Preparation method for single-layer graphite-type carbon nitride nanosheet solution

A technology of graphite-type carbon nitride and single-layer graphite, applied in the field of nanomaterials, can solve problems such as unfavorable industrial production, long reaction time period, complicated process, etc., and achieves reduction of van der Waals force, widening of interlayer spacing, and improvement of efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

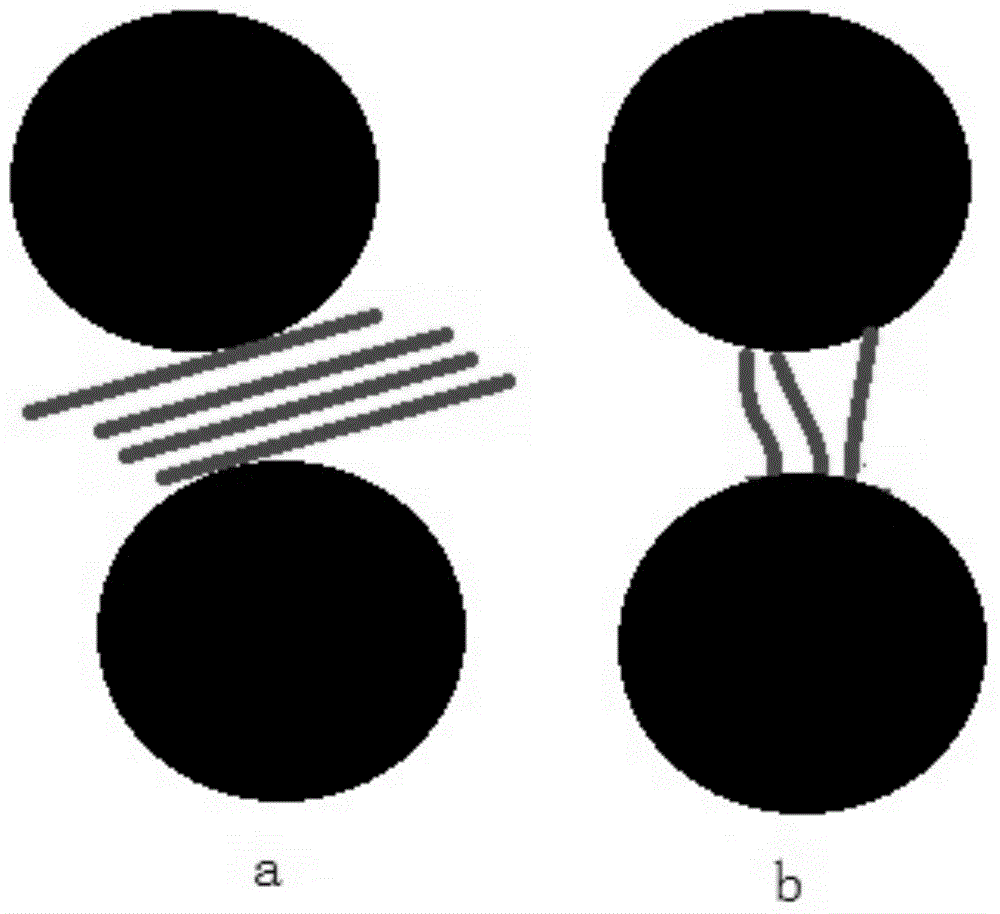

[0021] First prepare graphite-type carbon nitride powder, weigh 10g of melamine in a crucible, place it in a muffle furnace, heat it up to 550°C for 4 hours, take it out after cooling and grind it for later use; weigh 0.5g of graphite-type carbon nitride powder The body was placed in a ball mill jar filled with 200 ml of water, wherein 500 zirconia microbeads with a diameter of 1 mm were housed in the mill jar. The concentration of graphite-type carbon nitride powder is 2.5mg / mL, and the ball mill jar is placed on the jar mill for ball milling for 24h (such as figure 1 shown); take out the carbon nitride suspension solution treated by ball milling, place it in an ultrasonic disperser for ultrasonic peeling, ultrasonic power 200w, ultrasonic time 1h; centrifuge the solution through ultrasonic peeling for 1h, centrifuge speed 4000rpm, take The supernatant can be used to obtain a single-layer graphitic carbon nitride nanosheet solution with a concentration of 1.5 mg / mL.

Embodiment 2

[0023] First prepare graphite-type carbon nitride powder, weigh 15g of melamine in a crucible, place it in a muffle furnace, heat it up to 550°C for 4 hours, take it out after cooling and grind it for later use; weigh 1g of graphite-type carbon nitride powder Place in a ball milling jar equipped with 200 ml of water / ethanol (volume ratio of 10 / 1), wherein 500 zirconia microbeads with a diameter of 1 mm are housed in the grinding jar. The concentration of graphite carbon nitride powder is 5mg / mL, and the ball mill jar is placed on the jar mill for 12h (such as figure 1 shown); take out the carbon nitride suspension solution treated by ball milling, place it in an ultrasonic disperser for ultrasonic peeling, ultrasonic power 100w, ultrasonic time 1h; centrifuge the solution through ultrasonic peeling for 0.5h, centrifuge speed 3000rpm, The supernatant was taken to obtain a single-layer graphitic carbon nitride nanosheet solution with a concentration of 0.65 mg / mL.

Embodiment 3

[0025] First prepare graphite-type carbon nitride powder, weigh 10g of dicyandiamide in a crucible, place it in a muffle furnace, heat it up to 550°C for 4 hours, take it out after cooling and grind it for later use; weigh 0.8g of graphite-type The carbon nitride powder was placed in a ball mill jar filled with 200 ml of water / ethanol (volume ratio 6 / 1), wherein 500 zirconia microbeads with a diameter of 1 mm were housed in the mill jar. The concentration of graphite-type carbon nitride powder is 4mg / mL, and the ball mill jar is placed on the jar mill for 20h ball milling (such as figure 1 shown); take out the carbon nitride suspension solution treated by ball milling, put it in an ultrasonic disperser for ultrasonic stripping, ultrasonic power 120w, ultrasonic time 1h; centrifuge the solution through ultrasonic stripping for 1h, centrifuge speed 4000rpm, take The supernatant can be used to obtain a single-layer graphitic carbon nitride nanosheet solution with a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com