Patents

Literature

212 results about "Template free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

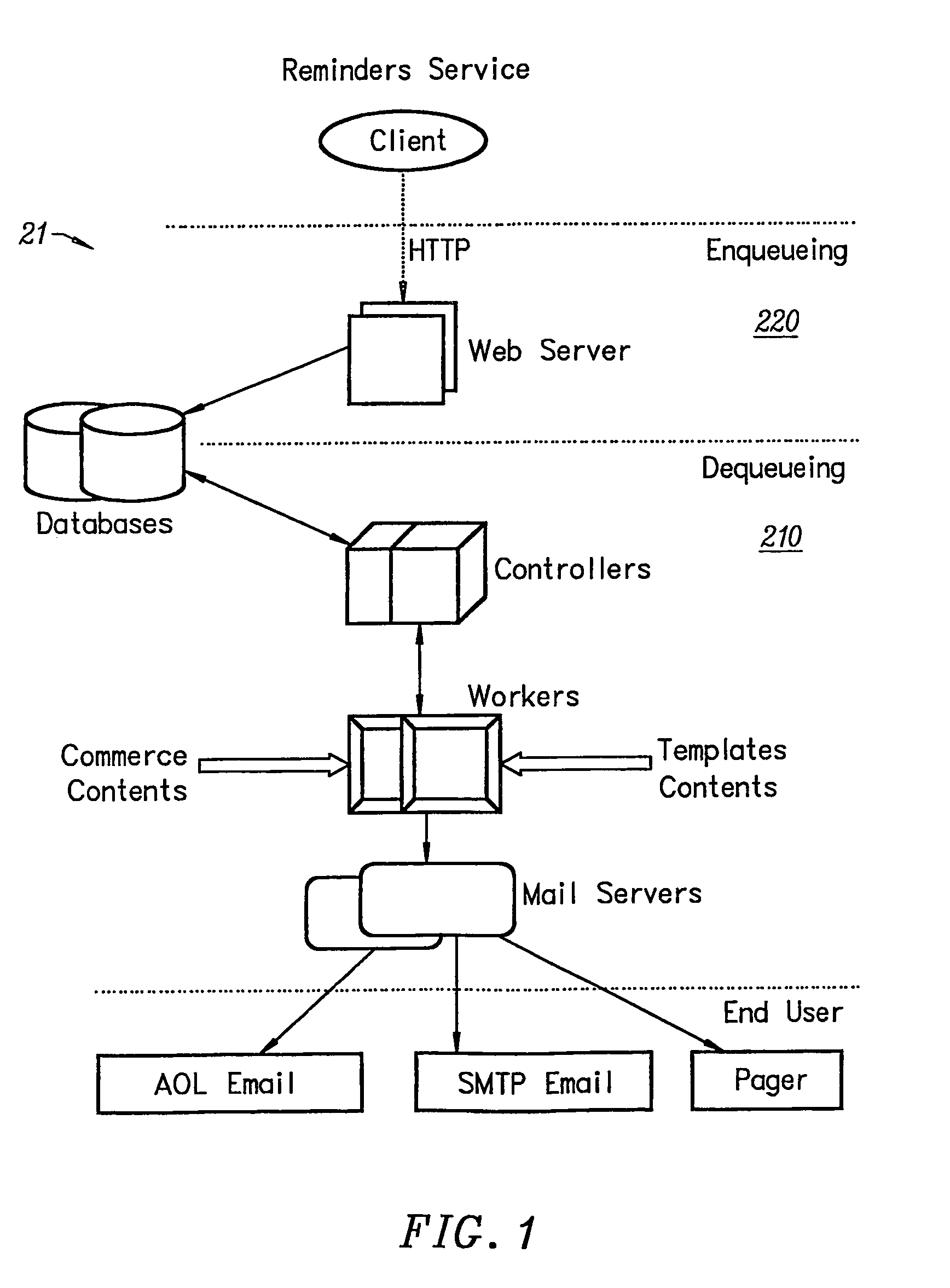

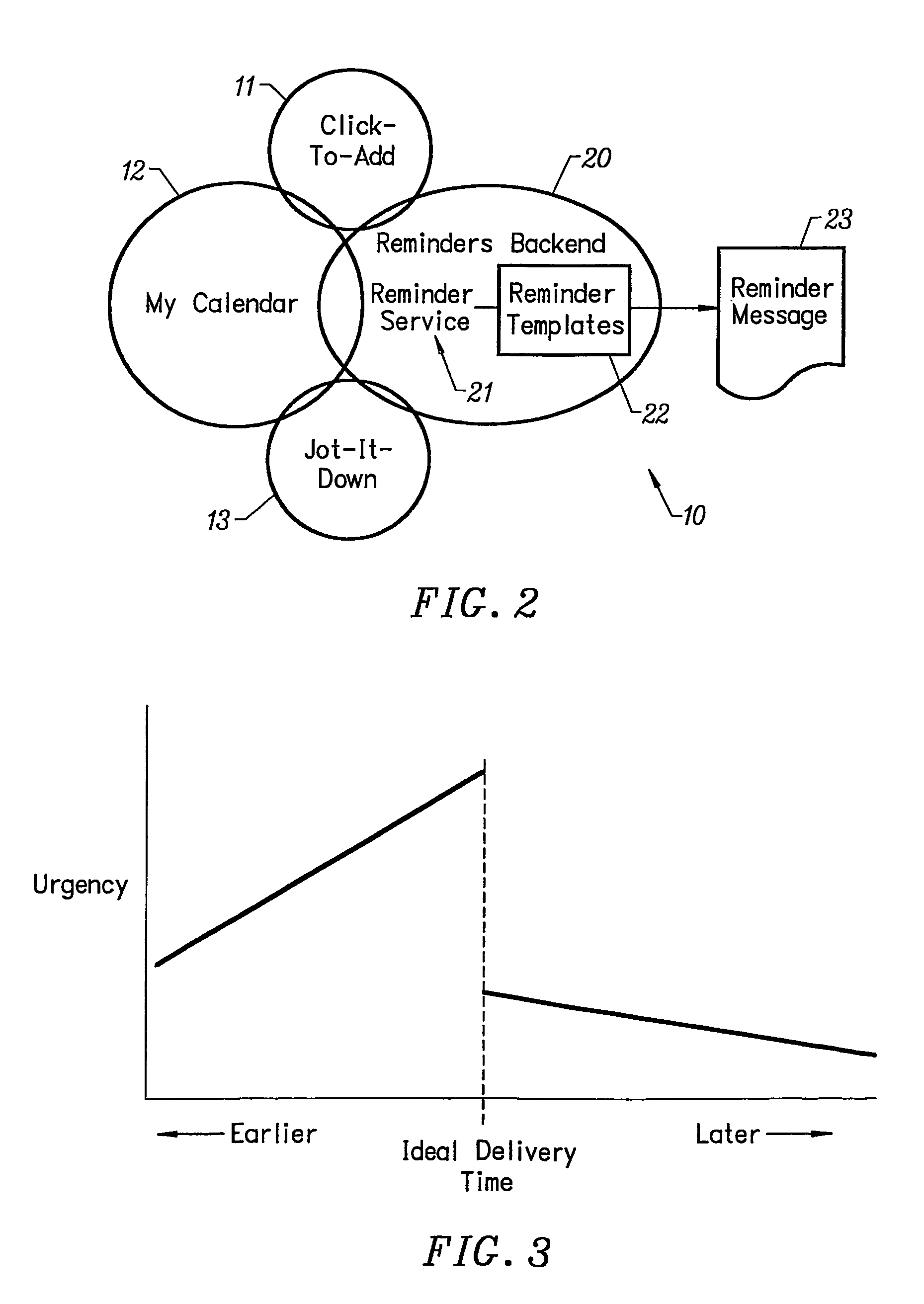

Method and apparatus for calendaring reminders

InactiveUS20040243547A1Reduce in quantityOptimize the numberDigital data information retrievalDigital data processing detailsWorkloadComputer science

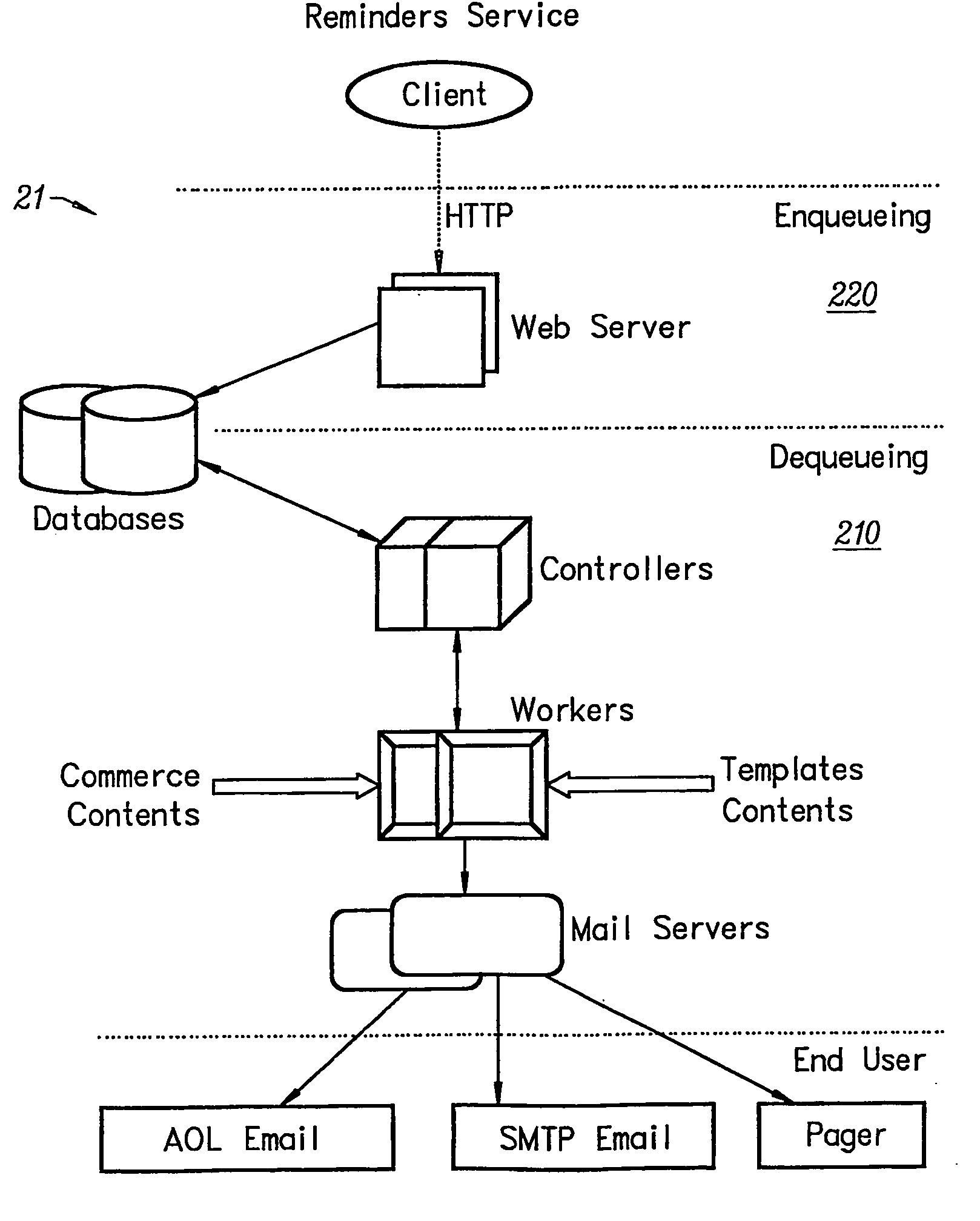

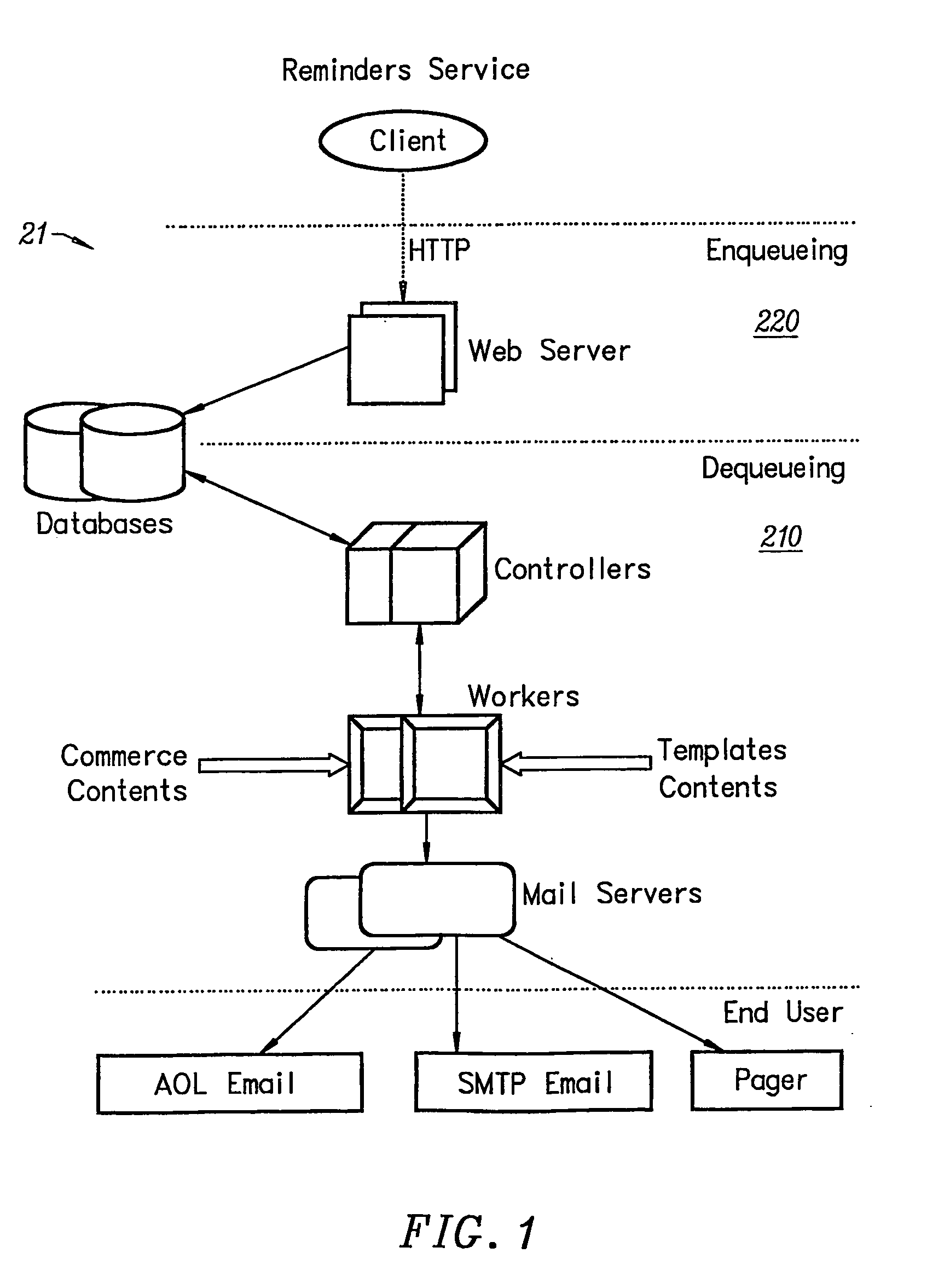

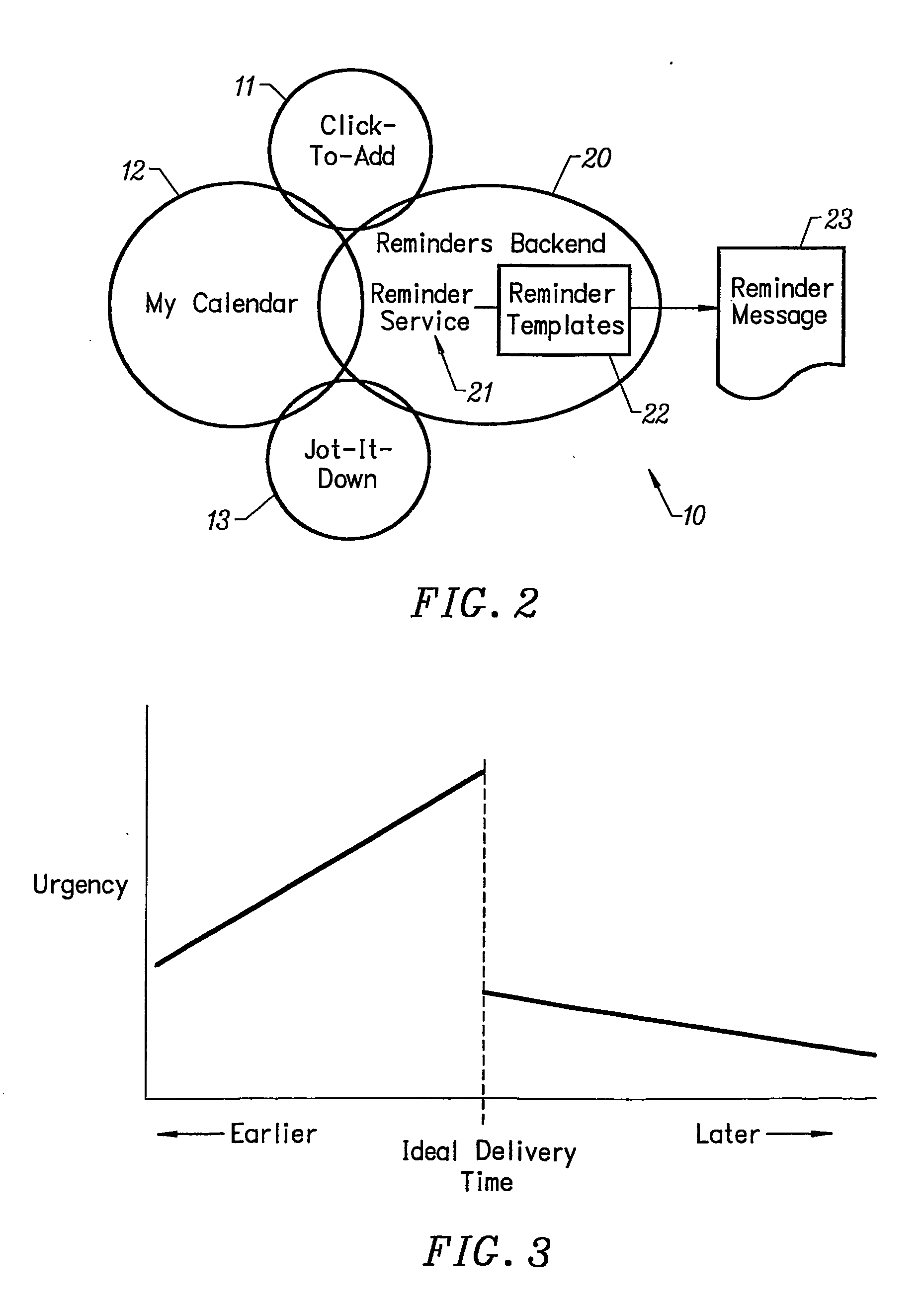

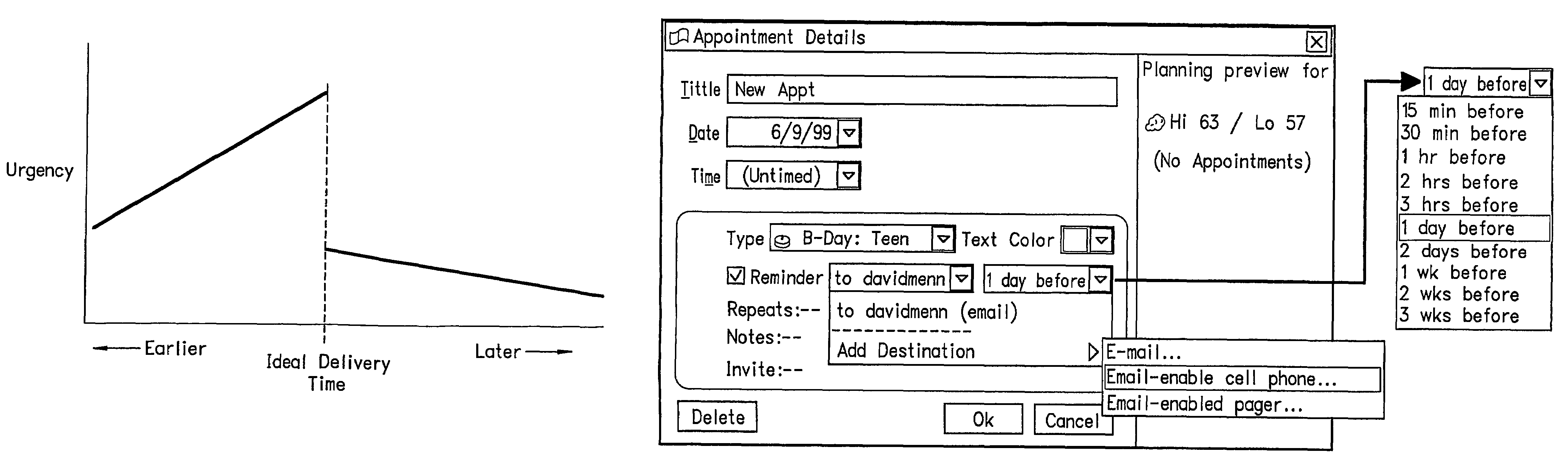

An electronic calendar includes such features as recurring reminders, dividing unpredictable work loads into equal pieces, template free parsing, a reminders scheduling algorithm to reduce spikes, dynamic delivery and recovery algorithms, methods for splitting the work load between controllers and workers and for monitoring progress, all within the context of a calendar architecture for a large enterprise.

Owner:META PLATFORMS INC

Method and apparatus for calendaring reminders

InactiveUS7334000B2Reduce in quantityOptimize the numberDigital data information retrievalDigital data processing detailsComputer scienceParsing

An electronic calendar includes such features as recurring reminders, dividing unpredictable work loads into equal pieces, template free parsing, a reminders scheduling algorithm to reduce spikes, dynamic delivery and recovery algorithms, methods for splitting the work load between controllers and workers and for monitoring progress, all within the context of a calendar architecture for a large enterprise.

