Patents

Literature

215results about How to "Reduce van der Waals forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high purity and high concentration graphene suspension

InactiveCN101830458AFacilitate the reduction reactionInhibition of agglomerationHigh concentrationUltrasonic radiation

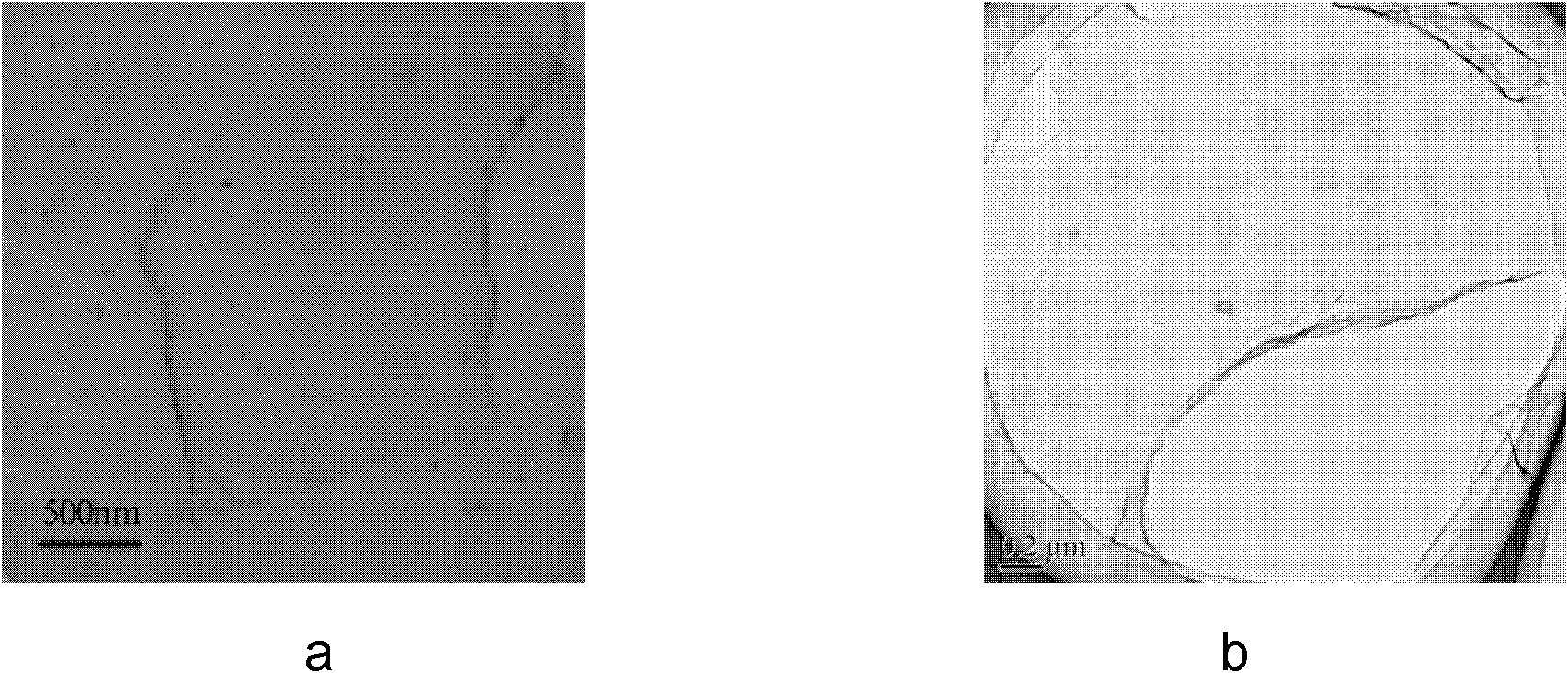

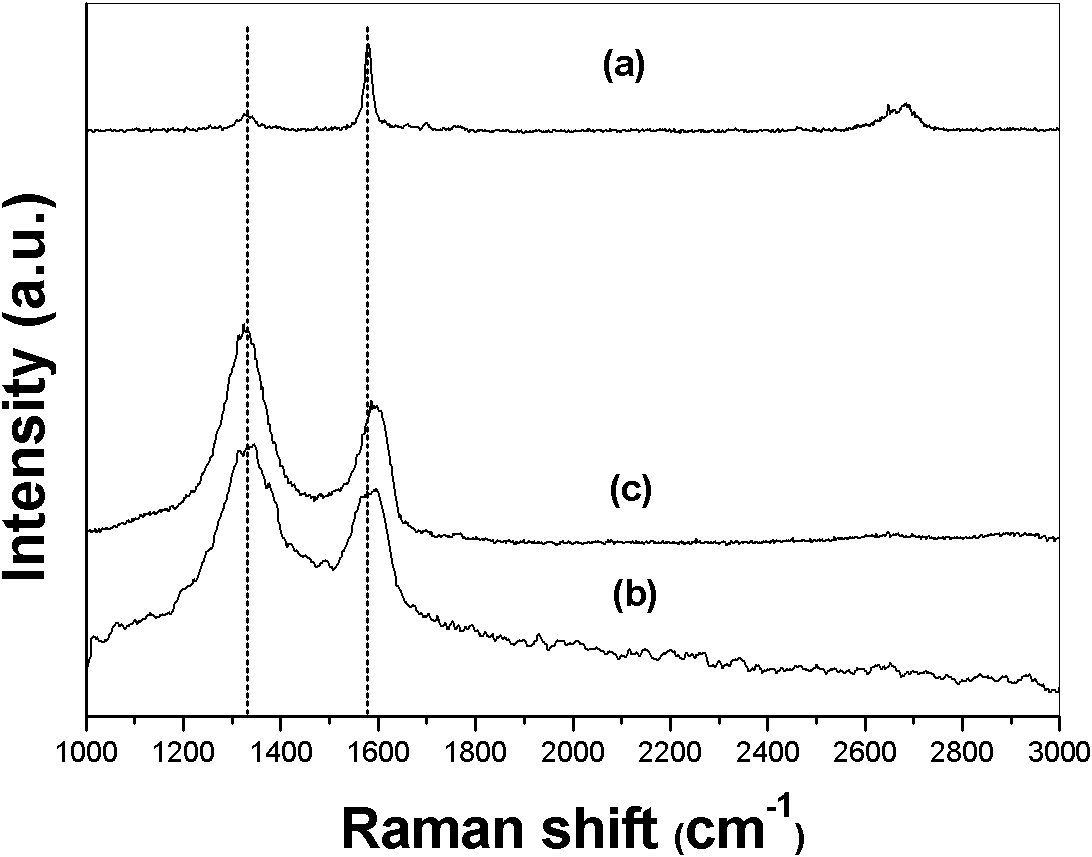

The invention relates to a preparation method of a high purity and high concentration graphene suspension, which comprises the following steps of: reacting natural crystalline flake graphite with a strong oxidizer to obtain graphite oxide; spreading the graphite oxide into a dispersing agent, and obtaining a graphene oxide suspension by ultrasonic dispersion; mixing the graphene oxide suspension with hydrazine hydrate under the protection of nitrogen and reacting at constant temperature under ultrasonic radiation to prepare stable graphene suspension. Compared with the traditional method for preparing the graphene suspension, the method introduces ultrasonic in the reduction process of the graphite oxide. The invention has the following advantages that the prepared graphene suspension has high concentration (higher than 1 mg.mL<-1>), high purity (without influence of surface active agents and other impurities), high dispersionstability (time for stable dispersion is more than 60 days) and the like; the graphene prepared by the method has high electrical conductivity (high than 700 S.m<-1>), less number of layers, is simple and easy to implement, and is very suitable for large scale production in industy.

Owner:XI AN JIAOTONG UNIV

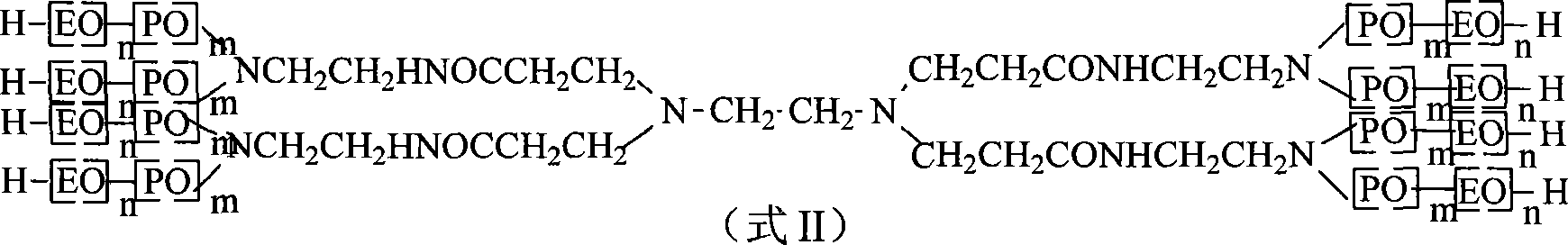

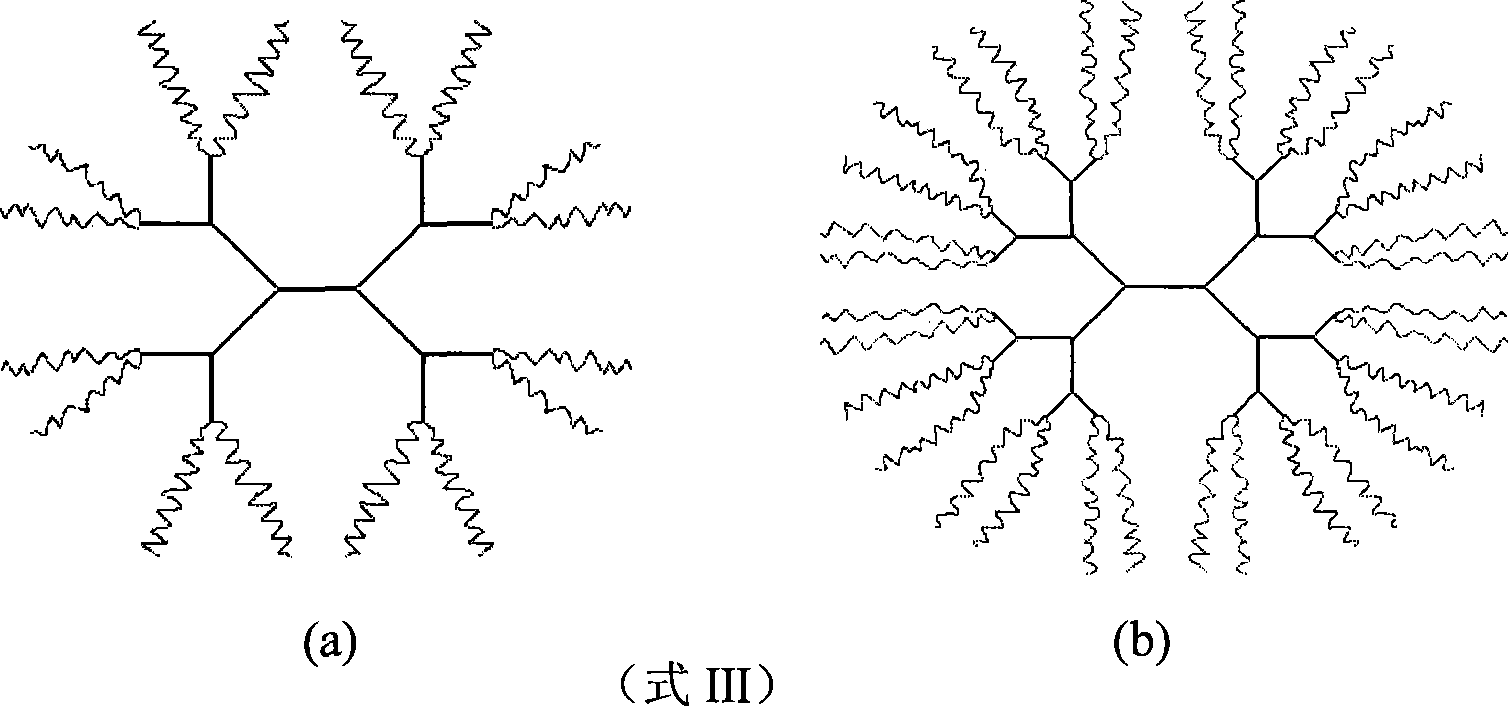

Crude de-emulsifier and its preparing process

InactiveCN101418230AHigh molecular weightImprove surface propertiesHydrocarbon oil dewatering/demulsificationEpoxyEmulsion

The invention discloses a de-emulsifying agent and a method for preparing the same. The de-emulsifying agent is a polyether compound prepared by alkoxylation reaction of poly (amidoamine) (PAMAM) and epoxy compounds. The invention adopts the PAMAM with a dendritic multi-branch structure as an initiator for synthesis the de-emulsifying agent. The obtained de-emulsifying agent has the characteristics of a plurality of branched and large molecular weight. The de-emulsifying agent has good interfacial activity, infiltrability, good crude oil emulsion de-emulsifying performance, and wide applications in crude oil exploration, oil refining and other fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

