Carbon nanotube and process for producing the same

a carbon nanotube and process technology, applied in the field of carbon nanotubes, can solve the problems of increased production costs, low productivity, unsuitable as a mass production method of carbon nanotubes, etc., and achieve the effect of simplifying the process for producing carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0119] 35 ml of a MMA monomer and 35 mg of potassium persulfate (hereinafter referred to as “KPS”) as a radical polymerization initiator were added to 350 ml of deionized water and mixed together, and the resultant mixture was bubbled with a nitrogen gas for 30 minutes. Thereafter, the mixture was reacted at 70° C. for 4.5 hours and then at 80° C. for 30 minutes while stirring at 300 rpm, thereby obtaining a suspension containing PMMA core particles.

[0120] 90 ml of the thus obtained suspension was mixed with 4 ml of an acrylonitrile monomer, 5 mg of KPS and 270 ml of deionized water, and the resultant mixture was bubbled with a nitrogen gas for 30 minutes. Thereafter, the mixture was reacted at 70° C. for 7.5 hours and then at 80° C. for 30 minutes while stirring at 300 rpm, thereby obtaining a suspension containing PMMA core particles coated with a carbon precursor resin.

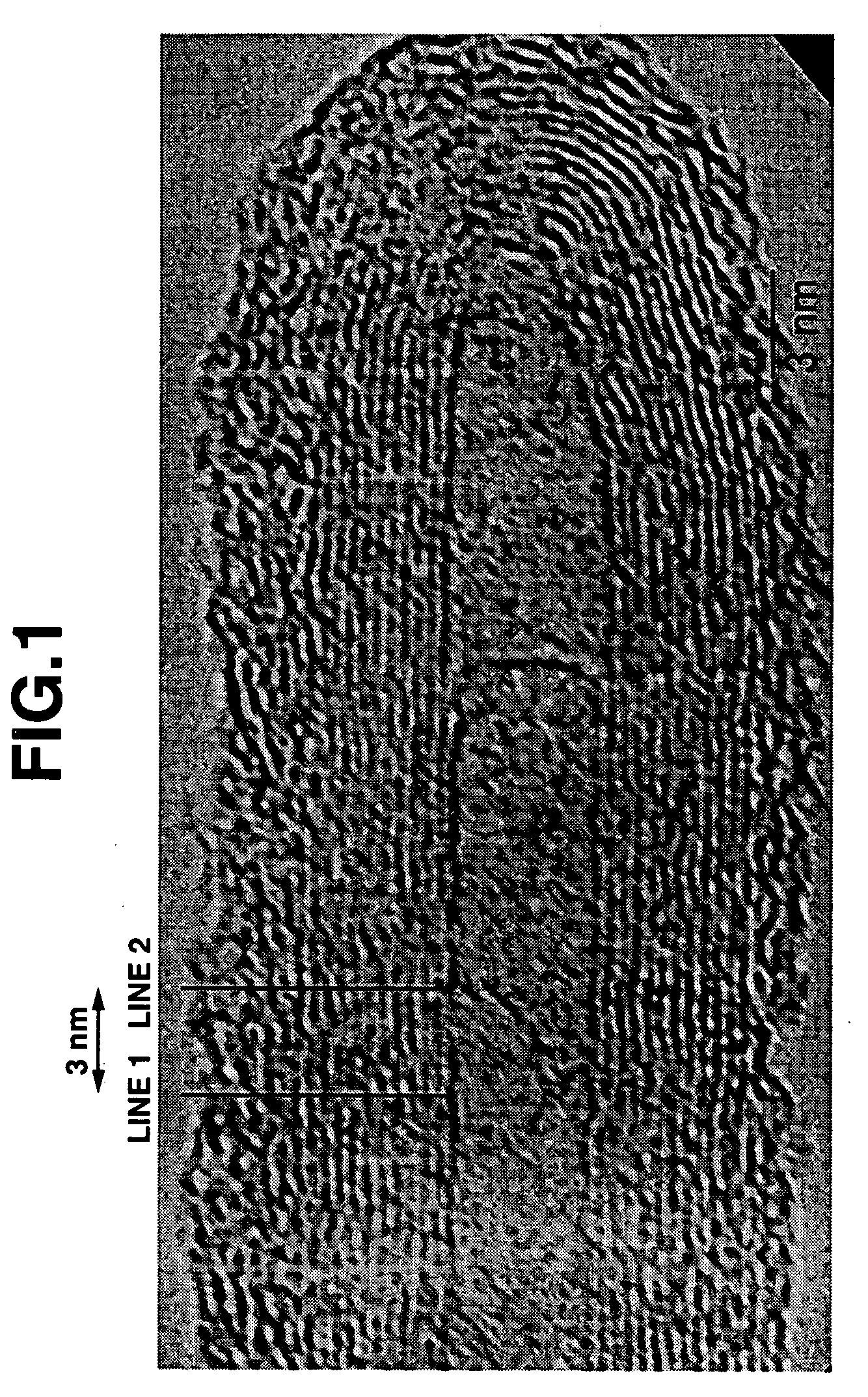

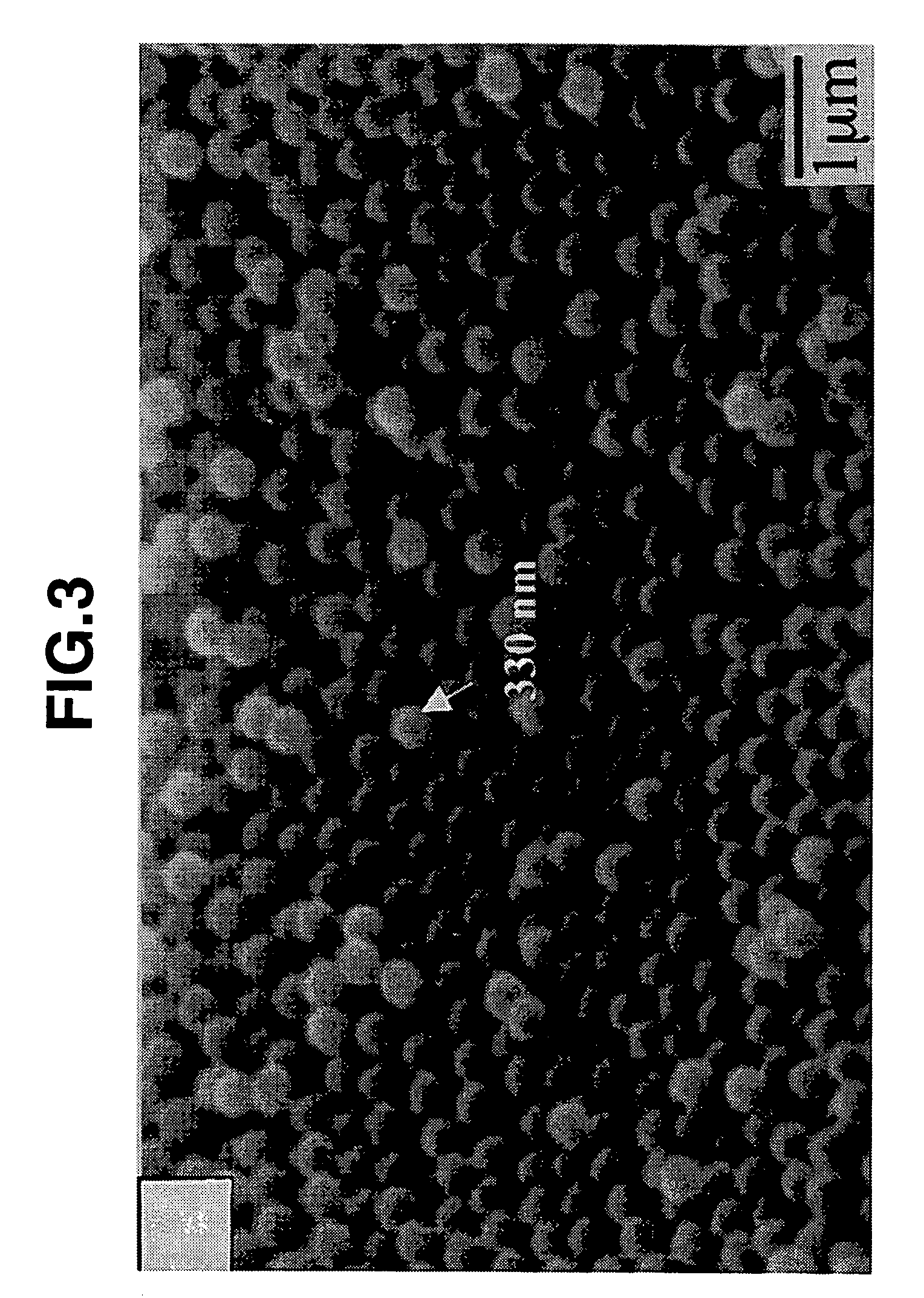

[0121] In FIG. 3, there is shown a SEM (scanning electron microscope) image (used instead of drawing) of avera...

