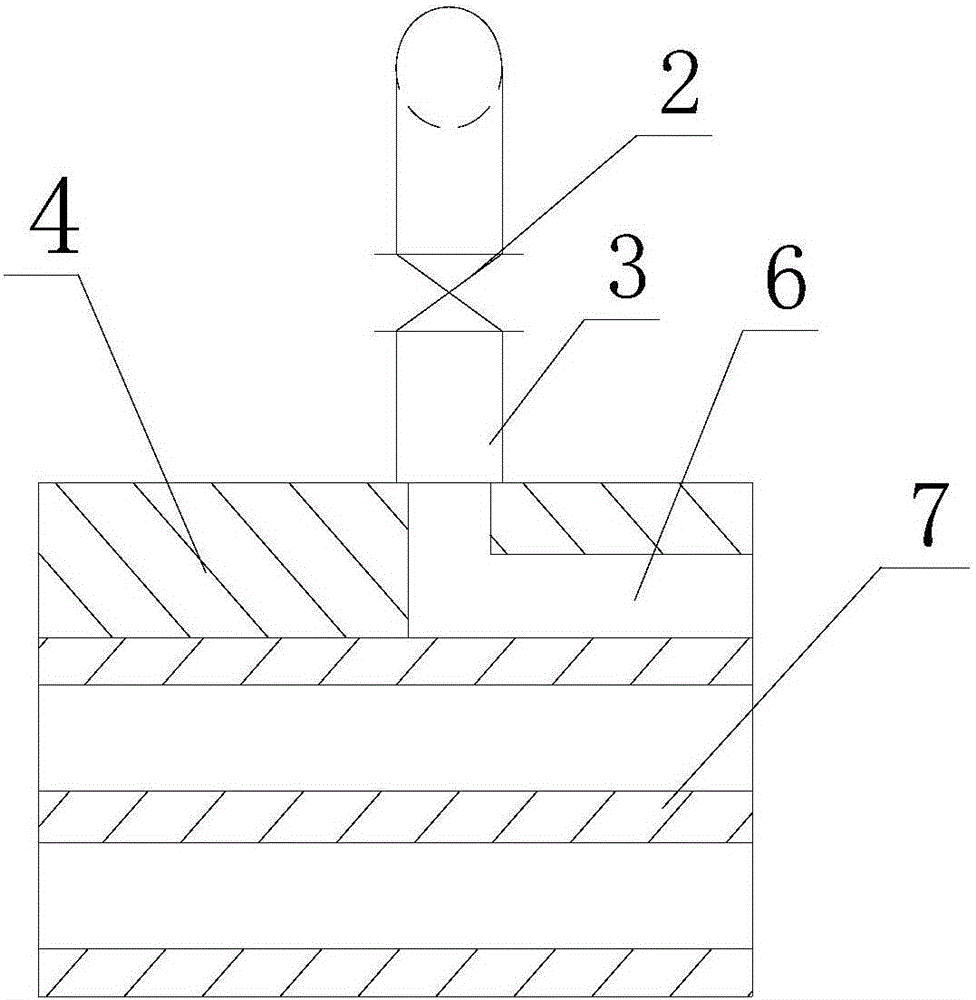

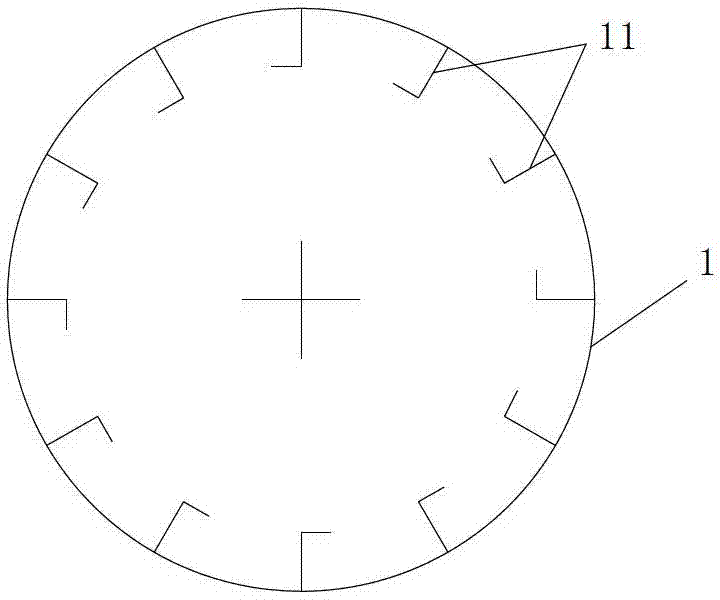

Preparation method of superfine slag powder admixture

The invention discloses a preparation method of a superfine slag powder admixture and relates to superfine slag powder. The preparation method of the superfine slag powder admixture can overcome disadvantages of the existing independent powder milling process. A dryer is adopted to dry slag; water content of the dried slag is controlled within 0.5-1.0%; a flap valve is arranged at a feed port of the dryer; the front part and the rear part of the dryer are sealed by labyrinth seal rings; a barrel of the dryer is provided with a thermal insulation layer; raising plates of the dryer are L-shaped and are centripetally and uniformly distributed; the number of the raising plates is 10-16 generally; a de-ironing separator is adopted to remove iron impurities from the dried slag; the slag is then fed into a ball mill for powder milling; and the superfine slag powder admixture is obtained.

