Patents

Literature

88results about How to "Good fluidization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

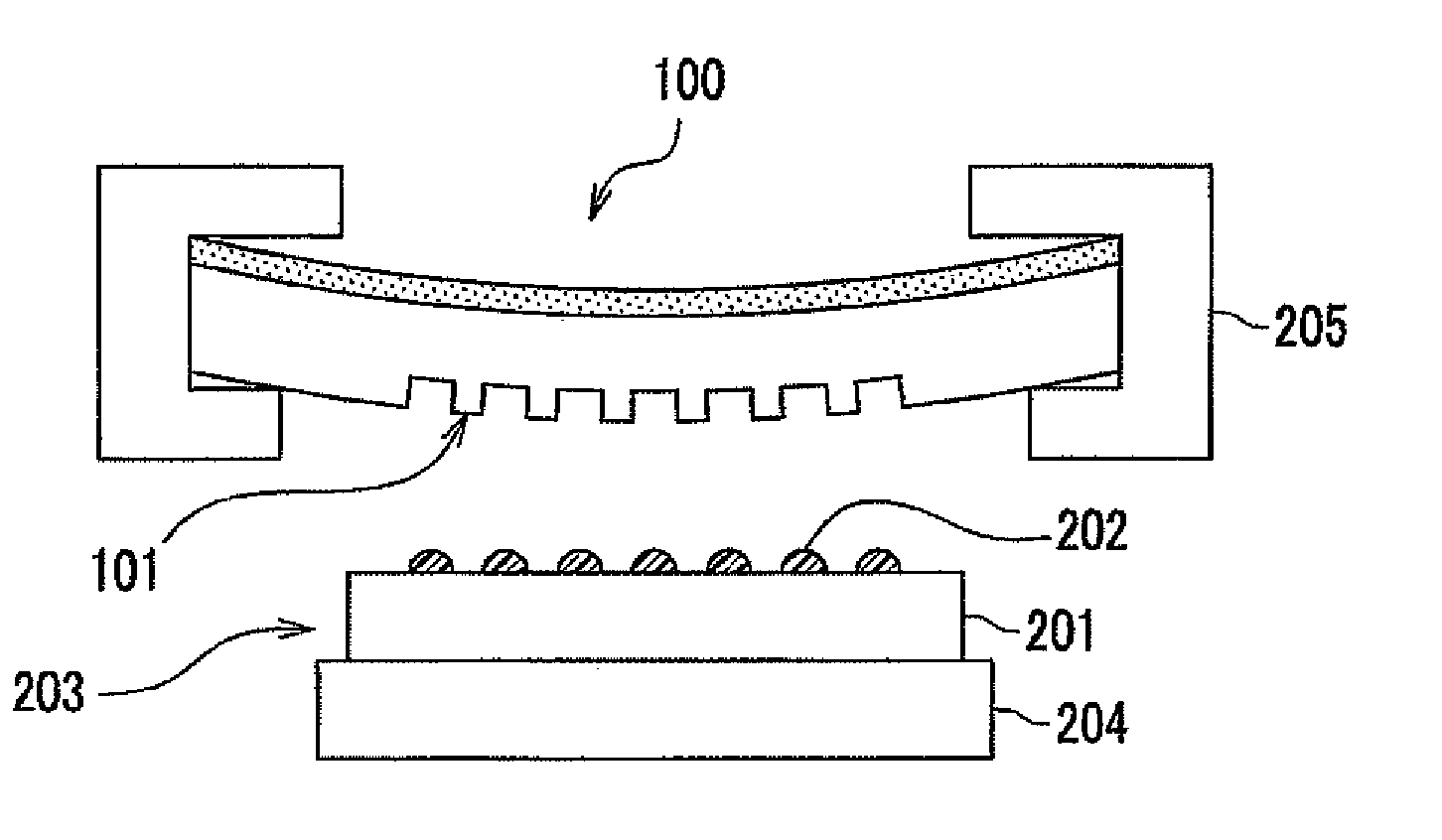

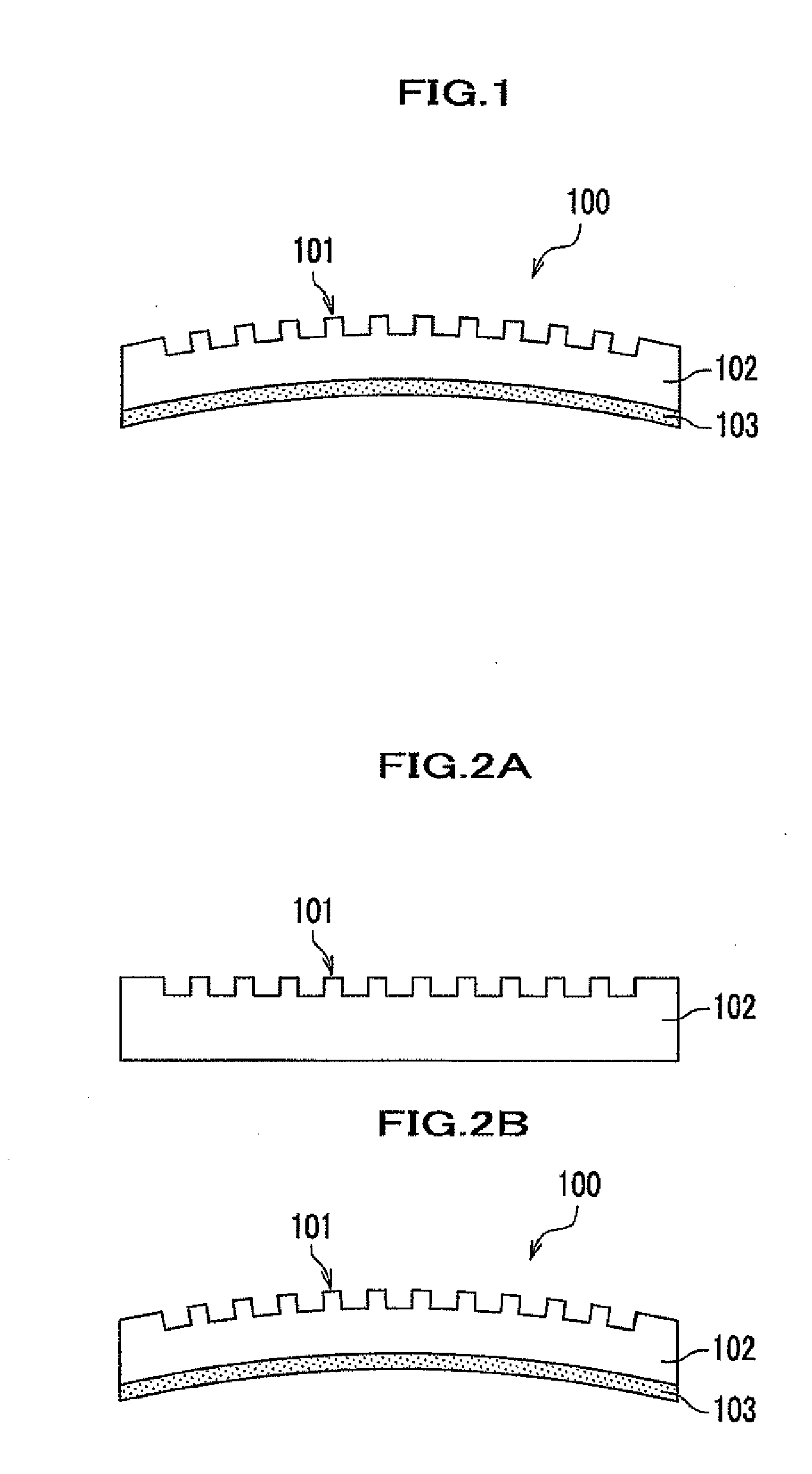

Stamper for minute structure transfer and a method for manufacturing the same

InactiveUS20100062098A1Increased durabilityGood fluidization effectDecorative surface effectsOrnamental structuresMetallurgyInternal stress

The present invention can provide a stamper for minute structure transfer to be excellent in durability. The present invention is characterized by which a minute pattern as formed in one side of a substrate comes in contact with a material to be transferred and the minute pattern is transferred on a resin layer of a surface of the material to be transferred. At least one layer of a thin film is mounted on at least one side of both surfaces of the substrate, the substrate and the thin film are different in a coefficient of linear expansion each other, and the substrate is curved to swell up to be convex in the side of the minute pattern by an internal stress generated in the thin film.

Owner:HITACHI CABLE

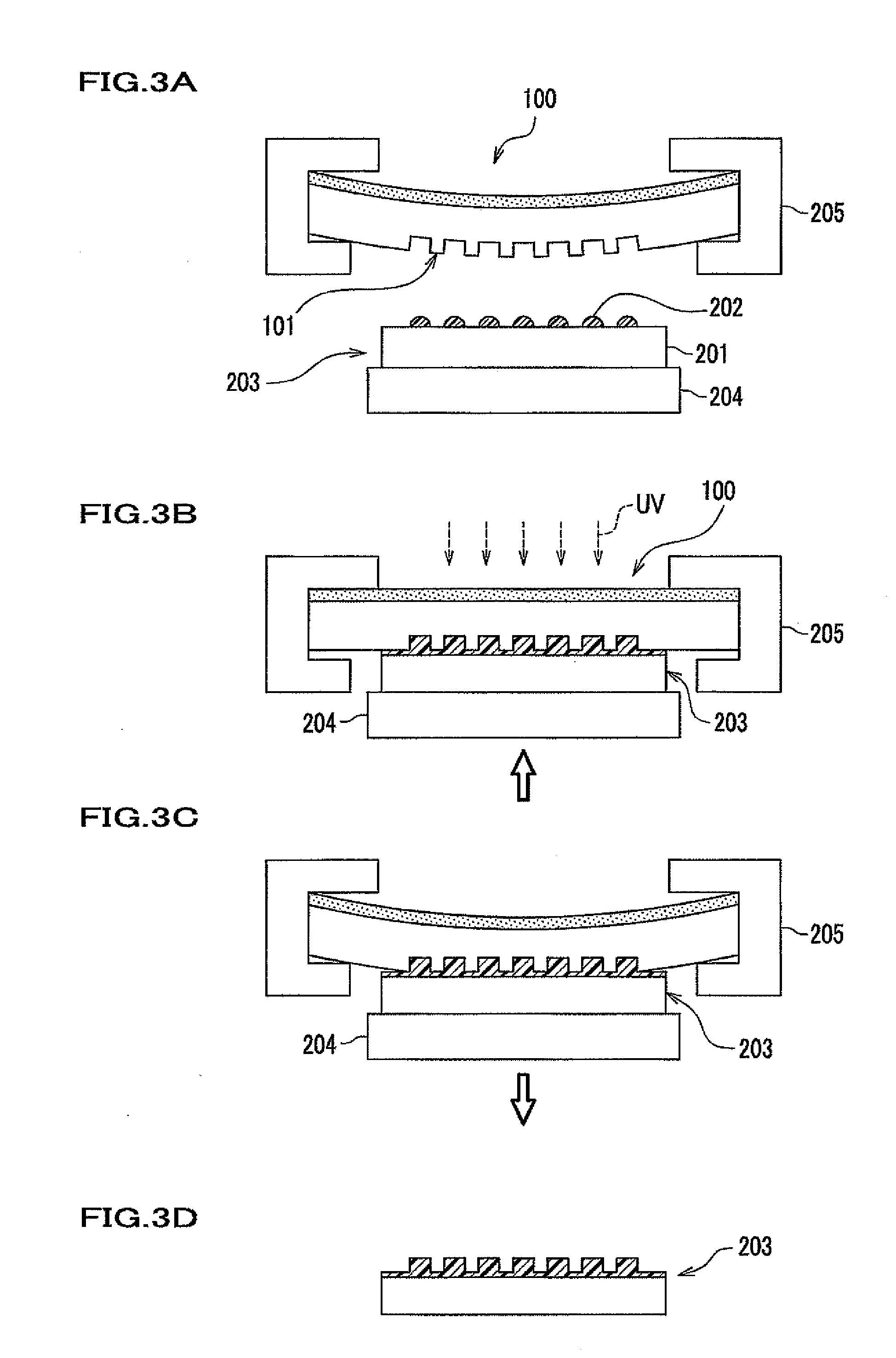

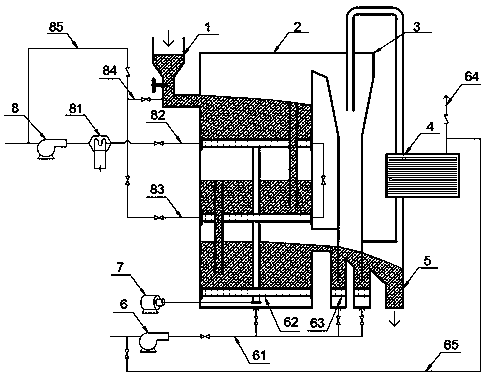

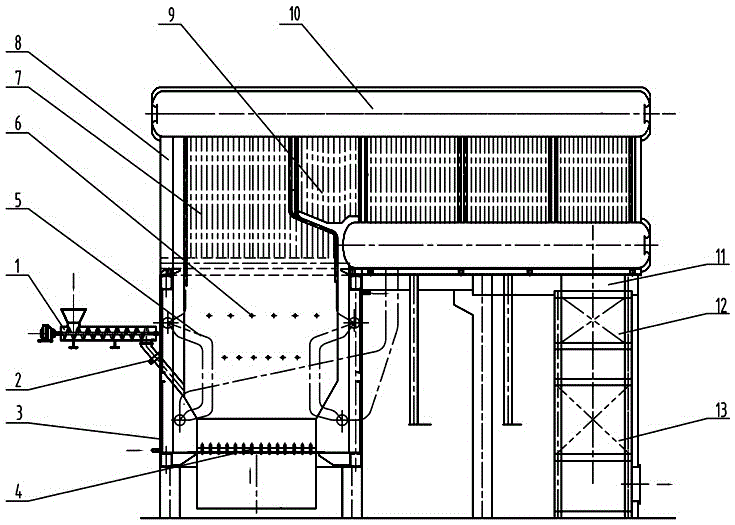

Multi-jet composite fluidized bed coal and biomass gasifier

InactiveCN1974733ARealize gasificationGood fluidization effectCombined combustion mitigationGranular/pulverulent flues gasificationFluidized bedWater vapor

The multi-jet composite fluidized bed coal and biomass gasifier consists of a fluidized bed, a synthesized gas outlet, a water vapor inlet and jet pipes. The fluidized bed consists of three parts, including the lower conic bed body, the middle expanding section and the upper expanding section, and has one cyclonic separator inside the upper expanding section. The synthesized gas outlet is in the top of the cyclonic separator. The jet pipes in the lower bed body include radial auxiliary material feeding jet pipes in two layers and main material feeding jet pipes in the center of bed body. The bed body has cinder outlet in the conic bottom and water vapor inlet beside the cinder outlet and the fluidized bed has outside heat insulating layer. The present invention has the advantages of simple structure, low cost and easy operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

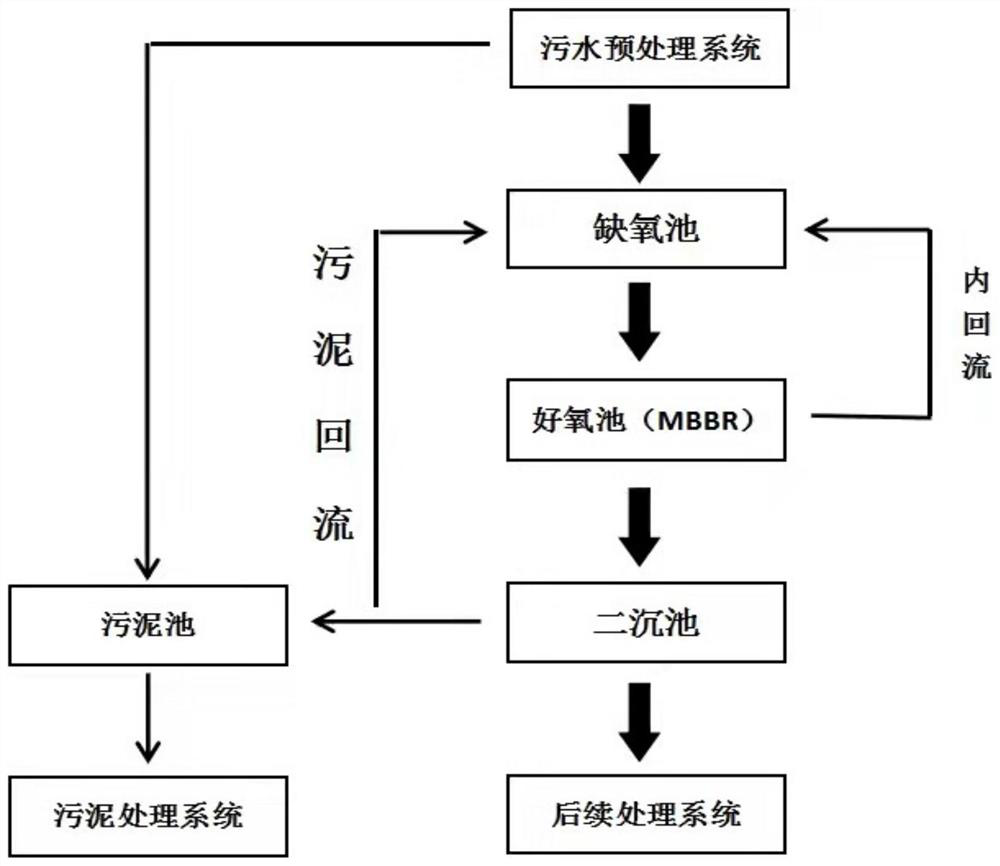

Technology of treating coking wastewater by biomembrance process

ActiveCN101597125AWater quality fluctuates greatlyGuaranteed emission standardsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAnaerobic bacteriaFiltration

The invention relates to a technology of treating coking wastewater by biomembrance process, belongs to the field of environmental protection and difficult degradable industrial wastewater treatment, is mainly used to treat coking wastewater, can also be used to treat high COD and high ammonia nitrogen industrial wastewater and can realize that COD can be removed effectively and denitrification can be carried out effectively. The reactors used by the invention comprise an anaerobic bacteria filter, an aerobic biological fluidized bed, an anoxic biofilter and a settling pond. The technology is that the pretreated coking wastewater flows through the anaerobic bacteria filter for hydrolysis acidification, the aerobic biological fluidized bed for oxidation, then the anoxic biofilter for filtration, the settling pond for removing suspended matter and the treated water generated in the settling pond is directly discharged and part of the treated water flows back to the anaerobic bacteria filter. The COD removal rate of effluent can be above 95%, and the other indexes can all reach the primary standard of the national standard (GB8978-1996) for effluent discharge. The treatment technology has higher hydraulic loading and resistance shocking and lower floor area.

