Cementing buffer

A buffer and cementing technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of casing retaining cement plugs, inability to effectively reduce the falling speed of cement slurry, and return of cement slurry, etc. problem, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

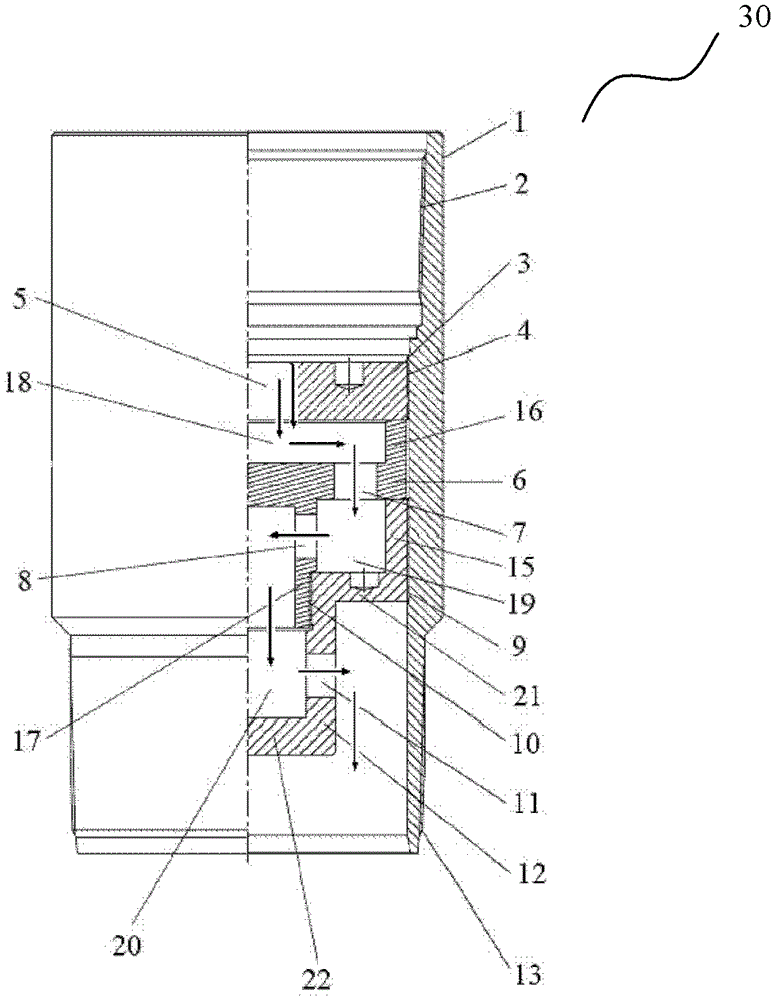

[0027] figure 1 A cementing buffer 30 according to the invention is schematically shown. Such as figure 1 As shown, the cementing buffer 30 includes a casing 1 . Threads are provided at both ends of the housing 1 so as to be connected with adjacent pipe strings (not shown). exist figure 1 In the illustrated embodiment, an internal thread 2 is provided on the inside of the first end of the housing 1 and an external thread 13 is provided on the outside of the second end of the housing 1 .

[0028] A first buffer component is arranged inside the housing 1, such as figure 1 The baffle shown in 3. A first flow hole 5 is arranged on the baffle plate 3 to receive the fluid entering the well. In a preferred embodiment, the first flow hole 5 is arranged at the center of the baffle 3 . The baffle 3 is fixedly connected with the housing 1 . In one embodiment, threads are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com