Owner:厦门市易亨利工贸有限公司

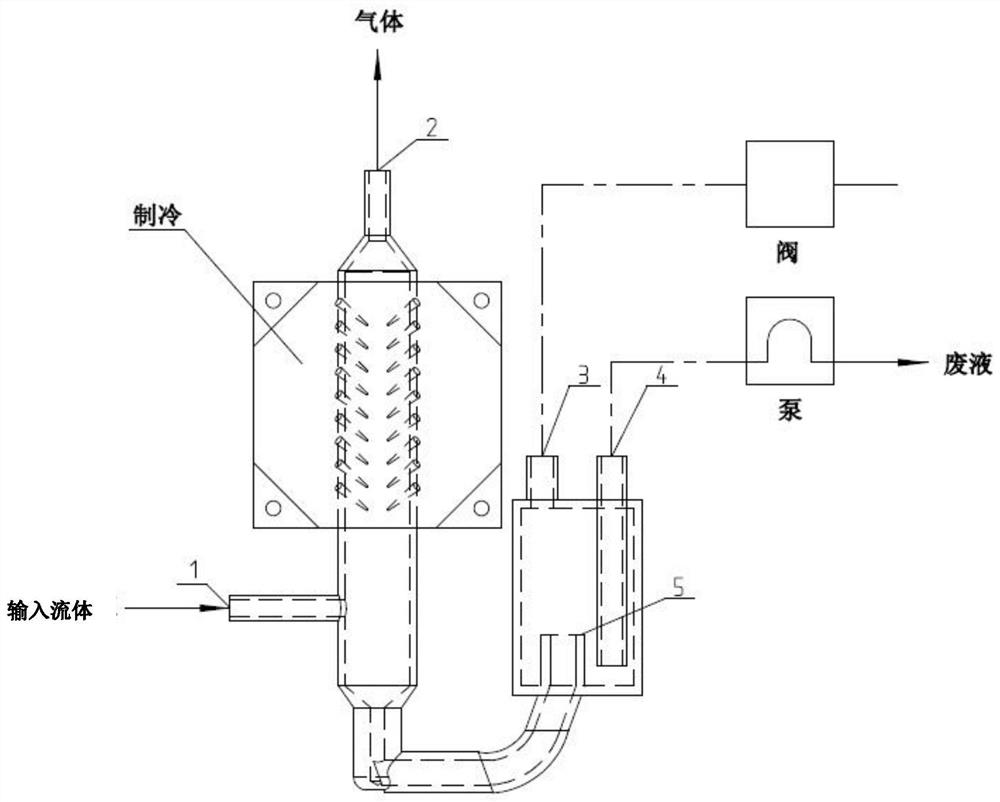

Gas-liquid separation device and gas-liquid separation method for gas-phase molecular absorption spectrometer

PendingCN113092216AImprove separation efficiencyAvoid churnPreparing sample for investigationColor/spectral properties measurementsVapor–liquid separatorOptical spectrometer

The invention provides a gas-liquid separation device for a gas-phase molecular absorption spectrometer. The gas-liquid separation device is characterized by comprising a gas-liquid separation unit and a liquid collection unit, wherein the gas-liquid separation unit comprises a fluid input port, a gas outlet and a liquid outlet; the liquid collection unit is communicated with the liquid outlet and comprises an atmosphere regulation and control port and a waste liquid discharge port; and the atmosphere regulation and control port is communicated with the atmosphere, and a closing mechanism is arranged at the opening position of the atmosphere regulation and control port. By modifying the separation structure, the efficiency of the gas-liquid separator in the separation process is improved.

Owner:上海北裕分析仪器股份有限公司

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

ActiveCN102926356BImprove overall efficiencyGood drainage abilityArtificial water canalsMedicineDrainage canal

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

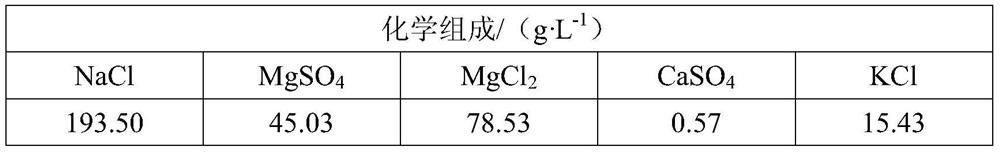

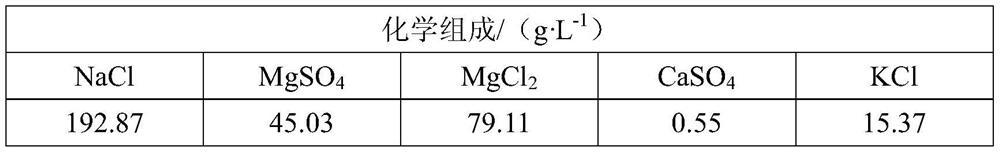

Process and system for producing refined salt by using salt production waste liquid

ActiveCN112811441AAvoid cloggingPrevent sediment cloggingAlkali metal chloridesProcess engineeringSlurry

The invention relates to the technical field of salt production, in particular to a process for producing refined salt by using salt production waste liquid. The process comprises the following steps of: (1) filtering and preheating: filtering the salt production waste liquid by using a semipermeable membrane, and preheating the waste liquid in a preheater to obtain primary waste liquid; (2) evaporation and thickening: heating and evaporating the primary waste liquid to generate secondary waste liquid with the concentration of 32-35 degrees Be'; (3) cooling and devitrifying: cooling the secondary waste liquid, and filtering to remove the secondary waste liquid to obtain crystallized salt slurry; (4) washing and devitrification: enabling crystallized salt slurry to enter a salt leaching device for saturated brine washing, enabling the washed crystallized salt slurry to enter a salt storage bin and then enter a centrifugal machine through a cyclone to dewater the washed crystallized salt slurry so as to obtain wet salt, and enabling brine mother liquor removed by the centrifugal machine to flow back to the salt leaching device; and (5) drying. By optimizing the process, the phenomena of blockage and refined salt caking in the salt manufacturing process are avoided, and the continuity and stability of salt manufacturing production are ensured.

