Preparation method and device of transition metal lithium oxide compound

A technology for metal compounds and transition metals, applied in the field of preparation of transition metal lithium oxide compounds, can solve the problems of low production efficiency, many production control points, and complex processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides a kind of preparation method of transition metal lithium oxygen compound, comprises the following steps:

[0044] A) adding the lithium salt and the precursor to the reactor for pre-calcination after mixing;

[0045] The particle size D50 of the lithium salt is 10-20 μm; the particle size D50 of the precursor is 1-20 μm;

[0046] The precursor is one or more of transition metal hydroxy lithium oxy compounds, transition metal hydrogen lithium oxy compounds and transition metal carbonates;

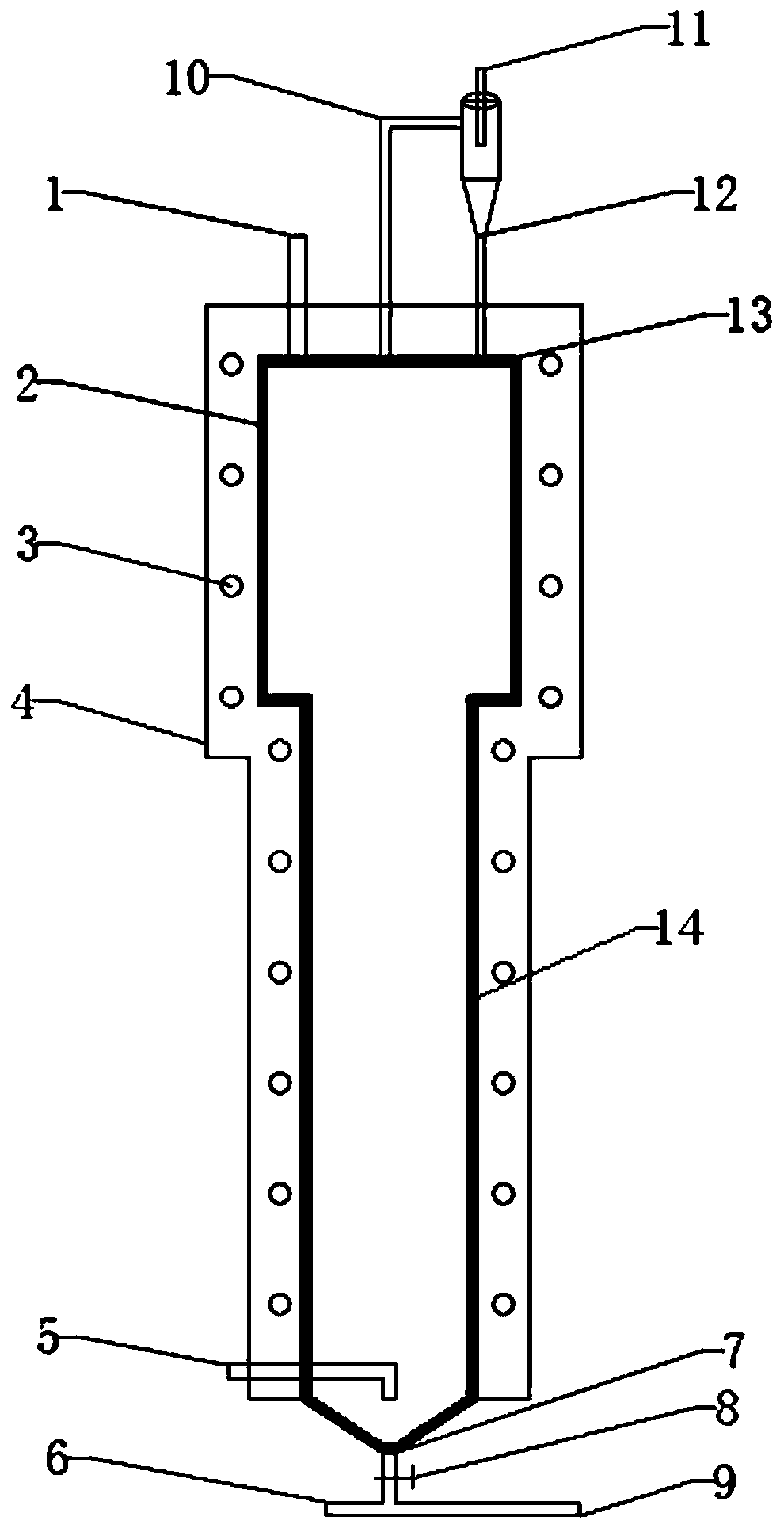

[0047] B) adding the product obtained by pre-calcination into a fluidized bed reactor, performing primary calcination and secondary calcination in sequence to obtain a transition metal lithium oxide compound;

[0048] The raw material for the preparation of the transition metal lithium oxy compound also includes an oxygen-containing main group metal compound, and the oxygen-containing main group metal compound is added in the pre-calcination stage, the ...

