Method for improving particle fluidization quality and separation density stability and matched device

A particle fluidization and stability technology, applied in chemical instruments and methods, separating solids from solids with airflow, solid separation, etc., can solve problems such as reduction, achieve simple operation and maintenance, efficient sorting, and increase expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

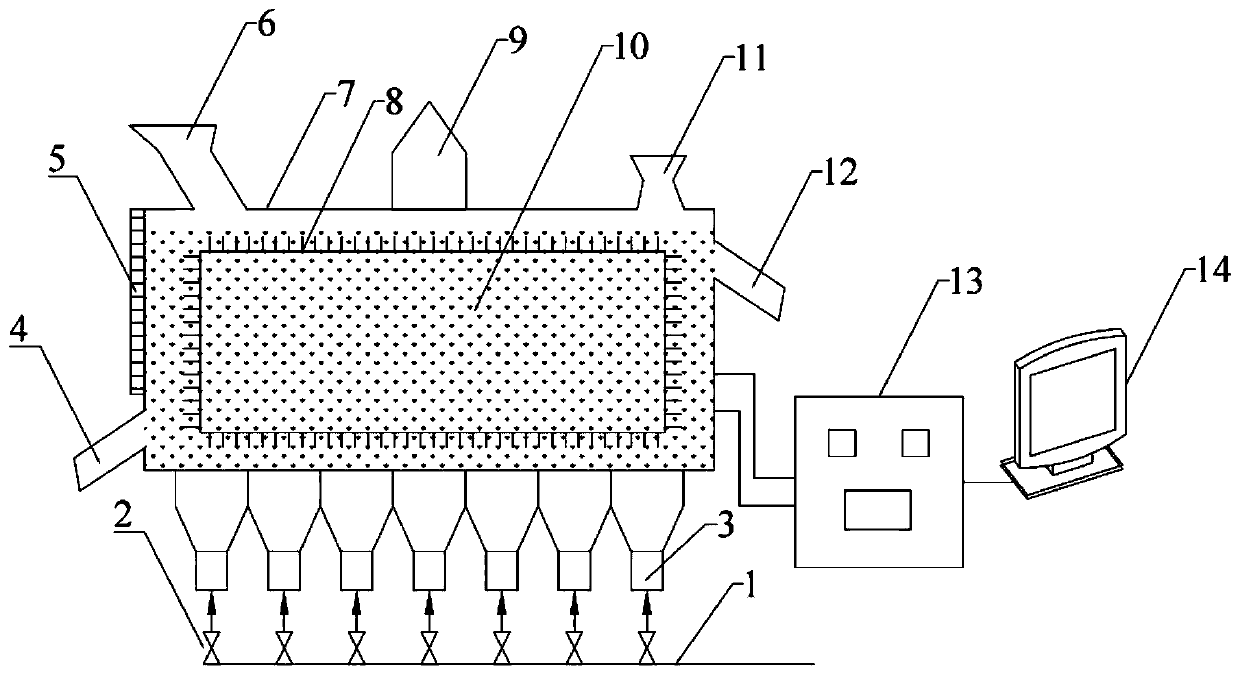

[0020] In order to better understand a method for improving particle fluidization quality and sorting density stability in a gas-solid fluidized bed dry sorting system of the present invention and its supporting devices, the following will be described with examples.

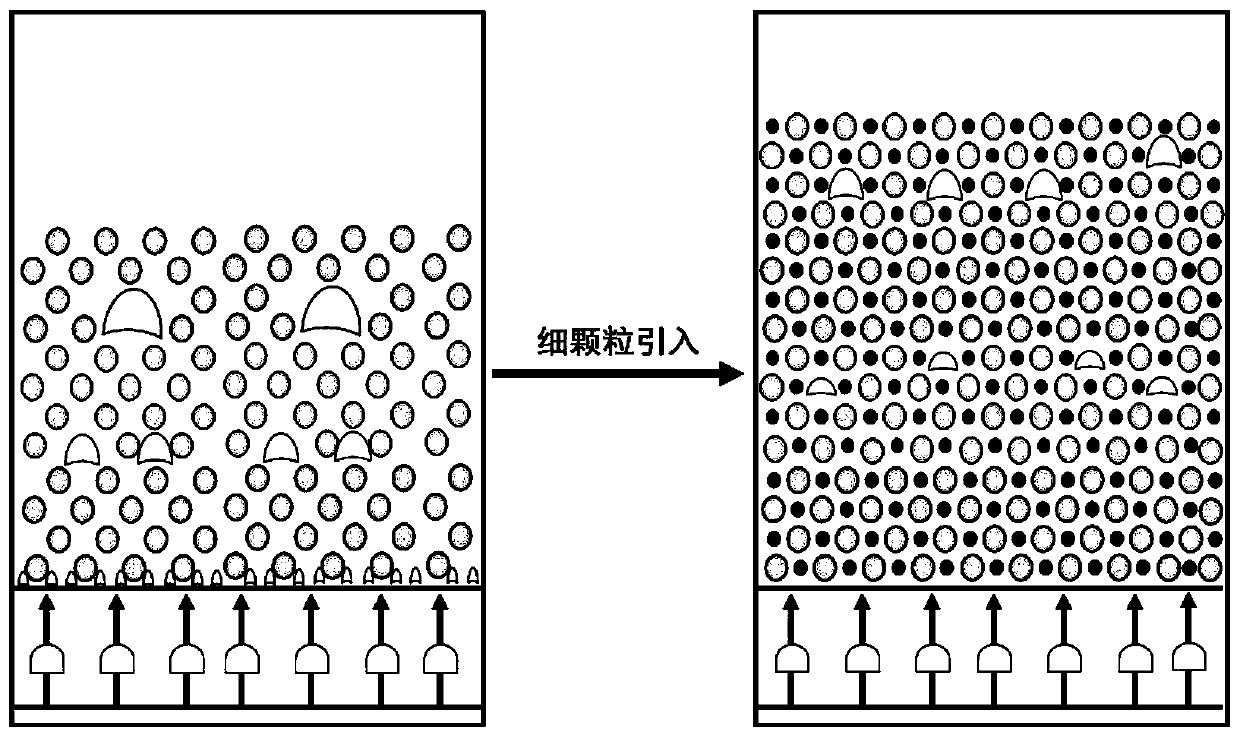

[0021] Such as figure 1 As shown, in the gas-solid fluidized bed dry separation system, coarse particles and fine particles are selected as the separation medium to ensure that the coarse particles and fine particles are fully mixed, and a separation bed with a certain density is formed under the action of air flow Through the introduction of fine particles, the fluidization performance of the particles is improved, the bulk expansion of the particle phase is promoted, and the size of the bubbles is reduced, thereby improving the stability of the sorting density.

[0022] The coarse particles are the main medium in the gas-solid fluidized bed, and the fine particles are the additional medium. The volume fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com