Carbon doped graphite phase carbon nitride film and preparation method thereof

A graphite phase carbon nitride and carbon nitride technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of weak photoresponse current and difficult control of film uniformity, and achieve Low cost, excellent photocatalytic activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

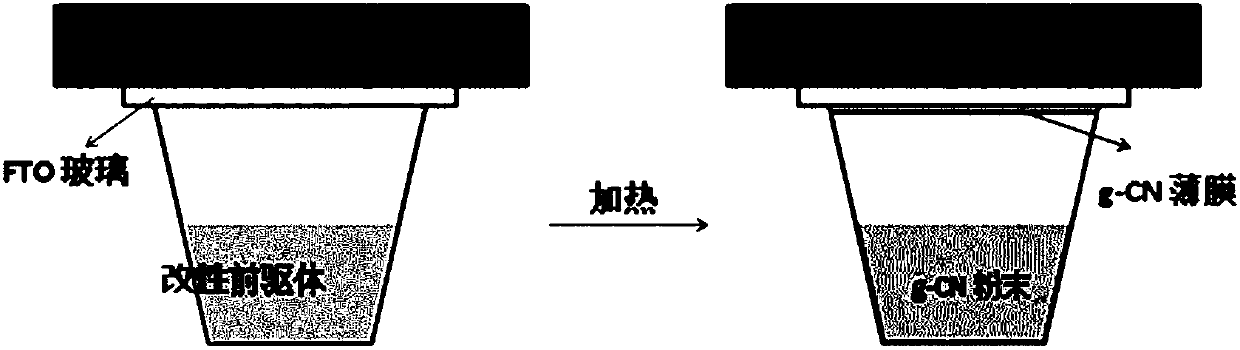

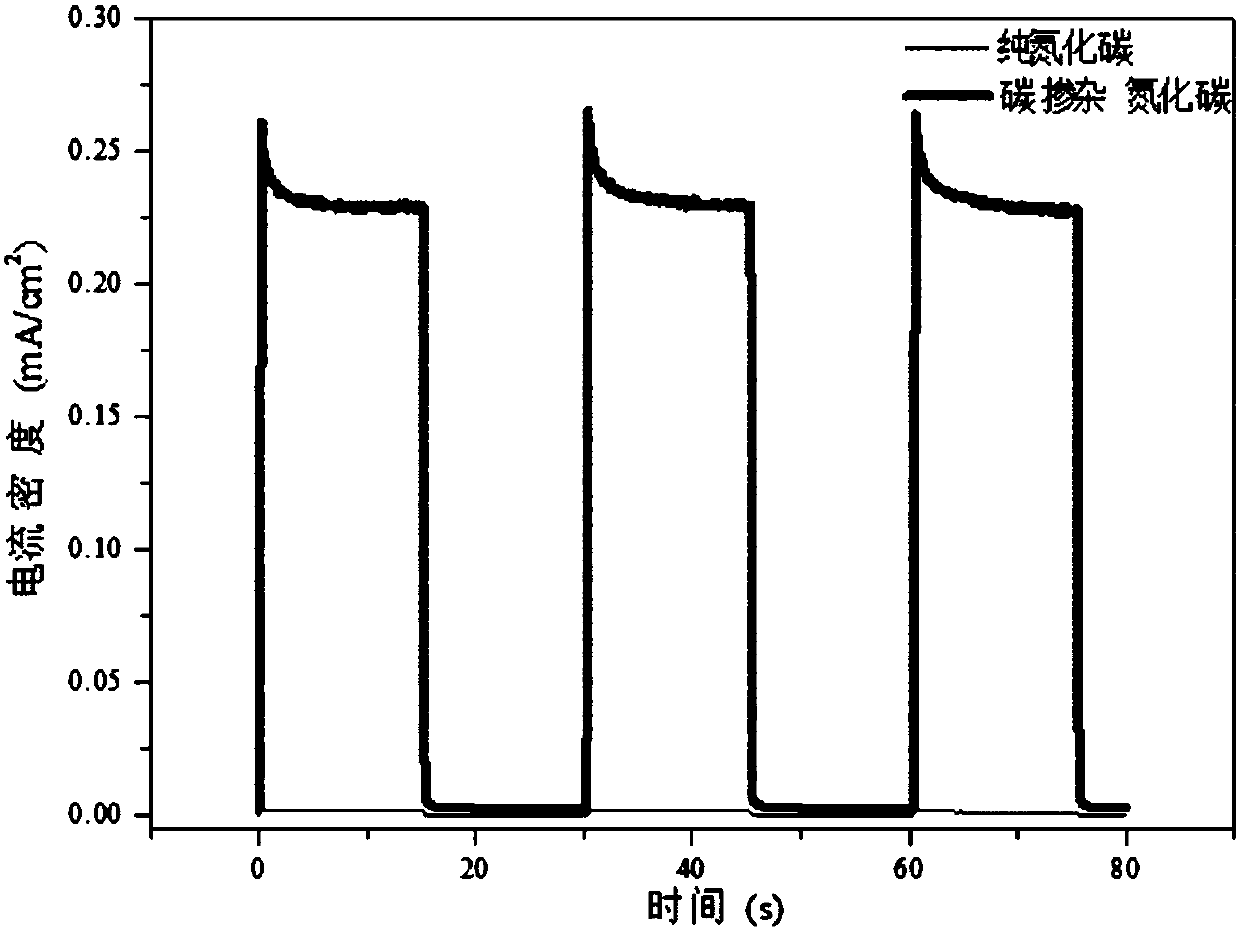

[0029] This embodiment provides a method for preparing a carbon-doped graphite phase carbon nitride film, the process flow is as follows figure 1 shown, including the following steps:

[0030] Mix 9g of urea, 2.4g of formaldehyde solution (aqueous solution with a concentration of 37%) and 150mL of deionized water evenly, heat to 85°C, add 6mL of sulfuric acid solution with a concentration of 2mol / L, react for 10min, and filter and dry to obtain the modified Carbon nitride precursor;

[0031] Take 3g of the modified precursor and put it into the crucible, cover it with 5cm×5cm×0.32cm FTO glass, with the conductive surface facing the inside of the crucible, cover it with a heavy object, transfer the crucible to the muffle furnace at a rate of 3°C / min Raise the temperature to 550° C. for 3 hours, and cool to room temperature after heating to obtain a carbon-doped graphite phase carbon nitride film with a thickness of 200 nm.

[0032] figure 2 It is a scanning electron microgr...

Embodiment 2

[0036] This embodiment provides a method for preparing a carbon-doped graphite phase carbon nitride film, comprising the following steps:

[0037] Mix 6.3g of melamine, 0.8g of formaldehyde solution (aqueous solution with a concentration of 37%) and 150mL of deionized water evenly, heat to 85°C, add 5mL of sulfuric acid solution with a concentration of 2mol / L, react for 10min, filter and dry to obtain the modified carbon nitride precursor;

[0038] Take 3g of the modified precursor and put it into the crucible, cover it with 5cm×5cm×0.32cm FTO glass, with the conductive surface facing the inside of the crucible, cover it with a heavy object, transfer the crucible to the muffle furnace at a rate of 3°C / min Raise the temperature to 550°C for 3 hours, then cool to room temperature after heating to obtain a carbon-doped graphite phase carbon nitride film with a photoresponse current density of 203.2 μA cm -2 , film thickness is 100nm.

Embodiment 3

[0040] This embodiment provides a method for preparing a carbon-doped graphite phase carbon nitride film, comprising the following steps:

[0041] Mix 10g of thiourea, 2.1g of formaldehyde solution (aqueous solution with a concentration of 37%) and 150mL of deionized water evenly, heat to 85°C, add 3mL of sulfuric acid solution with a concentration of 2mol / L, react for 10min, filter and dry to obtain the modified carbon nitride precursor;

[0042] Take 3g of the modified precursor and put it into the crucible, cover it with 5cm×5cm×0.32cm FTO glass, with the conductive surface facing the inside of the crucible, cover it with a heavy object, transfer the crucible to the muffle furnace at a rate of 3°C / min Raise the temperature to 550°C for 3 hours, then cool to room temperature after heating to obtain a carbon-doped graphite phase carbon nitride film with a photoresponse current density of 101.5 μA cm -2 , film thickness is 80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com