Owner:UNIV OF SCI & TECH BEIJING

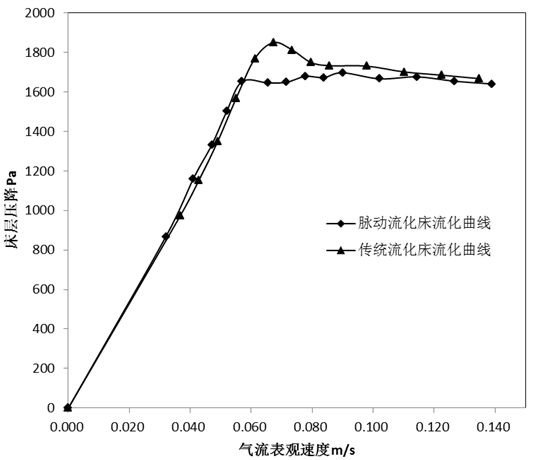

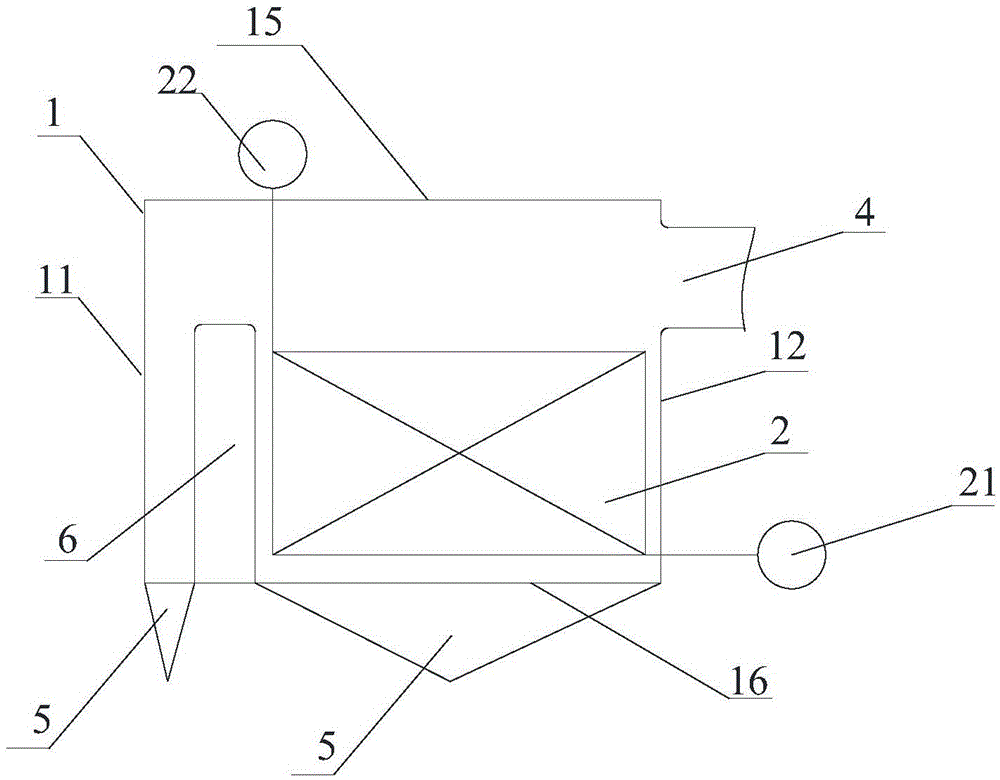

Gas-solid fluidized bed sorting machine based on pulse airflow

InactiveCN102652940AImprove uniformity and stabilitySimple structureGas current separationFluidized bedEngineering

The invention discloses a gas-solid fluidized bed sorting machine based on pulse airflow. The gas-solid fluidized bed sorting machine mainly comprises a sorting groove, an air distributing plate, a dedusting cover and a support, wherein the tail end of the sorting groove is provided with a light product material discharge wheel; the tail end of a rear air distributing chamber is provided with a rear heavy product material discharge wheel; the tail end of a front air distributing chamber is provided with a front heavy product material discharge wheel; the bottom parts of the rear air distributing chamber and the front air distributing chamber are respectively provided with a rear air tube and a front air tube; the rear air tube and the front air tube are connected with an air inlet tube through a three-way connector; and the air inlet tube is provided with a pulse airflow generator and an airflow quantity regulating valve in sequence. According to the invention, the pulse airflow is introduced into a gas-liquid fluidized bed, materials are conveyed forward relying on the oblique angle of the sorting groove and the effect of the pulse airflow; floating materials and sediment materials are respectively discharged through the light product material discharge wheel and the heavy product material discharge wheels, and the medium circulating quantity is reduced effectively; and the height of a front support leg can be adjusted, the front support leg can be used for regulating the oblique angle of the sorting groove, the regulation of coal conveying speed and sorting time can be realized.

Owner:CHINA UNIV OF MINING & TECH

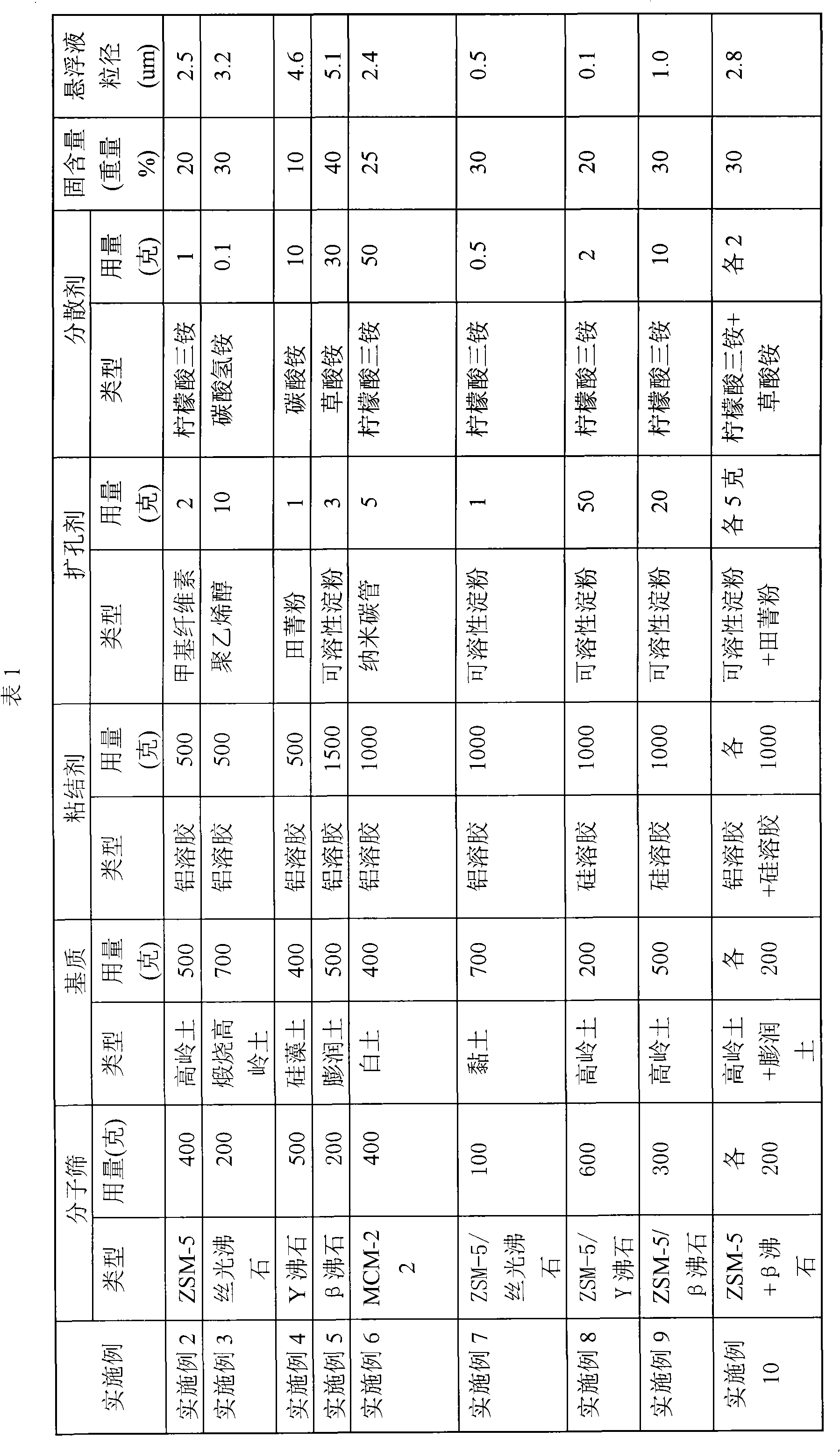

Molecular screen microspherical catalyst

The invention relates to a molecular sieve micro-balloon catalyst which mainly resolves the problem that the two indexes of macro-mole sieve capacity and good mechanic strength of catalyst can't exist at the same time. It adopts molecular sieve and adds alumina, silicon oxide and clay so that the packing density of catalyst is at 0.6-0.9 gram / milliliter which can be used in industry preparation of fixed bed, fluid bed or moved bend molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

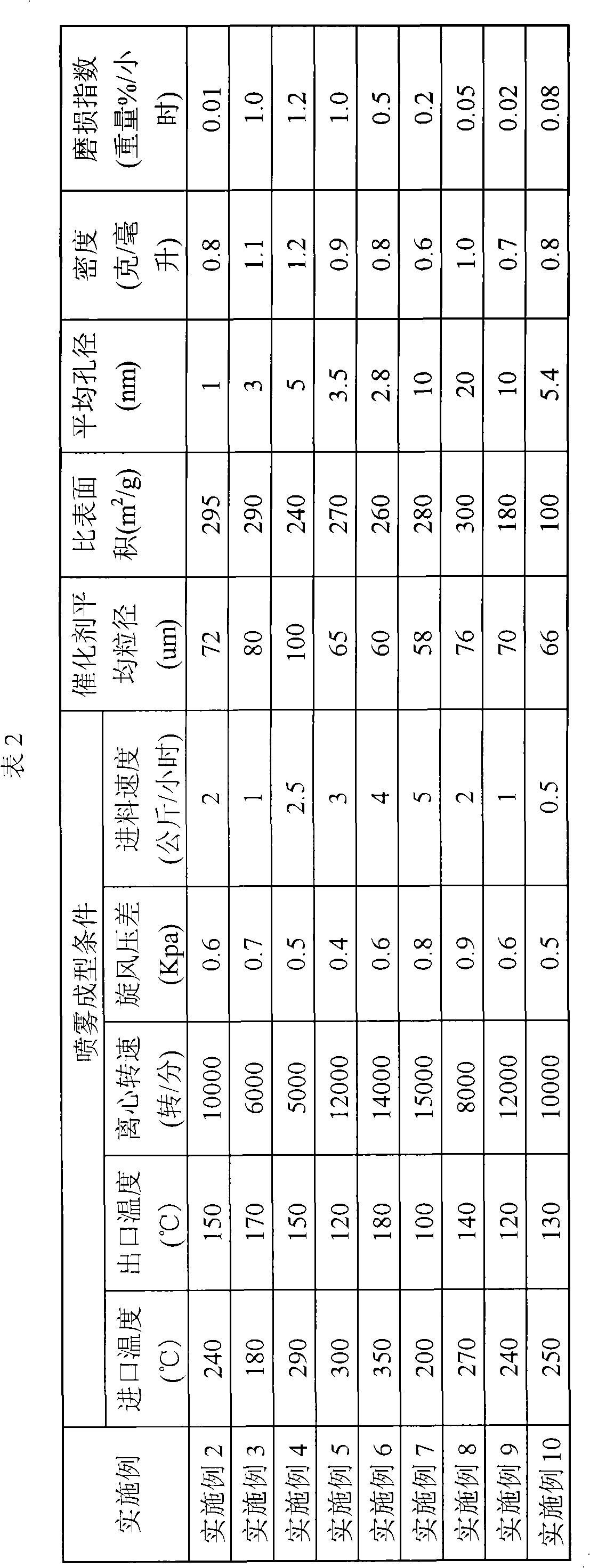

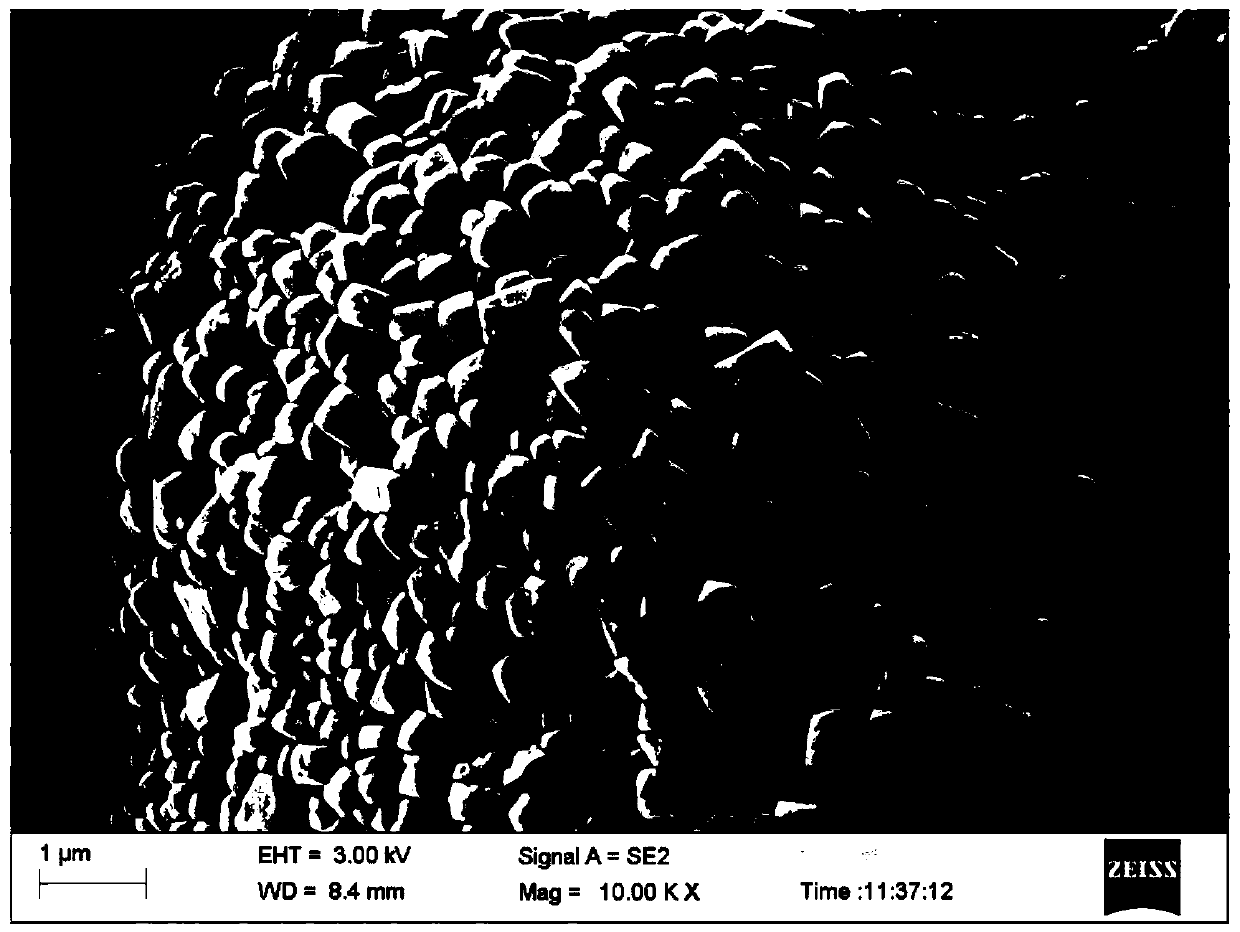

Preparation method of fluid catalyst

ActiveCN102371168AHigh activityEvenly dispersedMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCatalytic pyrolysis

The invention relates to a preparation method of a fluid catalyst, and mainly solves the problem of low wear resistance of fluid catalysts in existing technologies. The method comprises the following steps of: (a) mixing a molecular sieve, a binder, a matrix material, a pore-expanding agent, a dispersing agent and a liquid medium uniformly so as to form a suspension; (b) controlling the particle size of materials in the suspension ranging from 0.1 to 5 micrometers; (c) conducting spray drying to the suspension so as to form a microsphere catalyst; (d) roasting the microsphere catalyst, thus obtaining a finished catalyst. The technical method provided in the invention well solves the above problem, and can be used in the reaction process of carbon olefin production through light oil catalytic pyrolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

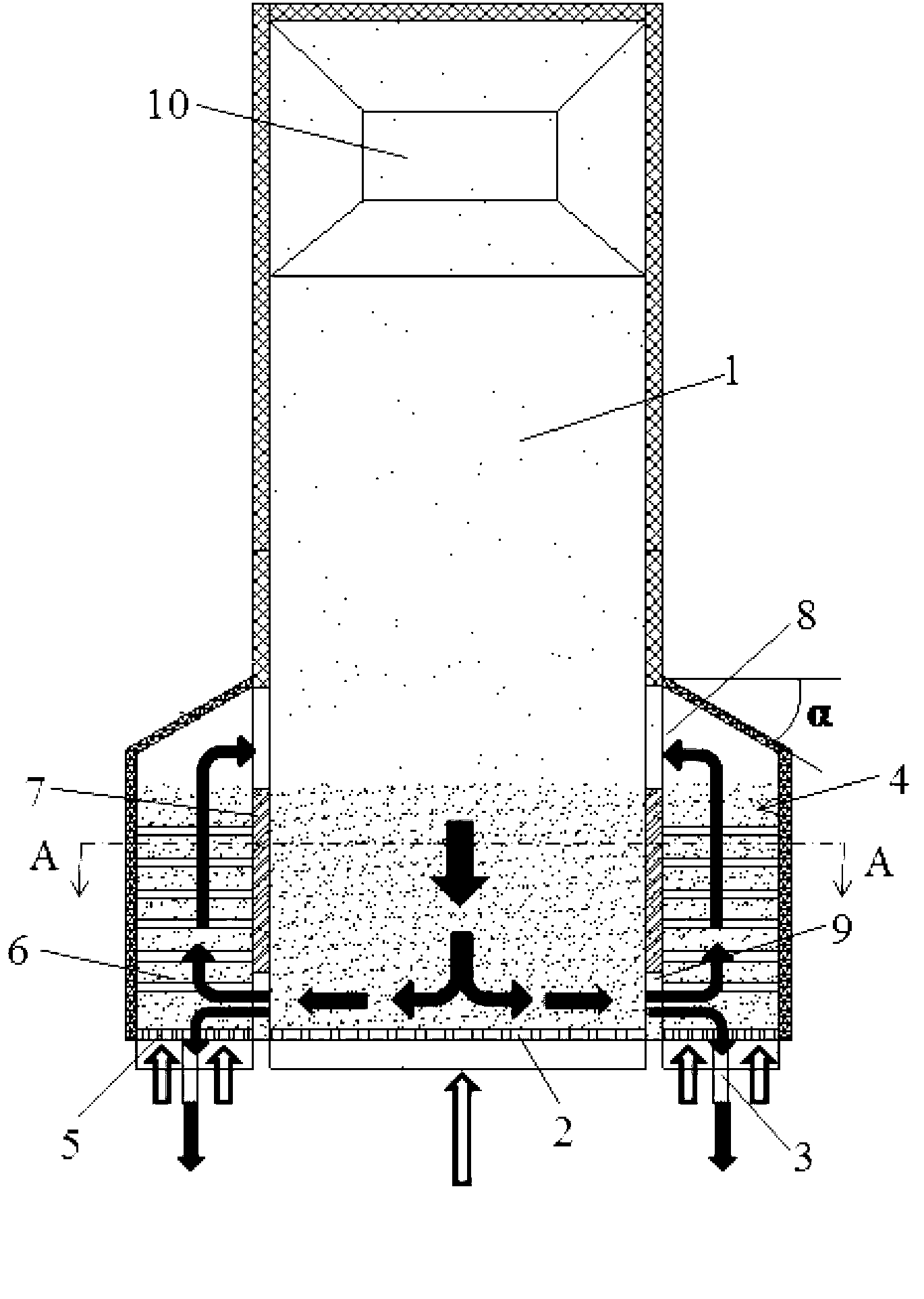

Circulating fluid bed boiler and fluidizing method using same

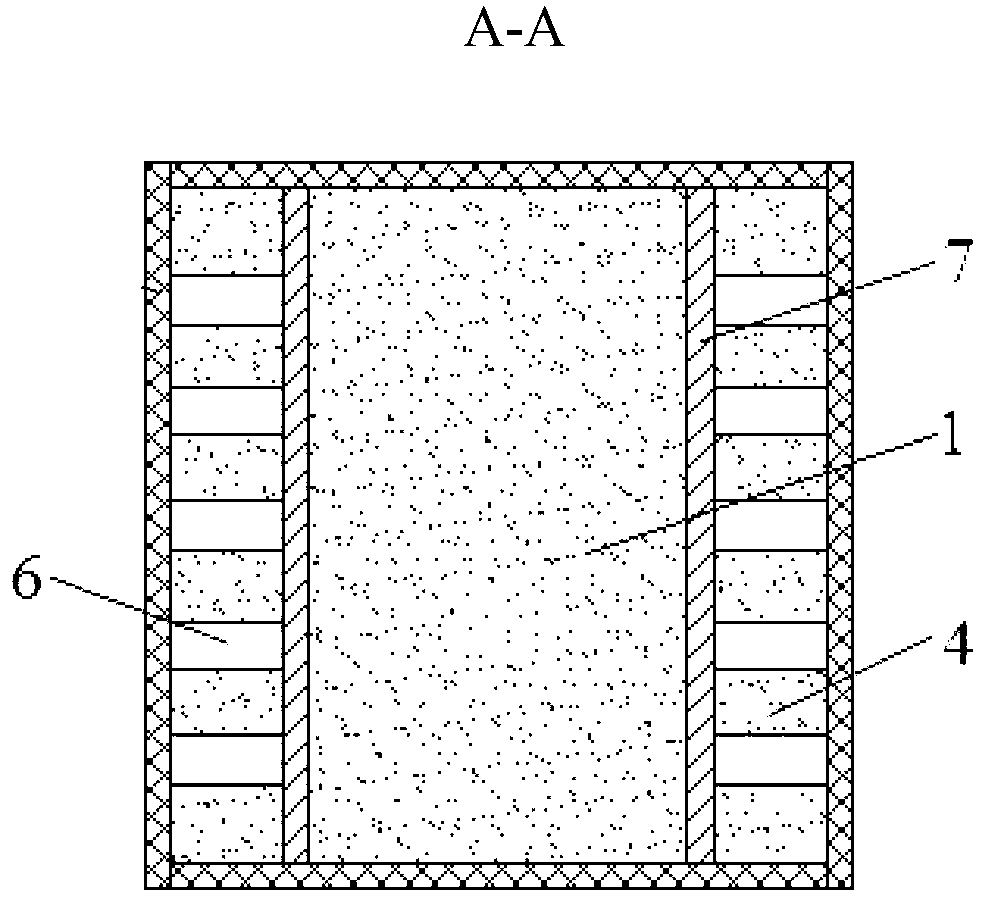

InactiveCN103292320AGood fluidization effectImprove liquidityFluidized bed combustionApparatus for fluidised bed combustionSlagEngineering

