Preparation method of cetyl trimethyl ammonium bromide modified montmorillonite

A technology of hexadecyltrimethylammonium bromide and montmorillonite, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problem of insufficient stripping and complete dispersion, insignificant modification effect, and problems in the experimental process. Complicated problems, low raw material prices, reduced van der Waals force, and good modification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Proceed as follows:

[0036] (1) Get 5g montmorillonite (sodium montmorillonite, its cation exchange capacity is 100meq / 100g)

[0037] Disperse in water under magnetic stirring to prepare a 0.1% exfoliated montmorillonite suspension;

[0038] (2) Under the action of mechanical stirring, add 0.91 g of hexadecyltrimethylammonium bromide equivalent to 0.5 times the exchange capacity of montmorillonite to the montmorillonite suspension, at a reaction temperature of 60 ° C The reaction was carried out for 120min.

[0039] (3) The reaction product obtained in step (2) is subjected to centrifugation and washing 3 times, each time at a speed of 8000r / min for 8 minutes, then the centrifuged product is dried at 80°C for 24 hours, and finally ground to obtain hexadecyl tri Montmorillonite modified with methyl ammonium bromide.

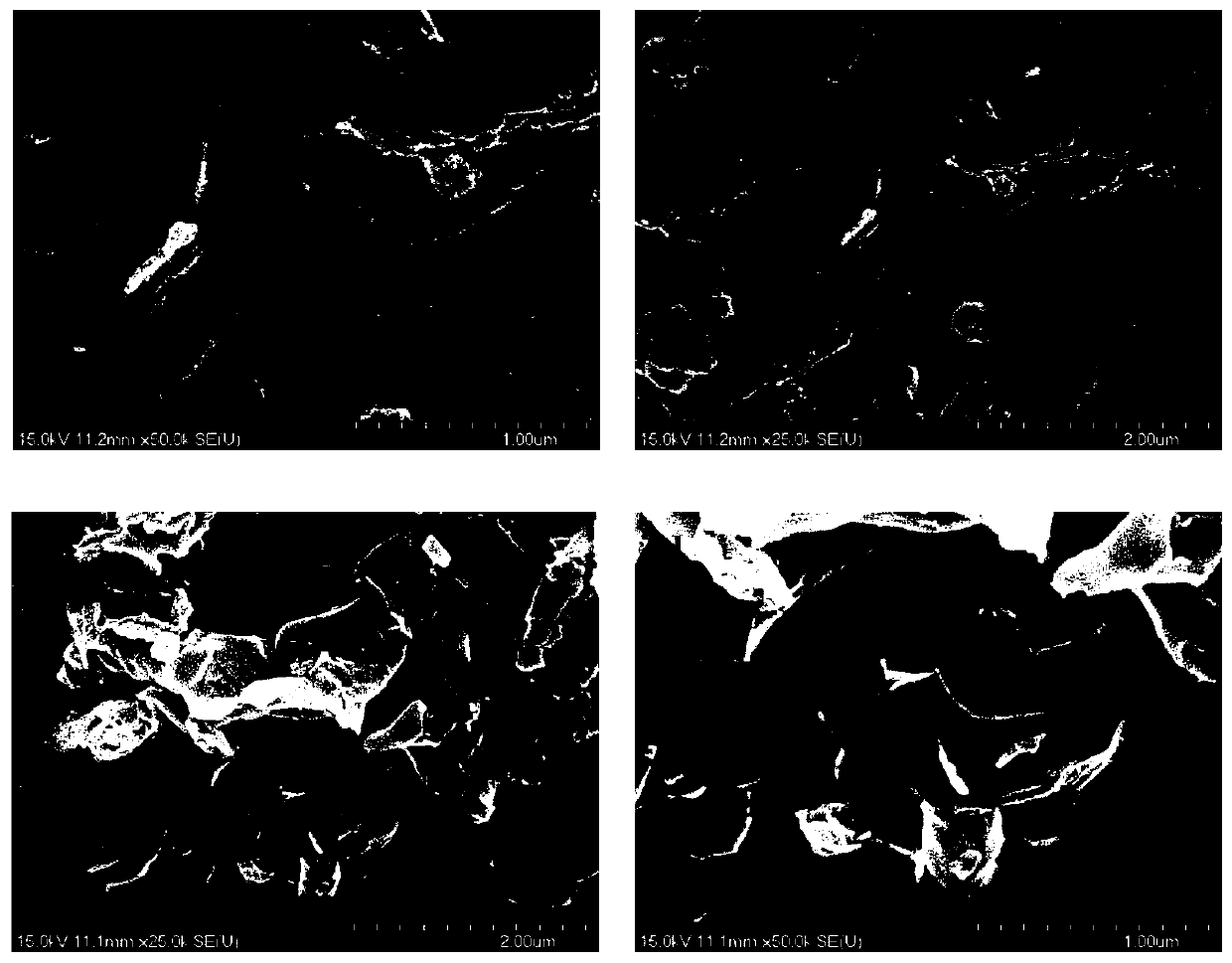

[0040] The SEM comparison chart of montmorillonite raw material and stripped montmorillonite can be found in figure 1 . a and b are raw materials of ...