Owner:肥城胜利盐业有限公司

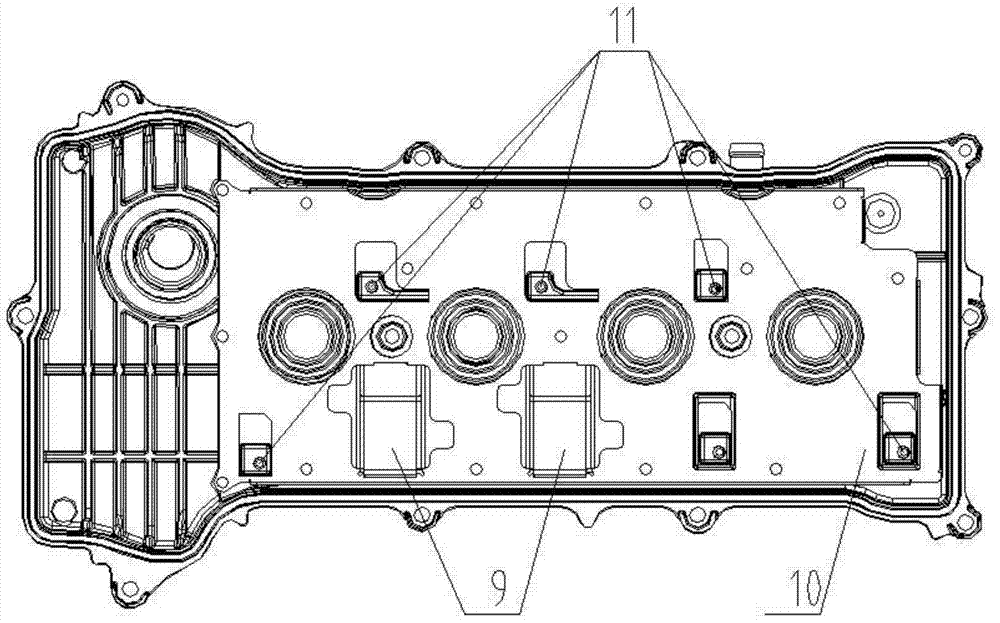

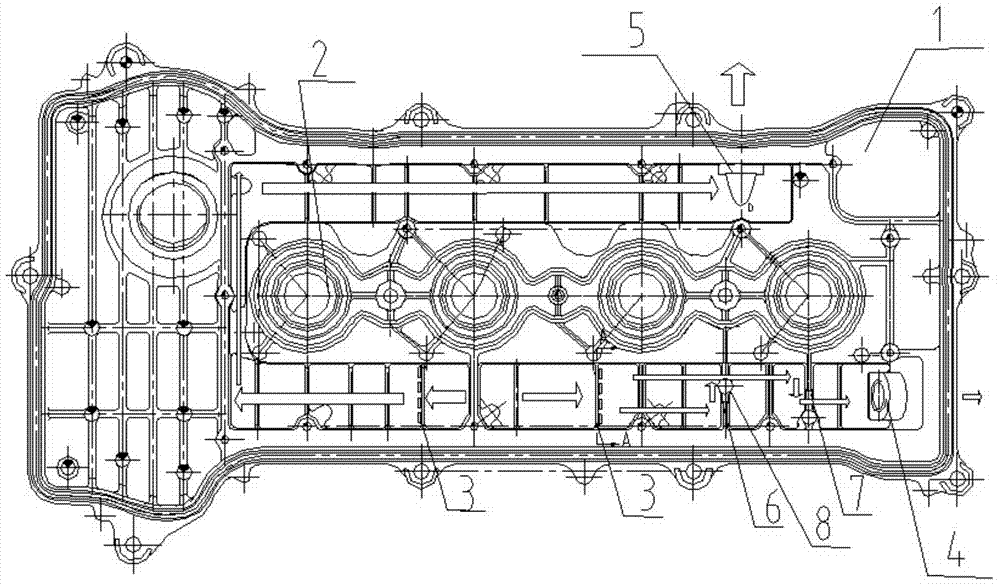

Engine oil-gas separation device with good oil-gas separation effect

InactiveCN104747252AReasonable flow rateIncrease flow rateMachines/enginesCrankcase ventillationEngineeringMixed gas

The invention discloses an engine oil-gas separation device with the good oil-gas separation effect. The engine oil-gas separation device comprises an oil-gas separation cavity, and is characterized in that an accelerating device is arranged in the oil-gas separation cavity, a through hole is formed in the accelerating device, mixed gas flows through the through hole and then enters the oil-gas separation cavity for oil-gas separation, and the through hole is a taper hole. The oil-gas separation efficiency is improved, and oil-mist separation is complete.