The invention discloses a circulating fluid bed boiler, which comprises a hearth (1), a first air distribution plate (2), a deslagging pipe (3) and a deslagging bed area (4), wherein the first air distribution plate and the deslagging pipe are arranged at the bottom of the hearth; the deslagging bed area (4) enables slag to be in a fluidized state and is arranged at the outer side of the lower part of the hearth (1) and communicated with the hearth (1); the deslagging pipe (3) is arranged at the bottom of the deslagging bed area (4). The invention discloses a fluidizing method using the circulating fluid bed boiler. The circulating fluid bed boiler can reduce the loss of fine bed materials when slag is discharged, the material fluidity near the deslagging pipe is good, flow dead zones do not exist, the temperature field is uniform, and the heat utilization rate is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Calcium oxide-based high-temperature CO2 adsorbent and its preparation method

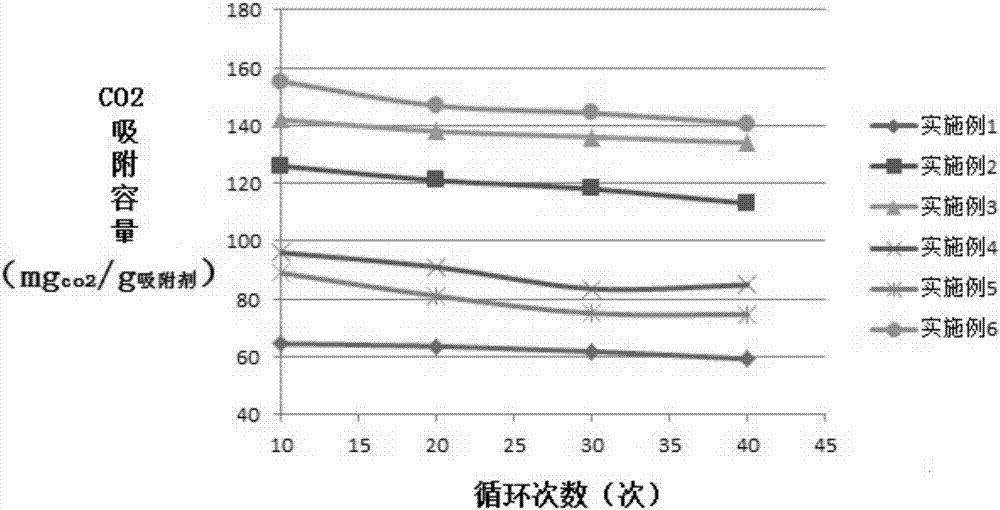

ActiveCN107376826AImprove wear resistanceImprove thermal stabilityGas treatmentOther chemical processesChemistryCo2 adsorption

The invention discloses a calcium oxide-based high-temperature CO2 adsorbent and a preparation method thereof. The adsorbent comprises a carrier M and a main active component CaO loaded on the carrier M. The carrier M is further loaded with a structural stabilizing aid A. The general formula of calcium oxide-based high-temperature CO2 adsorbent is <x>CaO.A.<100-x-a>M, wherein x is the mass percentage of CaO; a is the mass percentage of A; x is no less than 5% and no more than 60%; and a is no less than 0.1% and no more than 50%. The calcium oxide-based high-temperature CO2 adsorbent in the invention has high wear resistance, high thermal stability and high activity; the adsorbent loses no more than 20% of CO2 adsorption capacity after 40 adsorption-desorption cycles and has a wear rate is 0.1 to 1 wt% / h; the adsorbent can be prepared by using individual impregnation solutions or a mixed impregnation solution; and the preparation method provided by the invention is simple in process, free of production of waste water, friendly to environment, easy to repeat and especially suitable for large-scale industrial production and application.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

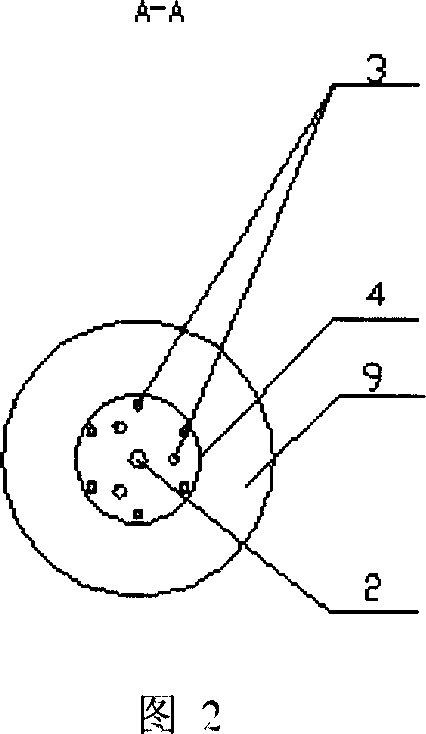

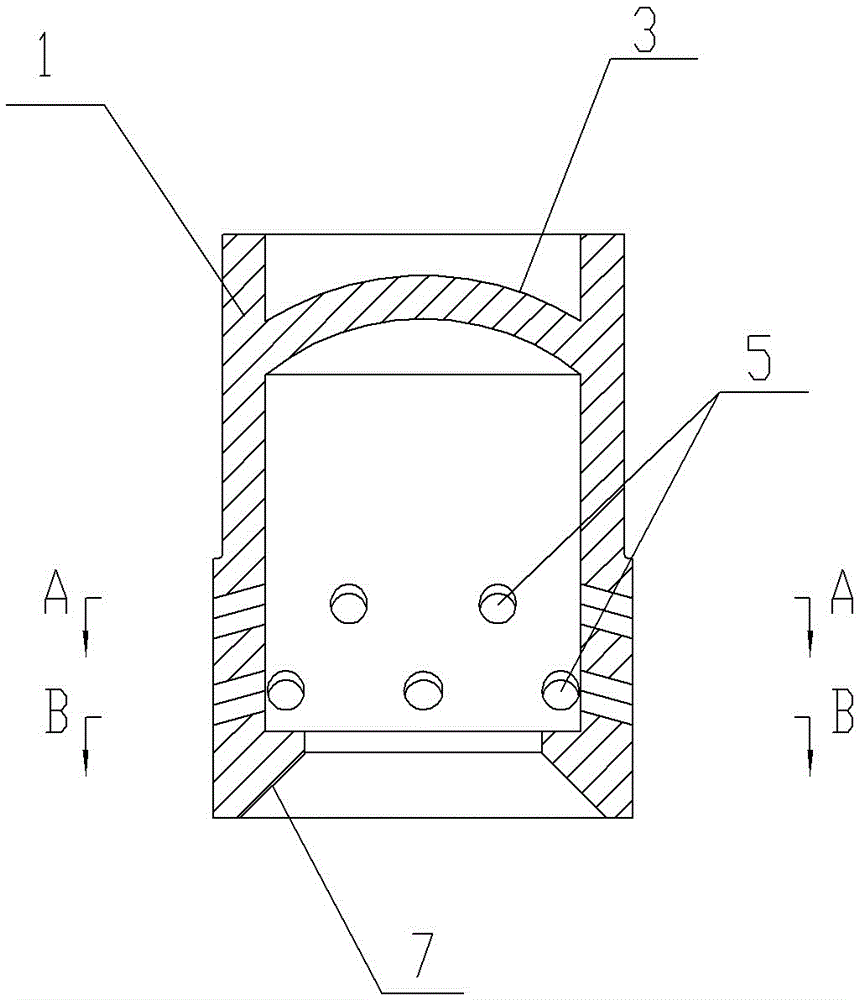

Gas distributor for ash agglomerating fluidized-bed gasification furnace

InactiveCN102827644AAvoid scour wearAvoid Vibration FractureGranular/pulverulent flues gasificationFluidized bed gasifierEngineering

The invention provides a gas distributor for an ash agglomerating fluidized-bed gasification furnace. The gas distributor comprises a gasification furnace shell, a tapered distribution plate, at least three distributed injection pipes, a slagging pipe and a gas inlet pipe of a gas chamber, wherein one end of the slagging pipe is connected to the bottom of the tapered distribution plate, and is open, and the other end of the slagging pipe penetrates through the gasification furnace shell, and is connected with a gasification agent gas source. The gas distributor is characterized in that one end of each distributed injection pipe is connected to the lower part of the tapered distribution plate, and is open, and the other end of each distributed injection pipe penetrates through the gasification furnace shell, and is connected with the gasification agent gas source; and openings of the distributed injection pipes in the tapered distribution plate are symmetrically and uniformly distributed about the center of the slagging pipe. The gas distributor is high in fluidization performance, adapted to long-cycle running, simple in structure and applicable to a large-sized fluidized-bed gasification furnace.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

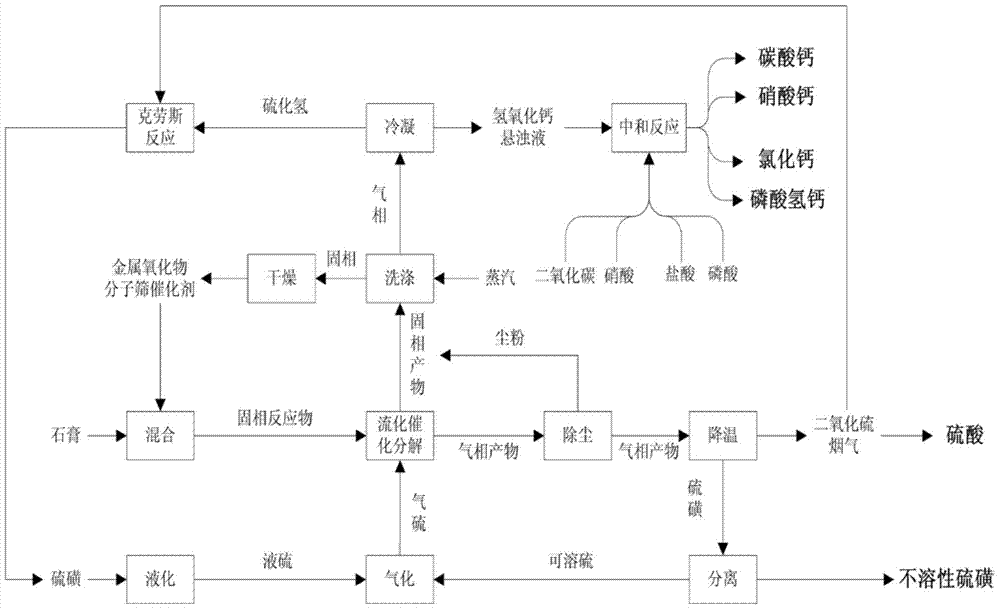

Method for fluidized catalytic decomposition of gypsum

InactiveCN104724678ALower reaction barrierReduce reaction energy consumptionCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesGas phaseCatalytic decomposition

The invention discloses a method for fluidized catalytic decomposition of gypsum. The method comprises the following steps: mixing gypsum with a metal oxide molecular sieve catalyst evenly, and adding to a fluidized reactor; feeding a sulphur gas from the bottom of the fluidized reactor, enabling the sulphur gas with a solid material, and reacting for decomposing the gypsum; washing a solid phase obtained by reaction with steam, wherein the washed solid phase is the metal oxide molecular sieve catalyst; drying and using in cycle; condensing the washed gas phase to obtain a Ca(OH)2 turbid liquid for preparation of a calcium salt; preparing sulphur employing individual uncondensed gas phase or SO2 in a gas-phase product obtained by decomposition reaction of the uncondensed gas phase and the gypsum according to claus reaction, and using the sulphur as a reducing agent in cycle; carrying out dust removal on the gas phase obtained by decomposition reaction of the gypsum, cooling and separating to obtain insoluble sulphur; and using the soluble sulphur as the reducing agent in cycle, and preparing the sulphur from the residual gas phase and H2S for cyclic use as the reducing agent or production of sulfuric acid. The gypsum decomposition is low in energy consumption and high in decomposition rate; the additional value of the product is high; and the process is environment-friendly and advanced.

Owner:SICHUAN UNIV

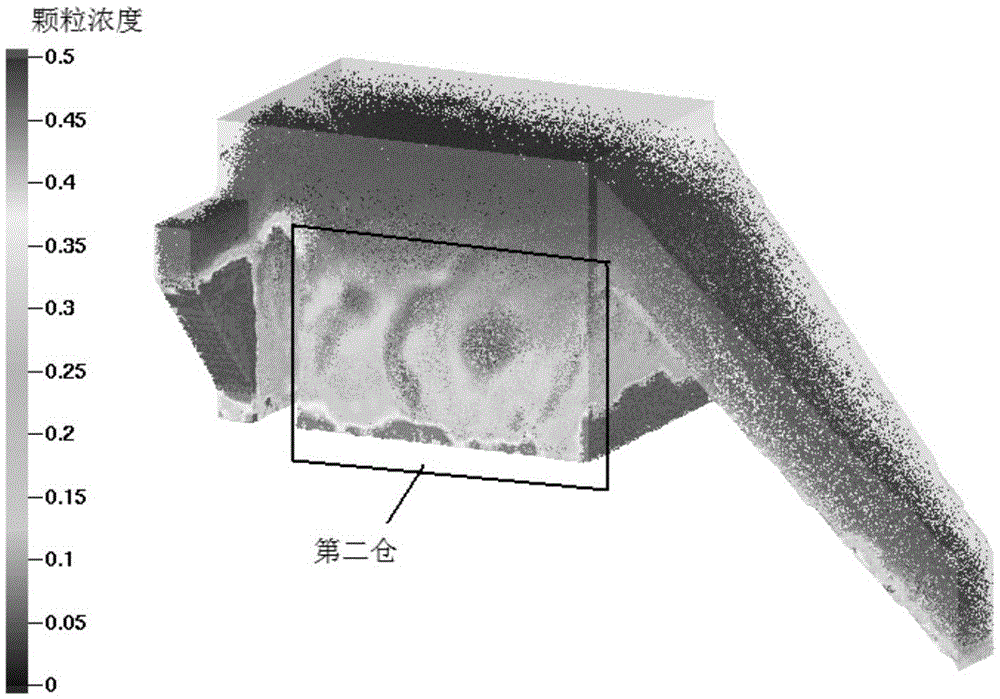

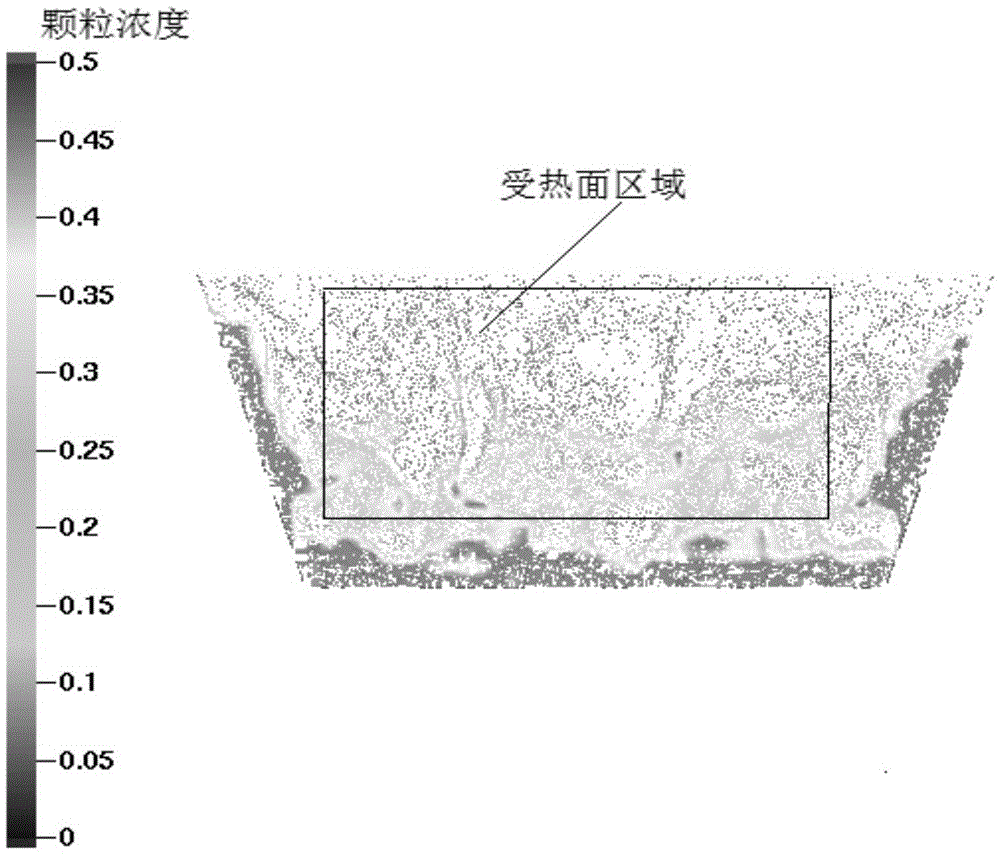

Method for eliminating heat deviation of working medium of external heat exchanger

ActiveCN105650629AEliminate thermal deviation of working fluidGood fluidization effectFluidized bed combustionApparatus for fluidised bed combustionAir volumeEngineering

The invention relates to the technical field of external heat exchangers of circulating fluidized bedboilers and aims to provide a method for eliminating heat deviation of a working medium of an external heat exchanger. A first side wall and a second side wall of a shell of the external heat exchanger incline outwards. An included angle beta formed between the first side wall and the extending face of a bottom face wind distribution plate and an included angle beta formed between the second side wall and the extending face of the bottom face wind distribution plate range from 30 degrees to 90 degrees. Blast capacities entering a bin from a hood on the bin inner bottom face wind distribution plate where a heating surface pipe screen is located are sequentially distributed from outside to inside according to the sequence from large to small. Through the methods thata heating surface pipe is not arranged in a side shielding area of the external heat exchanger, or the working medium does not circulate in the heating surface pipe in the side shielding area and the like, so that the heat deviation is eliminated. The technical scheme is combined with actual operation data of the external heat exchanger, by means of theoretical analysis and numerical calculation, the fluidization effect of the side shielding area is effectively improved, or the poor fluidization area is avoided, the heat deviation of the working medium of the external heat exchanger is eliminated, and the foundation is laid for developing the circulating fluidized bedboilers with efficient ultra-supercritical parameters or above.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

