Method for preparing two-dimensional nano-sheet materials by adopting liquid-phase stripping

A two-dimensional nano, liquid phase exfoliation technology, applied in the field of preparation of two-dimensional nanosheet materials, can solve the problems of low exfoliation efficiency, unstable nanosheets, long ultrasonic time, etc., to reduce van der Waals force and prevent recurrence Stacked, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) At room temperature, molybdenum disulfide and epigallocatechin were added into water according to a certain proportion and mixed uniformly to obtain molybdenum disulfide and epigallocatechin concentrations of 10 mg / mL and 4 mg / L respectively. The volume is 100mL;

[0037] (2) At room temperature, the solution in step (1) was ultrasonically treated with a cell pulverizer at a power of 300W for 4 hours;

[0038] (3) At room temperature, centrifuge the ultrasonic solution in step (2) for 60 minutes at a speed of 8000 rpm, and separate the supernatant to obtain a two-dimensional nanosheet material with good dispersibility The solution is dried to obtain a two-dimensional nano sheet material powder.

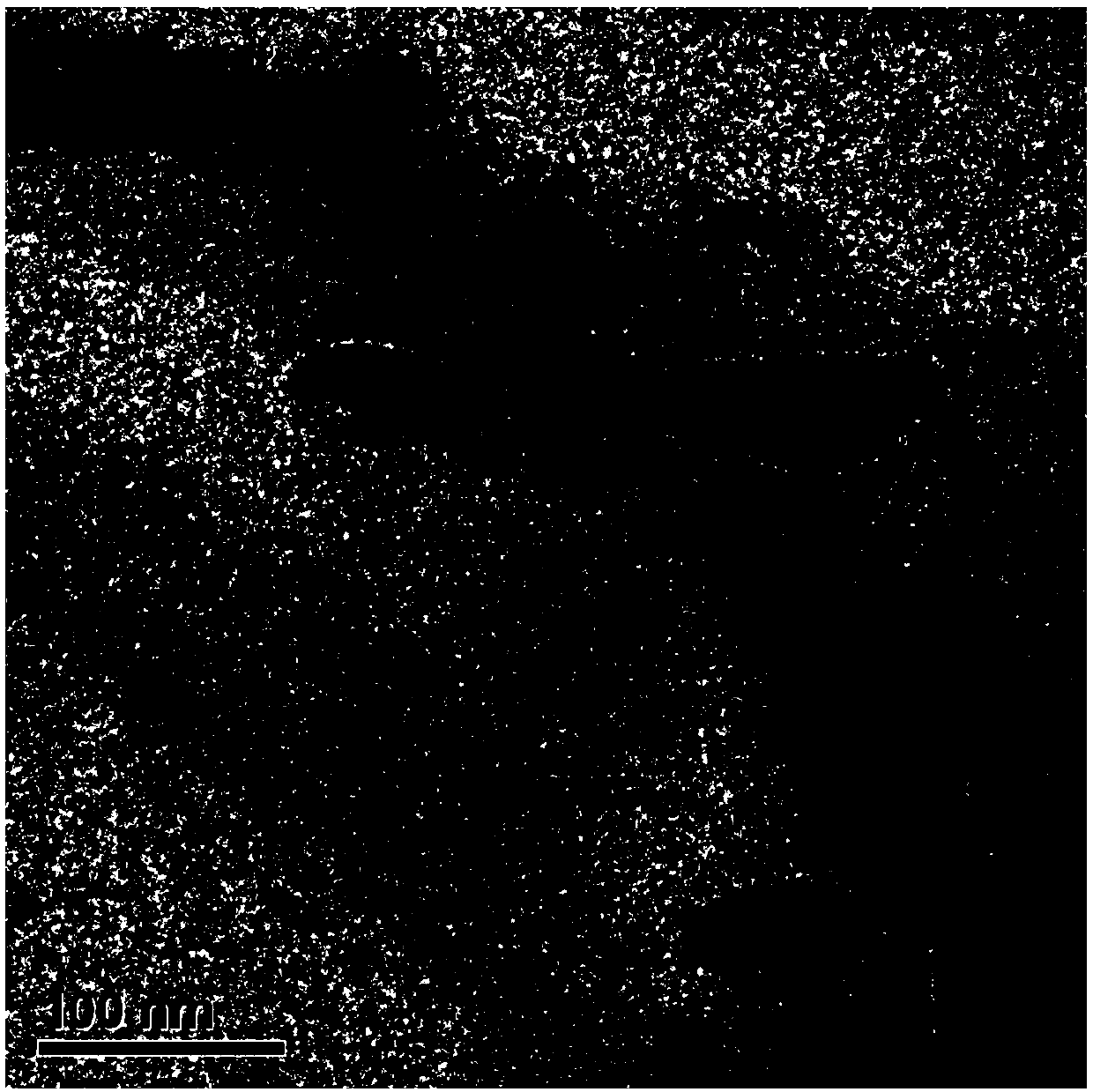

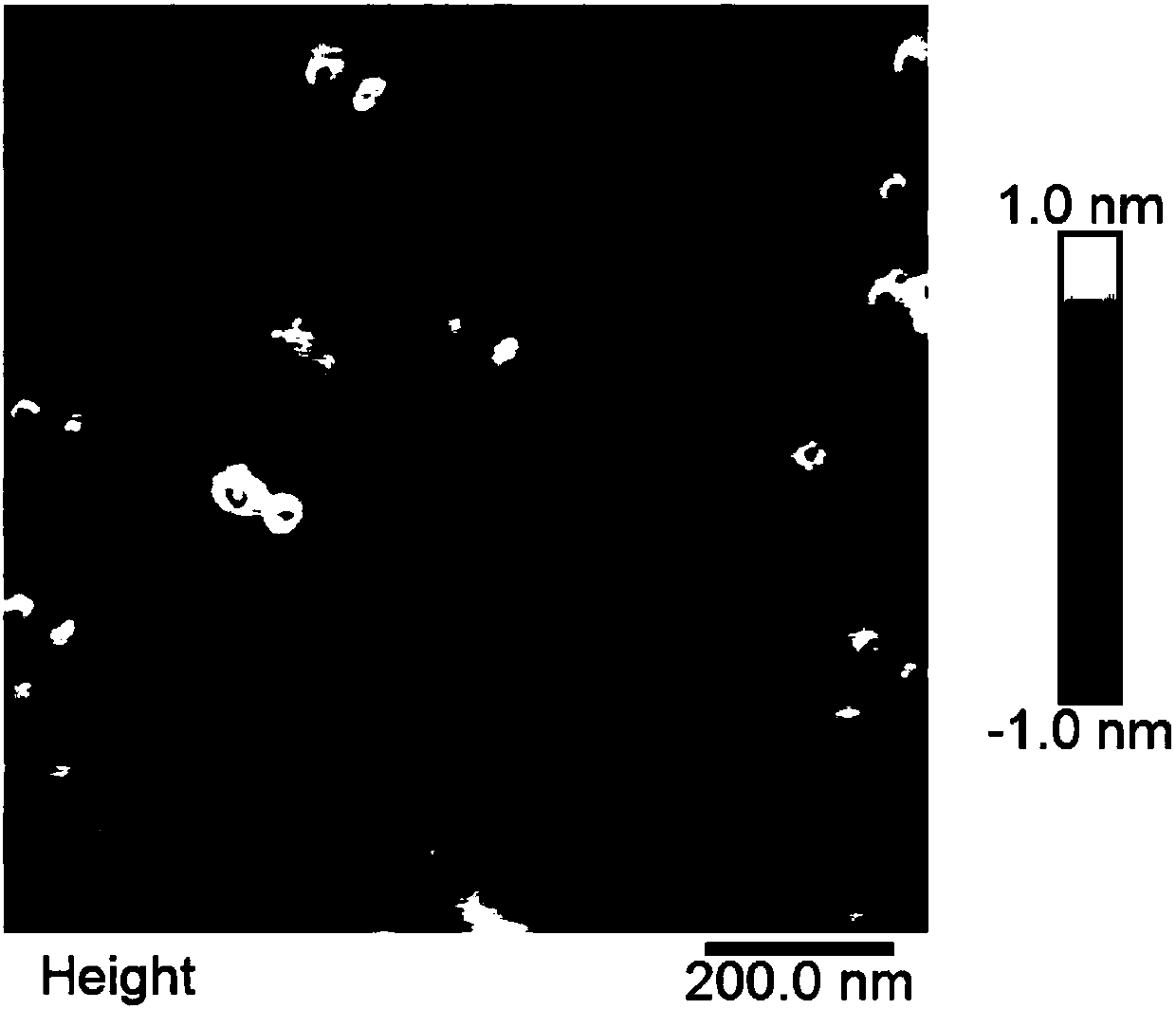

[0039] The transmission electron microscopy and atomic force microscopy images of the two-dimensional nanosheet material prepared by the above method are as follows: figure 1 and figure 2 As shown, it can be seen from the figure that the prepared two-dimensional nanoshe...

Embodiment 2~4

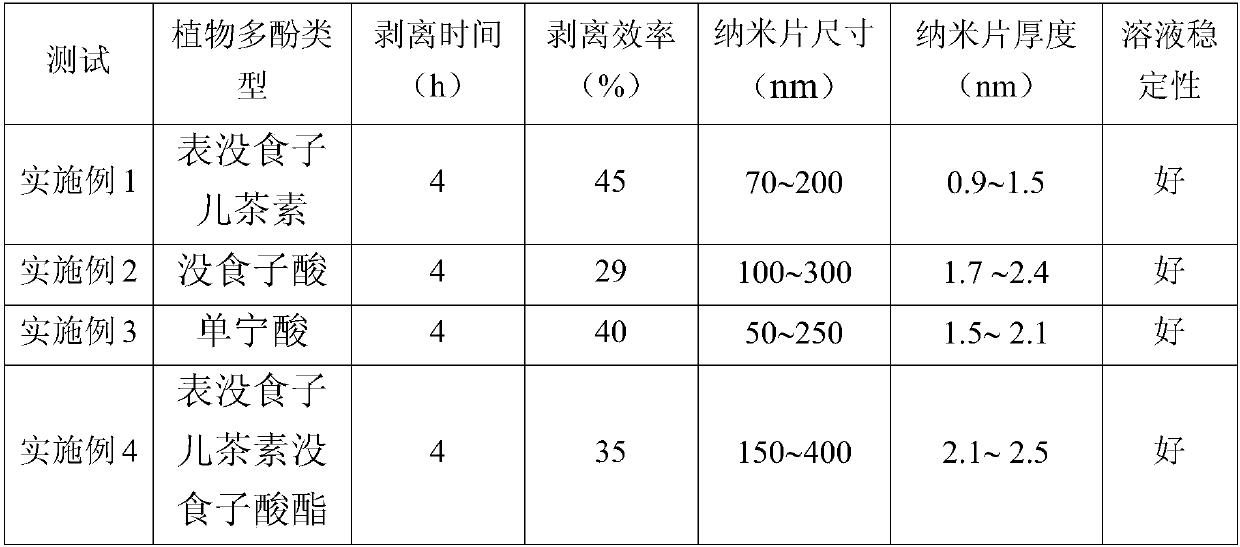

[0041]The epigallocatechin in Example 1 was replaced successively with gallic acid, tannic acid and epigallocatechin gallate, and the rest of the conditions were consistent with Example 1. The experimental results of Examples 1-5 are shown in Table 1.

[0042] Table 1 Experimental results of molybdenum disulfide stripped by different plant polyphenols

[0043]

Embodiment 5

[0045] (1) At room temperature, add tungsten disulfide and epigallocatechin into water according to a certain proportion and mix them uniformly to obtain concentrations of tungsten disulfide and epigallocatechin of 10 mg / mL and 5 mg / L respectively. The volume is 100mL;

[0046] (2) Under room temperature conditions, the solution in step (1) is ultrasonically treated with a cell pulverizer; the ultrasonic treatment time is 4 hours, and the ultrasonic power is 300W;

[0047] (3) At room temperature, centrifuge the ultrasonic solution in step (2) for 60 minutes at a speed of 8000 rpm, and separate the supernatant to obtain a two-dimensional nanosheet material with good dispersibility The solution is dried to obtain a two-dimensional nano sheet material powder.

[0048] The experimental results are shown in Table 2.

[0049] Table 2 Experimental results of stripping tungsten disulfide in Example 5

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com