Owner:META PLATFORMS INC

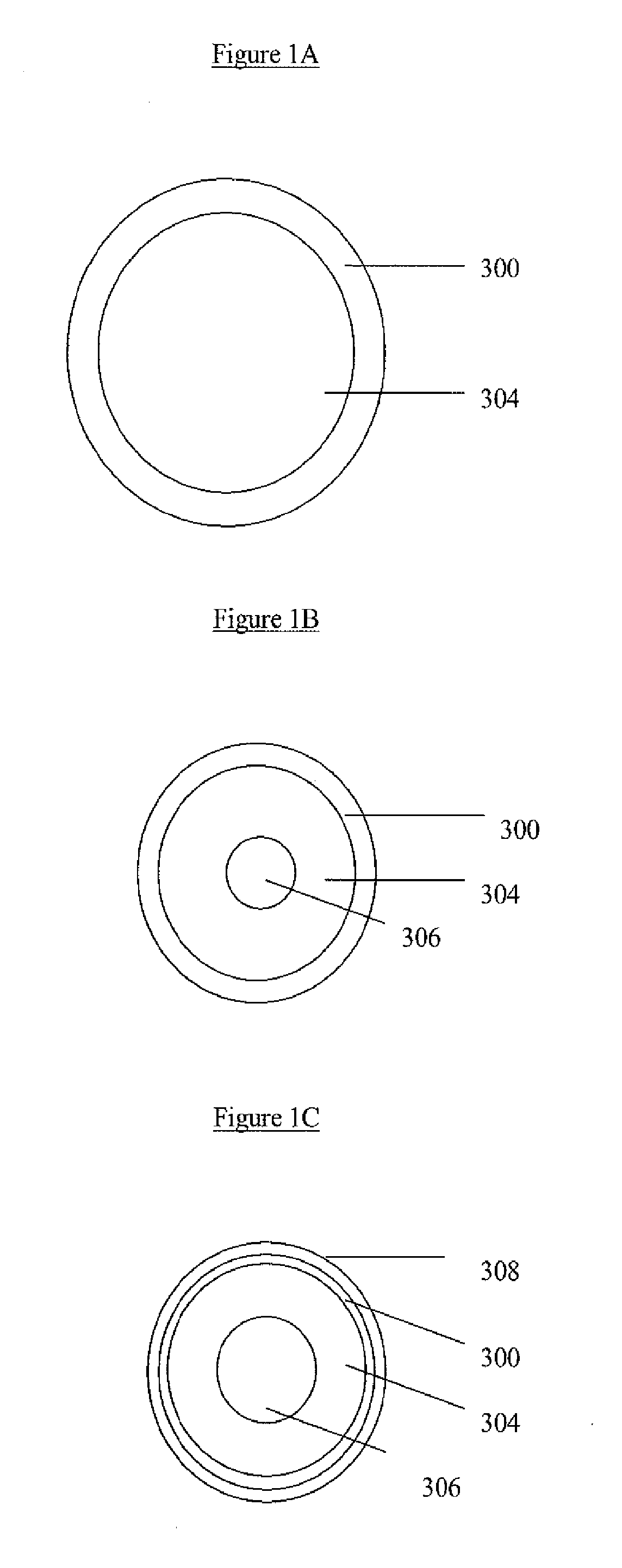

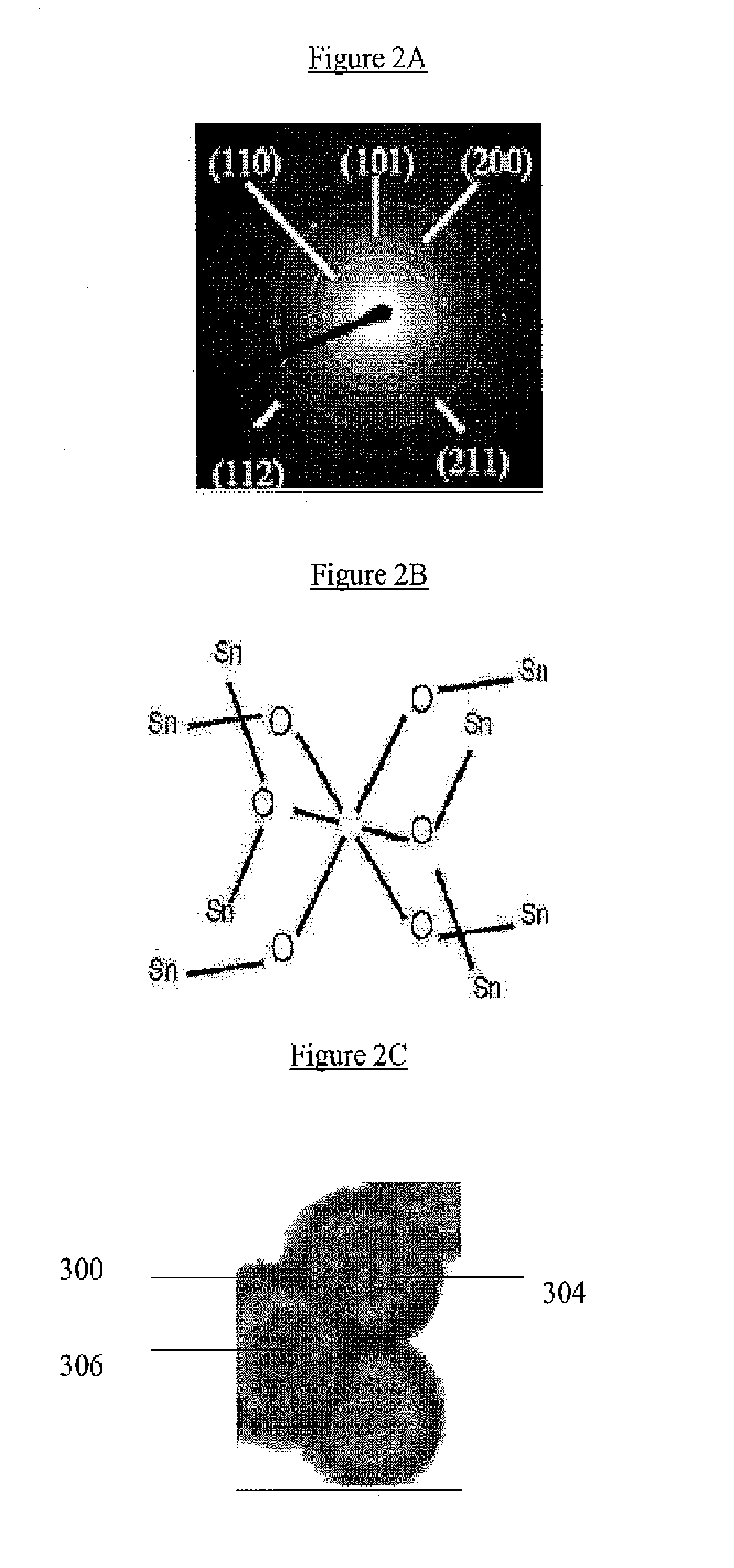

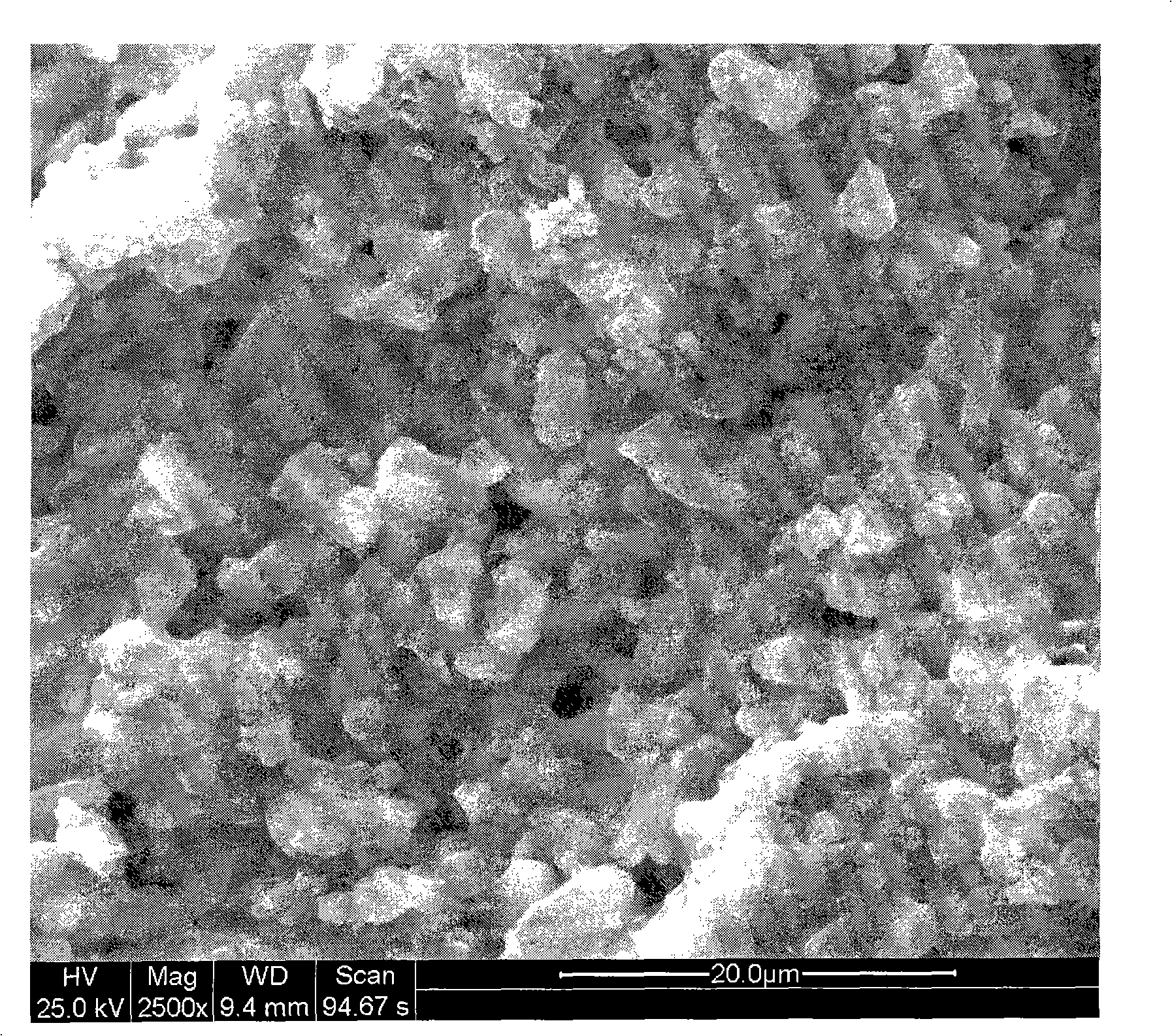

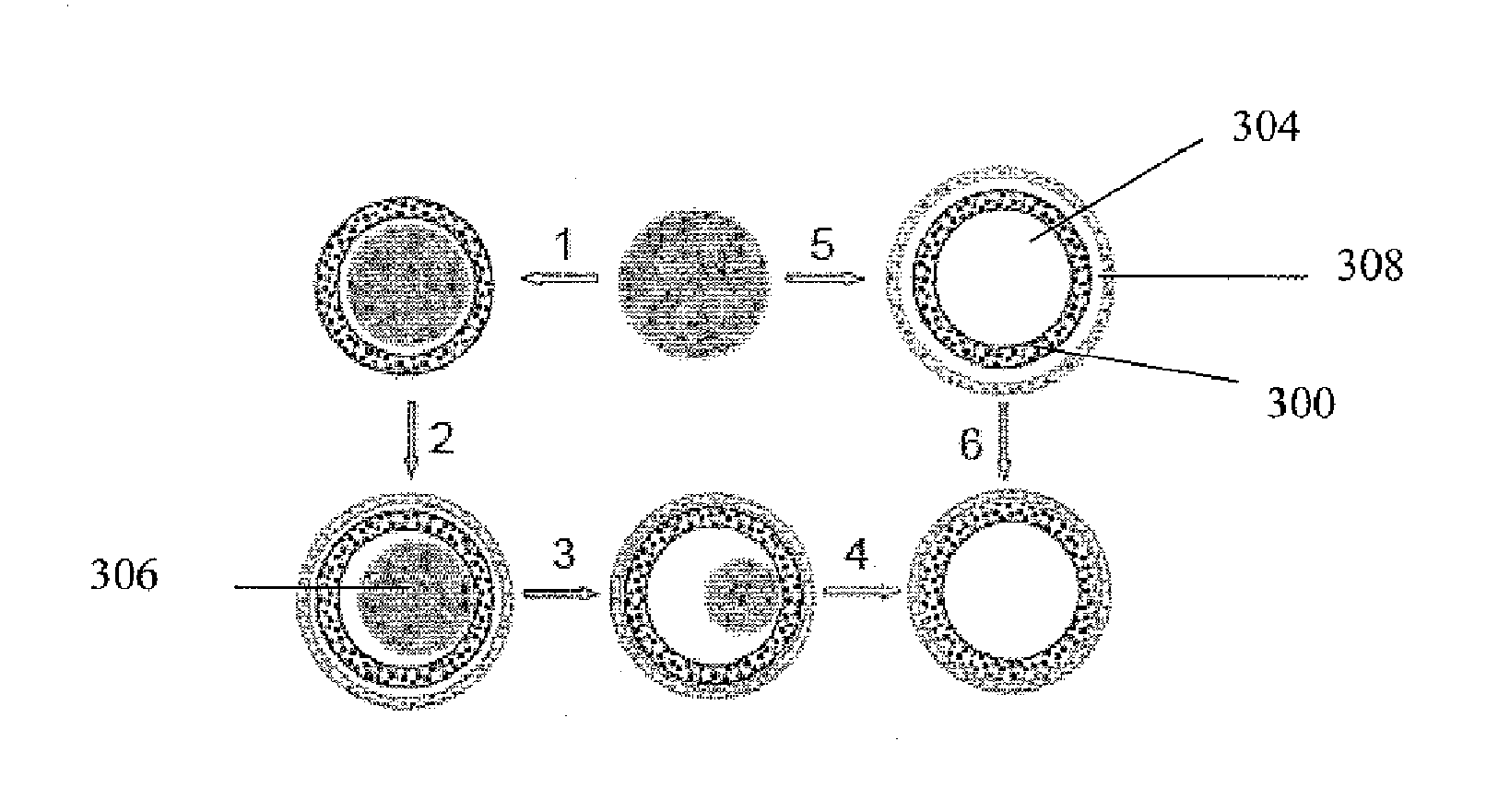

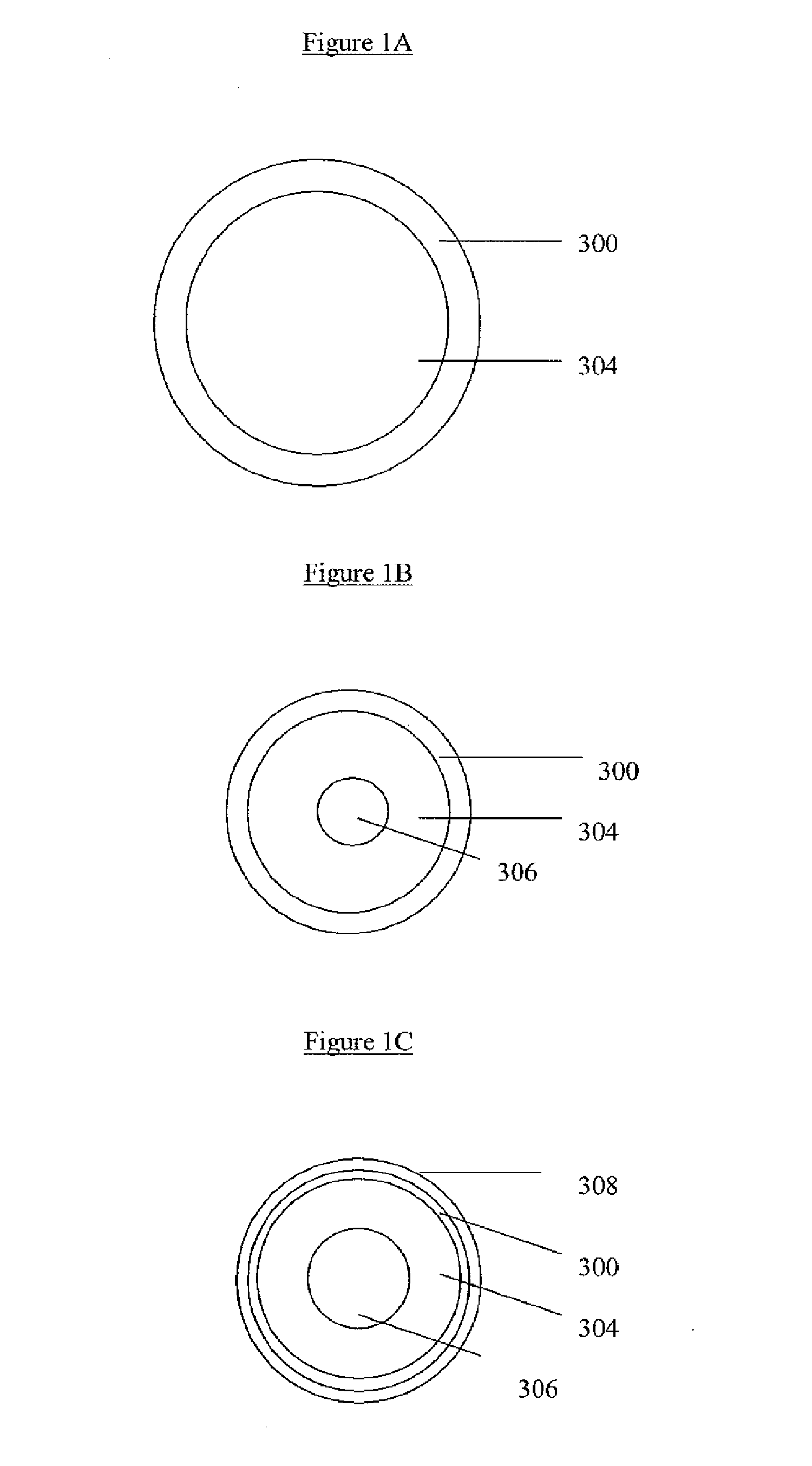

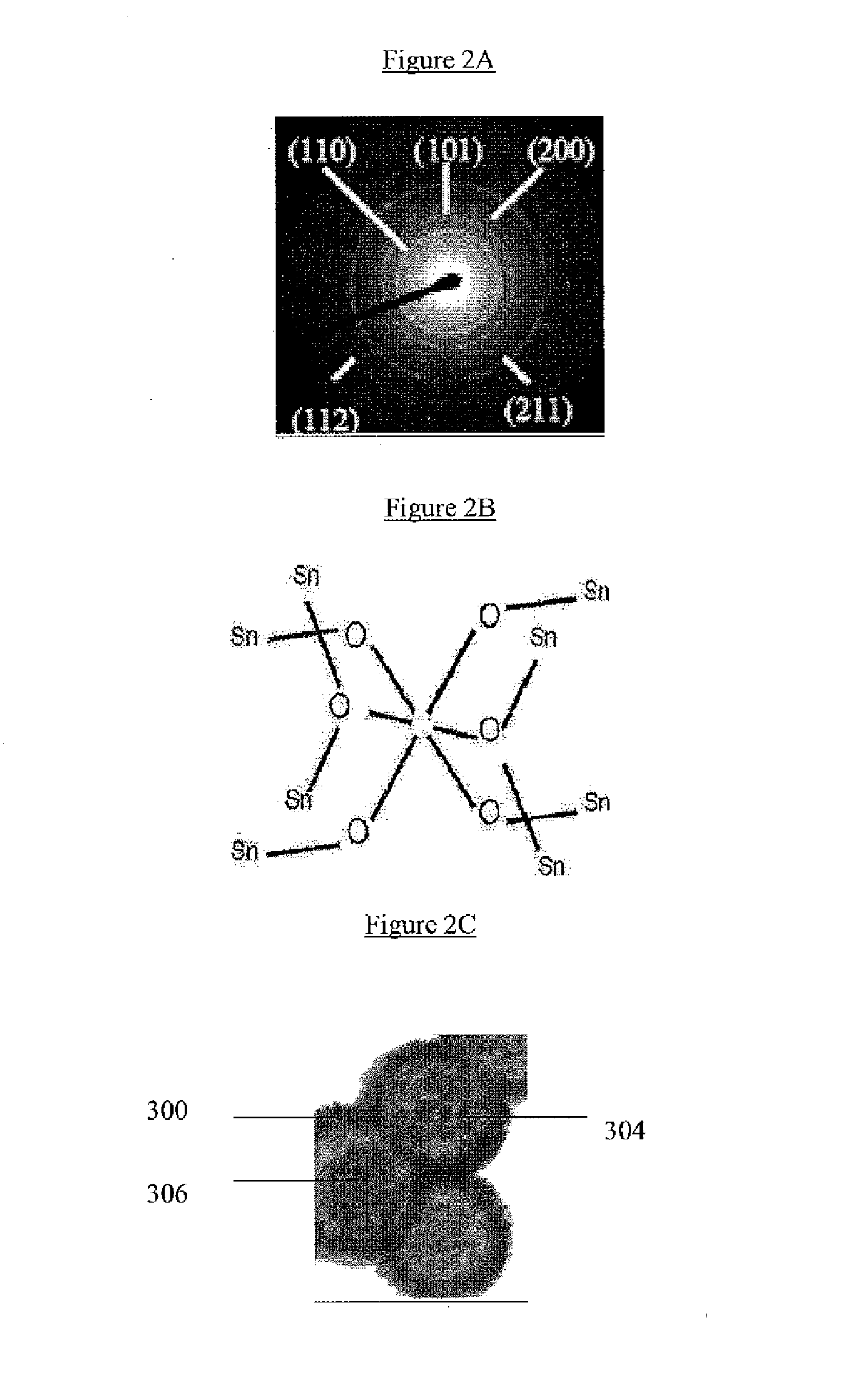

Nanostructured Metal Oxides Comprising Internal Voids and Methods of Use Thereof

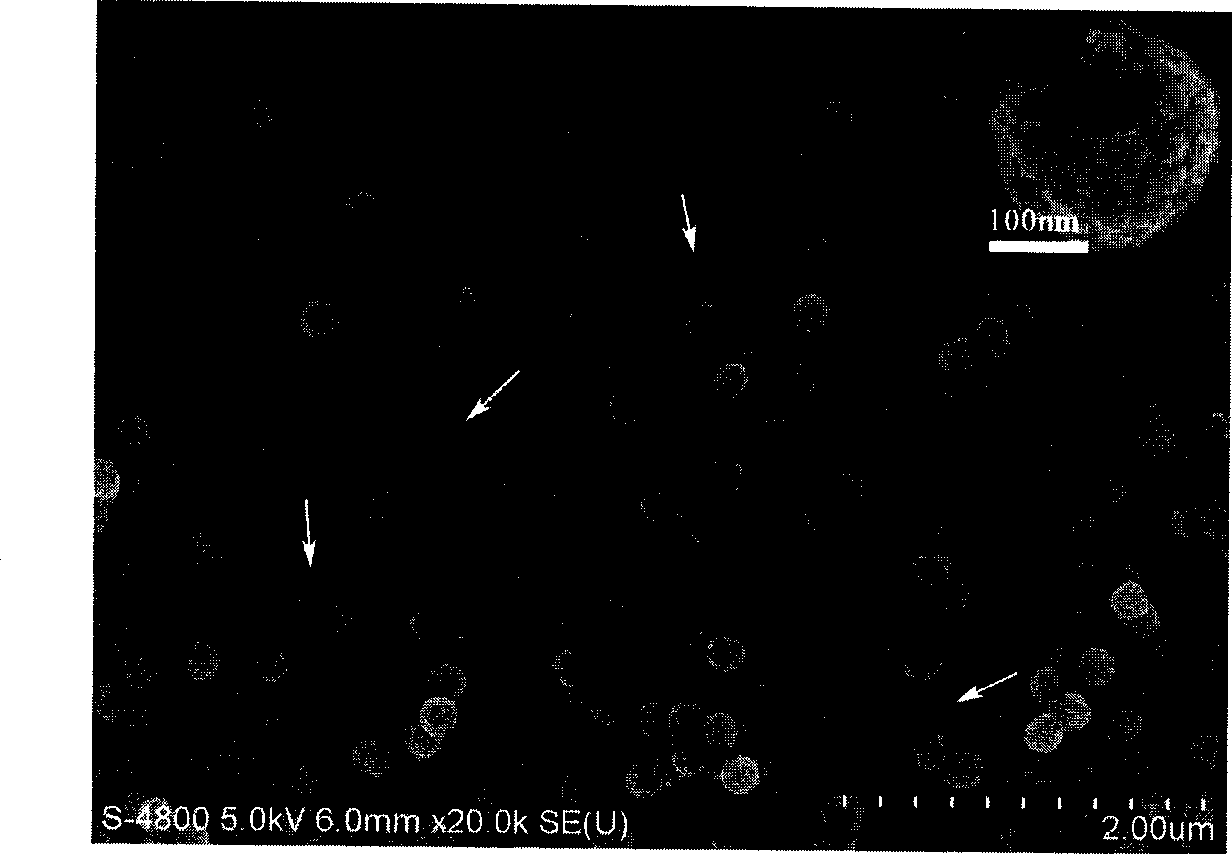

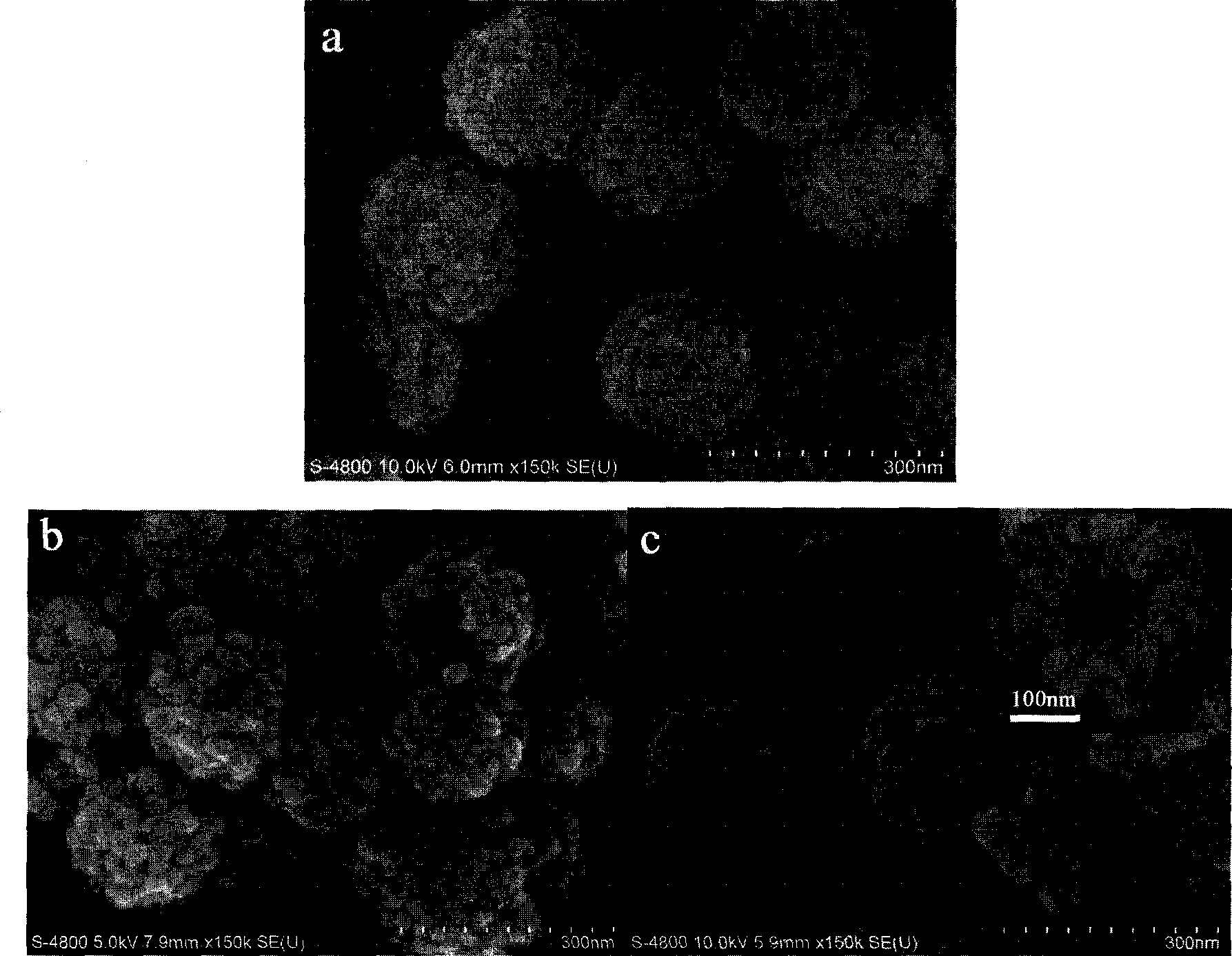

InactiveUS20100258759A1Controllable sizeEasy to useMaterial nanotechnologyElectrolytic capacitorsNanoparticleNanostructured metal

The present invention relates to nano structures of metal oxides having a nanostructured shell (or wall), and an internal space or void. Nanostructures may be nanoparticles, nanorod / belts / arrays, nanotubes, nanodisks, nanoboxes, hollow nanospheres, and mesoporous structures, among other nanostructures. The nanostructures are composed of polycrystalline metal oxides such as SnO2. The nanostructures may have concentric walls which surround the internal space of cavity. There may be two or more concentric shells or walls. The internal space may contain a core such ferric oxides or other materials which have functional properties. The invention also provides for a novel, inexpensive, high-yield method for mass production of hollow metal oxide nanostructures. The method may be template free or contain a template such as silica. The nanostructures prepared by the methods of the invention provide for improved cycling performance when tested using rechargeable lithium-ion batteries.