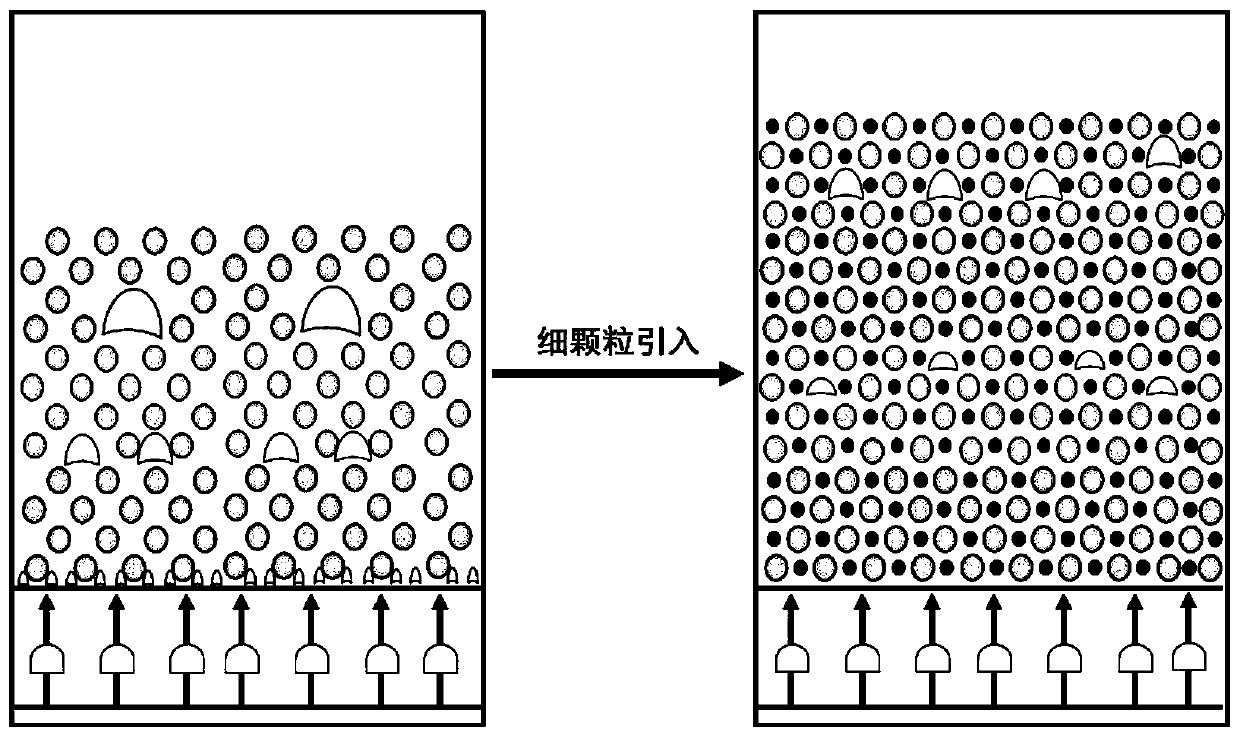

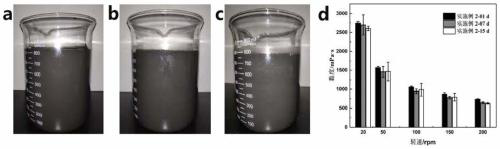

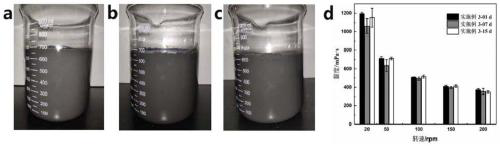

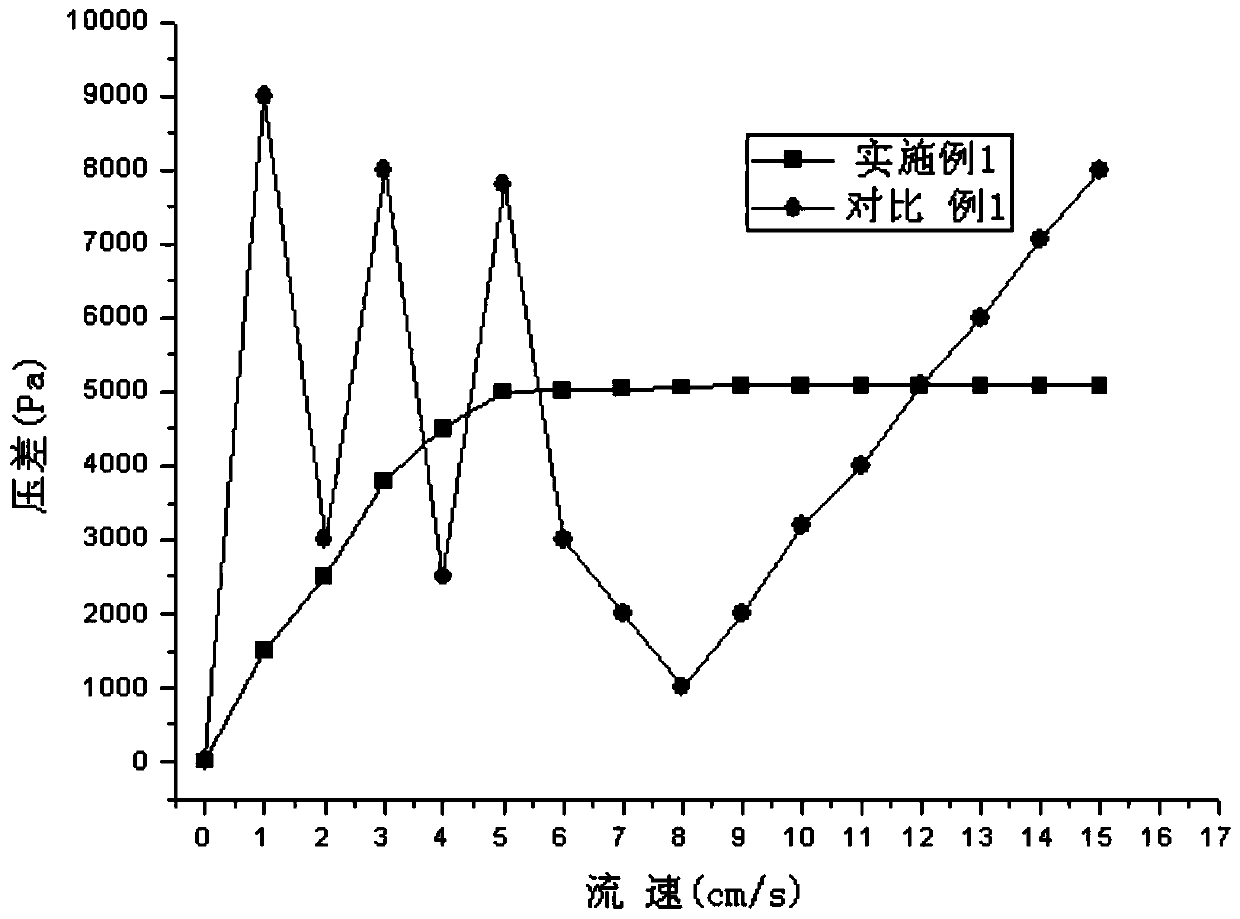

Method for improving particle fluidization quality and separation density stability and matched device

ActiveCN110328140ASmall particle sizeUniform Dispersion ExpansionGas current separationSocial benefitsEngineering

The invention discloses a method for improving particle fluidization quality and separation density stability and a matched device. In a gas-solid fluidized bed dry separation system, coarse particlesand fine particles are selected as separation media, the coarse particles and the fine particles are sufficiently mixed, a separation bed layer having a certain density is formed under the action ofairflow, the size of the coarse particles is not larger than 500 microns, the size of the fine particles is not larger than 45 microns, and the aerodynamic diameter ratio of the coarse particles to the fine particles is not less than 5. The matched device comprises a gas-solid fluidized bed body, a wind supply device, a material level height testing device, a scraper conveyor device, a density measuring device and a dust removing device. According to the method and the matched device, the fine particles are introduced, so that the fluidization quality of the medium particles is improved, the bubble size is reduced, the separation density stability is improved, the mineral separation accuracy is improved, and efficient separation of coal is achieved. The device does not need water, is simple in operation and maintenance, free of pollution and low in investment and operation cost, and has significant economic and social benefits.

Owner:CHINA UNIV OF MINING & TECH

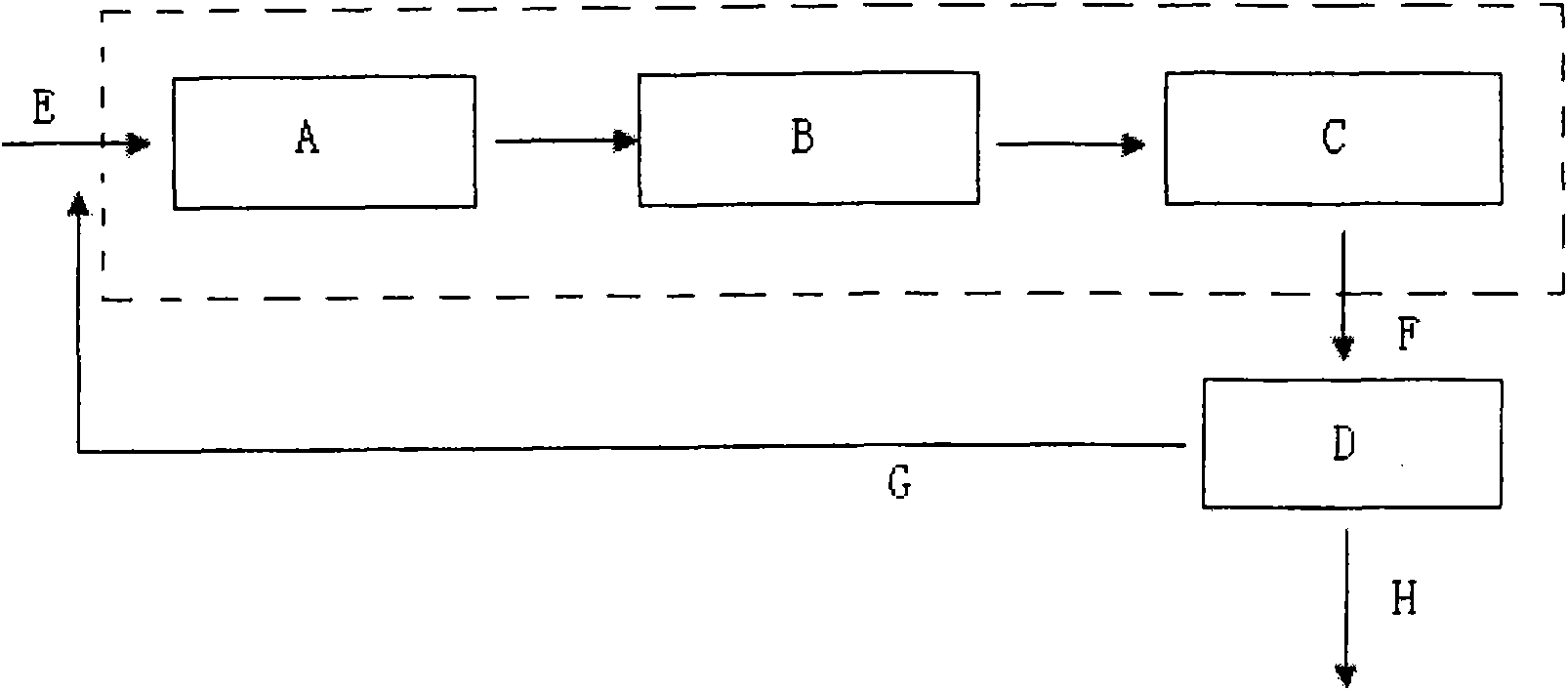

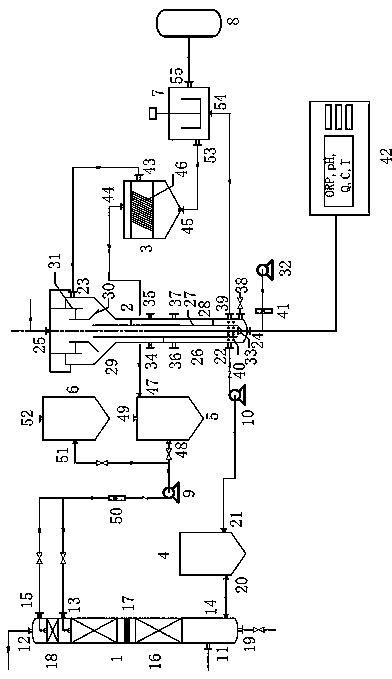

Skid-mounted microorganism desulfurization and sulphur recovery apparatus

InactiveCN105505495AAvoid safety hazardsHydrophilicBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismTower

The invention relates to a skid-mounted microorganism desulfurization and sulphur recovery apparatus, which comprises an absorption tower, a bioreactor, a settling tank, a pregnant solution tank, a barren solution tank, a clear water tank, a centrifuge, a sulphur recovery tank, a barren solution pump, a pregnant solution pump and other equipment, wherein the top portion of the absorption tower, the barren solution tank and the clear water tank are connected through the barren solution pump and pipelines, the bottom portion of the pregnant solution tank and the bottom portion of the bioreactor are connected through the pregnant solution pump and a pipeline, the top portion of the bioreactor and the settling tank are connected through a pipeline, the top portion of the settling tank and the barren solution tank are connected through a pipeline, the bottom portion of the settling tank and the centrifuge are connected through a pipeline, and the centrifuge, the sulphur recovery tank and the bioreactor are connected through pipelines. The skid-mounted microorganism desulfurization and sulphur recovery apparatus of the present invention has advantages of simple structure, easy operation, stable and safe operation, high automation degree, high desulfurization efficiency, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-resilience high-strength shotcrete enhancer

The invention discloses a high-strength shotcrete enhancer with low resilience and high stability. The high-strength shotcrete enhancer is prepared from rice hull ash, cellulose nanofibers, a six-carbon water reducing agent, plant polysaccharide and water. The plant polysaccharide powder is fully swollen, a water reducing agent is added and fully stirred, then rice hull ash and cellulose nanofibers are added and rapidly stirred, and the high-strength sprayed concrete enhancer with low resilience rate and high stability is obtained. According to the invention, the rebound rate of shotcrete andthe like can be reduced to below 2% while the dispersity and fluidity of the reinforcer are ensured, the stability is improved, the problems of layering and precipitation caused by long-time placementare solved, and the performance of the reinforcer is prevented from being damaged. Furthermore, in the actual application process, the enhancer can be used in real time after being conveyed to a construction site, has the advantages of accurate on-site addition and measurement, easiness in uniform mixing, environmental friendliness, no pollution and the like, can effectively reduce the rebound rate of sprayed concrete and improve the compression resistance, impermeability, wear resistance and other properties, provides convenience for actual construction, and has very good performance and very high operation practicability.

