Patents

Literature

178 results about "Graphitic carbon nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

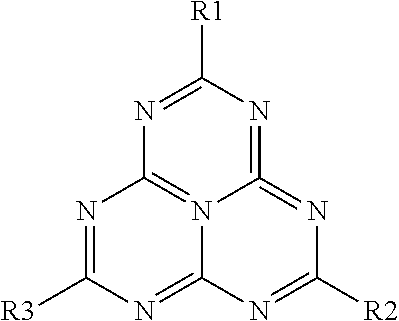

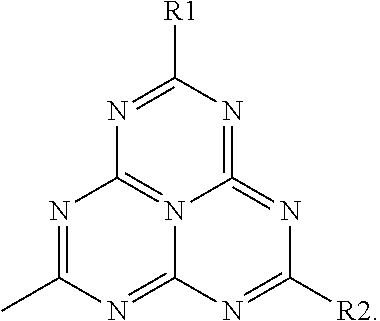

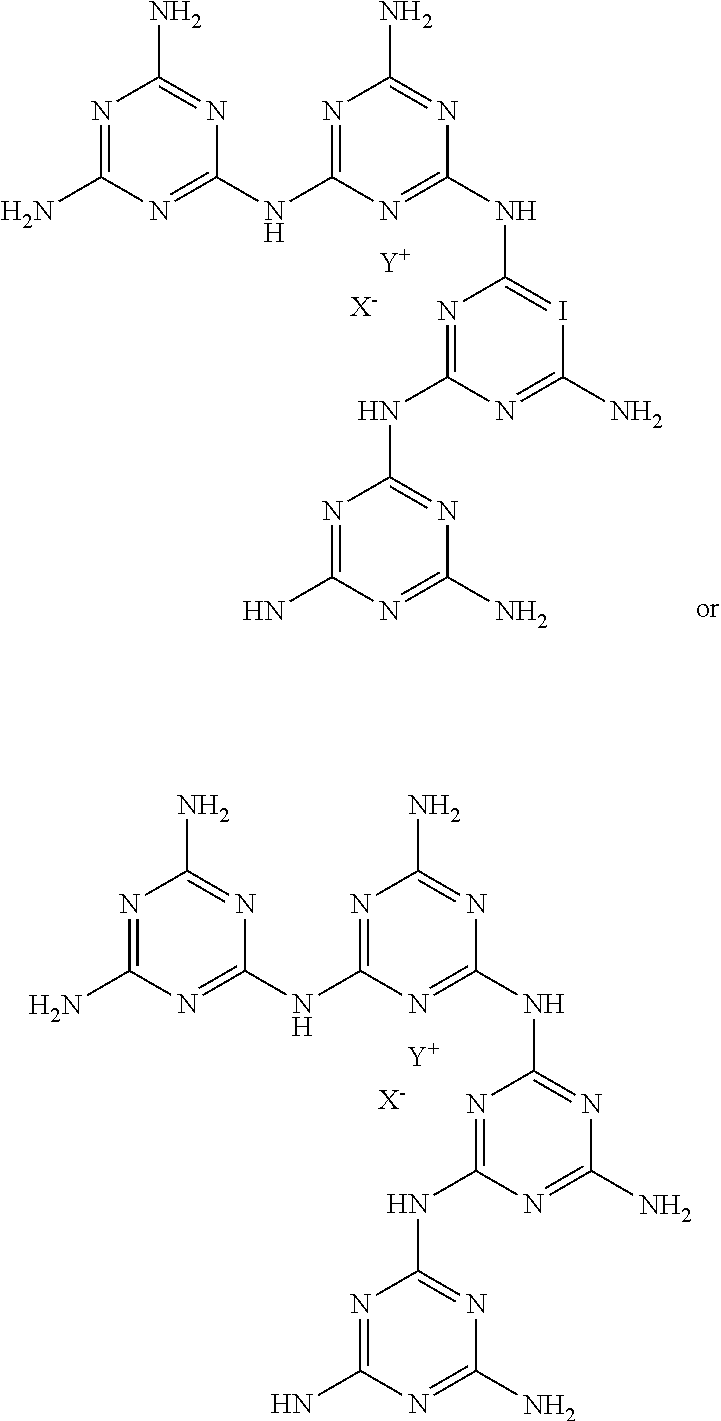

Graphitic carbon nitride (g-C₃N₄) is a family of carbon nitride compounds with a general formula near to C₃N₄ (albeit typically with non-zero amounts of Hydrogen) and two major substructures based on heptazine and Poly(Triazine imide) units which, depending on reaction conditions, exhibit different degrees of condensation, properties and reactivities.

Pnictide containing catalysts for electrochemical conversion reactions and methods of use

ActiveUS20160233487A1Increase electrode kineticsReducing electrode charge transfer resistanceFinal product manufacturePositive electrodesLithium–sulfur batteryLithium sulfur

This patent application describes graphitic carbon nitride materials that are useful in electrochemical cells such as Lithium-Sulfur batteries. Also disclosed are lithium-sulfur batteries designed to incorporate these materials and methods of manufacturing the same. Batteries that include this material exhibit increased electrode kinetics of the lithium-sulfur electrochemical couple, phenomena that improve the specific capacity, usable lifetime and other desirable characteristics of these batteries.

Owner:RGT UNIV OF CALIFORNIA +1

Graphitic carbon nitride material, and its synthetic method and applications

InactiveUS20170057821A1Synthetic is simpleImprove distributionNitrogen-metal/silicon/boron binary compoundsEnergy based wastewater treatmentCarbon nitrideCalcination

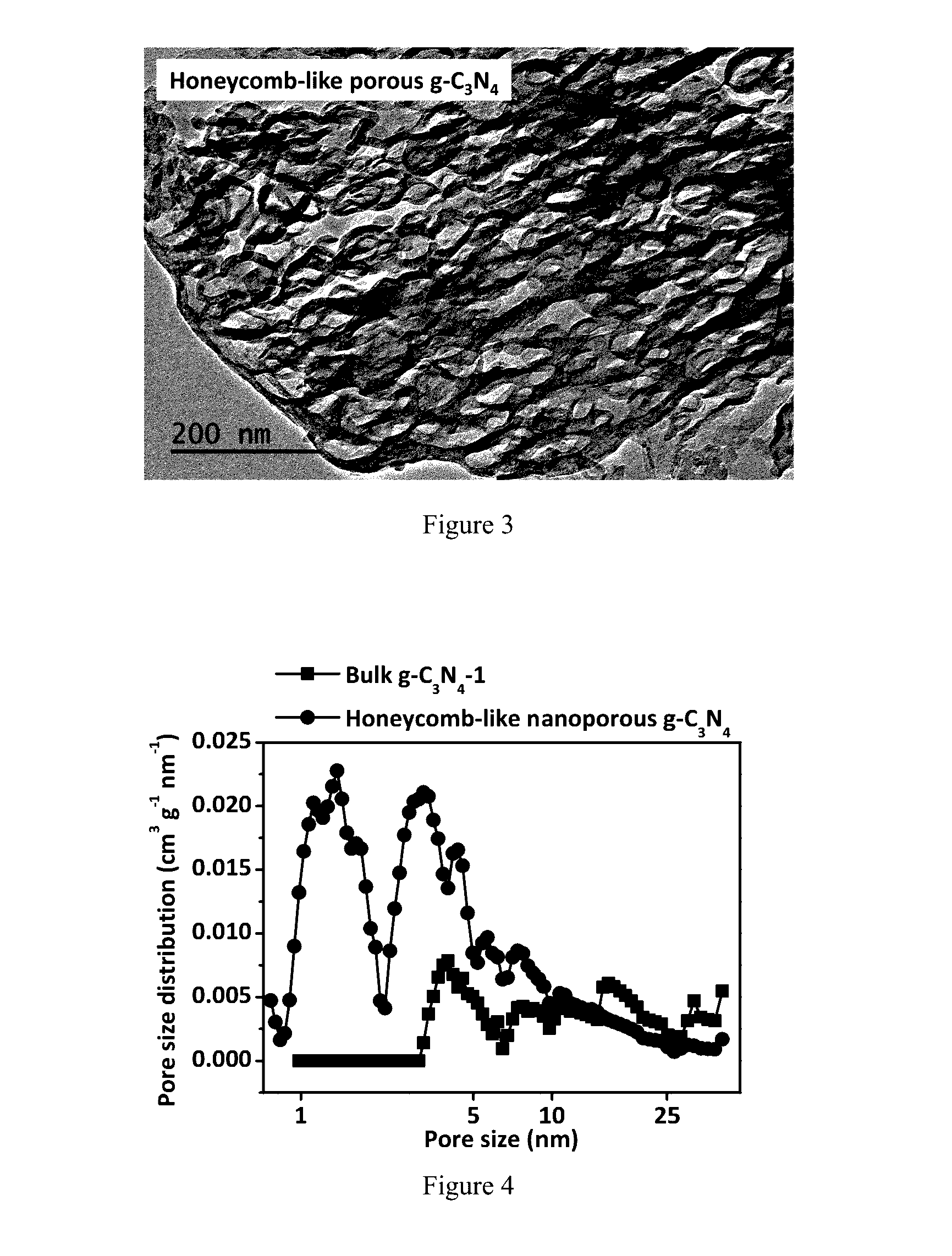

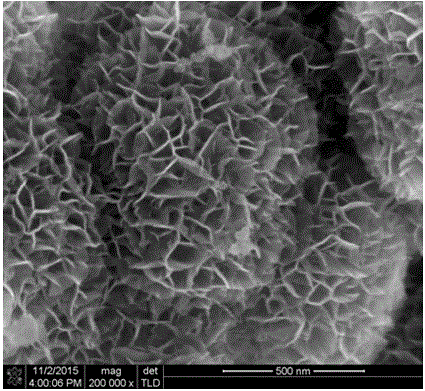

The present invention relates to a synthetic method of graphitic carbon nitride material. The method involves a homogenous mixing of carbon nitride precursor and ammonium salt, and calcining the mixture to obtain a porous graphitic carbon nitride material. Wherein, the ammonium salt is any one or a combination of at least two which could release gaseous NH3 during thermolysis. The present invention uses thermolabile ammonium salt as a pore former; the thermolysis of ammonium salt could release soft gas bubbles during the calcination; the later burst of bubbles leads to the formation of nanoporous structure. The proposed method is template-free and environmentally-friendly, and the resultant material exhibits high photocatalytic activity in the field of gas and water decontamination.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of graphite phase carbon nitride/rutile monocrystal titanium dioxide (TiO2) nanowire array

InactiveCN102125863ALow costEasy to useCatalyst activation/preparationSingle crystalCyanamide compound

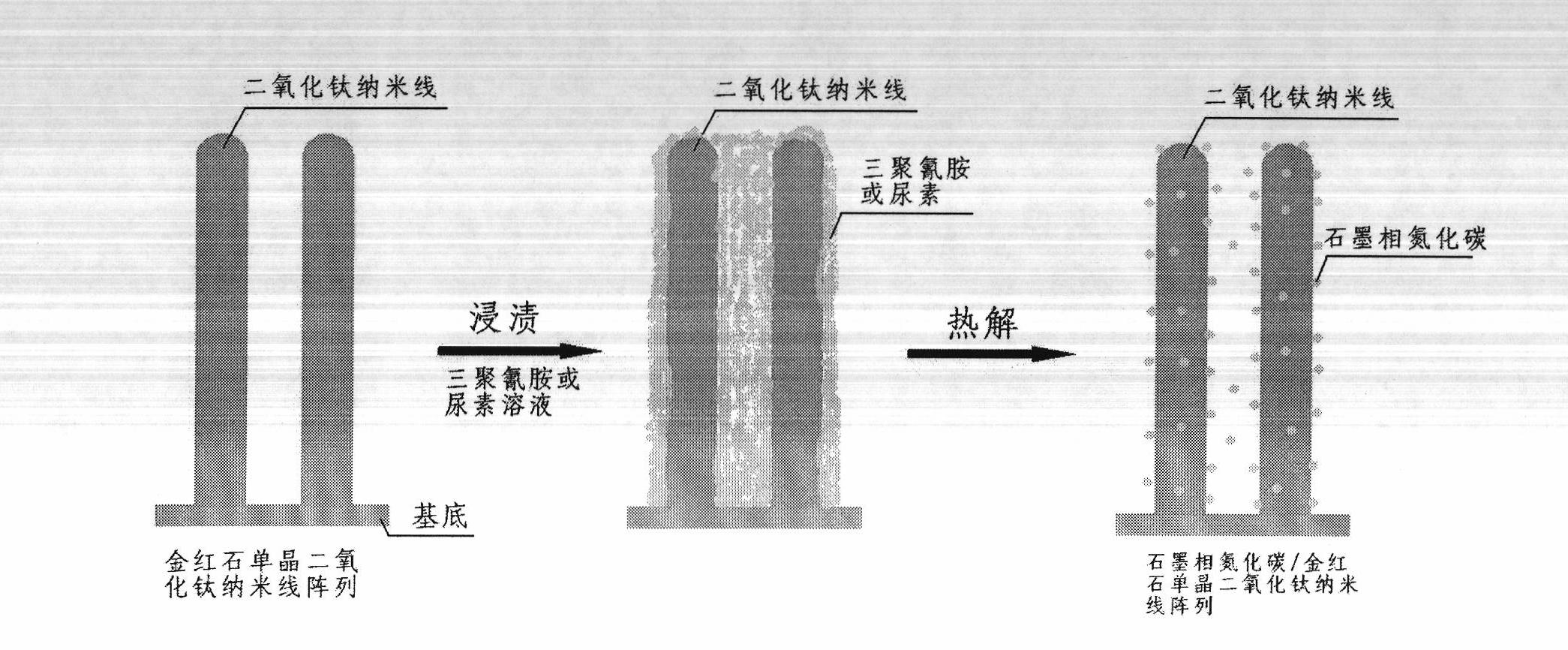

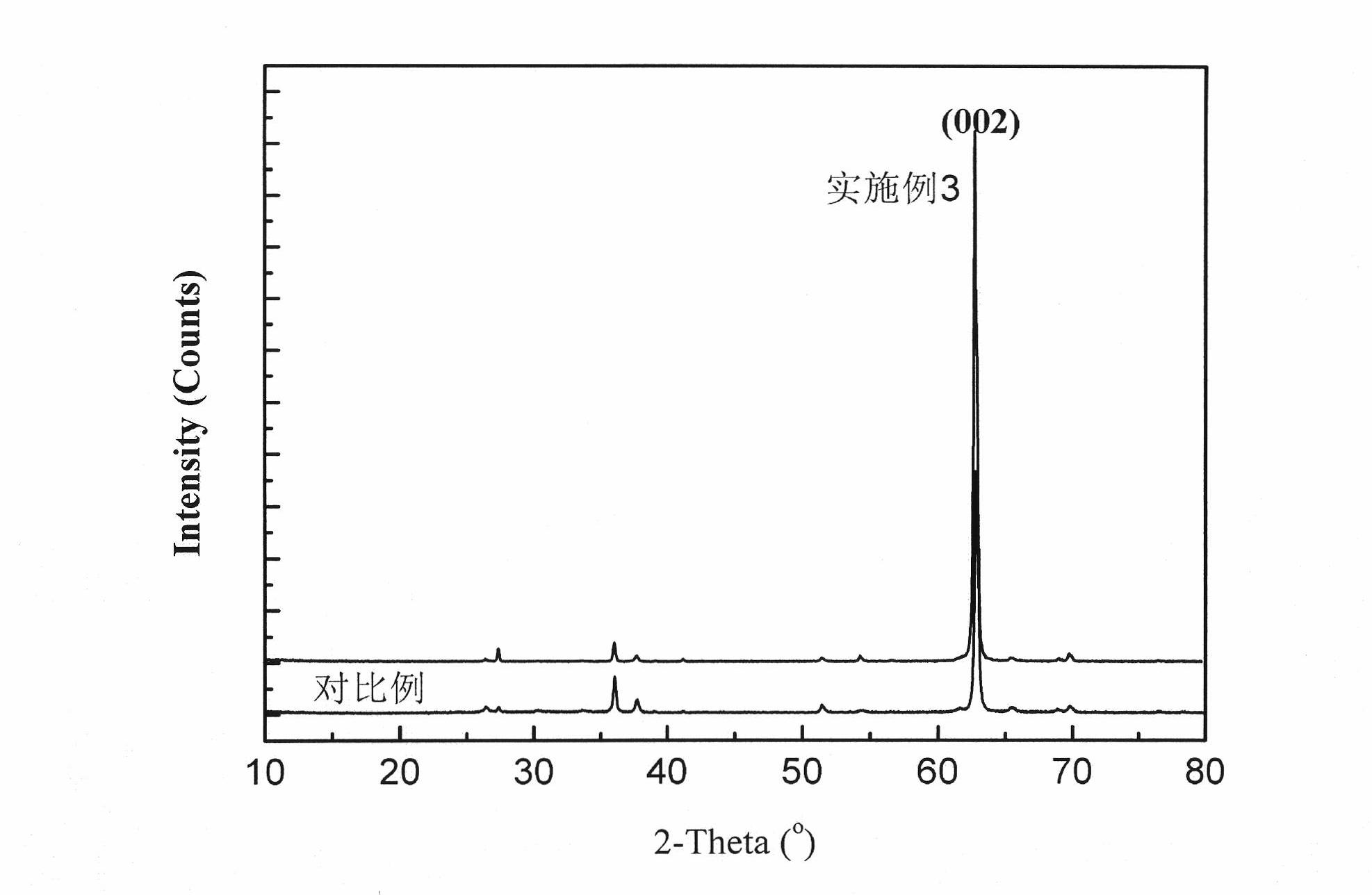

The invention discloses a preparation method of a graphite phase carbon nitride / rutile monocrystal titanium dioxide (TiO2) nanowire array. The preparation method is characterized by comprising the following steps: (a) dissolving a cyanamide compound or urea in a solution, immersing the prepared rutile monocrystal TiO2 nanowire array into the obtained cyanamide compound or urea solution, and then taking out and drying the nanowire array; and (b) performing heat treatment on the dried nanowire array to finally obtain the graphite phase carbon nitride / rutile monocrystal TiO2 nanowire array. The preparation method has the advantages of simple process and low cost, thus being applicable to large-scale industrial production; and the prepared graphite phase carbon nitride / rutile monocrystal TiO2 nanowire array has good visible light response activity, and can be widely applied to the fields such as photocatalysis, hydrogen production by photocatalytic decomposition of water, photoelectric conversion and the like.

Owner:XIANGTAN UNIV

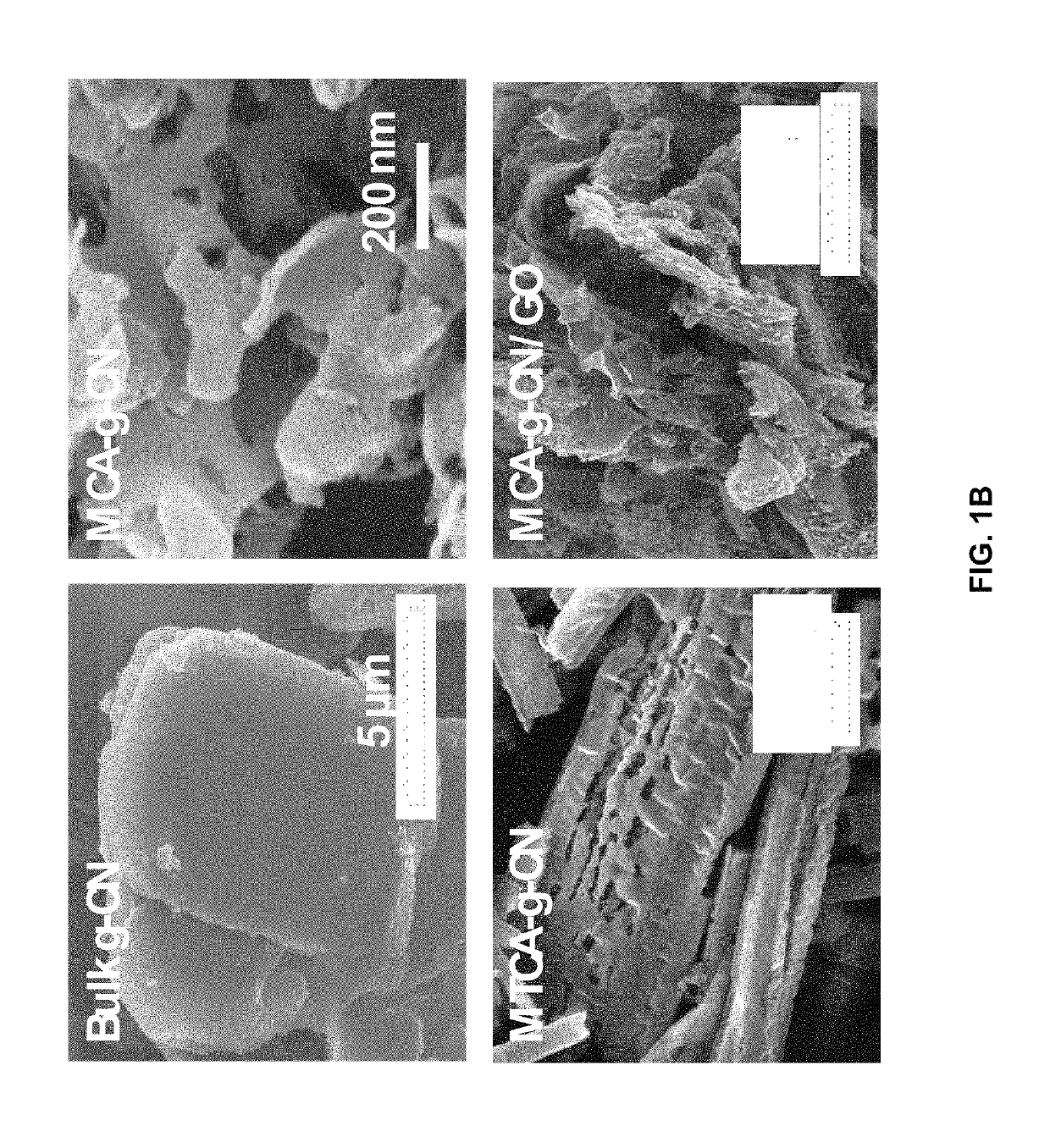

Composite visible-light-responding photocatalyst material, and preparation method and application thereof

