Method for preparing two-dimensional graphitic carbon nitride dispersion liquid through ultrasonic coupling supergravity rotating bed stripping

A supergravity rotating bed, graphitic carbon nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc. Quality and dispersion effects, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

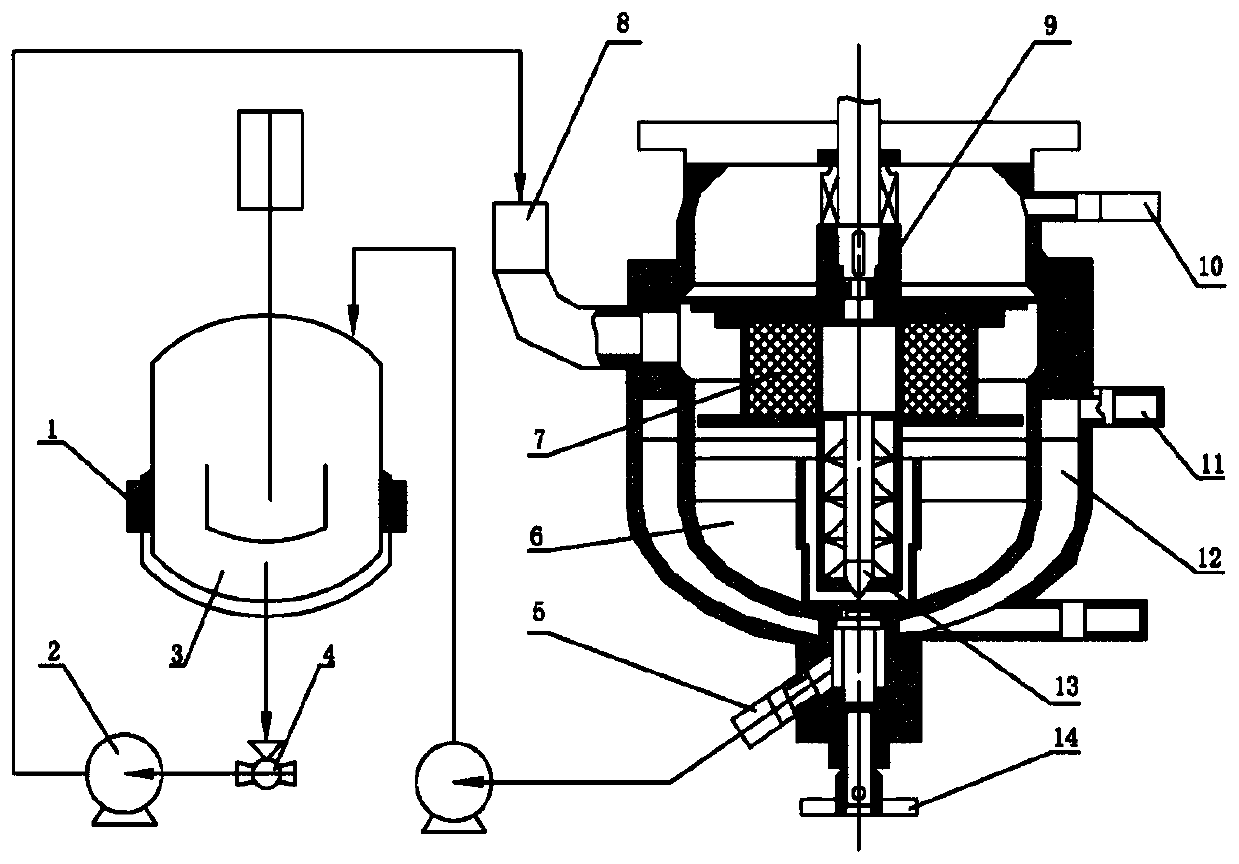

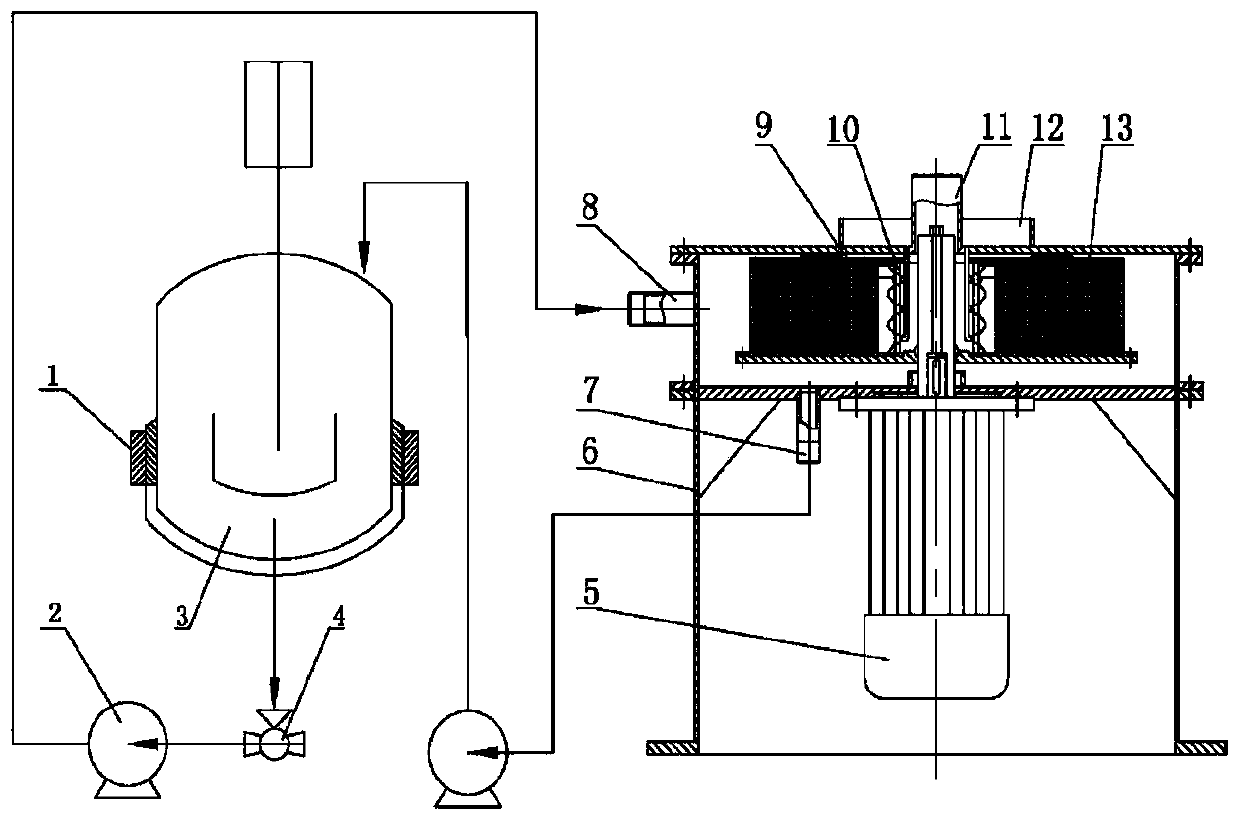

Method used

Image

Examples

Embodiment 1

[0048] (1) Accurately weigh 30g of urea and put it into 6 crucibles, cover the crucibles and put them into a muffle furnace, raise the temperature to 550°C, the heating rate is 2°C / min, keep it warm for 4h, then cool it naturally, grind it fully, put The prepared powder is named bulk g-C 3 N 4 ;

[0049] (2) Weigh 10g bulk g-C 3 N 4 , add 200ml of concentrated sulfuric acid, stir magnetically at room temperature for 6h, then add 100ml of deionized water, continue to stir for 2h, filter and wash with water until pH = 7, freeze-dry to obtain protonated carbon nitride (protonated carbon nitride, p-g-C 3 N 4 ).