Owner:CORNELL RES FOUNDATION INC

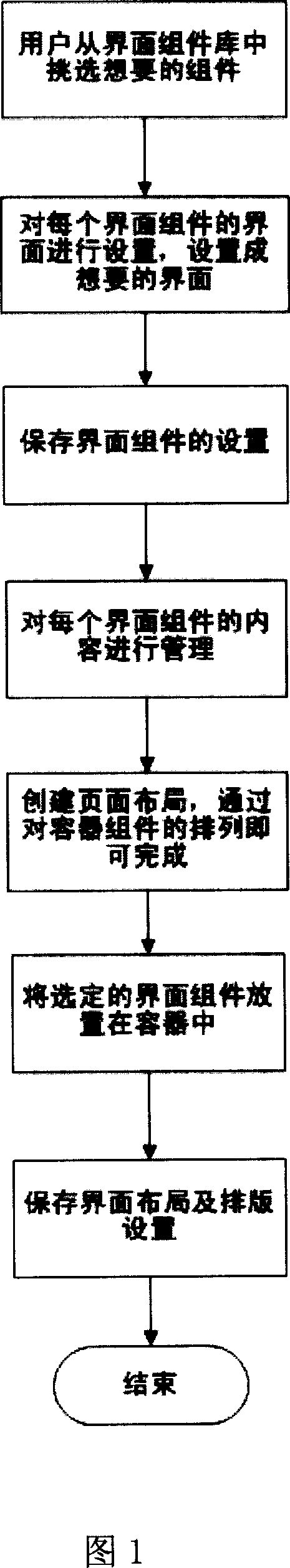

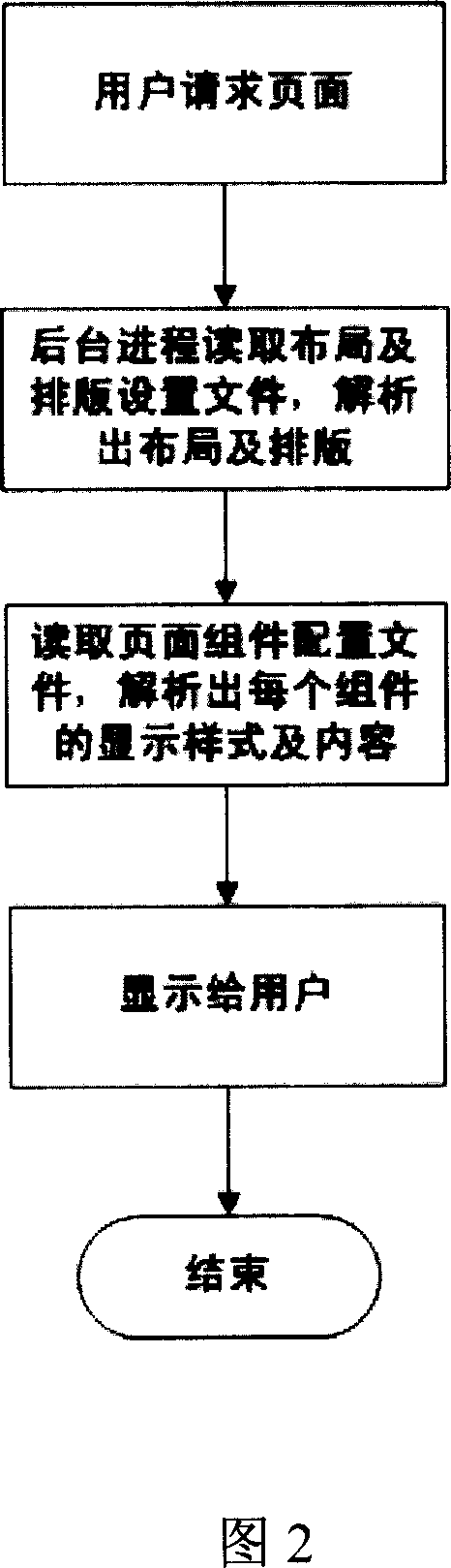

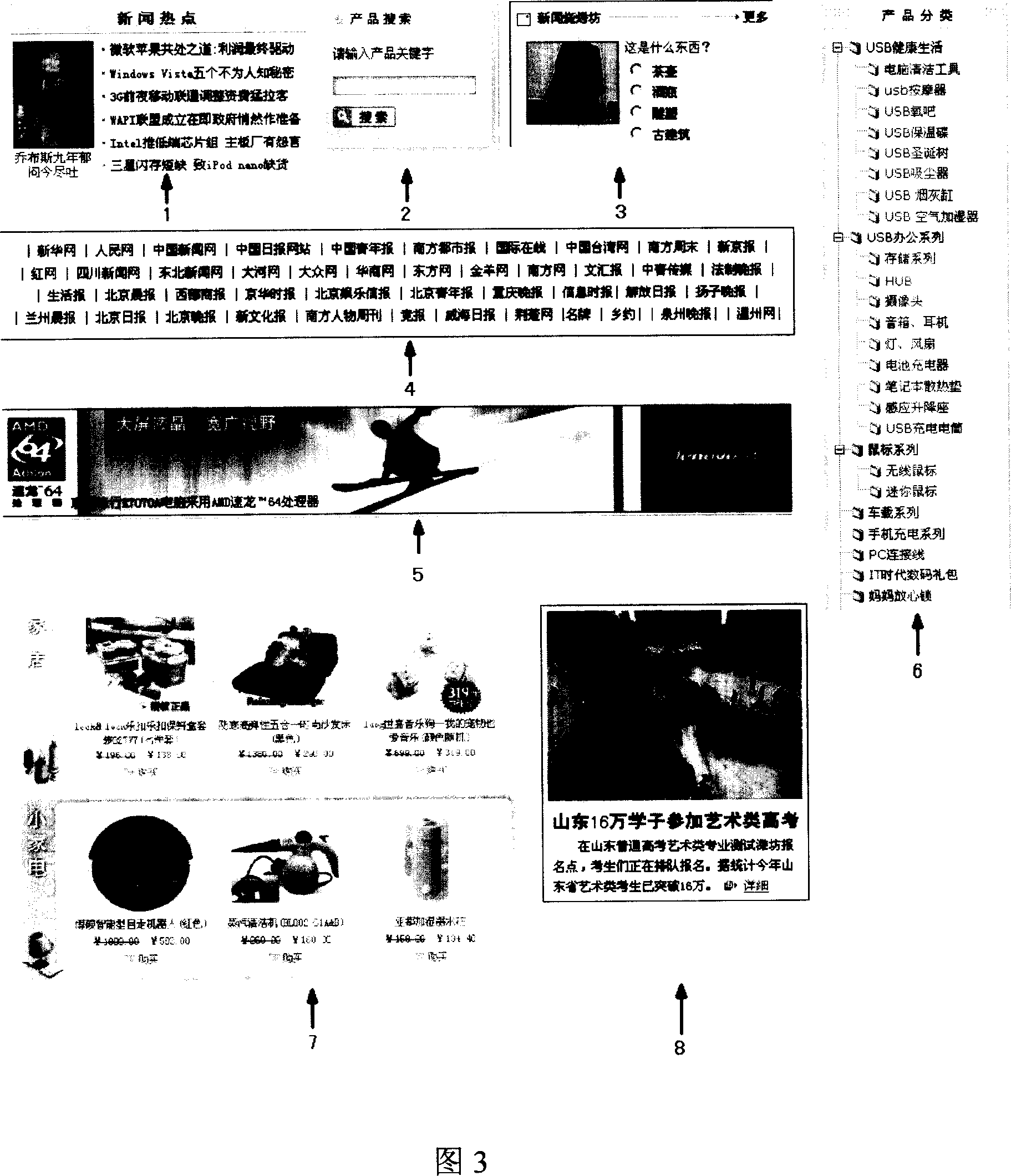

Template-free dynamic website generating method

InactiveCN101025738AEasy to createRealize free typesettingSpecial data processing applicationsWeb siteDatabase

The invention discloses a template-free dynamic website generating method, mainly comprising the steps of: (A) building page component library for users to call as building websites; (B) calling the needed page components from the page component library and setting user-required interface contents and then saving the setting; (C) building page layout and freely composing the page components and saving the interface layout and composition setting, where the page component library is an extensible page component library; each page component is a dynamic maintainable page component comprises color, font, display style and other attributes. And the method is based on dynamic page components to implement free composition and can convert the user's work of writing program as building a dynamic website into the work of calling and maintaining page components, and can quickly build an extremely individual dynamic website without professional software engineer and artistic designer.

Owner:李定

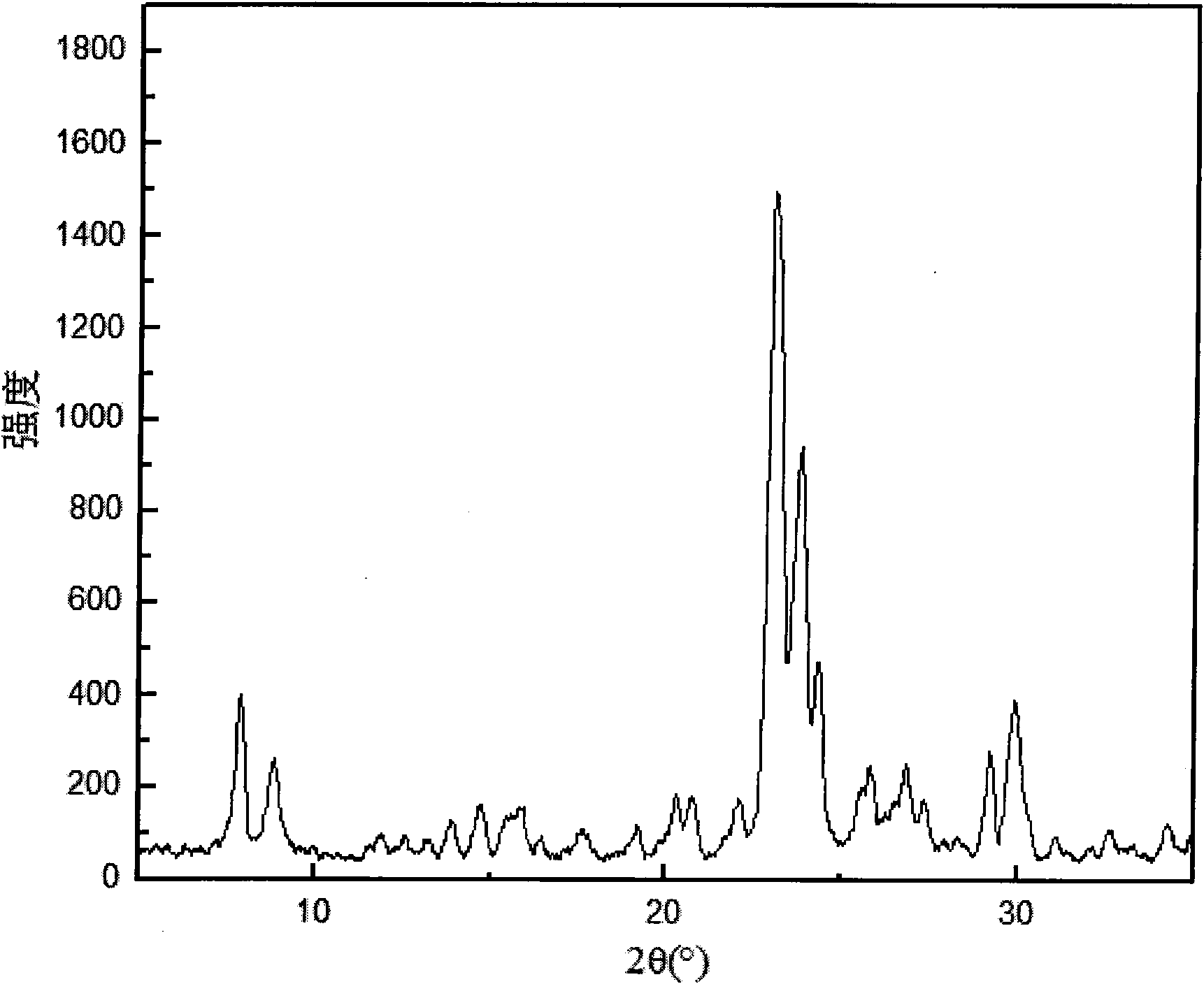

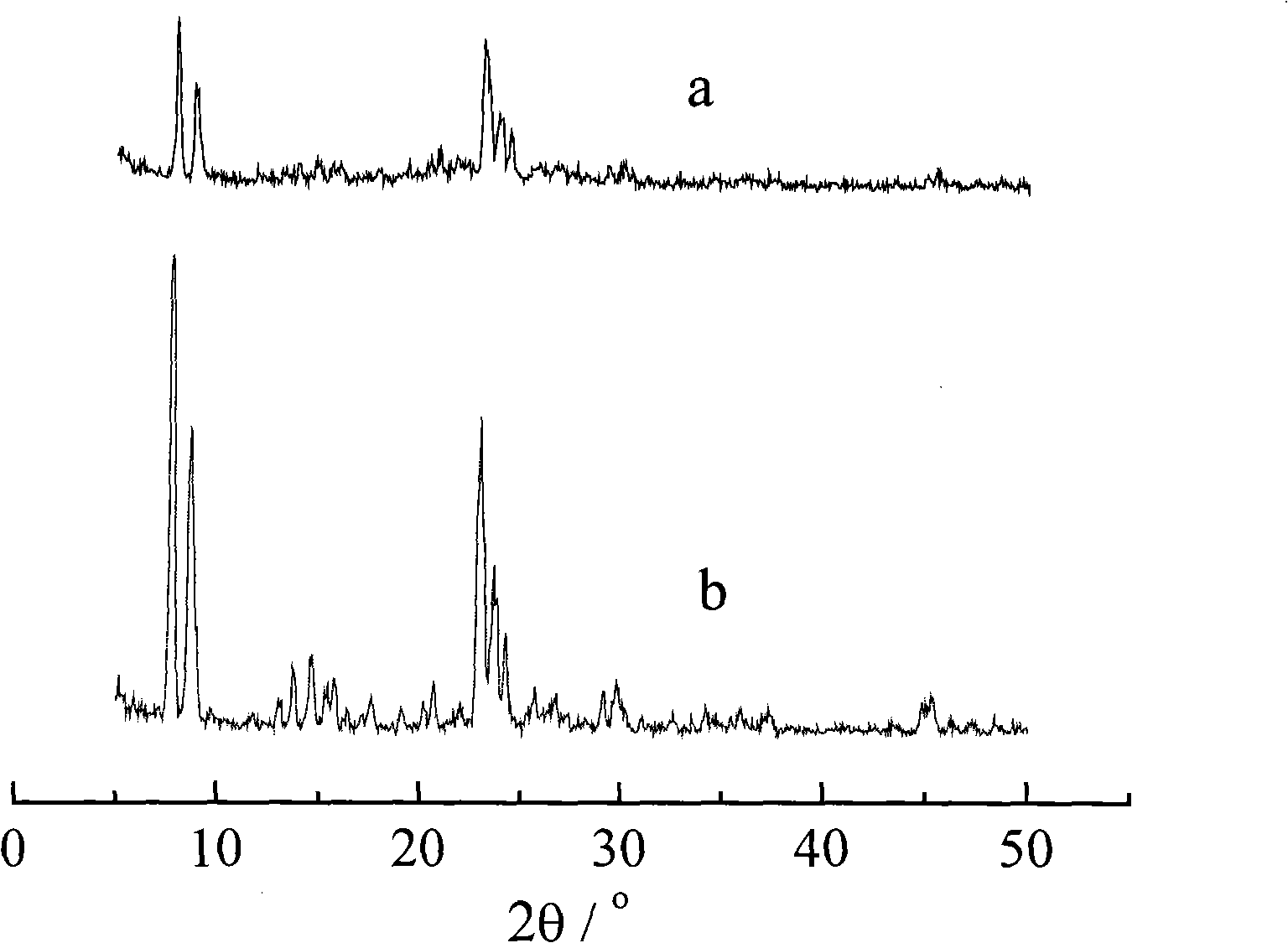

Method for making MTT zeolites without an organic template

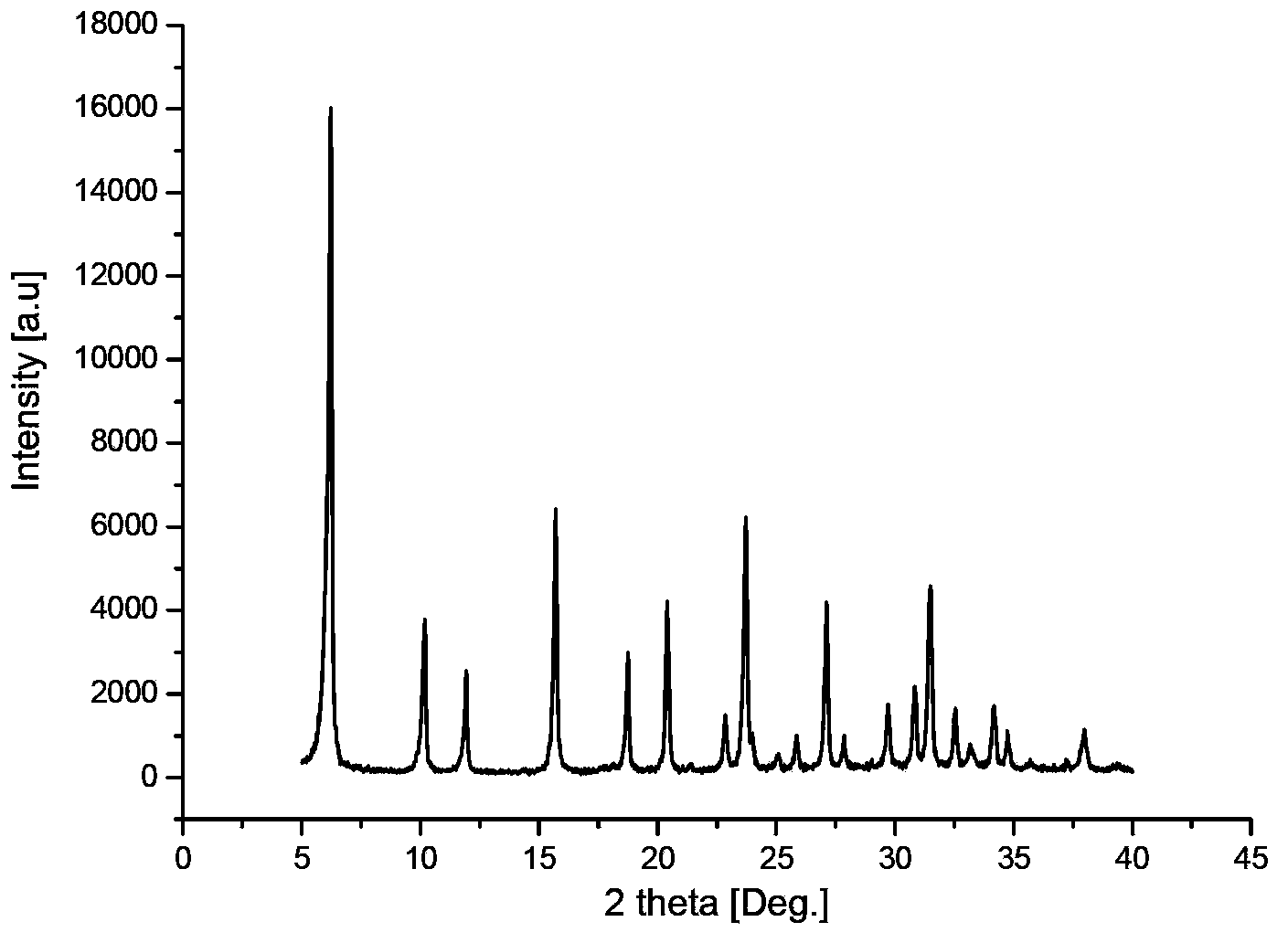

InactiveUS6099820ALow raw material costMinimize wasteAluminium compoundsMolecular-sieve and base-exchange compoundsSufficient timeX-ray

The invention includes a method for preparing a crystalline zeolite having the X-ray diffraction lines of Table 1. The method includes preparing a template-free reaction mixture including at least one active source of a first oxide selected from the group consisting of an oxide of silicon, germanium or both, optionally at least one active source of a second oxide selected from the group consisting of an oxide of aluminum, boron, gallium, iron or a mixture thereof; and heating the reaction mixture at crystallization conditions for sufficient time to form a crystallized material containing zeolite crystals having the X-ray diffraction lines of Table 1, where said zeolite crystals have a first oxide / second oxide molar ratio greater than 12.

Owner:CHEVROU USA INC

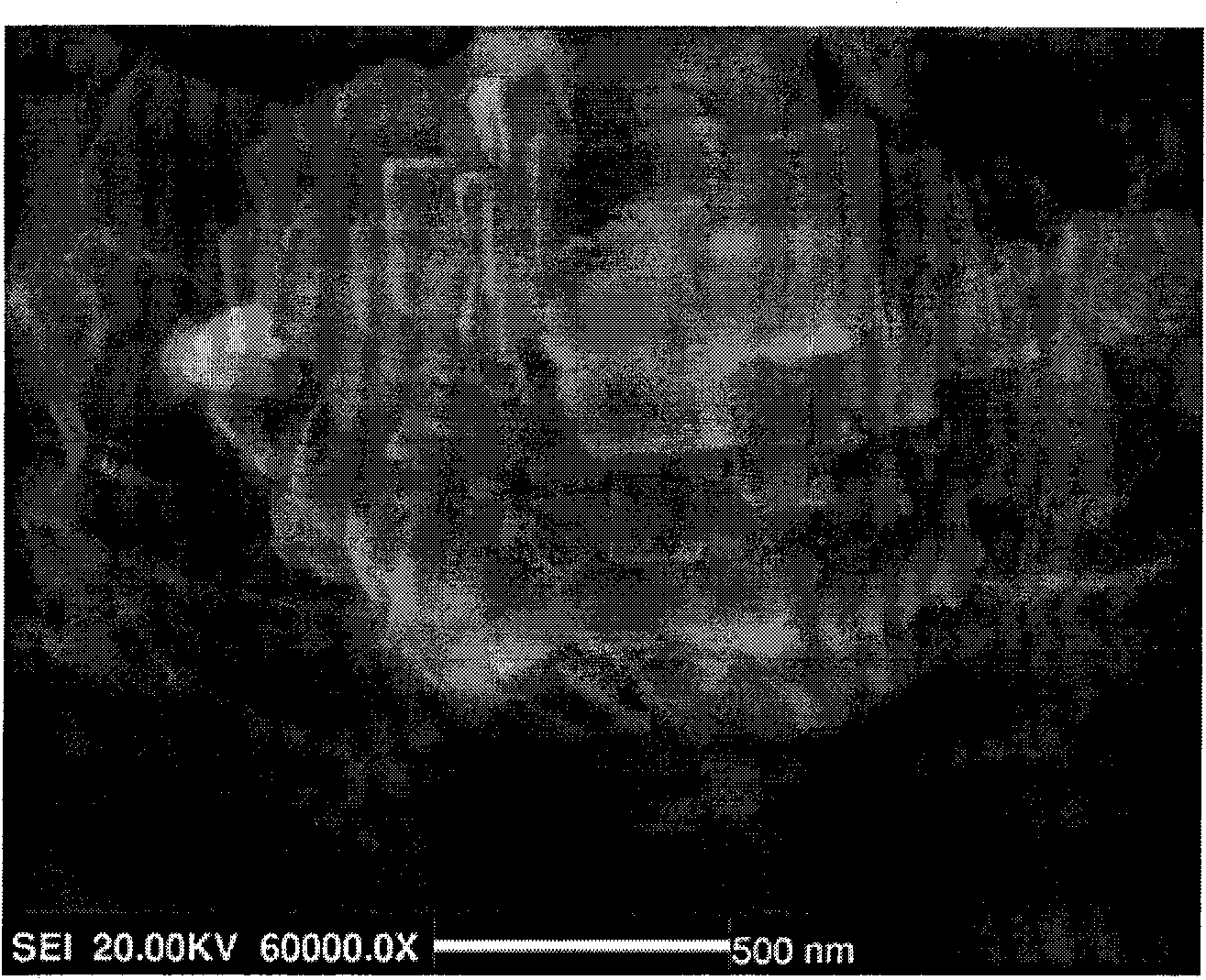

Preparation method of nano-ZSM-5 molecular sieve

InactiveCN101643219ASolve the costSolve pollutionPentasil aluminosilicate zeoliteRoom temperatureNanoscopic scale

The invention relates to a preparation method of a nano-ZSM-5 molecular sieve, which belongs to the field of preparation of zeolite molecular sieve catalysts. The preparation method can solve the problem that the existing synthesis technology has the defects of easy emergence of mixed crystal phase, high cost, environmental pollution and easy loss of features of nanomaterials. The method is as follows: adding pre-crystallized crystal seeds into a gel system of the template-free synthetic nano-ZSM-5 molecular sieve, carrying out crystallization for 24 hours at the temperature of 160-180 DEG C,cooling to room temperature, carrying out centrifugal filtration on products, washing, drying and baking. The prepared nano-ZSM-5 molecular sieve is highly concentrated nanoscale crystals without themixed crystal phase; and the method has the advantages of low cost and environmental protection.