Owner:CHONGQING KAITE POWER SCI & TECH

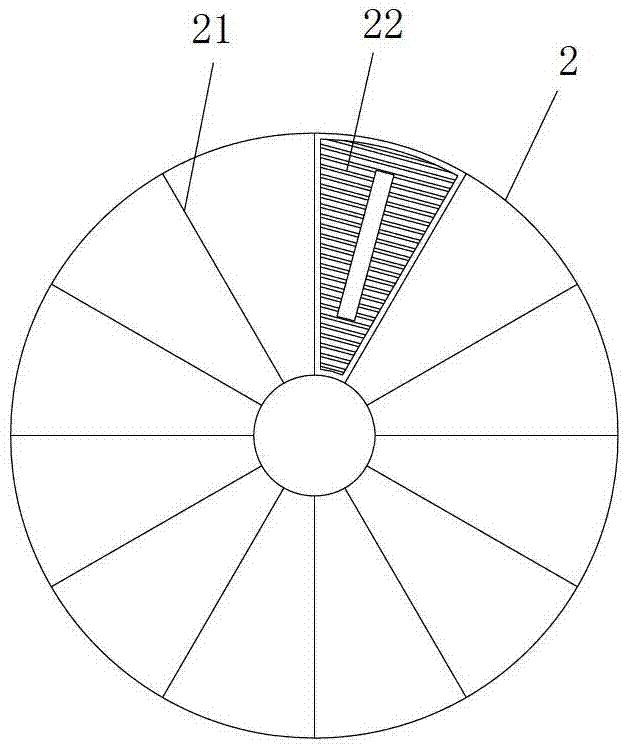

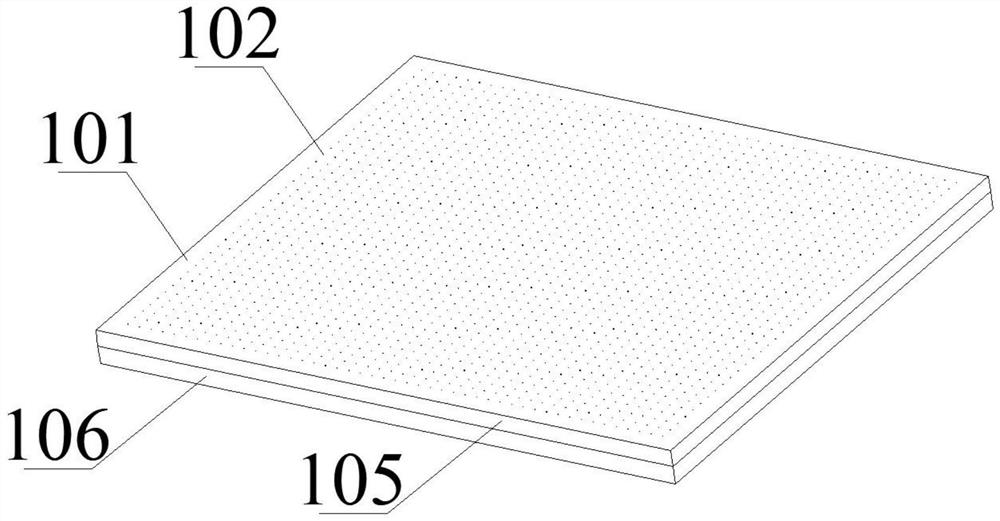

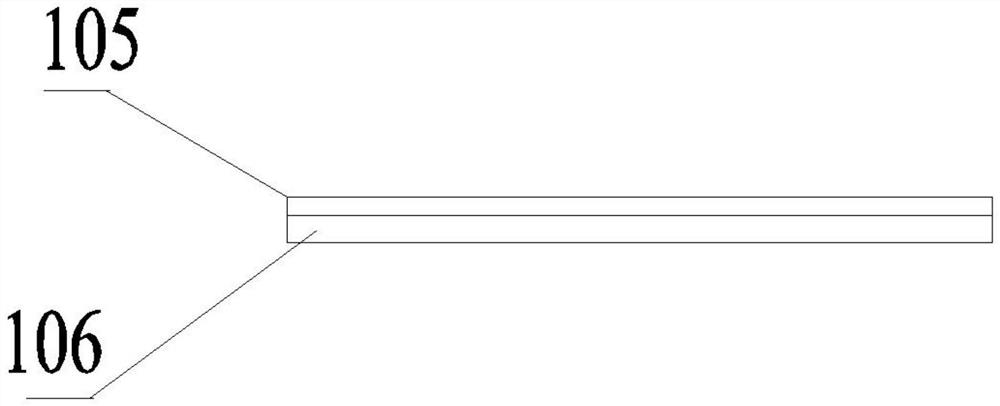

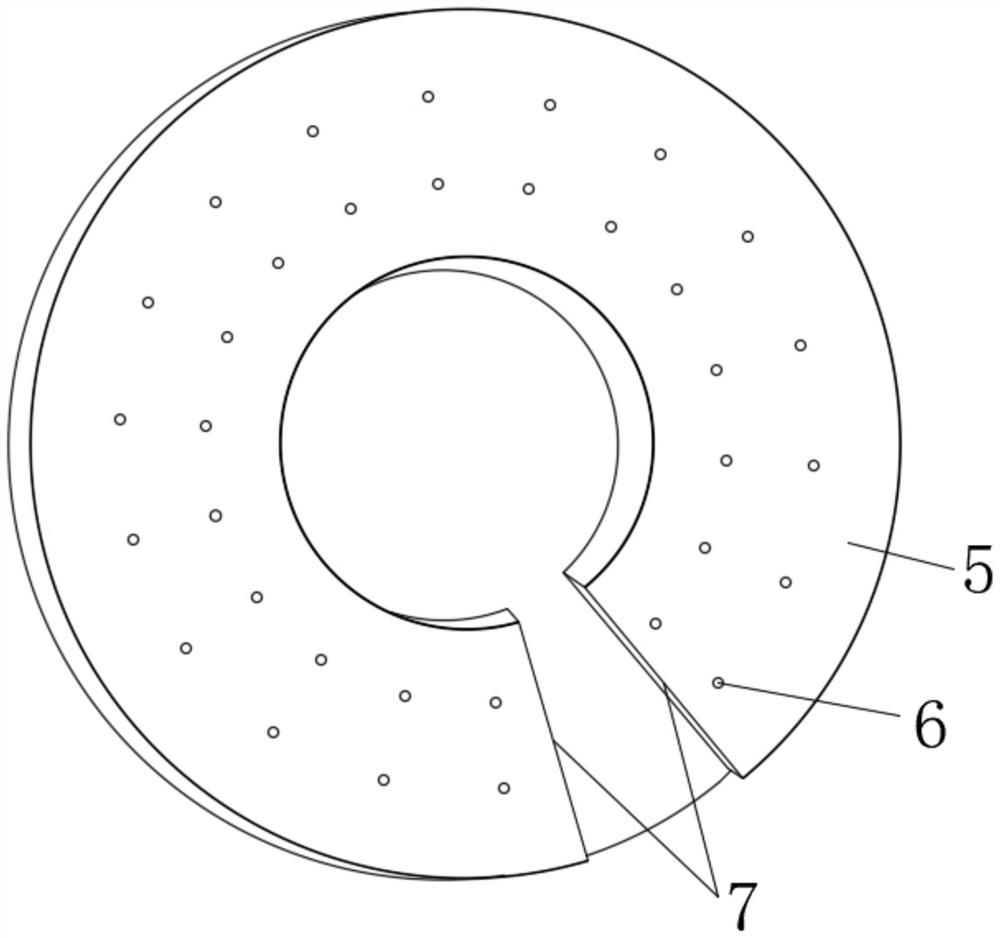

Vacuum adsorption disc, polishing machine, polishing method, full-automatic polishing machine system and full-automatic polishing method

