Patents

Literature

2458results about "Carbon nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

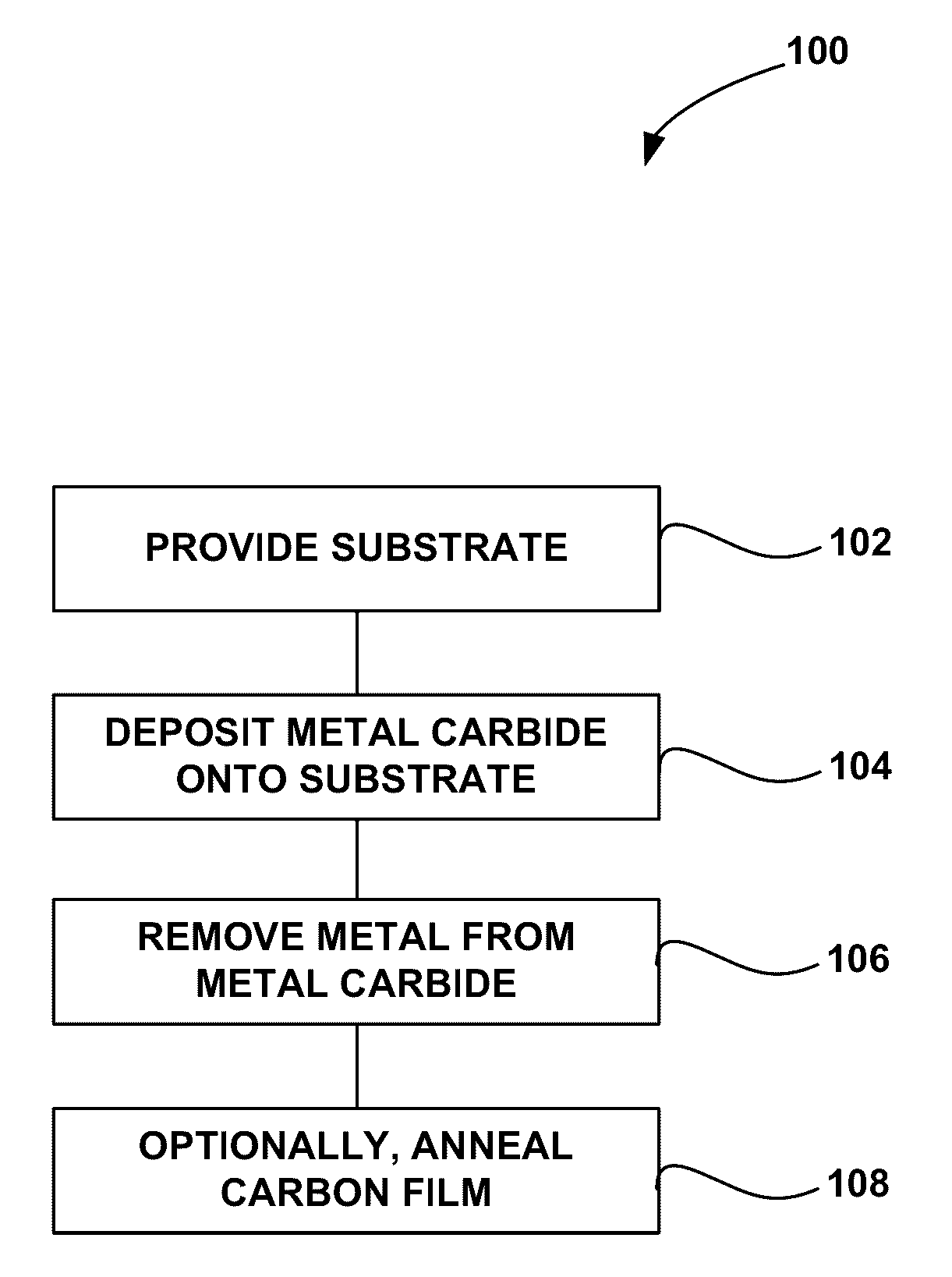

Method for forming conformal carbon films, structures conformal carbon film, and system of forming same

Methods of forming carbon films, structures and devices including the carbon films, and systems for forming the carbon films are disclosed. A method includes depositing a metal carbide film using atomic layer deposition (ALD). Metal from the metal carbide film is removed from the metal carbide film to form a carbon film. Because the films are formed using ALD, the films can be relatively conformal and can have relatively uniform thickness over the surface of a substrate.

