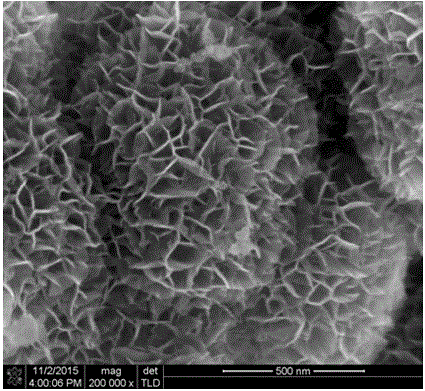

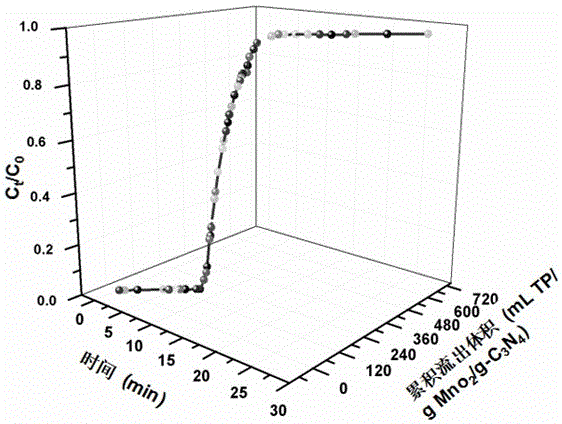

Metal oxide/graphitic carbon nitride composite material having three-dimensional structure and preparation thereof

A composite material and three-dimensional structure technology, applied in the field of materials, can solve problems such as harmful to the experimenter and the environment, side reactions, cumbersome reaction process, etc., and achieve the effect of simple preparation method, large pore volume, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) g-C 3 N 4 Preparation of nanosheet solutions

[0028] a. Spread 20g of white melamine powder on the bottom of a 50mL crucible, close the lid tightly, place it in a muffle furnace, raise the temperature to 600°C at a rate of 3.0°C / min, keep it warm for 2 hours, and then cool it down at a rate of 3.0°C / min. to room temperature, a pale yellow g-C 3 N 4 solid;

[0029] b. Add 0.3g of the obtained g-C 3 N 4 After the solid is ground into powder, pour it into a 250mL flat-bottomed flask, add 200mL of ultrapure water, 150W ultrasonic stripping for 3h, and centrifuge the resulting solution at 3000rpm for 5min, collect the supernatant, and remove the unstripped solid in the lower layer;

[0030] c. Evaporate the obtained supernatant on a rotary evaporator at 60°C to a volume of 50 mL to obtain g-C with a concentration of 0.1 mol / L 3 N4 Nanosheet solution;

[0031] 2) Three-dimensional structure metal oxide / g-C 3 N 4 Preparation of composite materials

[0032] a. Di...

Embodiment 2

[0038] 1) g-C 3 N 4 Preparation of nanosheet solutions

[0039] a. Spread 20g of white melamine powder on the bottom of a 50mL crucible, close the lid tightly, place it in a muffle furnace, raise the temperature to 550°C at a rate of 2.5°C / min, keep it warm for 4 hours, and then cool it down at a rate of 2.5°C / min. to room temperature, a pale yellow g-C 3 N 4 solid;

[0040] b. Add 0.1g of the obtained g-C 3 N 4 After the solid is ground into powder, pour it into a 250mL flat-bottomed flask, add 200mL of ultrapure water, 100W ultrasonic stripping for 4h, and centrifuge the resulting solution at 1000rpm for 4min, collect the supernatant, and remove the unstripped solid in the lower layer;

[0041] c. Evaporate the obtained supernatant on a rotary evaporator at 40°C to a volume of 50 mL to obtain g-C with a concentration of 0.2 mol / L 3 N 4 Nanosheet solution;

[0042] 2) Three-dimensional structure metal oxide / g-C 3 N 4 Preparation of composite materials

[0043] a. ...

Embodiment 3

[0046] 1) g-C 3 N 4 Preparation of nanosheet solutions

[0047] a. Spread 20g of white melamine powder on the bottom of a 50mL crucible, close the lid tightly, place it in a muffle furnace, raise the temperature to 580°C at a rate of 2.8°C / min, keep it warm for 3 hours, and then cool it down at a rate of 2.8°C / min. to room temperature, a pale yellow g-C 3 N 4 solid;

[0048] b. Add 0.2g of the obtained g-C 3 N 4 After the solid is ground into powder, pour it into a 250mL flat-bottomed flask, add 200mL of ultrapure water, 200W ultrasonic stripping for 1h, and centrifuge the resulting solution at 2000rpm for 3min, collect the supernatant, and remove the unstripped solid in the lower layer;

[0049] c. Evaporate the resulting supernatant on a rotary evaporator at 50°C to a volume of 50 mL to obtain g-C with a concentration of 0.05 mol / L 3 N 4 Nanosheet solution;

[0050] 2) Three-dimensional structure metal oxide / g-C 3 N 4 Preparation of composite materials

[0051] a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com