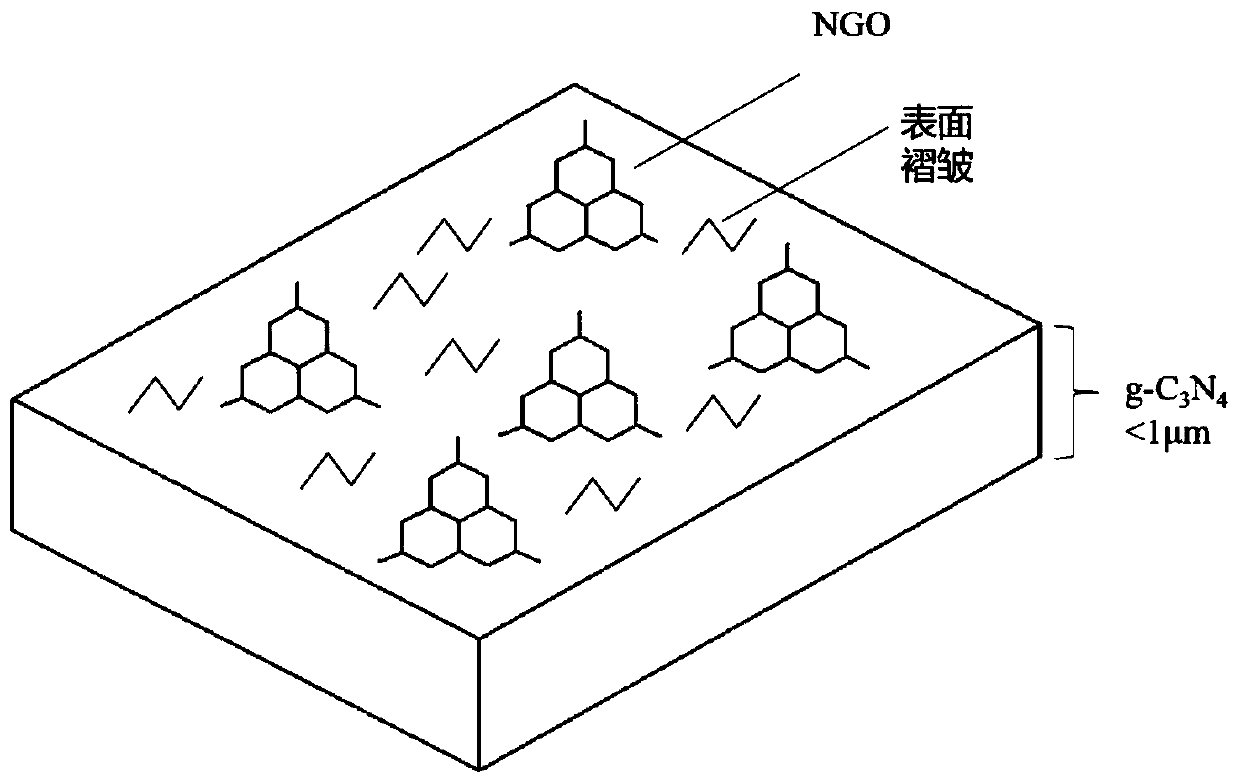

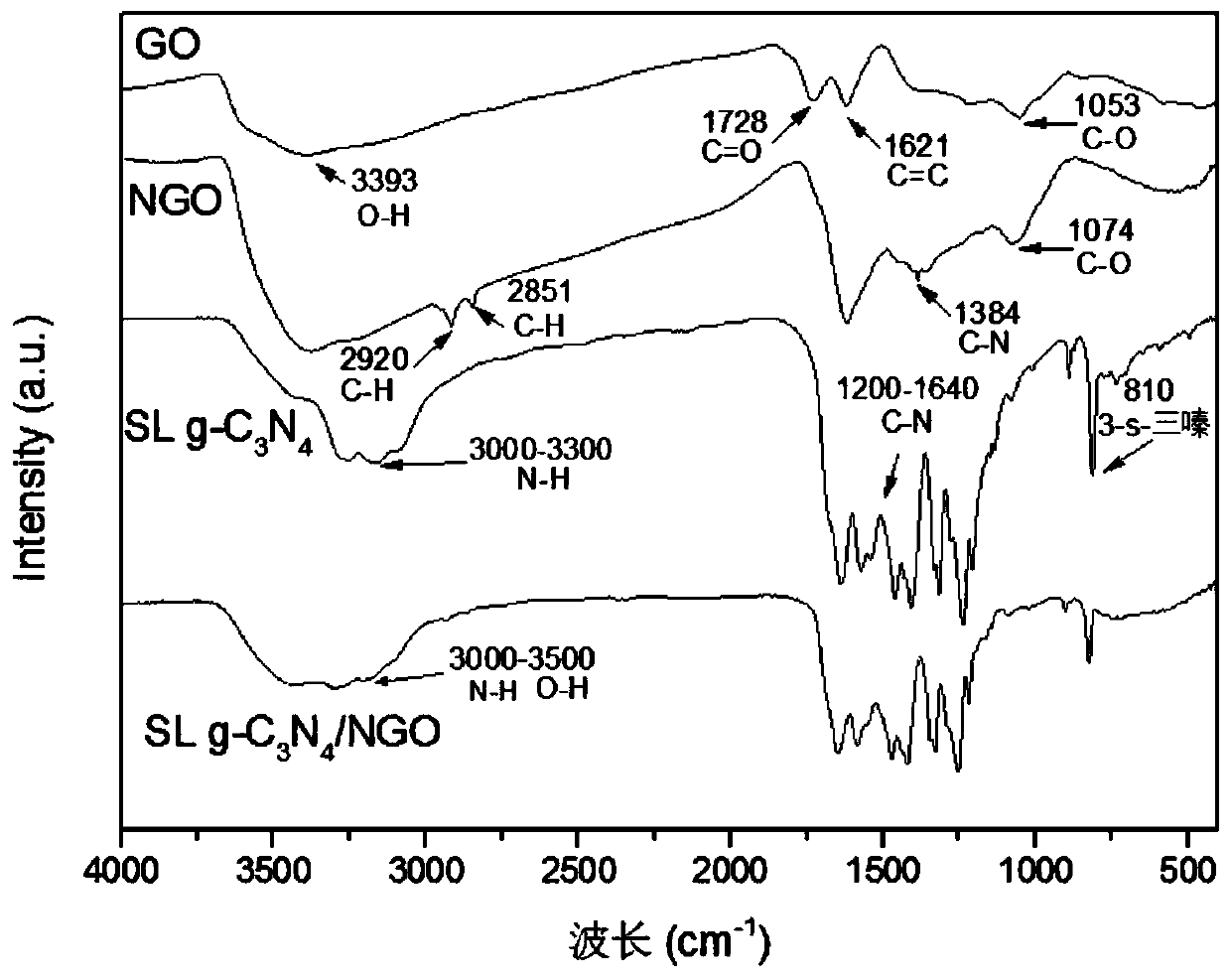

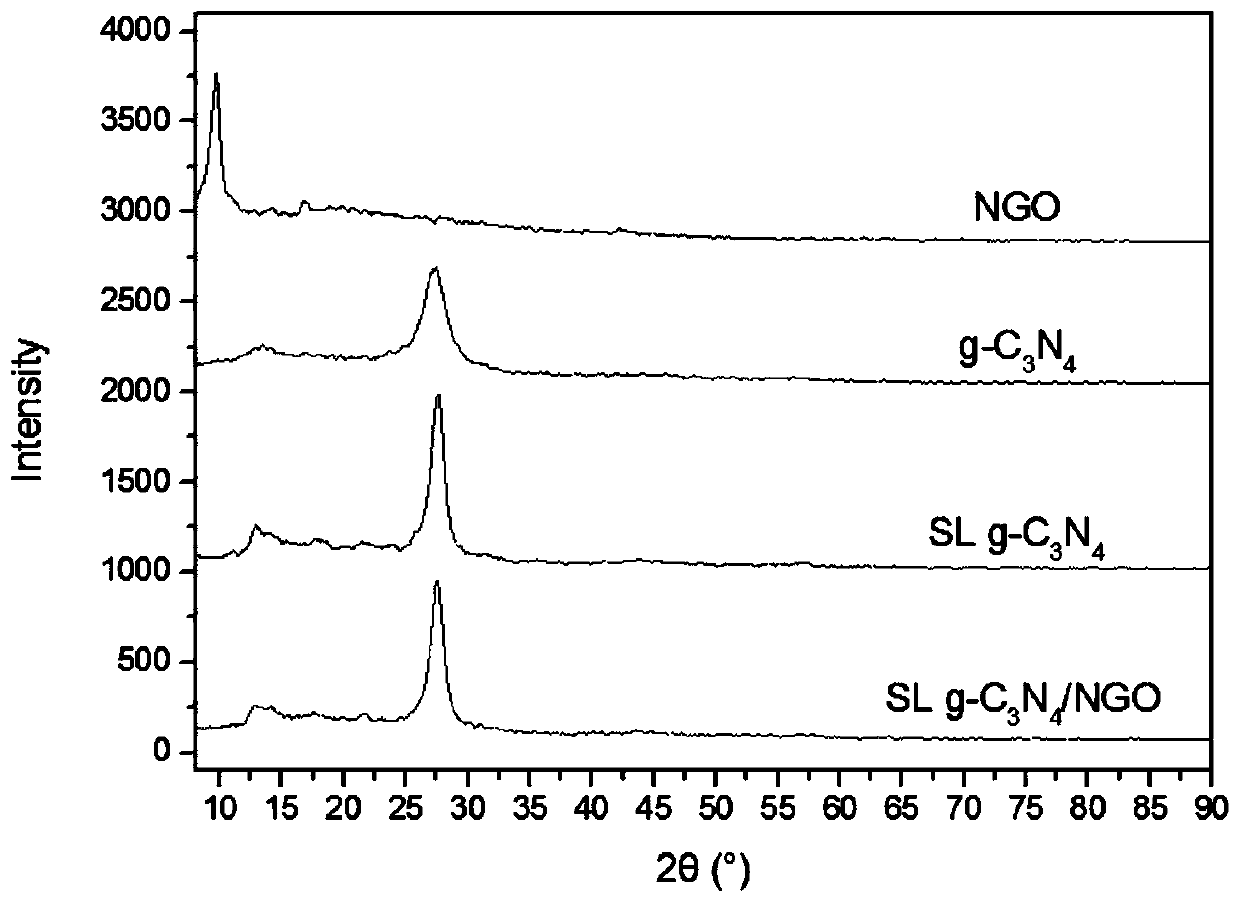

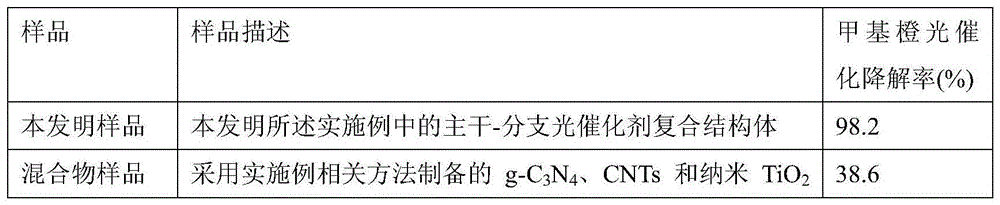

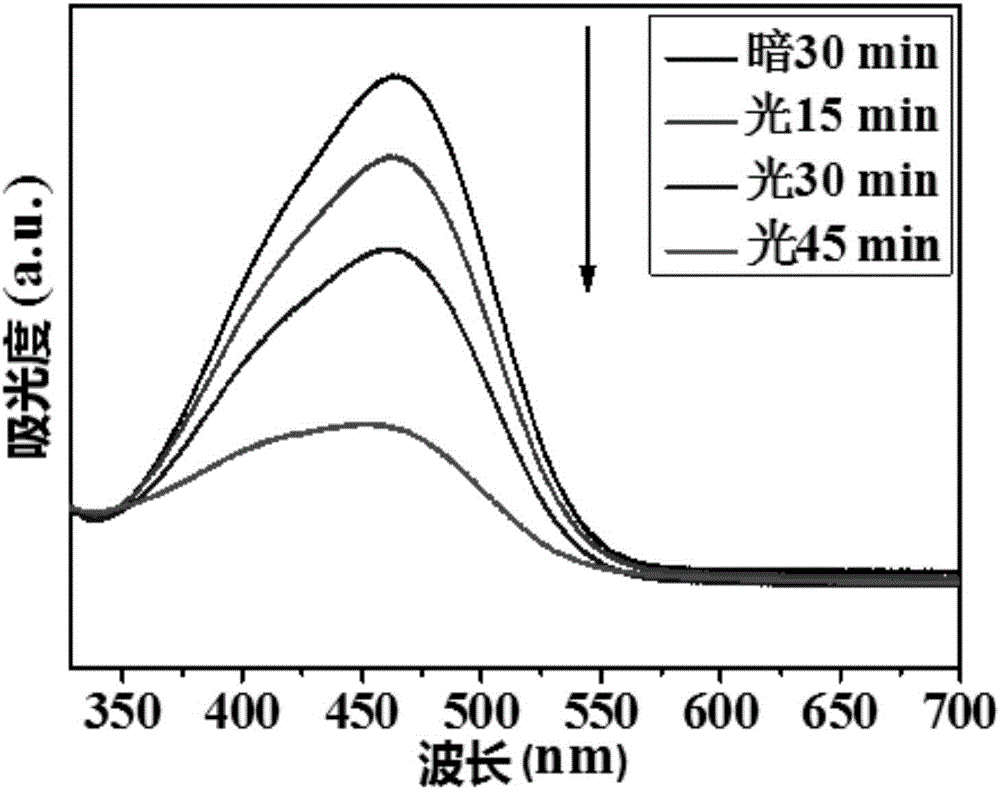

InactiveCN110538672AImprove hydrophilicityPromote absorptionPhysical/chemical process catalystsWater/sewage treatment by irradiationEthylenediamineHeterojunction

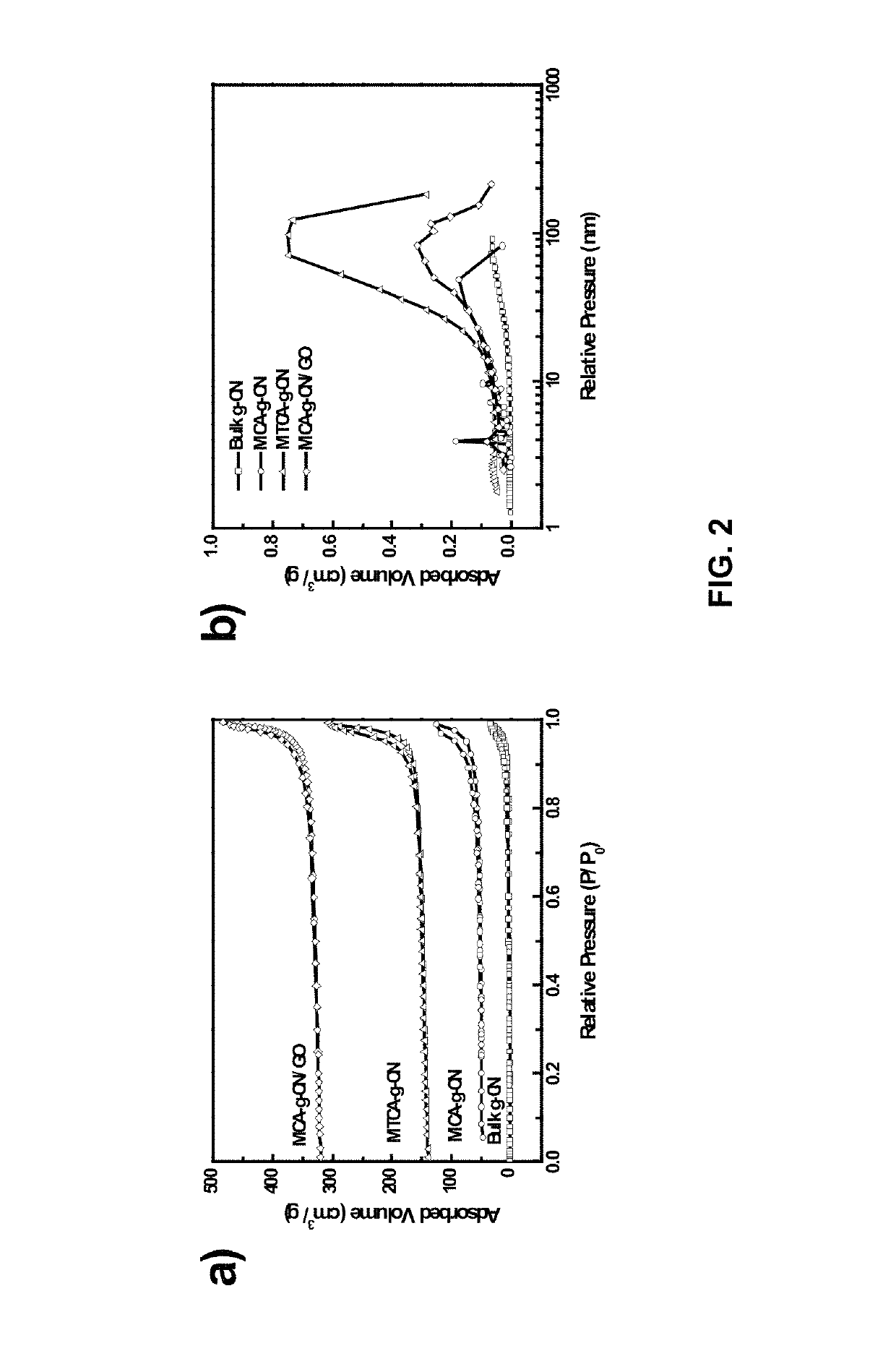

The invention belongs to the technical field of environment and water treatment, and discloses a composite visible-light-responding photocatalyst material, and a preparation method and application thereof. The preparation method comprises the following steps: preparing graphite-like carbon nitride (g-C3N4) by adopting a thermal polycondensation synthesis process, and then carrying out secondary calcination on the g-C3N4 by adopting a thermal oxidation etching process so as to obtain graphitic carbon nitride (SL g-C3N4) of a monatomic nanometer lamellar structure; reducing graphene oxide (GO) by using ethylenediamine, and introducing an amino group to prepare aminated graphene oxide (NGO) with electropositivity; subjected SL g-C3N4 and NGO to ultrasonic mixing so as to prepare an SL g-C3N4 / NGO heterojunction. Through photocatalytic degradation research on the cationic dye rhodamine B and the anionic dye methyl orange, the optimal preparation conditions of the composite visible-light catalyst heterojunction are obtained, and the visible-light catalytic activity and stability of the composite photocatalyst material are significantly improved.

Owner:GUANGDONG UNIV OF TECH

Photocatalyst composite structure and preparation method thereof

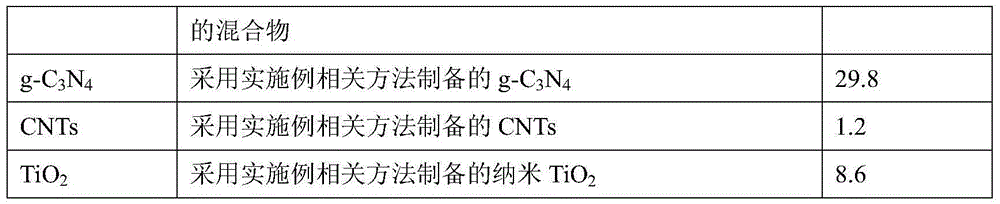

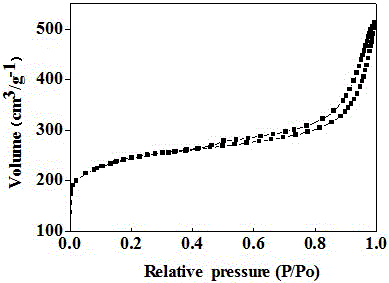

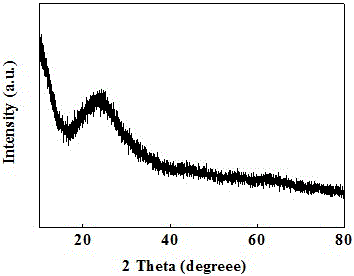

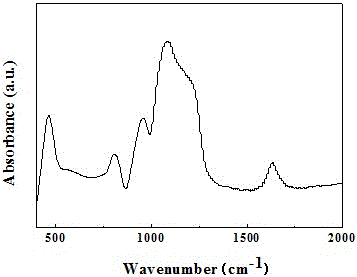

InactiveCN104801325AImprove adsorption capacityLarge specific surface areaPhysical/chemical process catalystsHydrogen productionDecompositionCarbon nanotube

Owner:EAST CHINA UNIV OF SCI & TECH +1

Visible-light-driven photocatalyst for degrading dye in wastewater, and preparation and application thereof

ActiveCN106732741AHigh activityGood dispersionMolecular sieve catalystsWater/sewage treatment by irradiationMesoporous silicaLight driven

Owner:BINZHOU UNIV

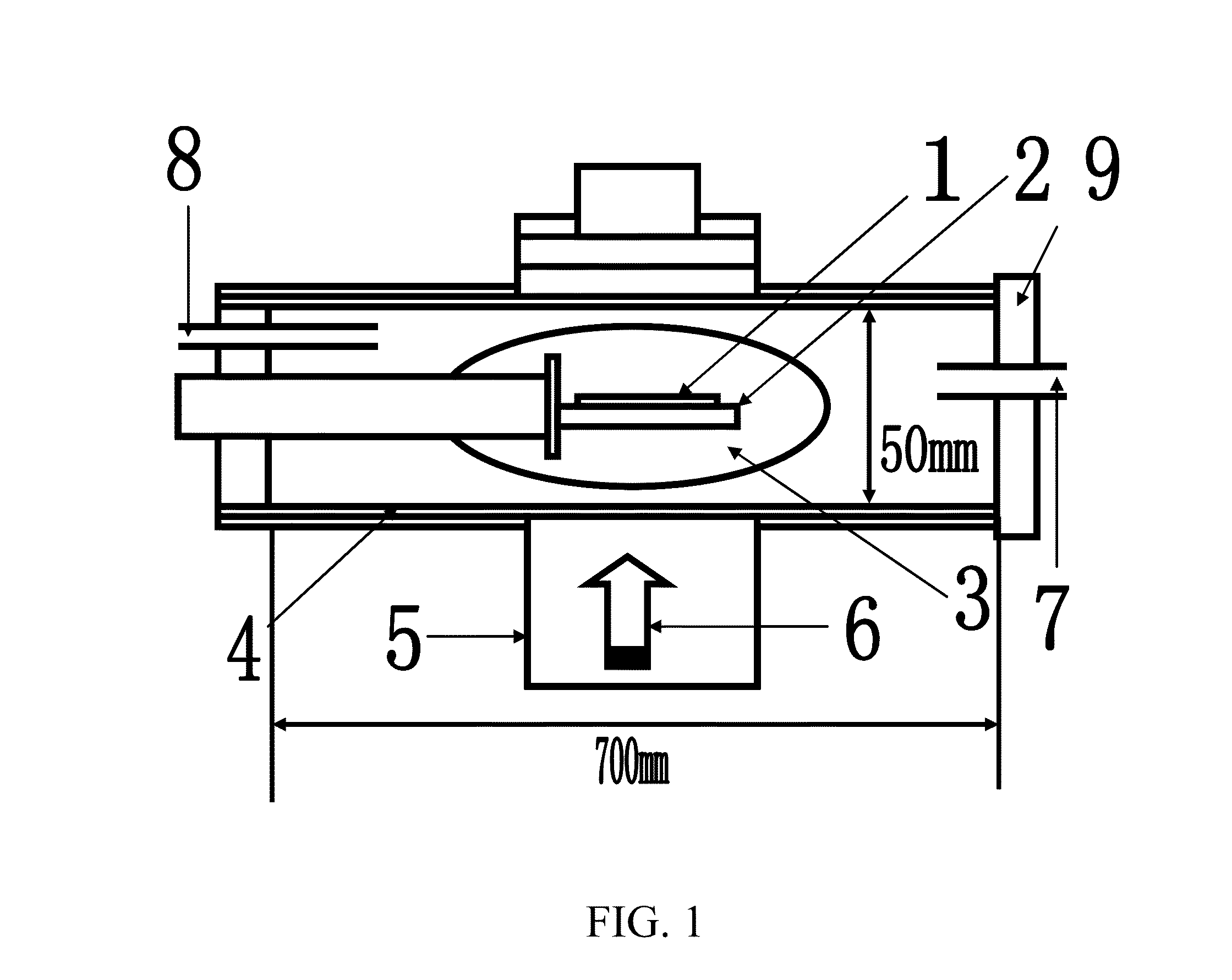

Method of producing triazine-based graphitic carbon nitride films

ActiveUS20160240851A1High specific capacityImprove cycle stabilityNitrogen compoundsElectrode melt handlingTriazeneMicrowave power

Methods for fabricating triazene-based graphitic carbon nitride films are provided. A substrate can be coated with silk fibroin, submerged in the central zone of plasma, and provided with microwave power. The substrate can then be dried to give a triazene-based graphitic carbon nitride film. Methods of the subject invention can be easily scaled up to industrial levels and produce triazene-based graphitic carbon nitride films that show excellent electrical properties as anodes in lithium-ion batteries.