Owner:HEILONGJIANG UNIV

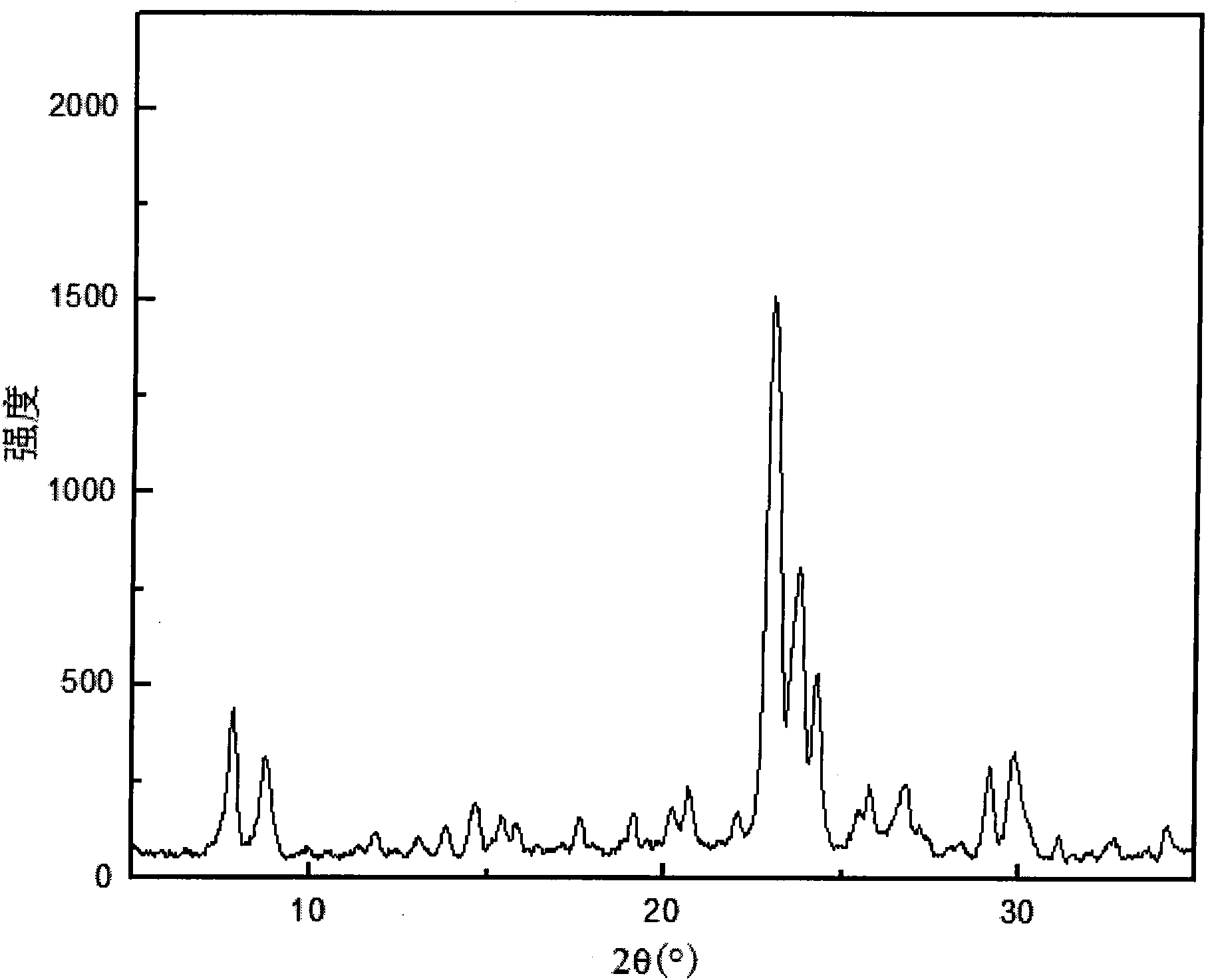

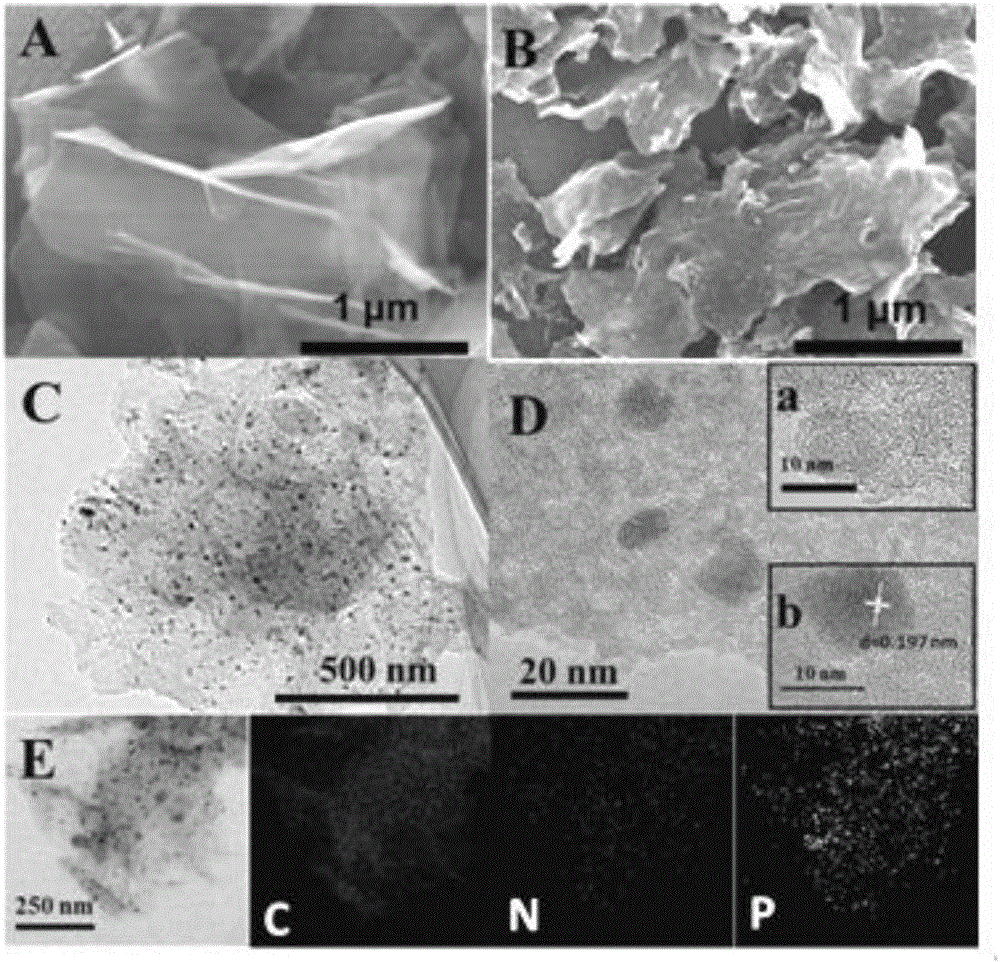

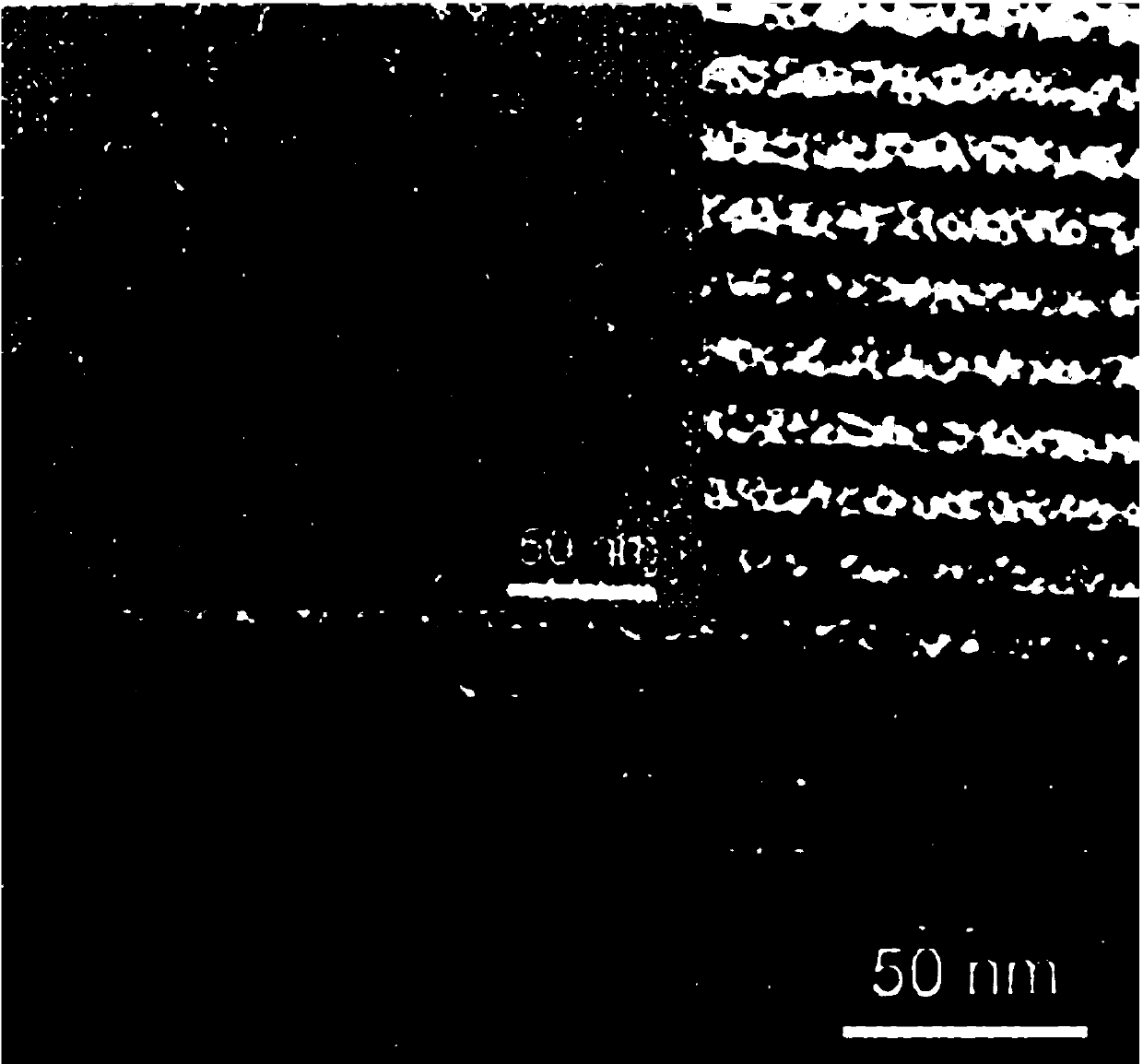

Preparation method of nitrogen-phosphorus co-doped carbon nanosheet and application of preparation method

ActiveCN105762376APositive onset potentialIncrease current densityMaterial nanotechnologyCell electrodesHigh current densityElectron transfer reactions

The invention discloses a preparation method of a nitrogen-phosphorus co-doped carbon nanosheet and application of the preparation method.Nitrogen-phosphorus co-doped carbon nanosheet catalyst material is prepared by: calcining at high temperature, template-free one-step self-assembled precursors: melamine and phytic acid.Oxygen reduction tests show that prepared N-P / CNS-1000 shows corrected initial potential and higher current density, represents four-electron transfer reaction, can match with commercial Pt / C and shows both excellent ethanol resistance and long-range stability in alkali solutions.

Owner:QINGDAO UNIV

Graphitic carbon nitride material, and its synthetic method and applications

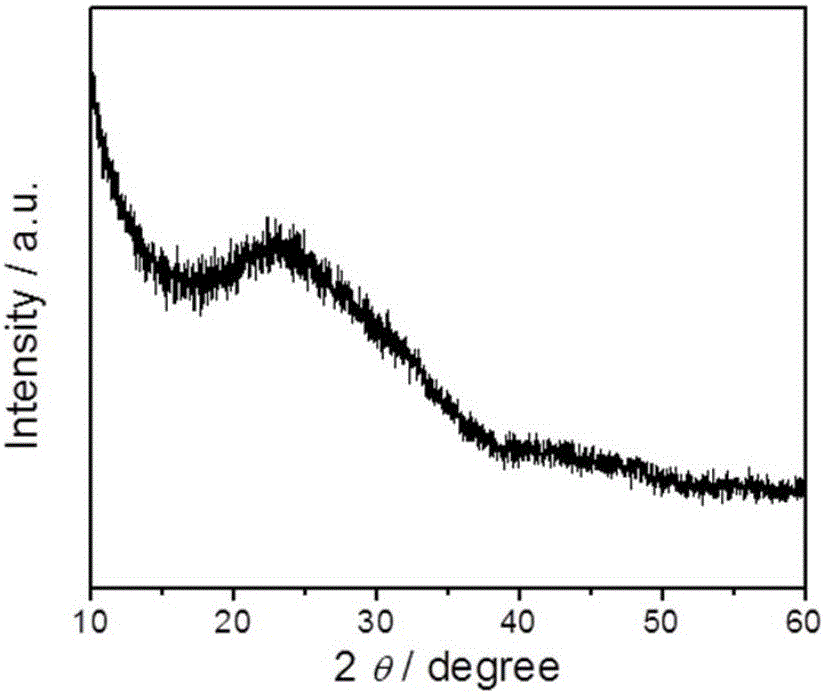

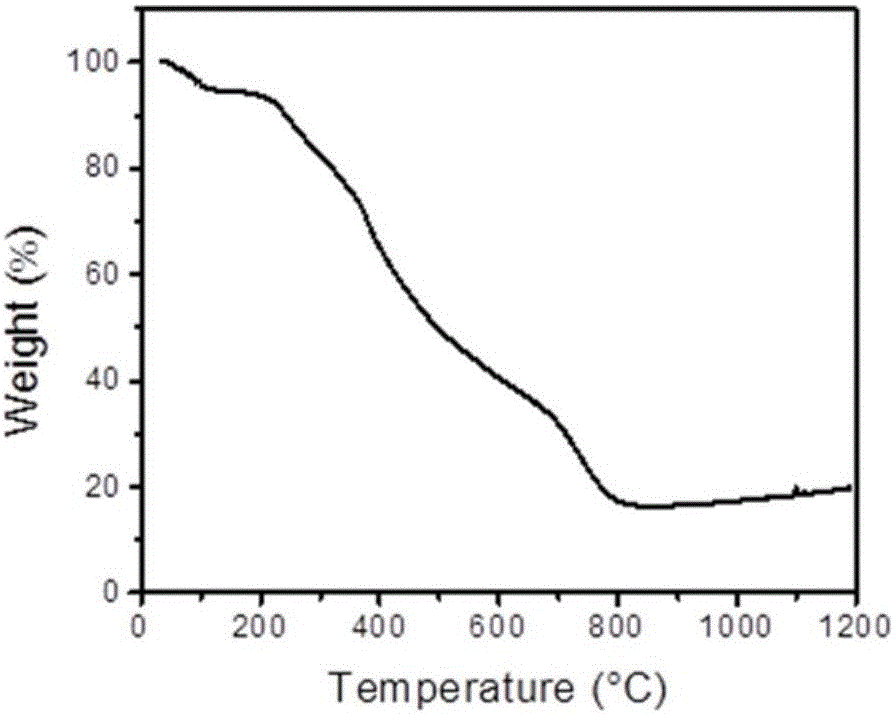

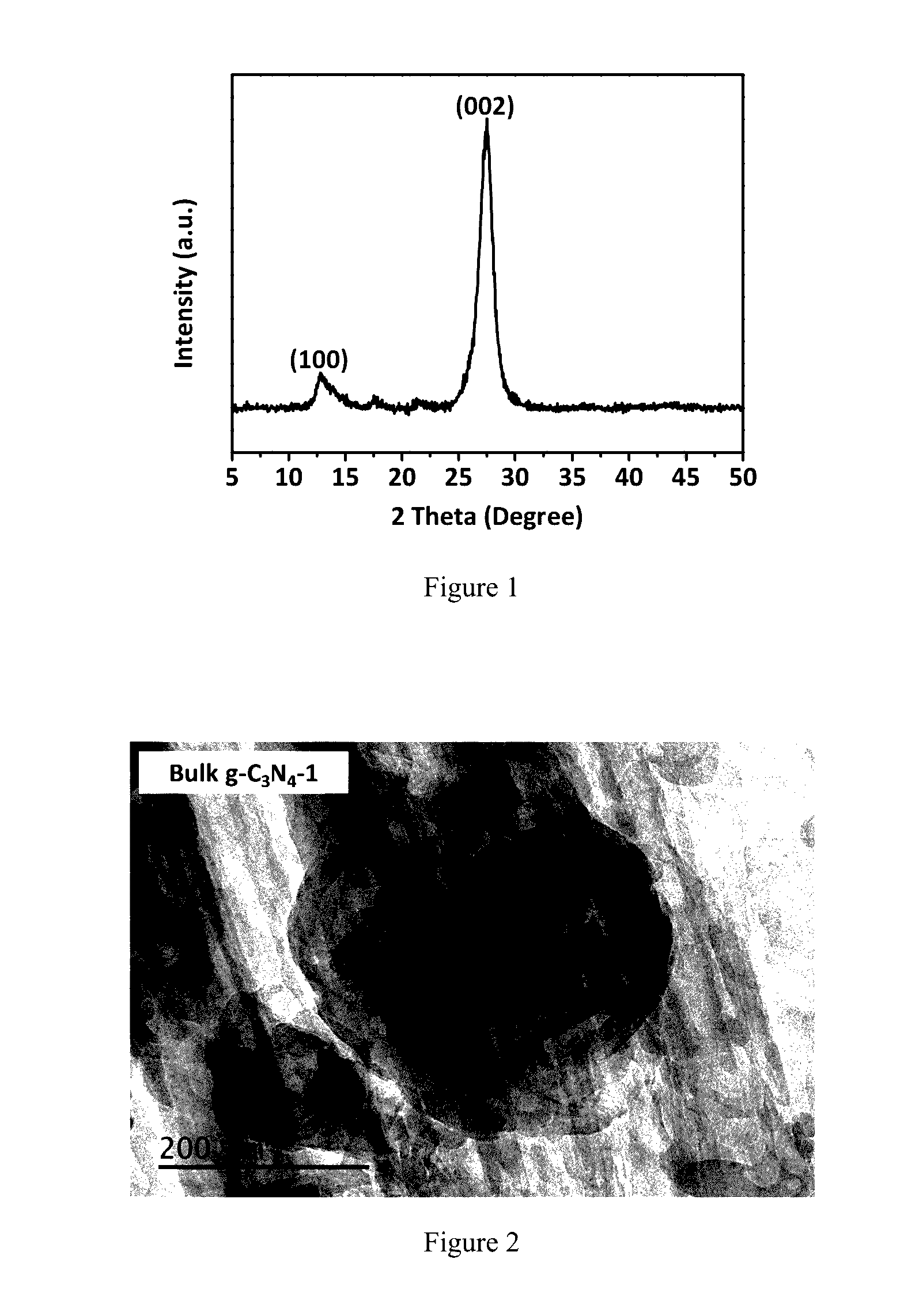

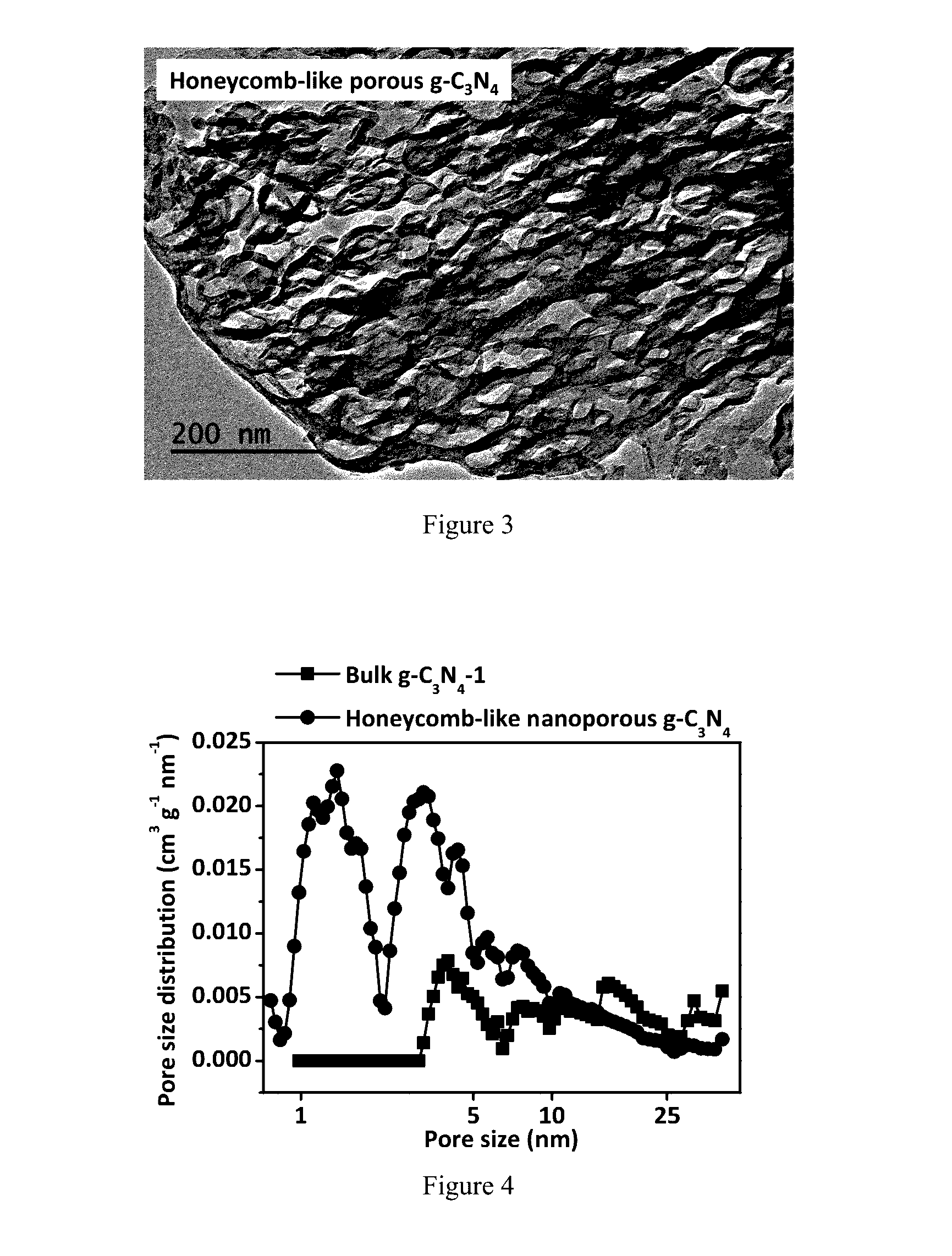

InactiveUS20170057821A1Synthetic is simpleImprove distributionNitrogen-metal/silicon/boron binary compoundsEnergy based wastewater treatmentCarbon nitrideCalcination

The present invention relates to a synthetic method of graphitic carbon nitride material. The method involves a homogenous mixing of carbon nitride precursor and ammonium salt, and calcining the mixture to obtain a porous graphitic carbon nitride material. Wherein, the ammonium salt is any one or a combination of at least two which could release gaseous NH3 during thermolysis. The present invention uses thermolabile ammonium salt as a pore former; the thermolysis of ammonium salt could release soft gas bubbles during the calcination; the later burst of bubbles leads to the formation of nanoporous structure. The proposed method is template-free and environmentally-friendly, and the resultant material exhibits high photocatalytic activity in the field of gas and water decontamination.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for making ZSM-5 zeolites

InactiveUS6261534B1Sufficient amountMinimize wasteAluminium compoundsMolecular sieve catalystsX-rayZSM-5

The invention includes a method for preparing a crystalline zeolite having the X-ray diffraction lines of Table 1. The method includes preparing a template-free reaction mixture including at least one active source of a first oxide selected from the group consisting of an oxide of silicon, germanium or both, optionally at least one active source of a second oxide selected from the group consisting of an oxide of aluminum, boron, gallium, iron or a mixture thereof; and heating the reaction mixture at crystallization conditions for sufficient time to form a crystallized material containing zeolite crystals having the X-ray diffraction lines of Table 1, where said zeolite crystals have a first oxide / second oxide molar ratio greater than 12.