Owner:天津如米基业新材料有限公司

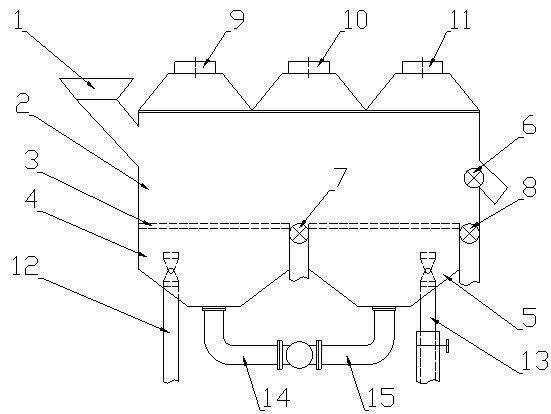

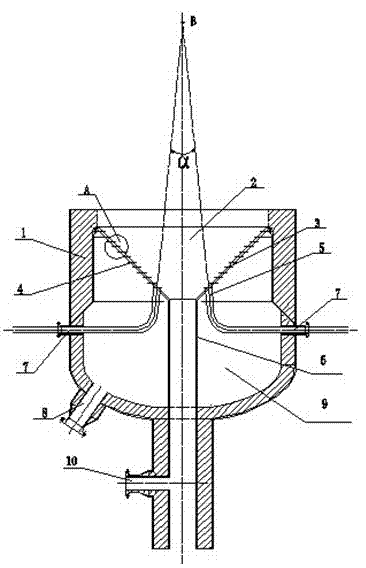

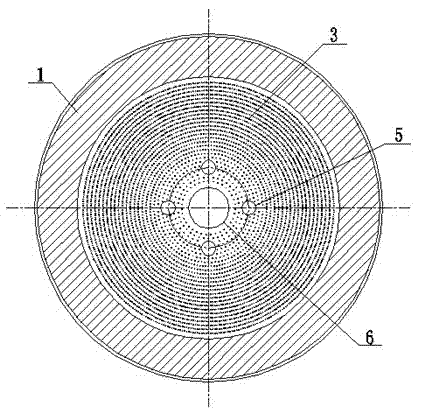

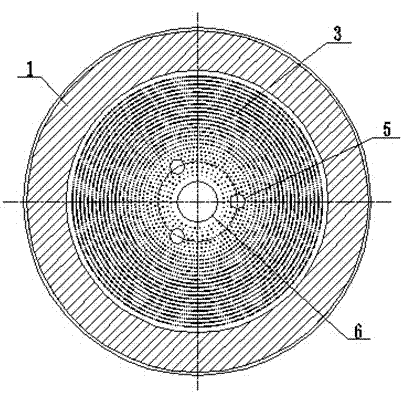

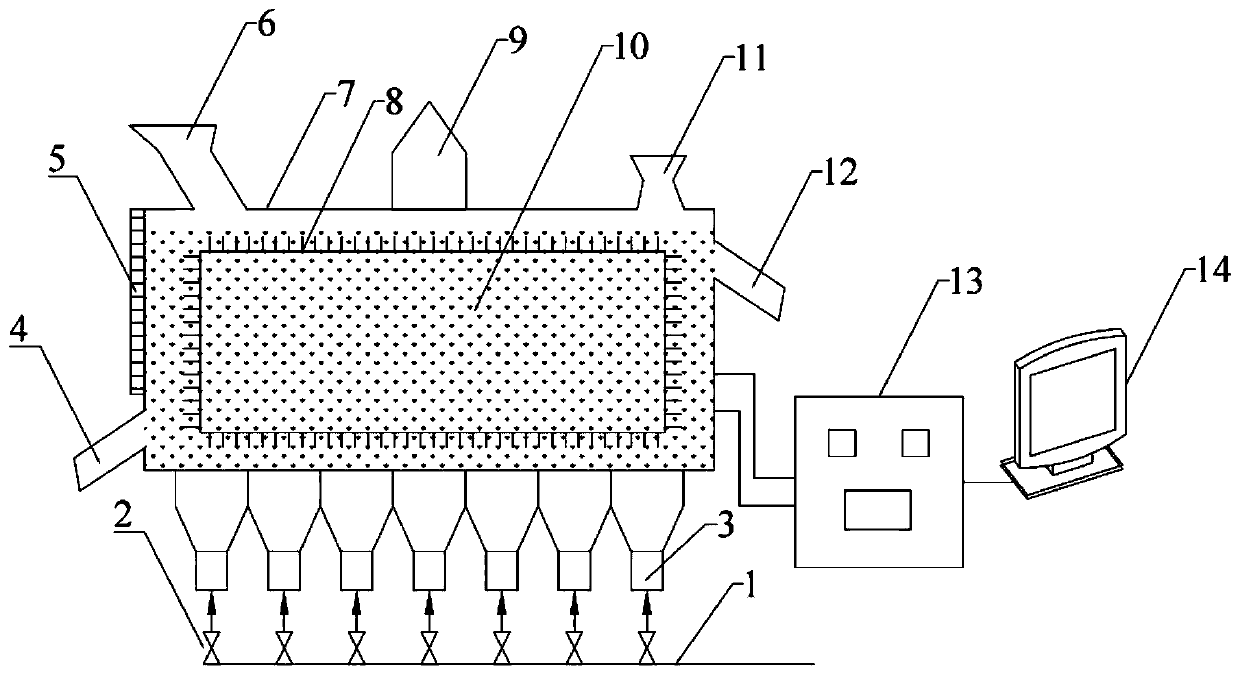

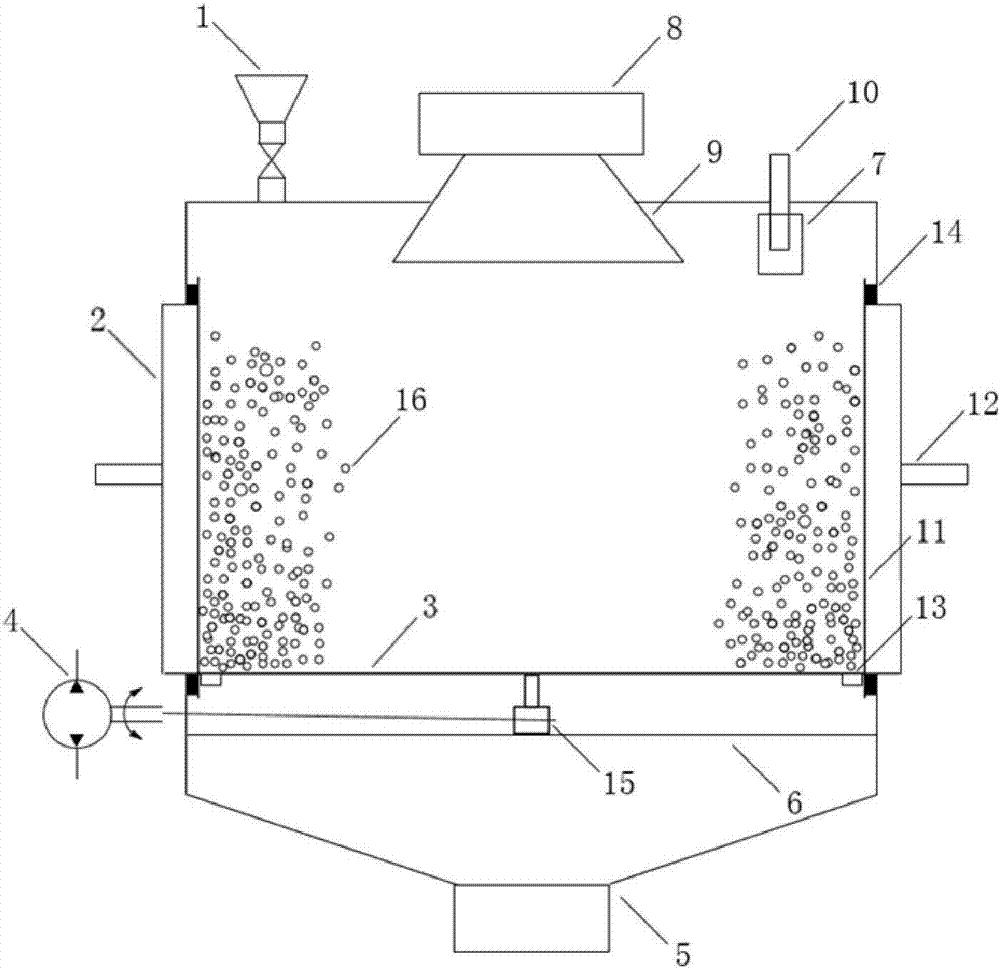

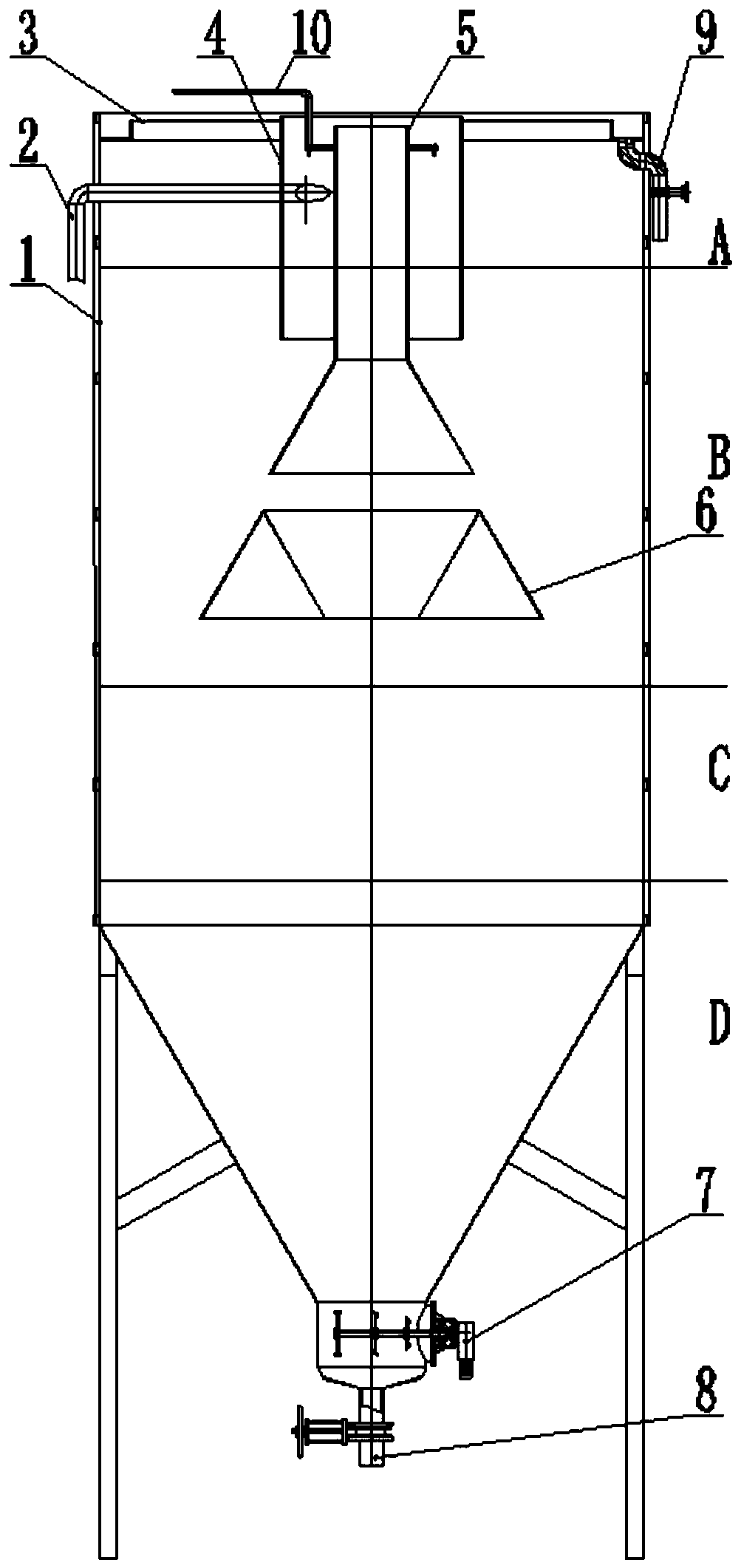

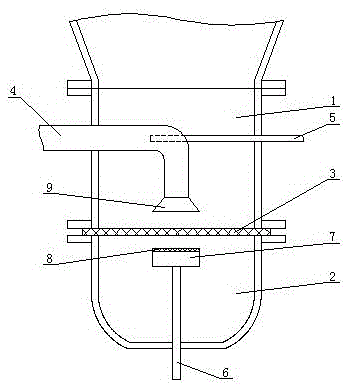

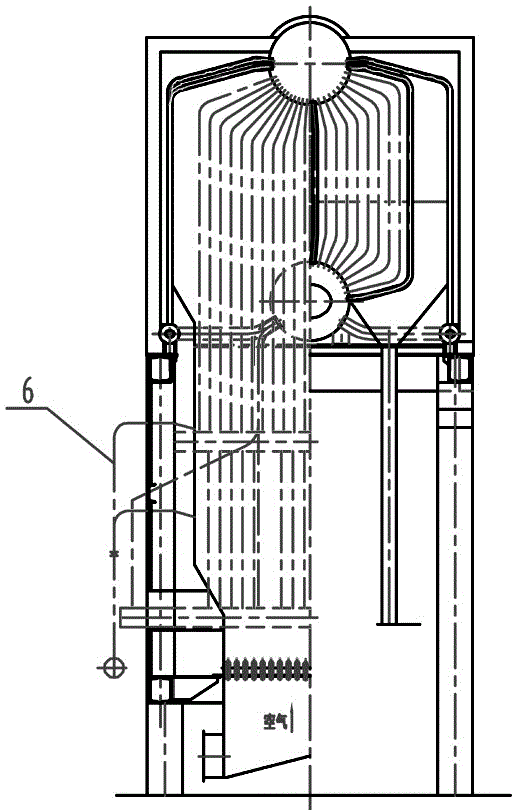

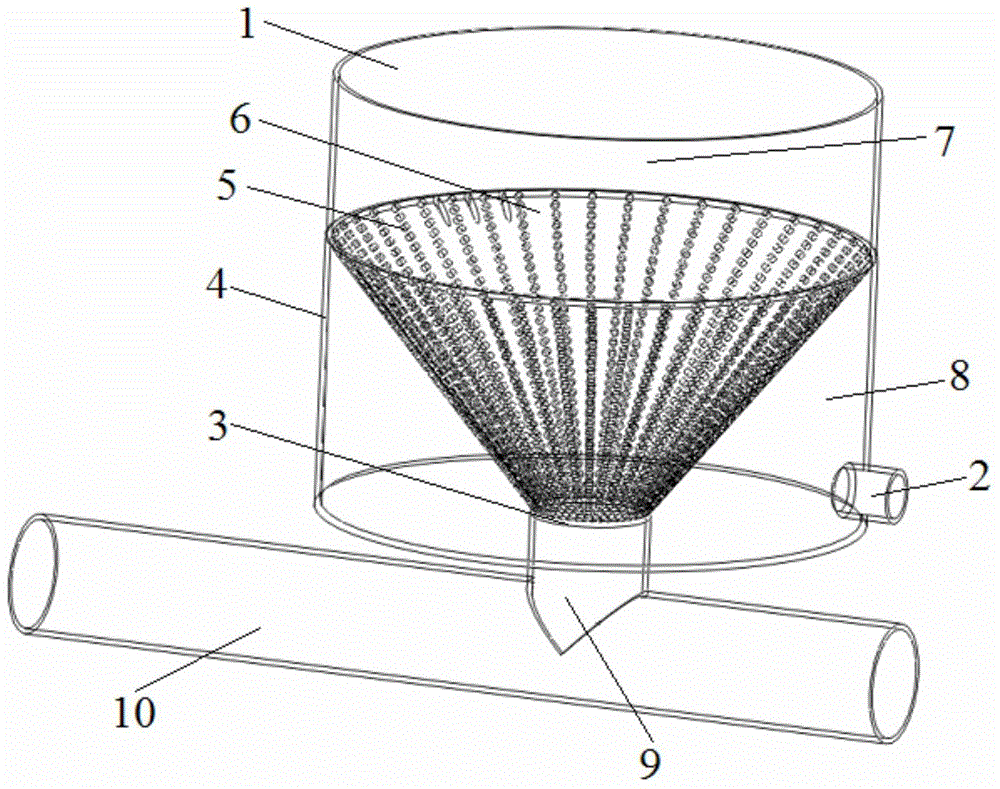

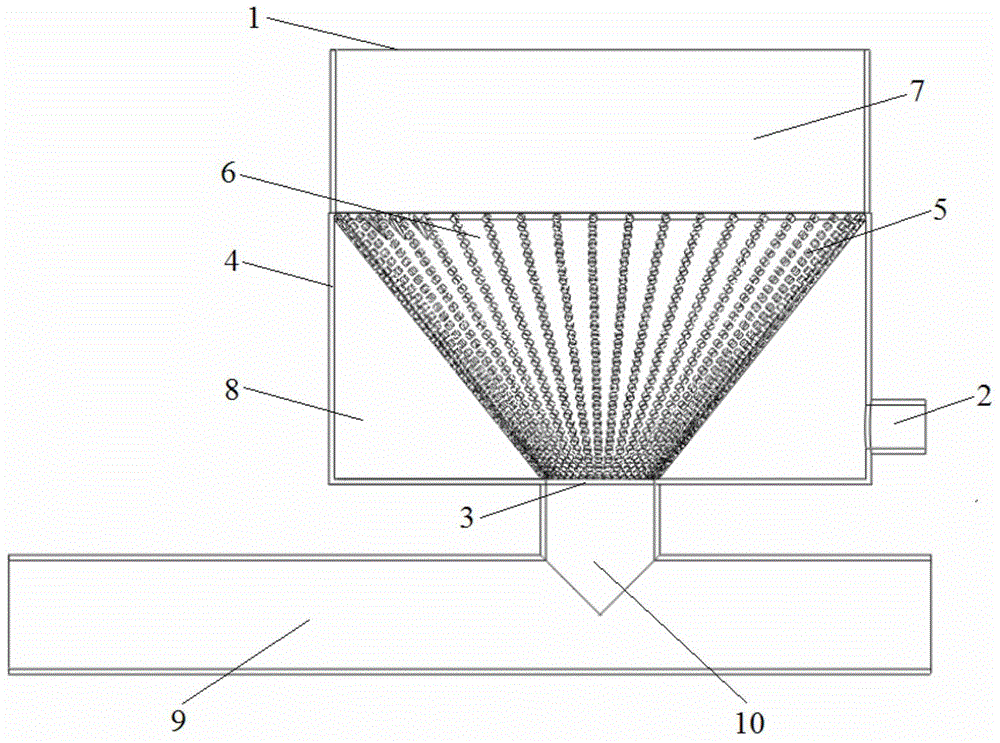

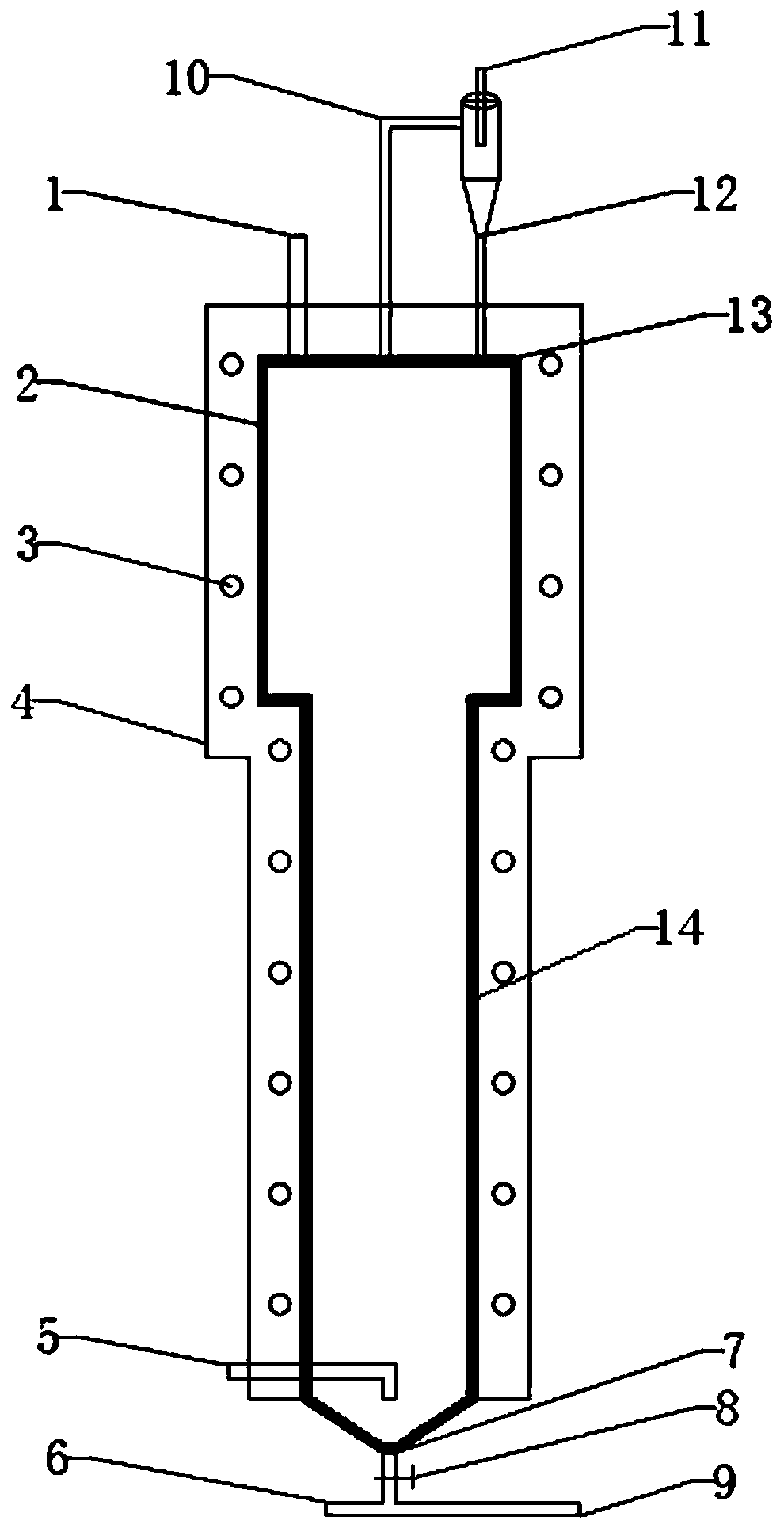

Device for cooperatively enhancing fluidization of nanoparticles by centrifugal field and sound field

InactiveCN106994322AOvercoming AdhesionGood fluidization behaviorEnergy based chemical/physical/physico-chemical processesBaghouseNanoparticle

The invention provides a device for cooperatively enhancing the fluidization of nanoparticles by a centrifugal field and a sound field. The device comprises a feeding hopper (1), an annular air inlet chamber (2), a centrifugal fluidized bed body (3), a stepping motor (4), a discharging hopper (5), a bed body supporting frame (6), a cloth bag dust collector (7), a sounder (8), a loudspeaker (9), an air outlet (10), an annular air distribution plate (11), an air inlet (12), an inner discharging hole (13), a sealing gasket (14) and a right-angle transmission gear box (15). According to the device provided by the invention, the fluidization of the nanoparticles is enhanced through the centrifugal field and the sound field, and abnormal fluidization phenomena including channeling, slugging even normal fluidization and the like of the nanoparticles in a fluidized bed can be effectively eliminated; an agglomeration-crushing process of particle agglomeration is enhanced and mixing between the particles is enhanced; the heat and mass transportation capability between the particles and a main body is improved; process application and amplification are easy to realize; the device has strong operation controllability and is stable to operate.

Owner:SOUTHEAST UNIV

Multilayer-rotation grain-drying fluidized bed

InactiveCN110057167AGood fluidization effectDry evenlyDrying solid materials with heatDrying gas arrangementsFluidized bed dryingEngineering

The invention relates to a multilayer-rotation grain-drying fluidized bed which comprises a receiving hopper, a bubbling fluidized bed dryer, a cyclone separator, a dehumidifier, a collector, a fluidization air blower, a motor and a heating air blower. The multilayer-rotation grain-drying fluidized bed is characterized int hat the receiving hopper is connected with the bubbling fluidized bed dryer; a rotary air distribution plate is arranged in the bubbling fluidized bed dryer; rotating power is provided by the motor; and heating is provided for the heating air blower. The cyclone separator isconnected to the tail part, the collector is connected to a material side in a concave way, the dehumidifier is connected to an air side, and an exhaust port and an air return pipe are arranged on the tail part, so that after materials are added, grains can be high-efficiently dehumidified in an energy-saving environmental-friendly way through the device. The multilayer-rotation grain-drying fluidized bed provided by the invention is high-efficiency in use, energy-saving, environmental-friendly, and easy to popularize.