example 2

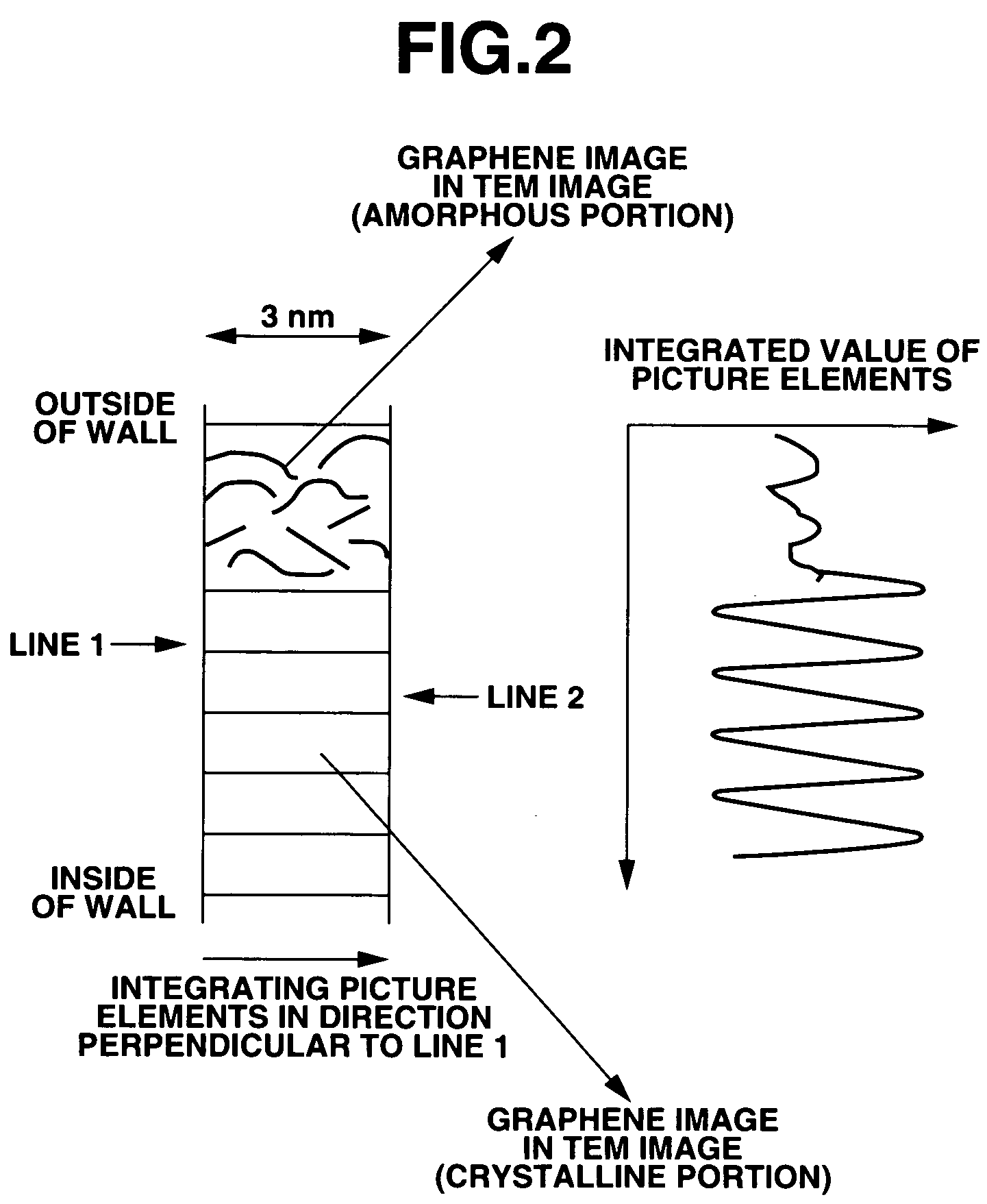

[0125] The same procedure as defined in Example 1 was conducted except that the acrylonitrile added upon polymerization for production of the carbon precursor resin was used in an amount of 2 ml, and the carbonization treatment was performed at 900° C. for 30 minutes, thereby producing carbon nanotubes. As a result, it was confirmed that the thus obtained carbon nanotubes had an average particle diameter of 10 nm, an average central cavity diameter of 2.4 nm and an average wall thickness of about 4 nm. The TEM image (used instead of drawing) of the obtained average carbon nanotubes is shown in FIG. 7. As a result of observing the TEM image, it was confirmed that the wall of the respective carbon nanotubes had an outside region of an amorphous structure and an inside region of a crystalline structure made of graphene sheets. In addition, in the image, there were observed no shades due to metals contained in the carbon nanotubes, and there were further observed images showing the incl...

example 3

[0126] 35 ml of a MMA monomer and 35 mg of KPS as a radical polymerization initiator were added to 350 ml of deionized water and mixed together, and the resultant mixture was bubbled with a nitrogen gas for 30 minutes. Thereafter, the mixture was reacted at a temperature of 70 to 80° C. for 8 hours while stirring at 300 rpm, thereby obtaining a suspension containing PMMA particles.

[0127] 90 ml of the thus obtained suspension was mixed with 2 ml of an acrylonitrile monomer, 5 mg of KPS and 260 ml of deionized water, and the resultant mixture was bubbled with a nitrogen gas for 30 minutes. Thereafter, the mixture was reacted at a temperature of 70 to 80° C. for 8 hours while stirring at 300 rpm, thereby obtaining a suspension containing PMMA core particles coated with a carbon precursor resin. 350 ml of the thus obtained suspension was mixed with 35 ml of a MMA monomer, 5 mg of KPS and 350 ml of deionized water, and the resultant mixture was bubbled with a nitrogen gas for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com