Owner:ASM IP HLDG BV

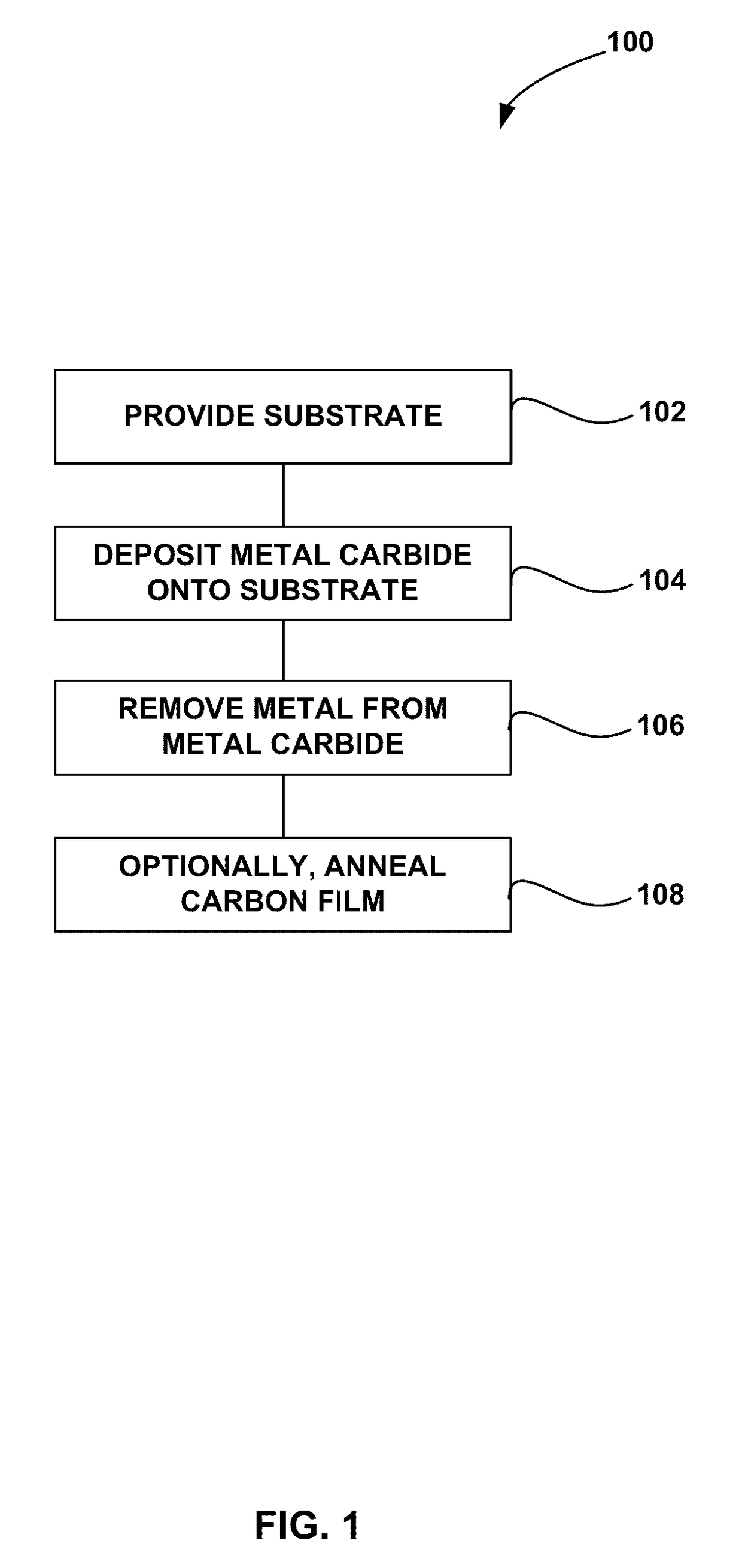

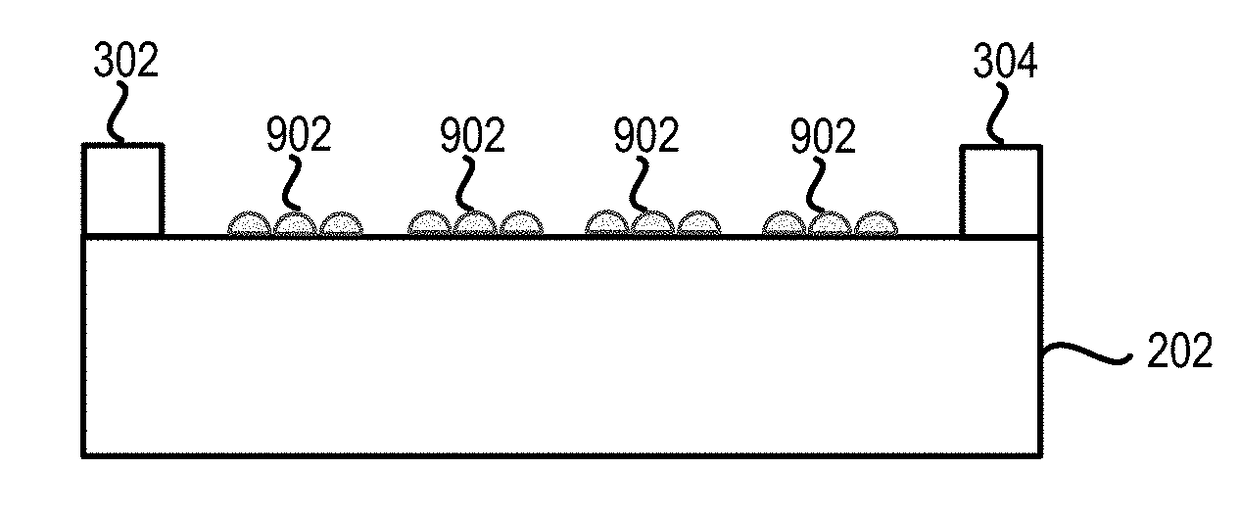

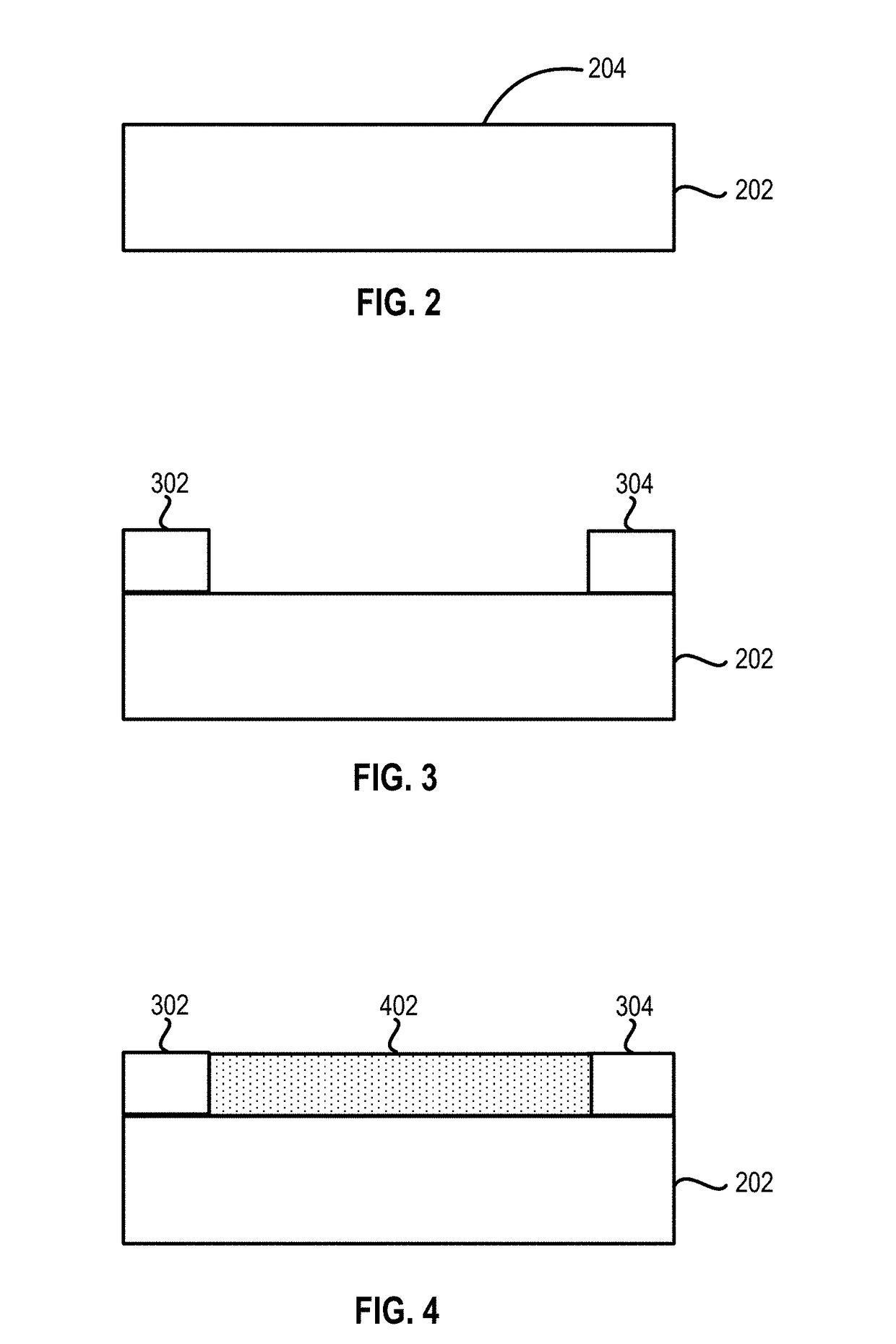

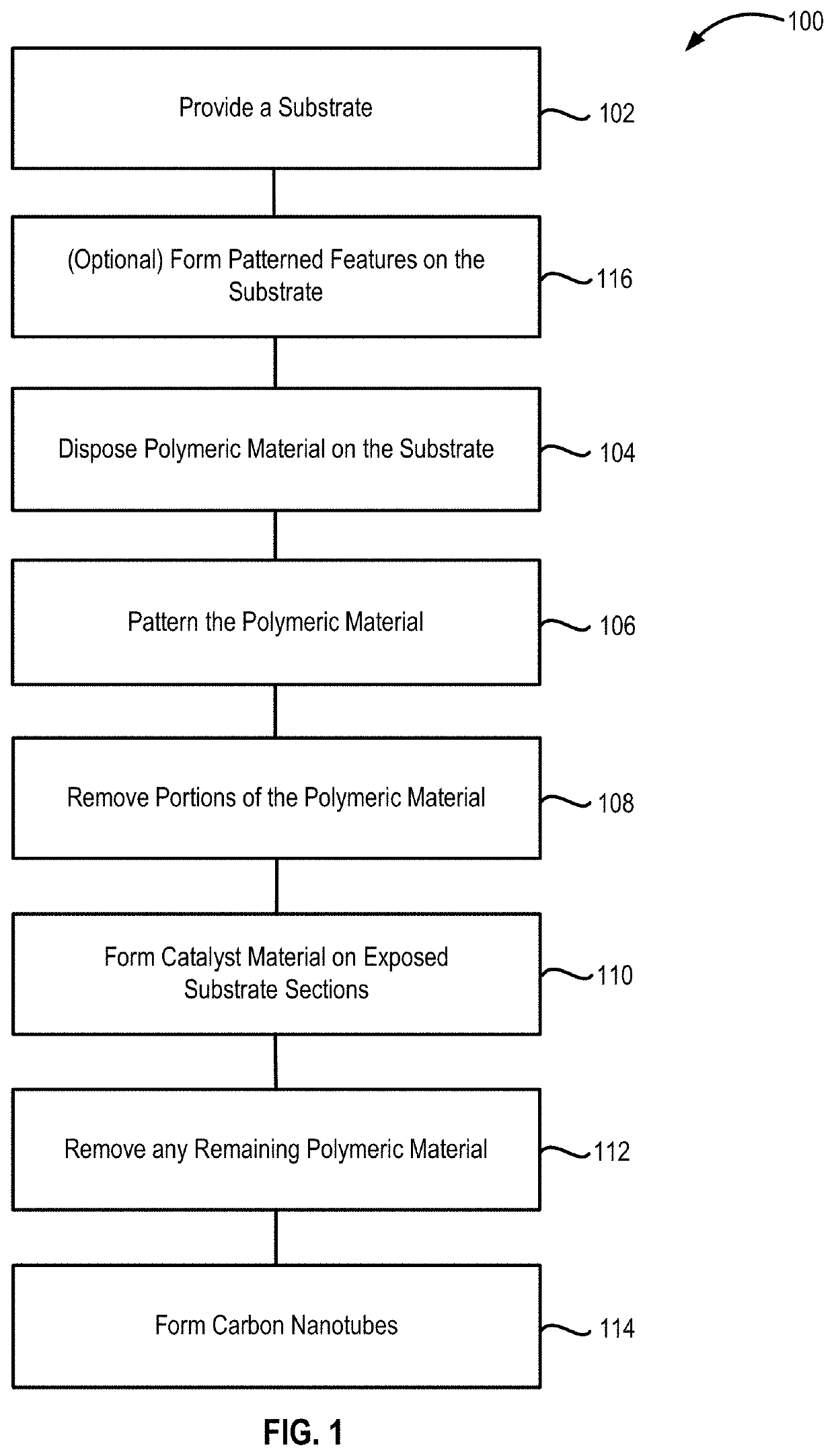

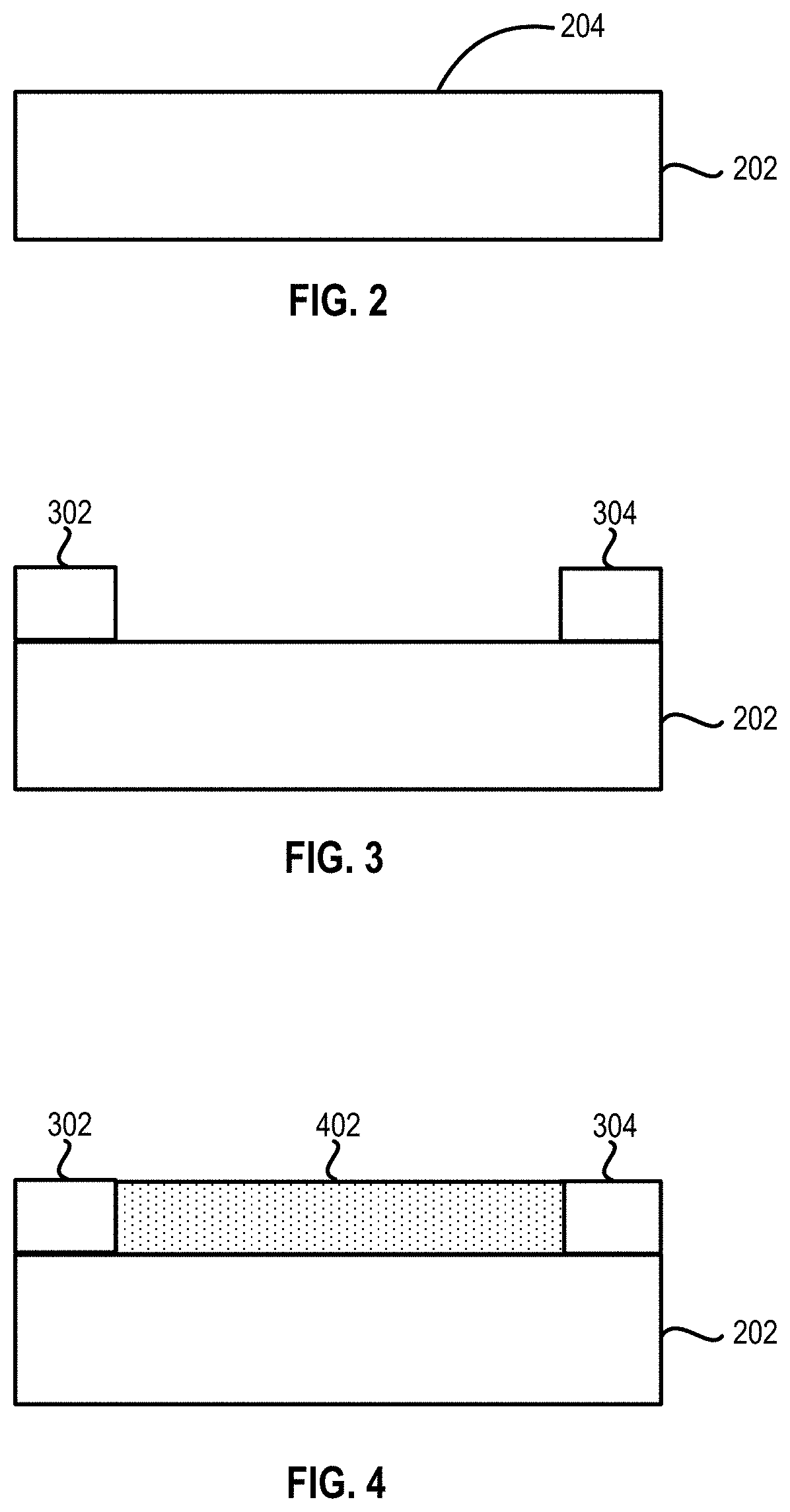

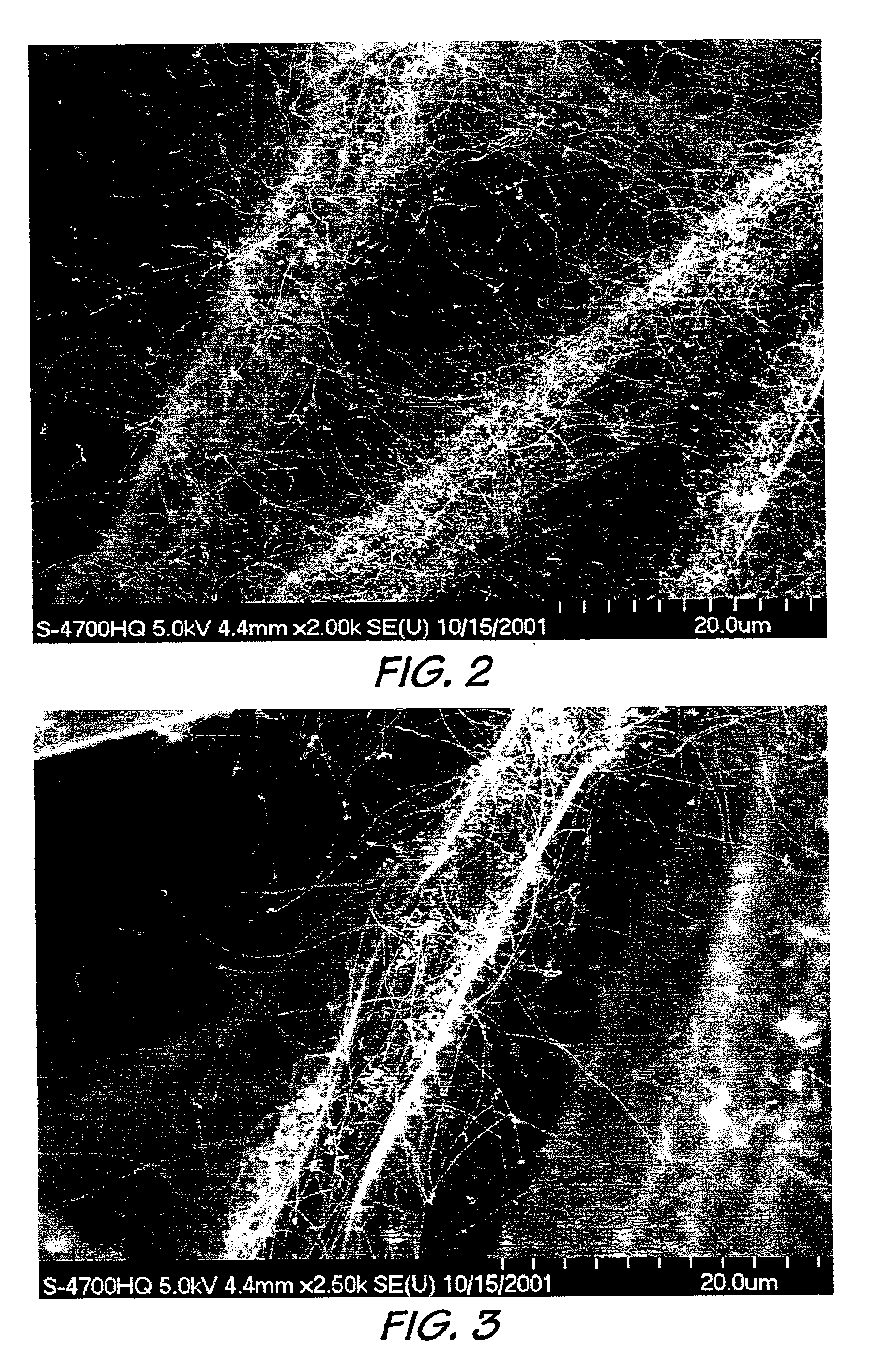

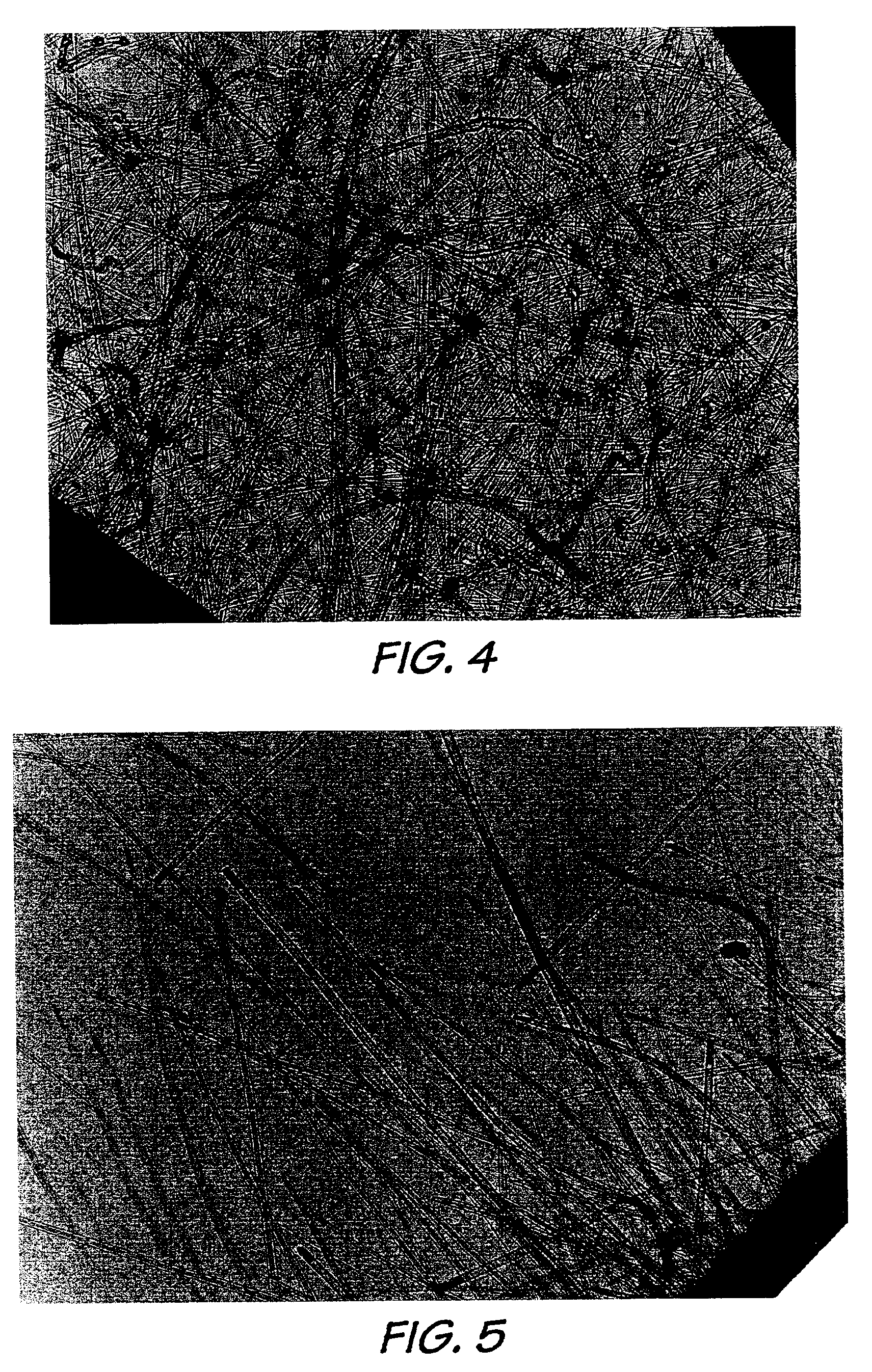

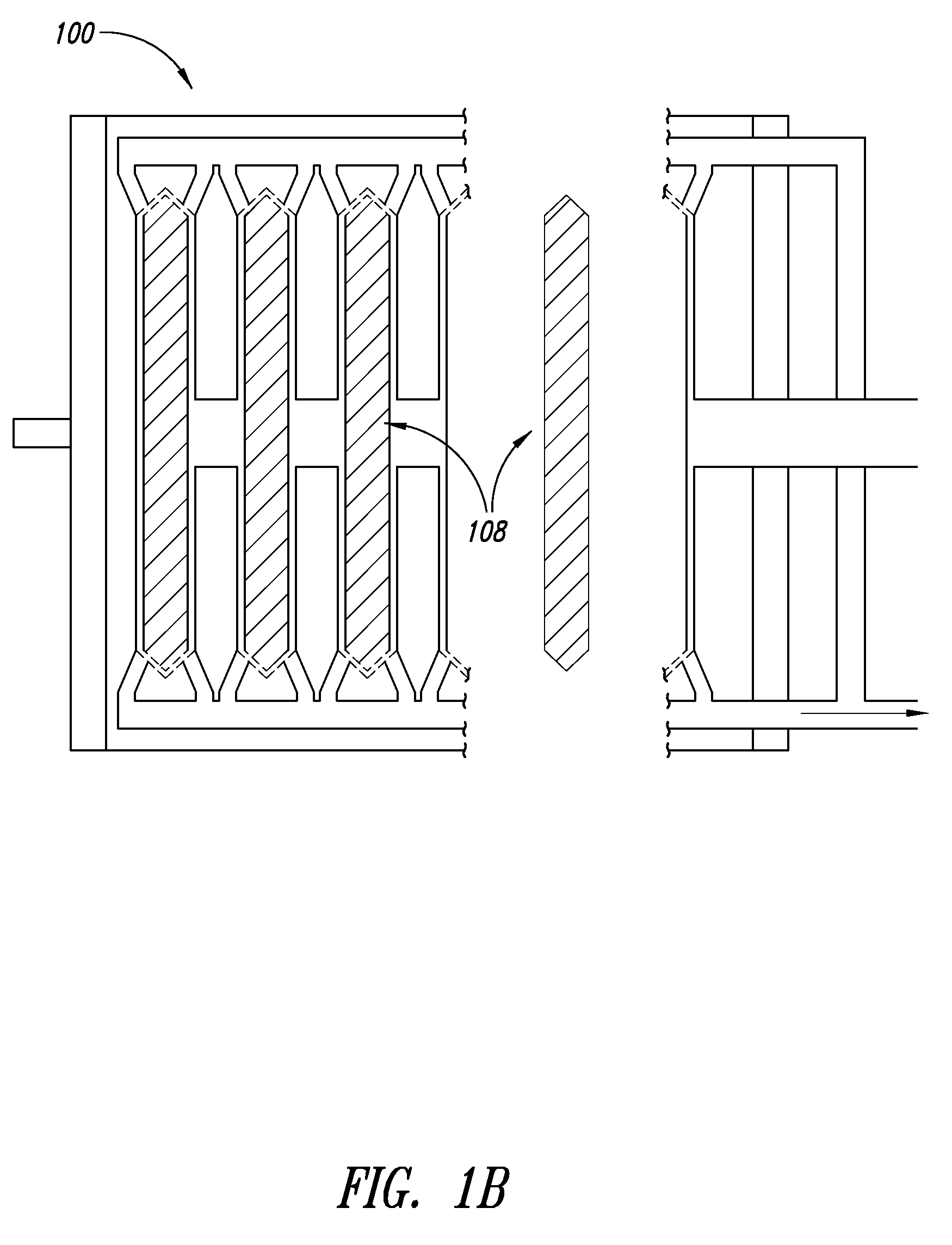

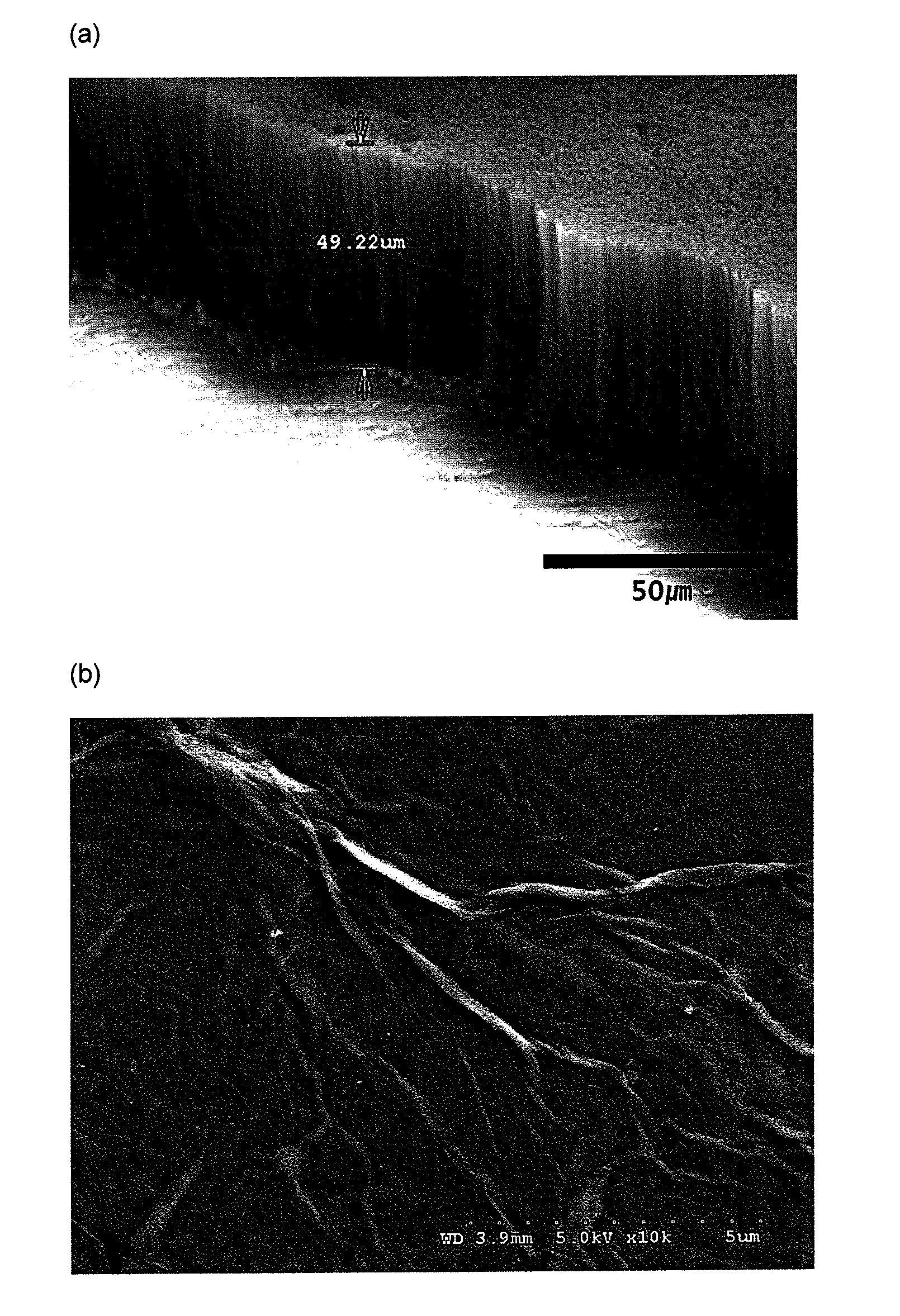

Aligned carbon nanotubes

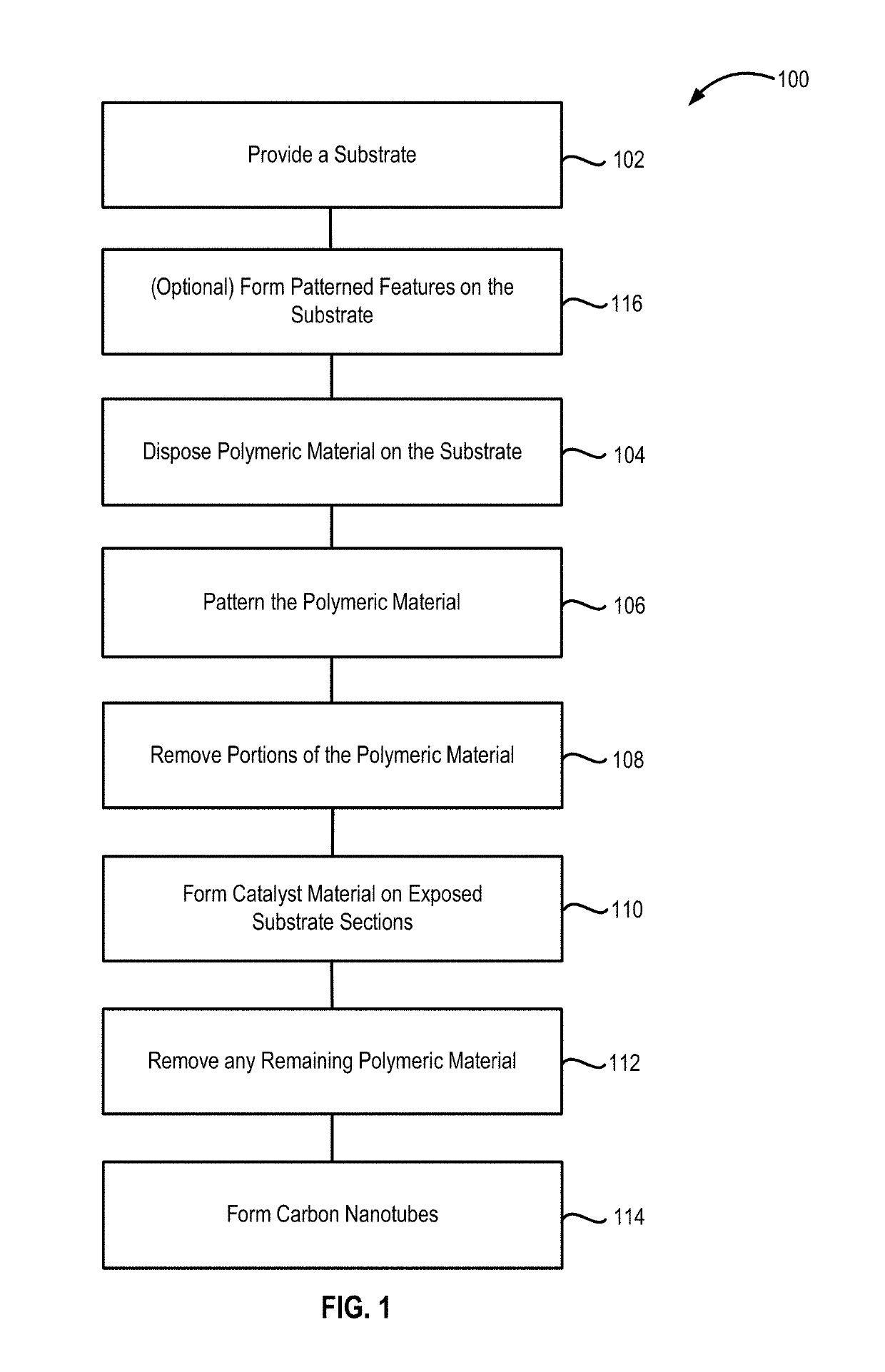

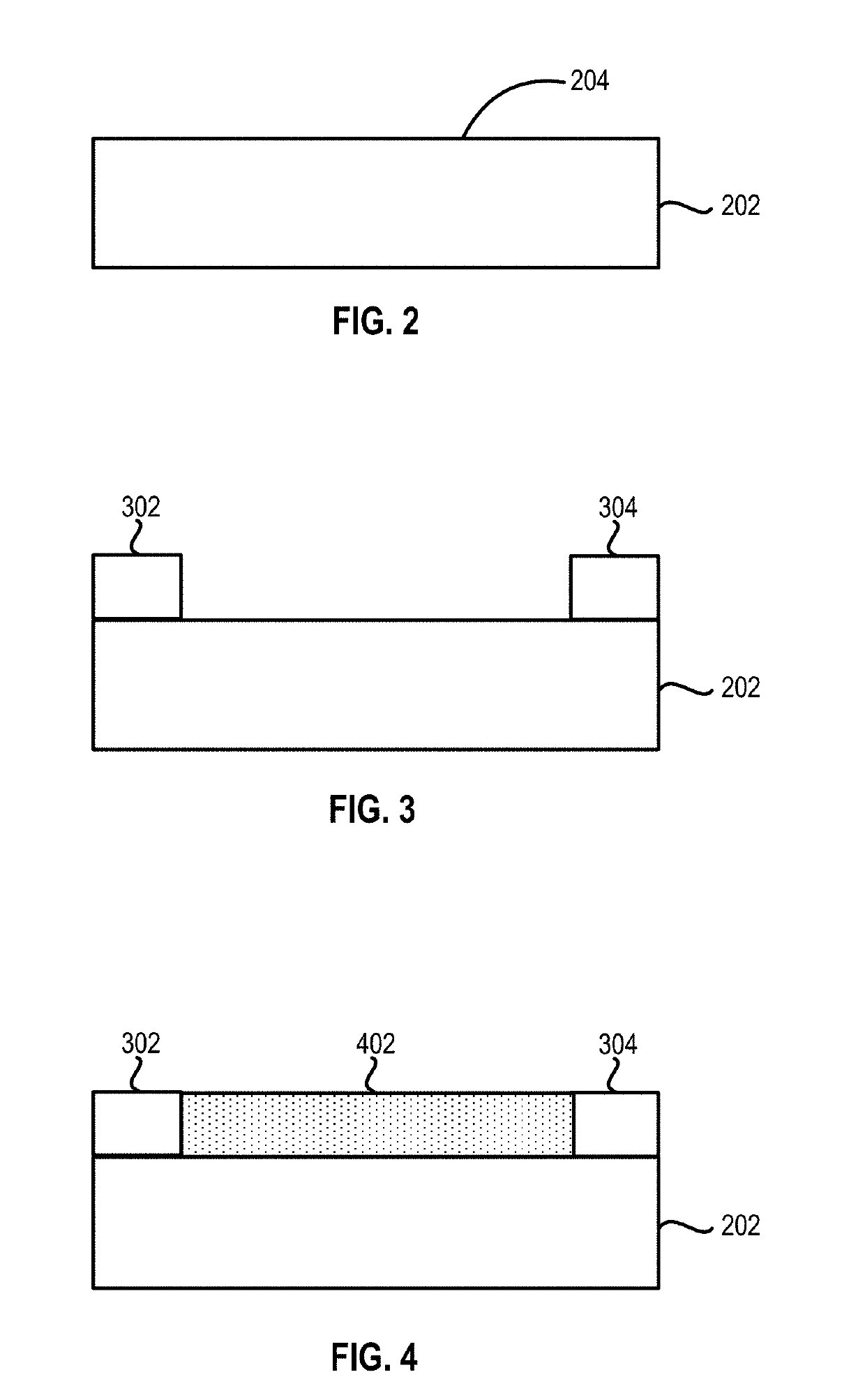

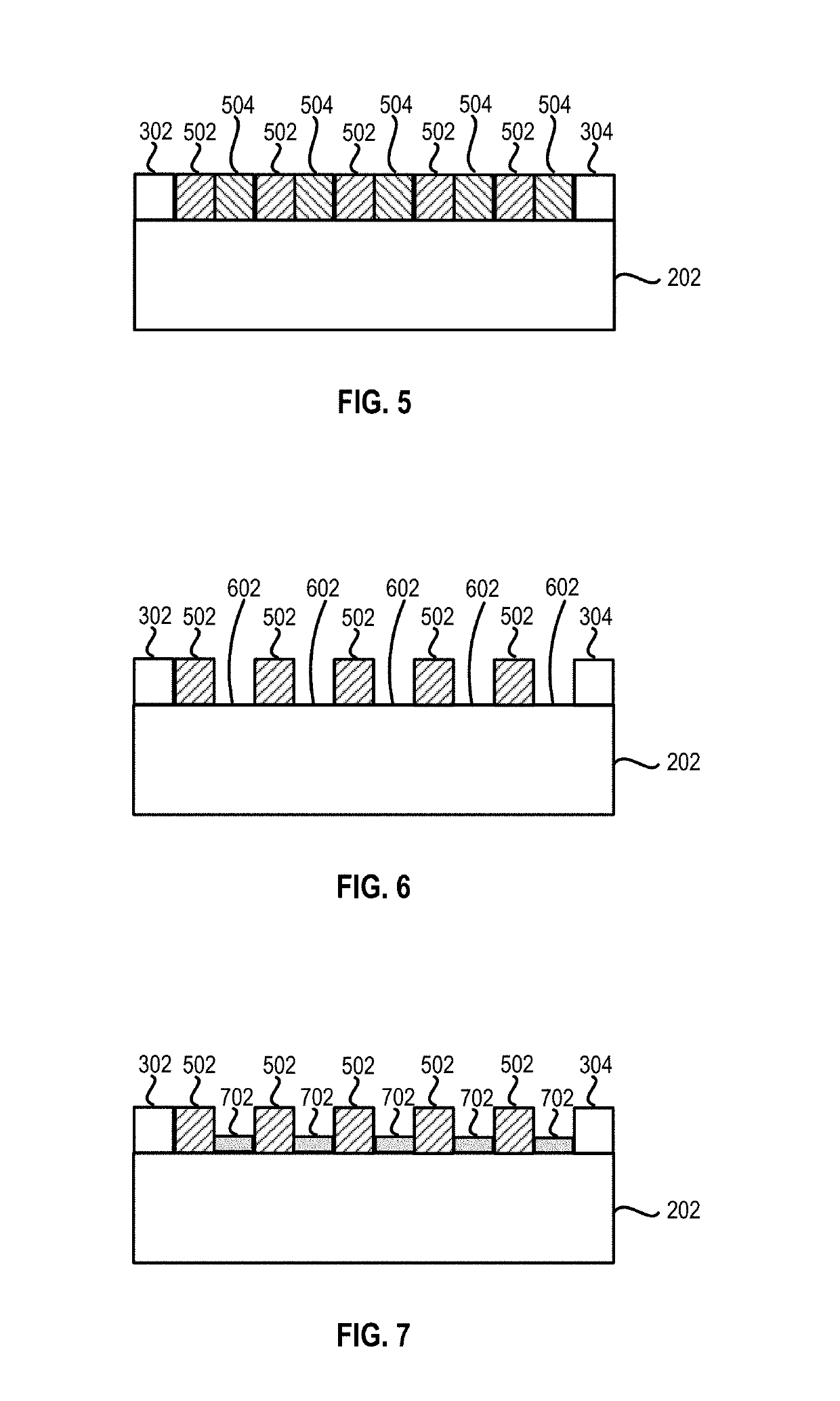

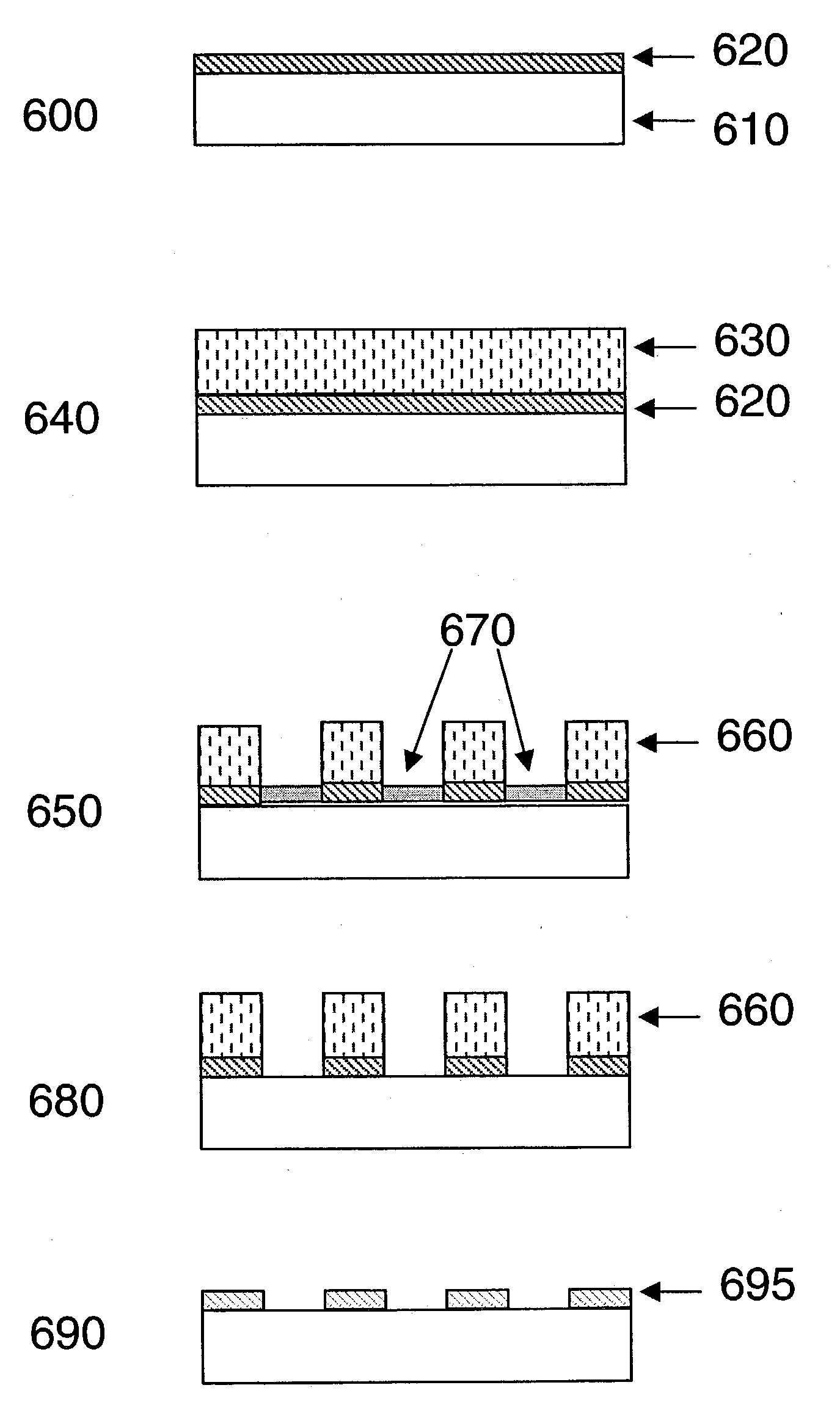

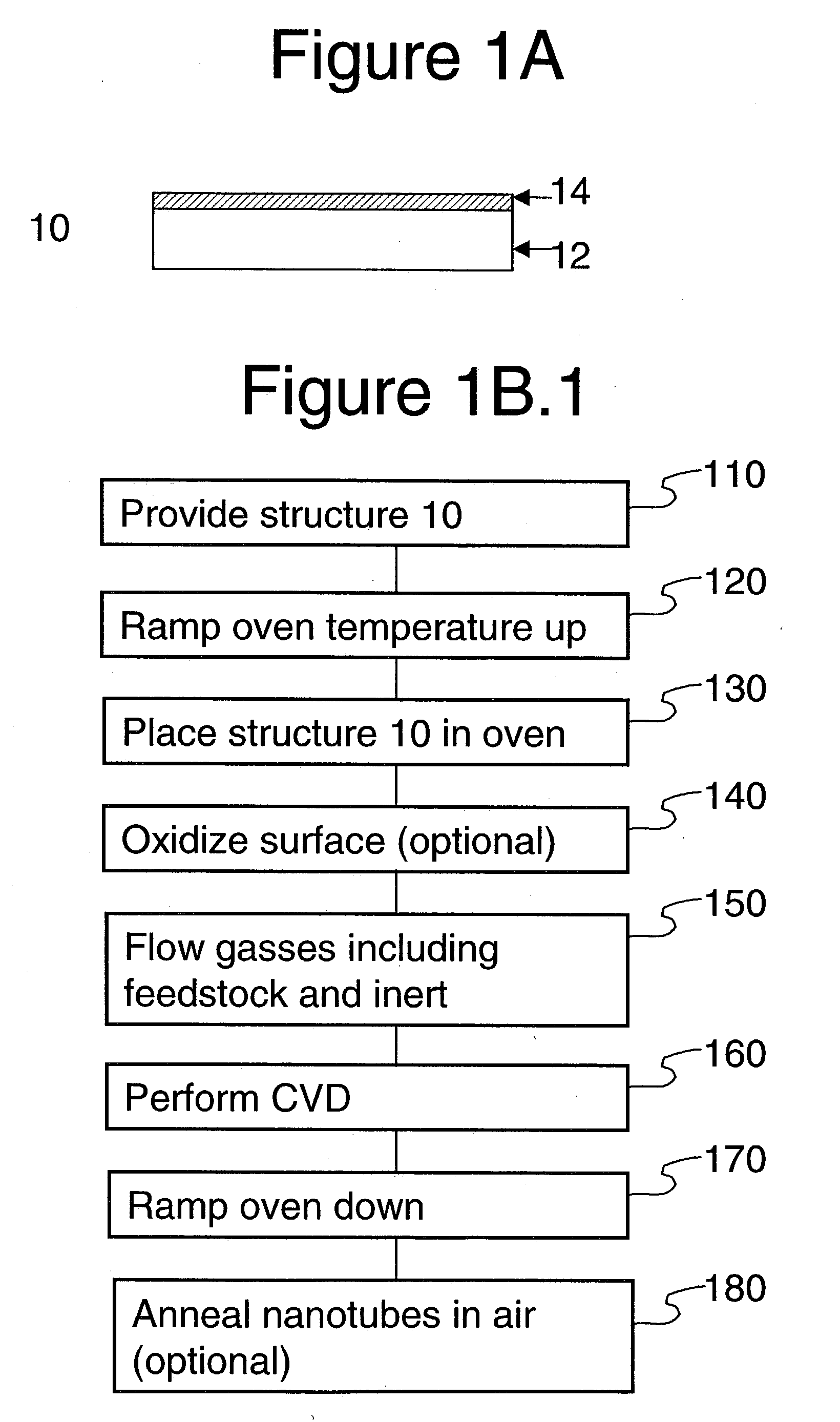

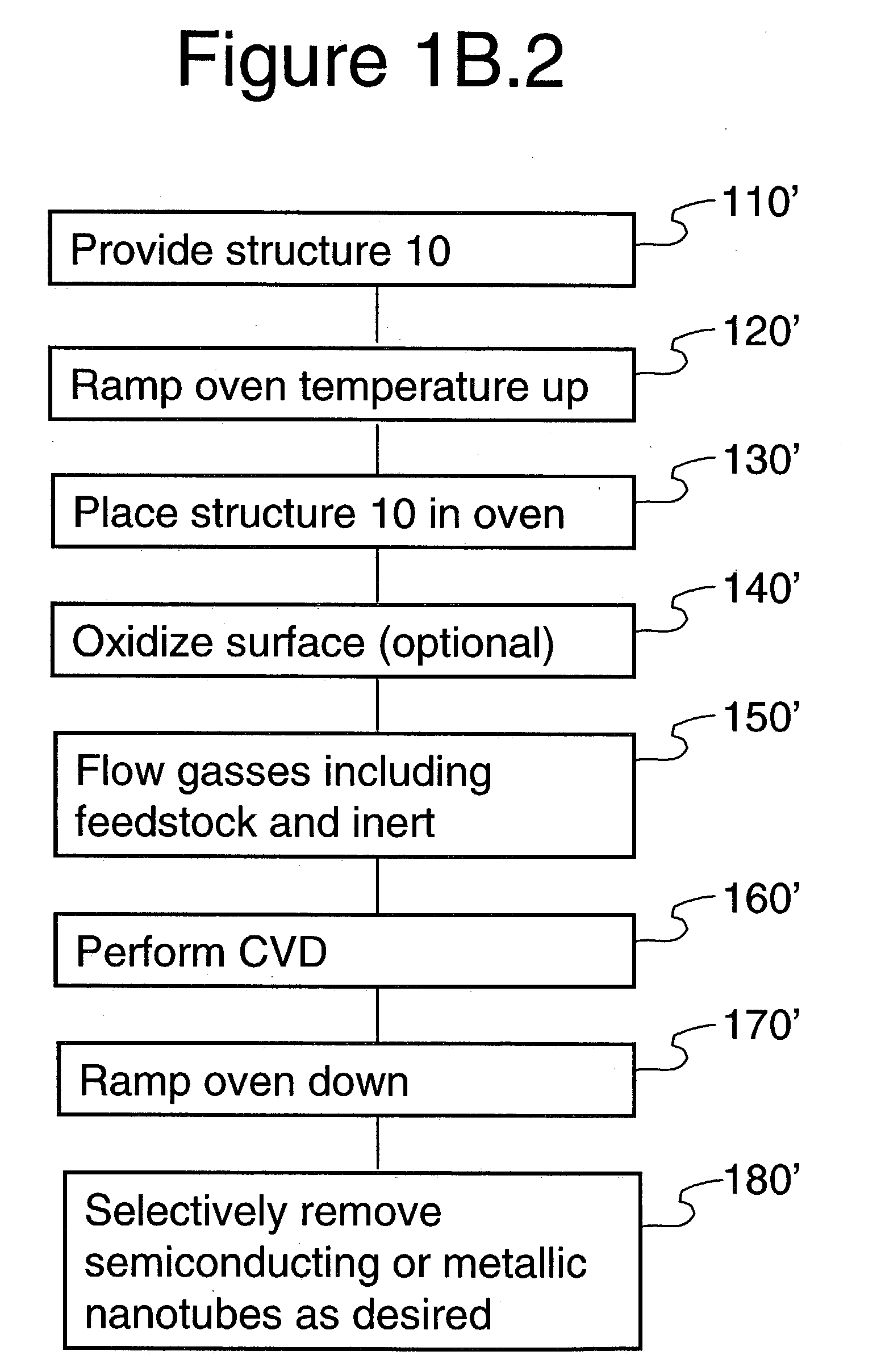

Methods of forming carbon nanotubes and structures and devices including carbon nanotubes are disclosed. Methods of forming the carbon nanotubes include patterning a surface of a substrate with polymeric material, removing portions of the polymeric material to form exposed substrate surface sections, and forming the carbon nanotubes on the exposed substrate sections.

Owner:ASM IP HLDG BV

Aligned carbon nanotubes

Methods of forming carbon nanotubes and structures and devices including carbon nanotubes are disclosed. Methods of forming the carbon nanotubes include patterning a surface of a substrate with polymeric material, removing portions of the polymeric material to form exposed substrate surface sections, and forming the carbon nanotubes on the exposed substrate sections.

Owner:ASM IP HLDG BV

Aligned carbon nanotubes

Methods of forming carbon nanotubes and structures and devices including carbon nanotubes are disclosed. Methods of forming the carbon nanotubes include patterning a surface of a substrate with polymeric material, removing portions of the polymeric material to form exposed substrate surface sections, and forming the carbon nanotubes on the exposed substrate sections.