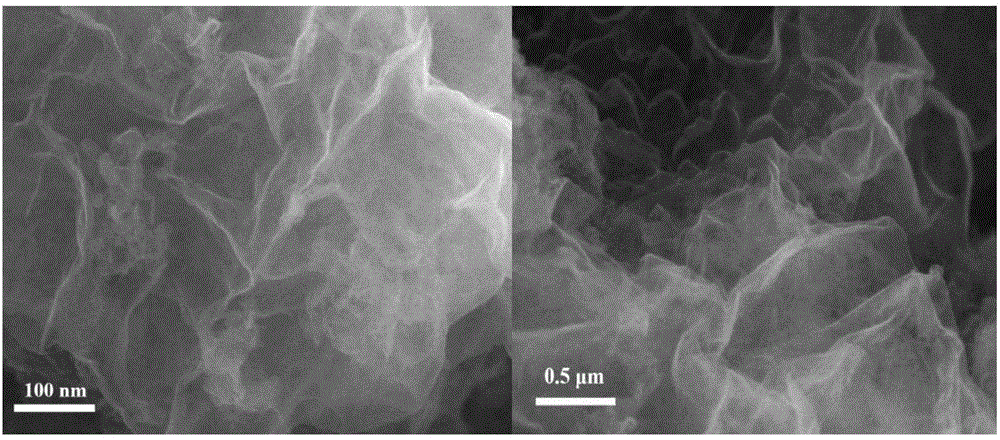

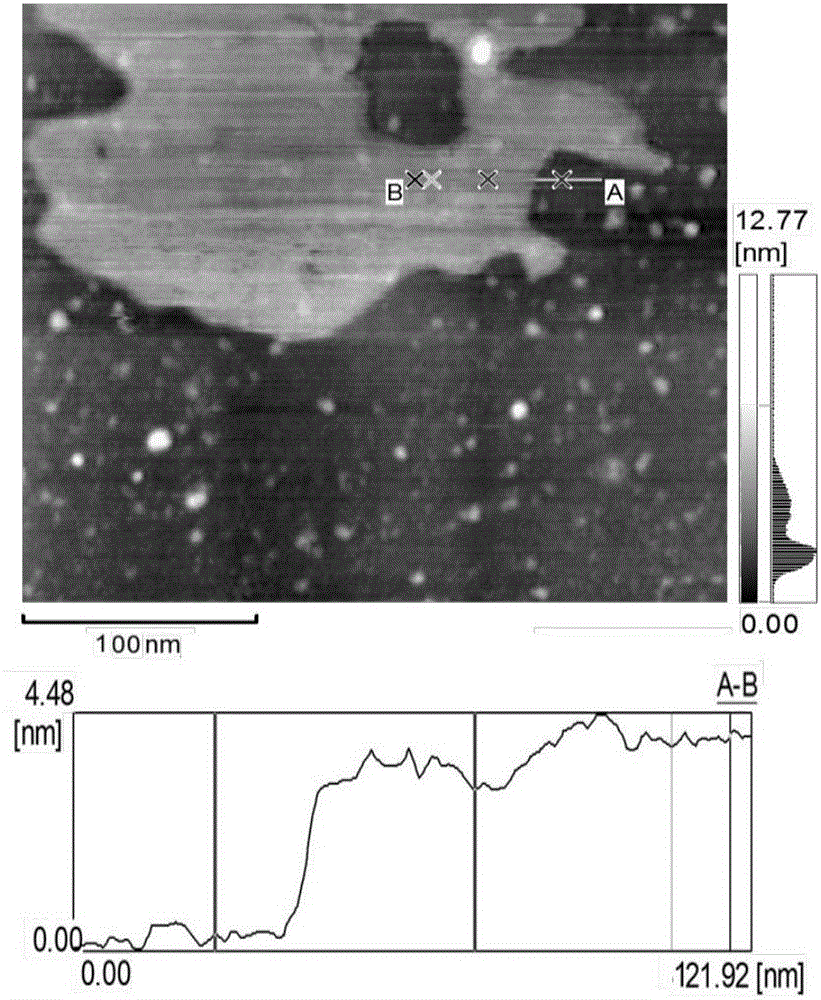

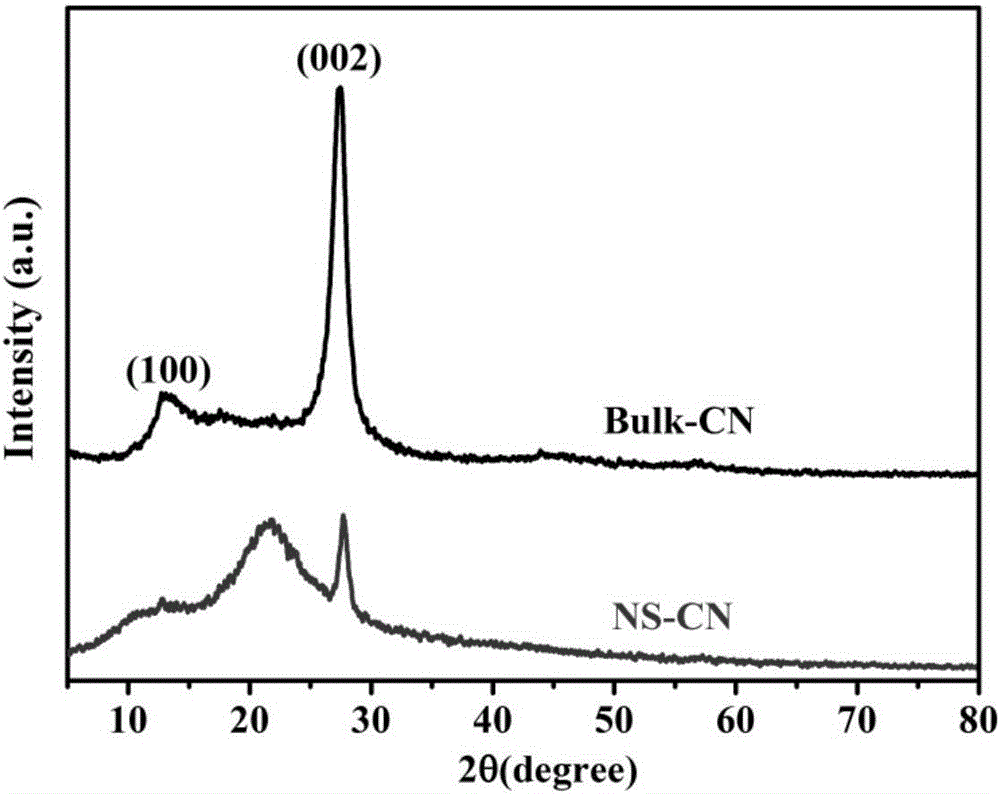

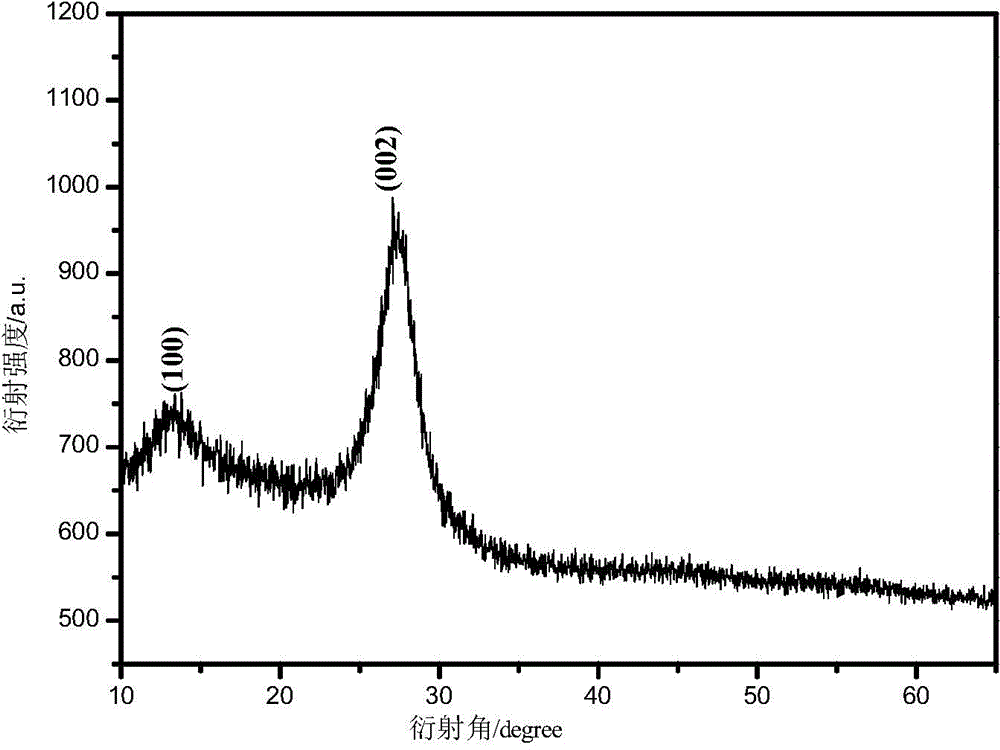

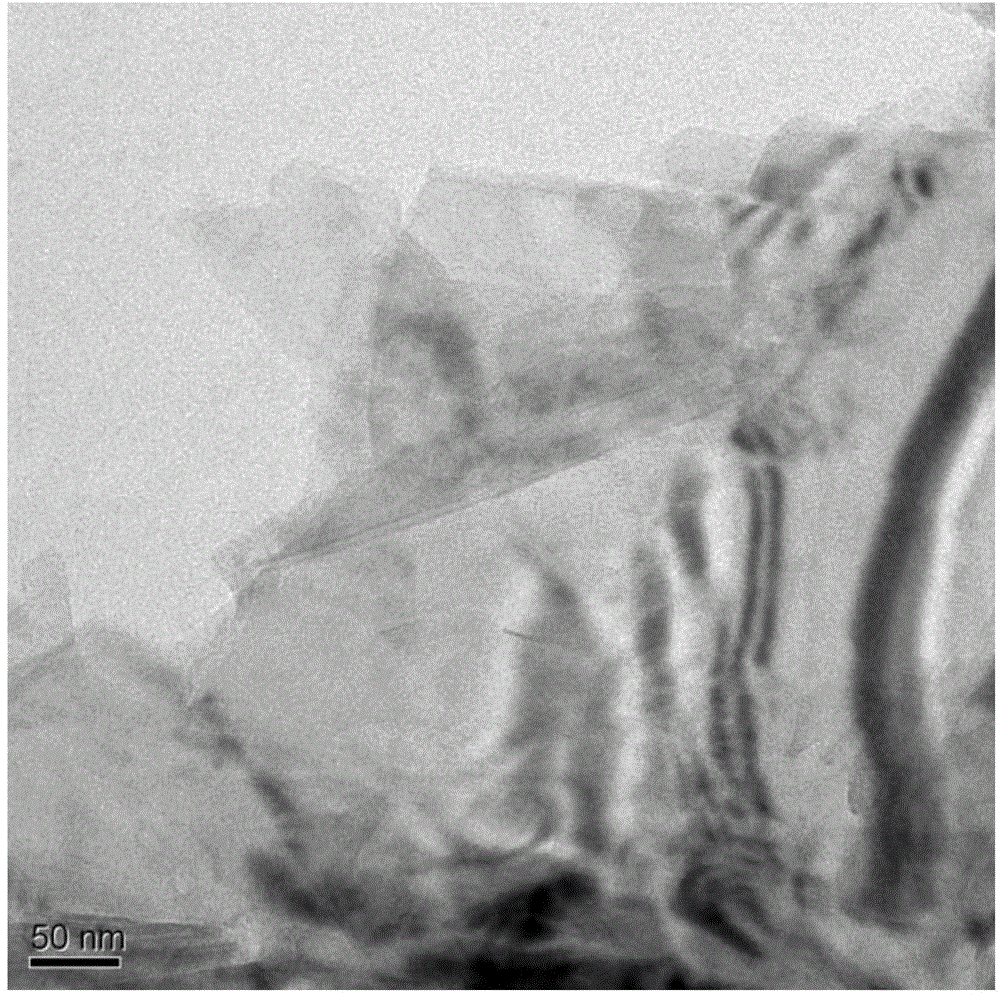

Ammoniated ultrathin graphite-phase carbonitride photocatalyst and preparation method thereof

ActiveCN106563481AScattering effect is smallEasy to separateCatalyst activation/preparationTube furnaceGraphite

The invention discloses an ammoniated ultrathin graphite-phase carbonitride photocatalyst material and a preparation method thereof. The ammoniated ultrathin graphite-phase carbonitride photocatalyst material resembles wrinkled tulle, is in the shape of tulle with wrinkles and has a uniform thickness of 3 to 5 nm; and the surface of the material is smooth and contains rich amino groups. The preparation method comprises the following steps: acidifying melamine so as to obtain a protonated melamine supermolecular structure crystal, carrying out calcining in an inert protective atmosphere so as to prepare a graphite-phase carbonitride material and carrying out uniformization so as to obtain ultrafine powder of a graphite-phase carbonitride photocatalyst material; and placing the ultrafine powder of the graphite-phase carbonitride photocatalyst material and an ammonia-source substance capable of producing ammonia gas through thermal decomposition into a tubular furnace, introducing inert gas for deoxygenation and then carrying out gradient calcining in the inert protective atmosphere, i.e., carrying out heating to 500 to 540 DEG C at first, maintaining the temperature for 2 to 4 h, then carrying out heating to 560 to 600 DEG C, maintaining the temperature for 2 to 3 h and then carrying out cooling. The ammoniated ultrathin graphite-phase carbonitride photocatalyst material has substantially improved photocatalysis efficiency and present excellent photocatalysis performance when applied to catalytic reduction of CO2.

Owner:WUHAN UNIV OF TECH

Preparation method for single-layer graphite-type carbon nitride nanosheet solution

InactiveCN104401948AIncrease layer spacingReduce van der Waals forcesMaterial nanotechnologyNitrogen and non-metal compoundsSolventBall mill

The invention discloses a preparation method for a single-layer graphite-type carbon nitride nanosheet solution. The preparation method comprises the following steps: selecting tripolycyanamide or urea or bipolydicyanamide as a precursor, and performing pyrolytic reaction to obtain graphite-type carbon nitride powder; weighing carbon nitride powder, putting the carbon nitride powder into a ball milling jar with an aqueous solution of a polar solvent or a surfactant, and putting into a jar mill for ball milling; after ball milling for a certain time, pouring out a suspension, performing ultrasonic exfoliation by using an ultrasonic dispersion instrument, and centrifuging the obtained solution; taking a supernatant, namely the single-layer graphite-type carbon nitride nanosheet solution. Compared with the prior art that the single-layer graphite-type carbon nitride nanosheet solution is obtained by using a high-power ultrasonic exfoliation instrument, the preparation method provided by the invention has the advantages as follows: after ball milling pretreatment, the ultrasonic exfoliation on the carbon nitride powder is carried out, so that energy consumption is lower in the preparation process, and the prepared graphite-type carbon nitride nanosheet solution is higher in concentration and relatively low in cost.

Owner:CHANGAN UNIV

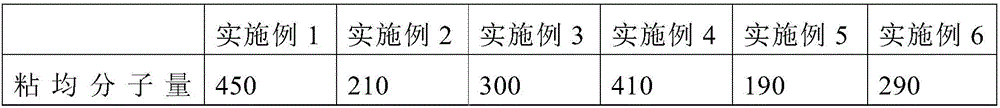

Preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene)

The invention relates to a preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene). The preparation method comprises the following steps: adding a certain amount of solvent oil in a dispersion medium, and polymerizing, thus obtaining UHMWPE containing the solvent oil; extruding through a screw extruder after mixing a flow modifier, a function additive processed by a coupling agent, an antioxidant and the UHMWPE containing the solvent oil at high speed, thus obtaining the injection molding grade UHMWPE. Compared with the prior art, the injection molding grade UHMWPE prepared by the method has good liquidity and good mechanical performance, can be machined and formed on a common injection molding and extrusion device, the machining efficiency is increased, and the injection molding grade UHMWPE can be widely applied to many fields of spaceflight, military industry, automobiles, high-speed rails, rail transit, spinner accessories and the like.

Owner:SHANGHAI RES INST OF CHEM IND

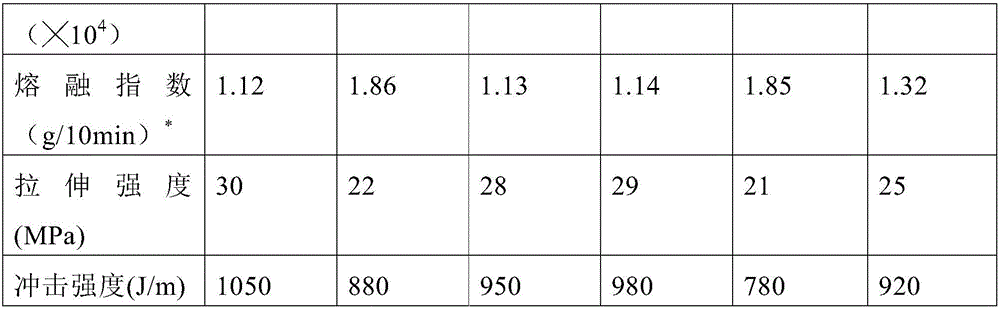

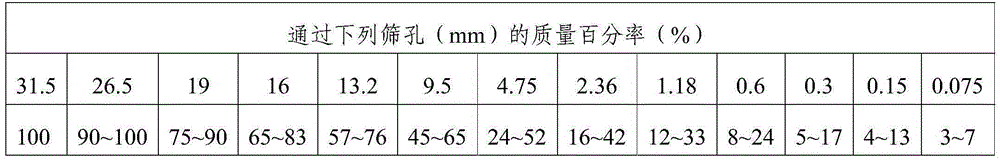

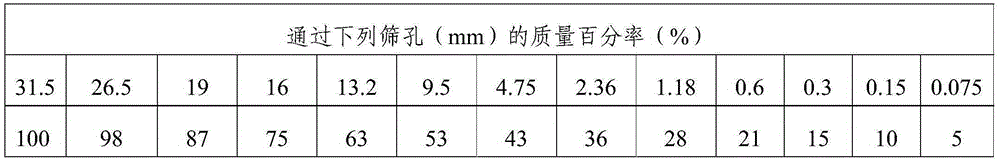

Warm-mixing recycled asphalt mixture preparation method

ActiveCN105293996AEmission reductionImprove road performanceClimate change adaptationMass contentAsphalt

The invention discloses a warm-mixing recycled asphalt mixture preparation method which comprises the following steps: I, preparing a compound regenerant; II, preparing a compound warm-mixing agent; III, measuring the mass content and natural gradation of old asphalt in an RAP material and respectively determining mass ratios of novel aggregate and novel mineral powder which are required for preparing the warm-mixing recycled asphalt mixture to the RAP material; IV, preparing a warm-mixing recycled asphalt mixture sample and determining an optimum asphalt-aggregate ratio of the warm-mixing recycled asphalt mixture; V, under the condition of the optimum asphalt-aggregate ratio, preparing the warm-mixing recycled asphalt mixture. According to the invention, the recycling rate of the RAP material reaches 70% or above, meanwhile, secondary aging of the asphalt mixture is avoided, the advantages of energy saving and carbon emission and harmful gas emission reduction are realized and the warm-mixing recycled asphalt mixture prepared through the preparation method has good pavement performance.