Owner:ZHANG YANG

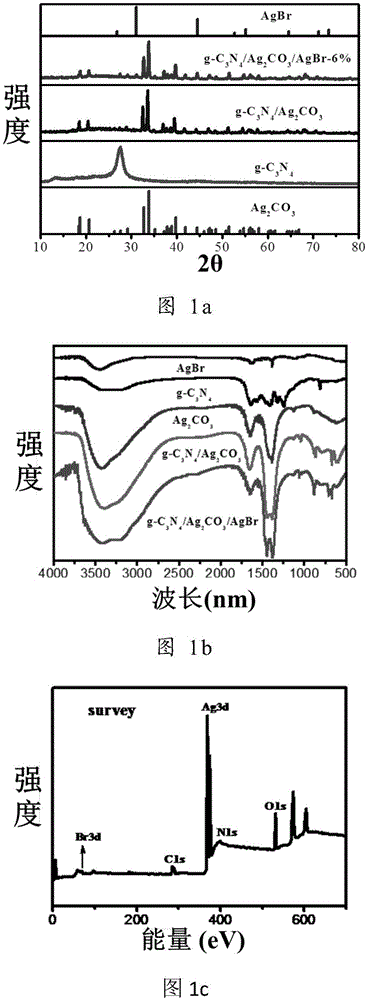

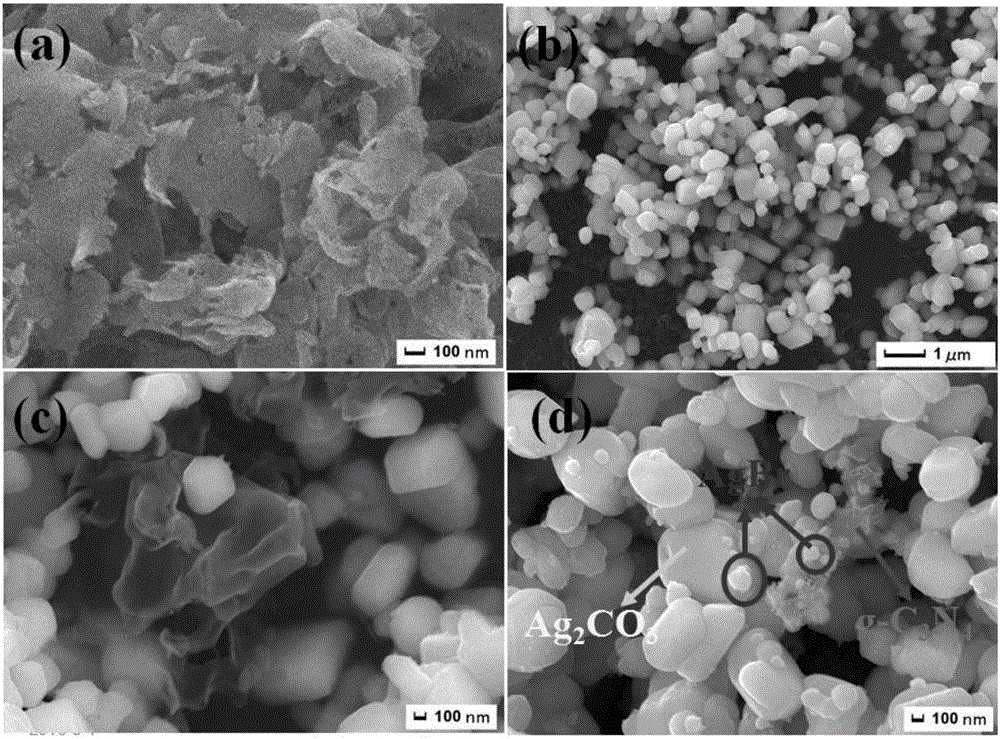

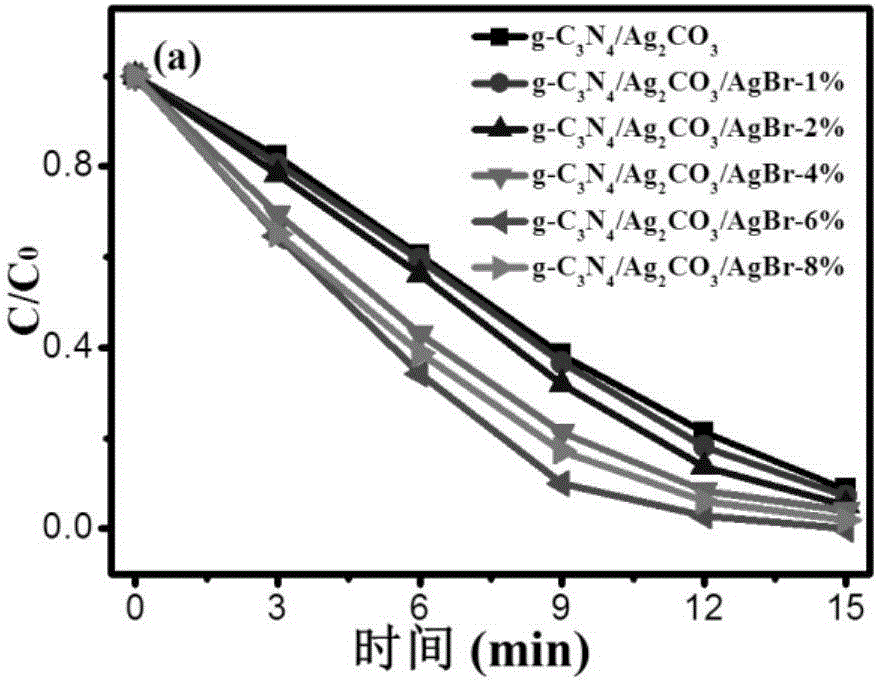

A graphitic carbon nitride/silver carbonate/silver bromide ternary composite nano-material, a preparing method thereof and uses of the nano-material

InactiveCN106378170AHigh yieldImprove photocatalytic performancePhysical/chemical process catalystsSilver carbonateCarbonate

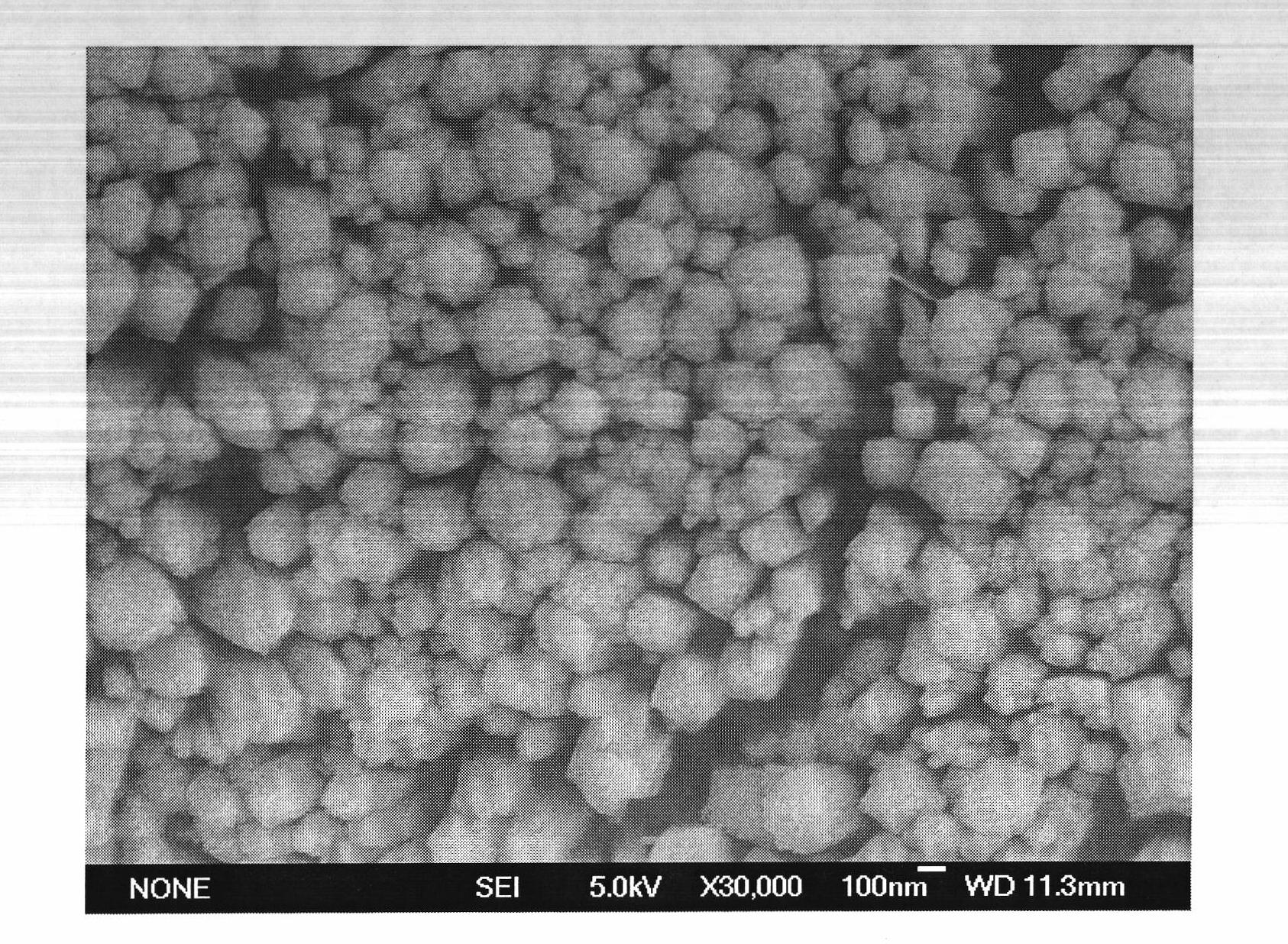

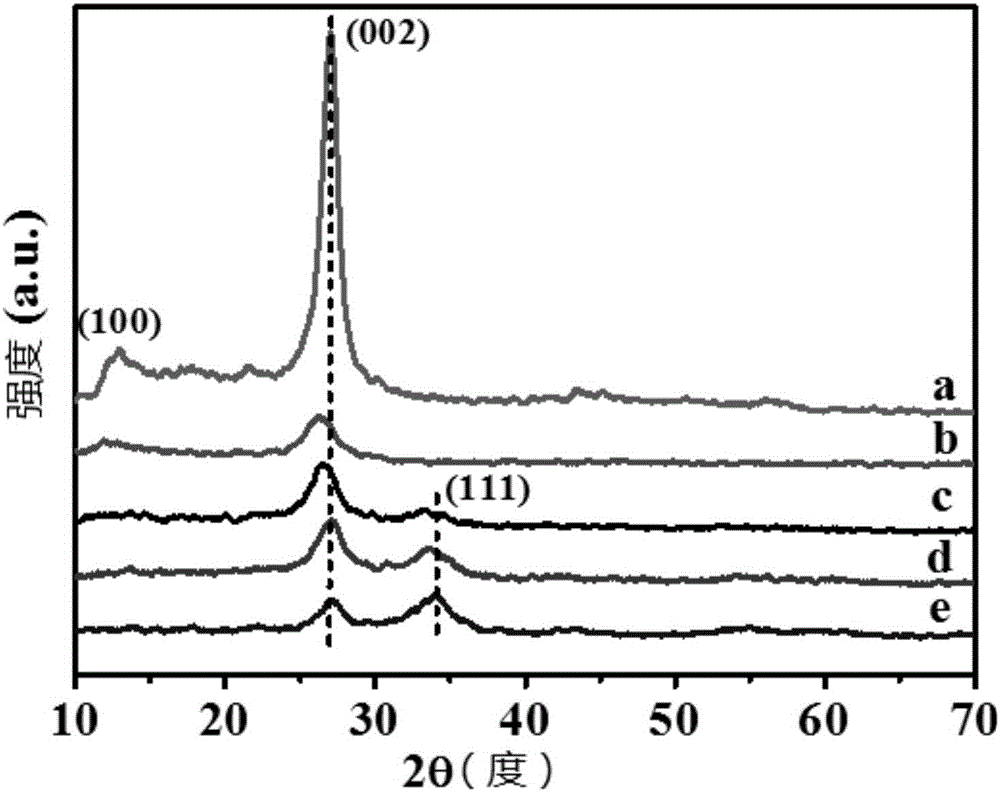

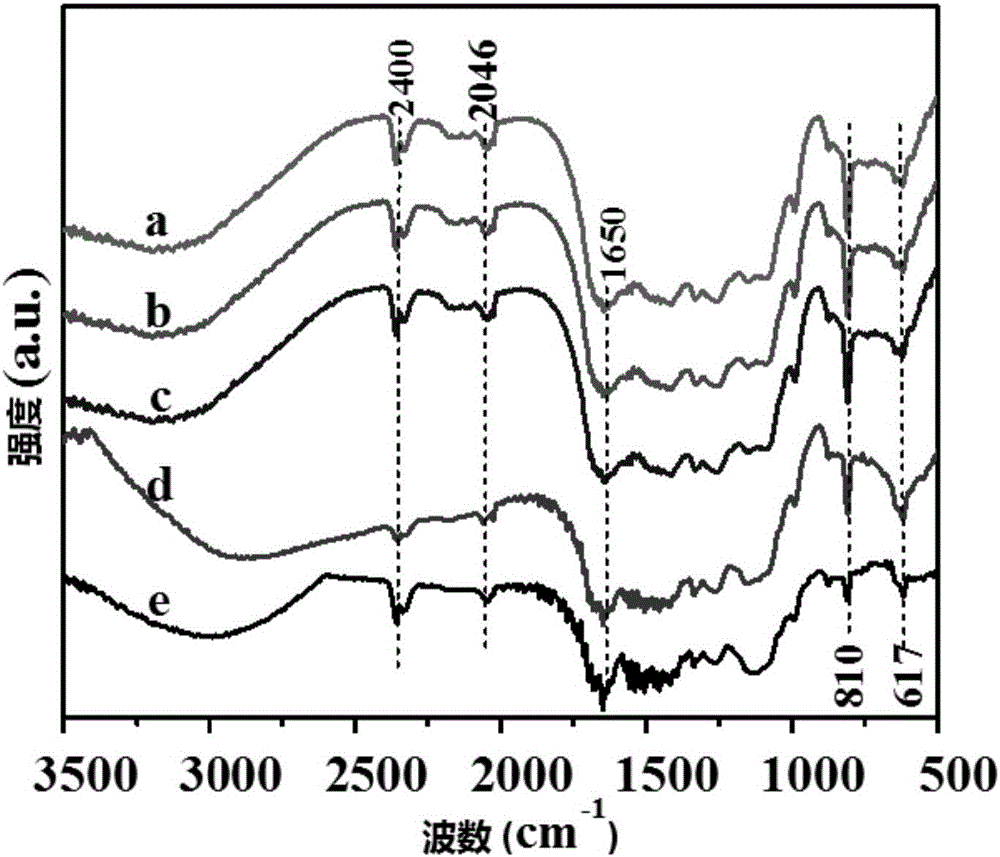

A graphitic carbon nitride / silver carbonate / silver bromide ternary composite nano-material, a preparing method thereof and uses of the nano-material are disclosed. Rodlike Ag<2>CO3 and g-C3N4 having a lamellar structure grow together, and AgBr particles are attached to the surface of the Ag<2>CO3. The nano-material comprises 5-30 wt% of the g-C3N4 and 1-8 wt% of the AgBr, with the balance being the Ag<2>CO3. The preparing method includes (1) subjecting urea and melamine to high-temperature solid-phase sintering to obtain a g-C3N4 lamellar structure, (2) synthesizing the g-C3N4 nanosheet, a soluble silver salt and a carbonate or bicarbonate into g-C3N4 / Ag<2>CO3 particles through a solution precipitation reaction, and (3) introducing Br<-> to the g-C3N4 / Ag<2>CO3 particles. The prepared ternary composite nano-material is high in yield and can be adopted as a photocatalyst.

Owner:ZHENJIANG COLLEGE

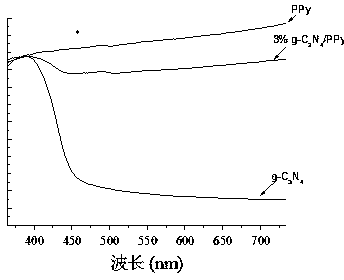

Graphitic carbon nitride/polypyrrole composite photocatalytic material and preparation method thereof

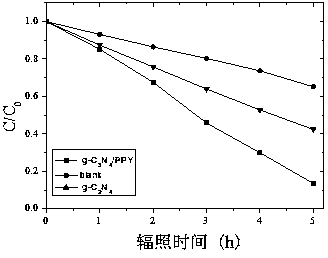

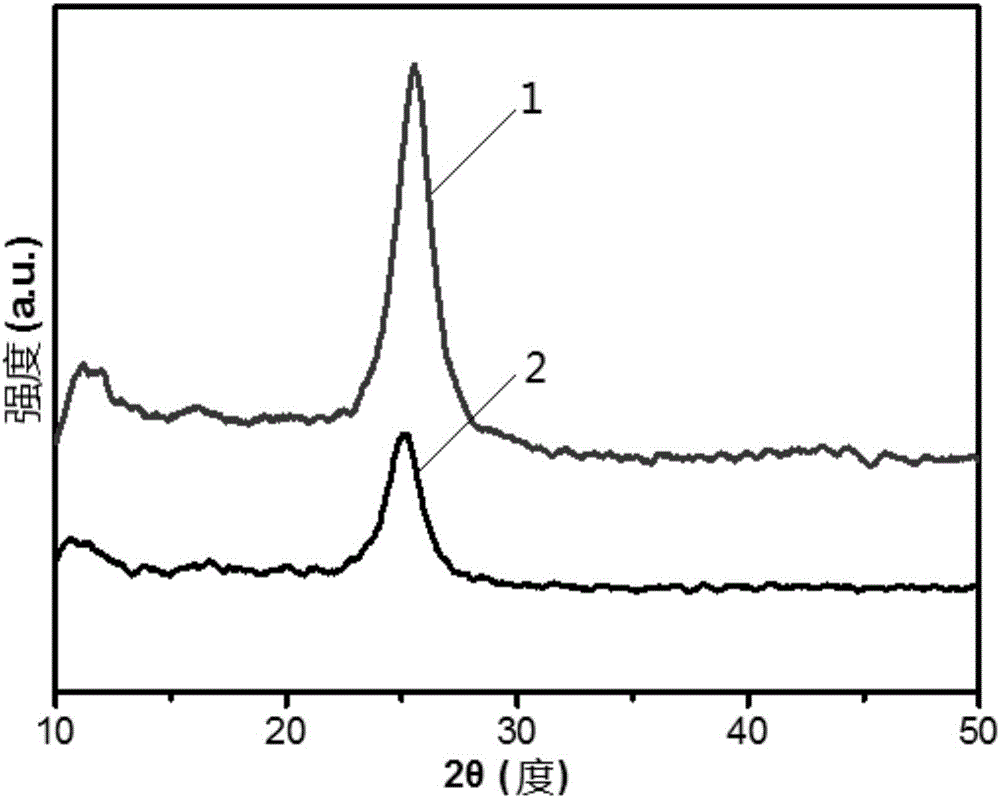

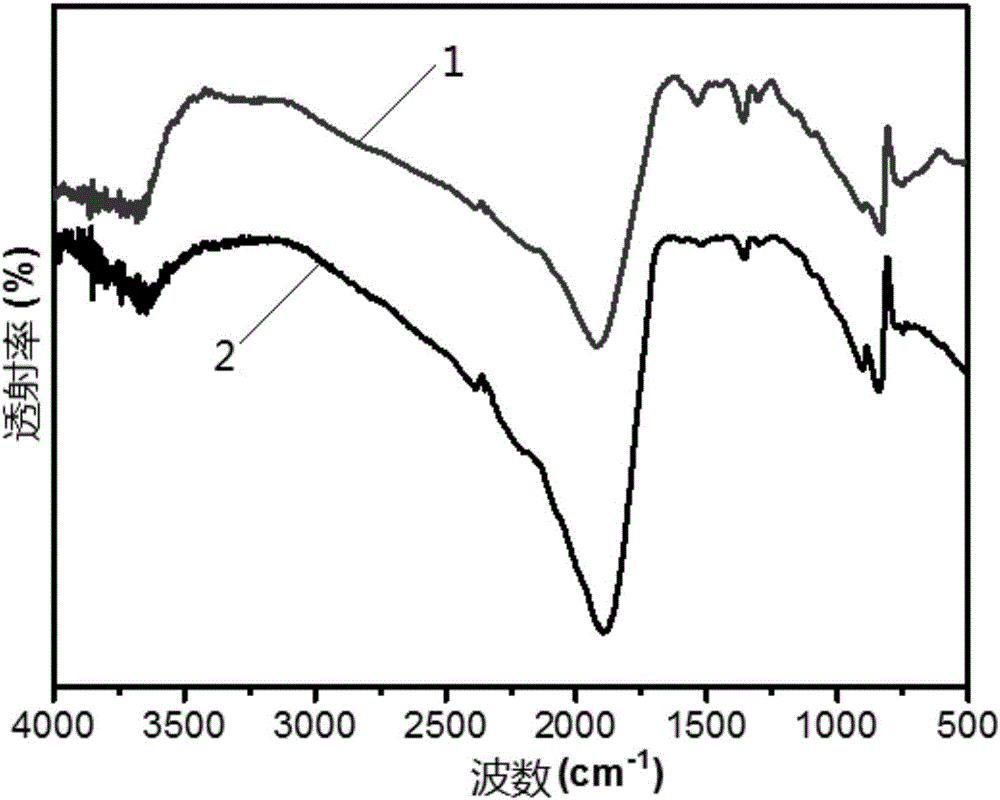

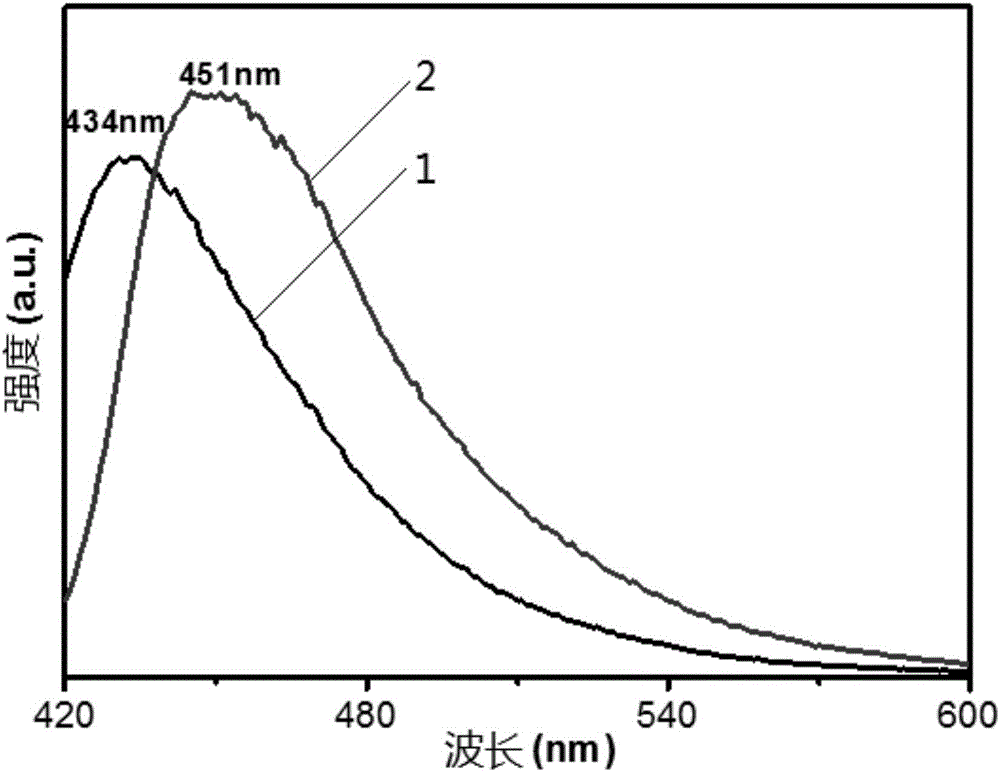

InactiveCN103657719AGood dispersionGood molding effectOrganic-compounds/hydrides/coordination-complexes catalystsPolypyrroleOrganic dye

The invention discloses a graphitic carbon nitride / polypyrrole composite photocatalytic material and a preparation method thereof. The technical process of the preparation method comprises the steps as follows: dispersing graphitic carbon nitride in a medium, stirring the medium at the temperature of 0-10 DEG C for 30 min to obtain a graphitic carbon nitride dispersing liquid, dropwise adding pyrrole into the graphitic carbon nitride dispersing liquid with stirring to obtain a mixed solution, stirring the mixed solution at the temperature of 0-10 DEG C for 30 min, dropwise adding a prepared initiator solution into the mixed solution, stirring the mixture at the temperature of 0-10 DEG C for reaction for 10 h, washing an obtained product for several times, and performing vacuum drying on the product to obtain the graphitic carbon nitride / polypyrrole composite photocatalytic material. The graphitic carbon nitride / polypyrrole composite photocatalytic material and the preparation method thereof have the advantages that the preparation technology is simple, the cost is low, and the large-scale industrial production is facilitated; and the graphitic carbon nitride / polypyrrole composite photocatalytic material has good environmental stability, has a better degradation effect on organic dye rhodamine B with certain concentration and can be applied to treatment of contaminated wastewater.