Owner:ASM IP HLDG BV

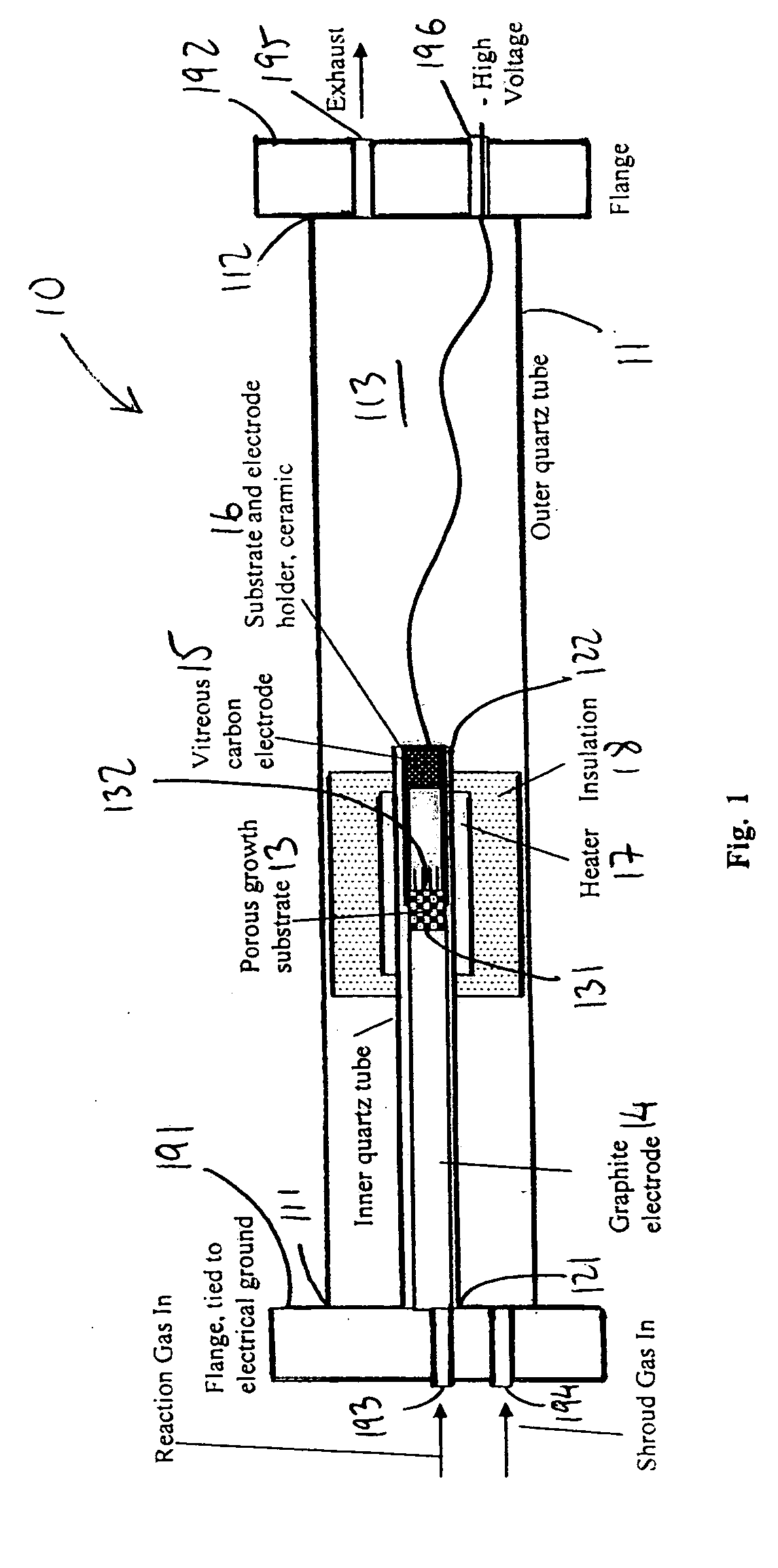

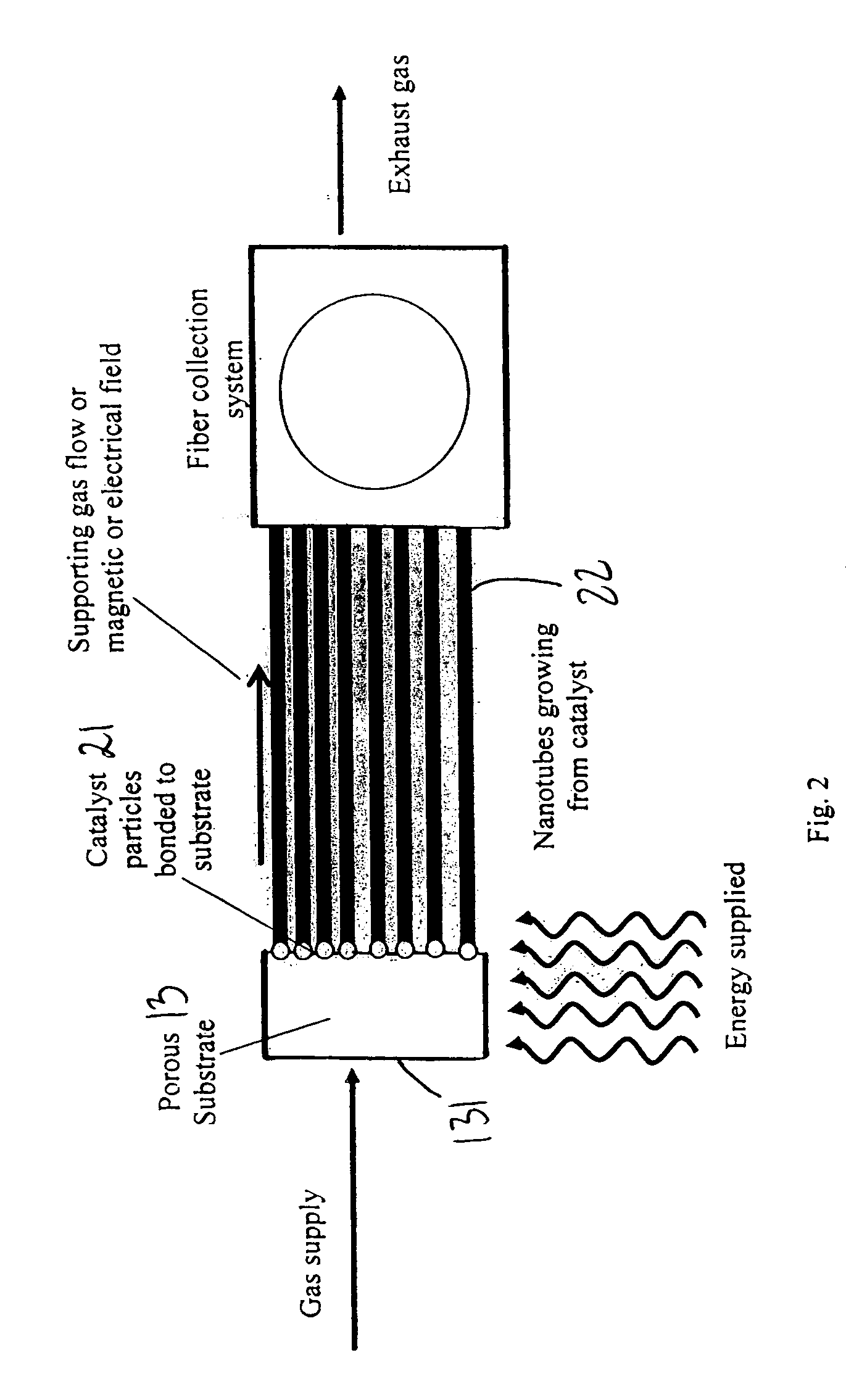

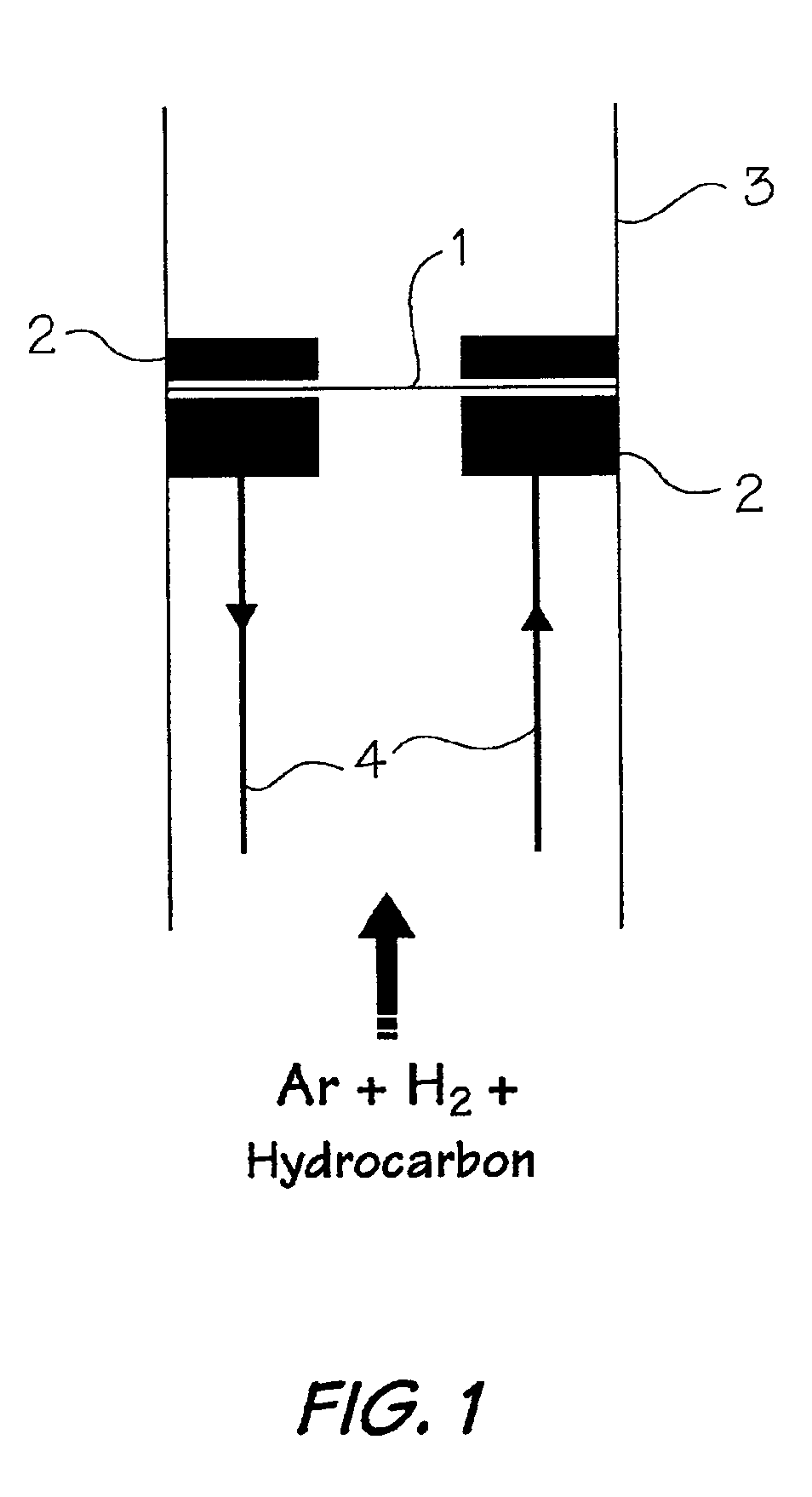

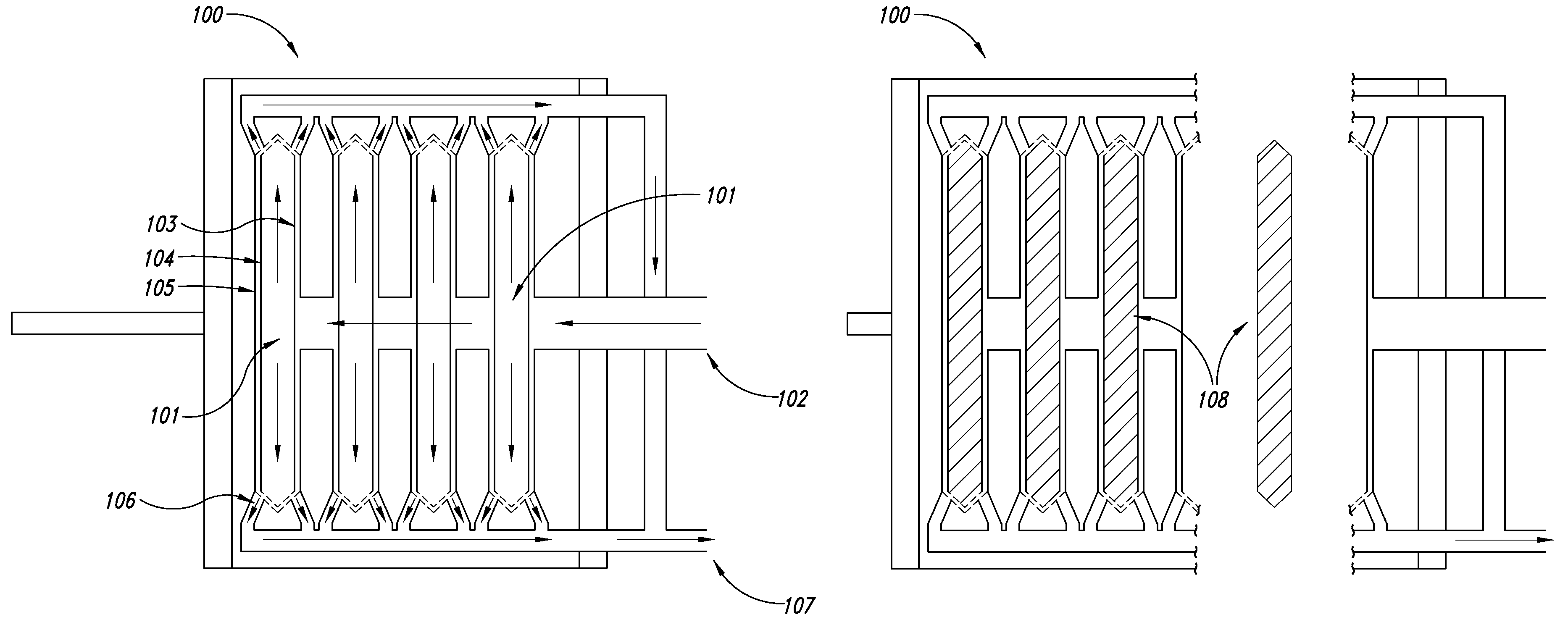

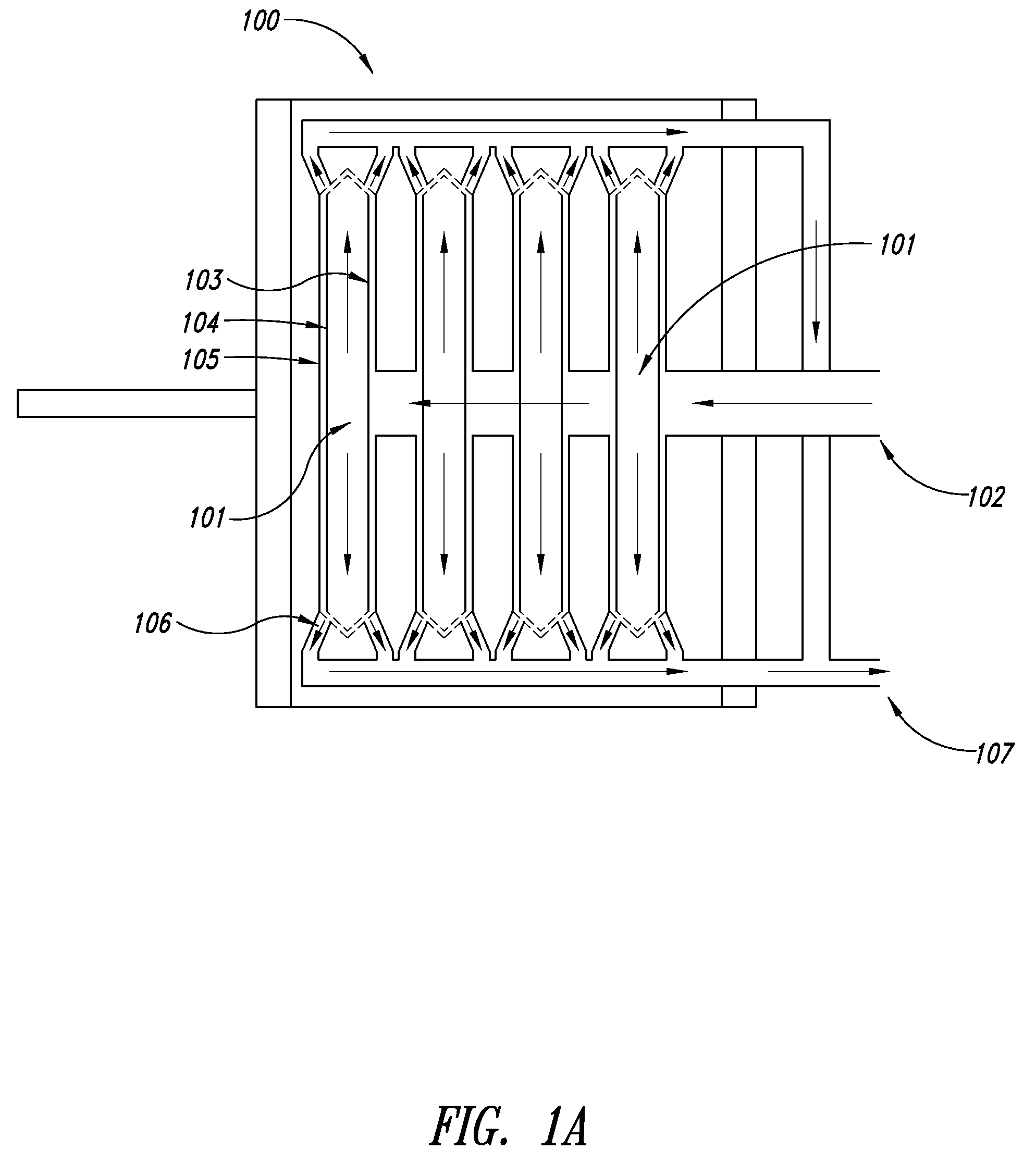

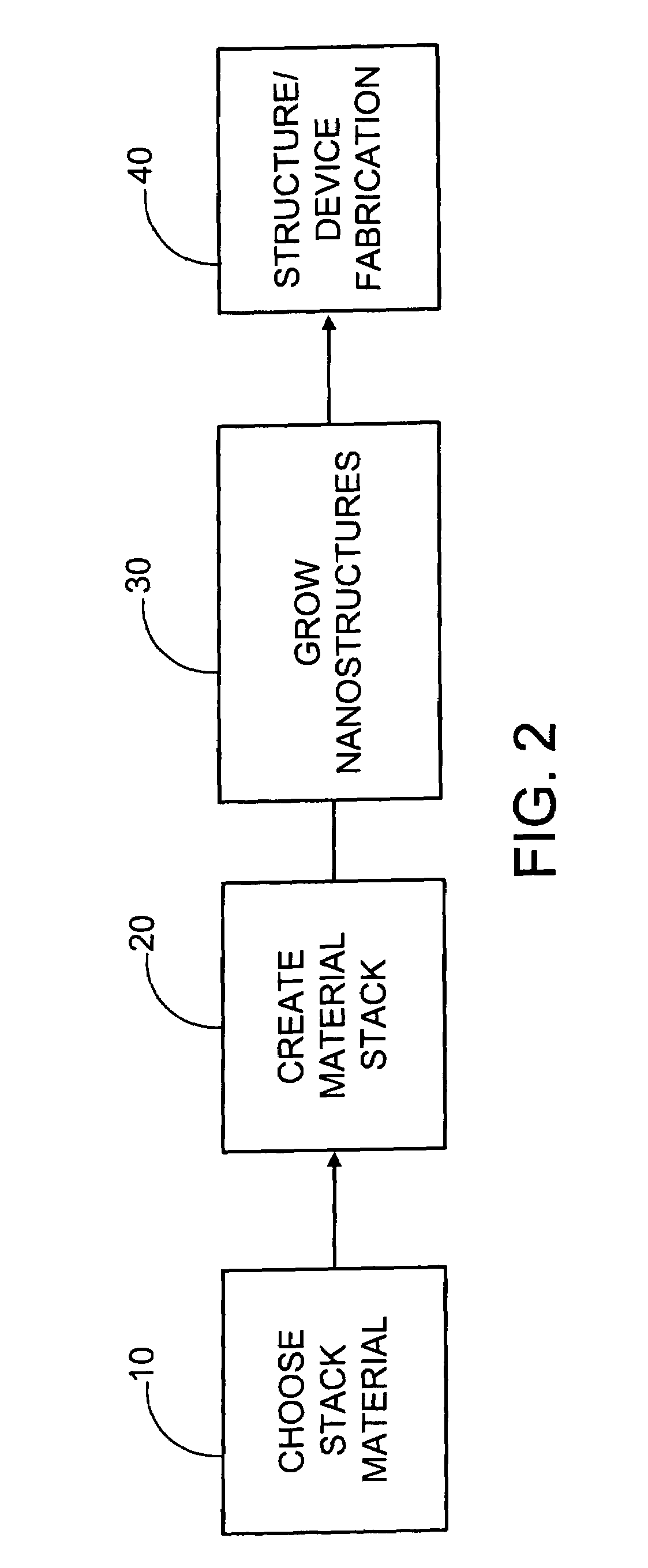

Systems and methods for synthesis of extended length nanostructures

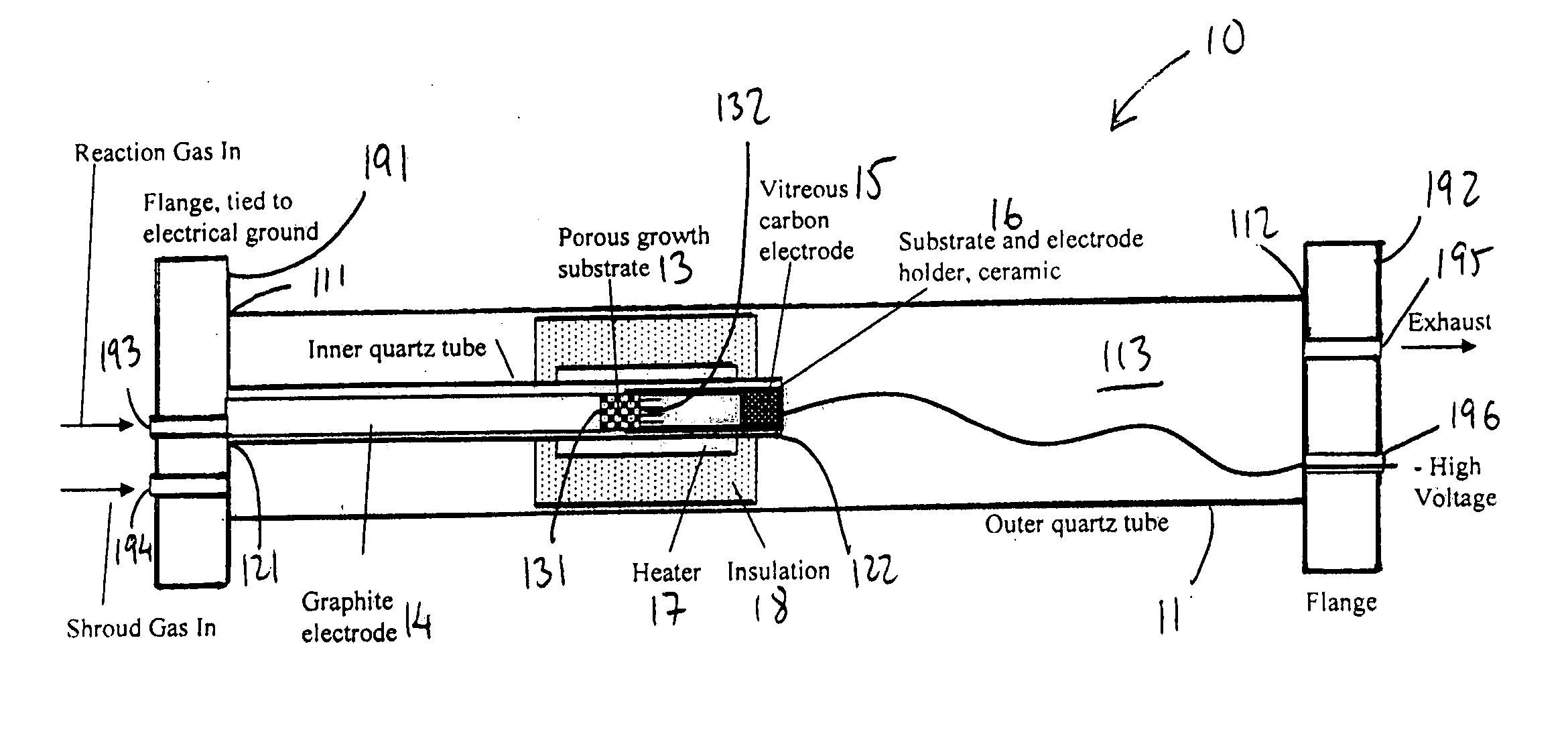

ActiveUS20050170089A1Equally distributedMaterial nanotechnologyRadiation applicationsPorous substrateGas phase

A system for synthesizing nanostructures using chemical vapor deposition (CVD) is provided. The system includes a housing, a porous substrate within the housing, and on a downstream surface of the substrate, a plurality of catalyst particles from which nanostructures can be synthesized upon interaction with a reaction gas moving through the porous substrate. Electrodes may be provided to generate an electric field to support the nanostructures during growth. A method for synthesizing extended length nanostructures is also provided. The nanostructures are useful as heat conductors, heat sinks, windings for electric motors, solenoid, transformers, for making fabric, protective armor, as well as other applications.

Owner:NANCOMP TECHNOLOGIES INC

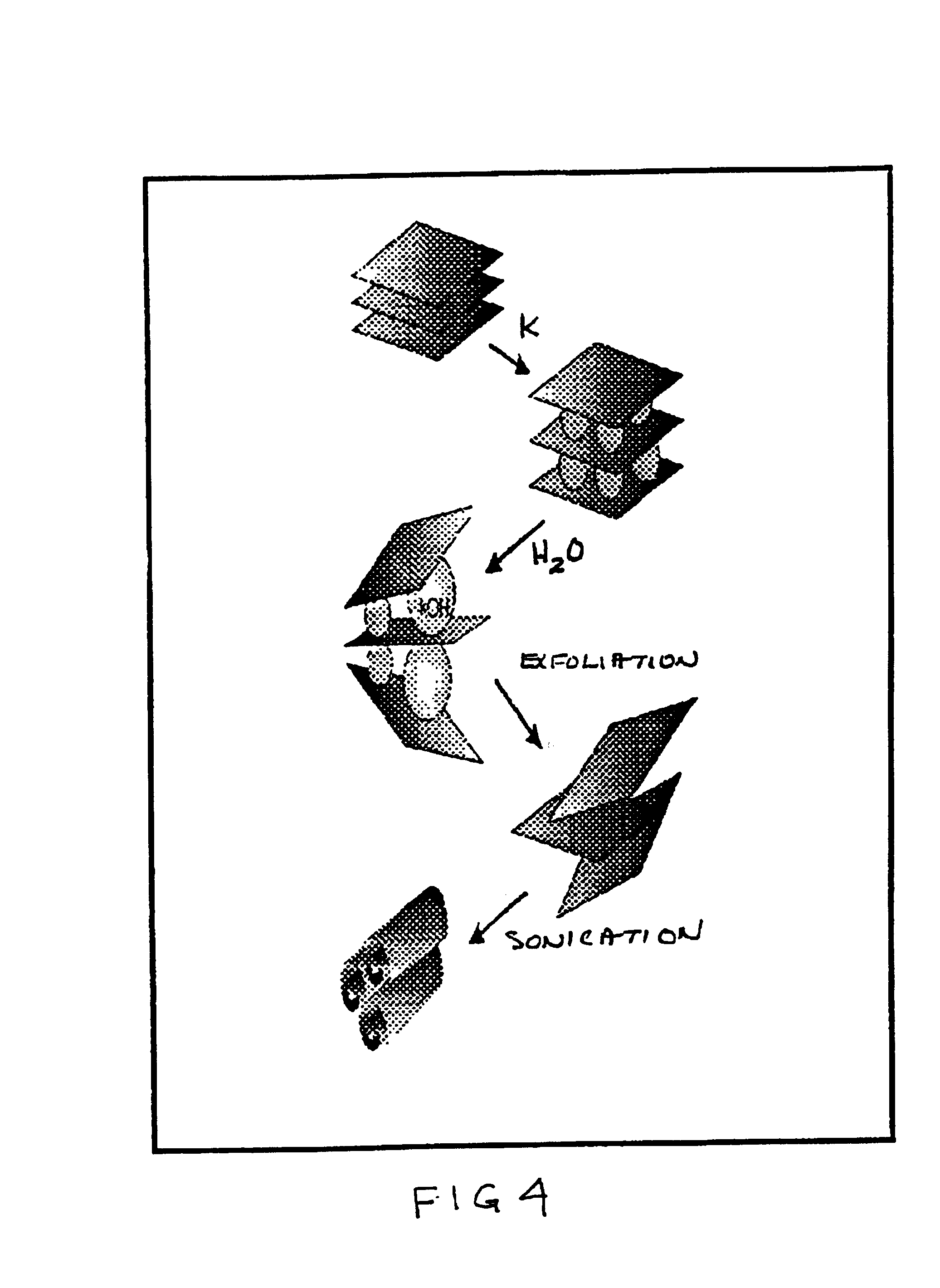

Chemical manufacture of nanostructured materials

InactiveUS6872330B2High strengthIncrease volumeMaterial nanotechnologyOxide/hydroxide preparationInorganic compoundTe element

A low temperature chemical route to efficiently produce nanomaterials is described. The nanomaterials are synthesized by intercalating ions into layered compounds, exfoliating to create individual layers and then sonicating to produce nanotubes, nanorods, nanoscrolls and / or nanosheets. It is applicable to various different layered inorganic compounds (for example, bismuth selenides / tellurides, graphite, and other metal complexes, particularly transition metal dichalcogenides compounds including oxygen, sulfur, tellurium or selenium).

Owner:RGT UNIV OF CALIFORNIA

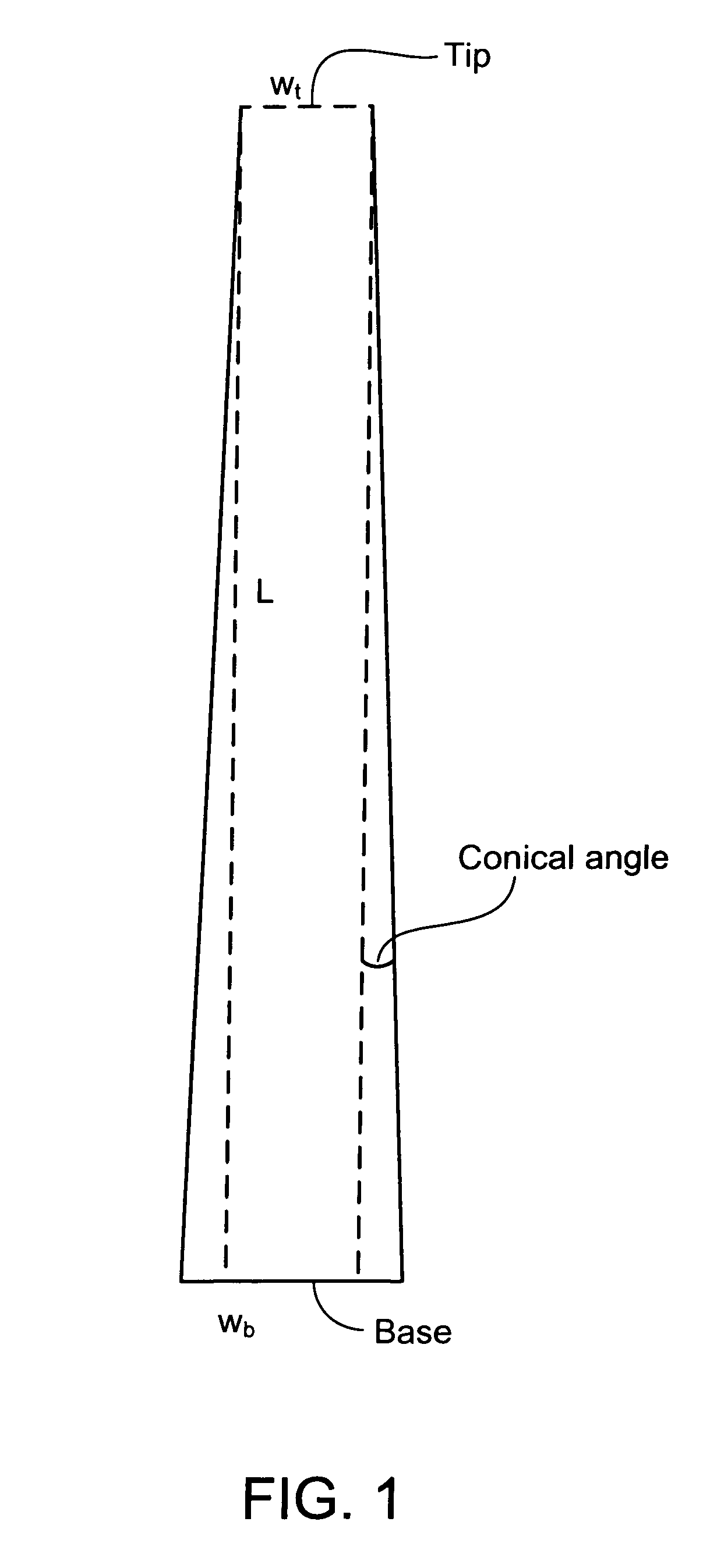

Method for providing nano-structures of uniform length

This invention relates to the field of nanotechnology. Specifically the invention describes a method for cutting a multiplicity of nano-structures to uniform dimensions of length, length and width, or area, or to a specific distribution of lengths or area using various cutting techniques.