PendingCN113385999AGuaranteed mechanical propertiesConsistent pressureGrinding feedersGrinding work supportsRobot handPolishing

The invention discloses a vacuum adsorption disc capable of being used for a polishing machine, the polishing machine with the vacuum adsorption disc, a polishing method for polishing a polishing piece, a full-automatic polishing machine system and a full-automatic polishing method using the full-automatic polishing machine system. According to the vacuum adsorption disc, the polishing machine, the polishing method, the full-automatic polishing machine system and the full-automatic polishing method, the polishing piece is adsorbed by adopting the vacuum adsorption disc, a polishing pad does not need to be adopted, feeding and discharging of the polishing piece are achieved through connection and disconnection of vacuum, an automatic feeding and discharging mechanical arm is adopted for grabbing materials, and a foundation is laid for achieving automation of glass polishing.

Owner:湖南永创机电设备有限公司

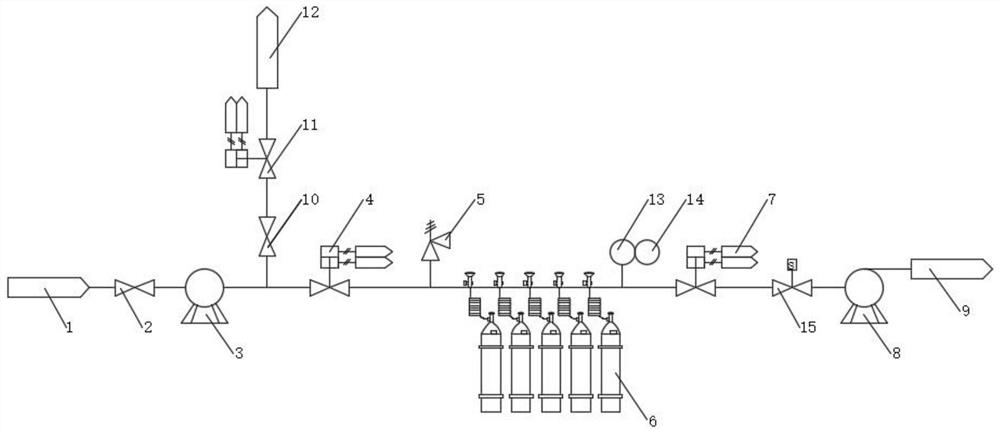

Standard gas multi-element mixing system

PendingCN113769594AAvoid corrosionExtended service lifeMixer accessoriesMixing gases with gases/vapoursThermodynamicsBusbar

The invention discloses a standard gas multi-element mixing system which comprises a first mixed gas circuit, a steel cylinder busbar, a second mixed gas circuit and an exhaust circuit, the first mixed gas circuit is communicated with the steel cylinder busbar, and a second manual stop valve, a third pneumatic stop valve, and a second exhaust port are arranged on the exhaust circuit. The arrangement mode that the second manual stop valve and the third pneumatic stop valve are matched is utilized, mixed gas is introduced into a first mixed gas path, then the mixed gas enters the first mixed gas path through a mixed gas inlet, a pipeline of the first mixed gas path is blocked through a first pneumatic stop valve, and then the third pneumatic stop valve is opened, so that mixed gas and corrosive gas are discharged together, the corrosive gas is prevented from continuously remaining in the pipeline to corrode the pipeline, and the service life of the pipeline and various components in the first mixed gas path is prolonged.

Owner:苏州晟宇气体设备有限公司

Large air-cooling steam turbo generator stator capable of improving aeration-cooling effect

ActiveCN101917074BHomogenization of temperature zonesIncrease heat loadMagnetic circuit stationary partsCooling effectEngineering

The invention discloses a large air-cooling steam turbo generator stator capable of improving aeration-cooling effect and relates to a large air-cooling steam turbo generator stator. For reducing the maximum temperature rise of an air-cooling steam turbo generator stator bar, the invention adopts the technical points that: an orifice of inner bores of iron core sections which are positioned at the two ends of a stator main body is provided with a chamfer angle (alpha) of between 60 and 75 DEG, the orifice is an axial opening close to one side of an axial midperpendicular plane of the stator main body, and the depth (C) of the chamfer angle is 6 to 12mm. The heat radiating efficiency of a motor cooling system can be effectively improved due to the adoption of the generator stator structureprovided by the invention; and under the condition of a given inlet and fixed outlet pressure, when a chamber angle scheme is adopted, experiments prove that the maximum temperature is 3 DEG C lower than that of the conventional scheme after the temperature of the generator stator structure is solved, so the temperature of the hottest section of a motor is effectively reduced, and the whole temperature area of the motor is uniformized.

Owner:HARBIN UNIV OF SCI & TECH

Horizontal pulverized coal boiler with single furnace pipe

ActiveCN112984500AIncrease flow rateLess prone to turbulenceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A horizontal pulverized coal boiler with a single furnace pipe of the present disclosure comprises a combustor, a furnace pipe assembly and a reversal chamber, wherein the combustor is arranged at one end of the furnace pipe assembly, and the reversal chamber is arranged at the other end of the furnace pipe assembly. The furnace pipe assembly comprises a combustion ring forming a combustion chamber, a furnace pipe body and a reversal ring forming a channel. The furnace pipe body comprises at least two pipe sections which are spliced to form the furnace pipe body, wherein a connecting ring groove is formed in the end face of one pipe section, an annular connecting rib matched with the connecting ring groove is arranged on the end face of the other pipe section spliced with the pipe section, and a turbulator is arranged in the furnace pipe body. According to the scheme, in the practical application process, the turbulator is arranged in the furnace pipe body and is mainly used for disturbing the flow speed of smoke in the furnace pipe body, so that the furnace pipe body has higher heat transfer efficiency, and the boiler power can be improved. The inner side walls of the pipe sections are wave-shaped, so that the circulation state of the flue gas in the furnace pipe body is further optimized, and the performance of the boiler is optimized.