Owner:JIANGSU UNIV

Photocatalyst graphite oxide phase carbon nitride and preparation method thereof

InactiveCN106622328AIncrease productivityEasy to operatePhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeCarbon nitride

The invention provides photocatalyst graphite oxide phase carbon nitride and a preparation method thereof. The photocatalyst is graphite phase carbon nitride prepared by roasting a carbon and nitrogen source; an oxidant is added for oxidizing and then is removed; finally, the photocatalytic degradation efficiency of the prepared graphite oxide phase carbon nitride to organic dye is remarkably improved.

Owner:FUYANG NORMAL UNIVERSITY

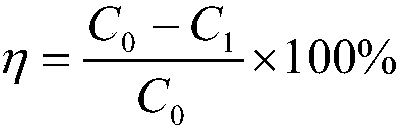

Photocatalytic cement mortar containing graphite phase carbon nitride

InactiveCN108609930ARealize the function of catalytic purificationHigh strengthPhysical/chemical process catalystsNitrogen and non-metal compoundsPhotocatalytic reactionCement mortar

The invention discloses photocatalytic cement mortar containing graphite phase carbon nitride. The photocatalytic cement mortar comprises the following components in part by weight: 1 part of cement,0.01-0.05 part of graphite phase carbon nitride, 0.03-0.07 part of a polymer, 2-5 parts of construction sand and 0.025-0.035 part of an admixture with thickening, water holding and plasticity-stabilizing effects. The photocatalytic cement mortar is prepared by mixing and stirring the graphite phase carbon nitride, the cement, the construction sand, the polymer, the admixture and water. The photocatalytic cement mortar disclosed by the invention has the benefits that the graphite phase carbon nitride is utilized for absorbing blue and violet light in a solar spectrum to generate photocatalyticreaction, so that nitrogen oxides and volatile organic compounds (VOC) in an atmospheric environment are catalyzed and removed in real time, and the function of purifying the atmosphere is realized. Apreparation method of the photocatalytic cement mortar disclosed by the invention is simple in steps and has popularization and utilization values in engineering construction.

Owner:SHANDONG JIAOTONG UNIV

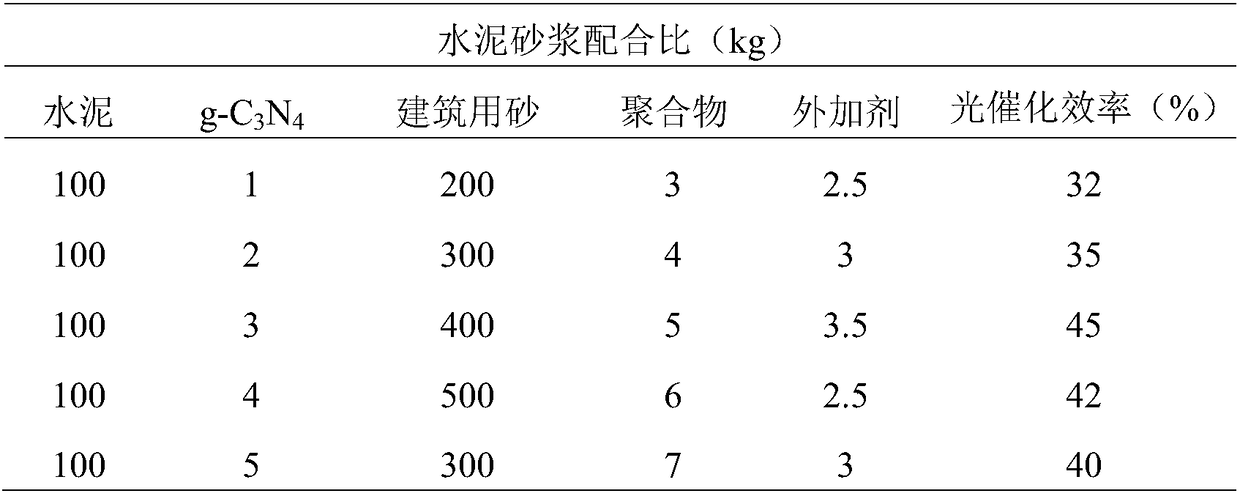

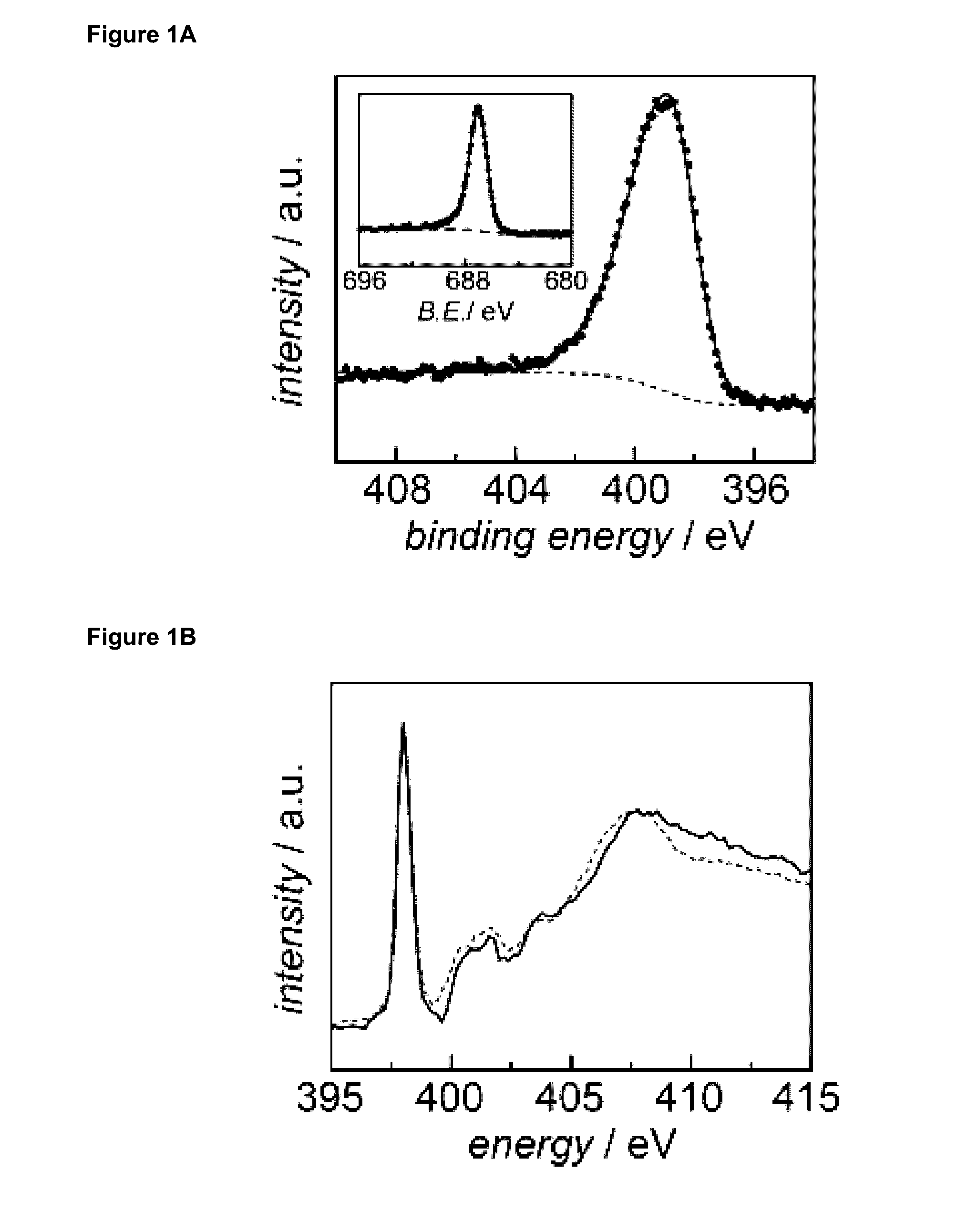

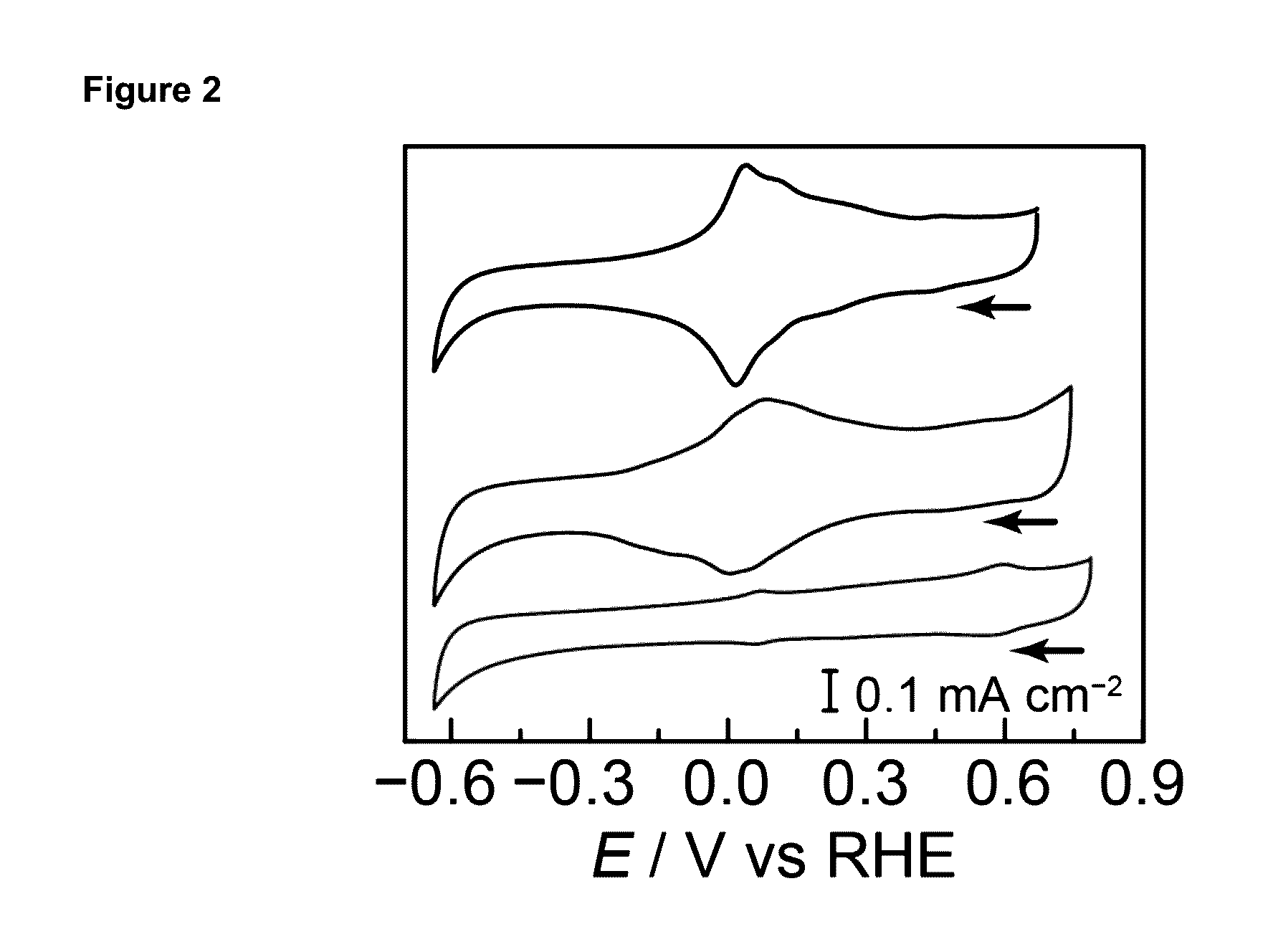

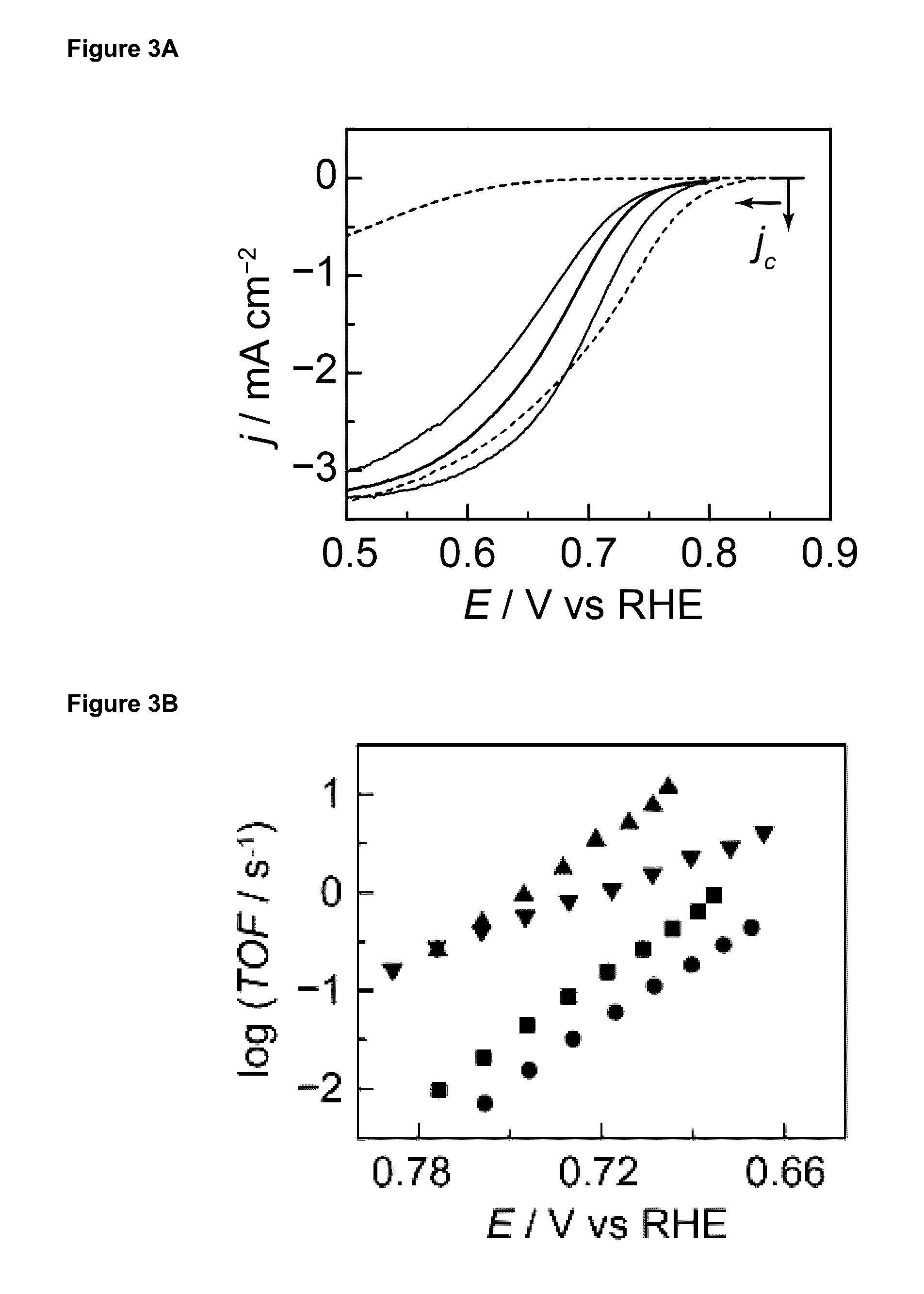

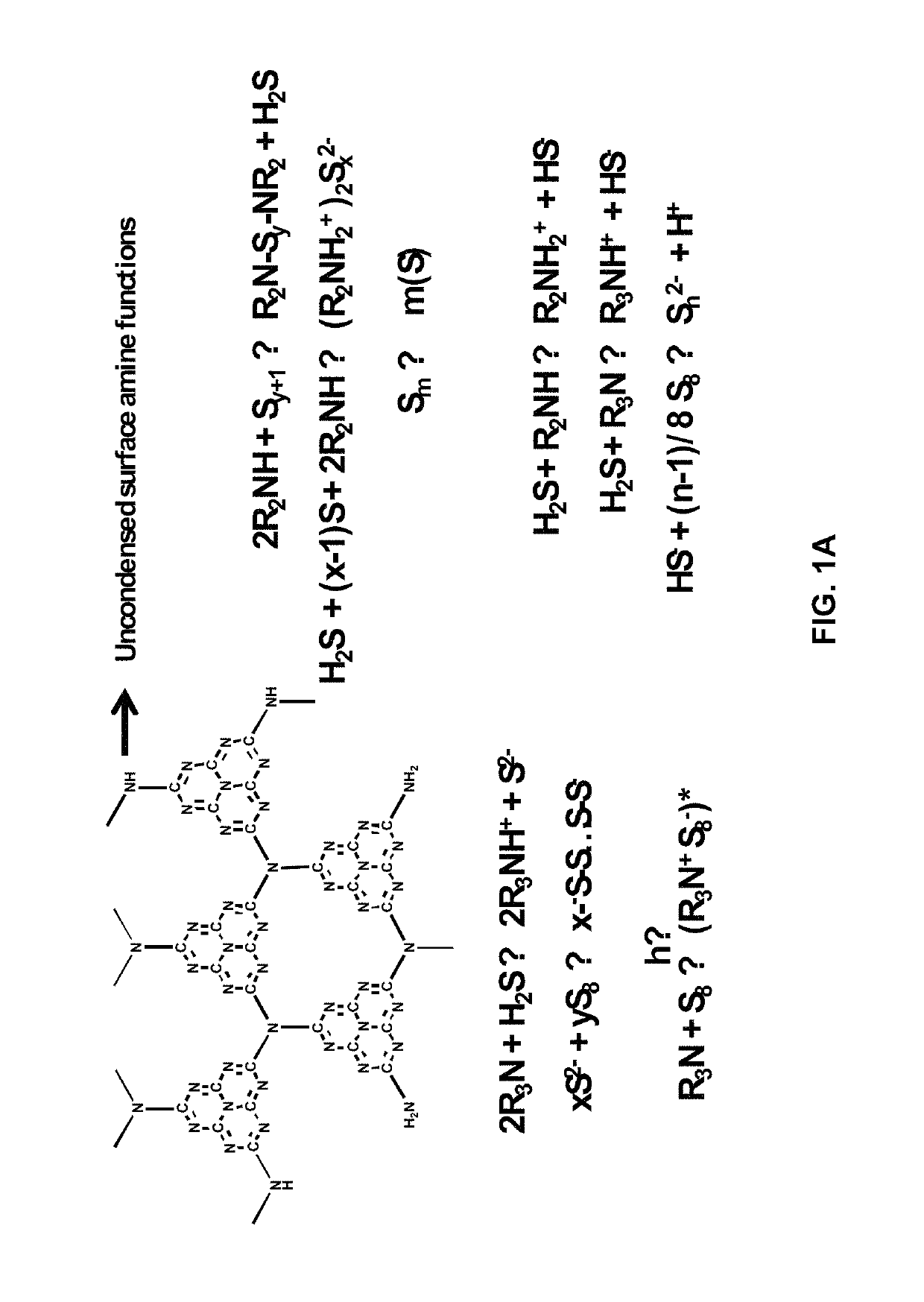

Molecularly tunable heterogeneous catalysts by edge functionalization of graphitic carbons

ActiveUS20170047592A1Ruthenium organic compoundsIndium organic compoundsSolventHomogeneous catalysis

Disclosed are surface immobilized (electro)catalysts that may be prepared by a condensation reaction that generates an aromatic unit that is robust to acid and base and elevated temperatures. Among their many desirable characteristics, the catalysts are far less prone to the bimolecular deactivation pathways commonly observed for homogeneous catalysts, and may be used in solvents with a range of polarities and dielectric strengths. The catalysts are suitable for a wide array of thermal catalytic reactions (polymerization, oxidation, hydrogenation, cross-coupling etc.) and as anodes and / or cathodes in fuel cells, electrolyzers, and in batteries and supercapacitors.

Owner:MASSACHUSETTS INST OF TECH

Method of producing triazine-based graphitic carbon nitride films

ActiveUS9735427B2High specific capacityImprove cycle stabilityNitrogen-metal/silicon/boron binary compoundsElectrode melt handlingTriazeneMicrowave power

Methods for fabricating triazene-based graphitic carbon nitride films are provided. A substrate can be coated with silk fibroin, submerged in the central zone of plasma, and provided with microwave power. The substrate can then be dried to give a triazene-based graphitic carbon nitride film. Methods of the subject invention can be easily scaled up to industrial levels and produce triazene-based graphitic carbon nitride films that show excellent electrical properties as anodes in lithium-ion batteries.