Owner:CHEVROU USA INC

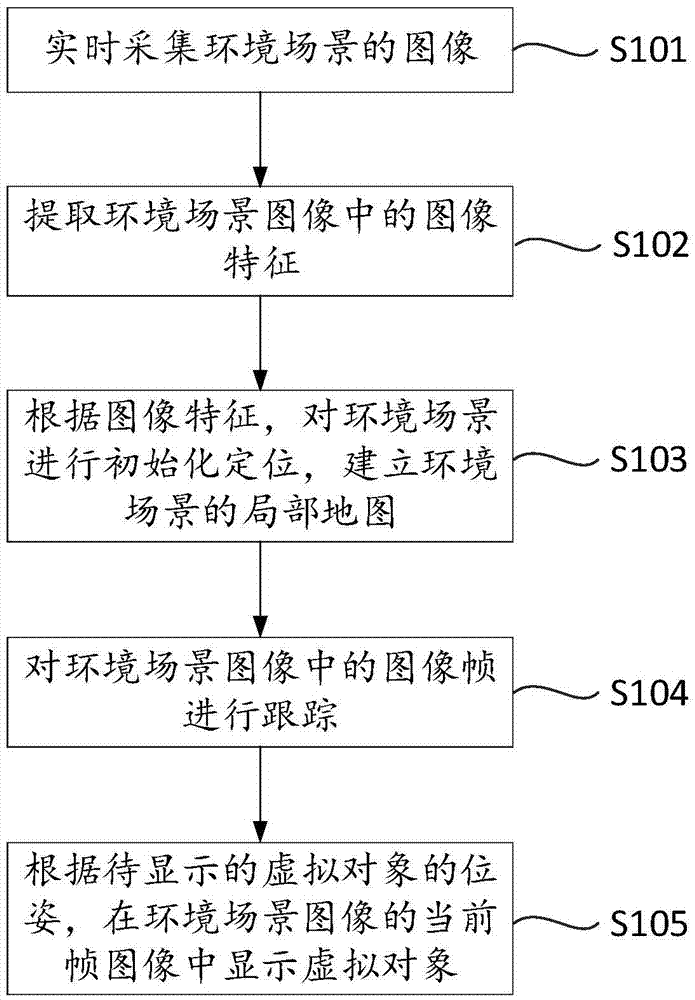

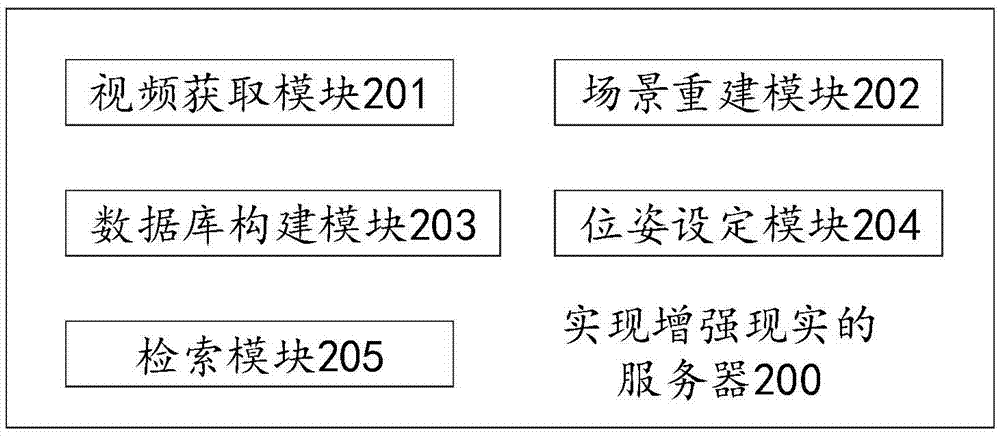

AR (Augmented Reality) realizing method, server, terminal and system

ActiveCN107025662AImprove coordinationImprove consistencyImage analysisImaging FeatureComputer science

The invention provides an AR realizing method. The method comprises the following steps that an image of an environment scene is collected in real time; image features are extracted from the image of the environment scene; according to the image features, the image scene is positioned initially, and a local map of the environment scene is established; image frames in the image of the environment scene are tracked; and according to a pose of a virtual object to be displayed, the virtual object is displayed in a present frame of the image of the environment scene. The invention provides an AR realizing server, terminal and system. Via the AR realizing method, server, terminal and system, images of the virtual object of the environment scene or target object can be displayed in an overlapped way under the template free condition, rely on a planar template of a present AR technology is reduced effectively, the real-time registering accuracy between the virtual object and the real environment scene is improved, and the virtual object is much more coordinated and consistent with the overlapped image of the environment scene.

Owner:CHENGDU IDEALSEE TECH

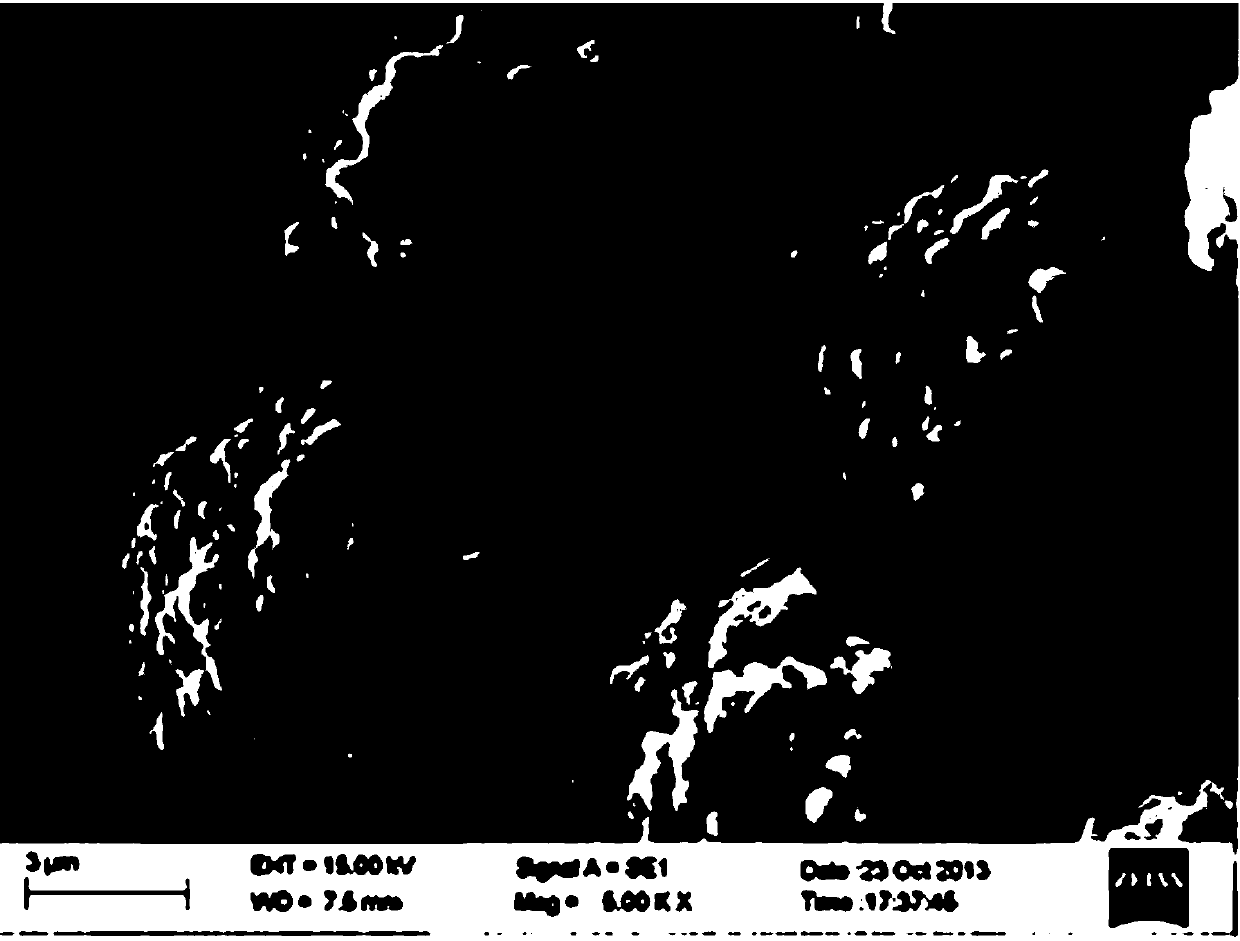

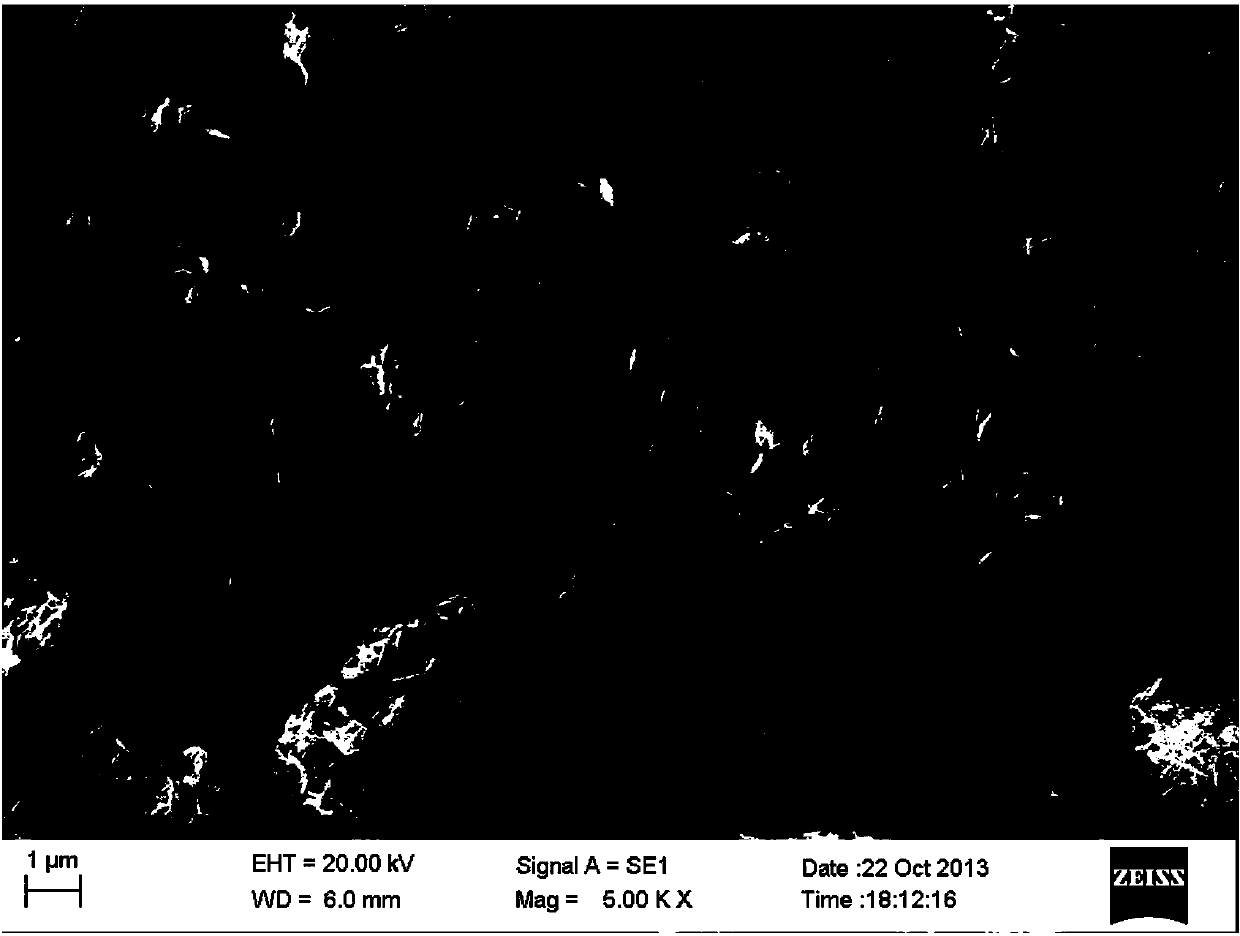

Preparation method of size-controllable nano structural conductive polyaniline

The invention relates to a method of preparing size-controllable nano structure conductive polyaniline, which includes steps: adding solution of monomer aniline to solution of oxidant under temperature of 0-5 DEG C, carrying polymerization reaction according conventional interfacial polymerization method or homopolymerization method, after conventional post-treatment, obtaining the size-controllable nano structure conductive polyaniline. The oxidant is selected according to diameter of the needed polyaniline nano structure by following formula: log d=0.69+0.71Eox, wherein d is diameter of nano structure polyaniline, Eox is oxidation-reduction potential of used oxidant. Compared with traditional ''template method'' and ''soft template method'', advantages of the invention are: template and post-treatment thereof is avoided, reaction medium is simplified, method is more simple and low-cost, defect of bad controllability to production configuration and size of traditional template-free method is overcomed, and size completely controllable conductive polyaniline nano fiber can be prepared by selecting oxidant with fitting oxidation-reduction potential.

Owner:INST OF CHEM CHINESE ACAD OF SCI

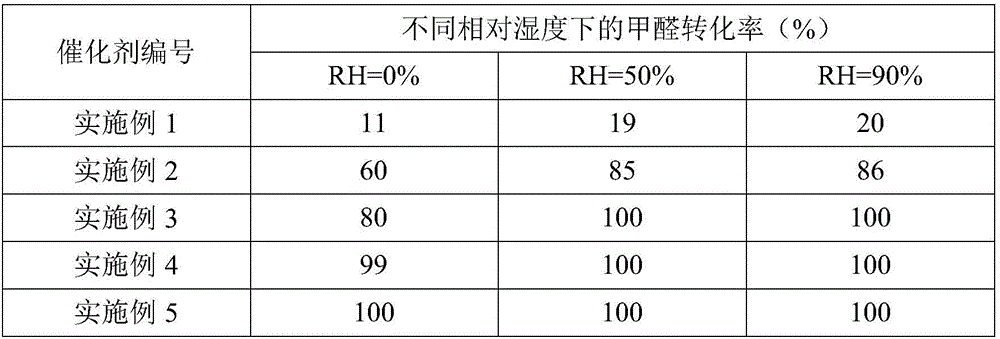

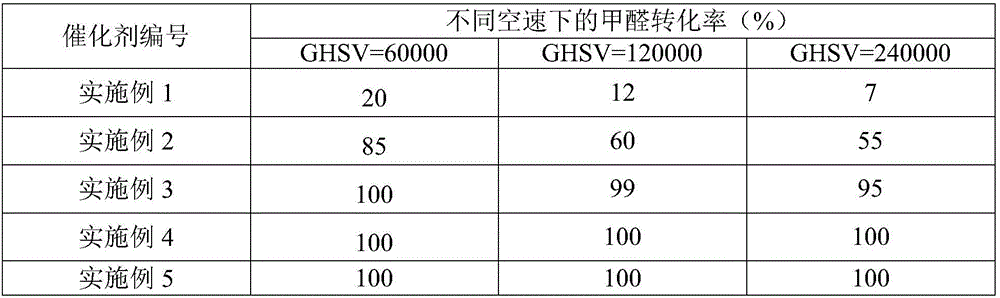

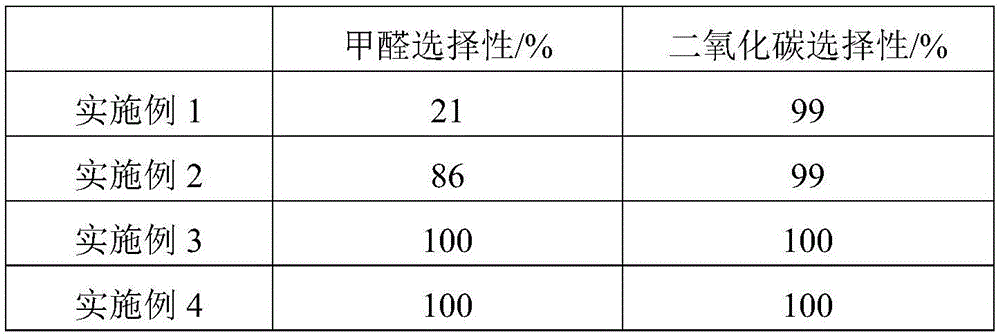

Catalyst for elimination of formaldehyde at room temperature and preparation method thereof

ActiveCN106540741ASimple conditions of useEasy to operateGas treatmentMolecular sieve catalystsCatalytic oxidationMoisture resistance

The invention relates to the field of environmental catalysis and provides a catalyst for elimination of formaldehyde at a room temperature and a preparation method thereof. The catalyst comprises a Beta molecular sieve obtained by an organic template-free seed crystal method and a noble metal active component supported on a Beta molecular sieve. The noble metal active component comprises one or at least two of noble metals such as platinum, ruthenium, gold, silver and palladium. The catalyst has the advantages of simple use condition and convenient operation, can be effectively used for catalytic oxidation of the main pollutant formaldehyde in the room at the room temperature, does not produce by-products such as formic acid, carbon monoxide and methyl formate, has a formaldehyde conversion rate of 100%, a less catalyst use amount and excellent resistance to a high speed, does not need a specific light source, does not consume power and heat, saves energy and has excellent stability and moisture resistance.

Owner:苏州美吉科环保科技有限公司

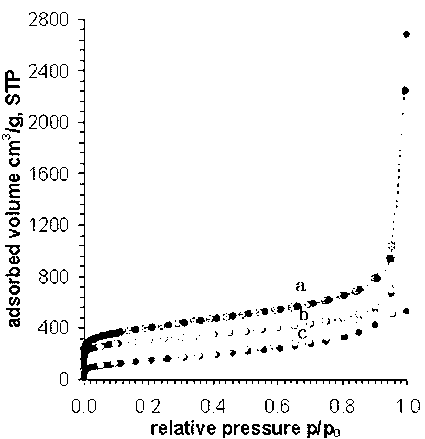

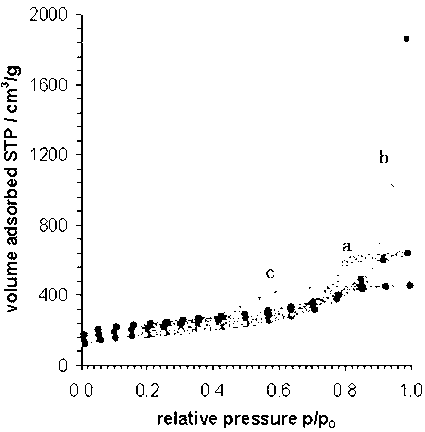

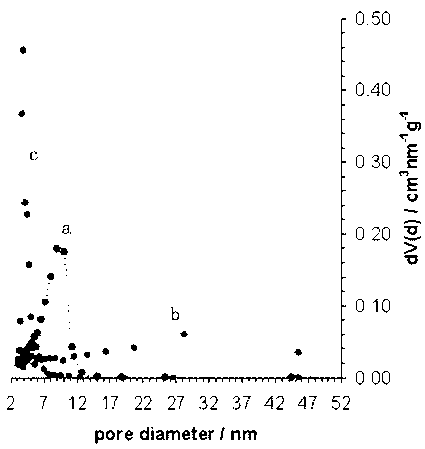

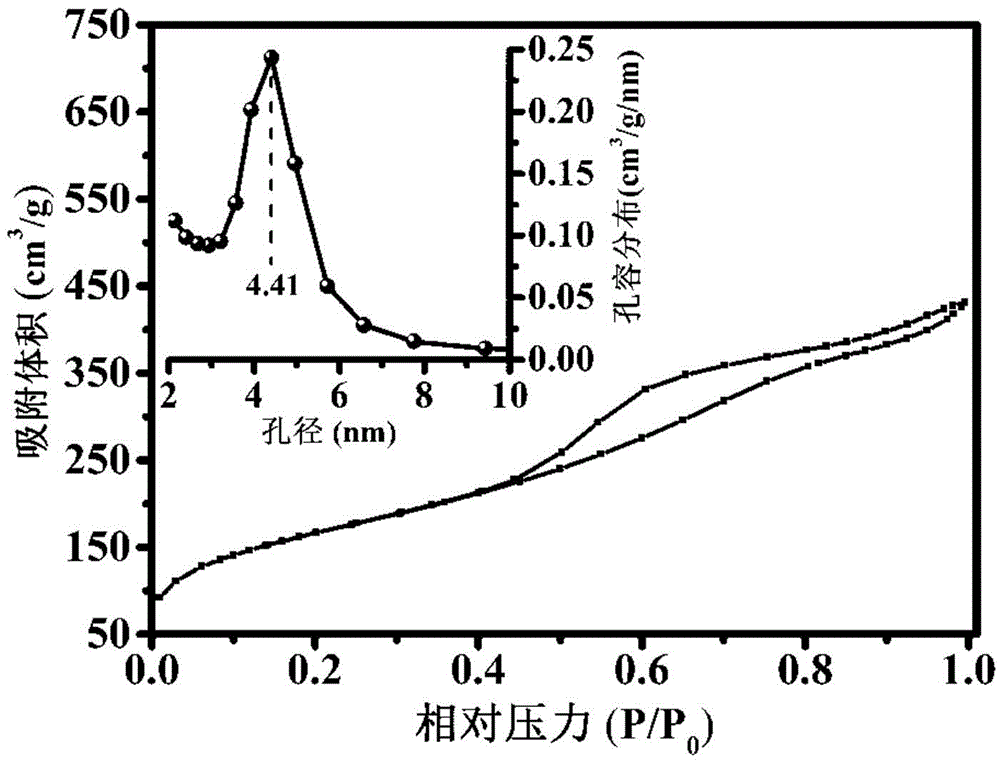

N-rich mesoporous carbon material and template-free preparation method thereof as well as method for manufacturing working electrode and application of working electrode

InactiveCN102701183AHigh degree of polymerizationHighly ordered channelsCarbon preparation/purificationCapacitanceCarbonization

The invention discloses an N-rich mesoporous carbon material and a template-free preparation method thereof as well as a method for manufacturing a working electrode and an application of the working electrode, and belongs to the technical field of mesoporous carbon material preparation. In organic solvent, substituted dialdehyde and a melamine derivative are taken as building units; through heating reflux under the inert atmosphere, the building units are subject to the Schiff base reaction to obtain a mesoporous polyamid precursor, and are subject to the low-tempreature roasting under the inert atmosphere to be further carbonized to obtain N-rich mesoporous carbon; or the polyamid precursor is subject to one-step high-temperature carbonization to obtain N-rich mesoporous carbon. Through the adjusting of the structures of the substituted dialdehyde and the melamine derivative and the pyrolysis conditions of the polyamid precursor, the controllable synthesis of N-rich mesoporous carbon is achieved. The invention can achieve the template-free synthesis of the N-rich mesoporous carbon, and has the advantages of simplicity in operation, low cost and large-scale production. The optimized N-rich mesoporous carbon materials are made into an electrode which has a favorable capacitance performance, rapid current response and a stable cycle life under acidic and alkaline conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