Owner:EI DU PONT DE NEMOURS & CO

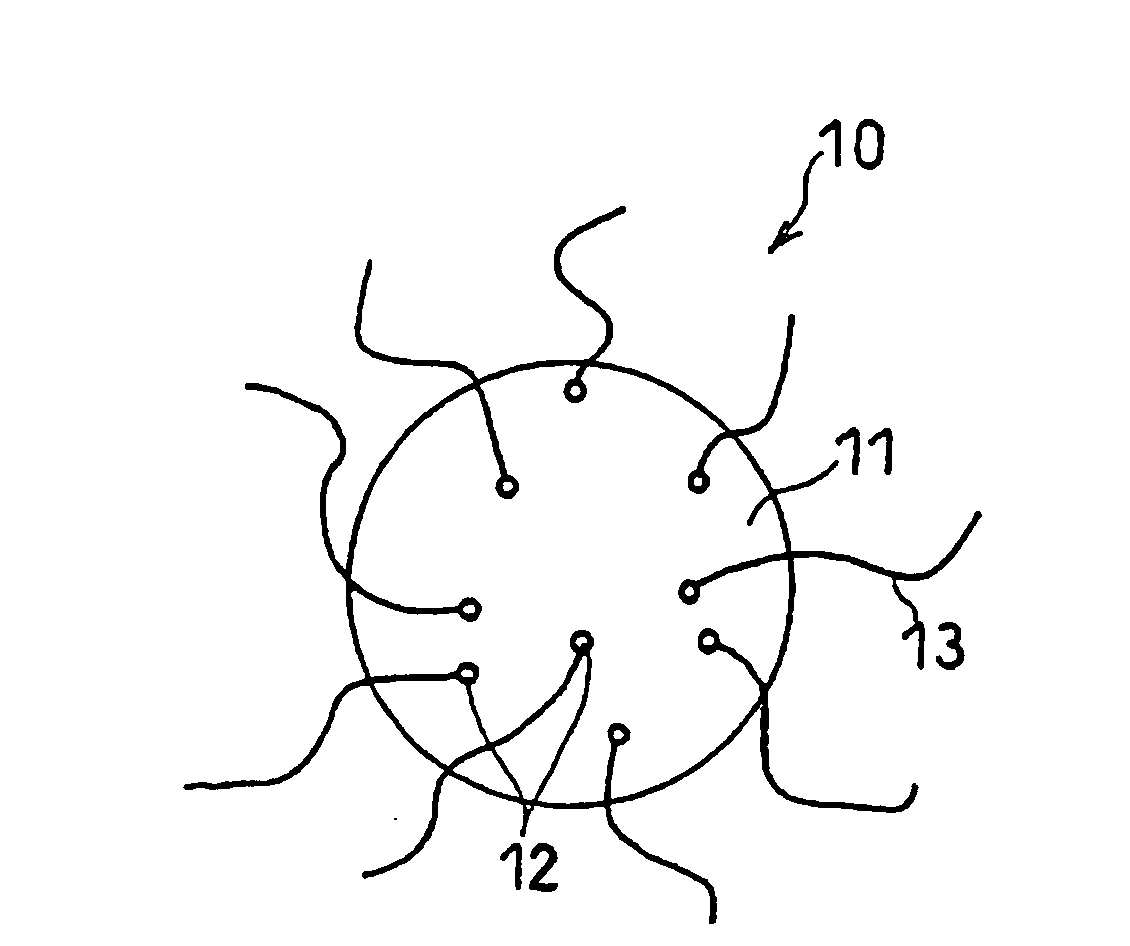

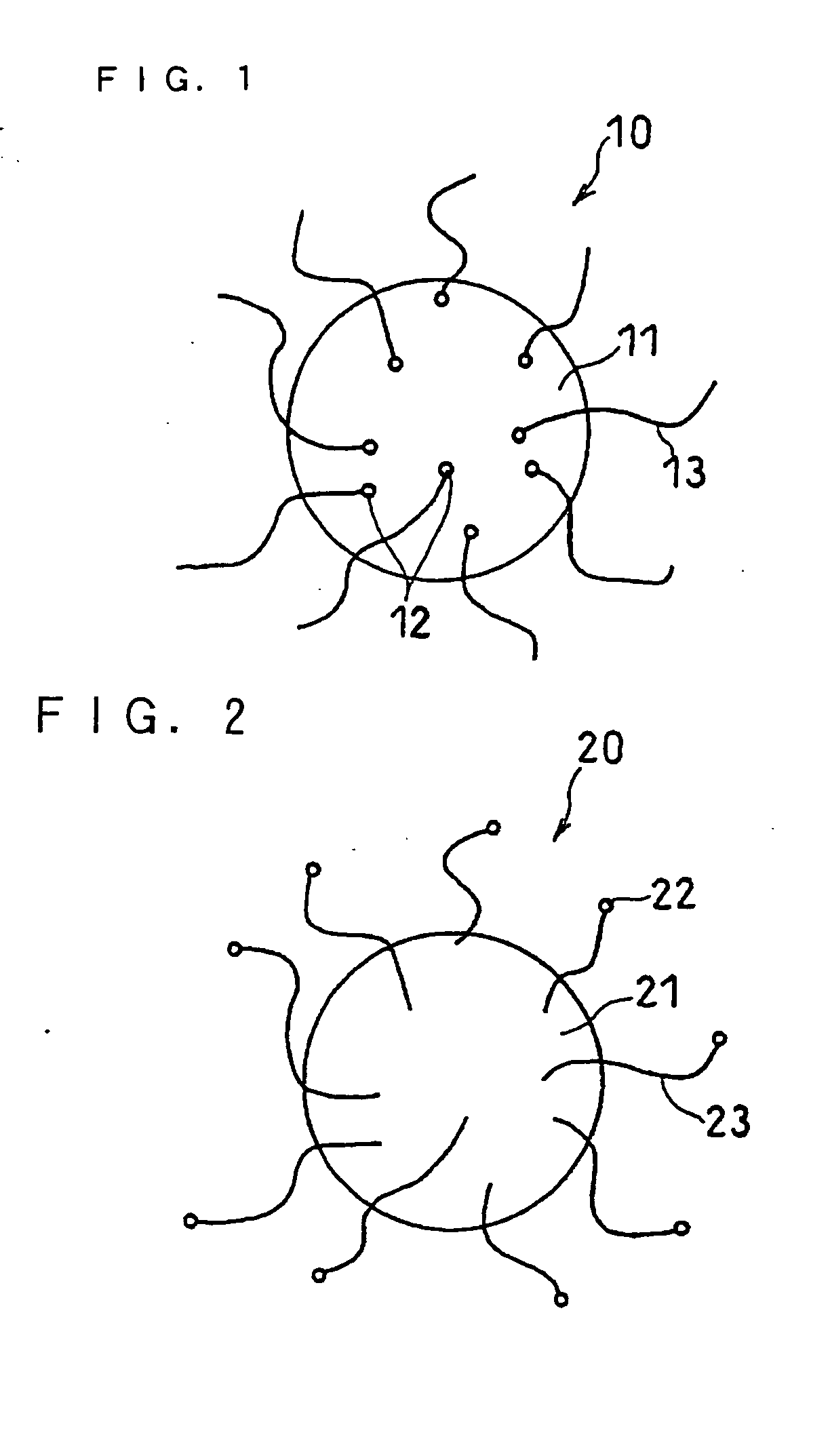

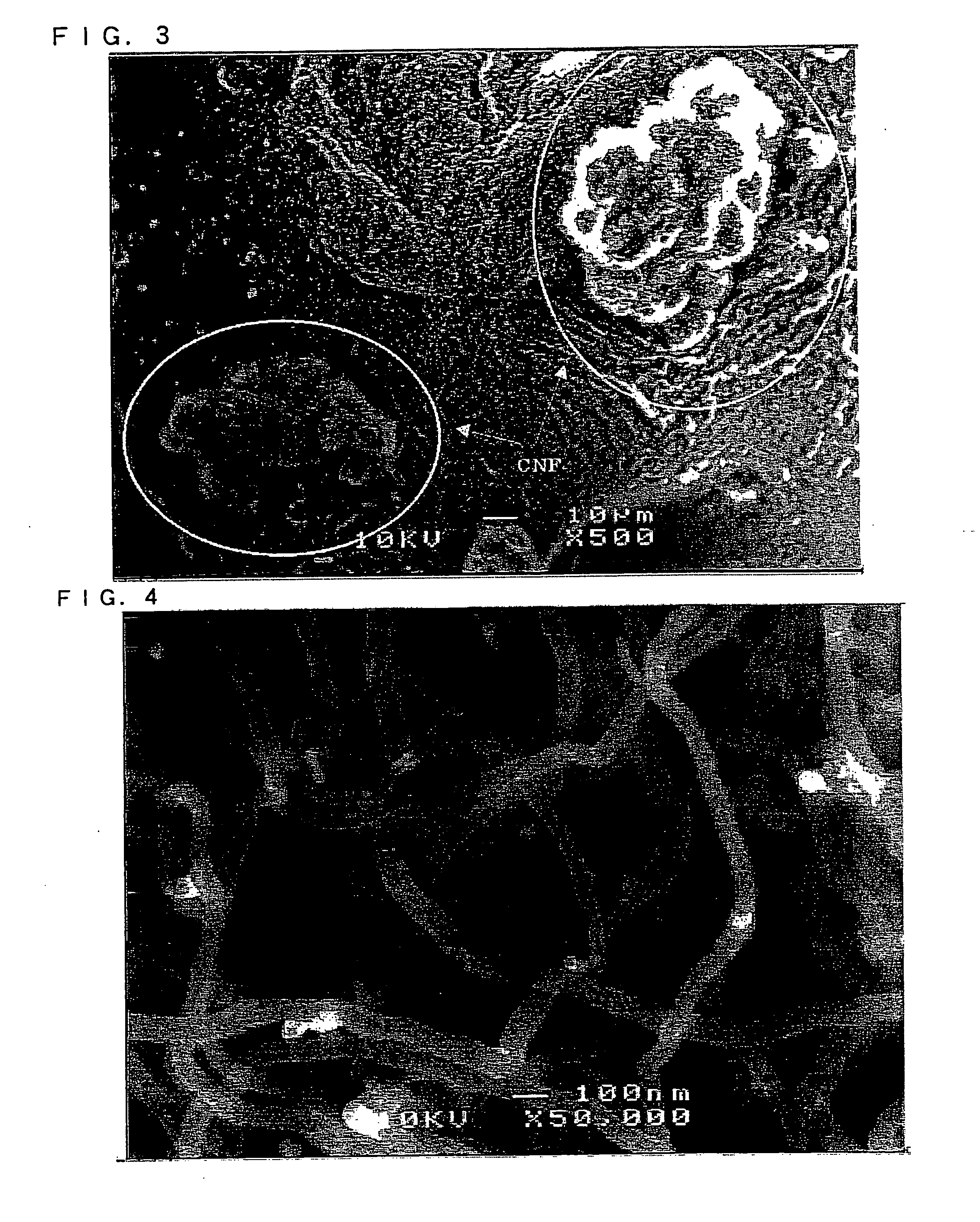

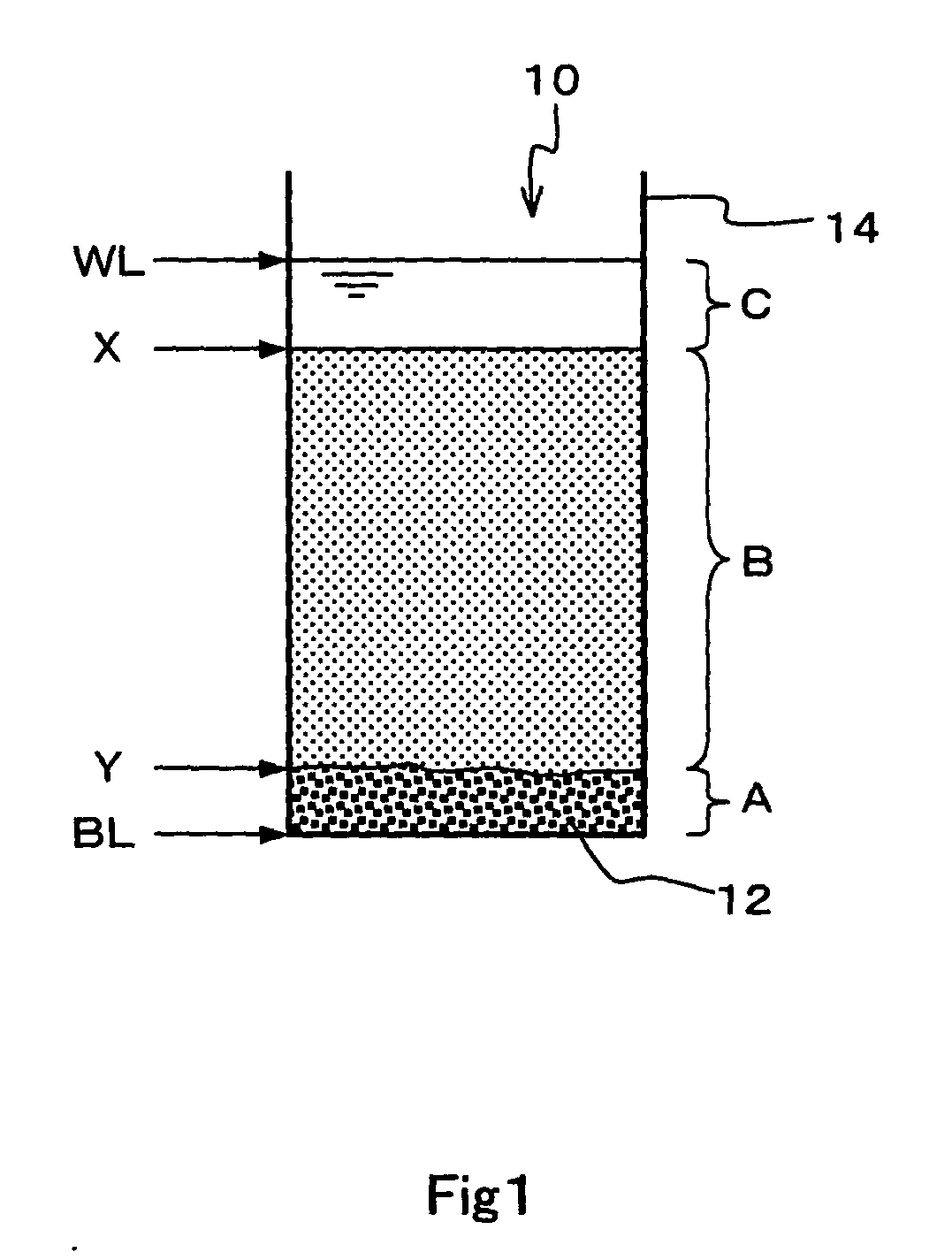

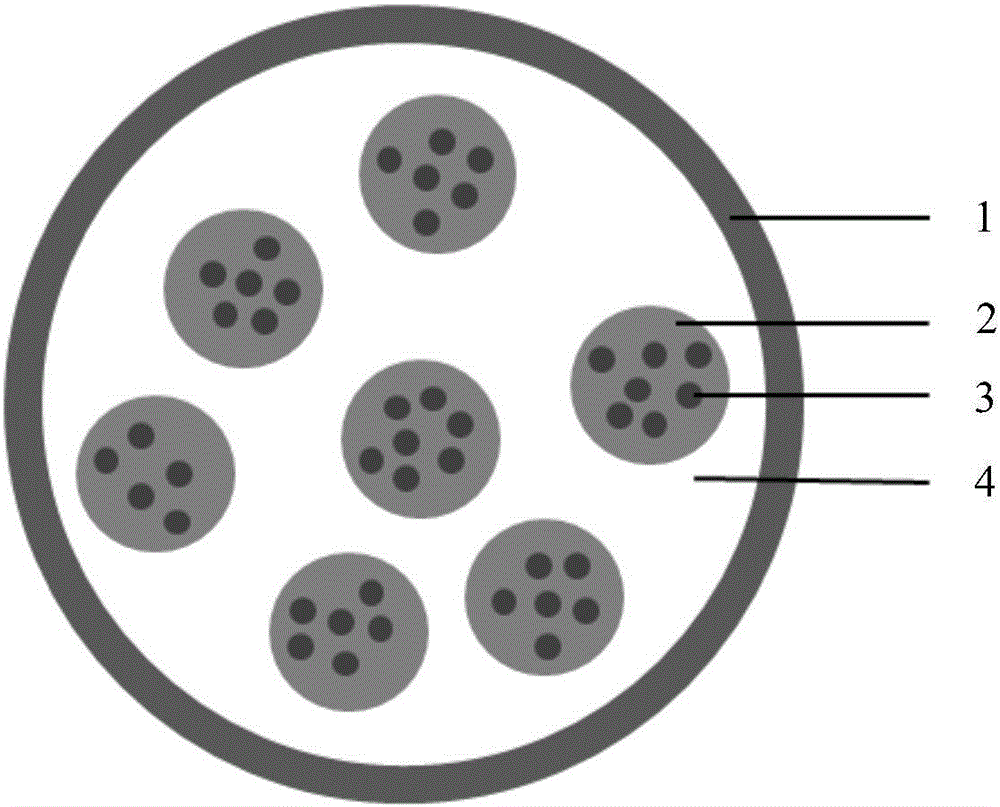

Composite Particle for Electrode, Method for Producing the Same and Secondary Battery

InactiveUS20080160409A1Improve electronic conductivityExcellent initial charge/discharge characteristicMaterial nanotechnologyElectrode manufacturing processesFiberSurface layer

A composite particle for an electrode including an active material particle, carbon nanofibers bonded to the surface of the active material particle, and a catalyst element for promoting the growth of the carbon nanofibers, wherein the active material particle includes an electrochemically active phase. As the catalyst element, for example, Au, Ag, Pt, Ru, Ir, Cu, Fe, Co, Ni, Mo, Mn and the like are used. The composite particle for an electrode may be produced, for example, by means of a method which includes: a step of preparing an active material particle including a catalyst element for promoting the growth of carbon nanofibers at least in the surface layer of the active material particle; and a step of growing carbon nanofibers on the surface of the active material particle in an atmosphere including a raw material gas.

Owner:PANASONIC CORP

Cnt-infused metal fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused metal fiber material which includes a metal fiber material of spoolable dimensions, a barrier coating conformally disposed about the metal fiber material, and carbon nanotubes (CNTs) infused to the metal fiber material. A continuous CNT infusion process includes: (a) disposing a barrier coating and a carbon nanotube (CNT)-forming catalyst on a surface of a metal fiber material of spoolable dimensions; and (b) synthesizing carbon nanotubes on the metal fiber material, thereby forming a carbon nanotube-infused metal fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

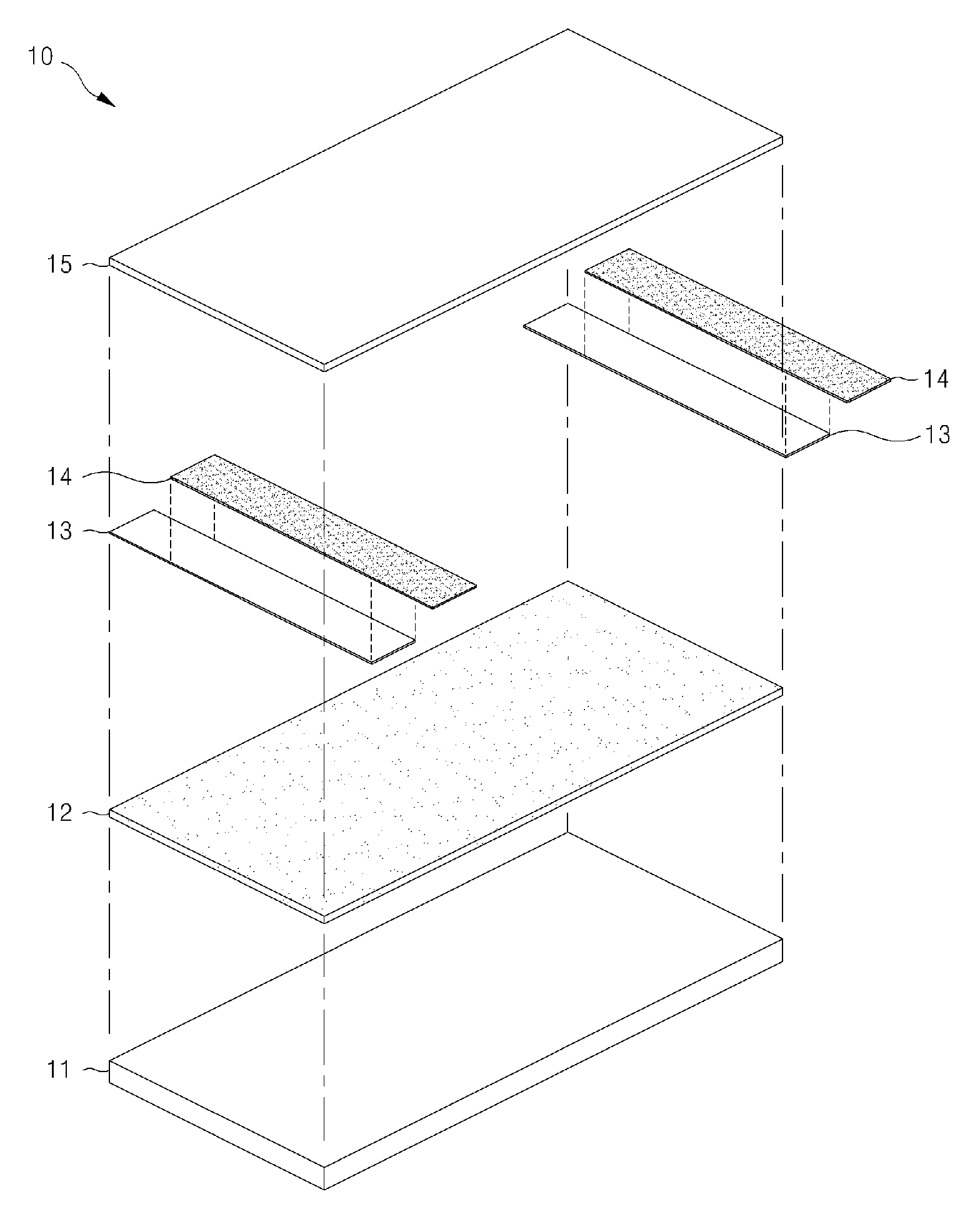

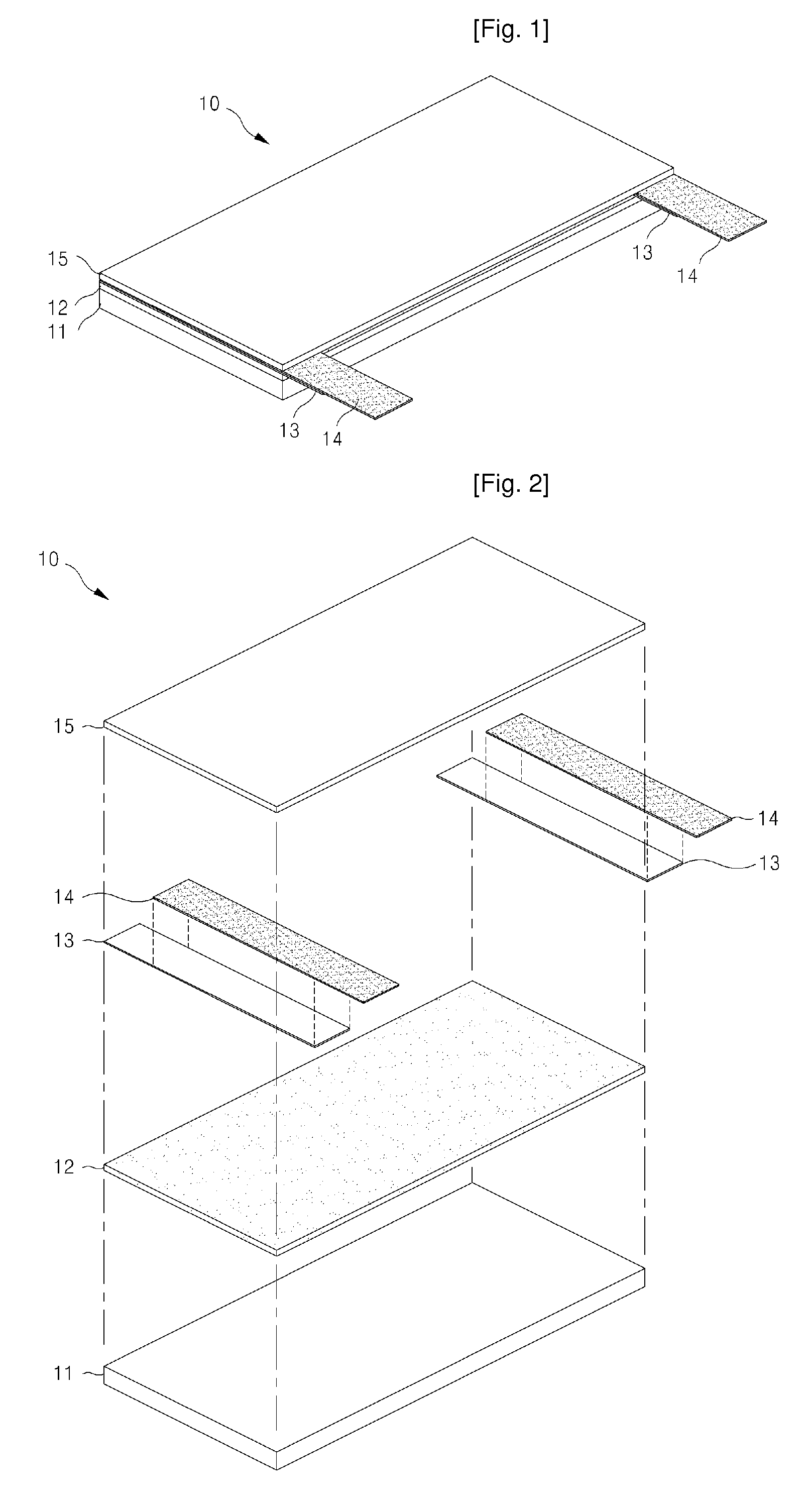

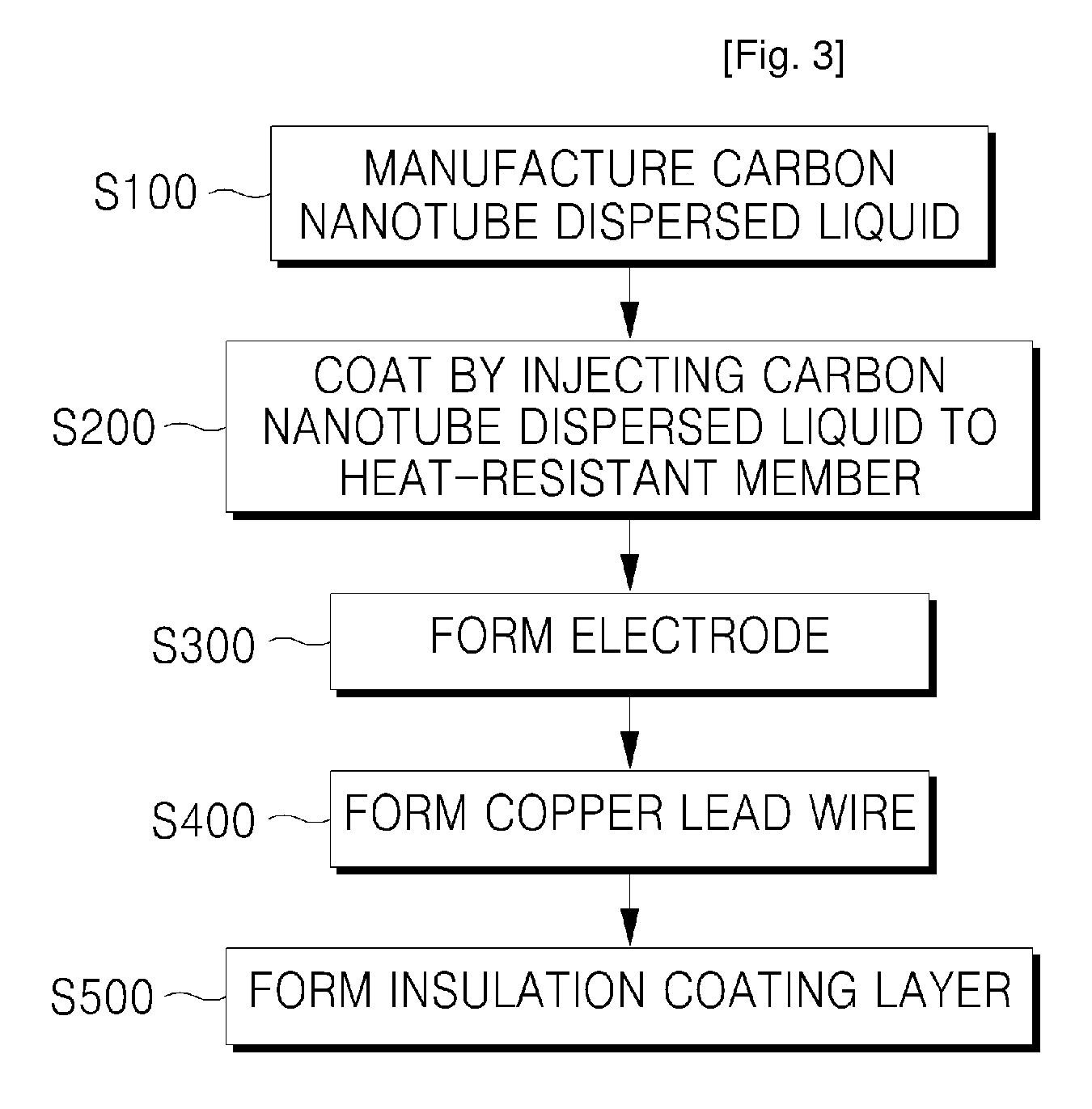

Heating element using carbon NANO tube

InactiveUS20090194525A1Easy to changeQuality improvementHeating element materialsCarbon nanotubesCarbon nanotubeCoating

Provided is a heating element using carbon nanotube including a heat-resistant member having a heat-resistant characteristic, a carbon nanotube coating layer formed on at least one surface of the heat-resistant member, and a pair of electrodes electrically connected to the carbon nanotube coating layer and inducing heating of the carbon nanotube coating layer when connected to power. The manufactured in a simple process of coating a heat-resistant member with carbon nanotube, relatively reduce the overall manufacturing time, easily change the shape and specifications, and have a heating efficiency higher than that of a heating element having a different shape and material.