Owner:ZHANG YANG

Carbon nitride preparation method

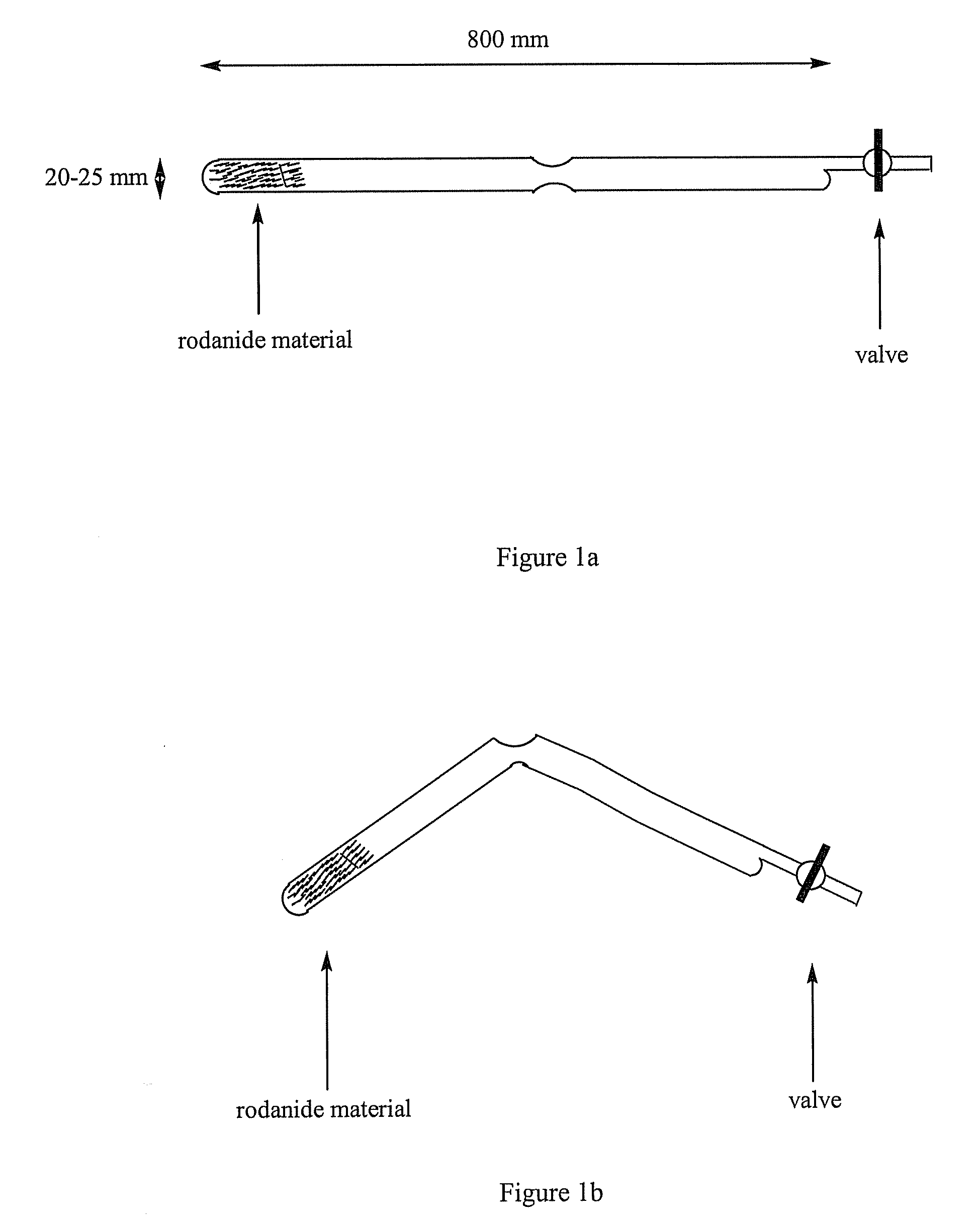

InactiveUS20100015030A1Simple and economically feasibleOutstanding propertyNitrogen-metal/silicon/boron binary compoundsThiocyanic acidCarbon nitrideNanotechnology

The present invention relates to a method for preparing carbon nitride material wherein organic rodanide is simply pyrolysed to give carbon nitride material in an efficient, economical and ecologically friendly manner. The present invention accomplishes preparation of graphitic carbon nitride materials having a carbon to nitrogen molar ratio of about 3:4. The employed starting materials are cheap and can be easily removed and / or washed away.

Owner:CARBODEON LTD OY

Metal element doped CNB photocatalyst and preparation method thereof

InactiveCN106582760AVisible light catalytic activity is highNo pollution in the processCatalyst activation/preparationOrganic dyeCarbon nitride

The invention provides a metal element doped CNB photocatalyst. According to the metal element doped CNB photocatalyst, metal elements and non-metal elements B are used for jointly doping graphite phase carbon nitride, and compared with pure graphite phase nitridation, prepared double-doped graphite phase carbon nitride has high visible-light catalytic activity to organic dyestuff. The invention further provides a preparation method of the catalyst. CNB is prepared through the method, the prepared CNB is compounded with the metal elements, the method is easy to operate, and the yield of the catalyst is high.

Owner:FUYANG NORMAL UNIVERSITY

Coating material, coating and coated object

InactiveUS20130104461A1Quality improvementImprove uniformityPigmenting treatmentWater-repelling agents additionDopantCarbon nitride

A coating material is used for coating a substrate by means of laser ablation. The coating material contains graphitic carbon nitride and a dopant in order to alter the properties of the coating produced as compared to a coating of pure carbon nitride.

Owner:PICODEON OY +1

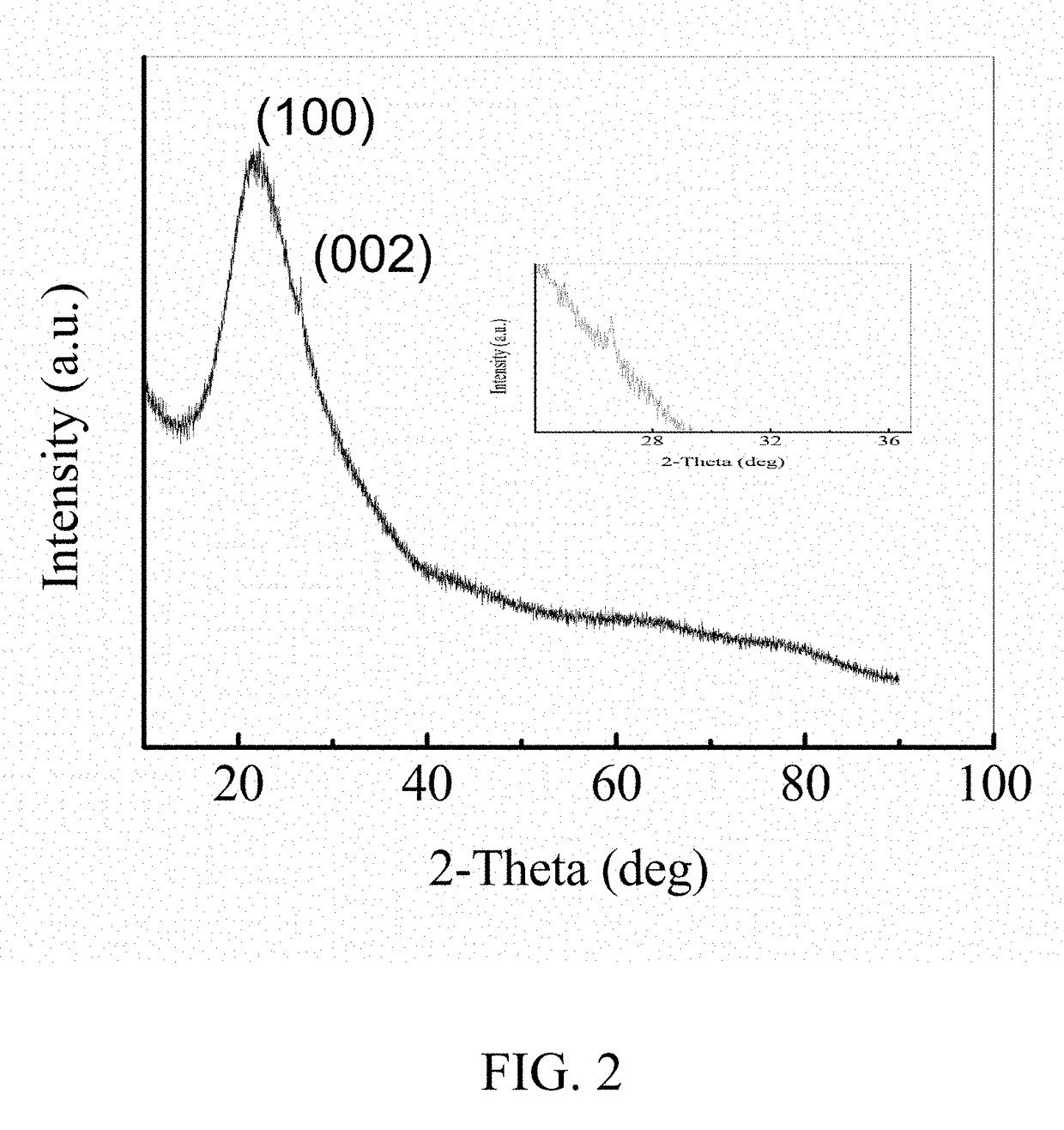

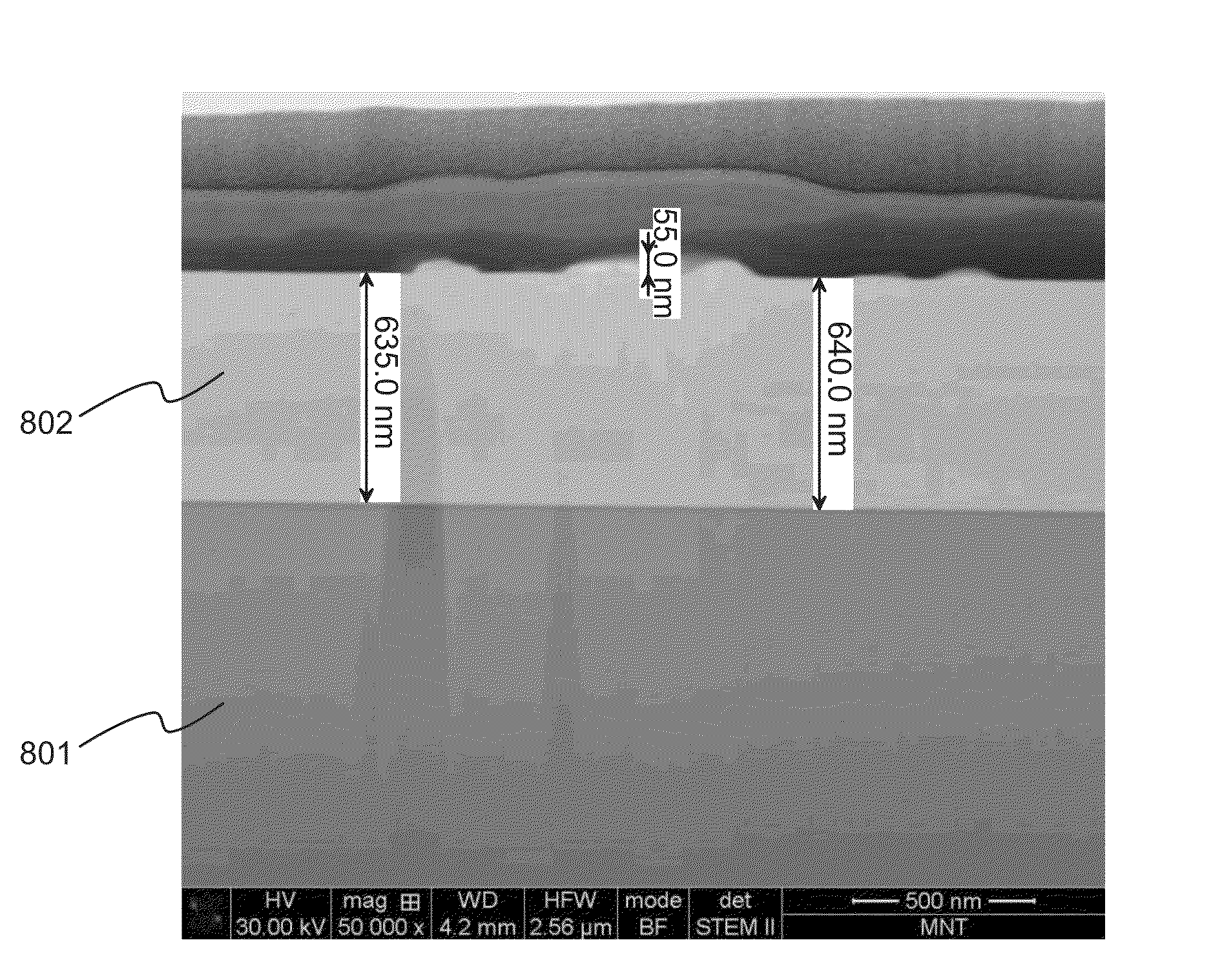

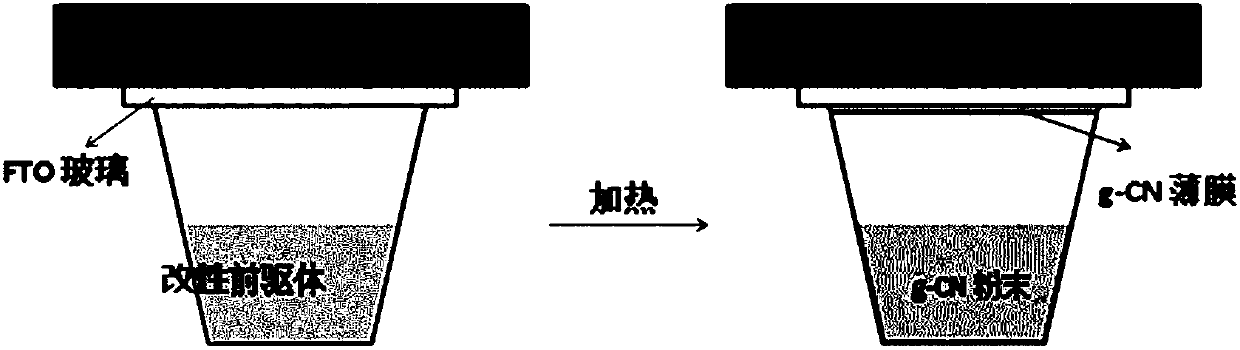

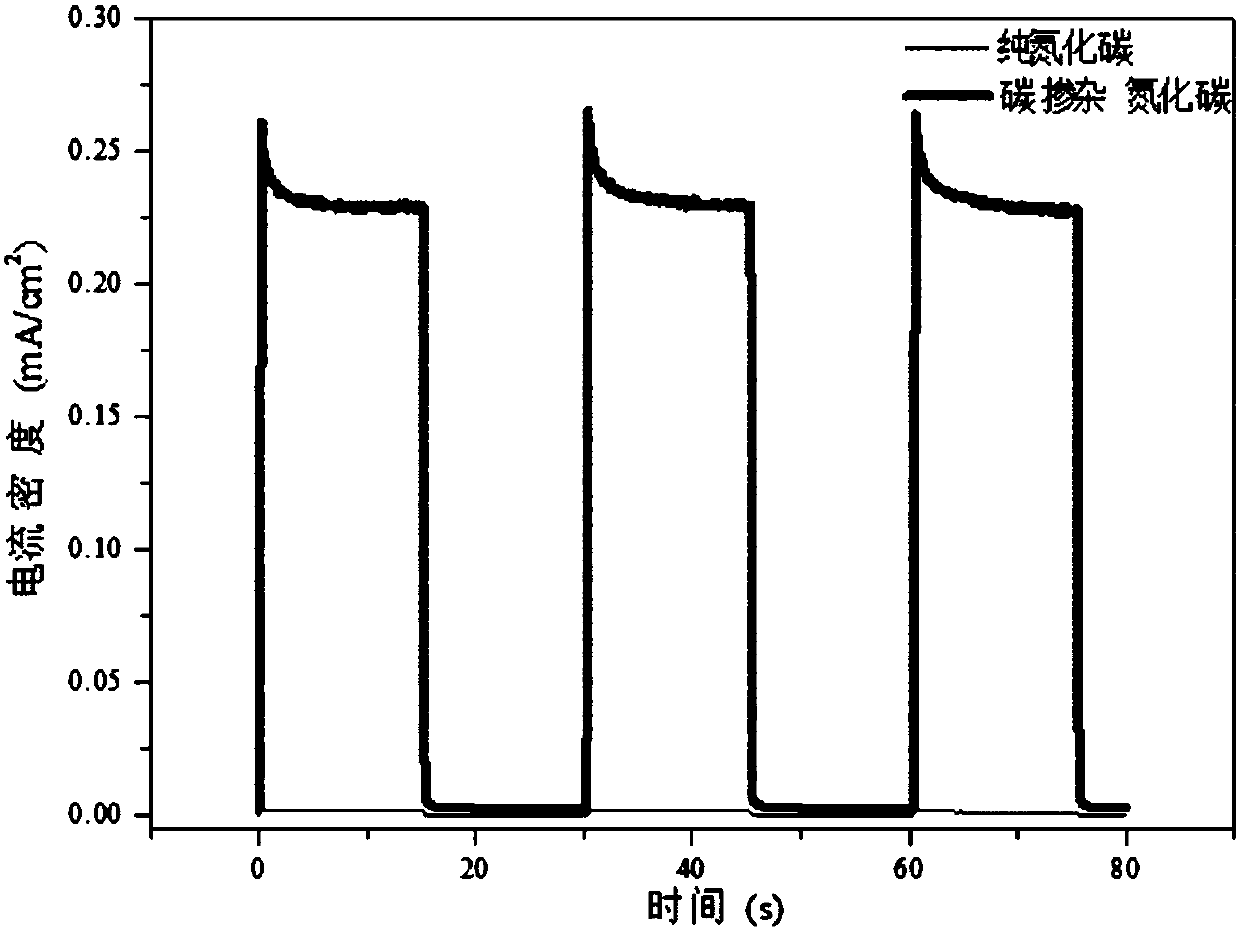

Carbon doped graphite phase carbon nitride film and preparation method thereof

InactiveCN109894134ASimple processImprove photocatalytic activityPhysical/chemical process catalystsCrucibleCarbon nitride

The invention provides a carbon doped graphite phase carbon nitride film and a preparation method thereof. The preparation method includes: dispersing a carbon source and a carbon nitride precursor inwater, carrying out polymerization reaction at 30DEG C-100DEG C in the presence of an acid catalyst, and conducting filtering and drying to obtain a modified precursor; and placing the modified precursor into a crucible, covering the crucible with a substrate, performing heating to 500DEG C-650DEG C and performing heat preservation for 0.5h-5h, thus obtaining the carbon doped graphite phase carbon nitride film. The invention also provides the carbon doped graphite phase carbon nitride film prepared by the above-mentioned preparation method. The carbon doped graphite phase carbon nitride filmprovided by the invention has the advantages of simple preparation process, low cost and excellent photocatalytic activity.

Owner:香港城市大学深圳研究院

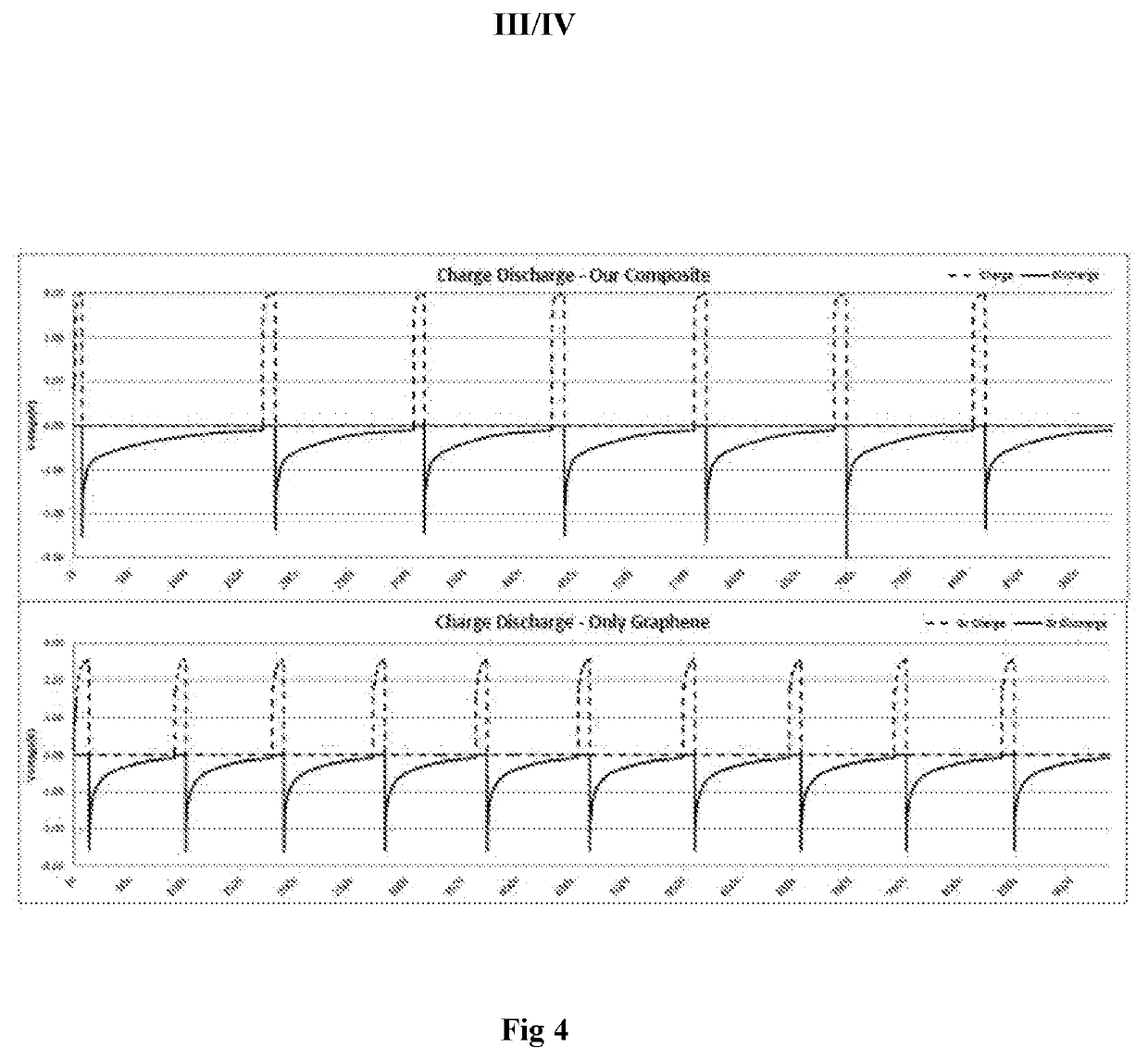

High capacitance composites

ActiveUS20200343054A1Increase energy densityFast chargingHybrid capacitor electrodesNitrogen-metal/silicon/boron binary compoundsCapacitanceHigh energy

The present invention discloses composite with high energy storage capacity in energy storage devices comprising graphene, mesoporous graphitic carbon nitride (mc@g-C3N4) and to the process for preparation thereof. The present invention further discloses electrodes employing the said compositie and fabrication of high energy high power storage devices such as the Electric Double Layer Capacitor (EDLC) with these electrodes.