Owner:CHANGAN UNIV

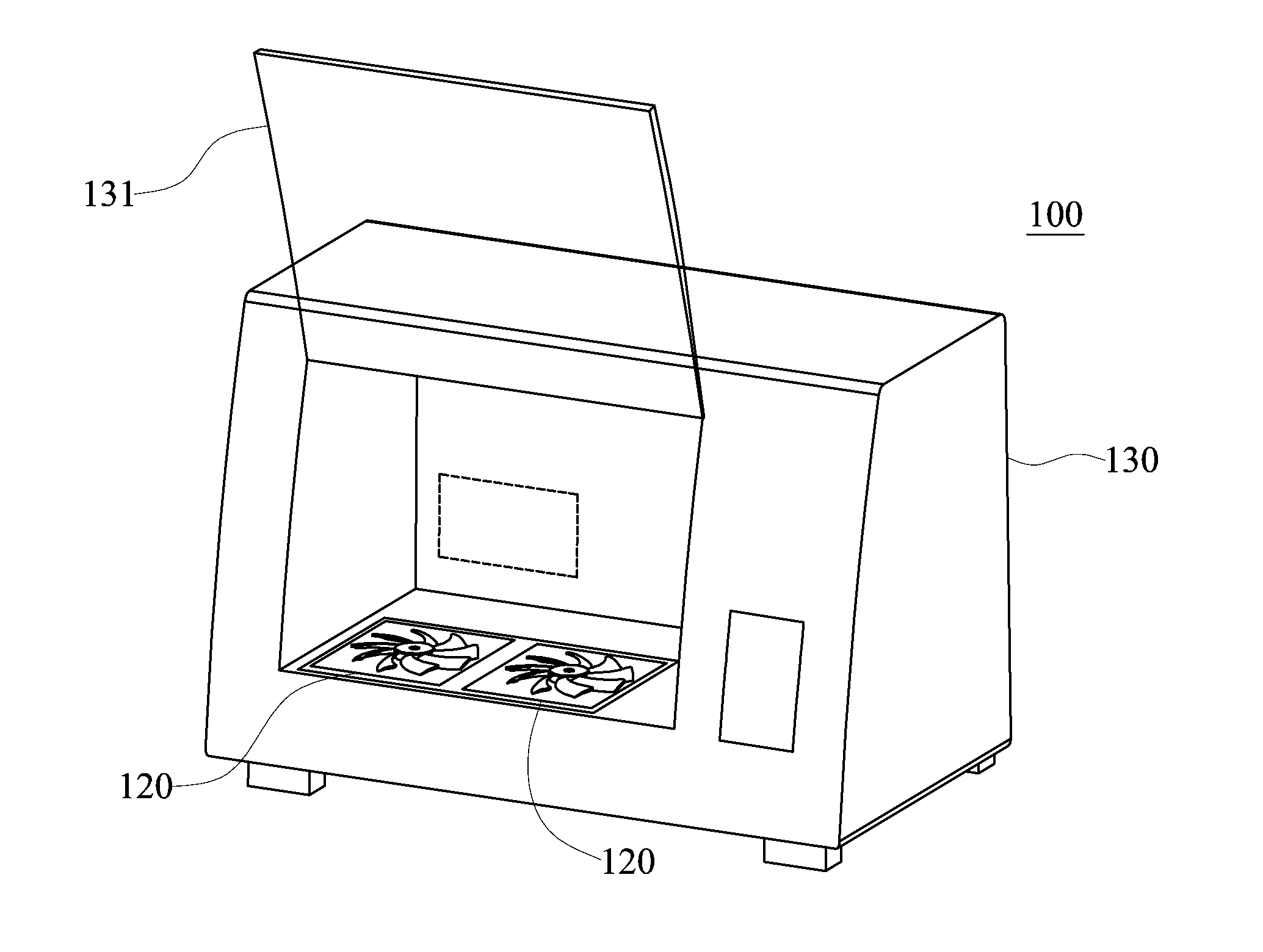

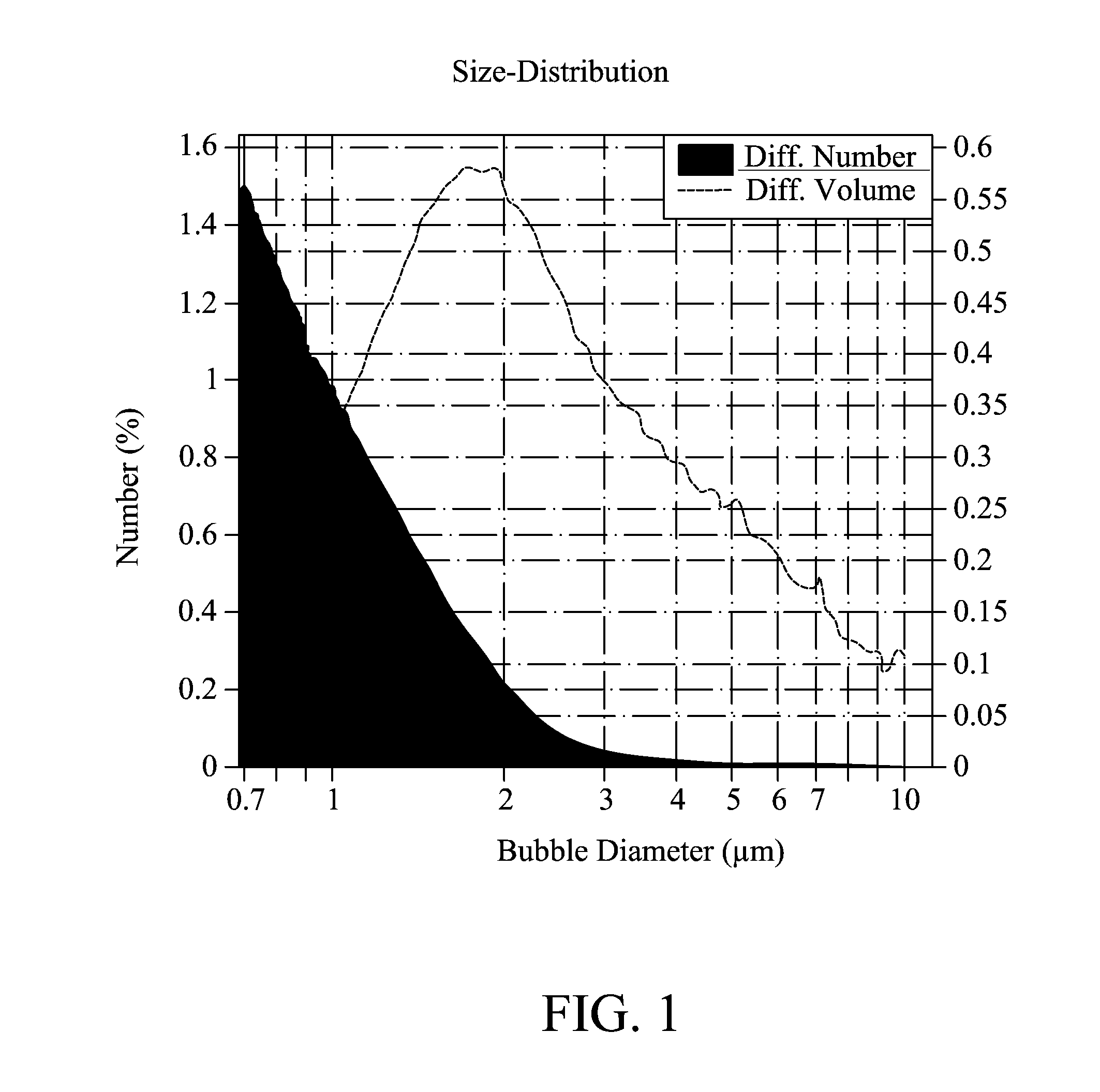

Method and device for producing optimized lipid-based micro/nano-bubbles

ActiveUS20140328767A1Optimal material utilization efficiencyImprove distributionUltrasonic/sonic/infrasonic diagnosticsShaking/oscillating/vibrating mixersTemperature controlSolvent

A method of producing lipid-based micro / nano bubbles includes steps of (a) preparing a lipid mixture including one or more first lipids with different phase transition temperature, and a second lipid bonding with a hydrophilic polymer moiety or molecules capable of getting across a lipid membrane and decreasing van der Waals forces between lipid bilayers; (b) emulsifying the lipid mixture with a solvent, to form a transparent lipid carrier solution; (c) placing the transparent lipid carrier solution in a closed vessel with halo-substituted hydrocarbon; (d) manipulating temperature of the transparent lipid carrier solution to be close to a main phase transition temperature thereof; and (e) agitating in a mechanical manner the vessel containing the transparent lipid carrier solution to form micro / nano bubbles within the closed vessel. This method contributes to form micro / nano bubbles with desired diameters in a way of optimal material utilization efficiency.

Owner:TRUST BIO SONICS

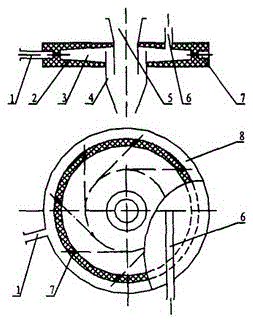

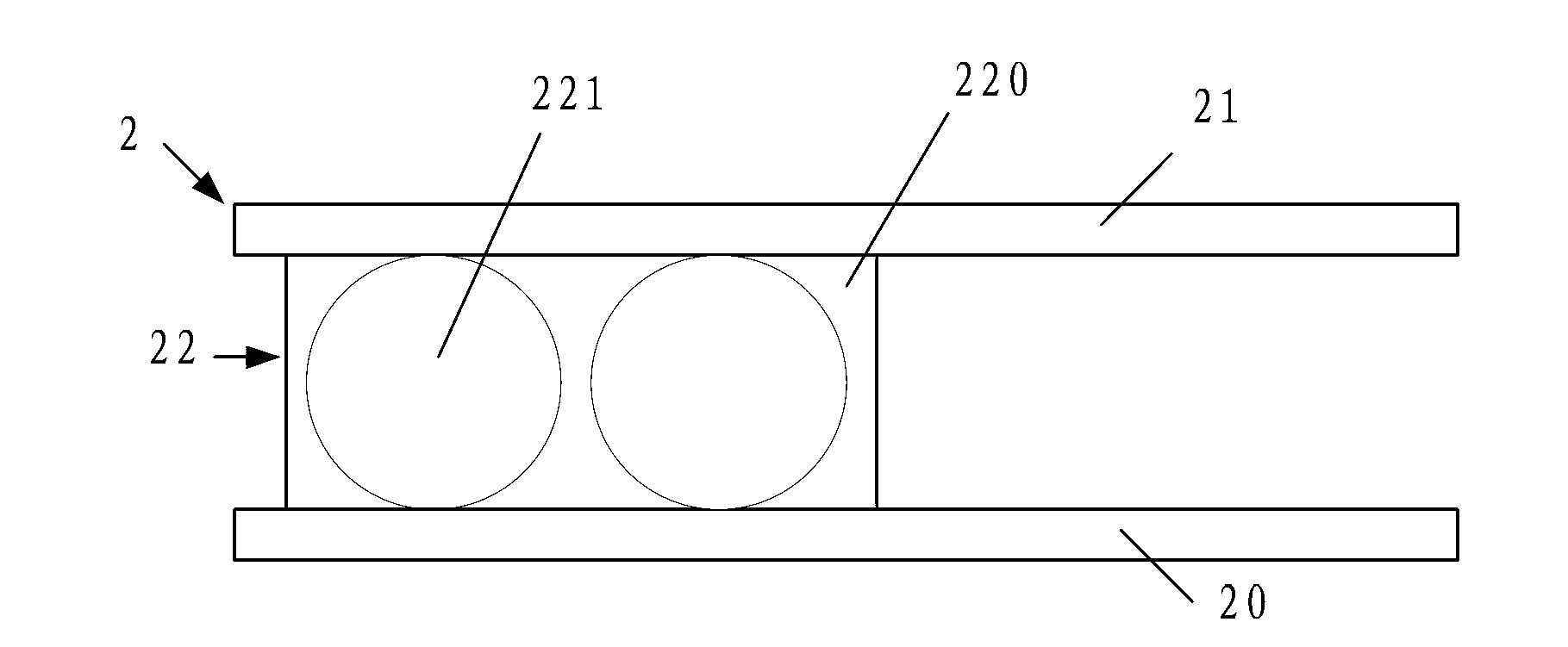

Method for preparing graphene nanoplatelets with disk type jet mill

ActiveCN105523550AFacilitate the promotion of large-scale applicationEvenly dispersedGraphenePolymer scienceGraphite

The invention relates to the field of graphene materials, in particular to a method for preparing graphene nanoplatelets with a disk type jet mill. Graphite powder is subjected to heat treatment firstly, then graphene is pretreated with an intercalation agent, Van der Waals's force between graphite layers is decreased, graphite layers are easier to strip, the graphite powder is added to the disk type jet mill, graphite rubs and collides with one another in jet stream collisions to produce shear force serving as the main force, friction force and impact force, graphite layers are stripped, and the graphene nanoplatelets are obtained. Continuous and mass production of the graphene nanoplatelets with uniform layers is realized, the yield is high, the cost is low, pollution is avoided, the layer thickness meets the use requirement in fields of rubber reinforcement, plastic reinforcement, coating corrosion prevention, lubrication and sewage treatment, and large-scale application of graphene is promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

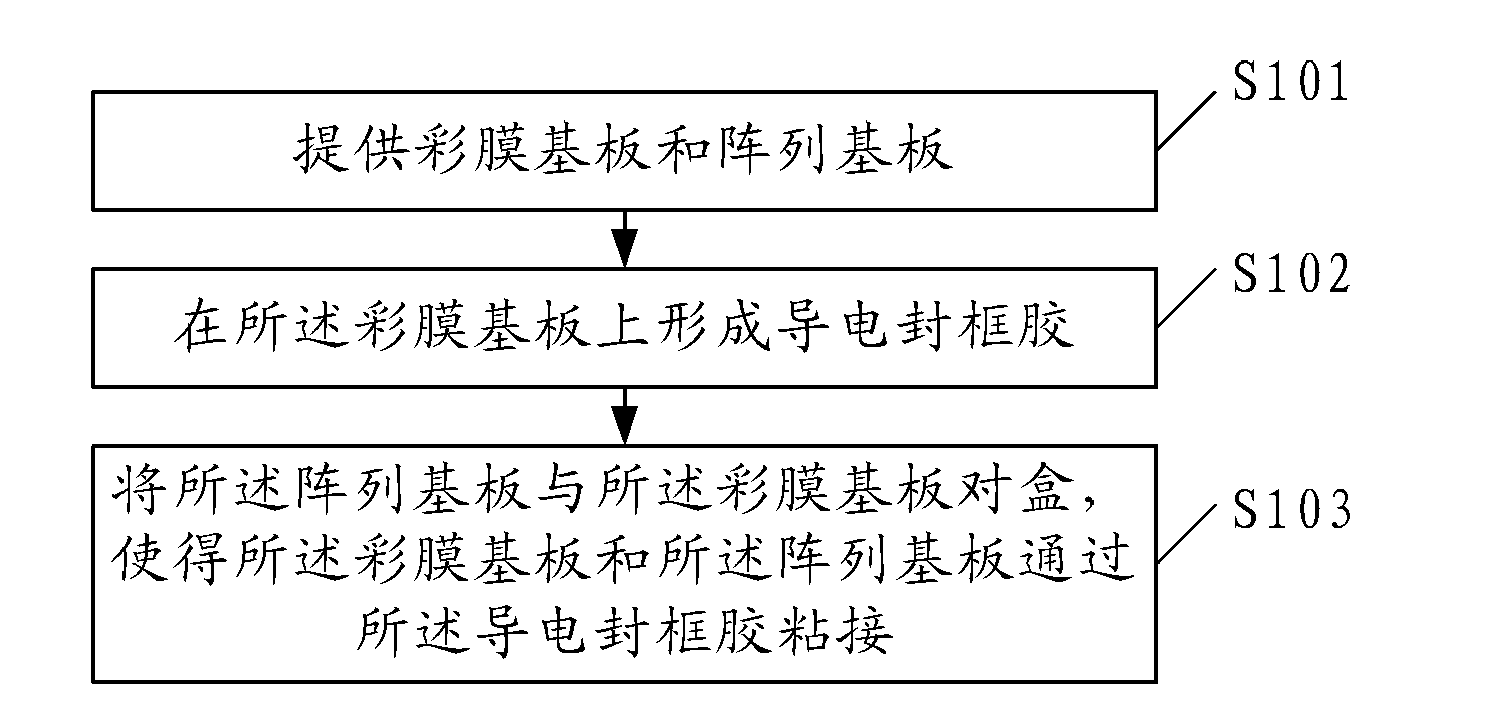

Conductive sealing agent, display panel and manufacturing method thereof, and display device

ActiveCN103232820AImprove conductivitySmall specific surface areaEster polymer adhesivesHydrocarbon polymer adhesivesDisplay deviceCarbon nanotube

The embodiment of the invention provides a conductive sealing agent, a display panel and a manufacturing method thereof, and a display device, relating to the technical field of display. The invention can solve the problem of poor conductive effect of the display panel due to aggregation of graphene in the prior art, and enhance the display effect of the display panel. The conductive sealing agent provided by the invention comprises a sealing agent material and conductive particles, wherein the conductive particles are a composite material formed by adding graphene or carbon nanotubes into a resin.

Owner:BOE TECH GRP CO LTD

Graphene pre-dispersed master batch as well as preparation method and application thereof

InactiveCN106117935AEvenly dispersedAvoid reunionRolling resistance optimizationPolymer scienceRolling resistance

The invention discloses a graphene pre-dispersed master batch. The graphene pre-dispersed master batch is prepared from the following components in percentage by weight: 10 to 60 percent of graphene, 9 to 36 percent of rubber carrier, 3 to 10 percent of silane coupling agent, 2 to 8 percent of calcium stearate, 5 to 12 percent of naphthenic oil and 5 to 25 percent of inorganic filler. According to the graphene pre-dispersed master batch disclosed by the invention, the rubber carrier is used as a base material; meanwhile, the silane coupling agent, the calcium stearate, the naphthenic oil and the inorganic filler are added, the graphene is prepared into a pre-dispersed master batch form, is enabled to be coated in the rubber carrier and is enabled to be uniformly pre-dispersed in master batch, so that the aggregation of the graphene is avoided, and the graphene is enabled to be uniformly dispersed in subsequent rubber products; the master batch is convenient to store, transport and weigh, the utilization rate of the graphene can be effectively improved, and the cost is reduced; the graphene pre-dispersed master batch can be particularly applied to tire tread rubber having higher requirements on processability, crosslinking density, tensile property, ageing-resistant performance, rolling resistance, abrasion property and wet skid resistance, or can be applied to other high-quality rubber products.