Owner:EXAENC CORP

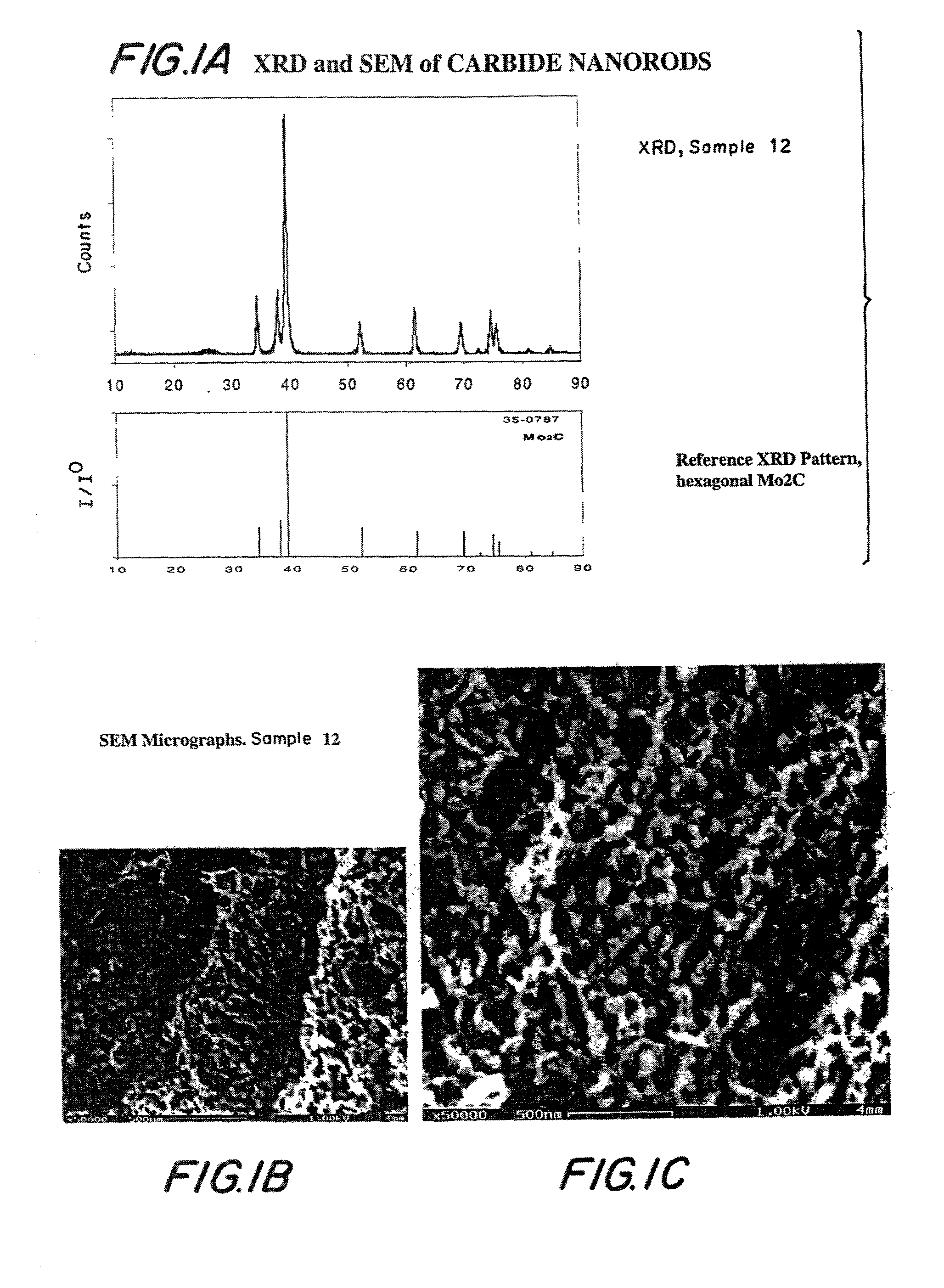

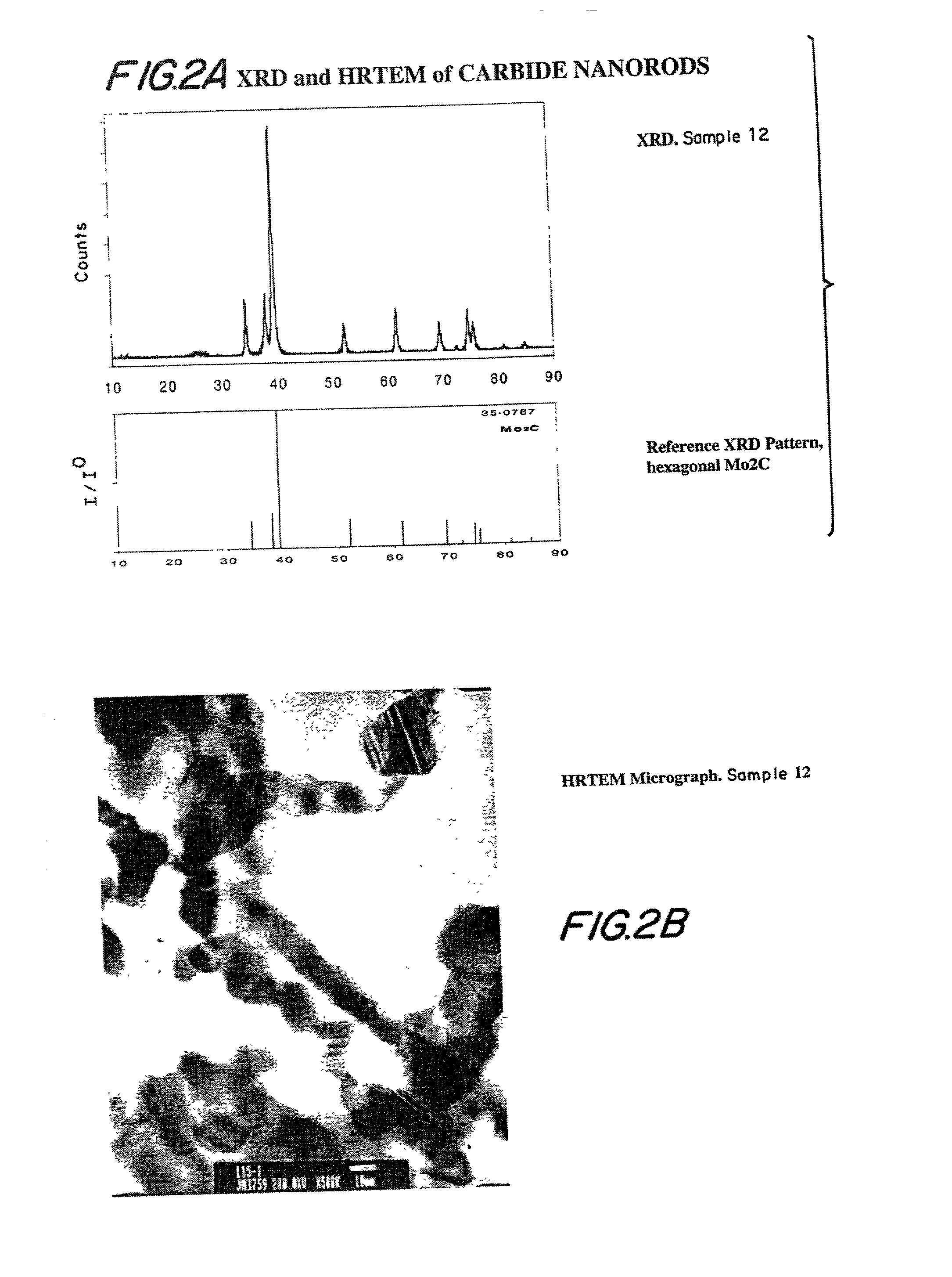

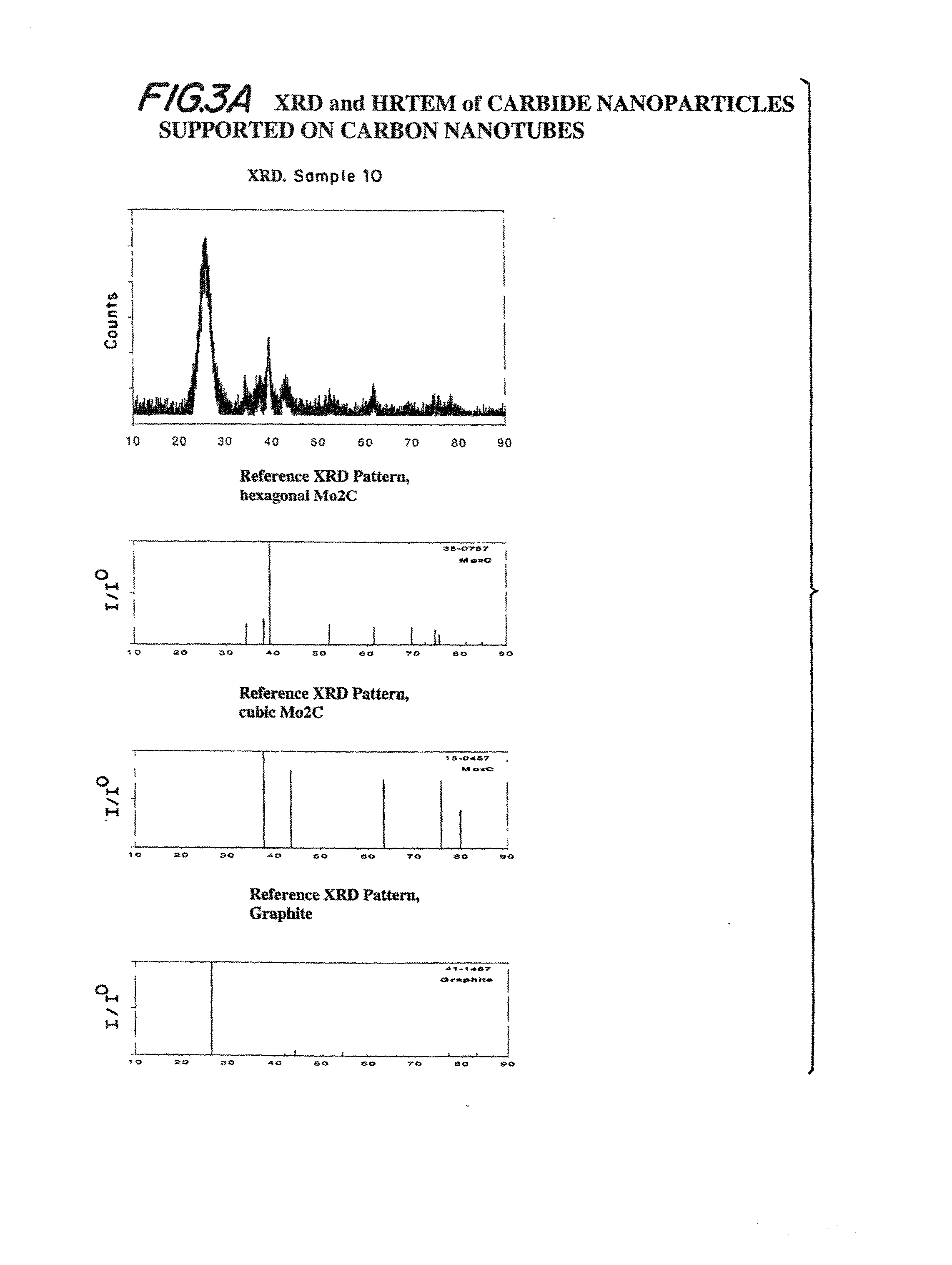

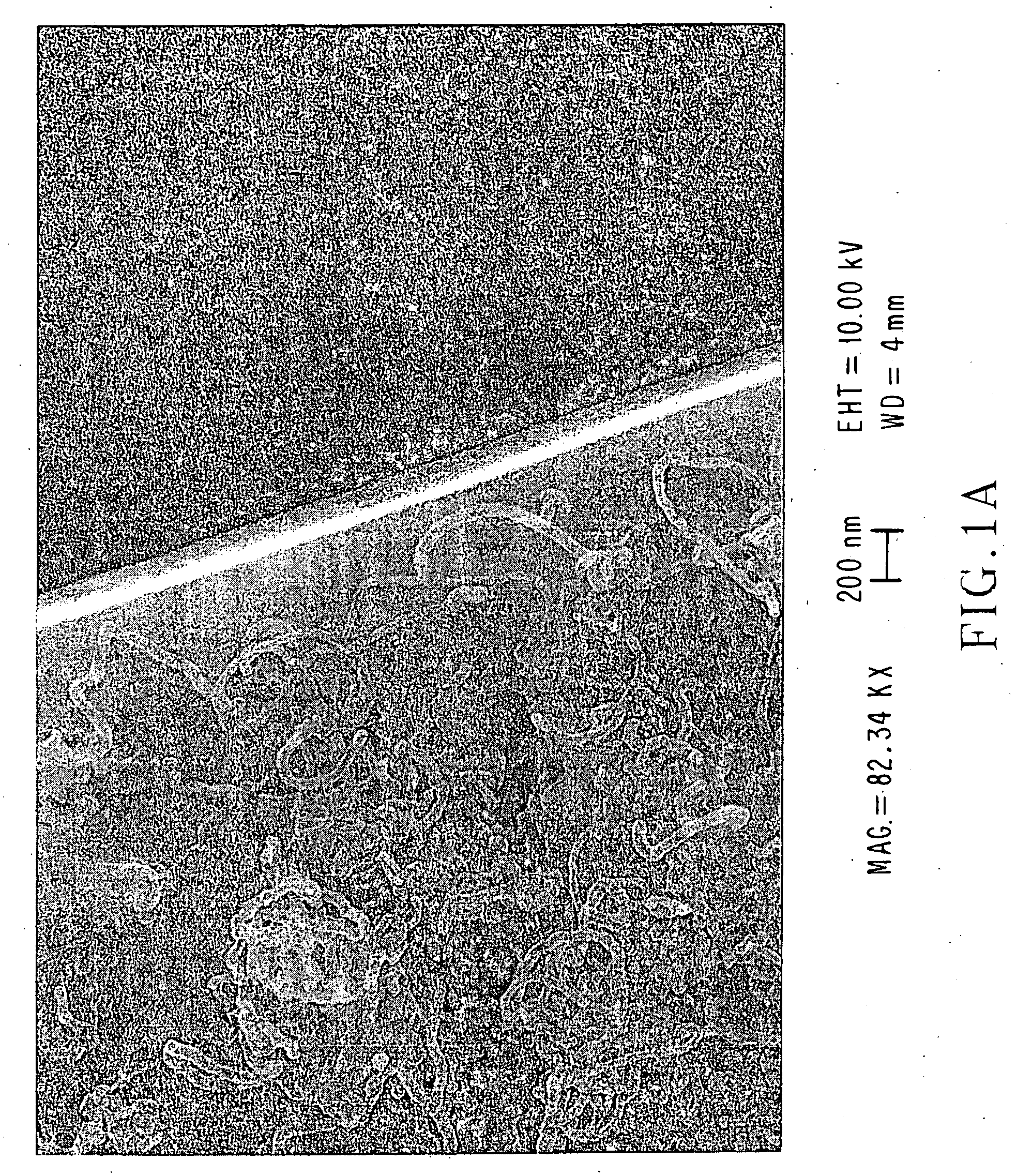

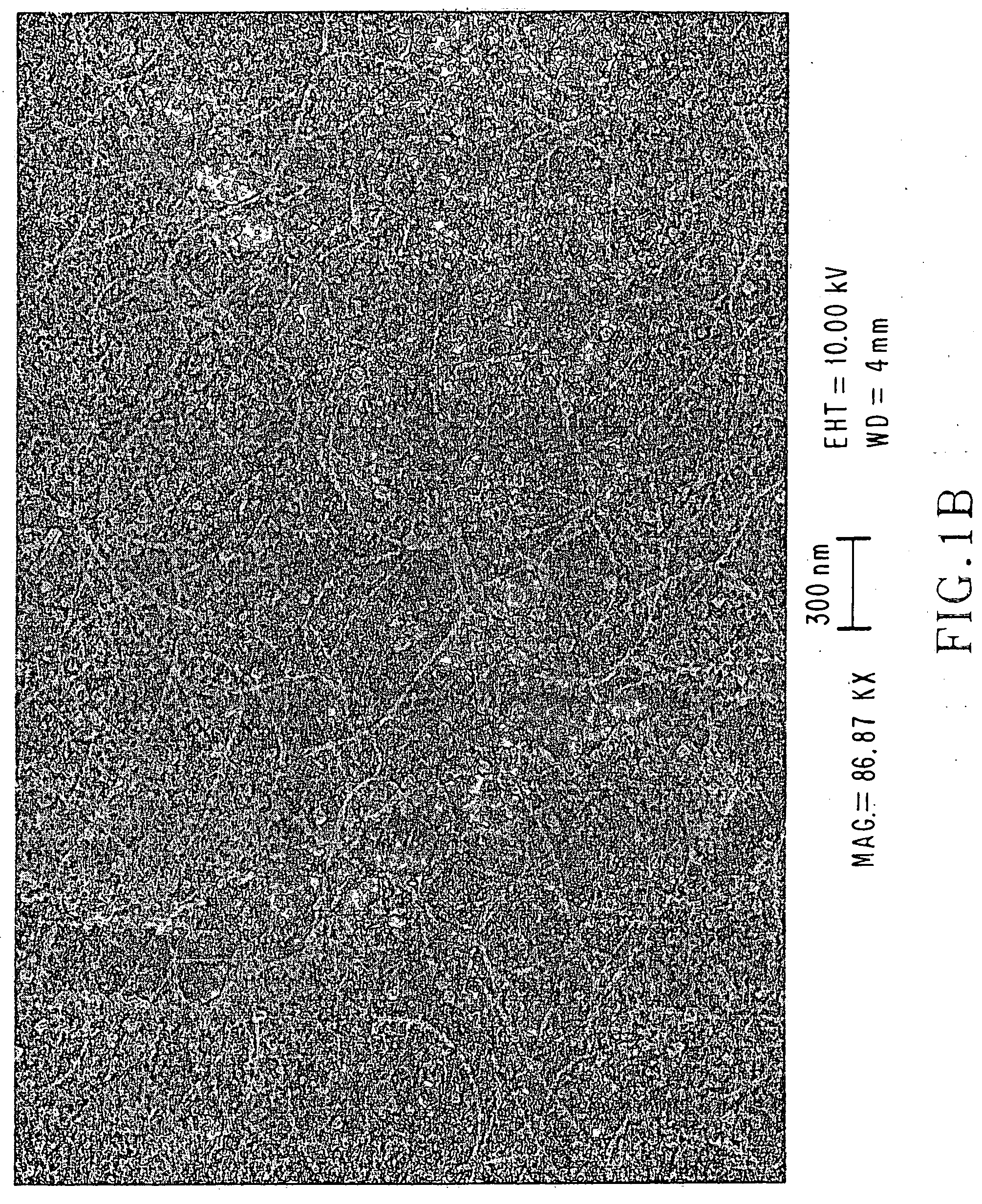

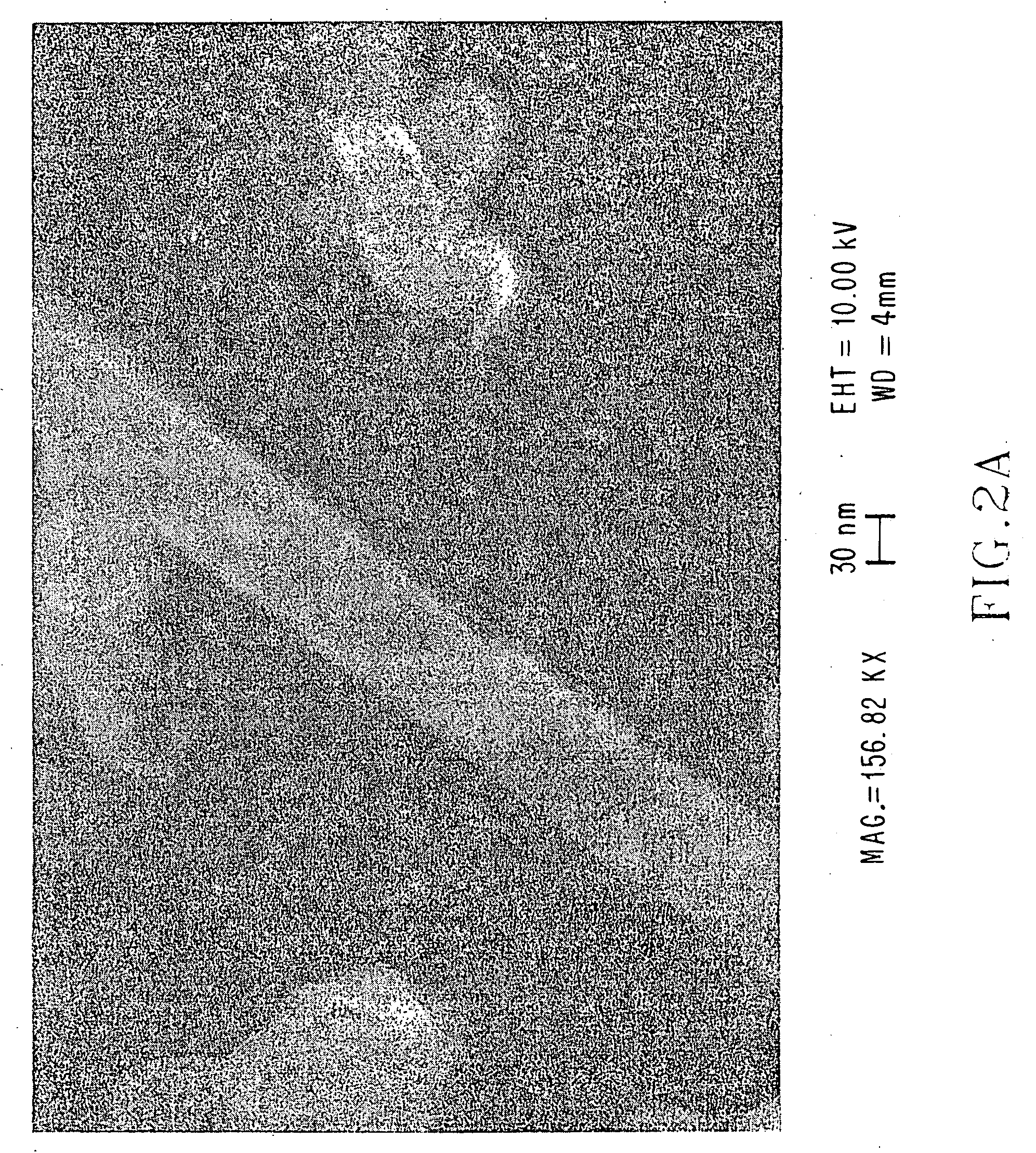

Method of using carbide and/or oxycarbide containing compositions

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

Control of carbon nanotube diameter using CVD or PECVD growth

The diameter of carbon nanotubes grown by chemical vapor deposition is controlled independent of the catalyst size by controlling the residence time of reactive gases in the reactor.

Owner:GLOBALFOUNDRIES US INC

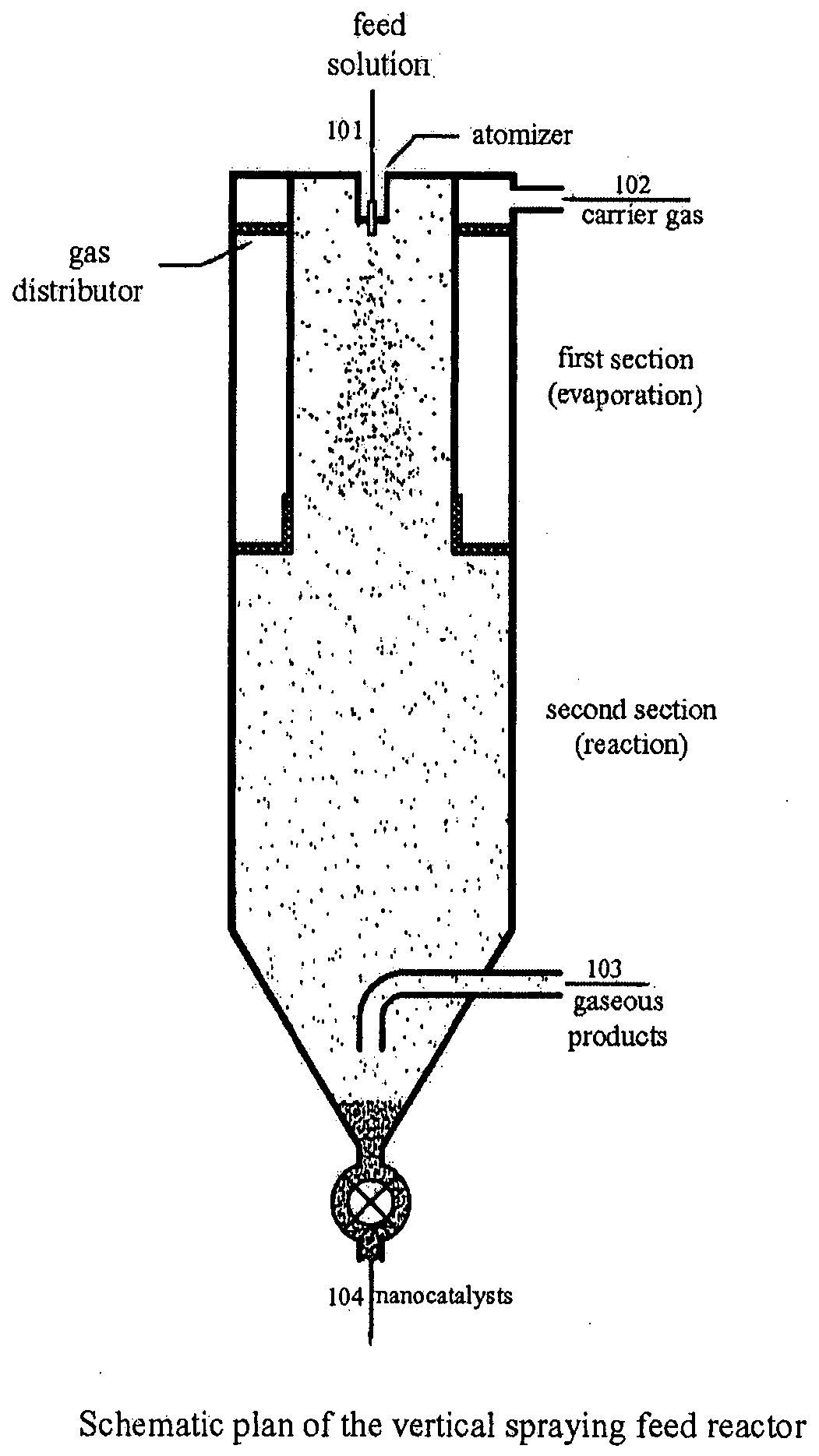

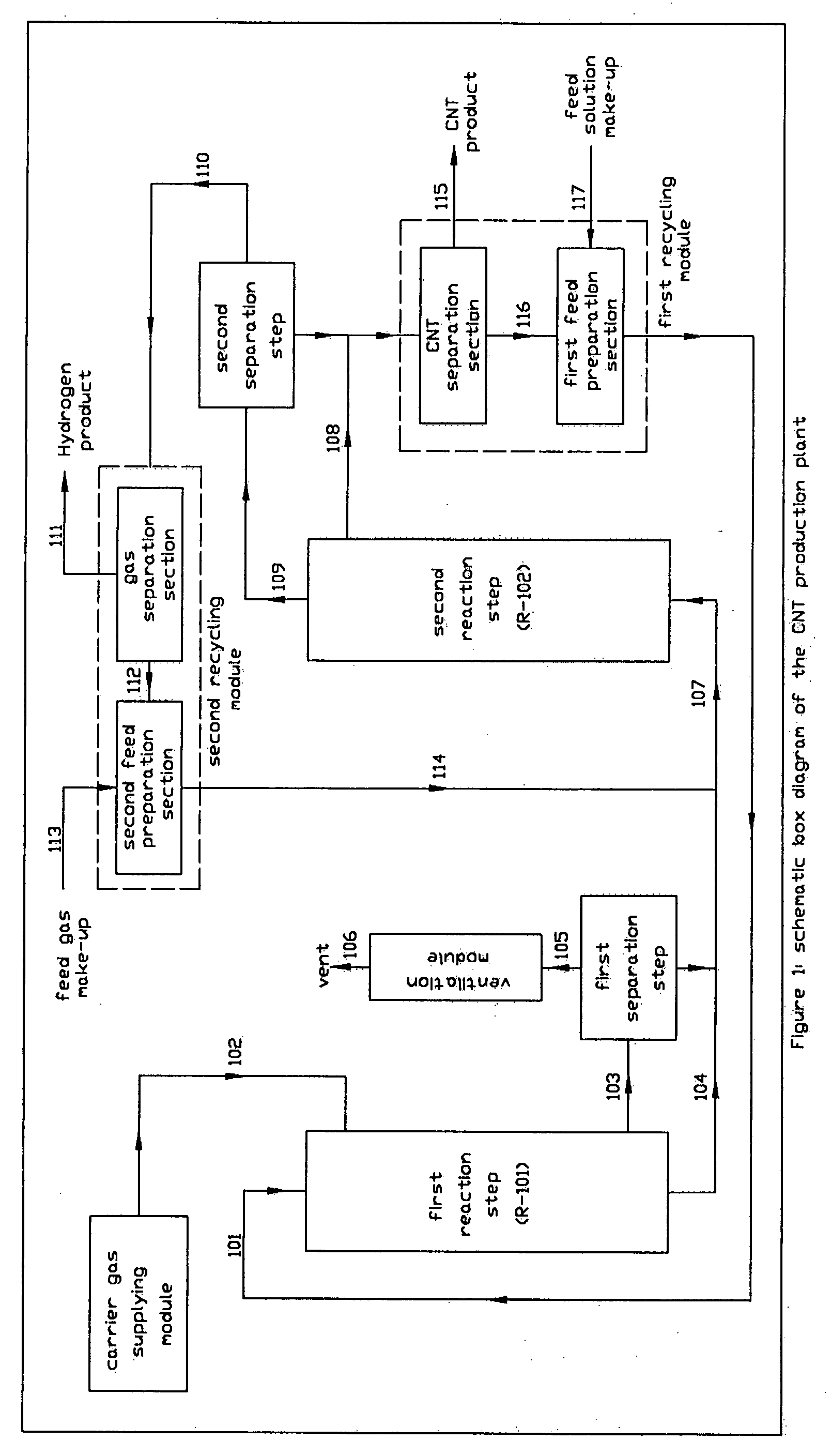

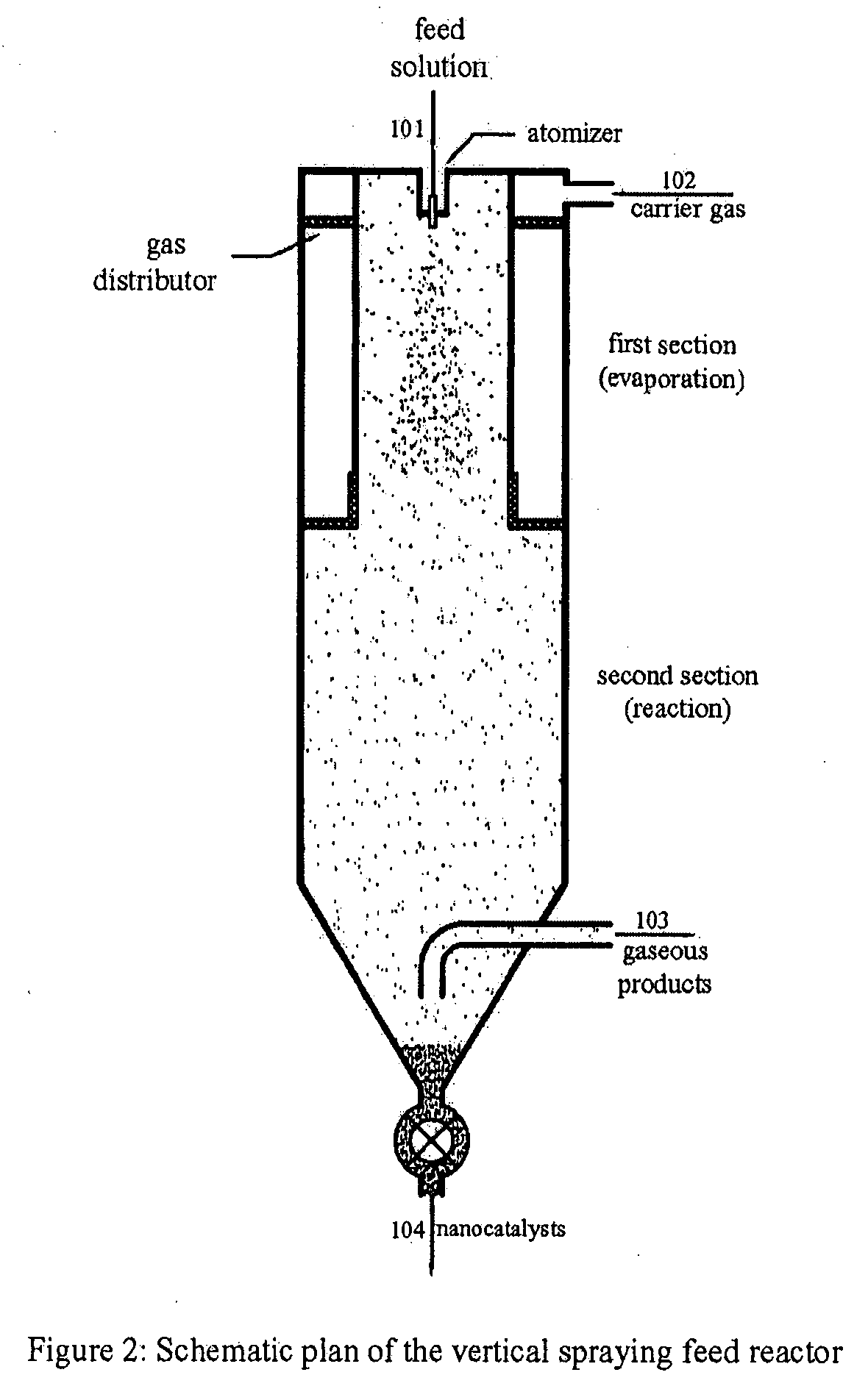

Continuous process for producing carbon nanotubes

The present invention relates to a continuous process for producing carbon nanotubes (herein after also referred to as “CNTs”) of single, double and / or multi-wall type, with any possible desired diameter and with high purity. The preferred embodiment provides means for continuous supply of a catalyst during the process for producing the carbon nanotubes, according to which one can achieve the advantageous continuity of the process.

Owner:RES INST OF PETROLEUM IND RIPI

Process for preparing carbon nanotubes

InactiveUS6887451B2Speed up the processMaterial nanotechnologyEnergy inputComposite electrodeSilanes

Carbon nanotubes are produced using a silane procedure, in which a substrate such as carbon paper or stainless steel mesh is immersed in a silane solution of a metal catalyst, preferable Co:Ni in a 1:1 ratio; and a feedstock gas containing a carbon source such as ethylene is fed through the substrate and the catalyst deposited thereon while the substrate is heated by applying an electrical current thereto. Thus, a reaction occurs between the catalyst and the gas to yield carbon nanotubes supported on the conductive substrate. These composite electrodes may be used in electrochemistry or in field emitting applications.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

Method for isolation of nanomaterials

Methods for isolation and / or purification of nanomaterials, such as nanowires, are provided. The disclosed methods include isolation of nanomaterials via a filter press and are amenable to large-scale production of nanomaterials. Related methods for isolation, purification and / or doping of nanomaterials are also provided.

