A kind of biological filler for strengthening the adsorption of phosphorus and its preparation method and use

A biological filler and phosphorus adsorption technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems affecting the treatment effect, investment cost and operating cost, etc. Low cost and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the preparation method of the present invention, the adsorptive properties of diatomite are innovatively used, and when the marble is foamed with glass, the biofiller produced not only has the characteristics of the filler itself, but also has good adsorption of phosphorus in water. This effect. This is an improvement over biological fillers and provides new application areas for cellular glass. Phosphorus removal by adsorption method is to use the adsorption affinity of some porous or large specific surface solid substances to phosphate ions in water to realize the process of phosphorus removal from wastewater.

[0038] The diatomite used in the present invention is common siliceous ore; the glass used can be discarded flat glass, embossed glass, bottle glass or cathode ray tube glass, etc. for recycling. Borax is used as a flux, which can increase the foaming temperature range and make the sample foam in a larger temperature range; improve the pore structure, make...

Embodiment 1

[0040] The waste glass and marble are ground to more than 200 mesh, and 18g of glass powder and 2g of marble powder are mixed to obtain a powder batch material, which is used to prepare biological filler through foaming and annealing treatment. Waste glass can be discarded flat glass, patterned glass, bottle glass or cathode ray tube glass, etc. The specific preparation method of biological filler is:

[0041] The powder batch prepared above is piled into the mold in the box-type resistance furnace, and the powder batch is rapidly cooled in the box-type resistance furnace after preheating, heating and foaming to obtain sintered foam heating Then take the sintered and foamed heating material out of the resistance furnace and cool it naturally to room temperature to obtain the biological filler with adsorption effect. The specific temperature control is as follows: from room temperature to 500 °C at a heating rate of 15 °C / min, Insulate for 30 minutes; then heat up to 1000°C at...

Embodiment 2

[0052] Grind waste glass, marble, borax and sodium phosphate dodecahydrate to more than 200 meshes, get 18g glass powder, 2g marble powder, 0.5g borax powder and 0.5g sodium phosphate dodecahydrate powder to mix to obtain powder batch material, use The biological filler is prepared by foaming and annealing. The specific preparation method of the biological filler is the same as that of Example 1, but there are differences in the specific temperature control.

[0053] In this embodiment, the temperature control is as follows: from room temperature to 400°C at a heating rate of 10°C / min, and keep warm for 20 minutes; The cooling rate is to reduce the temperature to 800° C., and finally cool naturally to normal temperature to obtain the biological filler. The basic physical and chemical properties of the filler obtained by sintering are roughly the same as those in Example 1.

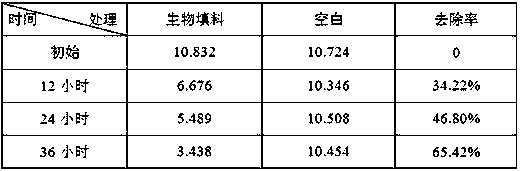

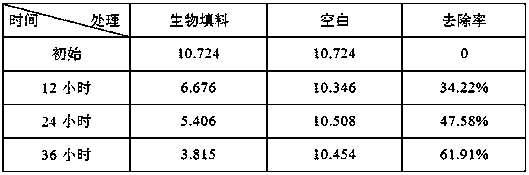

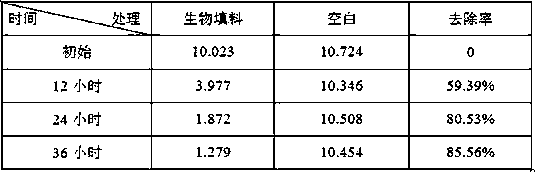

[0054] Also verify the adsorption effect of the biofiller prepared in this example according to the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com