Owner:NINGBO ACTMIX POLYMER

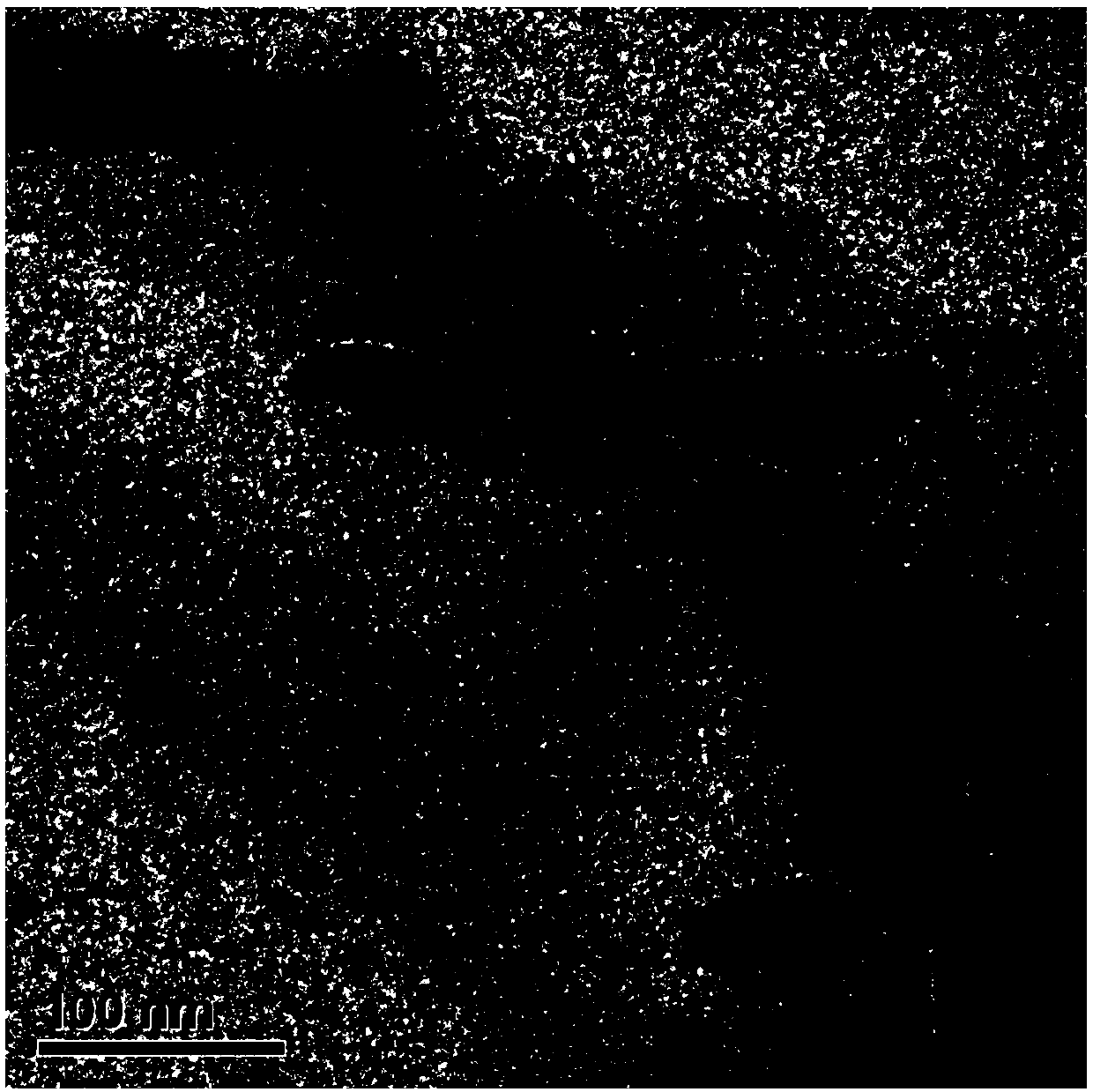

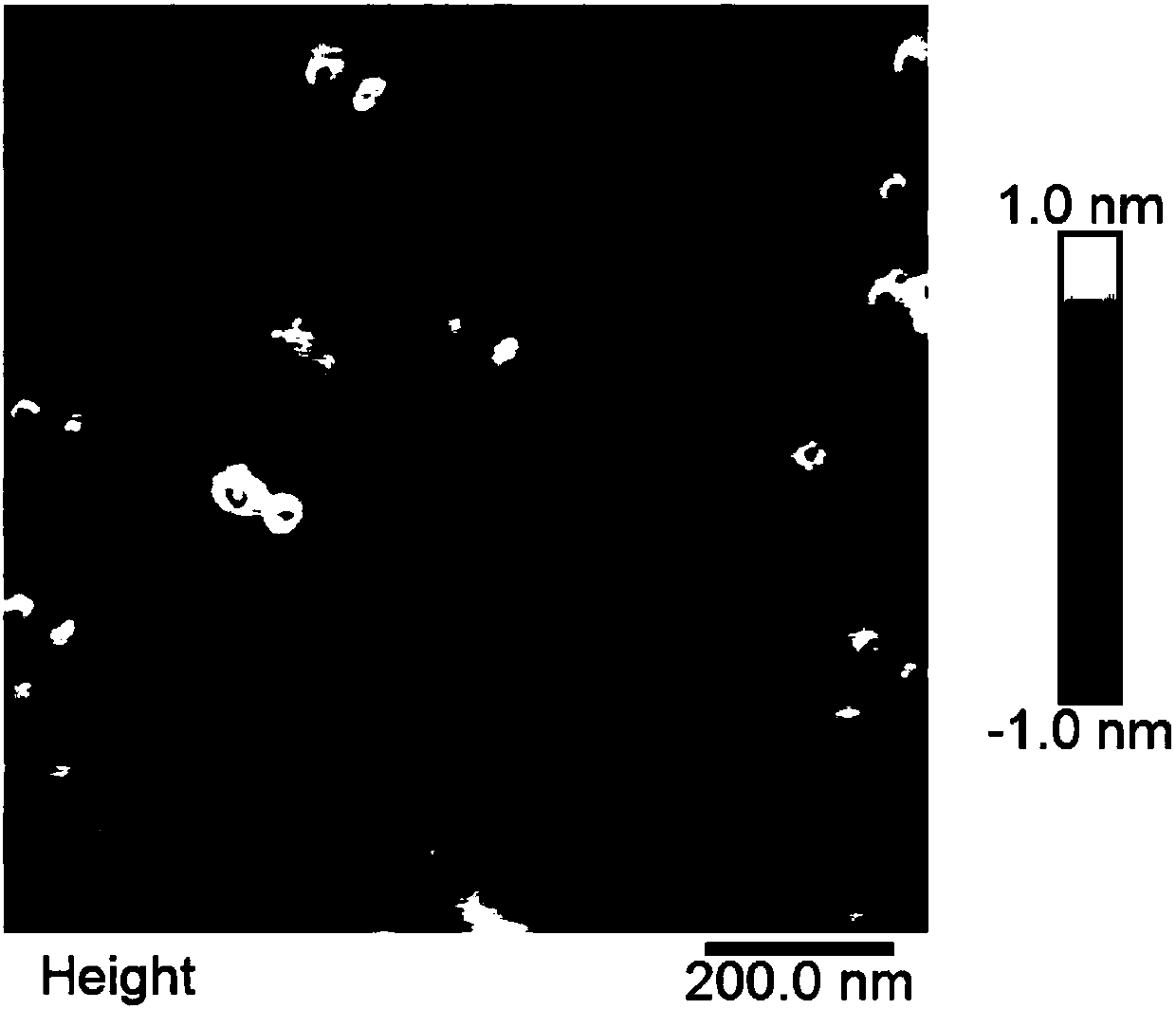

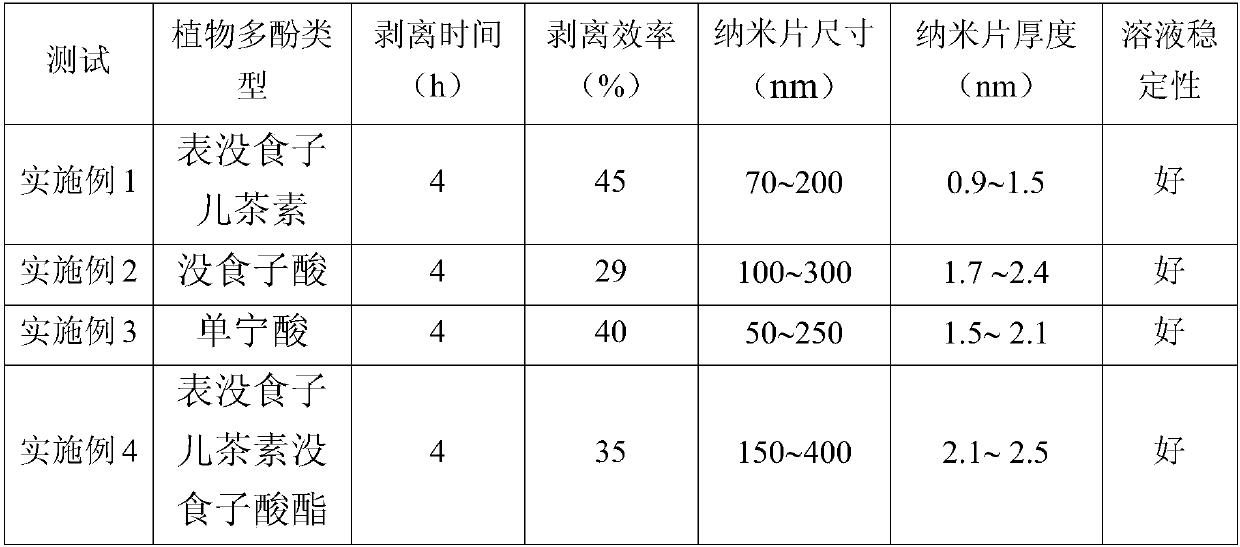

Method for preparing two-dimensional nano-sheet materials by adopting liquid-phase stripping

InactiveCN108033487AStrong adhesionReduce van der Waals forcesCarbon compoundsNitrogen and non-metal compoundsChemistryAqueous solution

The invention discloses a method for preparing two-dimensional nano-sheet materials by adopting liquid-phase stripping. The method includes the steps of 1), adding layered three-dimensional materialsand plant polyphenol into water for even mixing to form a mixture and performing ultrasonic treatment; 2), performing centrifugal separation on the mixture subjected to ultrasonic treatment, wherein asupernatant separated is a water solution of the two-dimensional nano-sheet materials; 3), drying the water solution of the two-dimensional nano-sheet materials to obtain powder of the two-dimensional nano-sheet materials. In the method, the natural plant polyphenol is taken as an additive to assist an ultrasonic liquid phase in having the various layered three-dimensional materials into the two-dimensional nano-sheet materials, the plant polyphenol is super adhesive force and can be quickly adsorbed to surfaces of various two-dimensional nano-sheet materials, and excellent university and efficiency are achieved due to the super adhesive force.

Owner:ZHEJIANG UNIV

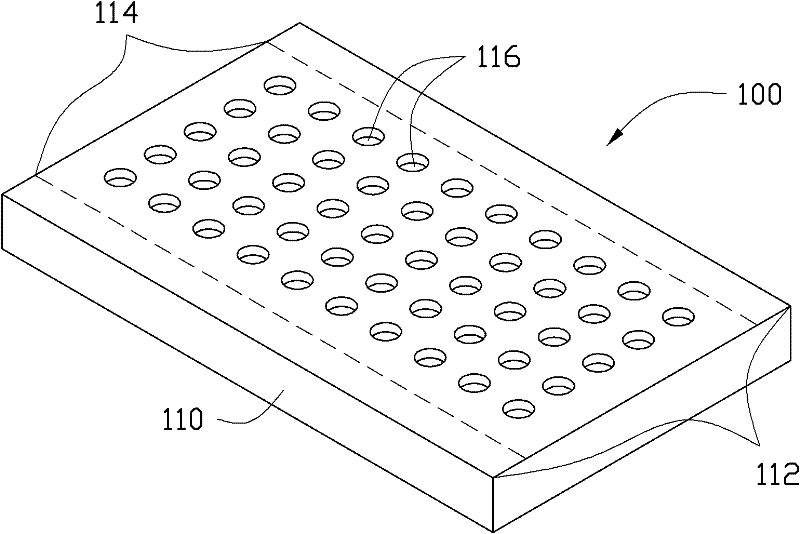

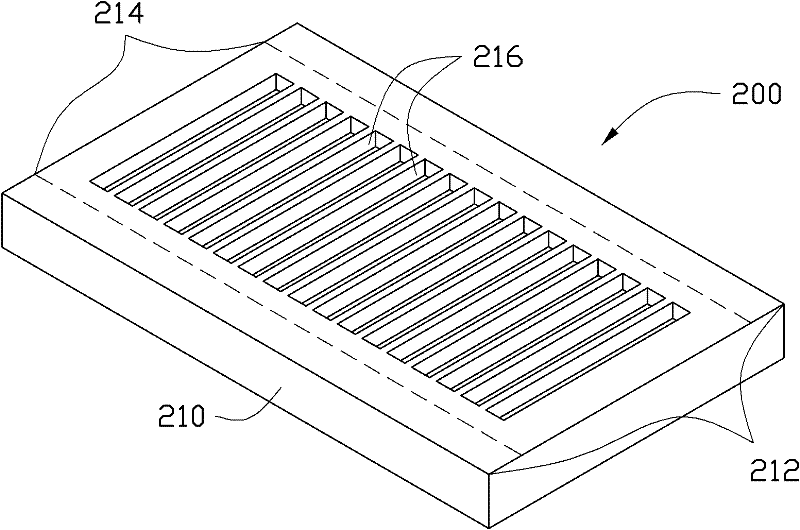

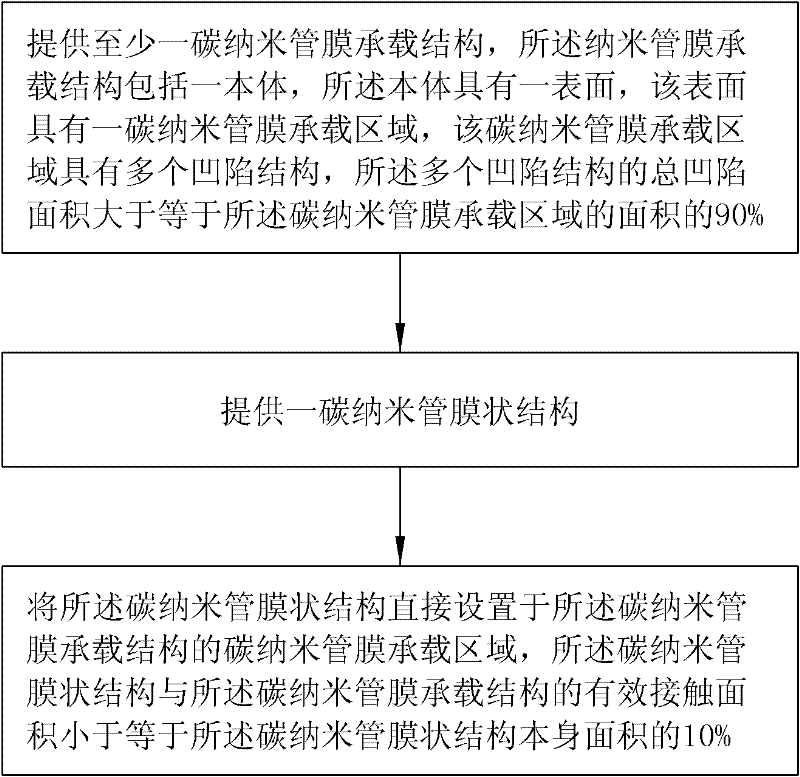

Carbon nanotube film carrying structure and use method thereof

ActiveCN102452647AAchieve preservationAchieve transferNanostructure manufactureCeramicwareCarbon nanotube

The invention relates to a carbon nanotube film carrying structure, which comprises a body, wherein the body is provided with a surface; the surface of the body is provided with a carbon nanotube film carrying area; the carbon nanotube carrying area is provided with a plurality of depression structures; and the total depression area of the plurality of depression structures is larger than or equal to 80 percent of the area of the carbon nanotube film carrying area. The carbon nanotube film carrying structure is used for carrying a carbon nanotube film-shaped structure, and the carbon nanotubefilm-shaped structure can be completely separated from the carrying structure after being contacted with the carrying structure. The invention further relates to a method for using the carbon nanotube film carrying structure.

Owner:BEIJING FUNATE INNOVATION TECH

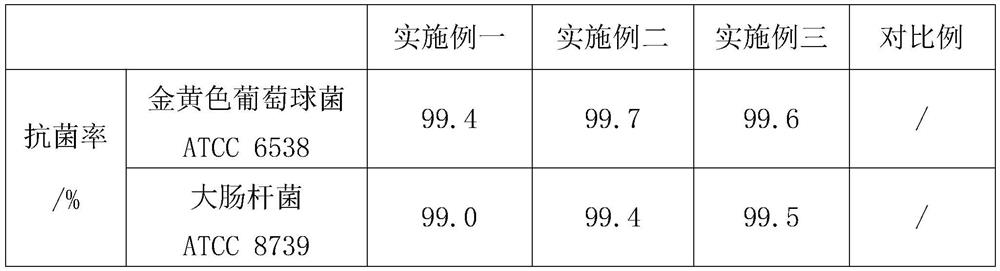

Antibacterial master batch and application thereof

PendingCN111909454AGive full play to antibacterial propertiesImprove antibacterial propertiesPolymer scienceGraphene

The invention relates to the field of high polymer materials, and provides an antibacterial master batch, which comprises the following raw materials in parts by weight: 70-90 parts of polypropylene resin, 3-6 parts of nano-silver loaded graphene, 1-3 parts of a dispersing agent and 0.4-0.8 part of a lubricating agent, wherein the nano-silver loaded graphene has the advantages of both graphene andnano-silver. The antibacterial master batch obtained after melt granulation with polypropylene resin has excellent antibacterial property, solves the problems that a product produced from a polypropylene material in the prior art does not have antibacterial property and is easily polluted by bacteria, and can be applied to production of disposable tableware.

Owner:泉州弘泰智能科技有限公司

Method for preparing nano Cu3.8 Ni alloy loaded on graphene by liquid phase reduction method

The invention relates to a method for preparing nano Cu3.8 Ni alloy loaded on graphene, in particular to a method for preparing the nano Cu3.8 Ni alloy loaded on the graphene by a liquid phase reduction method. The method takes the graphene as a surface active agent, and solves the problem that the existing surface active agent is difficult to treat. The method comprises the steps of firstly, preparing graphene oxide, and then mixing CuSO4 5H2O solution, NiSO4 6H2O solution, NaOH solution and hydrazine hydrate solution with the graphene oxide for treatment. Related report of preparing the nano Cu3.8 Ni alloy loaded on the graphene by a reduction method is not reported yet; the method is simple and fast, and any surface modifying agent does not need to be added. After the reduction method is adopted, nano alloy particles loaded on the graphene are well dispersed and are uniform in size and smaller in particle size. The hydrazine hydrate is taken as a reducing agent, and a great deal of N2 is generated in the reaction process, so that the oxide is effectively prevented from being generated in the reduction process under the protection of the N2.