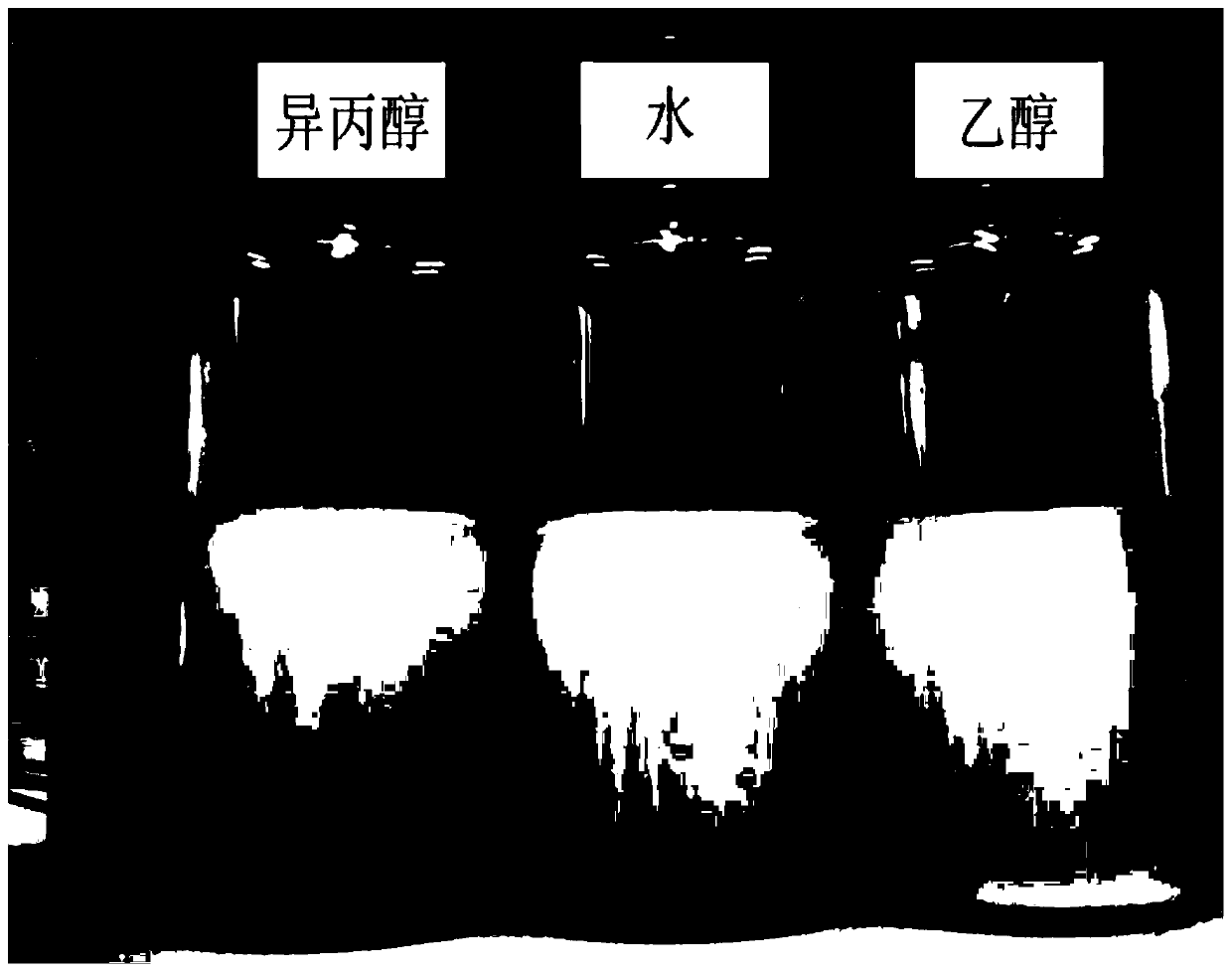

[0050] (3) Weigh 0.8g of protonated carbon nitride powder and 0.8g of polyvinylpyrrolidone, and add it to a beaker containing 800ml of isopropanol to form a carbon nitride bulk dispersion with a concentration of 1mg / ml;

[0051] (4) Add the carbon nitride bulk dispersion into the circulation tank, start the ultrasonic probe arranged on the side wall of the circulati...

Embodiment 2

[0057] (1) Accurately weigh 30g of urea and put it into 6 crucibles, cover the crucibles and put them into a muffle furnace, raise the temperature to 550°C, the heating rate is 2°C / min, keep it warm for 2h, then cool naturally, grind fully, put The prepared powder is named bulk g-C 3 N 4 ;

[0058] (2) Weigh 10g bulk g-C 3 N 4 , add 200ml of concentrated sulfuric acid, stir magnetically at 35°C for 10h, then add 100ml of deionized water, continue to stir for 2h, filter and wash with water until pH = 7, freeze-dry to obtain protonated carbon nitride (p-g-C 3 N 4 ).

[0059] (3) Weigh 1.0 g of protonated carbon nitride powder and 2.0 g of CTAB, and add it to a beaker containing 800 ml of ethanol to form a carbon nitride bulk dispersion with a concentration of 1.25 mg / ml;

[0060] (4) Add the carbon nitride bulk dispersion into the circulation tank, and start the ultrasonic probe arranged on the side wall of the circulation tank, and first peel off the carbon nitride bulk d...

Embodiment 3

[0062] (1) Accurately weigh 30g of urea and put it into 6 crucibles, cover the crucibles and put them into a muffle furnace, raise the temperature to 500°C, the heating rate is 2°C / min, keep it warm for 2h, then cool it naturally, grind it fully, put The prepared powder is named bulk g-C 3 N 4 ;

[0063] (2) Weigh 10g bulk g-C 3 N 4 , add 200ml of concentrated sulfuric acid, stir magnetically at 50°C for 6h, then add 100ml of deionized water, continue stirring for 2h, filter and wash with water until pH = 7, freeze-dry to obtain protonated carbon nitride (p-g-C 3 N 4 ).

[0064] (3) Take 1.2g of protonated carbon nitride powder and add it to a beaker containing 800ml of tetramethylammonium hydroxide 50% aqueous solution to form a carbon nitride bulk dispersion with a concentration of 1.5mg / ml ;

[0065] (4) Add the carbon nitride bulk dispersion into the circulation tank, and start the ultrasonic probe arranged on the side wall of the circulation tank, and first peel of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com