Photocatalytic cement mortar containing graphite phase carbon nitride

A technology of graphite phase carbon nitride and cement mortar, which is applied in the field of building materials to achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Graphite carbon nitride (g-C 3 N 4 ) Preparation of photocatalyst

[0019] (1) Weigh 10g of urea, cyanamide, dicyandiamide, and melamine respectively, and place them in four 50ml porcelain crucibles with lids. At the same time, place it in a muffle furnace, set the heating rate at 10°C / min, raise it to 550°C, and keep it warm for 2h.

[0020] (2) Grinding the collected product when the furnace is cooled to room temperature to obtain graphite phase carbon nitride with a particle size of 300nm-500nm, which is set aside.

Embodiment 2

[0022] Preparation of Photocatalytic Cement Mortar Containing Graphite Phase Carbon Nitride

[0023] In parts by weight (Kg): 1 part of cement, 0.03 part of graphite carbon nitride, 0.05 part of polymer, 3 to 4 parts of construction sand, 0.035 part of admixture (wherein the admixture is from Shandong Jiangtai Building Materials Technology Co., Ltd. Special admixture for mortar produced by the company).

[0024] The photocatalytic cement mortar containing graphite phase carbon nitride is prepared by mixing graphite phase carbon nitride with cement, construction sand, polymer, and admixture with water according to the set component content by weight, and stirring.

Embodiment 3

[0026] The photocatalytic functional cement mortar is prepared by using red mud, which is suitable for engineering plastering construction.

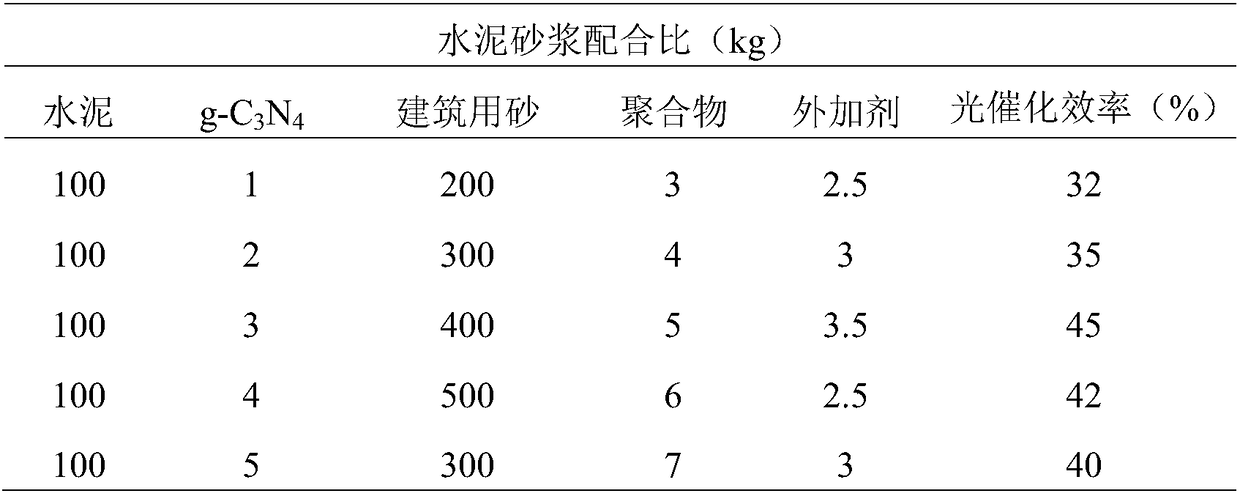

[0027] With g-C prepared by the method of embodiment 1 3 N 4 For the raw material, the specific raw material mixing ratio is shown in Table 1.

[0028] Catalyst performance evaluation is achieved by the following devices:

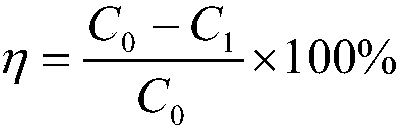

[0029] Reactor: airtight ventilation pipe, filled with 2 pieces of cement mortar in the middle, and an ultraviolet lamp is installed on the top of the device. Nitric oxide is used as the simulated gas pollutant, the gas flow rate is 1.00L / min, the temperature is room temperature, and the air humidity is 50±5%. Every 30 minutes, collect gas samples at the inlet and outlet sampling points, test the concentration of pollutants, and calculate the photocatalytic efficiency of photocatalytic cement mortar according to the following formula:

[0030]

[0031] Among them, C 0 is the inlet concentration, C 1 is the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com