Owner:HEILONGJIANG UNIV

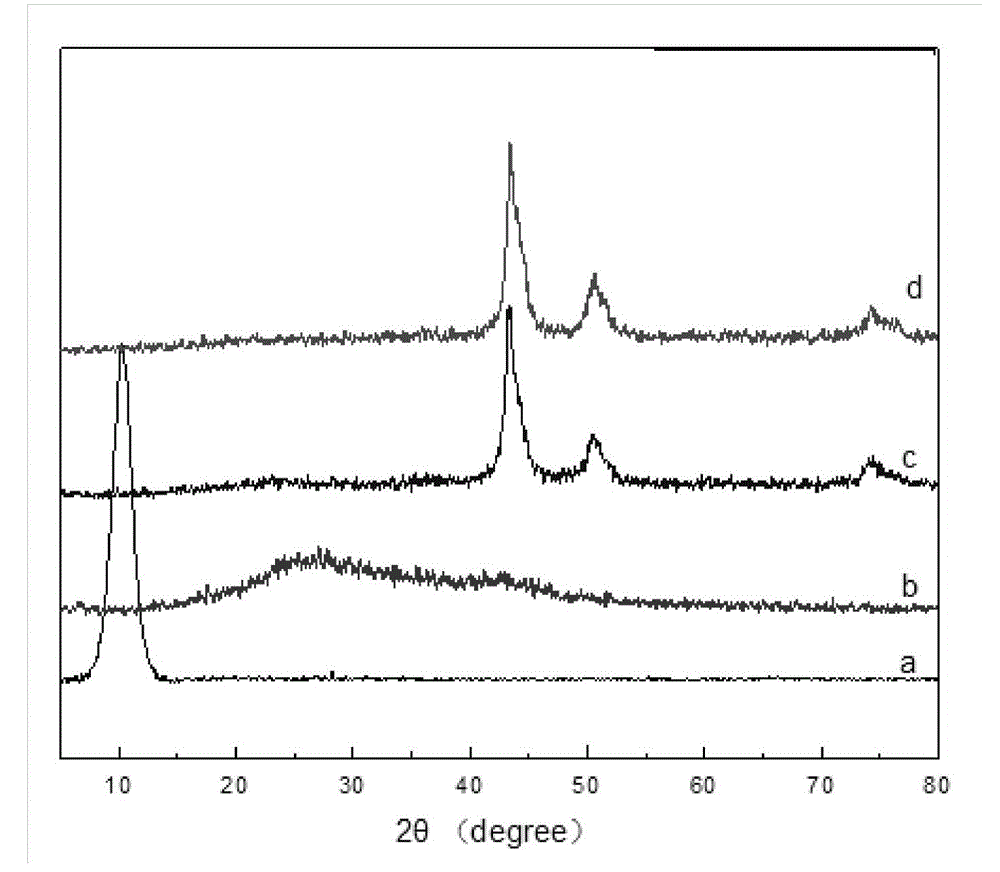

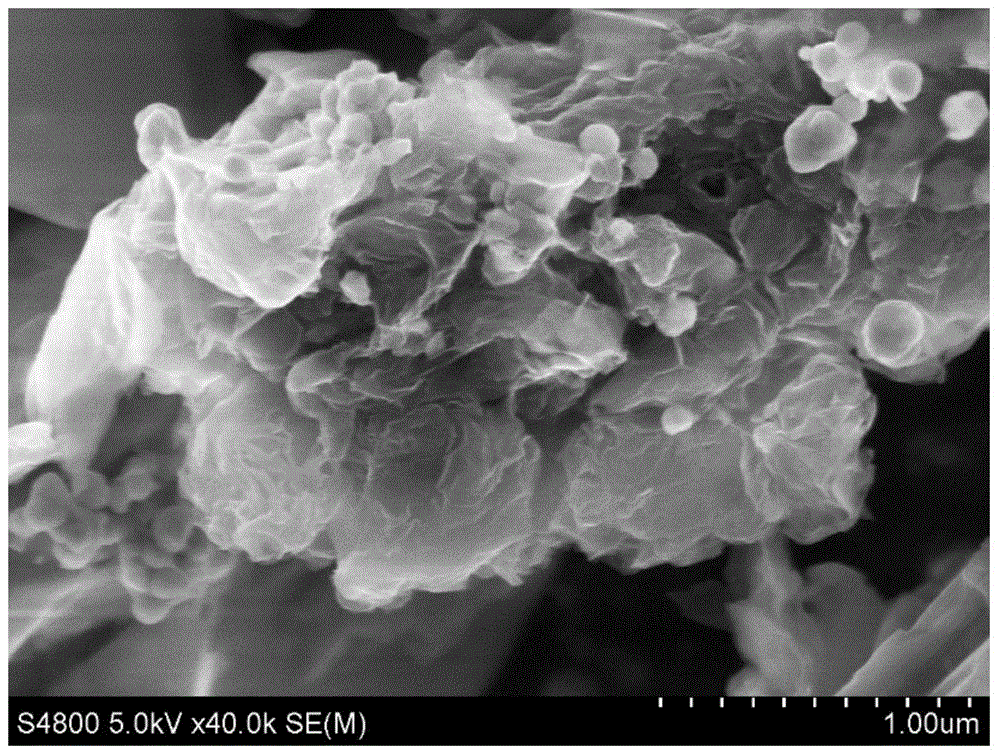

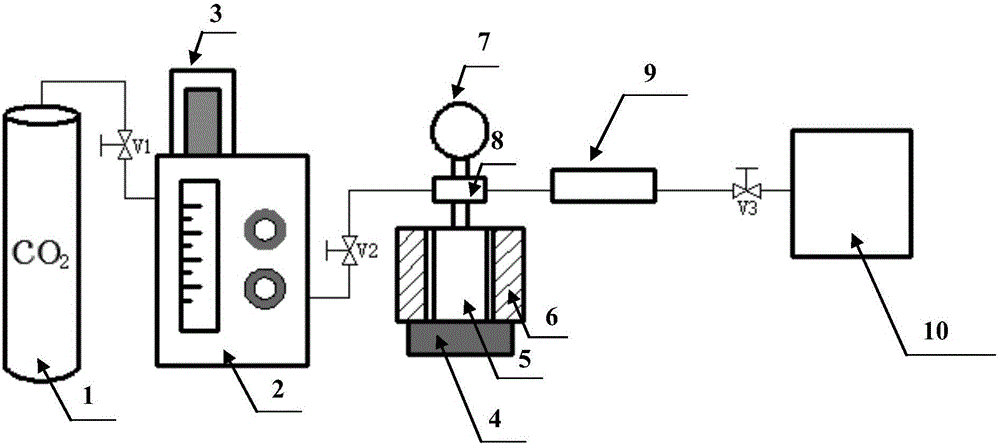

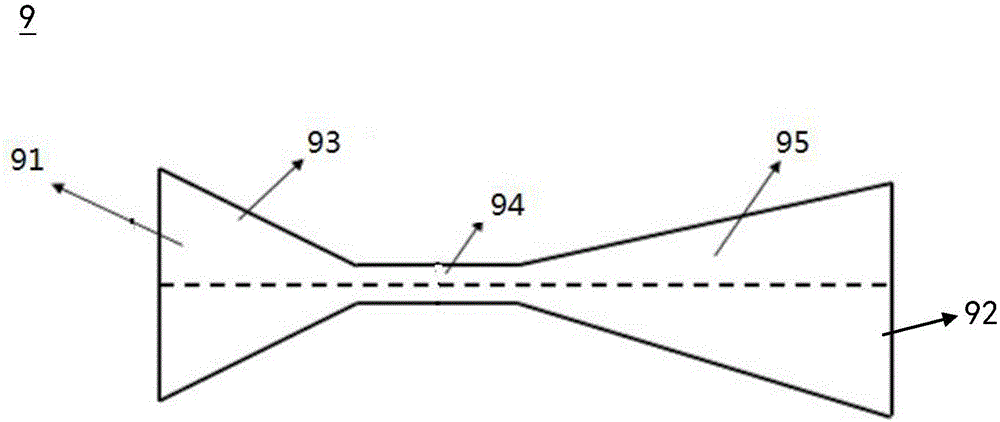

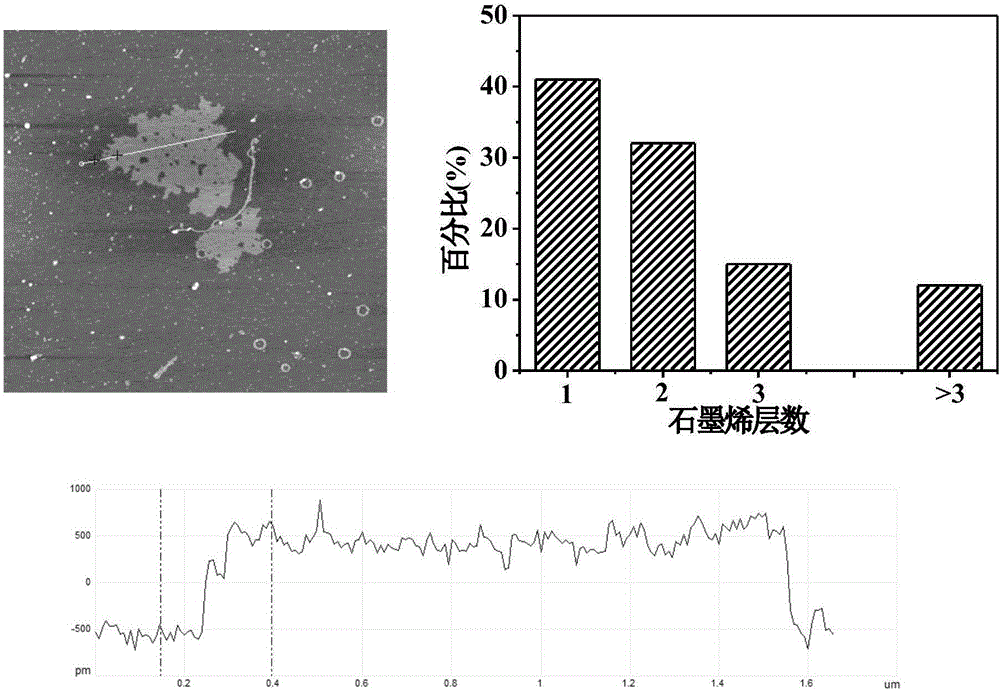

Preparation method for few-layer graphene

ActiveCN106744889AReduce van der Waals forcesQuality improvementMaterial nanotechnologySingle layer grapheneUltrasonic assistedFew layer graphene

The invention discloses a method for preparing graphene by combining an ultrasonic-assisted supercritical carbon dioxide technique with micro-jetting. The method comprises the following steps: performing supercritical carbon dioxide intercalation ultrasonic treatment on a material; quickly putting into a micro-jetting stripping device; violently high-speed moving the fluid and quickly jetting into a normal-pressure receiving tank, thereby acquiring a graphene product. Compared with the prior art, the method has the advantages that high-quality graphene can be prepared; 88-94% of graphene is in the layer quantity being less than three; more than 40% of graphene is in single-layer; the method disclosed by the invention is environment-friendly; the process flow is simple; a new method is supplied for cleanly preparing the high-quality graphene on a large scale.

Owner:XIAMEN UNIV

Preparation method for graphene-like reinforced building ceramic glaze surface

PendingCN108164141AImprove hardness and wear resistanceGood application prospectSingle layer grapheneClaywaresIndustrial scaleCeramic glaze

The invention relates to a preparation method for a graphene-like reinforced building ceramic glaze surface. The preparation method comprises the following steps: respectively adding 1 to 3% of high-temperature quenched graphite and 3 to 8% of a sugar or starch substance in terms of the mass of a building ceramic glaze material, applying a ball-milled glaze pulp onto a ceramic green body, carryingout drying, and carrying out sintering in a roller kiln so as to obtain a building ceramic tile. According to the invention, by utilization of a method of combining high-temperature quenching and mechanical ball-milling, a graphene oxide material with a single-layer or multi-layer structure is obtained, and is reduced into graphene-like under the action of high temperature, so the hardness and wear resistance of the building ceramic glaze surface are greatly improved. The product glaze surface provided by the invention has a microhardness of 726 to 755 Hv and reaches a wear-resistant grade of5 grades or more. The method provided by the invention has the advantages of simple and rapid operation, low cost, applicability to industrial scale production and good application prospects.

Owner:JINGDEZHEN CERAMIC INSTITUTE

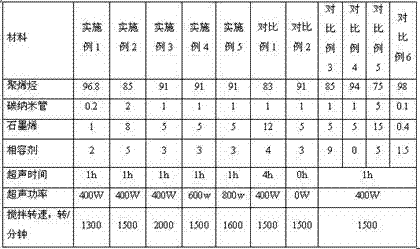

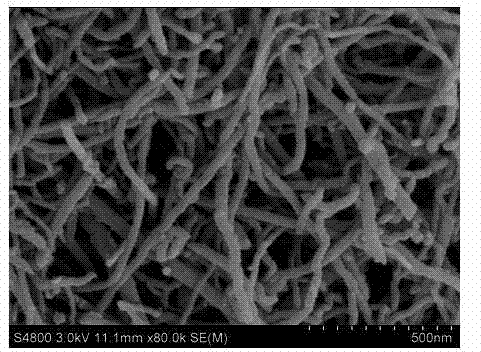

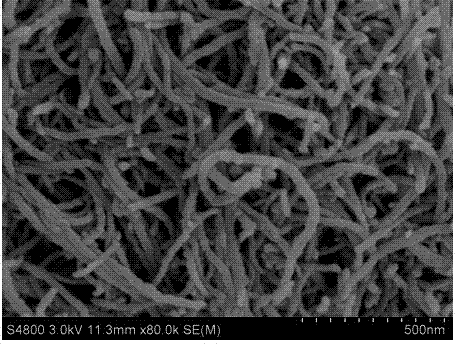

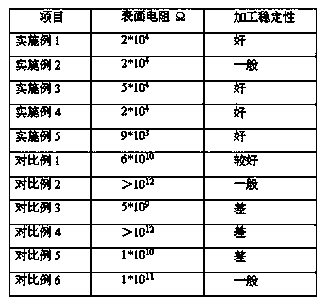

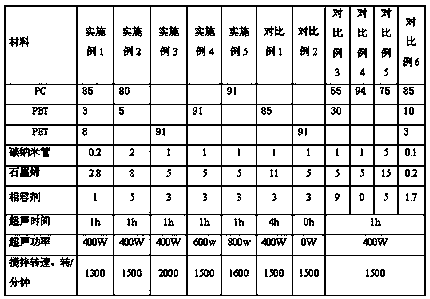

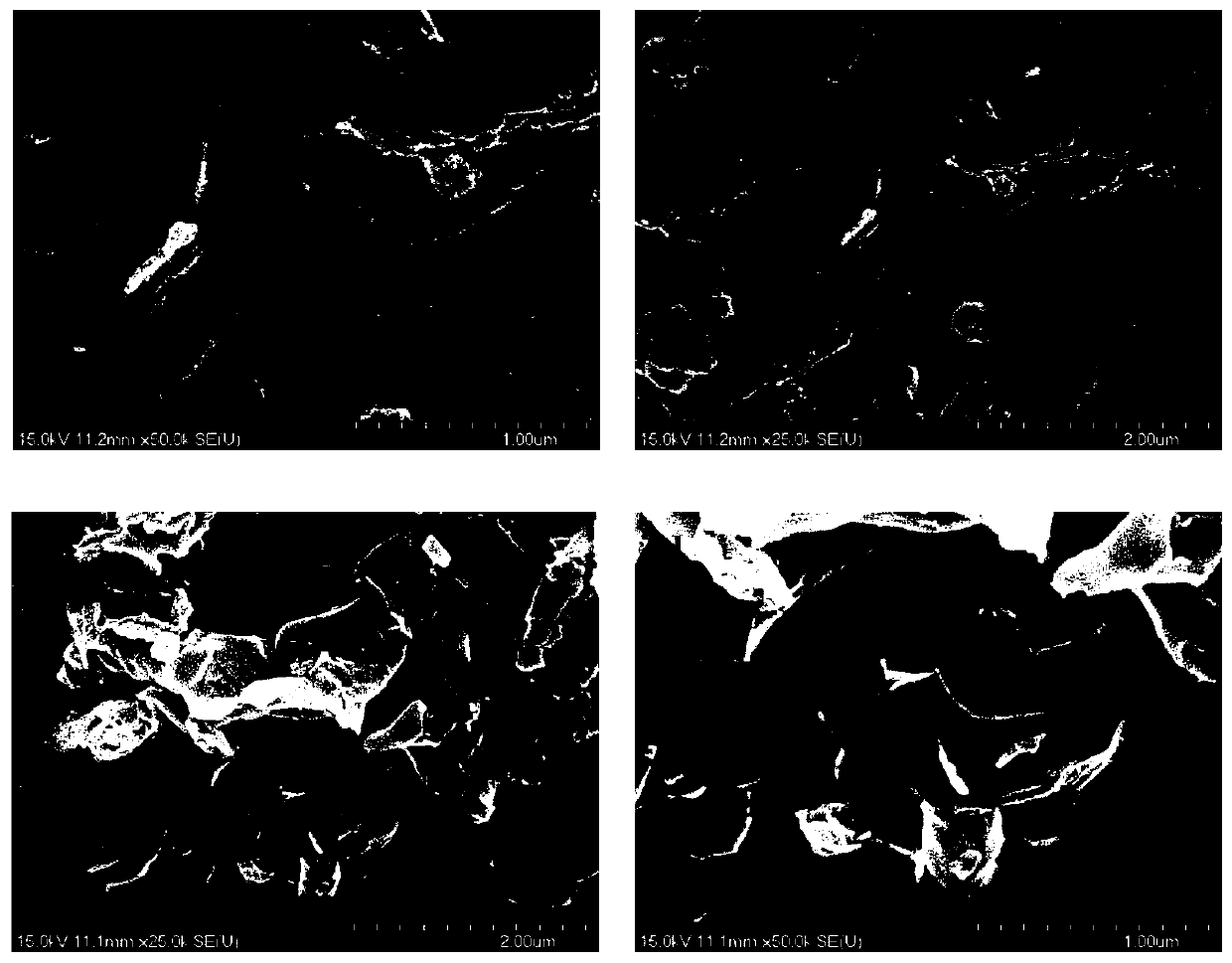

Polyolefin-based conductive master batch based on carbon nano tube and graphene compounded system and preparation method thereof

The invention provides a polyolefin-based conductive master batch based on a carbon nano tube and graphene compounded system and a preparation method thereof. The preparation method comprises the following steps: firstly respectively uniformly dispersing carbon nano tubes and graphene into a volatile inert solvent, respectively treating for 1 hour by virtue of an ultrasonic treatment device, thenstirring the treated dispersion liquid with raw materials in a high-speed stirring machine in proportion, then mixing with a compatilizer in a certain ratio at room temperature, and then carrying outmelt extrusion by virtue of a twin screw, so that the conductive master batch is prepared. The prepared composite material has excellent conductivity, is easy to add and can be widely applied to the fields of injection molding, extrusion and modification.

Owner:上海统慧科技发展有限公司

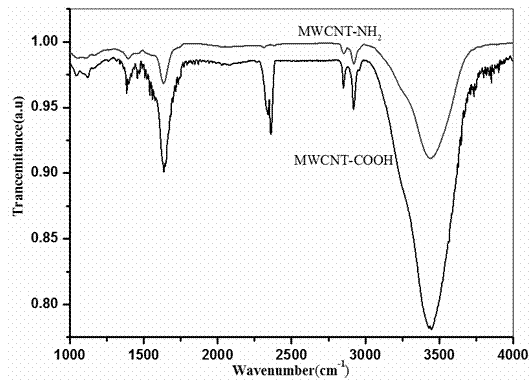

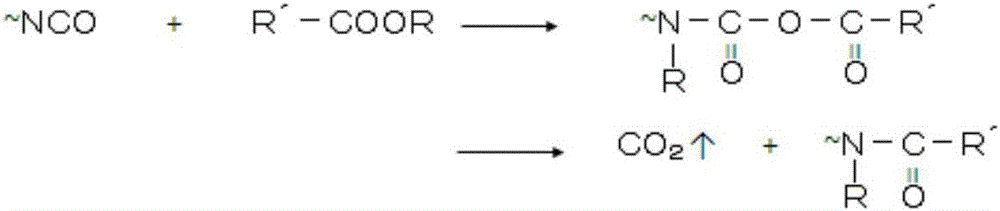

Preparation method of modified multi-wall carbon nano-tube material

ActiveCN104845381AImprove organic compatibilityGood interface fastnessChemical analysis using titrationElastomerPolymer science

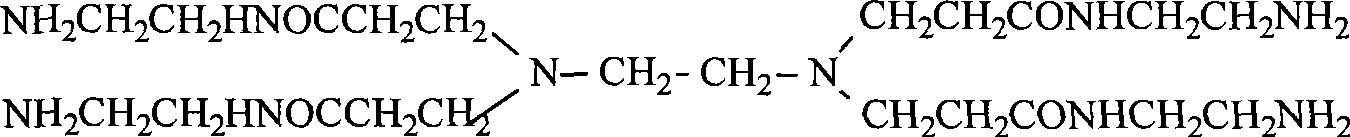

The invention provides a preparation method of a modified multi-wall carbon nano-tube material. The preparation method takes N,N-methylene bisacrylamide (MBA) and diethylenetriamine (DETA) as raw materials and adopts a Michael addition method for a one-step method to synthesize a golden yellow viscous liquid terminated amino hyperbranched polymer (NH2-HBP). The preparation method comprises the following steps: weighing a certain amount of NH2-HBP and putting into a three-opening flask; adding ultrapure water and completely dissolving; then adding a certain amount of terminated carboxyl carbon nano-tubes into a water bath at 45-55 DEG C; reacting for 3-5 hours at a stirrings peed of 20r / min-30r / min; then drawing and filtering to obtain modified multi-wall carbon nano-tubes; repeatedly washing the modified multi-wall carbon nano-tubes by the ultrapure water for a plurality of times; and drying at 60 DEG C to obtain the multi-wall carbon nano-tubes subjected to terminated amino hyperbranched grafting and modification. The tube walls of the grafted and modified terminated amino hyperbranched multi-wall carbon nano-tubes have a lot of amino so that the product has very good water solubility and solvent solubility; the modified multi-wall carbon nano-tube material can be used as a very good additive and can be dispersed into polymers including a polyurethane coating, a rubber elastic body, functional plastic and the like very well so that the foundation is provided for obtaining a uniform modified multi-wall carbon nano-tube polymer composite material, and the application prospect is wide.