Owner:HARBIN UNIV OF SCI & TECH

High-efficient and pollution-reducing fuel oil accelerant

The invention relates to a high-efficient and pollution-reducing fuel oil accelerant, which is particularly suitable for factory production, automobiles and ships. The invention provides the high-efficient and pollution-reducing fuel oil accelerant, which can reduce fuel oil consumption, improves fuel oil efficiency and reduces environmental pollution. The high-efficient and pollution-reducing fuel oil accelerant comprises the following raw materials: 1 to 10 percent of vegetable lipase, 5 to 10 percent of aether, 5 to 20 percent of acetone, 0.05 to 4.5 percent of ferrocene, 0.1 to 4.4 percent of trinitrotoluene, 0.01 to 2 percent of nitrobenzene, 20 to 70 percent of xylene, 14 to 16 percent of sodium nitrate, 0.2 to 0.4 percent of potassium permanganate, 0.5 to 1.5 percent of sodium carbonate, 0.3 to 0.7 percent of potassium oxide and 0.1 to 1 percent of baking soda.

Owner:吴勇

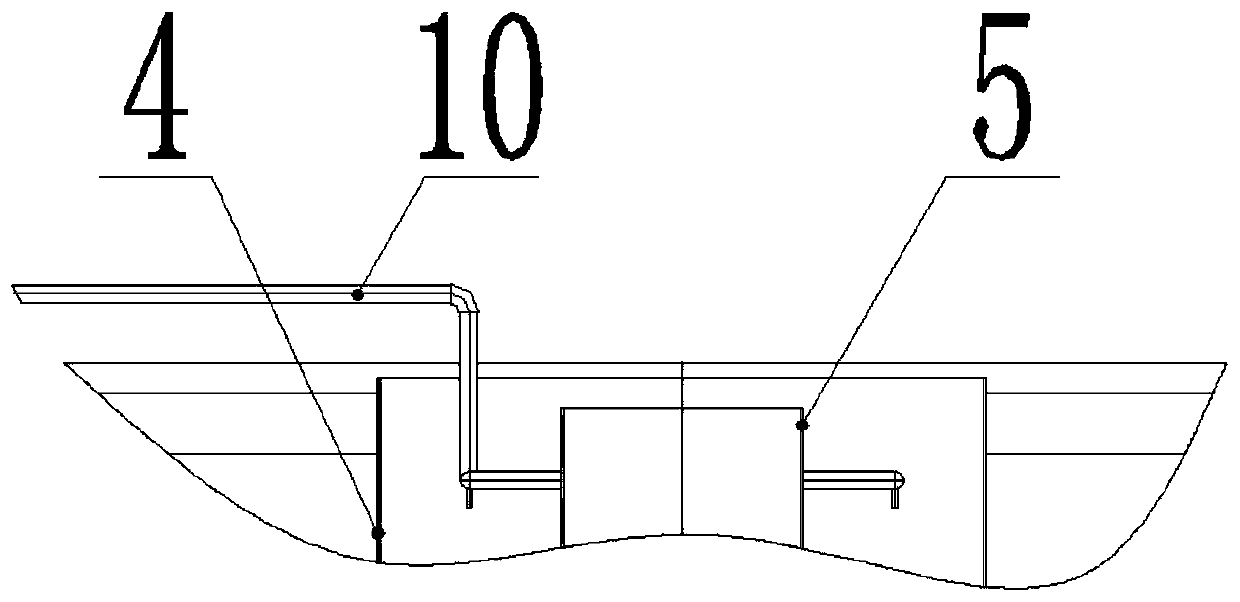

Deep-cone thickening sand bin with fluidized sand discharging device

PendingCN110152358AAccelerate the speed of flocculation and agglomerationReduce concentrationSettling tanks feed/dischargeCentrifugal force sediment separationEngineeringTailings

The invention relates to a deep-cone thickening sand bin with a fluidized sand discharging device. The deep-cone thickening sand bin with a fluidized sand discharging device comprises a sand bin body,a material feeding pipe, a flocculant inlet pipe, an overflow tank, a material feeding well, a circulation well, an annular guide cone and a stirring fluidization device, wherein the overflow tank isfixedly connected to the top of the inner wall of the sand bin body, and communicates with a supernatant return pipe, the material feeding well is disposed at the center of the top of the sand bin body, and is fixedly connected with the sand bin body, and the circulation well is disposed in the material feeding well, and is fixedly connected with the material feeding well; a material feeding zoneis formed between the material feeding well and the circulation well, the material feeding pipe communicates with the material feeding zone, and the annular guide cone is disposed directly below thecirculation well, and is fixedly connected with the inner wall of the sand bin body; and the diameter of the top of the annular guide cone is the same as the diameter of the circulation well, a material outlet is formed in the bottom of the sand bin body, and the stirring fluidization device is fixedly connected with the mouth outlet. A special flow field is formed after tailings is introduced into the sand bin, no consumption of waterpower and gas power is generated, the fluidization effect is good, and it is ensured that the mortar concentration and the thickening effect are not reduced.

Owner:金诚信矿山工程设计院有限公司

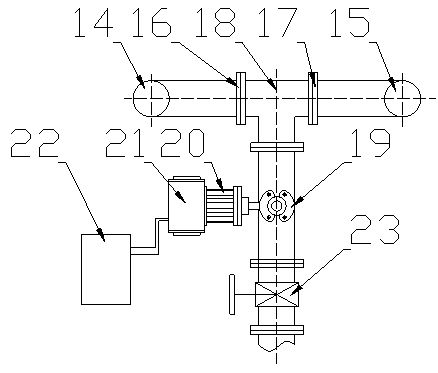

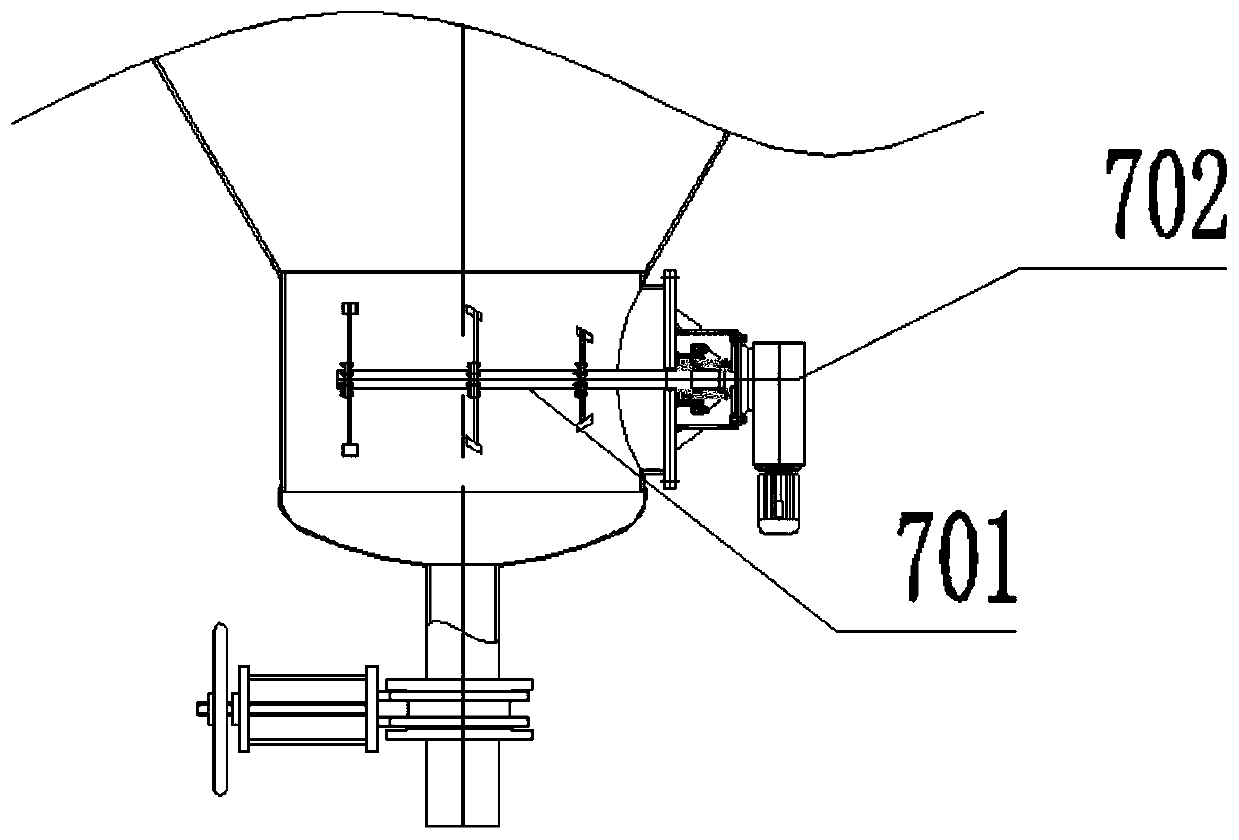

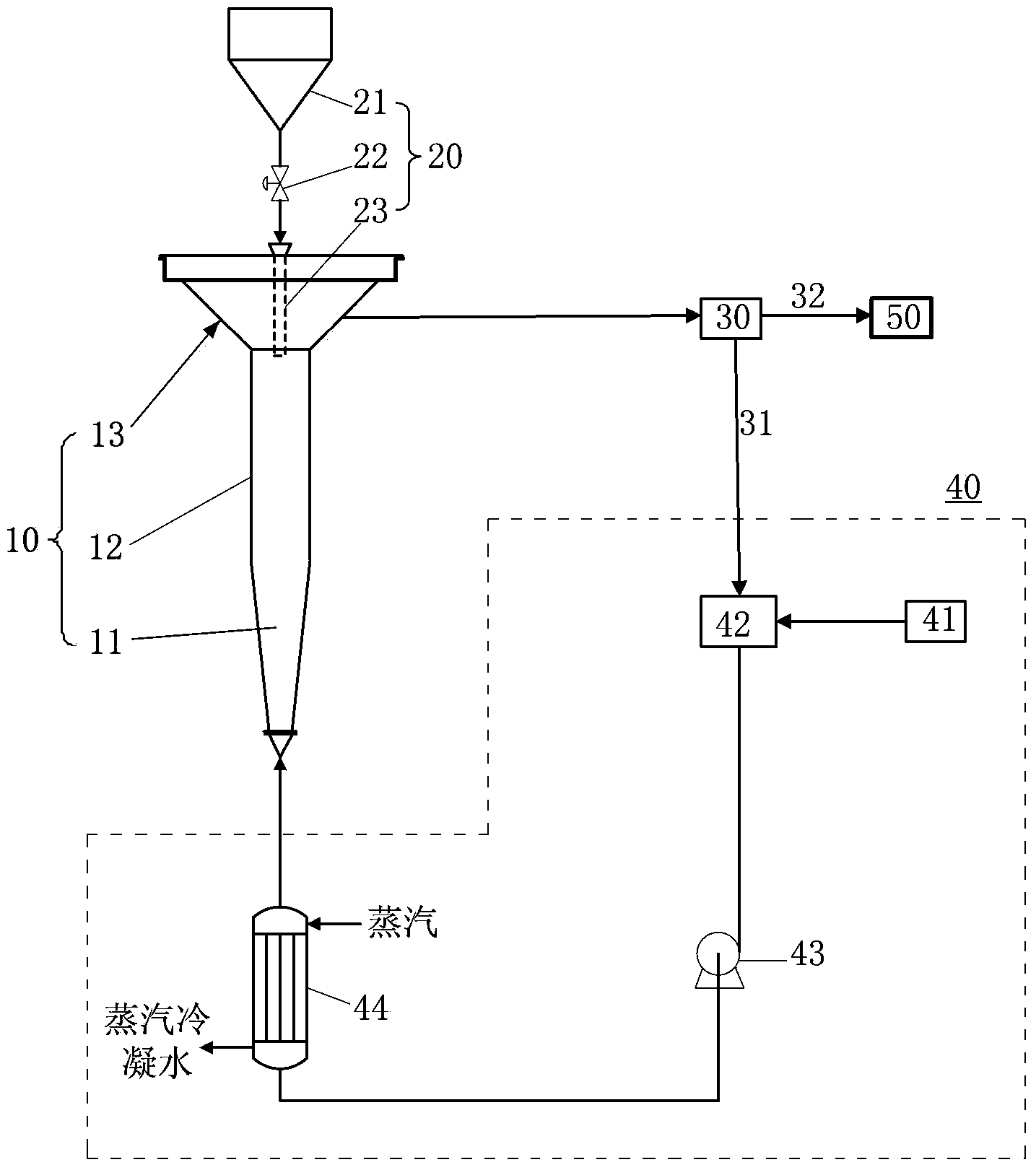

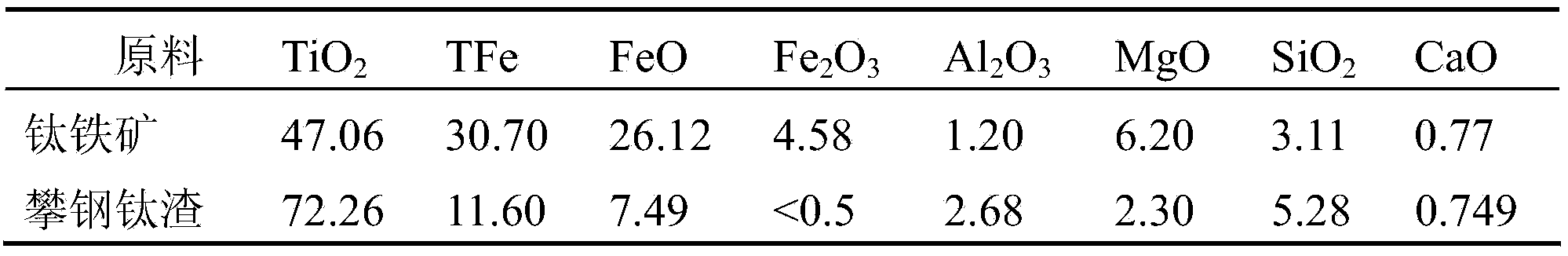

Method and device for preparing titanium solution from fluidized acidolysis titanium-containing material

InactiveCN103482696ASolving Recycling ProblemsReduce dosageTitanium dioxideReaction temperatureTitanium

The invention provides a method and device for preparing a titanium solution from a fluidized acidolysis titanium-containing material. The method comprises the following steps: a titanium-containing material and an acid solution are added into a fluidization reactor, and the titanium-containing material is subjected to acidolysis reaction in a fluidization reaction region formed by the acid solution, wherein the reaction temperature is 70-100 DEG C; an acidolysis solution generated by the acidolysis reaction overflows from the fluidization reactor, and is compounded with fresh acid to form an acid solution so as to return to the fluidization reactor for further acidolysis; and when the titanium content in the acidolysis solution reaches a required value, the overflowing acidolysis solution is diverted to form a first branch and a second branch, wherein the acidolysis solution in the first branch further returns to the acidolysis step, and the acidolysis solution in the second branch is filtered to obtain the titanium solution. According to the method, acidolysis is performed on the titanium solution through a fluidization technology, the titanium content in the titanium solution can be controlled by controlling the diversion timing and the diversion flow rate in the acidolysis process, and continuous production can be realized. Besides, the method has the advantages of simple process, high acidolysis rate, low cost and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

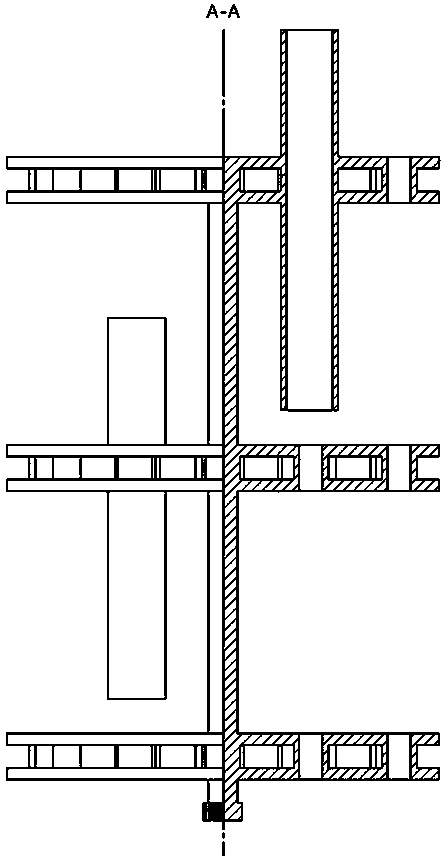

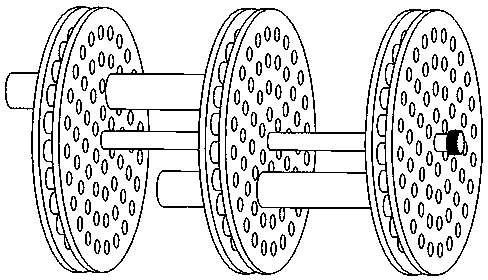

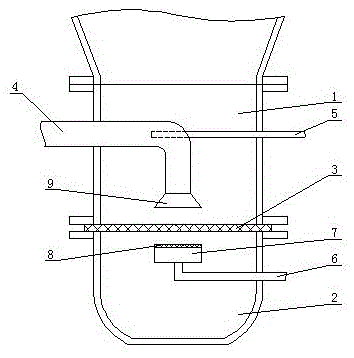

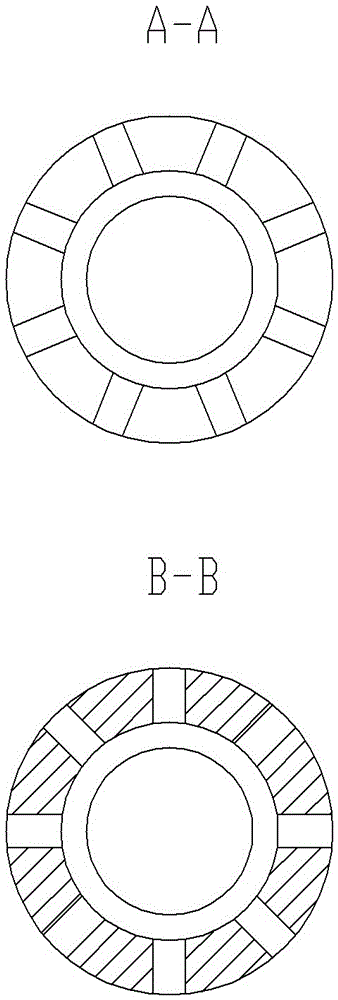

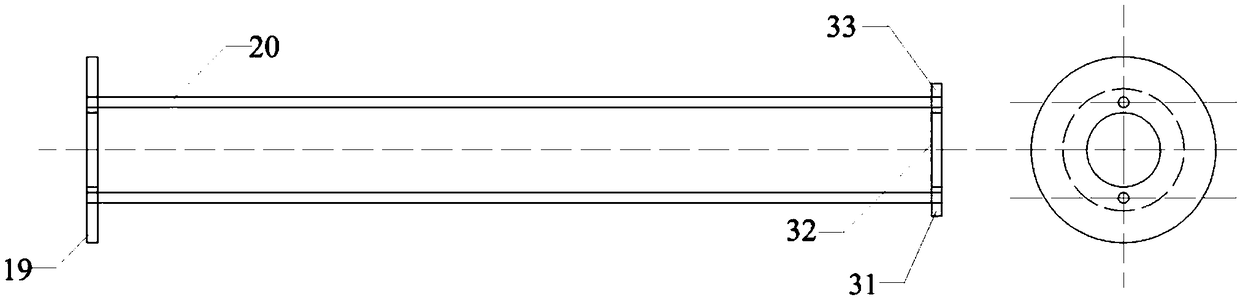

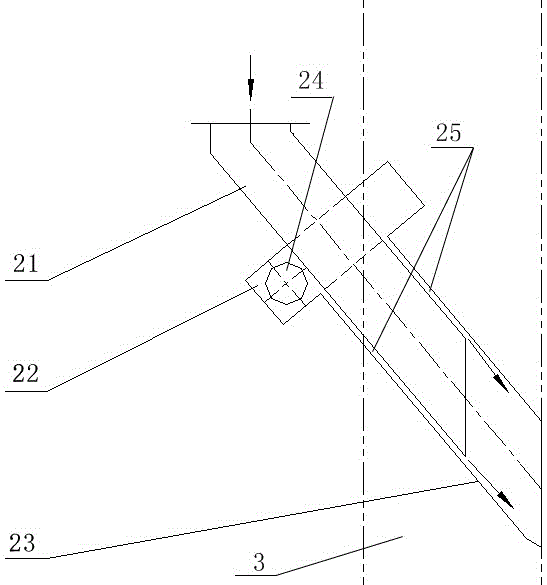

Pulverized coal fluidizing and injection device for blast furnace

InactiveCN105586449APromote energy saving and emission reductionReasonable structural designBlast furnace detailsEngineeringCoal

The invention relates to a pulverized coal fluidizing and injection device for a blast furnace. The pulverized coal fluidizing and injection device for the blast furnace comprises an injection chamber and a fluidizing chamber; the fluidizing chamber is arranged below the injection chamber; the fluidizing chamber communicates with the injection chamber through a fluidizing plate; after entering the injection chamber from one side of the injection chamber, a pulverized coal conveying pipe vertically bends downward; after entering the injection chamber from the other side of the injection chamber, a pulverized coal blowdown pipe extends into the pulverized coal conveying pipe; a fluidizing gas inlet pipe extends into the fluidizing chamber; the outlet end of the fluidizing gas inlet pipe is provided with a fluidizing gas distribution device; and the fluidizing gas distribution device is located in a central region of the fluidizing chamber. The pulverized coal fluidizing and injection device disclosed by the invention is reasonable in structural design, and fluidizing gas is enabled to be evenly distributed in the fluidizing chamber, especially the most important central region of the fluidizing chamber, so that uniformity and stability of pulverized coal conveyance are ensured, a stability degree of a furnace condition of the blast furnace is increased, and energy saving and emission reduction of the blast furnace are promoted.