Owner:SILURIA TECH INC

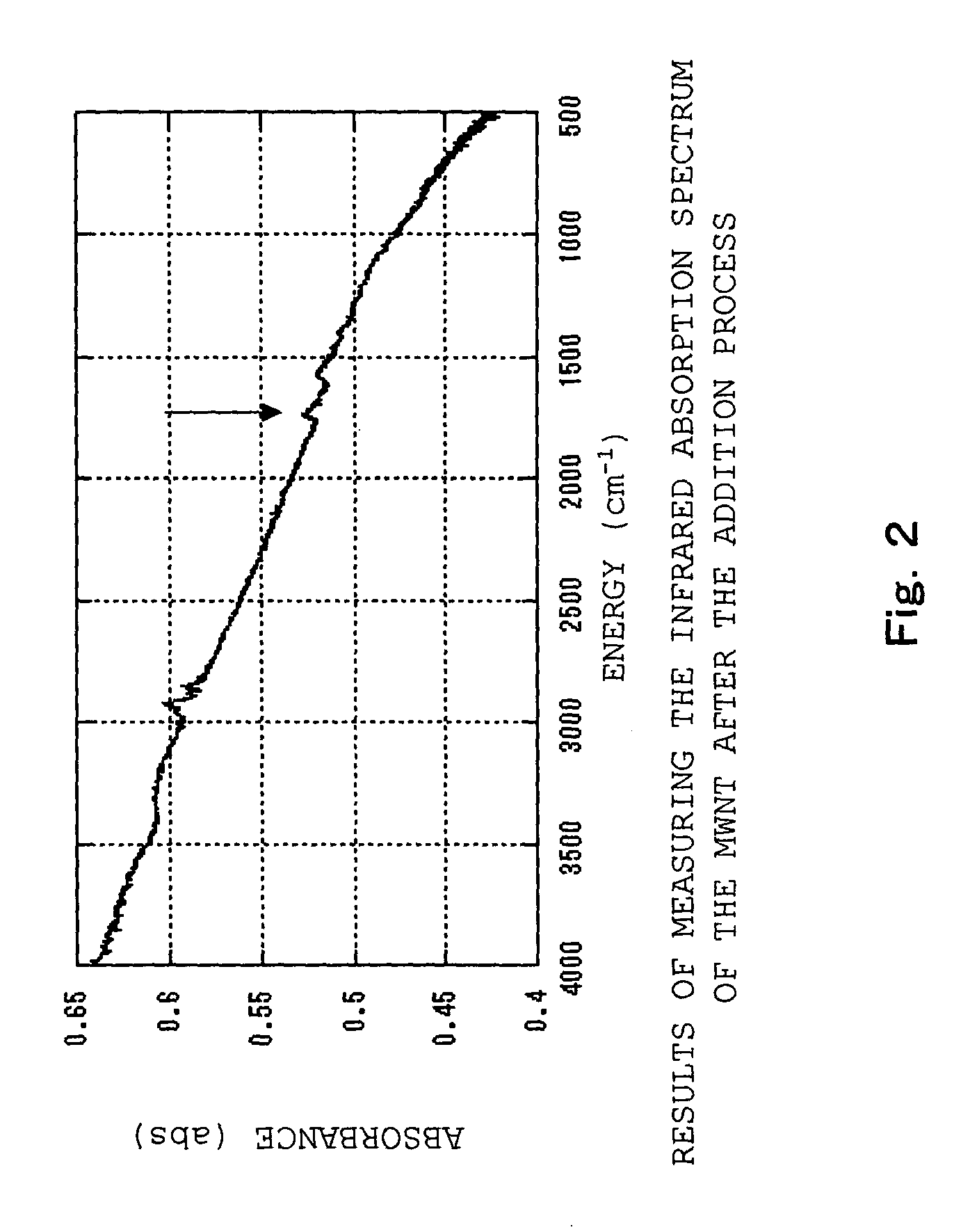

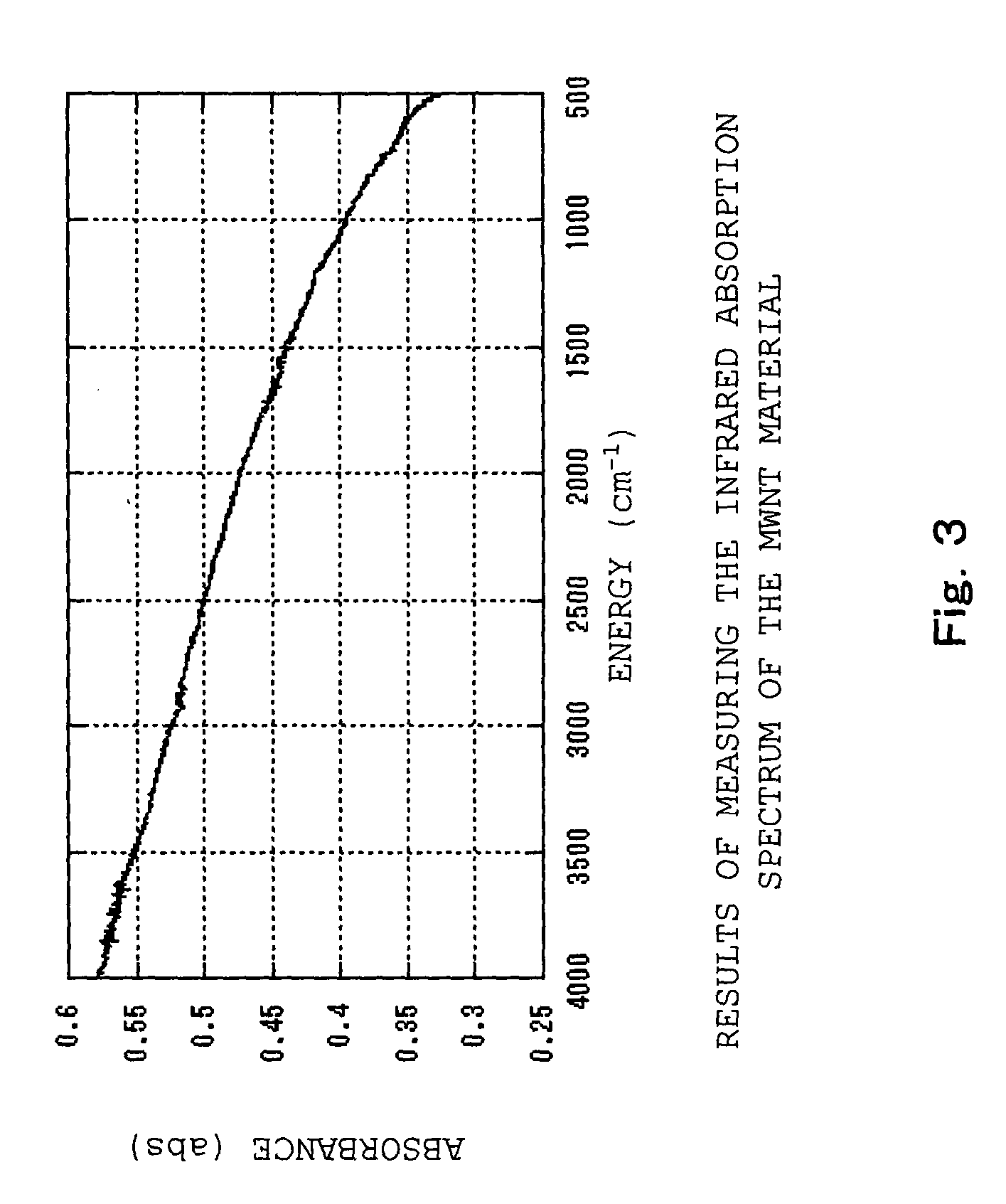

Carbon nanotube dispersion liquid and method for producing the same and polymer composite and method for producing the same

InactiveUS20040136894A1Easy to storeGood dispersionMaterial nanotechnologyIndividual molecule manipulationDispersion stabilityActive agent

By employing a method of producing a carbon nanotube dispersion liquid, in which a carbon nanotube modified with a basic or acidic functional group is dispersed in a polar solvent having a polarity opposite to a polarity of the functional group, there is provided a carbon nanotube dispersion liquid having a high dispersion stability, in which a carbon nanotube is uniformly dispersed without using any surfactant or the like. By using the carbon nanotube dispersion liquid, a polymer composite in which a carbon nanotube is uniformly dispersed without being mixed with an impurity can be provided. In addition, a method for producing the polymer composite by relatively simple procedures is also provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Carbonaceous material for forming electrically conductive matrail and use thereof

ActiveUS20060035081A1Improve conductivityLow resistance anisotropyMaterial nanotechnologyNon-insulated conductorsFiberCarbon fibers

(1) A carbonaceous material for forming an electrically conductive composition, comprising a vapor grown carbon fiber, each fiber filament of the carbon fiber having an outer diameter of 2 to 500 nm and an aspect ratio of 10 to 15,000, or the carbon fiber containing boron in an amount of 0.01 to 5 mass %, and graphitic particles and / or amorphous carbon particles, wherein the amount of the vapor grown carbon fiber is 10 to 90 mass %, the amount of the graphitic particles is 0 to 65 mass %, and the amount of the amorphous carbon particles is 0 to 35 mass %; (2) an electrically conductive composition comprising the carbonaceous material for forming an electrically conductive composition, and a producing method thereof; (3) an electrically conductive coating material comprising, as an electrically conductive material, the electrically conductive composition, and an electrically conductive coating film and electric device using the electrically conductive coating material.

Owner:RESONAC CORP

Combustion-Assisted Substrate Deposition Method For Producing Carbon Nanosubstances

InactiveUS20090191352A1Suitable mechanical strengthMaterial nanotechnologyMolten spray coatingCombustionProduct gas

The present invention provides a combustion-based method and apparatus for producing and isolating carbon nanotubes. The nanotubes are formed when hot combustion gases are contacted with a catalytic surface, which is readily separated from the catalyst support and subsequently dissolved. The process is suitable for large-scale manufacture of carbon nanotubes.

Owner:NANODYNAMICS INC

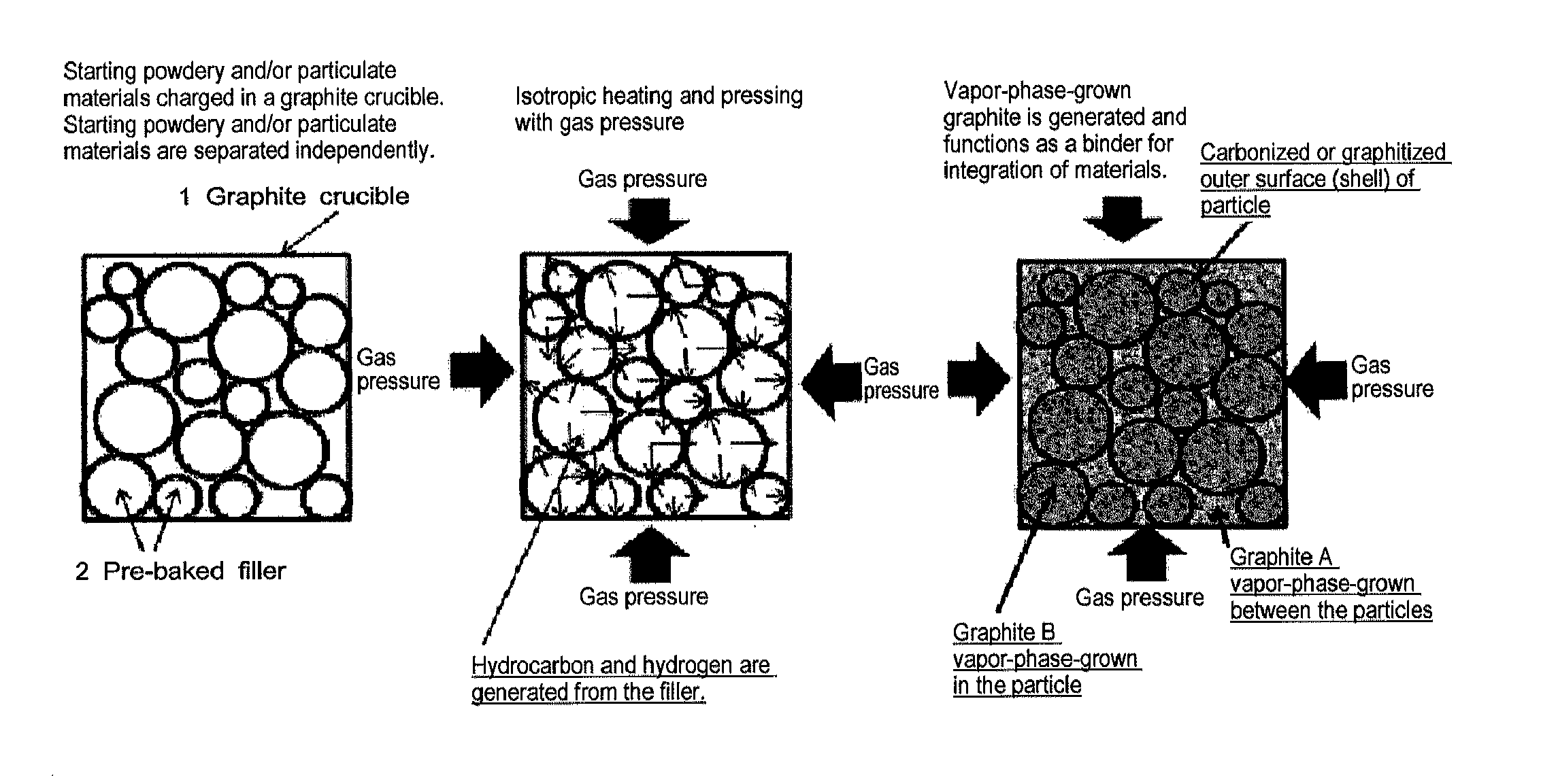

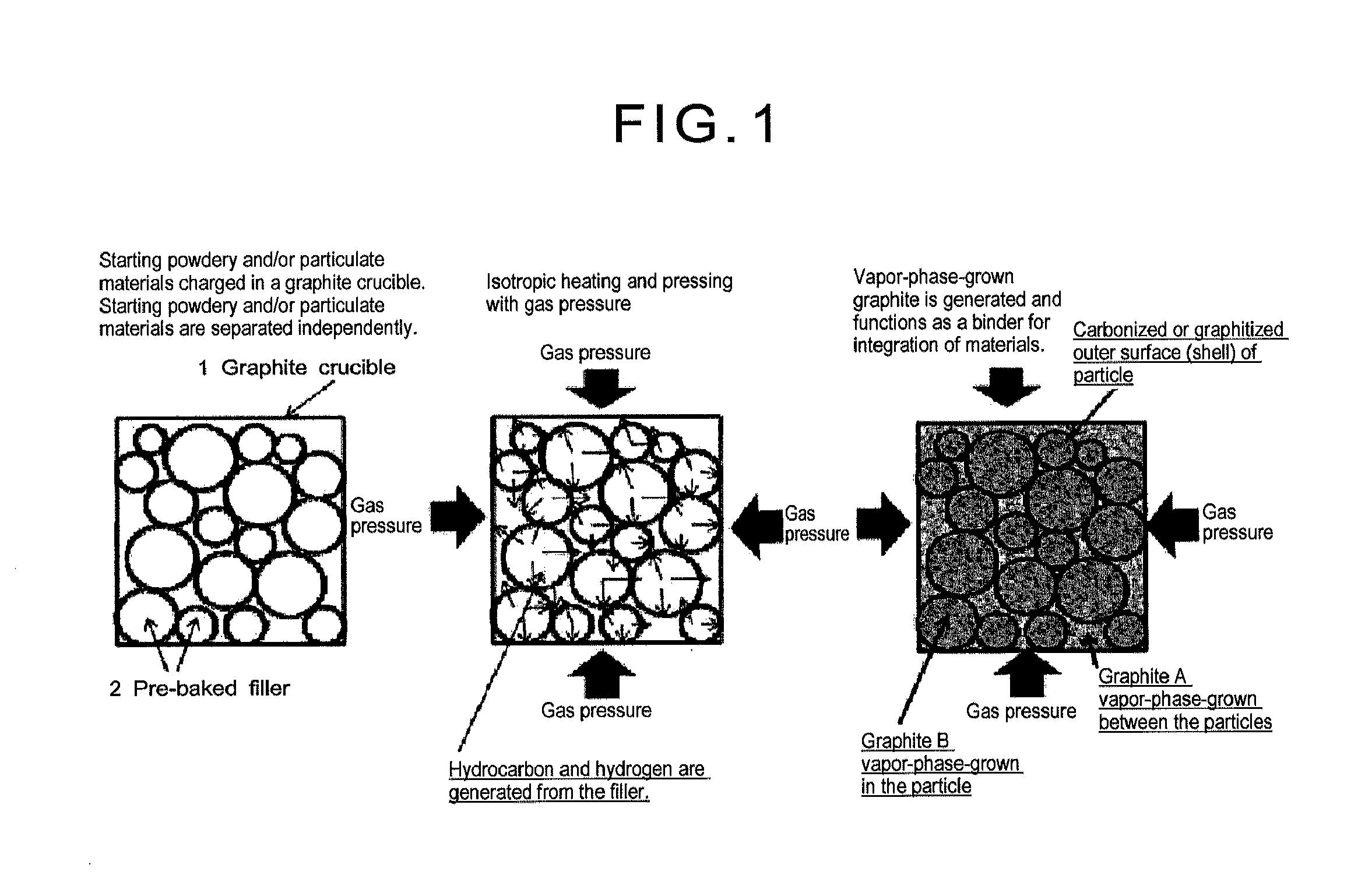

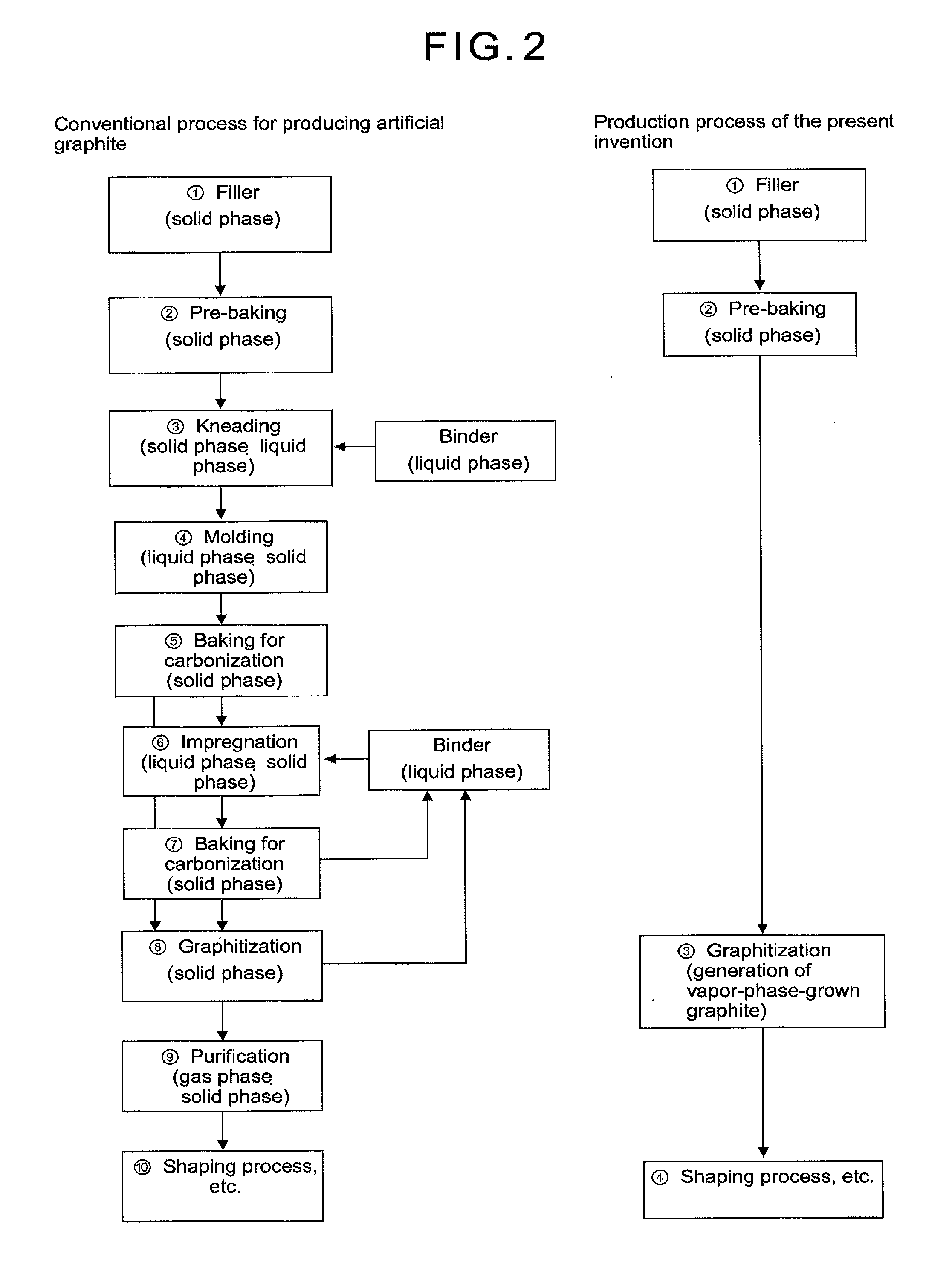

Carbon material and method for producing same

ActiveUS20120077020A1Simple processLow costMaterial nanotechnologyFullerenesGas phaseSource material

(Problem)In conventional method for producing artificial graphite, in order to obtain a product having excellent crystallinity, it was necessary to mold a filler and a binder and then repeat impregnation, carbonization and graphitization, and since carbonization and graphitization proceeded by a solid phase reaction, a period of time of as long as 2 to 3 months was required for the production and cost was high and further, a large size structure in the shape of column and cylinder could not be produced. In addition, nanocarbon materials such as carbon nanotube, carbon nanofiber and carbon nanohorn could not be produced.(Means to Solve)A properly pre-baked filler is sealed in a graphite vessel and is subsequently subjected to hot isostatic pressing (HIP) treatment, thereby allowing gases such as hydrocarbon and hydrogen to be generated from the filler and precipitating vapor-phase-grown graphite around and inside the filler using the generated gases as a source material, and thereby, an integrated structure of carbide of the filler and the vapor-phase-grown graphite is produced. In addition, nanocarbon materials are produced selectively and efficiently by adding a catalyst or adjusting the HIP treating temperature.

Owner:INCUBATION ALLIANCE

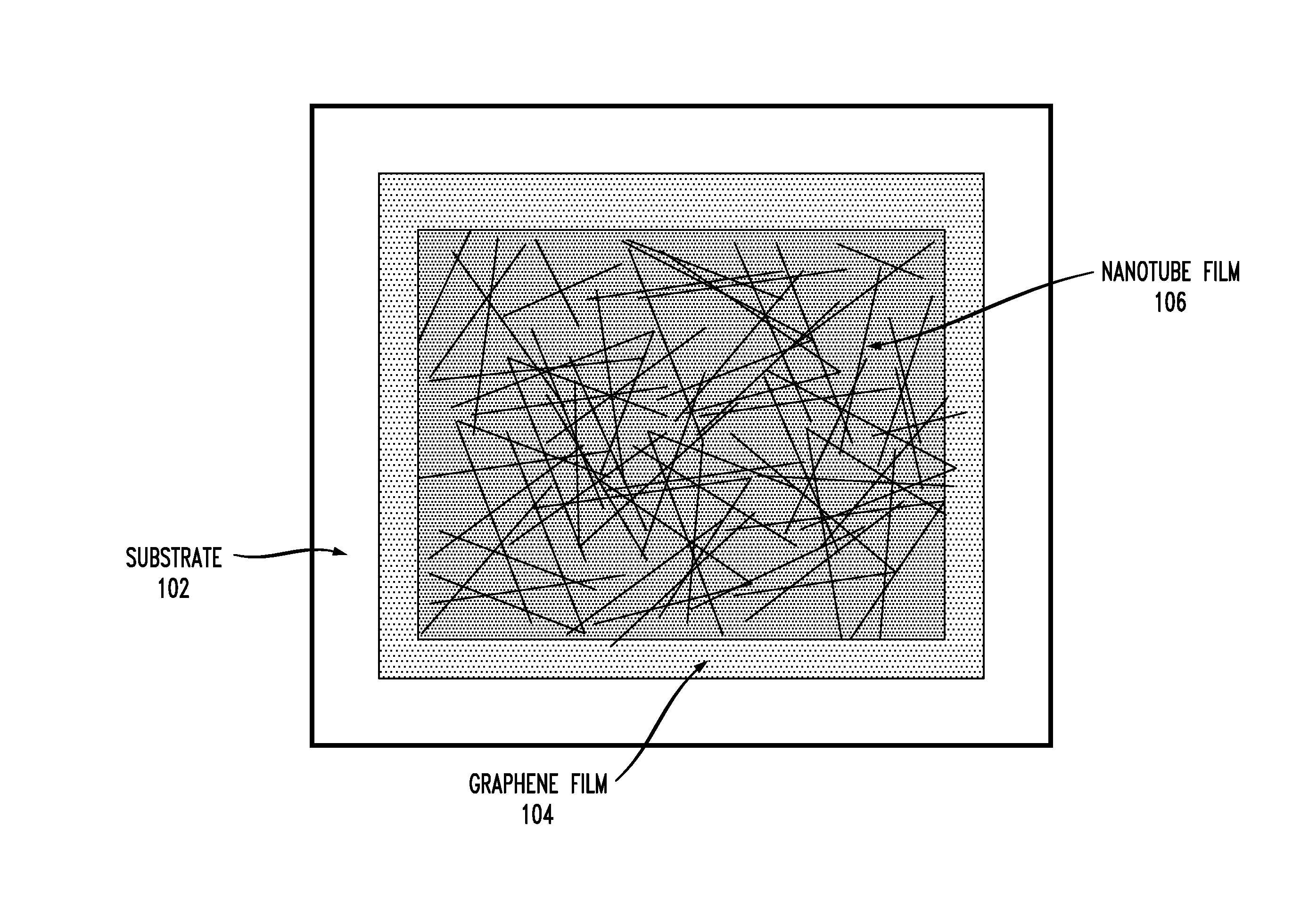

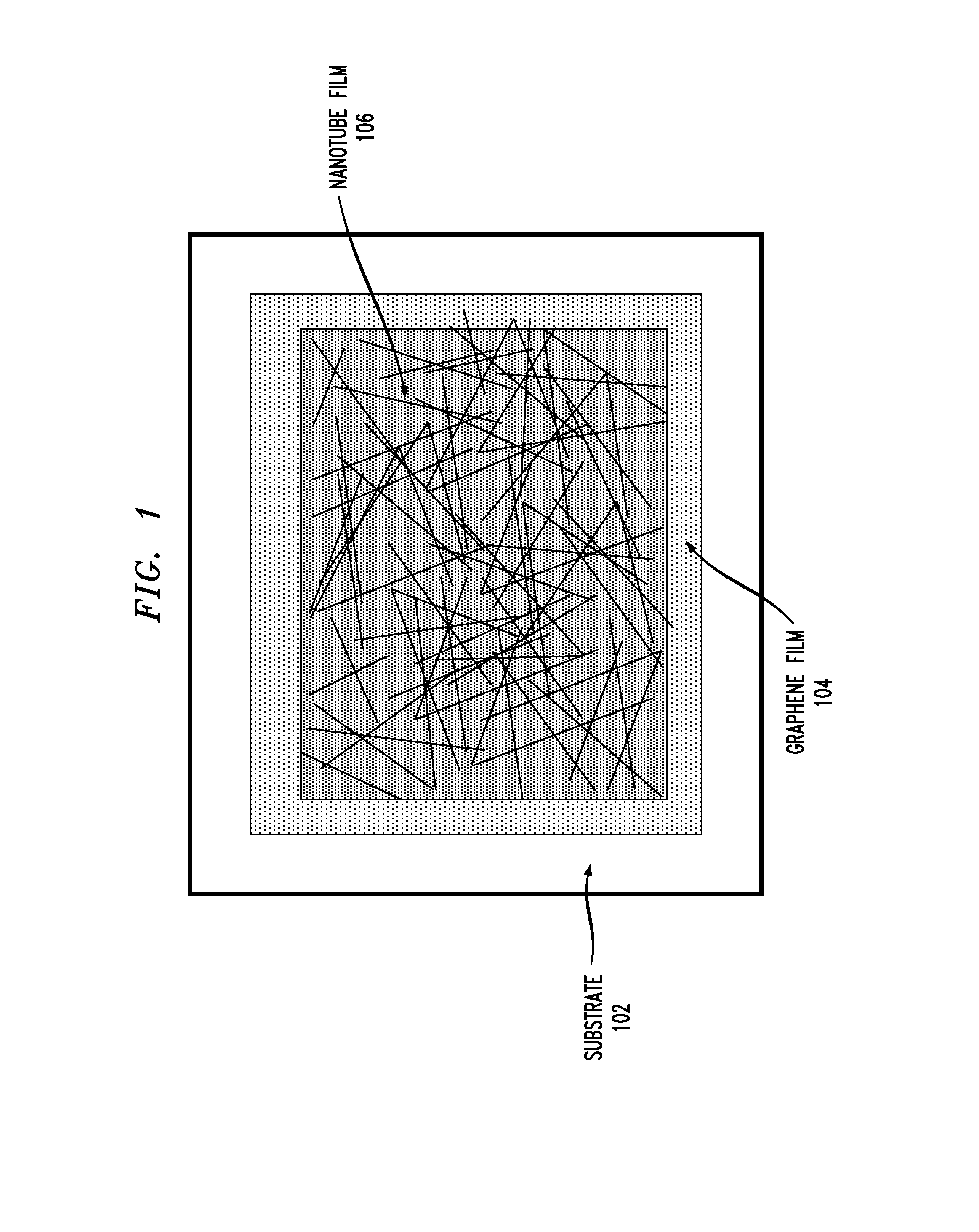

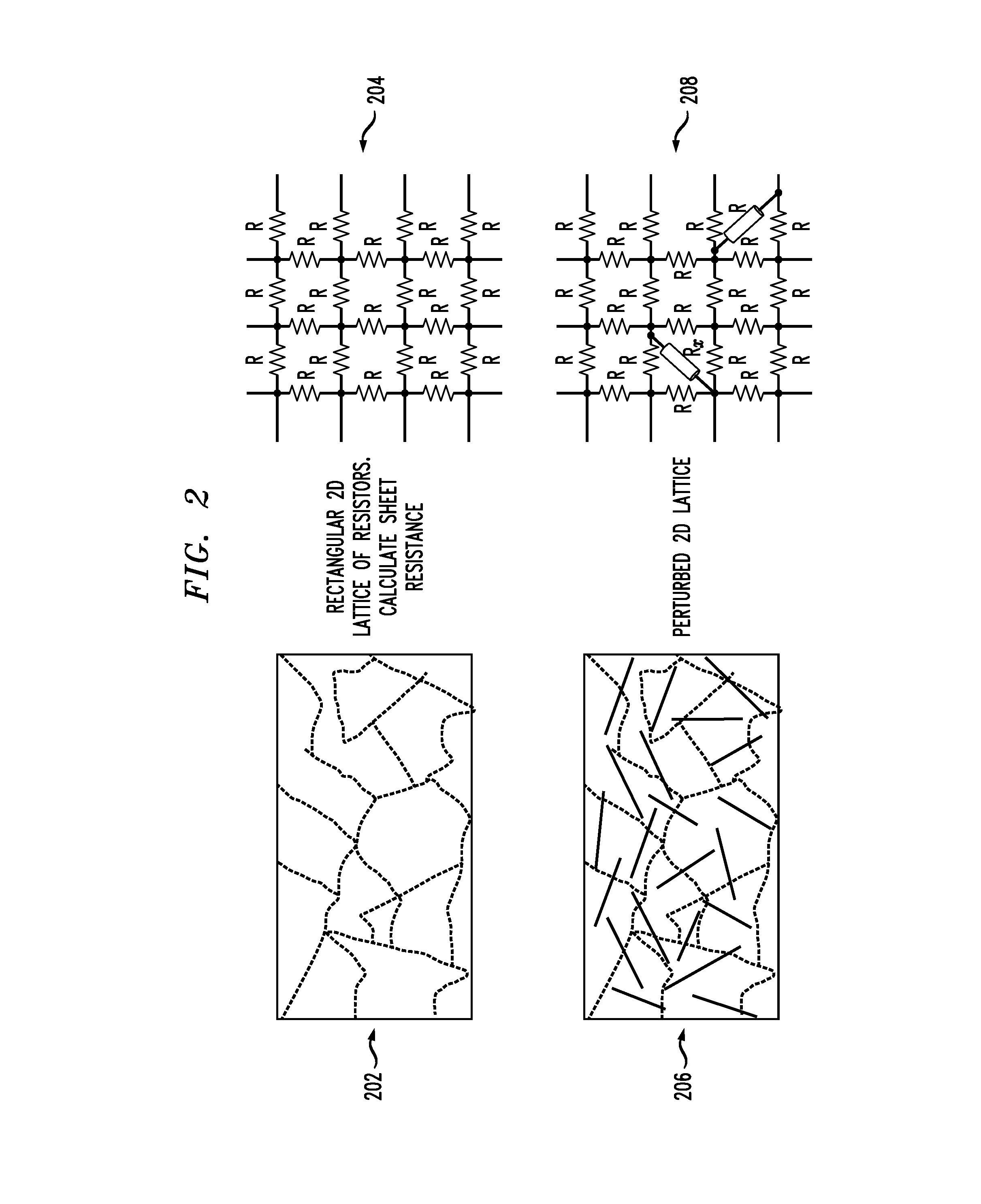

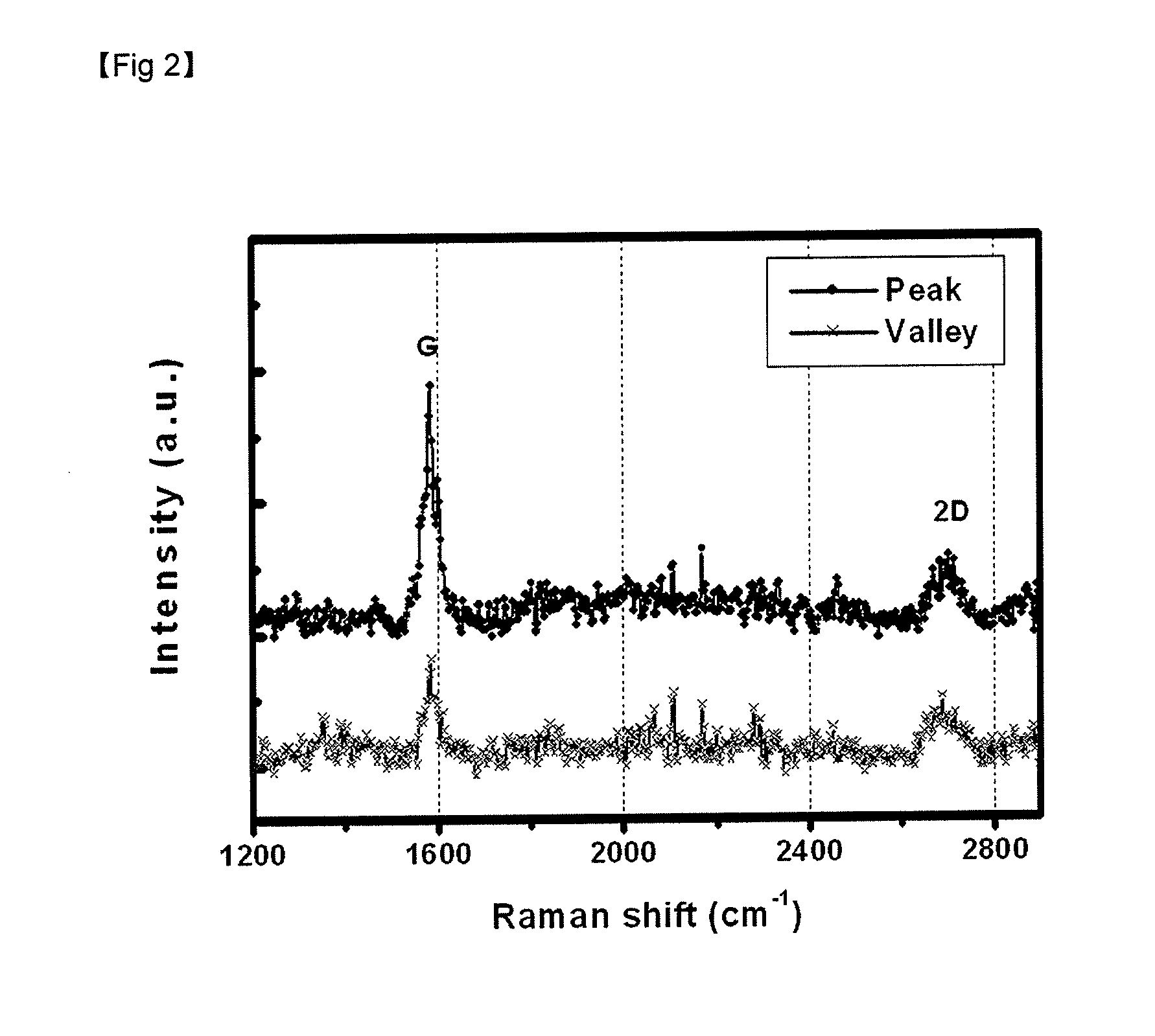

Carbon Nanotube-Graphene Hybrid Transparent Conductor and Field Effect Transistor

ActiveUS20130130037A1Improve electrical performanceDecreasing nanotubeMaterial nanotechnologyNanoinformaticsElectrical conductorMetal foil

A nanotube-graphene hybrid film and method for forming a cleaned nanotube-graphene hybrid film. The method includes depositing nanotube film over a substrate to produce a layer of nanotube film, removing impurities from a surface of the layer of nanotube film not contacting the substrate to produce a cleaned layer of nanotube film, depositing a layer of graphene over the cleaned layer of nanotube film to produce a nanotube-graphene hybrid film, and removing impurities from a surface of the nanotube-graphene hybrid film to produce a cleaned nanotube-graphene hybrid film, wherein the hybrid film has improved electrical performance. Another method includes depositing nanotube film over a metal foil to produce a layer of nanotube film, placing the metal foil with as-deposited nanotube film in a chemical vapor deposition furnace to grow graphene on the nanotube film to form a nanotube-graphene hybrid film, and transferring the nanotube-graphene hybrid film over a substrate.

