Composite, preparation method and application thereof in lithium ion secondary battery

A composite and lithium compound technology, applied in the field of Si-O-C-Li composites, can solve problems such as not being able to be used in batches, difficult to process, etc., achieve structural stability, reduce silicon expansion problems, and avoid agglomeration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] SiO with a carbon coating on the surface x (x=0.95) 50g, lithium source LiNH 2 12.5g was dispersed at a high speed until uniformly mixed; then placed in an argon atmosphere for heat treatment at 500°C for 2 hours, cooled naturally to room temperature to take out the composite, and then removed impurities by impregnation and dried to obtain a surface-treated composite.

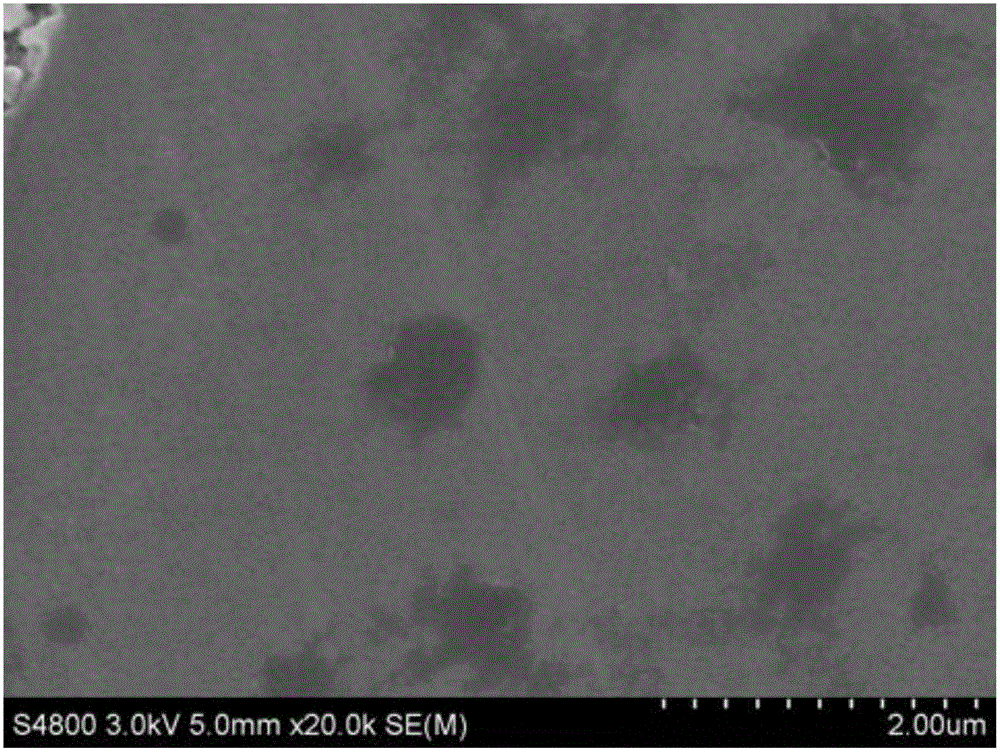

[0082] image 3 It is the SEM picture of the compound obtained in this embodiment. It can be seen from the figure that the dark area formed by the nano-silicon inlaid lithium-containing compound is uniformly distributed in the particles, forming an island with the nano-silicon inlaid lithium-containing compound as an island. Island structure for the sea.

Embodiment 2

[0084] SiO with a carbon coating on the surface x (x=0.95) 500g, lithium source Li 2 CO 3 125g was dispersed at a high speed until uniformly mixed; then placed in an argon atmosphere for heat treatment at 500°C for 2 hours, cooled naturally to room temperature to take out the composite, and then removed impurities by impregnation and dried to obtain a surface-treated composite.

Embodiment 3

[0086] Take SiO with a carbon coating on the surface x (x=0.95) 50g, lithium source metal lithium powder 10.8g were mixed under vacuum for 3h; then placed in an argon atmosphere for heat treatment at 500°C for 2h, cooled naturally to room temperature to take out the composite, and then removed impurities by impregnation and dried , to obtain a surface-treated composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com