Graphitic carbon nitride/polypyrrole composite photocatalytic material and preparation method thereof

A technology of graphite phase carbon nitride and composite photocatalysis, which is applied in the field of composite materials and photocatalysis, can solve the problems of less research on photocatalysts, and achieve the effects of low raw material cost, excellent electrical conductivity, improved dispersibility and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 0.5g of graphite phase carbon nitride into a three-necked flask equipped with 10g of deionized water, stir magnetically for 30 minutes at 10°C, then add 0.005g of pyrrole to the above-mentioned graphite phase carbon nitride dispersion, Under magnetic stirring for 30 minutes, 1g of ammonium persulfate solution (containing 0.12gAPS) was added dropwise to the mixed solution for in-situ deposition oxidation polymerization reaction, and the reaction was carried out under magnetic stirring at 10°C for 10h, and the obtained product was washed with ethanol for 3 times Vacuum dry.

[0022] figure 1 The scanning electron microscope image of the graphite phase carbon nitride / polypyrrole composite photocatalytic material prepared for this example, it can be seen from the figure that after introducing polypyrrole, the polypyrrole particles are deposited on the graphite phase carbon nitride particle on the surface.

Embodiment 2

[0024] Add 0.5g of graphite phase carbon nitride into a three-necked flask equipped with 10g of deionized water, stir magnetically for 30 minutes at 0°C, then add 0.015g of pyrrole to the above-mentioned graphite phase carbon nitride dispersion, Under magnetic stirring for 30 minutes, 1 g of ammonium persulfate solution (containing 0.12 g of APS) was added dropwise to the mixed solution for in-situ deposition oxidation polymerization reaction, and the reaction was carried out under magnetic stirring at 0°C for 10 h, and the obtained product was washed with ethanol for 3 times Then vacuum dry.

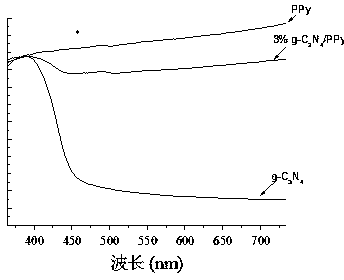

[0025] figure 2 The ultraviolet-visible diffuse reflectance spectrogram of the graphitic phase carbon nitride / polypyrrole composite photocatalytic material prepared for this embodiment, as can be seen from the figure, the composite photocatalyst has more energy in the visible light region than the pure graphitic phase carbon nitride. Strong absorption, red shift occurs. This is mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com