Owner:IBM CORP +1

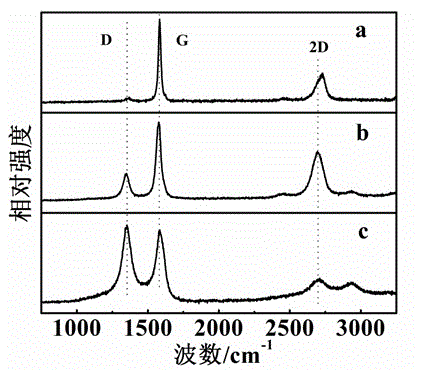

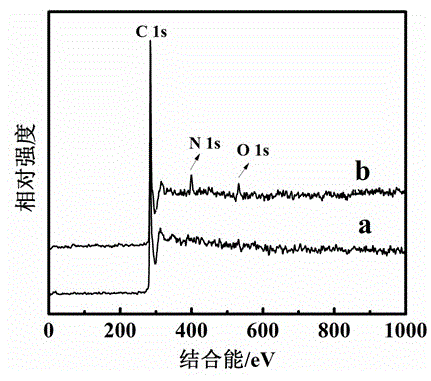

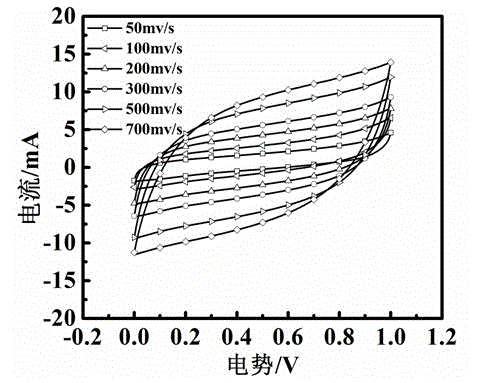

Method for preparing three-dimensional graphene-carbon nitrogen nanotube composite

InactiveCN102745679ASimple preparation processLow costMaterial nanotechnologyNitrogen preparationGrapheneChemical vapor deposition

The invention discloses a simple method of using foam nickel as a substrate to prepare a three-dimensional graphene-carbon nitrogen nanotube composite. Effective composite of three-dimensional graphene and carbon nanotubes is realized by directly growing the carbon nanotubes on the surface of the three-dimensional graphene by means of the two-step chemical vapor deposition technique, and functionalization of a carbon-based three-dimensional structure is realized by introducing nitrogen-doped atoms into the carbon nanotubes. Compared with other methods for preparing the three-dimensional graphene-carbon nitrogen nanotube composite, the method has the advantages of simplicity in preparation process, low cost, high product conductivity, large specific surface area and the like. The three-dimensional graphene-carbon nitrogen nanotube composite obtained by the method has excellent performances in terms of catalysis oxygen reduction reaction, electrochemical capacitors, electrochemical biological sensing, super-hydrophobic oleophylic foams and the like, and has high potential application values in terms of ionic cells, drug transmission, microreactors and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

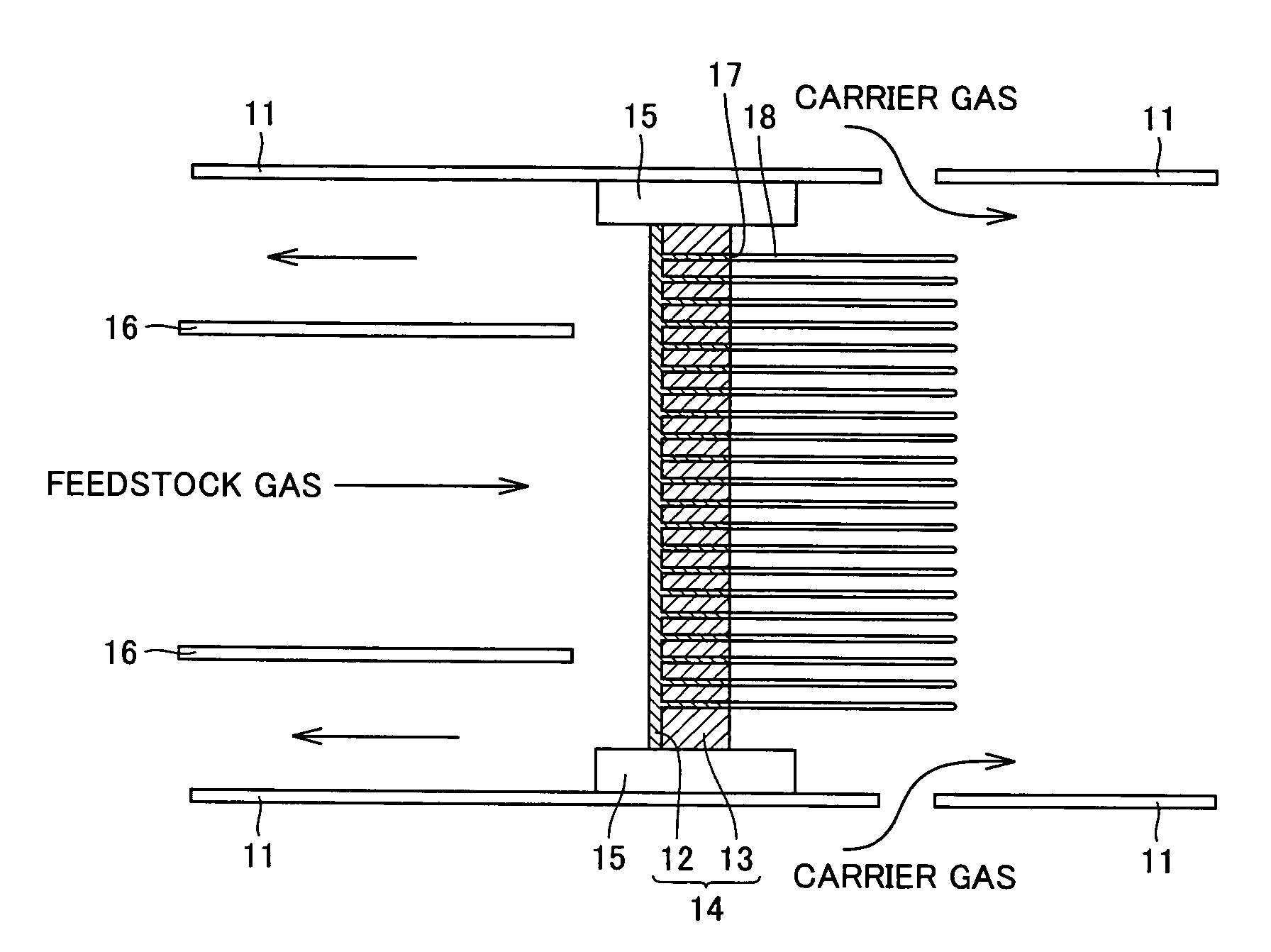

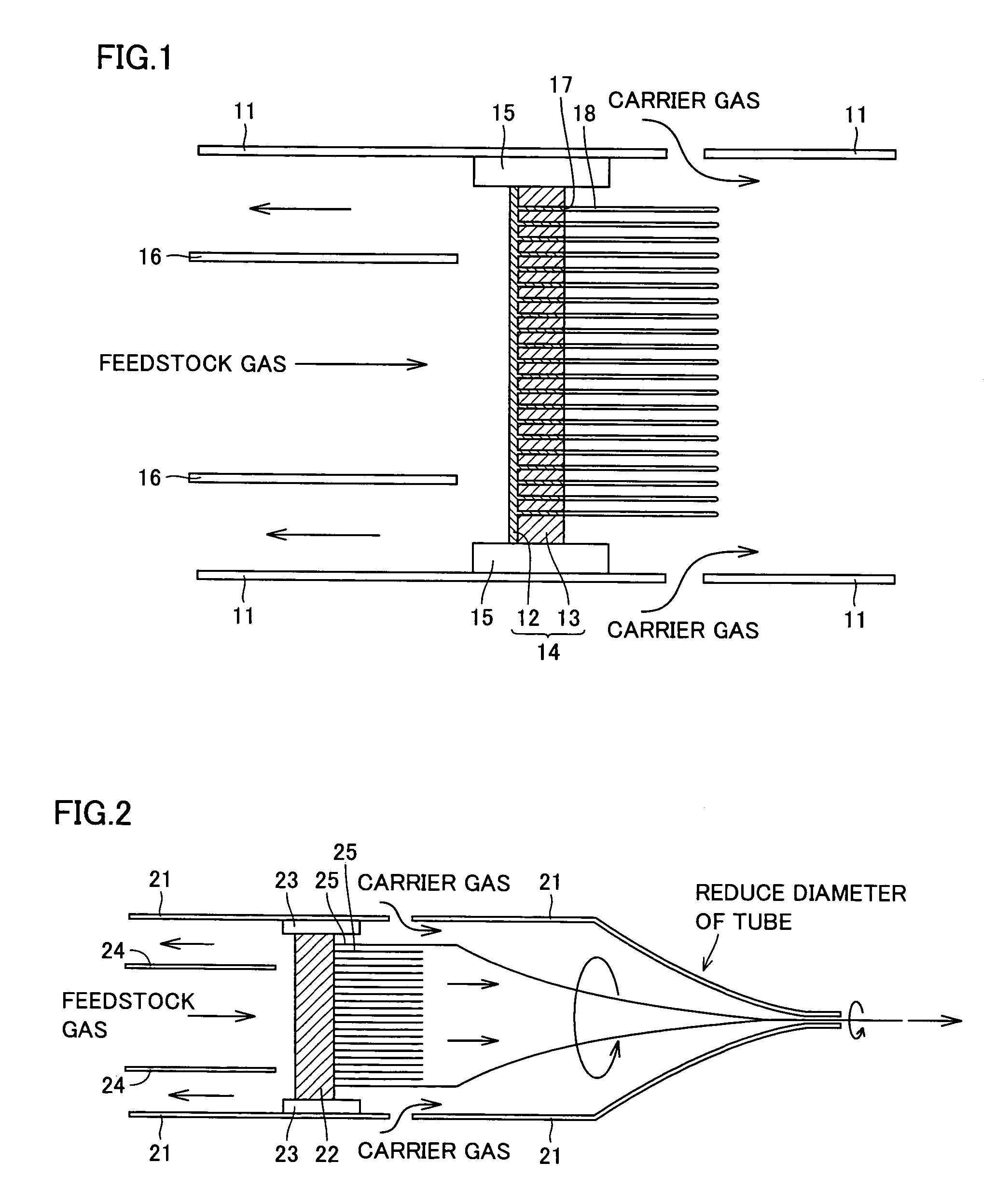

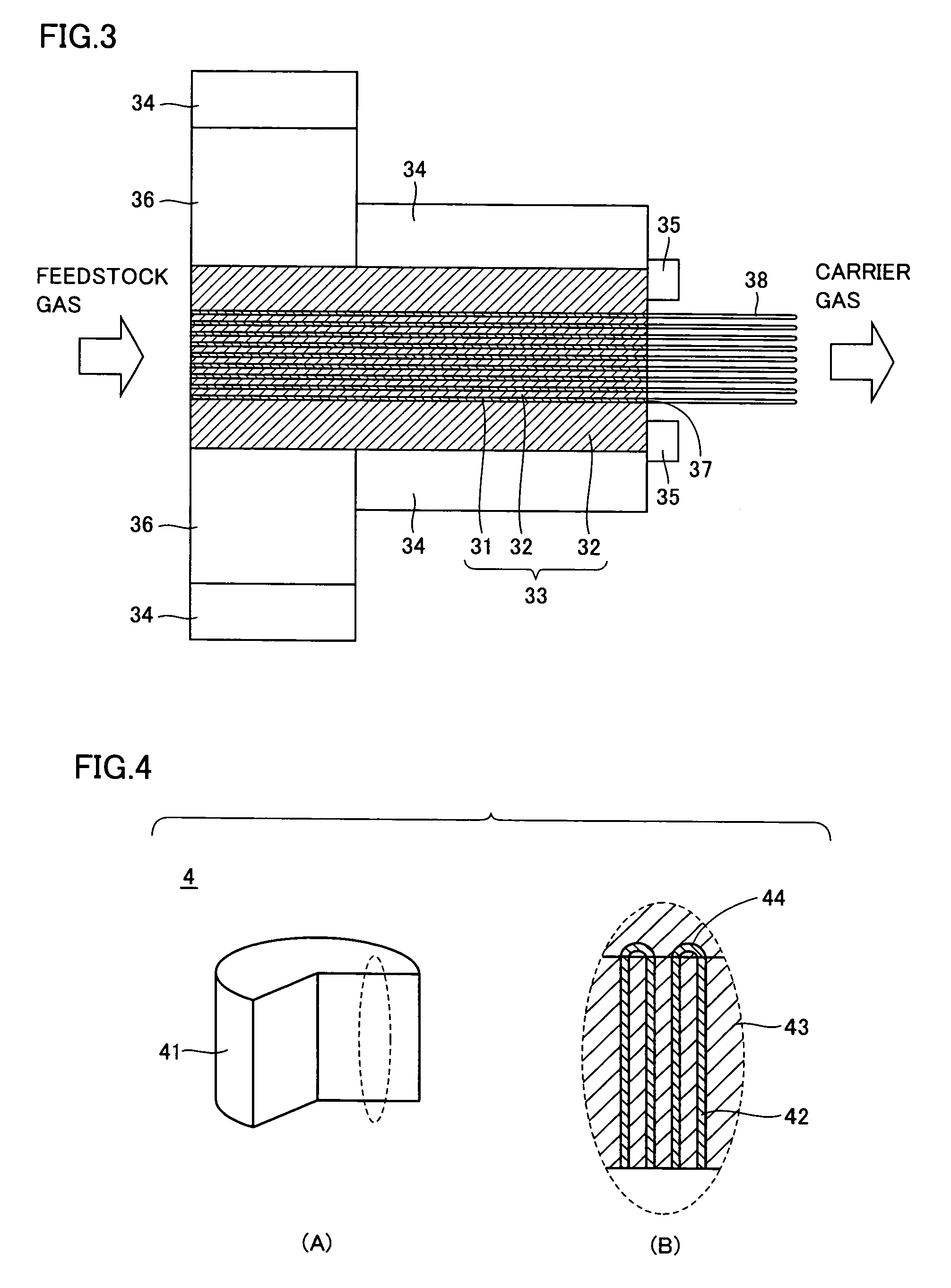

Method of manufacturing carbon nanostructure

ActiveUS7785558B2Uniform shapeHigh purityMaterial nanotechnologyPigmenting treatmentCarbon ionGas phase

The present invention relates to a method of manufacturing a carbon nanostructure for growing crystalline carbon by vapor deposition from a crystal growth surface of a catalytic base including a catalytic material, and in particular, to a method of manufacturing a carbon nanostructure where at least two gases including a feedstock gas are brought into contact with the catalytic base simultaneously. Preferably, the at least two gases are constituted by at least one feedstock gas and at least one carrier gas. Preferably, the carrier gas is brought into contact with the crystal growth surface, and the feedstock gas is brought into contact with at least a part of a region except for the crystal growth surface with which the carrier gas has been brought into contact. Preferably, the material gas contains an ion, and further preferably, it contains a carbon ion.

Owner:SUMITOMO ELECTRIC IND LTD

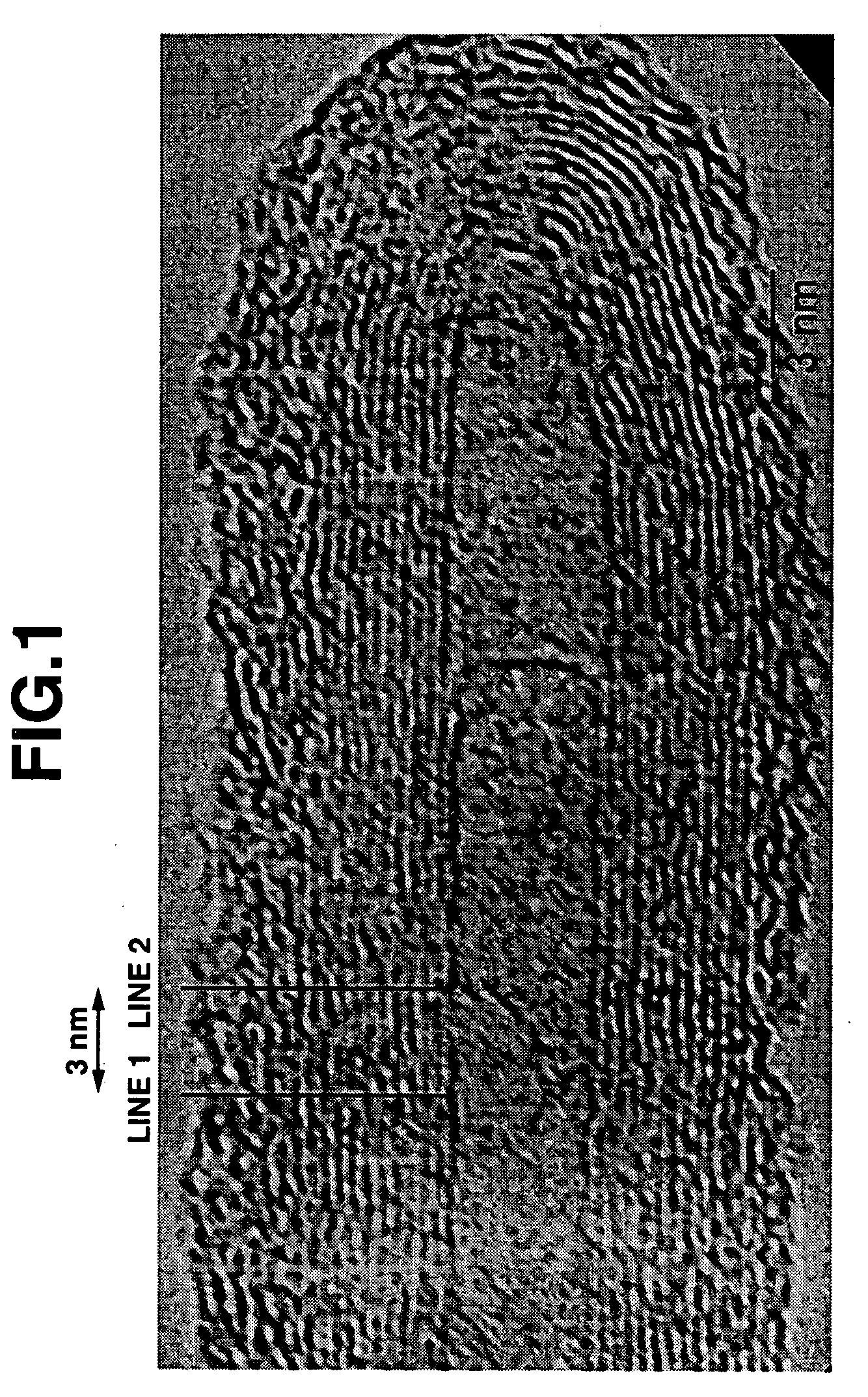

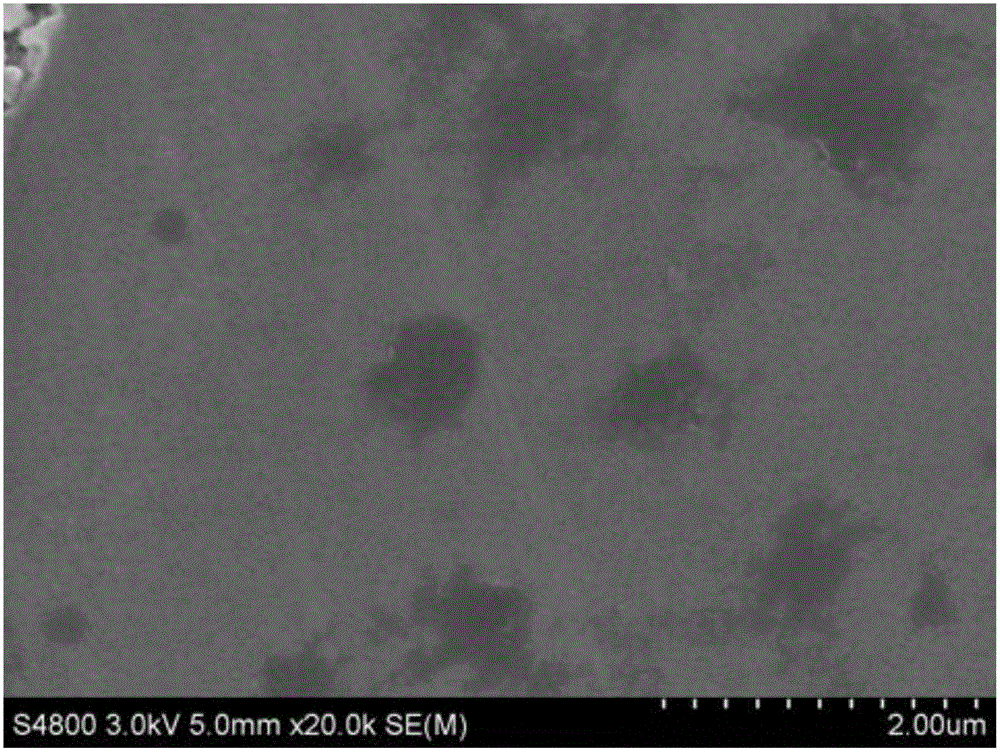

Carbon nanotube and process for producing the same

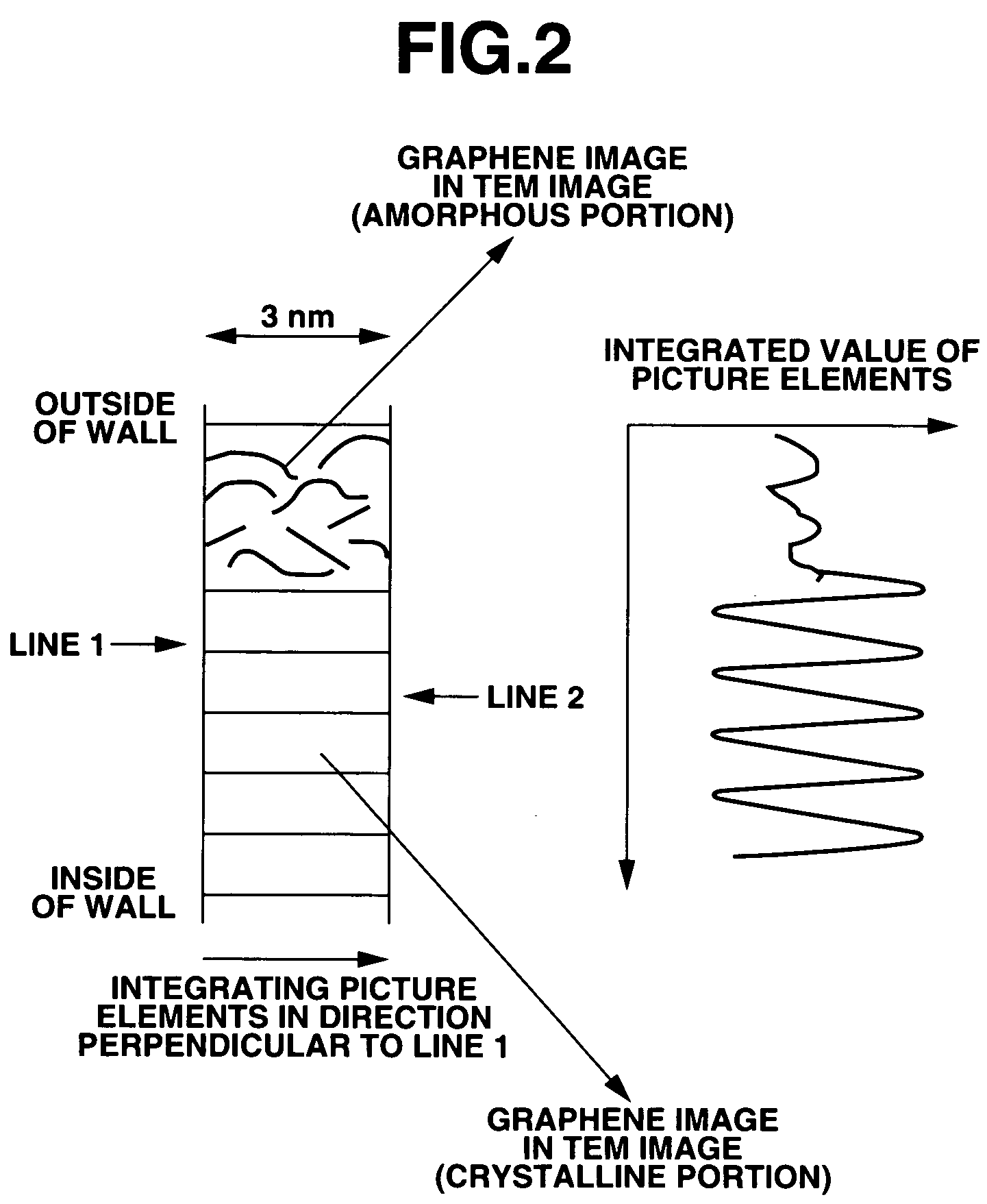

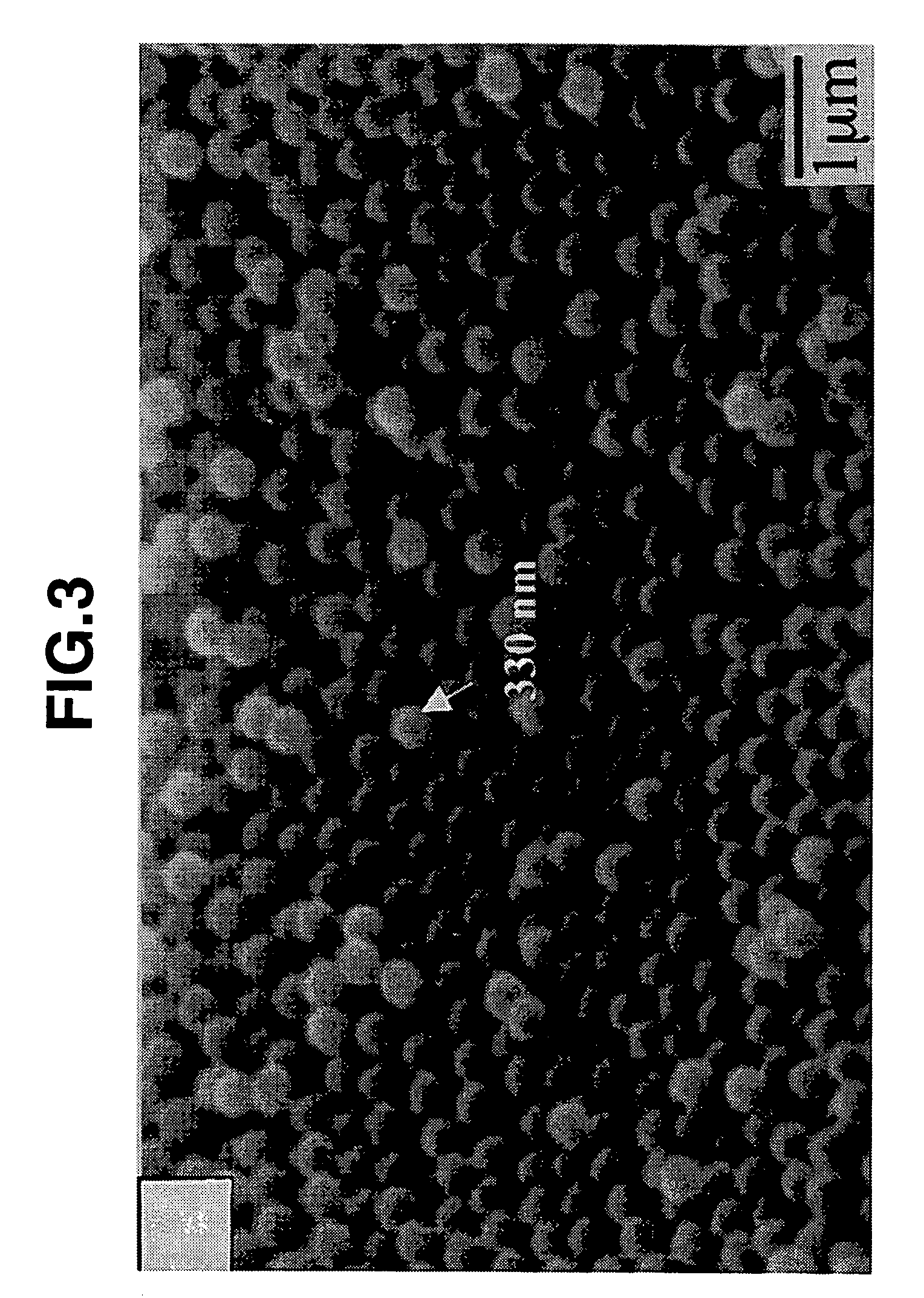

InactiveUS20050100499A1Reduce the overall diameterReduce overall outer diameterMaterial nanotechnologyCarbon nanotubesCarbon nanotubeCrystal structure

The carbon nanotube of the present invention has an outer diameter of not more than 500 nm and a length of not less than 50 nm, and comprises a wall which is made of carbon and includes an outside region of an amorphous structure and an inside region of a crystalline structure. The carbon nanotube of the present invention is a novel carbon nanotube which allows functional groups to be readily bonded to the surface thereof since the outside region of the wall has an amorphous structure, and can exhibit a high electrical conductivity and a high strength since the inside region of the wall has a crystalline structure.

Owner:MITSUBISHI CHEM CORP

Hybrid NANO sorbent

InactiveUS20110168018A1High activityHigh rateMaterial nanotechnologyMethane captureSorbentNanostructure

The invention relates to a hybrid nano sorbent that is capable of reducing and / or removing acidic gases in a gas stream. The hybrid nano sorbent includes at least (i) a nano-structured carbonous material including at least one organic functional group, (ii) at least one metal from at least one of groups 2A, 6B, 7B, 9B or 10B of the periodic table of elements, or (iii) a combination of (i) and (ii). The method for reducing and / or removing the acidic gases in a stream is also described.