Owner:GEGADYNE ENERGY LABS PVT LTD

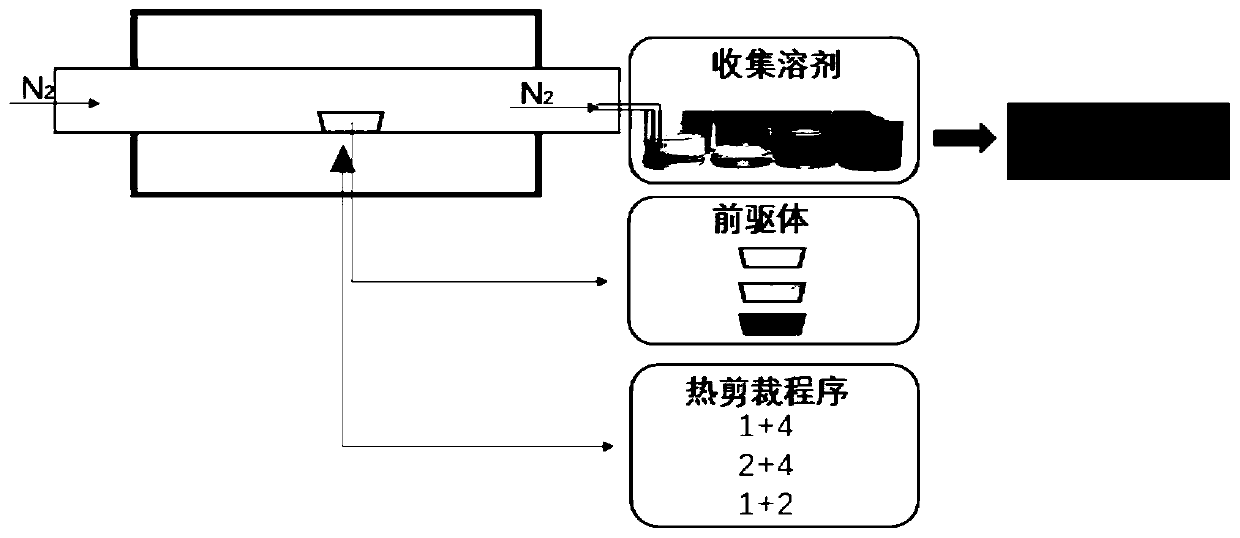

Carbon nitride nano material as well as preparation method and application thereof

ActiveCN109734060AWide applicabilityEnhance the imageMaterial nanotechnologyNitrogen and non-metal compoundsSolventHeat treated

The invention discloses a preparation method of a carbon nitride nano material. The preparation method of the carbon nitride nano material comprises the following steps: 1) performing heat treatment for a precursor at 600 to 750 DEG C in an inert atmosphere for 1 hour to 48 hours, wherein the precursor is one or more of graphite phase carbon nitride, melamine, dicyandiamide, urea, cyanamide and cyanuric acid; and 2) selecting a solvent according to the type of the target carbon nitride nano material, and collecting and screening the carbon nitride nano material from the heat treatment productin the step 1) by using the solvent. The invention also discloses the carbon nitride nano material prepared by the method and an application thereof. The method of the invention can obtain various morphologies of carbon nitride nanomaterials by selecting the precursor and collecting solvents, and has wide adjustability and applicability; and compared with commercial lysosome fluorescent probes, acarbon nitride quantum dot prepared by the method is better in light stability, and is more beneficial to the development of long-time real-time lysosome imaging applications.

Owner:SOUTHEAST UNIV

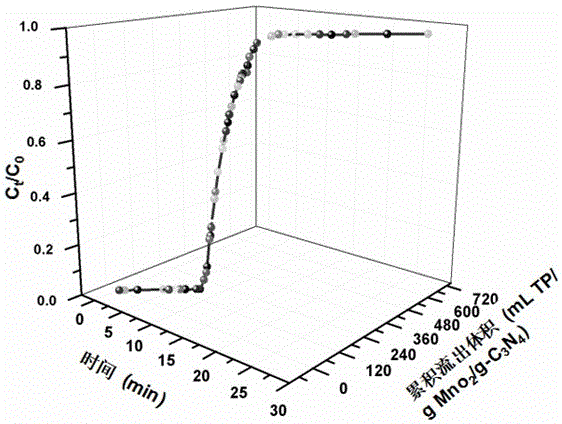

Metal oxide/graphitic carbon nitride composite material having three-dimensional structure and preparation thereof

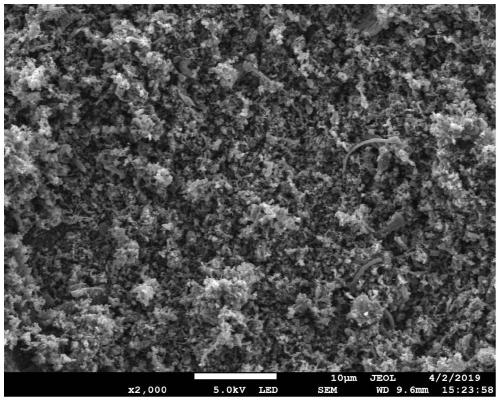

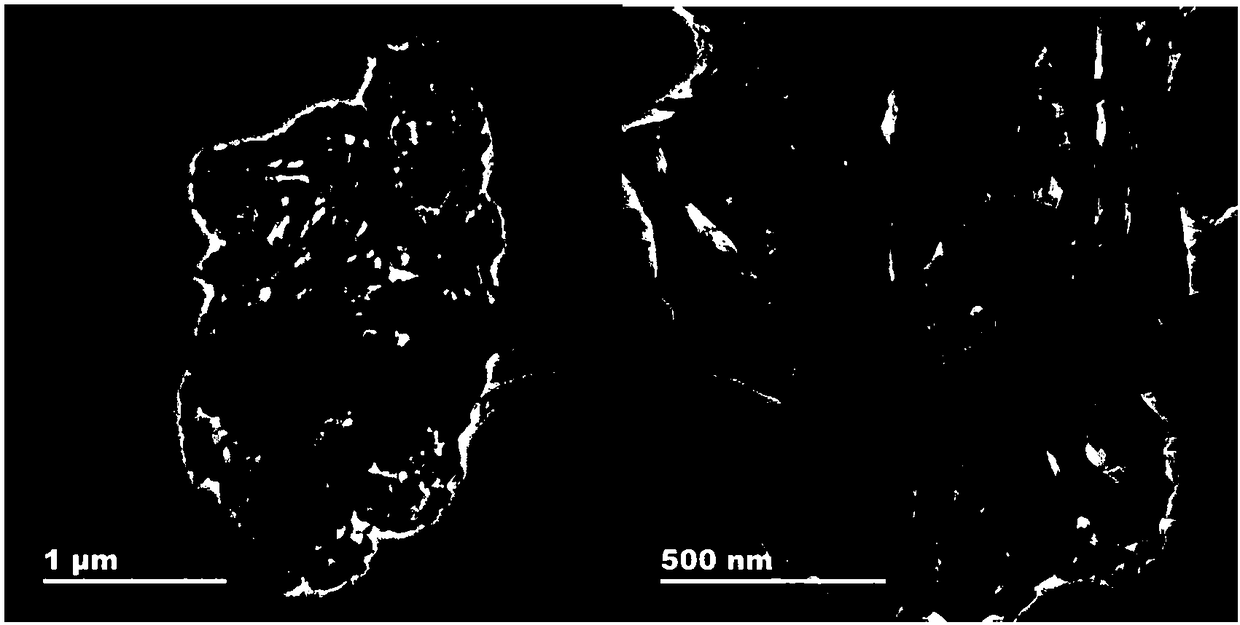

ActiveCN106732328AEasy to prepareEconomical method of preparationOther chemical processesHydrocarbon oils refiningCarbon nitrideGraphite

The invention discloses a metal oxide / graphitic carbon nitride composite material having a three-dimensional structure, and a preparation method and application thereof. The composite material is prepared by compounding g-C3N4 nanosheets and metal oxides, wherein the mass percent of the g-C3N4 nanosheets is 1-25%.The composite material obtained by the invention is prepared by taking a carbon nitride material having a graphene-like two-dimensional structure after peeling as a template, adding metal oxide precursor and stabilizer, and reacting in a high-pressure reaction kettle under the condition of stirring. Compared with a pure metal oxide, the specific surface area of the composite material is obviously increased; and the defect of the metal oxide such as high agglomeration possibility is overcome, so that the adsorption capacity is greatly improved. Thus, the composite material has favorable application prospects in the aspects of removing sulfides in diesel and the like.

Owner:FUZHOU UNIV

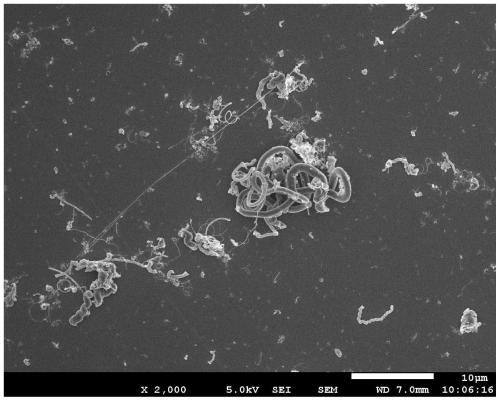

Spiral carbon nanotube prepared through molten salt method and preparation method and application thereof

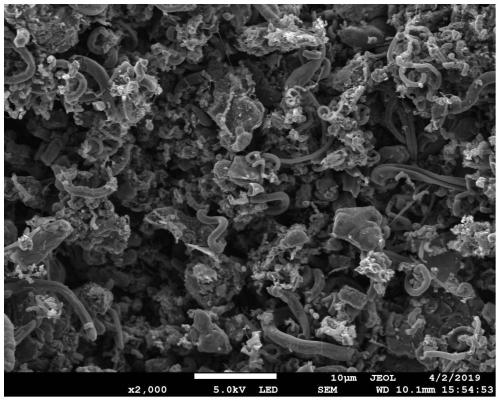

InactiveCN109879274AHigh mechanical strengthExcellent hydrogen and oxygen evolution performanceCarbon nanotubesManganeseCarbon nanotube

The invention provides a spiral carbon nanotube prepared through a molten salt method and a method thereof. Specifically, soluble molten salt is applied to a calcining process of manganese salt and melamine. As temperature rises, the melamine is carbonized into graphitic carbon nitride; carbon atoms and nitrogen atoms which are thermal decomposed by carbon nitride are gathered into manganese saltnano-particles under higher temperature and then precipitate to form a new graphitic layer sheet; and the graphitic layer sheet is curled so as to form the carbon nanotube. Compared with a straight carbon nanotube, the spiral carbon nanotube prepared by the invention is capable of displaying metallic and semiconductor behavior and displaying semimetallic behavior due to chirality of the spiral carbon nanotube and can serve as a superconductor. The spiral carbon nanotube has stable performances and can be applied to the fields of electromagnetic wave absorbing materials, bio-separation, water treatment, water detection, food safety detection, fully decomposed water, sensor fuel cells and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Palladium-graphitic carbon nitride-carbon nanotube composite electrode, and preparation method and application thereof

InactiveCN108195908ASolving Dispersion ProblemsImprove catalytic performanceMaterial electrochemical variablesCarbon nanotubeMaterials science

The invention discloses a palladium-graphitic carbon nitride-carbon nanotube composite electrode, and a preparation method and application thereof. According to the preparation method, a graphitic carbon nitride-carbon nanotube composite is prepared by using a solid grinding thermopolymerization process in virtue of Pi-Pi accumulation and electrostatic action between melamine and carbon nanotubes;then palladium nanoparticles are used as a precursor for further functionalized modification of the graphitic carbon nitride-carbon nanotube composite through self-assembing so as to obtain a composite material with good catalysis performance and stability; so electrocatalytic activity is improved, problems in the dispersibility of graphitic carbon nitride are overcome, and the application scopeof the composite material is broadened. The preparation method is simple in process, convenient to operate, low in the amount of consumed chemical raw materials and reagents, mild in reaction conditions, small in the number of used equipment, low in production cost, capable of realizing large-scale production, low in environmental pollution and beneficial for environmental protection; and the prepared composite electrode has higher sensitivity and better catalytic performance and stability, and is especially suitable for direct and rapid detection of estradiol in water samples, food samples, feed samples, biochemical product samples and other samples.

Owner:甘肃政法大学

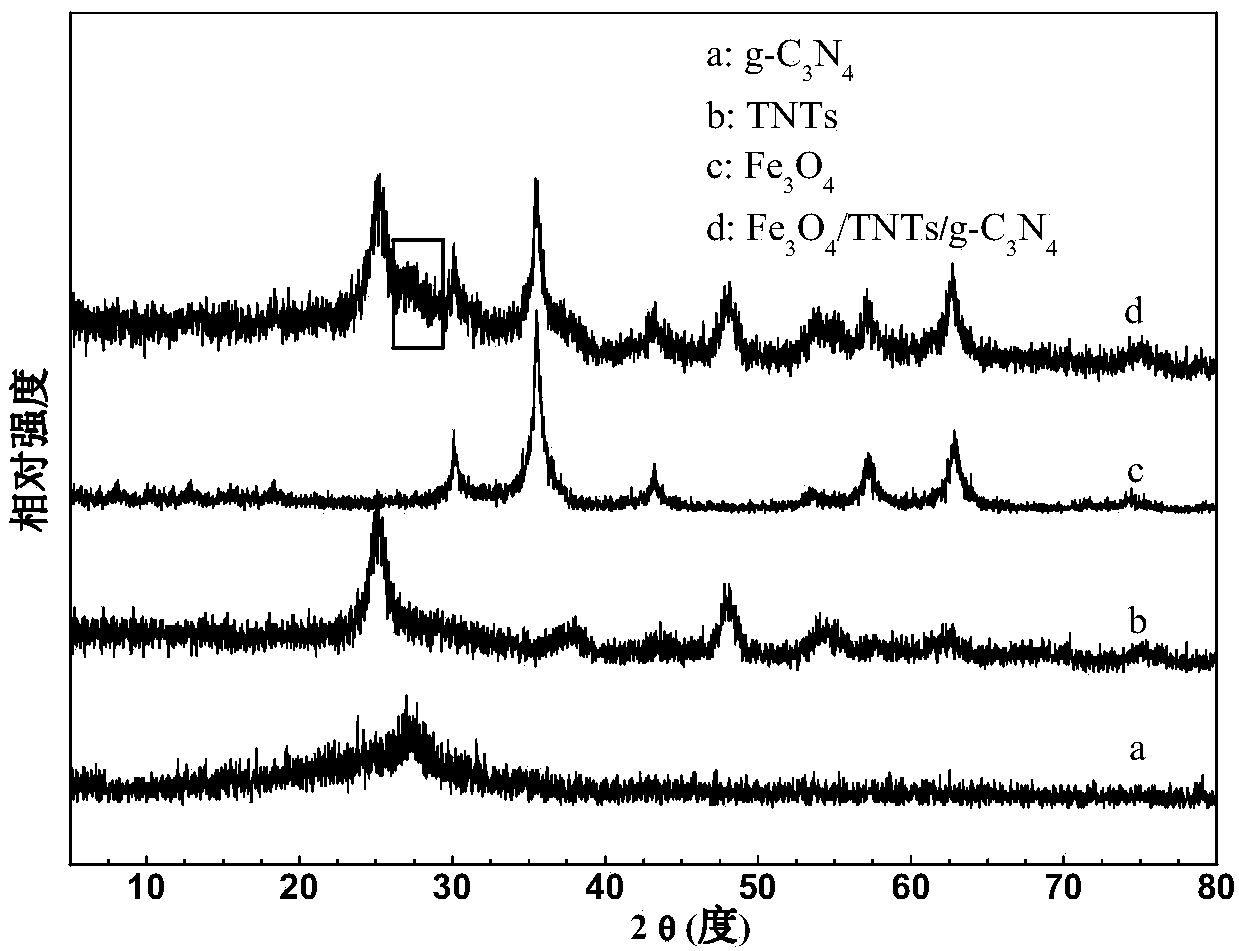

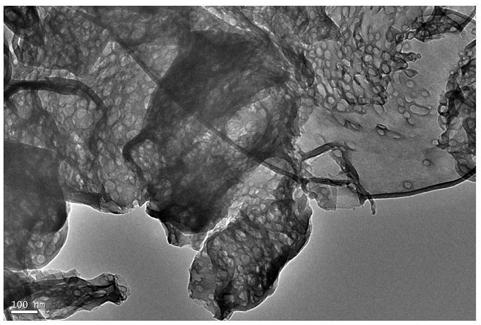

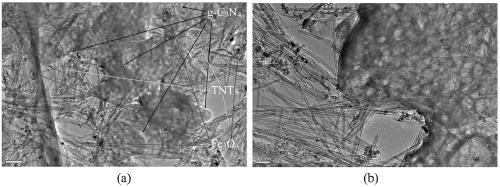

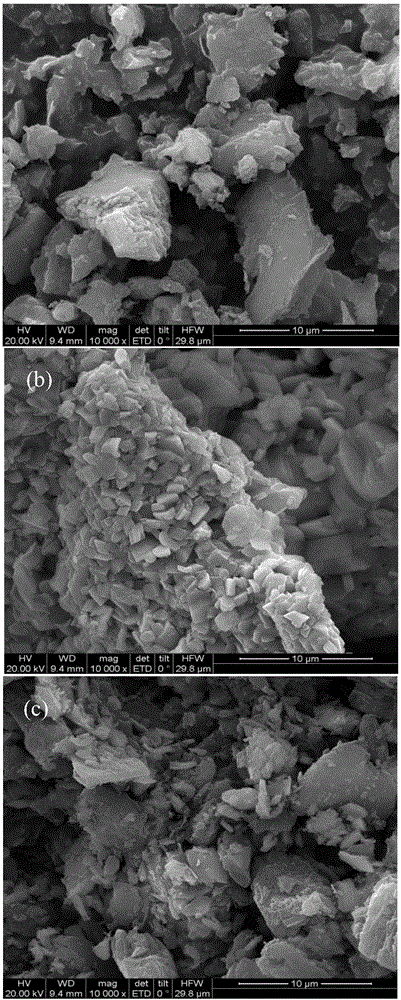

Preparation method and application of magnetically-separatable TNTs/g-C3N4 nano-composite material

ActiveCN109174161AImprove efficiencyHigh catalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationFerrous saltsMagnetization

The invention discloses a preparation method of a magnetically-separatable TNTs / g-C3N4 nano-composite material. The TNTs / Fe3O4-g-C3N4 nano-composite material is synthesized through in situ growth of Fe3O4 nano-particles and TiO2 nano-tubes (TNTs) on a g-C3N4 sheet under an alkaline hydrothermal condition by using g-C3N4, a water-soluble ferrous salt and a ferric iron salt as raw materials in orderto utilize the magnetic responsibility of the Fe3O4 and the excellent photocatalytic activity of graphitic carbon nitride (g-C3N4). The invention also discloses the magnetically-separatable TNTs / g-C3N4 nano-composite material prepared by the method. The magnetically-separatable TNTs / g-C3N4 nano-composite material has good magnetism, and the saturation magnetization intensity is 28.26 emu / g, so the separation and recovery of the composite material can be achieved; and the methylene blue removal rate of the TNTs / Fe3O4-g-C3N4 nano-composite material is 98.8% when illumination is carried out for60 min, and the prepared TNTs / Fe3O4-g-C3N4 nano-composite material has excellent adsorption performance, photocatalytic activity and magnetism, and can be separated and recovered by applying a magnetic field.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

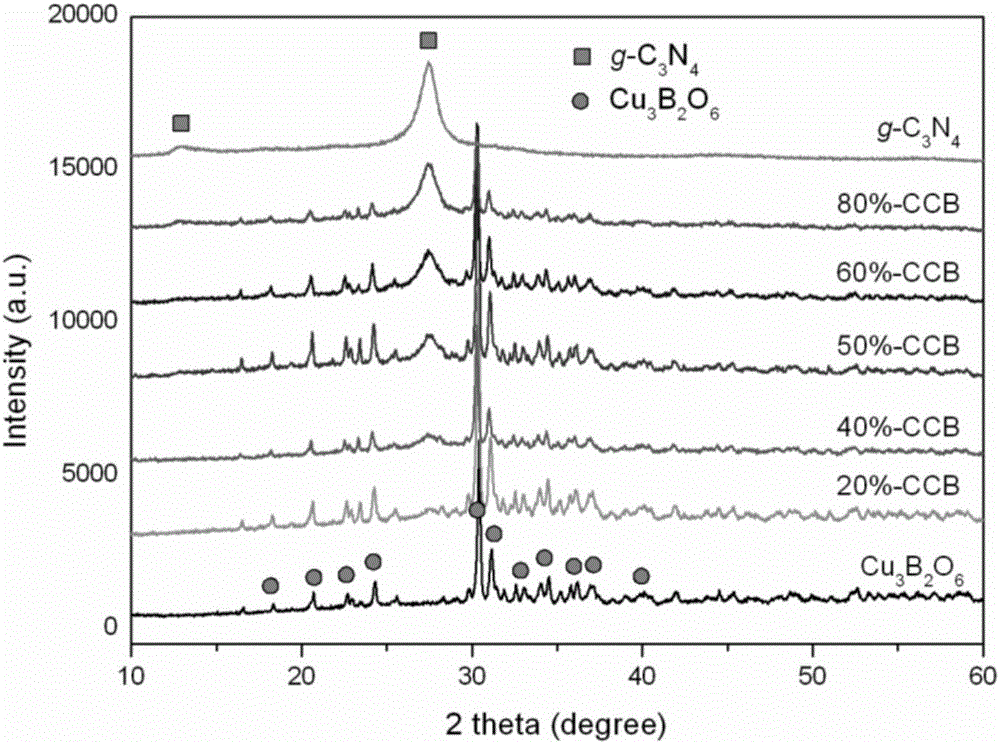

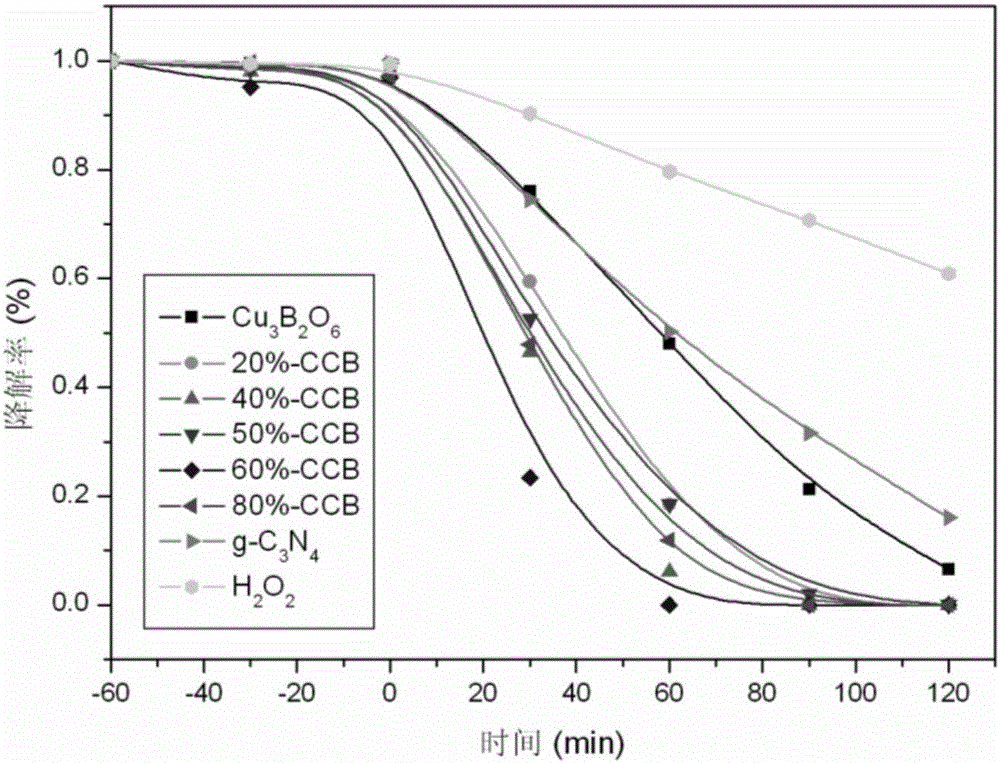

Preparation method of Cu3B2O6/g-C3N4 (cupric borate/graphitic carbon nitride) heterojunction photocatalyst and method for degrading methylene blue dye wastewater

InactiveCN105879896AEfficient use ofImprove degradation efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionCopper nitrate

The invention discloses a preparation method of a Cu3B2O6 / g-C3N4 (cupric borate / graphitic carbon nitride) heterojunction photocatalyst and a method for degrading methylene blue dye wastewater. The preparation method comprises the following steps of using citric acid, copper nitrate and boric acid as raw materials of Cu3B2O6, using melamine as raw material of g-C3N4, and adopting a grinding-calcining preparation method to prepare the heterojunction photocatalyst; under the radiation condition by visible light, degrading the methylene blue dye wastewater by the heterojunction photocatalyst. The preparation method has the advantages that the visible light can be efficiently utilized, the requirement on equipment is low, the energy consumption is little, the operation cost is low, the removal rate of methylene blue is 100% within a short time, and the Cu3B2O6 / g-C3N4 heterojunction photocatalyst can be regenerated.