Owner:SHAANXI UNIV OF SCI & TECH

Lignin functionalized modified graphene and preparation method thereof

ActiveCN107814378AWeakened van der Waals forceAvoid reunionGrapheneAnti-corrosive paintsMaterials preparationDispersion stability

The invention discloses a lignin functionalized modified graphene and a preparation method thereof and belongs to the technical field of functionalized graphene material preparation. The preparation method of the lignin functionalized modified graphene disclosed by the invention comprises the steps of evenly mixing lignin with oxidized graphene to make the lignin be fully adsorbed on the surface of the oxidized graphene, then adding sulfonate polyaniline, evenly stirring and then reacting for a certain time under a certain temperature to obtain the lignin functionalized modified graphene. Thegraphene disclosed by the invention has good dispersion stability and can be utilized as an environment-friendly graphene heavy anti-corrosion coating; furthermore, the preparation method is convenient, simple, easy and practical; a novel method for preparing the functionalized graphene materials is provided.

Owner:FUZHOU UNIV

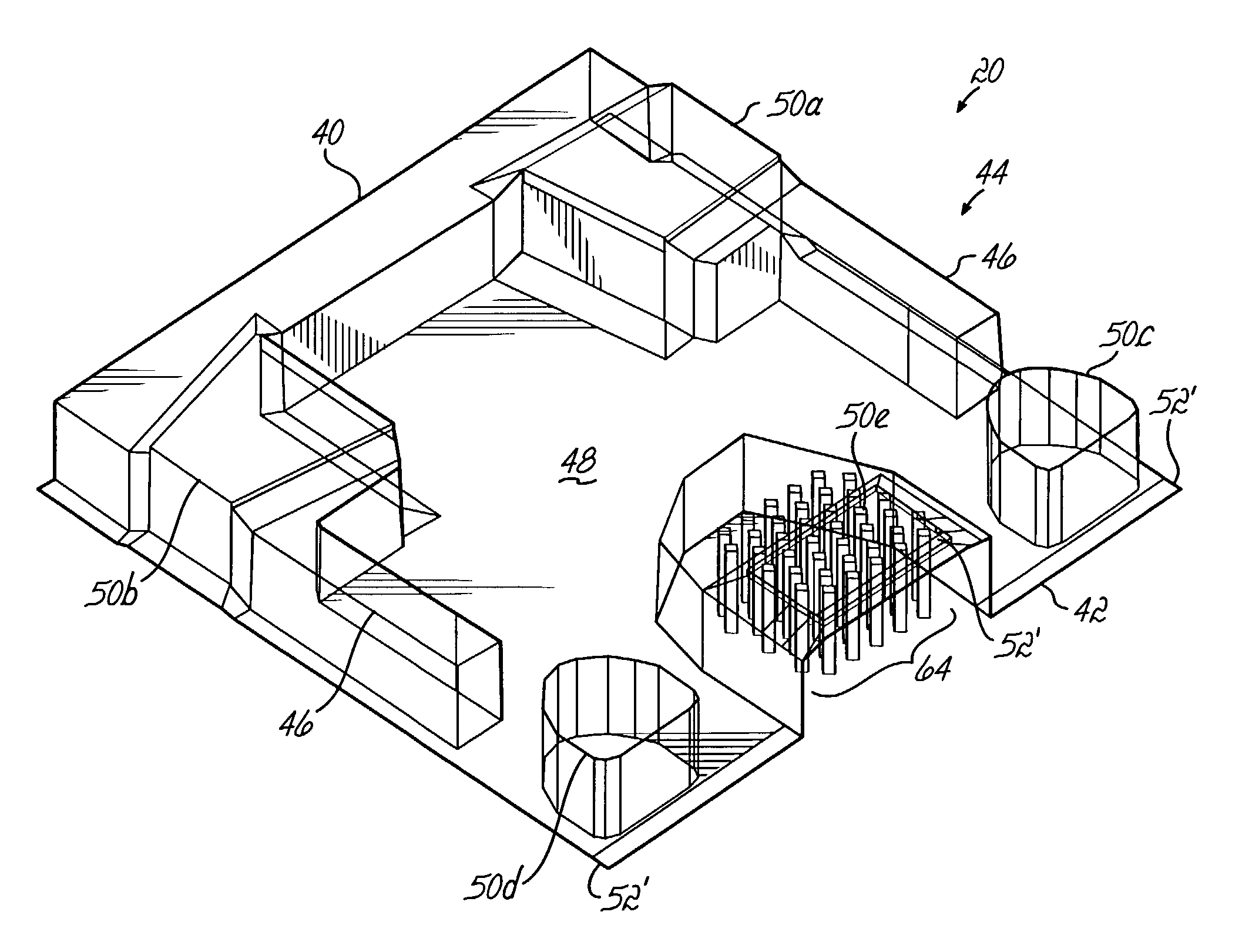

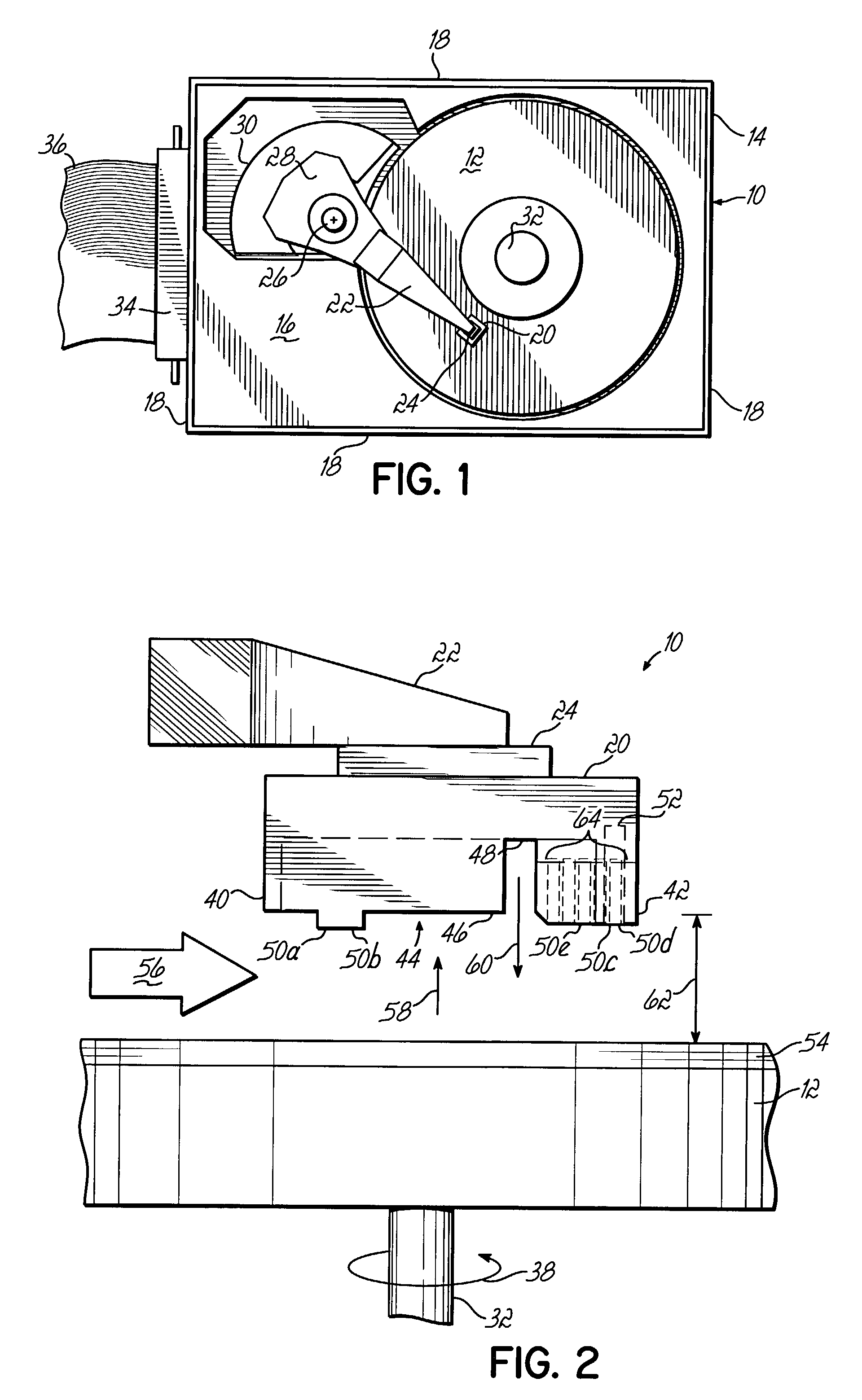

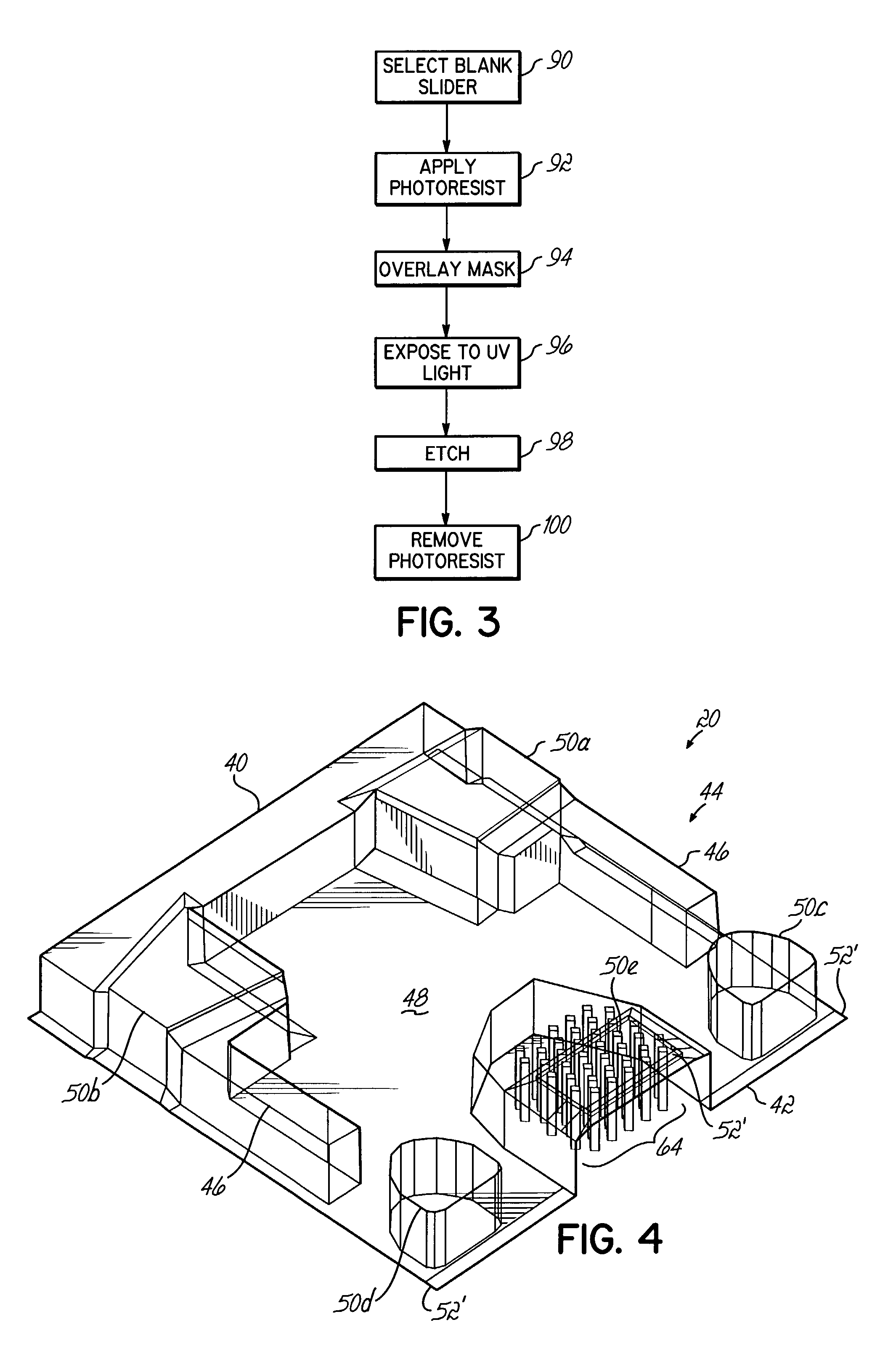

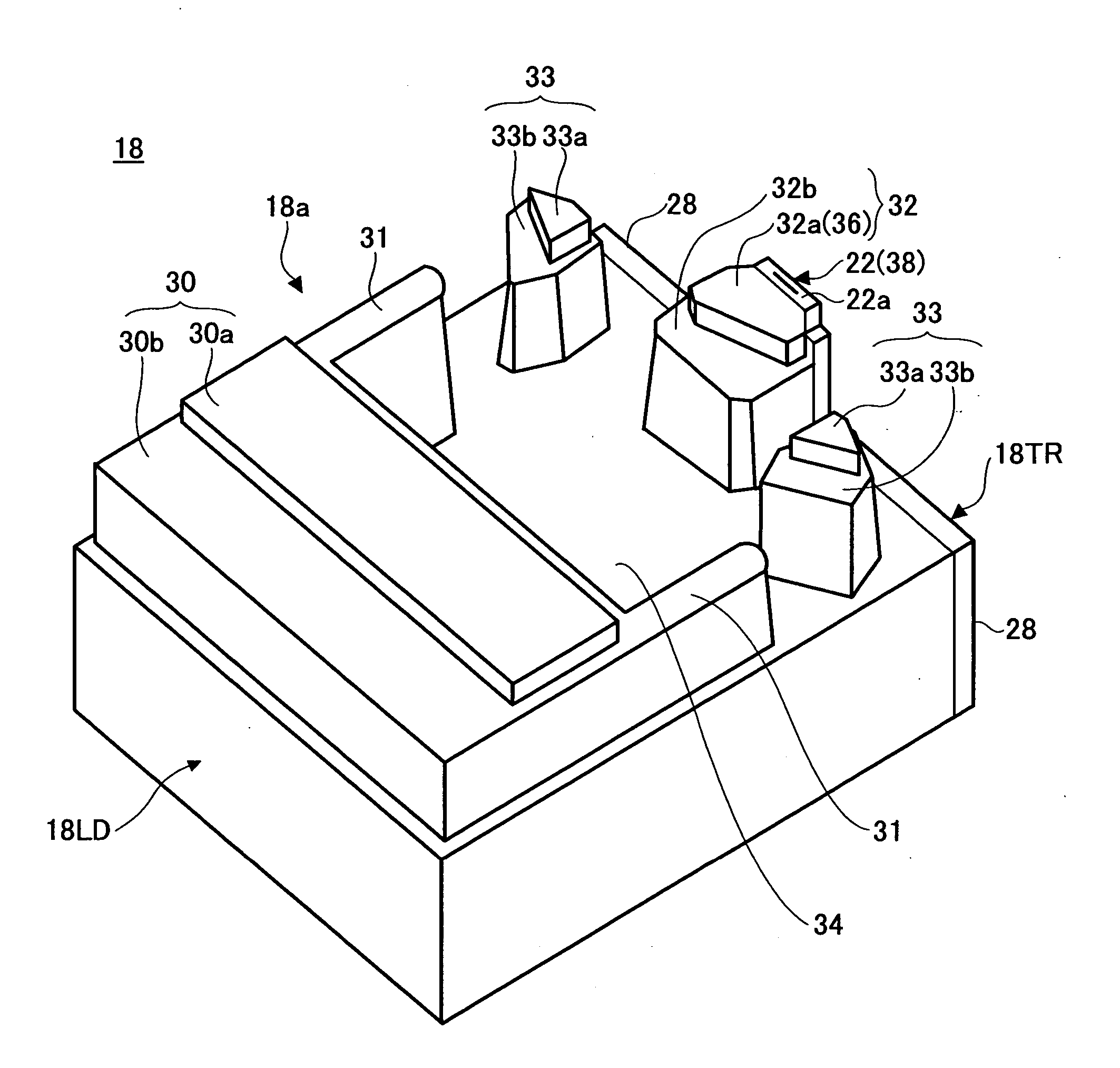

Air bearing designs to reduce external van der waals and electrostatic forces

InactiveUS7023664B2Reduce electrostatic forceReduce van der Waals forcesRecord information storageFluid-dynamic spacing of headsAir bearingAir bearing surface

A slider for a disk drive has an air bearing surface that opposes a rotatable disk of recordable media. The air bearing surface includes one or more interior cavities to reduce van der Waals and electrostatic forces that attract the slider to the disk.