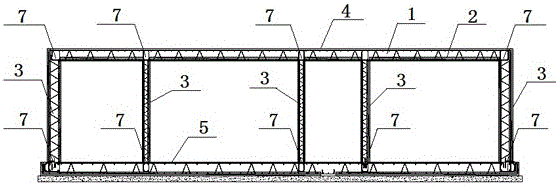

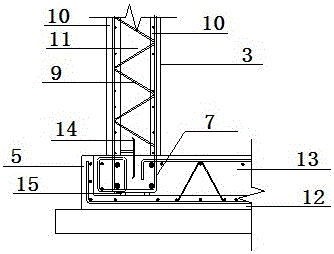

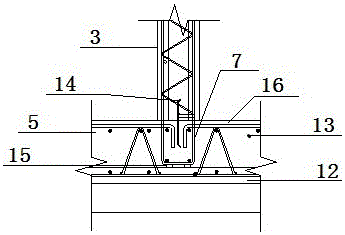

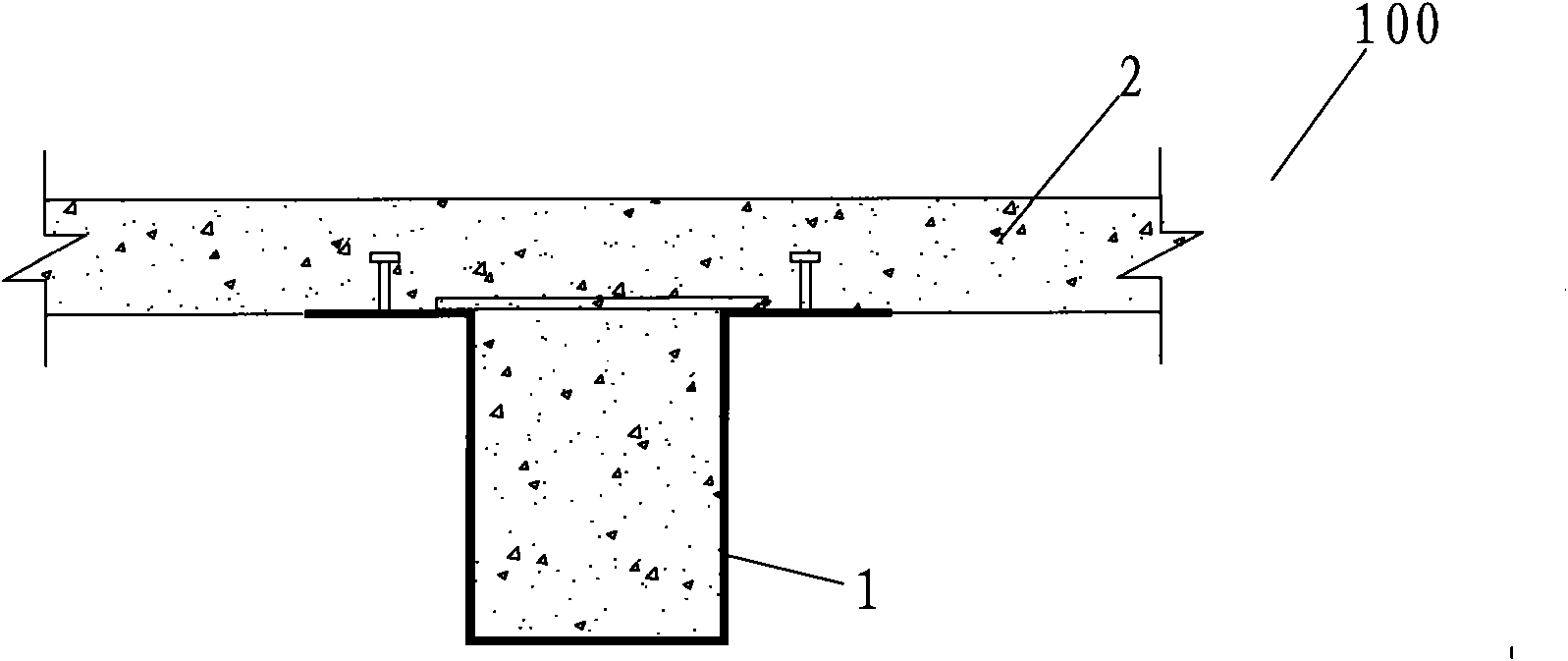

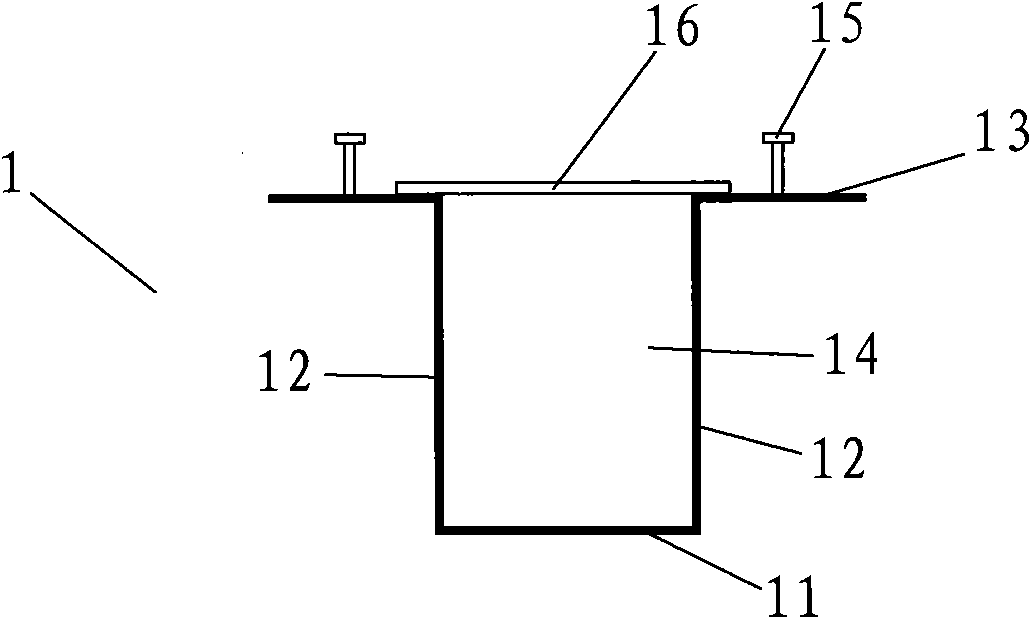

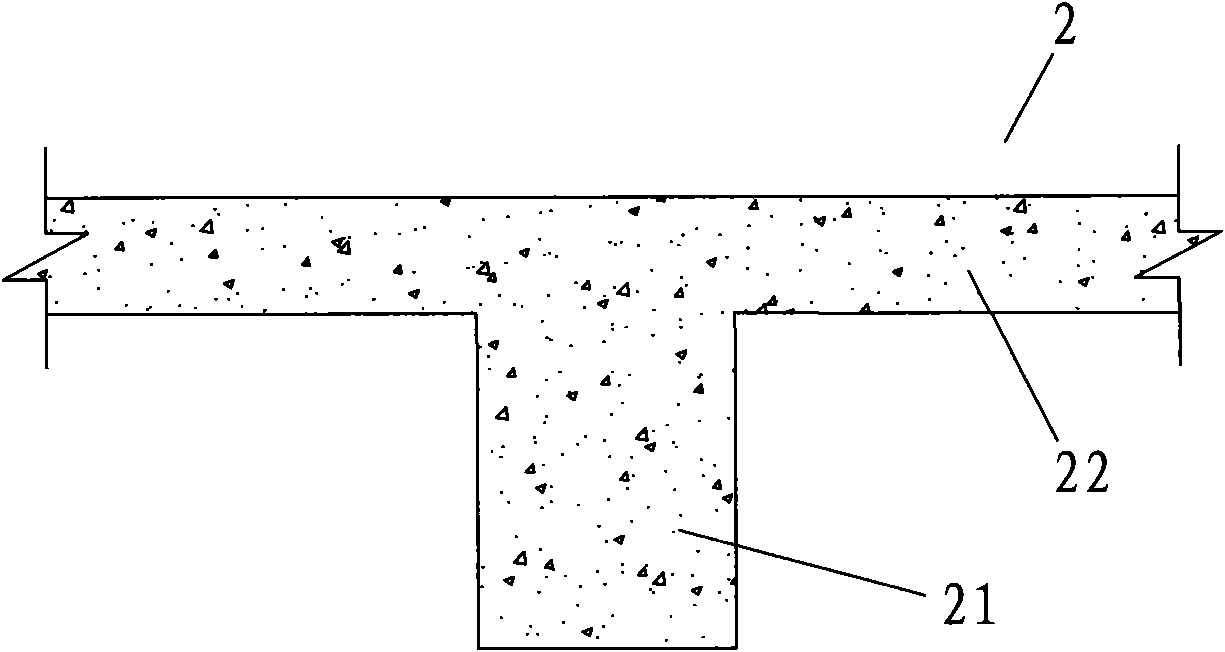

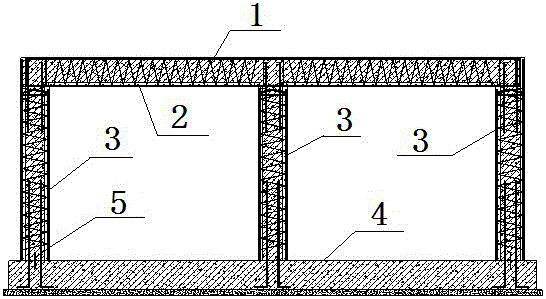

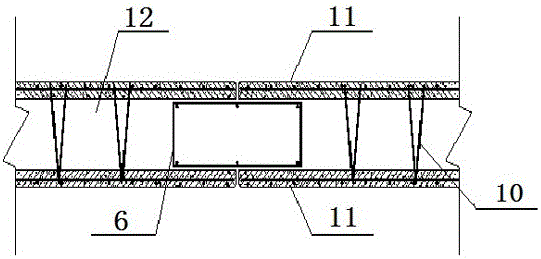

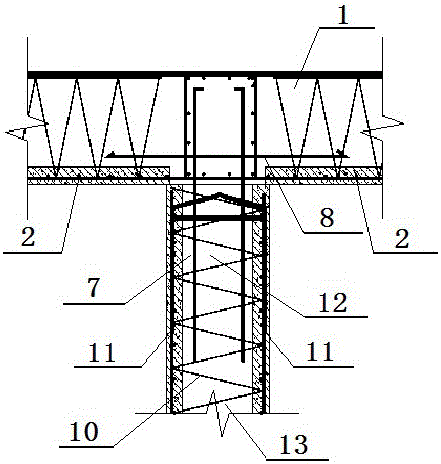

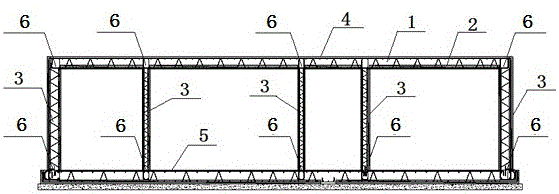

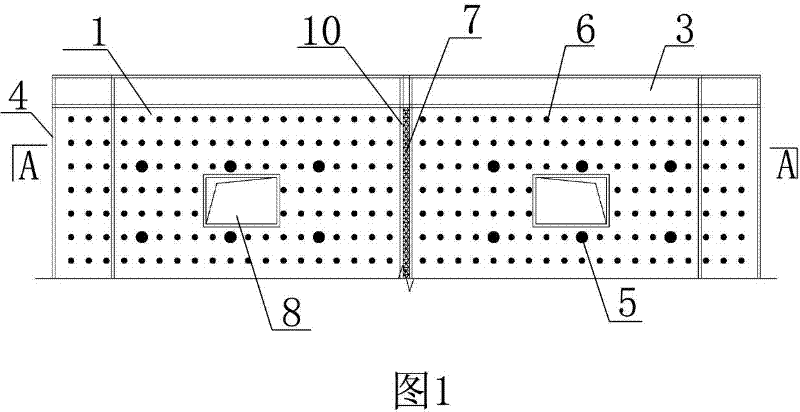

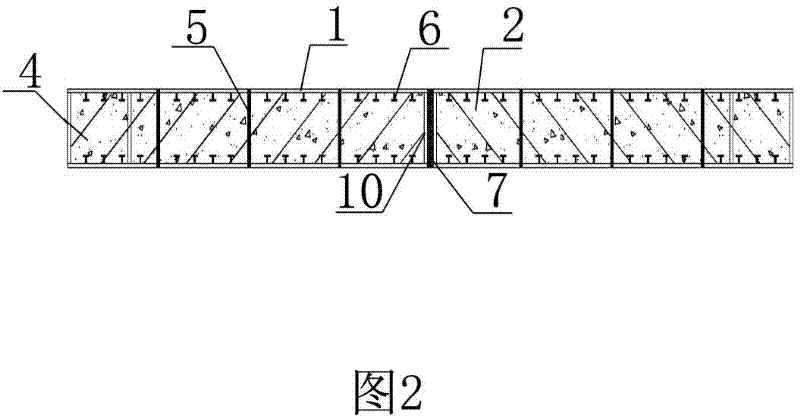

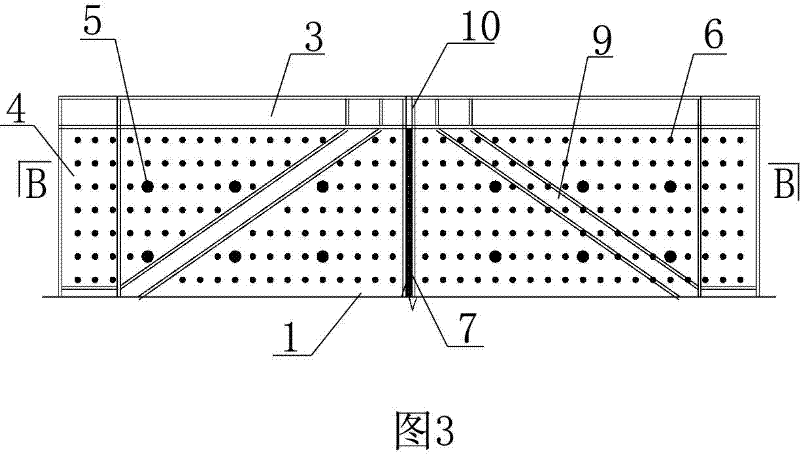

Total-prefabricated superimposed assembly type underground pipe gallery and connecting node thereof

InactiveCN105839666AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresEngineeringUtility tunnel

The invention discloses a total-prefabricated superimposed assembly type underground pipe gallery and a connecting node thereof. A bottom plate of the underground pipe gallery is a prefabricated superimposed bottom plate. A side wall or a side wall and middle wall body is a prefabricated sandwich superimposed wall. A top plate of the underground pipe gallery is a prefabricated superimposed plate. The bottom plate, the side wall or the side wall and middle wall body and the top plate are connected in a cast-in-place manner to form the underground pipe gallery. The shop prefabrication way and the superimposed cast-in-place way are combined, the advantages of the shop prefabrication way and the advantages of the cast-in-place way are fully taken, defects and deficiencies are overcome, especially the defects of low production efficiency and small transportation amount of a traditional prefabricated pipe gallery are overcome, the purposes of template-free cast-in-place construction, environmental protection, material saving, high quality and high efficiency are achieved, and the underground pipe gallery has high water resistance.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

Template-free U-shaped steel concrete combination beam

InactiveCN101851983AOvercoming the Shortcomings of Single AdoptionSave materialLoad-supporting elementsConcrete beamsEngineering

Owner:HUAQIAO UNIVERSITY

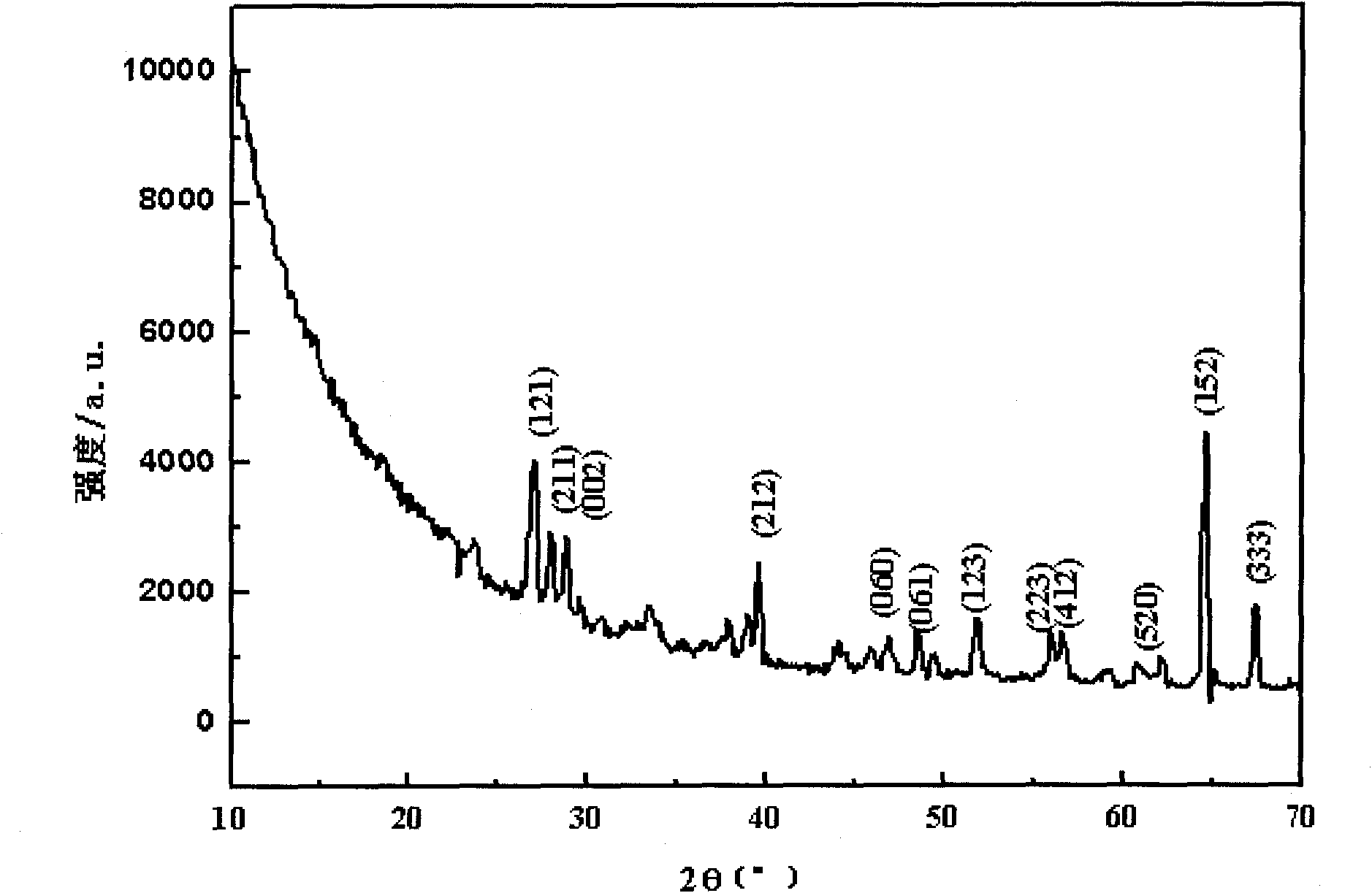

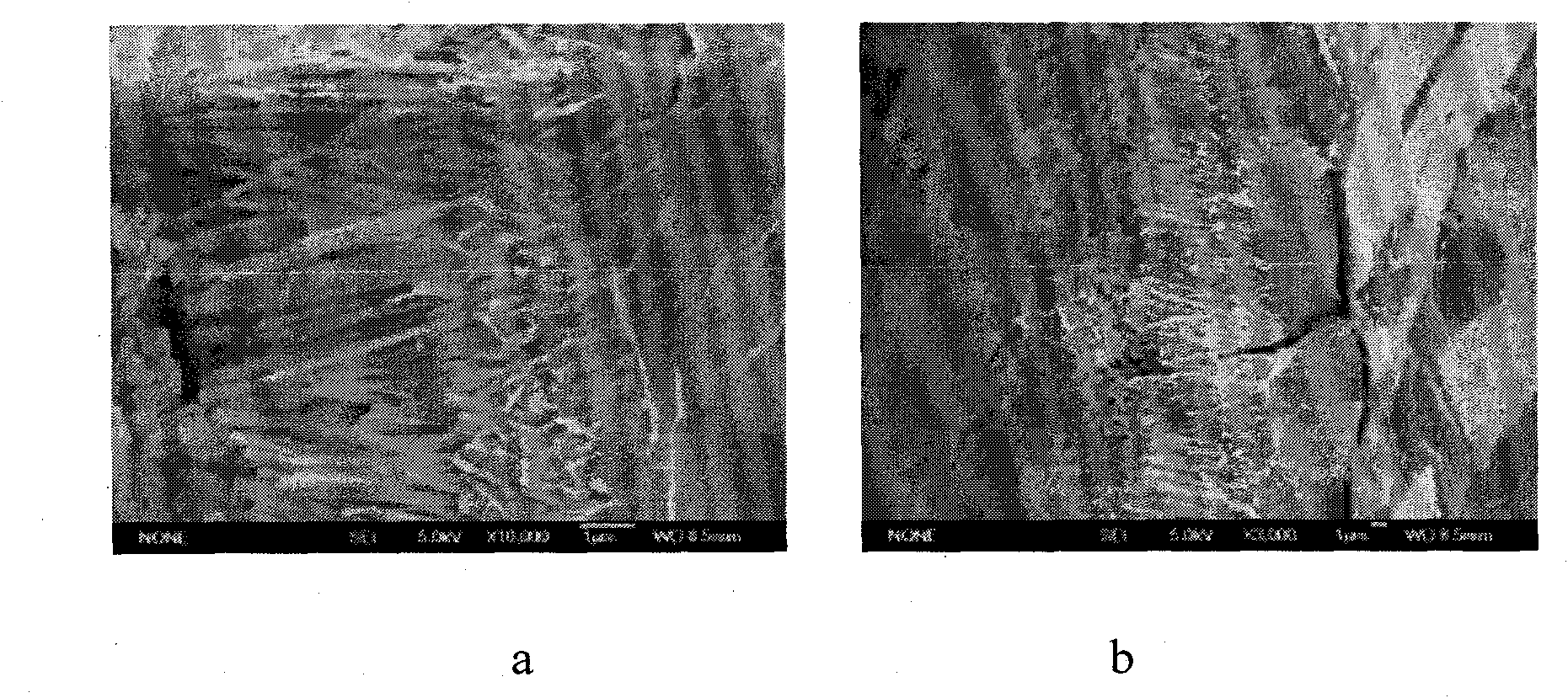

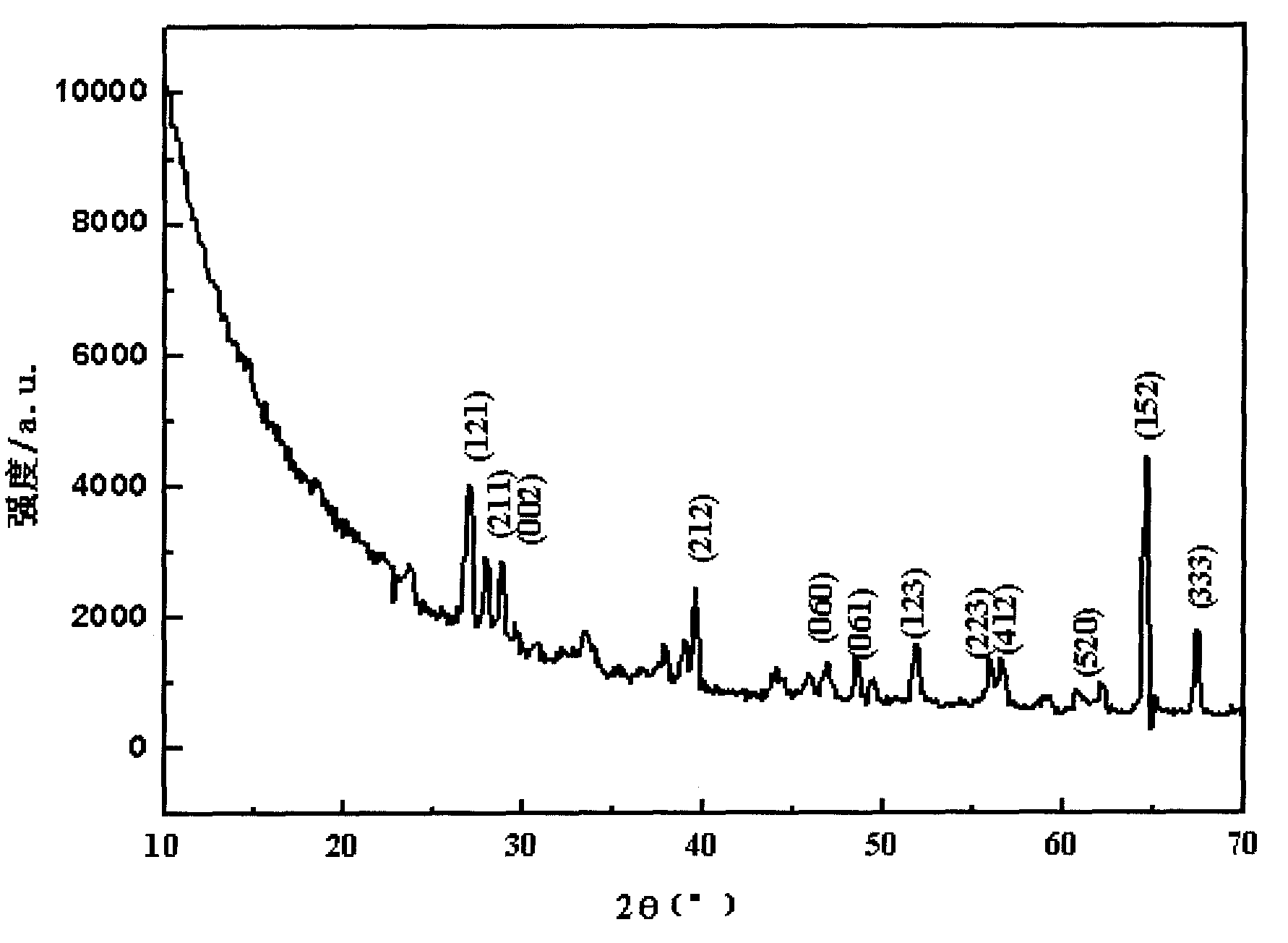

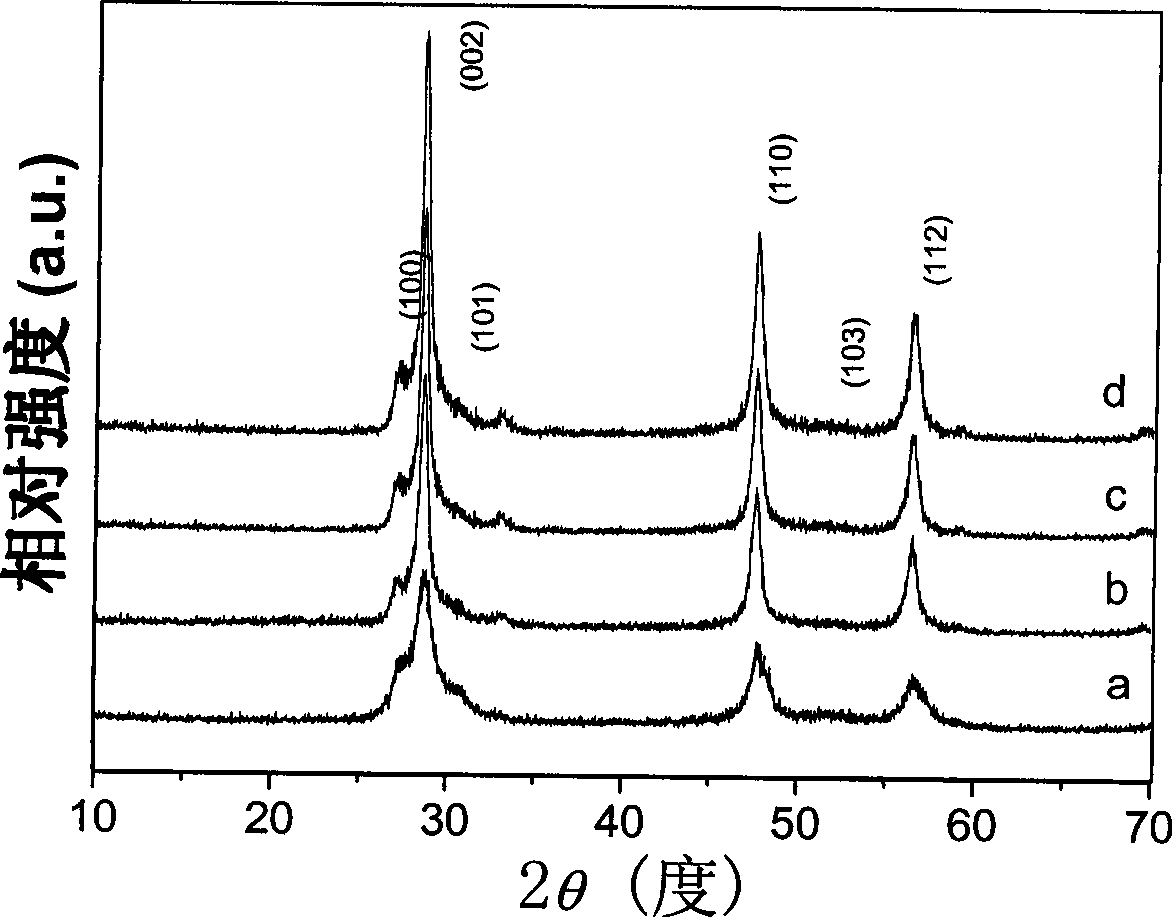

Method for template-free hydrothermal synthesis of one-dimensional nano-Bi2Fe4O9

The invention discloses a method for template-free hydrothermal synthesis of one-dimensional nano-Bi2Fe4O9. In the method, a hydrothermal preparation method is adopted and comprises the following steps of: dissolving Bi(NO3)3.5H2O and Fe(NO3)3.9H2O with the same amount in dilute nitric acid; and titrating by using the aqueous solution of NaOH for complete precipitation, and filtering and washing to obtain neutral solution; and the method is characterized by comprising the following steps of: dissolving the obtained precipitate into the solution of NaOH at the concentration of 8 to 20 Mol / L; putting the solution into a reaction kettle and adding a titanium plate, reacting for at the temperature of between 160 and 200 DEG C 12 to 72 hours, and growing the product on a titanium plate substrate; and after taking the titanium plate out, washing the titanium plate by using deionized water and alcohol, putting the titanium plate into a drying oven for drying, and obtaining the final product of the one-dimensional nano-Bi2Fe4O9 on the titanium plate.