Owner:SHANDONG IRON & STEEL CO LTD

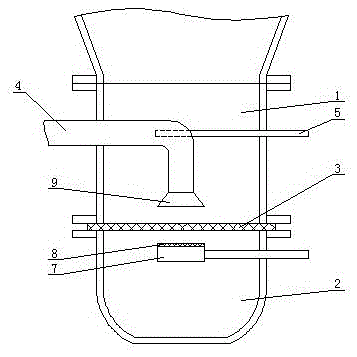

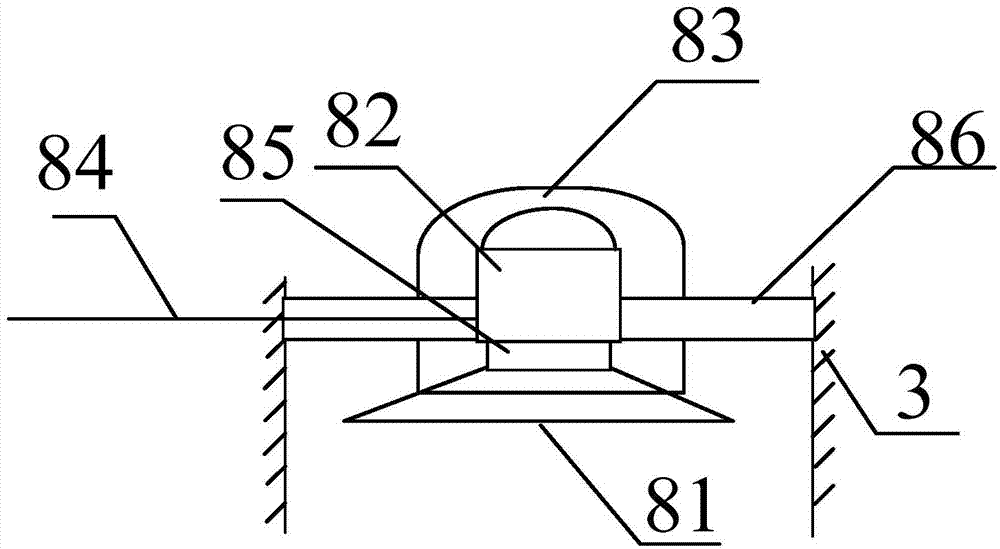

Hood for circulating fluidized bed boiler

InactiveCN106287684AReduce wearEasy to wearFluidized bed combustionApparatus for fluidised bed combustionCombustionEngineering

The invention relates to the technical field of hood structures in an air distributing device, in particular to a hood for a circulating fluidized bed boiler. By the adoption of the hood, blocking of an air hole can be effectively prevented, fluidization effect can be optimized, and combustion efficiency can be improved. The hood comprises a hood head and a connecting pipe, wherein the upper end of the connecting pipe is sleeved with the hood head, and the bottom of the hood head is connected with a boss of the connecting pipe. The hood is characterized in that at least two rows of connecting pipe air holes are formed in the peripheral direction of the side wall of the upper portion of the connecting pipe, hood air outlets are formed in the peripheral direction of the side wall of the lower portion of the hood head and are inclined downwards, and the bottom of the hood head is connected with the boss of the connecting pipe through welding.

Owner:WUXI HUAGUANG BOILER

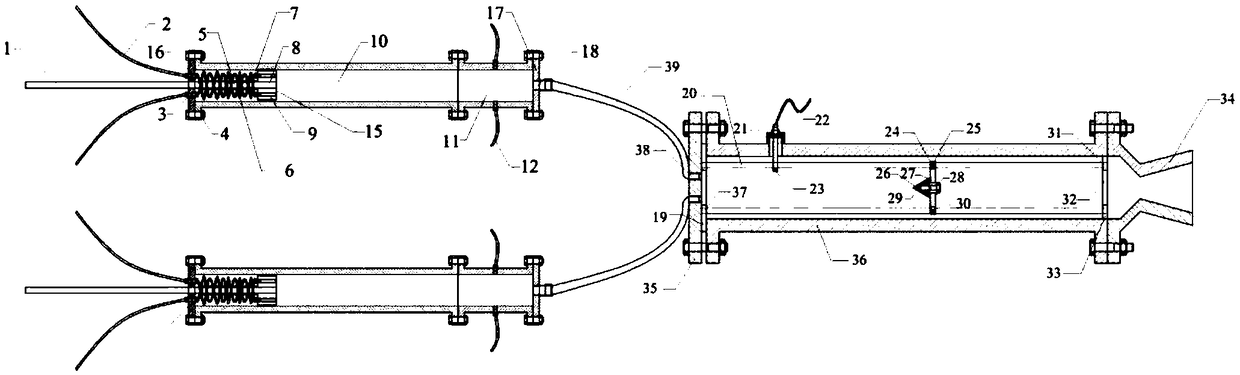

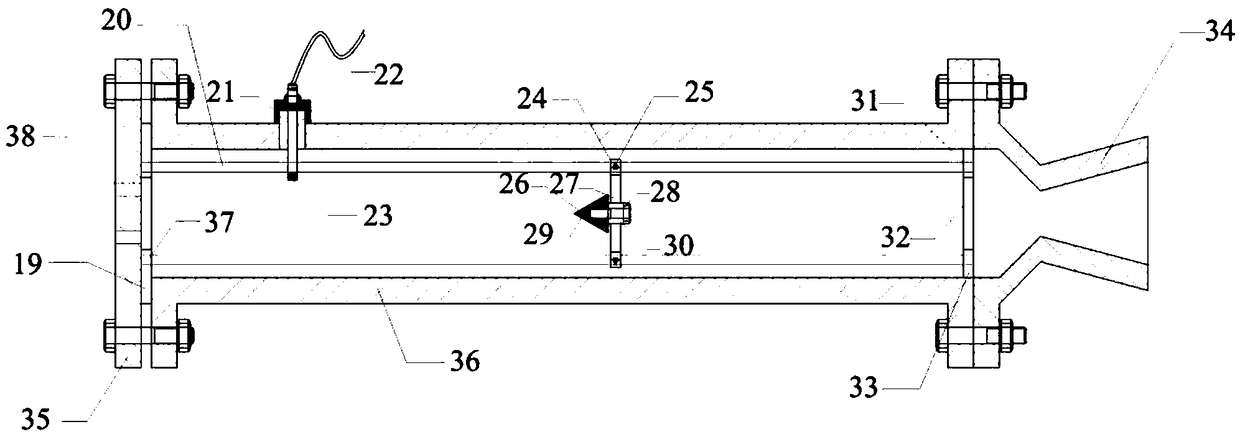

Powder engine with adjustable flame stabilizer position and method for installing flame stabilizer of powder engine

ActiveCN109057953ABurn fullySimple structureInternal combustion piston enginesPowdered engine fuelsCombustion chamberEngineering

The invention provides a powder engine with an adjustable flame stabilizer position and a method for installing a flame stabilizer of the powder engine. The engine comprises a powder fuel supplying device, a powder oxidizing agent supplying device, a combustion chamber 36 and a spraying pipe 34, wherein the powder fuel supply device, the powder oxidant supply device and the combustion chamber 36 are connected with the front end of the combustion chamber 36 through pipelines, the rear end of the combustion chamber 36 is connected with the spraying pipe 34, a flame stabilizer 29 is arranged in the combustion chamber 36, and the axial position of the flame stabilizer 29 in the combustion chamber 36 can be adjusted. The position of the flame stabilizer is adjustable, and the axial position ofthe flame stabilizer can be adjusted according to the requirements of different operating conditions of the engine, so that more sufficient combustion of fuel can be realized, and a detachable fixingdevice of the flame stabilizer is simple in structure, practical and convenient to adjust.

Owner:NANJING UNIV OF SCI & TECH

Combined fluidized bed biomass boiler

InactiveCN105066119AEasy to separateExtended burn timeFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEmission standard

The invention discloses a combined fluidized bed biomass boiler which comprises a hearth, a secondary air pipe, a water cooling pipe, a fluidized bed and a tempering preventing feeding device. The tempering preventing feeding device comprises a feeding pipe and a jacket, and an air supply interlayer is formed between the jacket and the feeding pipe. The combined fluidized bed biomass boiler is low in tempering accident rate, and multiple kinds of fuel can be combusted at the same time. The load adjusting range is wide, the environmental protection performance is excellent, emissions of NOx and SO2 are effectively controlled, and the national emission standard is met. Heat conduction in the boiler is even, high heat accumulation performance is achieved, the heat recovery efficiency is high, and a recovery heat source is stable. The recyclability of ash residues is high.

Owner:XIANGTAN BOILER

Method for preparing ethylene and propylene by taking naphtha as raw material

ActiveCN103435432AImprove conversion rateImproved hydrocarbon selectivityMolecular sieve catalystsBulk chemical productionNaphthaPolymer science

The invention belongs to the technical field for producing ethylene and propylene, and particularly relates to a method for preparing ethylene and propylene by taking naphtha as the raw material. The method for preparing ethylene and propylene by taking naphtha as the raw material comprises the following steps: (1) preparation of a composite catalyst; (2) catalyzed cracking; and (3) separation of products. The method for preparing ethylene and propylene by taking naphtha as the raw material has simple steps and reasonable design, and helps to substantially improve conversion rate of naphtha and yields of ethylene and propylene.