Owner:WESTERN DIGITAL TECH INC

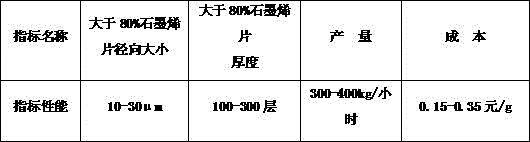

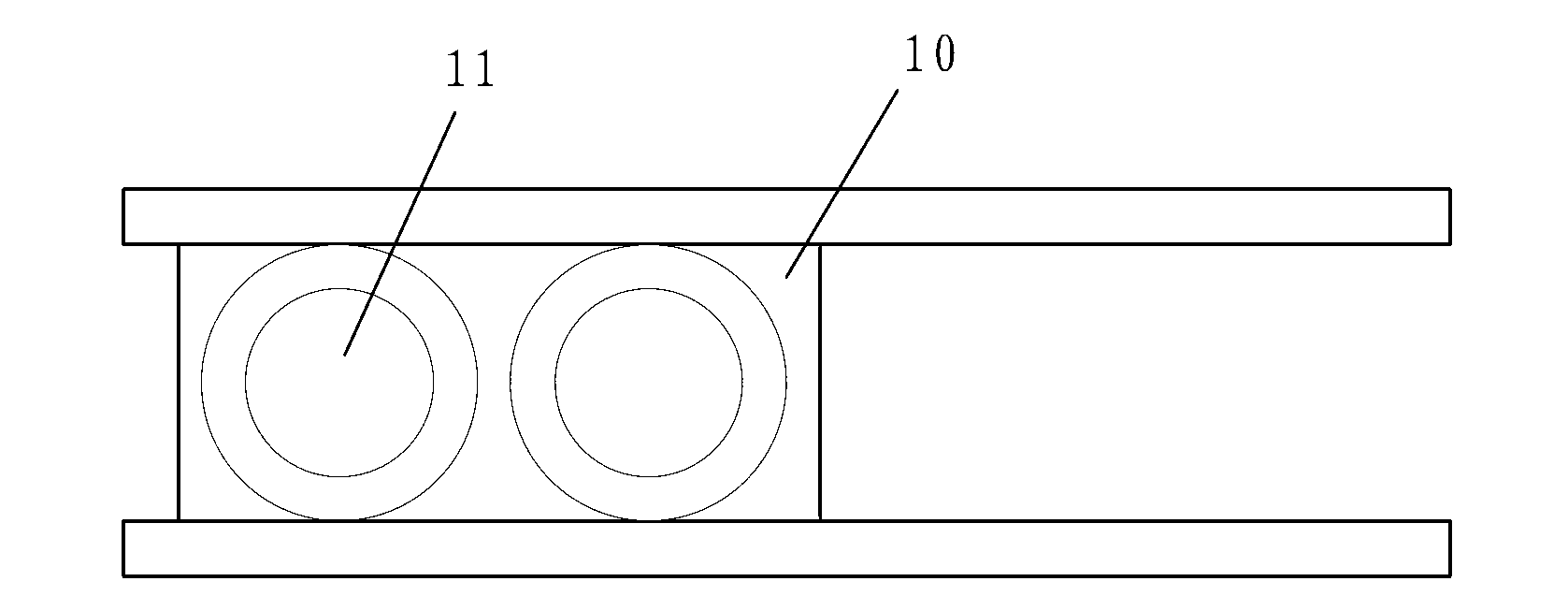

Method for preparing graphene nanoplatelets with pulsed high pressure water jet mill

The invention relates to the field of graphene materials, in particular to a method for preparing graphene nanoplatelets with a pulsed high pressure water jet mill.According to the method, a plugging layer is pressurized, Van der Waals' force among graphite powder layers is reduced, so that the graphite layers are easy to strip, then graphite powder is crushed and stripped under the action of water jet and turbulent flow and cavitation through pulsed high pressure water jet of the pulsed high pressure water jet mill, the evenly-dispersed graphene nanoplatelets with the number of layers ranging from 100 to 200 are obtained.Continuous and large-scale production of the graphene nanoplatelets with the number of layers being even is achieved, the yield is high, the cost is low, no pollution is caused, the layer thickness meets the use requirements in the fields of rubber enhancement, plastic enhancement, coating corrosion prevention, lubrication and sewage treatment, and it is convenient to promote large-scale application of graphene.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

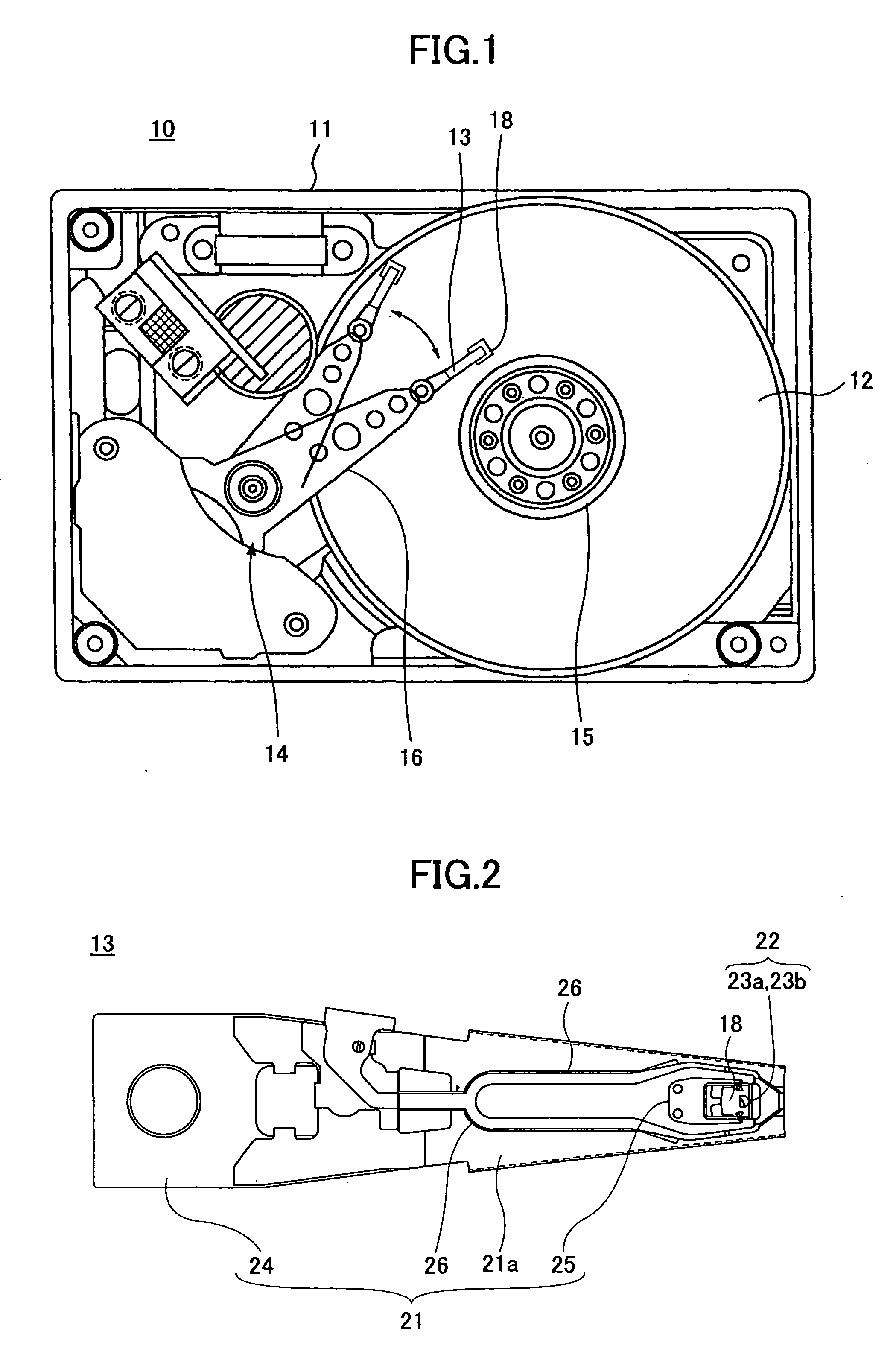

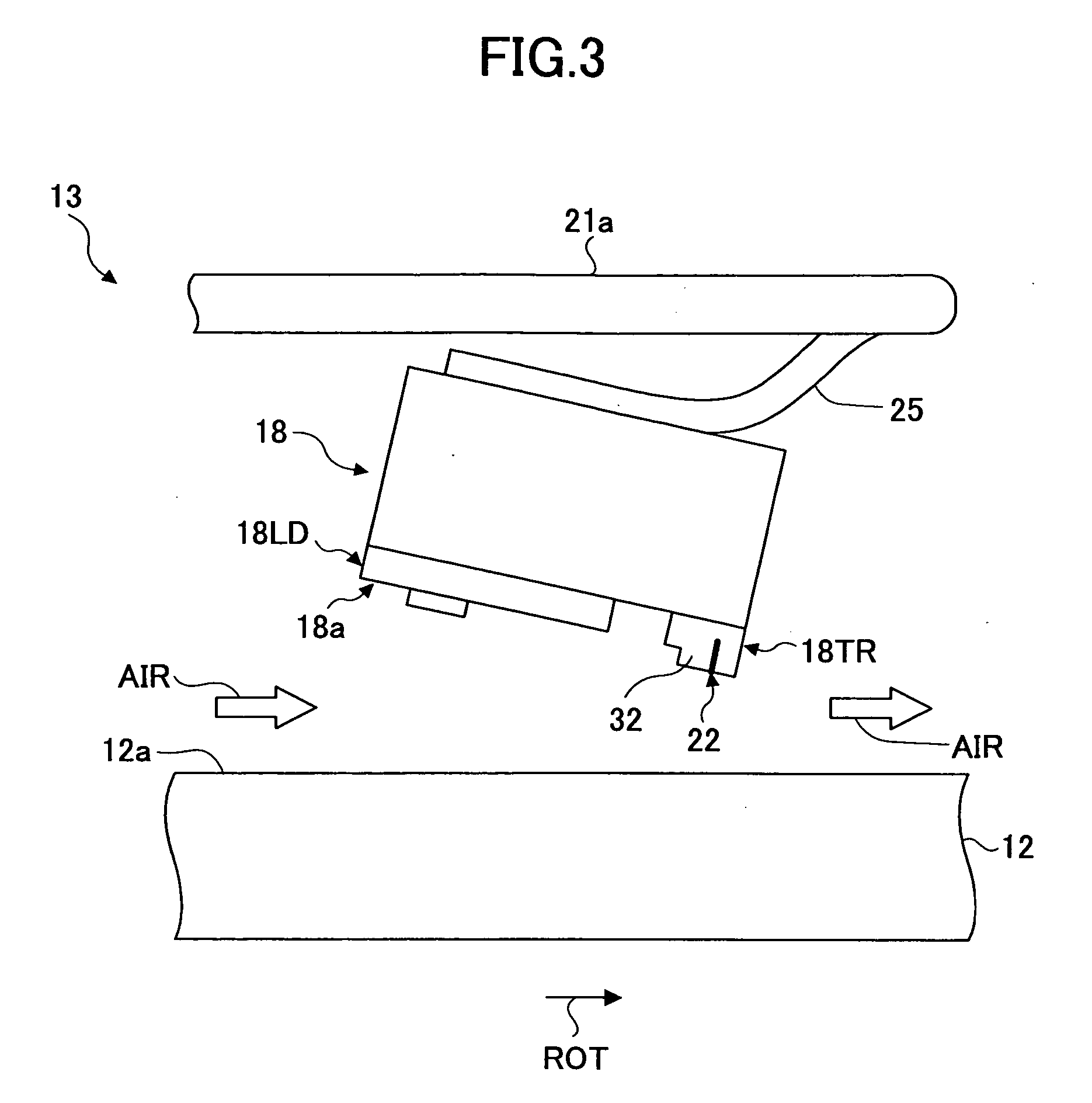

Magnetic head and manufacturing method of the same

InactiveUS20060221502A1Quality improvementImprove floating stabilityFluid-dynamic spacing of headsRecord information storageSurface roughnessWater repellent

A magnetic head includes a head slider configured to float above a recording medium and having an element part for recording to and reproducing from the recording medium, the element part being situated on a medium facing surface facing to the recording medium. The medium facing surface has a first air bearing surface situated in a vicinity of a side of an air flow-out end. The medium facing surface has a rear rail having the element part situated at the side of the air flow-out end of the first air bearing surface. The first air bearing surface is covered with a lubricating layer made of water repellent resin and has an average surface roughness larger than an average surface roughness of a surface of the element part.

Owner:FUJITSU LTD

Method for reducing fluid loss during drilling of a hydrocarbon formation using a water-based drilling fluid composition having a multifunctional mud additive

ActiveUS20150210912A1Reduce van der Waals forcesEnsure adequate lubricationFlushingDrilling compositionNanoparticleWell drilling

Embodiments of the invention provide a drilling, drill-in, and completion water-based mud composition containing micro or nanoparticles for use in hydrocarbon drilling. In accordance with at least one embodiment, there is provided a method of drilling a hydrocarbon formation, including contacting the hydrocarbon formation with a water-based drilling mud composition while drilling or completing a well. In accordance with at least one embodiment, the water-based drilling mud composition includes water, the water being present in an amount greater than about 90 wt % of the water-based drilling mud composition to maintain flowability of the water-based drilling mud composition; drilling mud, the drilling mud comprising particles, wherein the particles are selected from the group consisting of microparticles, nanoparticles, and combinations thereof; and a multi-functional mud additive in an amount of 0.8 wt % of the water-based drilling mud composition, the multi-functional mud additive comprising psyllium husk powder, such that the water-based drilling mud composition is operable to keep the particles stabilized and dispersed throughout the drilling mud composition in the absence of a surfactant.

Owner:SAUDI ARABIAN OIL CO

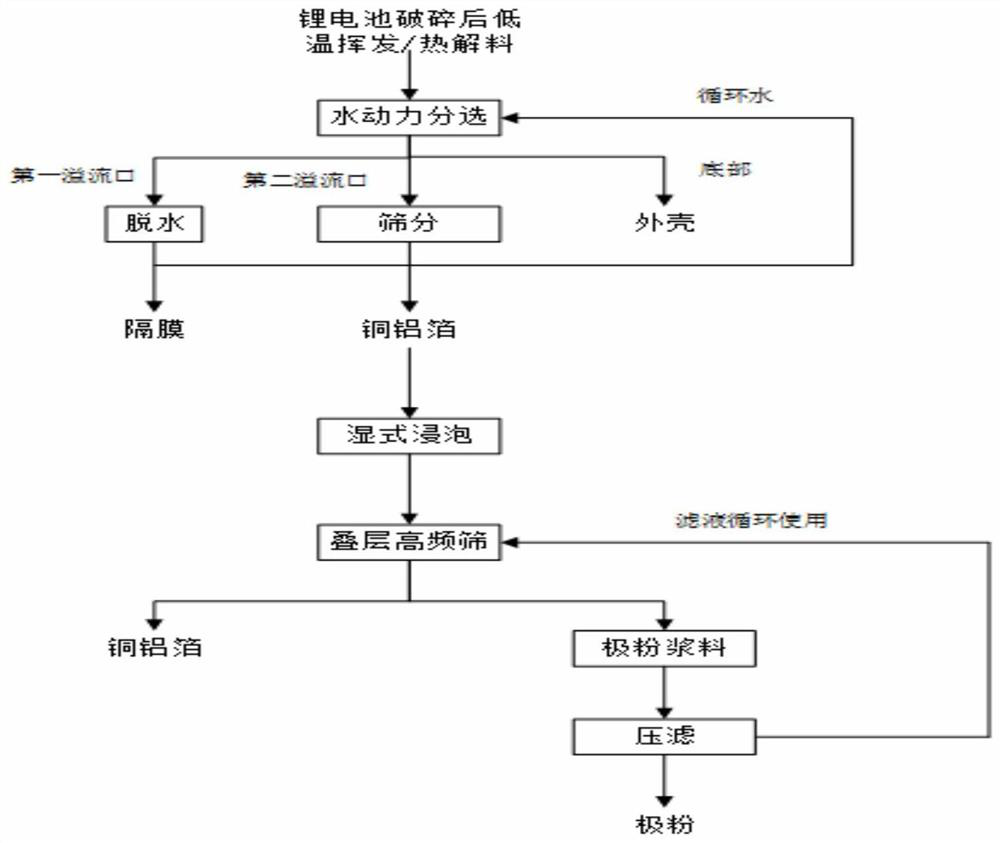

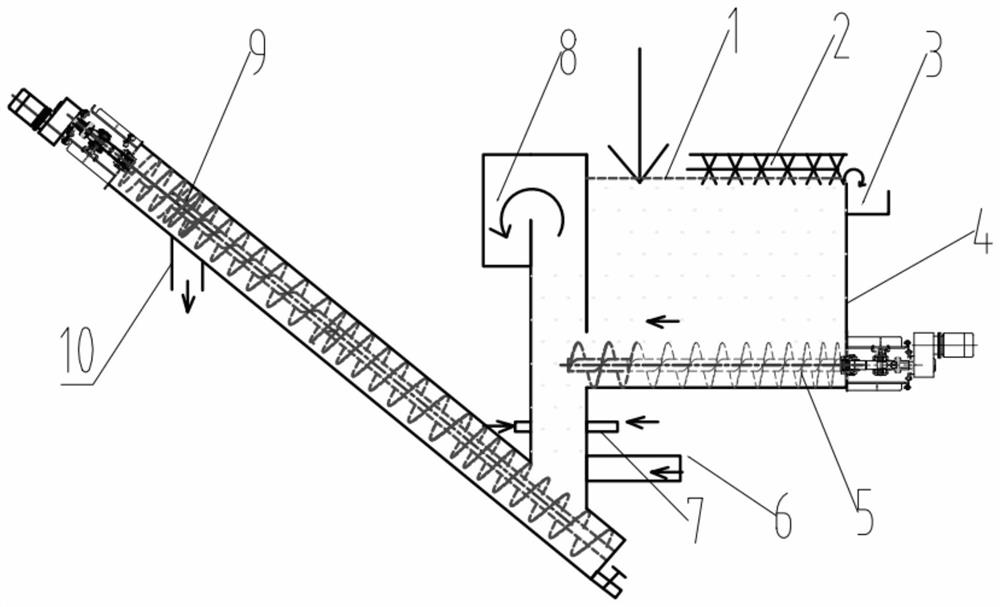

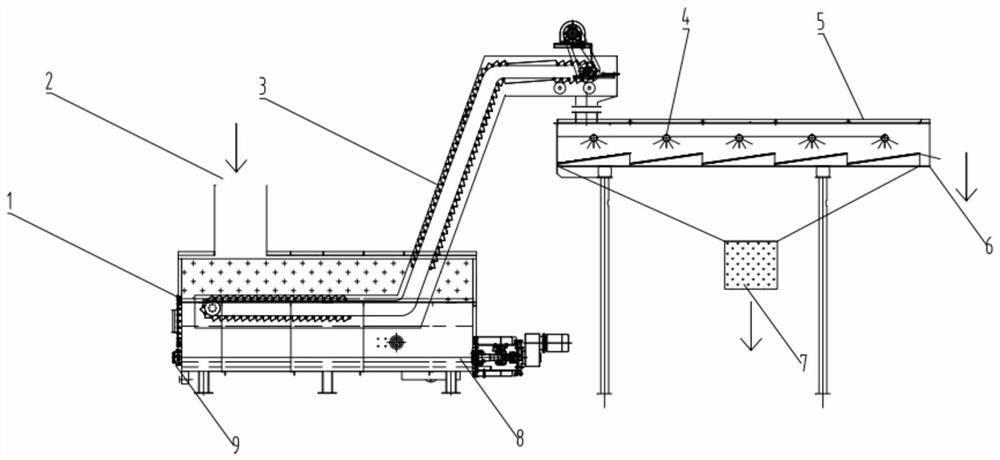

Hydrodynamic separation and wet stripping process for waste lithium ion battery broken materials

PendingCN113499853AAvoid Entrainment LossHigh recovery rateWaste processingSolid separationElectrolytic agentPhysical chemistry

The invention discloses a hydrodynamic separation and wet stripping process for waste lithium ion battery broken materials. The process comprises the following steps of firstly, carrying out crushing and electrolyte low-temperature volatilization or organic matter pyrolysis pretreatment on a waste battery, carrying out hydrodynamic separating on the treated crushed materials to separate out shells, then carrying out one-stage or multi-stage soaking on a sample by using a nucleophilic reagent, due to the fact that the nucleophilic reagent can chemically react with PVDF or aluminum and copper, some reagents can dissolve the PVDF or the aluminum and the copper, therefore, completely stripping and separating leached pole powder from the copper, the aluminum and the like, and improving the recovery rate and grade of the pole powder. According to the process, hydrodynamic force is adopted for efficient and clean pre-sorting of substances such as diaphragms, pole pieces and the shells, the separation effect is greatly improved compared with the prior art, and meanwhile the risks of dust raising, powder explosion and aluminum explosion of traditional wind power winnowing are avoided. The pole powder of the waste lithium ion battery is stripped by adopting a nucleophilic reagent leaching method, the pole powder falling effect is obvious, and the pole powder recovery rate and grade are high.