Embodiment 1

[0080] A. Put 2.8kg of LiOH·H 2 O, 0.65kg of nano-Al(OH) 3 and 6 kg of Ni with an average particle size of 10 microns 0.8 co 0.1 mn 0.1 (OH) 2 Add high-speed mixer for mixing;

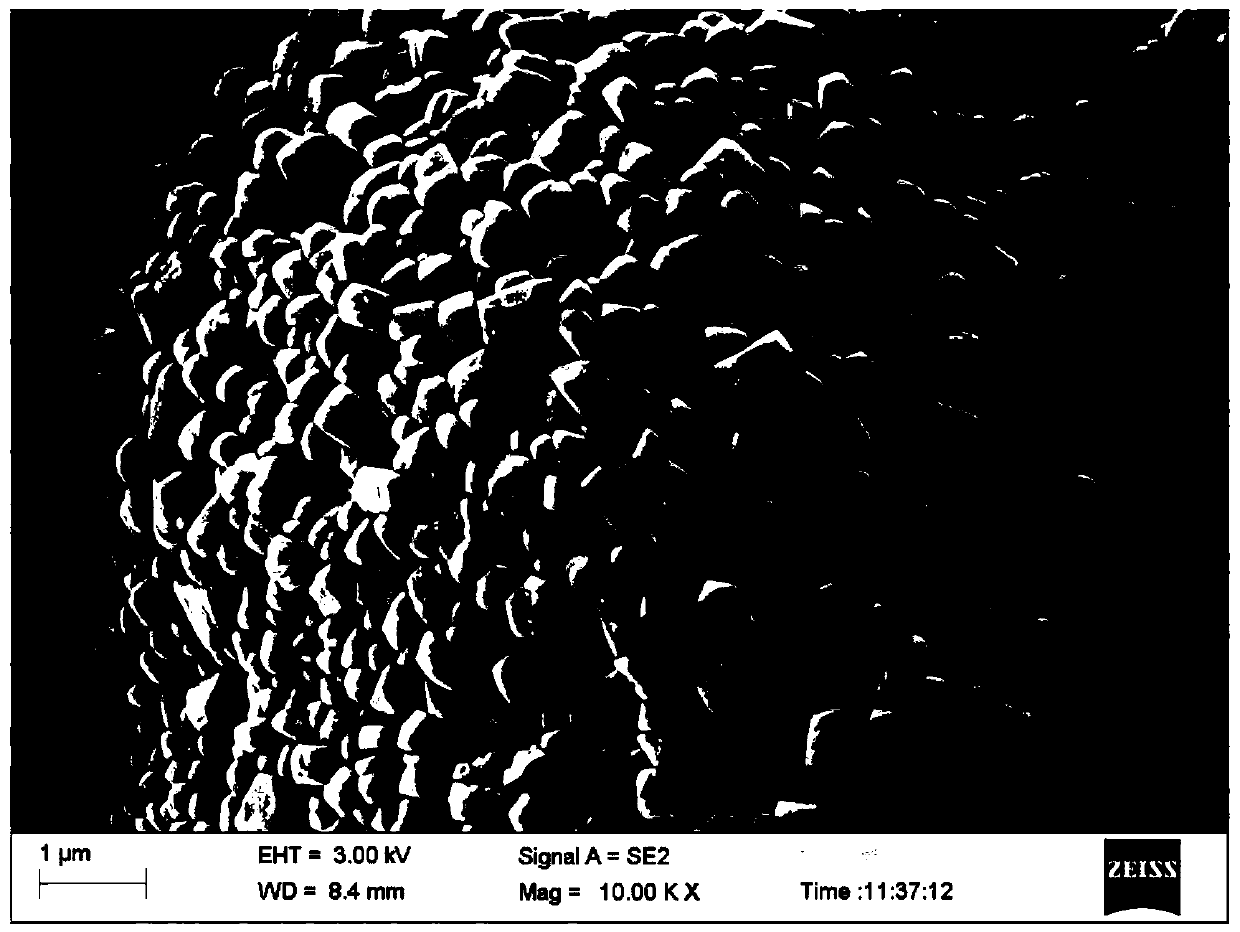

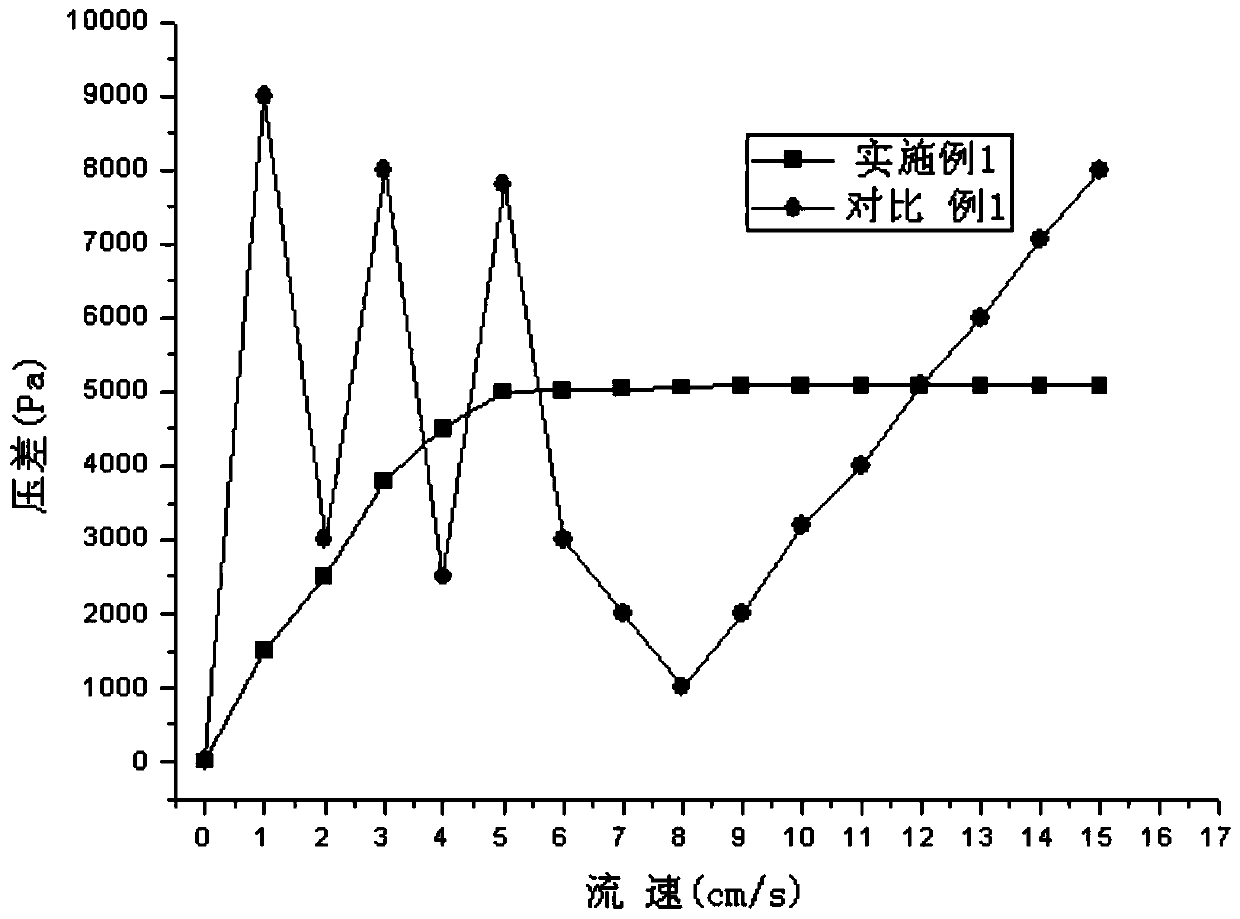

[0081] B. Add the obtained mixture into a fluidized bed reactor A with a diameter of 0.16m. The bottom of the reactor A is conical, and there is an integral surrounding heating device on the outside. The mixture in the reactor A is a columnar packed bed , the depth of the bed is 0.5m. When the temperature starts to rise, the high-purity oxygen is preheated by the preheating device and then passed into the interior of the reactor. To fluidize the material, the reactor A is equipped with an overall surrounding heating device, the heating method is radiation heat transfer, the heat transfer is uniform, and the solid mixture gradually heats up after gas-solid heat exchange and external heating, and the temperature rise rate is 5°C / min , heated to 150°C, and kept for 2 hours. During the heating proces...

Embodiment 2

[0085] A. Put 2.8 tons of LiOH·H 2 O, 0.65 tons of nano-Al(OH) 3 and 6 tons of Ni with an average particle size of 10 microns 0.8 co 0.1 mn 0.1 (OH) 2 mix;

[0086] B. Add the obtained mixture into a fluidized bed reactor A with a diameter of 1.6m. The bottom of the reactor A is conical, and there is an integral surrounding heating device on the outside. The mixture in the reactor A is a columnar packed bed , the depth of the bed is 5m. When the temperature starts to rise, the high-purity oxygen is preheated by the preheating device and then passed into the interior of the reactor. After being back-mixed at the bottom, it is fully in contact with the mixed solid particles. To fluidize the material, the reactor A is equipped with an overall surrounding heating device, the heating method is radiation heat transfer, the heat transfer is uniform, and the solid mixture gradually heats up after undergoing gas-solid heat exchange and external heating, and the heating rate is 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com