Owner:山东产研陶瓷研究院有限公司

Superimposed assembled type underground pipe gallery system and construction and manufacturing process

InactiveCN105862916AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresTechnological systemTechnology system

The invention provides a superimposed assembled type underground pipe gallery system and a construction and manufacturing process. A bottom plate is a cast-in-place bottom plate on an underground pipe gallery cushion layer, side walls and a middle wall body are prefabricated sandwich superimposed walls, a top plate is a prefabricated superimposed plate, and the bottom plate, the side walls and the middle wall body and the top plate are connected into an overall underground pipe gallery in a cast-in-place mode. According to the novel underground pipe gallery technology system, part is subjected to prefabrication in a factory, part is subjected to on-site superimposed cast-in-place, advantages of prefabrication in the factory and on-site cast-in-place are fully played, defects and disadvantages of prefabrication in the factory and on-site cast-in-place are overcome, particularly defects that a traditional superimposed pipe gallery is low in production efficiency and small in transport quantity are overcome, on-site template-free construction is achieved, environmentally friendliness and energy conservation are achieved, efficiency is high, and excellent waterproof performance is achieved.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

Method for preparing nano ZSM-5 molecular sieve

InactiveCN102001680ASimple processReduce manufacturing costPentasil aluminosilicate zeoliteMolecular sieveGranularity

The invention discloses a method for preparing a nano ZSM-5 molecular sieve, comprising the steps of preparing a precursor, crystallizing, filtering, drying and roasting. The precursor is prepared by adopting a two-step method; a mixed solution is prepared by adopting a template-free method; a mixed glue solution is prepared by a stirring and dropping method; and the granularity of the molecular sieve obtained by roasting is 50-100 nanometers. In the step of preparing the mixed solution by using the template-free method, NaOH and NaAlO2 in a reactor and deionized water are stirred at the rotating speed of 200-300 / min and the bath temperature of 60-90DEG C for 2-4 hours to obtain the uniformly-mixed solution, wherein the mass ratio of the NaOH to the NaAlO2 to the deionized water is 10:(3-6):(320-380). In the step of preparing the mixed glue solution by the stirring and dropping method, silica sol is slowly dropped in the solution according to the volume ratio while the mixed solution is continuously stirred; the mixed glue solution is obtained after the silica sol is dropped; and the volume ratio of the mixed solution to the silica sol is 200:(115-135).

Owner:岳阳三生化工有限公司

Construction and manufacturing process of total-prefabricated superimposed assembly type underground pipe gallery

ActiveCN105839667AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresPrefabricationBuilding construction

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

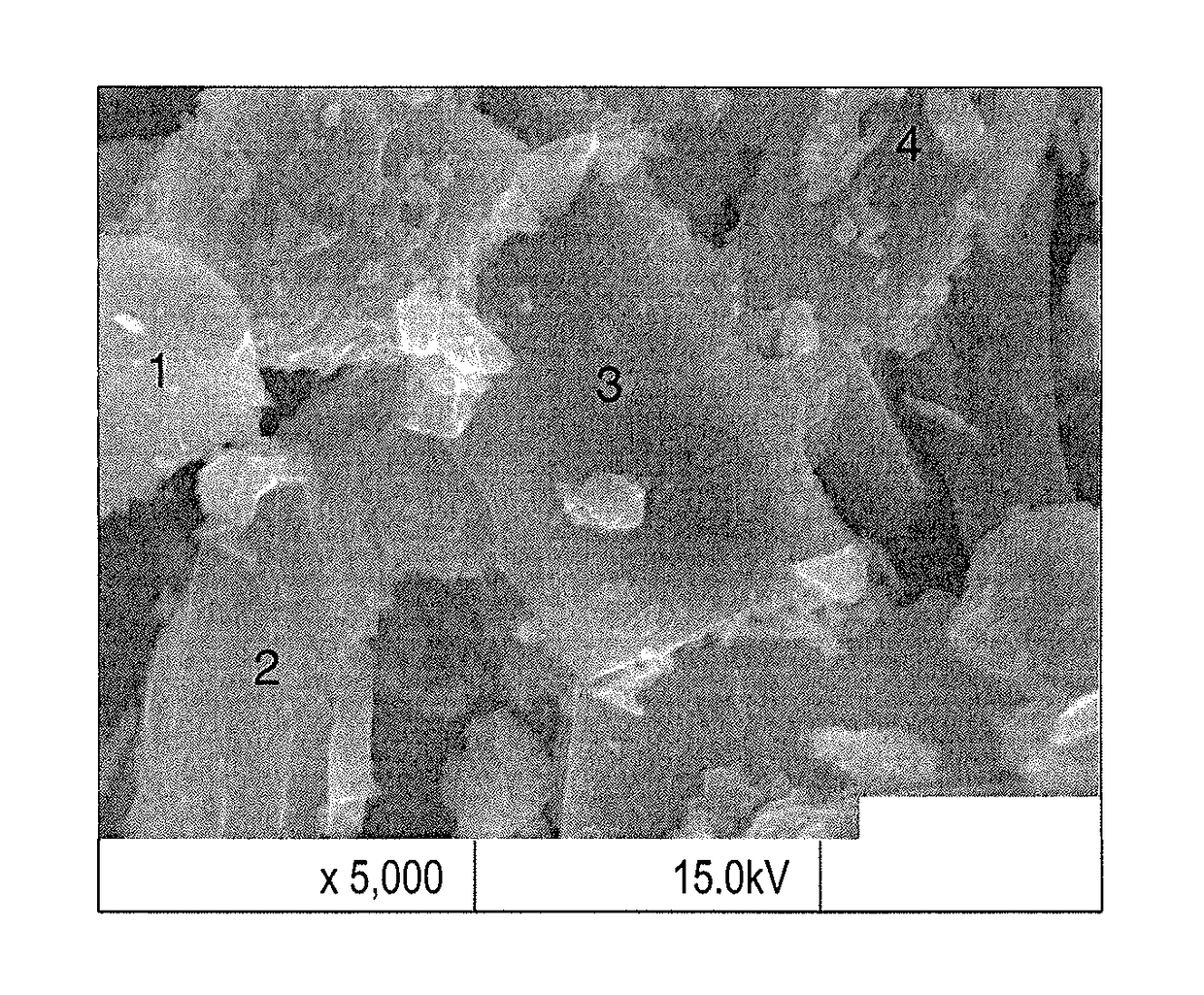

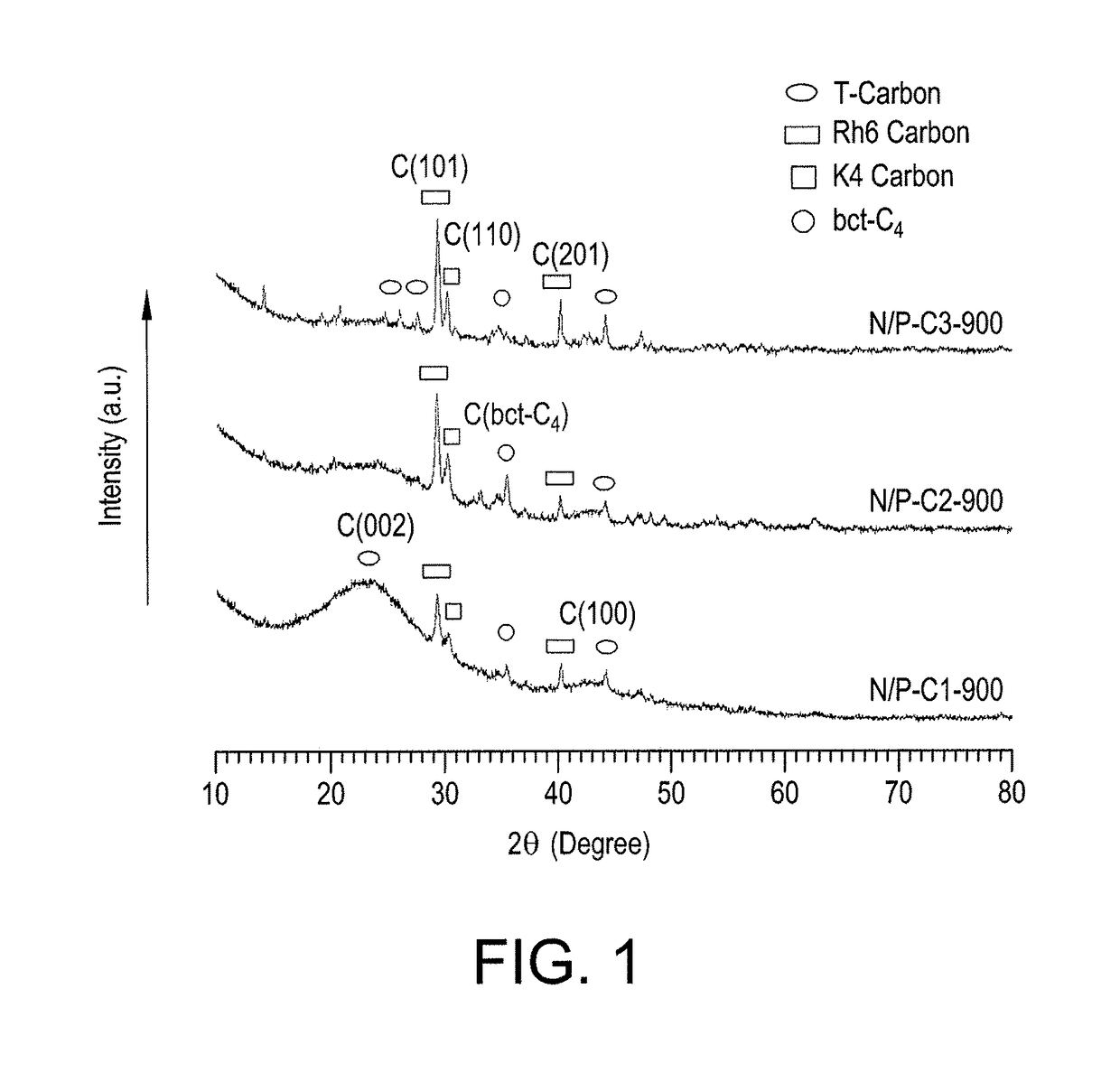

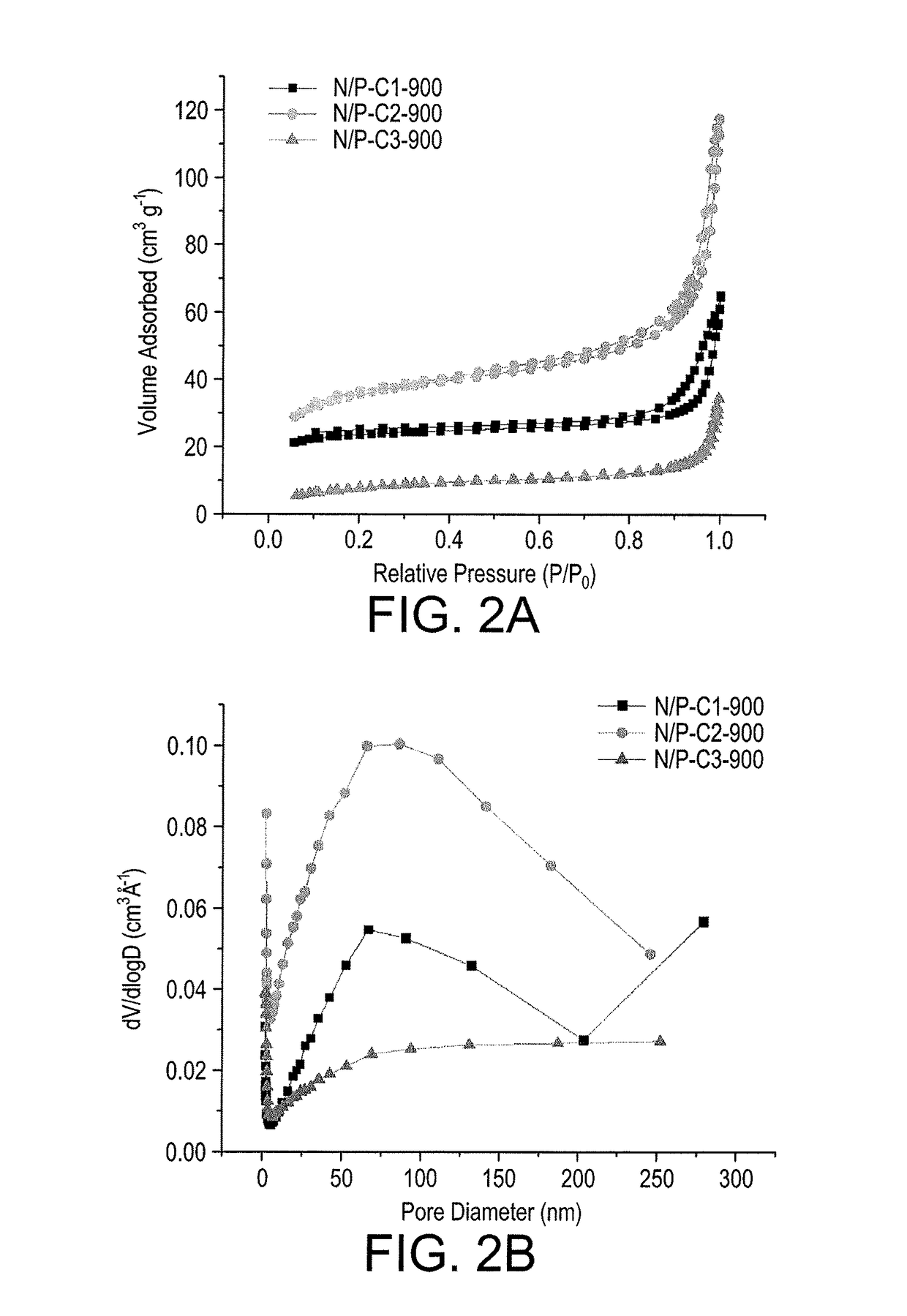

Nitrogen and phosphorus co-doped crystalline carbon materials

The nitrogen and phosphorus co-doped crystalline carbon materials are prepared by a template-free method that includes pyrolizing a precursor mixture including a carbon source, a nitrogen source, and a phosphorus source. The method involves mixing known amounts of the precursor components, dissolving the precursor mixture in deionized water, distilling solvent from the aqueous mixture, and vacuum drying the residue to a dry solid mixture. The mixture is then carbonized by pyrolysis at 900° C. in an argon atmosphere to obtain a nitrogen and phosphorus co-doped crystalline carbon material. The principles of the method are illustrated by a precursor mixture of sucrose, urea, and ammonium dihydrogen phosphate (NH4H2PO4). The amount of ammonium salt in the precursor mixture plays a key role in controlling the crystallinity, morphology, and composition of the N / P co-doped crystalline carbon material.

Owner:KING SAUD UNIVERSITY

Preparation of toluene shape-selective disproportionation without adhesive

InactiveCN101259424ARaw materials are easy to getWide variety of sourcesOrganic chemistryMolecular sieve catalystsActive componentCrystallinity

The invention relates to a preparation method for a binderless ZSM-5 zeolite catalyst used for shape-selective disproportionation of toluene. The preparation method mainly takes the ZSM-5 zeolite as the main active component and is prepared by a series of modifying methods of shaping, template-free hydrothermal crystallization, pickling, dealuminizing, siliceous reinforcing, and silicate ester chemical liquid phase sediment treatment. The content of the effective component, ZSM-5 zeolite, in the catalyst is high, the product has high crystallinity and relatively high mechanical strength; no organic amine template agents are adopted during the preparation process of the catalyst; the process is simple. The modified catalyst shows excellent catalytic activity and ultra-high selectivity to dimethyl benzene during the catalytic reaction of shape-selective disproportionation of toluene. The catalyst has simple preparation technique, lower cost and promising application prospect.

Owner:NANJING UNIV OF TECH

Template-free energy consumption steel plate shear wall and construction method thereof

InactiveCN102400506AImprove bearing capacityImprove ductilityWallsBuilding material handlingShock resistanceMechanical property

The invention relates to a template-free energy consumption steel plate shear wall and a construction method thereof, which belong to the technical field of building components. A shear wall body consists of a concrete inner core and outer covering steel plates, wherein the concrete inner core is clamped between the two mutually parallel outer covering steel plates, the mutually parallel outer covering steel plates are in tension connection through opposite-pull screw bolts, a vertical seam is preserved between the outer covering steel plates in the same plane, the outer covering steel plates are sealed and plugged at the vertical seam part through sealing and plugging steel plates, and energy consumption connecting elements are arranged in the vertical seams. The template-free energy consumption steel plate shear wall has the advantages that the shock resistance performance is good, the construction is convenient, the mechanical property of two kinds of major building materials of concrete and steel can be fully exerted, and the like. The template-free energy consumption steel plate shear wall can be widely applied to the shear wall structure of multi-storey or tall buildings and the construction of the shear wall structure.

Owner:姚攀峰

Method for synthesizing lithium nickel cobalt manganese oxide used as anode material for lithium ion battery by template method

ActiveCN104201324AEvenly distributedFacilitated DiffusionElectrode manufacturing processesSecondary cellsNickel saltPolyethylene glycol

A method for synthesizing lithium nickel cobalt manganese oxide used as an anode material for a lithium ion battery comprises the following specific steps: (1) lithium salt, nickel salt, cobalt salt and manganese salt are dissolved in water-organic solvent in a mole ratio to form a metallic solution, the mole ratio of lithium to nickel to cobalt to manganese is 1.1 to 1 / 3 to 1 / 3 to 1 / 3, and the mass ratio of water to the mixture is 10-40wt%; (2) a mixed aqueous solution of ammonia water, ammonium carbonate and polyethylene glycol is prepared; (3) a silicon dioxide molecular sieve is added into the solution obtained in the step (1), the mixed aqueous solution obtained in the step (2) is dripped into the solution under the condition of mechanical agitation, so that a precursor precipitate is obtained; (4) the precursor precipitate obtained in step (3) is washed and dried, so that a lithium nickel cobalt manganese oxide-SBA-15 material is obtained; (5) the lithium nickel cobalt manganese oxide-SBA-15 material prepared in the step (4) is agitated and washed, an SBA-template is removed, and thus the template-free lithium nickel cobalt manganese oxide material is obtained.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Preparation method for small-crystal-grain Y molecular sieve with high specific surface area and high silicon-aluminium ratio

InactiveCN104229822AGood hydrothermal stabilityHigh catalytic activityFaujasite aluminosilicate zeoliteMolecular sieveSynthesis methods

A provided preparation method for a small-crystal-grain Y molecular sieve with high specific surface area and high silicon-aluminium ratio comprises the concrete synthetic steps: firstly aging at 15-60 DEG C for 0.5-48 h to prepare a high-silicon crystallization guiding agent; then utilizing a silicon source, an aluminium source, an alkali source, water and the guiding agent and employing a segmented three-step method to prepare a finale crystallized mixture, standing and crystallizing at a certain temperature for a certain period, and performing filtering, washing and drying on the product to prepare the small-crystal-grain Y molecular sieve with high specific surface area, high silicon-aluminium ratio and the relative crystallization degree larger than 85%. The product prepared by utilizing the method has good hydro-thermal stability and catalytic activity. The product is obtained by employing a template-free direct synthesis method, the preparation method is simple, the raw materials are easy to obtain, environment pollution does not exist, and good industrial application prospect is provided.

Owner:天津神能科技有限公司

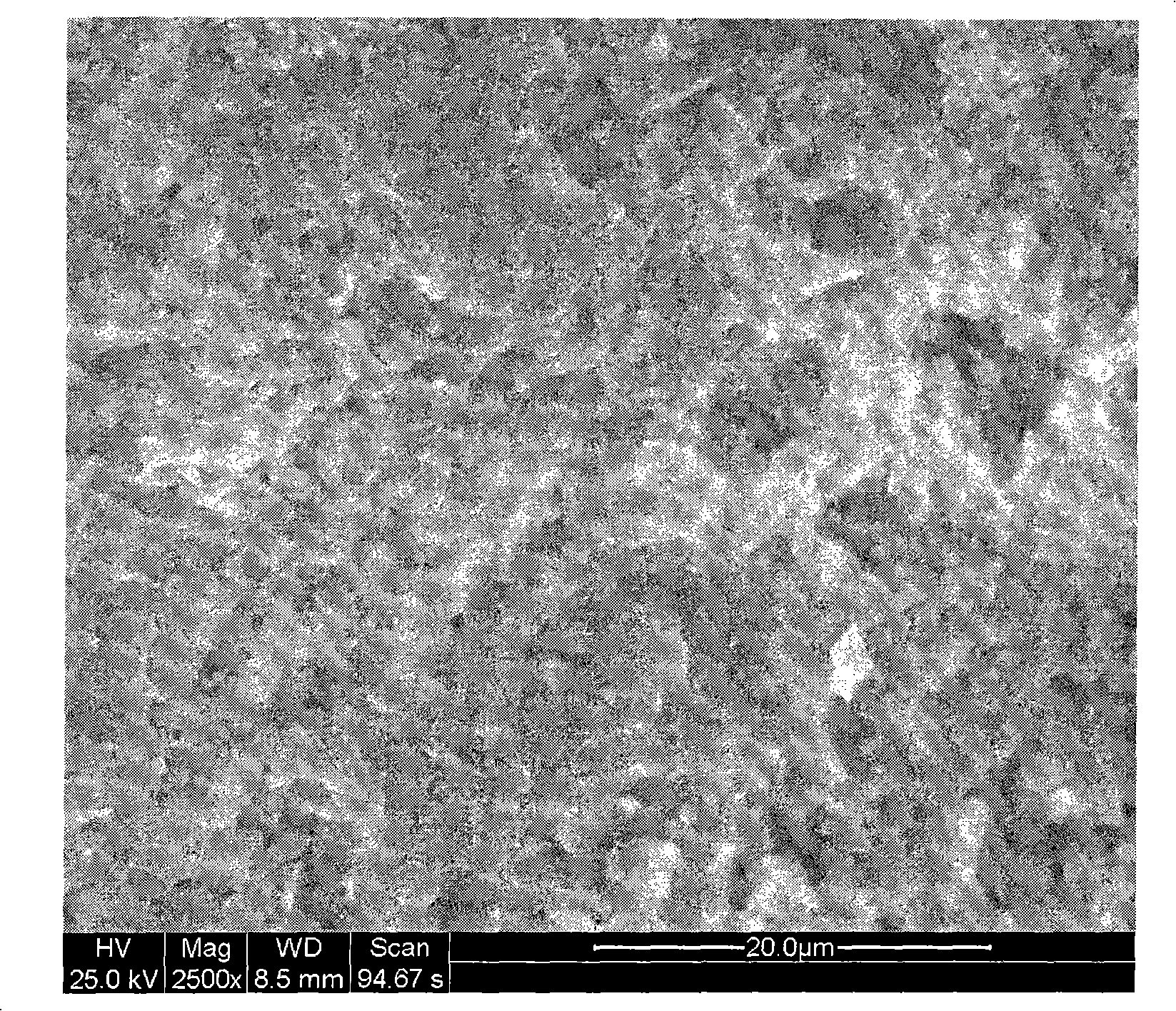

Nanostructured Metal Oxides Comprising Internal Voids and Methods of Use Thereof

InactiveUS20130130109A1Controllable sizeGood heat and electrical conductivity propertySilver accumulatorsMaterial nanotechnologyNanoparticleNanostructured metal