Owner:临沂星火知识产权服务有限公司

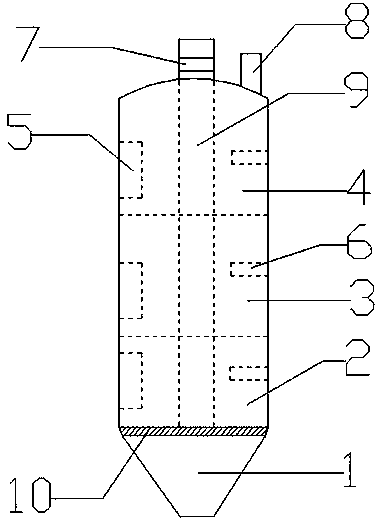

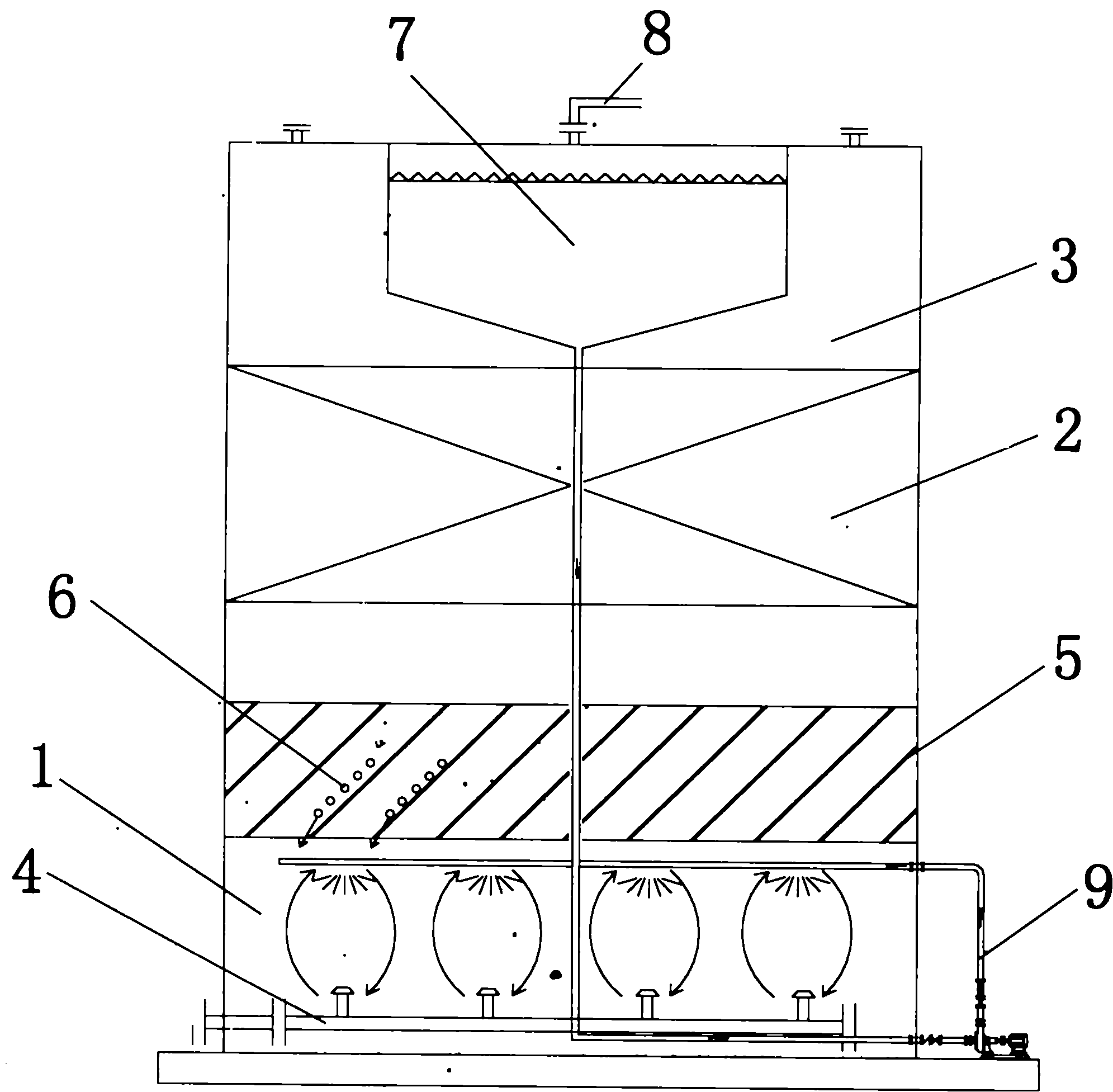

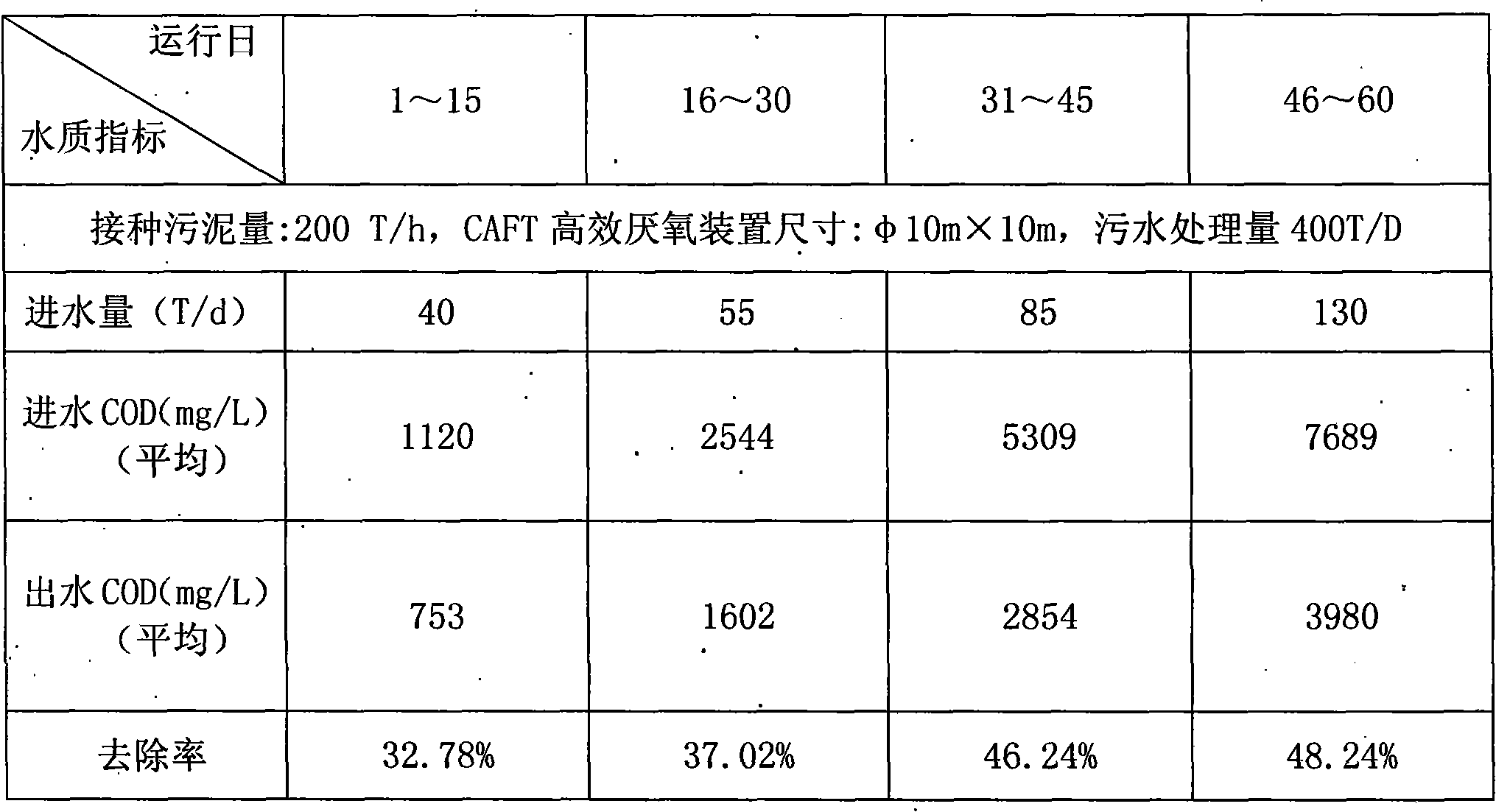

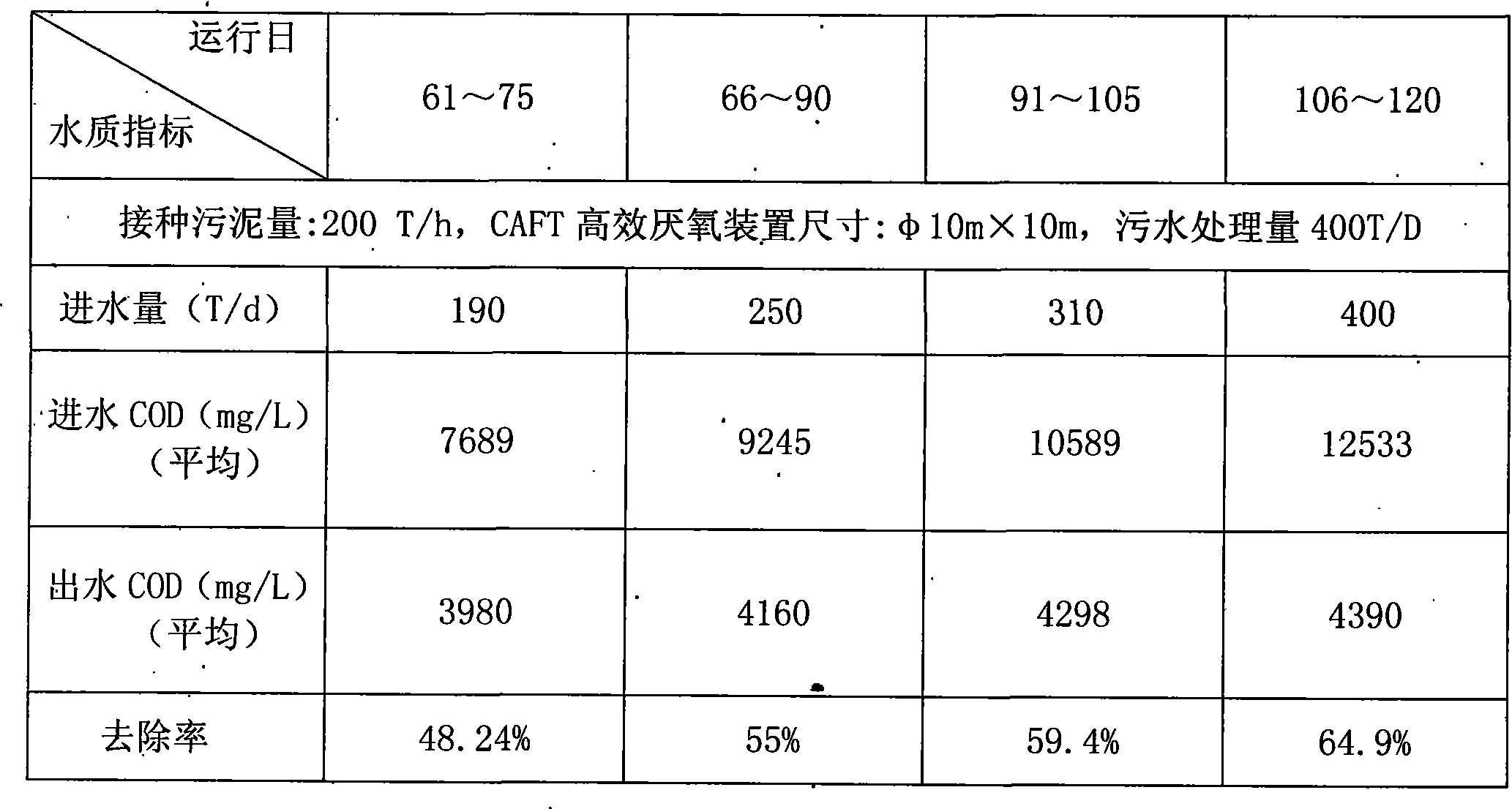

CAFT efficient anaerobe reactor for treating sewage

ActiveCN101870518AHigh removal rateImprove processing efficiencyWaste based fuelTreatment with anaerobic digestion processesHigh concentrationInstability

The invention discloses a CAFT efficient anaerobe reactor for treating sewage, which relates to sewage treating equipment. The CAFT efficient anaerobe reactor comprises a convection area, a suction area and a buffering area. The CAFT efficient anaerobe reactor is characterized in that: anaerobic microorganisms are placed in the convection area; a water distributor for inletting the sewage is arranged at the bottom of the convection area; a plurality of inclined tube settlers are slantways arranged on an upper part of the convection area; the suction area is in communicated connection with the upper part of the convection area; and fillers are placed in the suction area; the buffering area is arranged above the suction area; and a three-phase separator is arranged in the buffering area. The CAFT efficient anaerobe reactor for treating the sewage solves the problems of complicated structure of an anaerobe reactor, instability of a system, substandard water purification effect and high maintaining cost in the prior art, and the provided CAFT efficient anaerobe reactor has the characteristics of simple structure, low manufacturing and maintaining cost, and high removal rate of organic contaminants and the like. The CAFT efficient anaerobe reactor is mainly applied to treatment of wastewater with medium and high-concentration organic matters in brewage, starch processing, biological pharmacy, organic chemical industry, poultry farming, papermaking and the like.

Owner:JIANGSU ZEYU ENVIRONMENTAL ENG

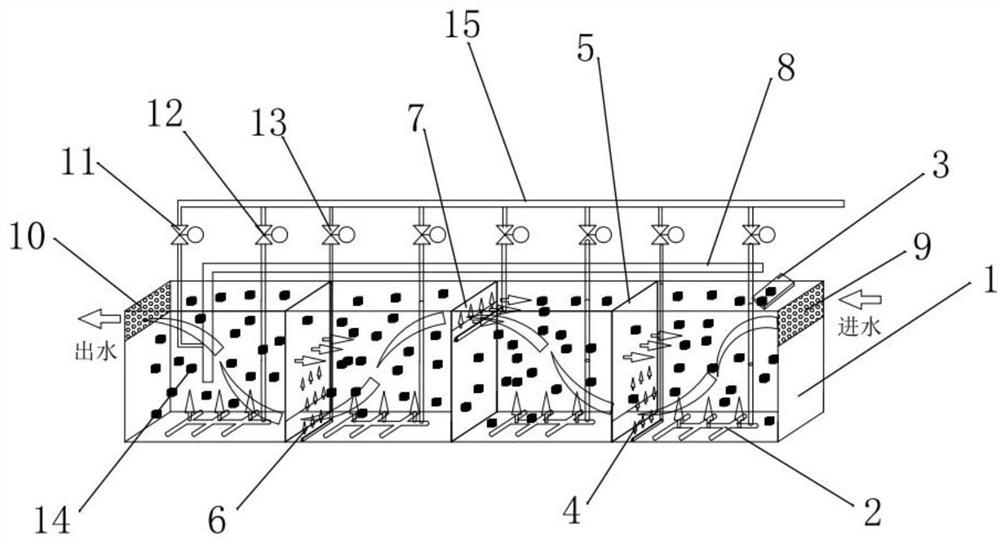

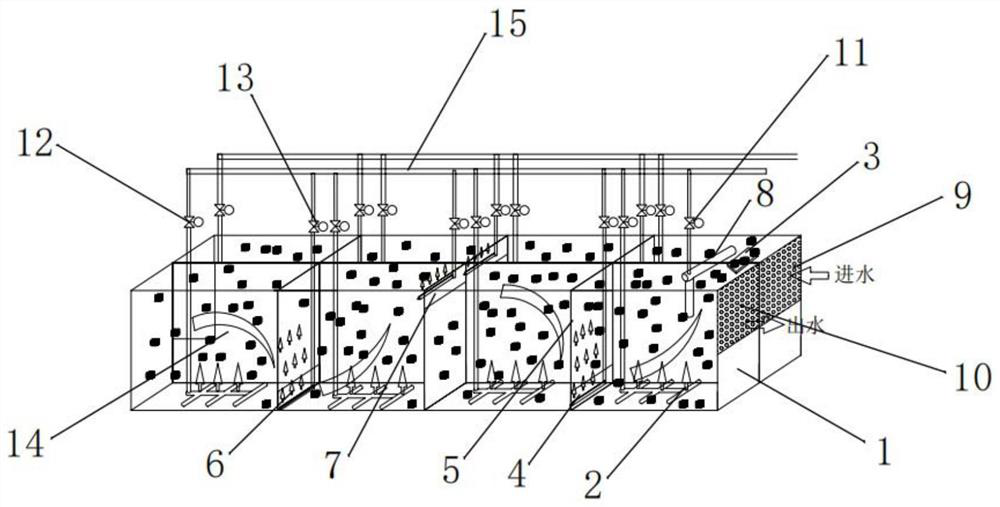

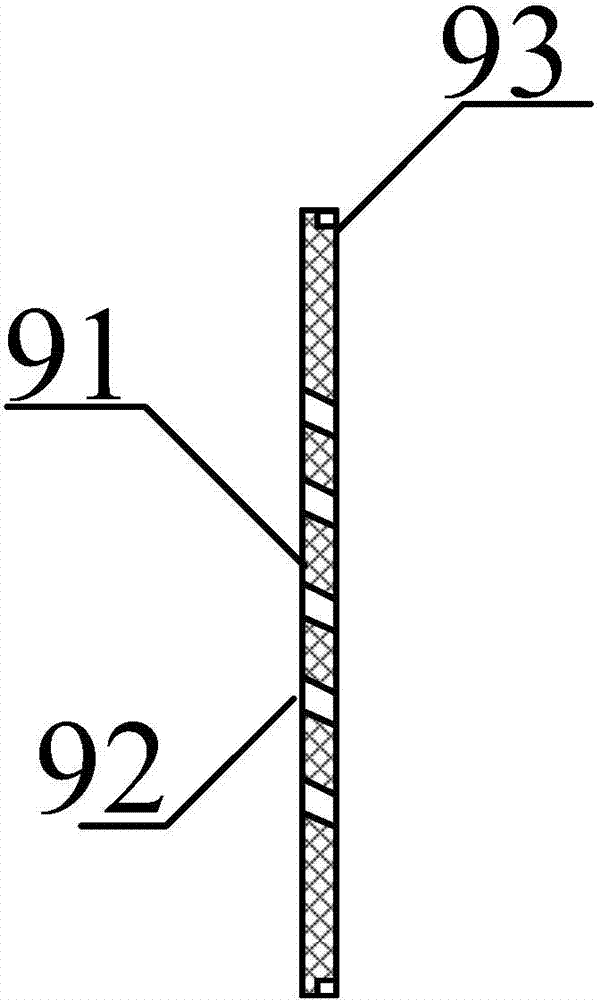

Baffled MBBR biochemical system of flexible suspended filler

PendingCN113912178ASolve the problem of uneven filler distributionEvenly distributedWater contaminantsBiological treatment apparatusOutfallMechanical engineering

The invention discloses a baffled MBBR biochemical system of a flexible suspended filler, aiming at solving the problems in the prior art that a suspended carrier is non-uniform in fluidization and is easy to accumulate at an interception net, the biomass of the filler is increased, and dead mud is formed in the filler. The system comprises a tank body, an aeration pipeline, an air blade, a main air supply device and an air stripping reflux device, the tank body is provided with a plurality of groups of baffle walls to be separated into a plurality of groups of baffle chambers, and the plurality of groups of baffle walls are sequentially provided with water outlets with opposite height positions according to the sequence from the water inlet of the tank body to the water outlet of the tank body; the air blade is arranged at water outlets of the multiple groups of baffle walls and jet air flow in the vertical direction; a water outlet intercepting net is arranged at the water outlet of the tank body, and a water inlet intercepting net is arranged at the water inlet of the tank body; an aeration pipeline is arranged at the bottom of the tank body and is connected with a main air supply device; the gas stripping reflux device is communicated with the baffling chamber where the water inlet of the tank body is located and the baffling chamber where the water outlet of the tank body is located to enable liquid to flow back, wherein the particle size of the flexible suspended filler is larger than that of meshes of the intercepting net, so that the flexible suspended filler can flow back along with liquid through the gas stripping reflux device.

Owner:李庆辉

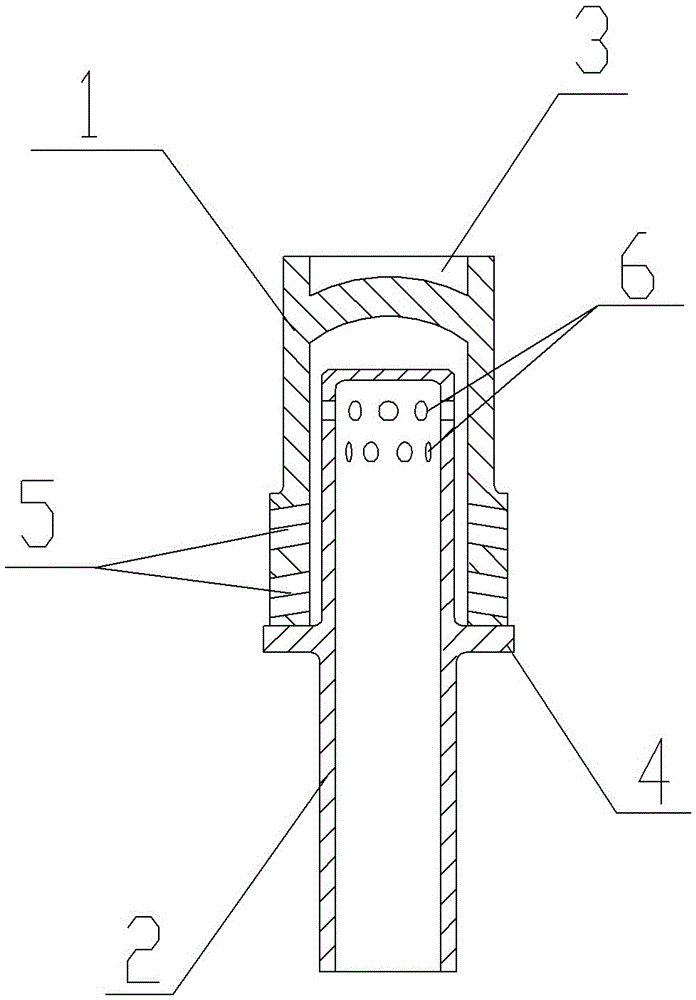

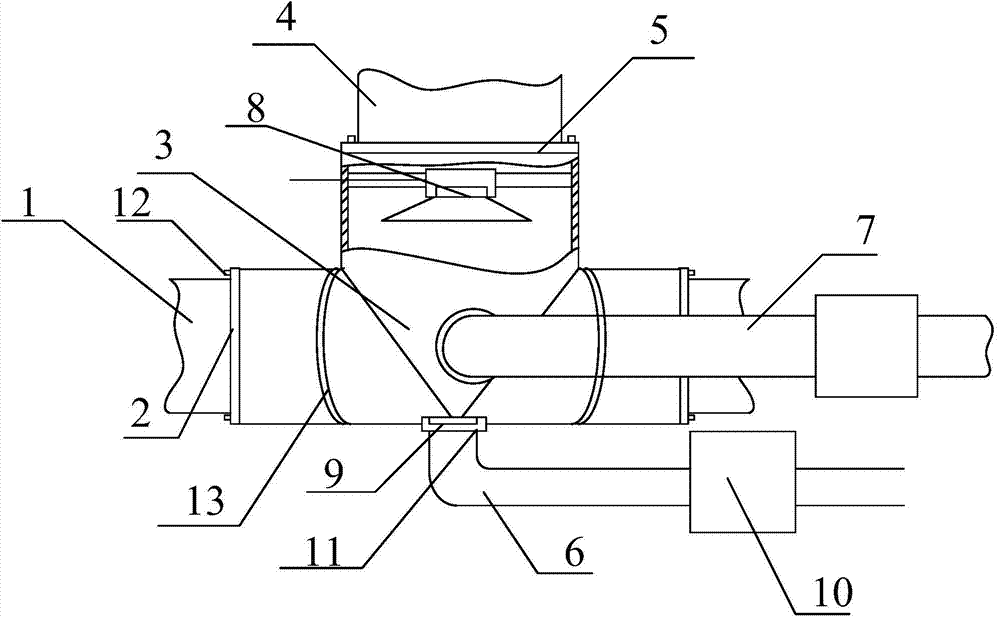

Tee joint material fluidistor of improved structure

ActiveCN104760829AImprove feeding efficiencyGood fluidization effectBulk conveyorsFailure rateDischarge rate

The invention provides a tee joint material fluidistor of an improvd structure. The fluidistor comprises side discharge ports, discharge flanges, a tee joint body, a top feed port, a feed flange, a bottom air inlet pipe, a side air inlet pipe, a vibration device, an intercepter plate, a preheating device, an air pipe joint, a fixed bolt and a protection plate, and the side discharge ports are installed at the left side and the right side of the tee joint body through the discharge flanges; the top feed port is installed on the upper portion of the tee joint body through the feed flange; the bottom air inlet pipe is installed at the lower side of the tee joint body through the air pipe joint. According to the fluidistor, through the arrangements of the vibration device, the preheating device, the intercepter plate and the protection plate, it is facilitated to improve the feeding efficiency, the fluidization degree is improved, the failure rate is reduced, and the market application and popularization are facilitated.

Owner:TIANJIN SHIDA ELECTRIC POWER EQUIP

Fluidizable carbon catalysts

InactiveUS20070299277A1Good fluidization effectHigh rateOrganic compound preparationPreparation by carbon monoxide or formate reactionPolymer sciencePtru catalyst

Disclosed are fluidizable catalysts comprising carbonized, polysulfonated vinylaromatic polymer particles. These carbonized polymer particles can be active catalysts by themselves or can act as supports for active catalyst components. These novel catalysts show excellent fluidization behavior over a wide range of gas velocities. Also disclosed are processes for making fluidizable catalysts, for fluidizing these catalysts, and for the preparation of carbonylation products with these catalysts.

Owner:EASTMAN CHEM CO

Blowing desulfurization fluidized chamber

InactiveCN104419797AStable feeding speedReduce processing timeCharge manipulationGas supplyProcess time

The invention discloses a blowing desulfurization fluidized chamber. The blowing desulfurization fluidized chamber comprises a shell (4) which comprises a desulfurizer inlet (1) and a desulfurizer outlet (3) formed in the height direction, an air supply duct (2) and an air distributing plate (6) provided with a plurality of air outlet holes (5) densely, wherein the upper edge of the air distributing plate (6) is attached to the inner wall of the shell (4) and the lower edge is connected with the desulfurizer outlet (3) so as to divide the shell (4) into a fluidized chamber (7) above the air distributing plate (6) and an air inlet chamber (8) below the air distributing plate (6); the air supply duct (2) is communicated with the air inlet chamber (8); and gas supplied from the air inlet chamber (8) enters into the air inlet chamber (8) and is sprayed into the fluidized chamber (7) through the plurality of air outlet holes (5) of the air distributing plate (6). According to the blowing desulfurization fluidized chamber disclosed by the invention, the desulfurizer is uniformly fluidized in the process of discharging the desulfurizer with a relatively good fluidizing effect, so that the desulfurizer is stable in discharging speed, the blowing process time is shortened, the spattering is reduced, and the iron loss is reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Preparation method and device of transition metal lithium oxide compound

ActiveCN110697801AReduce viscosityUniform particle sizeCobalt compoundsCalcinationLithium oxideMetallic lithium

The invention provides a transition metal lithium oxide compound preparation method, which comprises: A) mixing a lithium salt and a precursor, adding the mixture into a reactor, and pre-calcining, wherein the particle size D50 of the lithium salt is 10-20 [mu]m, the particle size D50 of the precursor is 1-20 [mu]m, and the precursor is one or a plurality of materials selected from a transition metal hydroxyl lithium oxide compound, a transition metal hydrogen lithium oxide compound and a transition metal carbonate; and B) adding the product obtained by the pre-calcining into a fluidized bed reactor, and sequentially carrying out primary calcination and secondary calcination to obtain a transition metal lithium oxide compound, wherein the preparation raw materials of the transition metal lithium oxide compound further comprise an oxygen-containing main group metal compound, the oxygen-containing main group metal compound is added in the pre-calcining stage, the primary calcining stageor the secondary calcining stage after the lithium salt and the precursor are added, and the particle size of the oxygen-containing main group metal compound is 10-100 nm. The invention also providesa fluidized bed reactor.

Owner:SHANDONG ZSTONE NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com