Embodiment 2

[0043] Proceed as follows:

[0044] (1) Get 5g montmorillonite (sodium-based montmorillonite, its cation exchange capacity is 110meq / 100g) and disperse it in water under magnetic stirring, and make the montmorillonite suspension that the mass fraction is 0.5%;

[0045] (2) Under the action of mechanical stirring, add 2.00 g of hexadecyltrimethylammonium bromide equivalent to 1 times the exchange capacity of montmorillonite to the montmorillonite suspension. The reaction was carried out for 150min.

[0046] (3) The reaction product obtained in step (2) was first centrifuged and washed 3 times, each time at a speed of 8000r / min for 8 minutes, and then the centrifuged product was dried at 80°C for 24h,

[0047] Finally grind to obtain cetyltrimethylammonium bromide modified montmorillonite.

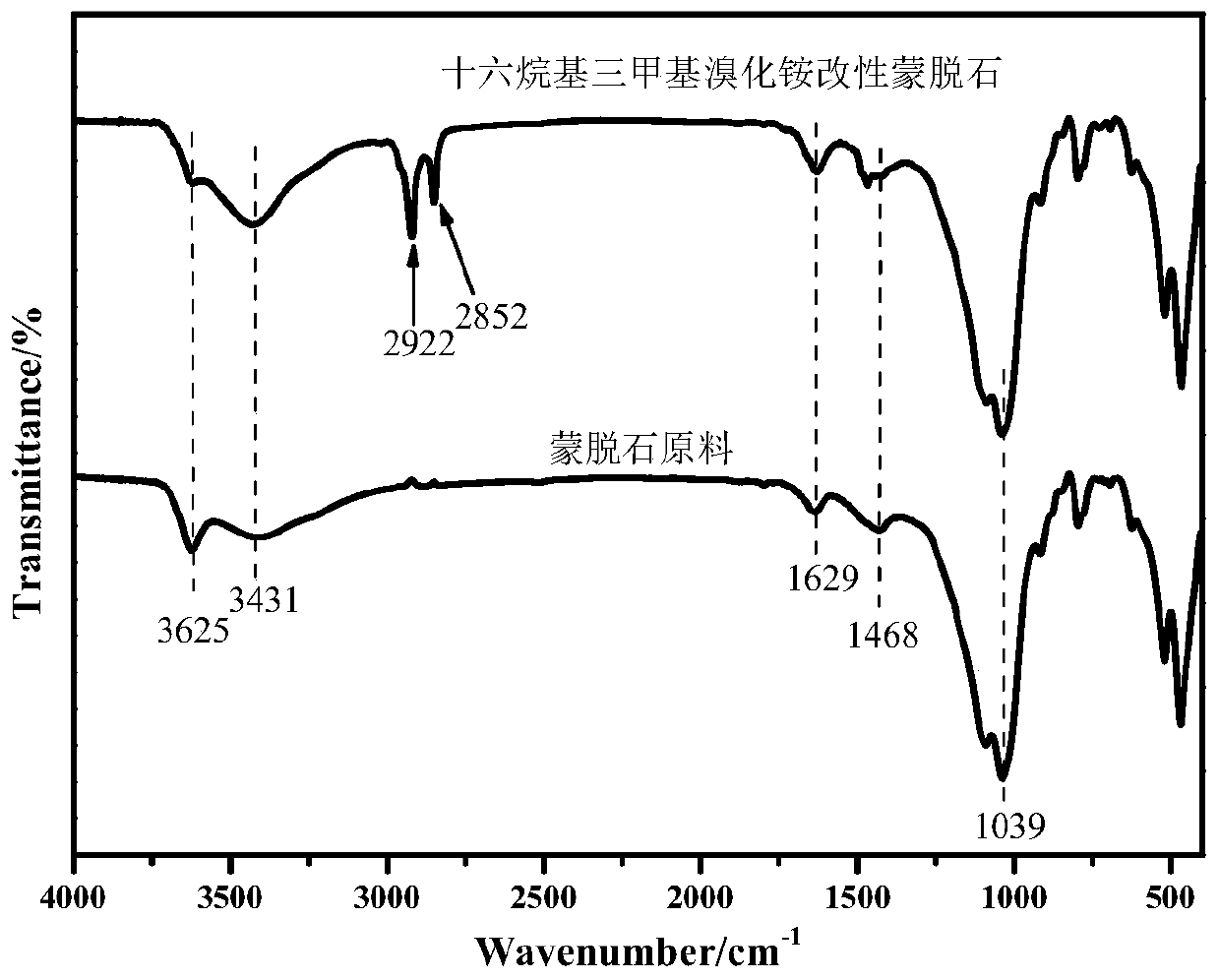

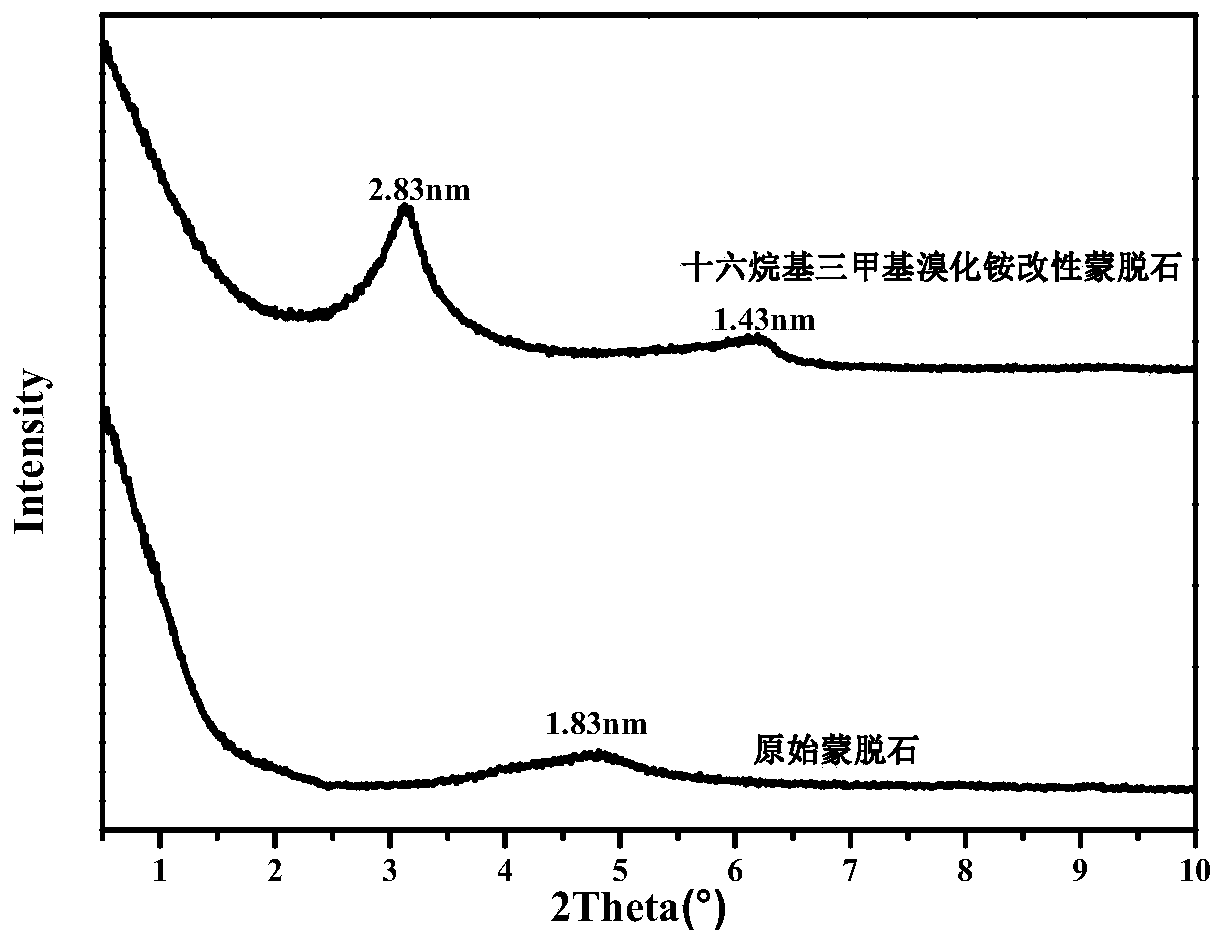

[0048] The montmorillonite modified with cetyltrimethylammonium bromide and the raw material montmorillonite were characterized by X'Pert PRO X-ray diffractometer of PANalytical Company in...

Embodiment 3

[0050] Proceed as follows:

[0051] (1) Get 5g montmorillonite (sodium-based montmorillonite, its cation exchange capacity is 120meq / 100g) and disperse in water under magnetic stirring, and make the montmorillonite suspension that the mass fraction is 1% to peel off;

[0052] (2) Under the action of mechanical stirring, add 2.19 g of hexadecyltrimethylammonium bromide equivalent to 1 times the exchange capacity of montmorillonite to the montmorillonite suspension. The reaction was carried out for 180min.

[0053] (3) The reaction product obtained in step (2) was first centrifuged and washed 3 times, each time at a speed of 8000r / min for 8 minutes, then the centrifuged product was dried at 80°C for 24 hours, and finally ground to obtain hexadecyl tri Montmorillonite modified with methyl ammonium bromide.

[0054] The OCA-20 video optical contact angle measuring instrument of German Dataphysics Company was used to test the montmorillonite modified by cetyltrimethylammonium bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com