Owner:HANGZHOU JUNENG BOILER

Inclined plate settling separating device

ActiveCN102225255BSolve problems that cannot be effectively separatedReasonable distribution of flow fieldUsing liquid separation agentSettling tanks feed/dischargeSlurryTower

The invention relates to an inclined plate settling separating device which comprises a tower, an inlet for ammonium sulfate slurry carrying dust, a dust deposition area, an finished product area, a finished product outlet area and a dust deposition discharge port, wherein an inclined plate separating device in the tower comprises an upper upright type inclined plate separator and a lower inclined type inclined plate separator; the upper upright type inclined plate separator is composed of an upper inclined plate component, an inclined plate supporter and an upper support grid plate; and the lower inclined type inclined plate separator is composed of a lower inclined plate component, an inclined plate supporter and a lower support grid plate. By adopting the technical scheme of the invention, the problem that a finished product cannot be separated from dust effectively is solved; the flow field distribution and flow speed of the ammonium sulfate slurry carrying dust in the separating device are reasonable; the separating speed and the de-dusting efficiency are increased; the inclined plate settling separating device is simple in shape and can be conveniently processed and assembled; and aiming at the problem that dust is gathered in a desulfurizing tower and cannot be cleared off and the stable running effect is seriously influenced, the inclined plate settling separating device can be widely applied to a process of a wet flue gas desulfurization de-dusting system and can meet the requirement of 10m<3>-550m<3> ammonium sulfate slurry de-dusting treatment.

Owner:山东华鲁恒升集团德化设计研究有限公司

A dilution water adding device and method for adjusting paper banner quantitative

InactiveCN105755886BGuaranteed performanceAvoid cross flowMachine wet endWater channelComputer module

The invention discloses a dilution water addition device and method for adjusting cross-direction paper basis weight.The device comprises a headbox, a dilution water header pipe, dilution water branch pipes and a concentration adjusting module; pulp distributing branch pipes are arranged in the headbox in a multi-column and side-by-side mode, the concentration adjusting module is arranged above the pulp distributing branch pipes and internally provided with multiple dilution water channels, and each dilution water channel is located above the corresponding column of pulp distributing branch pipes; multiple dilution water branch pipes are distributed on the dilution water header pipe, each dilution water branch pipe is communicated with a pulp distributing header pipe through the corresponding dilution water channel, and the flow direction of dilution water in each dilution water channel is opposite to that of pulp in the corresponding pulp distributing branch pipe.The method comprises the steps that the dilution water provided by the dilution water header pipe is distributed through the dilution water branch pipes and then enters the pulp distributing header pipe through the dilution water channels, and the dilution water is sent out by the pulp distributing branch pipes after being mixed with the pulp which is about to enter the pulp distributing branch pipes.By means of the dilution water addition device and method for adjusting the cross-direction paper basis weight, addition of the dilution water does not affect the outlet flow rates of the pulp distributing branch pipes, and the transverse flow phenomenon is effectively avoided.

Owner:SOUTH CHINA UNIV OF TECH

An air-cooled slag drying machine slag sensible heat recovery system

ActiveCN107741021BAvoid enteringPrevent returnIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

Jet flow drainage energy-saving water pump

InactiveCN107366641AStrong link structureGood drainageJet pumpsMachines/enginesInternal pressureEngineering

The invention discloses a jet flow drainage energy-saving water pump. The jet flow drainage energy-saving water pump comprises a water pump body. The top of the water pump body is connected with a water inlet, and the water inlet is detachably arranged on the water pump body. A connection plate is transversely arranged at the position, close to an inner top face, inside the water pump body. The two ends of the connection plate are fixed to the water pump body, the connection plate is provided with a jet device, the jet device is fixed to the connection plate, the bottom of the jet device is connected with a diffuser pipe, the top of the diffuser pipe is connected with the jet device, the bottom of the diffuser pipe is connected with an electric pump, the electric pump is connected with an inner bottom face of the water pump body through an installation base, a drainage plate is arranged on the side face of the installation base, and the drainage plate is vertically provided with a fluid plate. The jet flow drainage energy-saving water pump saves energy and is environmentally friendly, high in connection structure and capable of effectively conducting control operation through the electric pump, the internal pressure can be increased better, the drainage effect is better, the flow speed is reasonable, and the situation that relatively large impact force is generated through the too large flow speed cannot occur.

Owner:陈刚

Cementing buffer

The invention relates to a well cementation buffer and belongs to the field of petroleum machinery. The well cementation buffer comprises a casing communicated with a pipe string and a first buffer component arranged in the casing and provided with a first overflowing hole. At least one additional buffer component is arranged on the downstream of a baffle along the fluid flowing direction, an additional overflowing hole is arranged on the additional buffer component, and a curve fluid flowing channel is formed in the buffer. By means of the well cementation buffer, flowing speed of cement slurry can be reduced remarkably, protection of a well cementation tool on the lower portion of the buffer is achieved, and annulus blocking probability can be reduced remarkably.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wine-making condensation water-saving device