Owner:HUNAN AGRICULTURAL UNIV

Rapid preparation method of carbon-doped porous graphitic carbon nitride nano-dispersion system

ActiveCN106902858ARealize the structureFast batch preparationCatalyst activation/preparationHexamethylenetetramineDecomposition

The invention discloses a rapid preparation method of a carbon-doped porous graphitic carbon nitride nano-dispersion system and relates to the fields of nanoscience, material science, photocatalysis and the like. According to the method, high-temperature polymerization of melamine or dicyanodiamine is subjected to in-situ doping and structure control with gas produced through decomposition of hexamethylenetetramine at the high temperature, and a carbon-doped porous graphitic carbon nitride nanomaterial is obtained with a one-step method. Rapid batch preparation of the carbon-doped porous graphitic carbon nitride nano-dispersion system is realized under the high-shearing action, and the rapid preparation method has broad application prospect in the fields of photocatalysis, electrochemical sensing and the like.

Owner:UNIV OF JINAN

Pnictide containing catalysts for electrochemical conversion reactions and methods of use

ActiveUS10388947B2Increase electrode kineticsLower charge transfer resistanceNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium–sulfur batteryLithium sulfur

Owner:RGT UNIV OF CALIFORNIA +1

Simple electrochemiluminescence detection method of glyphosate pesticide

InactiveCN107247079AQuantitative determination of contentDetermination of contentChemiluminescene/bioluminescenceMaterial electrochemical variablesCarbon nitrideElectrochemiluminescence

The invention belongs to the field of pesticide detection, and discloses a simple electrochemiluminescence detection method of glyphosate pesticide, and especially relates to preparation and applications of a carbon nitride-based glyphosate electrochemiluminescence sensor. According to a preparation method, graphene carbon nitride (g-C3N4) is used for modifying glassy carbon electrode loaded with Ag<+> on the surface; Ag<+> is released from the g-C3N4 modified electrode surface under the complexing action of glyphosate in a solution with Ag<+> on the surface of the electrode, recovery of electroluminescent signals is realized, and detection of glyphosate is realized via detecting the electroluminescent signals.

Owner:UNIV OF JINAN

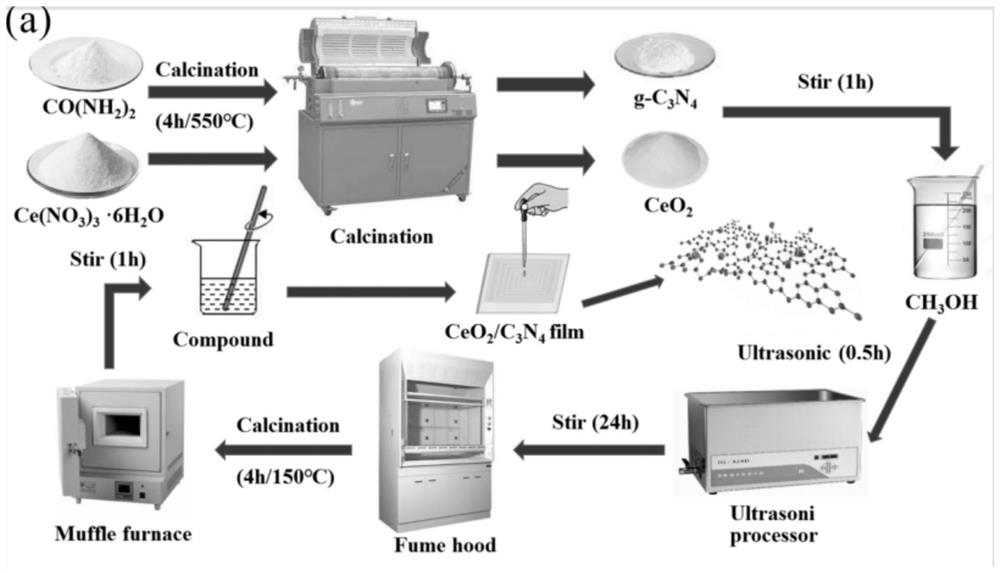

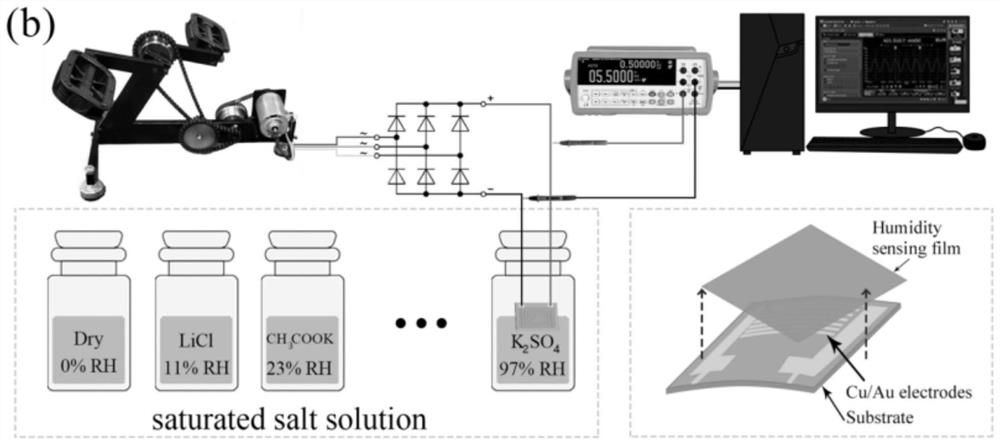

Humidity sensor of CeO2/g-C3N4 hybrid membrane as well as preparation method and application thereof

ActiveCN111704155AWide range of monitoringResponse value advantageCerium oxides/hydroxidesRespiratory organ evaluationGraphiteMoisture sensor

The invention relates to the technical field of humidity detection sensors, in particular to a humidity sensor of a CeO2 / g-C3N4 hybrid membrane as well as a preparation method and application thereof.The humidity sensor comprises a substrate, a humidity-sensitive material combined on the substrate and a resistance value detection device communicated with the humidity-sensitive material, wherein the humidity-sensitive material is a cerium oxide-graphite carbonitride hybrid membrane prepared from cerium oxide and graphite carbonitride. The humidity sensor of the CeO2 / g-C3N4 hybrid membrane hasa wider humidity monitoring range, and when the relative humidity (RH) is increased from 0% to 97%, the response value of the sensor is close to 7000. Compared with a traditional humidity sensor, thesensor has obvious advantages in the aspects of sensitivity, stability, responsiveness, repeatability, recovery time and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

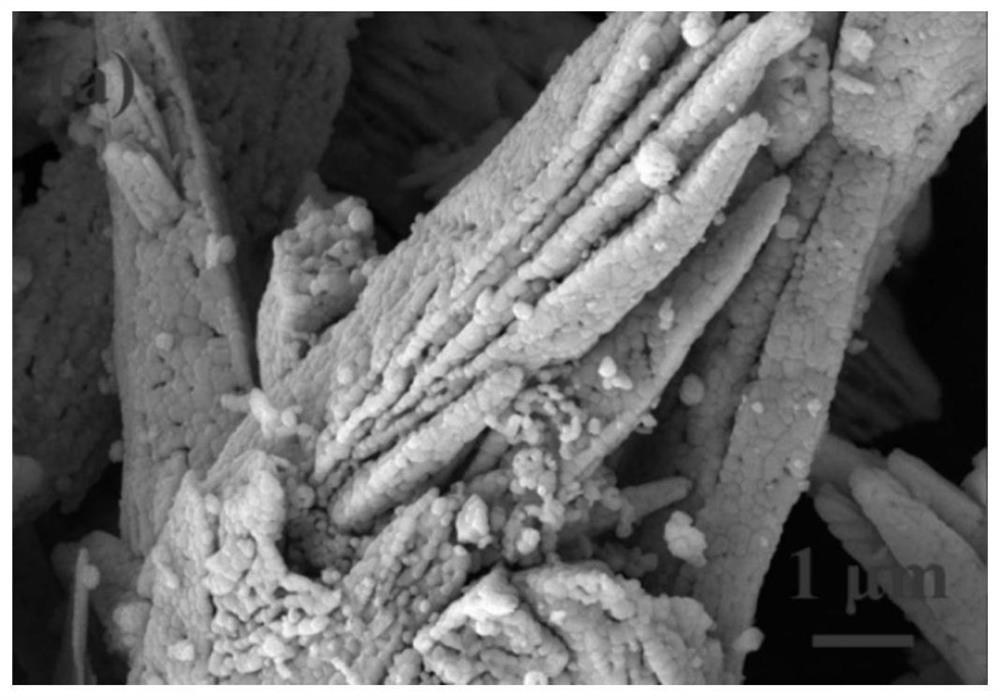

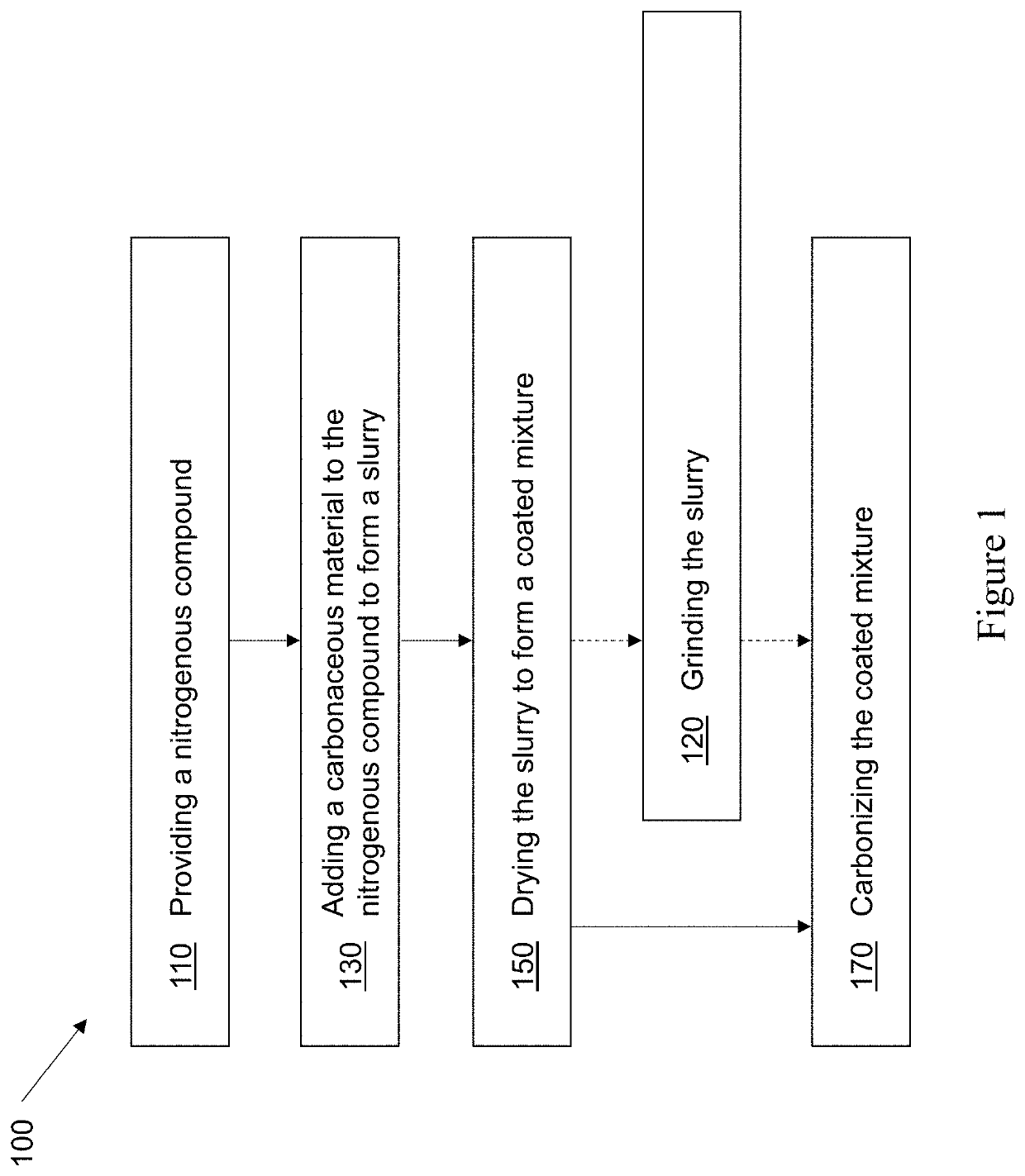

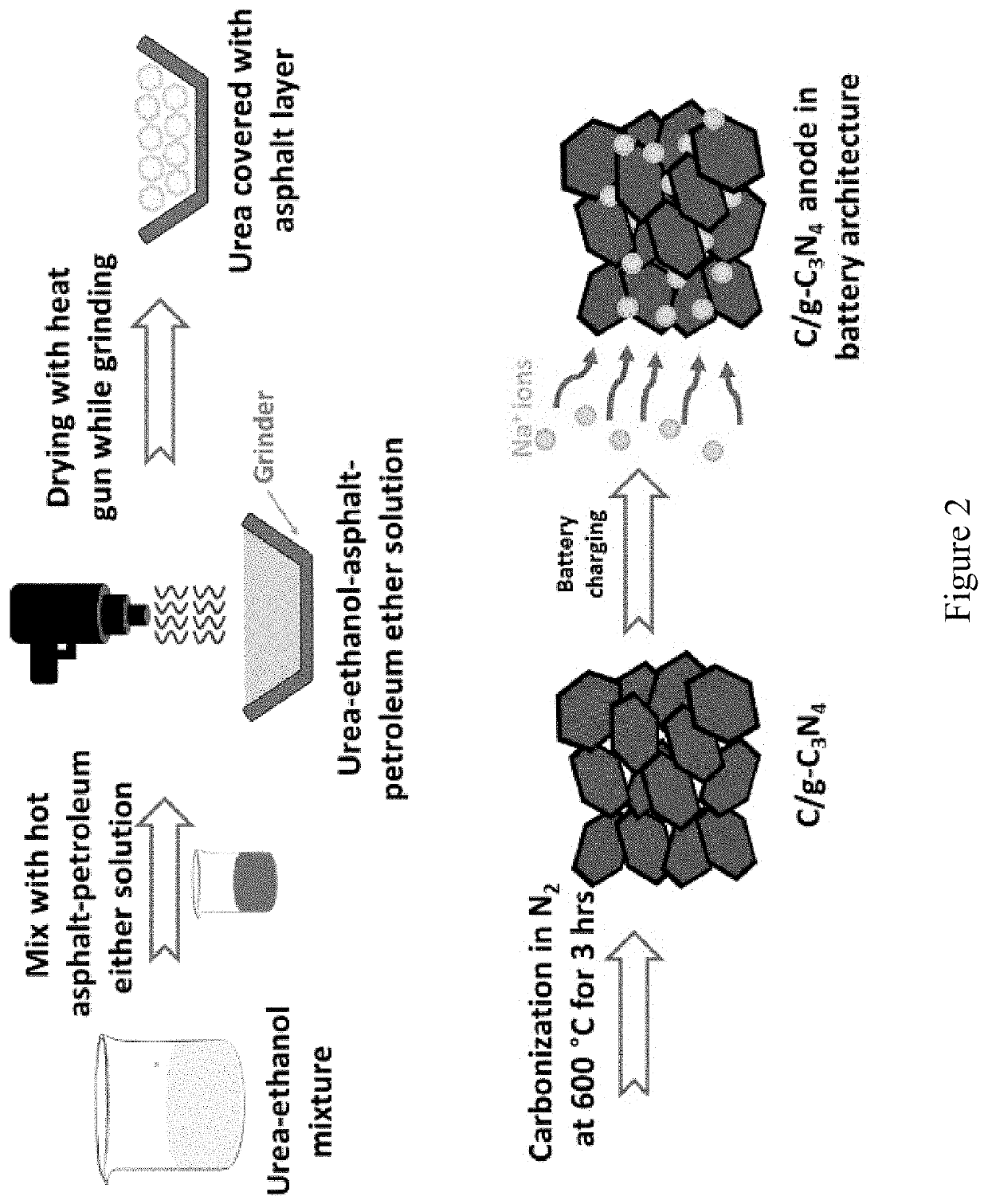

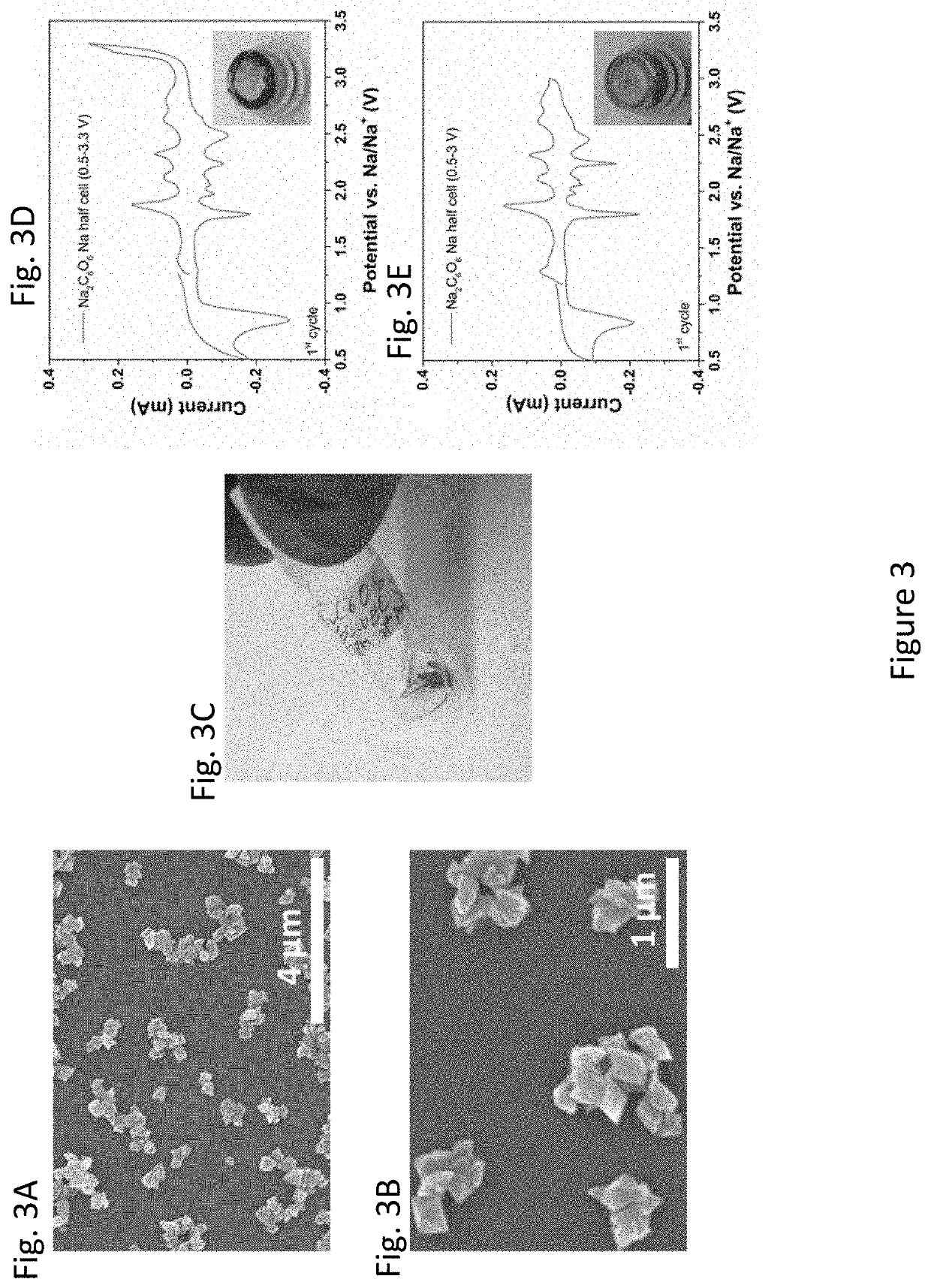

Graphitic carbon nitride materials and methods of making and use thereof

PendingUS20220013765A1Nitrogen-metal/silicon/boron binary compoundsSecondary cellsSodium-ion batterySlurry

A composition comprising a graphitic carbon nitride material and a conductive carbon material coating may be used in electrodes or in batteries such as sodium ion batteries. The composition may be prepared using a method comprising the steps of providing a nitrogenous compound; adding a carbonaceous material to the nitrogenous compound to form a slurry; drying the slurry to form a coated mixture; and carbonizing the coated mixture.