Owner:RES INST OF PETROLEUM IND RIPI

Methods of using thin metal layers to make carbon nanotube films, layers, fabrics, ribbons, elements and articles

ActiveUS20090111282A1Improve the immunityLow densityNanoinformaticsSemiconductor/solid-state device manufacturingThin metalThin layer

Methods of using thin metal layers to make Carbon Nanotube Films, Layers, Fabrics, Ribbons, Elements and Articles are disclosed. Carbon nanotube growth catalyst is applied on to a surface of a substrate, including one or more thin layers of metal. The substrate is subjected to a chemical vapor deposition of a carbon-containing gas to grow a non-woven fabric of carbon nanotubes. Portions of the non-woven fabric are selectively removed according to a defined pattern to create the article. A non-woven fabric of carbon nanotubes may be made by applying carbon nanotube growth catalyst on to a surface of a wafer substrate to create a dispersed monolayer of catalyst. The substrate is subjected to a chemical vapor deposition of a carbon-containing gas to grow a non-woven fabric of carbon nanotubes in contact and covering the surface of the wafer and in which the fabric is substantially uniform density.

Owner:ZEON CORP

Controlled growth of a nanostructure on a substrate

ActiveUS7687876B2Optimization mechanismMaterial nanotechnologyNanomagnetismField emission displayDisplay device

The present invention provides for nanostructures grown on a conducting substrate, and a method of making the same. The nanostructures grown according to the claimed method are suitable for manufacturing electronic devices such as an electron beam writer, and a field emission display.

Owner:SMOLTEK AB

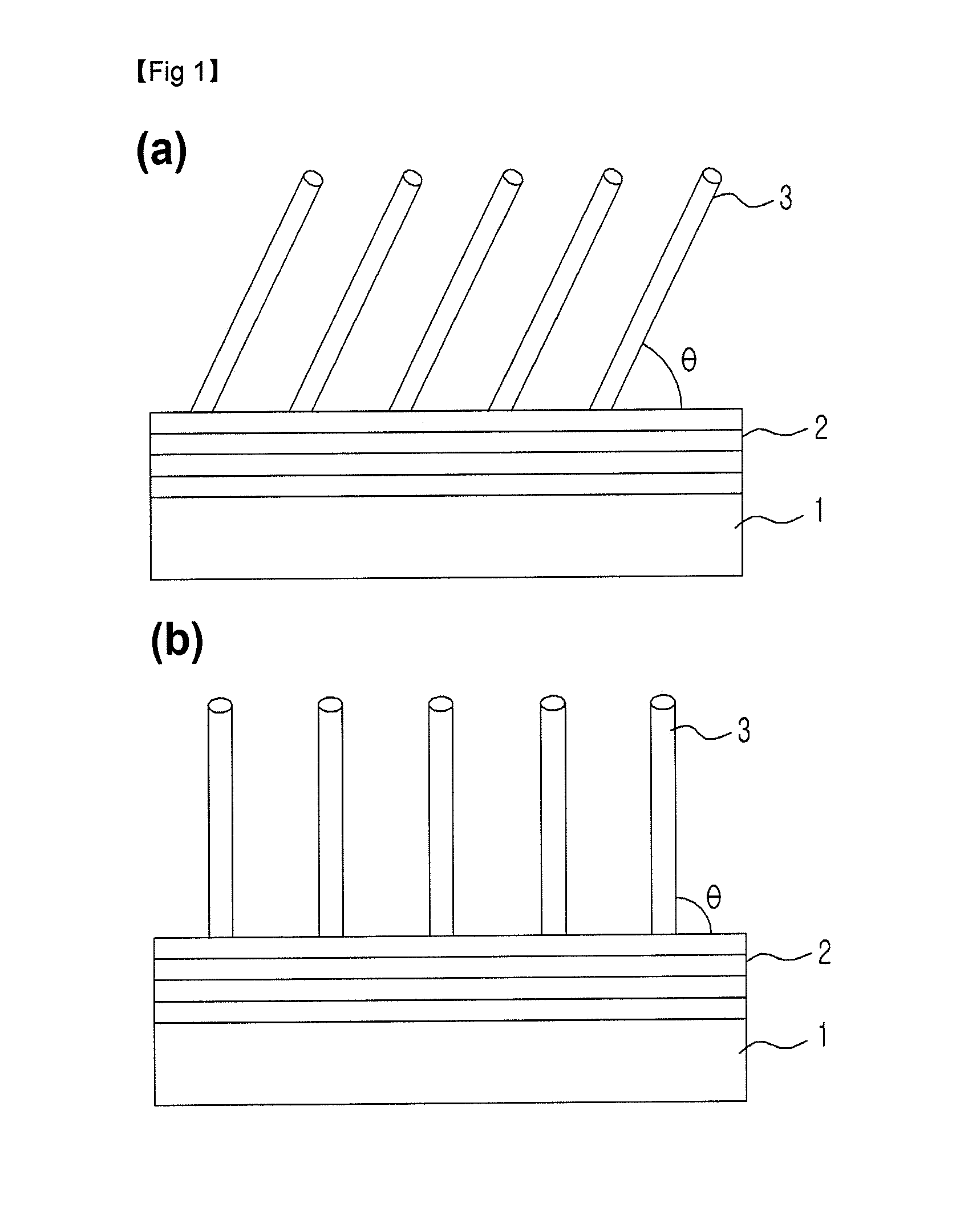

Carbonaceous Nanocomposite Having Novel Structure And Fabrication Method Thereof

ActiveUS20120192931A1Improve adhesionHigh densityMaterial nanotechnologyLayered productsHigh current densityElectrical resistance and conductance

Disclosed is a carbonaceous nanocomposite including: a substrate; a graphene sheet formed on a top surface of the substrate in parallel with the substrate; and a carbonaceous nanomaterial provided on another surface of the graphene sheet, the nanomaterial having an aspect ratio of 2 to 75,000 to make a predetermined angle with the graphene sheet. The carbonaceous nanocomposite according to the present disclosure has excellent adhesivity to the substrate and can be attached to the substrate without undergoing a pasting process. Since a two-directional current flow is generated, the electrical resistance of the graphene and carbon nanotube is considerably reduced. In addition, the graphene allows the carbon nanotube to have a high current density and a high specific surface area, thereby accelerating a redox reaction. The excellent heat-radiating property of the graphene sheet allows fast transfer of heat generated in the carbon nanotube to outside, thereby avoiding degradation of the carbon nanotube. Thus, when employed as an electrode for a battery or a field emission display, a higher current density and an extended lifespan can be achieved when compared with the existing art.

Owner:INJE UNIV IND ACADEMIC COOP FOUND

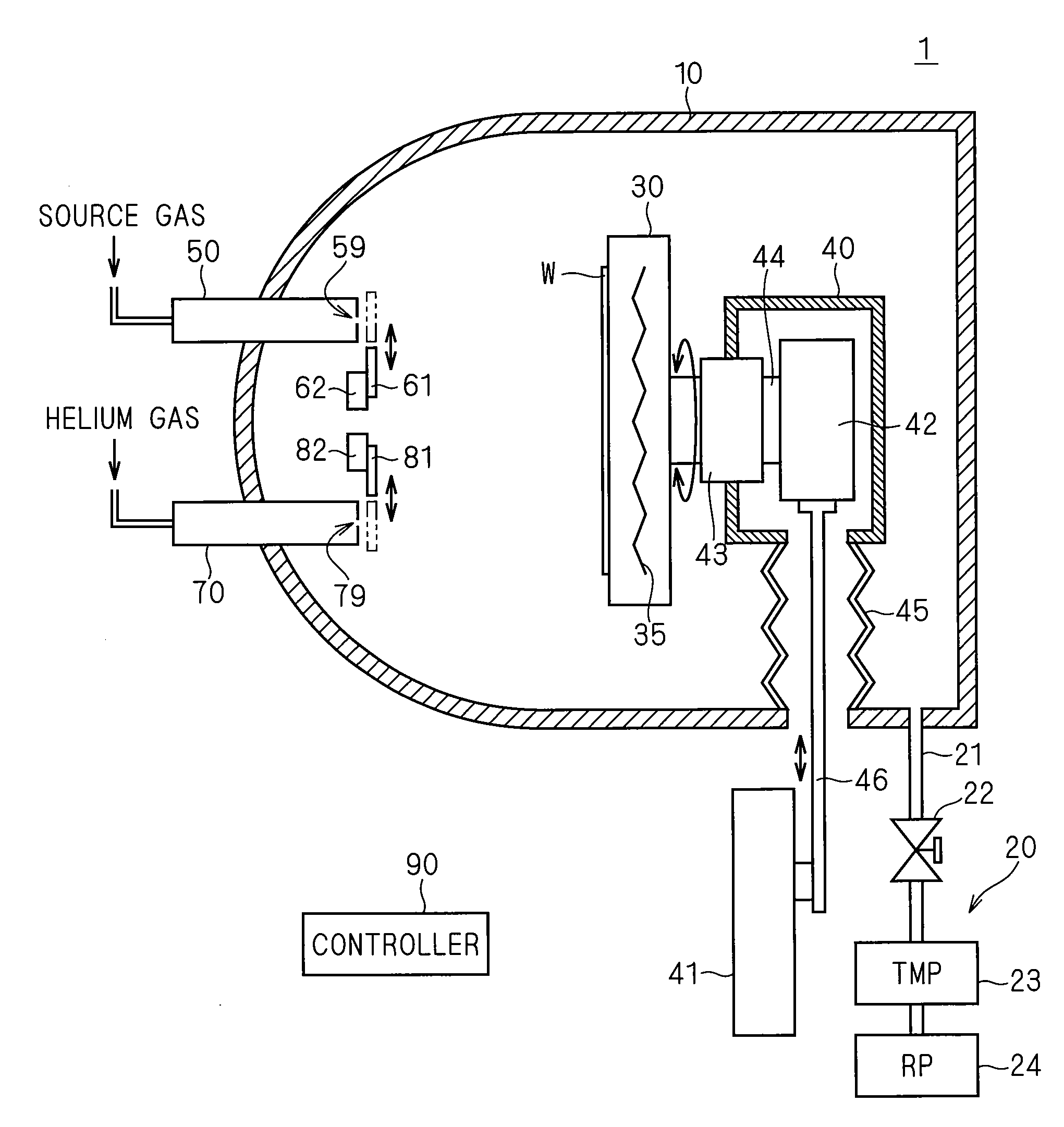

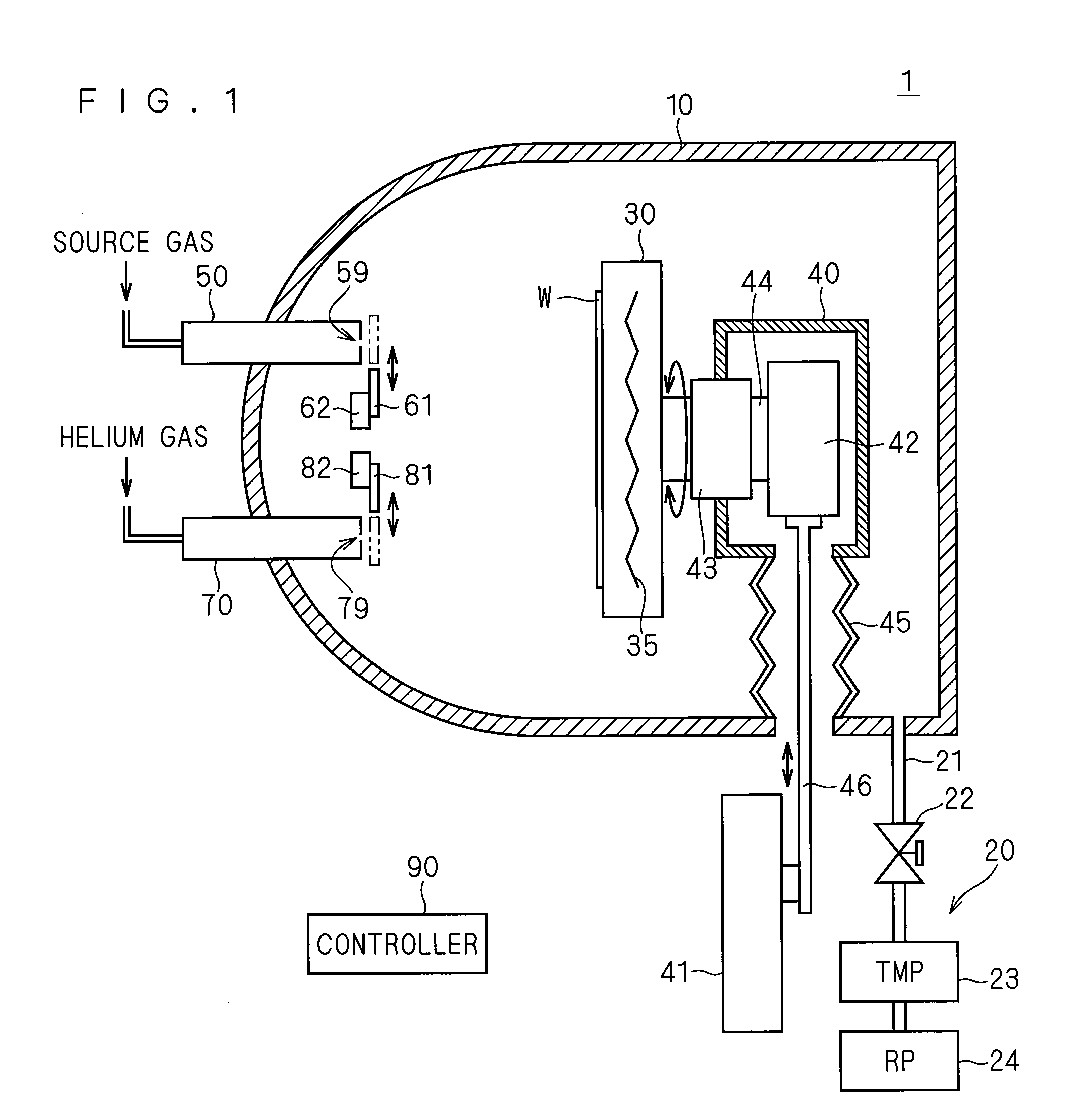

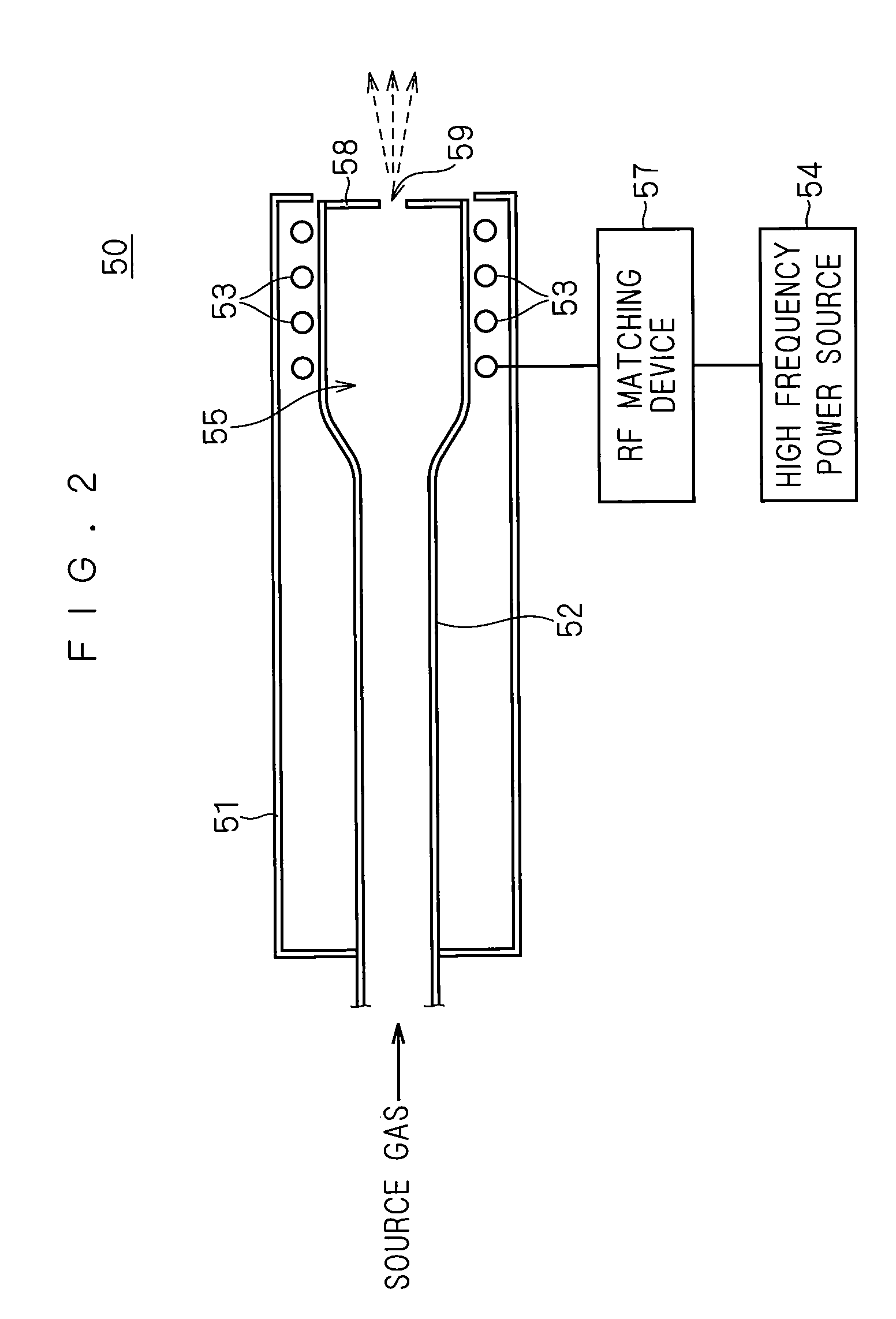

Apparatus for and method of forming carbon nanotube

InactiveUS20090214800A1Quality improvementImprove throughputSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeHigh pressure

A vacuum chamber includes a radical beam irradiation part and a nanoparticle beam irradiation part. A substrate is held by a substrate holding part. The nanoparticle beam irradiation part irradiates the substrate with a beam of metal nanoparticles serving as a catalyst to form the catalyst on the substrate. Thereafter, the radical beam irradiation part generates a plasma from a source gas to irradiate the substrate with a beam of generated neutral radical species to grow a carbon nanotube on the substrate. The provision of an aperture in the radical beam irradiation part allows a relatively high degree of vacuum of 10−5 Torr to 10−3 Torr to be maintained in the vacuum chamber if the generation of the plasma involves a high pressure.

Owner:DAINIPPON SCREEN MTG CO LTD

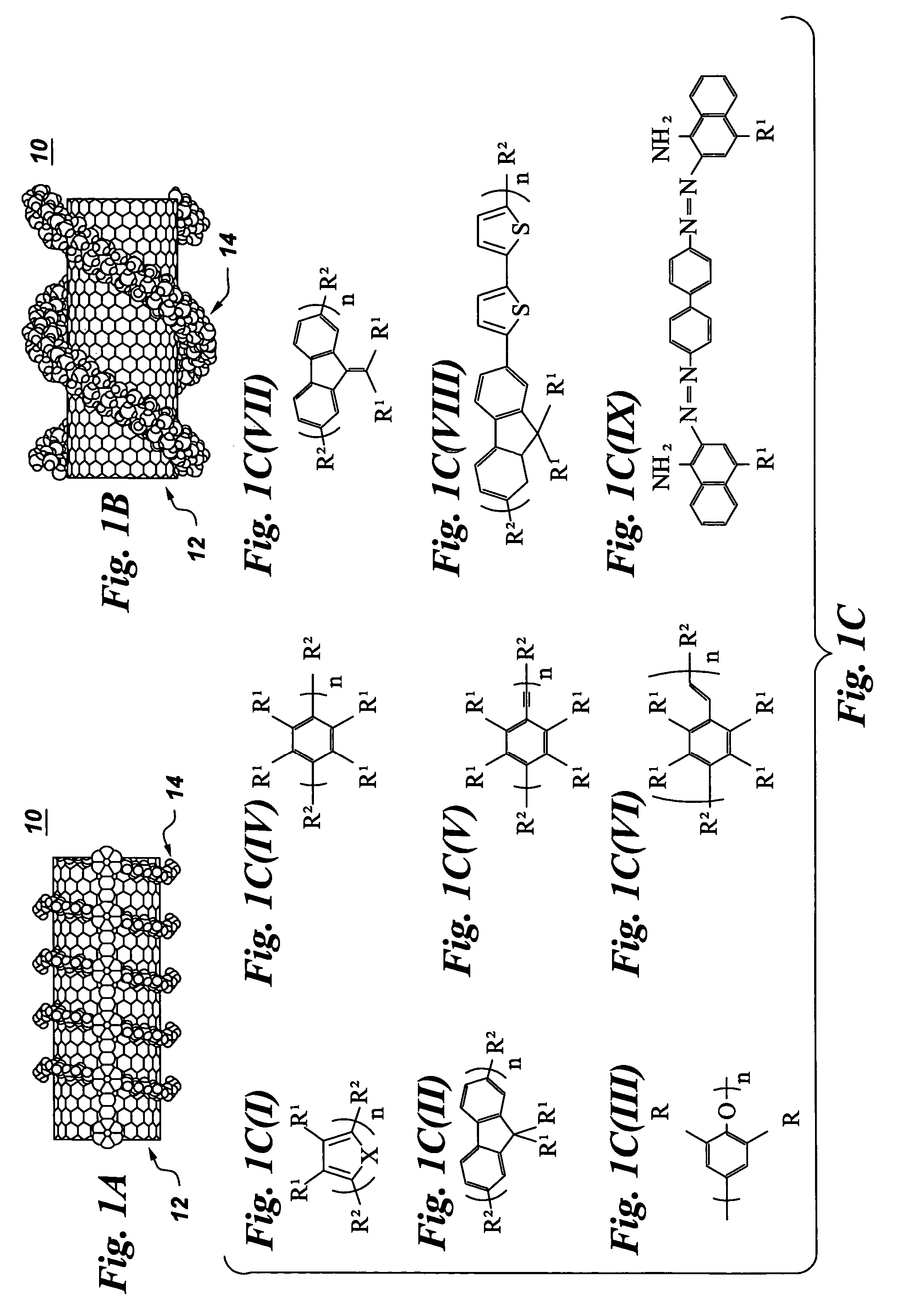

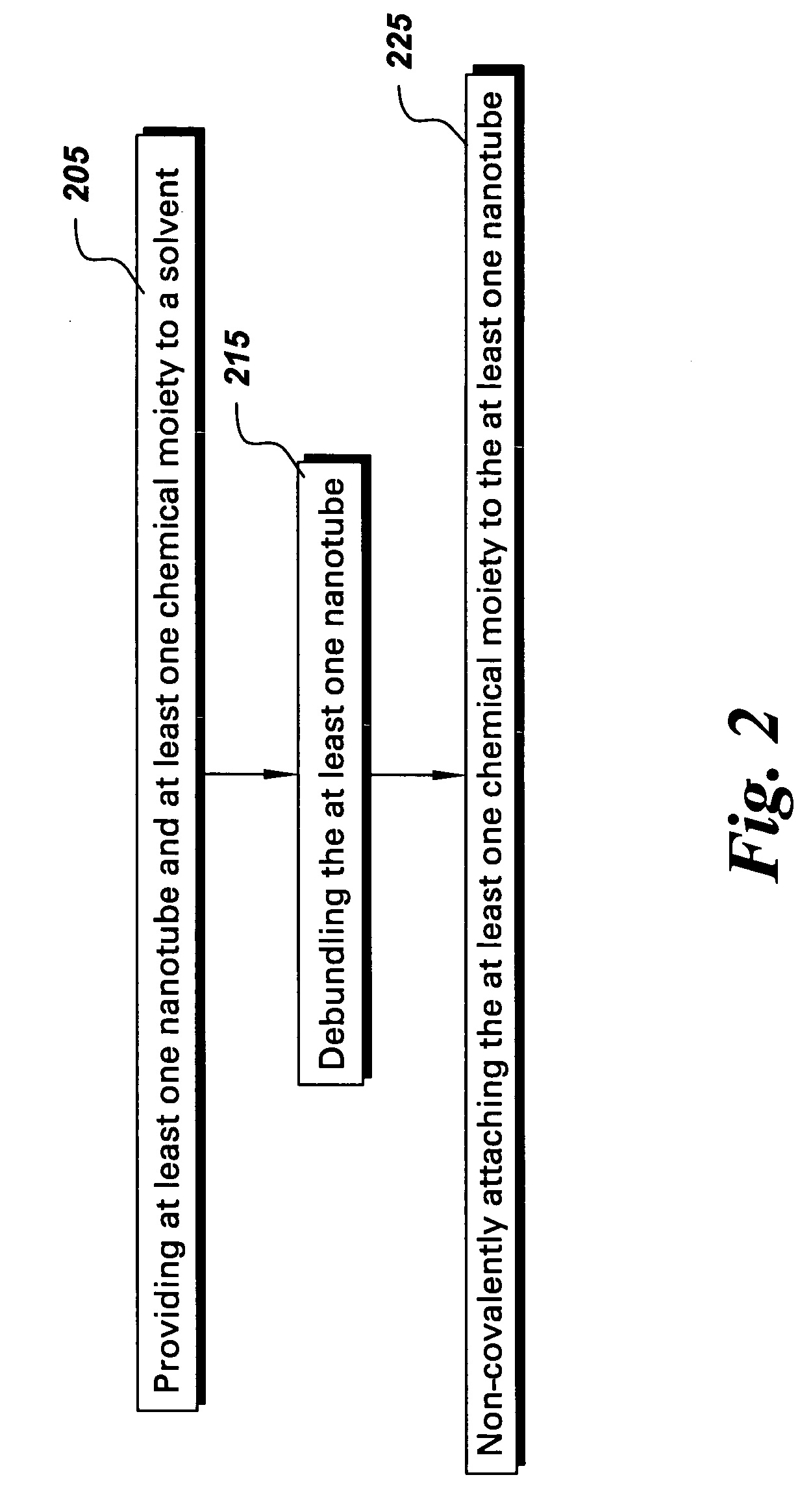

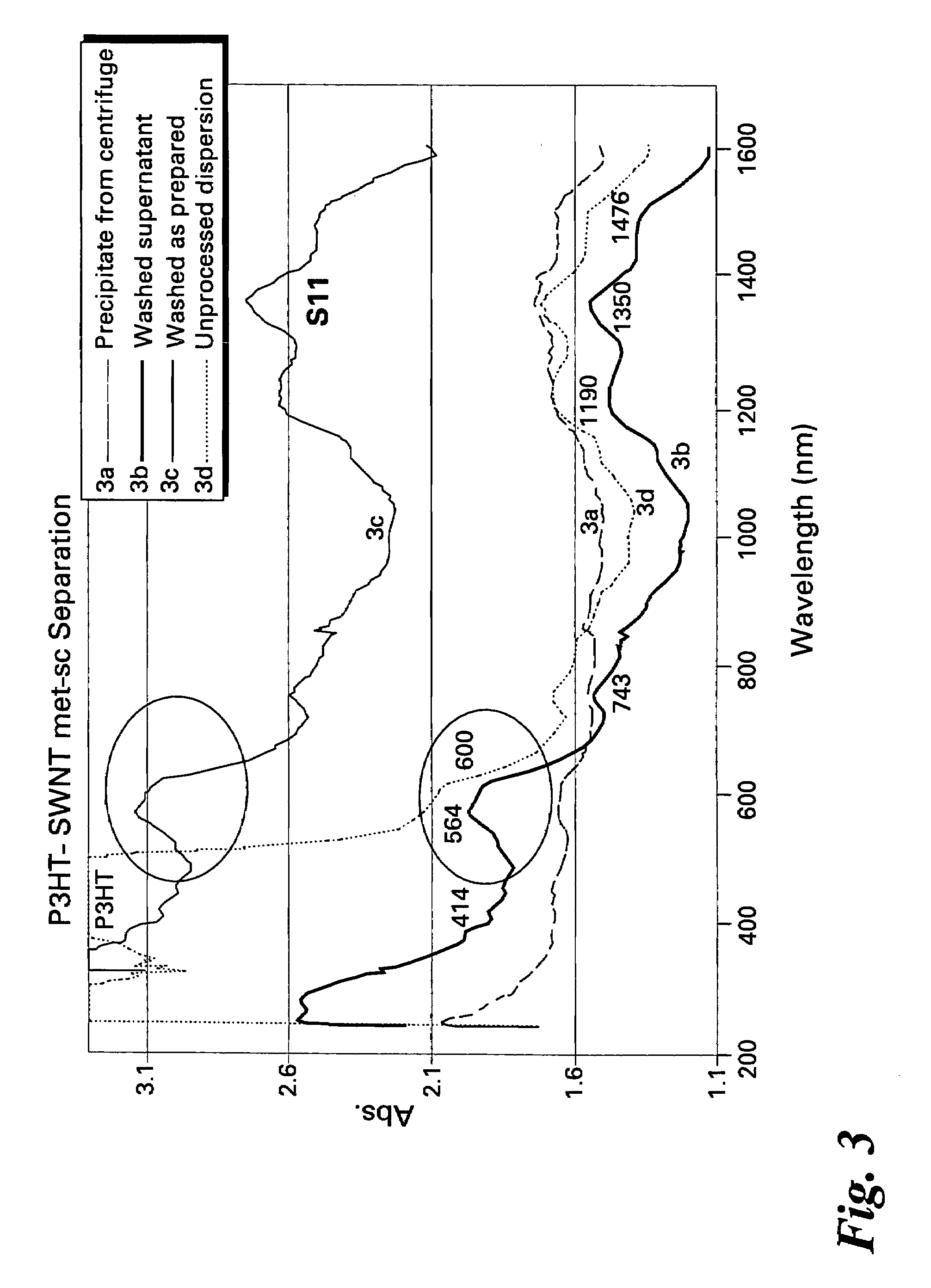

Nanotubes and methods of dispersing and separating nanotubes

A nanostructure having at least one nanotube and at least one chemical moiety non-covalently attached to the at least one nanotube. At least one dendrimer is bonded to the chemical moiety. The chemical moiety may include soluble polymers, soluble oligomers, and combinations thereof. A method of dispersing at least one nanotube is also described. The method includes providing at least one nanotube and at least one chemical moiety to a solvent; debundling the nanotube; and non-covalently attaching a chemical moiety to the nanotube, wherein the non-covalently attached chemical moiety disperses the nanotube. A method of separating at least one semi-conducting carbon nanotube is also described.

Owner:SABIC INNOVATIVE PLASTICS IP BV

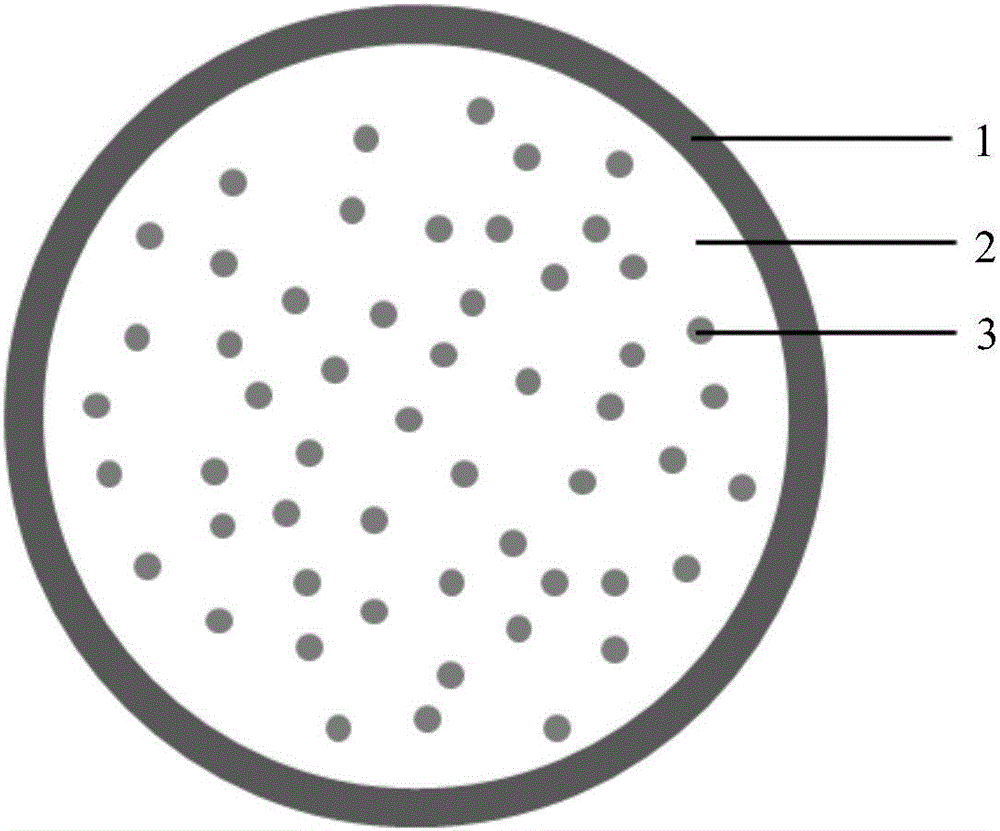

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com