Owner:湖南江冶新能源科技股份有限公司

Aluminum base carbon fiber graphite composite material and preparation method

The invention relates to an aluminum base composite material, in particular to an aluminum base carbon fiber graphite composite material and a preparation method. The method comprises the following steps of: firstly, adopting finely sorted, processed and checked graphite fluoride powder as raw materials for preparing spherical graphite particles through granulation and spheroidization; then, using a stainless steel plate as a cathode and pure aluminum as an anode, filling insert gas between the two electrodes, exerting voltage, soaking the spherical graphite particles by glucose amide containing 0.23 to 0.6 percent of boron, cleaning and baking the spherical graphite particles, placing the spherical graphite particles on a disc between the cathode and the anode, shaking the disc while exerting the voltage, and arranging latticed high-performance carbon fiber in a casting mold at the arrangement density determined according to the intensity requirement of the materials; filling the spherical graphite particles with the diameter between 1 and 5mm in the casting mold, finally, injecting aluminum liquid, applying pressure at the upper part of the mold so that the aluminum liquid can be filled between the spherical graphite particles, and obtaining products after cooling. The composite material is simple to prepare, and has the advantages of high product intensity, light weight, wear resistance, low raw material consumption and high production efficiency.

Owner:蔡乐勤

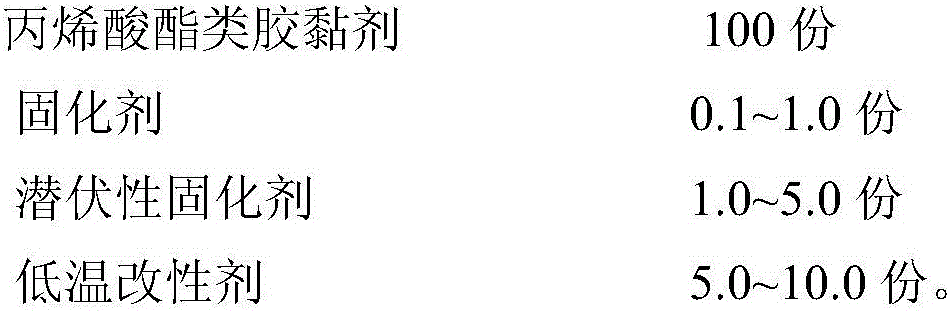

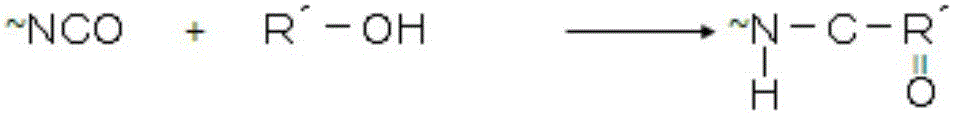

Environment-friendly and low temperature-resistant acrylate adhesive

InactiveCN106675459AHigh activityIncreased distance between molecular chainsNon-macromolecular adhesive additivesEster polymer adhesivesAdhesiveSolvent

The invention relates to an environment-friendly and low temperature-resistant acrylate adhesive which comprises the following raw materials in parts by weight: 100 parts of an acrylate adhesive, 0.1-1.0 part of a curing agent, 1.0-5.0 parts of a latent curing agent and 5.0-10.0 part of a low-temperature modifying agent. The invention further relates to a preparation method of the environment-friendly and low temperature-resistant acrylate adhesive. Compared with the prior art, the adhesive provided by the invention is higher in solid content (at least reach 60 percent), lower in relative molecular weight, easier for the introduction of a low-molecular segment and low in solvent content and toxicity, thereby being the environment-friendly adhesive; the initial viscosity is obviously improved in a low-temperature environment, and the adhesive force does not attenuate.

Owner:NINGBO SOKEN CHEM

Polyester-based conductive master batch based on carbon nanotube and graphene compound system and preparation method of polyester-based conductive master

ActiveCN108084686AImprove antistatic performanceImprove thermal conductivityPolyesterConductive polymer

The invention provides polyester-based conductive master batch based on a carbon nanotube and graphene compound system and a preparation method of the polyester-based conductive master. Firstly, carbon nanotubes and graphene are uniformly dispersed in a volatile inert solvent and treated by an ultrasonic treatment device for 1 h, the treated dispersion solution and raw materials are stirred in a high-speed stirrer in proportion, the obtained material is mixed with a compatilizer in a certain proportion at the room temperature, melt extrusion is performed through double screws, and the conductive master batch is prepared. The prepared composite has excellent conductivity, is easy to add and can be widely applied to fields of injection molding, extrusion, modification and the like.

Owner:江苏汉丰降解材料有限公司

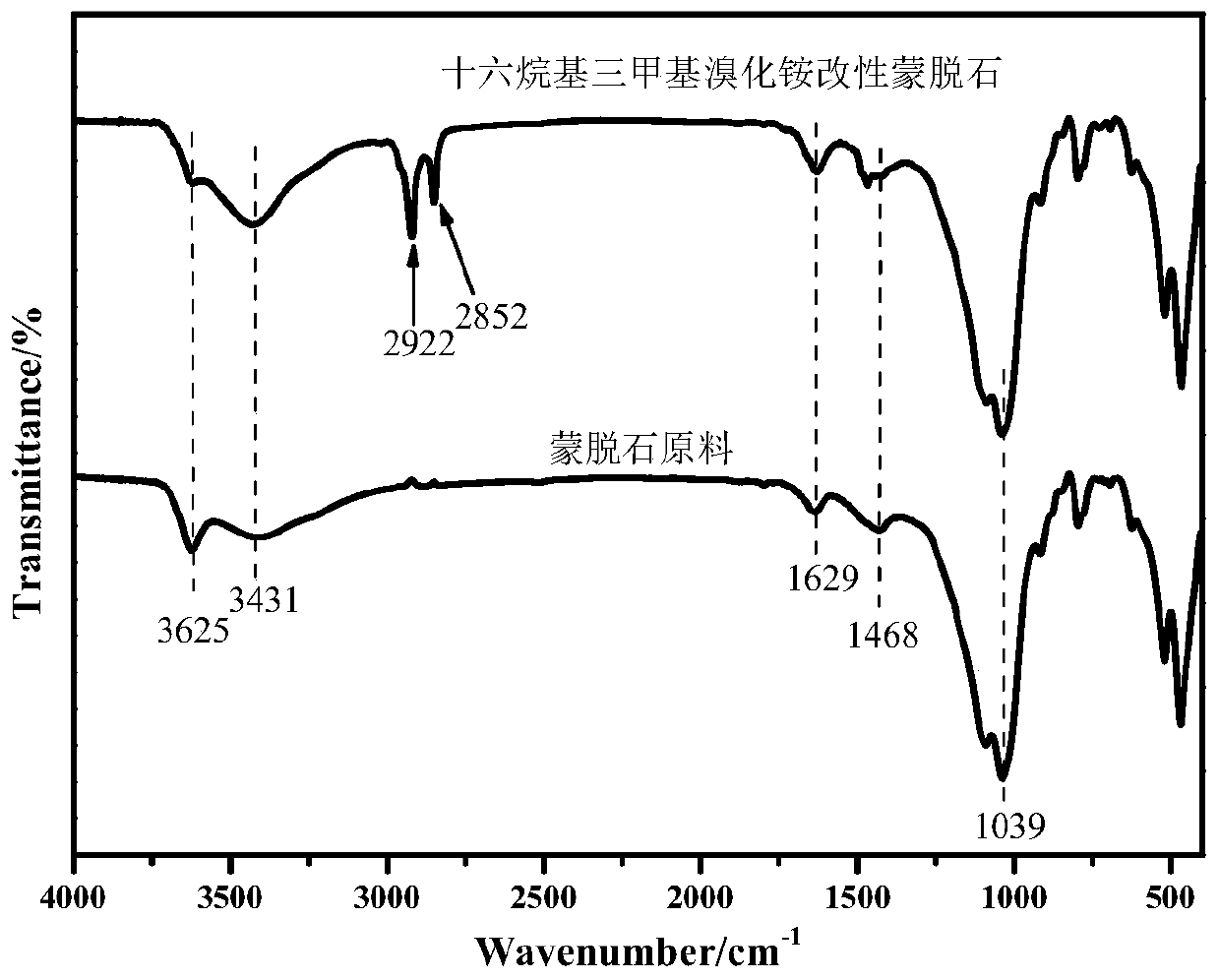

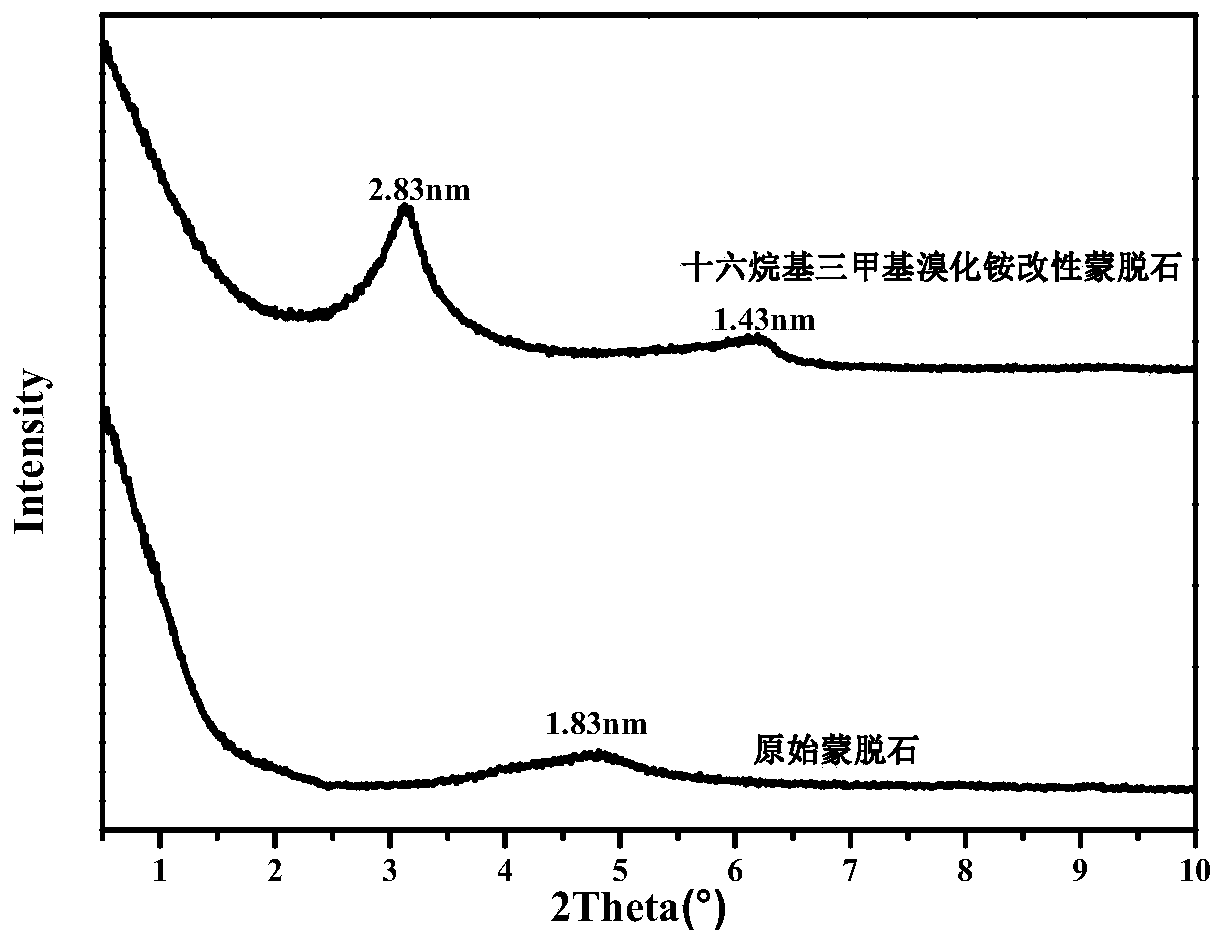

Preparation method of cetyl trimethyl ammonium bromide modified montmorillonite

PendingCN110801813AIncrease layer spacingReduce van der Waals forcesOther chemical processesCation exchange reactionNanoparticle

The invention relates to a preparation method of cetyl trimethyl ammonium bromide modified montmorillonite. According to the preparation method, sodium-based montmorillonite is taken as a raw material, the montmorillonite and water are first mixed according to a certain proportion, and after the montmorillonite is expanded by a large amount of water, a sol is formed and a Tyndall phenomenon is generated, wherein colloidal particles in the sol are all nano-sheets or nano-particles, and nanocrystallization is realized; then hexadecyl trimethyl ammonium bromide is taken as an intercalation agent,and the cetyl trimethyl ammonium bromide is intercalated into stripped nano sodium montmorillonite layers through a cation exchange reaction by mechanical stirring, so that the cetyl trimethyl ammonium bromide modified montmorillonite is obtained. According to the preparation method, the adopted raw materials are few and have low prices, operation is simple, production cost is low, performance such as mechanical strength, gas barrier property, hydrophobicity and the like of the montmorillonite are greatly improved, and the prepared organic montmorillonite can be widely used as a corrosion inhibitor in the field of corrosion prevention.

Owner:ZHEJIANG UNIV OF TECH

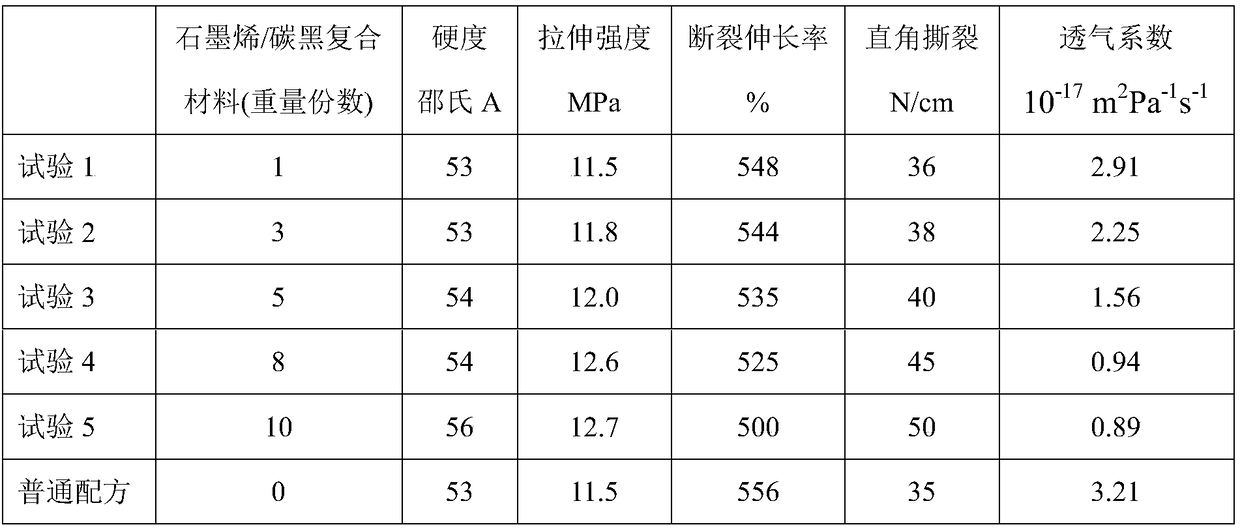

Tyre inner lining glue with graphene/carbon black composite and preparation method of tyre inner lining glue

InactiveCN109161110AImprove wear resistanceExtended service lifeSpecial tyresVulcanizationEngineering

The invention discloses tyre inner lining glue with a graphene / carbon black composite and a preparation method of the tyre inner lining glue. The tyre inner lining glue comprises the components in parts by weight of 100 parts of halogenated butyl rubber, 1-20 parts of a graphene / carbon black composite, 10-60 parts of a filling, 1-20 parts of extender oil, 1-10 parts of a viscosifying agent, 1-5 parts of a processing agent, 1-10 parts of an activator and 0.9-5 parts of a vulcanization system, wherein the graphene / carbon black composite is prepared by a home-position mechanical exfoliation method, self clumping between graphene slices is overcome, and the dispersibility and the compatibility of graphene and carbon black in rubber can be improved. In a tyre inner lining formula, the graphene / carbon black composite is added, and in a banburying mixing manner, the graphene is uniformly distributed in a polymer, so that the effect of separating gas molecules from infiltrating is achieved, the air tightness of the tyre is improved greatly, the service life of the tyre is prolonged, and the using properties of vehicles can be improved in many respects.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

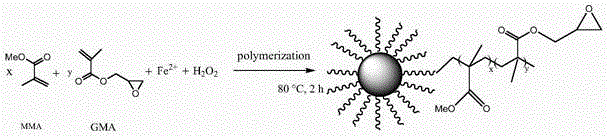

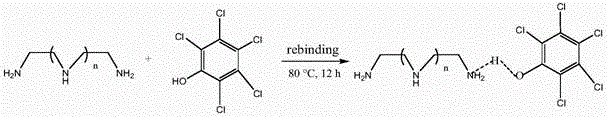

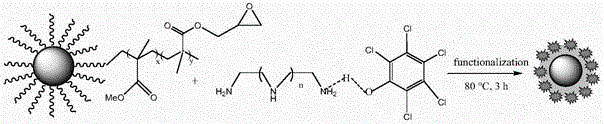

Magnetic field-induced preparation method of molecularly-imprinted magnetic enrichment material of trace quantity of chlorophenol pollutant molecules in seawater

InactiveCN104130441AAvoid easy reunionAvoid low magnetic contentOther chemical processesSeawater treatmentSolid phase extractionAmino functionalized

The invention discloses a magnetic field-induced preparation method of a molecularly-imprinted magnetic enrichment material of trace quantity of chlorophenol pollutant molecules in seawater. The preparation method comprises that under magnetic field induction, an epoxy group-functionalized magnetic polymer is prepared by suspension polymerization and in-situ oxidation, a chlorophenol environmental pollutant polyamine template molecule is obtained by an intermolecular hydrogen bonding self-assembling technology, an amino-functionalized magnetic molecularly-imprinted composite material bonding with the template molecule is prepared under magnetic field induction, and in the presence of an acid / alcohol extractant, through pH adjustment, the template molecule is eluted and the chlorophenol molecule-imprinted magnetic composite material is obtained. The preparation method has simple processes and a low cost and realizes uniform particle size distribution and stable properties of the desired product. The molecularly-imprinted magnetic enrichment material can realize high-efficiency and high-selectivity adsorption and removal of trace quantity of chlorophenol pollutants in seawater and can be used for base dispersion-magnetic solid phase extraction detection of trace quantity of chlorophenol pollutants in seawater.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com