Owner:NEW YORK UNIV

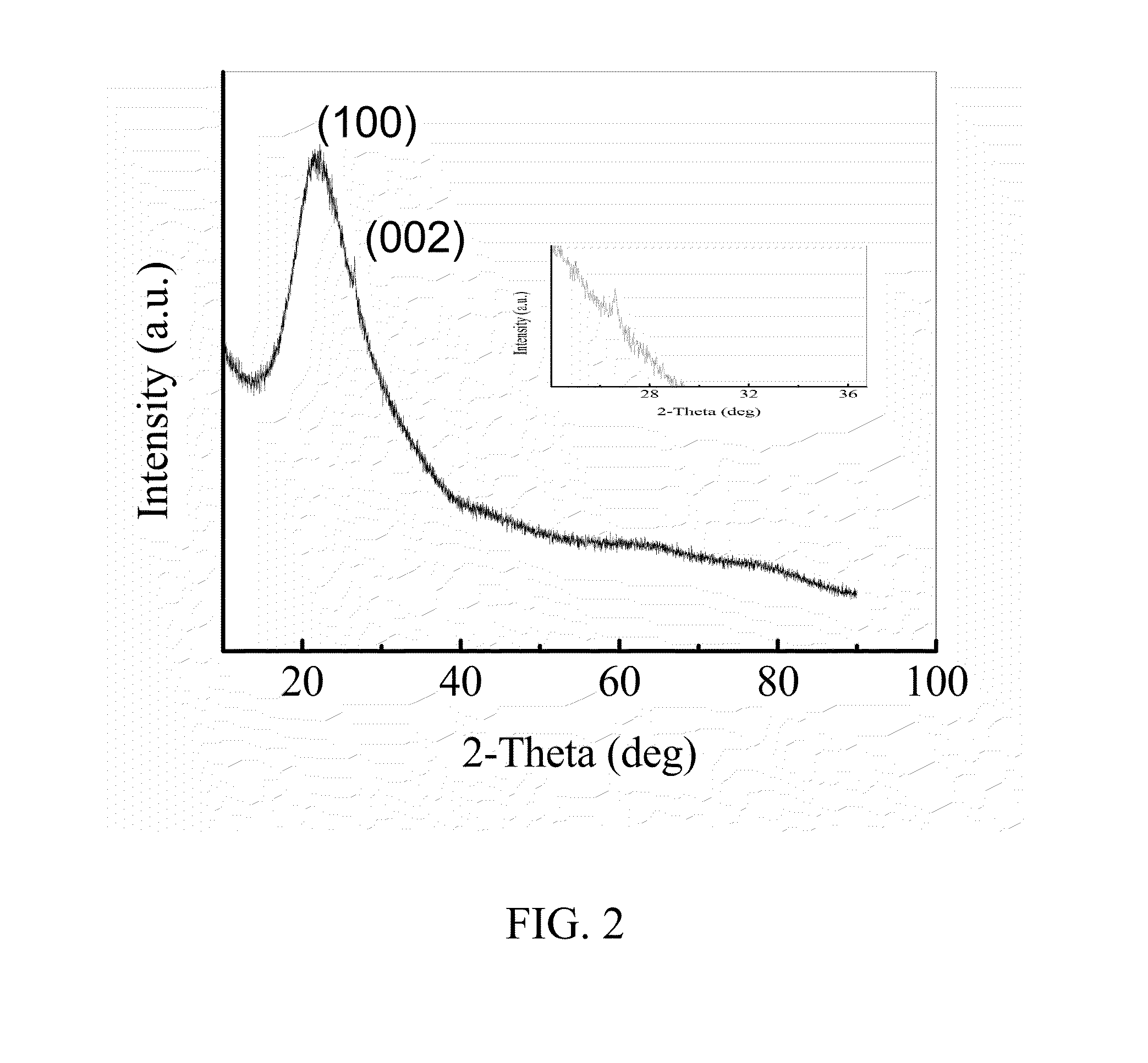

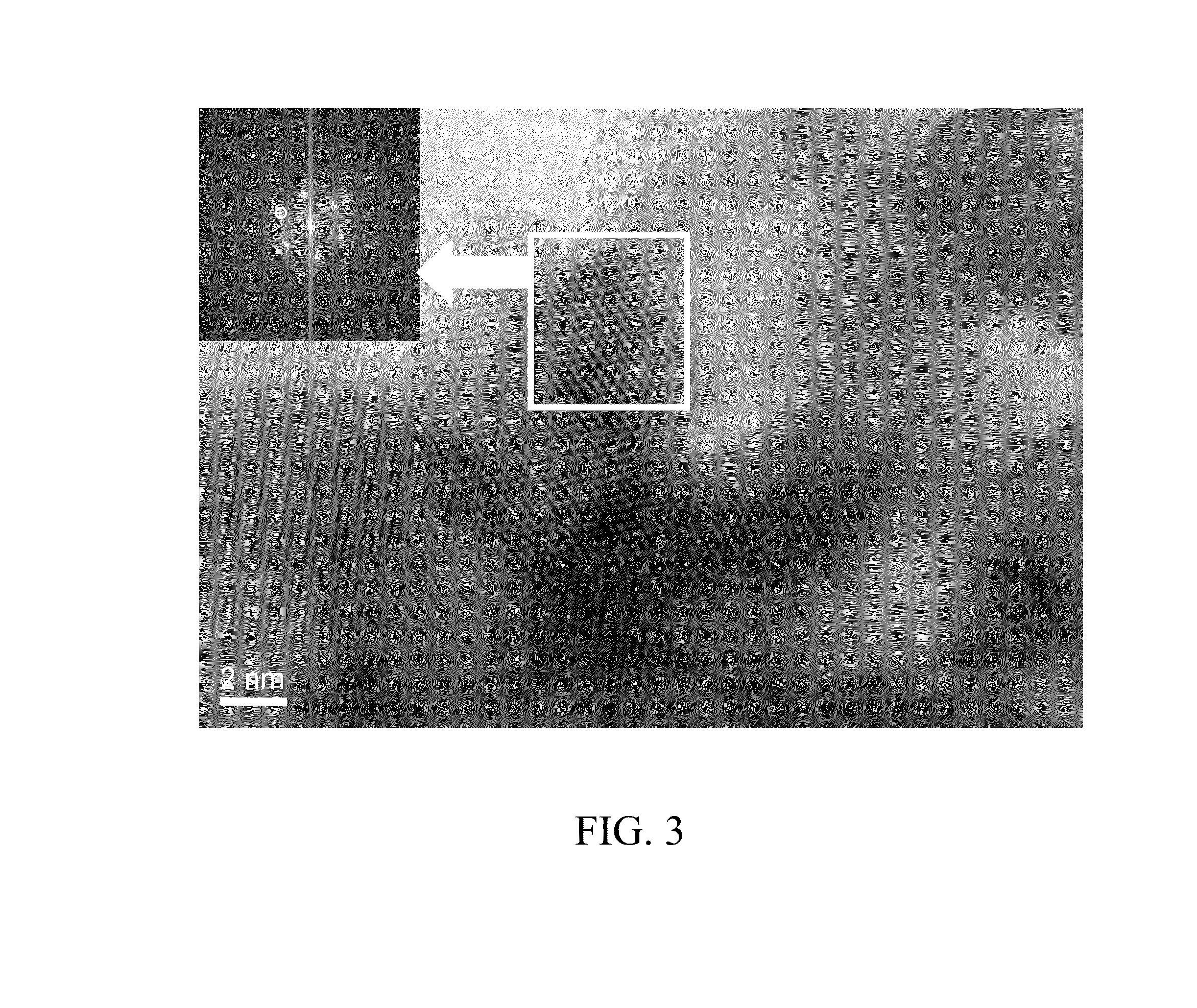

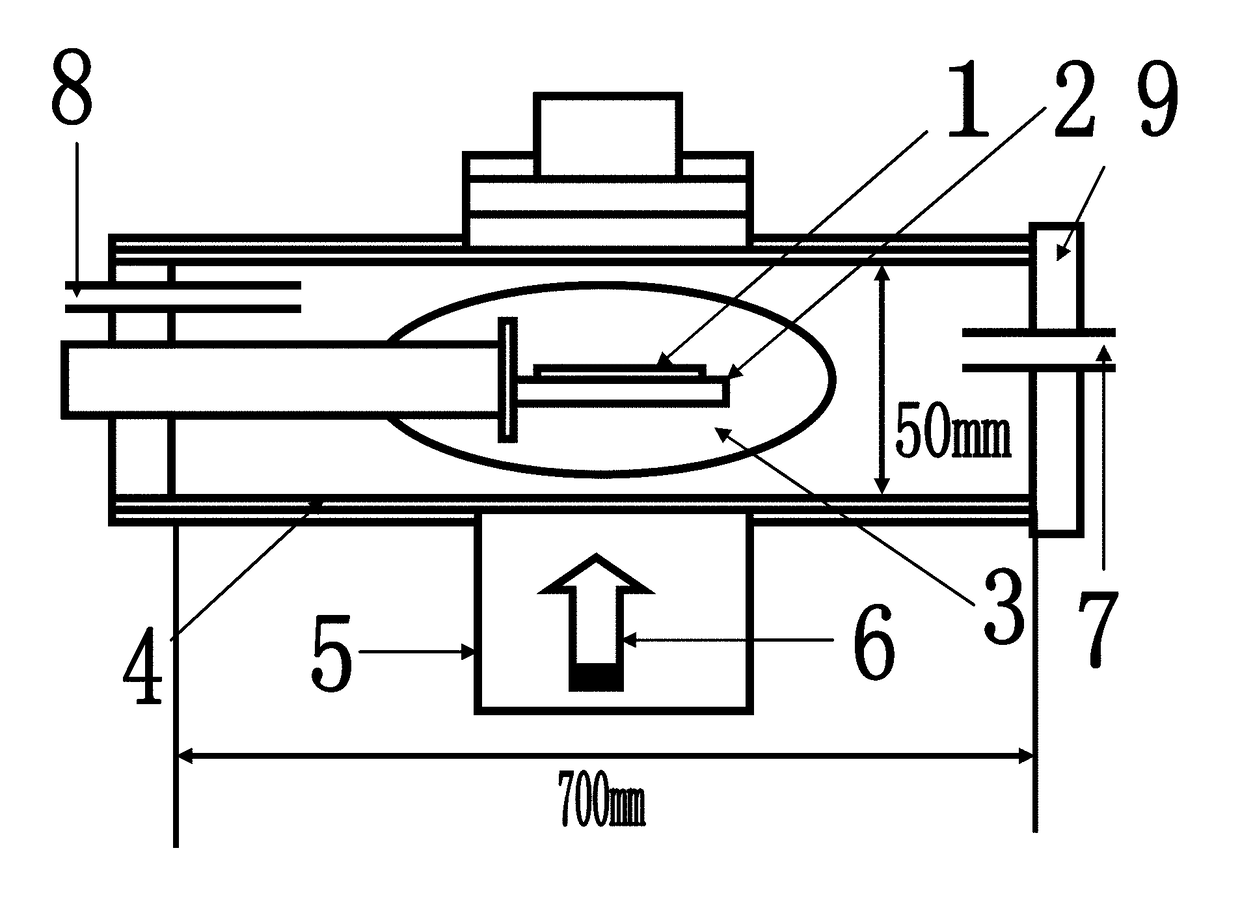

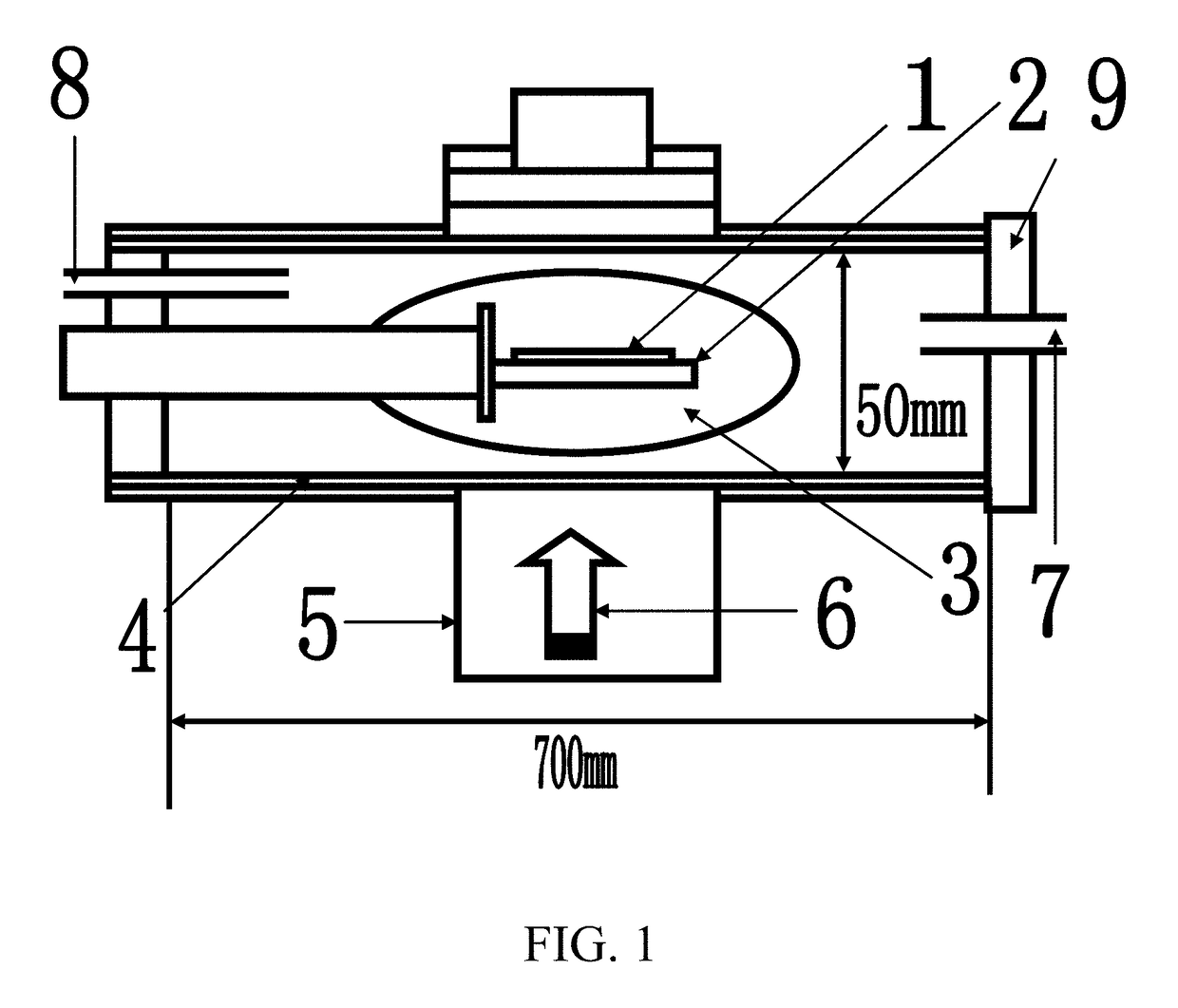

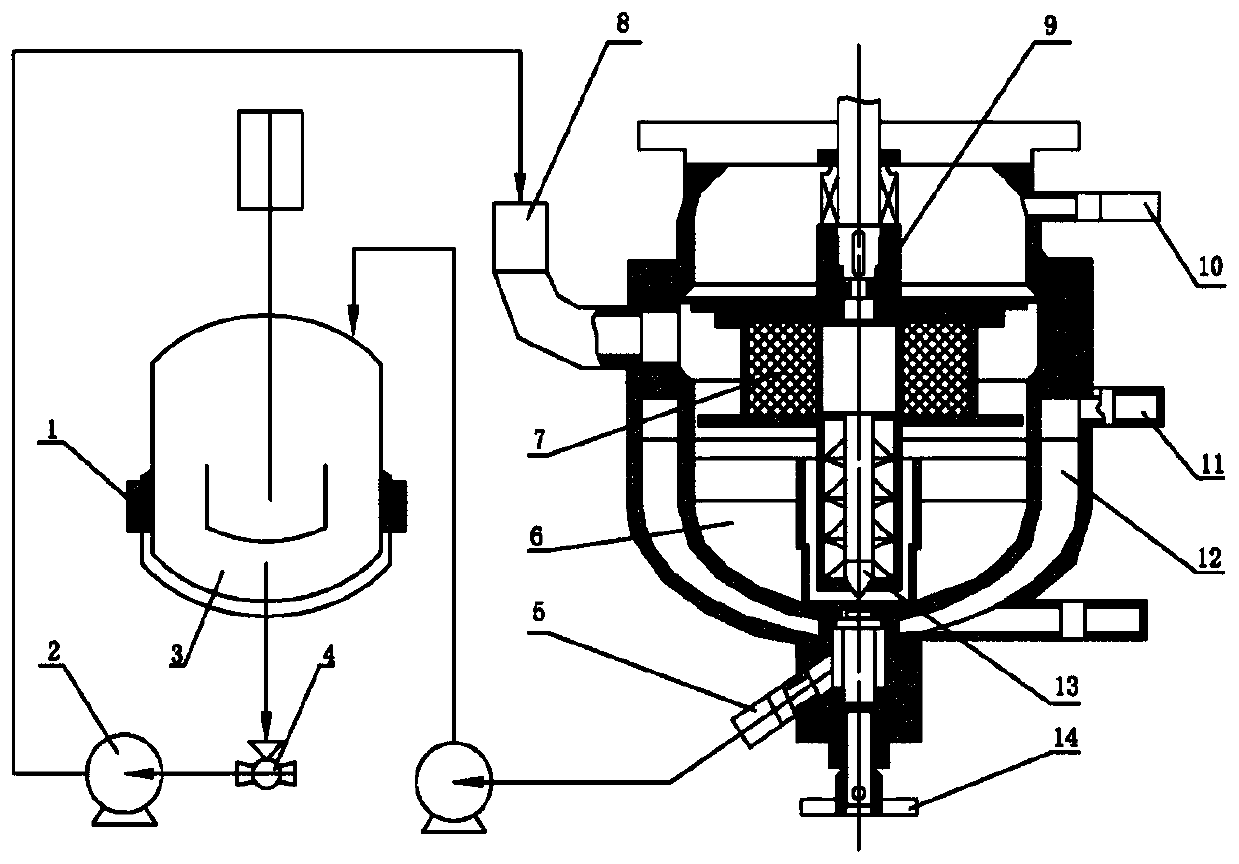

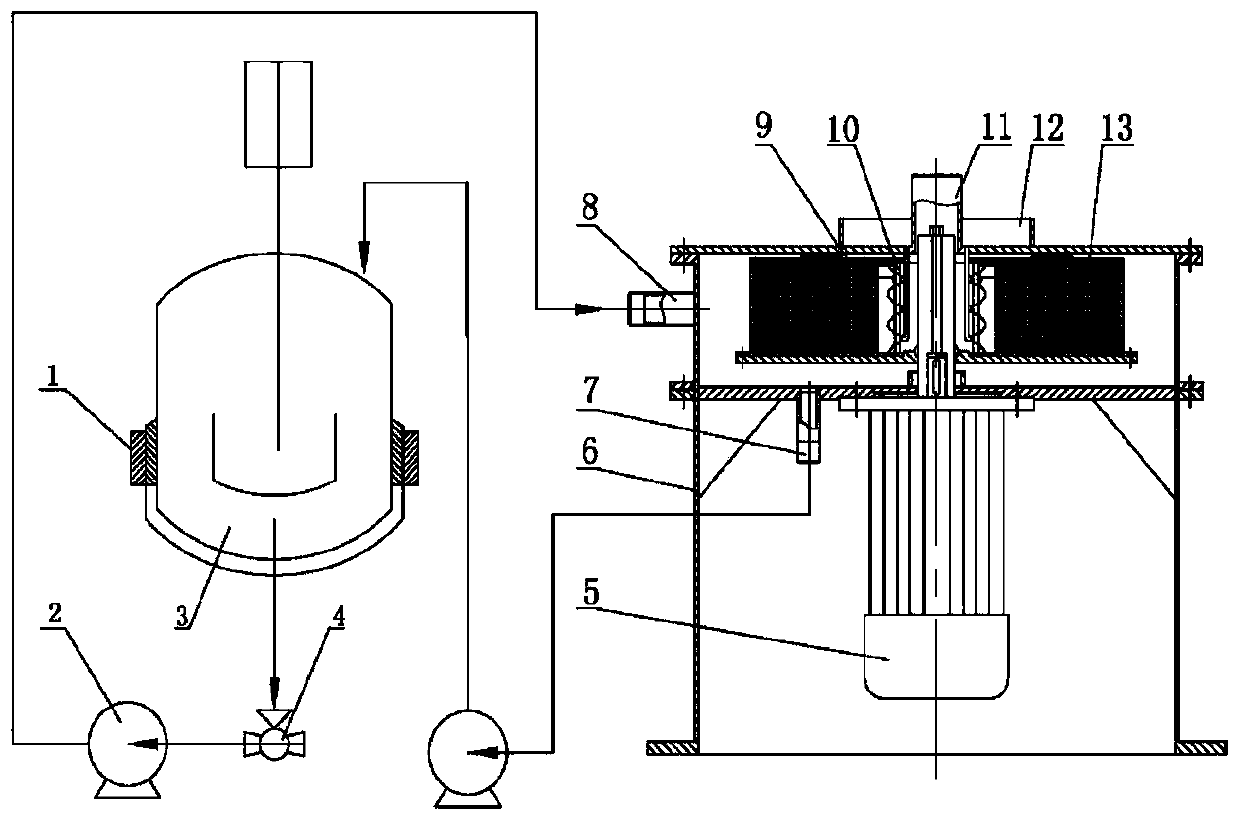

Method for preparing two-dimensional graphitic carbon nitride dispersion liquid through ultrasonic coupling supergravity rotating bed stripping

PendingCN110627025AHigh degree of peelingNo reunionMaterial nanotechnologyNitrogen and non-metal compoundsProtonationOrganic compound

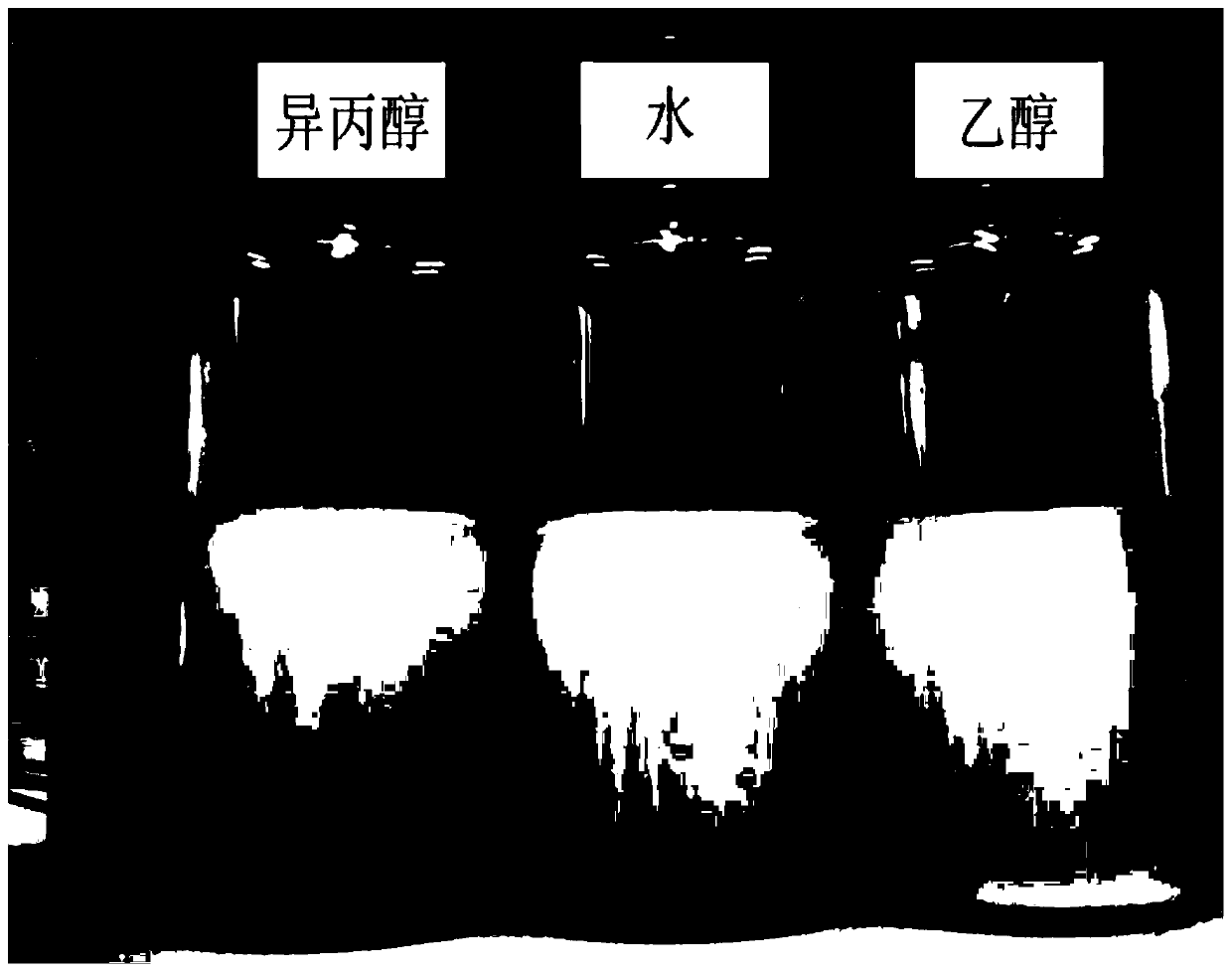

The invention discloses a method for preparing a two-dimensional graphitic carbon nitride dispersion liquid by using ultrasound coupling supergravity rotating bed through stripping, and belongs to thetechnical field of preparation of carbon nitride dispersion liquids. The method comprises the following steps: (1) carrying out a solid-phase thermal polycondensation reaction by taking a nitrogen-rich organic compound as a raw material to obtain blocky graphitic carbon nitride; (2) carrying out protonation modification on the blocky graphitic carbon nitride by adopting a protonic acid, carryingout washing, carrying out drying and carrying out grinding to obtain protonated carbon nitride; and (3) dispersing the protonated carbon nitride powder into a chemical liquid to obtain a material dispersion liquid, introducing the material dispersion liquid into an ultrasoud coupling supergravity rotating bed system, stripping the material under the synergistic effect of ultrasonic waves and supergravity shearing force, and carrying out centrifugal separation to obtain the carbon nitride dispersion liquid. The method is simple and easy to implement, low in cost, high in stripping efficiency and high in yield, can realize continuous large-scale production, and has a wide application prospect.

Owner:YULIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com