Owner:CORNELL RES FOUNDATION INC

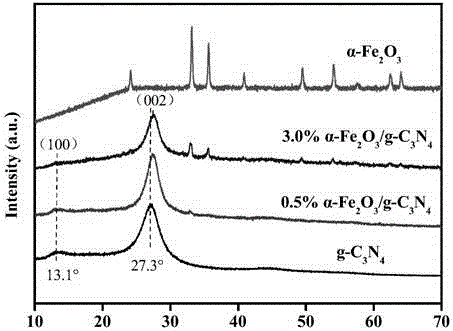

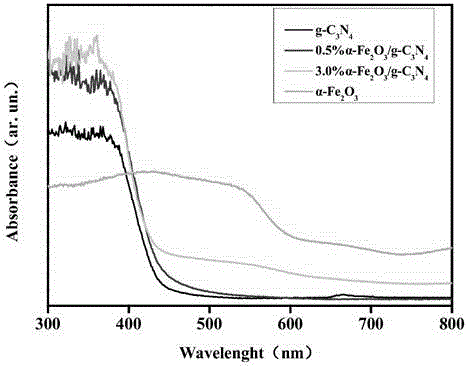

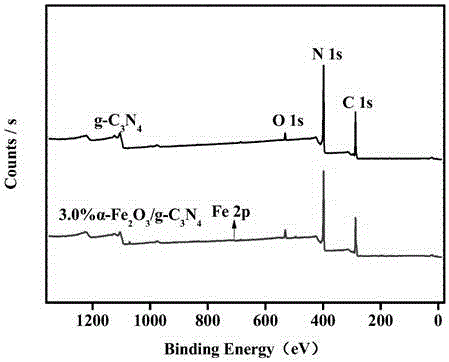

Porous-heterostructure composite photocatalyst and preparation method thereof

InactiveCN106345505ASave raw materialsSimple processPhysical/chemical process catalystsWater/sewage treatment by irradiationDiiron TrioxidePhotocatalytic degradation

The invention relates to the technical field of photocatalytic materials and a preparation method thereof, in particular to a porous-heterostructure composite photocatalyst and a preparation method thereof. The porous-heterostructure composite photocatalyst is characterized by being an iron trioxide and g-C3N4 compound, the iron trioxide is embedded in the surface or the inner surface of the g-C3N4 and is combined with the g-C3N4 through the Van der Waals' force; the specific surface area of the photocatalyst is 52.57-90.18m<2> / g, and the bore diameter of the photocatalyst is 20-100nm. By the arrangement of the porous-heterostructure catalyst of the a-Fe2O3 / g-C3N4 and the preparation method thereof, good performance of the catalyst on photocatalystic degradation of pollutants is achieved, and purification treatment of the pollutants in water is satisfied; compared with the prior art, the porous-heterostructure composite photocatalyst has the advantages that the template-free method is adopted, the high specific surface area of the a-Fe2O3 / g-C3N4 is achieved, and the porous-heterostructure composite photocatalyst is cheap in raw materials, simple in technology and high in application prospect and practical value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

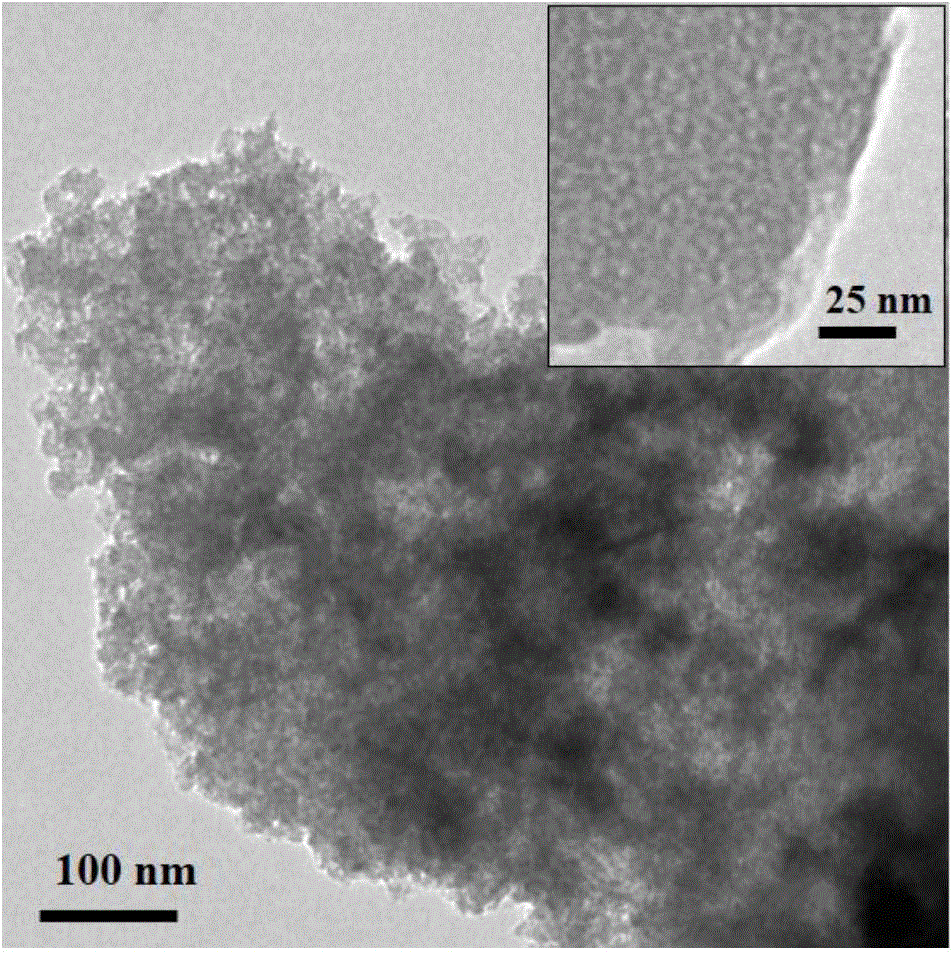

One-step template-free method for preparing a great amount of monodisperse ZnS hollow nanospheres

The invention relates to a one-step template-free method for preparing a great amount of monodisperse ZnS hollow nanospheres. The method comprises the following steps: the zinc acetate is dissolved in distilled water; thiourea is added to the solution and stirred in the solution at the room temperature until the solution is clear; the obtained solution is transferred to a stainless steel reaction vessel with a polytetrafluoroethylene lining for sealing, then the reaction vessel is heated to the reaction temperature and kept at the reaction temperature for 1 to 48 hours, and the thiourea is decomposed and reacts with the zinc acetate to generate deposition; and after the reaction, the reaction vessel is cooled to the room temperature, then the clear solution on the upper layer is removed, and the obtained deposition is washed with the distilled water and dried in a vacuum drying oven at 30-100 DEG C to obtain the monodisperse ZnS hollow nanospheres. By adopting the method, the monodisperse ZnS hollow nanospheres with radius of 200 nm and with casing layers assembled by nano-particles can be prepared at a large scale. The method is simple and environment-friendly, needs lower temperature and no template and additive agent and takes the water as the solvent. The method can prepare other transition metal oxide hollow nanospheres, such as manganese sulfide, cadmium sulfide, and the like.

Owner:WUHAN UNIV OF TECH

Preparation method of kaolin-based mesoporous silica material

The invention relates to the field of mesoporous materials, and in particular relates to a process for preparing a kaolin-based mesoporous silica material by employing a template-free method. A preparation method of the kaolin-based mesoporous silica material is characterized by comprising the following steps: (1) calcinations and activation, namely calcining and activating kaolin to obtain metakaolin; (2) hydrothermal alkali activation, namely activating the metakaolin in a hot solution containing OH<-> and Na<+>; and (3) acid etching, namely etching the metakaolin which is subjected to hydrothermal alkali activation in an acid solution to obtain the kaolin-based mesoporous silica material. The method is low in production cost; and the obtained kaolin-based mesoporous silica material has high specific surface area.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

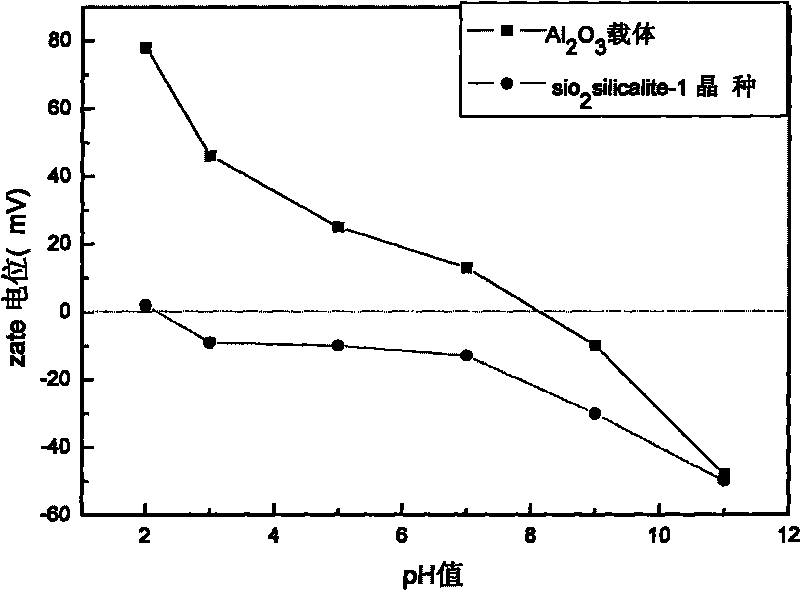

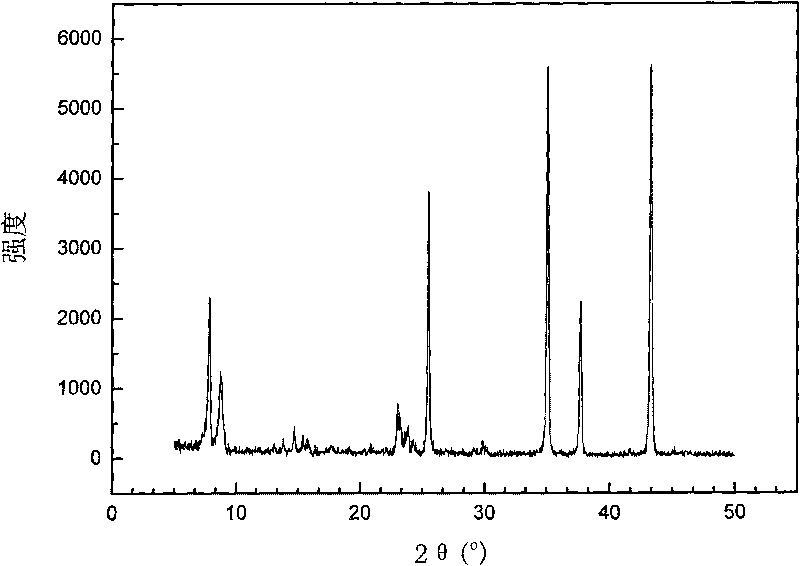

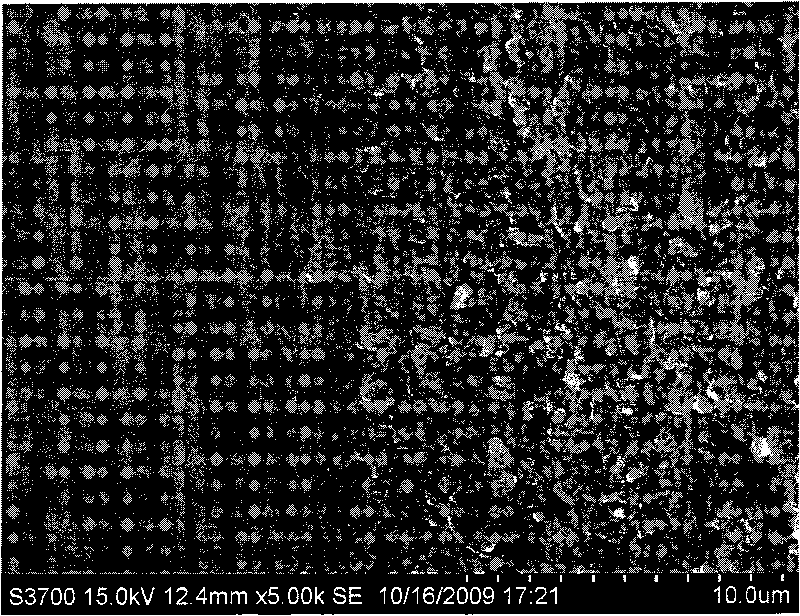

Method for synthesizing silicalite-1 zeolite membranes

InactiveCN101696018AGood repeatabilityNo crystallizationMolecular-sieve and base-exchange compoundsMolecular-sieve compoundsHydrothermal synthesisZeolite membranes

The invention discloses a method for synthesizing silicalite-1 zeolite membranes. The method comprises: preparing synthetic fluid of crystal seeds, performing hydrothermal synthesis for 0.5 to 3 days, obtaining crystal seeds uniform in particle size and preparing a crystal-seed solution; impregnating a carrier with the crystal-seed solution for 5 to 10 seconds, drying and roasting the obtained product; preparing template-free zeolite membrane mother liquor, placing diaphragms containing crystal-seed layers in the mother liquor and performing hydrothermal reaction in a reaction kettle for 4 to 8 hours; and washing and drying membranes. As the synthetic fluid has no template, roasting is not needed after secondary growth, so that defect-free pure silicon zeolite membranes can be obtained. The zeolite membranes are resistant to heat and chemicals, have good stability, and can be applied to the permeation and separation of gas and liquid steam at high temperature and other aspects.

Owner:SOUTH CHINA UNIV OF TECH

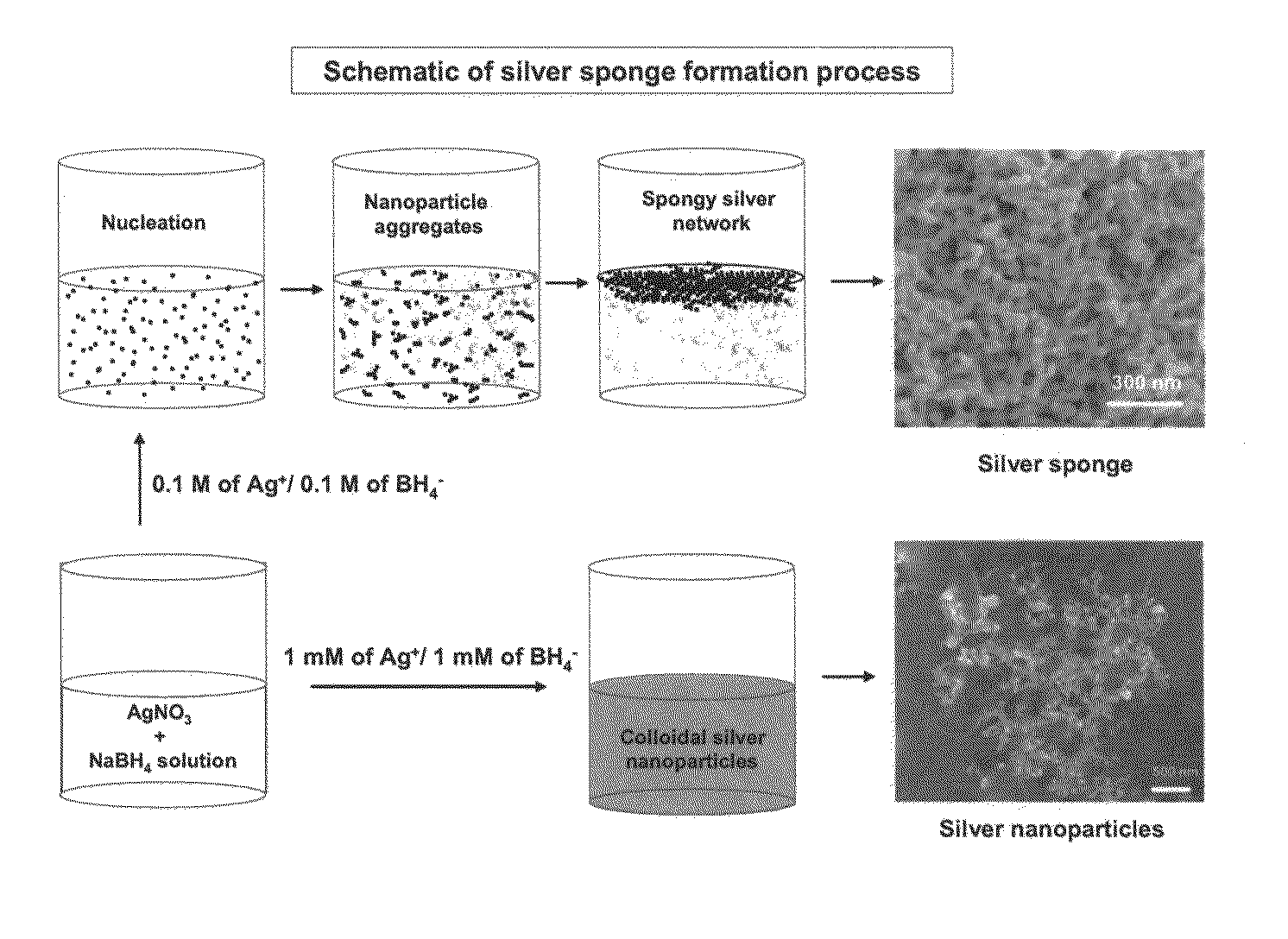

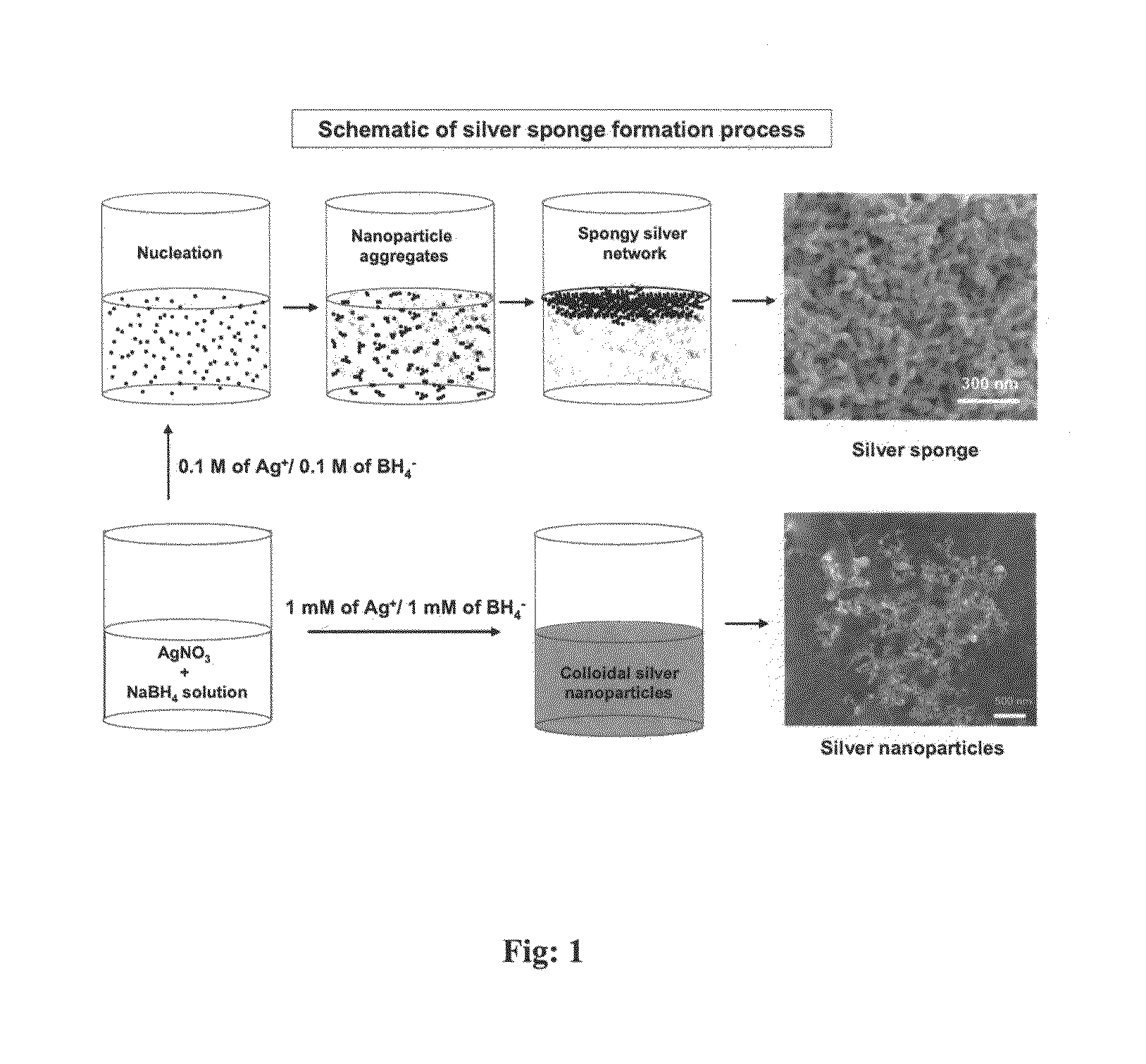

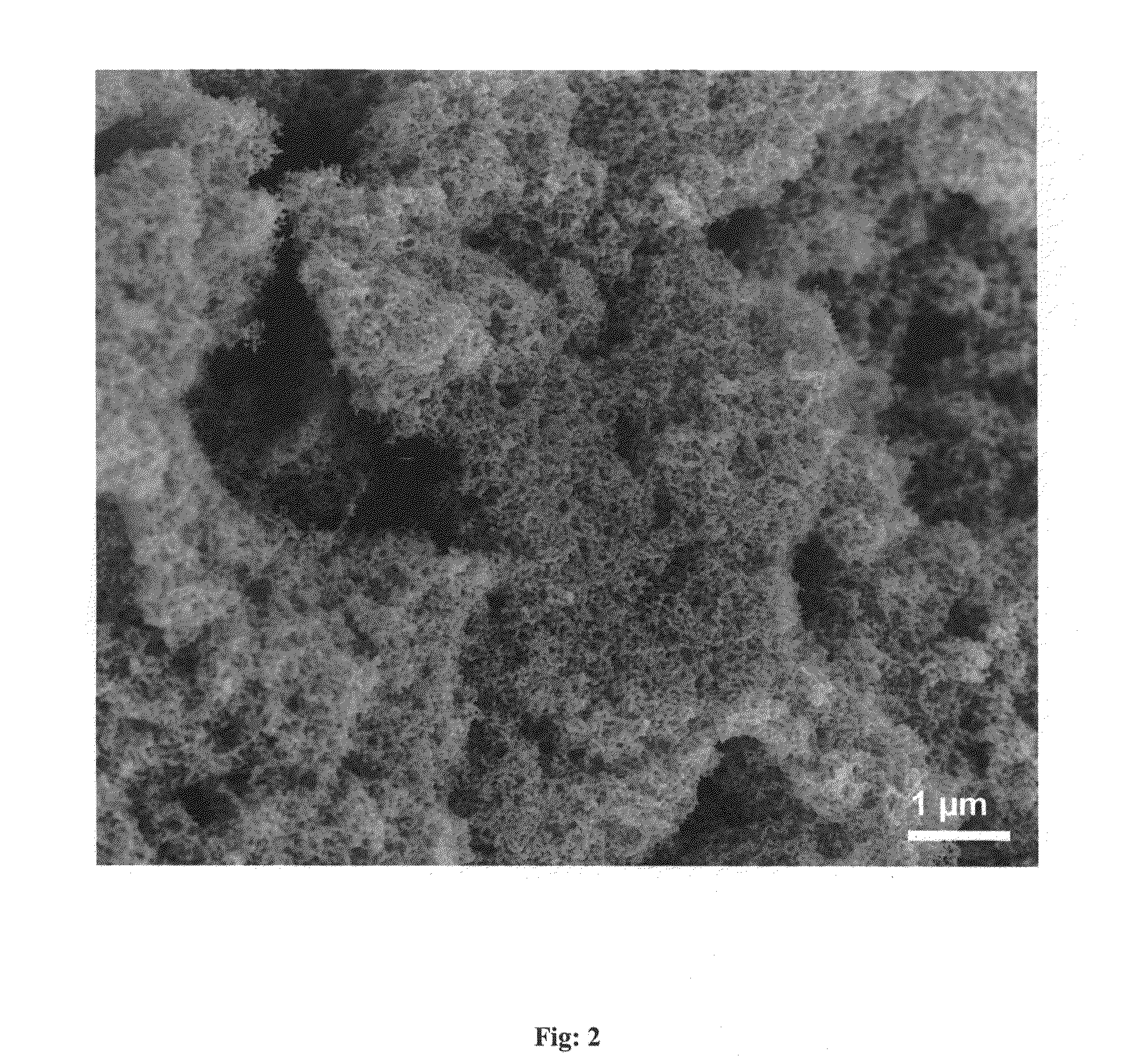

Template Free and Polymer Free Metal, Nanosponge and a Process Thereof

InactiveUS20110014300A1Large specific surface areaLow densityBiocideInorganic active ingredientsSurface-enhanced Raman spectroscopyAntibacterial activity

The present invention provides solution to the problem involved in preparation of metal nanosponges using templates and polymers. The instant invention is successful in providing a simple, template free single step process for the preparation of metal nanosponges having porous low density and high surface area. These metal nanosponges were found to be good self-supported substrates for surface-enhanced Raman spectroscopy (SERS) and have shown significant anti-bacterial activity.

Owner:JAWAHARLAL NEHRU CENT FOR ADVANCED SCI RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com