Method for preparing graphene oxide through ultrasonic-assisted process

An ultrasonic-assisted, fossil technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of complex process and poor peeling degree, and achieve the effect of simple preparation process, improving peeling degree and saving preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

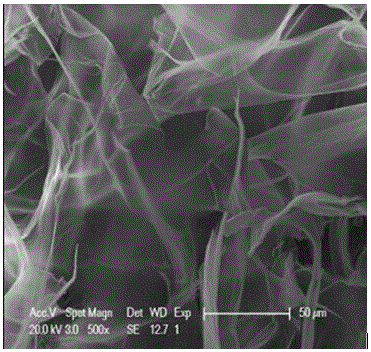

Image

Examples

Embodiment 1

[0033] Mix 40ml of concentrated sulfuric acid and 4ml of concentrated phosphoric acid in a beaker evenly, add 250mg of 325 mesh natural flake graphite, place in an ultrasonic cleaner at 10°C, ultrasonicate for 30min, take out the beaker, and slowly add 0.5g of potassium permanganate during stirring , placed in an ultrasonic cleaner at 10°C, 200W ultrasonic for 1h, take out the beaker, slowly add 2g of potassium permanganate during the stirring process, place the beaker in a 60°C water bath, keep the constant temperature for 2h, pour it into 125ml of ice cubes, add dropwise 5ml of hydrogen peroxide, washed to neutral, 100W ultrasonic dispersion.

Embodiment 2

[0035] Mix 36ml of concentrated sulfuric acid and 4ml of concentrated phosphoric acid in a beaker evenly, add 250mg of 325 mesh natural flake graphite, place it in an ultrasonic cleaner at 10°C, ultrasonicate for 30min, take out the beaker, and slowly add 0.5g of potassium permanganate during stirring , placed in an ultrasonic cleaner at 10°C, 200W ultrasonic for 1h, took out the beaker, slowly added 1.5g of potassium permanganate during stirring, placed the beaker in a water bath at 60°C, kept the constant temperature for 2h, poured it into 125ml of ice cubes, dripped Add 5ml hydrogen peroxide, wash until neutral, 100W ultrasonic dispersion.

Embodiment 3

[0037] Mix 35ml of concentrated sulfuric acid and 5ml of concentrated phosphoric acid in a beaker evenly, add 1g of 325 mesh natural flake graphite, place it in an ultrasonic cleaner at 10°C, ultrasonicate for 30min, take out the beaker, and slowly add 1.5g of potassium permanganate during stirring , placed in an ultrasonic cleaner at 10°C, 200W ultrasonic for 1h, take out the beaker, slowly add 4g potassium permanganate during stirring, place the beaker in a water bath at 80°C, keep the constant temperature for 2h, pour it into 125ml ice cubes, add dropwise 10ml of hydrogen peroxide, washed to neutral, 100W ultrasonic dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com