Environment-friendly and low temperature-resistant acrylate adhesive

An acrylate-based, low-temperature-resistant technology, applied in the direction of adhesive additives, ester copolymer adhesives, adhesive types, etc., can solve the problems of low initial adhesion of tapes, increased production costs, and reduced production efficiency, and achieves Low temperature initial viscosity is strong, the initial viscosity is improved, and the adhesion is not weakened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail.

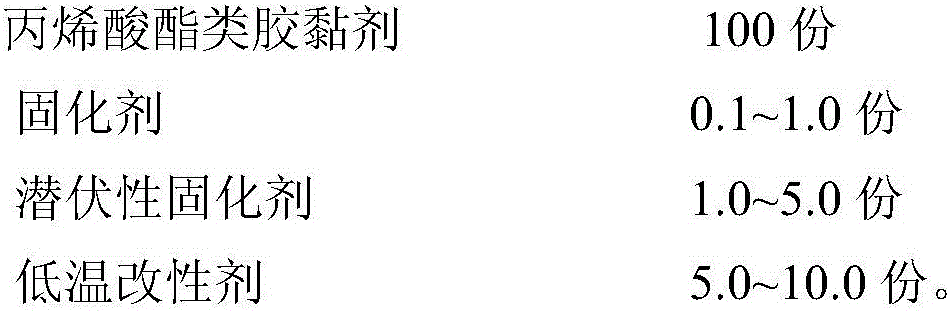

[0018] An environmentally friendly low temperature resistant acrylic adhesive, which consists of the following raw materials and their parts by mass:

[0019]

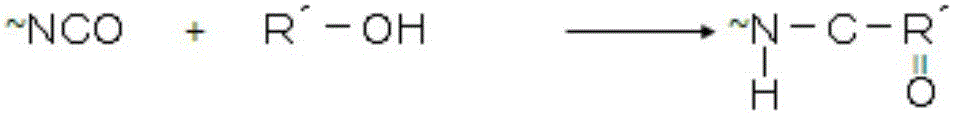

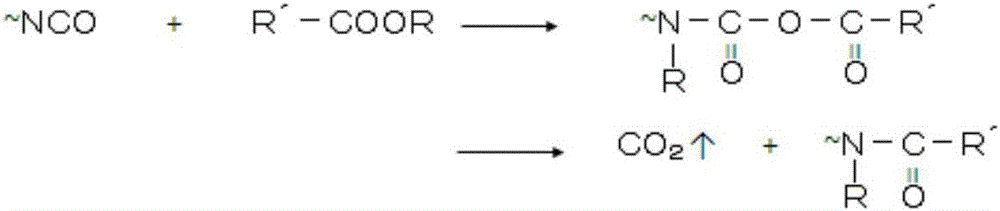

[0020] Wherein, the above-mentioned low-temperature modifier is butyl benzyl phthalate, dioctyl phthalate, epoxy tetrahydrophthalate dioctyl, or epoxy soybean oleic acid 2-ethylhexyl at least one. The curing agent is at least one of toluene diisocyanate, isophorone diisocyanate, hexamethylene diisocyanate, and 4,4'-dicyclohexylmethane diisocyanate. The latent curing agent is at least one of 2-methylimidazole, 2-ethyl-4-methylimidazole, 2-phenylimidazole and aluminum acetylacetonate.

[0021] The preparation method of the environmentally friendly low-temperature resistant acrylic adhesive is as follows: according to the above-mentioned parts by mass, add the latent curing agent and the low-temperature modifier in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com