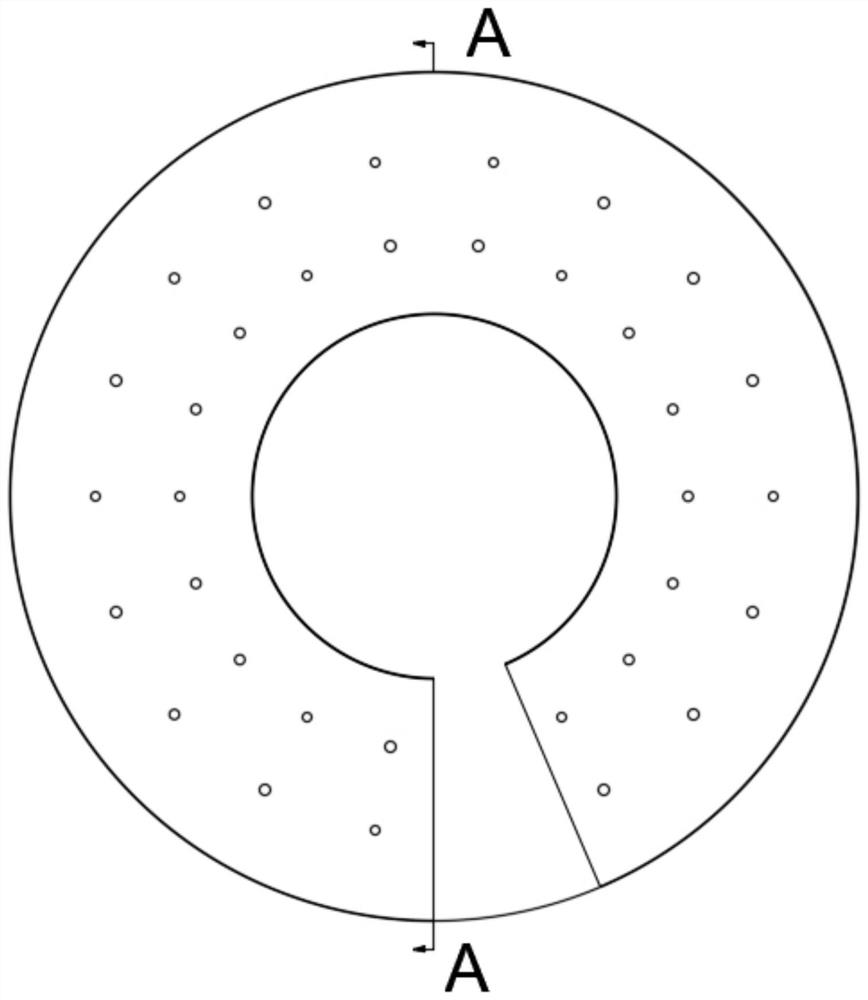

PendingCN112797812AThe overall structure is simple and reliableReasonable flow rateAlcoholic beverage preparationSteam/vapor condensersWater savingSteam condensation

The invention relates to a wine-making condensation water-saving device, and belongs to the technical field of liquor steam condensation devices in a liquor production process. The device comprises a cooler and a cooling barrel, wherein a cooling water inlet pipe is mounted at the lower end of the cooling barrel, an overflow opening is formed in the upper end of the side wall of the cooling barrel, the cooler is mounted inside the cooling barrel, a liquor steam butt-joint opening is connected to the upper end of the cooler, a liquor receiving pipe is connected to the lower end of the cooler, a water spraying disc is further mounted inside the cooling barrel, the water spraying disc is mounted below the cooler, a water inlet of the water spraying disc is connected to the water outlet end of the cooling water inlet pipe, and the water spraying disc is provided with a plurality of water outlet holes distributed annularly. According to the device, cooling water firstly passes through the water spraying disc and then is evenly sprayed out through the water outlet holes of the water spraying disc, the condensation effect can be fully guaranteed, then the heat exchange efficiency is improved, and water resources are saved. In addition, the water spraying disc is simple and reliable in structure and low in manufacturing cost and maintenance cost.

