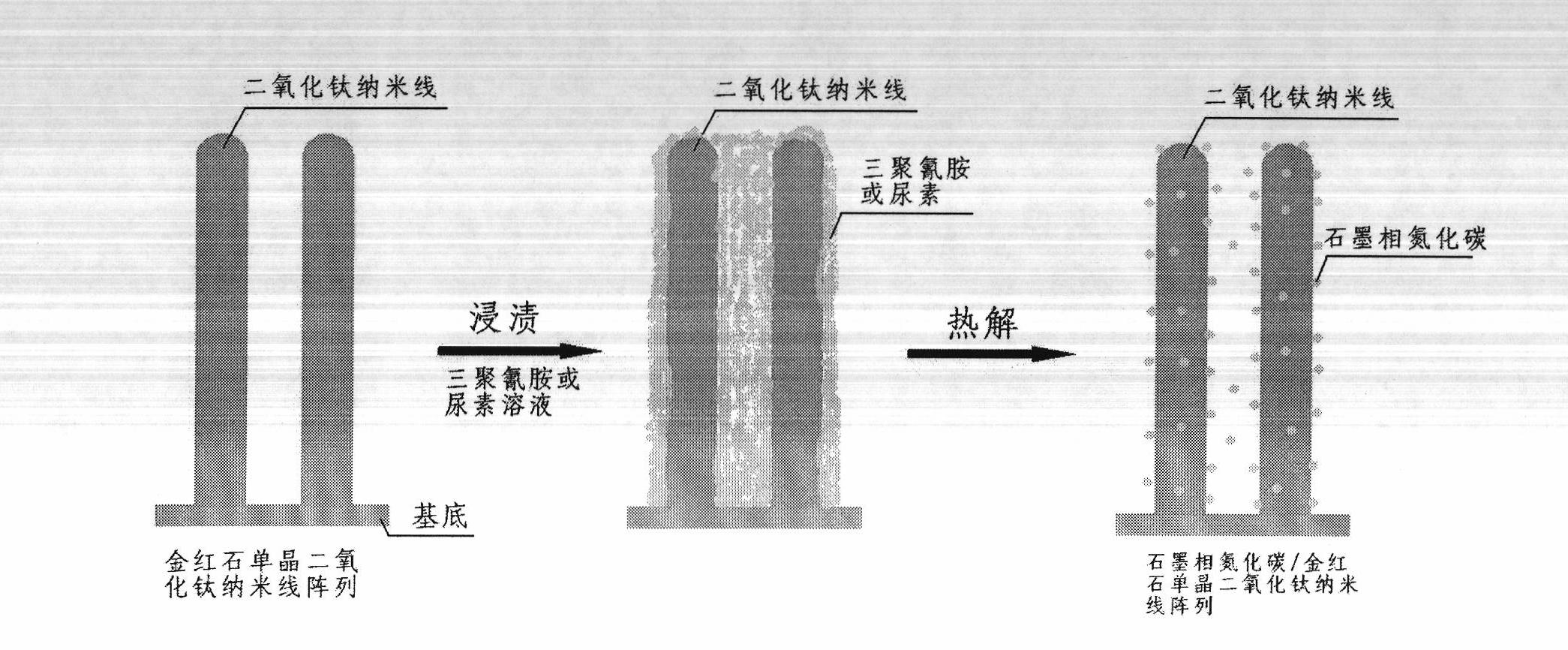

Preparation method of graphite phase carbon nitride/rutile monocrystal titanium dioxide (TiO2) nanowire array

A graphitic carbon nitride and nanowire array technology, applied in the field of photocatalysis, can solve the problems of unfavorable continuous process sewage treatment, cannot reduce photogenerated carrier recombination, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation of the rutile single crystal titania nanowire array can refer to the following method, but it is not necessary to follow the following method. The variation of the preparation method of the rutile single crystal titanium dioxide nanowire array does not constitute a limitation of the present invention.

[0024] Preparation of rutile single-crystal titanium dioxide nanowire arrays: under vigorous stirring, add 12ml of titanium tetrachloride to 400ml of ice water, cool in an ice-water bath, stir for 30 minutes, remove the ice-water bath, and continue stirring at room temperature for 2 hours to obtain hydrolyzed titanium tetrachloride liquid. At room temperature, immerse the cleaned substrate (conductive glass, silicon wafer, titanium wafer, glass, quartz or ceramics, etc.) in titanium tetrachloride hydrolyzed solution for 24 hours, take it out, wash it with absolute ethanol three times, dry it, and then heat it at 550°C for 30 minutes , that is, dip-coated...

Embodiment 1

[0028] The prepared rutile single crystal titanium dioxide nanowire array (titanium sheet as the substrate) was immersed in 30 g / L melamine aqueous solution for 48 hours, then taken out, and dried at 120° C. Then, under an argon atmosphere, pyrolyze at 300° C. for 3 hours to obtain a graphitic carbon nitride / rutile single crystal titanium dioxide nanowire array.

Embodiment 2

[0030] The prepared rutile single-crystal titanium dioxide nanowire array (ceramic as the substrate) was immersed in 50 g / L cyanamide aqueous solution for 24 hours, then taken out, and dried at 120° C. Then, under nitrogen atmosphere, pyrolyze at 600° C. for 1 hour to obtain graphite phase carbon nitride / rutile single crystal titanium dioxide nanowire array.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com