Visible-light-driven photocatalyst for degrading dye in wastewater, and preparation and application thereof

A catalyst and visible light technology, applied in the field of photocatalysis, can solve the problems that the active components cannot be fully and efficiently utilized, there is no rigid carrier with a large specific surface, and the catalyst is difficult to separate and recycle, etc., and achieves improved reaction stability, low cost, and ease of use. The effect of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

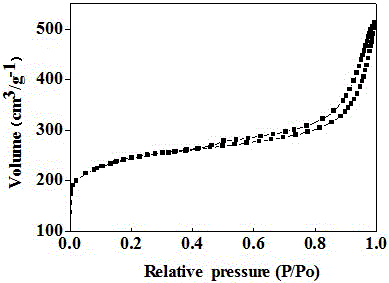

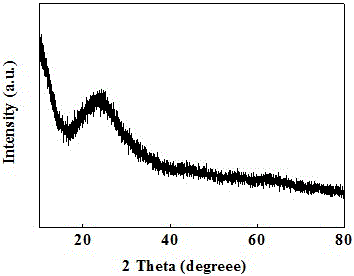

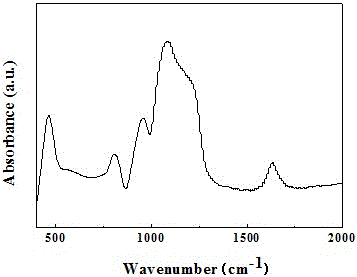

[0036] At room temperature, dissolve 3.1 g of cetyltrimethylammonium bromide in a mixture of 250 ml of ethanol and deionized water (the volume ratio of absolute ethanol and deionized water is 1:4) to obtain solution A After 30 minutes, in solution A, add dropwise 50 ml25% ammoniacal liquor successively, 13 milliliters of tetraethyl orthosilicate and 0.2 milliliters of titanium isopropoxides, continue stirring at room temperature after 4 hours, obtain solid substance B by suction filtration, then solid Substance B was dried at 110°C for 5 hours, calcined at 500°C for 6 hours, and cooled to obtain mesoporous MCM-48 (Ti-MCM-48) solid particles with Ti atoms in the skeleton.

[0037] In 15 ml deionized water, add 0.2 g dicyandiamide, 0.02 g CuCl 2 ·H 2 O and 1 g of the Ti-MCM-48 obtained above were stirred at 100 °C for 2 hours, and the blue solid powder C was obtained by ordinary distillation; then the obtained blue solid powder C was dried at 110 °C for 5 h, and then heated at ...

Embodiment 2

[0044] At room temperature, dissolve 3.1 g of cetyltrimethylammonium bromide in a mixture of 250 ml of ethanol and deionized water (the volume ratio of absolute ethanol and deionized water is 1:4) to obtain solution A After 30 minutes, in solution A, add dropwise 50 ml25% ammoniacal liquor successively, 13 milliliters of ethyl orthosilicate and 0.032 milliliters of titanium isopropoxides, continue to stir at room temperature after 4 hours, get solid substance B by suction filtration, then solid Substance B was dried at 110°C for 5 hours, calcined at 500°C for 6 hours, and cooled to obtain mesoporous MCM-48 (Ti-MCM-48) solid particles with Ti atoms in the skeleton.

[0045] In 15 ml deionized water, add 0.2 g dicyandiamide, 0.02 g CuCl 2 ·H 2 O and 1 g of the Ti-MCM-48 obtained above were stirred at 100 °C for 2 hours, and the blue solid powder C was obtained through ordinary distillation. Then the obtained blue solid powder C was dried at 110 °C for 5 h, calcined at 550 °C f...

Embodiment 3

[0048] At room temperature, dissolve 3.1 g of cetyltrimethylammonium bromide in a mixture of 250 ml of ethanol and deionized water (the volume ratio of absolute ethanol and deionized water is 1:4) to obtain solution A After 30 minutes, in solution A, add dropwise 50 ml25% ammoniacal liquor successively, 13 milliliters of ethyl orthosilicate and 0.32 milliliters of titanium isopropoxides, continue to stir at room temperature after 4 hours, get solid substance B by suction filtration, then solid Substance B was dried at 110°C for 5 hours, calcined at 500°C for 6 hours, and cooled to obtain mesoporous MCM-48 (Ti-MCM-48) solid particles with Ti atoms in the skeleton.

[0049] In 15 ml deionized water, add 0.2 g dicyandiamide, 0.02 g CuCl 2 ·H 2 O and 1 g of the Ti-MCM-48 obtained above were stirred at 100 °C for 2 hours, and the blue solid powder C was obtained by ordinary distillation; then the obtained blue solid powder C was dried at 110 °C for 5 h, and then dried at 550 °C un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com