Carbon nitride nano material as well as preparation method and application thereof

A nanomaterial, carbon nitride technology, applied in the field of material chemistry, can solve the problems of unfavorable imaging application of carbon nitride quantum dots, blue shift, complex synthesis methods, etc., to achieve long-term real-time lysosome imaging applications, good Photostability, the effect of reducing light damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

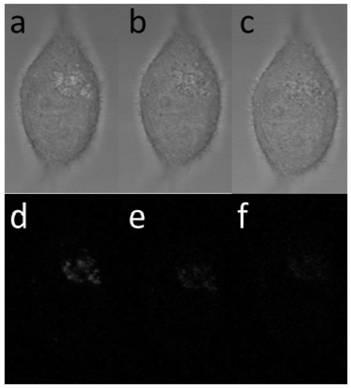

[0027] Water-soluble carbon nitride quantum dots (carbon nitride quantum dots-H 2 O) Preparation

[0028] (1) Preparation of graphite phase carbon nitride CN450

[0029] Place dicyandiamide in a crucible in a muffle furnace, raise the temperature to 450°C at a heating rate of 10°C / min, and keep it warm for 4 hours to obtain light yellow graphite phase carbon nitride, which is ground into powder for later use.

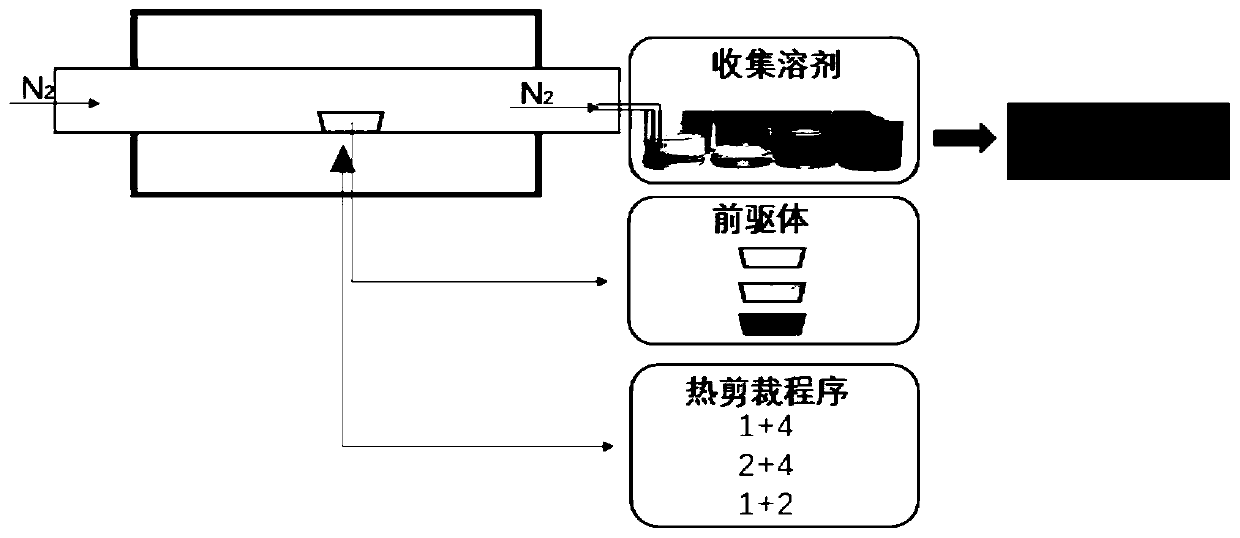

[0030] (2) the graphite phase carbon nitride CN450 powder prepared by step (1) is placed in the ark, the ark is placed in the center of the quartz tube of the tube furnace, the flange gasket is tightened, and the flange gas outlet is externally connected to a 30cm long silicone tube. Insert the other end of the silicone tube into a 100 mL wide-mouth conical flask filled with 50 mL of ultrapure water for the collection solvent, so that the mouth of the silicone tube is completely submerged in the water.

[0031] (3) The tube furnace program is set: in the first stage at ...

Embodiment 2

[0037] Preparation of Carbon Nitride Quantum Dots (Carbon Nitride Quantum Dots-DMF) whose luminescence is 89nm red-shifted than graphite phase carbon nitride CN450.

[0038] (1) Preparation of graphite phase carbon nitride CN450

[0039] Place dicyandiamide in a crucible in a muffle furnace, raise the temperature to 450°C at a heating rate of 10°C / min, and keep it warm for 4 hours to obtain light yellow graphite phase carbon nitride, which is ground into powder for later use.

[0040] (2) the graphite phase carbon nitride CN450 powder prepared by step (1) is placed in the ark, the ark is placed in the center of the quartz tube of the tube furnace, the flange gasket is tightened, and the flange gas outlet is externally connected to a 30cm long silicone tube. Insert the other end of the silicone tube into a 100mL wide-mouth conical flask containing 50mL of the collection solvent N,N-dimethylformamide (DMF), so that the mouth of the silicone tube is completely submerged in N,N-di...

Embodiment 3

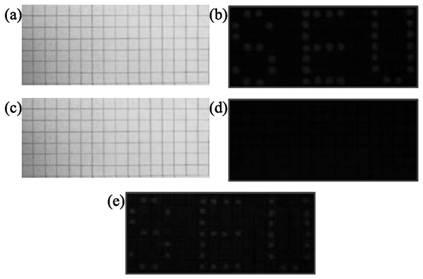

[0048] Preparation of Carbon Nitride Nanoleaf

[0049] (1) Put the dicyandiamide in the ark, place the ark in the center of the quartz tube of the tube furnace, tighten the flange gasket, connect a 30cm-long silicone tube to the air outlet of the flange, and insert the other end of the silicone tube into a 50mL container Put the solvent in a 100mL wide-mouth Erlenmeyer flask of ultrapure water, so that the mouth of the silicone tube is completely submerged in water.

[0050] (2) Set up the tube furnace program: in the first stage, pass nitrogen gas to the tube furnace at a flow rate of 10L / h for 1 hour to empty the air in the quartz tube; The temperature was raised to 680°C at a heating rate of 11°C / min, and kept at 680°C for 4 hours to collect the carbon nitride nanoleaf produced by thermal shearing.

[0051] (3) Ultrasonicate the dispersion liquid of the carbon nitride nano-leaf and other shape materials collected in step (2) for 30 min at a power of 400 W to make it more u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com