Photocatalyst composite structure and preparation method thereof

A photocatalyst and structure technology, applied in the production of hydrogen and other directions, can solve the problem of limited improvement of photocatalytic performance, and achieve the effects of improving photocatalytic degradation efficiency, separation efficiency and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

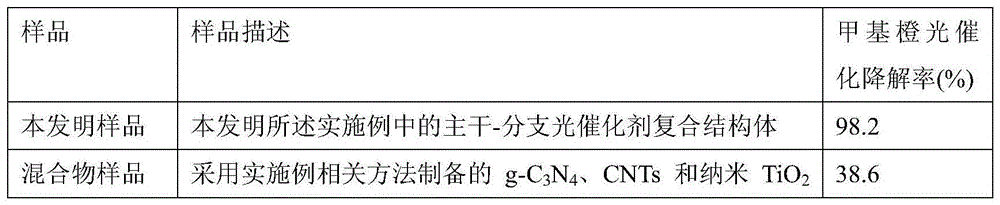

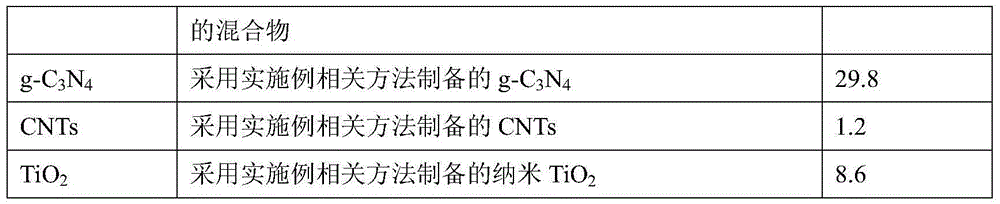

Examples

Embodiment 1

[0031] g-C 3 N 4 trunk

[0032] Take 5g of melamine in 100ml of deionized water, ultrasonically disperse, add a certain amount of dilute H 2 SO 4 (volume ratio H 2 SO 4 :H 2 O=1:1), stirred for 2 hours, filtered and washed with deionized water, and dried at 80°C for 12 hours. Then take 3g of the dried sample at the bottom of the porcelain ark, put it into a tube furnace, and bake it at 600°C for 4h under the protection of argon to obtain g-C 3 N 4 .

[0033] g-C 3 N 4 impregnated with metal ions

[0034] Mix 100ml of nickel nitrate aqueous solution with different concentrations and 2g g-C 3 N 4 Ultrasonic mixing, wherein the concentration of nickel nitrate aqueous solution is between 0.005M and 0.02M, after stirring for about 2 hours, centrifuge to separate the solid and liquid, and dry the solid at 60°C to obtain g-C loaded with nickel ions 3 N 4 .

[0035] g-C 3 N 4 On in situ grown CNTs branched structure

[0036] g-C loaded with nickel nitrate 3 N 4 Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com