Owner:四川绵竹剑南春酒厂有限公司

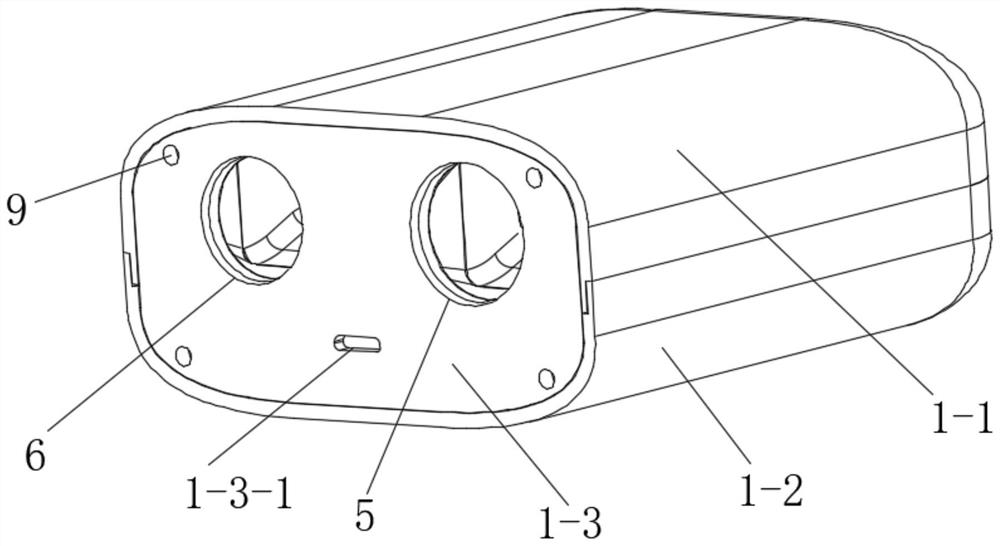

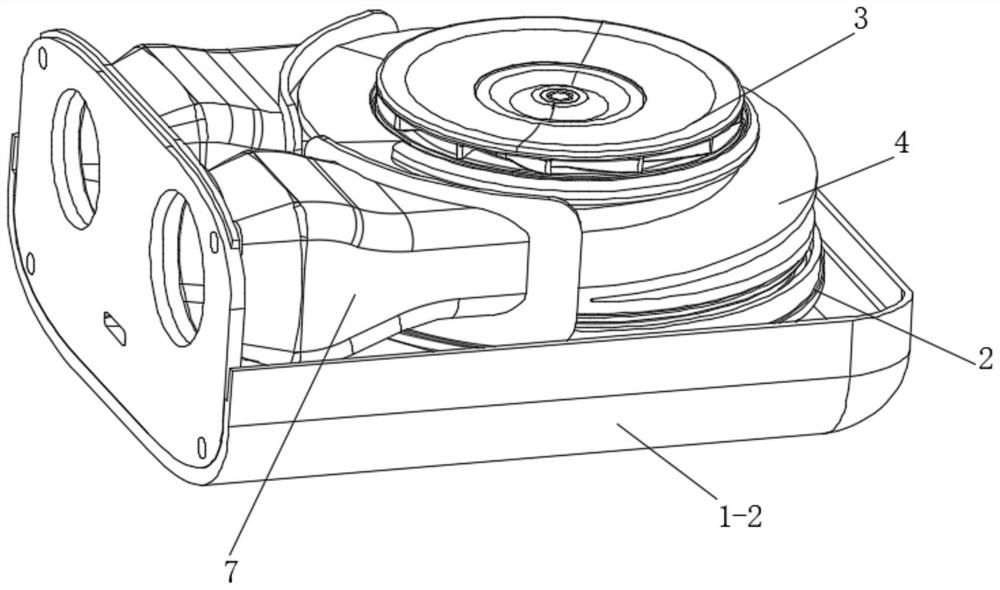

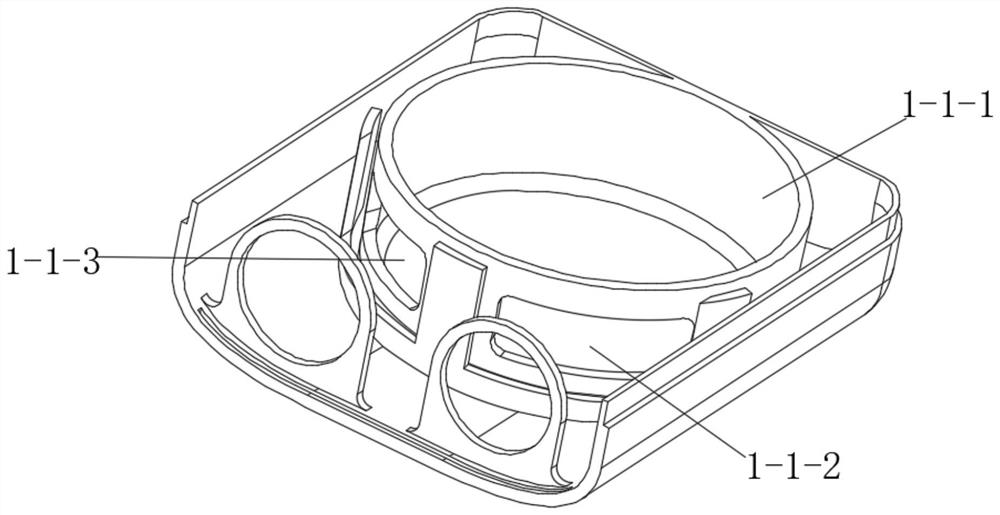

Air source device and portable breathing machine

PendingCN114776610AReduce noisePromote the development of miniaturizationRespiratorsPump componentsElectric machineryEngineering

The invention discloses an air source device and a portable breathing machine, an air source assembly comprises a shell assembly and a motor assembly arranged in the shell assembly, an impeller assembly is fixedly installed at the output end of the motor assembly, an air duct assembly is arranged between the impeller assembly and the motor assembly, the air duct assembly is coaxially and fixedly installed on the motor assembly, and the air duct assembly is fixedly installed on the shell assembly. A gap is formed between the impeller and the impeller assembly; a first airflow channel and a second airflow channel which communicate with the impeller assembly are formed between the air duct assembly and the shell assembly, and an inlet of the first airflow channel and an outlet of the second airflow channel are distributed in the circumferential direction of the air duct assembly. The shell assembly is provided with an air source inlet and an air source outlet which are communicated with an inlet of the first airflow channel and an outlet of the second airflow channel respectively. The internal structure is highly integrated, miniaturization development of breathing machine equipment is better facilitated, meanwhile, through structural optimization, the air inlet direction and the air outlet direction are located on the same plane, and meanwhile air duct noise is greatly reduced.

Owner:杭州贝丰科技股份有限公司 +1

Bioreactor

PendingCN113564049AAvoid harmSolve technical problems that cannot surviveBioreactor/fermenter combinationsBiological substance pretreatmentsThermodynamicsEngineering

The invention provides a bioreactor, which comprises a culture tank, an air extraction component and a gas heating component, wherein the culture tank is provided with an air outlet and an air inlet; the air extraction component communicates with the air outlet of the culture tank, and the air extraction component is configured to be capable of extracting gas in the culture tank; and one end of the gas heating component communicates with the gas extraction component, the gas extraction component can convey the gas in the culture tank to the gas heating component, and the other end of the gas heating component communicates with the gas inlet of the culture tank. the gas extraction component sucks air in the culture tank from the air outlet of the culture tank and conveys the air in the culture tank to the gas heating component, the gas heating component conveys the gas at a specific temperature set by a user into the culture tank through the air inlet of the culture tank, and therefore, oxygen and other gases at the top of the culture tank can be fully dissolved in a culture solution at the bottom of the culture tank to promote absorption of cells. In addition, the gas heating component can heat the air to a proper temperature and then send the air into the culture tank, and the preheating time of liquid in the culture tank is shorter.

Owner:南京海创佳生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com